Page 1

BEG/PJ-IOT-C MAY 2020

Bosch AGV Control

System

Cloud Robotics

Page 2

What is Bosch

AGV Control System?

Page 3

Bosch Engineering | BEG/PJ-IOT | 2020-05

© Bosch Engineering GmbH 2018. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distrib ution, as well as in the event of applications for industrial property rights.

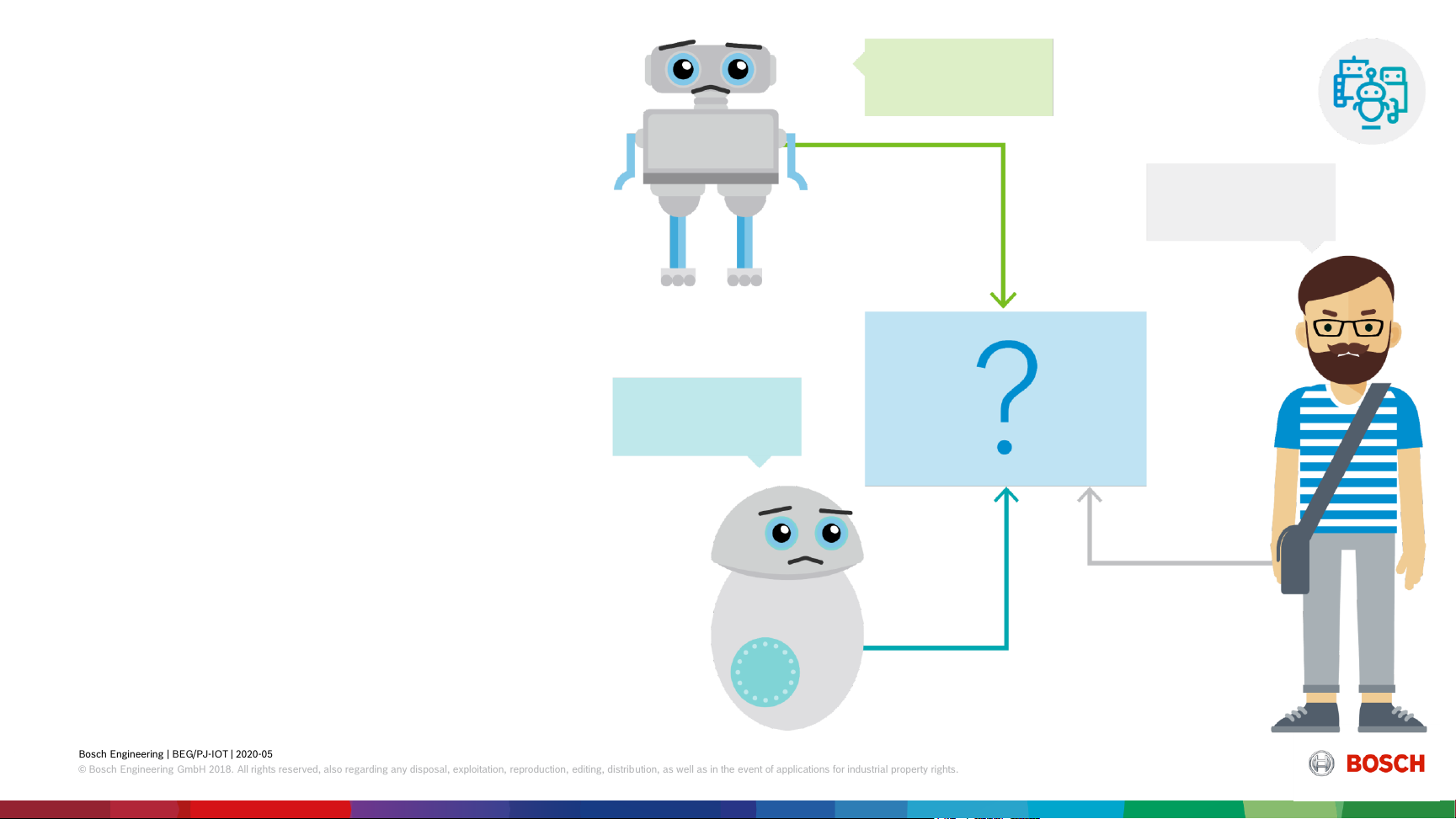

Why AGV Control System?

