Page 1

Data Logger C60

Manual

Version 1.0 12/03/2019

Page 2

Content

ii/108 Data Logger C 60 Bosch Motorsport

Content

1 Onboard Network Concept............................................................................................................................................ 4

2 Preparation...................................................................................................................................................................... 5

3 Power Supply .................................................................................................................................................................. 6

4 Error Memory .................................................................................................................................................................. 7

4.1 Error memory representation in RaceCon .................................................................................................................................................. 7

4.2 Information on errors available from the error memory ...................................................................................................................... 9

4.3 Analog Input Diagnosis...................................................................................................................................................................................... 13

5 Technical Data................................................................................................................................................................. 15

6 Disposal............................................................................................................................................................................ 20

7 Mechanical Drawing ....................................................................................................................................................... 21

8 Starting up the C 60........................................................................................................................................................ 22

8.1 Before starting ....................................................................................................................................................................................................... 22

8.2 Feature activation................................................................................................................................................................................................. 25

8.3 First recording (Quick start).............................................................................................................................................................................. 25

8.4 Status LEDs.............................................................................................................................................................................................................. 26

8.5 Set Time & Date.................................................................................................................................................................................................... 27

9 CAN Bus ........................................................................................................................................................................... 28

9.1 CAN bus trivia ........................................................................................................................................................................................................ 28

9.2 CAN input................................................................................................................................................................................................................ 28

9.3 CAN output............................................................................................................................................................................................................. 33

10 Analog and Frequency Inputs ....................................................................................................................................... 36

10.1 Features.................................................................................................................................................................................................................... 36

10.2 Analog inputs......................................................................................................................................................................................................... 36

10.3 Configuring inputs ............................................................................................................................................................................................... 37

10.4 Computed sources............................................................................................................................................................................................... 48

10.5 Hysteresis................................................................................................................................................................................................................. 49

10.6 Configuring PWM outputs................................................................................................................................................................................ 52

10.7 Analog inputs......................................................................................................................................................................................................... 55

10.8 Configuring inputs ............................................................................................................................................................................................... 55

10.9 Computed sources............................................................................................................................................................................................... 64

10.10 Hysteresis................................................................................................................................................................................................................. 65

10.11 Configuring PWM outputs................................................................................................................................................................................ 67

11 Online Measurement ...................................................................................................................................................... 70

11.1 Achieving an online connection ..................................................................................................................................................................... 70

11.2 Setting up an online measurement............................................................................................................................................................... 71

11.3 Online calibration of measurement channels............................................................................................................................................ 73

11.4 Group adjustment ................................................................................................................................................................................................ 75

11.5 Online calibration of multipoint adjustment channels .......................................................................................................................... 77

12 Recording and Telemetry............................................................................................................................................... 79

12.1 Features.................................................................................................................................................................................................................... 79

12.2 Configuration of recordings............................................................................................................................................................................. 79

12.3 Configuration of online telemetry ................................................................................................................................................................. 83

12.4 Configuration of burst telemetry ................................................................................................................................................................... 85

Page 3

Content

Bosch Motorsport Data Logger C 60 iii/108

12.5 Setup for USB recording.................................................................................................................................................................................... 85

13 Lap Trigger ...................................................................................................................................................................... 89

13.1 Lap trigger (timing beacon).............................................................................................................................................................................. 89

13.2 Counting outing/laps/fragments ................................................................................................................................................................... 92

13.3 Lap timing................................................................................................................................................................................................................ 93

14 Firmware .......................................................................................................................................................................... 97

14.1 Firmware and configuration............................................................................................................................................................................. 97

14.2 Firmware update................................................................................................................................................................................................... 97

15 Clone the Unit ................................................................................................................................................................. 99

16 Fuel Consumption Calculation ...................................................................................................................................... 100

16.1 Setting up fuel consumption calculation and tank management..................................................................................................... 100

16.2 Fuel consumption diagnosis/counter reset................................................................................................................................................ 100

16.3 Example .................................................................................................................................................................................................................... 101

17 GPS Sensor....................................................................................................................................................................... 102

17.1 GPS (Global Positioning System).................................................................................................................................................................... 102

17.2 Protocol.................................................................................................................................................................................................................... 102

17.3 Sensor recommendation ................................................................................................................................................................................... 102

17.4 Measurement labels ............................................................................................................................................................................................ 102

17.5 GPS troubleshooting........................................................................................................................................................................................... 103

18 RaceCon Shortcuts.......................................................................................................................................................... 105

Page 4

1 | Onboard Network Concept

4/108 Data Logger C 60 Bosch Motorsport

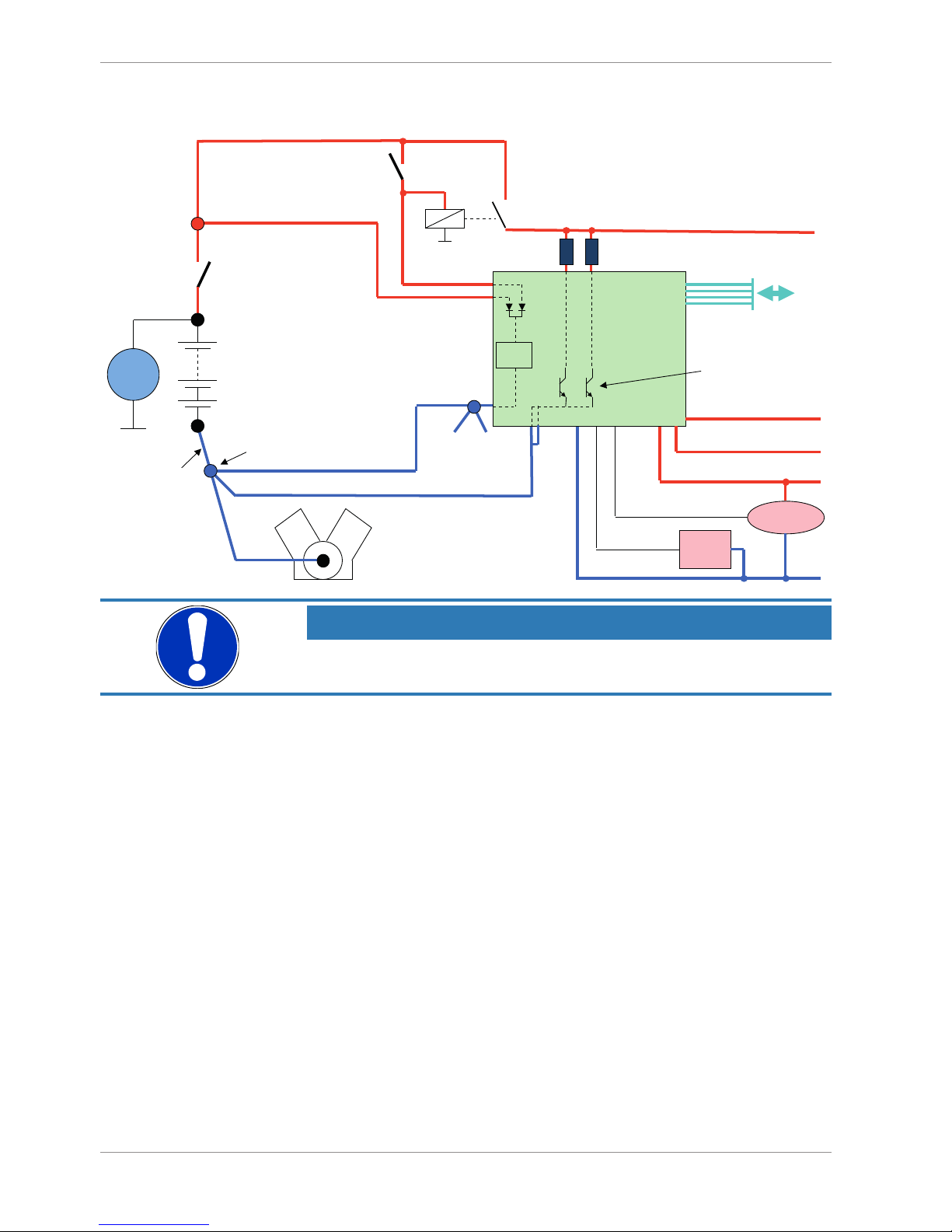

1 Onboard Network Concept

G

Engine_GND

GND_Starpoint

Chassis

KL31

LS_GND_1

LS_GND_2

Main

Switch

UBAT

Star connection

(term30)

positive terminal

Electric Loads

IGN-

Switch

KL15

SENSPWR5

SENSGND

active

Sensor

ANA_IN(xx)

NTC

Sensor

ANA_IN(xy)

switched pos. terminal

Star connection

dig. sensors

(e.g. wheelspeed)

µC

As short as

possible

SENSPWR10

UBATT_FUSE

KL30

LS_SWITCH1…4

Bosch Motorsport

diagnosis connector

PC

Device

NOTICE

This schematic is not device specific, please see the section “Technical Data for the specifications of your device.

Page 5

Preparation | 2

Bosch Motorsport Data Logger C 60 5/108

2 Preparation

Use the C 60 only as intended in this manual. Any maintenance or repair must be performed by authorized and qualified personnel approved by Bosch Motorsport.

Operation of the C 60 is only certified with the combinations and accessories that are specified in this manual. The use of variant combinations, accessories, and other devices outside the scope of this manual are only permitted when they have been determined to be

compliant from a performance and safety standpoint by a representative from Bosch

Motorsport.

Read the manual carefully and follow the application hints step by step. Do not hesitate to

contact us, contact data can be found on the last page of this document.

Disclaimer

Due to continuous enhancements, we reserve the rights to change any illustrations, photos and technical data within this manual.

Please retain this manual for your records.

NOTICE

In this document, all screenshots are created by way of example for a

display. Please consider this and replace the product names with the

name of your device.

Page 6

3 | Power Supply

6/108 Data Logger C 60 Bosch Motorsport

3 Power Supply

Please ensure that you have a good ground installation. That means:

– A ground that has a solid, low resistance connection to the negative battery terminal

– Connection should be free from dirt, grease, paint, anodizing, etc.

– Use large diameter wire

– More metal-to-metal contact is better!

The following notations for power signals are used:

– KL 15 is a switched battery rail controlled by the IGN-switch

– KL 30 is an unswitched battery positive rail (same as battery positive terminal)

– KL 31 is an unswitched ground rail (same as battery negative terminal)

Be careful to observe current limits of wires and connector pins!

Page 7

Error Memory | 4

Bosch Motorsport Data Logger C 60 7/108

4 Error Memory

In this chapter “Error Memory”, a lot of screenshots are created by way of example for

DDU 8. Please consider this and replace the product name ‘DDU 8’ in this case with the

name of your product.

