Bosch GSB 10 Professional, GSB 10 RE Professional, GSB 13 Professional, GSB 13 RE Professional, GSB 16 Professional User guide [ml]

...Page 1

OBJ_DOKU-929-005.fm Page 1 Tuesday, June 28, 2011 2:38 PM

Robert Bosch GmbH

Power Tools Division

70745 Leinfelden-Echterdingen

Germany

www.bosch-pt.com

1 609 929 M43 (2011.06) O / 54 ASIA

GSB Professional

10 | 10 RE | 13 | 13 RE | 16 | 16 RE

en Original instructions

cn 正本使用说明书

tw 正本使用說明書

ko 사용 설명서 원본

th หนังสือคูมือการใชงานฉบับตนแบบ

id Petunjuk-Petunjuk untuk

Penggunaan Orisinal

vi BΩng hõëng dÿn nguy›n bΩn

fr Notice originale

ar

fa

Ϡλ έΎ ίήσ ΎϤϨϫέ

ΕΎϤϴϠόΗϞϴϐθΘϟΔϴϠλϷ

Page 2

v

v

OBJ_BUCH-61-006.book Page 2 Tuesday, June 28, 2011 2:41 PM

2 |

English . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 6

中文 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 页 11

中文 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 頁 15

한국어 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 면 19

ภาษาไทย . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . หนา 23

Bahasa Indonesia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Halaman 29

Tiøng Vi·t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Trang 34

Français . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 39

v

v

cccc

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

vÝ—U

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

ΔΤϔλ

ϪΤϔλ

1 609 929 M43 | (28.6.11) Bosch Power Tools

Page 3

OBJ_BUCH-61-006.book Page 3 Tuesday, June 28, 2011 2:41 PM

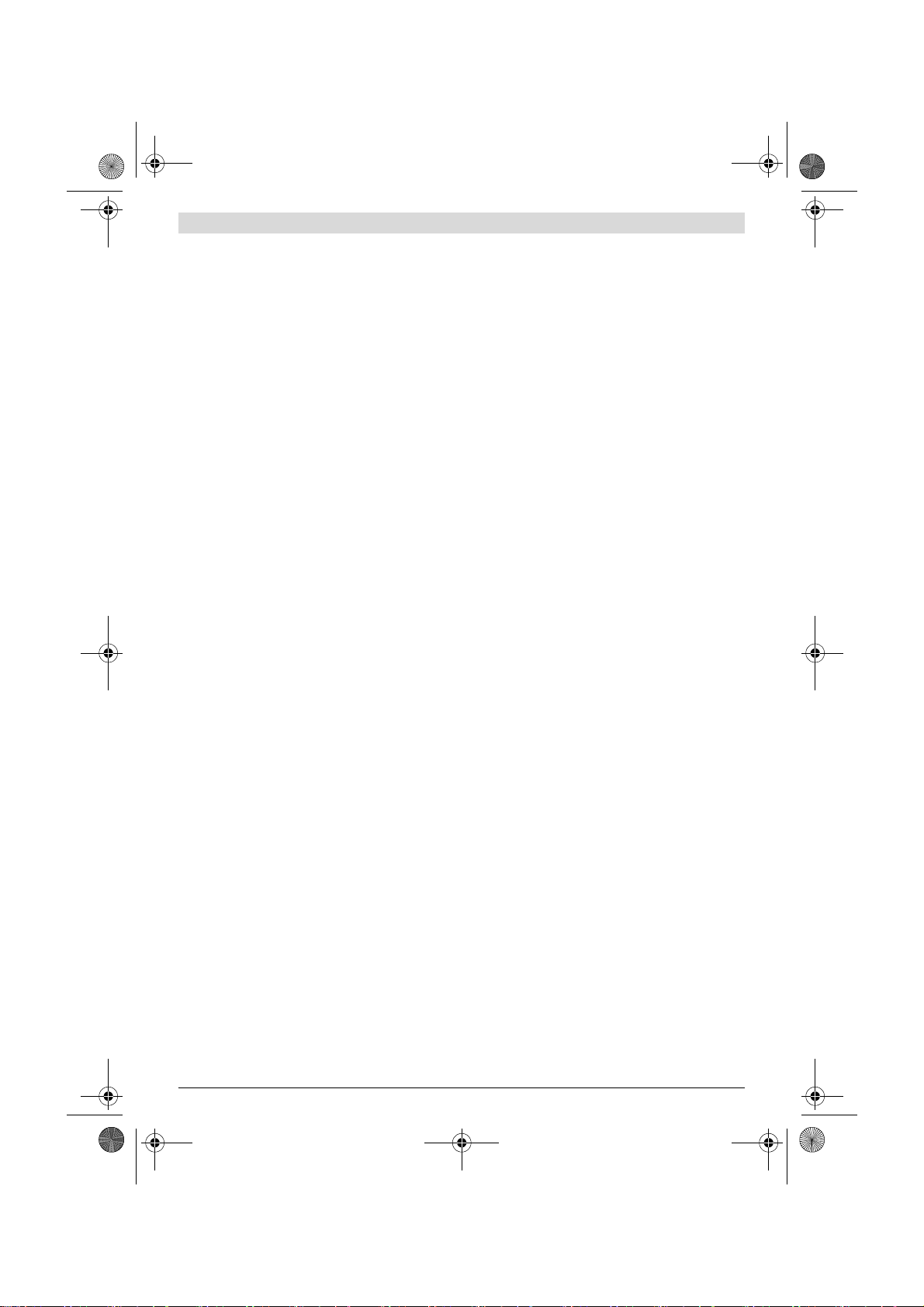

GSB 16 RE:

2 608 180 009

(DP 500)

GSB 16 RE:

2 608 030 053

(MS 65)

2 608 030 055

(MS 80)

| 3

1 607 950 045

2 602 025 094

GSB 10/GSB 10 RE:

2 608 571 078

GSB 13/GSB 13 RE/

2 603 001 009

GSB 16/GSB 16 (RE):

2 608 571 079

GSB 13/GSB 13 RE/

GSB 16/GSB 16 (RE):

2 608 571 080

2 607 990 050

2 609 160 112

Bosch Power Tools 1 609 929 M43 | (28.6.11)

(S 41)

Page 4

OBJ_BUCH-61-006.book Page 4 Tuesday, June 28, 2011 2:41 PM

4 |

12

GSB 16 RE

Professional

10

11

4

5

6

7

8

9

13

11

1

3

2

A

X

12

1 609 929 M43 | (28.6.11) Bosch Power Tools

910

11

B

3

2

Page 5

OBJ_BUCH-61-006.book Page 5 Tuesday, June 28, 2011 2:41 PM

| 5

E

14

DC

16

17

15

F

11918

119 18

HG

8

Bosch Power Tools 1 609 929 M43 | (28.6.11)

8

Page 6

OBJ_BUCH-61-006.book Page 6 Tuesday, June 28, 2011 2:41 PM

6 | English

f Prevent unintentional starting. Ensure the switch is in

English

Safety Notes

General Power Tool Safety Warnings

WARNING

and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mainsoperated (corded) power tool or battery-operated (cordless)

power tool.

Work area safety

f Keep work area clean and well lit. Cluttered or dark areas

invite accidents.

f Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ignite the dust

or fumes.

f Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

Electrical safety

f Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

f Avoid body contact with earthed or grounded surfaces,

such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock if your body is

earthed or grounded.

f Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric

shock.

f Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool. Keep cord away

from heat, oil, sharp edges and moving parts. Damaged

or entangled cords increase the risk of electric shock.

f When operating a power tool outdoors, use an exten-

sion cord suitable for outdoor use. Use of a cord suitable

for outdoor use reduces the risk of electric shock.

f If operating a power tool in a damp location is unavoid-

able, use a residual current device (RCD) protected

supply. Use of an RCD reduces the risk of electric shock.

Personal safety

f Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a power

tool while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while op-

erating power tools may result in serious personal injury.

f Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal injuries.

1 609 929 M43 | (28.6.11) Bosch Power Tools

Read all safety warnings and all instructions. Failure to follow the warnings

the off-position before connecting to power source

and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energising power tools that have the switch on invites accidents.

f Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a ro-

tating part of the power tool may result in personal injury.

f Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

f Dress properly. Do not wear loose clothing or jewel-

lery. Keep your hair, clothing and gloves away from

moving parts. Loose clothes, jewellery or long hair can be

caught in moving parts.

f If devices are provided for the connection of dust ex-

traction and collection facilities, ensure these are connected and properly used. Use of dust collection can re-

duce dust-related hazards.

Power tool use and care

f Do not force the power tool. Use the correct power tool

for your application. The correct power tool will do the

job better and safer at the rate for which it was designed.

f Do not use the power tool if the switch does not turn it

on and off. Any power tool that cannot be controlled with

the switch is dangerous and must be repaired.

f Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments, changing accessories, or storing power

tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

f Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

f Maintain power tools. Check for misalignment or bind-

ing of moving parts, breakage of parts and any other

condition that may affect the power tool’s operation. If

damaged, have the power tool repaired before use.

Many accidents are caused by poorly maintained power

tools.

f Keep cutting tools sharp and clean. Properly maintained

cutting tools with sharp cutting edges are less likely to bind

and are easier to control.

f Use the power tool, accessories and tool bits etc. in ac-

cordance with these instructions, taking into account

the working conditions and the work to be performed.

Use of the power tool for operations different from those

intended could result in a hazardous situation.

Service

f Have your power tool serviced by a qualified repair per-

son using only identical replacement parts. This will en-

sure that the safety of the power tool is maintained.

Page 7

OBJ_BUCH-61-006.book Page 7 Tuesday, June 28, 2011 2:41 PM

English | 7

Safety Warnings for Drills

GSB 13/ GSB 13 RE/ GSB 16/ GSB 16 RE

f Use auxiliary handle(s), if supplied with the tool. Loss

of control can cause personal injury.

f When working with the machine, always hold it firmly

with both hands and provide for a secure stance. The

power tool is guided more secure with both hands.

GSB 10/ GSB 10 RE/ GSB 13/GSB 13 RE /GSB 16 /

GSB 16 RE

f Wear ear protectors when impact drilling. Exposure to

noise can cause hearing loss.

f Hold power tool by insulated gripping surfaces, when

performing an operation where the cutting accessory

may contact hidden wiring or its own cord. Cutting ac-

cessory contacting a “live” wire may make exposed metal

parts of the power tool “live” and could give the operator an

electric shock.

f Use suitable detectors to determine if utility lines are

hidden in the work area or call the local utility company

for assistance. Contact with electric lines can lead to fire

and electric shock. Damaging a gas line can lead to explosion. Penetrating a water line causes property damage or

may cause an electric shock.

f Switch off the power tool immediately when the tool in-

sert jams. Be prepared for high reaction torque that

can cause kickback. The tool insert jams when:

— the power tool is subject to overload or

— it becomes wedged in the workpiece.

f Secure the workpiece. A workpiece clamped with clamp-

ing devices or in a vice is held more secure than by hand.

f Always wait until the machine has come to a complete

stop before placing it down. The tool insert can jam and

lead to loss of control over the power tool.

Products sold in GB only: Your product is fitted with a

BS 1363/A approved electric plug with internal fuse (ASTA

approved to BS 1362).

If the plug is not suitable for your socket outlets, it should be

cut off and an appropriate plug fitted in its place by an authorised customer service agent. The replacement plug should

have the same fuse rating as the original plug.

The severed plug must be disposed of to avoid a possible

shock hazard and should never be inserted into a mains socket elsewhere.

Products sold in AUS and NZ only: Use a residual current device (RCD) with a rated residual current of 30 mA or less.

Product Description and

Specifications

Read all safety warnings and all instructions. Failure to follow the warnings and in-

structions may result in electric shock, fire

and/or serious injury.

Intended Use

The machine is intended for impact drilling in brick, concrete

and stone as well as for drilling in wood, metal and plastic. Ma chines with electronic control and right/left rotation are also

suitable for screwdriving and thread-cutting.

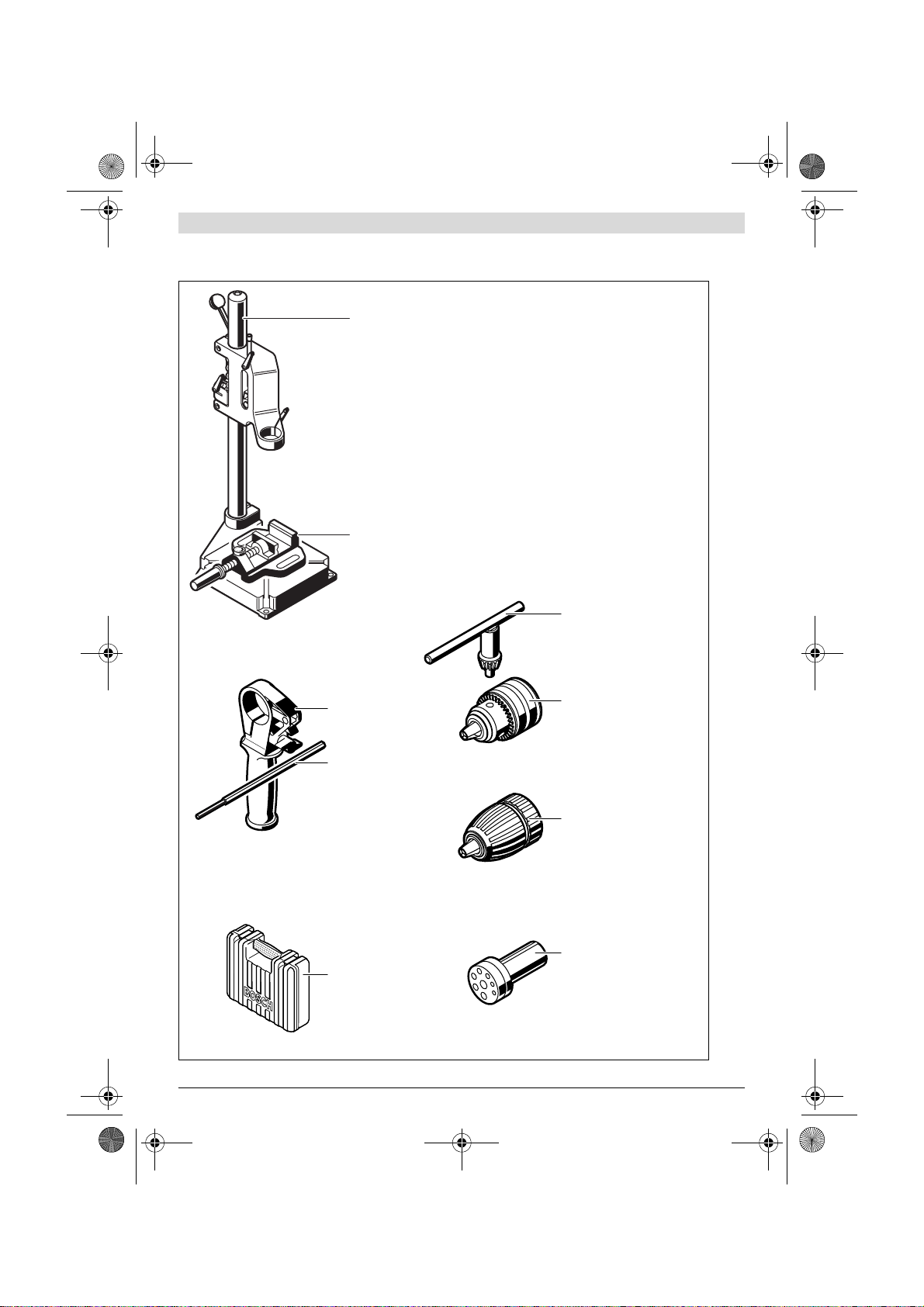

Product Features

The numbering of the product features refers to the illustration of the machine on the graphics page.

1 Keyless chuck*

2 Front sleeve

3 Rear sleeve

4 “Drilling/Impact Drilling” selector switch

5 Lock-on button for On/Off switch

6 On/Off switch

7 Thumbwheel for speed preselection (GSB 16 RE)

8 Rotational direction switch

(GSB 10 RE/GSB 13 RE /GSB 16 RE)

9 Button for depth stop adjustment*

10 Wing bolt for adjustment of auxiliary handle*

11 Auxiliary handle (insulated gripping surface)*

12 Depth stop*

13 Handle (insulated gripping surface)

14 Chuck key*

15 Key type drill chuck*

16 Universal bit holder*

17 Screwdriver bit *

18 Allen key**

19 Open-end spanner **

*Accesso ries shown or described are not part of the standard delivery scope of the product. A complete overview of accessories

can be found in our accessories program.