AGV Control System

3

There are lots of different robot manufacturers on the market

with a great variety of functionalities. As a customer, you

have to buy several types of mobile robots from separate

manufacturers to cover all requirements originating from

various use cases. This leads to the problem that robots can-

not cooperate with one another because they cannot

communicate with robots from other manufacturers due to

each using different platforms, systems and standards.

That is why a centralized mission control and fleet manage-

ment platform is needed to connect mobile robots so they can

communicate with one another allowing them to intelligently

cooperate to solve sophisticated tasks. This leads to profit in-

crease to the customer because of: reduced operation cost,

reduced human error, increased uptime, increased efficiency.

Ce???

Quoi??

Go Charging!

Robot “Bambi“

Robot Type B

Robot “Collins“

Robot Type A

Page 4

Bosch Engineering | BEG/PJ-IOT | 2020-05

© Bosch Engineering GmbH 2018. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distrib ution, as well as in the event of applications for industrial property rights.

4

Bosch AGV Control System is

a platform that connects mobile

robots from different manufacturers to

communicate with one another

allowing them to intelligently coope-

rate to solve sophisticated tasks.

Page 5

Bosch Engineering | BEG/PJ-IOT | 2020-05

© Bosch Engineering GmbH 2018. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distrib ution, as well as in the event of applications for industrial property rights.

