Bosch CLIMATE 5000 VRF RDCI, RDCI10/28-3, RDCI8/25-3, RDCI12/33-3, RDCI16/45-3 Installation Manual

...Page 1

Before using your air conditioner unit, please read this manual carefully and keep it for future reference.

6 720 862 437 (2016/10)

Installation manual

CLIMATE 5000 VRF

RDCI Series – All DC Inver ter Outdoor Units

RDCI8/25-3, RDCI10/28-3, RDCI12/33-3, RDCI14/40-3, RDCI16/45-3

Page 2

6 720 862 437 (2016/10)

RDCI Series – All DC Inverter Outdoor Units

2 | PRECAUTIONS

1. PRECAUTIONS

Read all installation manuals prior to installation.

■ This Installation manual is for the outdoor unit.

■ When installing indoor units please refer to indoor unit installation

manual.

■ Prior to installation of this unit, please ensure correct power supply

is available. Only qualified personal to undertake these works.

■ When installing a heat recovery switch box, ensure you consult the

switch box manual.

The safty precautions listed here are divided into two categories. Ensure you

read both categories prior to installation.

WARNING

Failure to observe a warning may result in serious injury.

CAUTION

Failure to observe a caution may result in injury or damage to the

equipment.

After completing the installation, ensure the unit operates properly during

the start-up operation. Please instruct the customer on how to operate the

unit and keep it maintained. Also, inform customers that they should store

this installation manual along with the owner‘s manual for future reference.

WARNING

■ Only trained and qualified service personnel to install, repair

or service the equipment as per the service and installation

manual.

Improper installation, repair, and maintenance may result in electric

shocks, short-circuit, leaks, fire or other damage to the equipment.

■ When installing the unit in a room, ensure you meet the

requirement of national regulations.

Excessive refrigerant in a closed environment can lead to oxygen

deficiency.

■ Only use authorised accessories and parts are to be used, failure

to do so may invalidate your warranty.

■ If required consult a structural engineer for advice on suitable

installation and load bearing area.

■ The appliance must not be installed in a laundry room.

■ Before obtaining access to electrical terminals, all power supply

circuits must be safely isolated.

■ The condenser must have a local isolation within accordance of

UK wiring regulations.

■ The enclosure of the appliance shall be marked by word, or by

symbols, with the direction of the refrigerant flow.

■ All electrical work must comply with the local national wiring

regulations and the instructions set out in this manual.

If National regulations are not followed this may cause injur y,

damage or fire to property.

■ When installing refrigerant pipework, ensure all pipes are

protected to avoid any unwanted particles entering.

■ If the refrigerant leaks during installation, ventilate the area

immediately.

Toxic gas may be produced should refrigerant comes into contact

with a naked flame.

CAUTION

■ When installing this unit ensure you check installation

guidelines to meet the requirements.

■ Ensure correct earthing of all appliances as per national

electrical guidelines.

■ The unit should only be operated by authorised personnel.

■ Do not install the air conditioning unit in the following locations:

• Where flammable gases, liquids or materials are stored.

• Where there is salty air surrounding (near the coast).

• Where there is caustic gas (sulfide, for example) existing in the air.

• Where electrical voltage fluctuates.

• Where there is strong electromagnetic waves exist.

• Where there is acid or alkaline liquid evaporating.

2. INSTALLATION CHECKS

■ Acceptance and Unpacking

• Before accepting delivery, ensure you check all of the equipment for

damage. If damage is found please contact your supplier.

• Check whether the model, specification and quantity of the

equipment conform what has been ordered.

• After removing the outer packaging, please keep the operation

instructions safe and count the accessories.

■ Refrigerant pipework

• Prior to installation, check the correct model numbers have been

delivered.

• Project schematic must be consulted for all refrigerant pipe sizes

and correct diameters.

• The refrigerant pipework should be sufficiently insulated. This will

prevent condensation occurring.

• After installation of the pipework is complete, ensure a full strength/

tightness test and vacuum test has performed.

■ Strength/tightness test

The new refrigerant pipework must undergo a strength test (with

40kgf/cm

2

nitrogen). For tightness testing, please refer to F Gas

Regulations.

■ Creating a vacuum

Ensure you vacuum the system down to 1.5 Torr, to ensure all

moisture is extracted.

CONTENTS PAGE

1. PRECAUTIONS .................................................................... 2

2. INSTALLATION CHECKS ....................................................... 2

3. ACCESSORIES .................................................................... 3

4. OUTDOOR UNIT INSTALLATION ............................................ 3

5. REFRIGERANT PIPE ............................................................. 8

6. CONNECTING PIPES TO SBOX ............................................ 13

7. SBOX WIRING NAMEPLATE ................................................ 14

8. ELECTRIC WIRING ............................................................. 15

9. TEST RUN ......................................................................... 21

Page 3

RDCI Series – All DC Inverter Outdoor Units

6 720 862 437 (2016/10)

ACCESSORIES | 3

■ Refrigerant replenishment

• Additional refrigerant must be added prior to turning the units on.

Correct refrigerant charge must be calculated using the guidelines

within this manual.

• On completion of the refrigerant installation you must record the

exact additional refrigerant charge.

■ Electric wiring

• When selecting the size of the power supply cable, consult

this manual along with national regulations. When selecting

communication wiring follow guidelines set out in this manual.

• When installing communication cabling, ensure you read electrical

installation guideline in this manual.

■ Test Run

• Before operation, remove the six pieces of PE foaming which are

used at the rear of the unit for protecting the condenser. Be careful

not to damage the fins. Otherwise, the heat exchange performance

may be affected.

• Prior to test run, ensure the power has been on for a minimum of

12 hours.

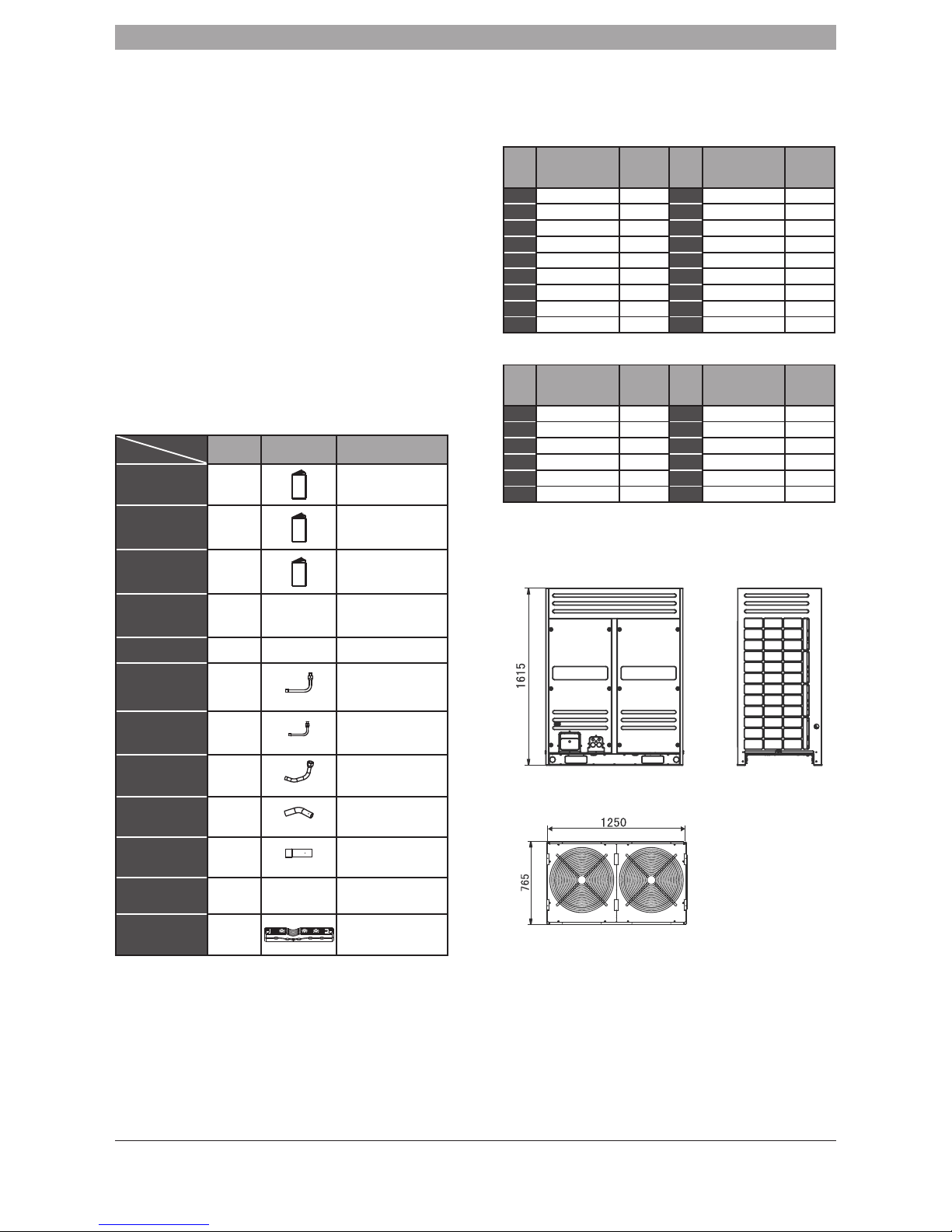

3. ACCESSORIES

Table.3-1

Model

Name

All of units Outline Function

Outdoor unit

installation manual

1

___________

Outdoor unit owner’s

manual

1

Upon completion leave

with customer

Indoor unit owner’s

manual

1

On completion leave with

customer

90° elbow

1 (8HP, 10HP)

2 (12HP~

16HP)

________ For connecting pipes

Seal plug 8 ________ For pipe cleaning

Connective pipe

accessory

1

(used in 8HP~16HP)

Connect to the high-pressrue

gas balance side

Connective pipe

accessory

1

(used in 8HP~16HP)

Connect to the liquid

pipe side

Connective pipe

accessory

1

(used in 8HP, 10HP, 12HP)

Connect to the highpressure gas pipe side

Connective pipe

accessory

1

(used in 14HP, 16HP)

Connect to the highpressure gas pipe side

Connective pipe

accessory

2

(used in 12HP)

Connect to the low-pressure

gas pipe or liquid pipe side

Screw bag 1 ________ Stored for service

Cable clip kit

1

(Optional)

