Bosch FHP560 Applications Manual

FHP560 Multi-Protocol Heat Pump Controller

For integration with systems running industry standard protocols

Applications Manual

2

|

FHP560 Controller Applications Manual

Bosch Thermotechnology Corp.

Data subject to change Page____ of ____

1 Explanation Of Symbols

1.1 Key To Symbols

Warnings

Warnings in this document are identifi ed by a

warning triangle printed against a grey background.

Keywords at the start of a warning indicate the type

and seriousness of the ensuing risk if measures to

prevent the risk are not taken.

The following keywords are defi ned and can be used in this document:

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could result in minor to moderate injury.

NOTICE is used to address practices not related to personal injury.

Important information

This symbol indicates important information where

there is no risk to people or property.

CAUTION: DISCLAIMER

1 - Programming the Master BAS Building Controller is NOT provided by Bosch.

2 - The included sequence of operation and points list should be verifi ed to ensure

compliance with all required specifi cation. If not meeting specifi cation, additional

custom programming costs will be incurred.

3 - When making selections in BST to place an order, be sure to select the necessary

Bosch sensors under accessories (eg. wall sensors, duct sensors, outdoor air

sensors, etc) and any additional options or accessories that may be required.

4 - Extra DDC customization to interface with non Bosch sensors will incur additional

special pricing.

5 - DDC controls by others will receive unit status alarm (error / no error) but won’t

be able to interpret the fault code - must use Bosch DDC to get cause of error

fault codes to BAS.

6 - On series evap, DDC (or controls by others) is required for heating and cooling

control. The controller is confi gured to prevent stage 2 compressor from running

when in heating mode. Without controls, this feature won’t work properly in

heating mode as 2nd stage compressor (piped for straight cool) will cool while 1st

stage is trying to heat. Circuit 1 will have HGRH & HGBP, circuit 2 will be straight

cool.

7 - DDC controls need to be fi eld confi gured per job site requirements.

8 - When specifying controls by others to be factory mounted all request should

be submitted in writing and signed off on by both parties. Bosch will assume

no responsibility for any oversights, unspoken intents, or assumptions in factory

mounting any third-party controllers.

9 - For orders requiring special software programming a requirements specifi cation

document must be generated to notify the approving party of Bosch’s

comprehension of the desired sequence. It is the responsibility of the approving

agency/individual to carefully review the requirements and ensure that all intended

actions have been clearly stated and correctly interpreted.