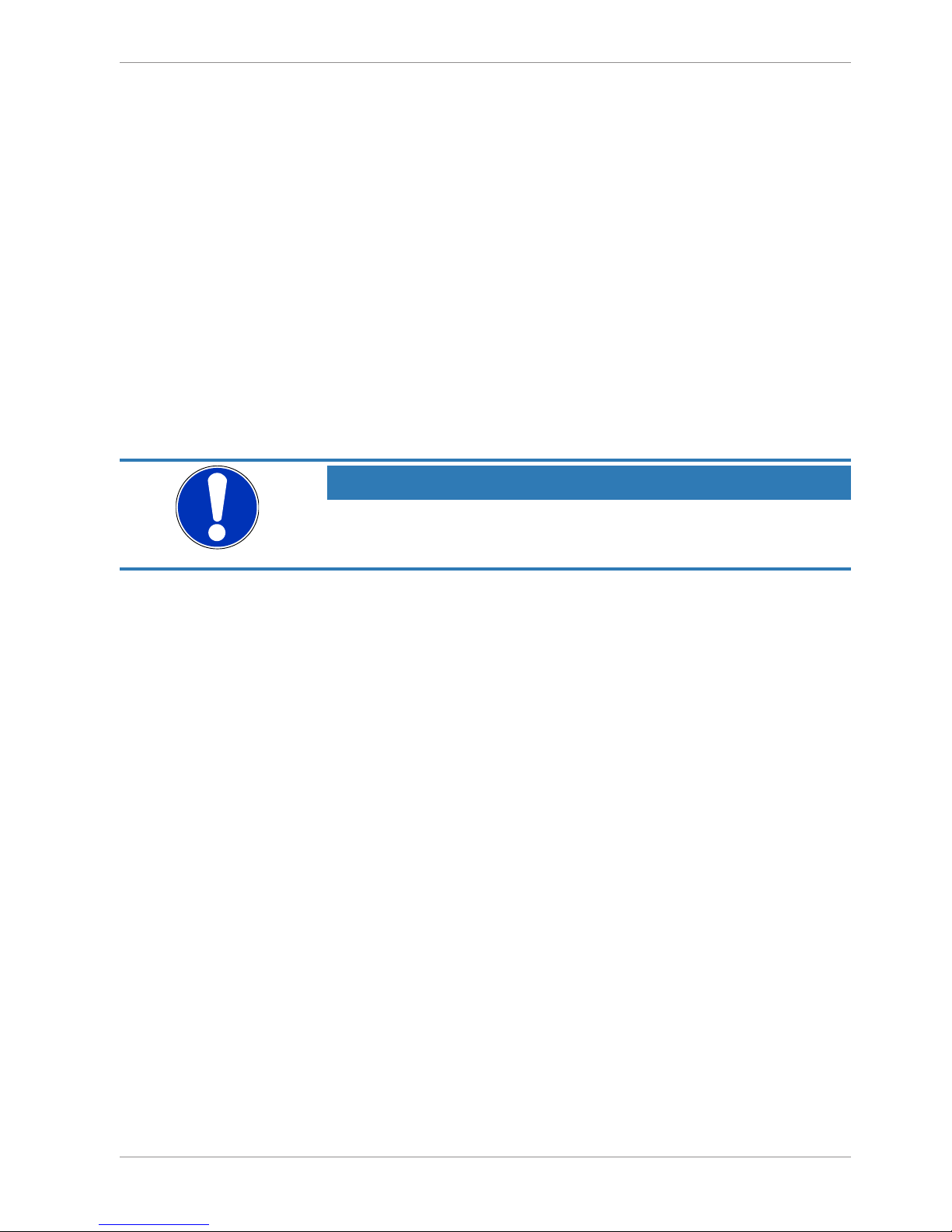

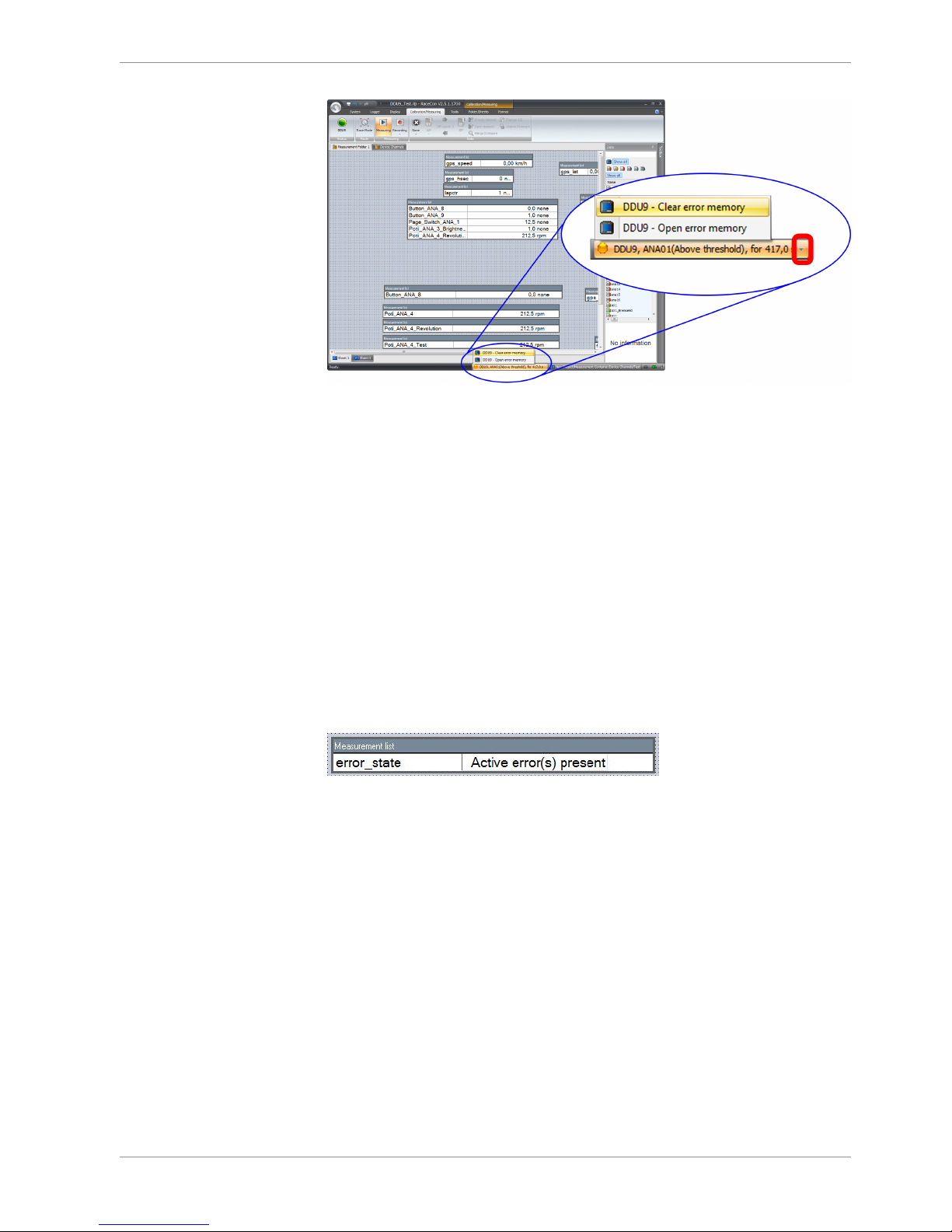

4.1 Error memory representation in RaceCon

Bosch Motorsport devices feature an error memory. Information on errors can be visualized via RaceCon (online measurement) or can be transmitted via telemetry.

4.1.1 Accessing the memory

The error memory can be accessed as shown in the illustration:

Page 8

4 | Error Memory

8/108 Data Logger C 60 Bosch Motorsport

The memory is situated inside the device and is non‐volatile. As a consequence, an error

which has occurred and has not been cleared by the user will remain in the error memory

even after a power cycle. The error state will then reflect if the error is still active or not.

An error is deleted from the list when

– the user actively clears the error memory

– the user updates the firmware

The error memory is not cleared by a configuration download and is not cleared by a

power cycle.

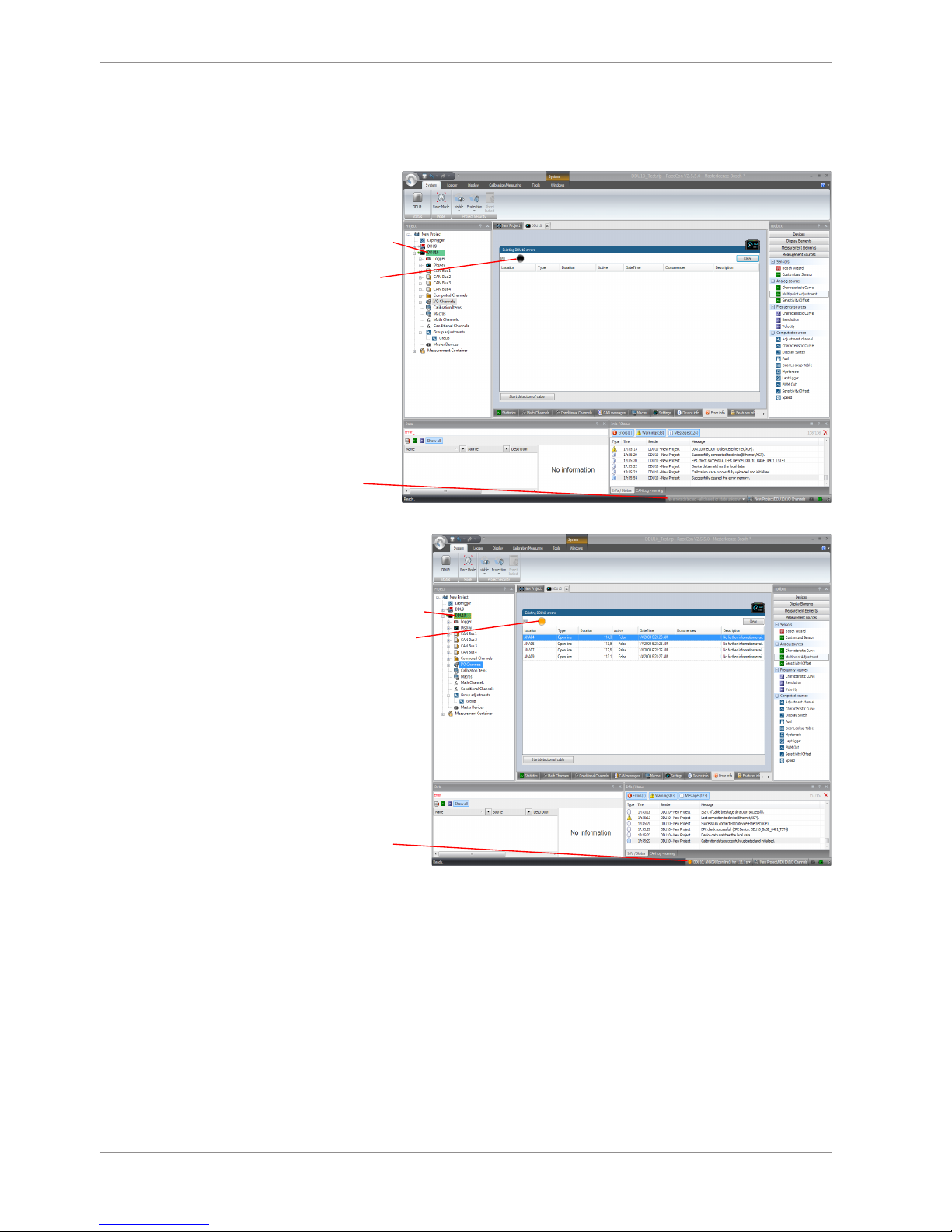

4.1.2 Clearing the error memory

There are two ways of clearing the error memory, both are shown in the following illustration:

Page 9

Error Memory | 4

Bosch Motorsport Data Logger C 60 9/108

4.2 Information on errors available from the

error memory

In general, properties of the error memory and properties of an individual error need to

be distinguished.

4.2.1 Error Memory Properties

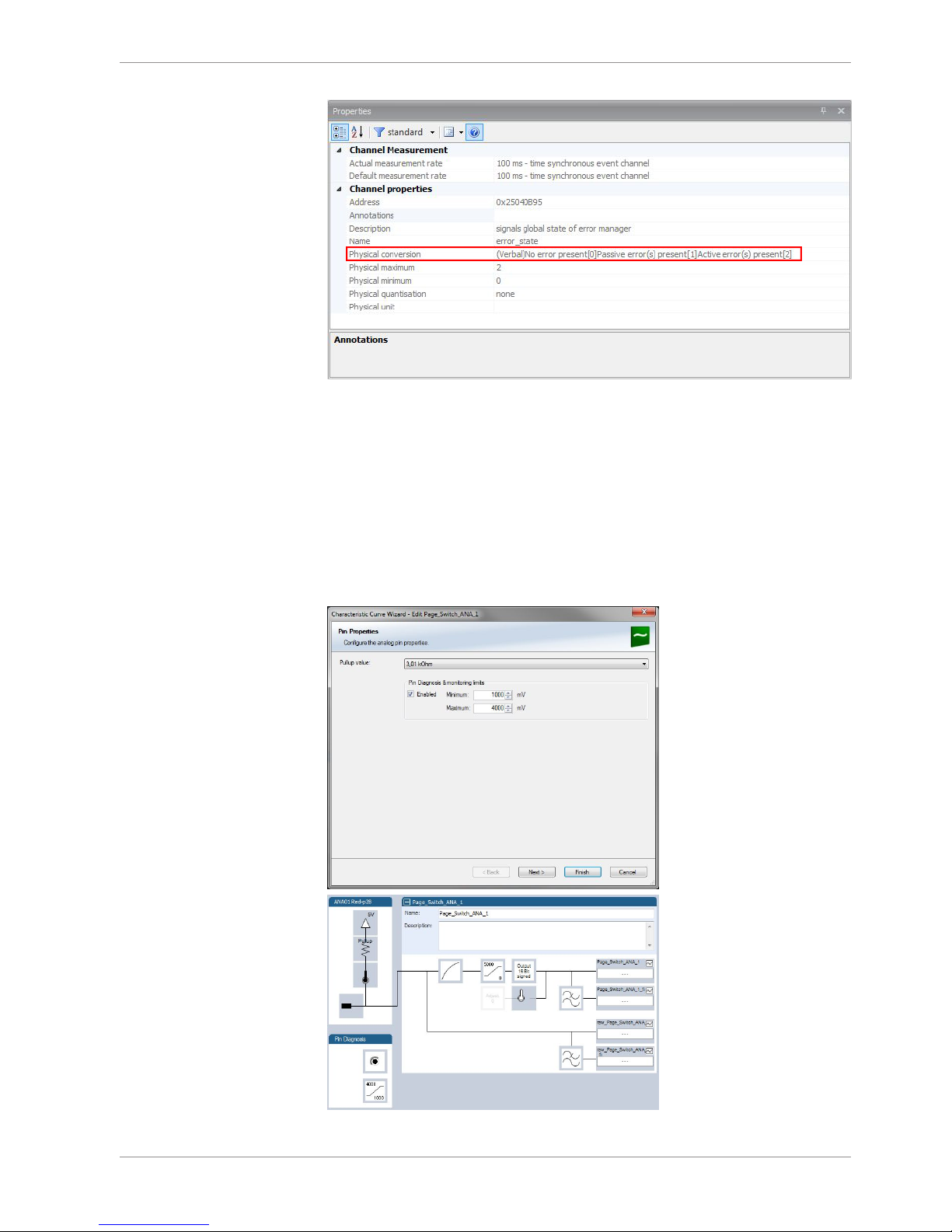

The following property is available for the error memory itself:

– Error Status (device measurement label “error_state”)

0: no error present in memory

1: at least one inactive error present in memory, no active errors

2: at least one active error present in memory

If displayed in a measurement sheet, this property’s value (0, 1 or 2) is translated into a

verbal description:

Page 10

4 | Error Memory

10/108 Data Logger C 60 Bosch Motorsport

It is also represented by a color scheme within RaceCon (provided RaceCon is online with

the system):

0 (no error present in memory):

No orange border

MIL off (black)

No entries

1 (at least one inactive error present in memory, no active errors):

Constantly orange border

Info cycling through

errors, present in

error memory

MIL constantly orange

Page 11

Error Memory | 4

Bosch Motorsport Data Logger C 60 11/108

2 (at least one active error present in memory):

