Bosch ACS 753, ACS 763, ACS 863 Repair Instructions

ACS 753 - ACS 763 - ACS 863

en

Repair instruction

A/C Service Unit

ACS 753, ACS 763, ACS 863 Service Manual

Robert Bosch GmbH

Franz-Oechsle-Straße 4

1119D-73201 Plochingen

SERVICE: bosch.prueftechnik@bosch.com

© Robert Bosch GmbH

SP00D00609 2018-03-26 Robert Bosch GmbH

2

ACS 753, ACS 763, ACS 863 Service Manual

Table of ConTenTs

Safety Warnings ...................................................................................................4

Introduction .......................................................................................................... 8

Introduction ........................................................................................................................ 9

UnitSpecications .......................................................................................................... 20

Maintenance Schedule .................................................................................................... 22

Diagnostics and Testing .................................................................................... 23

Diagnostics and Testing ................................................................................................. 28

Depressurizing the Unit .................................................................................................. 40

Troubleshooting .............................................................................................................. 41

Error Messages ................................................................................................................ 54

Electrical System Operation and Repair .......................................................... 57

Electrical System Repair ................................................................................................. 65

Plumbing and Mechanical System Operation and Repair .............................. 72

Plumbing and Mechanical System Repair .................................................................... 75

Component Application Charts ...................................................................................... 85

Flow Diagrams ................................................................................................................. 87

Main Component Descriptions ....................................................................... 106

Notes ................................................................................................................. 109

Functional Check ............................................................................................................. 24

Electrical System Operation ........................................................................................... 58

Plumbing and Mechanical System Operation ............................................................... 73

3

SP00D00609 2018-03-26Robert Bosch GmbH

ACS 753, ACS 763, ACS 863 Service Manual

Safety Warnings

Explanation of Safety Signal Words Used in this Manual

Safety signal words designate the degree, or level, of hazard seriousness.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result

in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury.

CAUTION: Used without the safety alert symbol indicates a potentially hazardous situation which,

if not avoided, may result in property damage.

These safety messages cover situations Bosch is aware of. Bosch cannot know, evaluate, or

advise you as to all possible hazards. You must verify that conditions and procedures do not

jeopardize your personal safety.

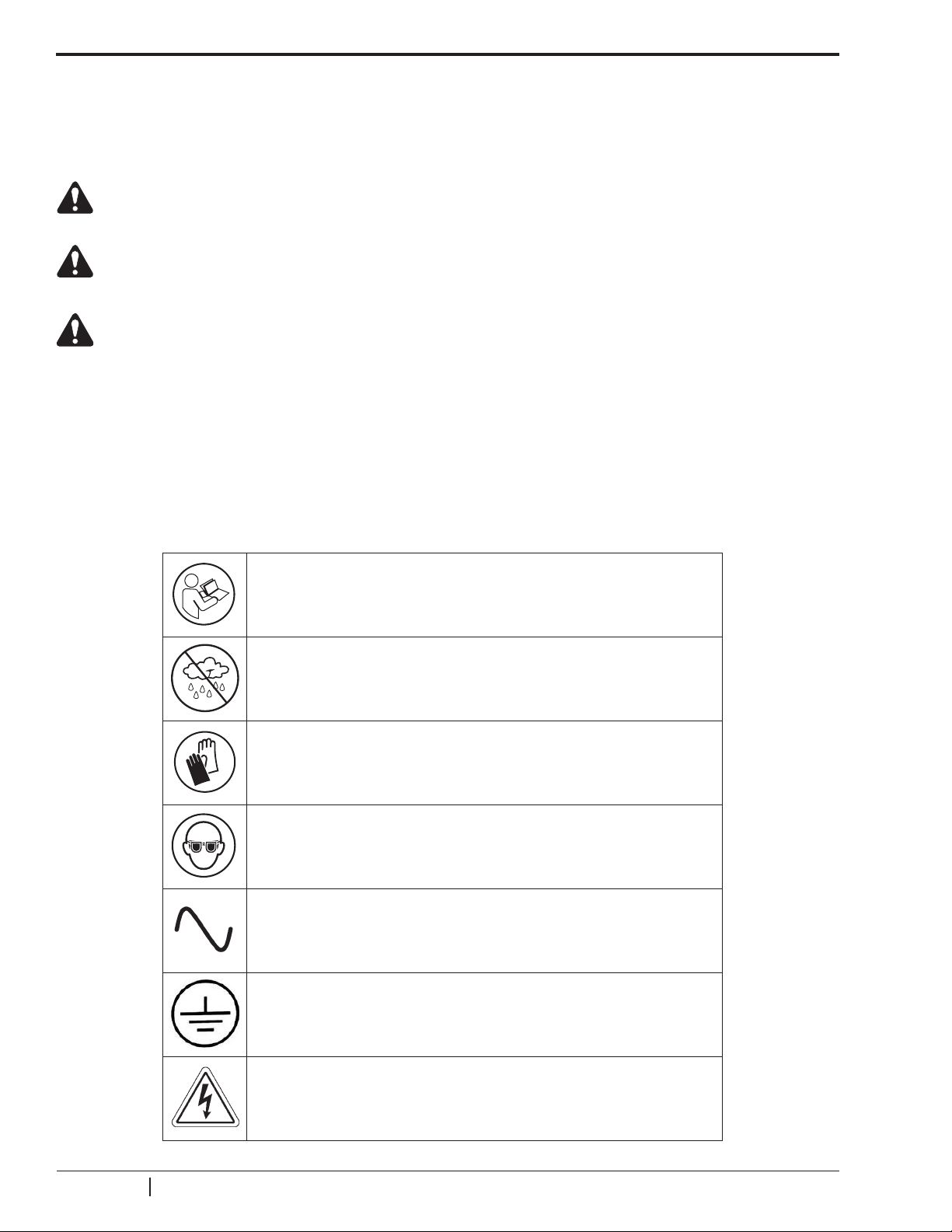

Explanation of Safety Decals Used on the Machine

Carefully read all instructions.

Do not use in open air in case of rain or high humidity.

Wear gloves.

Wear protection goggles.

Alternating voltage.

Grounding protection.

Electrical shock hazard.

SP00D00609 2018-03-26 Robert Bosch GmbH

4

ACS 753, ACS 763, ACS 863 Service Manual

WARNING: To prevent personal injury,

ALLOW ONLY QUALIFIED PERSONNEL TO OPERATE THE MACHINE. Before operating

the machine, read and follow all instructions and warnings in this manual. The operator must

be familiar with air conditioning and refrigeration systems, refrigerants, and the dangers of

pressurized components. If the operator cannot read this manual, all operating instructions

and safety precautions must be read and discussed in the operator’s native language.

USE THE MACHINE AS OUTLINED IN THIS MANUAL. Using the machine in a manner for

which it was not designed will compromise the machine and nullify the protections provided.

PRESSURIZED TANK CONTAINS LIQUID REFRIGERANT. Do not overll the internal

storage vessel (ISV), because overlling may cause explosion resulting in personal injury

or death. Do not recover refrigerants into a nonrellable container; use only type-approved

rellable containers that have a pressure relief valve.

HOSES MAY CONTAIN LIQUID REFRIGERANT UNDER PRESSURE. Contact with

refrigerant may cause personal injury, including blindness and frozen skin. Wear protective

equipment, including goggles and gloves. Disconnect hoses using extreme caution. Ensure

the phase has been completed before disconnecting the machine to prevent the release

of refrigeration to the atmosphere.

DO NOT BREATHE REFRIGERANT AND LUBRICANT VAPOR OR MIST. Refrigerant

reduces the oxygen available for breathing, resulting in drowsiness and dizziness. Exposure

to high concentrations of refrigerant causes asphyxiation, injury to the eyes, nose, throat,

and lungs, and can affect the central nervous system. Use the machine in locations with

mechanical ventilation that provides at least one air change per hour. If accidental system

discharge occurs, ventilate the work area before resuming service.

DO NOT DISPERSE THE REFRIGERANT INTO THE ENVIRONMENT. Such a precaution

is necessary to prevent the possible presence of refrigerant in the working environment.

The refrigerant R1234yf (ACS 763, ACS 863 only) is heavier than air and tends to

concentrate in the pits of the workshop.

TO REDUCE THE RISK OF FIRE, do not use the machine in the vicinity of spilled or open

containers of gasoline or other ammable substances.

TO REDUCE THE RISK OF FIRE, do not use an extension cord. An extension cord may

overheat and cause re. If you must use an extension cord, use the shortest possible cord

with a minimum size of 14 AWG.

TO REDUCE THE RISK OF FIRE, do not use the machine in the vicinity of ames and

hot surfaces. Refrigerant decomposes at high temperatures, freeing toxic substances to

the environment which are noxious to the user.

TO REDUCE THE RISK OF FIRE, do not use the machine in environments containing

explosive gases or vapors.

TO REDUCE THE RISK OF FIRE, Do not use this machine in ATEX classied zones

or areas. Protect the machine from conditions that may cause electrical failure or other

hazards relating to ambient interaction.

5

SP00D00609 2018-03-26Robert Bosch GmbH

ACS 753, ACS 763, ACS 863 Service Manual

DO NOT USE COMPRESSED AIR TO PRESSURE TEST OR LEAK TEST THE MACHINE

OR VEHICLE AIR CONDITIONING SYSTEM. Mixtures of air and refrigerant can be

combustible at elevated pressures. These mixtures are potentially dangerous and may

result in re or explosion causing personal injury and/or property damage.

HIGH VOLTAGE ELECTRICITY INSIDE THE MACHINE HAS A RISK OF ELECTRICAL

SHOCK. Exposure may cause personal injury. Disconnect the power before servicing the

machine.

NEVER LEAVE THE MACHINE LIVE IF AN IMMEDIATE USE IS NOT SCHEDULED.

Disconnect the electrical supply before a long period of inactivity or before internal

maintenance is performed. To ensure that unauthorized personnel cannot run the machine,

use the Lockout / Tag Out feature.

NOTE (R1234yf only): To minimize the risk of ignition, the unit software guided leak check is periodically performed otherwise the unit will lock. For same purpose, also hardware features such

as ventilation fan monitoring system, suitably located vents on cart bottom (R1234yf is heavier

than air) and sealed power switching circuits are present.

CAUTION:Themachineisnotintendedtooperatewithoilsclassiedasammable

or hazardous according to EN 1272/2008 (CLP).

CAUTION : To prevent equipment damage,

TO PREVENT CROSS-CONTAMINATION, USE THIS MACHINE WITH R1234yf

(ACS 763, ACS 863) OR R134a (ACS 753) REFRIGERANT ONLY. The machine is

equipped with special connectors to recover, recycle, and recharge only R1234yf (ACS 763,

ACS 863) or R134a (ACS 753) refrigerant. Do not attempt to adapt the machine for another

refrigerant. Do not mix refrigerant types through a system or in the same container; mixing

of refrigerants will cause severe damage to the machine and the vehicle air conditioning

system.

Do not use refrigerants other than those indicated on the technical data plate. It is also

recommended to buy it from specialized companies that guarantee its good quality.

DO NOT USE THIS MACHINE OUTDOORS DURING RAIN OR HIGH HUMIDITY. Protect

the machine from conditions that may cause electrical failure or other hazards relating to

ambient interaction.

DO NOT USE THIS MACHINE IN DIRECT SUNLIGHT. Position the machine far from heat

sources, such as direct sunlight which can cause excessive temperatures. The use of this

machine under normal environmental conditions (10°C to 50°C) keeps pressures under

reasonable limits. Make sure the machine does not exceed the operating temperature

indicated on the technical data plate.

DO NOT USE THIS MACHINE IN AREAS WHERE THERE IS A RISK OF EXPLOSION.

Place the station on a at surface and in sufcient lighting conditions; lock the front wheels

and do not subject them to vibration.

Further information regarding health and safety may be obtained from the refrigerant

manufacturer.

SP00D00609 2018-03-26 Robert Bosch GmbH

6

ACS 753, ACS 763, ACS 863 Service Manual

Protective devices

The machine is equipped with the following protective devices:

• Over pressure valves.

• A maximum pressure switch stops the compressor when excessive pressure is sensed.

WARNING: Tampering with these protective devices could result in serious injury.

WARNING: Do not modify the pressure relief valve or change the control system

settings. Using the machine in a manner for which it was not designed will compromise

the machine and nullify the protections provided.

CAUTION: Check always the pressure gauges values to ensure that pressures are

maintainedwithinthelimitsspeciedinthe“Unitspecications”section.

Door switch

Door switch on service rear door disconnects electrical power to the unit when opened.

WARNING: Do not tamper the interlock switch. During normal operation, the rear

service door must always be closed and the above panel in place.

Refrigerant Tank Test

Ofcial records and recurring tests necessary for pressurized instruments are governed by laws

and / or national regulations depending on the country where the refrigerant tank is used. The

system manager is responsible for respect of laws, regulations, and technical rules. During normal service, refrigerant tanks do not need maintenance. Refer to the Maintenance section of this

manual for more information.

Machine handling

The unit should normally be moved on at surfaces with a maximum slope of 15 ° and on the four

wheels, avoiding excessive shaking. When stopped then the brake on the front wheels must be

inserted. On slightly irregular surfaces, the unit can be moved by keeping it slightly inclined and

grounded on the two rear wheels by making sure to have a rm grip on the rear handle.

CAUTION: Although heavier components of the unit are installed on the bottom of

the unit in order to lower as much as possible the center of gravity, it’s however not

completely removed the risk of overturning.

