500 Series Photoelectric Detectors

FCP-500 | FCP-500-P | FCP-500-C | FCP-500-C-P

en Installation Guide

FCP-500 Series

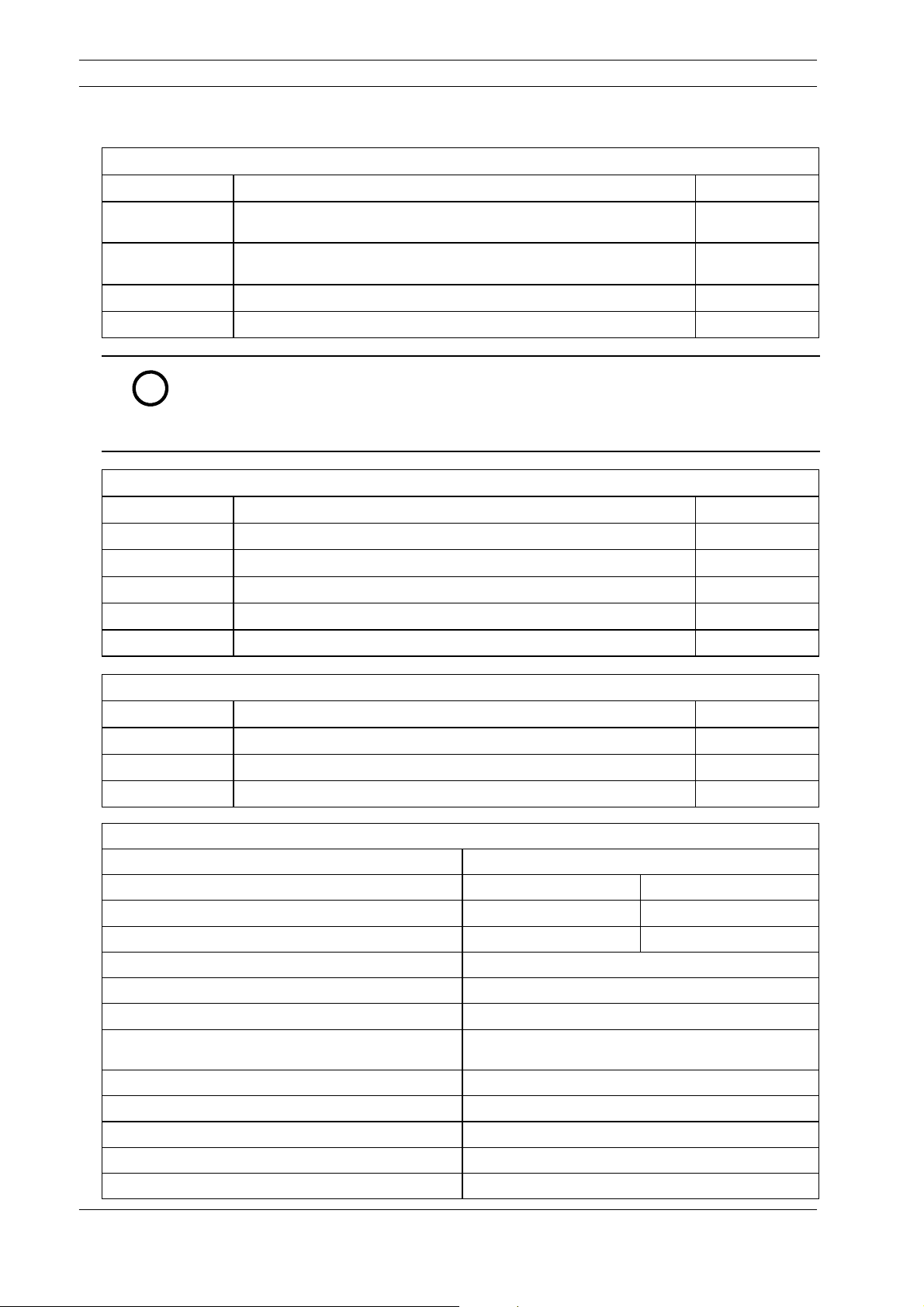

1. Specifications

Table 1: Models

Type Description Material No.

