Page 1

Fire Alarm Systems | FIRERAY 5000-UL Reflective Beam Smoke Detector

FIRERAY 5000-UL Reflective Beam Smoke

Detector

www.boschsecurity.com

u Extended monitoring range

u Up to 2 detectors per system controller

The Fireray5000‑UL Linear Smoke Detector covers

distances between 26.25 ft and 330 ft (8 m and

100 m). A reflective prism allows for the accurate

detection of smoke particles within the given distance

range.

For ranges between 26.25 ft and 164 ft (8 m and

50 m), one prism is sufficient. For ranges between

164 ft and 330 ft (50 m and 100 m), four prisms are

required. The additional prisms are included in the

FRay5000‑LR‑Kit Long Range Kit.

Key application areas are large halls such as historical

buildings, churches, museums, shopping centers,

factory halls, warehouses, etc.

The Fireray5000‑UL Linear Smoke Detector is suitable

for use in areas where point-type detectors are not

effective

The Fireray5000-UL Linear Smoke Detector can be

upgraded with one additional FRAY5000-HEADUL Detector Head. The system controller can control

two detectors. Each head can be programmed

separately.

u Two pairs of fire and fault relays (one per detector)

u Transmitter and receiver integrated into a compact

housing

u Integral LASER alignment

Functions

The transmitter emits an invisible infrared light beam

(850 nm) that is focused through a lens. The light

beam is reflected by the prism mounted opposite and

returned to the transmitter/receiver combination.

If the IR beam is obscured by smoke and the signal

received drops below the selected threshold (standard

10 s, adjustable), the detector triggers a fire alarm and

the alarm relay closes.

The sensitivity can be adjusted according to the

environmental conditions. The default settings of 25%

(sensitive), 35% and 50% (non-sensitive) can be

changed in steps of 1%. Each detector can be adjusted

individually. The standard setting is 35%.

The alarm relay can be set to auto-reset or latched

mode.

The LEDs indicate three different operating states:

• Alarm

• Fault

• Operation

You can control and set all parameters via the system

controller and LCD display for each detector head.