MIL blinking orange

Blinking orange border

Info cycling through

errors present in

error memory

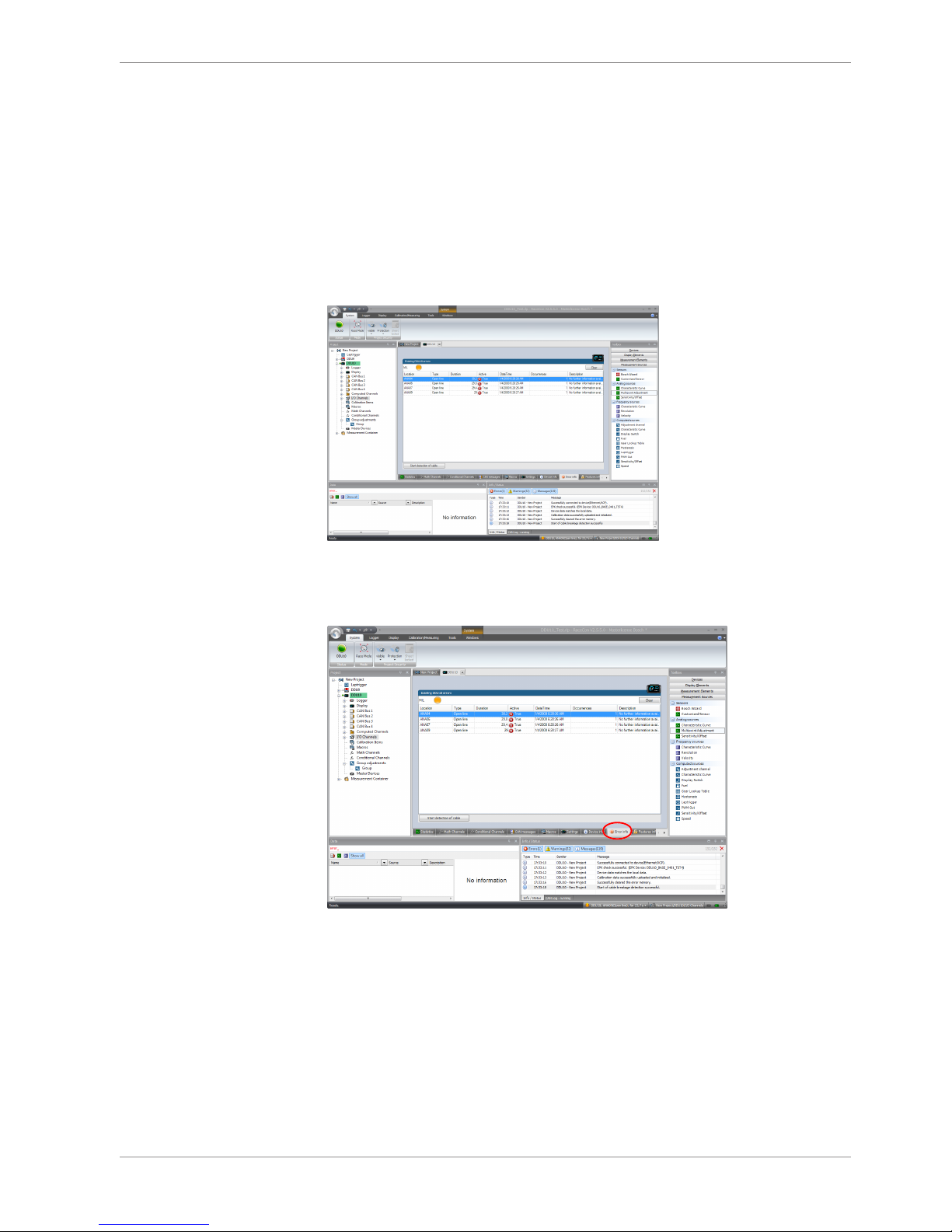

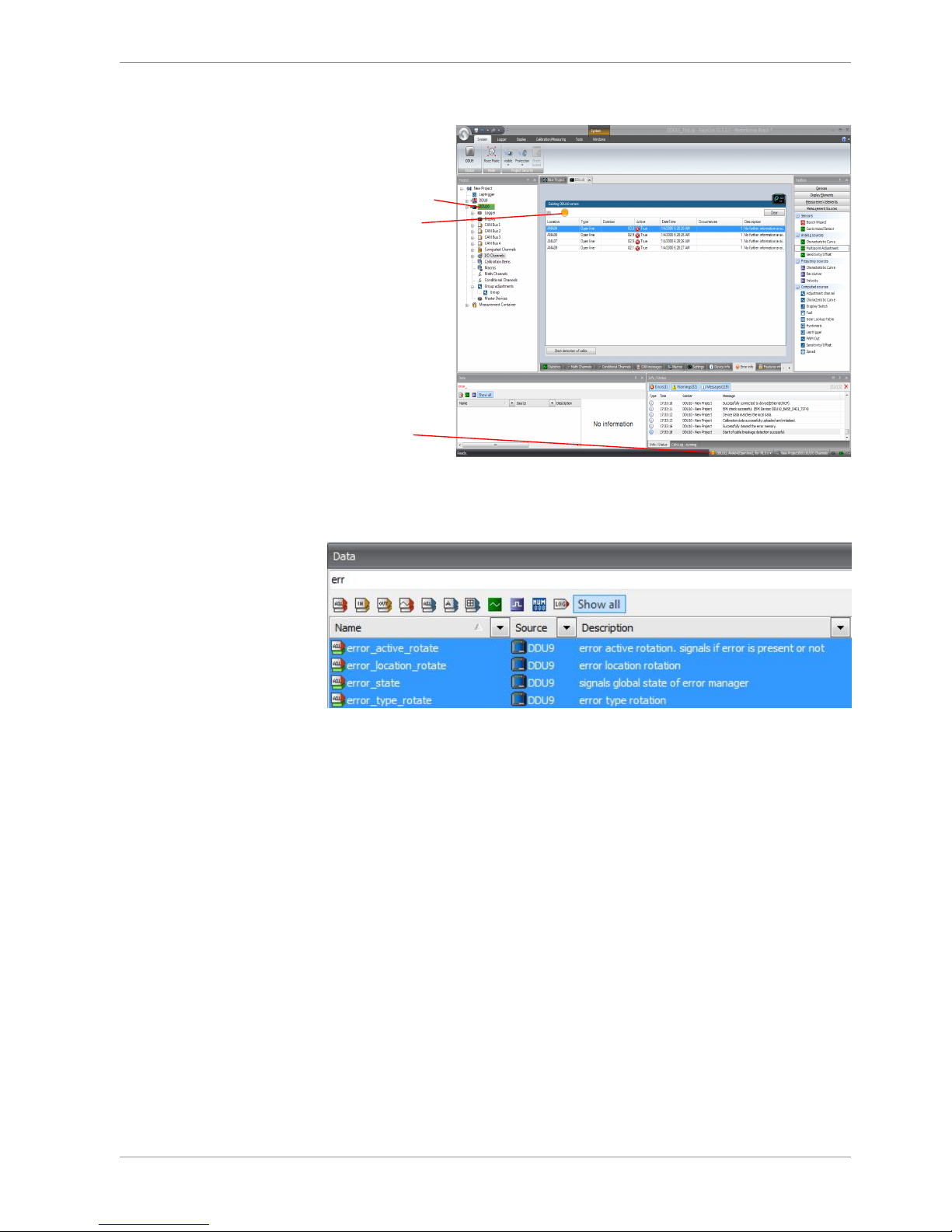

4.2.2 Error Properties

The following channels are recognized and memorized inside the devices:

– Error type (device label “error_type_rotate”):

e.g. “below_threshold” for a violation of the minimum voltage range defined in the

configuration, “shortcut_Batt” for a shortcut to battery voltage etc.

– Error locations (device label “error_location_rotate”):

e.g. “ANA01” for an error concerning the first ANA channel

– Error durations

How long has the error been active? If an error encounters a non-active period before

being cleared from the memory and is then detected again, the error duration keeps

on accumulating. The number of active periods can be seen from the “number of occurrences”.

– Number of occurrences

How many times has the error been detected since the last time the error memory

was cleared.

– Error active state (device label “error_active_rotate”)

All failure modes are continuously diagnosed; any error detected will be written to the

error memory. Once an error is detected, it is qualified as “active”.

– 1 (TRUE) Error was detected in most recent diagnose run (active)

Page 12

4 | Error Memory

12/108 Data Logger C 60 Bosch Motorsport

– 0 (FALSE) Error is inactive: error was not detected in most recent diagnostic run,

however the error has not been cleared from the memory by the user and remains in the non‐volatile memory

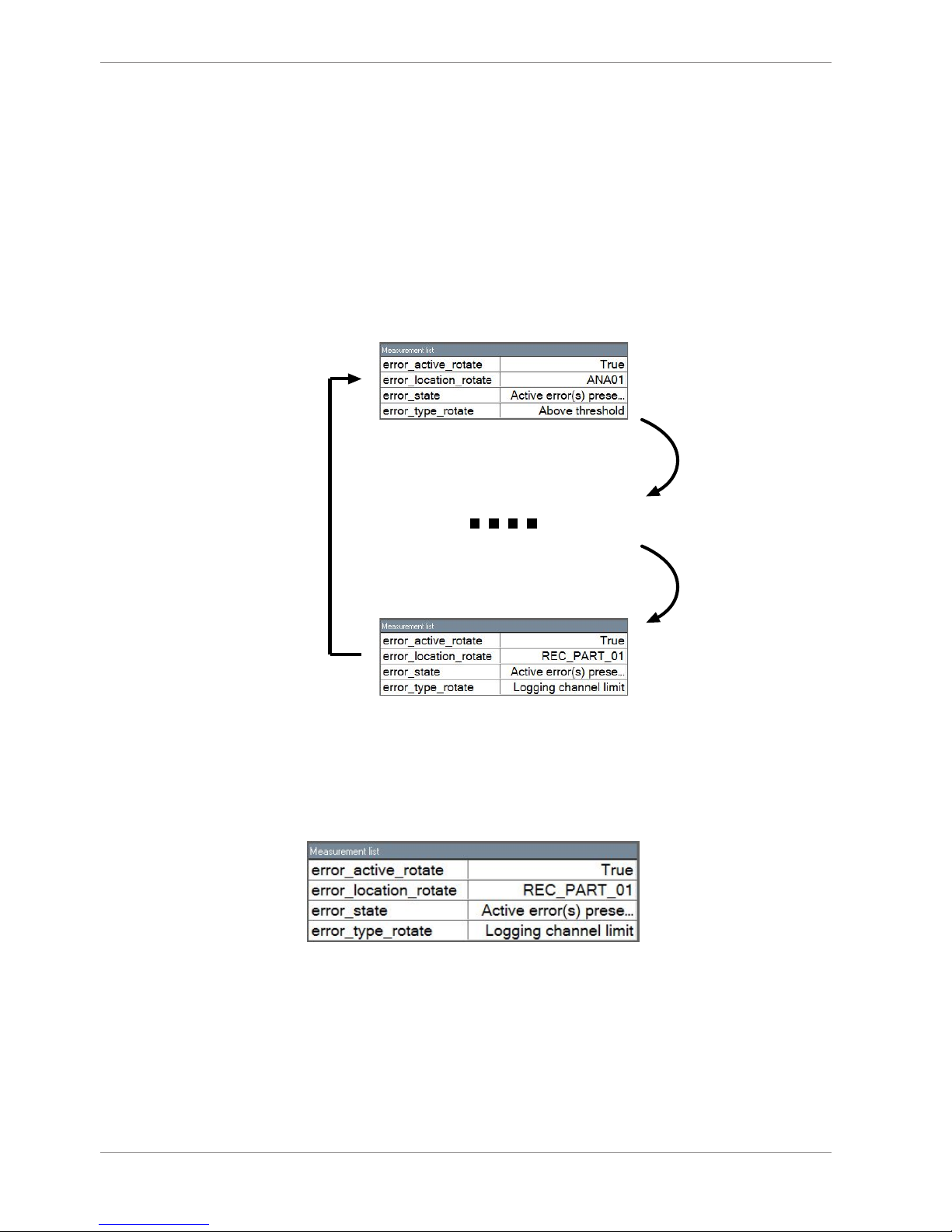

The aforementioned channels (error_active_rotate, error_location_rotate, error_type_rotate) are device specific properties (e.g. C 60) and are not related to the complete RaceCon project (e.g. “error no. 3 from the error memory”). Therefore, only one property label

is available in each device. The errors from the error memory (possibly more than one error possible per device) share these three labels. The labels cycle through the errors currently present in the memory and represent the respective property of each error periodically.

The following screenshot shows error properties, which can be displayed or logged:

Labels hold information

on error 1 (an ANA3 error)

Labels hold information

on error 2 ... n-1

Labels hold information

on error n (a CAN error)

After the last error and its error properties have been displayed, the labels will start again

with the first error in the error memory stack and its error properties will be displayed

again. Therefore, monitoring these labels over a sufficiently long period provides the information on all individual errors in the error memory.

To understand this behavior, it is recommended to observe the three labels in a measurement sheet (while more than one error is active) and watch the values change periodically:

The verbal representation of the numerical codes of these labels can be visualized in the

properties window of the measurement page:

