Bosch FCP‑320, FCH‑320 User Manual

Conventional Automatic Fire Detectors

FCP‑320/FCH‑320

en

User manual

Conventional Automatic Fire Detectors Table of contents | en 3

Table of contents

1

2

Product Description 5

System Overview 6

2.1 Configuration of the Detector 6

2.2 Functional Description of Sensor Technology 6

2.2.1 Optical Sensor (Smoke Detector) 6

2.2.2 Thermal Sensor (Heat Detector) 6

2.2.3 Chemical Sensor (Gas Sensor) 6

2.3 System Description 6

2.4 Features 7

3

Planning 8

3.1 Basic Planning Guidelines 8

3.2 Use in Fire Barriers Conforming to DIBt 8

4

Installation 9

4.1 Overview of Detector Bases 9

4.2 Overview of Detector Base Sounder 10

4.3 Mounting the Bases 10

4.4 Wiring 11

4.4.1 Wiring MS 400/MS 400 B 12

4.4.2 Wiring MSR 320 13

4.4.3 Wiring MSS 300 14

4.5 Installing the Detector Head 14

4.6 Detector Removal 15

5

Accessories 16

5.1 EOL Module for Line Termination According to EN 54-13 16

5.2 Support Plates for Detector Identification 16

5.3 SK 400 Protective Basket 16

5.4 SSK 400 Protective Dust Cover 17

5.5 WA400 Detector Console 17

5.6 MH 400 Detector Heating Element 17

5.7 Remote Indicators 17

6

Order Overview 22

6.1 Detector Variants 22

6.1.1 Detectors with 820 Ohm Alarm Resistor 22

6.1.2 Detectors with 470 Ohm Alarm Resistor* 22

6.2 Detector Bases 22

6.3 Detector Accessories 22

6.4 Installation Accessories 23

6.5 Detector Base Sounders 23

6.6 Remote Indicators 23

6.7 Service Accessories 23

7

Maintenance and Service 25

7.1 Coding of the Detector Types 26

7.2 Test Procedure for Detectors with C-Sensor 26

7.3 Test Procedure for Detectors without C-Sensor 27

7.4 Warranty 27

7.5 Repair 27

7.6 Disposal 27

7.7 Additional Documentation 27

Bosch Sicherheitssysteme GmbH

User manual

2021.03 | 11 | F.01U.004.377

4 en | Table of contents Conventional Automatic Fire Detectors

8

9

Specifications 28

Abbreviations 31

2021.03 | 11 | F.01U.004.377

User manual

Bosch Sicherheitssysteme GmbH

Conventional Automatic Fire Detectors Product Description | en 5

i

1 Product Description

Notice!

This Product Information describes the entire product range of the FCP-320/FCH-320

Conventional Automatic Fire Detectors.

The FCP-320/FCH-320 Conventional Automatic Fire Detectors works on the basis of the

conventional technology and combines standard detection methods such as scattered light

measurement and temperature measurement with gas measuring technology at the highest

configuration level.

This method uses state-of-the-art processing methods to evaluate the signals from the gas

sensor and scattered light sensor or thermal sensor.

Security against false alarms is thus increased significantly and detection time is reduced in

comparison with the fire detectors generally available on the market today.

Thanks to the higher information content of the multisensor detectors, the use of detectors is

possible in environments where pure smoke detectors cannot be used.

The detectors are available in the following configuration levels:

– FCP-OC320: Combined optical, gas-sensitive smoke detectors

– FCP-OT320: Combined optical, thermal smoke detectors

– FCP-O320: Optical smoke detectors

– FCH-T320: Thermal detectors.

The detector's timeless and innovative design is a result of the cooperation between engineers

and designers. With this design it is possible to reconcile the contradictory goals of a

generous installation space and a small detector.

The placement of the individual display on the detector tip is the first externally visible

characteristic of the installation-friendly development concept. The stable and robust detector

base need no longer be aligned due to the position-independent position of the individual

display.

It is suitable for surface and flush cable mounting and includes separate mounting points for

dropped ceiling and concealed sockets. In addition, it fits all common bore patterns. For

surface mounting, the cable may be fed through on the side.

The integrated strain relief for interfloor cables prevents the removal of cables from the

terminal after installation. The terminals are easily accessible; a retainer for the end of line

resistor is integrated. Cable diameters of up to 2.5mm2 can be used.