Contents

1 Explanation Of Symbols 2

1.1 Key To Symbols 2

2 FHP560 Overview 3

2.1 Key Features/Benefi ts 3

3 Specifi cation 4

4 Physical Dimensions 4

5 Controller Components & Features 5

6 Explanation Of DDC Options 6

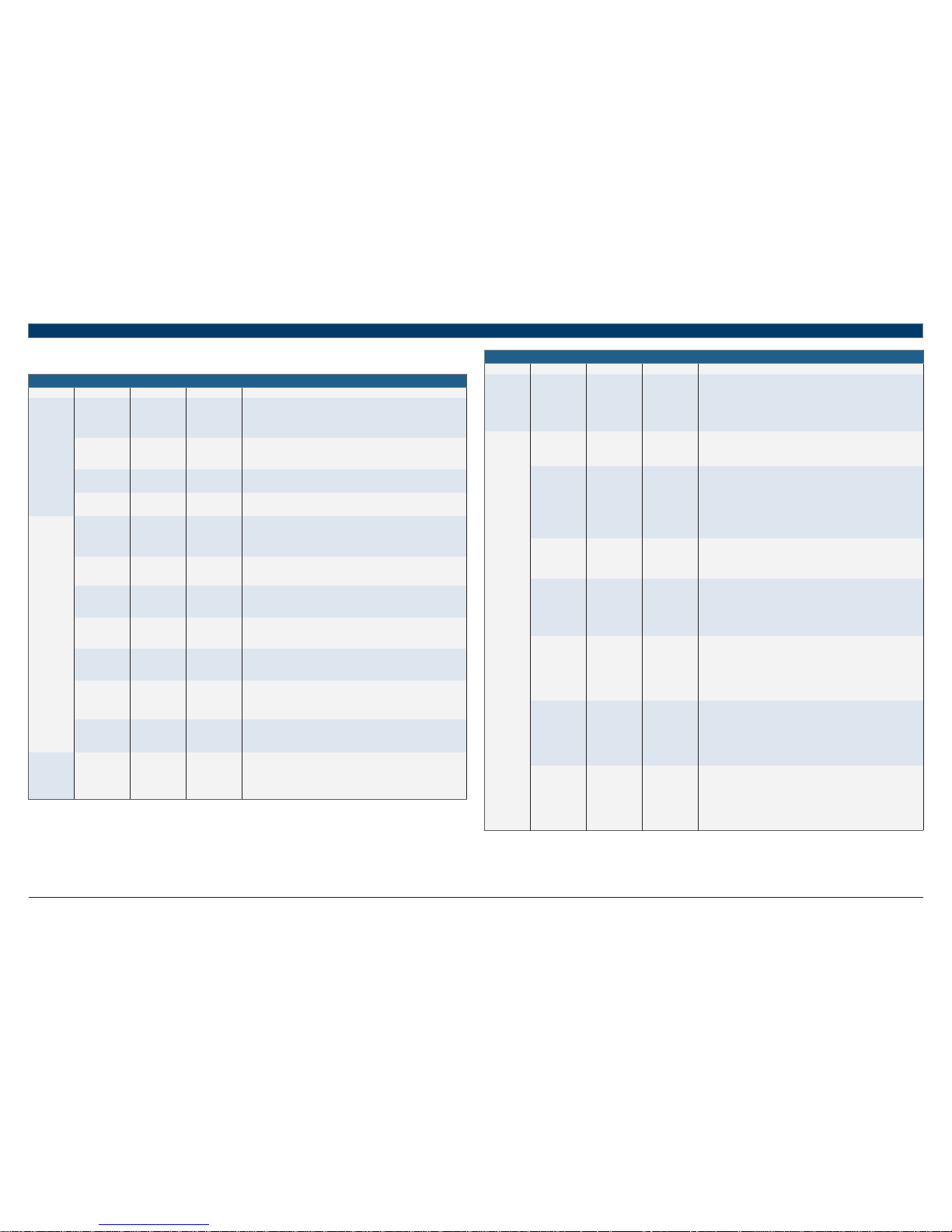

7 I/O Port Assignments And Overview 7

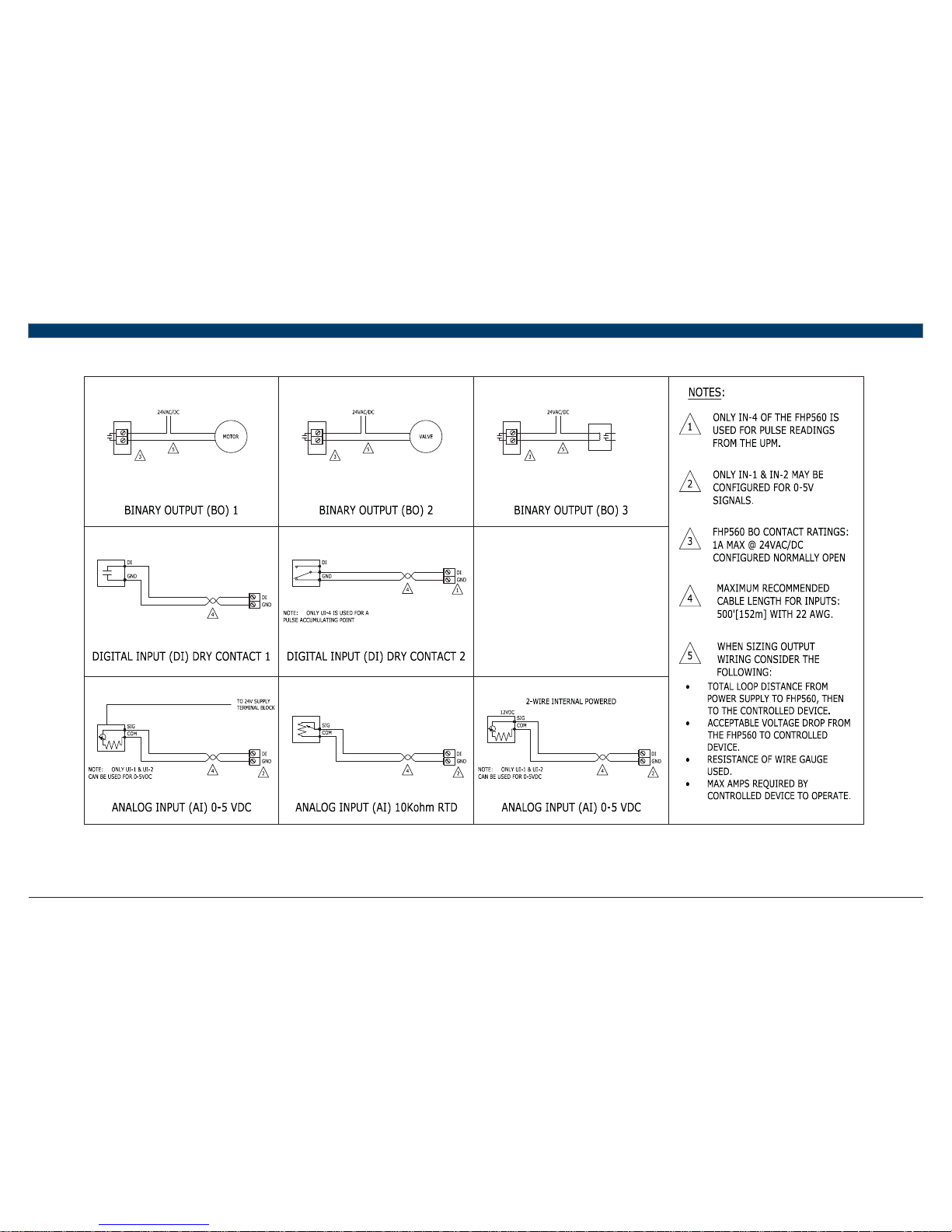

8 Wiring Termination Specs 9

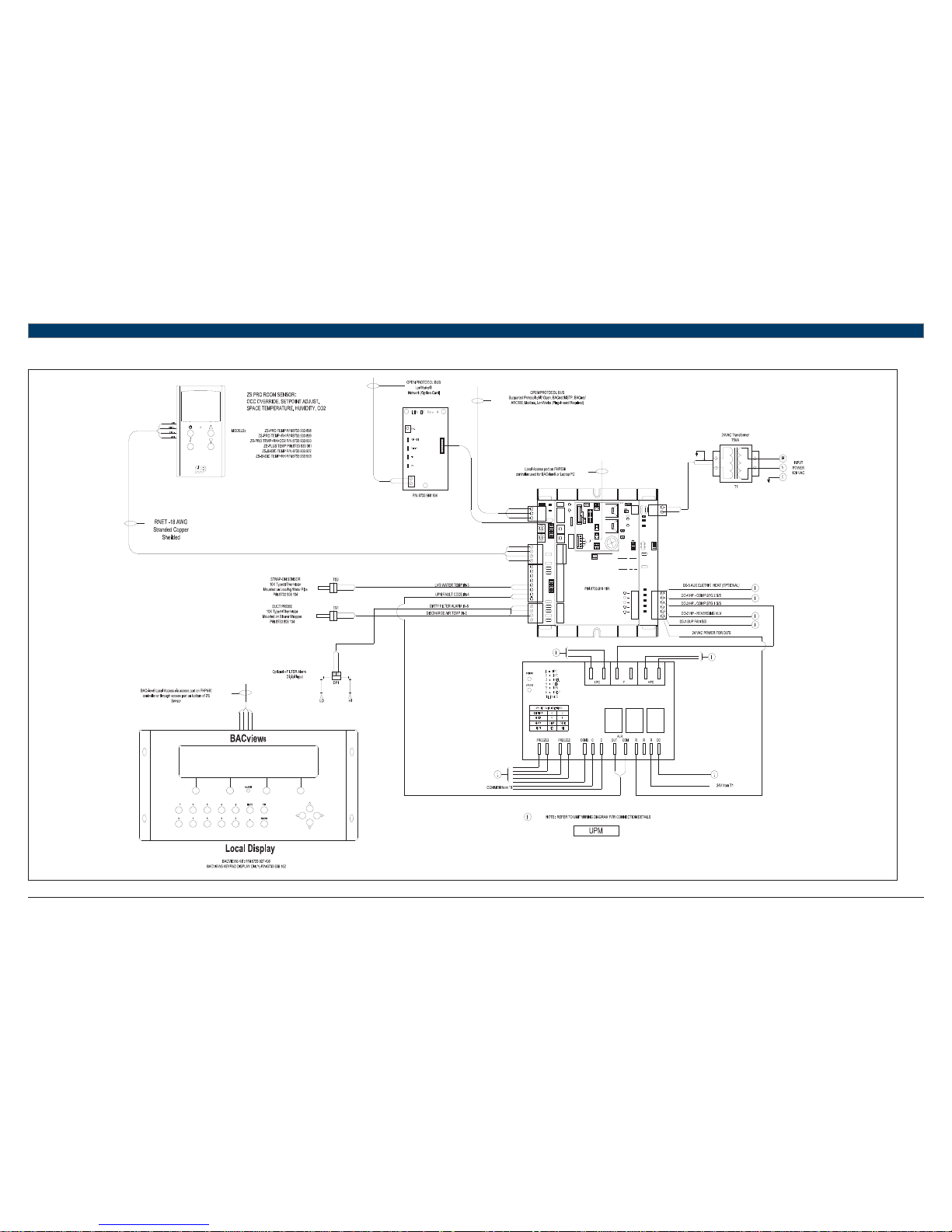

9 Electrical Schematic 10

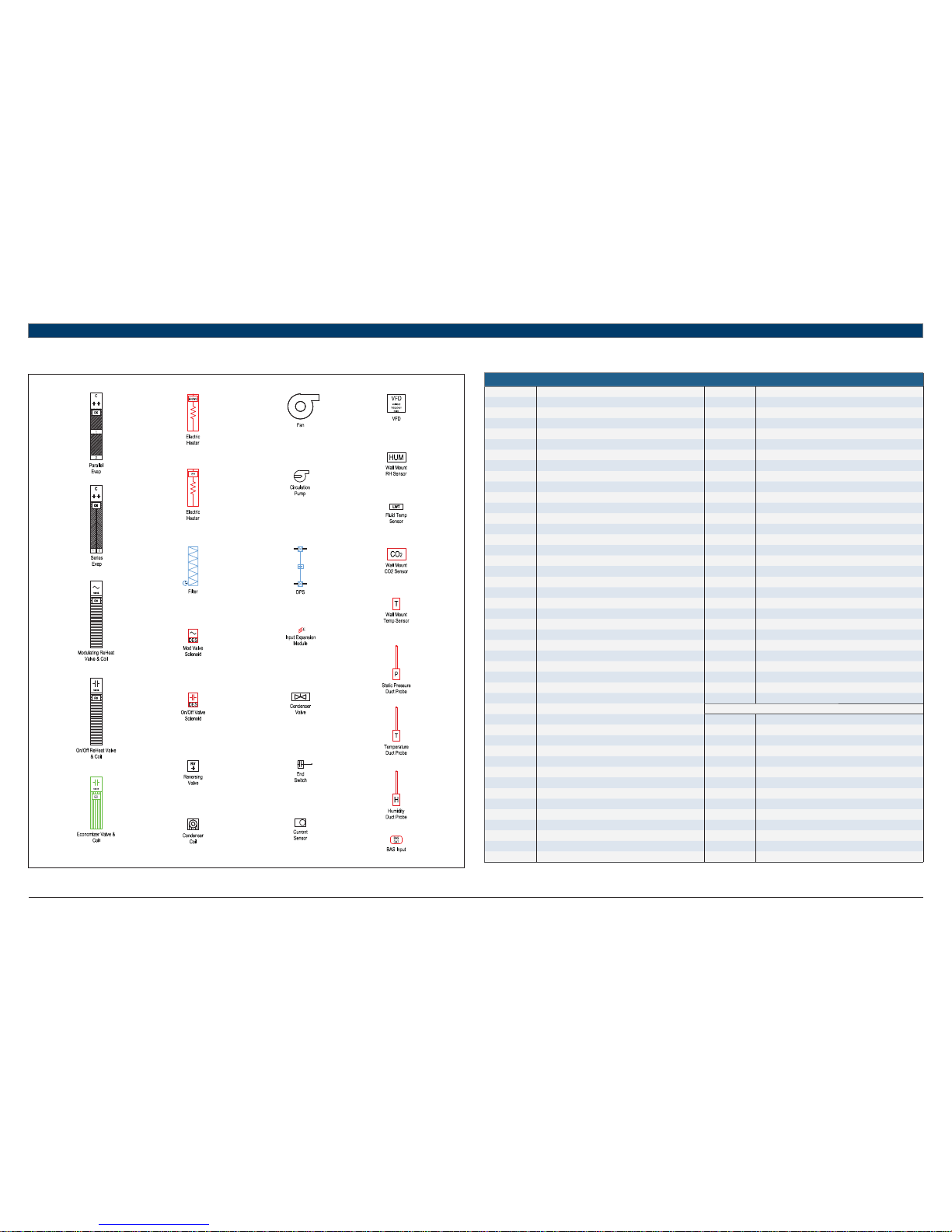

10 Symbol Legend 11

10.1 Common Abbreviations 11

11 Common Applications 12

11.1 HP Basic 12

11.2 HP + HGRH 13

11.3 STRAIGHT COOL + EH 14

11.4 STRAIGHT HP + CWV 15

11.5 HP + LP 16

11.6 HP + BOILERLESS 17

11.7 HP + ECONOMIZER 18

11.8 STRAIGHT COOL + ECONOMIZER 19

11.9 HP + DAMPER + CO₂ 20

11.10 HP + BOILERLESS + DPS 21

11.11 HP + BOILERLESS + HGRH + (SDS-SDP) 22

11.12 HP + ECONOMIZER + HGRH + (SDS-FSS-DFS) 23

11.13 HP + EH + CWV + (SDS-FSS-VES) 24

11.14 HP + HGRH + LP + (DFS-PSS) 25

12 Water-To-Air Sequence Of Operation 26

13 Integration Points List - Water-to-Air Standard Software 7.05.03 28

14 ZS Combination Sensors 36

14.1 ZS Sensor Overview 36

Fig. 6 ZS Sensors 36

14.2 ZS Sensor Specifi cations 36

14.3 ZS Sensor Dimensions 37

14.4 ZS Sensor Features 37

14.5 Addressing Sensors 38

14.6 Confi guring Multiple Sensors 38

14.7 Formatting Sensors 38

14.8 ZS Sensor Wiring Specifi cation 38

14.9 Wiring and Mounting a ZS Sensor 39

14.10 Electrical Schematic - Sensor Averaging 40

14.11 ZS Pro Sensors 41

14.12 Rnet Tags 43

15 The BACview Interfaces 44

15.1 BACview Hand-held Module 44

15.2 Virtual BACview 44

15.3 BACview Dimensions and Specifi cations 45

15.4 Rnet Wiring Specifi cations 45

15.3 Connecting the BACview to FHP560 46

15.4 To Communicate Using a Laptop & Virtual BACview 46

16 Troubleshooting 47

16.1 FHP560 Troubleshooting 47

16.2 ZS Sensors Troubleshooting 47

Applications Manual FHP560 Controller | 3

Bosch Thermotechnology Corp.

Data subject to changePage____ of ____

2 FHP560 Overview

The FHP560 Multi-Protocol Heat Pump controller is used in most confi gure-to-order applications requiring integration of Direct Digital Control

(DDC) systems. The controller is BACnet native but is fl exible enough to integrate into existing Building Automation Systems (BAS) via a choice of

the most widely used protocols including: BACnet MS/TP, N2, Modbus, and LON (requires additional hardware). The FHP560 may be run either in

stand-alone operation mode, or with the DDC network by integrating with a BAS.

Fig. 1 FHP560 Controller

The FHP560 is packaged with a highly sophisticated yet easily confi gurable software (version 7.05.03) that suits the different heat pump

applications. User parameters and options relating to the physical build of the corresponding heat pump unit (e.g. number of compressors,

reversing valve, reheat coil, etc) are usually programmed at the factory to facilitate a seamless integration in the fi eld. However, commissioning

of the controller in the fi eld is required to ensure the setup exactly matches the requirements of the jobsite. User settings of the factory standard

software, such as the time and test and balance set points, are usually set up during the installation and commissioning process.

When properly connected to a Bosch Water Source Heat Pump (WSHP), the FHP560 controller works in tandem with the onboard Unit Protection

Module (UPM) to protect the unit compressor from faults such as high/low pressure, high condensate, freeze evaporator/condensor coils, and

brown-outs. The controller monitors the alarm contacts of the UPM board, then decodes and broadcasts any fault conditions that may arise over a

network if one is available.

The controller also works with multi-functional ZS room sensors that, depending on model, are capable of reading not only the zone temperature,

but also CO₂ and relative humidity levels. When wired correctly, the controller commands the heat pump unit to operate in heating or cooling

mode, and can also provide commands for other options such as hot gas reheat to manage relative humidity while cooling. The operating

parameters of the unit may be communicated to a BAS over the DDC network if available.

2.1 Key Features/Benefi ts

Flexible and easily configured software package for options including:

— Hot Gas Reheat

— Auxiliary Electric Heat

— Condenser Water Valve Control

— Loop Pump Control

— Field supplied Fresh Air Damper Control

— Water-Side Economizer

— Boilerless Electric Heat Control

— Air Economizer

Provides multi-protocol communications for seamless integration with systems running industry standard protocols such as:

— BACnet MS/TP

— Johnson Controls N2

— Modbus

— Lon Works (additional hardware required for Lon).

Ruggedly built for quality and reliability

Stand-alone operation or networked DDC operation capable

Removable wiring connectors for ease of field service

Allows application parameters to be saved and recovered following power loss

4

|

FHP560 Controller Applications Manual

Bosch Thermotechnology Corp.