**Commer cially available (not included in the delivery scope)

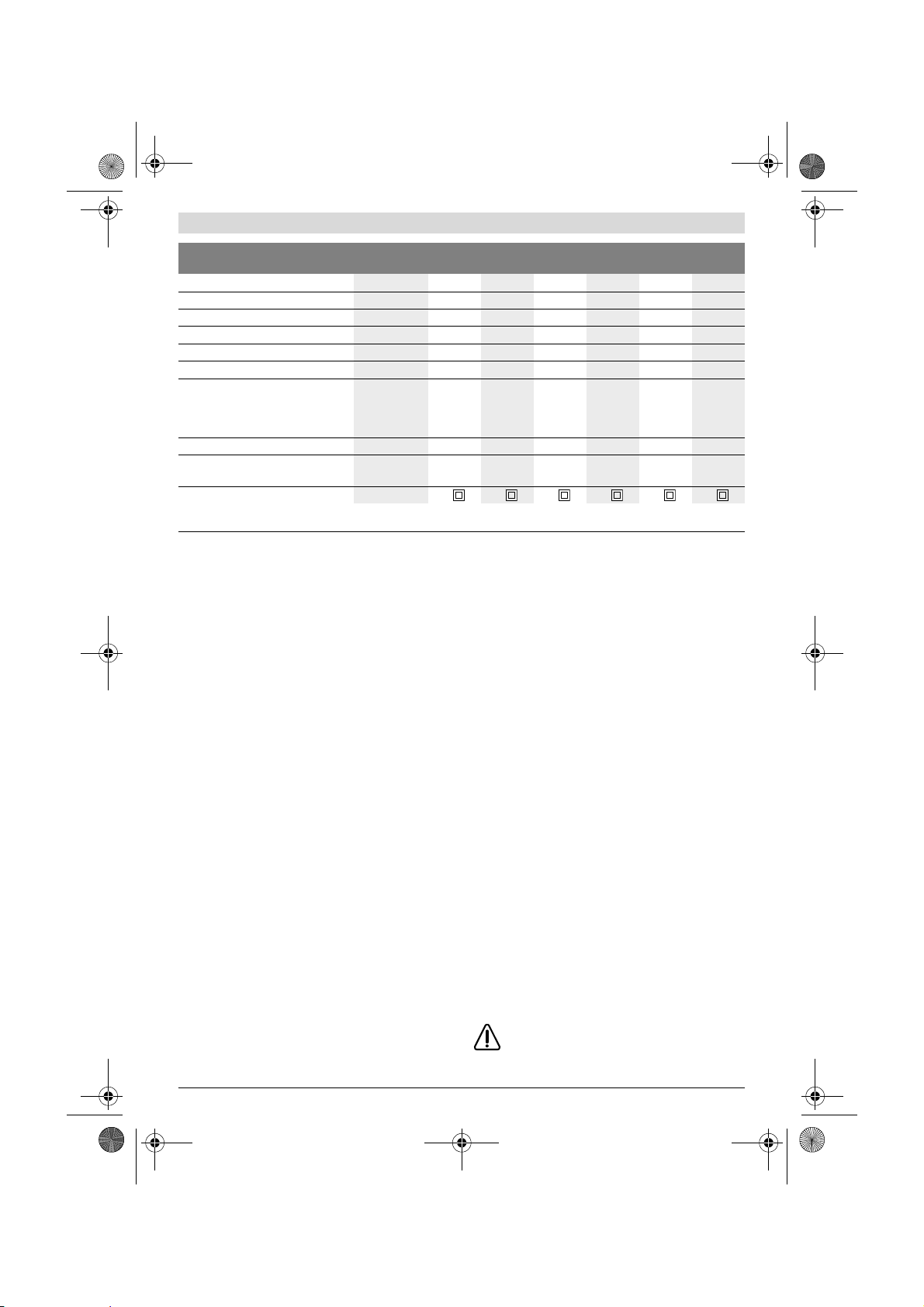

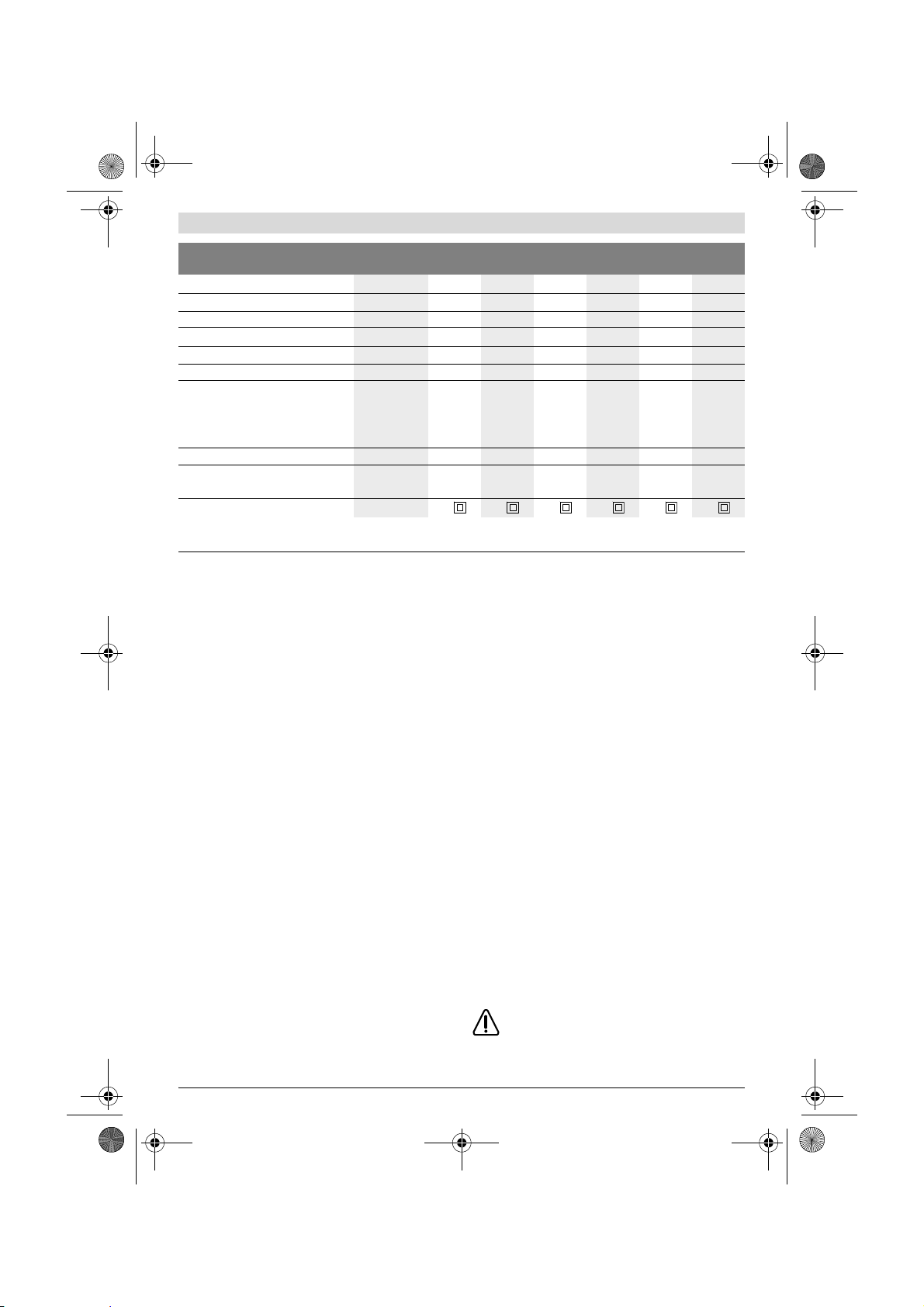

Technical Data

Impact Drill GSB ...

Article number 3 601 ... B16 0.. B16 1.. B17 0.. B17 1.. B18 0.. B18 1..

Rated power input

Output power

No-load speed

The values given are valid for a nominal voltage [U] of 230 V. For different voltages and models for specific countries, these values can vary.

Please observe the article number on the type plate of your machine. The trade names of the individual machines may vary.

Professional

min

W 500 500 600 600 701 701

W 250 250 301 301 351 351

-1

10 10 RE 13 13 RE 16 16 RE

2600 0 – 2600 2800 0 – 2800 30 00 0–3000

Bosch Power Tools 1 609 929 M43 | (28.6.11)

Page 8

OBJ_BUCH-61-006.book Page 8 Tuesday, June 28, 2011 2:41 PM

8 | English

Impact Drill GSB ...

Rotational speed under load, max.

Impact rate

Rated torque

Speed preselection

Right/left rotation

Spindle collar dia.

Max. drilling dia.

– Concrete

– Steel

– Wood

Chuck clamping range

Weight according to EPTA-Procedure

01/2003

Protection class

The values given are valid for a nominal voltage [U] of 230 V. For different voltages and models for specific countries, these values can vary.

Please observe the article number on the type plate of your machine. The trade names of the individual machines may vary.

Professional

-1

min

min-125 700 25700 25070 25 070 26 270 26 270

Nm 1.5 1.5 1.8 1.8 2.0 2.0

mm 43 43 43 43 43 43

mm

mm

mm

mm 1.5 – 10 1.5 – 10 1.5 – 13 1.5 – 13 1.5 – 13 1.5 – 13

kg 1.5 1.5 1.7 1.7 1.9 1.9

Assembly

f Before any work on the machine itself, pull the mains

plug.

Auxiliary Handle (see figure A)

(GSB 13/GSB 13 RE/GSB 16/ GSB 16 RE)

f Operate your machine only with the auxiliary handle

11.

The auxiliary handle 11 can be set to any position for a secure

and low-fatigue working posture.

Turn the wing bolt for adjustment of the auxiliary handle 10 in

anticlockwise direction and set the auxiliary handle 11 to the

required position. Then tighten the wing bolt 10 again in

clockwise direction.

Adjusting the Drilling Depth (see figure A)

The required drilling depth X can be set with the depth stop

12.

Press the button for the depth stop adjustment 9 and insert

the depth stop into the auxiliary handle 11.

Pull out the depth stop until the distance between the tip of

the drill bit and the tip of the depth stop correspond with the

desired drilling depth X.

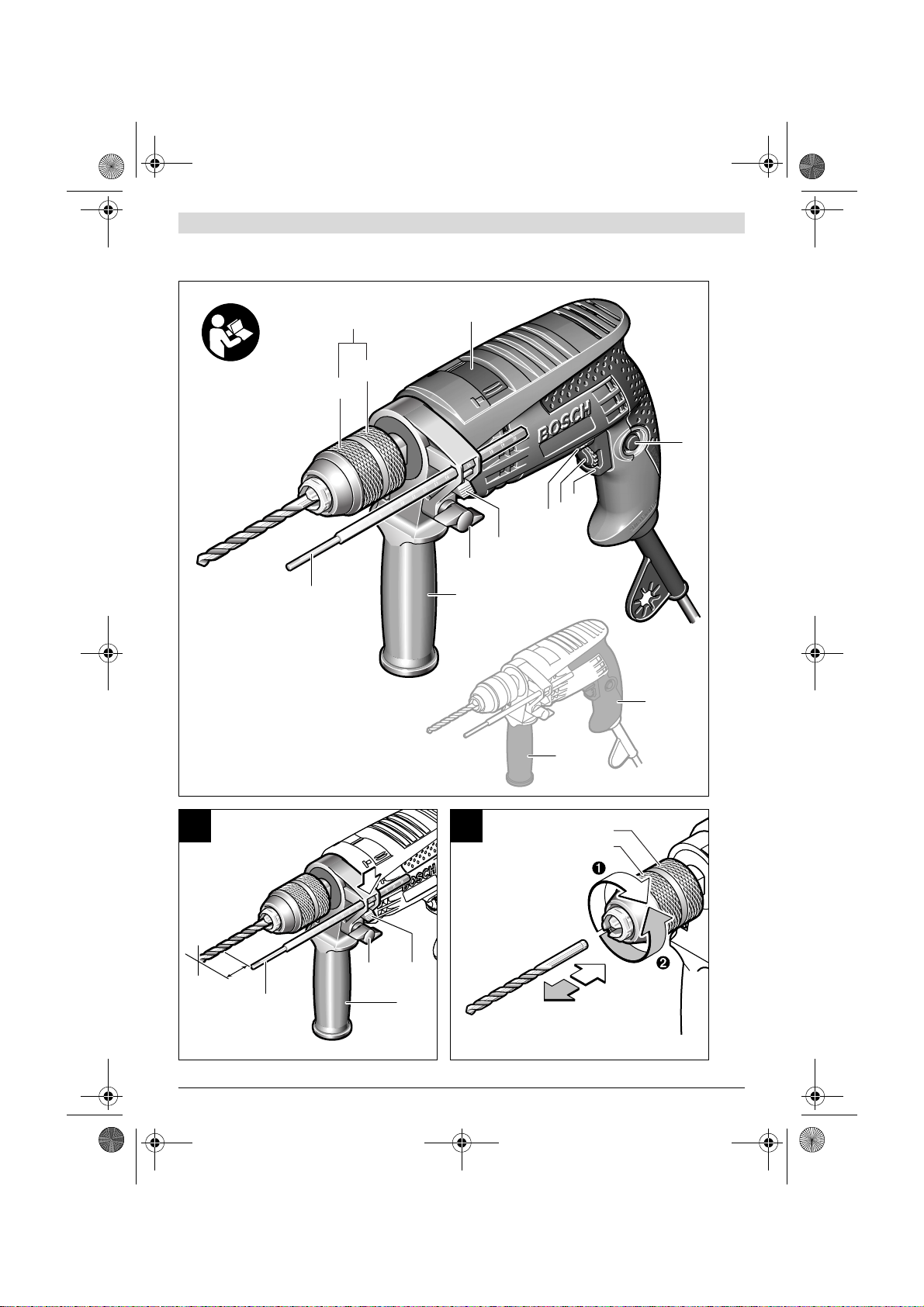

Changing the Tool

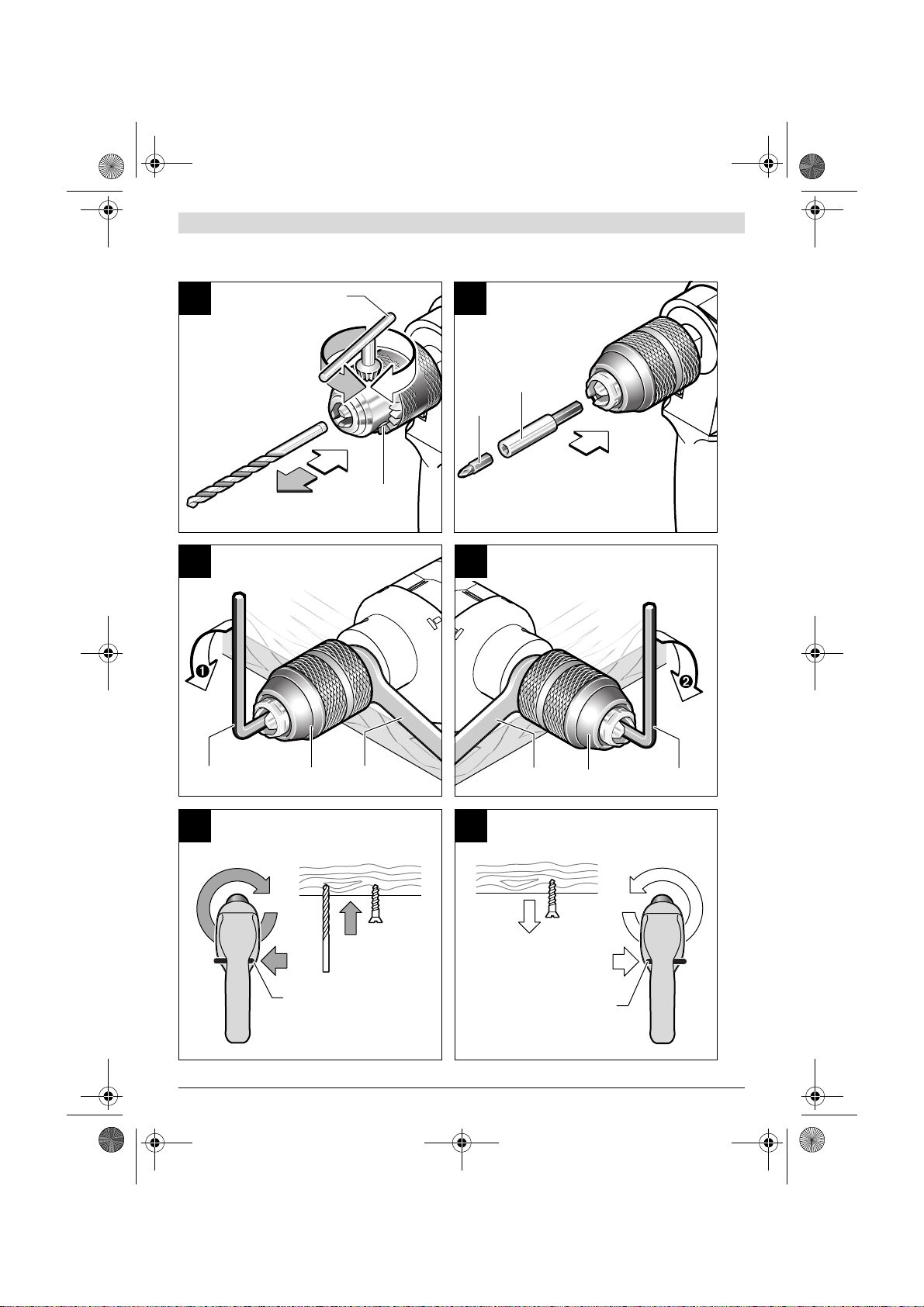

Keyless Chuck (see figure B)

Hold the rear sleeve 3 of the keyless chuck 1 tight and turn the

front sleeve 2 in rotation direction n, until the tool can be inserted. Insert the tool.

Hold the rear sleeve 3 of the keyless chuck 1 tight and firmly

turn the front sleeve 2 in rotation direction o by hand until

the locking action is no longer heard. This automatically locks

the drill chuck.

The locking is released again to remove the tool when the

front sleeve 2 is turned in the opposite direction.

10 10 RE 13 13 RE 16 16 RE

1610 1610 1570 1 570 1 640 1640

– ––––z

– z – z – z

10

8

20

/II / II /II / II /II / II

Key Type Drill Chuck (see figure C)

f Wear protective gloves when changing the tool. The

Open the key type drill chuck 15 by turning un til the tool can

be inserted. Insert the tool.

Insert the chuck key 14 into the corresponding holes of the

key type drill chuck 15 and clamp the tool uniformly.