7

SP00D00609 2018-03-26Robert Bosch GmbH

Introduct i o n

ACS 753, ACS 763, ACS 863 Service Manual

I n TroduCT I o n

Introduction .........................................................................................................9

Icon Legend ....................................................................................................................10

Glossary .......................................................................................................................... 11

Setup Menu ..................................................................................................................... 11

General Maintenance .....................................................................................................14

Electrical Protection ....................................................................................................... 14

Tank Fill ........................................................................................................................... 14

Filter Maintenance .......................................................................................................... 15

InternalRefrigerentIdentierMaintenance(ACS863only) ....................................... 16

Vacuum Pump Maintenance ..........................................................................................16

Edit Print Header ............................................................................................................17

Replace Printer Paper ....................................................................................................17

Calibration Check ........................................................................................................... 18

Scales Reset ...................................................................................................................18

Pressure Decay Leak Test (R1234yf only) .................................................................... 19

Lockout ............................................................................................................................19

UnitSpecications ............................................................................................ 20

Maintenance Schedule ......................................................................................22

Control Panel Functions ................................................................................................ 10

SP00D00609 2018-03-26 Robert Bosch GmbH

8

ACS 753, ACS 763, ACS 863 Service Manual

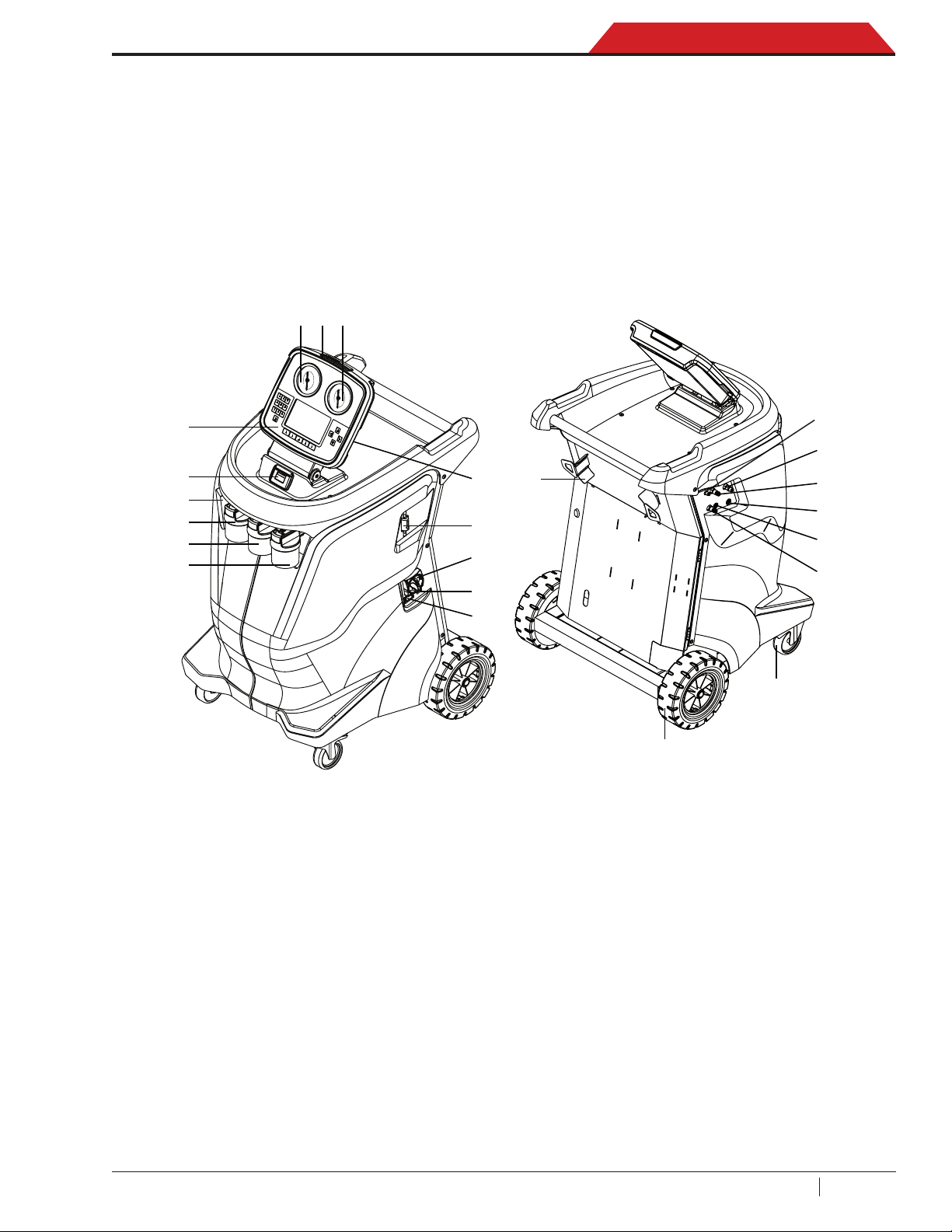

1 2 3

6

7

5

4

8

13

14

15

16

17

18

19

20

21

22

23

12

11

10

9

abc

def

jkl

mno

tuv

wxyz

ghi

pqrs

Introduct i o n

Introduction

These units are designed to be compatible with existing service equipment and standard service

procedures. These machines utilize a single-pass system that meets specications for recycled

refrigerant. Follow recommended service procedures for the containment of refrigerant.

Each unit includes a high-vacuum pump for fast, thorough evacuation. The compressor rst pulls

the A/C system to -0.4 bar; the compressor then works with the vacuum pump to pull a vacuum

to an absolute pressure of less than 1.0 bar.

NOTE: Refrigerant systems require special oils. Refer to the A/C system manufacturer’s service

manual for oil specications.

Figure 1-1. Description of machine

1. Gauge low pressure (LP)

2. Visual alert

3. Gauge high pressure (HP)

4. 2 x USB 2.0 slot

5. Identier Filter

(ACS 863 only)

6. Master switch

7. Circuit breaker

8. Power supply socket

9. UV dye bottle

10. Fresh oil bottle 2 (POE)

11. Fresh oil bottle 1 (PAG)

12. Used oil bottle

13. Printer

14. Display and control panel (HMI)

15. N2H2 or N2 inlet port max 14 bar (1.4 MPa)

16. Flush port (high pressure*)

17. Flush port (low pressure*)

18. Service hose port (high pressure*)

19. Service hose port (low pressure*)

20. Contaminant recovery outlet port

(ACS 863 only)

21. Front wheels with locking brake

22. Rear wheels

23. Hoses wraping support

(*) max 25 bar (2.5 MPa)

9

SP00D00609 2018-03-26Robert Bosch GmbH

Introduct i o n

Refrigerant

Main Menu

09:36

V 076.026.050

Standby

3.544 kg

7.34 bar

205 ml

POE

205 ml

PAG

205 ml

Dye

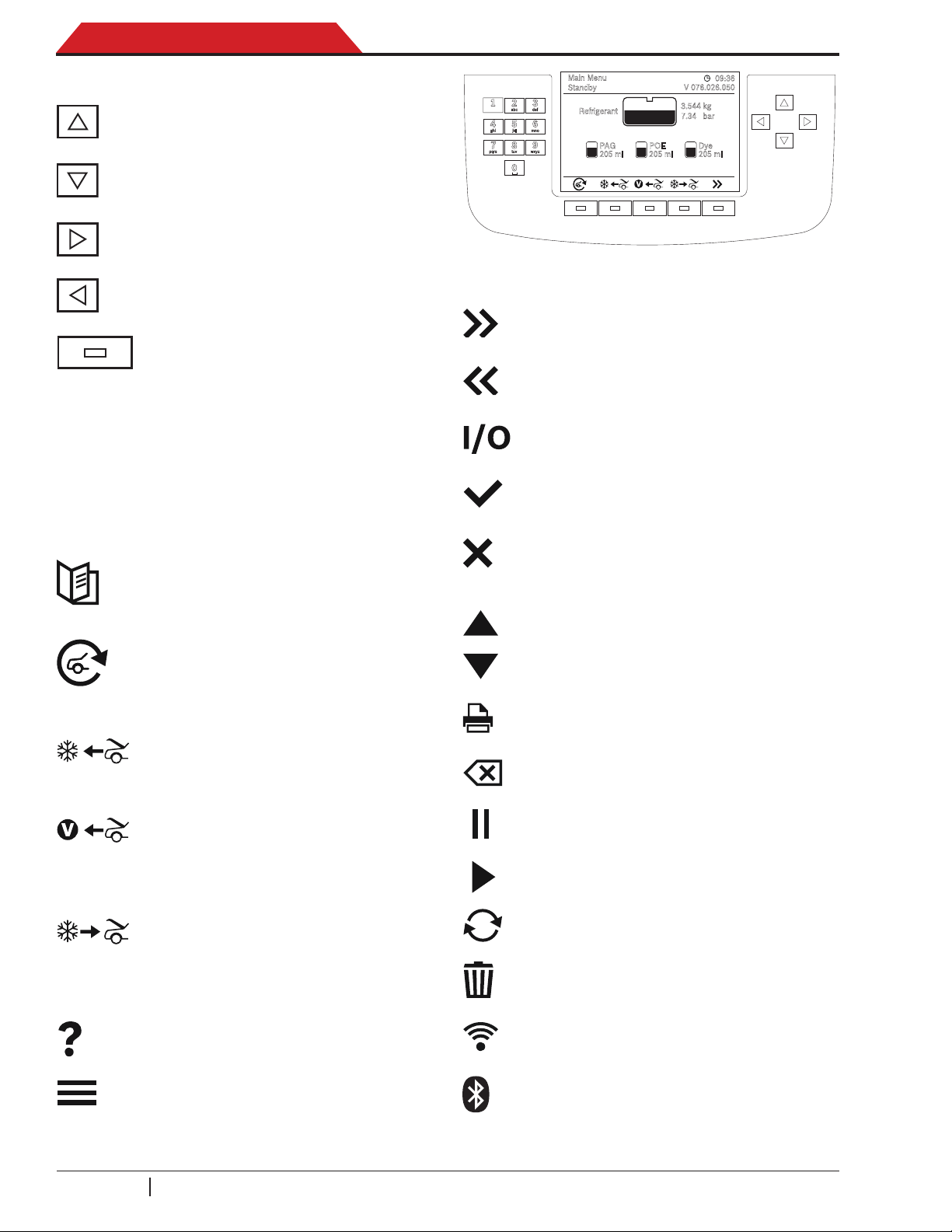

Control Panel Functions

ARROW UP moves selection of a

menu item to the previous item.

ARROW DOWN moves selection of

a menu item to the following item.

ARROW RIGHT scrolls to next

screen.

ARROW LEFT scrolls to previous

screen.

SELECTION KEYS (function keys)

to select the functions shown on

display (bottom icons).

ACS 753, ACS 763, ACS 863 Service Manual

Figure 1-2. Control Panel Keyboard

NEXT to move to the next screen

or step.

BACK to return to the previous

screen or step.

0...9

A...Z

The input keys can be used to

enter letters, numbers and special

characters in the input boxes.

Icon Legend

DATABASE supplies information

regarding charge capacity by vehicle

model.

AUTOMATIC activates a menu that

helps the user set up an automatic

recover / vacuum / leak test / charge

sequence.

RECOVER activates the sequence

to recover refrigerant from the vehicle

A/C system.

VACUUM activates the sequence

that pulls a deep vacuum on the

vehicle A/C system to remove air

and moisture.

ON/OFF to enable or disable the

selected function.

OK to confirm, proceed or save

settings.

ESC to cancel the operation and

return to the previous function or the

Main menu.

UP to move menu selection upward.

DOWN to move menu selection

downward.

PRINT to perform a print.

BACKSPACE to erase the character

to the left of the cursor.

PAUSE to pause a process.

PLAY to resume a paused process.

CHARGE activates the sequence

RETRY to repeat the last step.

that charges the vehicle A/C system

with a programmed amount of

refrigerant.

HELP displays information related to

the current display.

MENU accesses additional functions

and parameters.

SP00D00609 2018-03-26 Robert Bosch GmbH

10

DELETE to delete a selected entry

from the memory of the machine.

WIFI indicates that the WiFi

connection is enabled.

BLUETOOTH indicates that the

Bluetooth connection is enabled.

ACS 753, ACS 763, ACS 863 Service Manual

Introduct i o n

HS LS to set which side to charge

thru (high pressure, low pressure or

both sides).

ml oz to set the unit of measurement

(ml or oz).

kg oz lb to set the unit of measurement

(kg, oz or lb).

USB to export data onto a USB key.

Glossary

A/C System: The vehicle air conditioning

system being serviced.

Evacuation: Moisture and other incondensables

are removed from an A/C system by using a

vacuum pump.

Internal Storage Vessel (ISV): The tank

designed specifically for this machine has

refrigerant disposable capacity of 17.4 kg,

except the ACS 753 have a disposable capacity

of 19.4 kg.

Machine: Model No. ACS 753, ACS 763 or

ACS 863.

PAG/POE: Different oil types in the vehicle airconditioning system depending on the vehicle

manufacturer.

Recovery/Recycling: Refrigerant is recovered

from an A/C system, ltered, and stored in the

ISV.

Refrigerant: R134a (ACS 753) or R1234yf.

Source (or External Tank): A disposable tank

of new refrigerant used to rell the ISV; not

included.

Setup Menu

The machine launches into the initial Setup

mode (the rst time the machine is powered up).

NOTE: It is needed to complete all the setup

procedure sequence before to use the A/C unit.

Carry out the following setup:

1. Language selection.

2. License agreement review.

3. Units (Metric/Imperial) selection.

4. Date and Time adjustment.

5. Print Header Editor.

6. Identier setting (ACS 763 only).

7. Service Vacuum.

8. Internal Tank Fill.

At the end of the initial setup procedure it is

suggested to:

• Perform check scale.

• Perform air ow calibration.

Functions Menu

1. Call up the Main Menu.

2. Select NEXT icon.

3. Select MENU icon.

• Select Functions to access the following

functions.

A/C Perfomance Test

Performs a pressure test on an A/C system of

a vehicle with a refrigerant already present.

N2H2 or N2 Test

To search the leaks of the A/C system of a vehicle by means of an external bottle of Nitrogen

or a mixture of nitrogen and hidrogen.

Flush Hoses

Flushes residual oil from the machine to pre-

pare for the service of next vehicle.

System Flush

Provides a method of removing oil and impu-

rity by forcing liquid refrigerant through an A/C

system or components of an A/C system. After

ushing, the refrigerant is recovered by the

machine and ltered by the recycling circuit.

Tank Fill

Use this function to transfer refrigerant from a

source tank to the ISV. The tank ll value may

be adjusted up or down to suit the user’s needs.

Refer to Tank Fill in the Maintenance section.

11

SP00D00609 2018-03-26Robert Bosch GmbH

Introduct i o n

ACS 753, ACS 763, ACS 863 Service Manual

Periodic Leak Test

Performs double test (in vacuum and pressure)

to detect any leakage on the machine.

Refrigerant Tracking

Function to memorize the refrigerant amount

recovered and charged for every vehicle. The

display shows ve selection options:

√ Display: to show data of recovered and

charged refrigerant.

√ Export to USB: to extract the report with

recovered and charged refrigerant amount

in the vehicle. Data extraction via USB

stick, recommended size 2 GB and FAT

format (support is not part of scope delivery). Data are transferred as .csv le.

√ Erase all records: to erase all data stored

on the machine.

√ Print all records: to print all data stored

on the machine.

√ Disable Tracking: to disable the Refriger-

ant tracking function.

Oil Load Cells

To enable or disable the operation of fresh oil

PAG, fresh oil POE, used oil and UV dye scales.

RefrigerantIdentier(ACS763only)

To enable or disable the purity test of the

external refrigerant identier connected to the

USB port of the machine. The display shows

three selection options:

√ Alwaysdisplayidentierprompts: Dis-

plays the steps required to perform the

purity test.

√ Skip display identifier prompts: Not

displays the steps required to perform the

purity test.

√ Askusertoconnectidentier: Ask a

user, with a special message, to conrm

whether or not to perform the purity test.

Default Vacuum Leak Test Time

Program the machine to change duration of the

vacuum leak test time.

• Select BACK icon to return to the Setup

Menu.

Settings Menu

• Select Settings to access the following

functions.

Select Language

Select a language for screen prompts. English

is the default language.

Select Units

Program the machine to display metric or

imperial values. The default display is in a

metric system.

Date and Time

Program the machine for current date and time.

Edit Print Header

Programs information that will appear on the

printout each time a print function is used.