Data subject to change Page____ of ____

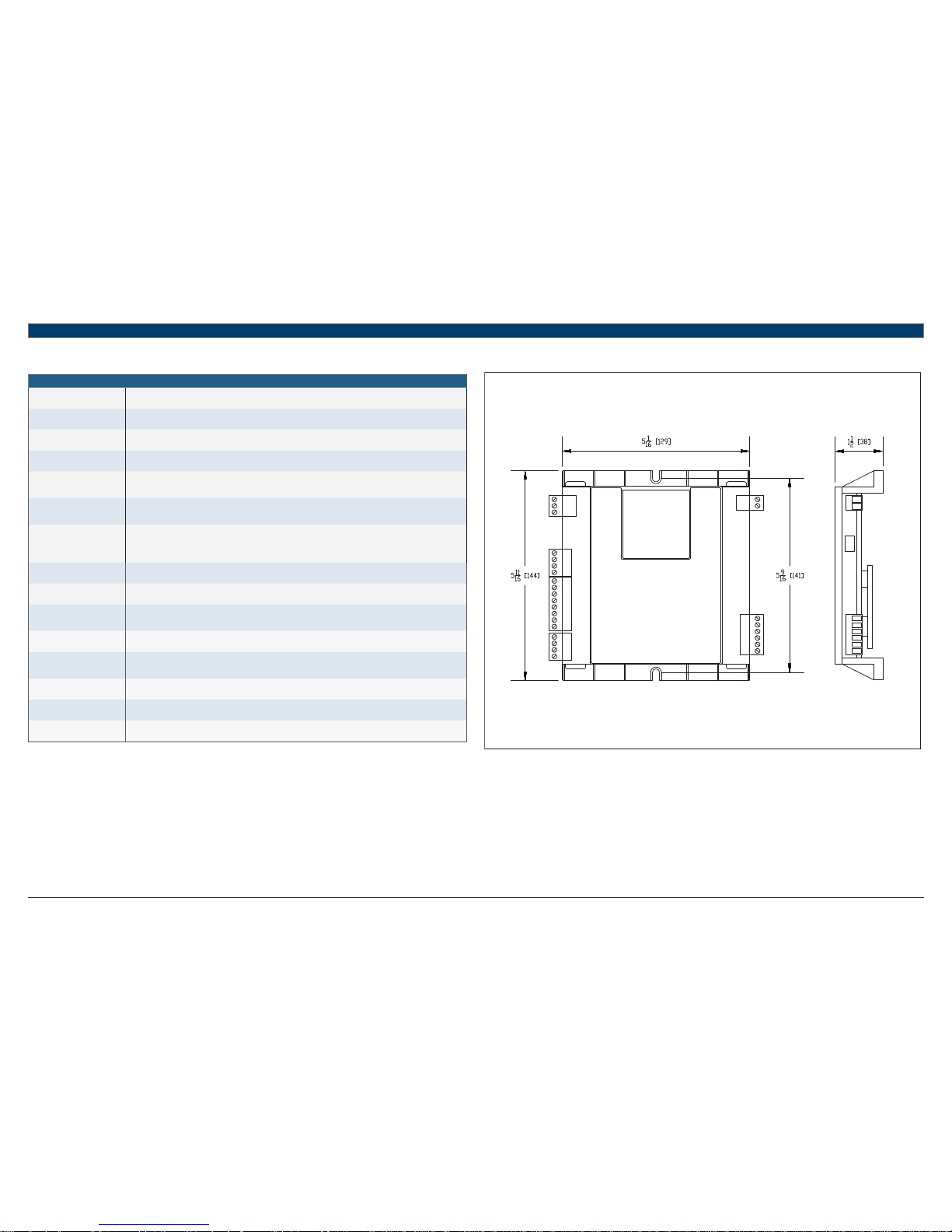

3 Specifi cation

Product Specifi cations

Power 24VAC ± 10%, 50-60Hz, 20VA power consumption; Single Class II source only; 100VA or less

Physical Rugged plastic housing protects circuitry

Environmental Operating Range 0° to 130°F (-17.8° to 54.4°C); 10 to 90% relative humidity, non-condensing

Digital Outputs Five (5) binary outputs: Form A relay contacts rated at 1A resistive @ 24VAC; confi gured as dry contact, normally open

Universal Inputs

Six (6) universal inputs. All six inputs are confi gurable for pulse, 10kohm @ 77°F (25°C) thermistor, or dry contact. In addition,

inputs 1 and 2 are confi gurable for 0-5Vdc.

Standard Communication

3-pin port confi gurable for ARC156 (BACnet-over-ARC156) or EIA-485 communications (BACnet MS/TP, Modbus RTU, Lon, or

N2)

Ports

Rnet Port: 4-pin port for interface with remote mounted BACview6 or ZS sensors

Local Access Port: For local communication with a laptop computer running WebCTRL, Virtual BACview, or for communication

with a BACview6.

BACnet Support Advanced Application Controller (B-AAC), as defi ned in BACnet 135-2001 Annex L Communication Ports

Status Indication Visual (LED) status of network communication, run status, errors, power, and all digital outputs

Battery

Lithium 3V coin cell battery, CR2032, provides a minimum of 10,000 hours of data retention (based on installation in

conditioned space) during power outages.

Protection Surge and transient protection circuitry for power and communications

Listed by

FCC Part 15 - Subpart B - Class A. Pending listings at the time of publishing this document: UL 916 (PAZX), cUL C22.2 No. 205M1983 (PAZX7), CE (1997)

Weight 0.6 Lbs. (0.27 Kg).

Overall Dimensions

(W x H x D):

5-1/16” (129mm) x 5-11/16” (144mm) x 1-1/2” (38mm) (recommended panel depth)

Mounting Hole Dimensions Two mounting holes located center line of controller with 5-9/16” (141mm) vertical spacing

Table 1

4 Physical Dimensions

Fig. 2 FHP560 Controller Dimensions in Inches (mm)

Applications Manual FHP560 Controller | 5

Bosch Thermotechnology Corp.

Data subject to changePage____ of ____

5 Controller Components & Features

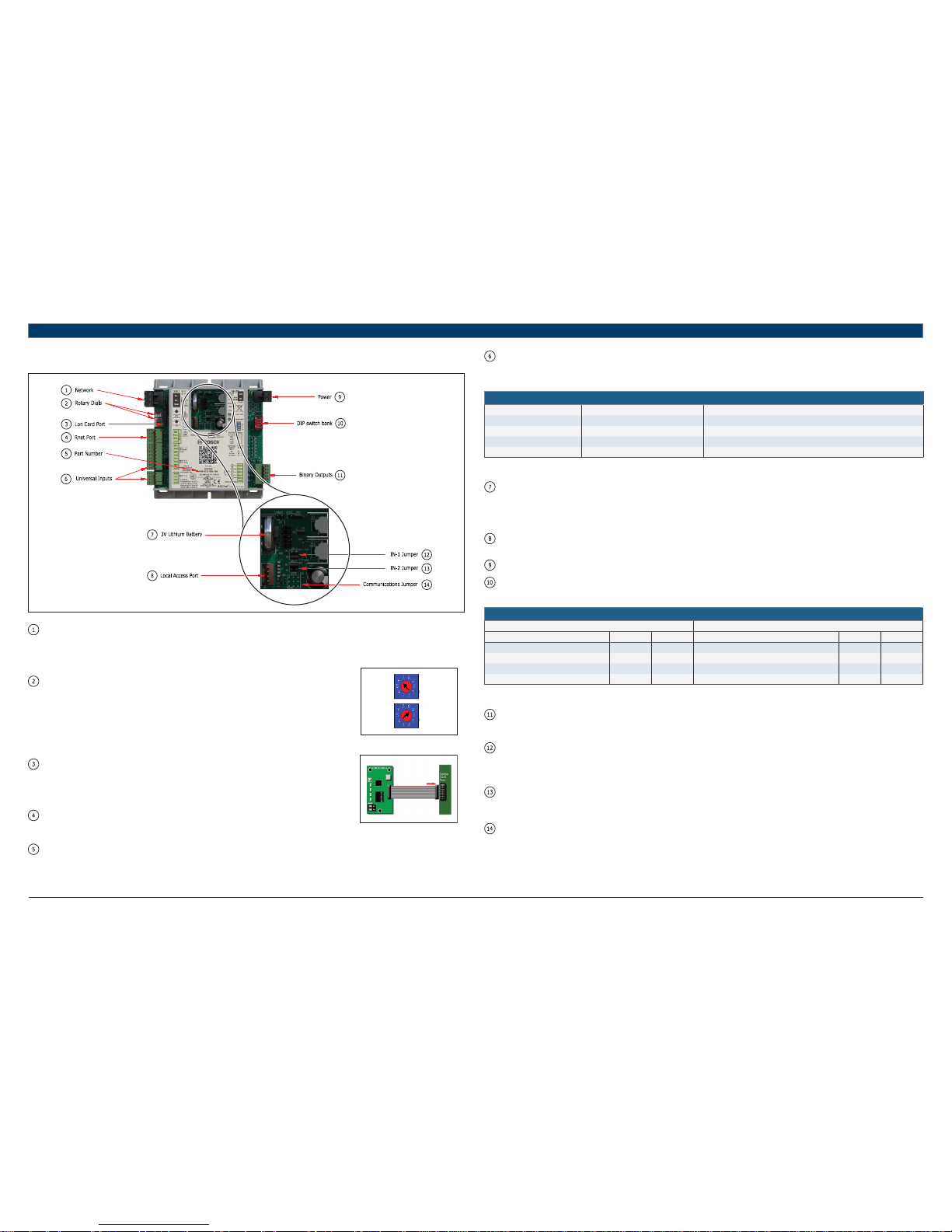

Fig. 3 FHP560 Components

Network: This block represents the communications port on the FHP560. The comm port can be confi gured to communicate in two ways

(RS-485 or BACnet over ARC156) using the Communications Jumper. The communications wiring should be landed at the Net+, Net-,

and Shield terminals, ensuring the same polarity is maintained throughout the network segment. The “BAS Port Settings” DIP switch

is used to set the baud rate for the network, using the same baud rate for all controllers on the network. The LEDs (Rx and Tx) fl ash

repeatedly when the controller is communicating with the network.

Rotary Dials: The rotary dials are used to address the FHP560 so it can be uniquely identifi ed over a network.

Ones Tens

The top dial represents the Tens digit while the bottom one represents the Ones digit, allowing

for hardware-based addressing of up to address 99. Before setting or changing the address

make sure the FHP560 is powered off; the controller only reads the address when the module

is turned on. In the example shown in Fig. 4, the rotary dial is set to address 69.

Fig. 4 Rotary Dials

Lon Port: For network integration applications involving the LonWorks network platform, the LON card

will be required to enable communication over this protocol. The card is ordered separately

and connects to the controller port as shown. Ensure that the communications jumper is in the

top position (EIA-485) and the BAS port settings are confi gured using the DIP switch bank

(see DIP Switch).

Rnet Port: The Rnet port is a four-connector block used mainly for wiring the ZS combo sensors to

the FHP560. It consists of 2 points for power (12VDC, Gnd) and 2 points for communication

(Rnet + and Rnet -). This port may also be used to hardwire a BACview6 module.

Fig. 5 Lon Connection

Part Number: The FHP560 part number represents both the hardware and software components of the FHP560, and therefore changes if the

controller is ordered with a special software other than the standard (7.05.03) version.