For cable fastening

4. OUTDOOR UNIT INSTALLATION

4.1 Outdoor unit combination

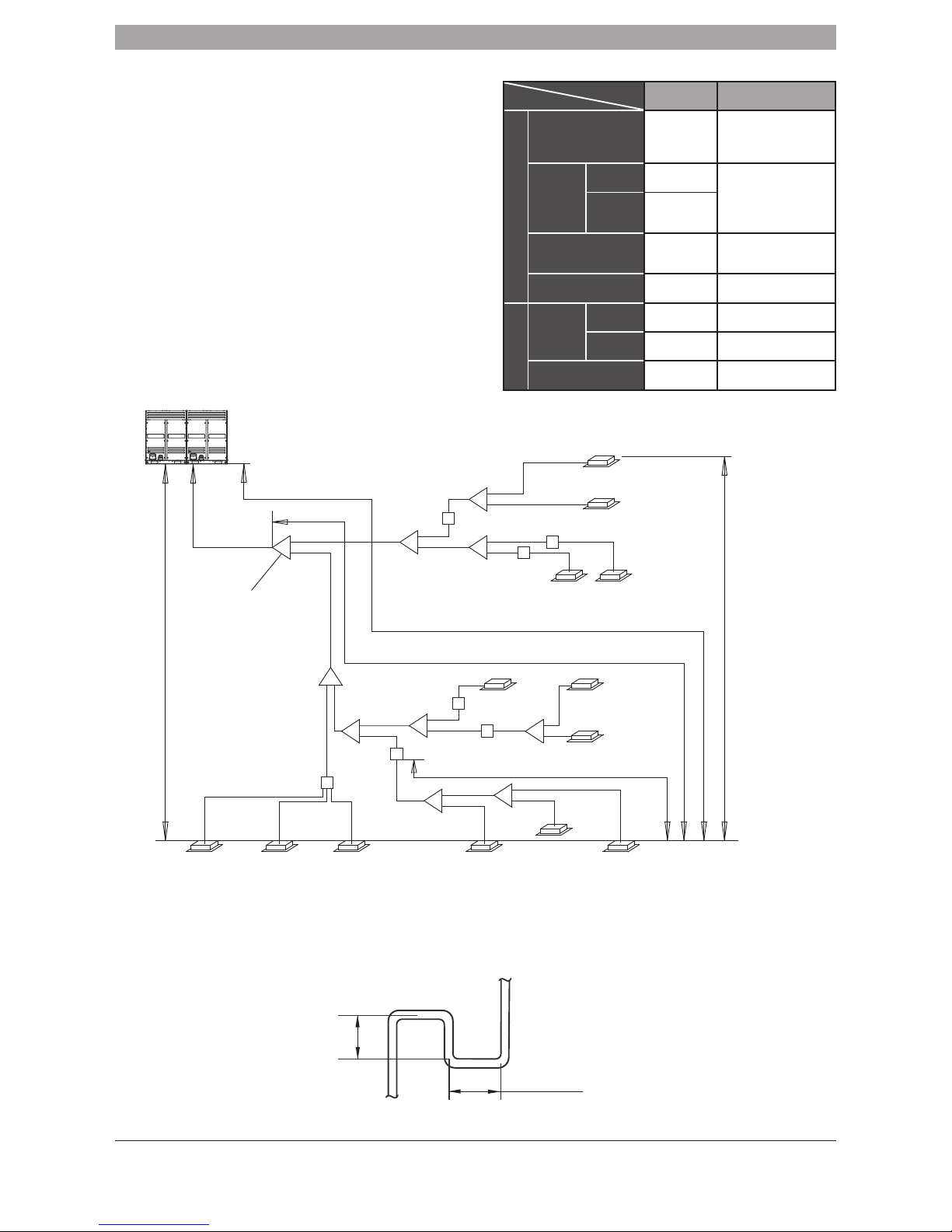

Table.4-1

HP Mode

Max Qty.

of indoor

unit

HP Mode

Max Qty.

of indoor

unit

8 8HP×1 13 26 10HP+16HP 43

10 10HP×1 16 28 14HP×2 46

12 12HP×1 20 30 14HP+16HP 50

14 14HP×1 23 32 16HP+16HP 53

16 16HP×1 26 34 10HP×2+14HP 56

18 8HP+10HP 29 36 10HP×2+16HP 59

20 10HP+10HP 33 38

10HP+12HP+16HP

63

22 10HP+12HP 36 40

10HP+14HP+16HP

64

24 10HP+14HP 39 42 14HP×3 64

Table.4-2

HP Mode

Max Qty.

of indoor

unit

HP Mode

Max Qty.

of indoor

unit

44 14HP×2+16HP 64 56

10HP+14HP+16HP×2

64

46 14HP+16HP×2 64 58 14HP×3+16HP 64

48 16HP×3 64 60 14HP×2+16HP×2 64

50

8HP+10HP+16HP×2

64 62 14HP+16HP×3 64

52

10HP×2+16HP×2

64 64 16HP×4 64

54

10HP+12HP+16HP×2

64

4.2 Dimensions of outdoor unit

4.3 Selecting installation location

■ Ensure that the outdoor unit is installed in a well-ventilated location.

■ Ensure that the noise and exhaust ventilation of the outdoor

unit does not affect the neighbours of the property owner or its

surroundings.

■ Where possible ensure the shortest pipe route.

■ Ensure that the outdoor unit is installed in a cool location without

direct sunshine exposure or direct radiation.

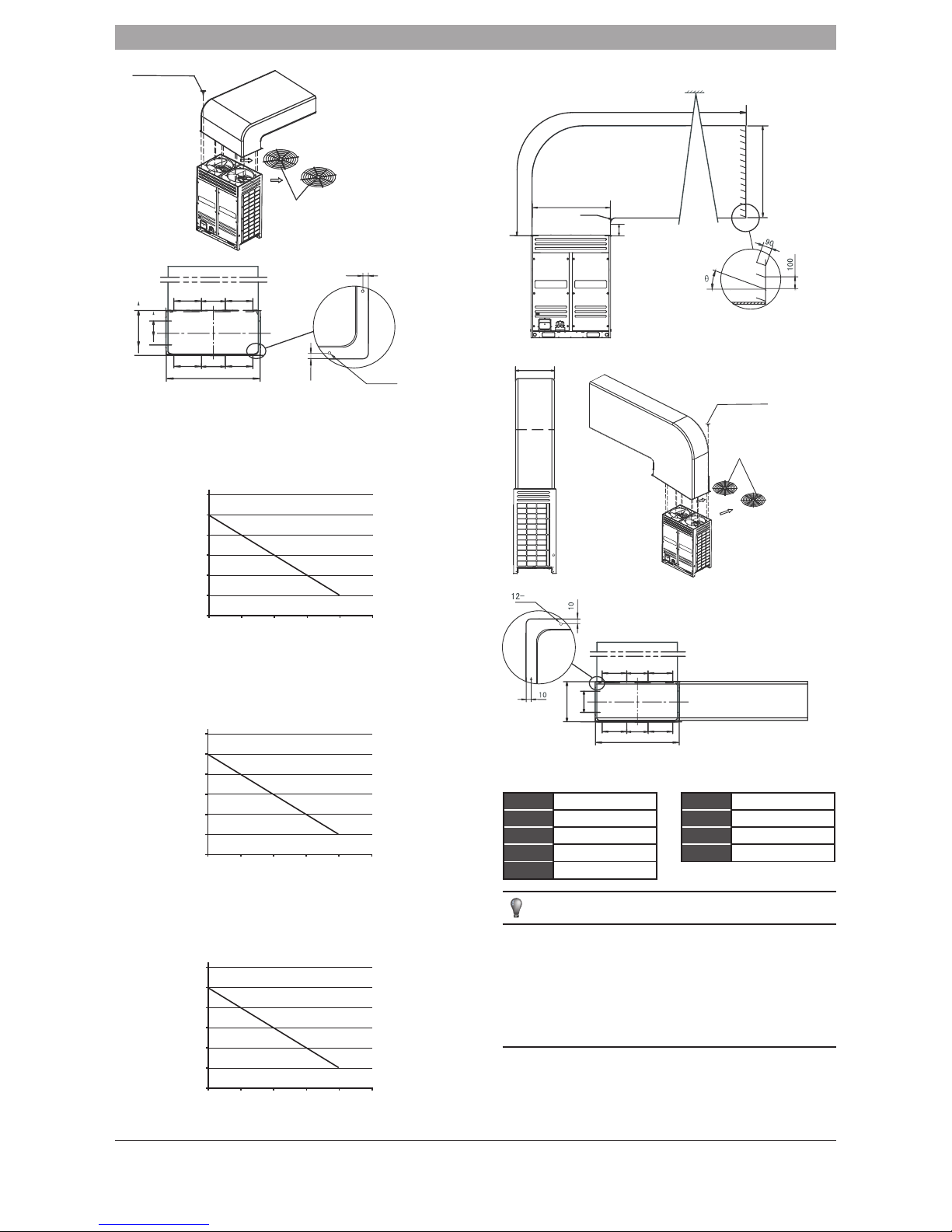

Fig. 4-1

Unit: mm

Page 4

6 720 862 437 (2016/10)

RDCI Series – All DC Inverter Outdoor Units

4 | OUTDOOR UNIT INSTALLATION

■ Do not install the outdoor unit in a dirty or severely polluted location,

to avoid blockages in the heat exchanger of the outdoor unit.

■ Do not install the outdoor unit in a location with oil pollution, high

salt content air or high content of harmful gases such as sulfurous

gas.