Unit Activation

Failure to register and activate the machine

within 30 days of initial startup will cause the

machine to lock out and not function. Select

this Settings Menu item and follow the prompts

before the trial period expires.

Set Buzzer

Program the machine to turn the buzzer on or

off.

Firmware Update

To upgrade the rmware through a USB stick

or via WiFi. The display shows three selection

options:

√ Check for Update: To check if new rm-

ware updates are available.

√ USB Update: To upgrade the firmware

through a USB stick.

√ Wi-Fi Update: To upgrade the rmware

through a WiFi network. If the unit is connected to WiFi network and the WiFi network is connected to Internet, it will automatically start searching for new updates.

SP00D00609 2018-03-26 Robert Bosch GmbH

12

ACS 753, ACS 763, ACS 863 Service Manual

Introduct i o n

WiFiConguration

To congure the WiFi connection to the machine. The display shows four selection options:

√ Search WiFi Networks: To search for

available WiFi networks.

√ WiFi status: To display some WiFi con-

nection data used.

√ Test WiFi connection: to perform a WiFi

network connection test used by the machine.

√ Disconnect current network: To disable

the WiFi network connection stored on the

machine.

Asanetwork

To enable or disable the asanetwork function.

For further information contact Customer Service.

Connected Repair [CoRe]

To enable or disable the CoRe function.

For more information see Connected Repair

[CoRe] chapter on the user manual.

• Select BACK icon to return to the Setup

Menu.

Maintenance Menu

• Select Maintenance to access the following functions.

Filter Maintenance

The lter removes acid, particulates, and moisture from the refrigerant. To meet requirements,

it is mandatory to replace the lter after (SEE

TABLE) of refrigerant has been ltered.

Pump Maintenance

Displays the amount of time remaining until

the next vacuum pump oil change is needed.

For maximum vacuum pump performance,

change vacuum pump oil every time the

lter is replaced. Refer to the Vacuum Pump

Maintenance in the Maintenance section.

ISV Purge Condition

Displays internal storage vessel (ISV) pressure

and temperature. It is used to eliminate

incondensables gas and helps to limit the

pressure in the ISV.

Calibration Check

Use to verify internal scale calibration. Refer to

Calibration Check in the Maintenance section

of this manual.

Adjust Zero Offset

To reset the fresh oil PAG, fresh oil POE, used

oil and UV dye scales.

Display Tittle Info

To activate or deactivate the pressure and

temperature values display of the machine.

System Information

Displays the revision level of the software in

the unit.

Service Menu

For service center use only.

Production Menu

For production use only.

• Select BACK icon to return to the Setup

Menu.

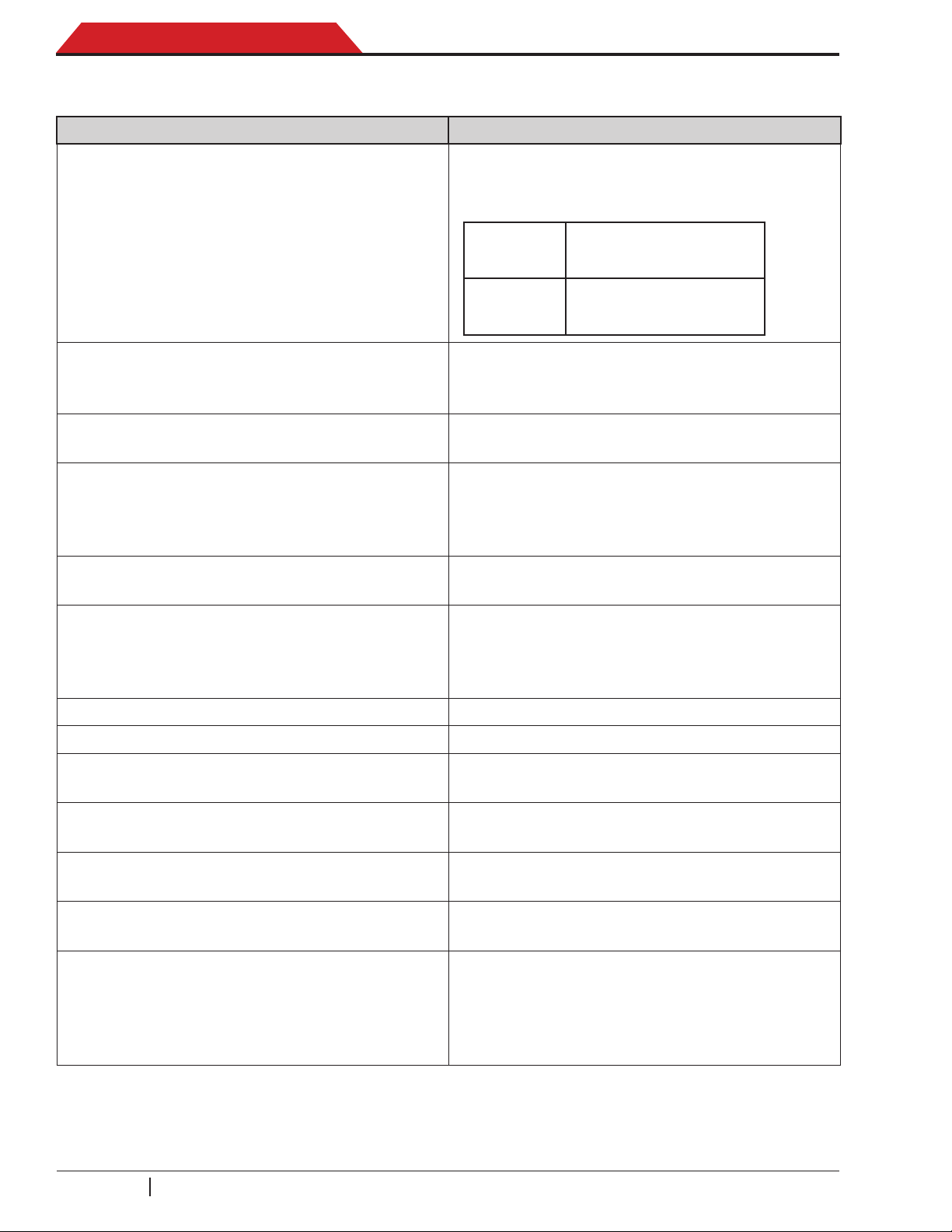

Model

R134a

Model

R1234yf

Replacement lter at: 68 kg

(alert 56 kg)

Replacement lter at: 150 kg

(alert 138 kg)

This menu item displays the lter capacity remaining until the machine locks down and no

longer functions. Refer to Filter Maintenance in

the Maintenance section.

13

SP00D00609 2018-03-26Robert Bosch GmbH

Introduct i o n

ACS 753, ACS 763, ACS 863 Service Manual

General Maintenance

Do not use abrasive cleaning agents, solvents

(petrol, diesel, etc.) and coarse workshop cloths

to clean the machine. Clean only using a soft

cloth and neutral cleaning agents.

NOTE: In cases of refrigerant leaks, such

as during installation, maintenance or repair

of machine, or even during normal use after

machine rest, there will be no refund by the

manufacturer.

CAUTION: Disconnect the power

supply before any maintenance.

Electrical Protection

The machine is equipped with a circuit breaker

to the side of the machine below the ON/OFF

switch. If the breaker trips, its button will pop

out. A tripped circuit breaker will cause the

machine to lose all power. Press the circuit

breaker button to reset. If the circuit breaker

does not reset or continues to trip, there is a

fault in the unit electrical system. Troubleshoot

and repair the affected component(s).

8. Select OK icon to start the tank ll process.

9. The machine (ACS 863 only) checks the

refrigerant in the source tank to verify it

is R1234yf and not contaminated. The

machine displays the following screens:

INITIALIZING REFRIGERANT IDENTIFIER

ANALYZING REFRIGERANT SAMPLE

REFRIGERANT PURITY PASSED

10. The machine begins filling the internal

storage vessel (ISV) and automatically

stops when the preset tank fill level is

reached. To stop the tank fill before the

preset level is reached, select PAUSE icon.

1

Tank Fill

This menu (available on Function menu) is

used to transfer refrigerant from a source tank

to the ISV.

1. Call up the Main Menu.

2. Select NEXT icon.

3. Select MENU icon.

4. Select TANK FILL from the Functions

Menu. The machine displays:

FILL AMOUNT: xx.xxyy

RECOVER CAPACITY: xx.xxyy

CHARGE CAPACITY: xx.xxyy

5. Enter the ll amount (at least 5 kg) to ensure

enough liquid refrigerant is available for

charging and select OK icon. Unit is set

with 2.2 kg dead space (rst 2.2 kg are not

shown on display anymore). If the source

tank is empty, or has insufcient refrigerant

for transfer, tank ll will stop.

6. Connect the low pressure service hose

(blue) to the liquid connector on a full source

tank.

7. Position the source tank in such a way

that liquid refrigerant is supplied to the

connection. Open the source tank valve.

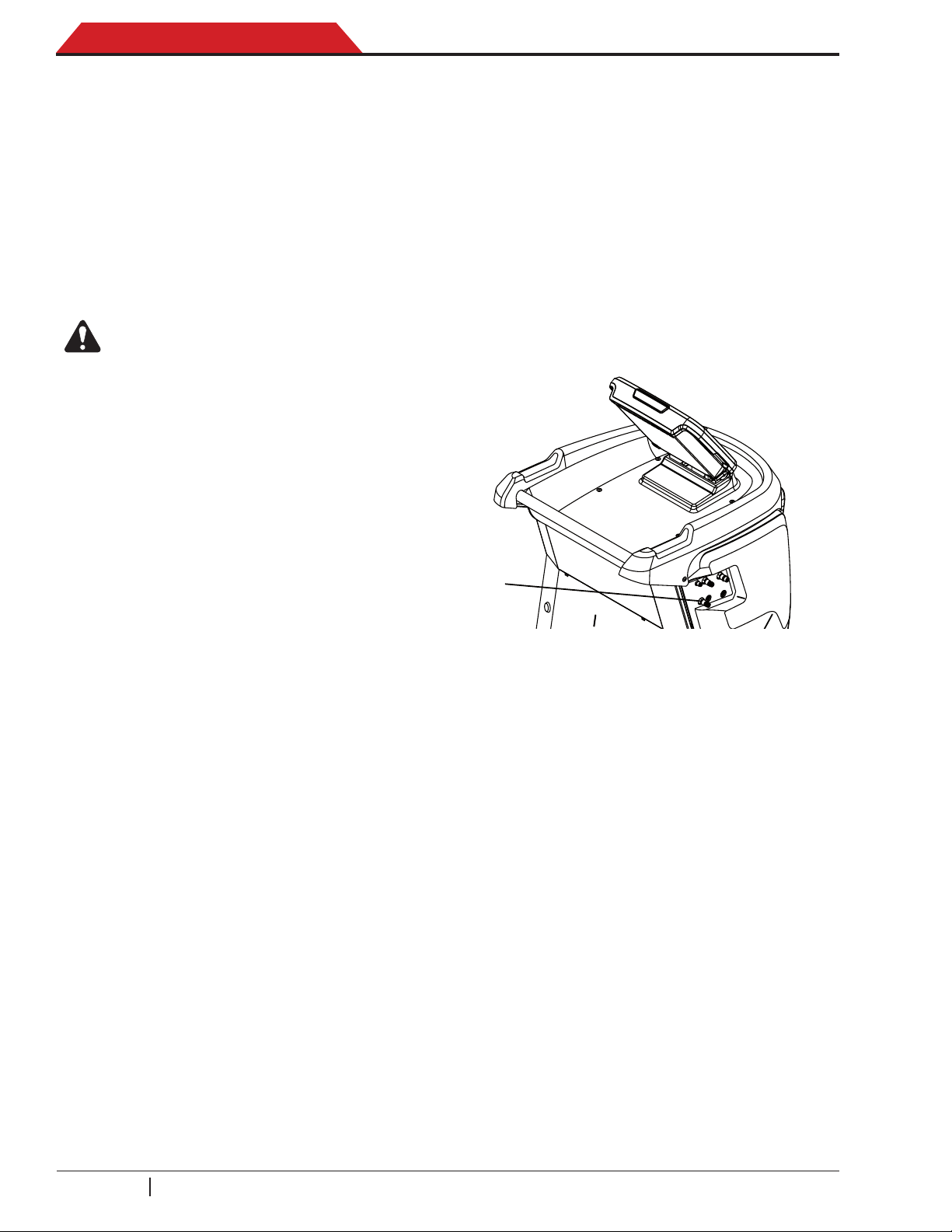

Figure 1-3. Contaminant recovery outlet port

11. Close the liquid valve and remove the hose

from the source tank.

12. Select OK icon to return to the Function

Menu.

Operating Tips (ACS 863 only)

1. If the machine displays

REPLACE IDENTIFIER FILTER

• the refrigerant identifier filter must be

replaced. Select OK icon to conrm, and

refer to the Refrigerant Identier chapter

of this manual for instructions.

2. If the machine displays

REFRIGERANT PURITY FAILED

RECOVER CONTAMINATED

REFRIGERANT FROM SYSTEM AND HOSES

• the refrigerant in the source tank is either

not R1234yf or it is contaminated. In either

case, it should not be added to the internal

storage vessel in the machine. The refrigerant purity is 95%.

SP00D00609 2018-03-26 Robert Bosch GmbH

14

ACS 753, ACS 763, ACS 863 Service Manual

Introduct i o n

• Connect a second recovery machine to

the tting (1) located on the side of the

machine. See Figure 1-3. Run a recovery

to remove the refrigerant sampled by the

refrigerant identier in the machine.

Filter Maintenance

The lter is designed to trap acid and particulates,

and to remove water from refrigerant. To meet

this mandate, the lter must be replaced after

(SEE TABLE) of refrigerant has been ltered.

The unit gives a warning when (SEE TABLE) of

the lter capacity has been used; the unit locks

(

down when the

been reached and will no longer function.