Page 13

Error Memory | 4

Bosch Motorsport Data Logger C 60 13/108

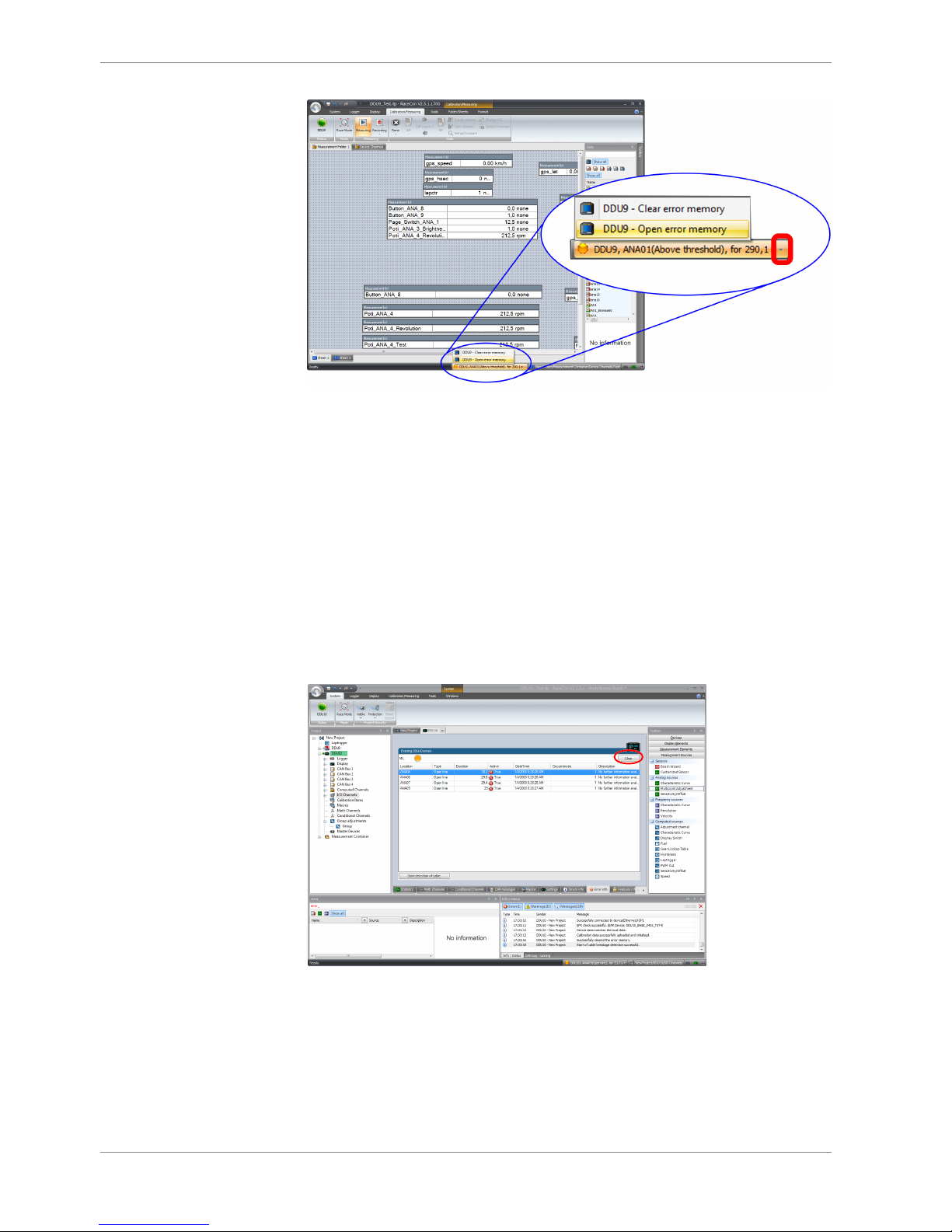

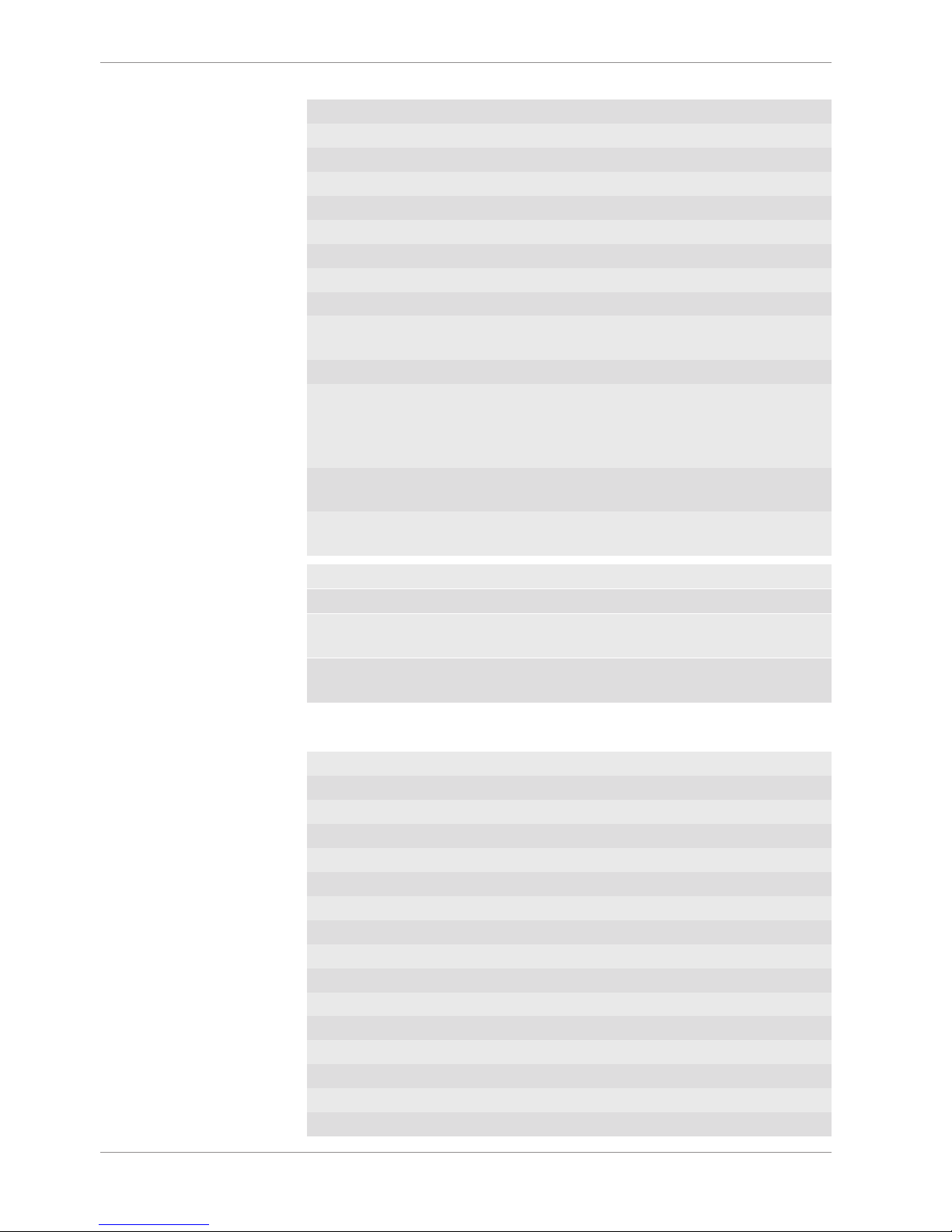

4.3 Analog Input Diagnosis

4.3.1 Monitoring limits / Shortcut Detection / Cable

Breakage

The pin diagnosis functionality (check whether measurement is within the desired range)

can be activated in the ANA pin setup wizard; to allow for a diagnosis regarding shortcut

to ground, shortcut to battery voltage and cable breakage, a minimum / maximum has to

be defined.

Page 14

4 | Error Memory

14/108 Data Logger C 60 Bosch Motorsport

4.3.2 Open Line Detection

The implementation of open line detection consists of pull up resistors being activated

and deactivated; evaluating the behavior of the measured value detects cable breakage,

regardless of the pull up resistor being activated by the user.

1. Open the Error Memory of the Device.

2. Click "start detection of cable".

3. Check the Error Memory for new fault entries, regarding "Open line errors".

Page 15

Technical Data | 5

Bosch Motorsport Data Logger C 60 15/108

5 Technical Data

Application

Technical Specifications

Mechanical Data

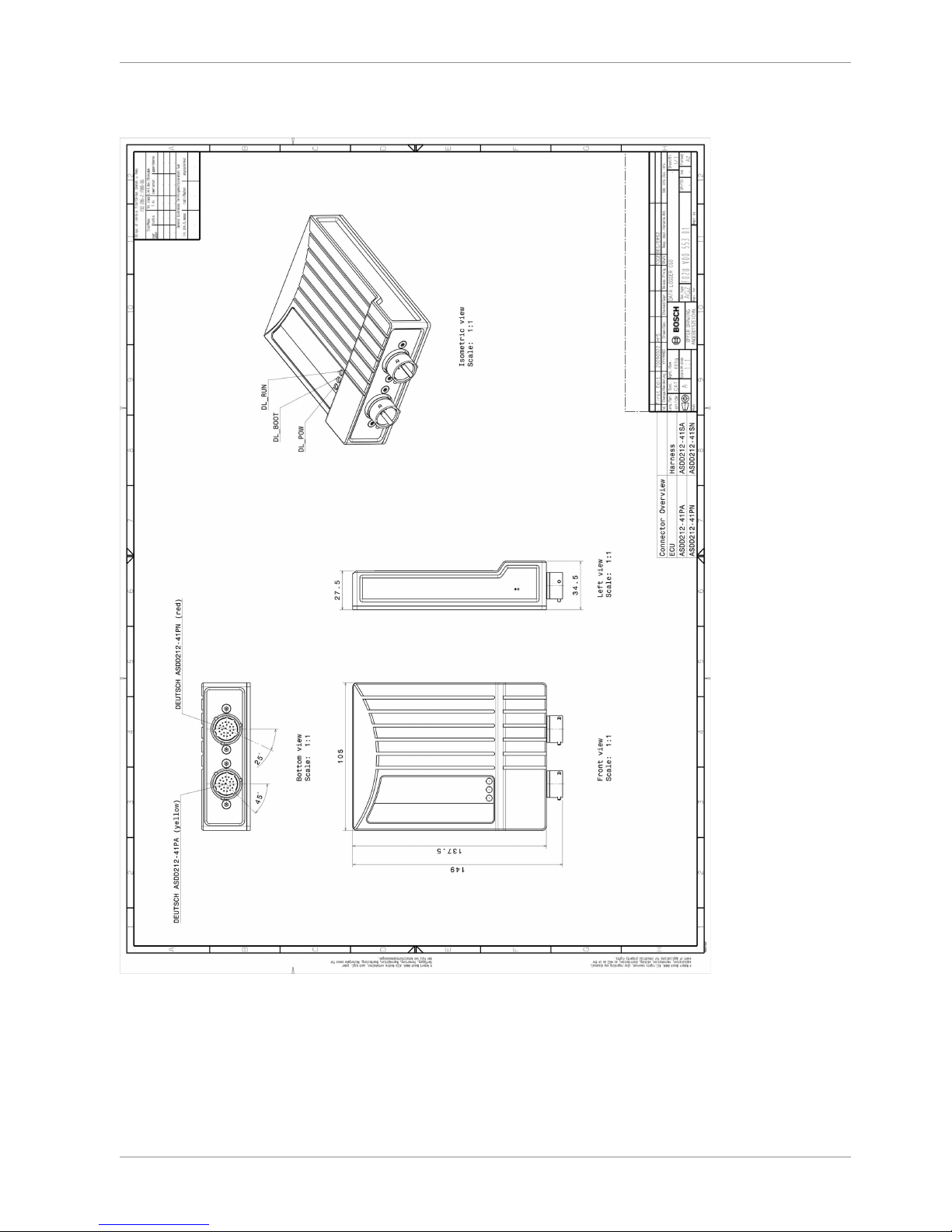

Size 105 x 34.5 x 137.5 mm

Weight 495 g

Protection Classification IP67 to DIN 40050, Section 9, Issue 2008

Operating temperature (internal) -20 to 65°C

Max. vibration Vibration profile 1 (see Appendix or

www.bosch-motorsport.com)

Electrical Data

Supply voltage 8 to 18 V

Max. power consumption (w/o loads) 10 W at 14 V

Inputs

Analog channels 6

Input range 0 to 5 V

Resolution 12 bit

Switchable pull up resistor 3 kΩ

Outputs

PWM outputs (low side switch 2 A each) 4

Sensor supply 5 V ± 1 % (250 mA) 1

Environment

Software Upgrade 1

Page 16

5 | Technical Data

16/108 Data Logger C 60 Bosch Motorsport

GPS input

Additional analog channels 20

Rotational channels (input Hall/inductive) 4

Additional sensor supply 5 V (250 mA each) 3

Sensor supply 10 V (250 mA) 1

Sensor supply 12 V (1 A), non regulated 1

RS232 GPS

F 02U V00 703-01

Software Upgrade 2

CCP-Master (ASAP 2 file from ECU manufacturer required)

F 02U V00 797-01

Software Upgrade 3

USB-Port unlocked (Rugged USB flash drive

2 GB Bosch File System (BFS) format included, works with Bosch File System (BFS)

preformatted USB Flash drive only)

F 02U V00 872-02

Adapter cable to USB-Port (included in Upgrade)

F 02U V01 343-01

Adapter for wiring harness (included in Upgrade)

F 02U 002 996-01

Connectors and Wires

Motorsports connectors double density 2 x 41 pins

Mating connector I

AS-DD 6-12-41SN

F 02U 002 216-01

Mating connector II

AS-DD 6-12-41SA

F 02U 004 180-01

Pin Layout

ASDD-2-12-41PN

Pin Name Description

1 KL30

2 KL15

3 KL15

4 KL31

5 KL31

6 Ethernet Channel0 Tx plus Wire Ethernet_0 - TX+

7 Ethernet Channel0 Tx minus Wire Ethernet_0 - TX-

8 Ethernet Channel0 Rx plus Wire Ethernet_0 - RX+

9 Ethernet Channel0 Rx minus Wire Ethernet_0 - RX-

10 Ethernet Schirm Ethernet Schirm

11 Ethernet Channel1 Tx plus Wire Ethernet_0 - TX+

12 Ethernet Channel1 Tx minus Wire Ethernet_0 - TX-

13 Ethernet Channel1 Rx plus Wire Ethernet_0 - RX+

14 Ethernet Channel1 Rx minus Wire Ethernet_0 - RX-

Page 17

Technical Data | 5

Bosch Motorsport Data Logger C 60 17/108

15 Ethernet Channel2 Tx plus Wire Ethernet_0 - TX+

16 Ethernet Channel2 Tx minus Wire Ethernet_0 - TX-

17 Ethernet Channel2 Rx plus Wire Ethernet_0 - RX+

18 Ethernet Channel2 Rx minus Wire Ethernet_0 - RX-

19 CAN_A_H CAN_A - HIGH

20 CAN_A_L CAN_A - LOW

21 CAN_B_H CAN_B - HIGH

22 CAN_B_L CAN_B - LOW

23 USB Power 500mA USB_Power

24 USB Data Plus USB_OTG_Plus

25 USB Data Minus USB_OTG_Minus

26 USB GND USB_Ground

27 SENSPWR5_1

28 SENSGND

29 Timestamp

30 LS_GND_1 Low-Side Ground2

31 LS_SWITCH_1 lowside switch 2A

32 LS_SWITCH_2 lowside switch 2A

33 LS_SWITCH_3 lowside switch 2A

34 LS_SWITCH_4 lowside switch 2A

35 LS_GND_2 Low-Side Ground2

36 ANAIN_M1_1 0 to 5V Analog

37 ANAIN_M1_2 0 to 5V Analog

38 ANAIN_M1_3 0 to 5V Analog

39 ANAIN_M1_4 0 to 5V Analog

40 ANAIN_M1_5 0 to 5V Analog

41 ANAIN_M1_6 0 to 5V Analog

ASDD-2-12-41PA

Pin Name Description

1 UBATT_FUSE1

2 SENSPWR10_1

3 SENSPWR5_2

4 SENSPWR5_3

5 SENSPWR5_4

6 SENSGND

7 SENSGND

8 RS232A TX RS232A - Transmit

9 RS232A RX RS232A - Receive

10 RS232B TX RS232A - Transmit

11 RS232B RX RS232A - Receive

12 RS232_GND RS232_GND

13 REV1_P DHE I/P or Inductive - KW+

14 REV1_M DHE I/P or Inductive - KW-

Page 18

5 | Technical Data

18/108 Data Logger C 60 Bosch Motorsport

15 REV2_P DHE I/P or Inductive - KW+

16 REV2_M DHE I/P or Inductive - KW-

17 REV3_P DHE I/P or Inductive - KW+

18 REV3_M DHE I/P or Inductive - KW-

19 REV4_P DHE I/P or Inductive - KW+

20 REV4_M DHE I/P or Inductive - KW-

21 ANAIN_M1_7 0 to 5V Analog

22 ANAIN_M1_8 0 to 5V Analog

23 ANAIN_M1_9 0 to 5V Analog

24 ANAIN_M1_10 0 to 5V Analog

25 ANAIN_M1_11 0 to 5V Analog

26 ANAIN_M1_12 0 to 5V Analog

27 ANAIN_M1_13 0 to 5V Analog

28 ANAIN_M1_14 0 to 5V Analog

29 ANAIN_M1_15 0 to 5V Analog

30 ANAIN_M1_16 0 to 5V Analog

31 ANAIN_M2_1 0 to 5V Analog

32 ANAIN_M2_2 0 to 5V Analog

33 ANAIN_M2_3 0 to 5V Analog

34 ANAIN_M2_4 0 to 5V Analog

35 ANAIN_M2_5 0 to 5V Analog

36 ANAIN_M2_6 0 to 5V Analog

37 ANAIN_M2_7 0 to 5V Analog

38 ANAIN_M2_8 0 to 5V Analog

39 ANAIN_M2_9 0 to 5V Analog

40 ANAIN_M2_10 0 to 5V Analog

41 LAPTRIGGER

Communication

Configuration via RaceCon over Ethernet or MSA-Box II

CAN interfaces 2

Ethernet 100BaseT 3

RS232 Telemetry

Lap trigger input 1

Installation Notes

The required software (.pst file) for this device is available in the download area of our

homepage www.bosch-motorsport.com.

Download data and save configurations before sending device as it will be reset during

service.

Internal accumulator for data preservation and clock included

Recommended service interval: 24 months (inclusive accumulator change)

Send device to Bosch dealer for service.