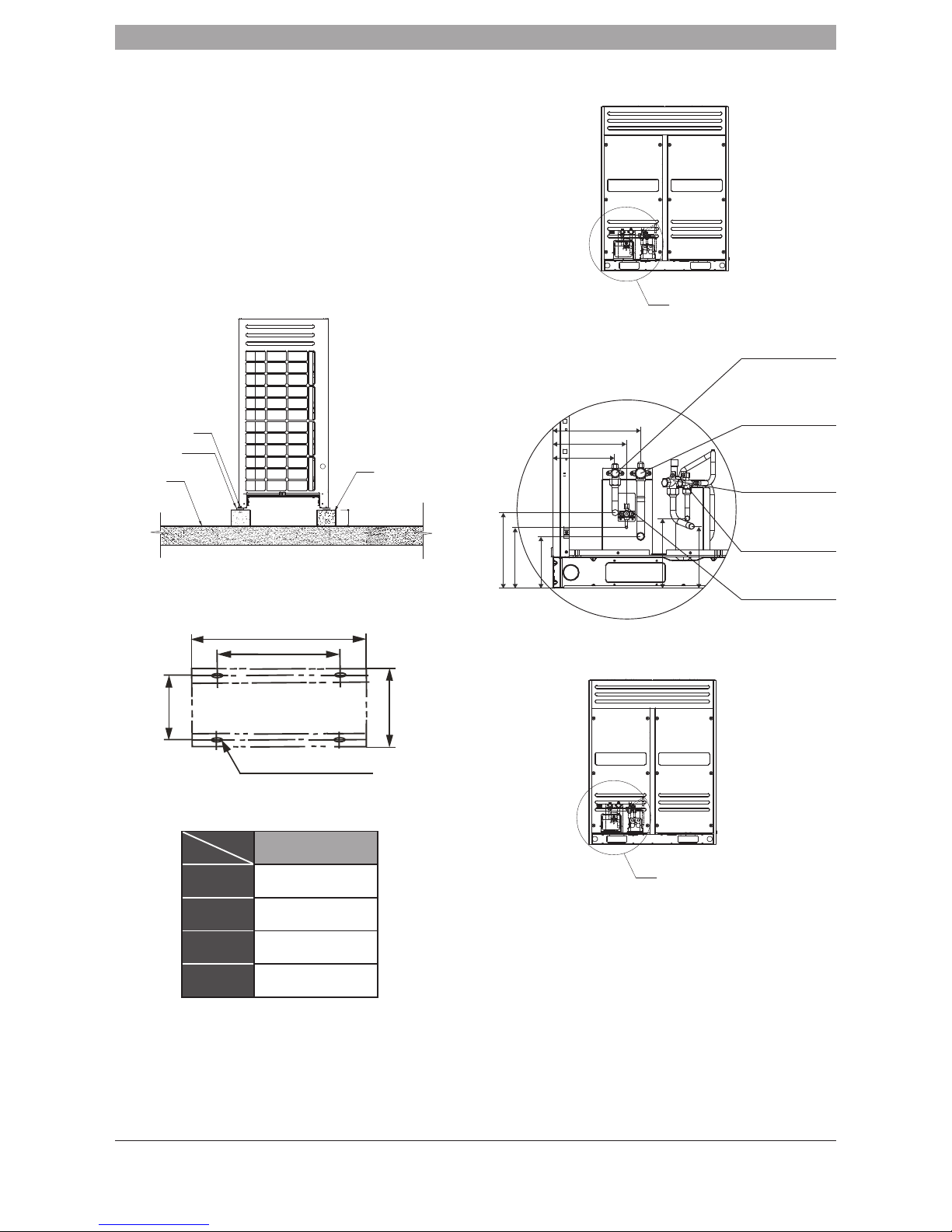

4.4 Base for outdoor unit

■ Base types

• Steel structure base

• Ensure you consult a construction engineer before installation.

Ensure the base has been installed to the correct dimensions set out

in this manual. Raise the unit at least 200mm from the floor.

■ Position illustration of screw bolt (Unit: mm)

Table.4-3 Unit: mm

HP

SIZE

8~16

A 1120

B 1250

C 736

D 765

■ Centering position illustration for each connective pipe (Unit: mm)

1) 8HP, 10HP

2) 12HP

Ø10 Expansion bolt

Rubber shocking

proof mat

Concrete base

h=200mm

Solid ground or

roofing

200 mm

Fig. 4-2

B

A

C

D

15×23long U-shape hole

Fig. 4-3

R

Fig. 4-4

250

205

245

290

230

205

200

170

Fig. 4-5

High-pressure

gas balance valve

Low-pressure gas

side of shut-off valve

High-pr

essure gas

side of shut-off valve

L

iquid side of

shut-off valve

Oil balance valve

R amplification

The connective pipe

diameter Ø19.1

The connective pipe

diameter Ø22.2

The connective pipe

diameter Ø19.1

The connective pipe

diameter Ø12.7

For the Cascaded Units

R

Fig. 4-6

Page 5

RDCI Series – All DC Inverter Outdoor Units

6 720 862 437 (2016/10)

OUTDOOR UNIT INSTALLATION | 5

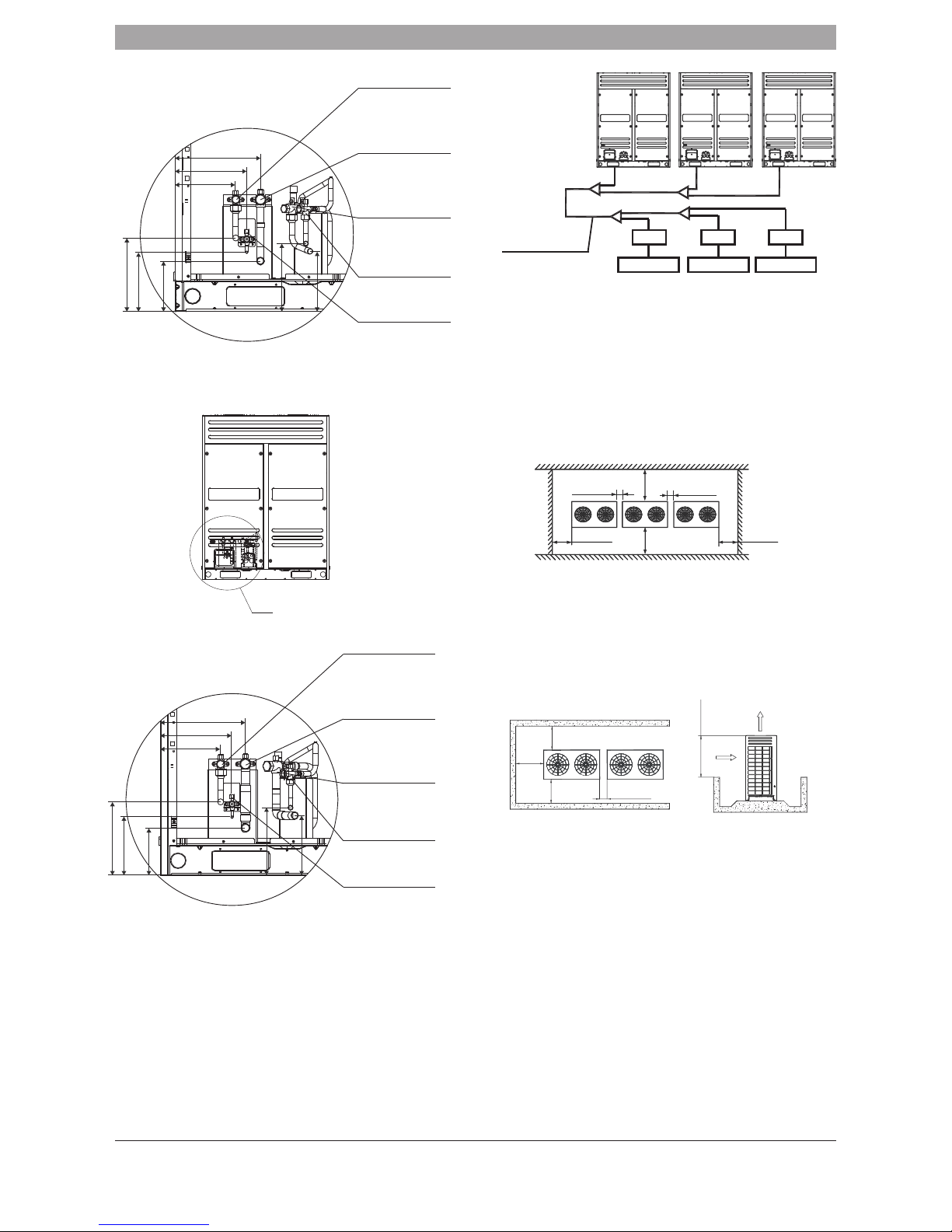

3) 14HP, 16HP

4.5 Outdoor Unit Cascade Sequence

A system with one or more outdoor units installed, will need to follow this

method: Outdoor units should be placed from large capacity to small

capacity. The largest should be installed nearest to the first branch joint. You

need to set the largest capacity as the master unit.

1) Place the 16HP at a side of the first branch joint site.

2) Place the unit from the large capacity to the small (See the detail

placement illustration)

3) Set 16HP as the main unit, while the 12HP and the 10HP as the slave

unit.

4.6 Installation space for outdoor unit

■ When installing the unit, leave a space for maintenance shown in

Fig.4-12 Install the power supply at the side of the outdoor unit. For

correct installation procedure, read installation manual.

■ In case there are obstacles surrounding the unit, refer to 4-17.

4.7 Layout

■ When the outdoor unit is higher than the surrounding obstacle

• One row

250

205

245

290

230

205

200

170

Fig. 4-7

High-pressure

gas balance valve

L

ow-pressure gas

side shut-off valve

High-pr

essure gas

side shut-off valve

L

iquid side

shut-off valve

Oil balance valve

R amplification

The connective pipe

diameter Ø19.1

The connective pipe

diameter Ø25.4

The connective pipe

diameter Ø19.1

The connective pipe

diameter Ø15.9

For the Cascaded Units

R

Fig. 4-8

250

205

245

290

230

205

200

165

Fig. 4-9

High-pressure

gas balance valve

L

ow-pressure gas

side shut-off valve

High-pr

essure gas

side shut-off valve

L

iquid side

shut-off valve

Oil balance v

alve

R amplification

The connective pipe

diameter Ø19.1

The connective pipe

diameter Ø28.6

The connectiv

e pipe

diameter Ø22.2

The connective pipe

diameter Ø15.9

F

or the Cascaded Units

Fig. 4-10

Outdoor unit

(38HP)

16HP

The 1st branch joint

12HP 10HP

SBOX SBOX SBOX

Indoor unit A Indoor unit B Indoor unit C

Fig. 4-12

100mm~500mm 100mm~500mm

>1000mm

>1000mm

>1000mm

>1000mm

Top view of the outdoor unit

Fig. 4-13

Front

100-500mm

Front

>1m

>1m>1m

>800mm

Page 6

6 720 862 437 (2016/10)

RDCI Series – All DC Inverter Outdoor Units

6 | OUTDOOR UNIT INSTALLATION

• Two rows

• More than two rows

■ If the minimum clearance of 800mm above the unit can not be met,

see the figure below.

■ Ensure the surroundings are no more than 800mm high. If this is not

possible install mechanic exhaust device.

4.8 Set the snow-proof facility

■ In snowy areas, precautions should be taken to avoid unit failure or

lack of performance.

4.9 Explanation of valve

Table.4-4

Low-pressure gas pipe

Oil balance pipe

High-pressure gas balance pipe

Liquid pipe

High-pressure gas pipe

■ Installation illustration

Fig. 4-14

Front

100-500mm

Front

Front Front

>1m

>1m

>1m

>1m

>800mm

Fig. 4-15

Front

100-500mm

Front Front

Front Front

Front

>1m

>1m

>800mm

>1m>1m>1m

Fig. 4-16

Front

100-500mm

Front

>1m

>1m>1m

A

B

C

D

B

A

B

A

C

D

B

A

Fig. 4-17

Front view

Front view

Side view

Front view

>45° >300mm

>1000mm Airflow deflector

1

2

3

4

5

Fig. 4-19

Notes: 16HP as an example

1210

C

A

725

B

001

Fig. 4-20

Fig. 4-21

Example A

Support

Radius

Air outlet louver dimension (optional)

Page 7

RDCI Series – All DC Inverter Outdoor Units

6 720 862 437 (2016/10)

OUTDOOR UNIT INSTALLATION | 7

■ Curve diagram of static pressure, air flow volume.