Check Remaining Filter Capacity

1. Call up the Main Menu.

2. Select NEXT icon.

3. Select MENU icon.

4. Select Filter Maintenance from the

Maintenance Menu or when the machine

prompts. The machine displays:

SEE TABLE) lter capacity has

3. Switch off the machine.

4. Open the service rear door.

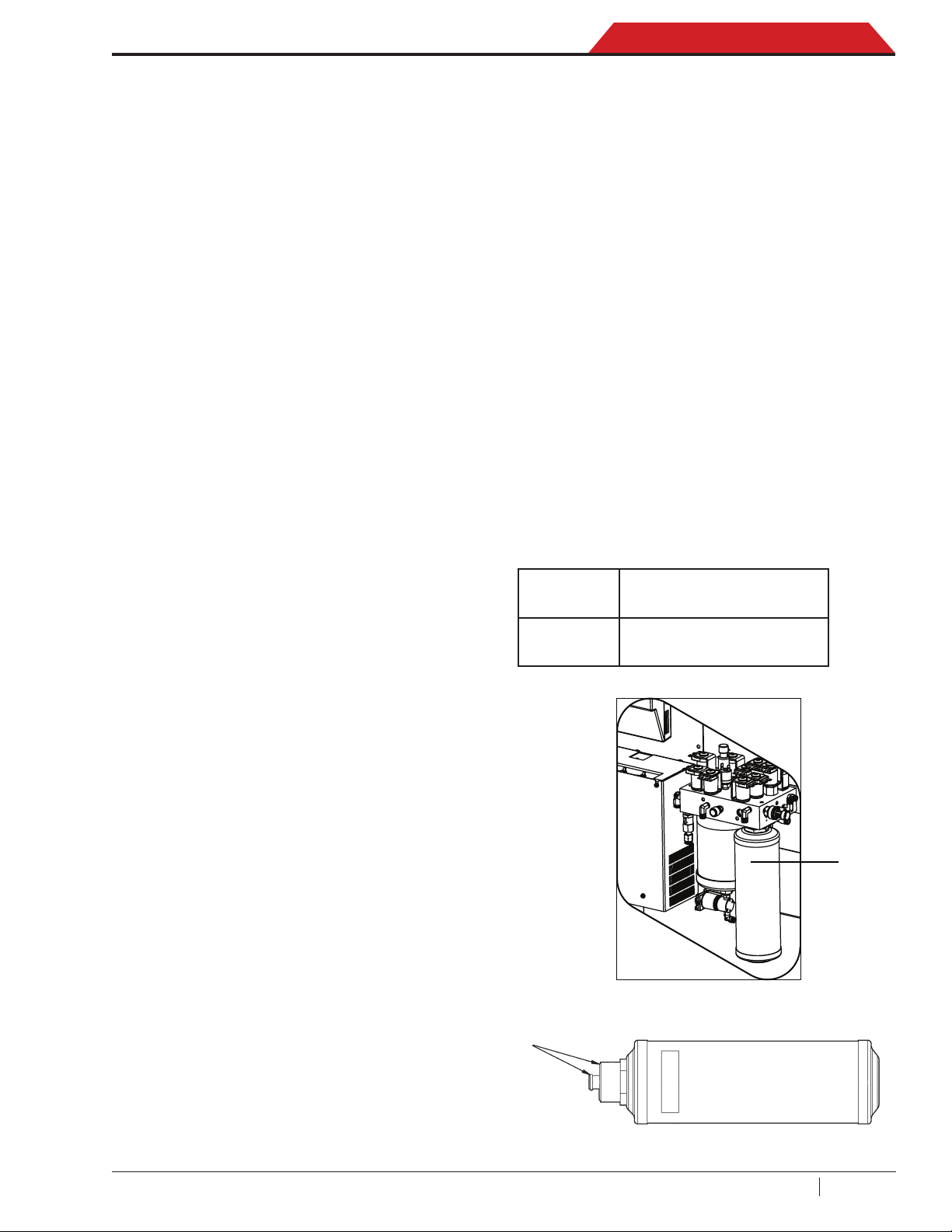

5. Remove the old lter (1) by turning it clock-

wise. Refer to Figure 1-4.

6. Look at the new lter. Verify both O-rings

are lubricated and correctly located in the

grooves as shown in Figure 1-5.

7. Install the new lter by threading it counter-

clockwise into place. Verify the lter is positioned correctly. Tighten the lter to 20 Nm.

8. Close the service rear door.

9. Switch on the machine.

10. Machine starts with vacuum pump oil

change (Refer to the “Vacuum Pump Maintenance” in this section).

11. Recycle the lter that was removed from

the machine according to the laws in your

jurisdiction.

CAUTION:UseonlyauthenticBoschlters

in this machine. All performance tests and

claimsarebasedonusingthisspeciclter.

REMAINING FILTER CAPACITY: XXX.XYY

REPLACE FILTER NOW?

• The machine displays amount of lter ca-

pacity remaining until the machine locks

down. This message may occur at anytime

during the course of an A/C system main

tenance action.

5. Select OK icon to change the lter; Select

ESC icon to resume using the machine.

Replace the Filter

1. If OK icon was selected to change the lter,

the unit will clear the lter, then prompts for

the new lter code to be entered:

ENTER NEW FILTER SERIAL NUMBER

NOTE: If SERIAL NUMBER WRONG is

displayed, the serial number has been incorrectly

entered or the lter has already been used in this

machine.

2. Use the keypad to enter the serial number

that appears on the new lter and select OK

icon to continue.

• The machine clears the existing lter and

displays:

-

Model

R134a

Model

R1234yf

O-rings

Replacement lter at: 68 kg

(alert 56 kg)

Replacement lter at: 150 kg

(alert 138 kg)

1

Figure 1-4. Filter Location

TURN POWER OFF

AND REPLACE FILTER

15

Figure 1-5. O-ring Location

SP00D00609 2018-03-26Robert Bosch GmbH

Introduct i o n

ACS 753, ACS 763, ACS 863 Service Manual

InternalRefrigerentIdentier

Maintenance (ACS 863 only)

A refrigerant identifier samples refrigerant

going into the ISV to verify it is R1234yf and

not contaminated. Replace the sample hose

assembly during every lter change and also if

prompted by an error message saying the hose

is clogged. See Figure 1-6.

1. Switch off the machine.

2. Open the service rear door.

3. Remove the rear cover (above the service

door) by pushing it up and extract it by pulling it out.

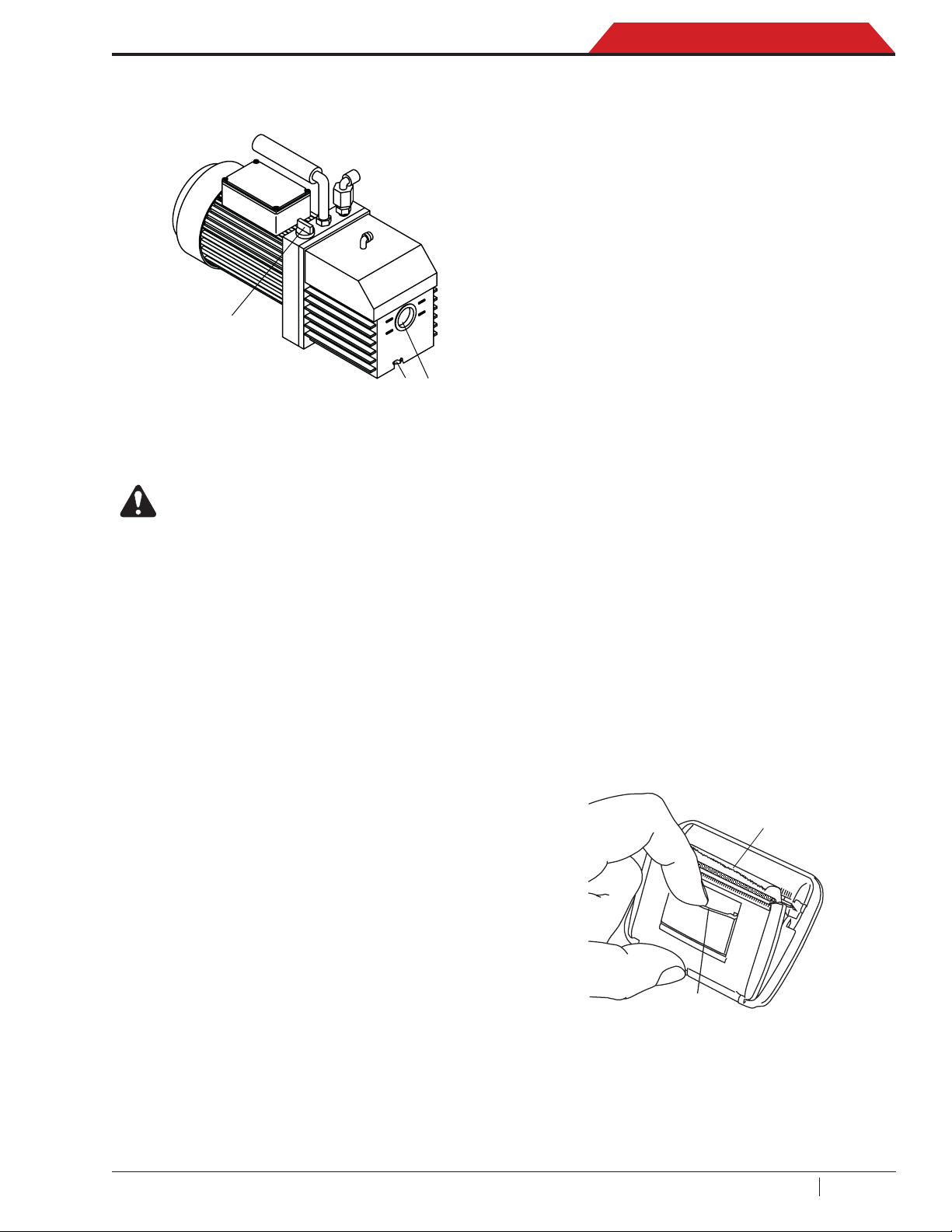

Vacuum Pump Maintenance

NOTE: Vacuum pump oil must be changed with

every lter change, every 100 hours pump runs

or more often as necessary.

1. Call up the Main Menu.

2. Select NEXT icon.

3. Select MENU icon.

4. Select Pump Maintenance from the

Maintenance Menu or when prompted. The

display shows how long the vacuum pump

has operated since the last oil change.

REMAINING OIL LIFE XXX:XX (hhh:mm)

CHANGE OIL NOW?

5. Select OK icon to change vacuum pump oil.

6. If the the machine displays:

WARMING OIL FOR DRAIN

• allow the vacuum pump to run for two

minutes to warm up the oil.

7. If the oil is already warm, the display shows:

1

Figure1-6.Internalrefrigerentidentierlocation

2

4. Disconnect the existing sample hose as-

sembly (2) between the rear side of the

manifold and the refrigerant identier, and

install a new sample hose assembly. If the

lter is any color but white, the lter must

be replaced.

5. Pull the lter barbs from the rubber hoses.

Snap the lter (1) out of the clip.

6. Install a new lter with the arrow pointing

downward as shown on the refrigerant iden-

tier. Do not kink the rubber hoses. Push

the rubber hoses back into the refrigerant

identier housing until they are straight.

7. Insert the rear cover so that the 4 holes on

the sides the cover t into the 4 clips on the

machine. Push down to hook the rear cover.

8. Close the service rear door.

DRAIN USED OIL FROM PUMP AND REPLACE

WITH 550 ML OF NEW OIL REMOVE CAP TO

SPEED DRAINING OF OIL

8. Switch off the machine.

9. Open the service rear door.

10. Slowly open the oil ll port cover (2) to verify

there is no pressure in the machine. Then

carefully remove the cover. See Figure 1-7.

11. Remove the oil drain tting cap (3) and drain

the oil into a suitable container for disposal.

Install the cap and close tightly.

12. Slowly add vacuum pump oil to the pump

through the oil ll port until the oil reaches

the center of the sight glass (1)

.

13. Install the cap on the oil ll port and close

tightly.

14. Close the service rear door.

15. Switch on the machine.

16. Select OK icon to continue.

17. The display show a message that indicate

to the user to check that the oil level is at

the center of the sight glass pump.

NOTE: In case it is necessary to add more oil,

repeat steps 8, 9, 10, 12, 13, 14 and 15 for

add oil.

SP00D00609 2018-03-26 Robert Bosch GmbH

16

ACS 753, ACS 763, ACS 863 Service Manual

1

3

Introduct i o n

18. Select ESC icon to return to the Maintenance Menu.

2

Figure 1-7. Oil Ports

CAUTION: To prevent personal injury,

do NOT operate the machine at any

other time without the oil ll port

cap installed, because the vacuum

pump is pressurized during normal

operation.

NOTE: Review the laws and regulations in your

jurisdiction to determine correct disposal procedures for pump oil. It is the responsibility of the

user to determine if a material is a hazardous

waste at the time of disposal. The user must

ensure compliance with all applicable laws and

regulations.

Edit Print Header

To make changes to the printer text (available

in Setting menu) appearing in the header on

each printout:

1. Call up the Main Menu.

2. Select NEXT icon.

3. Select MENU icon.

4. Select Edit Print Header in the Settings

Menu. The cursor is in the rst eld.

5. Update the text by using the arrows and the

multi-tap interface on the numeric keypad:

• BACKSPACE icon acts as a backspace

key.

• Right or left arrow moves the cursor to the

right or to the left.

• Zero (0) key also acts as a spacebar.

• Up and Down arrows navigate between

the rows.

6. Select OK icon to save the changes and

return to the Settings Menu.

7. Select ESC icon to exit and return to the

Settings Menu.

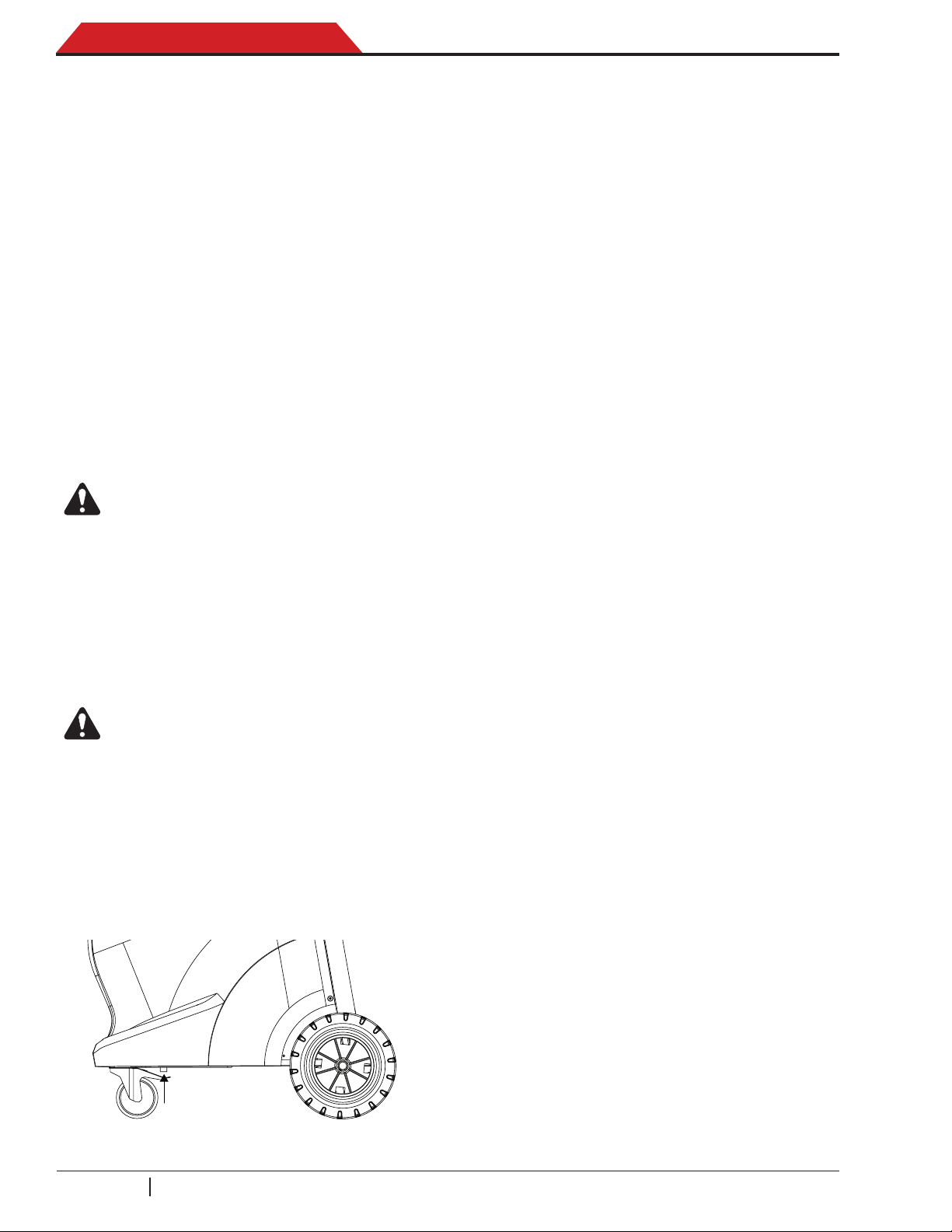

Replace Printer Paper

To install a new paper roll in the printer:

1. Remove the cover on the printer by pulling

out on the tab (2) as shown in Figure 1-8.