It can be equipped with a damp room seal so that all installation requirements can be covered

with one base.

The 320 Series detectors are available with either a 470Ω alarm resistor or a 820Ω alarm

resistor. The operating voltage range is 8.5V DC to 30VDC, which allows the detectors to be

used with almost every common conventional fire panel.

Bosch Sicherheitssysteme GmbH

User manual

2021.03 | 11 | F.01U.004.377

6 en | System Overview Conventional Automatic Fire Detectors

6

4

5

2

1

3

3

2 System Overview

2.1 Configuration of the Detector

1 Smoke measurement chamber with

optical sensor

2 Thermal sensor

3 Chemical sensor (covered on the cross-

section)

4 Individual display

5 PC board with evaluation electronics

6 Detector base

Configuration of the Detector

2.2 Functional Description of Sensor Technology

2.2.1 Optical Sensor (Smoke Detector)

The optical sensor uses the scattered-light method.

An LED sends light into the measuring chamber (item1); this light is absorbed by the labyrinth

structure. In the event of a fire, smoke enters the measuring chamber. The light is scattered by

the smoke particles and hits the photo diodes, which transform the quantity of light into a

proportional electrical signal.

2.2.2 Thermal Sensor (Heat Detector)

A thermistor (item2) in a resistance network is used as a thermal sensor; an analog-digital

converter measures the temperature-dependent voltage at regular intervals.

The temperature sensor switches to an alarm state if the maximum temperature exceeds

54°C (thermal maximum) or if there is a defined temperature increase within a particular

timeframe (thermal differential).

2.2.3 Chemical Sensor (Gas Sensor)

The gas sensor (item3) detects mainly the carbon monoxide

(CO) that is produced by a fire, but it also detects hydrogen

(H) and nitrogen monoxide (NO).

The underlying measurement principle is CO oxidation and the

measurable current that it creates. The sensor signal value is

proportional to the concentration of gas.

The gas sensor supplies additional information in order to

reliably suppress deception variables.

Chemical Sensor

2.3 System Description

2021.03 | 11 | F.01U.004.377

Up to two detection principles are integrated into the FCP-320/FCH-320 Series Fire Detectors:

– Optical (for smoke): O

– Thermal (for heat): T

– Chemical (for gas): C

User manual

Bosch Sicherheitssysteme GmbH

Conventional Automatic Fire Detectors System Overview | en 7

All sensor signals are analyzed continually by the internal signal analysis electronics and are

linked with each other. If a signal combination fits the detector’s programmed code field, an

alarm is automatically triggered.

By linking the sensors (combined detectors), the detector can also be used in places where

the work carried out gives rise to light smoke, steam or dust.

The FCP-OC320/FCP-OC320-R470 detectors analyze the present CO concentration and adjust

the threshold of the optical sensor in accordance with the CO concentration. If no CO is in the

air, the alarm is triggered nonetheless at a certain level of smoke density and above. However,

the alarm is not triggered if only CO is detected in the air.

The FCP-OT320/FCP-OT320-R470 detectors trigger an alarm in the case of smoke as well as in

the case of a temperature rise. Additionally, the threshold of the optical sensor is adjusted in

accordance with the absolute temperature and the rate of temperature rise.

2.4 Features

– Active adjustment of the threshold (drift compensation) if the optical sensor becomes

contaminated.

– Active adjustment of the threshold (drift compensation) of the chemical sensor.

– Activation of a remote external detector alarm display is possible.

– Optional mechanical removal safeguard (can be activated/deactivated).

– Dust-resistant labyrinth and cap construction.

– Every detector has a “Chamber Maid Plug” (a cleaning opening with a plug) for blowing

out the optical chamber with compressed air (not required for the FCH‑T320/

FCH‑T320‑R470/FCH‑T320‑FSA Heat Detectors).

– Connectable to Bosch fire panels and the majority of conventional fire panels available on

the market.

– Two variants with 820Ω alarm resistor and 470Ω alarm resistor enables the detector

application with nearly all conventional fire panels.

– An unshielded cable may be used for the primary line.

Bosch Sicherheitssysteme GmbH

User manual

2021.03 | 11 | F.01U.004.377

8 en | Planning Conventional Automatic Fire Detectors

i

3 Planning

Notice!