Page 19

Technical Data | 5

Bosch Motorsport Data Logger C 60 19/108

Charge accumulator for > 6 h after installation (supply with power).

Charge accumulator twice per year for > 6 h (supply with power).

Page 20

6 | Disposal

20/108 Data Logger C 60 Bosch Motorsport

6 Disposal

Hardware, accessories and packaging should be sorted for recycling in an environmentfriendly manner.

Do not dispose of this electronic device in your household waste.

Waste electronic equipment must be disposed of properly according to Electrical and

Electronics Act (ElektroG) and the European WEE directive.

Page 21

Mechanical Drawing | 7

Bosch Motorsport Data Logger C 60 21/108

7 Mechanical Drawing

Page 22

8 | Starting up the C 60

22/108 Data Logger C 60 Bosch Motorsport

8 Starting up the C 60

8.1 Before starting

Install the software required C 60 operation. It is developed for Windows 2000/XP/Vista/7.

Following software versions are used in this manual:

– C 60 setup, configuration and calibration: RaceCon 2.1.0

– Measurement data analysis: WinDarab V7

Set up the 100 Mbit Ethernet connection to the C 60.

– All three Ethernet ports of C 60 are internally connected by a network switch

– All Ethernet ports have ‘cable auto crossover’ functionality

Minimum wiring loom of the Life connector (red):

Pin Description

Pin 1+2+3 12 V supply voltage

Pin 4+5 GND supply voltage

Pin 6 Ethernet Tx+

Pin 7 Ethernet Tx-

Pin 8 Ethernet Rx+

Pin 9 Ethernet Rx-

Pin 10 Ethernet Screen

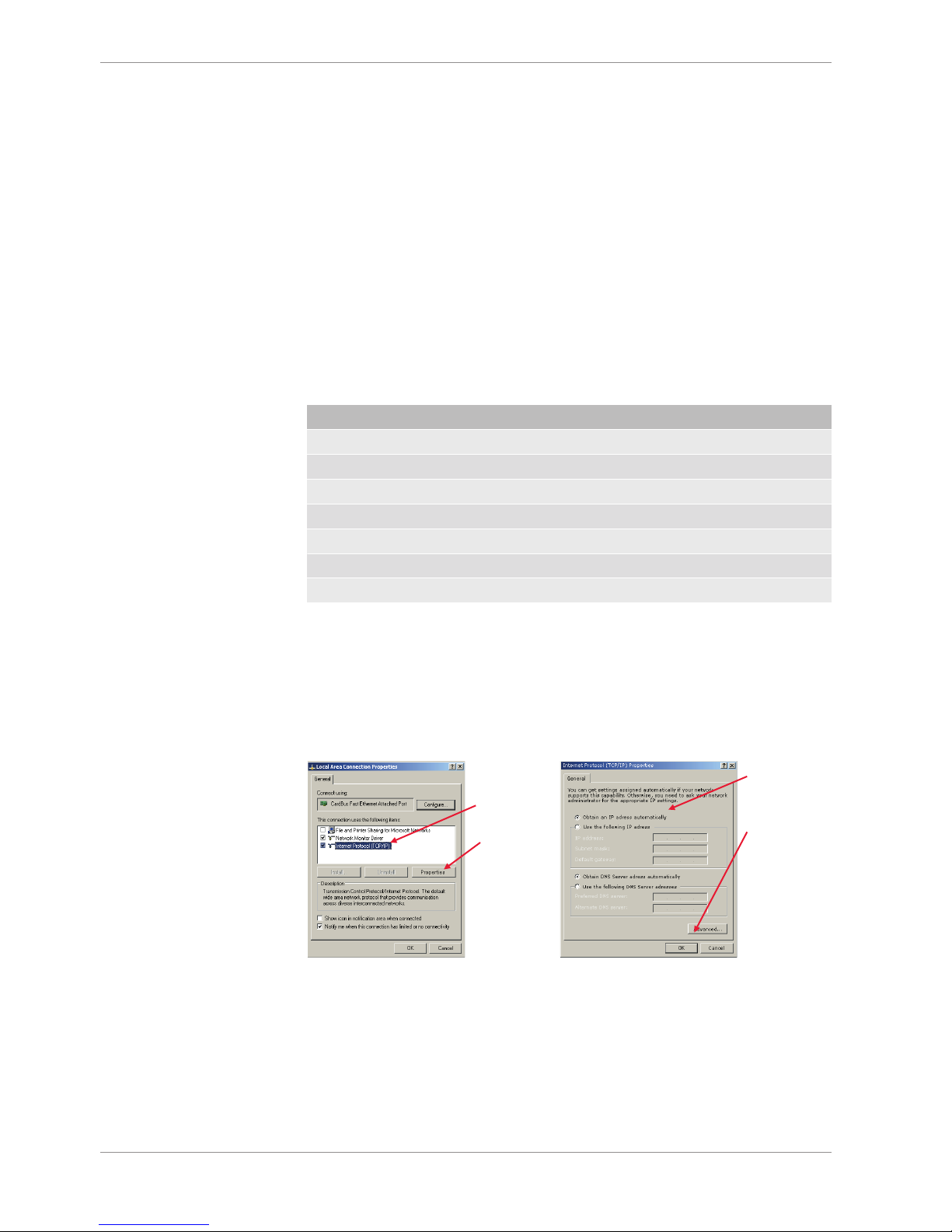

8.1.1 Setting up the network interface

The C 60 contains a DHCP server, network addresses can be assigned automatically to the

configuration PC. The IP address of C 60 is 10.10.0.207.

1. Switch off the PC’s firewall.

2. Set up the PC’s network interface as shown in the screenshots.

Select

‘Internet

Protocol

(TCP/IP)’

Click

‘Properties’

Select ‘Obtain

an IP address

automatically’

Click ‘OK’

when done

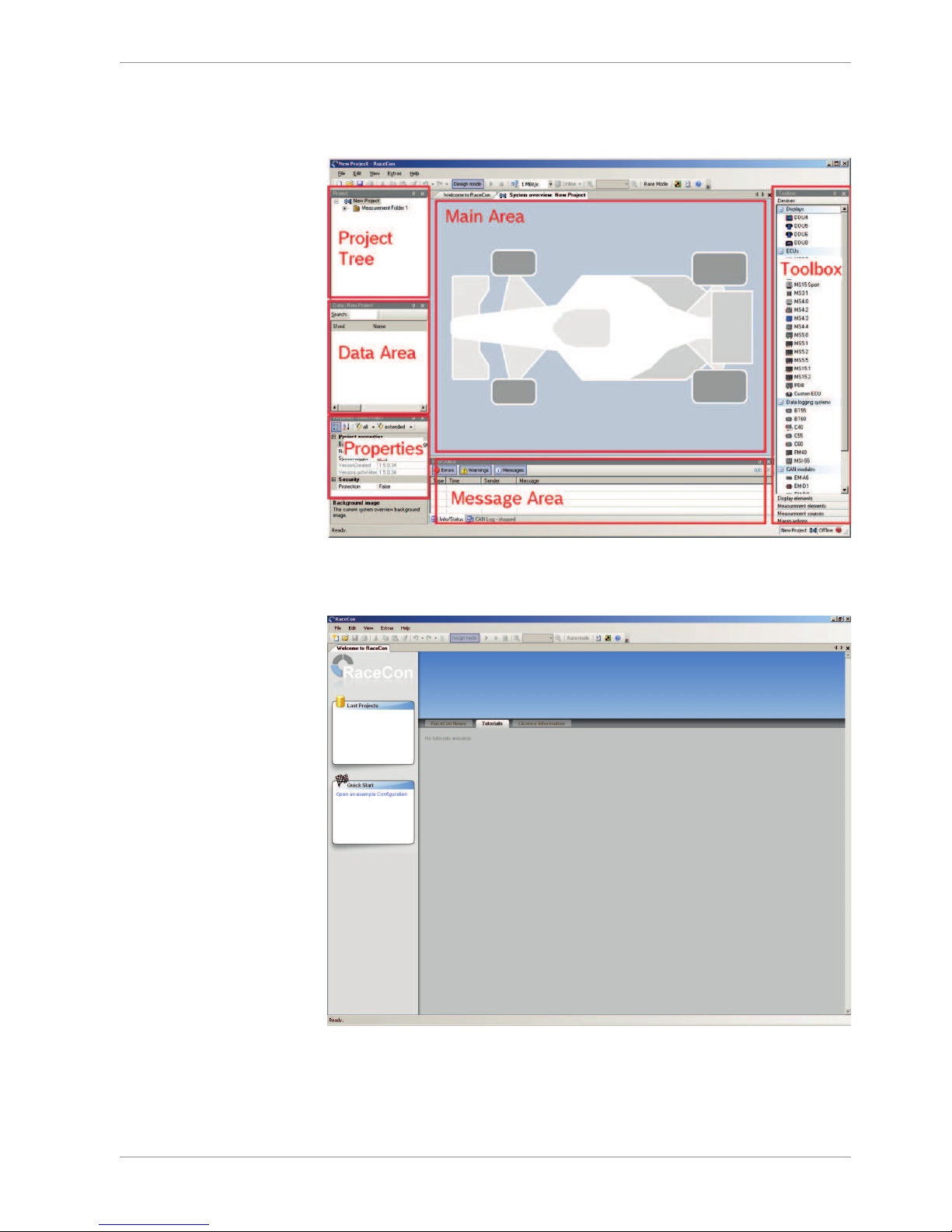

8.1.2 About RaceCon

RaceCon is an all integrated software tool for configuration and calibration of Bosch

Motorsport hardware products. It is used to set up, configure and calibrate the C 60.

For better understanding, Bosch Motorsport offers a video tutorial that explains many

functions of RaceCon. The video tutorial is available in the ‘Software Download’ section of

www.bosch-motorsport.com.

Page 23

Starting up the C 60 | 8

Bosch Motorsport Data Logger C 60 23/108

8.1.3 Connecting the Unit to RaceCon

The following screenshot shows an overview of the RaceCon Main Screen with its areas.

All (sub-) windows are resizable and dockable.

1. Start the RaceCon software.

Page 24

8 | Starting up the C 60

24/108 Data Logger C 60 Bosch Motorsport

In the ‘File’ menu select ‘New’ to create a new project.

In the Toolbox select the C 60 and drag it into the Main Area. A pop up window to specify

the C 60 program archive appears.

1. An information shows that the archive is valid or not.

Select the program archive delivered with the C 60 (.PST file).

Click ‘Next’.

1. Select ‘Race track’.

2. Choose the way to switch display pages that fits to your hardware configuration.

3. Click ‘Finish’. The C 60 is inserted into the project and RaceCon tries to connect to the

device.

4. RaceCon detects configuration differences between the C 60 and the RaceCon project

and asks for permission for data download.

5. Click ‘OK’ to proceed.

The download starts and the C 60 carries out a reset.

After the reset RaceCon reconnects to the C 60. Local configuration on both the PC and C

60 match (Indicated by green background and dot). The C 60 is now connected to RaceCon.

Page 25

Starting up the C 60 | 8

Bosch Motorsport Data Logger C 60 25/108

8.2 Feature activation

– Optional software feature packages are available for the C 60 If you have purchased

an optional software feature package, it must be activated before it becomes operational.

– The feature activation status is stored permanently in the device and requires activat-

ing once only.

– As the activation key is device specific, a key delivered with one C 60 does not work

on any other C 60 .

– If you have not purchased an option package, the next steps can be skipped.

To activate a feature, double-click on ‘C 60’ in the Project Tree and click on the ‘Features

info’ tab in the Main Area.

The ‘C 60 features info’ window appears.

Double-click on the feature you want to activate. A feature unlock window appears.

Enter the activation key you received for this feature on this device and click ‘OK’ when

done. The feature’s status changes to ‘unlocked’.

Perform these steps to activate other features you purchased.

Switch the car’s ignition off and on again to cycle the power of C 60.

8.3 First recording (Quick start)

This chapter explains the configuration of the recording of the battery voltage channel.

See chapter ‘Recording and Telemetry [}79]’ for a detailed instruction to configure recordings.

This function requires the installation of Software Upgrade 1. For data recording on the C

60 , the software upgrade ‘C 60 Datalogger’ must be activated. See chapter ‘Feature activation’ for an instruction to activate software upgrades on C 60.

1. Expand the C 60 Project Tree by clicking ‘+’.

2. Expand the Logger Tree by clicking ‘+’.

3. Double-click on ‘Recording’.

4. The C 60 recording configuration area opens.

In C 60 Project Tree, click on ‘C 60’ to display the available measurement channels. In the

data window, scroll down to ‘ub’ (measurement channel for battery voltage).

Drag + drop the ‘ub’ measurement channel into the recording area.

Right-click on ‘C 60’ in the C 60 Project Tree and choose ‘Download configuration’.

The configuration download starts and the C 60 carries out a reset.

1. As we did not define global start conditions, recording starts immediately.

2. Start the WinDarab software.

3. Disconnect the C 60 network cable.

4. Click on the ‘Import/Export’ icon.

Page 26

8 | Starting up the C 60

26/108 Data Logger C 60 Bosch Motorsport

5. Select ‘Data logger C50/C55/C60/DDU7/DDU8’ and click ‘OK’ when done.

6. The ‘Read measurement Data’ dialog opens.

7. Click on ‘Modify’ button and select the base folder.

8. Choose ‘FTP’ as data transmission method.

9. Choose ‘XXXXXXXXXXX’ in the Vehicle dropdown list.

10. Activate ‘Auto save’.

11. Click ‘Save’ when done.

Connect the C 60 network cable. Data transmission from the C 60 starts automatically.

Measurement files are stored automatically in the base folder.

1. Click on ‘Close’ when transmission has finished.

2. Click on the Start button and choose ‘Open measurement file’.

3. Select the measurement files from the storage folder.

4. Click on ‘Open’.

5. Click in ‘New Desktop‘ to open a new measurement data window.

6. Drag the ‘ub’ measurement channel from the Channel list and drop it into the measurement data window. ‘ub’ measurement channel‘s graph is displayed.

NOTICE

For more detailed descriptions and instructions refer to the WinDarab V7 manual.

8.4 Status LEDs

Illustration1:

Page 27

Starting up the C 60 | 8

Bosch Motorsport Data Logger C 60 27/108

8.5 Set Time & Date

The C 60 is equipped with a real time clock which is supplied by an internal accumulator.

Once this accumulator is charged correctly by 12 V supply of the C 60, ‘Date & Time’ can

be programmed by RaceCon. We recommend min. 5 hours charge time.

Please connect the C 60 to the PC and click on ‘Set Date & Time’ in the Context menu of

the C 60.

Page 28

9 | CAN Bus

28/108 Data Logger C 60 Bosch Motorsport

9 CAN Bus

C 60 has two fully configurable CAN buses.