2. Remove the paper core.

3. Install the new roll of paper with the end of

the paper at the top of the roll.

4. Assemble the cover onto the printer with the

leading edge of the paper over the roller (1).

1

2

Figure 1-8. Replace Print Paper

17

SP00D00609 2018-03-26Robert Bosch GmbH

Introduct i o n

ACS 753, ACS 763, ACS 863 Service Manual

Calibration Check

This function is used to ensure the machine’s

internal scale is always calibrated. During this

test, use only the calibration weight provided

with the machine.

1. Verify the magnet on the bottom of the machine is clean. Refer to Figure 1-9.

2. Call up the Main Menu.

3. Select NEXT icon.

4. Select MENU icon.

5. Select Calibration Check from the Mainte-

nance Menu. The machine displays:

PLACE CALIBRATION WEIGHT ON MAGNET

LOCATED ON THE BOTTOM OF MACHINE

6. Attach the calibration weight to the magnet

(1) on the bottom of the machine.

7. Select OK icon to continue.

ALERT:Unitshown“Reading,donot

disturb”.

The machine displays:

REMOVE CALIBRATION WEIGHT

FROM MAGNET LOCATED ON THE BOTTOM

OF MACHINE

8. Remove calibration weight from magnet

located on the bottom of machine.

9. Select OK icon to continue.

Scales Reset

This procedure should be carried out regularly,

as the deviation from the zero point of the

oil/dye scales is corrected in the process.

1. Call up the Main Menu.

2. Select NEXT icon.

3. Select MENU icon.

4. Select Adjust Zero Offset from the Maintenance Menu.

5. Select the scale type to reset and conrm

with OK icon.

6. A message appears on the display to re-

move the oil bottles and/or the UV dye bottle

(according the selected scale type).

7. Carefully remove the bottle shown on the

display.

NOTE: To remove the “PAG”, “POE” and “UV

Dye” bottles, you must pull the lever on the

colored covers of the bottles slightly to unlock

and pull them outward. Instead to remove the

oil drain bottle it is enought pulling it straight

outwards.

8. Select OK icon to conrm and reset the

selected scale.

9. Repeat the same procedure to reset the

other scales.

10. Zero position of the 4 scales will be set.

ALERT: Do not touch the unit in this

phase!

• If the display shows Calibration passed

the scale is calibration. Select OK icon to

return to the Maintenance Menu.

• If the display shows Calibration failed the

scale is out of calibration. Select RETRY

icon to retry. If calibration continues to fail,

contact an authorized service center for

assistance.

1

Figure 1-9. Magnet Location

SP00D00609 2018-03-26 Robert Bosch GmbH

18

ACS 753, ACS 763, ACS 863 Service Manual

a

bc

d

ef

jkl

mno

tuv

wxyz

ghi

pq

r

s

Introduct i o n

Pressure Decay Leak Test

This function is available on Function menu.

To ensure a safe, environmentally friendly,

and economic operation, the unit performs a

software-controlled self-test in regular intervals

every 10 days (for R1234yf only).

1. Follow the on-screen prompts to connect

the hose service couplers to the storage

connectors on the side of the machine.

Open the hose couplers by turning the collars clockwise.

2. Select OK icon to start the test.

3. The machine performs a self-recovery and

displays:

RECOVER IN PROGRESS

4. The machine performs a 30-second vacuum

test and displays:

VACUUM CHECK IN PROGRESS

• If the vacuum test fails, the machine will

prompt to check for leaks.

5. Once the machine passes the vacuum test,

a controlled pressure is applied to its internal

components. The machine displays:

PRESSURE CHECK IN PROGRESS

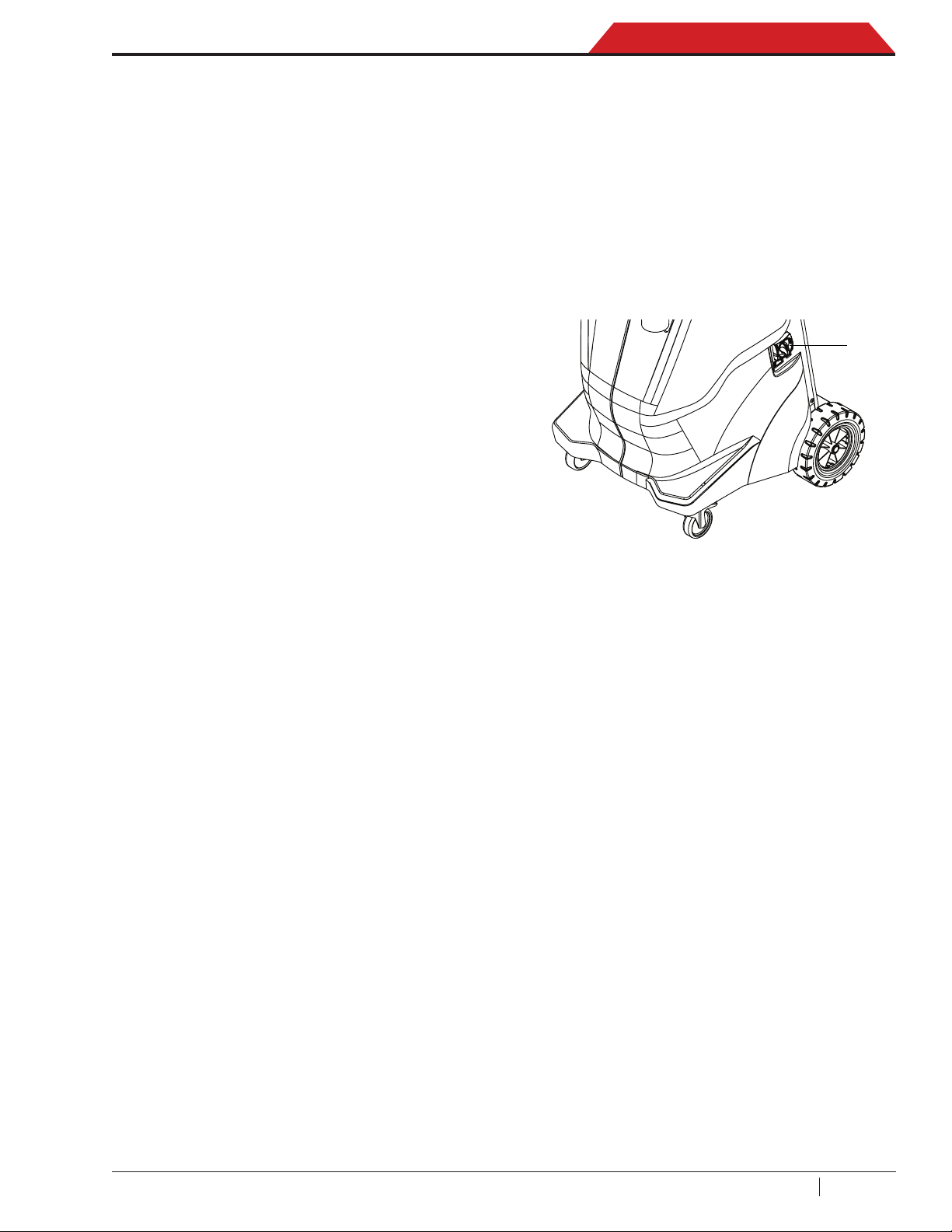

Lockout

Never leave the machine live if an immediate

use is not scheduled. To ensure that unauthorized personnel cannot run the machine, use the

Lockout as shown in Figure 1-10.

1. Turn the Lockout lever (1) counterclockwise

(CCW).

2. Insert a padlock or other item through the

aligned holes so the lever cannot be turned

clockwise (CW) to start the machine.

1

Figure 1-10. Lockout

6. Pressure is held for ve minutes and moni-

tored for decay. Minutes and seconds count

down on the display.

• If an acceptable pressure decay is detected, the machine recovers refrigerant

and returns to the Functions Menu, ready

for normal operation.

• If an unacceptable pressure decay is detected, the machine will prompt to check for

leaks. Take the machine to an authorized

service center for repair.

NOTE: Leak Check may also be selected at

any time from the Functions Menu. If you decline to run the Leak Check when prompted,

the machine will continue to prompt for the test

at each power-up until the test is completed

(for R1234yf only).

19

SP00D00609 2018-03-26Robert Bosch GmbH

Introduct i o n

ACS 753, ACS 763, ACS 863 Service Manual

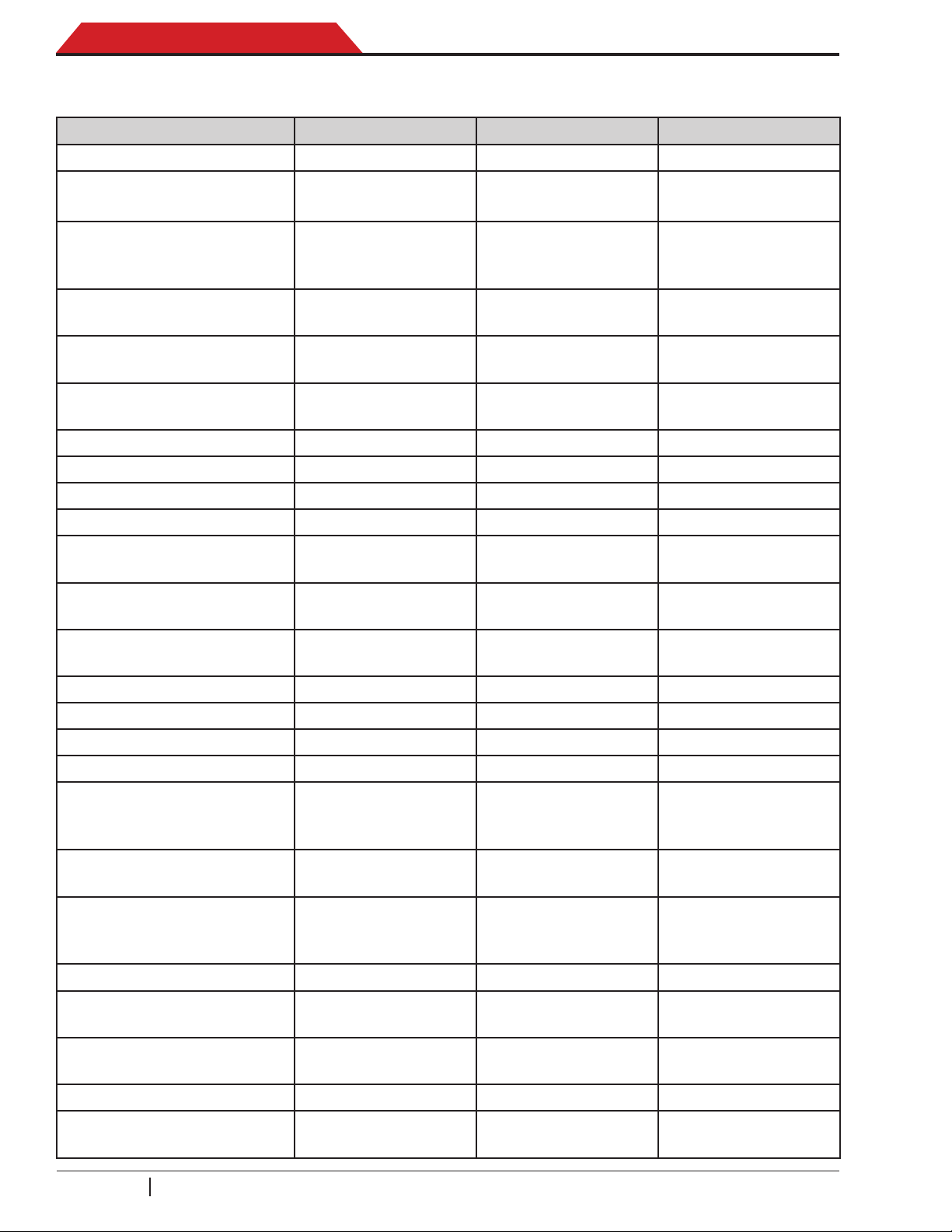

UNIT SPECIFICATIONS

ACS 763 ACS 863 ACS 753

Refrigerant R1234yf R1234yf R134a

ISV total capacity (water

capacity)

Internal Vessel Maximum

Storage Capacity (kg of

refrigerant)

Fluid Maximum Working

Pressure (PS)

Fluid Operating Tempera-

ture Range (TS)

Maximum Recovery Speed

(liquid phase)

Overall Leak Rate <80g/year <80g/year <80g/year

Power Supply 230 Vac/1 50/60 Hz 230 Vac/1 50/60 Hz 230 Vac/1 50/60 Hz

Overvoltage category II II II

Power Consumption 1100 W 1100 W 1100 W

Unit Storage Temperature

Range

Unit Operating Tempera-

ture Range

19.655 kg of R1234yf

(17.4 kg manageable

25 bar (2.5 Mpa) 25 bar (2.5 Mpa) 25 bar (2.5 Mpa)

-10 °C ÷ +120 °C -10 °C ÷ +120 °C -10 °C ÷ +120 °C

+10 °C ÷ +50 °C +10 °C ÷ +50 °C +10 °C ÷ +50 °C

22 l 22 l 22 l

19.655 kg of R1234yf

(17.4 kg manageable

by operator)

- - -

-20 °C ÷ +60 °C -20 °C ÷ +60 °C -20 °C ÷ +60 °C

by operator)

21.671 kg of R134a

(19.4 kg manageable

by operator)

Humidity (non-condensing) 32.2°C (90°F), 86%

RH

Maximum Altitude 2000 m (6561.66 ft) 2000 m (6561.66 ft) 2000 m (6561.66 ft)