Table.4-5 Unit: mm Table.4-6 Unit: mm

A A≥300 A A≥300

B B≥250 B B≥250

C C≤3000 C C≤3000

D 750≤D≤760

θ

θ≤15°

θ

θ≤15°

NOTE

■ Before installing the air deflector, please ensure the fan grill has

been taken off.

■ Once air deflector has been installed, the air volume, cooling/

heating capacity will decrease. The maximum angle allowed for the

shutter is 15 degrees.

■ Only one bend set is allowed.

■ Install anti vibration pads in between the unit and air deflector.

Fig. 4-22

12 ST3.9 self-threading screws

Remove the fan grills

10

01

12-Ø3.2

393

567

1250

411 411213

411 411213

Fig. 4-23

9500

10000

10500

11000

11500

12000

12500

0 5 10 15 20 25

Fig. 4-24

8/10HP

Air pressure curve diagram

(Remove the fan grills)

Air volume (m

3

/h)

Static pressure (Pa)

10500

11000

11500

12000

12500

13000

13500

0 5 10 15 20 25

Fig. 4-25

12HP

Air pressure curve diagram

(Remove the fan grills)

Air volume (m

3

/h)

Static pressure (Pa)

12500

13000

13500

14000

14500

15000

15500

0 5 10 15 20 25

Fig. 4-26

14/16HP

Air pressure curve diagram

(Remove the fan grills)

Air volume (m

3

/h)

Static pressure (Pa)

B

0921

C

1210

A

Fig. 4-27

Example B

Support

Radius

Air outlet louver dimension (optional)

725

Ø3.2

393

567

1250

411 411

213

411 411213

Fig. 4-28

Fig. 4-29

12 ST3.9 self-threading screws

Remove the fan grills

Page 8

6 720 862 437 (2016/10)

RDCI Series – All DC Inverter Outdoor Units

8 | REFRIGERANT PIPE

5. REFRIGERANT PIPE

5.1 Length and drop height permitted

for the refrigerant pipework

Note: Ensure a distance of at least 0.5m between branch pipes.

Table.5-1

Permitted

value

Pipework

Pipe length

Total pipe length (Actual)

1000m

(Please refer to

the caution 5 of

conditions 2)

L1+(L2+L3+L4+L5+L6+L7

+L8+L9+L10+L11+L12+

L13)×2+a+b+c+d+e+f+g+

h+i+j+k+l+m+n

Maximum

pipework (L)

Actual

length

175m

L1+L7+L9+L11+j+k+n

Equivalent

length

200m

(Please refer to

caution 1)

Pipework (furthest from

the first line pipe branch)

equivalent length

40m/90m

(Please refer to

caution 5)

L7+L9+L11+j+k+n

SBOX to indoor unit

equivalent length

40m j+k+n

Drop height

Indoor unit

to outdoor

unit drop

height

outdoor

unit up

70m*

(Please refer

to caution 3)

outdoor unit

down

110m

(Please refer

to caution 4)

Indoor unit to indoor unit

drop height

30m _____________

N3

(140)

N5

(140)

N6

(71)

N7

(71)

N9

(56)

N8

(28)

N2

(71)

N4

(28)

N1

(71)

N10

(56)

A

B

C

E

F

Ⅱ

Ⅳ

Ⅲ

Ⅰ

b

c

d

f

g

j

h

i

l

k

m n

e

L

1

L2

L9

L13

L11

L10

L12

L3

a

SB1

SB2

SB3

SB4

SB5

SB6

L4

L5

L6

D

N11

(140)

p

N12

(140)

q

N13

(56)

r

L

8

L7

SB7

Fig. 5-1

Indoor unit

The first line branch pipe

Maximum height between outdoor and indoor units

unit and outdoor unit H≤110m

Maximum height from indoor unit to indoor unit.

drop height H≤30m

Outdoor unit

(one or more outdoor units)

Max pipework equivalent length L≤200m

(From the first line branch pipe) Maximum

pipework equivalent length L≤40m/90m

SBOX to indoor unit equivalent length L≤40m

* A system with a height difference above 70m is not supported as standard but is available on request for customisation.

Fig. 5-2

≥300m

≥300m

Page 9

RDCI Series – All DC Inverter Outdoor Units

6 720 862 437 (2016/10)

REFRIGERANT PIPE | 9

CAUTION

1. The length between the branch pipes should be a minimum of 0.5m.

2. When the outdoor unit is installed above the indoor units and the distance

is greater than 20m, you must install oil return taps every 10m. Refer to

5-2.

3. When the outdoor unit is installed below the internal units and the length

exceeds 40m, the liquid pipe needs to be increased one size.

4. When the outdoor unit is installed below the internal units, the first

branch joint connection should be shorter than 40m. However when

certain conditions are met, the length can increase up to 90m.

Conditions

1. For all pipe sizing and limitations please follow the conditions below.

Conditions

■ L7+L9+L11+j+k+n≤90m L2~L13

Increasing the pipe diameter of the distribution pipe

■ To increase the pipe size, see below

Ø9.5 → Ø12.7 Ø12.7 → Ø15.9 Ø15.9 → Ø19.1

Ø19.1 → Ø22.2 Ø22.2 → Ø25.4 Ø25.4 → Ø28.6

Ø28.6 → Ø31.8 Ø31.8 → Ø38.1 Ø38.1 → Ø41.3

Ø41.3 → Ø44.5 Ø44.5 → Ø54.0

5.2 Select the refrigerant pipework type

Conditions

2. When calculating actual length of pipe, follow the example below.

L1+(L2+L3+L4+L5+L6+L7+L8+L9+L10+L11+L12+L13)

x2+a+b+c +d+e+f+g+h+i+j+k+l+m+n<1000m

Examples

Reference Figure. 5-1

Conditions

3. The length from the indoor unit to the nearest branch joint assembly

or SBOX ≤40m;

b, c, d, e, f, h, i, l, m, n, p, q, r ≤40m(Pipe diameter requirements, please

refers to table.5-8).

Examples

Reference Figure. 5-1

Conditions

4. The distance between [the outdoor unit to the furthest indoor unit]

and [the outdoor unit to the nearest indoor unit] is ≤40m.

The furthest indoor unit N10

The nearest indoor unit N11

(L1+L7+L9+L11 +j+k+n)-(L1 +L7+L8+p) <40m

Examples

Reference Figure. 5-1

L1

M

L

g1

j j j j j j

g2 g3

G1

N3

(140)

N5

(140)

N6

(71)

N7

(71)

N9

(56)

N8

(28)

N2

(71)

N4

(28)

N1

(71)

N10

(56)

A

B

C

E

F

Ⅱ

Ⅳ

Ⅲ

Ⅰ

b

c

d

f

g

j

h

i

l

N11

(140)

p

N12

(140)

q

N13

(56)

r

k

m n

e

L

2

L9L8

L7

L13

L11

L10

L12

L3

a

SB1

SB2

SB3

SB4

SB5

SB6

L4

L5

L6

D

SB7

W3

(10)W2(12)W1(16)

Fig. 5-3

Page 10

6 720 862 437 (2016/10)

RDCI Series – All DC Inverter Outdoor Units

10 | REFRIGERANT PIPE

Table.5-2

Pipe name

Code (As per

the Fig. 5-2)

Main pipe L1

Indoor unit main pipe L2~L13

Indoor unit aux. pipe a, b, ...r

Indoor unit main pipe branching pipe assembly A, B, C, D, E

Indoor unit aux. pipe branching pipe assembly I, II, III, IV

Outdoor unit branching pipe assembly L, M

Outdoor unit connective pipe g1, g2, g3, G1

SBOX equipment SB1, ...SB7

5.3 Size of joint pipes for indoor unit

Table.5-3 Size of joint pipes for R410A indoor unit

Capacity of

indoor unit A

(×100W)

Indoor unit main pipe (inches)

Low-pressure

gas side

High-pressure

gas side

Liquid

side

Available

branching pipe

A<56 Ø12.7 Ø9.5 Ø6.4 IDU-BJR01

56≤A<166 Ø19.1 Ø15.9 Ø9.5 IDU-BJR01

166≤A<230 Ø22.2 Ø19.1 Ø9.5 IDU-BJR02

230≤A<330 Ø22.2 Ø19.1 Ø12.7 IDU-BJR02

330≤A<460 Ø28.6 Ø22.2 Ø12.7 IDU-BJR03

460≤A<660 Ø28.6 Ø22.2 Ø15.9 IDU-BJR03

660≤A<920 Ø34.9 Ø28.6 Ø19.1 IDU-BJR04

920≤A<1350 Ø41.3 Ø34.9 Ø19.1 IDU-BJR05

1350≤A Ø44.5 Ø38.1 Ø22.2 IDU-BJR05

e.x.1: Refer to Fig.5-2, the capacity of downstream units to L2 is

71×2+140+28=310, i.e. low pressure gas pipe for L2 is Ø22.2, high

pressure gas pipe is Ø19.1, high pressure liquid pipe is Ø12.7.

5.4 Size of joint pipes for outdoor unit

Based on the following tables, select the diameters of outdoor unit main

connective pipe. When the main pipe accessory is larger on the indoor unit,

use the larger pipe accessory.

Table.5-4 Size of joint pipes for R410A outdoor unit

Model

When the equivalent length of all liquid

pipes < 90m, the size of main pipe (inches)

Low-pressure

gas side

High-pressure

gas side

Liquid

side

The 1st

branching pipe for

indoor unit

8HP Ø22.2 Ø19.1 Ø9.5

IDU-BJR02

10HP Ø22.2 Ø19.1 Ø12.7

IDU-BJR02

12HP Ø25.4 Ø19.1 Ø12.7

IDU-BJR03

14~16HP Ø28.6 Ø22.2 Ø15.9

IDU-BJR03

18~22HP Ø31.8 Ø28.6 Ø15.9

IDU-BJR03

24HP Ø34.9 Ø28.6 Ø15.9

IDU-BJR04

26~32HP Ø34.9 Ø28.6 Ø19.1

IDU-BJR04

34~48HP Ø41.3 Ø34.9 Ø19.1

IDU-BJR05

50~64HP Ø44.5 Ø38.1 Ø22.2

IDU-BJR05

Table.5-5 Size of joint pipes for outdoor unit (R410a)

Model

When the equivalent length of all liquid

pipes ≥ 90m, the size of main pipe (inches)

Low-pressure

gas side

High-pressure

gas side

Liquid

side

The 1st

branching pipe for

indoor unit

8HP Ø22.2 Ø19.1 Ø12.7

IDU-BJR02

10HP Ø22.2 Ø19.1 Ø12.7

IDU-BJR02

12HP Ø25.4 Ø19.1 Ø15.9

IDU-BJR03

14~16HP Ø28.6 Ø22.2 Ø15.9

IDU-BJR03

18~22HP Ø31.8 Ø28.6 Ø19.1

IDU-BJR03

24HP Ø34.9 Ø28.6 Ø19.1

IDU-BJR04

26~32HP Ø34.9 Ø28.6 Ø22.2

IDU-BJR04

34~48HP Ø41.3 Ø34.9 Ø22.2

IDU-BJR05

50~64HP Ø44.5 Ø38.1 Ø25.4

IDU-BJR05

5.5 Branch pipes for outdoor unit

Table.5-6

Model

Outdoor unit pipe connective opening dimension (inches)

Low-pressure gas

side

High-pressure gas

side

Liquid side

8~12HP Ø22.2 Ø19.1 Ø12.7

14, 16HP Ø28.6 Ø22.2 Ø15.9

5.6 Multi pipe connection assembly and pipe

diameter for outdoor unit

Based on Table 5-7 select the branch pipe assembly for the outdoor unit.