Screwdriver Tools (see figure D)

When working with screwdriver bits 17, a universal bit holder

16 should always be used. Use only screwdriver bits that fit

the screw head.

For driving screws, always position the “Drilling/Impact Drill-

ing” selector switch 4 to the “Drilling” symbol.

10

20

drill chuck can become very hot during longer work periods.

13

8

10

25

13

10

25

16

12

30

Replacing the Drill Chuck

Removing the Drill Chuck (see figure E)

To dismount the keyless chuck 1, clamp an Allen key 18 into

the keyless chuck 1 and position an open-end spanner 19

(size 12 mm) against the spanner flats of the drive spindle.

Place the machine on a firm support, e.g., a workbench. Hold

the open-end spanner 19 firmly and loosen the keyless chuck

1 by turning the Allen key 18 in rotation direction n. Loosen

a tight seated keyless chuck by giving the long end of the Allen

key 18 a blow. Remove the Allen key from the keyless chuck

and completely unscrew the keyless chuck.

The key type drill chuck 15 is removed in the same manner as

the keyless chuck.

Mounting the Drill Chuck (see figure F)

The keyless chuck/key type drill chuck is mounted in reverse

order.

The drill chuck must be tightened with a tightening

torque of approx. 30 –35 Nm.

16

12

30

1 609 929 M43 | (28.6.11) Bosch Power Tools

Page 9

OBJ_BUCH-61-006.book Page 9 Tuesday, June 28, 2011 2:41 PM

Dust/Chip Extraction

f Dusts from materials such as lead-containing coatings,

some wood types, minerals and metal can be harmful to

one’s health. Touching or breathing-in the dusts can cause

allergic reactions and/or lead to respiratory infections of

the user or bystanders.

Certain dusts, such as oak or beech dust, are considered

as carcinogenic, especially in connection with wood-treatment additives (chromate, wood preservative). Materials

containing asbestos may only be worked by specialists.

– Provide for good ventilation of the working place.

– It is recommended to wear a P2 filter-class respirator.

Observe the relevant regulations in your country for the

materials to be worked.

f Prevent dust accumulation at the workplace. Dusts can

easily ignite.

Operation

Starting Operation

f Observe correct mains voltage! The voltage of the pow-

er source must agree with the voltage specified on the

nameplate of the machine. Power tools marked with

230 V can also be operated with 220 V.

Reversing the Rotational Direction (see figures G –H)

(GSB 10 RE/ GSB 13 RE/ GSB 16 RE)

The rotational direction switch 8 is used to reverse the rotational direction of the machine. However, this is not possible

with the On/Off switch 6 actuated.

Right Rotation: For drilling and driving in screws, push the

rotational direction switch 8 left to the stop.

Left Rotation: For loosening and unscrewing screws and

nuts, press the rotational direction switch 8 through to the

right stop.

Setting the Operating Mode

Drilling and Screwdriving

Set the selector switch 4 to the “Drilling” symbol.

Impact Drilling

Set the selector switch 4 to the “Impact drilling”

symbol.

The selector switch 4 engages noticeably and can also be actuated with the machine running.

Switching On and Off

To start the machine, press the On/Off switch 6 and keep it

pressed.

To lock the pressed On/Off switch 6, press the lock-on button

5.

To switch off the machine, release the On/Off switch 6 or

when it is locked with the lock-on button 5, briefly press the

On/Off switch 6 and then release it.

English | 9

Adjusting the Speed/Impact Frequency

(GSB 10 RE/ GSB 13 RE/ GSB 16 RE)

The speed/impact rate of the switched on power tool can be

variably adjusted, depending on how far the On/Off switch 6

is pressed.

Light pressure on the On/Off switch 6 results in low speed/impact rate. Further pressure on the switch increases the

speed/impact rate.

Preselecting the Speed/Impact Frequency ( GSB 16 RE)

With the thumbwheel for speed preselection 7, the required

speed/impact frequency can be preselected even during operation.

The required speed/impact frequency depends on the material and the working conditions, and can be determined

through practical testing.

Working Advice

f Apply the power tool to the screw/nut only when it is

switched off. Rotating tool inserts can slip off.

After longer periods of working at low speed, allow the machine to cool down by running it for approx. 3 minutes at maximum speed with no load.

For drilling in tiles, set the selector switch 4 to the “Drilling”

symbol. Do not switch over to the symbol “Impact Drilling” or

work with impact until after drilling through the tile.

Use carbide tipped drill bits when working in concrete, masonry and brick wall.

For drilling in metal, use only perfectly sharpened HSS drill

bits (HSS =high-speed steel). The appropriate quality is gua ranteed by the Bosch accessories program.

Twist drills from 2.5 –10 mm can easily be sharpened with

the drill bit sharpener (see accessories).

GSB 16 RE

We recommend the use of a drill stand (see accessories) for

work where greater precision is particularly required.

The machine vice, which is available as an accessory, enables

secure clamping of workpieces. This prevents the workpiece

from turning and any accidents this would cause.

Maintenance and Service

Maintenance and Cleaning

f Before any work on the machine itself, pull the mains

plug.

f For safe and proper working, always keep the machine

and ventilation slots clean.

If the machine should fail despite the care taken in manufacturing and testing procedures, repair should be carried out by

an after-sales service centre for Bosch power tools.

In all correspondence and spare parts order, please always include the 10-digit article number given on the type plate of

the machine.

Bosch Power Tools 1 609 929 M43 | (28.6.11)

Page 10

OBJ_BUCH-61-006.book Page 10 Tuesday, June 28, 2011 2:41 PM

10 | English

After-sales Service and Customer Assistance

Our after-sales service responds to your questions concerning maintenance and repair of your product as well as spare

parts. Exploded views and information on spare parts can also be found under:

www.bosch-pt.com

Our customer service representatives can answer your questions concerning possible applications and adjustment of

products and accessories.

People’s Republic of China

China Mainland

Bosch Power Tools (China) Co., Ltd.

567, Bin Kang Road

Bin Jiang District 310052

Hangzhou, P.R. China

Service Hotline: 400 826 8484

Fax: +86 571 8777 4502

E-Mail: contact.ptcn@cn.bosch.com

www.bosch-pt.com.cn

HK and Macau Special Administrative Regions

Robert Bosch Hong Kong Co. Ltd.

21st Floor, 625 King’s Road

North Point, Hong Kong

Customer Service Hotline: +852 (21) 02 02 35

Fax: +852 (25) 90 97 62

E-Mail: info@hk.bosch.com

www.bosch-pt.com.hk

Indonesia

PT. Multi Mayaka

Kawasan Industri Pulogadung

Jalan Rawa Gelam III No. 2

Jakarta 13930

Indonesia

Tel.: +62 (21) 46 83 25 22

Fax: +62 (21) 46 82 86 45 /68 23

E-Mail: sales@multimayaka.co.id

www.bosch-pt.co.id

Philippines

Robert Bosch, Inc.

28th Floor Fort Legend Towers,

3rd Avenue corner 31st Street,

Fort Bonifacio Global City,

1634 Taguig City, Philippines

Tel.: +63 (2) 870 3871

Fax: +63 (2) 870 3870

matheus.contiero@ph.bosch.com

www.bosch-pt.com.ph

Bosch Service Center:

9725-27 Kamagong Street

San Antonio Village

Makati City, Philippines

Tel.: +63 (2) 899 9091

Fax: +63 (2) 897 6432

rosalie.dagdagan@ph.bosch.com

Malaysia

Robert Bosch (S.E.A.) Pte. Ltd.

No. 8A, Jalan 13/6

G.P.O. Box 10818

46200 Petaling Jaya

Selangor, Malaysia

Tel.: +60 (3) 7966 3194

Fax: +60 (3) 7958 3838

cheehoe.on@my.bosch.com

Toll-Free: 1800 880 188

www.bosch-pt.com.my

Thailand

Robert Bosch Ltd.

Liberty Square Building

No. 287, 11 Floor

Silom Road, Bangrak

Bangkok 10500

Tel.: +66 (2) 6 31 18 79 – 18 88 (10 lines)

Fax: +66 (2) 2 38 47 83

Robert Bosch Ltd., P. O. Box 2054

Bangkok 10501, Thailand

Bosch Service – Training Centre

2869-2869/1 Soi Ban Kluay

Rama IV Road (near old Paknam Railway)

Prakanong District

10110 Bangkok

Thailand

Tel.: +66 (2) 6 71 78 00 – 4

Fax: +66 (2) 2 49 42 96

Fax: +66 (2) 2 49 52 99

Singapore

Robert Bosch (SEA) Pte. Ltd.

11 Bishan Street 21

Singapore 573943

Tel.: +65 6571 2772

Fax: +65 6350 5315

leongheng.leow@sg.bosch.com

Toll-Free: 1800 333 8333

www.bosch-pt.com.sg

Vietnam

Robert Bosch Vietnam Co. Ltd

10/F, 194 Golden Building

473 Dien Bien Phu Street

Ward 25, Binh Thanh District

84 Ho Chi Minh City

Vietnam

Tel.: +84 (8) 6258 3690 ext. 413

Fax: +84 (8) 6258 3692

hieu.lagia@vn.bosch.com

www.bosch-pt.com

1 609 929 M43 | (28.6.11) Bosch Power Tools

Page 11

OBJ_BUCH-61-006.book Page 11 Tuesday, June 28, 2011 2:41 PM

Australia, New Zealand and Pacific Islands

Robert Bosch Australia Pty. Ltd.

Power Tools

Locked Bag 66

Clayton South VIC 3169

Customer Contact Center

Inside Australia:

Phone: +61 (01300) 307 044

Fax: + 61 (01300) 307 045

Inside New Zealand:

Phone: +64 (0800) 543 353

Fax: +64 (0800) 428 570

Outside AU and NZ:

Phone: +61 (03) 9541 5555

www.bosch.com.au

Disposal

The machine, accessories and packaging should be sorted for

environmental-friendly recycling.

Do not dispose of power tools into household waste!

Subject to change without notice.

中文

安全规章

电动工具通用安全警告

阅读所有警告和所有说明 ! 不遵照以下警告

和说明会导致电击、着火和/或严重伤害。

保存所有警告和说明书以备查阅。

在所有下列的警告中术语 " 电动工具 " 指市电驱动 (有

线)电动工具或电池驱动 (无线)电动工具。

工作场地的安全

f 保持工作场地清洁和明亮。 混乱和黑暗的场地会引发

事故。

f 不要在易爆环境,如有易燃液体、气体或粉尘的环境

下操作电动工具。 电动工具产生的火花会点燃粉尘或

气体。

f 让儿童和旁观者离开后操作电动工具。 注意力不集中

会使你失去对工具的控制。

电气安全

f 电动工具插头必须与插座相配。绝不能以任何方式改

装插头。 需接地的电动工具不能使用任何转换插头。

未经改装的插头和相配的插座将减少电击危险。

f 避免人体接触接地表面,如管道、散热片和冰箱。 如

果你身体接地会增加电击危险。

f 不得将电动工具暴露在雨中或潮湿环境中。 水进入电

动工具将增加电击危险。

中文 | 11

f 不得滥用电线。绝不能用电线搬运、拉动电动工具或

拔出其插头。使电线远离热源、油、锐边或运动部

件。 受损或缠绕的软线会增加电击危险。

f 当在户外使用电动工具时,使用适合户外使用的外接

软线。 适合户外使用的软线将减少电击危险。

f 如果在潮湿环境下操作电动工具是不可避免的,应使

用剩余电流动作保护器 (RCD)。 使用 RCD 可减小

电击危险。

人身安全

f 保持警觉,当操作电动工具时关注所从事的操作并保

持清醒。当你感到疲倦,或在有药物、酒精或治疗反

应时,不要操作电动工具。 在操作电动工具时瞬间的

疏忽会导致严重人身伤害。

f 使用个人防护装置。始终佩戴护目镜。 安全装置,诸

如适当条件下使用防尘面具、防滑安全鞋、安全帽、

听力防护等装置能减少人身伤害。

f 防止意外起动。确保开关在连接电源和 / 或电池盒、

拿起或搬运工具时处于关断位置。 手指放在已接通电

源的开关上或开关处于接通时插入插头可能会导致危

险。

f 在电动工具接通之前,拿掉所有调节钥匙或扳手。 遗

留在电动工具旋转零件上的扳手或钥匙会导致人身伤

害。

f 手不要伸展得太长。时刻注意立足点和身体平衡。 这

样在意外情况下能很好地控制电动工具。

f 着装适当。不要穿宽松衣服或佩戴饰品。让你的衣

服、手套和头发远离运动部件。 宽松衣服、佩饰或长

发可能会卷入运动部件中。

f 如果提供了与排屑、集尘设备连接用的装置,要确保

他们连接完好且使用得当。 使用这些装置可减少尘屑

引起的危险。

电动工具使用和注意事项

f 不要滥用电动工具,根据用途使用适当的电动工具。

选用适当设计的电动工具会使你工作更有效、更安

全。

f 如果开关不能接通或关断工具电源,则不能使用该电

动工具。 不能用开关来控制的电动工具是危险的且必

须进行修理。

f 在进行任何调节、更换附件或贮存电动工具之前,必

须从电源上拔掉插头和/或使电池盒与工具脱开。 这

种防护性措施将减少工具意外起动的危险。

f 将闲置不用的电动工具贮存在儿童所及范围之外,并

且不要让不熟悉电动工具或对这些说明不了解的人操

作电动工具。 电动工具在未经培训的用户手中是危险

的。

f 保养电动工具。检查运动件是否调整到位或卡住,检

查零件破损情况和影响电动工具运行的其他状况。如

有损坏,电动工具应在使用前修理好。 许多事故由维

护不良的电动工具引发。

Bosch Power Tools 1 609 929 M43 | (28.6.11)

Page 12

OBJ_BUCH-61-006.book Page 12 Tuesday, June 28, 2011 2:41 PM

12 | 中文

f 保持切削刀具锋利和清洁。 保养良好的有锋利切削刃

的刀具不易卡住而且容易控制。

f 按照使用说明书,考虑作业条件和进行的作业来使用

电动工具、附件和工具的刀头等。 将电动工具用于那

些与其用途不符的操作可能会导致危险。

维修

f 将你的电动工具送交专业维修人员,使用同样的备件

进行修理。 这样将确保所维修的电动工具的安全性。

针对电钻的安全规章

GSB 13/ GSB 13 RE / GSB 16 / GSB 16 RE

f 如果电动工具提供了辅助手柄便要使用它。 操作时失

控可能导致伤害。

f 工作时必须用双手握紧电动工具,並且要确保立足稳

固。 使用双手比较能够握稳电动工具。

GSB 10/ GSB 10 RE / GSB 13 / GSB 13 RE/GSB 16/

GSB 16 RE

f 使用冲击电钻时要戴好耳罩。 暴露在噪声中会引起听

力损伤。

f 工作时如果安装在电动工具上的工具可能割断隐藏的

电线或电动工具本身的电源线,一定要握住绝缘手柄

操作电动工具。 安装在电动工具上的工具如果接触了

带电的线路,电动工具上的金属部件会导电,可能造

成操作者触电。

f 使用合适的侦测装置侦察隐藏的电线,或者向当地的

相关单位寻求支援。 接触电线可能引起火灾並让操作

者触电。损坏了瓦斯管会引起爆炸。凿穿水管不仅会

造成严重的财物损失,也可能导致触电。

f 如果安装在机器上的工具被夹住了,必须马上关闭电

动工具並保持镇静。此时机器会产生极高的反应力

矩,並进而造成回击。 安装在机器上的工具容易被夹

住如果:

– 电动工具超荷了,或者

– 安装在机器上的工具在工件中歪斜了。

f 固定好工件。 使用固定装置或老虎钳固定工件,会比

用手持握工件更牢固。

f 等待电动工具完全静止后才能够放下机器。 机器上的

工具可能在工作中被夹住,而令您无法控制电动工

具。

产品和功率描述

阅读所有的警告提示和指示。 如未确实遵

循警告提示和指示,可能导致电击、火灾

並且 / 或其他的严重伤害。

按照规定使用机器

本机器适合在砖块、混凝土和石材上进行冲击钻。另外

也可以在木材、金属、陶瓷和塑料上钻孔。配备电子调

速装备和正 / 逆转功能的机型,也能够鬆 / 紧螺丝和攻

牙。

插图上的机件

机件的编号和电动工具详解图上的编号一致。

1 快速夹头*

2 前套筒

3 后套筒

4 " 正常钻 / 冲击钻 " 的转换开关

5 起停开关的锁紧键

6 起停开关

7 设定转速的指拨轮 ( GSB 16 RE)

8 正逆转开关 (GSB 10 RE / GSB 13 RE /GSB 16 RE)

9 调整深度尺的按键*

10 调整辅助手柄的蝶翼螺丝*

11 辅助手柄 (绝缘握柄)*

12 深度尺*

13 手柄 (绝缘握柄)

14 夹头扳手*

15 齿环夹头*

16 通用批嘴连杆*

17 螺丝批嘴*

18 内六角扳手**

19 开口扳手**

*图表或说明上提到的附件,并不包含在基本的供货范围中。

本公司的附件清单中有完整的附件供应项目。

**可以在市面上购得 (不包含在供货范围中)。

技术数据

冲击电钻

物品代码

额定输入功率

输出功率

无负载转速

本说明书提供的参数是以 230 V 为依据,於低电压地区,此数据有可能不同。

请认清电动工具铭牌上的物品代码。电动工具在销售市场上没有统一的商品名称。

1 609 929 M43 | (28.6.11) Bosch Power Tools

GSB ...

Professional

3 601 ... B16 0.. B16 1.. B17 0.. B17 1.. B18 0.. B18 1..