FCP-320/FCH-320 Conventional Automatic Fire Detectors are not designed for exterior use.

3.1 Basic Planning Guidelines

– The planning of multisensor fire detectors takes place according to the guidelines for

optical detectors, until an independent guideline has been worked out with the VdS (see

DIN VDE0833 Part2 and VDS2095):

– Maximum monitoring area 120m

– Maximum installation height 16m.

– Maximum permitted air speed: 20m/s.

– A maximum of 32 detectors can be connected per primary line. This number is limited to

20detectors when connected to an UGM2020 (GIF/GIF2).

3.2 Use in Fire Barriers Conforming to DIBt

The FCH‑T320‑FSA and FCP-O320 are available for use in fire barriers conforming to the

guideline of the DIBt (Deutsches Institut für Bautechnik/German Institute for Building

Technology).

When planning for fire barriers conforming to DIBt, the FCH-T320‑FSA detector has already

been set to class A1R.

Both models have DIBt approval.

2

2021.03 | 11 | F.01U.004.377

User manual

Bosch Sicherheitssysteme GmbH

Conventional Automatic Fire Detectors Installation | en 9

4 Installation

4.1 Overview of Detector Bases

The FCP-320/FCH-320 Series detector head is used in one of the following listed detector

bases, which are suitable for both flush-mounted and surface-mounted cable feed. They have

separate attachment points for ceiling mount/flush-mounted back boxes. In addition, they fit

all standard bore patterns.

The detector bases are made from white ABS plastic (color similar to RAL9010) and have a

matte surface finish.

The bases have screw terminals for connection of the detector and its accessories to the fire

panel. Contacts connected with the terminals provide for a secure electrical connection when

mounting the FCP-320/FCH-320 detector heads. Cables up to 2.5mm2 can be used.

To protect against unauthorized removal, the detector head can be secured with a variable

locking.

MS400

The MS400 Detector Base is the standard detecor base. It has

seven screw terminals.

MS400B

The standard MS400 Detector Base with Bosch-branding.

FAA-420-SEAL

Seal for using the MS400 and MS400B detectors in a humid

environment. The TPE seal protects the detector reliably against

the penetration of condensed water.

MSR320

The MSR320 Conventional Detector Base with Relay is provided

with an integrated relay that has NO/C/NC contacts for switching

applications (e.g. non EN-54 third party applications, dampers,

door holders, etc.).

Bosch Sicherheitssysteme GmbH

User manual

2021.03 | 11 | F.01U.004.377

10 en | Installation Conventional Automatic Fire Detectors

i

MSC420

The MSC420 Additional Base was designed specially for surface

mounted cable feed via cable protection conduits. It is used in

combination with any of the above listed bases. It has two

opposing pre-cut inlets of 20mm diameter and two additional

opposing and prepared inlets for up to 28mm diameter.

The additional base has a diameter of 120mm and a height of

36.7mm.

To protect against condensed water penetration, a seal made of

TPE is situated on the base of the MSC420.

4.2 Overview of Detector Base Sounder

Detector base sounders are used if the acoustic signaling of an alarm is required directly at

the location of the fire.

– MSS300 Base sounder white, for conventional

technology, connection via the detector C point.

– MSS300 WH-EC Base Sounder, white for conventional

technology, with external activation.

The integrated tone generator has 11 tones for selection (incl.

tones according to DIN33404 and EN457) with sound

pressure of max. 100dBA, depending on the type of tone

selected.

The tone type on conventional variants is set via four DIP

switches and the volume adjusted continuously via a

potentiometer.

Surface mounted and flush mounted cable feed are possible.