IP Protection Rating IP20 IP20 IP20

Pollution dregree 2 2 2

Noise <70 dB(A) <70 dB(A) <70 dB(A)

Dimensions 105 x 75 x 77 cm

with HMI on shipping

position

Weight

(empty tank + accessories)

Display 7in. TFT WVGA

(800x480) color LCD

Filter 700 cc dessicant 700 cc dessicant 700 cc dessicant

Manometer Ø 100 mm

Bottles (Oils and Dye) 3 x 250 ml

112 kg 112 kg 112 kg

with LED backlight

EN 837-1 Class 1

sealed

32.2°C (90°F), 86%

RH

105 x 75 x 77 cm

with HMI on shipping

position

7in. TFT WVGA

(800x480) color LCD

with LED backlight

Ø 100 mm

EN 837-1 Class 1

3 x 250 ml

sealed

3°C (90°F), 86% RH

105 x 75 x 77 cm

with HMI on shipping

position

7in. TFT WVGA

(800x480) color LCD

with LED backlight

Ø 100 mm

EN 837-1 Class 1

3 x 250 ml

sealed

Service hoses 250 cm / SAE J2888 250 cm / SAE J2888 250 cm / SAE J639

Quick Couplers For R1234yf,

SAE J2888

SP00D00609 2018-03-26 Robert Bosch GmbH

20

For R1234yf,

SAE J2888

For R134a,

SAE J639

ACS 753, ACS 763, ACS 863 Service Manual

ACS 763 ACS 863 ACS 753

Flush Port Yes Yes Ye s

Introduct i o n

RefrigerantIdentier Optional as external

device

Flush Kit Optional for R1234yf Optional for R1234yf Optional for R134a

N2H2 Yes, embedded port

for external tank

Wireless Wi/BT usb dongle

into scope of delivery

External source cylinder

adapters

1234YF LS J639

MALE TO

W21.8-1/14LH

ADAPTER

ADAPTER 1234YF

LS J639 MALE

M26.2x1.8

ADAPTER 1234YF

LS J639 MALE

12.7 mm ACME16

Compressor

Power 1/4 HP 1/4 HP 1/4 HP

Displacement 8.85 cm

3

Embedded -

Yes, embedded port

for external tank

Wi/BT usb dongle

into scope of delivery

1234YF LS J639

MALE TO

W21.8-1/14LH

ADAPTER

ADAPTER 1234YF

LS J639 MALE

M26.2x1.8

ADAPTER 1234YF

LS J639 MALE

12.7 mm ACME16

8.85 cm

3

Yes, embedded port

for external tank

Wi/BT usb dongle

into scope of delivery

QUICK COUPLER

FOR COMMERCIAL

TANK 1/4” SAE

TANK ADAPTER

R134a - 21,8-14

G/1/4

8.85 cm

3

Recovery performance

- - -

(maximum, liquid phase)

Power Supply 230 Vac/1 50/60 Hz 230 Vac/1 50/60 Hz 230 Vac/1 50/60 Hz

Vacuum Pump

Free Air Displacement 170 l/min (6 CFM) 170 l/min (6 CFM) 170 l/min (6 CFM)

Ultimate Vacuum (min) 40 microns 40 microns 40 microns

Oil Capacity 700 ml 700 ml 700 ml

Type 2 stages oil bath 2 stages oil bath 2 stages oil bath

Power Supply 230 Vac/1 50/60 Hz 230 Vac/1 50/60 Hz 230 Vac/1 50/60 Hz

Scales

ISV scale accuracy ±15 g ±15 g ±15 g

Bottle scales accuracy ±2 g ±2 g ±2 g

21

SP00D00609 2018-03-26Robert Bosch GmbH

Introduct i o n

ACS 753, ACS 763, ACS 863 Service Manual

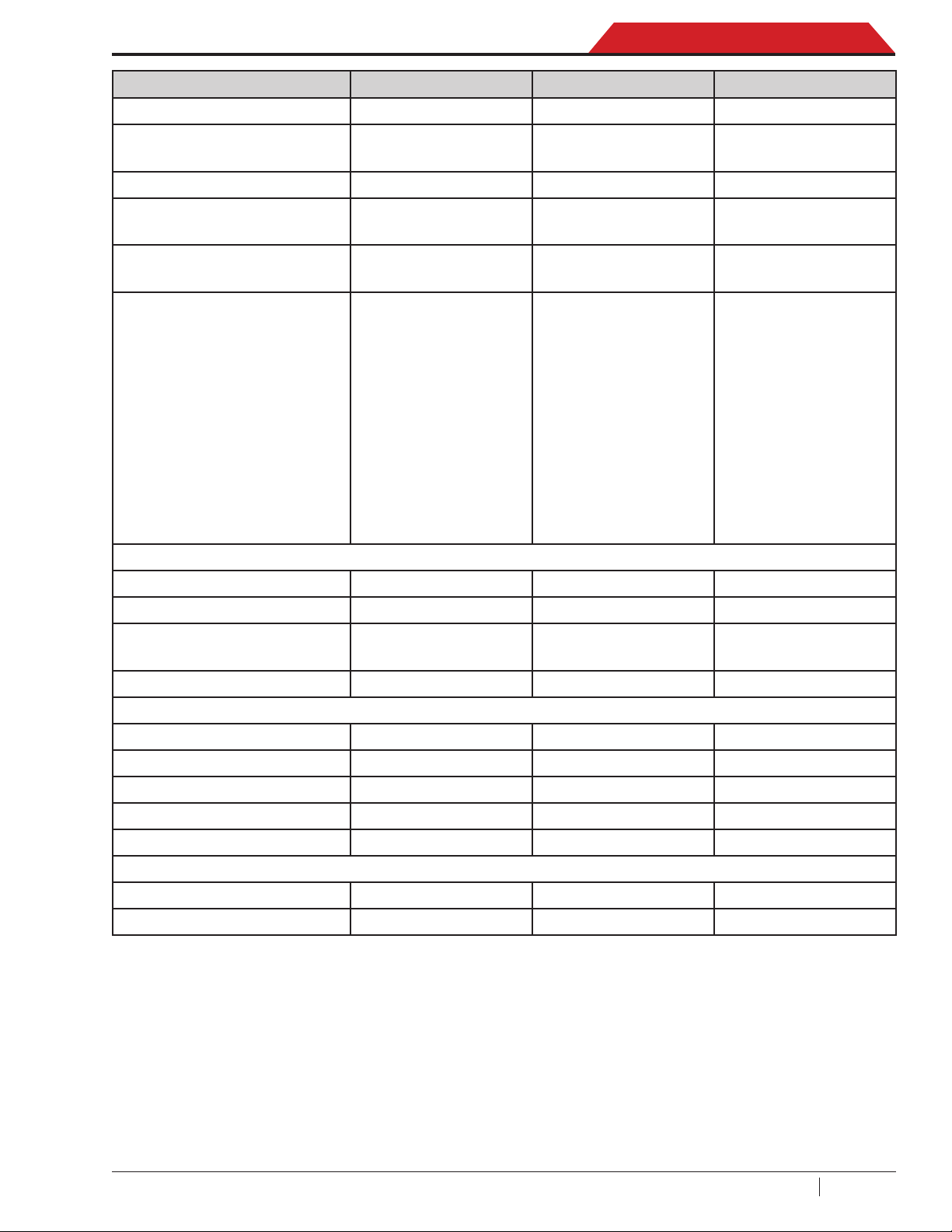

MAINTENANCE SCHEDULE

MAINTENANCE TASK RECOMMENDED INTERVAL

After (SEE TABLE) of refrigerant has

been ltered. Refer to Filter Change in the

Maintenance section of this manual.

Changelter

Change vacuum pump oil

Check casters and wheels for ease of

operation

Check internal scale calibration

Reset of PAG and POE Injection Oil, drain

oil and UV dye scales

Check machine for leaks

Model

R134a

Model

R1234yf

Replacement lter at:

68 kg (alert 56 kg)

Replacement lter at:

150 kg (alert 138 kg)

When the lter is replaced or every 100 hours.

Refer to Change Vacuum Pump Oil in the

Maintenance section of this manual.

Monthly.

Monthly. Refer to Calibration Check in the

Maintenance section of this manual. Every year

all scales must be calibrated by an authorized

service center.

Whenever it is necessary. Refer to Scales Reset

in the Maintenance section of this manual.

Automatic every 10 days (for R1234yf) or every

yearly (for R134a). Refer to Pressure Decay

Leak Test in the Maintenance section of this

manual.

Clean air intake panels Monthly. Use a clean cloth.

Clean cabinet and control panel Monthly. Use a clean cloth.

Inspect power cord and hoses for cuts

and abrasions

Lubricate wheel bearings and brake

components

Solenoid valves inspection

Checktheinternalrefrigerantidentier

lter(ACS863only)

Daily.

Monthly.

Every yearly — performed by an authorized

service center.

Daily.

Every six months or whenever it is dirty and / or

Changelterandsamplehoseofthe

internalrefrigerantidentier(ACS863

only)

clogged. Replace the sample hose assembly

during every lter change. Refer to Refrigerant

Identier Maintenance in the Maintenance

section of this manual.

Due to normal wear and tear, these units require regular maintenance to ensure safe operation

and optimum performance. The above chart provides a schedule of the minimum recommended

maintenance tasks.

SP00D00609 2018-03-26 Robert Bosch GmbH

22

ACS 753, ACS 763, ACS 863 Service Manual

Diagnostics and Testing

d I a g n o s T I C s and TesTIng

Functional Check ..................................................................................................24

Updating System Software Instruction ............................................................................24

Recover Function ...............................................................................................................25

Charge Function ................................................................................................................. 26

Diagnostics and Testing ....................................................................................... 28

Service Center Menu .......................................................................................................... 28

Diagnostics and Troubleshooting .....................................................................................28

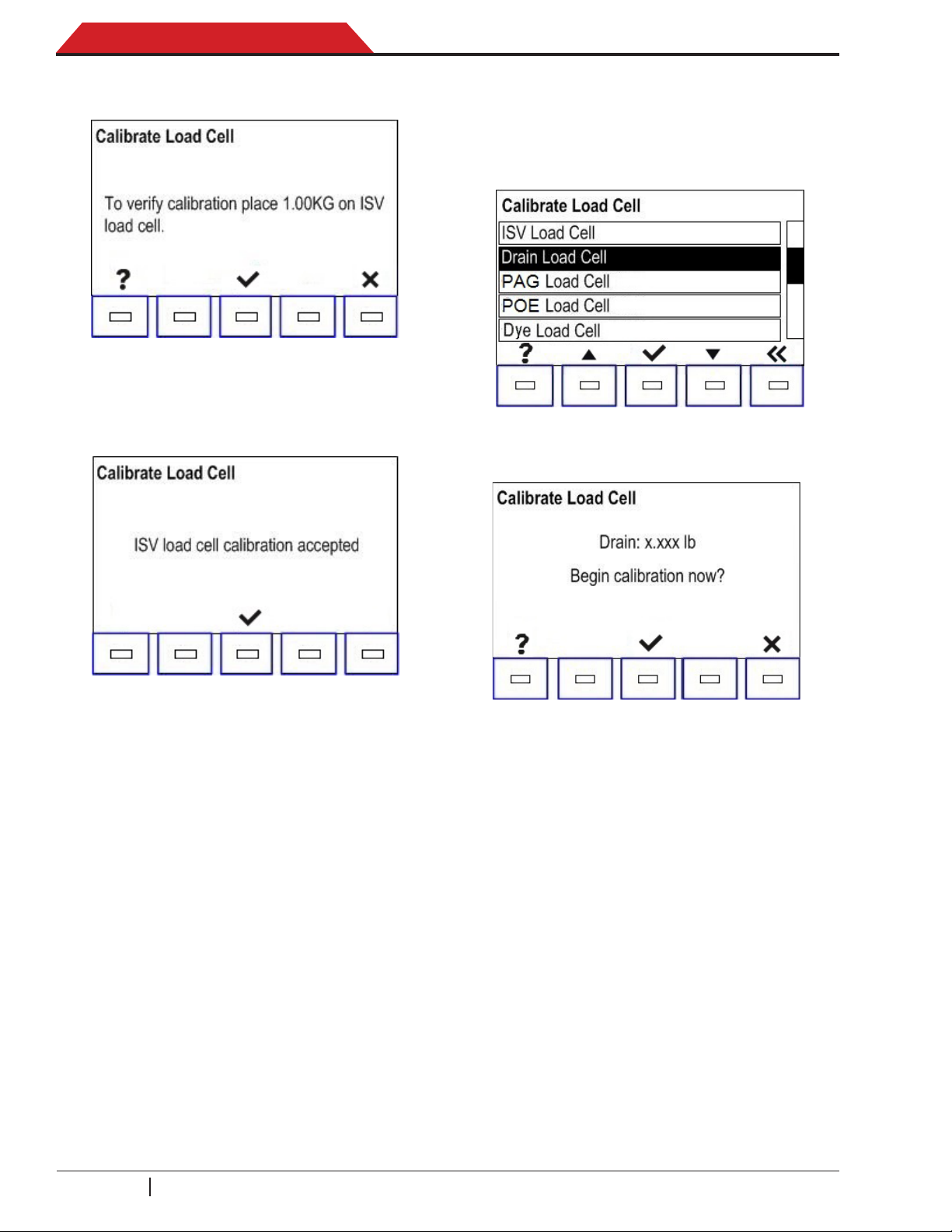

Calibrate Load Cells ........................................................................................................... 28

Output Test .......................................................................................................................... 32

Input Test ............................................................................................................................. 33

Calibrateairow .................................................................................................................33

A/C unit Internal Clearing ..................................................................................................34

Service Vacuum ..................................................................................................................34

End User Install ..................................................................................................................35

Maintenance Counters ....................................................................................................... 35

Keypad Test ........................................................................................................................ 37

Set Serial Number ...............................................................................................................37

Set Manufacturing Date .....................................................................................................37

Set Boot Mode ....................................................................................................................38

Reset Board ........................................................................................................................38

RefrigerantIdentier(ACS863only) ................................................................................ 39

Charge Leak Test ................................................................................................................ 39

10 Days Leak Test (R1234yf only) ..................................................................................... 39

Default Vacuum Time ......................................................................................................... 39

Default Vacuum Leak Test Time ........................................................................................39

Default Precharge Leak Test Time .................................................................................... 39

Service hose length ............................................................................................................39

Depressurizing the Unit ........................................................................................ 40

Unit is Functional ...............................................................................................................40

Unit is Not Functional ........................................................................................................40

Troubleshooting ....................................................................................................41

Grounding, Noise, and Power Issues ...............................................................................41

Will Not Power-Up, No Display .......................................................................................... 42

Will Not Fill Tank ................................................................................................................. 43

Stuck In Clearing ................................................................................................................43

Will Not Recover ................................................................................................................. 44

Will Not Deep Recover .......................................................................................................45

Will Not Drain Oil ................................................................................................................46

Will Not Air Purge ...............................................................................................................46

Will Not Evacuate (Vacuum) ..............................................................................................47

Fails Leak Test .................................................................................................................... 48

Will Not Inject Oil or Dye .................................................................................................... 48

Will Not Charge ................................................................................................................... 49

Slow Charge ........................................................................................................................ 49

Will Not Hose Flush ............................................................................................................ 49

Will Not Print ....................................................................................................................... 50

Power Board Troubleshooting ..........................................................................................51

Control Board Troubleshooting ........................................................................................51

Compressor Troubleshooting ...........................................................................................52

Vacuum Pump Troubleshooting ........................................................................................53

Error Messages .....................................................................................................54

23

SP00D00609 2018-03-26Robert Bosch GmbH

Diagnostics and Testing

FUNCTIONAL CHECK

ACS 753, ACS 763, ACS 863 Service Manual

Prior to performing a functional or diagnostic

check, make sure the software version is

current. This is especially true if the control

and/or power boards have been replaced. If

the software version is not current, corrupt,

or unknown, follow the procedure in Updating

System Software Instruction.