瓦

瓦

次 / 分 2600 0 –2600 2800 0–2800 3000 0–3000

10 10 RE 13 13 RE 16 16 RE

500

250

500 600 600 701 701

250 301 301 351 351

Page 13

OBJ_BUCH-61-006.book Page 13 Tuesday, June 28, 2011 2:41 PM

冲击电钻

最大负载转速

冲击次数

额定扭力

设定转速

正 / 逆转功能

主轴颈直径

最大钻孔直径

– 混凝土

– 钢

– 木材

夹头的夹紧范围 毫米

重量符合 EPTA-Procedure

01/2003

绝缘等级

本说明书提供的参数是以 230 V 为依据,於低电压地区,此数据有可能不同。

请认清电动工具铭牌上的物品代码。电动工具在销售市场上没有统一的商品名称。

GSB ...

Professional

次 / 分 1610 1610 1570 1570 1640 1640

次 / 分 25 700 25 700 25070 25070 26270 26 270

牛頓米

毫米

毫米

毫米

毫米

公斤

10 10 RE 13 13 RE 16 16 RE

1,5

– ––––z

– z – z – z

43

10

8

20

1,5 – 10

1,5

/II /II /II /II /II /II

中文 | 13

1,5 1,8 1,8 2,0 2,0

43 43 43 43 43

10

20

1,5 – 10 1,5 –13 1,5 –13 1,5 – 13 1,5 –13

1,5 1,7 1,7 1,9 1,9

13

8

10

25

13

10

25

16

12

30

16

12

30

安装

f 维修电动工具或换装零、配件之前,务必从插座上拔

出插头。

辅助手柄 (参考插图 A)

(GSB 13/GSB 13 RE / GSB 16/GSB 16 RE)

f 操作电动工具时务必使用辅助手柄 11.

您可以根据需要改变辅助手柄 11 的位置,以提高工作

安全和增加工作的舒适性。

朝着逆时钟的方向拧转调整辅助手柄的蝶翼螺丝 10, 把

辅助手柄 11 摆动到需要的位置上, 接著再顺着时钟的

转向拧紧调整辅助手柄的蝶翼螺丝 10。

调整钻深 (参考插图 A)

使用深度尺 12 可以设定需要的钻深 X。

按下调整深度尺的按键 9,再把深度尺装入辅助手柄 11

中。

适当调整深度尺,从钻咀尖端到深度尺尖端的距离必须

和需要的钻深 X 一致。

更换工具

快速夹头 (参考插图 B)

握紧快速夹头 1 的后套筒 3,朝 着 n 的方向拧转前套筒

2, 必须拧转至能够装入工具为止。安装好工具。

握牢快速夹头 1 上的后套筒 3, 接著再朝着转向 o 用力

地拧转前套筒 2,必须拧转至不再听见齿轮滑开的磨擦

声为止。此时夹头已经 自动锁定。

当您在拆卸工具时,反向拧转前套筒 2,锁定便自动解

除。

齿环夹头 (参考插图 C)

f 更换工具时必须佩戴手套。 长期工作之后夹头会变得

十分炽热。

转动齿环夹头 15 至能够装入工具为止,安装好工具。

把夹头扳手 14 插入夹头 15 上的收紧孔中,並正确地夹

紧工具。

起子机的工具 (参考插图 D)

以螺丝批嘴 17 作业时,一定要使用通用批嘴连杆 16。

只能选用能够配合螺丝头的螺丝批嘴。

旋转螺丝时必须把"正常钻 / 冲击钻"的转换开关 4 调

整到"正常钻"的符号上。

更换夹头

拆卸夹头 (参考插图 E)

拆卸快速夹头 1 时必须把内六角扳手 18 固定在快速夹

头 1 上。 并且把开口扳手 19 (开口 12 毫米)固定在

主轴上的扳手安装位置。把电动工具放在稳固的底座

上,例如工作台。 握牢开口扳手 19,朝着转向 n 拧转

内六角扳手 18 便可以放松快速夹头 1。 如果快速夹头卡

住了,轻敲内六角扳手 18 的长端便可以放松夹头。 从

快速夹头上拔出内六角扳手,接著再拧转取出快速夹

头。

採用拆卸快速夹头的方式,拆卸齿环夹头 15 。

安装夹头 (参考插图 F)

以相反的步骤安装快速夹头 / 齿环夹头。

使用约 30–35 牛顿米的拉紧扭力拧紧夹头。

Bosch Power Tools 1 609 929 M43 | (28.6.11)

Page 14

OBJ_BUCH-61-006.book Page 14 Tuesday, June 28, 2011 2:41 PM

14 | 中文

吸锯尘 / 吸锯屑

f 含铅的颜料以及某些木材、矿物和金属的加工废尘有

害健康。 机器操作者或者工地附近的人如果接触、吸

入这些废尘,可能会有 过敏反应或者感染呼吸道疾

病。

某些尘埃 (例如加工橡木或山毛榉的废尘)可能致

癌,特别是和处理 木材的添加剂 (例如木材的防腐

剂等)结合之后。 只有经过专业训练的人才能够加工

含石棉的物料。

– 工作场所要保持空气流通。

– 最好佩戴 P2 滤网等级的口罩。

请留心并遵守贵国和加工物料有关的法规。

f 避免让工作场所堆积过多的尘垢。 尘埃容易被点燃。

操作

操作机器

f 注意电源的电压!电源的电压必须和电动工具铭牌上

标示的电压一致。

改变转向 (参考插图 G – H)

(GSB 10 RE/GSB 13 RE/GSB 16 RE)

使用正逆转开关 8 可以改变机器的转向。如果按住了起

停开关 6,则无法改变转向。

正转: 适用於正常钻和转紧螺丝时,把正逆转开关 8 向

左推到底。

逆转: 适用於放鬆 / 转出螺丝和螺母,把正逆转开关 8

向右推到底。

设定操作模式

正常钻和旋转螺丝

把转换开关 4 调整到"正常钻"的符号上。

冲击钻

把转换开关 4 设定在"冲击钻"的符号上。

调整转速 / 冲击次数

(GSB 10 RE/GSB 13 RE/GSB 16 RE)

随著在起停开关 6 上施压大小,可以无级式地提高或降

低转速 / 冲击次数。

轻按起停开关 6,机器以低转速

施加在起停开关上的压力,可以提高机器的转速 / 冲击

次数。

设定转速 / 冲击次数 (GSB 16RE)

使用指拨轮 7 可以设定需要的转速 / 冲击次数。即使在

机器运作中也可以改变转速 / 冲击次数。

正确的转速 / 冲击次数必须视加工物料和工作状况而

定,唯有实际操作才能够得到最合适的结果。

/ 冲击次数运作。增强

有关操作方式的指点

f 先关闭电动工具,然后再把工具放置在螺母/螺丝上。

安装在接头上的工具如果仍继续转动,容易从螺丝头

上滑开。

在机器以低转速长期运作之后,可让机器在空载的状况

下,以最高转速旋转 3 分钟,以加速冷却。

在瓷砖上钻孔时,必须把转换开关 4 调整在"正常钻"

的符号上。待穿透瓷砖后,再把转换开关调整在

"冲击钻"的符号上,並以冲击钻的功能继续作业。

在混凝土、石材和砖墙上钻孔时,必须使用硬金属钻

头。

在金属上钻孔时只能使用完好,经过研磨的 HSS 钻头

(HSS = 高效率高速钢)。在博世的附件产品系列中,

有符合 这个品质等级的产品。

使用钻头研磨器 (参考附件),可轻易地补磨

2,5–10 毫米的麻花钻头。

GSB 16 RE

进行精密的钻孔工作时,最好使用钻床架 (参考附

件)。

机器台钳属於附件,能够牢牢地夹住工件。它可以避免

工件滑动,並能够防止因为工件走滑而发生的意外。

在设定的过程中,可以明显地感觉到转换开关 4 齿合。

机器运作中也可以进行调整。

开动 / 关闭

操作电动工具 时先按下电动工具的起停开关 6,並持续

按著。

按下锁紧键 5 即可锁定被按住的起停开关 6。

放开起停开关 6 即可关闭电动工具。如果起停开关被锁

紧键 5 固定了,先按下起停开关 6 並随即将其放开。

1 609 929 M43 | (28.6.11) Bosch Power Tools

维修和服务

维修和清洁

f 维修电动工具或换装零、配件之前,务必从插座上拔

出插头。

f 电动工具和通风间隙都必须保持清洁,这样才能够提

高工作品质和安全性。

本公司生产的电动工具都经过严密的品质检验,如果机

器仍然发生故障,请将机器交给博世电动工具公司授权

的顾客服务处修理。

询问和订购备件时,务必提供机器铭牌上标示的 10 位

数物品代码。

Page 15

OBJ_BUCH-61-006.book Page 15 Tuesday, June 28, 2011 2:41 PM

顾客服务处和顾客咨询中心

本公司顾客服务处负责回答有关本公司产品的修理,维

护和备件的问题。以下的网页中有爆炸图和备件的资

料:

www.bosch-pt.com

博世顾客咨询团队非常乐意为您解答有关购买,使用和

设定本公司产品及附件的问题。

有关保证,维修或更换零件事宜,请向合格的经销商查

询。

中国大陆

博世电动工具 (中国)有限公司

中国 浙江省 杭州市

滨江区滨康路 567 号

邮政编码:310052

免费服务热线: 400 826 8484

传真:+86 571 8777 4502

电邮:contact.ptcn@cn.bosch.com

www.bosch-pt.com.cn

羅伯特 x 博世有限公司

香港北角英皇道 625 號 21 樓

客戶服務熱線:+852 (21) 02 02 35

傳真:+852 (25) 90 97 62

電郵:info@hk.bosch.com

網站:www.bosch-pt.com.hk

制造商地址:

罗伯特博世有限公司

营业范围电动工具

邮箱号码 100156

70745 Leinfelden-Echterdingen (莱菲登 - 艾希德登)

Deutschland (德国)

处理废弃物

必须以符合环保的方式,回收再利用损坏的机器、附件

和废弃的包装材料。

不可以把电动工具丢入家庭垃圾中 !

保留修改权。

中文

安全規章

電動工具通用安全警告

閱讀所有警告和所有說明。 不遵照以下警告

和說明會導致電擊、著火和/或嚴重傷害。

保存所有警告和說明書以備查閱。

在所有下列的警告中術語 " 電動工具 " 指市電驅動 (有

線)電動工具或電池驅動 (無線)電動工具。

中文 | 15

工作場地的安全

f 保持工作場地清潔和明亮。 混亂和黑暗的場地會引發

事故。

f 不要在易爆環境,如有易燃液體、氣體或粉塵的環境

下操作電動工具。 電動工具產生的火花會點燃粉塵或

氣體。

f 讓兒童和旁觀者離開後操作電動工具。 注意力不集中

會使你失去對工具的控制。

電氣安全

f 電動工具插頭必須與插座相配。絕不能以任何方式改

裝插頭。 需接地的電動工具不能使用任何轉換插頭。

未經改裝的插頭和相配的插座將減少電擊危險。

f 避免人體接觸接地表面,如管道、散熱片和冰箱。 如

果你身體接地會增加電擊危險。

f 不得將電動工具暴露在雨中或潮濕環境中。 水進入電

動工具將增加電擊危險。

f 不得濫用電線。絕不能用電線搬運、拉動電動工具或

拔出其插頭。使電線遠離熱源、油、銳邊或運動部

件。 受損或纏繞的軟線會增加電擊危險。

f 當在戶外使用電動工具時 , 使用適合戶外使用的外接

軟線。 適合戶外使用的軟線,將減少電擊危險。

f 如果在潮濕環境下操作電動工具是不可避免的,應使

用剩餘電流動作保護器 (RCD)。 使用 RCD 可減小

電擊危險。

人身安全

f 保持警覺,當操作電動工具時關注所從事的操作並保

持清醒。當你感到疲倦,或在有藥物、酒精或治療反

應時,不要操作電動工具。 在操作電動工具時瞬間的

疏忽會導致嚴重人身傷害。

f 使用個人防護裝置。始終佩戴護目鏡。 安全裝置,諸

如適當條件下使用防塵面具、防滑安全鞋、安全帽、

聽力防護等裝置能減少人身傷害。

f 防止意外起動。確保開關在連接電源和 / 或電池盒、

拿起或搬運工具時處於關斷位置。 手指放在已接通電

源的開關上或開關處於接通時插入插頭可能會導致危

險。

f 在電動工具接通之前,拿掉所有調節鑰匙或扳手。 遺

留在電動工具旋轉零件上的扳手或鑰匙會導致人身傷

害。

f 手不要伸展得太長。時刻注意立足點和身體平衡。 這

樣在意外情況下能很好地控制電動工具。

f 著裝適當。不要穿寬鬆衣服或佩戴飾品。讓你的衣

服、手套和頭髮遠離運動部件。 寬鬆衣服、佩飾或長

髮可能會捲入運動部件中。

f 如果提供了與排屑、集塵設備連接用的裝置,要確保

他們連接完好且使用得當。 使用這些裝置可減少塵屑

引起的危險。

Bosch Power Tools 1 609 929 M43 | (28.6.11)

Page 16

OBJ_BUCH-61-006.book Page 16 Tuesday, June 28, 2011 2:41 PM

16 | 中文

電動工具使用和注意事項

f 不要濫用電動工具,根據用途使用適當的電動工具。

選用適當設計的電動工具會使你工作更有效、更安

全。

f 如果開關不能接通或關斷工具電源,則不能使用該電

動工具。 不能用開關來控制的電動工具是危險的且必

須進行修理。

f 在進行任何調節、更換附件或貯存電動工具之前,必

須從電源上拔掉插頭和/或使電池盒與工具脫開。 這

種防護性措施將減少工具意外起動的危險。

f 將閒置不用的電動工具貯存在兒童所及範圍之外,並

且不要讓不熟悉電動工具或對這些說明不瞭解的人操

作電動工具。 電動工具在未經培訓的用戶手中是危險

的。

f 保養電動工具。檢查運動件是否調整到位或卡住,檢

查零件破損情況和影響電動工具運行的其他狀況。如

有損壞,電動工具應在使用前修理好。 許多事故由維

護不良的電動工具引發。

f 保持切削刀具鋒利和清潔。 保養良好的有鋒利切削刃

的刀具不易卡住而且容易控制。

f 按照使用說明書,考慮作業條件和進行的作業來使用

電動工具、附件和工具的刀頭等。 將電動工具用於那

些與其用途不符的操作可能會導致危險。

檢修

f 將你的電動工具送交專業維修人員,必須使用同樣的

備件進行更換。 這樣將確保所維修的電動工具的安全

性。

針對電鑽的安全規章

GSB 13/ GSB 13 RE / GSB 16 / GSB 16 RE

f 如果電動工具提供了輔助手柄便要使用它。 操作時失

控可能導致傷害。

f 工作時必須用雙手握緊電動工具,並且要確保立足穩

固。 使用雙手比較能夠握穩電動工具。

GSB 10/ GSB 10 RE / GSB 13 / GSB 13 RE/GSB 16/

GSB 16 RE

f 使用衝擊電鑽時要戴好耳罩。 暴露在噪聲中會引起聽

力損傷。

f 工作時如果安裝在電動工具上的工具可能割斷隱藏的

電線或電動工具本身的電源線,一定要握住絕緣手柄

操作電動工具。 安裝在電動工具上的工具如果接觸了

帶電的線路,電動工具上的金屬部件會導電,可能造

成操作者觸電。

f 使用合適的偵測裝置偵察隱藏的電線,或者向當地的

相關單位尋求支援。 接觸電線可能引起火災並讓操作

者觸電。損壞了瓦斯管會引起爆炸。鑿穿水管不僅會

造成嚴重的財物損失,也可能導致觸電。

f 如果安裝在機器上的工具被夾住了,必須馬上關閉電

動工具並保持鎮靜。此時機器會產生極高的反應力

矩,並進而造成回擊。 安裝在機器上的工具容易被夾

住如果﹕

– 電動工具超荷了,或者

– 安裝在機器上的工具在工件中歪斜了。

f 固定好工件。 使用固定裝置或老虎鉗固定工件,會比

用手持握工件更牢固。

f 等待電動工具完全靜止後才能夠放下機器。 機器上的

工具可能在工作中被夾住,而令您無法控制電動工

具。

產品和功率描述

閱讀所有的警告提示和指示。 如未確實遵

循警告提示和指示,可能導致電擊、火災

並且 / 或其他的嚴重傷害。

按照規定使用機器

本機器適合在磚塊、混凝土和石材上進行沖擊鑽。另外

也可以在木材、金屬、陶瓷和塑料上鑽孔。配備電子調

速裝備和正 / 逆轉功能的機型,也能夠鬆 / 緊螺絲和攻

牙。

插圖上的機件

機件的編號和電動工具詳解圖上的編號一致。

1 快速夾頭*

2 前套筒

3 後套筒

4 " 正常鑽 / 沖擊鑽 " 的轉換開關

5 起停開關的鎖緊鍵

6 起停開關

7 設定轉速的指撥輪 ( GSB 16 RE)

8 正逆轉開關 (GSB 10 RE / GSB 13 RE /GSB 16 RE)

9 調整深度尺的按鍵*

10 調整輔助手柄的蝶翼螺絲*

11 輔助手柄 (絕緣握柄)*

12 深度尺*

13 手柄 (絕緣握柄)

14 夾頭扳手*

15 齒環夾頭*

16 通用批嘴連桿*

17 螺絲批嘴*

18 內六角扳手**

19 開口扳手**

*圖表或說明上提到的附件,並不包含在基本的供貨範圍中。

本公司的附件清單中有完整的附件供應項目。

**可以在市面上購得 (不包含在供貨範圍中)。

1 609 929 M43 | (28.6.11) Bosch Power Tools

Page 17

OBJ_BUCH-61-006.book Page 17 Tuesday, June 28, 2011 2:41 PM

技術性數據

沖擊電鑽

物品代碼

額定輸入功率

輸出功率 瓦

無負載轉速

最大負載轉速

沖擊次數

額定扭力

設定轉速

正 / 逆轉功能

主軸頸直徑 毫米

最大鑽孔直徑

– 混凝土

– 鋼

– 木材

夾頭的夾緊範圍

重量符合 EPTA-Procedure

01/2003

絕緣等級

本說明書提供的參數是以 230 伏特為依據,於低電壓地區,此數據有可能不同。

請認清電動工具銘牌上的物品代碼。電動工具在銷售市場上沒有 統一的商品名稱。

GSB ...