Inputs: There are 6 universal inputs on the FHP560. All inputs are capable of accepting thermistor (analog), pulse or dry contact (binary)

signals, but the fi rst 2 inputs (IN-1 and IN-2) are also capable of reading 0-5VDC signals; use the corresponding jumpers to select

between Therm/dry and 0-5V for these inputs. Refer to the “Ports Assignment and Overview” page for further details on confi guring

these inputs.

Inputs

Input Signal Type Supported Description

IN-1 and IN-2 0-5Vdc Input impedance of the FHP560 is approx. 30-kOhm

All Thermistor Precon type 2 (10-kOhm @ 77°F/25°C)

All Dry Contact 3.3Vdc wetting voltage detects contact position

All Pulse Pulse counting up to 10 pulses per second.

Table 2

Battery: The 10-year Lithium CR2032 3V battery retains data (e.g. control programs, modifi ed parameters, schedules, etc) for a

maximum of 10,000 hours during power outages. If the FHP560 experiences RAM loss (e.g. due to low voltage on the controller

or high voltage on the network), it may be reset by recycling the battery power. This operation should be performed with the

FHP560 powered off (no 24Vac power), and resolves most of all “bad controller” issues. All previously saved parameters are

retained upon power up.

Local Access: The local access port is available for system start-up, servicing and troubleshooting using a BACview Interface (handheld or

virtual) or Field Assistant.

Power: Input power for the FHP560. 24Vac +/-10%, 50-60Hz; 20VA power consumption, Single Class 2 source only, 100VA or less.

DIP Switch: The BAS Port Settings DIP switch bank is used to set the appropriate network confi guration when the FHP560 is integrated into

a Building Automation System (BAS). The following table details the different settings available (this information is also on the

FHP560 label):

Available Settings

BAUD RATE SETTING PROTOCOL

SW1 SW2 SW3 SW4

9.6kbps Off Off BACnet® MS/TP Off Off

19.2kbps Off On N2 On Off

38.4kbps On Off Modbus Of f On

76.8kbps On On Option Card (LON) On On

Table 3

Outputs: The FHP560 has fi ve (5) binary outputs that can each be connected to a maximum of 24Vac/26Vdc. Each output is a dry contact

(Form A) rated at 1A, 24V max. Refer to the “Ports Assignment and Overview” page for further details on confi guring these

outputs.

IN-1 Jumper: This two-position jumper is used to set the input type selection for IN-1 as follows:

— Top position is labeled W4 and configures IN-1 for dry/therm signals

— Bottom position is labeled W5 and configures IN-1 for 0-5V signals

The jumper is default to the bottom position (W5) for 0-5V from factory.

IN-2 Jumper: This two-position jumper is used to set the input type selection for IN-2 as follows:

— Top position is labeled W6 and configures IN-2 for dry/therm signals

— Bottom position is labeled W7 and configures IN-2 for 0-5V signals

The jumper is default to the top position (W6) for Dry/Therm from factory.

Com Jumper: This two-position jumper is used to confi gure the network communication mode for the FHP560 as follows:

— Top position is labeled EIA-485 and configures the FHP560 for RS-485 communications for BACnet MS/TP, N2, ModBus, or

Lon.

— Bottom position is labeled BACnet over ARC156 and configures the FHP560 for BACnet over ARC156 at 156kbps. This

selection is a unique implementation of the industry standard ARCNET protocol and the jumper should only be set to this

position if employing that protocol.

The jumper is default to the top position (EIA-485) from factory.

6

|

FHP560 Controller Applications Manual

Bosch Thermotechnology Corp.

Data subject to change Page____ of ____

6 Explanation Of DDC Options

AUXILIARY ELECTRIC HEAT:

Used to provide a single stage of electric heat by way of a factory-installed electric heater option, or fi eld-installed electric heater accessory. It may

be used as a supplementary source of heating for units with mechanical heating/cooling capabilities where additional heating capacity is needed

to maintain space setpoint; or as the sole source of heat for straight cool units (mechanical cooling only). The confi gured controller output is

energized to enable the heater based on unit confi guration and parameter setup.

BOILERLESS CONTROL:

An option that allows a water source heat pump to be operated in heating safely when installed in a system that has no means of heating the water

loop. A factory installed Entering Water Temperature (EWT) sensor (thermistor) is connected to the FHP560 controller and used with this option.

During a thermostat call for heating, if the EWT sensor detects a drop in water temperature below a pre-set limit (adjustable in the software), the

FHP560 will disengage the compressor output(s) and provide a 24VAC signal to divert unit operation from compressor heating to an alternate heat

source (generally fi eld-installed electric heat). The option is also used to proactively prevent coils from freezing.

FAN PROVING:

This option uses an optional factory-installed current sensor to prove fan operation prior to unit operation. The status output of the current sensor

is used to establish fan operation for the unit when a proven fan call is established. If confi gured the FHP560 disables unit compressor operation

when the current in the monitored conductor drops below the rated threshold, indicating the fan is non-operational. The current sensor output

may be wired directly to the FHP560, or to an Input Expansion Module (IEM) connected to the FHP560 when multiple options requiring switched

inputs are involved. Please consult the applications department when including this option as an engineering add-on.

FLOW PROVING (DPS):

This option employs the use of an optional Differential Pressure Switch (DPS) to prove water fl ow across a unit’s water-to-refrigerant heat

exchanger. If confi gured the software enables unit compressor operation when a pressure drop of 1.5 psi or more is detected across the water

to refrigerant heat exchanger, indicating adequate water fl ow. This option prevents nuisance cut outs on high head pressure or freeze protection

when there are interruptions in water fl ow.

LOOP WATER VALVE CONTROL:

This option uses an optional factory-installed condenser water valve to control water fl ow through the condenser coil. The normally closed valve

includes an auxiliary end switch that may be wired to the controller to determine the status of the valve. When the FHP560 is confi gured for this

option, compressor operation is disabled until valve-open status from the Valve End Switch is verifi ed.

HOT GAS REHEAT (ON/OFF):

Hot gas reheat helps actively control humidity by reheating cooled and dehumidifi ed air back to a neutral temperature using waste heat from the

compressor. Doing this allows the unit to continue to operate and remove moisture from the space after the sensible cooling set point has been

satisfi ed. Hot gas reheat is well suited for conditioning outside ventilation air and for maintaining ideal humidity levels in schools, commercial

buildings and even homes. A binary output on the FHP560 controller is used to provide the signal for activating the reheat valve when the

necessary conditions are met. Relative humidity readings may be acquired from a wall-mounted ZS combo sensor, a third-party hardwired 0-5V

humidity sensor, or from RH values pushed to the FHP560 over a network.

INPUT EXPANSION MODULE (IEM):

The IEM is used when multiple options that require a binary input are desired for a single application with DDC. The IEM is connected in input

#5 (IN-5) of the FHP560 controller and is software confi gured to enable a trio of preset combinations that include: Fan Status, Valve Status,

Damper Status, Pump Status, Filter Status, Secondary Drain Pan Status, Differential Pressure Switch Status, and Smoke/Fire Detector Status. The

appropriate switches (binary inputs) must be fi eld installed where applicable.

LOOP PUMP CONTROL:

The Loop Pump option uses the FHP560 and a factory installed current sensor to control and monitor a fi eld or factory installed loop pump for

the WSHP units. The pump is indexed to turn on by the controller whenever there’s a call for heating or cooling. The status output of the current

sensor may be used to establish pump operation for the unit when a proven pump call is established. The FHP560 is confi gured to disable unit

compressor operation when the current in the pump’s monitored conductor drops below the rated threshold, indicating pump is not operational.

The current sensor output may be wired directly to the FHP560, or to an Input Expansion Module (IEM) connected to the FHP560 when multiple

options requiring switched inputs are involved. Please consult the applications department when including this option as an engineering add-on.

OUTSIDE AIR DAMPER:

Allows the capability for pre-fi ltered outside air to enter the unit while in operation via a remote motorized damper, based on unit occupancy, fan

operation, or CO₂ levels in the monitored space. A binary output on the FHP560 controller is used to provide the signal for activating the damper

solenoid when the necessary conditions are met. CO₂ readings may be acquired from a wall-mounted ZS combo sensor, a third-party hardwired

0-5V CO₂ sensor, or from CO₂ values pushed to the FHP560 over a network. A damper end switch connected to the FHP560 may be used to verify

damper status and disable compressor operation when the damper fails.

WATER SIDE ECONOMIZER:

An option package consisting of a water-to-air heat exchanger (economizer coil), a thermistor (EWT sensor), and a 3-way diverting valve. When

there is a call for cooling, the EWT sensor connected to the FHP560 will monitor the entering water temperature to the unit and determine if the

compressor should be used for cooling or if the water temperature is low enough to cool the entering air with the economizer coil. If the entering

water temperature is below a selected user-adjustable setpoint, the diverting valve will be indexed by the FHP560 to divert the entering water

through the economizer coil to cool the air stream. The water is then passed through the water to refrigerant coil in case additional cooling is

required. This DDC option can only be used for cooling operations.

AIR ECONOMIZER:

This option utilizes a fi eld-installed fresh air damper, and requires an outdoor air temperature and humidity combo sensor. When there’s a call

for cooling, the OAT/RH sensor connected to the FHP560 will monitor the outside air temperature and humidity levels and determine if the

compressor should be used for cooling or if the outdoor air is ideal to condition the space with just the fan. If the air temperature and humidity is

within a user-confi gurable range, the damper solenoid will be energized to open by the FHP560, the compressors will be indexed off, and the fan is

used to cool the space. This option is only available in the cooling mode.

Applications Manual FHP560 Controller | 7

Bosch Thermotechnology Corp.

Data subject to changePage____ of ____

7 I/O Port Assignments And Overview

Universal Inputs

Port Inputs Accepted Signal Type Jumper Position Overview

IN-1

Digital Input

Enable

Dry Top (W4)

This input is selected when a dry contact (e.g. room occupancy sensor) is required

to enable the unit, and Digital Input has been selected for Occupancy Command.

Unit is placed in occupied mode upon a percieved contact closure at the input, and

placed in unoccupied mode 10 minutes after the contacts open.

Humidity Sensor 0-5VDC Bottom (W5)

This input is used if RH readings are not desired from a ZS Combo sensor or over

a network. An example would be a duct mounted humidity sensor or third party

humidity sensor with 0-5VDC output.

CO₂ Sensor 0-5VDC Bottom (W5)

This input is used if CO₂ readings are not desired from a ZS Combo sensor or over

a network. An example would be a third party CO₂ sensor with 0-5VDC output.

Static Pressure

Sensor

0-5VDC Bottom (W5) This input is used for applications requiring static pressure readings.

IN-2

Zone Remote

Sensor

Therm Top (W6)

This input is used if zone temperature readings for controlling the unit are not

desired from a ZS Combo sensor or over a network. An example would be a third

party wall or duct mounted sensor. Temperature sensor must be a Type II 10kohm

@ 77°F(25°C) type sensor.

Outdoor Air

Temperature

Sensor

Therm Top (W6) This input is selected if outside air temperature readings are required.