Updating System Software Instruction

To upgrade the rmware through a USB stick

or via WiFi (see Firmware update in the Setup

Menu function section).

Download and install current Software

with USB stick

Equipment Requirements:

(1) USB stick

This item may be purchased from most retail

office supply/electronics stores or from any

online retailer that carries computer accessories.

In case of Firmware update with USB stick

follow the instruction:

1. Insert the USB stick to your computer.

2. Format as FAT32.

3. Download the current software from:

\EDIS\software\systemsw\acs6xx_7xx\.

4. Put the zip package as is into the root folder

of the USB stick.

5. Insert the USB stick into the USB port on

the unit.

6. Turn ON the unit.

7. Call up the Main Menu.

8. Select NEXT icon.

9. Select MENU icon.

10. Select Settings

USB Update.

11. Allow the unit to install the software completely and then remove the USB stick, this

operation may requires several minutes.

12. Wait the screen that ask to reboot the unit at

the end of the update process and so recyle

the unit power.

13. When the unit reboot conrm the installation

procedure by press <Yes> button when the

bootloader black and white screen is shown.

" Firmware update and

14. The unit will go through a le updating pe-

riod (it can take several minutes) to nalize

the entire update procedure, then will display the Main Menu.

Install Current Software with WiFi

Once WiFi connection has been established

select Wi-Fi Update (Call up the Main Menu and

select Next " Menu " Settings " Firmware

update " Wi-Fi Update)

.

1. Manual path:

Select Wi-Fi Update and check the new

software availability then select HELP

icon to look into release note or OK icon

to start the update procedure that is

composed by the following steps:

• Downloading compressed software package.

• Decrypt the software package and validate it to be sure that is a not corrupted.

• Decompress the content.

• Install all new les.

• Request user to reboot unit and complete

the install procedure.

• When the unit reboot conrm the installation procedure by press <Yes> button

when the bootloader black and white

screen is shown.

• The unit will go through a le updating

period (it can take several minutes) to

nalize the entire update procedure, then

will display the Main Menu.

2. Automatic path:

After the connection to internet network is

available, when the ACS unit is switched

on, it’s automatically connect to the same

network and immediately (before to show

the Main Menu) it will search for new software is available of not, if yes it will show

a message to process as above (point 1).

SP00D00609 2018-03-26 Robert Bosch GmbH

24

ACS 753, ACS 763, ACS 863 Service Manual

Diagnostics and Testing

NOTE: Refer to Scale Calibration at

Replacement Scale Assembly/Magnet in the

Electrical section, if necessary.

The Recover and Charge function tests must be

performed sequentially, in the order presented

here.

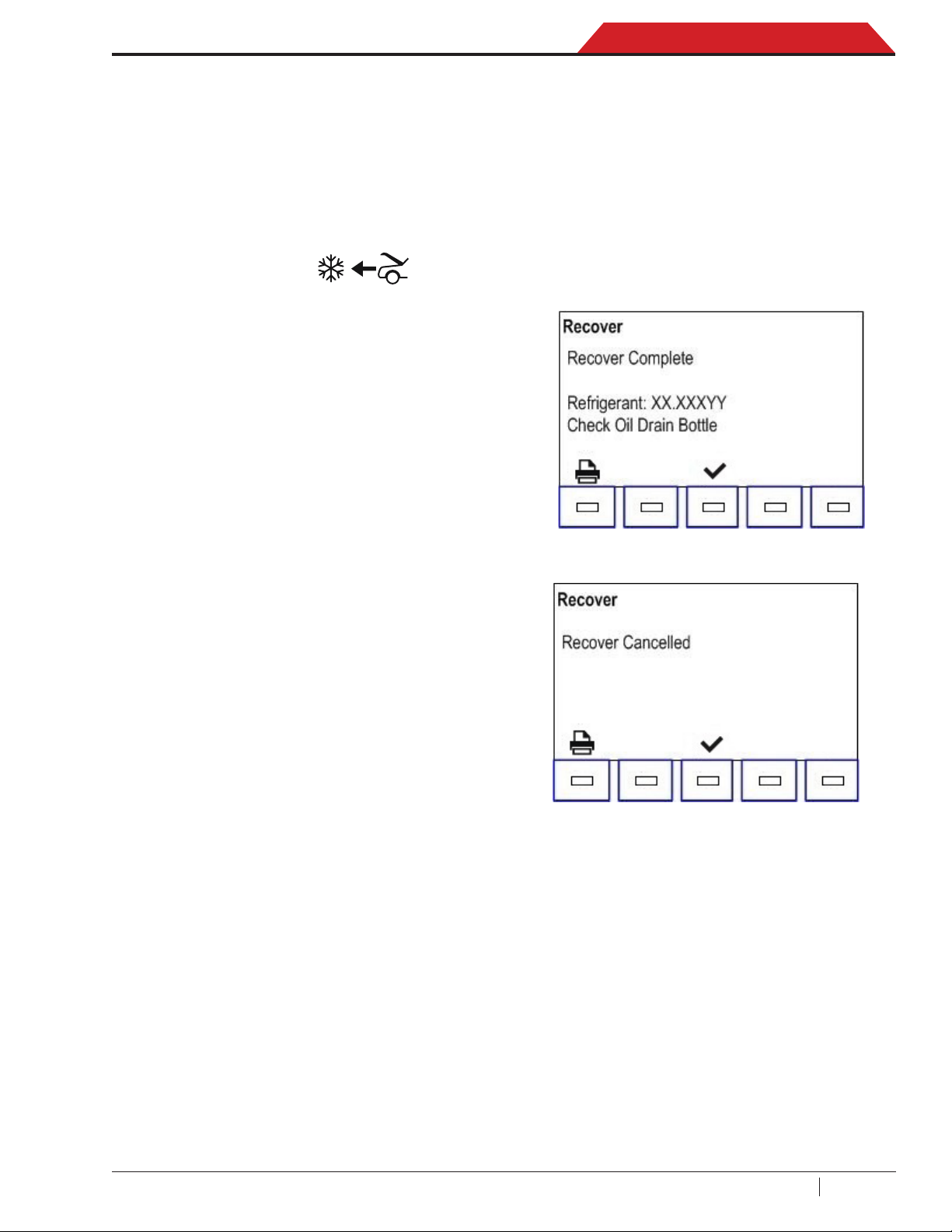

Recover Function

During the Recover process, the system will

initiate a lter check, service data entry, and

inlet pressure check.

1. Empty the oil drain bottle before starting a

recovery.

2. Connect the high-side (red) and/or low-side

(blue) hoses to the test tank.

3. Open the coupler valves on the hoses by

turning the collars clockwise.

4. Select the RECOVER icon from the main

menu.

5. The screen will message display: “Connect

both service hoses to AC system being

serviced and open both coupler valves”.

6. Select OK icon and unit perform:

• inlet pressure check.

• A/C unit internal clearing process.

• 1st recovery stage.

• 2 st recovery stage (deep recover).

7. Select OK icon to continue or ESC icon to

cancel.

11. 2th stage recovery. Unit perform special

deep recovery function where pump and

compressor are working togheter to intake all

refrigerant small parts still in the A/C vehicle

system. Deep recover min tiem is 5 minutes.

Then Oil drain process to evacuate the

accumulator from used oil recoverd by vehicle.

12. After the oil drain is complete, a summary

of the amount of refrigerant recovered and

oil drained is displayed. The unit displays:

Or:

8. The machine (ACS 863 only) checks the

refrigerant in the source tank to verify it

is R1234yf and not contaminated. The

machine displays the following screens:

INITIALIZING REFRIGERANT IDENTIFIER

ANALYZING REFRIGERANT SAMPLE

REFRIGERANT PURITY PASSED

9. The unit will run low-side clearing then enter

st

into a 1

stage Recovery.

10. When the system has recovered to

-0.4 bar, the vacuum pump starts and runs

until recover is complete.

13. Select Print icon to print out recovery

information and pre-recover diagnostics or

select OK icon to return the main menu.

The displayed recovered weight can vary

depending on ambient conditions and

should not be used as an indicator of

scale accuracy. The amount of oil that was

removed from the A/C system is the amount

of new oil that can be charged into the A/C

system after evacuation is complete.

• Use only new oil to replace the oil removed

during the recycling process.

• Dispose of used oil according to government

laws and regulations.

Recovery is complete.

25

SP00D00609 2018-03-26Robert Bosch GmbH

Diagnostics and Testing

ACS 753, ACS 763, ACS 863 Service Manual

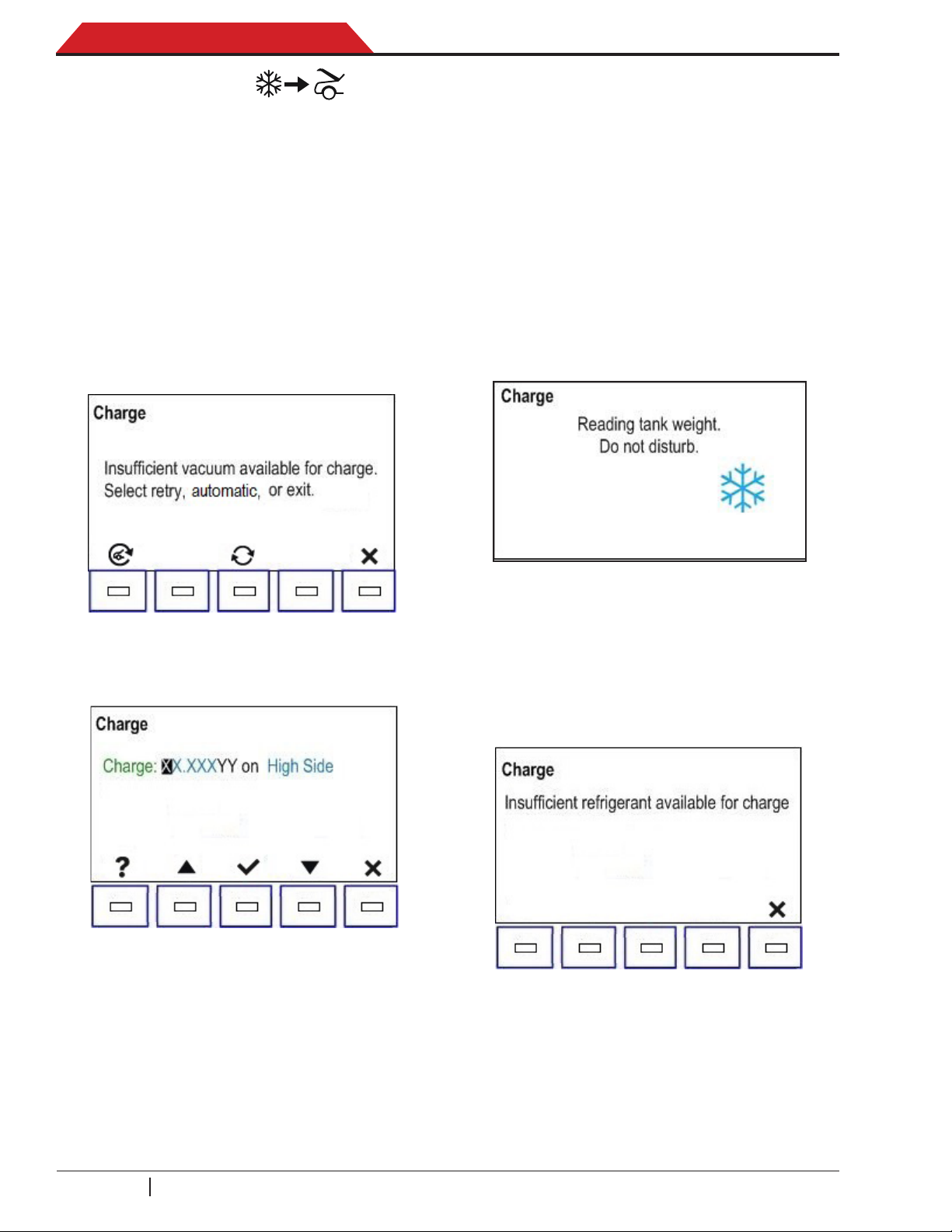

Charge Function

Automatic leak tests will be performed during

the charge function. To avoid false failures,

the temperature of the vehicle system and the

temperature of the recovery machine should be

within ±5 degrees °C of each other.

1. Connect (or verify) both service hoses to

the test tank and turn the quick couplers

clockwise.

2. Select the CHARGE icon from the main

menu. Unit show the ENTER VEHICLE

DATA input page, confirm with OK icon.

The following display may show:

Machine is asking to input:

• Oil inject (Yes or No). If select No unit

don’t inject any oil (neither the recovered

one).

• Oil amount: xxx ml (is possible set as ml,

oz or lb).

• Oil type: 2 option (PAG or POE).

• Dye inject amount: xxx ml (is possible set

as ml, oz or lb).

4. Conrm with OK icon and begin the charge

process. Moving or bumping the unit at this

point may result in an inaccurate charge.

Charging please wait displays:

If there is sufficient vacuum available, this

displays:

Machine is asking to input:

• Charge amount (min is 10 g).

• Select charge hoses (3 option: High, Low

and Both side).

3. Select OK icon to continue.

5. When the charge cycle gets close to the

desired weight value, the machine slows

down. It will charge, settle, charge again,

settle, etc.