Professional

3 601 ... B16 0.. B16 1.. B17 0.. B17 1.. B18 0.. B18 1..

瓦

次 / 分 2600 0 –2600 2800 0–2800 3000 0–3000

次 / 分 1610 1610 1570 1570 1640 1640

次 / 分 25 700 25 700 25070 25070 26270 26 270

牛頓米 1,5 1,5 1,8 1,8 2,0 2,0

毫米

毫米

毫米

毫米

公斤

10 10 RE 13 13 RE 16 16 RE

500

250

– ––––z

– z – z – z

43

10

8

20

1,5 – 10

1,5

/II /II /II /II /II /II

中文 | 17

500 600 600 701 701

250 301 301 351 351

43 43 43 43 43

10

20

1,5 – 10 1,5 –13 1,5 –13 1,5 – 13 1,5 –13

1,5 1,7 1,7 1,9 1,9

13

8

10

25

13

10

25

16

12

30

16

12

30

安裝

f 維修電動工具或換裝零、配件之前,務必從插座上拔

出插頭。

輔助手柄 (參考插圖 A)

(GSB 13/GSB 13 RE / GSB 16/GSB 16 RE)

f 操作電動工具時務必使用輔助手柄 11。

您可以根據需要改變輔助手柄 11 的位置,以提高工作

安全和增加工作的舒適性。

朝著逆時鐘的方向擰轉調整輔助手柄的蝶翼螺絲 10, 把

輔助手柄 11 擺動到需要的位置上, 接著再順著時鐘的

轉向擰緊調整輔助手柄的蝶翼螺絲 10。

調整鑽深 (參考插圖 A)

使用深度尺 12 可以設定需要的鑽深 X。

按下調整深度尺的按鍵 9,再把深度尺裝入輔助手柄 11

中。

適當調整深度尺,從鑽咀尖端到深度尺尖端的距離必須

和需要的鑽深 X 一致。

Bosch Power Tools 1 609 929 M43 | (28.6.11)

更換工具

快速夾頭 (參考插圖 B)

握緊快速夾頭 1 的後套筒 3,朝 著 n 的方向擰轉前套筒

2, 必須擰轉至能夠裝入工具為止。安裝好工具。

握牢快速夾頭 1 上的後套筒 3,接著再朝著轉向 o 用力

地擰轉前套筒 2,必須擰轉至不再聽見齒輪滑開的磨擦

聲為止。此時夾頭已經 自動鎖定。

當您在拆卸工具時,反向擰轉前套筒 2,鎖定便自動解

除。

齒環夾頭 (參考插圖 C)

f 更換工具時必須佩戴手套。 長期工作之後夾頭會變得

十分熾熱。

轉動齒環夾頭 15 至能夠裝入工具為止,安裝好工具。

把夾頭扳手 14 插入夾頭 15 上的收緊孔中,並正確地夾

緊工具。

起子機的工具 (參考插圖 D)

以螺絲批嘴 17 作業時,一定要使用通用批嘴連桿 16。

只能選用能夠配合螺絲頭的螺絲批嘴。

旋轉螺絲時必須把 〝正常鑽 / 沖擊鑽〞的轉換開關 4 調

整到 〝正常鑽〞的符號上。

Page 18

OBJ_BUCH-61-006.book Page 18 Tuesday, June 28, 2011 2:41 PM

18 | 中文

更換夾頭

拆卸夾頭 (參考插圖 E)

拆卸快速夾頭 1 時必須把內六角扳手 18 固定在快速夾

頭 1 上。 並且把開口扳手 19 (開口 12 毫米)固定在

主軸上的扳手安裝位置。把電動工具放在穩固的底座

上,例如工作台。 握牢開口扳手 19,朝著轉向 n 擰轉

內六角扳手 18 便可以放松快速夾頭 1。 如果快速夾頭卡

住了,輕敲內六角扳手 18 的長端便可以放松夾頭。 從

快速夾頭上拔出內六角扳手,接著再擰轉取出快速夾

頭。

採用拆卸快速夾頭的方式,拆卸齒環夾頭 15。

安裝夾頭 (參考插圖 F)

以相反的步驟安裝快速夾頭 / 齒環夾頭。

使用約 30–35 牛頓米的拉緊扭力擰緊夾頭。

吸鋸塵 / 吸鋸屑

f 含鉛的顏料以及某些木材、礦物和金屬的加工廢塵有

害健康。 機器操作者或者工地附近的人如果接觸、吸

入這些廢塵,可能會有 過敏反應或者感染呼吸道疾

病。

某些塵埃 (例如加工橡木或山毛櫸的廢塵)可能致

癌,特別是和處理 木材的添加劑 (例如木材的防腐

劑等)結合之後。 只有經過專業訓練的人才能夠加工

含石棉的物料。

– 工作場所要保持空氣流通。

– 最好佩戴 P2 濾網等級的口罩。

請留心並遵守貴國和加工物料有關的法規。

f 避免讓工作場所堆積過多的塵垢。 塵埃容易被點燃。

操作

操作機器

f 注意電源的電壓!電源的電壓必須和電動工具銘牌上

標示的電壓一致。

改變轉向 (參考插圖 G– H)

(GSB 10 RE/GSB 13 RE/GSB 16 RE)

使用正逆轉開關 8 可以改變機器的轉向。如果按住了起

停開關 6,則無法改變轉向。

正轉﹕ 適用於正常鑽和轉緊螺絲時,把正逆轉開關 8 向

左推到底。

逆轉﹕ 適用於放鬆 / 轉出螺絲和螺母,把正逆轉開關 8

向右推到底。

1 609 929 M43 | (28.6.11) Bosch Power Tools

設定操作模式

正常鑽和旋轉螺絲

把轉換開關 4 調整到 〝正常鑽〞的符號上。

沖擊鑽

把轉換開關 4 設定在 〝沖擊鑽〞的符號上。

在設定的過程中,可以明顯地感覺到轉換開關 4 齒合。

機器運作中也可以進行調整。

開動 / 關閉

操作電動工具時先按下電動工具的 起停開關 6,並持續

按著。

按下鎖緊鍵 5 即可鎖定被按住的起停開關 6。

放開起停開關 6 即可關閉電動工具。如果起停開關被鎖

緊鍵 5 固定了,先按下起停開關 6 並隨即將其放開。

調整轉速 / 沖擊次數

(GSB 10 RE/GSB 13 RE/GSB 16 RE)

隨著在起停開關 6 上施壓大小,可以無級式地提高或降

低轉速 / 沖擊次數。

輕按起停開關 6

施加在起停開關上的壓力,可以提高機器的轉速 / 沖擊

次數。

設定轉速 / 沖擊次數 (GSB16 RE)

使用指撥輪 7, 可以設定需要的轉速 / 沖擊次數。即使在

機器運作中也可以改變轉速 / 沖擊次數。

正確的轉速 / 沖擊次數必須視加工物料和工作狀況而

定,唯有實際操作才能夠得到最合適的結果。

,機器以低轉速 / 沖擊次數運作。增強

有關操作方式的指點

f 先關閉電動工具,然后再把工具放置在螺母 / 螺絲上。

安裝在接頭上的工具如果仍繼續轉動,容易從螺絲頭

上滑開。

在機器以低轉速長期運作之後,可讓機器在空載的狀況

下,以最高轉速旋轉 3 分鐘,以加速冷卻。

在瓷磚上鑽孔時,必須把轉換開關 4 調整在 〝正常鑽〞

的符號上。待穿透瓷磚後,再把轉換開關調整在 〝沖擊

鑽〞的符號上,並以沖擊鑽的功能繼續作業。

在混凝土、石材和磚牆上鑽孔時,必須使用硬金屬鑽

頭。

在金屬上鑽孔時只能使用完好,經過研磨的 HSS 鑽頭

(HSS = 高效率高速鋼)。在博世的附件產品系列中,

有符合這個品質等級的產品。

使用鑽頭研磨器 (參考附件),可輕易地補磨

2,5–10 毫米的麻花鑽頭。

GSB 16 RE

進行精密的鑽孔工作時,最好使用鑽床架 (參考附

件)。

機器台鉗屬於附件,能夠牢牢地夾住工件。它可以避免

工件滑動,並能夠防止因為工件走滑而發生的意外。

Page 19

OBJ_BUCH-61-006.book Page 19 Tuesday, June 28, 2011 2:41 PM

한국어 | 19

維修和服務

維修和清潔

f 維修電動工具或換裝零、配件之前,務必從插座上拔

出插頭。

f 電動工具和通風間隙都必須保持清潔,這樣才能夠提

高工作品質和安全性。

本公司生產的電動工具都經過嚴密的品質檢驗,如果機

器仍然發生故障,請將機器交給博世電動工具公司授權

的顧客服務處修理。

詢問和訂購備件時,務必提供機器銘牌上標示的 10 位

數物品代碼。

顧客服務處和顧客咨詢中心

本公司顧客服務處負責回答有關本公司產品的修理,維

護和備件的問題。以下的網頁中有爆炸圖和備件的資料 :

www.bosch-pt.com

博世顧客咨詢團隊非常樂意為您解答有關購買,使用和

設定本公司產品及附件的問題。

台灣

台灣羅伯特博世股份有限公司

建國北路一段 90 號 6 樓

台北市 10491

電話 : +886 (2) 2515 5388

傳真 : +886 (2) 2516 1176

www.bosch-pt.com.tw

制造商地址 :

羅伯特博世有限公司

營業範圍電動工具

郵箱號碼 100156

70745 Leinfelden-Echterdingen (萊菲登 - 艾希德登)

Deutschland (德國)

處理廢棄物

必須以符合環保的方式,回收再利用損壞的機器、附件

和廢棄的包裝材料。

不可以把電動工具丟入家庭垃圾中。

保留修改權。

앞으로의 참고를 위해 이 안전수칙과 사용 설명서를 잘 보관

하십시오 .

다음에서 사용되는 “전동공구” 라는 개념은 전원에 연결하여

사용하는 전동 기기 ( 전선이 있는 ) 나 배터리를 사용하는 전

동 기기

( 전선이 없는 ) 를 의미합니다 .

작업장 안전

f 작업장을 항상 깨끗이 하고 조명을 밝게 하십시오 .

작업장 환경이 어수선하거나 어두우면 사고를 초래할 수

있습니다 .

f 가연성 유체 , 가스 또는 분진이 있어 폭발 위험이 있는 환

경에서 전동공구를 사용하지 마십시오 . 전동공구는 분진

이나 증기에 점화하는 불꽃을 일으킬 수 있습니다 .

f 전동공구를 사용할 때 구경꾼이나 어린이 혹은 다른 사람

이 작업장에 접근하지 못하게 하십시오 . 다른 사람이 주의

를 산만하게 하면 기기에 대한 통제를 잃기 쉽습니다 .

전기에 관한 안전

f 전동공구의 전원 플러그가 전원 콘센트에 잘 맞아야 합니

다 . 플러그를 조금이라도 변경시켜서는 안됩니다. 접지된

전동공구를 사용할 때 어댑터 플러그를 사용하지 마십시

오 . 변형되지 않은 플러그와 잘 맞는 콘센트를 사용하면

감전의 위험을 감소할 수 있습니다 .

f 파이프 관 , 라디에이터 , 레인지 , 냉장고와 같은 접지 표면

에 몸이 닿지 않도록 하십시오 . 몸에 닿을 경우 감전될 위

험이 높습니다 .

f 전동공구를 비에 맞지 않게 하고 습기 있는 곳에 두지 마십

시오 . 전동공구에 물이 들어가면 감전될 위험이 높습니다.

f 전원 코드를 잡고 전동공구를 운반하거나 걸어 놓아서는

안되며 , 콘센트에서 전원 플러그를 뽑을 때 전원 코드를

잡아 당겨서는 절대로 안됩니다. 전원 코드가 열과 오일에

접촉하는 것을 피하고 , 날카로운 모서리나 기기의 가동 부

위에 닿지 않도록 주의하십시오 . 손상되거나 엉킨 전원 코

드는 감전을 유발할 수 있습니다 .

f 실외에서 전동공구로 작업할 때는 실외용으로 적당한 연

장 전원 코드만을 사용하십시오. 실외용 연장 전원 코드를

사용하면 감전의 위험을 줄일 수 있습니다 .

f 전동공구를 습기 찬 곳에서 사용해야 할 경우에는 누전 차

단기를 사용하십시오 . 누전 차단기를 사용하면 감전 위험

을 줄일 수 있습니다 .

사용자 안전

f 신중하게 작업하십시오. 작업을 할 때 주의를 하며, 전동공

한국어

안전 수칙

구를 사용할 때 경솔하게 행동하지 마십시오 . 피로한 상태

이거나 약물 복용 및 음주한 후에는 전동공구를 사용하지

마십시오. 전동공구를 사용할 때 잠시라도 주의가 산만해

지면 중상을 입을 수 있습니다 .

f 작업자 안전을 위한 장치를 사용하십시오 . 항상 보안경을

전동공구용 일반 안전수칙

모든 안전수칙과 지시 사항을 상세히 읽고 지켜

야 합니다 . 다음의 안전수칙과 지시 사항을 준

수하지 않으면 화재 위험이 있으며 감전 혹은 중상을 입을 수

있습니다 .

Bosch Power Tools 1 609 929 M43 | (28.6.11)

착용하십시오 . 전동공구의 종류와 사용에 따라 먼지 보호

마스크 , 미끄러지지 않는 안전한 신발 , 안전모 또는 귀마

개 등의 안전한 복장을 하면 상해의 위험을 줄일 수 있습니

다 .

Page 20

OBJ_BUCH-61-006.book Page 20 Tuesday, June 28, 2011 2:41 PM

20 | 한국어

f 실수로 기기가 작동되지 않도록 주의하십시오 . 전동공구

를 전원에 연결하거나 배터리를 끼우기 전에, 혹은 기기를

들거나 운반하기 전에 , 전원 스위치가 꺼져 있는 지 다시

확인하십시오 . 전동공구를 운반할 때 전원 스위치에 손가

락을 대거나 전원 스위치가 켜진 상태에서 전원을 연결하

면 사고 위험이 높습니다 .

f 전동공구를 사용하기 전에 조절하는 툴이나 나사 키 등을

빼 놓으십시오 . 회전하는 부위에 있는 툴이나 나사 키로

인해 상처를 입을 수 있습니다 .

f 자신을 과신하지 마십시오 . 불안정한 자세를 피하고 항상

평형을 이룬 상태로 작업하십시오. 안정된 자세와 평형한

상태로 작업해야만이 의외의 상황에서도 전동공구를 안

전하게 사용할 수 있습니다 .

f 알맞은 작업복을 입으십시오 . 헐렁한 복장을 하거나 장신

구를 착용하지 마십시오 . 머리나 옷 또는 장갑이 가동하는

기기 부위에 가까이 닿지 않도록 주의하십시오 . 헐렁한 복

장 , 장신구 혹은 긴 머리는 가동 부위에 말려 사고를 초래

할 수 있습니다 .

f 분진 추출장치나 수거장치의 조립이 가능한 경우 , 이 장치

가 연결되어 있는 지 , 제대로 작동이 되는 지 확인하십시

오. 이러한 분진 추출장치를 사용하면 분진으로 인한 사고

위험을 줄일 수 있습니다 .

전동공구의 올바른 사용과 취급

f 기기를 과부하 상태에서 사용하지 마십시오 . 작업을 하는

데 이에 적당한 전동공구를 사용하십시오 . 알맞은 전동공

구를 사용하면 지정된 성능 한도 내에서 더 효율적으로 안

전하게 작업할 수 있습니다 .

f 전원 스위치가 고장 난 전동공구를 사용하지 마십시오 . 전

원 스위치가 작동되지 않는 전동공구는 위험하므로 , 반드

시 수리를 해야 합니다 .

f 기기에 세팅을 하거나 액세서리 부품을 교환하거나 혹은

기기를 보관할 때 , 항상 전원 콘센트에서 플러그를 미리

빼어 놓으십시오 . 이러한 조치는 실수로 전동공구가 작동

하게 되는 것을 예방합니다 .

f 사용하지 않는 전동공구는 어린이 손이 닿지 않는 곳에 보

관하고, 전동공구 사용에 익숙지 않거나 이 사용 설명서를

읽지 않은 사람은 기기를 사용해서는 안됩니다 . 경험이 없

는 사람이 전동공구를 사용하면 위험합니다 .

f 전동공구를 조심스럽게 관리하십시오 . 가동 부위가 하자

없이 정상적인 기능을 하는지 , 걸리는 부위가 있는지 , 혹

은 전동공구의 기능에 중요한 부품이 손상되지 않았는지

확인하십시오 . 손상된 기기의 부품은 전동공구를 다시 사

용하기 전에 반드시 수리를 맡기십시오 . 제대로 관리하지

않은 전동공구의 경우 많은 사고를 유발합니다 .

f 절단 공구를 날카롭고 깨끗하게 관리하십시오 . 날카로운

절단면이 있고 잘 관리된 절단공구는 걸리는 경우가 드물

고 조절하기도 쉽습니다 .

f 전동공구 , 액세서리, 장착하는 공구 등을 사용할 때 , 이 지

시 사항과 특별히 기종 별로 나와있는 사용 방법을 준수하

십시오 . 이때 작업 조건과 실시하려는 작업 내용을 고려하

십시오 . 원래 사용 분야가 아닌 다른 작업에 전동공구를

사용할 경우 위험한 상황을 초래할 수 있습니다 .