1

FCP-500-C Photoelectric Detector with Carbon Monoxide Detection,

Color White

FCP-500-C-P Photoelectric Detector with Carbon Monoxide Detection,

Transparent with Color Inserts

FCP-500 Photoelectric Detector, Color White 4.998.150.702

FCP-500-P Photoelectric Detector, Transparent with Color Inserts 4.998.150.704

The CO sensor has not been evaluated to the requirements of UL 2075 or for its ability to

i

Table 2: Options (included)

Type Description Material No.

FAA-500-BB-UL Ceiling Mount Back Box for US F.01U.510.767

FCA-500 Four-Wire Base (six conductors) 4.998.151.300

FCA-500-E Four-Wire EOL Base (six conductors) 4.998.151.301

FAA-500-TR-W Trim Ring, White 4.998.151.295

FAA-500-TR-P Trim Ring, Transparent with Color Inserts 4.998.151.296

detect a fire.

The FCP-500-C and FCP-500-C-P detect CO as a component of a fire.

Do not use the FCP-500-C and FCP-500-C-P as CO detectors.

4.998.150.703

4.998.150.705

Table 3: Options (optional)

Type Description Material No.

DRA-5 Remote LED Annunciator -

FAA-500-TTL Test Adapter with Magnet F.01U.508.725

FAA-500-RTL Removal Tool F.01U.508.720

Table 4: Technical Data

Operating Voltage 9.7 V DC to 30 V DC

Current Consumption Standby Alarm/Trouble

- FCA-500 / FCA-500 with DRA-5 3mA/3mA 47 mA / 52 mA

- FCA-500-E / FCA-500-E with DRA-5 24 mA / 24 mA 47 mA / 58 mA

Alarm Output Alarm resistance 680 Ω or 0 Ω (US only)

Remote LED Output Maximum 20 mA

Rating of Trouble/Alarm Relay 1A@30VDC

Reset Time

Max. Start-up Time 22 sec

Sensitivity 1.3 ...2.9 %/ft (4.3 ... 9.5 %/m)

Mounting Locations Refer to NFPA-72 guidelines.

Maximum Mounting Height Refer to NFPA-72 guidelines.

Minimum Mounting Height 9.0 ft (2,7 m)

The detector resets if power is interrupted for at

least 2 sec.

Bosch Security Systems

BDL-F01U000626 | A7 | 2007.07

2

Table 4: Technical Data (continued)

Maximum Thickness of False Ceiling 1.25 in. (32 mm), flush mount applications only

Minimum Clearance for False Ceiling 6 in. (15.2 cm)

Required Hole

Minimum Distance from Lamps 1.6 ft (0.5 m)

Maximum Airflow 300 ft/min (1.5 m/s)

Operating Temperature +32 _F to +100 _F(0_Cto+38_C)

Humidity < 95%, non-condensing

Protection Class as per IEC 60529

- FCP-500-C and FCP-500-C-P IP 33

- FCP-500 and FCP-500-P IP 53

Dimensions

-Detectoronly 4.5 in. x 2.2 in. (113 mm x 55 mm)

- Detector with Trim Ring 5.9 in. x 2.2 in. (150 mm x 55 mm)

- Detector with Trim Ring and Base 5.9 in. x 2.75 in. (150 mm x 70 mm) with base

Compliance UL 268

5-1/16in., tolerance -1/16in. to +3/16in.

(130 mm, tolerance -1 mm to +5 mm)

FCP-500 Series

2. Installation Considerations

i

Caution:

D Do not remove the plastic film from the detector head until construction of the installation area is

finished.

D Protect the detector sensor windows from paint or contaminates. Remove the detector head during

remodelling and store it in a clean dr y location.

. If you do not follow these cautions, the detector might not operate.

Detector Location and Spacing:

D BOSCH recommends spacing the sensors in compliance with NFPA-72. In low air flow applications with

smooth ceilings, space sensors with a maximum distance of 30 ft. For specific information regarding

sensor spacing, placement and special application refer to NFPA-72.