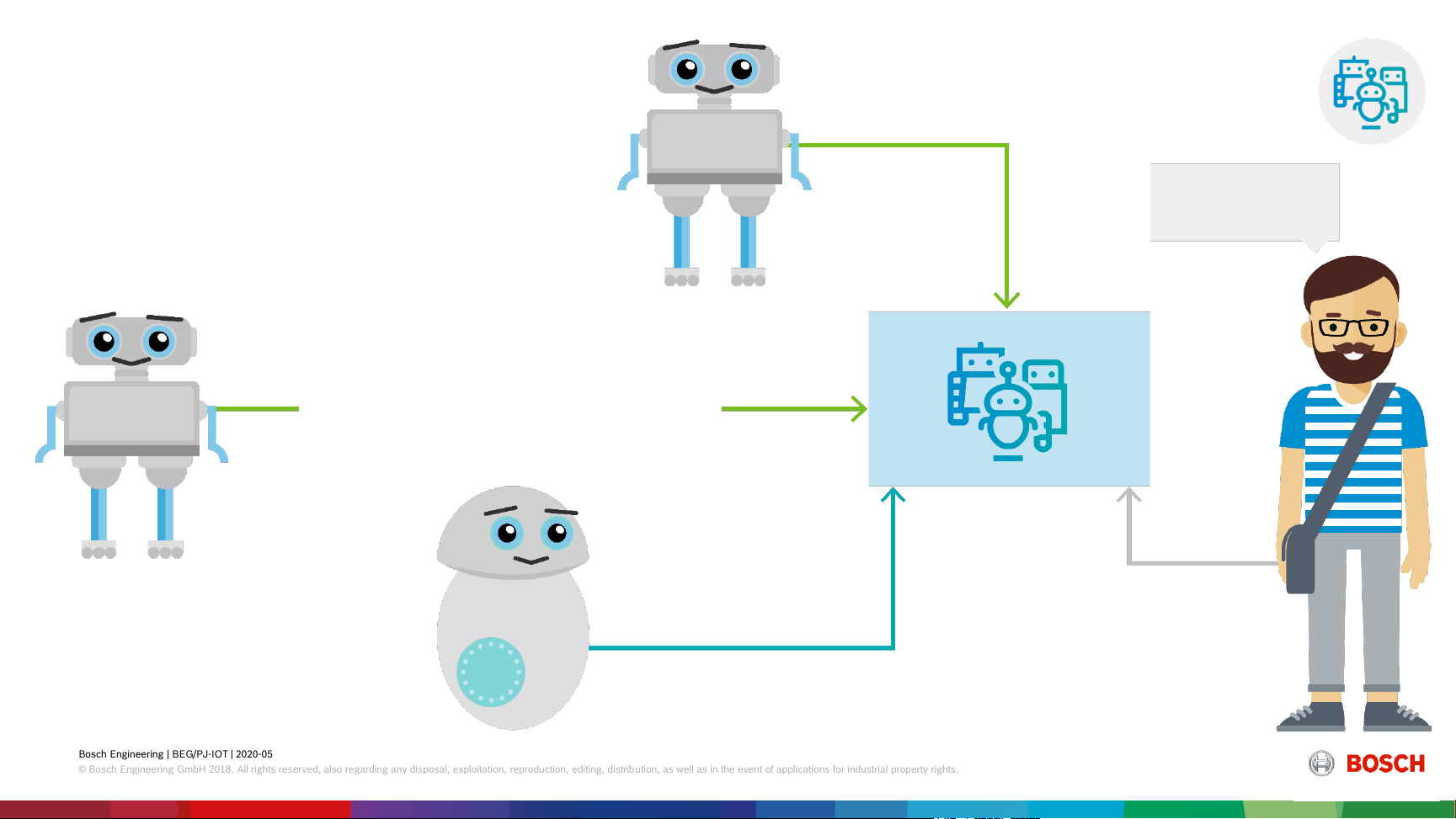

How does it work?

AGV Control System

5

Fahrt zum Laden

Robot

“Pocahontas“

Robot Type B

Robot “Bambi“

Robot Type B

Robot “Collins“

Robot Type A

Robot Management

Service

Bosch has developed a robot management service that can

read and translate actions and messages in both directions!

The translation of generic system actions

that can be triggered by the system or the

user through the interface results in a

specific action for each robot type.

The translation of raw robot messages,

written in its native language, into Bosch

AGV Control System compatible generic

messages.

Page 6

Bosch Engineering | BEG/PJ-IOT | 2020-05

© Bosch Engineering GmbH 2018. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distrib ution, as well as in the event of applications for industrial property rights.

How does it work?