– Baudrate (125 kBit … 1 MBit)

– 11 Bit or 29 Bit identifiers

– Input configuration: Read messages from CAN bus and convert to C 60 measure-

ment/display variables. CAN bus supports row counter configuration.

– Output configuration: Write C 60 measurement variables to CAN messages, output

frequency and row counter are configurable, CAN gateway functionality (transfer from

one bus to the other).

9.1 CAN bus trivia

CAN message

– 11 Bit (standard) or 29 Bit (extended) identifier

– Up to 8 bytes of data payload

CAN bus

– Needs termination resistors (120 Ohm) in wiring harness

– All devices connected to the bus must use identical data rate

Configuration of C 60 bus data rate by double click on the CAN bus

in project tree (1 MBaud, 500 kBit, 250 kBit, 125 kBit)

Row counter concept

– Re-use (multiplex) of message identifiers

– One byte of message contains row counter

– 7 bytes payload remaining

– Position of row counter is configurable

Payload Area

Row

Row

Counter

Payload Area

Message

Id

9.2 CAN input

9.2.1 Input configuration

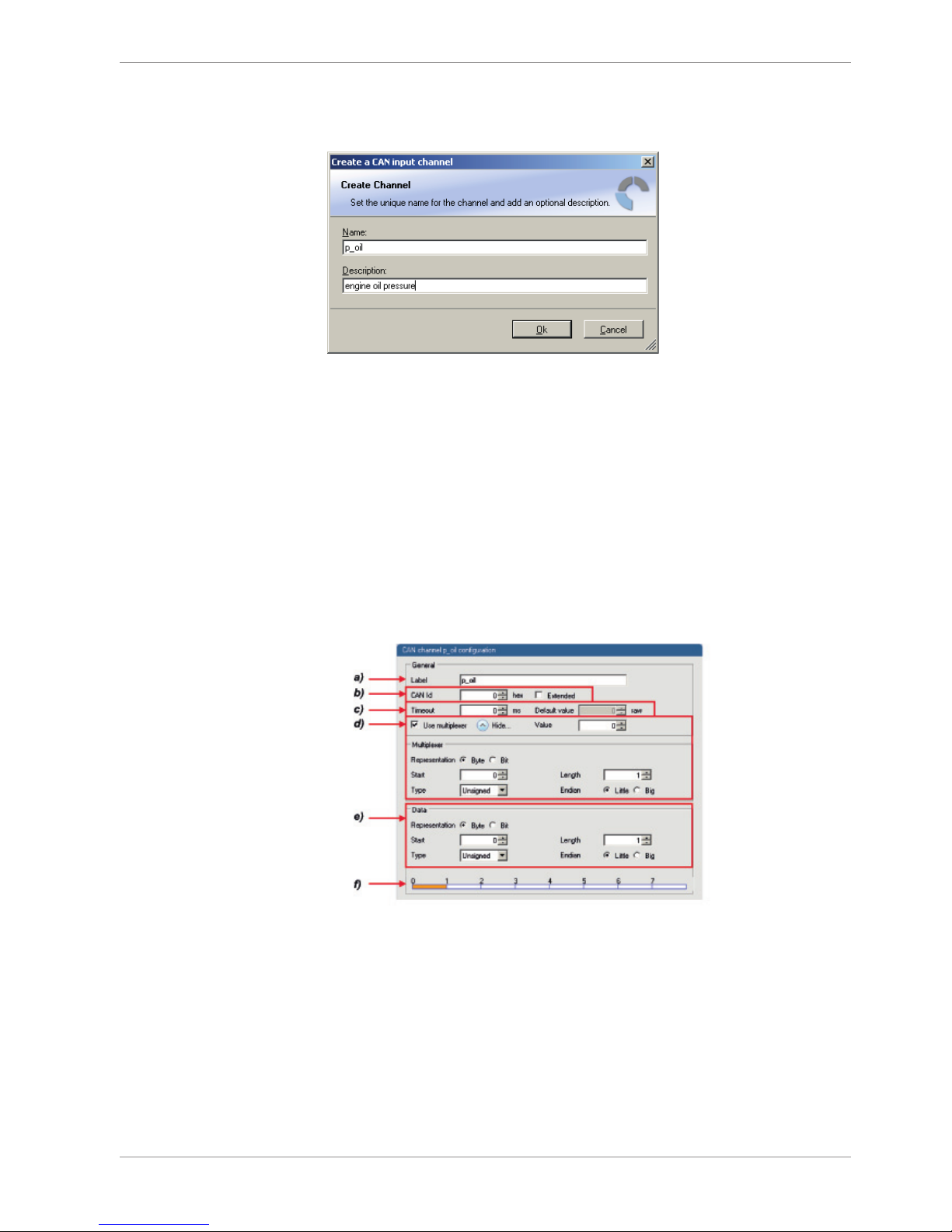

9.2.2 Create a new CAN channel

1. Right-click on CAN Input of desired bus (CAN1 or CAN2).

Page 29

CAN Bus | 9

Bosch Motorsport Data Logger C 60 29/108

2. Select ‘New CAN Channel’ from menu.

3. Insert name and description of channel.

4. Click ‘OK’ when done.

The channel is listed in the Data window and a CAN channel configuration window opens.

9.2.3 CAN channel configuration

9.2.4 Extracting data from CAN bus

Representation: Byte

Some CAN devices need to be addressed by a byte represented CAN channel. The address can be assigned in this window and is illustrated by a bargraph.

a) Enter name of the CAN-channel.

b) Enter CAN message ID. Check the box, if extended IDs (29 bit) are used.

c) If replacement values are used, specify time-out period and raw value.

d) Check the box, if a multiplexer (row counter) is used.

e) Enter data position, length and format.

f) The bargraph shows assignment of the bytes.

• Red colored fields show the assignment of the data bytes.

• Orange colored fields show the assignment of the multiplexer bytes.

Representation: Bit

Some CAN devices need to be addressed by a bit represented CAN channel. The address

can be assigned in this window and is illustrated by a matrix table.

Page 30

9 | CAN Bus

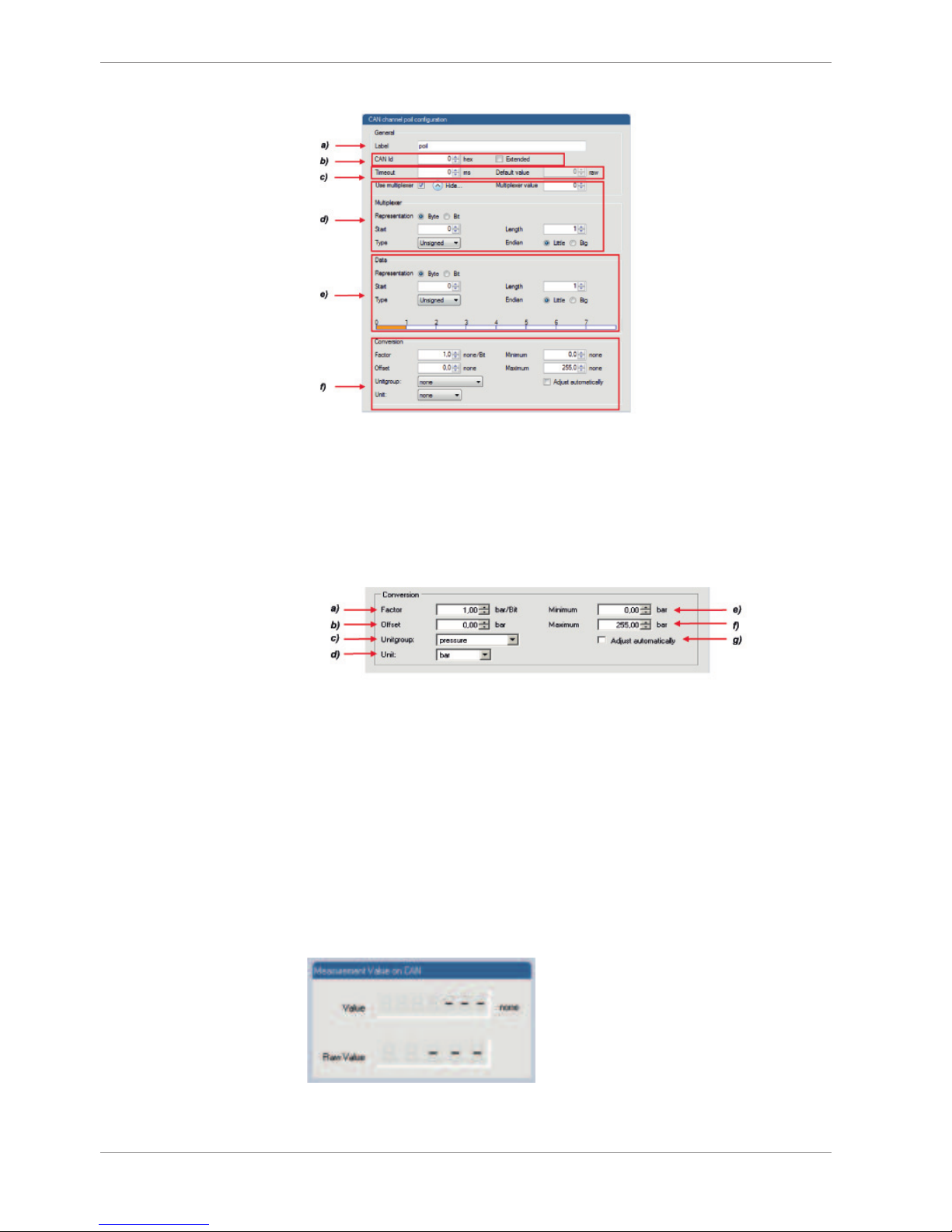

30/108 Data Logger C 60 Bosch Motorsport

a) Enter name of the CAN-channel.

b) Enter CAN message ID. Check the box, if extended IDs (29 bit) are used.

c) If replacement values are used, specify time-out period and raw value.

d) Check the box, if a multiplexer (row counter) is used.

e) Enter data position, length and format. The matrix table shows the assignment of the bits.

f) Enter a Conversation to get physical values

9.2.5 Conversion to physical values

a) Enter factor (gain) for conversion to physical value.

b) Enter offset for conversion to physical value.

c) Select type of physical value.

d) Select unit of physical value.

e) Enter minimum physical limit of the channel. (for manual setup)

f) Enter maximum physical limit of the channel. (for manual setup)

g) Check the box to automatically adjust the limits of the channel.

9.2.6 Special features

CAN analyzer functionality

This functionality is only available, if a MSA-Box (I & II) is used to connect the C 60 to the

PC. Choose the CAN bus that is connected to the MSA-Box to display the raw value and

the converted physical value here.

Page 31

CAN Bus | 9

Bosch Motorsport Data Logger C 60 31/108

Automatic creation of online measurement sheets

The CAN channel can be automatically inserted to a measurement sheet. Insert a name for

a new sheet or select an existing sheet from the listbox.

For an online view of the value measured by the C 60, insert the channel in an online

measurement sheet which is described in the next chapter.

9.2.7 Online view of CAN channels in vehicle

1. Double-click on ‘Sheet 1’ in Project Tree.

Measurement Sheet 1 is displayed in Main Area.

1. Click on ‘Measurement elements’ in the Toolbox.

2. Drag the desired Measurement element (e.g. Numeric Indicator) and drop it on the

Measurement Sheet.

1. Click on folder ‘CAN Input’ of desired CAN bus to display available channels.

2. Drag desired Measurement channel and drop it on the Measurement element.

The measurement element displays the values of the assigned channel.

1. Connect PC to the vehicle and switch to ‘Race Mode’ by clicking ‘F11’ on the keyboard to display online data.

9.2.8 Import a CAN database (DBC) file

1. Right-click on CAN Input of desired bus (CAN1 or CAN2).

2. Select ‘Import DBC file’ from menu.

A file browser opens.

3. Select DBC file to import and click ‘OK’ when done.

A channel import window opens.

Page 32

9 | CAN Bus

32/108 Data Logger C 60 Bosch Motorsport

4. Select desired channels on the left and use the ‘Add’ button to add them to import

list.

5. Click ‘OK’ when complete.

The channels are inserted in the Data window.

9.2.9 Export RaceCon CAN configuration

1. Right-click on CAN Input of desired bus (CAN1 or CAN2).

2. Select ‘Export…’ from menu. An ‘Export Selection’ window opens.

3. Specify the filename.

4. Click ‘OK’ when done.

9.2.10 Import RaceCon CAN configuration

1. Right-click on CAN Input of desired bus (CAN1 or CAN2).

2. Select ‘Import…’ from menu.

A file browser opens.

3. Select the input file and click ‘OK’.

An ‘Import Selection’ window opens.

1. Select channels to import.

2. Drag and drop the channel to ‘CAN Input’ of desired CAN bus on right hand side.

Page 33

CAN Bus | 9

Bosch Motorsport Data Logger C 60 33/108

3. Click ‘Next’.

If a measurement channel belongs to more than one source (e.g. C 60 and ECU MS

5.1), the ‘Solve Label Ambiguity’ window opens.

4. Assign the ambiguous channels to the desired source.

5. Click ‘Finish’.

9.2.11 Export to dbc file

Click on this option to save the CAN configuration to a Vector dbc file format. It will open

an explorer window where the dbc file can be saved on the harddisc.

9.3 CAN output

9.3.1 Output configuratin

9.3.2 Create a new CAN output message channel

1. Right-click on CAN Output of desired bus (CAN1 or CAN2).

2. Select ‘New CAN Message’ from menu.

The ‘Create new CAN message’ window opens.

3. Enter name of message, CAN-Id and Grid (output interval).

4. Optionally, specify a row counter (multiplexer).

5. Click ‘OK’ when done.

A CAN message configuration window opens in the Main Area.

1. Click on ‘C 60’ in the C 60 Project Tree to display all labels.

2. Select the desired measurement channel and drop it on message’s bytes.

The measurement channel is assigned to the CAN message.

A double Click on one of the defined CAN channels opens the following dialogue:

Page 34

9 | CAN Bus

34/108 Data Logger C 60 Bosch Motorsport

In this dialogue additional settings are possible:

– Representation: Also a Bitwise CAN signal can be defined. Please define position and

length in this case.

– Quantization: Physical values can be calculated by entering Factor/Offset. Signed and

unsigned is optional.

9.3.3 Edit CAN Message Multiplexer settings

1. Click “Use multiplexer”, the Option “Hide” opens the multiplexer settings.

Representation: Choose Byte or Bit Type of multiplexer

Start, Length: Define start position and length of multiplexer (Byte or Bitwise possible)

Endianness: Define Byte order (Little Endian –LB, HB, Big Endian –HB, LB)

9.3.4 Export RaceCon CAN configuration

1. Right-click on CAN Output of desired bus (CAN1 or CAN2).

2. Select ‘Export…’ from menu. The ‘Export Selection’ window opens.

3. Specify the filename.

4. Click ‘OK’ when done.

Page 35

CAN Bus | 9

Bosch Motorsport Data Logger C 60 35/108

9.3.5 Import RaceCon configuration

1. Click right on CAN Output of desired bus (CAN1 or CAN2).

2. Select ‘Import…’ from menu.

A file browser opens.