D Not suitable for outdoor use.

D Do not install in areas where the detector is pointed at

direct or indirect sunlight.

D Do not mount detector in a cone of light from a lamp.

D Maintain a hemispherical radius of at least 19 in.

(50 cm) around the detector (see Fig. 1.).

Insure that this area in front and to the sides of the

detector is kept clear of all obstructions (see Fig. 1.).

Further Considerations:

D Only use end-of-line (EOL) resistors supplied or specified by the control panel manufacturer.

D Smoke detectors are not to be used with detector guards unless the combination has been evaluated and

found suitable for that purpose.

D This detector must be installed in compliance with the control panel system installation manual.

D Install, test and maintain this device according to this installation guide, NFPA-72, Local Codes and the

Authority Having Jurisdiction (AHJ). Failure to follow these procedures may cause the device to not

function properly. Bosch Security Systems is not responsible for any devices that are improperly

installed, tested or maintained.

For proper installation, read and understand NFPA-72, The National Fire Alarm Code before installation.

Ceiling

Fig. 1.

Detector

19 in.(50 cm)

Free space

BDL-F01U000626 | A7 | 2007.07

Bosch Security Systems

FCP-500 Series

3. Installation

Dismantling Detector

1. Push on the center of the detector’s front plate. The detector head springs out of the base.

2. Remove the detector head from the base.

3. Lift the trim ring by the edge to remove it from the base.

4. Loosen the four screws holding the base to the backbox.

5. Turn the base counter-clockwise until the screws line up with the large end of the slots. Remove the base

from the back box.

3

Inserting Color Rings (FCP-500-C-P and FCP-500-P)

1. Select a color.

2. From the selected color, insert the largest color ring in the trim ring.

3. Remove the detector front plate:

Insert the enclosed small opener tool (2) into the slot (3) above the

snap-fit (1) and secure it with your thumb. Grasp the edges of the detector

front plate, push gently, turn counter-clockwise, and lift.

4. From the selected color, insert the larger color ring in the outer ring, and

the smaller color ring in the inner ring of the detector front plate (see

Fig. 3.).

5. Replace the front plate cover. Ensure the tabs on the cover align with the

grooves in the detector head. The cover will lie flat on the detector head.

6. Turn the cover clockwise to lock it into place.

Note:

If the cover aligns properly, all the sensor openings in the detector head

are clearly exposed.

Ceiling Mount Back Box (FAA-500-BB-UL)

D For installation, refer to the FAA-500-BB-UL Installation Guide

(P/N 601-F.01U.003.008).

Wiring the Base (FCA-500 and FCA-500-E)

In applications which require UL listed units, the power of all connections (detector

i

power, trouble and alarm relay) must be taken from power limited supplies when the

cable is carried through the grommets.

Please check with the local authorities to insure mounting without the conduit connector

is allowed.

Fig. 2.

Fig. 3.

1

3

2

Note:

D Do not twist or loop the wires around the terminals. The wires for terminal connection must be cut,

stripped, and inserted as individual ends.

D Use the cable holders on the base for strain relief for the wires.

An FCA-500-E Four-Wire EOL Base is required

i

D EOL resistor: The last base on the stub line has to

be a FCA-500-E. For this, place the EOL resistor

between the two screw clamps (see Fig. 4.).

D Alarm resistor: If neccessar y, change the alarm

contact resistance from 0 Ω to 680 Ω by breaking

off the printed circuit board tongue (see Fig. 4.).

Bosch Security Systems

D for single detector installations

D always as the last base for each stub line.

An EOL resistor can only be attached to the FCA-500-E Four-Wire EOL Base.

For 680 Ω break off alarm resistor here!

EOL resistor

BDL-F01U000626 | A7 | 2007.07

Fig. 4.

4

y

Alarmrela

y

(

l

lycl

d

)

Table 5: Wiring Connections

(Inner Ring for Conventional)

Connection Term inal Wire

Alarm rela

(normally open)

b1/b2 yellow

a1/a2 white

Shielding not used -

Indicator output c white

Voltage + +V red

Voltage + +V red

Voltage - 0V black

t0(not connected)

Trouble relay

norma

ose

t1(common) * green

t2(normally closed) green

* Connect terminal b1/b2 of the last detector base with

terminal t

of the first detector base of the stub (see blue

1

wire in Fig. 7.).