AGV Control System

6

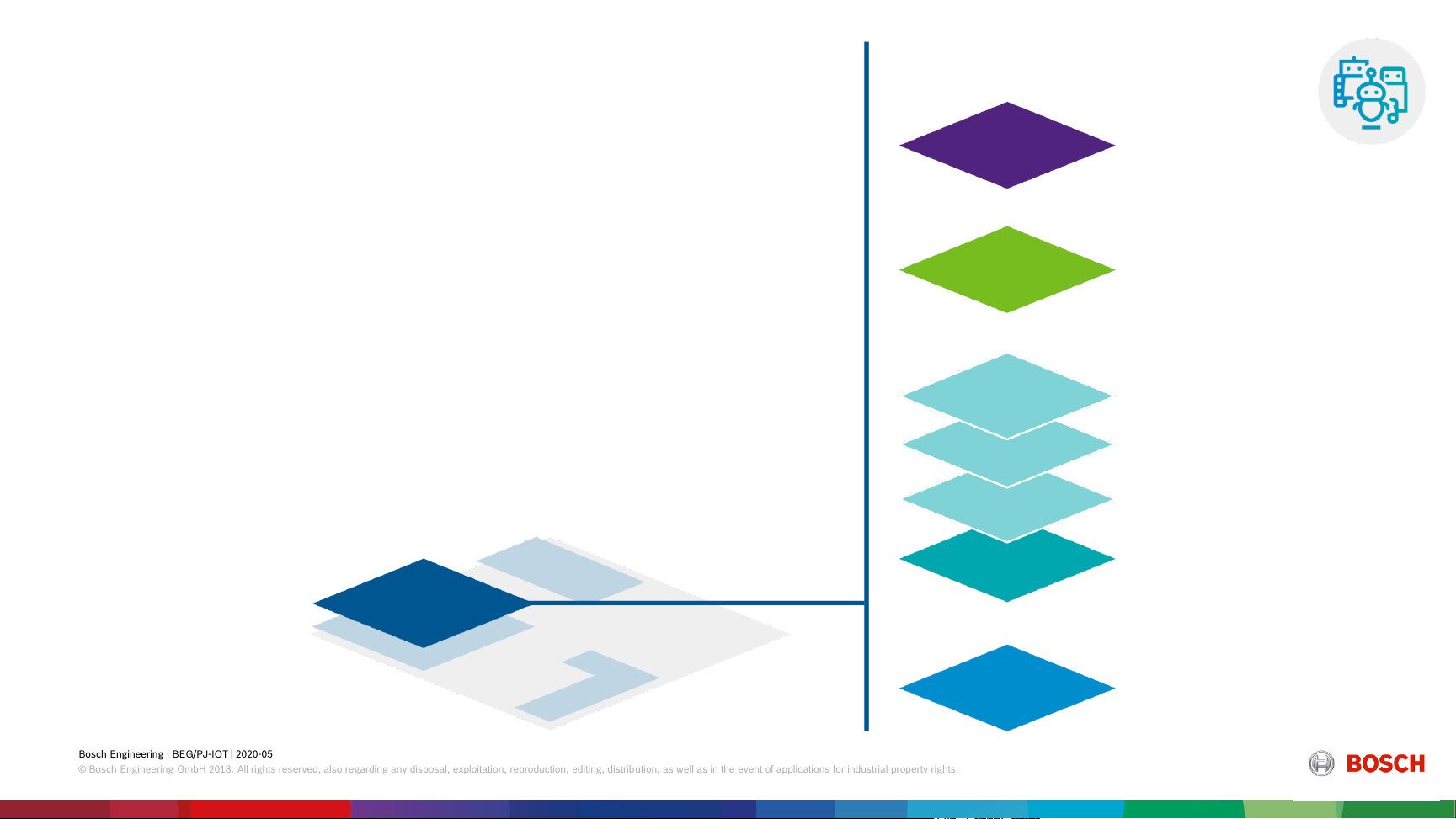

The system is based on different map types, which serve as

references for the robots so that they can locate themselves

indoors and outdoors. Because Bosch AGV Control System

can coordinate and manage robot types from different

manufac-turers in one tool, each type requires a specific

reference map. Sectors have to be created so that all robots

moving in the same area can communicate with one another

in spite of dis-tinct maps. Sectors define the accessible area

by grouping robots and their associated reference maps.

Sector A

Sector B

Sector C

Map Layers in Sector A

Wifi Heat Map

Path Network Map

Laser Maps

Blueprint Map

Geographical Map

Page 7

Bosch Engineering | BEG/PJ-IOT | 2020-05

© Bosch Engineering GmbH 2018. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distrib ution, as well as in the event of applications for industrial property rights.

How does it work?