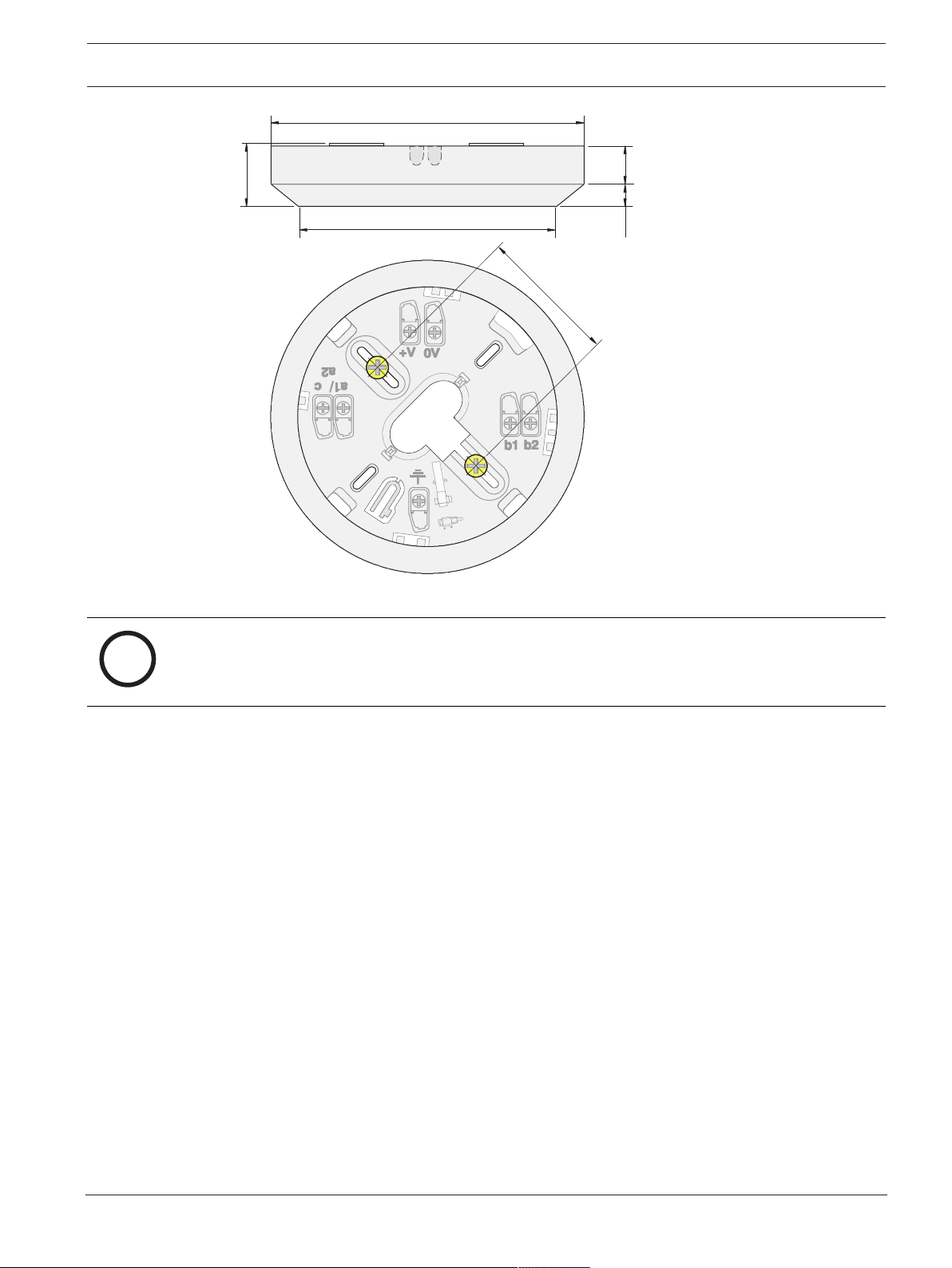

4.3 Mounting the Bases

The detector bases are screwed to the even, dry surface using two screws approx. 55mm

apart.

In the case of cable feed for surface mounting, break out the prepared entry points (X) on the

housing.

In the case of flush mounted cable feed, route the cable through the opening in the centre of

the base.

The short mounting bores marked in the sketch with “Y” may be used only for fixing over a

back box.

Notice!

Cable feed and outfeed can be on the same side.

For cable feed at the FAA-420-SEAL and MSC420 puncture the sealing with a pointed tool.

Do not cut the sealing with a knife.

2021.03 | 11 | F.01U.004.377

User manual

Bosch Sicherheitssysteme GmbH

Conventional Automatic Fire Detectors Installation | en 11

Ø 100

X

Ø 120

147.8

22.7

Y

Y

5

5

i

4.4 Wiring

Notice!

Keep screening wire as short as possible and insulate it.

Bosch Sicherheitssysteme GmbH

User manual

2021.03 | 11 | F.01U.004.377

Loading...

Loading...