Single Detector Wiring

to Power Supply

+

black

FCP-500 Series

Connection

terminals

Holder for

cable ties

Lettering on

conventional

connections

Fastening slot

Fig. 5.

red

FCA-500-E

to Control Panel

Multiple Detector Wring

+

-

to Power

Supply

to Control

Panel

FCA-500

yellow

white

BDL-F01U000626 | A7 | 2007.07

red

black

green

blue

yellow

white

yellow

FCA-500

white

green

blue

red

black

yellow

white

Fig. 6.

FCA-500-E

red

DRA-5

white

Fig. 7.

Bosch Security Systems

FCP-500 Series

Mounting the Base (FCA-500 and FCA-500-E)

1. Insert the base in the back box so that it fits over the four screws.

2. Turn the base clockwise until it stops to lock it in place.

3. Repeat steps 1 and 2 if you install multiple detectors in a line.

4. Slightly turn each base until the mark on the base aligns with the

other detectors’ marks (see Fig. 8.).

5. Tighten the screws with the supplied wrench.

5

Alignment mark

Inserting the Detector Head

1. Remove the protective film from the detector head.

2. Snap the trim ring into place on the base.

3. Place the detector head in the base and turn it until the detector head drops into the alignment grooves.

4. Push the center of the detector until it locks into place. It clicks and springs up.

Start-up

1. Check the wiring from the control panel to the last head on the run for proper polarity and continuity.

2. Make sure each run terminates with an EOL resistor as specified by the control panel manufacturer.

3. Apply power to the system. Check for alarm and troubles.

4. If single detectors alarmed or went in trouble, check if there is a free space of at least 19 in. (50 cm)

around these detectors. If the problem persists, replace these detectors or swap them with known good

units. If also the good units alarm or go in trouble, the sensitivity may have been affected by the

surrounding environment. Recheck if there are any obstructions around the detector which may reflect

the light emitted by the detector.

5. Activate the dr y reed contact of each detector for 10 sec with a magnet until the detector alarms (see

Section 5., Dry Reed Contact and Section 6., Electronical Function Test ). Then reset the detector by

removing the power for at least 2 seconds. After the reset, the detector will calibrate itself to the

surrounding environment.. Make sure that no objects or obstructions (like the test tool SOLO330 itself)

are in front of the detector during calibration for 15 sec.

After installation each detector must be calibrated. If there are any obstruction in front of

i

6. Perform the sensitivity test described in Section 7. at every detector.

the detector after the reset during its calibration (Electronic Function Test, Section 6.),

the sensitivity of the detector may be affected.

Fig. 8.