AGV Control System

7

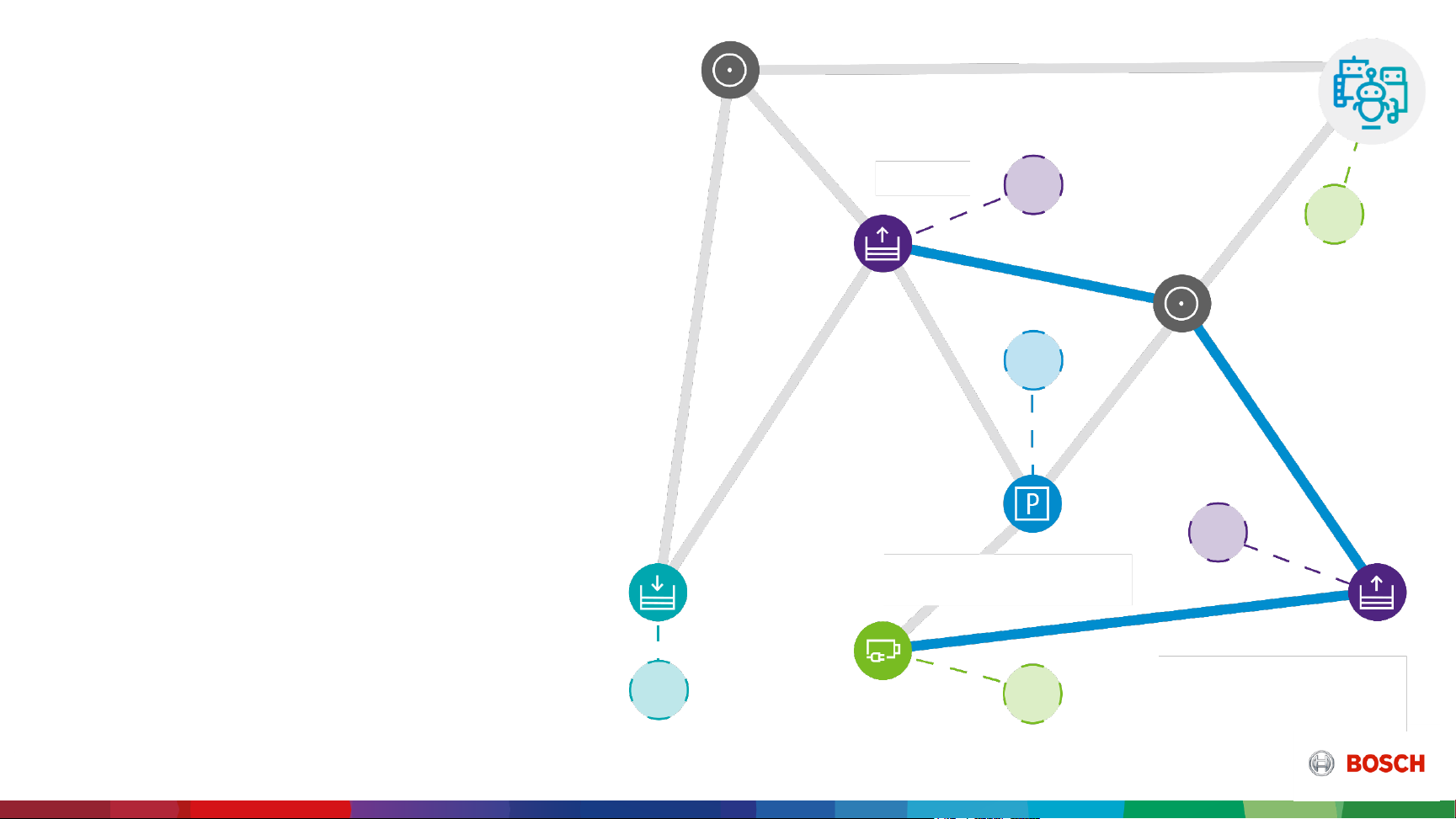

These maps later can be used to create a path network that

applies to the entire sector. All robots in this sector operate in

a common network.

Path elements have specific capabilities (pick up, drop off,

charge, etc). Each robot type also possesses different capa-

bilities to complete various actions. Therefore the actions

of one path element can only be completed by a specific robot

type with the corresponding capabilities.

When the user now starts a job, the intelligent fleet manage-

ment considers the path network to find the shortest path and

the closest robot with the fitting capabilities to complete the

job. This way it is guaranteed that jobs are always completed

in the fastest and most efficient way.

Souce_01

Charging_Station_01

Capability: Plugin Charger

Job Source_01 to

Charging station_01

Requirement: Plugin Charging

Page 8

Bosch Engineering | BEG/PJ-IOT | 2020-05

© Bosch Engineering GmbH 2018. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distrib ution, as well as in the event of applications for industrial property rights.

How does it work?

AGV Control System

8

Type A Profile

Related Robots

“Collins“

Robot Class Wallees

Capabilities Pick up,

Drop off, Flying, Plugin

Charger

Type B Profile

Related Robots

“Pocahontas“, “Bambi“

Robot Class Wallees

Capabilities Pick up,

Drop off, Swimming,

Inductive Charger

Souce_01

Charging_Station_01

Capability: Plugin Charger

Job Source_01 to

Charging station_01

Requirement: Plugin Charging

Page 9

Bosch Engineering | BEG/PJ-IOT | 2020-05

© Bosch Engineering GmbH 2018. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distrib ution, as well as in the event of applications for industrial property rights.

Role Management

AGV Control System

9

The Viewer

The Viewer is only enabled

to view the current state. He

is not allowed to make any

changes.

The Executer

The Executer is authorized

to execute and cancel jobs.

The Planner

The planner is responsible

for planning maps and jobs,

registering robots and their

overall administration.

The Manager

The manager represents

the administrative role

within the application.

Page 10

Bosch Engineering | BEG/PJ-IOT | 2020-05

© Bosch Engineering GmbH 2018. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distrib ution, as well as in the event of applications for industrial property rights.

Customer Journey

AGV Control System

10

01 // Create a Sector

02 // Register a new Robot

03 // Create a new layer

04 // Set up a path network

Page 11

Bosch Engineering | BEG/PJ-IOT | 2020-05

© Bosch Engineering GmbH 2018. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distrib ution, as well as in the event of applications for industrial property rights.

Customer Journey

AGV Control System

11

05 // Define a job template

06 // Execute a job template

07 // Information of executed jobs

Page 12

What our solution

looks like…

Page 13

Bosch Engineering | BEG/PJ-IOT | 2020-05

© Bosch Engineering GmbH 2018. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distrib ution, as well as in the event of applications for industrial property rights.

Feature Overview

AGV Control System

13

General Settings

Admiral Maps + Layers

Map View

Sector Management

Cross-System Settings

Notifications Overview

User Profile Mngmt.