Entering Water

Temperature

Sensor

Therm Top (W6)

This input should be selected for applications where the entering water

temperature needs to be monitored, or used to control options such as Economizer

or Boilerless Electric Heat.

Mixed Air

Temperature

Sensor

Therm Top (W6) This input is selected if mixed air temperature readings are required.

Return Air

Temperature

Sensor

Therm Top (W6)

This input is used if zone temperature readings for controlling the unit are desired

from a temperature probe placed in the return air duct. Temperature sensor must

be a Type II 10kohm @ 77°F(25°C) type sensor.

Digital Input

Enable

Dry Top (W6)

This input is selected when a dry contact (e.g. room occupancy sensor) is required

to enable the unit, and Digital Input has been selected for Occupancy Command.

Unit is placed in occupied mode upon a percieved contact closure at the input, and

placed in unoccupied mode 10 minutes after the contacts open.

Humidity Sensor 0-5VDC Bottom (W7)

This input is used if RH readings are not desired from a ZS Combo sensor or over

a network. An example would be a duct mounted humidity sensor or third party

humidity sensor with 0-5VDC output.

IN-3*

Leaving Water

Temperature

Sensor

Therm n/a

A thermistor is wired to this input from factory to monitor leaving water

temperature at the heat exchanger leaving water pipe. If the water temperature

rises above 135°F or drops below 40°F for more than 5 minutes while the unit

is running, compressor operation is halted and an alarm is generated. These

temperature trip values are user adjustable.

Table 4

* Non-confi gurable, factor y assigned I/O parameter

Universal Inputs

Port Inputs Accepted Signal Type Jumper Position Overview

IN-4* UPM Input Pulse n/a

The Unit Protection Module (UPM) is standard on all FHP heat pumps. The alarm

contacts of the UPM board are wired to the controller at this input from factory

to transmit error pulse codes to the FHP560. These alarm codes are then made

available to view via a BACview interface, ZS Pro Sensor, or over a network if one

is available. Faults include: High Pressure, Low Pressure, High Condensate, Freeze

Stat, and Brown out conditions.

IN-5

Dirty Filter Switch

(DFS)

Dry n/a

Selecting this option for this input provides an alternate means of alerting the end

user of a dirty fi lter condition by way of a contact closure instead of fan runtime

hours. An alarm is generated when FHP560 senses a contact closure at the input.

Entering Water

Temperature

Sensor

(Economizer

Cooling &

Boilerless Electric

Heat)

Therm n/a

This input should be the default location for an EWT sensor when the WaterSide Economizer or Boilerless option is selected. The temperature readings from

this input are used in determining when the economizer or electric heat action

is enabled and MUST be selected for the option to function properly. Default

economizer EWT trip value is 55°F (user adjustable). Default boilerless EH EWT trip

value is 40°F (user adjustable).

Differential

Pressure Switch

(DPS)

Dry n/a

A Differential Pressure Switch may be connected to this input to prove water

fl ow across a unit's water-to-refrigerant heat exchanger. Heat pump operation is

disabled until the status switch of the DPS is closed, after which if the contacts

open again unit operation is ceased after 3 minutes.

Secondary Drain

Pan (SDP)

Dry n/a

This option allows a secondary condensate pan installed on the heat pump to be

connected to this input to monitor condensate levels when the primary drain pan

fails. When a high condensate condition for the secondary drain pan is detected an

open contact status is reported at the input, and the compressors are locked out

until the condition is reversed. An alarm is generated when the FHP560 senses an

open contact at the input.

Fan Status Switch

(FSS)

Dry n/a

The status output from a factory installed current sensor used to monitor fan

operation may be connected to this input to provide fan status during unit

operation. The unit is allowed to run only when the sensor contacts are verifi ed

as closed at the input after the fan has been indexed to run. If there's no contact

closure after the fan has been commanded on, the unit is not allowed to run, and

an alarm is generated after 45 seconds. If the fan fails during normal unit operation

the compressors are shutdown after 20 seconds and an alarm is generated.

Valve End Switch

(VES)

Dry n/a

For units with a loop valve option, the Valve End Switch may be connected to this

input to monitor/verify valve status during unit operation. The factory-installed zone

valve is normally-closed and is indexed to open by the FHP560 when there's a call

for heating or cooling. If a contact closure is not detected at the input after the

valve is commanded on, unit operation is disabled and an alarm is generated after a

minute and a half has elapsed; this provides adequate time for the slow acting valve

to fully open.

Damper End

Switch (DES)

Dry n/a

A damper end switch may be connected at this input for units with the outside air

damper option. If connected, the unit is not allowed to run until a contact closure

is detected at the input after the damper has been indexed to open. Damper

operation may be based on occupancy, fan operation, or zone CO₂ levels (default

trip value is 1000ppm).

Table 5

* Non-confi gurable, factor y assigned I/O parameter

8

|

FHP560 Controller Applications Manual

Bosch Thermotechnology Corp.

Data subject to change Page____ of ____

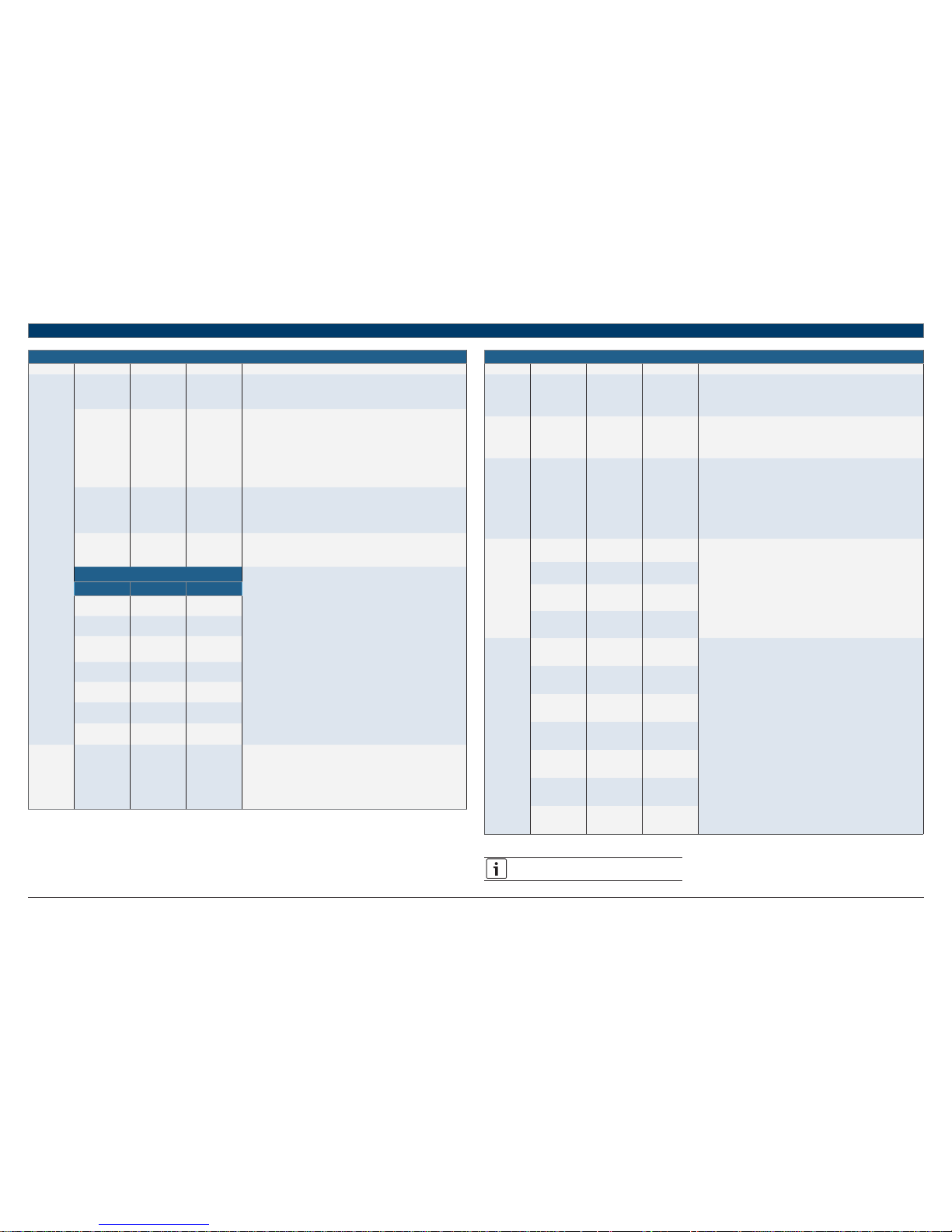

Universal Inputs

Port Inputs Accepted Signal Type Jumper Position Overview

IN-5

Smoke Detector

Switch (SDS)

Dry n/a

The normally-open contacts of a fi eld-installed smoke/fi re alarm detector may be

wired to this input to shut the heat pump unit down during an emergency. Unit

operation is ceased 5 seconds after a contact closure is detected at the input.

Pump Status

Switch (PSS)

Dry n/a

For units with a loop pump option, the status output from a factory installed

current sensor used to monitor pump operation may be connected to this input to

provide pump status during unit operation. The unit is allowed to run only when the

sensor contacts are verifi ed as closed at the input after the pump has been indexed

to run. If there's no contact closure after the loop pump has been commanded on,

the unit is not allowed to run, and an alarm is generated after 15 seconds. If the

pump fails during normal unit operation the compressors are shutdown after 20

seconds and an alarm is generated.

Mixed Air

Temperature

Sensor

Therm n/a

Select this confi guration parameter if a Mixed Air Temperature sensor is connected

in IN-5.

Input Expansion

Module (IEM)

Dry n/a

The Input Expansion Module is used in this input when multiple options that

require a binary input are required (up to 3 inputs). The combinations of these

options are limited only to the seven (7) sets of three listed below.

Input Expansion Module (IEM) Combination

These seven (7) sets of binary input combinations may be used with an IEM

connected to this input. The three (3) ports are labled (A, B, C) and must be

connected correspondingly. In situations where not all three inputs are used, the

other inputs may be disabled in the software, or the board may be jumpered if the

option requires a closed contact to function properly.

PORT 1 (A) PORT 2 (B) PORT 3 (C)

Dirty Filter Switch

(DFS)

Fan Status Switch

(FSS)

Valve End Switch

(VES)

Smoke Detector

Switch (SDS)

Fan Status Switch

(FSS)

Valve End Switch

(VES)

Dirty Filter Switch

(DFS)

Fan Status Switch

(FSS)

Differential

Pressure Switch

(DPS)

Smoke Detector

Switch (SDS)

Fan Status Switch

(FSS)

Dirty Filter Switch

(DFS)

Dirty Filter Switch

(DFS)

Fan Status Switch

(FSS)

Damper End

Switch (DES)

Smoke Detector

Switch (SDS)

Fan Status Switch

(FSS)

Secondary Drain

Pan (SDP)

Dirty Filter Switch

(DFS)

Fan Status Switch

(FSS)

Pump Status

Switch (PSS)

IN-6*

Discharge Air

Temperature

Therm n/a

A factory-installed thermistor mounted on the heat pump unit's blower housing

(air handler section) is connected to this input for all orders requiring the factory

installed DDC option. It is highly recommended that for applications requiring

a more accurate representation of the supply air temperature, a duct mounted

temperature probe be used instead to relocate the source of the discharge air

temperature just downstream of the supply air duct. If this recommendation is

followed the factory-installed thermistor may be disconnected from this input, and

replaced with the leads from the duct mounted sensor.