Before installation, please read the Outdoor Unit Branching Pipe Installation

Manual carefully.

Table.5 -7 Outdoor unit branch pipe assembly (Illustration)

Outdoor

unit Qty.

Illustration

Outdoor unit

connective pipe

diameter

Parallel connect with

the branching pipes

2 units

L

g1g2

g1, g2:

8~12HP:

Ø22.2/Ø19.1/Ø12.7

14, 16HP:

Ø28.6/Ø22.2/Ø15.9

L:

ODU-BJR02

3 units

L

M

g1g2

G1

g3

g1, g2, g3:

8~12HP:

Ø22.2/Ø19.1/Ø12.7

14, 16HP:

Ø28.6/Ø22.2/Ø15.9

G1: Ø34.9/Ø28.6/

Ø19.1

L+M:

ODU-BJR03

4 units

L

M

N

g1g2

G1 G2

g3g4

g1, g2, g3, g4:

8~12HP:

Ø28.2/Ø19.1/Ø12.7

14, 16HP:

Ø28.6/Ø22.2/Ø15.9

G1: Ø34.9/Ø28.6/Ø19.1

G2: Ø41.3/Ø34.9/Ø22.2

L+M+N:

ODU-BJR04

5.7 Example

1) Take (10+12+16) HP for the three modules as an example to clarify the

pipe selection.

2) Take Fig.5-2 as an example, providing that the equivalent length of all

pipes in this system is larger than 90m.

Table.5-8

Capacity

of indoor unit A

(×100W)

Indoor unit aux. pipe (between branch joint and branch

joint/SB) (inches)

The branch pipe

assembly of indoor

unit aux. pipe

Gas side Liquid side

A<160 Ø15.9 Ø9.5 IDU-BJR01

Capacity

of indoor unit A

(×100W)

Indoor unit aux. pipe (between indoor unit and branch joint/SB) (inches)

When branching

pipe’s length ≤10m

When branching pipe’s length>10m

Gas side Liquid side Gas side Liquid side

A<56 Ø12.7 Ø6.4 Ø15.9 Ø9.5

160≥A≥56 Ø15.9 Ø9.5 Ø19.1 Ø12.7

Main pipe

Main pipe

Main pipe

Page 11

RDCI Series – All DC Inverter Outdoor Units

6 720 862 437 (2016/10)

REFRIGERANT PIPE | 11

A Branching pipe at the inside of the unit.

There are b, c, d, e, f, h, i, l, m, n, p, q, r branching pipes at the inside

of the unit, the branching pipe diameter should be select as per Table

5-8.

B Main pipe and aux. pipe at the inside of the unit (Refer to Table 5-3

and Table 5-8)

1) The aux. pipe a with N1, N2 downstream indoor units that total

capacity is 71×2=142, the pipe a diameter is Ø15.9/Ø9.5, thus

select IDU-BJR01 for the branching pipe I.

2) The main pipe L3 with N1, N2 downstream indoor units that total

capacity is 71×2=142, the pipe L3 diameter is Ø19.1/Ø15.9/Ø9.5,

thus select SBOX02-1 for SB1.

3) The main pipe L5 with N3 downstream indoor units that total capacity

is 140, the pipe L5 diameter is Ø19.1/Ø15.9/Ø9.5, thus select

SBOX02-1 for SB2.

4) The main pipe L6 with N4 downstream indoor units that total capacity

is 28, the pipe L6 diameter is Ø12.7/Ø9.5/Ø6.4, thus select

SBOX02-1 for SB3.

5) The main pipe L4 with N3, N4 downstream indoor units that total

capacity is 140+28=168, the pipe L4 diameter is Ø22.2/Ø19.1/

Ø9.5, thus select IDU-BJR02 for the branching pipe C.

6) The main pipe L2 with N1~N4 downstream indoor units that total

capacity is 71×2+140+28=310, the pipe L2 diameter is Ø22.2/

Ø19.1/Ø12.7, thus select IDU-BJR02 for the branching pipe B.

7) The main pipe L12 with N5 downstream indoor units that total

capacity is 140, the pipe L12 diameter is Ø19.1/Ø15.9/Ø9.5, thus

select SBOX02-1 for SB4.

8) The aux. pipe g with N6, N7 downstream indoor units that total

capacity is 71×2=142, the pipe g diameter is Ø15.9/Ø9.5, thus

select IDU-BJR01 for the branching pipe II.

9) The main pipe L13 with N6, N7 downstream indoor units that total

capacity is 71×2=142, the pipe L13 diameter is Ø19.1/Ø15.9/

Ø9.5, thus select SBOX02-1 for SB5.

10) The main pipe L10 with N5~N7 downstream indoor units that total

capacity is 140+71×2=282, the pipe L10 diameter is Ø22.2/

Ø19.1/Ø12.7, thus select IDU-BJR02 for the branching pipe F.

11) The aux. pipe k with N9, N10 downstream indoor units that total

capacity is 56×2=112, the pipe k diameter is Ø15.9/Ø9.5, thus

select IDU-BJR01 for the branching pipe III.

12) The aux. pipe j with N8~N10 downstream indoor units

that total capacity is 28+56×2=140, the pipe j diameter

is Ø15.9/Ø9.5, thus select IDU-BJR01 for the branching

pipe IV.

13) The main pipe L11 with N8~N10 downstream indoor units that total

capacity is 28+56×2=140, the pipe L11 diameter is Ø19.1/Ø15.9/

Ø9.5, thus select SBOX02-1 for SB6.

14) The main pipe L9 with N5~N10 downstream indoor units that total

capacity is 140+56×2+71×2+28=422, the pipe L9 diameter is

Ø28.6/Ø22.2/Ø12.7, thus select IDU-BJR03 for the branching pipe

E.

15) The main pipe L8 with N11~N13 downstream indoor units that total

capacity is 140×2+56=336, the pipe L8 diameter is Ø28.6/Ø22.2/

Ø12.7, thus select SBOX04-1 for SB7.

16) The main pipe L7 with N5~N13 downstream indoor units that total

capacity is 140×3+71×2+56×3+28=758, the pipe L7 diameter is

Ø34.9/Ø28.6/Ø19.1, thus select IDU-BJR04 for the branching pipe

D.

17) The main pipe L1 with N1~N10 downstream indoor units that total

capacity is 140×4+71×4+56×3+28×2=1064, thus select IDUBJR05 for the branching pipe A.

C Main pipe (Refer to Table 5-3, Table 5-5):

Main pipe L1 in the Fig.5-2, which upstream outdoor units

total capacity is 16+12+10=38, base on table 5-5, the low

pressure gas/high pressure gas/liquid pipe diameter are Ø41.3/

Ø34.9/Ø22.2, total capacity of the downstream indoor unit is

140×4+71×4+56×3+28×2=1064, base on table 5-3, the low

pressure gas/high pressure gas/liquid pipe diameter are Ø41.3/

Ø34.9/Ø19.1, take the large one for your selection, final confirm the

main pipe diameter is: low pressure gas/high pressure gas/liquid pipe

Ø41.3/Ø34.9/Ø22.2.

D Parallel connect the outdoor units

1) The outdoor unit linked by Pipe g1 is 10HP, parallel connects with

outdoor unit. the connective pipe diameter to be selected according to

its connector size is Ø22.2/Ø19.1/Ø12.7;

The outdoor unit linked by Pipe g2 is 12HP, parallel connects with

outdoor unit. the connective pipe diameter to be selected according to

its connector size is Ø22.2/Ø19.1/Ø12.7;

The outdoor unit linked by Pipe g3 is 16HP, parallel connects with

outdoor unit. the connective pipe diameter to be selected according to

its connector size is Ø28.6/Ø22.2/Ø15.9.

2) G1 is the upstream of the two parallel connected outdoor units, refer

to Table 5-5 select the two parallel connected outdoor unit, the pipe

diameter is Ø34.9/Ø28.6/Ø19.1.

3) Parallel connect the three outdoor units, refer to Table 5-7 should

select ODU-BJR03 for outdoor unit connective pipes (L+M).

5.8 Caution for brazing

■ When brazing use nitrogen to pass through the pipework. This helps

stop oxidisation inside the refrigerant pipework.

■ Do not use anti-oxidants when brazing the pipe joints. Residue can

block pipes and cause damage to the equipment.

■ Do not use flux when brazing. Use phosphor copper brazing filler

alloy (BCuP) which does not require flux.

■ Flux is extremely harmful on refrigerant systems. This can cause

corrosion and deterioration of the refrigerant oil.

5.9 Removing the contaminants in the pipework

■ Ensure there is no dirt or water in the pipework before connecting.

■ Ensure you flush nitrogen through to clear the refrigerant pipe work.

This needs to be done before connecting to the outdoor unit.

5.10 Strength/Tightness Test

Pressure test the system with nitrogen to 40kgf/cm2. Ensure a 24 hour

strength test has been completed for all new installations. For guidance on

tightness testing for existing installations, please refer to F Gas Regulations.

Fig. 5-4

SBOX Indoor unit

Liquid pipe

Nitrogen

Nitrogen

Nitrogen

High-pressure gas pipe

Low-pressure gas pipe

Page 12

6 720 862 437 (2016/10)

RDCI Series – All DC Inverter Outdoor Units

12 | REFRIGERANT PIPE

CAUTION

• Pressurised nitrogen (3.9MPa; 40kgf/cm2) is used for strength

testing.

• Prior to connecting vacuum pump, ensure you release all the

nitrogen from all three pipes.

• Only Nitrogen can be used for pressure testing. Do not use any other

substances.

• Ensure the shut off valves are protected during brazing.

• A Torr gauge must be used to measure the vacuum state.

5.11 Triple vacuum process

1) Vacuum from all three ports down to 2Torr.

2) Break vacuum with nitrogen to absorb moisture. Then repeat vacuum

process down to 1.6Torr.

