Bosch ACS 751, ACS 651 Repair Instructions

ACS 651/751

en

Repair instructions

A/C service unit

2 | ACS 751/651 | en

Contents English

1. Important information 4

2. Testing and resources 4

3. Description 5

3.1 ACS 651/751 5

3.1.1 Front view 5

3.1.2 Rear view 5

3.2 Components 6

3.2.1 Mounting place 6

3.2.2 Human Machine Interface (HMI) 6

3.2.3 Refrigerant cylinder 7

3.2.4 Pressure manifold 7

3.2.5 Vacuum pump 7

3.2.6 Compressor 7

3.2.7 Fan 7

3.2.9 I/O board 8

3.2.8 Human Machine Interface board

(main board) 8

4. Troubleshooting 9

4.1 By status messages 9

4.2 By symptoms 15

4.3 Entering the debug mode 16

4.4 Overview of actuators 16

5. Scales 16

5.1 Calibration of scales 16

5.1.1 Fresh Oil / used oil / UV dye scales 16

5.1.2 Calibration of the refrigerant tank

scale 17

5.2 Replacing scales 18

5.2.1 Replacing used oil/fresh oil/ UV dye

scale 18

5.2.2 Replacing scale assembly for

refrigerant cylinder 19

6. Panels 19

6.1 Opening the top panel 19

6.2 Opening the front panel 20

6.3 Opening the rear panel 20

6.4 Opening the right panel 20

6.5 Opening the left panel 20

6.6 Replacing the front wheels 21

6.7 Replacing the rear wheels 21

7. HMI module 21

7.1 Opening the HMI 21

7.2 Replacing the LCD 22

7.3 Replacing the printer 22

7.4 Replacing the keypad 23

7.5 Replacing the pressure gauges 23

8. Boards 24

8.1 Replacing the HMI board 24

8.2 Replacing the Switch Mode Power Supply

(SMPS) 24

8.3 Replacing the I/O board 24

9. Refrigerant cylinder 25

9.1 Replacing the refrigerant cylinder 25

9.2 Air purging 25

9.3 Replacing the air purge manifold on the

cylinder 26

9.4 Replacing the temperature sensor on the

cylinder 27

10. Pressure Manifold 28

10.1 Replacing the valve block of the pressure

manifold 28

10.2 Replacing the hoses between the

cylinder and the pressure manifold 28

10.3 Replacing the POE solenoid valve 29

10.4 Replacing the POE plug 30

11. Vacuum pump 30

11.1 Replacing the vacuum pump 30

11.2 Checking the vacuum pump function 31

1 689 975 223 2013-10-21| Robert Bosch GmbH

12. Compressor and fan 31

12.1 Replacing the compressor 31

12.2 Checking the compressor function 32

12.3 Replacing the fan assembly 32

13. Replacing the wiring

harness 33

13.1 Replacing the wiring harness 1 33

13.2 Replacing the wiring harness 2 33

13.3 Replacing the wiring harness 3 33

13.4 Replacing the wiring harness 4 34

13.5 Replacing the wiring harness 5 34

13.6 Replacing the wiring harness 6 34

13.7 Replacing the connecting cable for the

temperature sensor 34

13.8 Replacing the USB host cable 34

13.9 Replacing the LED board cable 34

14. Replacing Hoses 35

14.1 Replacing the PA11 hose between the

compressor and the manifold 35

14.2 Replacing the PA11 hose for the HP/LP gauge 35

| ACS 751/651 | 3ACS 751/651 | 3 | 3

en

15. Replacing power supply 36

15.1 Replacing the cable socket 36

15.2 Replacing the fuse 36

14.3 Replacing the PA12 hose for the vacuum pump 36

14.4 Replacing the PA12 hose for the compressor 36

14.5 Replacing the silicon rubber hose for

Fresh-Oil, Used-Oil and UV-Dye 36

14.6 Replacing the hose between the oil separator

and the compressor 36

16. Test Points 37

17. Hydraulic circuit diagram 38

18. Electrical terminal diagram 39

1 689 975 223 2013-10-21| Robert Bosch GmbH

4 | ACS 751/651 | Important informationen

1. Important information

Installation and/or repairs may only be carried out by

trained and instructed Robert Bosch GmbH

customer service staff or organizations authorized by

Robert Bosch GmbH. Opening or modification of the

units by unauthorized persons will invalidate all

warranty entitlements.

Electrical systems and equipment may only be commissioned in proper condition (see Testing Technology

Information 0108_084 for details). This requirement

is met if, after modification or repair (initial test), it is

ensured that the requirements of the electrical engineering regulations are adhered to. To verify this, tests

should be performed, the type and scope of which

should be based on the measures defined in the electrical engineering regulations (e.g. in Germany BGV A3).

In Germany, the type and scope of the tests are described in VDE 0701/0702 Part 1. The corresponding

national regulations must be adhered to.