1 609 929 M43 | (28.6.11) Bosch Power Tools

서비스

f 전동공구 수리는 반드시 전문 인력에게 맡기고 , 수리 정비

시 보쉬 순정 부품만을 사용하십시오 . 그렇게 함으로서 기

기의 안전성을 오래 유지할 수 있습니다 .

드릴 머신용 안전 수칙

GSB 13/ GSB 13 RE/GSB 16 / GSB 16 RE

f 보조 손잡이가 전동공구와 함께 공급되는 경우 이를 사용

하십시오 . 통제를 잃게되면 상해를 입을 수 있습니다 .

f 전동공구를 두 손으로 꽉 잡고 안전한 자세로 작업하십시

오 . 전동공구는 두 손으로 사용하면 더 안전합니다 .

GSB 10/ GSB 10 RE/GSB 13 / GSB 13 RE/ GSB 16 /

GSB 16 RE

f 임팩트 드릴작업을 할 때 귀마개를 착용하십시오 . 소음으

로 인해 청각을 상실할 수 있습니다 .

f 작업할 때 톱날이 이지 않는 전선이나 기기 자체의 코드에

닿을 위험이 있으면 전동공구의 절연된 손잡이 면을 잡으

십시오. 톱날이 전류가 흐르는 전선에 접하게 되면 기기의

금속 부위에 전기가 통해 감전될 위험이 있습니다 .

f 보이지 않는 배관 설비를 확인하려면 적당한 탐지기를 사

용하거나 담당 에너지 공급회사에 문의하십시오 . 전선에

접하게 되면 화재나 전기 충격을 야기할 수 있습니다 . 가

스관을 손상시키면 폭발 위험이 있습니다 . 수도관을 파손

하게 되면 재산 피해를 유발하거나 전기 충격을 야기할 수

있습니다 .

f 툴 홀더에 끼워진 비트가 물리면 즉시 전동공구 스위치를

끄십시오 . 반동을 유발할 수 있는 강한 반동력이 생길 수

있습니다 . 툴 홀더에 끼워진 비트는 다음의 경우 물립니

다 :

— 전동공구가 과부하된 상태이거나

— 작업하려는 소재에 걸렸을 경우 물립니다 .

f 작업물을 잘 고정하십시오 . 고정장치나 기계 바이스에 끼

워서 작업하면 손으로 잡는 것보다 더 안전합니다 .

f 전동공구를 내려놓기 전에 기기가 완전히 멈추었는지를

확인하십시오 . 펀치가 걸리거나 전동공구에 대한 통제가

어려워질 수 있습니다 .

제품 및 성능 소개

모든 안전수칙과 지시 사항을 상세히 읽고 지

켜야 합니다 . 다음의 안전수칙과 지시 사항

을 준수하지 않으면 화재 위험이 있으며 감전

혹은 중상을 입을 수 있습니다 .

규정에 따른 사용

본 기기는 벽돌 콘크리트 석재에 임팩트 드릴작업 , 목재 금속

플라스틱에 드릴작업을 하는 데 사용해야 합니다 . 전자 제어

장치와 회전방향 선택 장치가 있는 모델은 스크류작업이나

나사산 절삭작업 ( 태핑작업 ) 도 가능합니다 .

Page 21

OBJ_BUCH-61-006.book Page 21 Tuesday, June 28, 2011 2:41 PM

제품의 주요 명칭

제품의 주요 명칭에 표기되어 있는 번호는 기기 그림이 나와

있는 면을 참고하십시오 .

1 키레스 척*

2 슬리브 앞부분

3 슬리브 뒷부분

4 “드릴 / 임팩트 드릴작업” 선택 스위치

5 전원 스위치 잠금 버튼

6 전원 스위치

7 속도 조절 다이얼 ( GSB 16 RE)

8 회전방향 선택 스위치

(GSB 10 RE/GSB 13 RE/GSB 16 RE)

9 깊이 조절자 조절용 버튼*

10 보조 손잡이 조절용 날개 나사*

11 보조 손잡이 ( 절연된

12 깊이 조절자*

13 손잡이 ( 절연된 손잡이 부위 )

14 드릴 척 키*

15 키 타입 척*

16 유니버설 비트 홀더*

17 스크류 드라이버 비트*

18 육각 키**

19 양구 스패너**

*도면이나 설명서에 나와있는 액세서리는 표준 공급부품에 속하지 않

습니다 . 전체 액세서리는 저희 액세서리 프로그램을 참고하십시오 .

**시중에서 구매 가능 ( 표준 공급 부품에 포함되지 않음 )

손잡이 부위 )*

제품 사양

임팩트 드릴

제품 번호

소비 전력

출력

무부하 속도

부하 시 최대 속도

타격률

정격 토크

속도 설정

역회전 기능

스핀들 칼라 직경

드릴 직경 , 최대

– 콘크리트

– 철재

– 목재

드릴 척 클램핑 범위

EPTA 공정 01/2003 에 따른 중량

안전 등급

자료는 정격 전압 [U] 230 V 를 기준으로 한 것입니다 . 전압이 낮거나 각국의 특수한 모델에 따라 달라질 수 있습니다 .

전동공구의 명판에 표시된 제품 번호를 확인하십시오 . 각 전동공구의 명칭이 시중에서 상이하게 사용될 수 있습니다 .

GSB ...

Professional

3 601 ... B16 0.. B16 1.. B17 0.. B17 1.. B18 0.. B18 1..

W 500 500 600 600 701 701

W 250 250 301 301 351 351

rpm 2600 0 – 2 600 2800 0 –2 800 3 000 0 –3000

rpm 1610 1 610 1 570 1570 1640 1640

min-125700 25 700 25 070 25070 26270 26 270

Nm 1.5 1.5 1.8 1.8 2.0 2.0

mm 43 43 43 43 43 43

mm

mm

mm

mm 1.5 – 10 1.5 – 10 1.5– 13 1.5 – 13 1.5 –13 1.5–13

kg 1.5 1.5 1.7 1.7 1.9 1.9

10 10 RE 13 13 RE 16 16 RE

– ––––z

– z – z – z

10

20

/II /II /II /II /II /II

10

8

20

13

8

10

25

13

10

25

한국어 | 21

16

12

30

16

12

30

조립

f 전동공구를 보수 정비하기 전에 반드시 콘센트에서 전원

플러그를 빼십시오 .

보조 손잡이 ( 그림 A 참조 )

(GSB 13/GSB 13 RE/GSB 16/GSB 16 RE)

f 반드시 보조 손잡이 11 을 장착하여 전동공구를 사용하십

시오 .

보조 손잡이 11 은 안전하고 피로가 적은 자세로 작업할 수 있

도록 모든 위치로 움직여 조립할 수 있습니다 .

Bosch Power Tools 1 609 929 M43 | (28.6.11)

보조 손잡이 조절용 날개 나사 10 을 시계 반대 방향으로 돌

리고 보조 손잡이 11 을 원하는 위치로 움직입니다 . 그리고

나서 날개 나사 10 을 시계 방향으로 돌려

천공 깊이 조절하기 ( 그림 A 참조 )

원하는 천공 깊이 X 는 깊이 조절자 12 로 조절할 수 있습니

다 .

깊이 조절자 조절용 버튼 9 를 누르고 깊이 조절자를 보조 손

잡이 11 안으로 밀어 넣습니다 .

드릴 비트의 끝과 깊이 조절자의 끝 부위의 간격이 원하는 천

공 깊이 X 가 될 때까지 깊이 조절자를

다시 조입니다 .

잡아 당깁니다 .

Page 22

OBJ_BUCH-61-006.book Page 22 Tuesday, June 28, 2011 2:41 PM

22 | 한국어

액세서리의 교환

키레스 척 ( 그림 B 참조 )

키레스 척 1 의 슬리브 뒷부분 3 을 꽉 잡고 비트가 끼워질 정

도까지 슬리브 앞부분 2 를 n 회전 방향으로 돌립니다 . 비트

를 끼우십시오 .

키레스 척 1 의 슬리브 뒷부분 3 을 꽉 잡고 슬리브 앞부분 2

를 더 이상 걸리는 소리가 나지 않을 때까지 손으로 힘껏 o

방향으로

돌리십시오 . 이렇게 하면 드릴 척이 자동으로 잠기

게 됩니다 .

비트를 탈착하기 위해 슬리브 앞부분 2 를 반대 방향으로 돌

리면 잠금 상태가 다시 해제됩니다 .

키 타입 척 ( 그림 C 참조 )

f 비트를 교환할 때 보호 장갑을 착용하십시오 . 장시간 작업

을 하면 드릴 척이 과열될 수 있습니다 .

키 타입 척 15 를 비트가 끼워질 수 있을 정도 까지 돌려 열어

준 다음에 비트를 끼웁니다 .

척 키 14 를 해당하는 키 타입 척 15 의 구멍에 끼우고 비트를

일정하게 고정합니다 .

스크류 드라이버 비트 ( 그림 D 참조 )

드라이버 비트 17 로 작업할 때 , 반드시 유니버설 비

스크류

트 홀더 16 을 사용해야 합니다 . 나사못 머리에 맞는 스크류

드라이버 비트만을 사용하십시오 .

스크류작업을 하려면 “드릴 / 임팩트 드릴작업” 선택 스위

치 4 가 반드시 “드릴작업” 위치에 있어야 합니다 .

드릴 척 교환하기

드릴 척 분해하기 ( 그림 E 참조 )

키레스 척 1 을 탈착하려면 육각 키 18 을 키레스 척 1 안으로

끼우고 양구 스패너 19 (SW 12) 을 구동 스핀들의 키 대는 면

에 대십시오 . 전동공구를 작업대와 같은 단단한 바닥에 놓으

십시오 . 양구 스패너 19 를 꽉 잡고 육각 키 18 을 n 방향으

로 돌려 키레스 척 1 을

육각 키 18 의 긴 쪽을 가볍게 두드려 주면 풀어 집니다 . 육각

키를 키레스 척에서 뺀 후 키레스 척을 돌려 완전히 빼십시오.

키 타입 척 15 도 키레스 척과 같은 방법으로 분해하면 됩니

다 .

드릴 척 조립하기 ( 그림 F 참조 )

키레스 척 / 키 타입 척 조립은 반대

드릴 척은 약 30– 35 Nm 의 고정 토크로 조여야 합니

다 .

풀어 줍니다 . 꽉 끼워진 키레스 척은

순서로 하면 됩니다 .

분진 및 톱밥 추출장치

f 납 성분을 포함한 페인트나 몇몇 나무 종류 , 또는 광물 성

분 그리고 철과 같은 재료의 분진은 건강을 해칠 수 있습니

다 . 이 분진을 만지거나 호흡할 경우 , 사용자나 주변 사람

들은 알레르기 반응이나 호흡기 장애를 일으킬 수 있습니

다 .

떡갈나무나 너도밤나무와 같은 특정한 분진은 암을 유발

시키며 , 특히 목재 처리용으로 사용되는 부가 원료 ( 크로

마트 , 목재 보호제 ) 와 혼합되면 암을 유발시키게 됩니다 .

석면 성분을 포함한 재료는 오직 전문가가 작업을 해야 합

니다 .

– 작업장의 통풍이 잘 되도록 하십시오 .

– 필터등급 P2 가 장착된 호흡 마스크를 사용하십시오 .

작업용 재료에 관해 국가가 지정한 규정을 고려 하십시오 .

f 작업장에 분진이 쌓이지 않도록 하십시오 . 분진이 쉽게 발

화할 수 있습니다 .

작동

기계 시동

f 공공 배전 전압에 주의 ! 공급되는 전원의 전압은 전동공구

의 명판에 표기된 전압과 동일해야 합니다 .

회전방향 설정하기 ( 그림 G–H 참조 )

(GSB 10 RE / GSB 13 RE /GSB 16 RE)

회전방향 선택 스위치 8 로 기기의 회전 방향을 선택할 수 있

습니다 . 그러나 전원 스위치 6 이 눌려진 상태에서는 작동이

불가능합니다 .

정회전 : 드릴작업이나 스크류작업을 하려면 회전방향 선택

스위치 8 을 왼쪽으로 끝까지 밉니다 .

나사못이나 너트를 느슨하게 하거나 푸는 작업을 하

역회전 :

려면 , 회전방향 선택 스위치 8 을 오른쪽 끝까지 밉니다 .

작동 모드 설정하기

드릴작업 및 스크류작업

선택 스위치 4 를 “드릴작업” 표시에 맞추십시

오 .

임팩트 드릴작업

선택 스위치 4 를 “임팩트 드릴작업” 표시에 맞

춥니다 .

선택 스위치 4 는 걸리는 소리가 확실히나며 , 기기가 작동 중

에도 선택이 가능합니다 .

전원 스위치 작동

전동공구를 작동하려면 전원 스위치 6 을 누르고 누른 상태

를 유지하십시오 .

전원 스위치 6 을 누른 상태로 유지하려면 , 잠금 버튼 5 를 누

르십시오 .

전동공구의 스위치를 끄려면 전원 스위치 6 을 놓거나 잠금

버튼 5 로 고정된 경우 전원 스위치 6 을 살짝 눌렀다가 다시

놓습니다 .

속도 / 타격률 조절하기

(GSB 10 RE / GSB 13 RE /GSB 16 RE)

전원 스위치 6 에 가하는 힘의

공구의 속도 / 타격률을 무단으로 조절할 수 있습니다 .

전원 스위치 6 을 살짝 누르면 낮은 속도 / 타격률로 작동합니

다 . 좀 더 세게 누르면 속도 / 타격률이 증가합니다 .

강약에 따라 작동 중에도 전동

1 609 929 M43 | (28.6.11) Bosch Power Tools

Page 23

OBJ_BUCH-61-006.book Page 23 Tuesday, June 28, 2011 2:41 PM

ภาษาไทย | 23

속도 / 타격률 설정하기 (GSB16RE)

속도 조절 다이얼 7 로 원하는 속도 / 타격률을 작동 중에도

선택할 수 있습니다 .

필요한 속도 / 타격률은 소재와 작업 조건에 따라 달라지므로

실제 시험을 통해 결정할 수 있습니다 .

사용방법

f 전동공구의 스위치가 꺼진 상태에서만 나사못에 대십시

오 . 회전하는 드릴 비트가 미끄러질 수 있습니다 .

낮은 속도로 장기간 연속 작업을 했을 경우 , 기기를 약 3 분

간 무부하 상태로 최고 속도로 운전한 후 식히십시오 .

타일에 드릴작업을 하려면 선택 스위치 4 를 “드릴작업”

표시에 맞춥니다 . 타일에 구멍을 완전히 뚫을 때 까지는 스위

치를 “임팩트 드릴작업” 표시로 바꾸거나

면 안 됩니다 .

콘크리트 석재 벽돌 등에 작업할 때는 경금속 드릴 비트를 사

용하십시오 .

금속에 드릴작업을 할 때 항상 하자가 없는 날카로운 HSS 드

릴 비트 (HSS = 하이 스피드 스틸 ) 만을 사용하십시오 . 보쉬

액세서리 프로그램은 이에 상응하는 품질을 보증합니다 .

드릴 비트 연마기 ( 별매 액세서리 ) 로 직경이 2.5– 10 mm 인

트위스트 드릴 비트를 쉽게

GSB 16 RE

특히 정밀한 작업을 할 때는 드릴 스탠드 ( 별매 액세서리 ) 를

사용하십시오 .

액세서리로 구입이 가능한 기계 바이스를 사용하면 작업물을

안전하게 고정할 수 있어 작업물이 흔들리거나 이로 인해 생

길 수 있는 사고를 방지할 수 있습니다 .

연마할 수 있습니다 .

임팩트작업을 하

한국로버트보쉬기전주식회사

Robert Bosch Korea Mechanics and Electronics Ltd.

전동공구 사업부

경기도 용인시 기흥구 보정동 298 번지

전화 : +82 31 270

팩스 : +82 31 270

고객지원본부

전화 : +82 31 270

팩스 : +82 31 270

E-Mail: Bosch-pt.hotline@kr.bosch.com

Internet: www.bosch-pt.co.kr

– 4143 /4148/ 4620

– 4144

– 4680 /4681/ 4682

– 4686

처리

기기와 액세서리 및 포장 등은 환경 친화적인 방법으로 재생

할 수 있도록 분류하십시오 .

전동공구를 가정용 쓰레기로 처리하지 마십시오 !

위 사항은 사전 예고 없이 변경될 수도 있습니다 .

ภาษาไทย

กฎระเบียบเพื่อความปลอดภัย

คําเตือนทั่วไปเพื่อความปลอดภัย

ในการใชเครื่องมือไฟฟา

ตองอานคําเตือนเพื่อความปลอดภัยและ

보수 정비 및 서비스

보수 정비 및 유지

f 전동공구를 보수 정비하기 전에 반드시 콘센트에서 전원

플러그를 빼십시오 .

f 안전하고 올바른 작동을 위하여 전동공구와 전동공구의

통풍구를상 깨끗이 하십시오 .