3) Break Vacuum for with nitrogen to absorb moisture. Repeat vacuum

to achieve 1.5 Torr or lower.

CAUTION

■ Do not add refrigerant when nitrogen is present. Do not mix

refrigerants.

■ Do not use refrigerant for air vacuuming.

■ Before adding refrigerant leave the system on a vacuum for 2 hours

to see if the gauges rise. If the gauges rise please repeat strength/

tightness test and check for leaks.

5.12 Refrigerant amount to be added

1) Calculate the added refrigerant according to the diameter and the

length of the liquid side pipe. The refrigerant is R410A.

Note:

1. Assume equivalent pipe length of the branching pipe header to be

0.5m.

2. The refrigerant amount to be added of SBOX02 is 0.3kg/per,

of SBOX04/SBOX06 is 0.5kg/per.

Table.5-9

Pipe size on liquid

side

Refrigerant to be

added per meter

Ø6.4 0.023kg

Ø9.5 0.060kg

Ø12.7 0.120kg

Ø15.9 0.180kg

Ø19.1 0.270kg

Ø22.2 0.380kg

Ø25.4 0.550kg

Ø28.6 0.710kg

2) Add the additional quantity of calculated refrigerant from the lowpressure pipe and liquid pipe.

5.13 The Key points of installing connective pipework between cascaded outdoor units

1) When connecting the outdoor units, the pipes should be installed

horizontally (Fig5-7, Fig 5-8). It is not permitted to use method

shown in Fig 5.9.

2) All connective pipework between the outdoor units are not to be

installed above the outlets of the condenser. See Fig. 5.10..

Connect manifold gauges and vacuum pump to all three pipe connections.

Perform vacuum until for minimum of 2 hours.

Shut off vacuum pump and pressure with nitrogen to absorb moisture.

Repeat vacuum process for a further two hours.

Shut off vacuum pump and break vacuum for with nitrogen to absorb moisture.

Repeat vacuum process for a further 2 hours and achieve a minimum

of 1.5Torr.

If 1.5Torr cannot be achieved, repeat re-pressure and find leak.

Re-peat Triple Vacuum process.

Perform a triple evacuation

Into the vacuum state

Fig. 5-7

√ Correct way

Fig. 5-8

√ Correct way

Fig. 5-9

× Wrong way

Page 13

RDCI Series – All DC Inverter Outdoor Units

6 720 862 437 (2016/10)

CONNECTING PIPES TO SBOX | 13

3) Branch joints must be installed horizontally at an angle of no more

than 10 degrees.

4) Ensure you install branch assembly joints correctly to stop the build

up of oil.

6. CONNECTING PIPES TO SBOX

Fig. 5-10

× Wrong way

Fig. 5-11

U-shaped branching pipe

A direction view

Horizontal surface

Wrong Correct

Fig. 5-12

Fig. 5-13

Fig. 6-1

Gas pipe (Ø15.9/Ø12.7)

Liquid pipe (Ø9.5/Ø6.4)

Low-pressure gas pipe (Ø25.4)

High-pressure gas pipe (Ø19.1)

Liquid pipe (Ø12.7)

SBOX02-1

SBOX02E-1

Fig. 6-3

Fig. 6-2

Gas pipe (Ø15.9/Ø12.7)

Gas pipe (Ø15.9/Ø12.7)

Liquid pipe (Ø9.5/Ø6.4)

Liquid pipe(Ø9.5/Ø6.4)

Low-pressure gas pipe (Ø31.8)

Low-pressure gas pipe (Ø31.8)

High-pressure gas pipe (Ø22.2)

High-pressure gas pipe (Ø22.2)

Liquid pipe (Ø15.9)

Liquid pipe (Ø15.9)

SBOX04-1

SBOX06-1

SBOX04E-1

Page 14

6 720 862 437 (2016/10)

RDCI Series – All DC Inverter Outdoor Units

14 | SBOX WIRING NAMEPLATE

7. SBOX WIRING NAMEPLATE

7.1 The nameplate of SBOX04-1, SBOX06-1

7.2 The nameplate of SBOX04E-1

M-O

M-I (1~4)

P Q E

P Q E P Q E

P Q E P Q E

P Q E P Q E

M-I (5,6)

T4C T4C1

Fig. 7-1

TRANS2

TO INDOOR6

BLUE

Blue

White

Black

Yellow

Black

Purple

Gray

Black

Orange

Green

Black

Blue

White

Black

Red

Brown

Black

Gray

Yellow

Black

Orange

RED

Y/G

TO INDOOR4

TO INDOOR2TO INDOOR5

TO INDOOR3

TO INDOOR1

TO OUTDOOR

POWER IN

TRANS1

M-O

M-I (1~4)

P Q E

P Q E

T4C T4C1

Fig. 7-2

TRANS2

TO INDOOR

TO OUTDOOR

POWER IN

TRANS1

Red

Brown

Black

Gray

Gray

Yellow

Yellow

Black

Black

BLUERED

Y/G

Page 15

RDCI Series – All DC Inverter Outdoor Units

6 720 862 437 (2016/10)

ELECTRIC WIRING | 15

7.3 The nameplate of SBOX02-1

7.4 The nameplate of SBOX02E-1

Table.7-1

Model of SBOX

SBOX02-1 SBOX04-1 SBOX06-1 SBOX02E-1 SBOX04E-1

Maximum

capacity

of single group

pipe

16kW ___________

Maximum indoor

units quantity of

single group pipe

4 1

Maximum

capacity of SB

28kW 45kW 28kW 56kW

Downstream of the

largest length

40m

NOTE

■ Single group pipe means one connecting liquid pipe and one

connecting gas pipe.

■ If you disable auto mode function you can connect up to 4 units via

an SBOX. If auto mode is selected then only one indoor unit can be

connected.

■ Indoor units connected together on the same connection ports at

the SBOX, auto mode cannot be selected. This will conflict modes

and cause error.

■ Prior to installing the SBOX, ensure a suitable location is selected, as

an SBOX will create operational noises.

■ The SBOX must be installed horizontally and level.

■ There must be at least 1m distance between an SBOX and a branch

joint pipe assembly.

■ There will be 30 seconds auto-checking function after the indoor

and outdoor units have been activated.

■ Indoor units must be manually addressed.

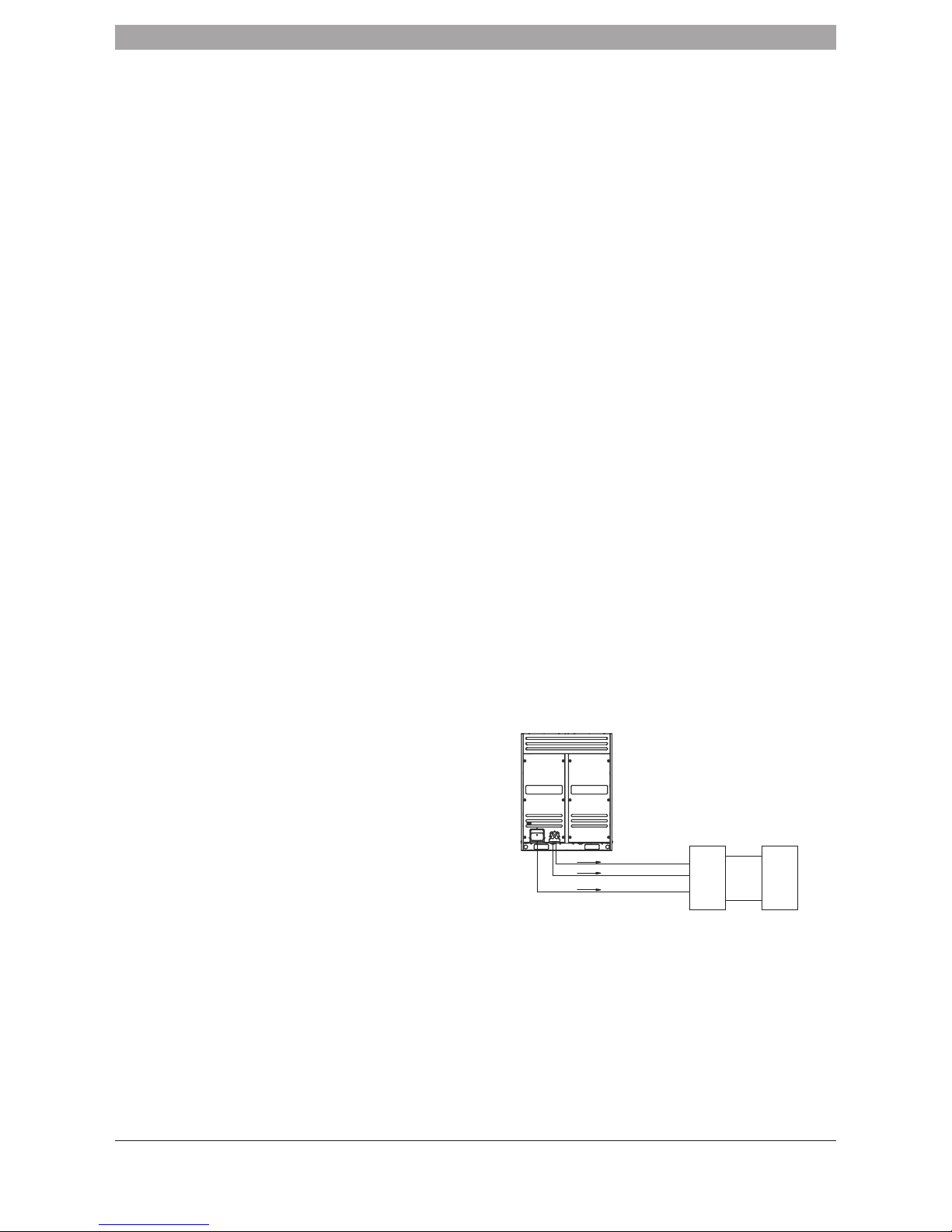

8. ELECTRIC WIRING

8.1 Terminal base function

M-O

M-I

P Q E

P Q E P Q E

T2C1 T2C2

CN13

Fig. 7-3

TO INDOOR2 TO INDOOR1

BLUE

RED

Y/G

TO OUTDOOR

POWER IN

TRANS

Blue

White

Black

Yellow

YELLOW

ORANGE

Black

Black

Gray

M-O

M-I

P Q E

P Q E

T2C1 T2C2

CN13

XT2

Fig. 7-4

TO INDOOR

BLUE

RED

Y/G

TO OUTDOOR

POWER IN

TRANS

Yellow

YELLOW

ORANGE

Black

Black

Gray

L1 L2 L3 N

Fig. 8-1

To 380-415V 3N~ 50Hz

Fig. 8-2

Outdoor units

centralised

monitoring

Network

accounting

Indoor units

centralised

controls

Indoor units

communication

Outdoor units

communication

Page 16

6 720 862 437 (2016/10)