6. If there is not sufcient refrigerant in the tank

to charge the system, the display shows:

7. Select ESC icon to exit. May require tank ll.

SP00D00609 2018-03-26 Robert Bosch GmbH

26

ACS 753, ACS 763, ACS 863 Service Manual

Diagnostics and Testing

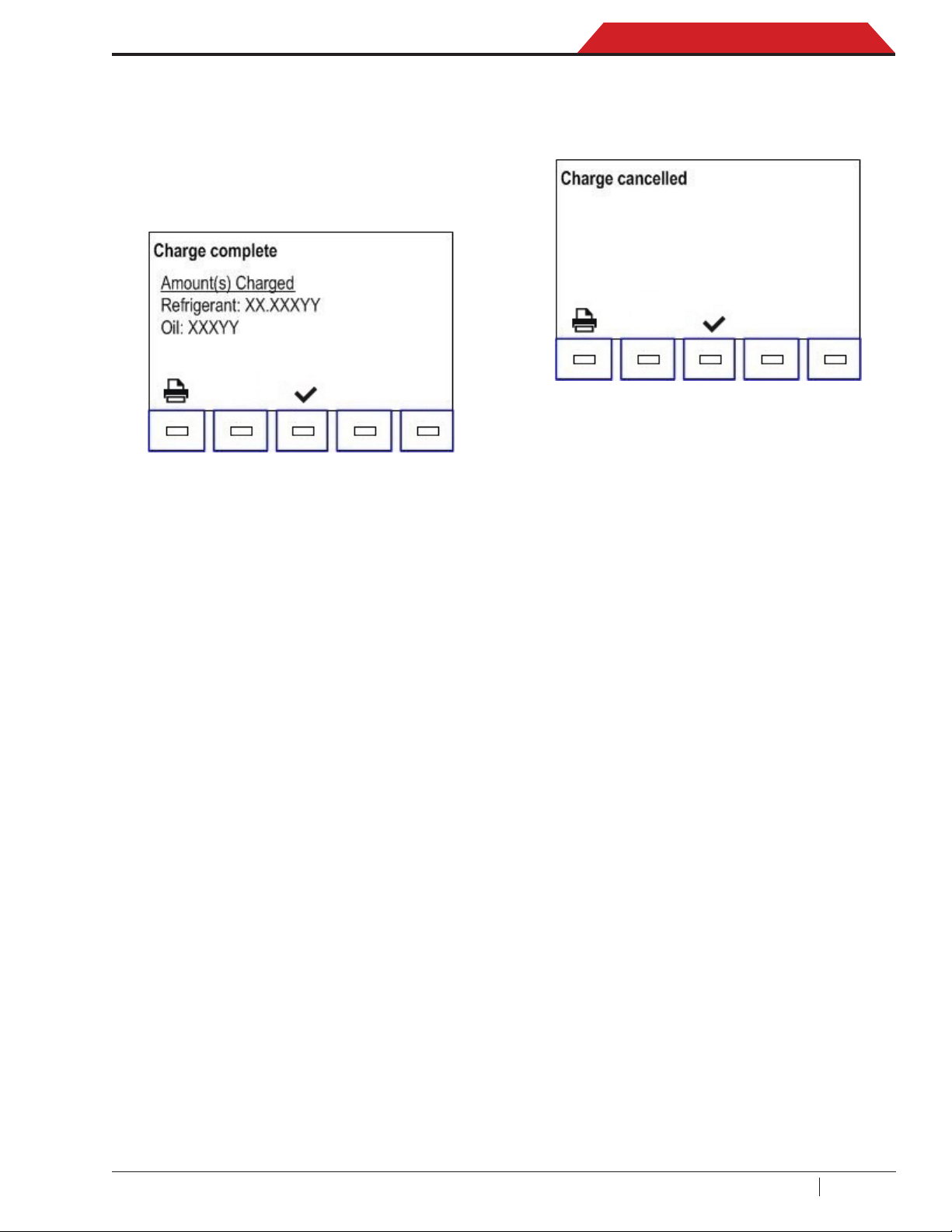

8. If the amount of refrigerant is sufficient

to charge the system to completion, the

display will show hoses compendation a

few seconds and then close coupler valves

and disconenct service hoses from vehicle.

The charge is complete:

9. Select OK icon then the unit will begin a

hose clearing process to remove refrigerant

from the hoses, followed by a short recovery.

10. At the end unit show the charged data and

print out option.

11. If the charge was cancelled, Charge

complete will change to Charge cancelled

and the values on the display will disappear:

12. Select OK icon to exit.

13. The unit will begin a hose clearing process

to remove refrigerant from the hoses,

followed by a short recovery.

Charge is complete.

27

SP00D00609 2018-03-26Robert Bosch GmbH

Diagnostics and Testing

ACS 753, ACS 763, ACS 863 Service Manual

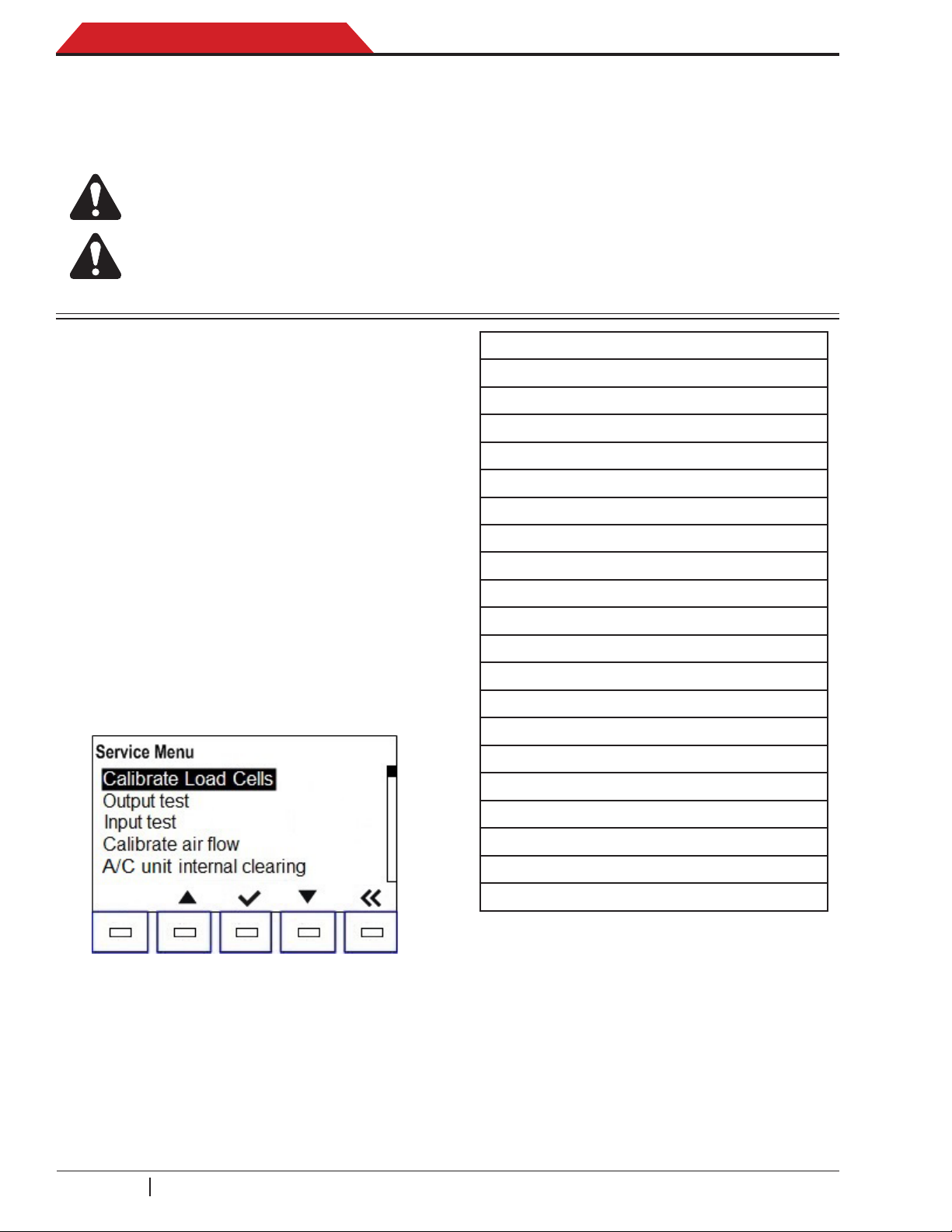

DIAGNOSTICS AND TESTING

NOTE: These are the Service Options at the time of printing this service manual. Some options

may be added or deleted in future circuit board and software updates and revisions.

WARNING: Never change the default settings unless directed by the factory.

Otherwise the unit may fail to operate properly.

WARNING: Never give the programming or service codes to customers.

Service Center Menu

NOTE: Consult the Technical Service Bulletins

for the latest software version as applicable. To

navigate through the Service Menu, use the

keypad and arrow keys.

Diagnostics and Troubleshooting

1. Turn unit on and allow it to run through the

boot sequence.

2. Select NEXT icon.

3. Select MENU icon.

4. Select MAINTENANCE.

5. From the maintenance menu, scroll up and

nd SERVICE MENU.

6. Enter yearly password then select OK icon.

The following displays:

Service Menu

• Calibrate Load cell

• Output test

• Input Test

• Calibrate air ow

• A/C unit internal clearing

• Service vacuum

• End user install

• Maintenance counters

• Keypad test

• Set serial number

• Set Manufacturing date

• Set boot mode

• Reset Board

• Refrigerant identier

• Charge leak test

• 10 days leak test

• Default vacuum time

• Default vacuum leak test time

• Default precharge leak test time

• Service hose length

Calibrate load cell

• To perform any of the checks in the Service

Menu, use the up and down arrows to scroll

to the desired test listed and select OK icon.

• To exit the Service Menu, select BACK icon.

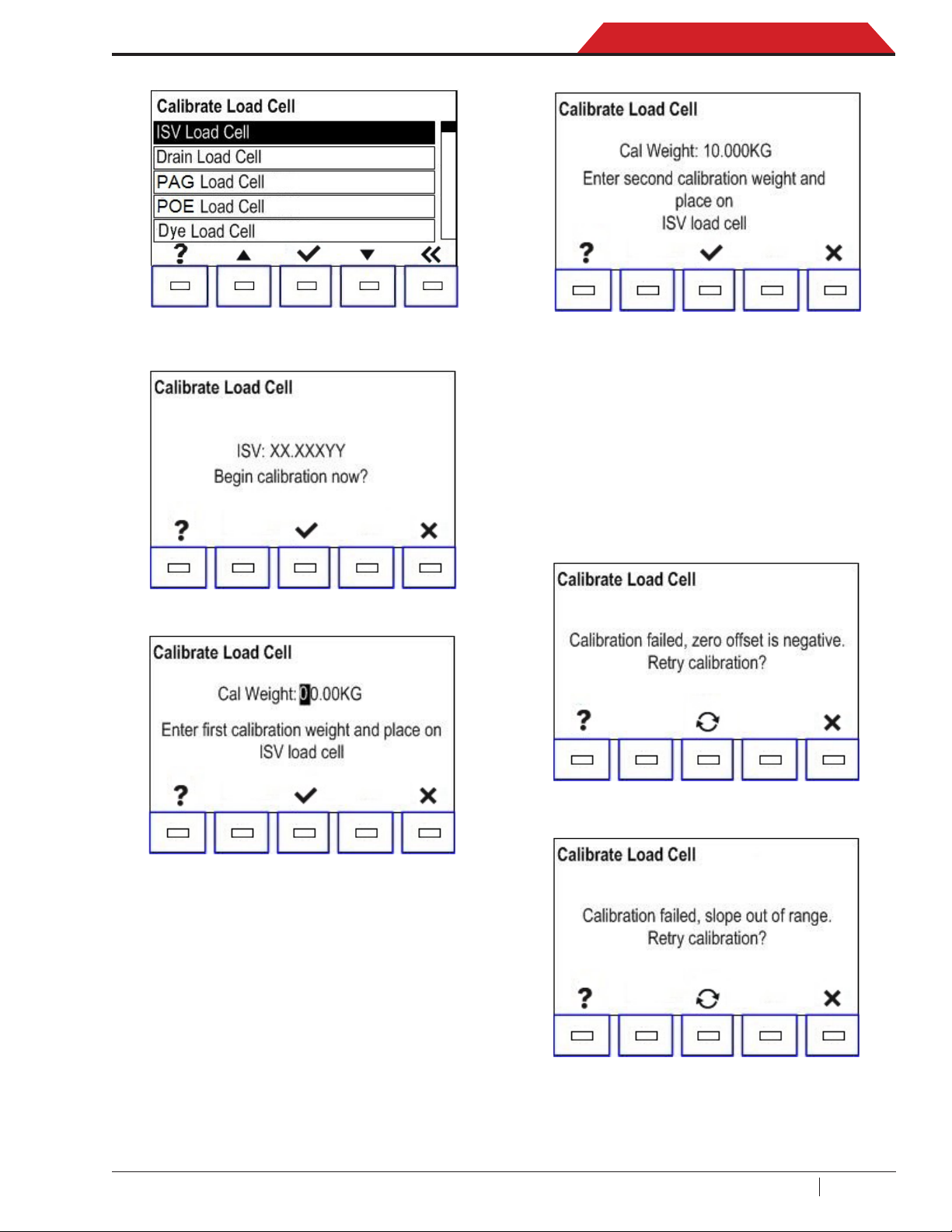

All units include load cell scales: ISV Load Cell,

Drain Load Cell, PAG Load Cell, POE Load Cell

and Dye Load Cell.

ISV Load Cell Calibration

1. After selecting Calibrate Load Cell from

the Service Menu by pressing OK icon, the

following displays:

SP00D00609 2018-03-26 Robert Bosch GmbH

28

ACS 753, ACS 763, ACS 863 Service Manual

Diagnostics and Testing

After 5 seconds:

2. Select OK icon to enter the ISV load cell

calibration.

3. Select OK icon to begin the calibration.

5. Place a 10 kg (editable) weight on the scale

and enter the weight using the keypad.

When nished, select OK icon to save the

entered weight value.

6. If the calibration is accepted, the offset and

slope will be calculated. If either calculation

fails, a fail screen for the offset or slope will

be displayed.

Offset Failure:

4. Use the calibration weight as displayed for

this step. (The rst weight should be 0 as

displayed on the screen.) Select OK icon to

save the displayed weight value.

NOTE: DO NOT DISTURB unit during weight

calibration.

Slope Failure:

The operator is given the opportunity to

retry the calculation or to exit the calibration

function.

29

SP00D00609 2018-03-26Robert Bosch GmbH

Diagnostics and Testing

ACS 753, ACS 763, ACS 863 Service Manual

7. If the calculation is accepted, the following

is displayed:

8. Typically adding 1.00 kg (2 lb) is sufcient

to perform this test.

9. If OK icon is selected and the calibration is

accepted, the following displays:

Drain Load Cell Calibration

1. With the Calibrate Load Cell menu displayed,

use the up/down arrow keys to toggle to the

Drain Load Cell service menu. The following

displays:

2. Select OK icon to enter the Drain Load Cell

calibration menu. The following displays:

10. Select OK icon to terminate.

11. If the calibration is not accepted, a Calibration

Failed screen is displayed as shown in Step 6.

12. Selecting ESC icon returns to Calibrate

Load Cell in the service menu.

3. Select OK icon to begin the calibration.

Selecting ESC icon returns to the Calibrate

Load Cell service menu.

Follow all remaining calibration instructions

displayed.

• First point calibration without nothing.

• Second point calibration with 500 g (editable).

• Check with 250 g (not editable) and con-

rm with OK icon.

NOTE: DO NOT DISTURB unit during weight

calibration.

SP00D00609 2018-03-26 Robert Bosch GmbH

30

Loading...

Loading...