세심한 제작과 검사에도 불구하고 전동공구가 불량한 경우가

있다면 보쉬 고객 지원본부나 가까운 보쉬 지정 전동공구 서

비스 센터에 수리를 의뢰하십시오 .

문의 사항이 있거나 스패어 부품을 주문할 때 반드시 전동공

구의 타입 표시판에 적힌 10 자리의 제품 번호를 알려 주십시

오 .

AS 센터 및 고객 상담

AS 센터에서는 귀하 제품의 수리 및 보수정비 , 그리고 부품

에 관한 문의를 받고 있습니다 . 제품의 분해도 및 부품에 관

한 정보는 다음의 주소에서도 보실 수 있습니다 :

www.bosch-pt.com

보쉬 AS 센터 팀은 제품과 액세서리의 구매 , 사용법 및 설정

에 관해 상담해 드립니다 .

Bosch Power Tools 1 609 929 M43 | (28.6.11)

คําสั่งอาจเปนสาเหตุใหถูกไฟฟาดูด เกิดไฟไหม และ/หรือไดรับ

บาดเจ็บอยางรายแรง

เก็บรักษาคําเตือนและคําสั่งทั้งหมดสําหรับเปดอานใน

ภายหลัง

คําวา "เครื่องมือไฟฟา" ในคําเตือนหมายถึง เครื่องมือไฟฟาของทาน

ที่ทํางานดวยพลังงานไฟฟาที่ตอจากเตาเส

เครื่องมือไฟฟาที่ทํางานดวยพลังงานไฟฟาจากแบตเตอรี่ (ไรสาย)

ความปลอดภัยในสถานที่ทํางาน

f รักษาสถานที่ทํางานใหสะอาดและมีไฟสองสวางดี

สถานที่ที่มืดหรือรกรุงรังนํามาซึ่งอุบัติเหตุ

f อยาใชเครื่องมือไฟฟาในสภาพแวดลอมที่เสี่ยงตอ

การติดระเบิดได เชน ในที่ที่มีของเหลว แกซ หรือ

ฝุนที่ติดไฟได เมื่อใชเครื่องมือไฟฟาจะเกิดประกายไฟซึ่ง

อาจจุดฝุนหรือไอใหลุกเปนไฟได

f ขณะใชเครื่องมือไฟฟาทํางาน ตองกันเด็กและผูยืนดู

ใหออกหาง การหันเหความสนใจอาจทําใหทานขาดการ

ควบคุมเครื่องได

คําสั่งทั้งหมด การไมปฏิบัติตามคําเตือนและ

ียบ (มีสายไฟฟา) และ

Page 24

OBJ_BUCH-61-006.book Page 24 Tuesday, June 28, 2011 2:41 PM

24 | ภาษาไทย

ความปลอดภัยเกี่ยวกับไฟฟา

f ปลั๊กของเครื่องมือไฟฟาตองมีขนาดพอดีกับเตาเสียบ

อยาดัดแปลงหรือแกไขตัวปลั๊กอยางเด็ดขาด อยาตอ

ปลั๊กตอใดๆ เขากับเครื่องมือไฟฟาที่มีสายดิน ปลั๊กที่

ไมดัดแปลงและเตาเสียบที่เขากันชวยลดความเสี่ยงจาก

การถูกไฟฟาดูด

f หลีกเลี่ยงไมใหรางกายสัมผัสกับพื้นผิวของสิ่งของที่

ตอสายดินไว เชน ทอ เครื่องทําความรอน เตา และ

ตูเย็น จะเสี่ยงอันตรายจากการถูกไฟฟาดูดมากขึ้นหาก

กระแสไฟฟาวิ่งผานรางกายของทานลงดิน

f อยาวางเครื่องมือไฟฟาตากฝนหรือทิ้งไวในที่ชื้นแฉะ

หากน้ําเขาในเครื่องมือไฟฟา จะเพิ่มความเสี่ยงจากการถูก

ไฟฟาดูด

f อยาใชสายไฟฟาอยางผิดๆ อยาถือเครื่องมือไฟฟา

ที่สาย อยาใชสายแขวนเครื่อง หรืออยาดึงสายไฟฟา

เพื่อถอดปลั๊กออกจากเตาเสียบ กันสายไฟฟาออก

หางจากความรอน น้ํามัน ขอบแหลมคม หรือสวนของ

เครื่องที่กําลังเคลื่อนไหว สายไฟฟาที่ชํารุดหรือพันกันยุง

เพิ่มความเสี่ยงจากการถูกไฟฟาดูด

f เมื่อใชเครื่องมือไฟฟาทํางานกลางแจง ใหใชสายไฟ

ตอที่ไดรับการรับรองใหใชตอในที่กลางแจงเทานั้น

การใชสายไฟตอที่เหมาะสมสําหรับงานกลางแจงชวยลด

อันตรายจากการถูกไฟฟาดูด

f หากไมสามารถหลีกเลี่ยงการใชเครื่องมือไฟฟาทํางาน

ในสถานที่เปยกชื้นได ใหใชสวิทชตัดวงจรเมื่อเกิดการ

รั่วไหลของไฟฟาจากสายดิน การใชสวิทชตัดวงจรเมื่อ

เกิดการรั่วไหลของไฟฟาจากสายดินชวยลดความเสี่ยงตอ

การถูกไฟฟาดูด

ความปลอดภัยของบุคคล

f ทานตองอยูในสภาพเตรียมพรอม ระมัดระวังในสิ่งที่

กําลังทําอยู และมีสติขณะใชเครื่องมือไฟฟาทํางาน

อยาใชเครื่องมือไฟฟาขณะที่ทานกําลังเหนื่อย หรือ

อยูภายใตการครอบงําของฤทธิ์ของยาเสพติด

แอลกอฮอล และยา เมื่อใชเครื่องมือไฟฟาทํางาน ในชั่ว

นาทีที่ทานขาดความเอาใจใสอาจทําใหบุคคลบาดเจ็บอยาง

รุนแรงได

f ใชอุปกรณปกปองรางกาย สวมแวนตาปองกันเสมอ

อุปกรณปกปอง เชน หนากากกันฝุน รองเทากันลื่น หมวก

แข็ง หรือประกบหูกันเสียงดัง ที่เลือกใชตามความเหมาะสม

กับสภาพการทํางาน สามารถลดอันตรายตอบุคคลได

f ปองกันการติดเครื่องโดยไมตั้งใจ ตองดูใหแนใจวา

สวิทชอยูในตําแหนงปดกอนเสียบปลั๊กไฟเขาใน

เตาเสียบ และ/หรือใสแทงแบตเตอรี่ ยกขึ้นหรือ

ถือเครื่องมือ การถือเครื่องโดยใชนิ้วหิ้วที่สวิทช หรือ

เสียบพลังไฟฟาขณะสวิทชเปดอยู อาจนําไปสูอุบัติเหตุที่

รายแรงได

f เอาเครื่องมือปรับแตงหรือประแจปากตายออกจาก

เครื่องมือไฟฟากอนเปดสวิทช เครื่องมือหรือประแจ

ปากตายที่วางอยูกับสวนของเครื่องที่กําลังหมุนจะทําให

บุคคลบาดเจ็บได

f หลีกเลี่ยงการตั้งทาที่ผิดปกติ ตั้งทายืนที่มั่นคงและ

วางน้ําหนักใหสมดุลตลอดเวลา ในลักษณะนี้ทาน

สามารถควบคุมเครื่องมือไฟฟาในสถานการณที่ไมคาดคิด

ไดดีกวา

f ใสเสื้อผาที่เหมาะสม อยาใสเสื้อผาหลวมหรือสวม

เครื่องประดับ เอาผม เสื้อผา และถุงมือออกหางสวน

ของเครื่องที่กําลังหมุน เสื้อผาหลวม เครื่องประดับ

และผมยาวอาจเขาไปติดในสวนของเครื่องที่กําลังหมุนได

f หากตองตอเครื่องมือไฟฟาเขากับเครื่องดูดฝุนหรือ

เครื่องเก็บผง ดูใหแนใจวาการเชื่อมตอและการใชงาน

เปนไปอยางถูกตอง การใชอุปกรณดูดฝุนชวยลดอันตราย

ที่เกิดจากฝุนได

การใชและการดูแลรักษาเครื่องมือไฟฟา

f อยาใชเครื่องมือไฟฟาอยางหักโหม ใชเครื่องมือไฟฟา

ที่ถูกตองตรงตามลักษณะงาน เครื่องมือไฟฟาที่ถูกตอง

จะทํางานไดดีกวาและปลอดภัยกวาในระดับสมรรถภาพที่

ออกแบบไว

f อยาใชเครื่องมือไฟฟาที่สวิทชเปดปดเสีย เครื่องมือ

ไฟฟาที่ไมสามารถควบคุมการเปดปดดวยสวิทชได เปน

เครื่องมือไฟฟาที่ไมปลอดภัยและตองสงซอมแซม

f กอนปรับแตงเครื่อง เปลี่ยนอุปกรณประกอบ หรือ

เก็บเครื่องเขาที่ ตองถอดปลั๊กไฟออกจากเตาเสียบ

และ/หรือถอดแทงแบตเตอรี่ออกจากเครื่องมือไฟฟา

มาตรการปองกันเพื่อความปลอดภัยนี้ชวยลดความเสี่ยง

จากการติดเครื่องโดยไมไดตั้งใจ

f เมื่อเลิกใชงานเครื่องมือไฟฟา ใหเก็บเครื่องไวในที่ที่

เด็กหยิบไมถึง และไมอนุญาตใหบุคคลที่ไมคุนเคย

กับเครื่องหรือบุคคลที่ไมไดอานคําแนะนํานี้ใชเครื่อง

เครื่องมือไฟฟาเปนของอันตรายหากตกอยูในมือของผูใชที่

ไมไดรับการฝกฝน

f เอาใจใสดูแลรักษาเครื่อง ตรวจหาสวนที่เคลื่อนไหว

ไดของเครื่องวาวางอยูตรงแนวหรือติดขัดหรือไม

ตรวจหาการแตกหักของชิ้นสวนและสภาพอื่นใดที่

อาจมีผลตอการทํางานของเครื่องมือไฟฟา หากชํารุด

ตองสงเครื่องมือไฟฟาซอมแซมกอนใชงาน อุบัติเหตุ

หลายอยางเกิดขึ้นเนื่องจากดูแลรักษาเครื่องไมดีพอ

1 609 929 M43 | (28.6.11) Bosch Power Tools

Page 25

OBJ_BUCH-61-006.book Page 25 Tuesday, June 28, 2011 2:41 PM

ภาษาไทย | 25

f รักษาเครื่องมือตัดใหคมและสะอาด หากบํารุงรักษา

เครื่องมือที่มีขอบตัดแหลมคมอยางถูกตอง จะสามารถตัด

ไดลื่นไมติดขัดและควบคุมไดงายกวา

f ใชเครื่องมือไฟฟา อุปกรณประกอบ เครื่องมือ และ

อุปกรณอื่นๆ ใหตรงตามคําแนะนํานี้ และในลักษณะ

ตามที่เครื่องมือไฟฟาประเภทนั้นๆ กําหนดไว โดยตอง

คํานึงถึงเงื่อนไขการทํางานและงานที่จะทําดวย การใช

เครื่องมือไฟฟาทํางานที่ตางไปจากวัตถุประสงคการใช

งานของเครื่อง อาจนําไปสูสถานการณที่เปนอันตรายได

การบริการ

f สงเครื่องมือไฟฟาใหชางผูเชี่ยวชาญตรวจซอมและใช

อะไหลเปลี่ยนของแทเทานั้น ในลักษณะนี้ทานจะแนใจ

ไดวาเครื่องมือไฟฟาอยูในสภาพที่ปลอดภัย

f กอนวางเครื่องลงบนพื้นทุกครั้ง ตองรอใหเครื่องหยุดนิ่ง

อยูกับที่เสมอ มิฉะนั้นเครื่องมือที่ใสอยูอาจติดขัดและนําไปสู

การสูญเสียการควบคุมเครื่องมือไฟฟา

รายละเอียดผลิตภัณฑและขอมูลจําเพาะ

ตองอานคําเตือนเพื่อความปลอดภัยและคําสั่ง

ทั้งหมด การไมปฏิบัติตามคําเตือนและคําสั่งอาจ

เปนสาเหตุใหถูกไฟฟาดูด เกิดไฟไหม และ/หรือ

ไดรับบาดเจ็บอยางรายแรง

ประโยชนการใชงานของเครื่อง

เครื่องนี้ใชสําหรับเจาะกระแทกในอิฐ คอนกรีต และหิน นอกจากนี้

ยังใชเจาะในไม โลหะ และพลาสติค เครื่องที่มีระบบควบคุม

อิเล็กทรอนิกสและการหมุนซาย/ขวาสามารถใชขันสกรูและ

คําแนะนําเพื่อความปลอดภัยสําหรับสวาน

GSB13/GSB13RE/GSB16/GSB16RE

f หากดามจับเพิ่มจัดสงมาพรอมกับเครื่อง ใหใชดามจับเพิ่ม

รวมดวย การสูญเสียการควบคุมอาจทําใหบุคคลบาดเจ็บได

f เมื่อใชเครื่องทํางาน ตองใชมือทั้งสองจับเครื่องใหแนน

และตั้งทายืนที่มั่นคงเสมอ เครื่องมือไฟฟาสามารถเคลื่อนนํา

ไดมั่นคงกวาเมื่อใชมือทั้งสองขางจับ

GSB 10/GSB 10 RE / GSB 13 / GSB 13 RE/ GSB 16/

GSB 16 RE

f สวมอุปกรณปองกันหูเมื่อเจาะกระแทก การไดรับเสียงดัง

อาจทําใหสูญเสียการไดยิน

f เมื่อทํางานในบริเวณที่อุปกรณตัดอาจสัมผัสกับสายไฟฟา

ที่ซอนอยูหรือสายไฟฟาของเครื่อง ตองจับเครื่องมือไฟฟา

ตรงดามจับที่หุมฉนวน หากอุปกรณตัดสัมผัสกับสายที่มี

กระแสไฟฟาไหลผานจะทําใหสวนที่เปนโลหะของเครื่องมือ

ไฟฟาเกิดมีกระแสไฟฟาดวย และสงผลใหผูใชเครื่องถูกไฟฟา

ดูดได

f ใชเครื่องตรวจที่เหมาะสมตรวจหาทอ สายไฟฟา หรือสาย

โทรศัพท ที่อาจซอนอยูในบริเวณที่ทํางาน หรือขอความ

ชวยเหลือจากบริษัทสาธารณูปโภคในทองถิ่น การสัมผัสกับ

สายไฟฟาอาจทําใหเกิดไฟไหมหรือถูกไฟฟาดูด การทําให

ทอแกซเสียหายอาจทําใหเกิดระเบิด การเจาะเขาในทอน้ํา

ทําใหทรัพยสินเสียหาย หรืออาจเปนเหตุใหถูกไฟฟาดูดได

f ปดเครื่องมือไฟฟาทันทีที่เครื่องมือที่ใสอยูเกิดติดขัด

เตรียมตัวรับแรงบิดสะทอนสูงที่ทําใหเกิดการตีกลับ

เครื่องมือที่ใสอยูติดขัดเนื่องจาก:

– เครื่องมือไฟฟาถูกใชงานเกินกําลังปกติ หรือ

– เครื่องมือทิ่มเอียงอยูในชิ้นงาน

f ยึดชิ้นงานใหแนน การยึดชิ้นงานดวยเครื่องหนีบหรือแทนจับ

จะมั่นคงกวาการยึดดวยมือ

Bosch Power Tools 1 609 929 M43 | (28.6.11)

ตัดเกลียวไดดวย

สวนประกอบผลิตภัณฑ

ลําดับเลขของสวนประกอบผลิตภัณฑอางถึงสวนประกอบของเครื่อง

ที่แสดงในหนาภาพประกอบ

1 หัวจับดอกชนิดจับเร็ว*

2 ปลอกหนา

3 ปลอกหลัง

4 สวิทชปรับ “เจาะ/เจาะกระแทก”

5 ปุมล็อคสวิทชเปด-ปด

6 สวิทชเปด-ปด

7 ปุมตั้งความเร็วรอบลวงหนา (GSB16RE)

8 สวิทชเปลี่ยนทิศทางการหมุน

(GSB 10 RE/GSB 13 RE / GSB 16 RE)

9 ปุมปรับกานวัดความลึก*

10 นอตปกสําหรับปรับดามจั

11 ดามจับเพิ่ม (พื้นผิวจับหุมฉนวน)*

12 กานวัดความลึก*

13 ดามจับ (พื้นผิวจับหุมฉนวน)

14 ประแจหัวจับดอก*

15 หัวจับดอกชนิดมีเฟองใน*

16 ดามจับดอกทั่วไป*

17 ดอกไขควง*

18 ประแจขันหกเหลี่ยม**

19 ประแจปากตาย**

*อุปกรณประกอบที่แสดงหรือระบุไมรวมอยูในการจัดสงมาตรฐาน

กรุณาดูอุปกรณประกอบทั้งหมดในรายการแสดงอุปกรณประกอบ

ของเรา

**หาซื้อไดทั่วไป (ไมรวมอยูในขอบเขตการจัดสง)

บเพิ่ม*

Page 26

OBJ_BUCH-61-006.book Page 26 Tuesday, June 28, 2011 2:41 PM

26 | ภาษาไทย

ขอมูลทางเทคนิค

สวานเจาะกระแทก GSB ...

10 10 RE 13 13 RE 16 16 RE

Professional

หมายเลขสินคา 3 601 ... B16 0.. B16 1.. B17 0.. B17 1.. B18 0.. B18 1..