3. Select the input file and click ‘OK’.

An ‘Import Selection’ window opens.

1. Select channels to import.

2. Drag and drop the channel to ‘CAN Output’ of desired CAN bus on right hand side.

3. Click ‘Next’.

If a measurement channel belongs to more than one source (e.g. C 60 and ECU MS

5.1), the ‘Solve Label Ambiguity’ window opens.

1. Assign the ambiguous channels to the desired source.

2. Click ‘Finish’.

Page 36

10 | Analog and Frequency Inputs

36/108 Data Logger C 60 Bosch Motorsport

10 Analog and Frequency Inputs

10.1 Features

24 analog inputs with Software Upgrade 2; 4 analog inputs without upgrade

– 0 … 5 V

– 12 bit A/D converter

– Switchable 3.01 kOhm pull-up resistor

– 8 kHz acquisition rate, up to 1 kHz recording rate

– Linear phase digital filter

4 frequency inputs with Software Upgrade 2; no frequency inputs without upgrade

– 5 V Hall-effect type, 2.5 V trigger level

– 20 kHz max. frequency

– 10 ms measurement window

4 PWM outputs

– Low-side switch

– Up to 2 A each

– Output frequency selectable

10.2 Analog inputs

Measurement channels

For each analog channel, several ‘subchannels’ are available.

Measurement labels with the characters ‘raw’ show the exact values in mV.

Measurement labels with the characters ‘_fi’ show filtered values.

The word ‘name’ in the table is a placeholder for the channel’s name.

Page 37

Analog and Frequency Inputs | 10

Bosch Motorsport Data Logger C 60 37/108

Measurement label Function

raw_name mV value of sensor

raw_name_fi filtered mV value of sensor

name physical value of sensor

name_fi filtered physical value

Filtered channels are routed through digital low pass filters:

– C 60 uses A/D converter oversampling and digital filtering to recording rate

– Digital filters eliminate ‘out-of-band’ noise

– Cut-off frequency automatically adjusted to recording rate

– Linear phase - no signal distortion

– Latency compensation - no filter delay in recorded data

10.2.1 Measurement channels

10.3 Configuring inputs

10.3.1 Configuring a predefined Bosch sensor with the

'Bosch Sensor Wizard'

1. Click on ‘Measurement Sources’ in the Toolbox.

2. Expand the list of ‘I/O Channels’ by clicking on ‘+’ in the C 60 Project Tree.

3. Drag the ‘Bosch Sensor Wizard’ from the Toolbox and drop it on the desired analog

input channel in the C 60 Project Tree. The ‘Bosch Sensor Wizard’ opens.

Page 38

10 | Analog and Frequency Inputs

38/108 Data Logger C 60 Bosch Motorsport

3rd: Select the

exact type

Opens sensor’s

datasheet

2nd: Narrow your

choice by

choosing a type

These calibration

values will be

used

1st: Choose

the sensor’s

category

4. Click ‘Finish’ when done.

5. The ‘Create channel’ window opens.

6. Enter channel name and description.

7. Click ‘Ok’ when done.

The channel is inserted into the C 60 Project Tree.

Calculation of

physical value with

characteristic curve

Input pin

Pull-up

resistor is

activated

Channel

is linked

to

ANA03

Available measurements for channel:

Measurement label Function

raw_name mV value of sensor

raw_name_fi filtered mV value of sensor

name physical value of sensor

name_fi filtered physical value

Page 39

Analog and Frequency Inputs | 10

Bosch Motorsport Data Logger C 60 39/108

10.3.2 Configuring a generic linear sensor

Example: Acceleration sensor 5 g

From sensor data sheet – operating characteristics:

Sensitivity 400 mV/g, Offset 2500 mV

The sensor has a linear output signal with sensitivity and offset

1. Click on ‘Measurement Sources’ in the Toolbox.

2. Expand the list of ‘I/O Channels’ by clicking on ‘+’ in the C 60 Project Tree.

3. Drag the ‘Sensitivity/Offset’ analog signal source from the Toolbox and drop it on the

desired analog input channel in the C 60 Project Tree. A ‘Sensitivity/Offset Wizard’

opens.

4. To activate the internal pullup-resistor, check the box.

The internal pullup-resistor is used to get a 5 V signal at the analog channel of the C

60.

It allows you to use a push-button.

The fixed value of the internal pullup-resistor is 3010 Ohm. If using an additional external pullup-resistor, set up the overall resistance.

5. Click ‘Next’ when done.

The second part of the ‘Sensitivity/Offset Wizard’ opens.

Page 40

10 | Analog and Frequency Inputs

40/108 Data Logger C 60 Bosch Motorsport

Choose unit

group and unit

of physical value

Enter values

from sensor

datasheet

Electrical

(pin) value

Physical

(channel)

value

6. Click ‘Next’ when done. The third part of the ‘Sensitivity/Offset Wizard’ opens.

NOTICE

Working with automatically created measurement sheets is explained in chapter ‘Setting up an online measurement’.

7. Click ‘Finish’ when done.

8. Enter channel name and description.

9. Click ‘OK’ when done.

The channel is inserted into the C 60 Project Tree.

Input pin

Pull-up

resistor is

deactivated

Sensitivity

and Offset

value for

sensor

Adjustment

is enabled

Channel is

linked to

ANA04

Available measurements for channel:

Page 41

Analog and Frequency Inputs | 10

Bosch Motorsport Data Logger C 60 41/108

Measurement label Function

raw_name mV value of sensor

raw_name_fi filtered mV value of sensor

name physical value of sensor

name_fi filtered physical value

10.3.3 Configuring a generic non-linear sensor

Example: Thermistor 5 kOhm

– From sensor data sheet: resistance values over temperature

– The sensor has a nonlinear behaviour

– Use characteristic curve for linearization

– Input voltage is the ratio between pull-up resistor and thermistor

Pin

Thermistor

+5V

3 kOhm

1. Click ‘Measurement Sources’ in the Toolbox.

2. Expand the list of ‘I/O Channels’ by clicking on ‘+’ in the C 60 Project Tree.

3. Drag the ‘Characteristic Curve’ analogue signal source from the Toolbox and drop it

on the desired analogue input channel in the C 60 Project Tree. A ‘Characteristic

Curve Wizard’ opens.

4. To activate the internal pull up-resistor, check the box.

The C 60 pull up-resistor is used to get a 5V signal at the analogue channel of the C

60.

It allows you to use a push-button.

The fixed value of the internal pull up-resistor is 3010 Ohm. If using an additional external pull up-resistor, set up the overall resistance.

Page 42

10 | Analog and Frequency Inputs

42/108 Data Logger C 60 Bosch Motorsport

5. Click ‘Next’ when done.

The second part of the ‘Sensitivity/Offset Wizard’ opens.

Select physical unit.

Physical

(channel)

value

Choose ‘Ohm’ to enter

datasheet values directly.

Enter

resistance/temperature

pairs from sensor datasheet

here (The 3.01 kOhm pullupresistor is automatically

taken into account)

6. Click ‘Next’ when done.

The third part of the ‘Characteristic Curve Wizard’ opens.

Enter physical limits

of the channel

Choose data type of the

measurement variable

This sensor does not

need offset calibration

Physical

limits of

channel

Enter name to

automatically create a new

measurement sheet

NOTICE

Working with automatically created measurement sheets is explained in chapter ‘Setting up an online measurement’.

7. Click ‘Finish’ when done.

8. Enter channel name and description.

Page 43

Analog and Frequency Inputs | 10

Bosch Motorsport Data Logger C 60 43/108

9. Click ‘OK’ when done.

The channel is inserted into the C 60 Project Tree.

Input pin

Pull-up

resistor is

activated

Characteristic

curve for

sensor

Adjustment

is disabled

Channel is

linked to

ANA05

Available measurements for channel:

Measurement label Function

raw_name mV value of sensor

raw_name_fi filtered mV value of sensor

name physical value of sensor

name_fi filtered physical value

10.3.4 Configuring a multipoint adjustment

Example: Measurement of wheel force

– Physical property ‘wheel force’ not directly measureable

– Load transfer through suspension kinematics

– Physical value at sensor position defined by vehicle

– Curve definition by online adjustment at vehicle

1. Click on ‘Measurement Sources’ in the Toolbox.

2. Expand the list of ‘I/O Channels’ by clicking on ‘+’ in the C 60 Project Tree.

3. Drag the ‘Multipoint Adjustment’ analog signal source from the Toolbox and drop it

on the desired analog input channel in the C 60 Project Tree.

4. A ‘Multipoint Adjustment Wizard’ opens.

5. To activate the internal pullup-resistor, check the box.

Page 44

10 | Analog and Frequency Inputs

44/108 Data Logger C 60 Bosch Motorsport

The internal pullup-resistor is used to get a 5 V signal at the analog channel of the C

60.

It allows you to use a push-button.

The fixed value of the internal pullup-resistor is 3010 ohm. If using an additional external pullup-resistor, set up the overall resistance.

6. Click ‘Next’ when done. The second part of the ‘Multipoint Adjustment Wizard’ opens.

7. Click ‘Next’ when done. The third part of the ‘Multipoint Adjustment Wizard’ opens.

Enter physical

limits of the sensor

Choose data type of

the measurement

variable

Enable additonal

online calibration

Physical

limits of

channel

Enter name to

automatically create a new

measurement sheet

NOTICE

Working with automatically created measurement sheet is explained

in chapter ‘Setting up an online measurement’.

Page 45

Analog and Frequency Inputs | 10

Bosch Motorsport Data Logger C 60 45/108

8. Click ‘Finish’ when done.

9. Enter channel name and description.

10. Click ‘OK’ when done.

The channel is inserted into the C 60 Project Tree.

Input pin

Pull-up

resistor is

deactivated

Characteristic

curve for

sensor

Adjustment

is enabled

Channel is

linked to

ANA06

Available measurements for channel:

Measurement label Function

raw_name mV value of sensor

raw_name_fi filtered mV value of sensor

name physical value of sensor

name_fi filtered physical value

Online definition of the curve is covered in the chapter ‘Online calibration of measurement

channels [}73]’ of this manual.

10.3.5 Digital filter details

C 60 uses A/D converter oversampling and digital filtering to recording rate.

Digital filters eliminate ‘out-of-band’ noise

Page 46

10 | Analog and Frequency Inputs

46/108 Data Logger C 60 Bosch Motorsport

Cut-off frequency automatically adjusted to recording rate

Example:

– 100 Hz recording rate (10 ms)

– < 40 Hz pass band (> 99 %)

– 50 Hz stop band (< 1 %)

Linear phase – no signal distortion

0 500 1000 1500 2000 2500 3000

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

Abtastwerte (roh)

Wert

10000Hz Abtastrate

0 5 10 15 20 25 30

-1.5

-1

-0.5

0

0.5

1

1.5

Abtastwerte (gefiltert)

Wert

100Hz Abtastrate

0 5 10 15 20 25 30

-1.5

-1

-0.5

0

0.5

1

1.5

Abtastwerte (dezimiert)

Wert

100Hz Abtastrate

Sensor signal with noise

Recorded signal 100Hz

(unfiltered)

Recorded signal 100Hz

(filtered)

Latency compensation – no filter delay in recorded data

– Filtering is (smart) averaging over several samples

– Filtered signal is delayed with respect to real time signal

– C 60 filters have constant, frequency independent delay

– Delay (e.g. 22 samples at 10 ms) is corrected during recording

– No delay filtered vs. unfiltered in recorded data

– Correction is (of course) not possible for real time data (display, online, PWM out)

– Use filtered data for recording, use unfiltered data for real-time

10.3.6 Configuring a frequency input

This function requires the installation of Software Upgrade 2.

Example: measurement of wheel speed

– Pulse wheel attached to wheel

– Each passing tooth of pulse wheel triggers hall sensor

– Calculation of wheel speed with wheel circumference

Page 47

Analog and Frequency Inputs | 10

Bosch Motorsport Data Logger C 60 47/108

1. Click ‘Measurement Sources’ in the Toolbox.

2. Expand the list of ‘I/O Channels’ by clicking on ‘+’ in the C 60 Project Tree.

3. Drag the ‘Velocity’ digital signal source from the Toolbox and drop it on the desired

‘REV’ input channel in the C 60 Project Tree.

4. The ‘Velocity Wizard’ opens.

Choose data type of the

measurement variable

Circumference of wheel for

speed calculation

Special functionality for sensors

with frequency offset (e.g.

Correvit) Set to ‘0’ for wheelspeed

measurement

Number of teeth on the pulse

wheel

Enter name to automatically

create a new measurement

sheet

5. Click ‘Finish’ when done.

6. Enter channel name and description.

7. Click ‘OK’ when done.

The channel is inserted into the C 60 Project Tree.

Input pin

has hall

interface

Number of

teeth

Wheel

circumference

Channel is

linked to

REV01

Available measurements for channel:

Measurement label Function

raw_name mV value of sensor

raw_name_fi filtered mV value of sensor

name physical value of sensor

name_fi filtered physical value

Page 48

10 | Analog and Frequency Inputs

48/108 Data Logger C 60 Bosch Motorsport

NOTICE

Measurement of ‘Revolution’ is similar.

10.4 Computed sources

10.4.1 Configuring computed sources

Computed sources receive data from a measurement channel rather than an input pin.

– Sensitivity/Offset calculation on input channel

– Characteristic curve calculation on input channel

– Computed vehicle speed

– PWM output control (covered in a special section)

– Lap trigger (covered in a special section)

Example: Sensitivity/offset calculation on input channel

1. Click ‘Measurement Sources’ in the Toolbox.

2. Drag the ‘Sensitivity/Offset’ computed source from the Toolbox and drop it on ‘Computed Channels’ in the C 60 Project Tree.

A ‘Computed Sensitivity/Offset Wizard’ opens.

Choose unit group

a

nd unit of output

Enter sensitivity and offset

o

f conversion formula

Choose input

c

hannel

3. Click ‘Next’ when done.

4. The second part of the ‘Computed Sensitivity/Offset Wizard’ opens.

Page 49

Analog and Frequency Inputs | 10

Bosch Motorsport Data Logger C 60 49/108

Enter physical limits

of the channel

Choose data type of

the measurement

variable

Check the box to force

the channel’s

quantization if the

quantization should be a

fixed value in the whole

CAN system

Physical

limits of

channel

Enter name to

automatically create a new

measurement sheet

NOTICE

Working with automatically created measurement sheets is explained in chapter ‘Setting up an online measurement’.