Table 6

* Non-confi gurable, factor y assigned I/O parameter

Binary Outputs

Port Outputs Accepted Signal Type Signal Label Overview

BO-1* Fan 24VAC G

Binary Output 1 is factory reserved for the fan command (G) and is wired to the

unit terminal block in the electrical box. The fan mode may be software confi gured

either for "continuous" mode (fan is energized continuously during occupied and

night set back modes), or confi gured to run in "auto" mode (fan is energized only

during a call for heating or cooling). Continuous mode is the factory default setting.

BO-2* Reversing Valve 24VAC O

Binary Output 2 is factory reserved for the reversing valve command (O) and is

wired to the valve via the unit terminal block in the electrical box. For heat pump

units, the output is energized during a call for cooling, and remains de-energized

for heating. For straight cool units (cooling only) where no reversing valve is

installed, the output is disabled and not used.

BO-3*

Compressor

Stage 1

24VAC Y1

Binary Output 3 is factory reserved for the compressor stage 1 command (Y1) and

is connected to the UPM I board's "Y" terminal ("Y1" for dual compressor units

using the UPM II board) via the unit terminal block in the electrical box. The Y1

output is off when zone setpoint is satisfi ed and within the temperature deadband

(between heating and cooling setpoints). As the zone temperature rises above

the cooling setpoint and demand exceeds 30%, Y1 is enabled and PID methods

are employed to ensure the zone temperature is maintained within 1°F of cooling

setpoint. As the zone temperature drops below the heating setpoint and demand

exceeds 30%, Y1 is enabled and PID methods are employed to ensure the zone

temperature is maintained within 1°F of heating setpoint.

BO-4

Compressor

Stage 2

24VAC Y2

Binary Output 4 is factory defaulted for the compressor stage 2 command (Y2) and

is connected to the second stage solenoid (Y2S) for 2-step, single compressors,

or to the “Y2” terminal for dual compressor units using the UPM II board, via the

unit terminal block in the electrical box. The Y2 output is off when zone setpoint

is satisfi ed and within the temperature deadband (between heating and cooling

setpoints). The Y2 output is energized after Y1 has been on for more than 7

minutes, and the heating/cooling demand exceeds 60%.

For 1 compressor 1 stage units, Binary Output 4 may be confi gured for one of the

following options: Hot Gas Reheat (On/Off), Single Stage Auxiliary Electric Heat, or

Outside Air Damper (On/Off).

Hot Gas Re-Heat

(On/Off)

24VAC H

Fresh Air Damper

(On/Off)

24VAC D

Heating Stage 1

(Aux Heat)

24VAC W

BO-5

Hot Gas Re-Heat

(On/Off)

24VAC H

Binary Output 5 may be factory or fi eld confi gured for one of the following

options: Hot Gas Reheat (On/Off), Single Stage Auxiliary Electric Heat, Outside Air

Damper (On/Off), Condenser Water Valve, Circulating Water Pump, Economizer, or

Boilerless Electric Heat.

Fresh Air Damper

(On/Off)

24VAC D

Heating Stage 1

(Aux Heat)

24VAC W

Boilerless Control

(Aux Heat)

24VAC W

Economizer

Cooling Control

24VAC EV

Circulation Water

(Loop) Pump

24VAC P

Condenser Water

Valve

24VAC CV

Table 7

* Non-confi gurable, factor y assigned I/O parameter

All I/Os must be selected/confi gured in the software or

over a BAS network.

Applications Manual FHP560 Controller | 9

Bosch Thermotechnology Corp.

Data subject to changePage____ of ____

8 Wiring Termination Specs

10

|

FHP560 Controller Applications Manual

Bosch Thermotechnology Corp.

Data subject to change Page____ of ____

9 Electrical Schematic

Power forB.O.'s

BACnet

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

Rx

Tx

BT485

Net +

Net -

Shield

Comm

10's1's

Batt

+

-

CR

2032

Rnet +

Inputs 1 & 2

0-5V, therm,

or dry

®

24 Vac

FHP560

Thermistor/dry

contact

0-5Vdc

Thermistor/dry

contact

0-5Vdc

1 2 3 4

ON

On

Communications Selection

4

3

2

1

EIA-485

BACnet

Over ARC156

Lstat

IN-5

Format

Short

pins

Rnet

Outputs

24V

Max,

1A Max

Inputs 3

& 4

Therm or

dry

Inputs 5 & 6

Therm or dry

Comm

Selector

DIP Switch

BAUD RATES

SW1 SW2

PROTOCOLS SW3 SW4

9600

19.2 K

38.4 K

76.8 K

Off

On

Off

On

BACnet

MS/TP

N2

Modbus Off On

Local

Access

Sense

+12V

Rnet-

Rnet+

Gnd

Gnd

Rnet +

Rnet -

+12V

IN-1

Gnd

IN-2

Gnd

IN-3

Gnd

IN-4

Gnd

Gnd

IN-5

IN-6

LED

BO-3

BO-2

BO-1

BUS

BO-4

BO-5

Gnd

Hot

Power

Run

Error

IN-1

IN-2

BO5

BO4

BO3

BO2

BO1

POWER

RUN

ERROR

RXD

TXD

Off

Off

On

On

OffOff

OffOn

Option Card

On On

UNIT PROTECTI ON MODULE

FHP P/N 8733 809 536

Applications Manual FHP560 Controller | 11

Bosch Thermotechnology Corp.

Data subject to changePage____ of ____

10 Symbol Legend

10.1 Common Abbreviations

Abbreviations

AFMS Air Flow Measuring Station MOD Modulating

AC Air Conditioning NC Normally Closed

ACU Air Conditioning Unit NO Normally Open

AHU Air Handling Unit OA Outdoor Air

AI Analog Input OAD Outdoor Air Damper

AO Analog Output OCC Occupancy

AUTO Automatic RA Return Air

AUX Auxiliary RF Return Fan

BAS Building Automation System RH Relative Humidity

BC Boilerless Control RV Reversing Valve

BI Binary Input SA Supply Air

BMS Building Management System SCR Silicon-Controlled Rectifi er

BO Binary Output SDP Secondar y Drain Pan

C Common (24VAC) SDS Smoke Detector Switch

CHW Chilled Water SECS Seconds

COND Condenser SF Supply Fan

COMP Compressor SOO Sequence of Operation

CW Condenser Water SP Static Pressure

CWP Circulating Water Pump S/S Start/Stop

DA Discharge Air STG Stage

DDC Direct Digital Control TEMP Temperature

DES Damper End Switch UI Universal Input

DFS Dirty Filter Switch UPM Unit Protection Module

DI Digital Input VAV Variable Air Volume

DO Digital Output VES Valve End Switch

DPS Differential Pressure Switch VFD Variable Frequency Drive

DX Direct Expansion VLV Valve

EA Exhaust Air WSE Water-Side Economizer

EF Exhaust Fan WSHP Water Source Heat Pump

EVAP Evaporator

EW Entering Water THERMOSTAT SIGNALS

F Fahrenheit G Fan Signal

FM Flow Meter O Reversing Valve Signal

FSS Fan Status Switch Y1 Compressor Stage 1 Signal

HGRH Hot Gas Re-Heat Y2 Compressor Stage 2 Signal

HP Heat Pump/High Pressure W Electric Heat Signal

HW Hot Water H Reheat Signal

IEM Input Expansion Module EV Economizer Valve Signal

LP Loop Pump/Low Pressure CV Condenser Valve Signal

LW Leaving Water P Pump Signal

MA Mixed Air

MAX Maximum

MIN Minimum

MINS Minutes

MISC Miscellaneous

Table 8

12

|

FHP560 Controller Applications Manual

Bosch Thermotechnology Corp.