Bosch Security Systems

BDL-F01U000626 | A7 | 2007.07

6

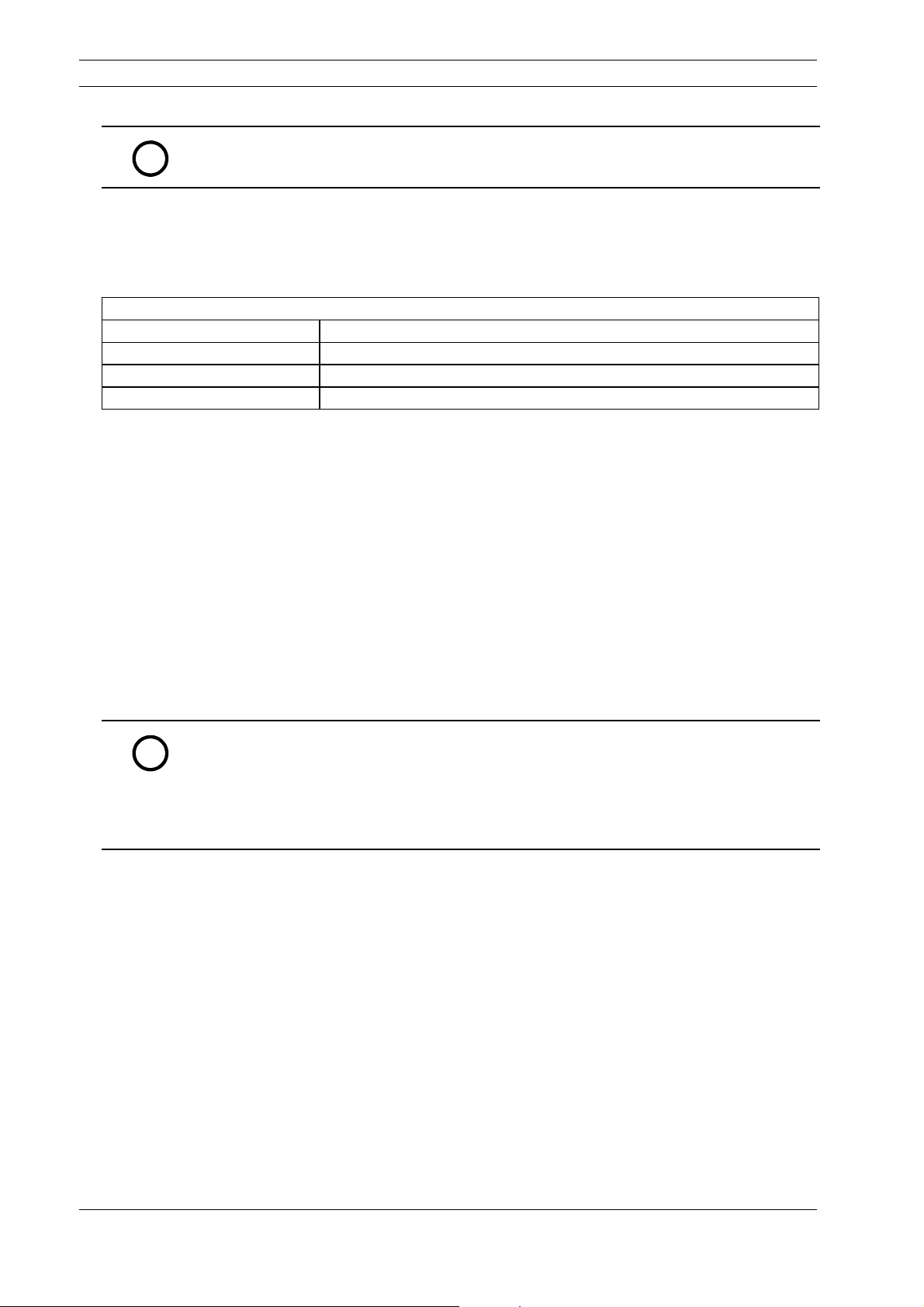

4. Maintenance and Service

D Trained personnel should perform a visual and physical test according Table 6 as recommended by

NFPA-72 (National Fire Alarm Code).

D For cleaning the detector surface, use a common window cleaner and a soft, clean cloth.

FCP-500 Series

i

Note:

D The FCP-500-C and FCP-500-C-P must be replaced every five years. The chemical (CO) sensor turns off

at five years of operation. The LED double-flashes ever y 8 to 12 sec, indicating trouble, and the detector

continues to function as an optical (O) detector.

Table 6: Testing Detector

Test Steps

1 Check the LED (see Table 7) X X

2 Check the detector’s mounting X X

Visually check for damage or contamination of the detector sur-

3

face

Check the area for factors (such as lightening) that could inhi-

4

bit the detector’s performance

5 Perform Electronic Functional Test (see Section 6.) X X

6 Perform Sensitivity Test (see Section 7.) X X

7 Test the optical sensor (see Section 8.) X X

8 Test the optical sensor and the CO sensor (see Section 9.) - X

Notify all concerned parties before any maintenance or testing of the fire alarm sy stem, and after completion of these activities.