RDCI Series – All DC Inverter Outdoor Units

16 | ELECTRIC WIRING

8.2 SW2 query instructions

Use application of the SW2 spot check

Table.8-1

No. Normal display Display content Note

1 0. -- Outdoor unit address 0, 1, 2, 3

2 1. -- Individual Outdoor unit capacity 8, 10, 12, 14, 16

3 2. -- Modular outdoor unit qty. Available for main unit

4 3. -- Operation mode 0, 2, 3, 4, 5, 6

5 4. -- Total capacity of outdoor unit Capacity requirement

6 5. -- Cooling capacity (Auxiliary unit only display) capacity for main mode

7 6. -- Heating capacity (Auxiliary unit only display) capacity for main mode

8 7. -- T4 ambient temp. revision of cooling capacity

9 8. -- T4 ambient temp. revision of heating capacity

10 9. -- The outdoor unit actual operating capacity Capacity requirement

11 10. -- Speed of fan A 0, 1, ······, 14, 15

12 11. -- Speed of fan B 0, 1, ······, 14, 15

13 12. -- T2 average temp. Actual value

14 13. -- T2B average temp. Actual value

15 14. -- T3 pipe temp. (Left pipe temp.) Actual value

16 15. -- T5 pipe temp. (Right pipe temp.) Actual value

17 16. -- T4 ambient temp. Actual value

18 17. -- Discharge temp. of inverter compressor A Actual value

19 18. -- Discharge temp. of inverter compressor B Actual value

20 19. -- Modual temp. Actual value

21 20. -- Discharge pressure corresponding to the saturation temperature Actual value+30

22 21. -- The minimum overheating temp. of discharge Actual value

23 22. -- Current of inverter compressor A Actual value

24 23. -- Current of inverter compressor B Actual value

25 24. -- State of the evaporator or condenser 0, 1, 2, 3

26 25. -- Opening angle of EXV A Actual value÷8

27 26. -- Opening angle of EXV B Actual value÷8

28 27. -- High pressure Actual value×10

29 28. -- Qty. of indoor units That can communicate with indoor units

30 29. -- Qty. of cooling indoor units Actual value

31 30. -- Qty. of heating indoor units Actual value

32 31. -- Reserve

33 32. -- Night noise control mode 0, 1, 2, 3

34

33. -- Static pressure mode 0, 1, 2, 3

35 34. -- DC voltage A Actual value÷10

36 35. -- DC voltage B Actual value÷10

37 36. -- Reserve

38 37. -- Reserve Display code 8.8.8

39 38. -- Remove fault number of times

40 39. -- Check end

The display contents as followings:

Normal display:

When standby, the above position displays the address of the outdoor unit, and the low position displays the Qty. of indoor units that can communicate with the

outdoor unit. When it is operating, it will display the rotation frequency of the compressor.

Operation mode:

0-Off; 2-Cooling; 3-Heating; 4-Forced cooling; 5-Mixed cooling; 6-Mixed Heating.

Fan speed:

0-stop; 1~15 speed increase sequentially, 15 is the max. fan speed. EXV opening angle: Pulse count=Display value×8;

State of the evaporator or condenser:

0-close/condenser; 1-All evaporator; 2-Left evaporator/right condenser; 3-Left evaporator/close

Night noise control mode:

0-Night noise control mode; 1-silent mode; 2-Super silent mode; 3-No priority

Static pressure mode:

0-static pressure is 0 Mpa; 1-Low static pressure; 2-Medium static pressrue; 3-High static pressure

Page 17

RDCI Series – All DC Inverter Outdoor Units

6 720 862 437 (2016/10)

ELECTRIC WIRING | 17

8.3 Explanation of mainboard

ENC1 ENC3 S12 S3

S7

S1

ENC2

S4

S2

ENC4

ENC4

Fig. 8-3

Outdoor address,

dial switch

Quantity setting

dial switch

of Indoor units

Force

cooling

Outdoor power

dial switch

Query button

Page 18

6 720 862 437 (2016/10)

RDCI Series – All DC Inverter Outdoor Units

18 | ELECTRIC WIRING

8.4 Dial codes definition

S1 definition

ON

S1

Starting time is set to 10 minutes

ON

S1

Starting time is set to 12 minutes (Default

Factory setting)

S2 definition

ON

S2

Night time selection for 6h/10h

(Default Factory setting)

ON

S2

Night time selection for 6h/12h

ON

S2

Night time selection for 8h/10h

ON

S2

Night time selection for 8h/12h

S3 definition

ON

S3

Night silent mode

(Default the Factory Set)

ON

S3

Silent mode

ON

S3

Super silent mode

ON

S3

None silent mode

S4 definition

ON

S4

Static pressure mode is 0 MPa (Default the

Factory Set)

ON

S4

Static pressure mode is low pressure

(Reserve position, use for customised unit)

ON

S4

Static pressure mode is medium pressure

(Reserve position, use for customised unit)

ON

S4

Static pressure mode is high pressure

(Reserve position, use for customise unit)

S7 definition

ON

S7

Reserve

ENC3 and S12 definition

ENC3

ON

S12

To set the number of indoor units

to 0-15

ENC3

ON

S12

To set the number of indoor units to

16-31

ENC3

ON

S12

To set the number of indoor units to

32-47

ENC3

ON

S12

To set the number of indoor units to

48-63

ENC1 definition

Outdoor unit address

Set the switch to address the unit 0-3

0 Stand for main unit

1-3 Stand for slave uint

ENC2 definition

Outdoor unit capacity setting switch Set the

switch to the correct HP output

For outdoor unit capacity setting

0: 8HP

1: 10HP

2: 12HP

3: 14HP

4: 16HP

S3 definition

Network address setting dial switch Set the

switch to the correct setting

For network address setting

0: system 1

1: system 2

2: system 3

...

7: system 8

Page 19

RDCI Series – All DC Inverter Outdoor Units

6 720 862 437 (2016/10)

ELECTRIC WIRING | 19

■ Explanation of main board

Table.8-2

No. Content

1

Discharge temp. Sensor port for inverter compressor A

2

Discharge temp. Sensor port for inverter compressor B

3

Temperature of module sensor port

4

Reserve

5

Wiring port for communication between indoor and outdoor units, indoor

unit network, outdoor unit network and network accounting

6

Three-phase detection port

7

Reserve

8

Power output of transformer No.1

9

Power output of transformer No.2

10

Heat output terminal of the inverter compressor A

11

Heat output terminal of the inverter compressor B

12

Exv A driving port

13

Exv B driving port

14

Four-way valve output terminal

15

One-way valve output terminal

16

Power control output terminal

17

Null line terminal

18

Power output of transformer No.1

19

Power output of transformer No.2

20

Activation port of inverter module B

21

Port for inverter module B voltage inspection

22

Port for inverter module A voltage inspection

23

Activation port of inverter module A

24

Power supply port for main control panel

25

ON/OFF signal input port for system high pressure inspection

26

ON/OFF signal input port for system low pressure inspection

27

Reserve

28

Reserve

29

Current inspection port of the inverter compressors A and B

30

Input port for system high pressure inspection

31

Communication ports between outdoor units

32

Detection port for outdoor ambient temp. and left pipe Temp.

33

Detection port for right pipe Temp.

34

Control port of DC fan B

35

Control port of DC fan A

8.5 Electric parameters of outdoor unit

Table.8-3

System

Outdoor Unit Power Current Compressor OFM

Voltage Hz Min. Max. MCA TOCA M FA MSC RLA KW FLA

8HP 380~415 50 342 440 18.4 20.8 25

— 17.4

0.42 3.6— 16.5

— 15.9

10HP 380~415 50 342 440 20.6 22.1 25

— 17.4

0.42 3.6— 16.5

— 15.9

12HP 380~415 50 342 440 21.8 22.8 25

— 17.4

0.42 3.6— 16.5

— 15.9

14HP 380~415 50 342 440 27.9 31.8 25

— 17.4+10.5

0.71 5.9— 16.5+10.0

— 15.9+9.6

16HP 380~415 50 342 440 33.4 32.8 25

— 17.4+10.5

0.71 5.9— 16.5+10.0

— 15.9+9.6

Notes:

1. The current value of combination unit is the total value of each basic

model(refer to Table.8-3)

For example: 46HP=14HP+16HP*2

Power current: MCA=27.9+33.4*2=94.7

TOCA=31.8+32.8*2=97.4

MFA=35+35*2=105

Compressor: RLA=(17.4+10.5)*3

OFM: FLA=5.9+5.9*2=17.7

2. RLA is based on the following conditions.

Indoor temp. 27°C DB/19°C WB;Outdoor temp. 35°C DB

3. TOCA means the total value of each OC set.

4. MSC means the Max. current during the starting of compressor.

5. Voltage range

Units are suitable for use on electrical systems where voltage supplied to

unit terminals is not below or above listed range limits.

6. Maximum allowable voltage variation between phase is 2%.

7. Selection wire size based on the larger value of MCA or TOCA.

8. MFA is used to select the circuit breaker and the ground fault circuit

interrupter (earth circuit breaker).

Remark:

MCA: Min. Current Amps. (A)

TOCA: Total Over-current Amps. (A)

MFA: Max. Fuse Amps. (A)

MSC: Max. Starting Amps. (A)

RLA: Rated Locked Amps. (A)

OFM: Outdoor Fan Motor.

FLA: Full Load Amps. (A)

KW: Rated Motor Output (kW)

Page 20

6 720 862 437 (2016/10)

RDCI Series – All DC Inverter Outdoor Units

20 | ELECTRIC WIRING

8.6 Electric wiring of indoor/outdoor units

CAUTION

■ Install a separate power supply for indoor unit and outdoor unit.

■ An all-pole disconnection device which has at least 3 mm separation

distance in all poles and a residual current device (RCD) shall be

incorporated into the fixed wiring in accordance with national wiring

regulations.

■ All indoor units must be connected to the same electrical power

supply incorporating a leak protector and must be able to be isolated

off one switch. Each indoor unit must also have an electrical

isolation as per the national wiring regulations.

■ 3 Core shielded cable must be used for communication wires.

8-6-1 Outdoor unit power wiring

■ With power facilities

■ Indoor power supply

CAUTION

■ Ensure the correct communication wires are with the correct

system.

■ Electrical power supply and communication cables must be installed

in separate containment. (Current capacity of power supply: less

than 10A--300mm, less than 50A--500mm.)

■ When connecting multiple outdoor units, ensure the address

settings have been done prior to powering on.

8.7 Signal wire of indoor/outdoor units

■ Communication wiring must be 3 core shielded cables and must be

> 0.75mm in size. Communication cables are polarity sensitive.