Data subject to change Page____ of ____

11 Common Applications

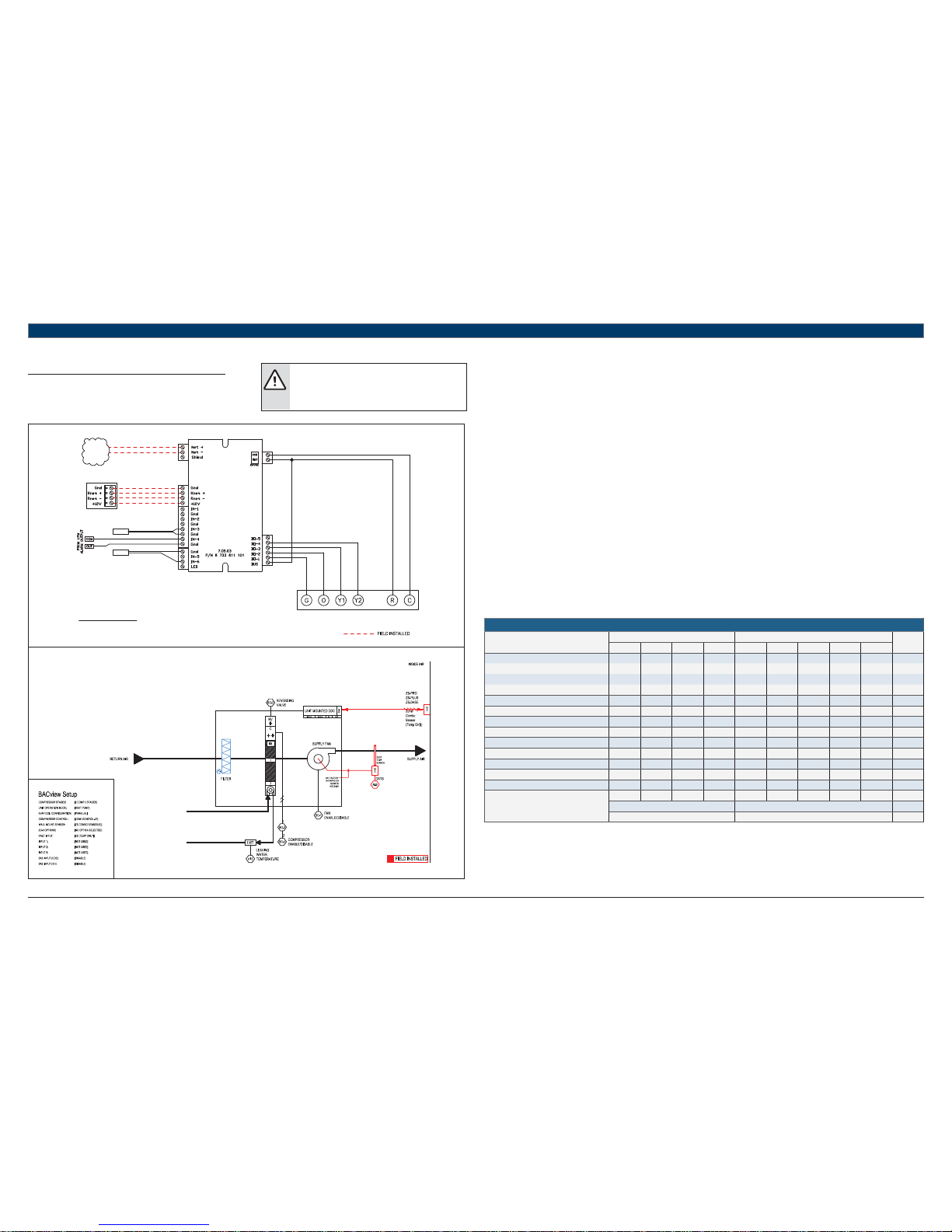

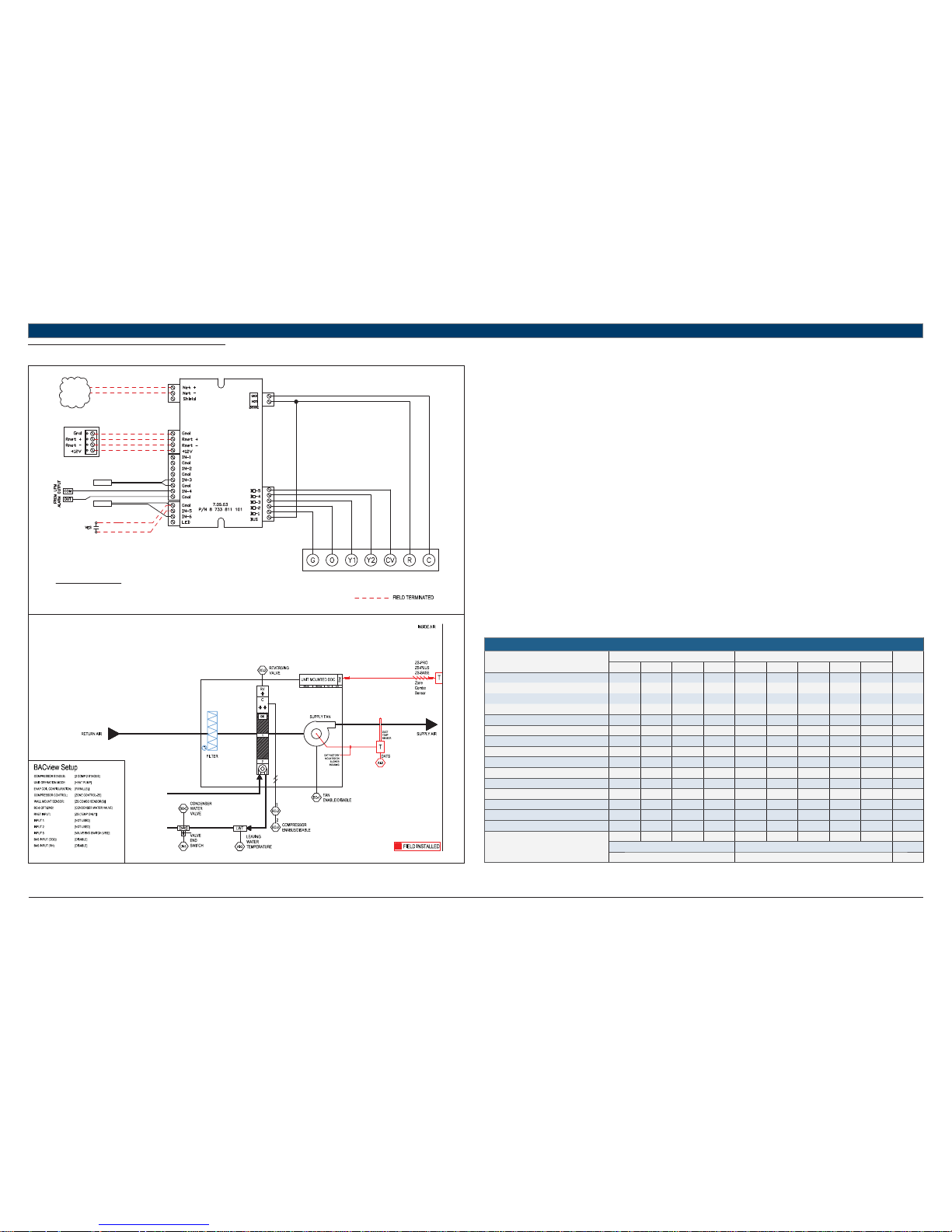

11.1 HP Basic

UNIT TERMINAL BLOCK

TO BACnet

MS/TP

NETWORK

LWTS

DATS

RED

GREEN

WHITE

BLACK

TERMINATION DETAIL

RNET: SENSORS

ZS COMBO SENSOR (TEMP ONLY)

STANDARD COMPONENTS:

DATS - DISCHARGE AIR TEMPERATURE SENSOR

LWTS - LEAVING WATER TEMPERATURE SENSOR

REFER TO UNIT WIRING DIAGRAM FOR FURTHER DETAILS

FHP560

Heat Pump Sequence of Operation – HP Basic

Supply Fan Start/Stop:

The supply fan will be started according to the schedule. After the supply fan has been started the control sequence will be enabled. Fan

operation is interlocked with heating and cooling operations. The fan may be confi gured for continuous operation during occupancy or for

operation based on heat/cool calls.

Zone Control:

The compressor will cycle to maintain the zone temperature at setpoint. To prevent short cycling there will be a 5 minute delay between

compressor stages. Additionally there’ll be a 1-minute delay when transitioning between heat and cool modes. The compressor will run subject to

internal safeties and controls provided by the upm.

Zone temperature may be supplied by a space ZS sensor, remote mounted sensor, or from a network value. All setpoints are adjustable via a

network, space ZS sensor Pro or plus, or with the BACview terminal. The ability to adjust setpoint from the space sensor, and the adjustment limit

(default +/-3 degress f) may be modifi ed via a network or BACview.

Heat Pump Control:

When the zone temperature falls below the zone temperature setpoint the reversing valve(s) will be disabled to provide heating when the

compressor is running. When the zone temperature rises above the zone temperature setpoint the reversing valve will be enabled to provide

cooling when the compressor is running.

A networked “loop valve enable” point must be enabled to allow compressor operation. This point is defaulted “on” from factory.

Night Setback:

When in “unoccupied”, the unit will cycle as necessary to maintain the night setback zone temperature at setpoint. A differential prevents the unit

from cycling excessively. During unoccupied operation the fan will only cycle to maintain a heat or cool setpoint.

Shutdown:

When the unit is shutdown by either a stop command or system safety the unit will be set as follows:

Supply fan will be on (user configurable)

Compressor(s) will be off

HEAT PUMP

Point Name

Hardware Points Software Points

Show On

Graphic

AI AO BI BO AV BV Sched Trend Alarm

Zone Temperature X X X X

Heating Setpoint X

Cooling Setpoint X

Supply Fan Command X

Compressor Stage 1 Output X

Compressor Stage 2 Output X

Reversing Valve Command X

Occupied Command X X X X

Discharge Air Temperature X

Leaving Water Temperature X

Condensate Overfl ow X

Lockout Alarm X

Schedule

Totals

3014311122

Total Hardware Total Software

882

Table 9

WARNING:

These diagrams are for reference purposes only. Please

refer to the actual unit wiring diagram for specifi c details

on how to wire your heat pump unit.

Applications Manual FHP560 Controller | 13

Bosch Thermotechnology Corp.

Data subject to changePage____ of ____

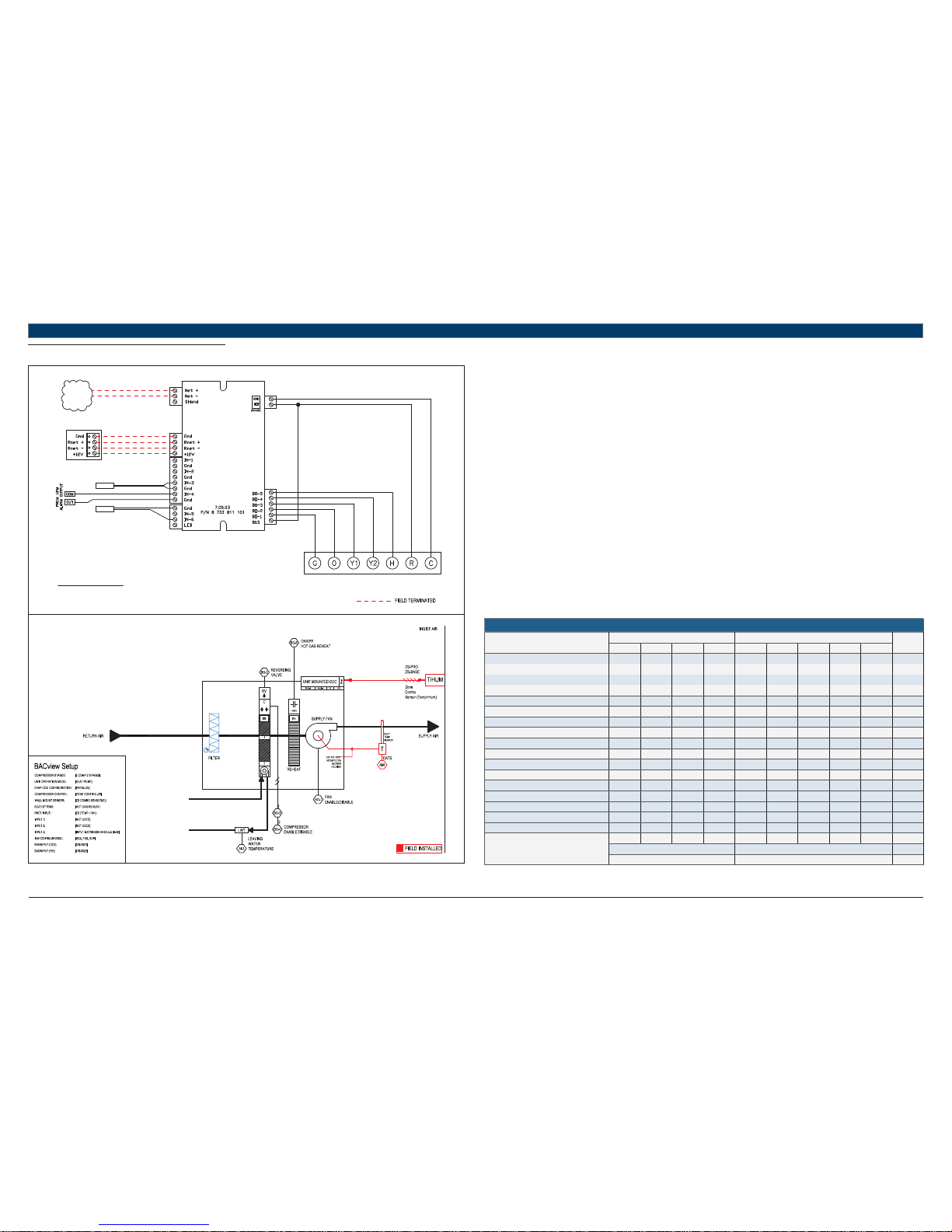

11.2 HP + HGRH

UNIT TERMINAL BLOCK

TO BACnet

MS/TP

NETWORK

LWTS

DATS

RED

GREEN

WHITE

BLACK

TERMINATION DETAIL

RNET: SENSORS

ZONE COMBO SENSOR (TEMP+RH)

STANDARD COMPONENTS:

DATS - DISCHARGE AIR TEMPERATURE SENSOR

LWTS - LEAVING WATER TEMPERATURE SENSOR

REFER TO UNIT WIRING DIAGRAM FOR FURTHER DETAILS

FHP560

Heat Pump Sequence of Operation – HP + HGRH

Supply Fan Start/Stop:

The supply fan will be started according to the schedule. After the supply fan has been started the control sequence will be enabled.