User Role Mngmt,

Overview of all Robots

Register Robots from

multiple brands

Mng.Robots Relation-

ships with the system

Overview of all

integrated map layers

Create new map layer

with many map types

Monitoring Maps (Path

Network, Laser Map…)

Monitoring Robots (Job

Execution, State …)

Robot Manual Control

Robot Live Video Stream

Map View Toolbar (Mng.

Map Layers + View)

Mini Map View

Map Layer Mngmt.

Live map update by realtime experience of robots

Notifications History

Already Developed

Not Yet Developed

Page 14

Bosch Engineering | BEG/PJ-IOT | 2020-05

© Bosch Engineering GmbH 2018. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distrib ution, as well as in the event of applications for industrial property rights.

Feature Overview

AGV Control System

14

Robots

Job Library Jobs

Reporting

Path Editor

Overview of all registered Robots in the sector

Detailed Robot Information about current state

Edit Robot Information +

Settings

Overview of all

generated job templates

Executing of existing job

template

Create new standart Job

Template

Create new complexe

Job Template

Edit / Delete existing Job

Template

Priorization of Jobs

Automated job allocation,

scheduling and execution

Intelligent Job planning &

optimization

Information about current

state of job execution

Job History (Job

Recordings, Infos…)

Regularly generated

reports

Analytics tool for

visualizing operational

data (jobs, routes, etc.)

Creating PDF Exports

Diagnostic Data

Overview of all set

Path Elements

Detailed Info of all

Path Elements

Path Editor Toolbar for

setting new Elements

Edit Mode Map View

Edit Information of

existing Path Element

Set a designated robot /

repetition for execution

Overview of pending &

executing jobs

Page 15

Bosch Engineering | BEG/PJ-IOT | 2020-05

© Bosch Engineering GmbH 2018. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distrib ution, as well as in the event of applications for industrial property rights.

Path Editor Tools

AGV Control System

15

Way Point

Source Point

Sink Point

Charging Point

Parking Point

Zones

Unidirectional Path

Bidirectional Path

Vestibules

Text Label

IoT Device

Adjusting Layers

Page 16

Bosch Engineering | BEG/PJ-IOT | 2020-05

© Bosch Engineering GmbH 2018. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distrib ution, as well as in the event of applications for industrial property rights.

Robot Section

AGV Control System

16

It provides an overview as well as detailed

information for all registered robots in the

opened sector.

Search Field

Robot Current Information

Robot State

Page 17

Bosch Engineering | BEG/PJ-IOT | 2020-05

© Bosch Engineering GmbH 2018. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distrib ution, as well as in the event of applications for industrial property rights.

Job Library Section

AGV Control System

17

The Job Library Section gives an overview of

all already created job templates. Job tem-

plates contain all information about a job and

can be created once and executed several

times.

Search Field

Job Template Species

Job Template Information

Create new Template

Quick Selection Job Execution

Page 18

Bosch Engineering | BEG/PJ-IOT | 2020-05

© Bosch Engineering GmbH 2018. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distrib ution, as well as in the event of applications for industrial property rights.

Job Section

AGV Control System

18

This section provides an overview and detailed

information about all current, pending, and

already executed jobs. Job Templates can be

executed as well.

Search Field

Job Information

Job History

Direct Job Execution

Job State

Page 19

Text Label

Path Point Base

Path Points

Edit Mode Tool

IoT Device

Direction &

Bidirectional Path

Vestibules

Map Origin

Zones

Multi Capability

Point

AGV Control System

Path Editor

Path Editor

Toolbar

Page 20

Happy Fleet Management

Cloud Robotics Team!

Page 21

Bosch Engineering | BEG/PJ-IOT | 2020-05

© Bosch Engineering GmbH 2018. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distrib ution, as well as in the event of applications for industrial property rights.

21

Contact for further information

AGV Control System

Jürgen Sojka

Project Manager

Tel. +49 7062 911 1984

Mobile +49 152 549 805 12

Juergen.Sojka2@de.bosch.com

Jordi Bas

Product Owner

Tel. +49 711 811 14410

Mobile +49 173 860 765 1

Jordi.Bas@de.bosch.com

David Lenhart

Technology & Engineering

Tel. +49 7062 911 7147

Mobile +49 173 609 309 9

David.Lenhart@de.bosch.com

Anna-Lena Borck

UX/UI Concept & Design

Tel. +49 7062 911 7147

Mobile +49 173 566 749 8

Anna-Lena.Borck@de.bosch.com

Loading...

Loading...