8.8 Example for power wire connection

Fig. 8-4

Leakage

protector

Outdoor unit

Outdoor unit

Outdoor unit

Outdoor unit

Branch box

GND

GND

GND

GND

Leakage

protector

Outdoor unit

power supply

380-415V 3N~ 50Hz

Manual

switch

Manual

switch

Fig. 8-5

Outdoor unit

Outdoor unit

Outdoor unit

Outdoor unit

Outdoor unit

Outdoor unit

Branch box

GND

GND

GND

GND

GND

GND

Leakage

protector

Power facilities 1

(with leakage protector)

Power facilities 12

(with leakage protector)

Manual

switch

192103114

12

5136147158

16

Fig. 8-6

Indoor power

Leakage protector

Manual switch Branch box Indoor unit

(P Q E)

P

Q

P

Q

P

Q

P

Q

P

Q

(P Q E)

(H1 H2 E) (H1 H2 E) (H1 H2 E)

(H1 H2 E)

Fig. 8-7

Outdoor unit

(master unit)

Outdoor unit

(slave unit)

Outdoor unit

(slave unit)

Outdoor unit

(slave unit)

Signal wire between outdoor units

SBOX

(open)

(open)

(open)

(open)

resistor

resistor

resistorresistor

resistor

(open)

group control

The indoor unit where the communication wire ends (last leg), should have a

resister (suppled) fitted between port P and port Q

Signal wire for indoor/

outdoor units

SBOX S BOX SBOX

Shielded layers must terminate to

ground.

L2 L3 NL1 P Q EEH2H1

L N EQP

L2 L3 NL1 P Q EEH2H1 L2 L3 NL1 P Q EEH2H1

C D EBA L N E C D EBA L N E C D EBAQP QP

L2 L3 NL1

C D EBA C D EBA C D EBA

L N EQP

EQP

L2

L3

N

L1

Outdoor unit (master unit)

Indoor unit

Signal wire between indoor/outdoor units

Branch Box Branch Box Branch Box Branch Box

Wire controller Wire controller Wire controller

Signal wire between outdoor units

Signal wire between indoor unit and wire controller

Power wire between indoor units

Indoor unit Indoor unit

Outdoor unit (slave unit) Outdoor unit (slave unit)

Power(380-415V 3N~ 50Hz)

SBOX

Fig. 8-8

Page 21

RDCI Series – All DC Inverter Outdoor Units

6 720 862 437 (2016/10)

TEST RUN | 21

9. TEST RUN

9.1 Inspection and confirmation before

commissioning

■ Check and confirm that refrigeration pipework and communication

wires on the indoor and outdoor units have been connected to the

correct refrigeration system.

■ Power voltage is within ±10% of rated voltage.

■ Before powering on, confirm there is no short circuit on each wire.

■ Ensure new installations have passed a nitrogen strength test.

■ Confirm the vacuum process has been carried out.

9.2 Preparation

■ Calculate the amount of refrigerant charge needed using table 5-12.

■ Have the system plan, system pipework diagram and control wiring

diagram to hand.

■ Record the setting address codes on the system plan.

■ Ensure the power to the compressors has been on for a minimum of

12 hours before starting the system.

■ Check whether the power phase sequence of outdoor unit is correct.

■ Ensure all dial switches on the indoor and outdoor units have been

set with accordance to the installation manual.

9.3 Fill the name of connected system

To clearly identify the connected systems between two or more indoor units

and outdoor units, select names for every system and record them on the

nameplate on the outdoor electric control box cover.

9.4 Caution on refrigerant leakage

■ This air conditioning unit uses R410a which is a non flammable

refrigerant.

■ The room for the air conditioning unit should be big enough to

ensure that a refrigerant leakage cannot reach a critical thickness.

■ Critical thickness-----the maximum exposure of refrigerant without

any harm to person. R410A critical thickness: 0.3 [kg/m3].

■ Calculate the critical thickness using the following steps, and take

necessary actions.

• Calculate the sum of the charge volume (A[kg]).

Total refrigerant volume=refrigerant volume when delivered

(nameplate)+superaddition

• Calculate the indoor cubage (B[m3]) (as the minimum cubage)

• Calculate the refrigerant thickness.

A [kg]

≤

Critical thickness: 0.3 [kg/m3]

B [m3]

■ Countermeasure against overhigh thickness

• Install mechanical ventilator to reduce the refrigerant thickness

under critical level. (ventilate regularly)

• Install leakage detector alarming device related to mechanical

ventilator if you can not regularly ventilate.

Fig. 9-1

Model(indoor unit)

Room Name

Eg: Indoor unit (A) of the first

system on second floor is

recorded as:-2F-1A

Fig. 9-2

Outdoor unit

Indoor unit

Room full of leaking refrigerant

(All the refrigerant has leaked)

Fig. 9-3

Indoor unit

OA

b. Leakage detector alarming device

related to mechanical ventilator

a. Ventilation peristome

Page 22

Notes

Installation Engineers Signature

Print Name

Commissioning Engineers Signature

Print Name

Commissioning Engineer

Engineers Commissioning Number

Engineers Service Number

Commissioning Date

Project Name:

Project Address

Project Reference Number

Page 23

Duration

Duration

Duration

Duration

Notes

Tripple Evacuated

Evacuation Reading (Must be 1.5 Torr or 0.5mb)

Pressure Tested Too

Strength Tested Too

Sbox Installation Condition

Sbox Acces Condition

Power Status

Indoor Unit Installation Condition

Indoor Unit Access

Leak Tested Too

Pre Commissioning Checks

Condenser Installation Condition

Condenser Access Condition

Page 24

Standard Refrigeration Charge

Power Supply

Additional Refrigerant

Outdoor Unit Address Setting

Total Pipe Length

Total Index of Indoors

Outdoor Serial Number

Compressor 1 Serial Number

Compressor 2 Serial Number

Outdoor Unit Details

Outdoor Location

Outdoor Serving Location

Outdoor Model Number

Page 25

Power Supply

Address Setting

Sbox Port Setting

Serial Number

Serial Number

Power Supply

Address Setting

Sbox Setting

Indoor Unit 4

Model Number

Model Number

Indoor Unit 2

Model Number

Serial Number

Power Supply

Address Setting

Sbox Port Setting

Indoor Unit 3

Power Supply

Address Setting

Sbox Port Setting

Serial Number

Indoor Details

Indoor Unit 1

Model Number

Page 26

Power Supply

Address Setting

Sbox Port Setting

Serial Number

Serial Number

Power Supply

Address Setting

Sbox Setting

Indoor Unit 8

Model Number

Model Number

Indoor Unit 6

Model Number

Serial Number

Power Supply

Address Setting

Sbox Port Setting

Indoor Unit 7

Power Supply

Address Setting

Sbox Port Setting

Indoor Details

Indoor Unit 5

Model Number

Serial Number

Page 27

Power Supply

Address Setting

Sbox Port Setting

Serial Number

Serial Number

Power Supply

Address Setting

Sbox Setting

Indoor Unit 12

Model Number

Model Number

Indoor Unit 10

Model Number

Serial Number

Power Supply

Address Setting

Sbox Port Setting

Indoor Unit 11

Power Supply

Address Setting

Sbox Port Setting

Indoor Details

Indoor Unit 9

Model Number

Serial Number

Page 28

Power Supply

Address Setting

Sbox Port Setting

Serial Number

Serial Number

Power Supply

Address Setting

Sbox Setting

Indoor Unit 16

Model Number

Model Number

Indoor Unit 14

Model Number

Serial Number

Power Supply

Address Setting

Sbox Port Setting

Indoor Unit 15

Power Supply

Address Setting

Sbox Port Setting

Indoor Details

Indoor Unit 13

Model Number

Serial Number

Page 29

Comms V

Return Air Cooling

Heating Off

Return Air Heating

Unit Address

Indoor Unit Data

Model Number

Cooling Off

Page 30

Power V Comms V Address

Compressor Serial Num 1 & 2

Compressor Serial Num 1 & 2

Compressor Serial Num 1 & 2

Heating

Cooling

Low Pressure Reading

Low Pressure Reading

Low Pressure Reading

Cooling

Heating

Acces To Sbox

Compressor Serial Num 1 & 2

Sbox Model Number

Serial Number

Compressor Discharge Temp

Compressor Frequency

High Pressure Reading

Low Pressure Reading

Serial Number

Serial Number

Compressor Discharge Temp

Compressor Frequency

High Pressure Reading

Outdoor 4

Model Number

Heating

Cooling

High Pressure Reading

Model Number

Outdoor 2

Model Number

Serial Number

Compressor Discharge Temp

Compressor Frequency

High Pressure Reading

Outdoor 3

Outdoor/Sbox Data

Outdoor 1

Model Number

Serial Number

Heating

Cooling

Compressor Discharge Temp

Compressor Frequency

Page 31

RDCI Series – All DC Inverter Outdoor Units

6 720 862 437 (2016/10)

| 31

Page 32

6 720 862 437 (2016/10)

RDCI Series – All DC Inverter Outdoor Units

32 | F-Gas information

Model Product Description

N.Cooling

Capacity

N.Heating

Capacity

Refrigerant GWP

CO2

equivalent

for pre-

charged

refrigerant

Pre-

charged

Refrigerant

Amount

Additionally

Charged

Refrigerant

Overall

amount of

refrigerant

after

charging

Overall CO2

equivalent

after charging

[kW] [kW] - - [tonnes] [kg] [kg] [kg] [kg]

RDCI8/25-3 Outdoor Unit, 3-pipe, 3ph 25,2 27 R-410A 2088 20,9 10

RDCI10/28-3 Outdoor Unit, 3-pipe, 3ph 28 31,5 R-410A 2088 20,9 10

RDCI12/33-3 Outdoor Unit, 3-pipe, 3ph 33,5 37,5 R-410A 2088 20,9 10

RDCI14/40-3 Outdoor Unit, 3-pipe, 3ph 40 45 R-410A 2088 27,1 13

RDCI16/45-3 Outdoor Unit, 3-pipe, 3ph 45 50 R-410A 2088 27,1 13

Frequency of Refrigerant Leak Checks

- If the amount of tons CO2 equivelant/circuit is from 5 to 50 tons, then frequency to check is 12 months

in case system is without a leakage dedection system or 24 months in case system is with a leakage

dedection system.

- If the amount of tons CO

2 equivelant/circuit is from 50 to 500 tons, then frequency to check is 6 months

in case system is without a leakage dedection system or 12 months in case system is with a leakage

dedection system.

- If the amount of tons CO

2 equivelant/circuit is over 500 tons, then frequency to check is 3 months

in case system is without a leakage dedection system or 6 months in case system is with a leakage

dedection system.

Page 33

Page 34

6 720 862 437 (2016/10)

RDCI Series – All DC Inverter Outdoor Units

34 |

Page 35

RDCI Series – All DC Inverter Outdoor Units

6 720 862 437 (2016/10)

| 35

Page 36

Loading...

Loading...