Zone Control:

The compressor will cycle to maintain the zone temperature at setpoint.

Heat Pump Control:

When the zone temperature falls below the zone temperature setpoint the reversing valve(s) will be disabled to provide heating when the

compressor is running. When the zone temperature rises above the zone temperature setpoint the reversing valve will be enabled to provide

cooling when the compressor is running.

Night Setback:

When in “unoccupied”, the unit will cycle as necessary to maintain the night setback zone temperature at setpoint. A differential prevents the unit

from cycling excessively.

Shutdown:

When the unit is shutdown by either a stop command or system safety the unit will be set as follows:

Supply fan will be on (user configurable)

Compressor(s) will be off

Hot Gas Reheat:

Once the heat/cool setpoint has been satisfi ed and relative humidity is above setpoint, the unit will operate in hot-gas reheat mode to actively

remove humidity from the space until the the humidity setpoint has been satisfi ed, or there’s another call for heating or cooling.

Relative humidity readings may be acquired from a space ZS combo Pro or standard sensor, 0-5V sensor in IN-1/IN-2, or over a network; software

must be confi gured accordingly.

Humidity setpoint may be adjusted from a space ZS sensor Pro, network, or BACview interface.

HEAT PUMP

Point Name

Hardware Points Software Points

Show On

Graphic

AI AO BI BO AV BV Sched Trend Alarm

Zone Temperature X X X X

Heating Setpoint X

Cooling Setpoint X

Supply Fan Command X

Compressor Stage 1 Output X

Compressor Stage 2 Output X

Reversing Valve Command X

Occupied Command X X X X

Discharge Air Temperature X

Leaving Water Temperature X

Dehumidifi cation Setpoint XX

Reheat Status

Reheat On/Off (Rh S/S) X X

High Return Air Humidity X

Condensate Overfl ow X

Lockout Alarm X

Schedule

Totals

3015411134

Total Hardware Total Software

9104

Table 10

14

|

FHP560 Controller Applications Manual

Bosch Thermotechnology Corp.

Data subject to change Page____ of ____

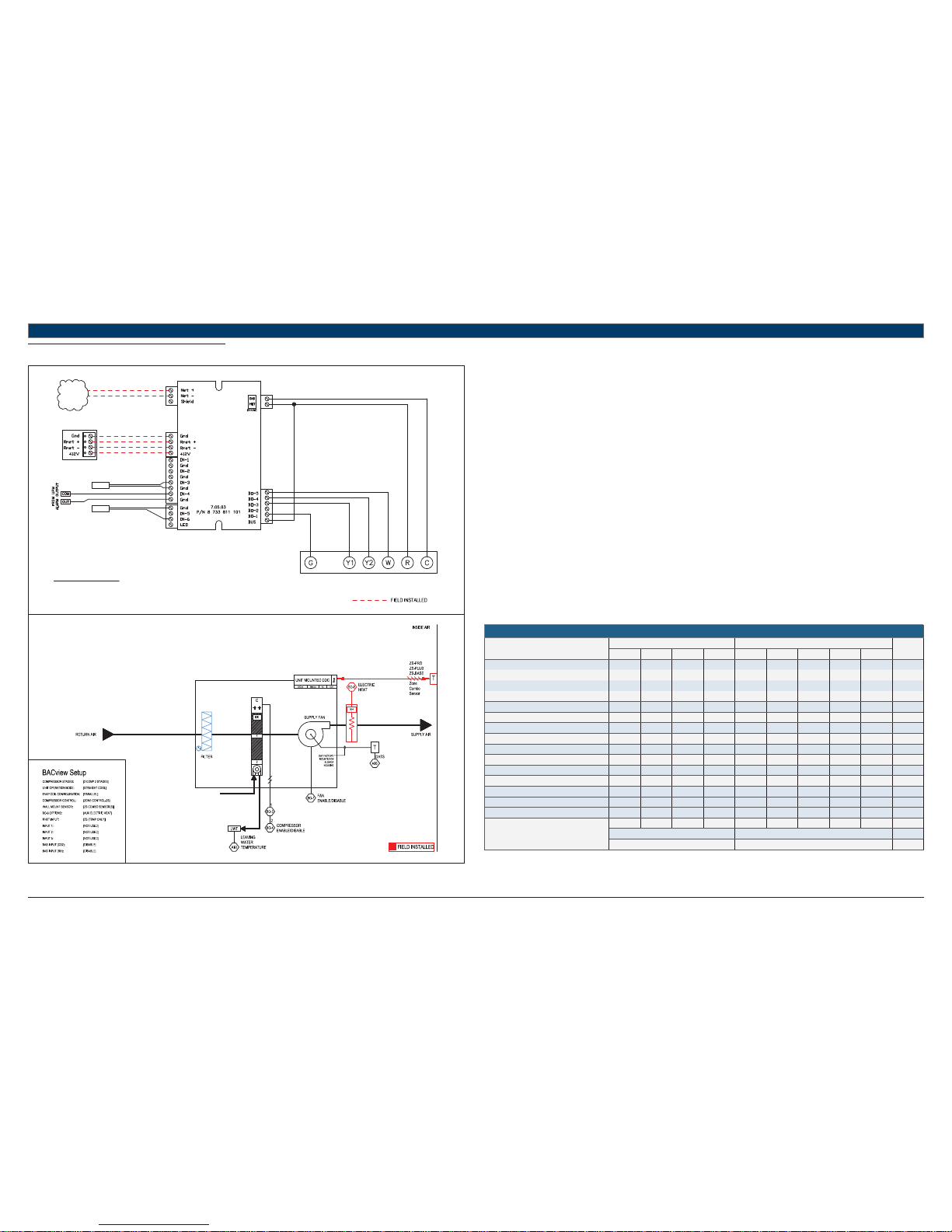

11.3 STRAIGHT COOL + EH

UNIT TERMINAL BLOCK

TO BACnet

MS/TP

NETWORK

LWTS

RED

GREEN

WHITE

BLACK

TERMINATION DETAIL

RNET: SENSORS

STANDARD COMPONENTS:

DATS - DISCHARGE AIR TEMPERATURE SENSOR

LWTS - LEAVING WATER TEMPERATURE SENSOR

REFER TO UNIT WIRING DIAGRAM FOR FURTHER DETAILS

FHP560

DATS

Heat Pump Sequence of Operation – STRAIGHT COOL + EH

Supply Fan Start/Stop:

The supply fan will be started according to the schedule. After the supply fan has been started the control sequence will be enabled.

Zone Control:

The compressor will cycle to maintain the zone temperature at setpoint.

Straight Cool Control:

Unit is confi gured for mechanical cooling only and the reversing valve is not installed. BO-2 is disabled and unused.

Night Setback:

When in “unoccupied”, the unit will cycle as necessary to maintain the night setback zone temperature at setpoint. A differential prevents the unit

from cycling excessively.

Shutdown:

When the unit is shutdown by either a stop command or system safety the unit will be set as follows:

Supply fan will be on (user configurable)

Compressor(s) will be off

Auxiliary electric heat:

Electric Heat (EH) option may be factory or fi eld installed and must be confi gured by the equipment integrator. Only one (1) stage of auxiliary

electric heat is supported and may be confi gured for BO-4 (single stage compressor units) or BO-5 (dual stage compressor units).

Upon a call for heating with demand greater than 90% (user confi gurable), the EH signal will be enabled to maintain setpoint at the confi gured

output as follows:

Straight cool units: enabled with no delay

Single stage heat pump units: enabled 5 mins after first stage of mechanical heat if demand is still above 90%.

Dual stage heat pump units: enabled 5 mins after second stage of mechanical heat if demand is still above 90%.

HEAT PUMP

Point Name

Hardware Points Software Points

Show On

Graphic

AI AO BI BO AV BV Sched Trend Alarm

Zone Temperature X X X X

Heating Setpoint X

Cooling Setpoint X

Supply Fan Command X

Compressor Stage 1 Output X

Compressor Stage 2 Output X

Reversing Valve Command

Occupied Command X X X X

Discharge Air Temperature X

Leaving Water Temperature X

Entering Water Temperature X

Aux Electric Heat Output X

Condensate Overfl ow X

Lockout Alarm X

Schedule

Totals

4014311122

Total Hardware Total Software

982

Table 11

Applications Manual FHP560 Controller | 15

Bosch Thermotechnology Corp.

Data subject to changePage____ of ____

11.4 STRAIGHT HP + CWV

UNIT TERMINAL BLOCK

TO BACnet

MS/TP

NETWORK

LWTS

DATS

RED

GREEN

WHITE

BLACK

TERMINATION DETAIL

RNET: SENSORS

STANDARD COMPONENTS:

DATS - DISCHARGE AIR TEMPERATURE SENSOR

LWTS - LEAVING WATER TEMPERATURE SENSOR

REFER TO UNIT WIRING DIAGRAM FOR FURTHER DETAILS

FHP560

Heat Pump Sequence of Operation – HP + CWV

Supply Fan Start/Stop:

The supply fan will be started according to the schedule. After the supply fan has been started the control sequence will be enabled.

Zone Control:

The compressor will cycle to maintain the zone temperature at setpoint.

Heat Pump Control:

When the zone temperature falls below the zone temperature setpoint the reversing valve will be disabled to provide heating when the

compressor is running. When the zone temperature rises above the zone temperature setpoint the reversing valve will be enabled to provide

cooling when the compressor is running.

Night Setback:

When in “unoccupied”, the unit will cycle as necessary to maintain the night setback zone temperature at setpoint.

Shutdown:

When the unit is shutdown by either a stop command or system safety the unit will be set as follows:

Supply fan will be on (user configurable)

Compressor(s) will be off

Condenser Water Valve:

Factory installed loop valve with Valve End Switch (VES) option must be confi gured by the equipment integrator. Upon a call for compressor

operation the normally closed valve is indexed to open via a 24Vac signal at BO-5. If the VES is confi gured, compressor operation is not enabled

until Valve End Switch is engaged (valve fully open).

Valve open status is verifi ed via the VES within 1.5 Mins of valve enable command.

If VES contacts do not engage within the specifi ed time, VES fail alarm is initiated. If valve opens without command from BO-5, valve in hand alarm

is initiated.

Compressor operation is disabled 20 secs after VES opens (fails) when loop valve has been indexed to open.

HEAT PUMP

Point Name

Hardware Points Software Points

Show On

Graphic

AI AO BI BO AV BV Sched Trend Alarm

Zone Temperature X X X X

Heating Setpoint X

Cooling Setpoint X

Supply Fan Command X

Compressor Stage 1 Output X

Compressor Stage 2 Output X

Reversing Valve Command X

Occupied Command X X X X

Discharge Air Temperature X X

Leaving Water Temperature X X

Loop Valve Command X X

Valve End Switch (Valve Status) X X

Condensate Overfl ow X

Lockout Alarm X

Schedule

Totals

3025531122

Total Hardware Total Software

10 12 2

Table 12

Loading...

Loading...