Page 2

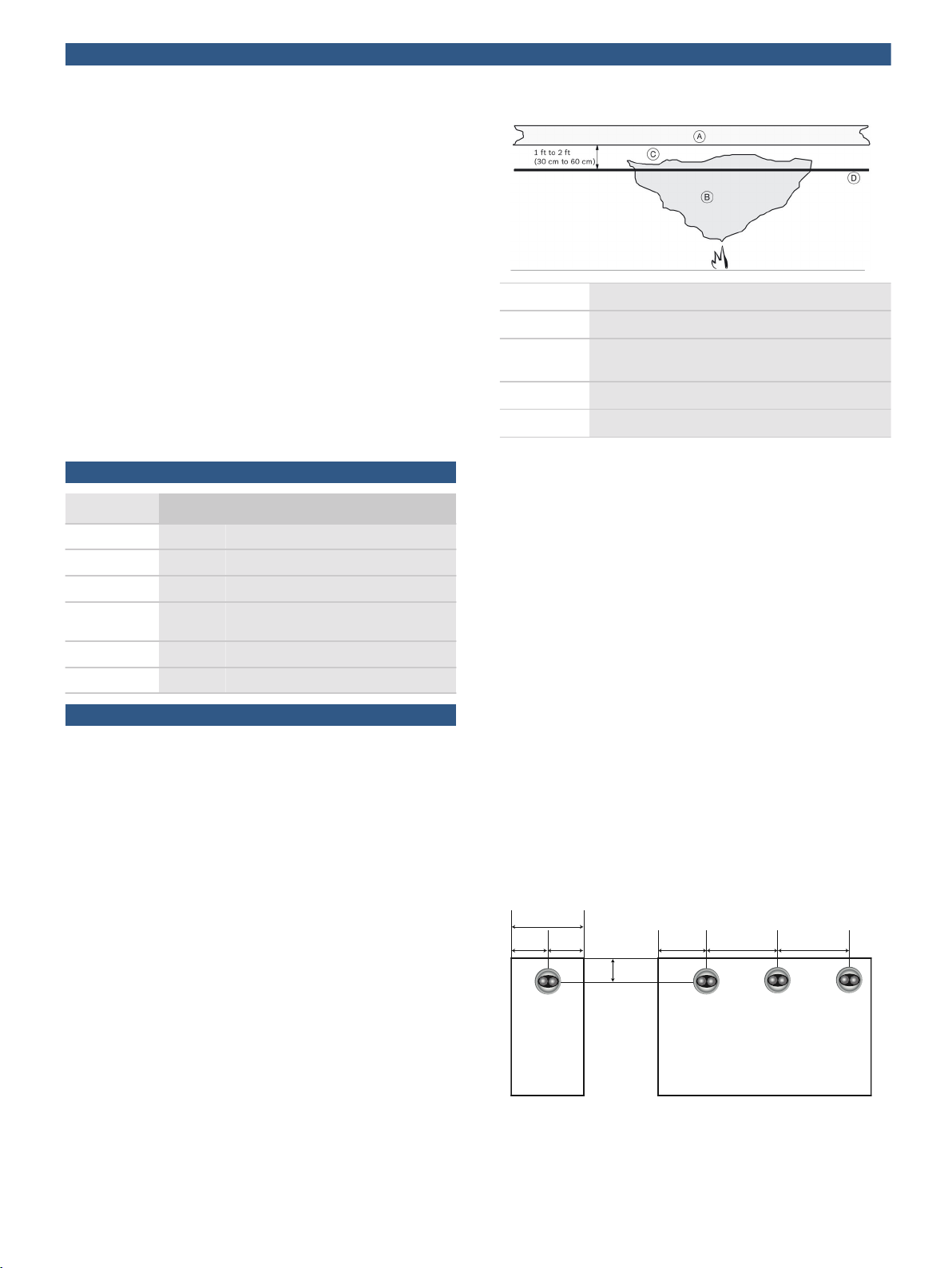

X1

30 ft

(9.1 m)

60 ft (18.25 m)

30 ft

(9.1 m)

60 ft (18.25 m) 60 ft (18.25 m)X2

1.6 ft (0.5 m) < X2 < 30 ft (9.1 m)

1 ft (0.3 m)

< X1 <

2 ft (0.6 m)

| FIRERAY 5000-UL Reflective Beam Smoke Detector

2

Slow changes in the operating states (e. g. component

aging, optics contamination, etc.) do not cause false

alarms, but are compensated by the automatic gain

control. Every 15 minutes, the system state is

compared with a default reference value and in the

case of a deviation, is corrected automatically

to 0.17 dB/h. If the compensation limit is reached,

"Fault" the fault signal is indicated.

If the IR beam is obscured within 2 s and the

obscuration is more than 87% and lasts for 10 seconds

and above (operator changeable), the fault relay

switches. Faults may be caused by an obstacle in the

beam path, by the covering of the reflector, etc. As

soon as the fault cause is removed, the fault relay is

cleared and after 5 s, the detector is automatically

reset to standard operation. The fire panel must be

reset separately.

The system has an alarm output, which is a relay with

a potential‑free change-over contact.

Certifications and approvals

Region Certification

USA UL UROX.S3417 Fireray5000-UL

FM 3037125 Fireray5000-UL

CSFM 7260-1508:0104 Fireray5000-UL

NYC-

22-08-E Fireray5000-UL

MEA

MSFM 2243 Fireray5000-UL

Canada ULC UROXC.S3417 Fireray5000-UL

Installation/configuration notes

• For connection to FPA-1000 and any UL-listed 24V

control panel.

• The line of sight between the detector and the

reflector always has to be clear and may not be

interfered by moving objects (e. g. overhead crane).

• Heat accumulation under the roof may prevent smoke

from rising up to the ceiling. Thus, the detector must

be mounted below the expected heat accumulation.

Accordingly, the benchmark values for X1 specified in

the table have to be exceeded.

• The mounting surface for the detector must be firm

and vibration-free. Metal supports that may be

affected by heat or cold are unsuitable for the

installation.

• The detector and the reflector are usually installed at

the same height and aligned with one another. The

wide angle of the IR beam allows for an easy

adjustment and for a reliable long-term stability.

• The detector must be mounted in a position where

the detector’s optical system is not exposed to direct

sunlight or artificial light. Normal ambient light has no

influence on the IR beam and the analysis.

Installation for smoke plume

Pos. Description

A Ceiling

B

C Heat accumulation

D IR beam

• Since the smoke from a fire does not simply rise

straight up, but rather spreads like a mushroom cloud

(depending on air current and accumulation), the

monitoring range is much greater than the diameter

of the IR beam.

• The lateral detection on either side of the beam is

24.6 ft (7.5 m).

• Country-specific Standards and guidelines on

planning must be observed.