2. Testing and resources

R General tools for electricians and A/C mechanics

R Digital multimeter

R Loctite 577 for hoses

R Cleaning medium (e.g. brake cleaner)

R Calibration weights for UV dye/oil bottles

(part number F 002 DG1 416)

R Weights for calibration of refrigerant scale - 6 kg

(part number F 002 DG1 650)

1 689 975 223 2013-10-21| Robert Bosch GmbH

Description | ACS 751/651 | 5ACS 751/651 | 5 | 5 en

0

2

4

6

8

10

0

5

10

15

20

25

30

35

12

HP

LP

14

!

2

ABC

3

DEF

6

MNO

ABC

123

8

TUV

7

PQRS

5

JKL

4

GHI

1

c

i

+

*

9

WXYZ

0

]

1 2 3

4

7

6

5

459897_18Nkv

8

9

10

459898_19Nkv

1

2

3

4

567

9

8

3. Description

3.1 ACS 751/651

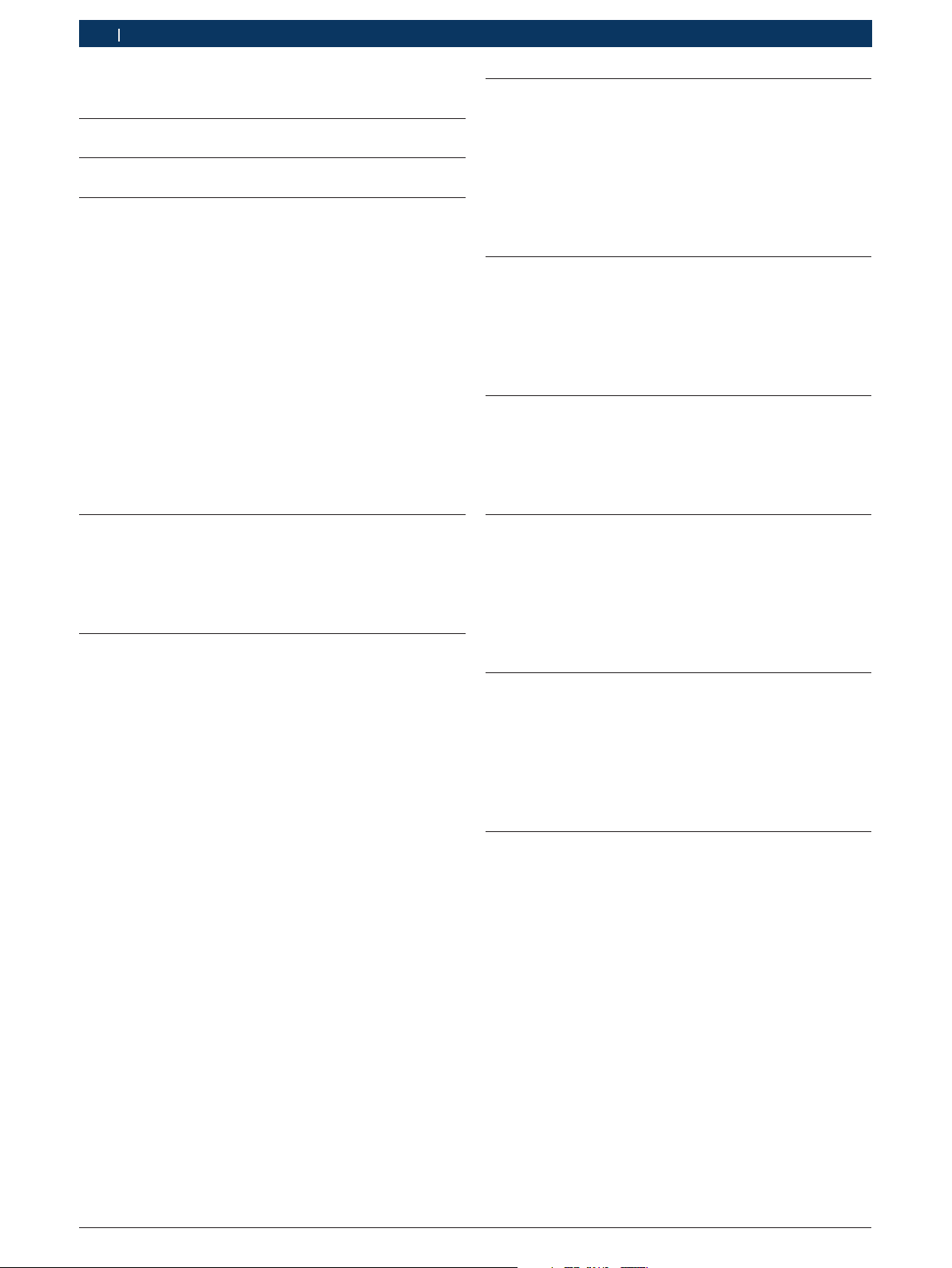

3.1.1 Front view

3.1.2 Rear view

Fig. 2: Rear view

1 HMI support

2 Power switch

Fig. 1: Front view

1 Handle

2 Human Machine Interface (HMI)

3 Top panel

4 Service hatch

5 HP quick coupler

6 Service hoses

7 LP quick coupler

3 Left service hatch

4 Left panel

5 Rear panel

6. Rear wheel with brake

7 Power inlet

8 Power cable

9 Cable holder

8 Front wheel

9 Front service hatch

10 Inline filters

1 689 975 223 2013-10-21| Robert Bosch GmbH

6 | ACS 751/651 | Descriptionen

i

C

!