5. Click ‘Finish’ when done.

6. Enter channel name and description.

7. Click ‘OK’ when done. The channel is inserted into the C 60 Project Tree.

10.5 Hysteresis

The hysteresis function avoids the high-frequent switchover of the measurement channel

value. The hysteresis can be adjusted for each input measurement channel individually

and can be used for further processing.

1. Click ‘Measurement Sources’ in the Toolbox.

2. Drag the ‘Hysteresis’ computed source from the Toolbox and drop it on ‘Computed

Channels’ in the C 60 Project Tree.

A ‘Hysteresis Wizard’ opens.

Page 50

10 | Analog and Frequency Inputs

50/108 Data Logger C 60 Bosch Motorsport

a) Choose input measurement channel.

b) Choose unit group and unit of output.

c) Enter output value of state A in the unit selected in b).

d) Enter threshold value when state changes from A to B.

e) Enter delay time when state changes from A to B.

f) Enter output value of state B in the unit selected in b).

g) Enter threshold value when state changes from B to A.

h) Enter delay time when state changes from B to A.

i) Enter time when the hysteresis function is activated after vehicle’s startup.

j) Enter the channel’s state (A or B) at startup.

3. Click ‘Next’ when done.

The second part of the ‘Hysteresis Wizard’ opens.

4. Click ‘Finish’ when done.

5. Enter channel name and description.

6. Click ‘OK’ when done.

The channel is inserted into the C 60 Project Tree.

Page 51

Analog and Frequency Inputs | 10

Bosch Motorsport Data Logger C 60 51/108

b)

a) Channels available in computed sources.

b) Available measurements for channel.

c) Calculation of hysteresis channel.

a)

c)

10.5.1 Special functionality: vehicle speed

This functionality allows:

– high performance vehicle owners to measure wheel spin under acceleration and

wheel slip/lock under braking.

– calculating vehicle ‘speed over ground’.

Vehicle speed calculation function

– Calculating vehicle speed of 2 wheel drive: (Wheel speeds of non-driven axle as input)

Calculated speed is average of both speeds if speed difference between wheels <

limit.

Calculated speed is maximum of both speeds if speed difference between wheels >

limit.

– Calculating vehicle speed of 4 wheel drive: (Wheel speeds of all wheels as input)

Calculated speed is speed of 2nd fastest wheel.

10.5.2 Setting up calculated speed

1. Click on tab ‘System Overview’.

2. Click on ‘Measurement Sources’ in the Toolbox.

3. Drag the ‘Speed’ computed source from the Toolbox and drop it on ‘Computed

Channels’ in the C 60 Project Tree. Do not drop it on ‘C 60’!

Page 52

10 | Analog and Frequency Inputs

52/108 Data Logger C 60 Bosch Motorsport

Drag + Drop

A ‘Calculated Speed Wizard’ opens.

Choose driven axle

Choose input source

(

internal / external)

Choose individual wheel speed

c

hannels

Set limit for speed difference

f

or calculation

Choose device

4. Click ‘Finish’ when done.

The speed calculation is inserted into the C 60 Project Tree.

Configuration

w

indow

Measurement

c

hannels

c

alculated

s

peed and

c

alculated

d

istance

Speed

c

alculation

i

n DDU 8

P

roject Tree

10.6 Configuring PWM outputs

PWM

– Pulse Width Modulation

– Output frequency is constant

– ‘On time’ (duty cycle) controlled by input channel

Page 53

Analog and Frequency Inputs | 10

Bosch Motorsport Data Logger C 60 53/108

C 60 has 4 PWM outputs

– Low-side switch

– Up to 2 A each

– Selectable output frequency

– Duty cycle controlled by characteristic curve

U

out

Time

Output frequency

Duty cycle 20%

(

switch closed)

Output frequency

Time

U

out

Duty cycle 80%

10.6.1 Configuring a PWM output

1. Click on ‘Measurement Sources’ in the Toolbox.

2. Drag the ‘PWM Out’ computed source from the Toolbox and drop it on the desired

‘PWM_OUT’ channel in the C 60 Project Tree.

3. A ‘PWM Out Wizard’ opens.

Choose output frequency

Define characteristic curve

Choose input

channel

Enter name to

automatically create a new

measurement sheet

Page 54

10 | Analog and Frequency Inputs

54/108 Data Logger C 60 Bosch Motorsport

NOTICE

Working with automatically created measurement sheets is explained in chapter ‘Setting up an online measurement’.

NOTICE

Choosing a filtered channel as an input for ‘PWM_OUT’ will cause

delayed reaction due to the delay introduced by the digital filter.

Use unfiltered values for this purpose.

NOTICE

The ‘power-on’ state of the PWM output is ‘switch open’ (0% duty

cycle).

4. Click ‘Finish’ when done.

5. Enter channel name and description.

6. Click ‘OK’ when done.

The channel is inserted into the C 60 Project Tree.

Characteristic

c

urve

Output

f

requency

Channel is

l

inked to

P

WM_OUT02

Measurement

c

hannels

Measurement label Function

pwm_err_ls_out_01_OL PWM output 1 error open load

pwm_err_ls_out_01_OT PWM output 1 error over temperature

pwm_err_ls_out_01_SCB PWM output 1 error short circuit to battery

pwm_err_ls_out_01_SCG PWM output 1 error short circuit to GND

Table1: Diagnostic channels

NOTICE

The diagnosis of PWM output 2-4 is similar.

Page 55

Analog and Frequency Inputs | 10

Bosch Motorsport Data Logger C 60 55/108

10.7 Analog inputs

10.7.1 Measurement channels

For each analog channel, several ‘subchannels’ are available.

Measurement labels with the characters ‘raw’ show the exact values in mV.

Measurement labels with the characters ‘_fi’ show filtered values.

The word ‘name’ in the table is a placeholder for the channel’s name.

Measurement label Function

raw_name mV value of sensor

raw_name_fi filtered mV value of sensor

name physical value of sensor

name_fi filtered physical value

Filtered channels are routed through digital low pass filters:

– C 60 uses A/D converter oversampling and digital filtering to recording rate

– Digital filters eliminate ‘out-of-band’ noise

– Cut-off frequency automatically adjusted to recording rate

– Linear phase – no signal distortion

– Latency compensation – no filter delay in recorded data

10.8 Configuring inputs

10.8.1 Configuring a predefined Bosch sensor with the

'Bosch Sensor Wizard'

1. Click on ‘Measurement Sources’ in the Toolbox.

2. Expand the list of ‘I/O Channels’ by clicking on ‘+’ in the C 60 Project Tree.

1. Drag the ‘Bosch Sensor Wizard’ from the Toolbox and drop it on the desired analog

input channel in the C 60 Project Tree. The ‘Bosch Sensor Wizard’ opens.

3rd: Select the

exact type

Opens sensor’s

datasheet

2nd: Narrow your

choice by

choosing a type

These calibration

values will be

used

1st: Choose

the sensor’s

category

2. Click ‘Finish’ when done.

Page 56

10 | Analog and Frequency Inputs

56/108 Data Logger C 60 Bosch Motorsport

3. The ‘Create channel’ window opens.

4. Enter channel name and description.

1. Click ‘Ok’ when done.

The channel is inserted into the C 60 Project Tree.

Available measurements for channel:

Measurement label Function

raw_name mV value of sensor

raw_name_fi filtered mV value of sensor

name physical value of sensor

name_fi filtered physical value

10.8.2 Configuring a generic linear sensor

Example: Acceleration sensor 5 g

From sensor data sheet – operating characteristics:

Sensitivity 400 mV/g, Offset 2500 mV

The sensor has a linear output signal with sensitivity and offset

1. Click on ‘Measurement Sources’ in the Toolbox.

2. Expand the list of ‘I/O Channels’ by clicking on ‘+’ in the C 60 Project Tree.

3. Drag the ‘Sensitivity/Offset’ analog signal source from the Toolbox and drop it on the

desired analog input channel in the C 60 Project Tree. A ‘Sensitivity/Offset Wizard’

opens.

4. To activate the internal pullup-resistor, check the box.

The internal pullup-resistor is used to get a 5 V signal at the analog channel of the C

60.

It allows you to use a push-button.

The fixed value of the internal pullup-resistor is 3010 Ohm. If using an additional external pullup-resistor, set up the overall resistance.

Page 57

Analog and Frequency Inputs | 10

Bosch Motorsport Data Logger C 60 57/108

5. Click ‘Next’ when done.

The second part of the ‘Sensitivity/Offset Wizard’ opens.

Choose unit

group and unit

of physical value

Enter values

from sensor

datasheet

Electrical

(pin) value

Physical

(channel)

value

6. Click ‘Next’ when done. The third part of the ‘Sensitivity/Offset Wizard’ opens.

NOTICE

Working with automatically created measurement sheets is explained in chapter ‘Setting up an online measurement’.

7. Click ‘Finish’ when done.

8. Enter channel name and description.

9. Click ‘OK’ when done.

Page 58

10 | Analog and Frequency Inputs

58/108 Data Logger C 60 Bosch Motorsport

The channel is inserted into the C 60 Project Tree.

Available measurements for channel:

Measurement label Function

raw_name mV value of sensor

raw_name_fi filtered mV value of sensor

name physical value of sensor

name_fi filtered physical value

10.8.3 Configuring a generic non-linear sensor

Example: Thermistor 5 kOhm

– From sensor data sheet: resistance values over temperature

– The sensor has a nonlinear behaviour

– Use characteristic curve for linearization

– Input voltage is the ratio between pull-up resistor and thermistor

Pin

Thermistor

+5V

3 kOhm

1. Click ‘Measurement Sources’ in the Toolbox.

2. Expand the list of ‘I/O Channels’ by clicking on ‘+’ in the C 60 Project Tree.

3. Drag the ‘Characteristic Curve’ analogue signal source from the Toolbox and drop it

on the desired analogue input channel in the C 60 Project Tree. A ‘Characteristic

Curve Wizard’ opens.

4. To activate the internal pull up-resistor, check the box.

The C 60 pull up-resistor is used to get a 5V signal at the analogue channel of the C

60.

It allows you to use a push-button.

The fixed value of the internal pull up-resistor is 3010 Ohm. If using an additional external pull up-resistor, set up the overall resistance.

Page 59

Analog and Frequency Inputs | 10

Bosch Motorsport Data Logger C 60 59/108

5. Click ‘Next’ when done.

The second part of the ‘Sensitivity/Offset Wizard’ opens.

Select physical unit.

Physical

(channel)

value

Choose ‘Ohm’ to enter

datasheet values directly.

Enter

resistance/temperature

pairs from sensor datasheet

here (The 3.01 kOhm pullupresistor is automatically

taken into account)

6. Click ‘Next’ when done.

The third part of the ‘Characteristic Curve Wizard’ opens.

Enter physical limits

of the channel

Choose data type of the

measurement variable

This sensor does not

need offset calibration

Physical

limits of

channel

Enter name to

automatically create a new

measurement sheet

NOTICE

Working with automatically created measurement sheets is explained in chapter ‘Setting up an online measurement’.

7. Click ‘Finish’ when done.

8. Enter channel name and description.

Page 60

10 | Analog and Frequency Inputs

60/108 Data Logger C 60 Bosch Motorsport

9. Click ‘OK’ when done.

The channel is inserted into the C 60 Project Tree.

Available measurements for channel:

Measurement label Function

raw_name mV value of sensor

raw_name_fi filtered mV value of sensor

name physical value of sensor

name_fi filtered physical value

10.8.4 Configuring a multipoint adjustment

Example: Measurement of wheel force

– Physical property ‘wheel force’ not directly measureable

– Load transfer through suspension kinematics

– Physical value at sensor position defined by vehicle

– Curve definition by online adjustment at vehicle

1. Click on ‘Measurement Sources’ in the Toolbox.

2. Expand the list of ‘I/O Channels’ by clicking on ‘+’ in the C 60 Project Tree.

3. Drag the ‘Multipoint Adjustment’ analog signal source from the Toolbox and drop it

on the desired analog input channel in the C 60 Project Tree.

4. A ‘Multipoint Adjustment Wizard’ opens.

5. To activate the internal pullup-resistor, check the box.

The internal pullup-resistor is used to get a 5 V signal at the analog channel of the C

60.

It allows you to use a push-button.

The fixed value of the internal pullup-resistor is 3010 ohm. If using an additional external pullup-resistor, set up the overall resistance.

Page 61

Analog and Frequency Inputs | 10

Bosch Motorsport Data Logger C 60 61/108

6. Click ‘Next’ when done. The second part of the ‘Multipoint Adjustment Wizard’ opens.

7. Click ‘Next’ when done. The third part of the ‘Multipoint Adjustment Wizard’ opens.

Enter physical

limits of the sensor

Choose data type of

the measurement

variable

Enable additonal

online calibration

Physical

limits of

channel

Enter name to

automatically create a new

measurement sheet

NOTICE

Working with automatically created measurement sheet is explained

in chapter ‘Setting up an online measurement’.

8. Click ‘Finish’ when done.

9. Enter channel name and description.

10. Click ‘OK’ when done.

The channel is inserted into the C 60 Project Tree.

Page 62

10 | Analog and Frequency Inputs

62/108 Data Logger C 60 Bosch Motorsport

Available measurements for channel:

Measurement label Function

raw_name mV value of sensor

raw_name_fi filtered mV value of sensor

name physical value of sensor

name_fi filtered physical value

Online definition of the curve is covered in the chapter ‘Online calibration of measurement

channels [}73]’ of this manual.

10.8.5 Digital filter details

C 60 uses A/D converter oversampling and digital filtering to recording rate.

Digital filters eliminate ‘out-of-band’ noise

Cut-off frequency automatically adjusted to recording rate

Example:

– 100 Hz recording rate (10 ms)

– < 40 Hz pass band (> 99 %)

– 50 Hz stop band (< 1 %)

Page 63

Analog and Frequency Inputs | 10

Bosch Motorsport Data Logger C 60 63/108

Linear phase – no signal distortion

0 500 1000 1500 2000 2500 3000

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

Abtastwerte (roh)

Wert

10000Hz Abtastrate

0 5 10 15 20 25 30

-1.5

-1

-0.5

0

0.5

1

1.5

Abtastwerte (gefiltert)

Wert

100Hz Abtastrate

0 5 10 15 20 25 30

-1.5

-1

-0.5

0

0.5

1

1.5

Abtastwerte (dezimiert)

Wert

100Hz Abtastrate

Sensor signal with noise

Recorded signal 100Hz

(unfiltered)

Recorded signal 100Hz

(filtered)

Latency compensation – no filter delay in recorded data

– Filtering is (smart) averaging over several samples

– Filtered signal is delayed with respect to real time signal

– C 60 filters have constant, frequency independent delay

– Delay (e.g. 22 samples at 10 ms) is corrected during recording

– No delay filtered vs. unfiltered in recorded data

– Correction is (of course) not possible for real time data (display, online, PWM out)