กําลังไฟฟาเขากําหนด

กําลังไฟฟาออก

ความเร็วรอบเดินตัวเปลา

ความเร็วรอบขณะใชงาน สูงสุด

อัตรากระแทก

กําลังบิดกําหนด

การตั้งความเร็วรอบลวงหนา

การหมุนซาย/ขวา

เสนผาศูนยกลางปลอกแกน

Ø-การเจาะ สูงสุด

– คอนกรีต

– เหล็ก

– ไม

วงหนีบหัวจับดอก

น้ําหนักตามระเบียบการ-

EPTA-Procedure 01/2003

ระดับความปลอดภัย

คาที่ใหนี้ใชไดกับแรงดันไฟฟาระบุ [U] 230 โวลท คาเหลานี้อาจผิดแผกไปสําหรับแรงดันไฟฟาที่ต่ํากวา และโมเดลที่สรางสําหรับเฉพาะประเทศ

เครื่องแตละเครื่องอาจมีชื่อทางการคาแตกตางกัน ดังนั้นกรุณาสังเกตหมายเลขสินคาบนแผนปายรุนของเครื่องของทาน

การประกอบ

f ดึงปลั๊กไฟออกจากเตาเสียบกอนปรับแตงเครื่อง

ดามจับเพิ่ม (ดูภาพประกอบ A)

(GSB 13/ GSB 13 RE /GSB 16/ GSB 16 RE)

f ใหใชเครื่องมือไฟฟาพรอมกับดามจับเพิ่ม 11 เสมอ

ทานสามารถจับดามจับเพิ่ม 11 หันไปยังตําแหนงใดก็ได เพื่อจะได

ทาทํางานที่มั่นคงและเหนื่อยนอย

หมุนนอตปกสําหรับปรับดามจับเพิ่ม 10 ไปในทิศทวนเข็ม

นาฬิกา และตั้งดามจับเพิ่ม 11 ไปยังตําแหนงที่ตองการ จากนั้น

จึงขันนอตปก 10

การปรับความลึกรูเจาะ (ดูภาพประกอบ A)

ความลึกรูเจาะที่ตองการ X สามารถตั้งไดดวยกานวัดความลึก 12

กดปุมปรับกานวัดความลึก 9 และสอดกานวัดความลึกเขาใน

ดามจับเพิ่ม 11

ดันกานวัดความลึกออกมาจนระยะหางระหวางปลายดอกสวาน

และปลายกานวัดความลึกเทากับความลึกรูเจาะที่ตองการ X

ไปในทิศตามเข็มนาฬิกากลับเขาใหแนน

วัตต 500 500 600 600 701 701

วัตต 250 250 301 301 351 351

รอบ/นาที 2600 0 – 2600 2800 0 – 2800 3000 0 – 3000

รอบ/นาที 1610 1610 1 570 1 570 1 640 1 640

/นาที 25700 25700 25070 25070 26270 26270

Nm 1,5 1,5 1,8 1,8 2,0 2,0

– ––––z

– z – z – z

มม.4343 43 43 43 43

มม.

มม.

มม.

10

8

20

10

8

20

13

10

25

13

10

25

16

12

30

มม.1,5– 10 1,5 – 10 1,5 – 13 1,5 –13 1,5 – 13 1,5 – 13

กก.1,51,5 1,7 1,7 1,9 1,9

/II /II /II / II / II /II

การเปลี่ยนเครื่องมือ

หัวจับดอกชนิดจับเร็ว (ดูภาพประกอบ B)

จับปลอกทาย 3 ของหัวจับดอกชนิดจับเร็ว 1 ใหแนน และหมุน

ปลอกหนา 2 ไปในทิศทางหมุน

จับเครื่องมือใสเขาไป

จับปลอกหลัง 3 ของหัวจับดอกชนิดจับเร็ว 1 ใหแนนและใชมือ

หมุนปลอกหนา 2 ไปตามทิศ

ในลักษณะนี้หัวจับดอกสวานจะล็อคโดยอัตโนมัติ

เมื่อตองการถอดเครื่องมือออก ตองปลดล็อคอีกครั้งโดยหมุน

ปลอกหนา 2 ไปในทิศตรงกันขาม

หัวจับดอกชนิดมีเฟองใน (ดูภาพประกอบ C)

f ใสถุงมือปองกันอันตรายเมื่อเปลี่ยนเครื่องมือ หัวจับดอก

จะรอนจัดขึ้นไดเมื่อใชเครื่องทํางานนานๆ

เปดหัวจับดอกชนิดมีเฟองใน 15 โดยการหมุนจนสามารถใส

เครื่องมือได จับเครื่องมือใสเขาไป

สอดประแจหัวจับดอก 14 เขาในรูที่ลงรอยกันบนหัวจับดอกชนิด

มีเฟองใน 15 และหนีบเครื่องมือเขาเสมอกัน

n จนสามารถสอดเครื่องมือได

o จนไมไดยินเสียงลงล็อคอีกตอไป

16

12

30

1 609 929 M43 | (28.6.11) Bosch Power Tools

Page 27

OBJ_BUCH-61-006.book Page 27 Tuesday, June 28, 2011 2:41 PM

เครื่องมือขัน (ดูภาพประกอบ D)

เมื่อใชดอกไขควง 17 ควรใชดามจับดอกทั่วไป 16 ดวยเสมอ ตองใช

ไขควงที่มีขนาดพอดีกับหัวสกรู

เมื่อตองการขันสกรู ใหสับสวิทชปรับ "เจาะ/เจาะกระแทก" 4 ไปที่

สัญลักษณ "เจาะ” เสมอ

การเปลี่ยนหัวจับดอก

การถอดหัวจับดอก (ดูภาพประกอบ E)

เมื่อตองการถอดหัวจับดอกชนิดจับเร็ว 1 ออก ใหหนีบประแจขัน

หกเหลี่ยม 18 เขาในหัวจับดอกชนิดจับเร็ว 1 และวางประแจ

ปากตาย 19 (ขนาด 12 มม.) เขากับพื้นที่ราบสําหรับประแจบน

แกนขับ วางเครื่องลงบนที่ค้ํายันที่มั่นคง ต.ย. เชน โตะทํางานของ

ชาง จับประแจปากตาย 19 อยางมั่นคง และคลายหัวจั

บดอกชนิด

จับเร็ว 1 ออกโดยหมุนประแจขันหกเหลี่ยม 18 ไปในทิศการหมุน n

คลายหัวจับดอกชนิดจับเร็วที่ติดแนนออกโดยเคาะที่ปลายดานยาว

ของประแจขันหกเหลี่ยม 18 เอาประแจขันหกเหลี่ยมออกจากหัวจับ

ดอกชนิดจับเร็ว และขันหัวจับดอกชนิดจับเร็วออกจนสุด

การถอดหัวจับดอกชนิดมีเฟองใน 15 ออกใหทําในลักษณะเดียวกับ

การถอดหัวจับดอกชนิดจับเร็ว

การประกอบหัวจับดอก (ดูภาพประกอบ F)

การประกอบหั

วจับดอกชนิดจับเร็ว/หัวจับดอกชนิดมีเฟองในเขา

ใหทําตามลําดับยอนหลัง

ตองขันหัวจับดอกเขาใหแนนดวยกําลังบิดการขัน

ประมาณ

30–35 Nm

การดูดฝุน/ขี้เลื่อย

f ฝุนที่ไดจากวัสดุ เชน เคลือบผิวที่มีสารตะกั่ว ไมบางประเภท

แรธาตุ และโลหะ อาจเปนอันตรายตอสุขภาพ การสัมผัสหรือ

การหายใจเอาฝุนเขาไปอาจทําใหเกิดปฏิกิริยาแพฝุน และ/

หรือนํามาซึ่งโรคติดเชื้อระบบหายใจแกผูใชเครื่องหรือผูที่ยืนอยู

ใกลเคียง

ฝุนบางประเภท เชน ฝุนไมโอก หรือไมบีช นับเป

มะเร็ง โดยเฉพาะอยางยิ่งเมื่อผสมกับสารเติมแตงเพื่อบําบัดไม

(โครเมต ผลิตภัณฑรักษาเนื้อไม) สําหรับวัสดุที่มีแอสเบสทอส

ตองใหผูเชี่ยวชาญทํางานเทานั้น

– จัดสถานที่ทํางานใหมีการระบายอากาศที่ดี

– ขอแนะนําใหสวมหนากากปองกันการติดเชื้อที่มีระดับ-

ไสกรอง P2

ปฏิบัติตามกฎขอบังคับสําคัญอื่นๆ ที่เกี

ที่บังคับใชในประเทศของทาน

f ปองกันการสะสมของฝุนในสถานที่ทํางาน ฝุนสามารถ

ลุกไหมอยางงายดาย

นสารที่ทําใหเกิด

่ยวกับวัสดุชิ้นงาน

ภาษาไทย | 27

การปฏิบัติงาน

เริ่มตนปฏิบัติงาน

f ใหสังเกตแรงดันไฟฟา! แรงดันไฟฟาจากแหลงจายไฟฟา

ตองมีคาตรงกับคาแรงดันไฟฟาที่ระบุไวบนแผนปายพิกัด

เครื่อง

การกลับทิศทางการหมุน (ดูภาพประกอบ G

(GSB 10 RE / GSB 13 RE /GSB 16 RE)

สวิทชเปลี่ยนทิศทางการหมุน 8 ใชสําหรับกลับทิศทางการหมุน

ของเครื่อง อยางไรก็ดี หากกดสวิทชเปด-ปด 6 อยู จะกลับทิศทาง

การหมุนไมได

การหมุนทางขวา: สําหรับการเจาะและขันสกรูเขา ใหสับสวิทช

เปลี่ยนทิศทางการหมุน 8 ไปทางซายจนสุด

การหมุนทางซาย: สําหรับการคลายและขันสกรูและนอตออก

ใหกดสวิทชเปลี

่ยนทิศทางการหมุน 8 ไปทางขวาจนสุด

การตั้งวิธีการปฏิบัติงาน

เจาะ และ ขันสกรู

สับสวิทชปรับ 4 ไปที่สัญลักษณ "เจาะ"

เจาะกระแทก

สับสวิทชปรับ 4 ไปที่สัญลักษณ “เจาะกระแทก”

สวิทชปรับ 4 จะลงสลักอยางเห็นไดชัด และสามารถสับขณะเครื่อง

กําลังเดินอยู

การเปด-ปดเครื่อง

เปดเครื่องทํางานโดยกดสวิทช

เปด-ปด 6 และกดคางไว

ล็อคสวิทชเปด-ปด 6 ที่กดคางไว โดยกดปุมล็อคสวิทชเปด-ปด 5

ปดเครื่องโดยปลอยนิ้วจากสวิทชเปด-ปด 6 หรือในกรณีที่ถูกล็อค

ดวยปุมล็อค 5 อยู ใหกดสวิทชเปด-ปด 6 สั้นๆ และปลอยนิ้ว

การปรับความเร็วรอบ/กระแทก

(GSB 10 RE / GSB 13 RE /GSB 16 RE)

ทานสามารถปรับอัตราความเร็วรอบ/กระแทกของเครื่องมือไฟฟา

ที่เปดสวิทชทํางานไดอยางตอเนื่อง ทั้งนี้ขึ้นอยูกับแรงที่กดลงบน

สวิทชเปด-ปด 6

กดสวิทชเปด-ปด 6 เบาจะไดอัตราความเร็วรอบ/กระแทกต่ํา

กดสวิทชแรงขึ้นอัตราความเร็วรอบ/กระแทกจะเพิ่มขึ้น

การตั้งความเร็วรอบ/กระแทกลวงหนา (GSB16RE)

ความเร็วรอบ/กระแทกที่ตองการสามารถตั้งลวงหนาได

ความเร็วรอบลวงหนา 7 และตั้งไดแมขณะเครื่องกําลังเดินอยู

ความเร็วรอบ/กระแทกที่ตองใชขึ้นอยูกับประเภทวัสดุและเงื่อนไข

การทํางาน และสามารถกําหนดไดจากการทดลองฝกปฏิบัติ

– H)

ดวยปุมตั้ง

Bosch Power Tools 1 609 929 M43 | (28.6.11)

Page 28

OBJ_BUCH-61-006.book Page 28 Tuesday, June 28, 2011 2:41 PM

28 | ภาษาไทย

ขอแนะนําในการทํางาน

f จับเครื่องมือไฟฟาเขาบนหัวสกรู/นอตเมื่อเครื่องปดอยู

เทานั้น เครื่องมือที่หมุนอยูอาจลื่นไถล

หลังจากใชเครื่องดวยความเร็วต่ําเปนเวลานาน ตองทําใหเครื่อง

เย็นลงโดยปลอยใหเครื่องเดินตัวเปลาที่ความเร็วสูงสุดนานประมาณ

3 นาที

เมื่อตองการเจาะกระเบื้อง ใหสับสวิทชปรับ 4 ไปที่สัญลักษณ

"เจาะ" อย

าสับสวิทชไปที่สัญลักษณ "เจาะกระแทก" หรือเจาะโดยการ

กระแทก จนกวาจะไดเจาะกระเบื้องทะลุแลว

เมื่อตองการเจาะคอนกรีต หิน และกําแพงอิฐ ตองใชดอกสวานที่

ทําจากโลหะแข็ง

ใหใชเฉพาะดอกสวาน HSS (HSS = high-speed steel) ที่ลับคม

อยางดีสําหรับเจาะโลหะ ดอกสวานที่เปนอุปกรณประกอบของแท

ของ บอช รับประกันคุณภาพการเจาะ

ดอกสวานเกลียวบิดขนาดตั้งแต

2,5– 10 มม สามารถลับไดอยาง

งายดายดวยที่ลับดอกสวาน (ดูอุปกรณประกอบ)

GSB 16 RE

เราขอแนะนําใหใชแทนเจาะ (ดูอุปกรณประกอบ) เมื่อตองทํางาน

ที่ใชความเที่ยงตรงสูง

ปากกาสําหรับจับวัตถุเปนอุปกรณประกอบ ใชสําหรับยึดชิ้นงาน

ใหแนนอยูกับที่ ชวยไมใหชิ้นงานหมุนไปมา และปองกัน อันตราย

ที่อาจจะเกิดข

ึ้นดวย

การบํารุงรักษาและการบริการ

การบํารุงรักษาและการทําความสะอาด

f ดึงปลั๊กไฟออกจากเตาเสียบกอนปรับแตงเครื่อง

f เพื่อใหทํางานไดอยางถูกตองและปลอดภัย ตองรักษา

เครื่องและชองระบายอากาศใหสะอาดอยูเสมอ

เครื่องมือไฟฟานี้ผานกรรมวิธีการผลิตและตรวจสอบอยางละเอียด

ถี่ถวนมาแลว ถึงกระนั้น หากเครื่องเกิดขัดของ ตองสงเครื่องใหศูนย

บริการหลังการขายสําหรับเครื่องมือไฟฟา บอช ซอมแซม

เมื่อตองการสอบถามและสั่งซื้ออะไหล กรุณาแจงหมายเลขสินคา

สิบหลักบนแผนป

ายรุนของเครื่องทุกครั้ง

การบริการหลังการขายและการใหคําแนะนําลูกคา

ศูนยบริการหลังการขายของเรายินดีตอบคําถามของทานที่

เกี่ยวกับการบํารุงรักษาและการซอมแซมผลิตภัณฑรวมทั้งเรื่อง

อะไหล ภาพขยายและขอมูลเกี่ยวกับอะไหล กรุณาดูใน:

www.bosch-pt.com

แผนกใหคําปรึกษาลูกคาของเราพรอมใหคําแนะนําที่ดีที่สุดแกทาน

ในเรื่องการซื้อผลิตภัณฑ การใชงานและการปรับแตงผลิตภัณฑ

และอุปกรณประกอบตางๆ

ในกรณีประกัน ซอมแซม หร

กรุณาติดตอผูขายที่ไดรับแตงตั้งเทานั้น

ประเทศไทย

สํานักงาน

บริษัท โรเบิรต บอช จํากัด

ชั้น 11 ตึกลิเบอรตี้ สแควร

287 ถนนสีลม

กรุงเทพฯ 10500

โทรศัพท +66 (0)2 / 6 31 18 79 – 18 88 (10 หมายเลข)

โทรสาร +66 (0)2 / 2 38 47 83

www.bosch.co.th

ตูไปรษณีย

บริษัท โรเบิรต บอช จํากัด

แผนกเครื่องมือไฟฟา

ตู

ปณ. 20 54

กรุงเทพฯ 10501

ประเทศไทย

ศูนยบริการซอมและฝกอบรม

ศูนยบริการซอมและฝกอบรมบอช

2869 – 2869/1 ซอยบานกลวย

ถนนพระรามที่ 4 (ใกลทางรถไฟสายปากน้ําเกา)

พระโขนง

กรุงเทพฯ 10110

ประเทศไทย

โทรศัพท +66 (0)2 / 6 71 78 00 – 4

โทรสาร +66 (0)2 / 2 49 42 96

โทรสาร +66 (0)2 / 2 49 52 99

ือซื้อชิ้นสวนมาเปลี่ยน

การกําจัดขยะ

เครื่องมือ อุปกรณประกอบ และหีบหอ ตองนําไปแยกประเภทวัสดุ

เพื่อนํากลับมาใชใหมโดยไมทําลายสภาพแวดลอม

อยาทิ้งเครื่องมือไฟฟาลงในขยะบาน!

ขอสงวนสิทธิ์ในการเปลี่ยนแปลงโดยไมตองแจงลวงหนา

1 609 929 M43 | (28.6.11) Bosch Power Tools

Page 29

OBJ_BUCH-61-006.book Page 29 Tuesday, June 28, 2011 2:41 PM

Bahasa Indonesia | 29