Detector arrangement

The detectors must be arranged according to the

following distances:

X1 Distance from the ceiling 1 ft to 2 ft (0.3 m to

0.6 m)

X2 Horizontal distance detector/wall min. 1.6 ft (0.5 m)

X3 Horizontal distance between two

detectors under gable roofs

Example: Gable roof, 10° roof pitch

X3 = 30 ft + (30 ft x 10%)

X3 = 30 ft + 3 ft

X3 = 33 ft

Positioning the detectors on flat ceilings

Page 3

X1

X1

X1

X1

X2

60 ft (18.25 m) 60 ft (18.25 m)

1.6 ft

(0.5 m)

Φ

X1

X2

10°

1 ft (0.3 m) < X1 < 2 ft (0.6 m)

X3

1.6 ft (0.5 m) < X2 < 24.6 ft (7.5 m)

X2

X3

3 | FIRERAY 5000-UL Reflective Beam Smoke Detector

Positioning the detectors under a shed roof

Positioning the detectors under a gable roof

Mechanics

LED indicators for

• Alarm Flashes red every 10 s

• Fault Flashes yellow every 10 s

• Operation Flashes green every 10 s

Dimensions (W x H x D)

• Detector 5.3 x 5.3 x 5.3 in

(135 x 135 x 135 mm)

• Prism reflector 3.9 x 3.9 x 0.4 in

(100 x 100 x 10 mm)

• Control unit 7.9 x 9.3 x 3.2 in

(200 x 235 x 81 mm)

Housing

• Color Light gray/black

• Material C6600, non-flammable

Weight

• Detector 1.1 lbs (500 g)

• Prism reflector 0.22 lbs (100 g)

• Control unit 2.2 lbs (1000 g)

Environmental conditions

Protection class as per EN 60529 IP 54

Parts included

Qty. Components

1 Fireray5000‑UL Linear Smoke Detector:

compact device with integrated transmitter and receiver

1 Reflective prism

1 Control unit

Permissible operating

temperature

Permissible operating

temperature, UL Listed

Installation

Planning

Permissible distance detectorreflector

-22°F to 131°F (-20°C to 55°C)

32°F to 100°F (0°C to 37.8°C)

Min. 26.25 ft (8 m) – max. 164 ft

(50 m)

1 Installation kit

•with FRay5000‑LR‑Kit Long

Technical specifications

Electrical

Operating voltage 14 V DC (-10%) to 36 V DC

(+10%)

Current consumption

• In standby (1 detector head) ≤ 6 mA @ 36 V DC

• In standby (2 detector heads) ≤ 8,5 mA @ 36 V DC

• In alignment mode (with 1 or 2

detector heads)

Reset control by power disruption > 5 s

Alarm relay (contact load) 100 mA @ 36 V

Fault relay (contact load) 100 mA @ 36 V

≤ 37 mA @ 36 V DC

Range Kit

Lateral detection

(on either sides of the light beam)

Connectable detectors per

system controller

Special features

Optical wavelength 850 nm

Tolerance of the axial deviation

• Detector ± 0.3°

• Reflective prism ± 5.0°

Min. 164 ft (50 m) – max. 330 ft

(100 m)

Max. 30 ft (9.1 m) (heed local

guidelines!)

1 or 2

Page 4

4 | FIRERAY 5000-UL Reflective Beam Smoke Detector

Represented by:

Americas: Europe, Middle East, Africa: Asia-Pacific: China: America Latina:

Bosch Security Systems, Inc.

130 Perinton Parkway

Fairport, New York, 14450, USA

Phone: +1 800 289 0096

Fax: +1 585 223 9180

security.sales@us.bosch.com

www.boschsecurity.us

Bosch Security Systems B.V.

P.O. Box 80002

5617 BA Eindhoven, The Netherlands

Phone: + 31 40 2577 284

Fax: +31 40 2577 330

emea.securitysystems@bosch.com

www.boschsecurity.com

Robert Bosch (SEA) Pte Ltd, Security

Systems

11 Bishan Street 21

Singapore 573943

Phone: +65 6571 2808

Fax: +65 6571 2699

apr.securitysystems@bosch.com

www.boschsecurity.asia

Bosch (Shanghai) Security Systems Ltd.

203 Building, No. 333 Fuquan Road

North IBP

Changning District, Shanghai

200335 China

Phone +86 21 22181111

Fax: +86 21 22182398

www.boschsecurity.com.cn

Robert Bosch Ltda Security Systems Division

Via Anhanguera, Km 98

CEP 13065-900

Campinas, Sao Paulo, Brazil

Phone: +55 19 2103 2860

Fax: +55 19 2103 2862

latam.boschsecurity@bosch.com

www.boschsecurity.com

© Bosch Security Systems 2015 | Data subject to change without notice

13228175627 | en, V3, 20. May 2015

Ordering information

FIRERAY 5000-UL Reflective Beam Smoke Detector

Reflective linear smoke detector with one detector

head and one prism, range min. 26.25ft - max. 164ft

(for ranges between 164 ft and 330 ft four prisms are

required), comply with UL

Order number FIRERAY5000-UL

Loading...

Loading...