Detector Type

FCP-500

FCP-500-P

X X

X X

FCP-500-C

FCP-500-C-P

Table 7: LED Operation

Status LED

Normal green, flashes every 8 sec

Alarm red, steady

Trouble green, double flash every 8 to12 sec

Test mode green, flashes once every second

5. Dry Reed Contact

1. Place the test tool with the FAA-500-TTL test adapter with magnet up against the detector head.

2. Turn the test tool until the magnet activates the

dry reed contact (see Fig. 9.). Normally the green

LED flashes once every 8 to 12 sec. When the dry

reed contact activates, the LED flashes once every

second.

CO sensor

(only FCP-500-C

detectors)

LED

6. Electronic Functional Test

1. Activate the dr y reed contact (Section 5, Dry Reed

Contact).

2. Leave the magnet on the test tool by the dry reed

contact for 10 sec. Count 10 flashes of the LED.

The detector activates a test alarm and the LED

turns red.

Dry reed

contact

Fig. 9.

BDL-F01U000626 | A7 | 2007.07

Bosch Security Systems

FCP-500 Series

7

i

Notify all concerned parties before any maintenance or testing of the fire alarm sy stem, and after completion of these activities.

7. Sensitivity Test

1. Activate the dr y reed contact (Section 5, Dry Reed Contact).

2. Leave the magnet on the test tool by the dry reed contact for 5 sec. Count 5 flashes of the LED.

3. Remove the test tool. Refer to Table 8 for the LED Display.

Table 8: Sensitivity Test LED Display

Number of Red LED Flashes Detector’s State

1to3 Operating normally with little or no dirt contamination

4to6 Dirty, needs immediate cleaning

7to10 Trouble condition, very dirty, clean and check detector immediately

8. Smoke Test for the FCP-500 / FCP-500-P

Note: No testing gas (smoke aerosol) is required! For testing use only:

- Test Tool for Optical Smoke Detectors Solo 330 (Product ID 4.998.112.071)

- with FAA-500-TTL Test Adapter with Magnet (Product ID F.01U.508.725)

1. Activate the dr y reed contact (Section 5., Dry Reed Contact).

2. Leave the magnet on the test tool by the dry reed contact for at least 2 sec and not more than 4 sec.

Count two flashes of the LED. The detector stays in test mode for 60 sec. The green LED blinks once a

second.

3. Hold the test tool under the detector so that the test beaker is flush with the trim ring.

Note: Do not tip the test tool, or the detector might come loose.

4. By covering the scattered light areas, both optical sensors are triggered simultaneously (no smoke

aerosol is required).

5. This can take up to 20 sec. An alarm activates and the red LED lights. If the panel is in test mode, the

alarm resets automatically.

9. CO and Smoke Test for the FCP-500-C / FCP-500-C-P

The CO sensor has not been evaluated to the requirements of UL 2075 or for its ability to

i

Note: For testing use only:

- T est Tool for Optical Smoke Detectors Solo 330 (Product ID 4.998.112.071)

- with FAA-500-TTL Test Adapter with Magnet (Product ID F.01U.508.725)

- Solo CO Testing Gas (Product ID 4.998.142.221)

1. Conduct step 1 to 5 of Section 8. (Smoke Test) to ensure that the smoke sensor is functioning. After this

an alarm activates and the red LED lights steady. Don’t reset the detector.

2. If over 70 ppm of carbon monoxide is applied to the detector, the red LED of the detector starts flashing.

This indicates that the carbon monoxide sensor is working.

3. Reset the detector by removing the power.

detect a fire.

The FCP-500-C and FCP-500-C-P detect carbon monoxide (CO) as a component of a fire.

It is not a CO detector and cannot activate an alarm in the presence of CO only. It is

used to adjust the sensitivity of the smoke detector.

Perform the CO sensor test once a year to confirm that the sensor is functioning.

Bosch Security Systems

BDL-F01U000626 | A7 | 2007.07

LEERER MERKERLEERER MERKER

Bosch Security Systems

130 Perinton Parkway

Fairport, NY 14450-9199

www.boschsecurity.us

Customer Service: (800) 289-0096

Technical Support: (888) 886-6189

Seite 8 von 8

Loading...

Loading...