HP

LP

1

2

3

5

4

6

7

1

2

3

4

5

6

7

8

9

*

+

0

ABC

123

]

459897_6Nkv

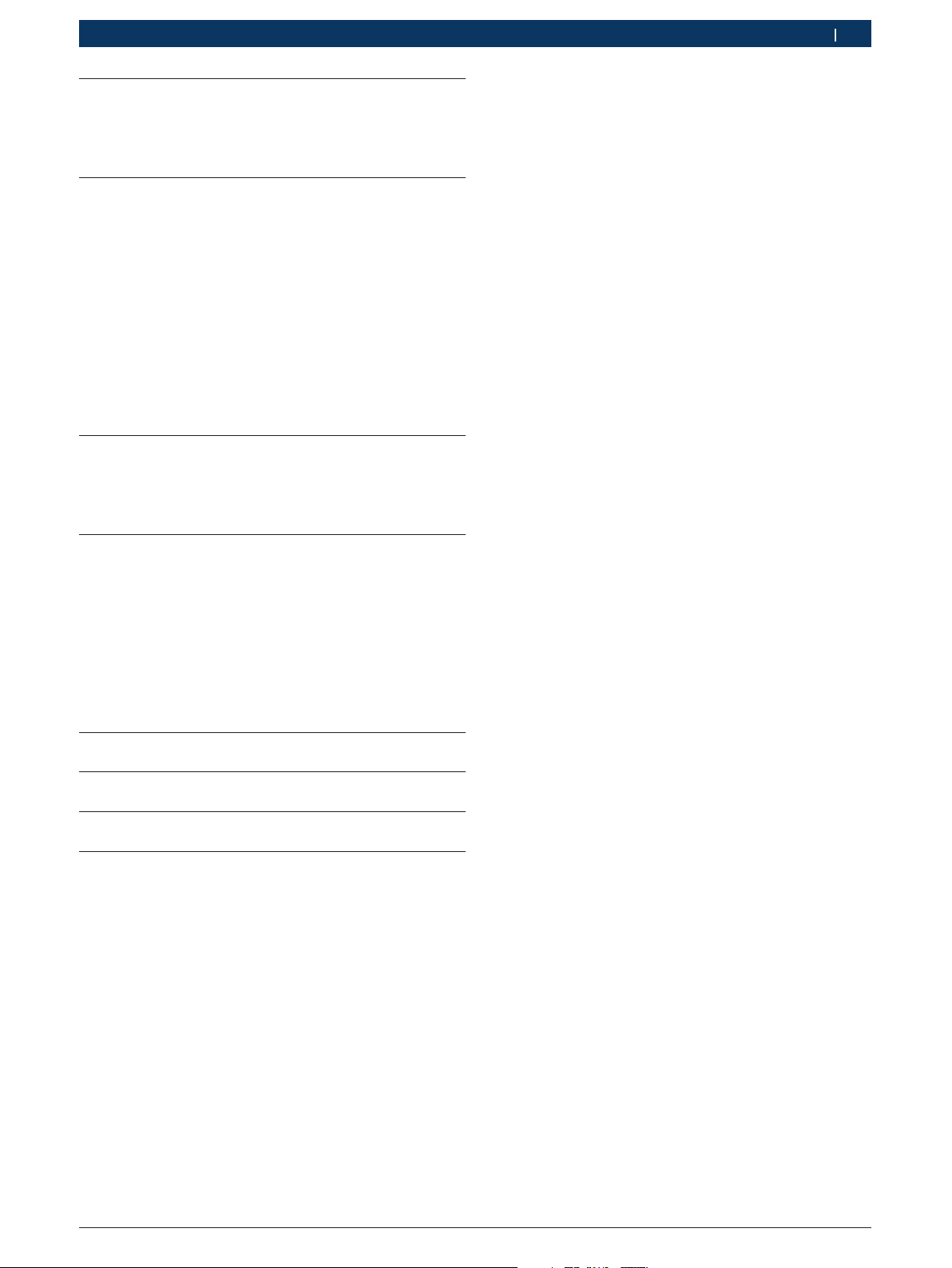

3.2 Components

3.2.1 Mounting place

15

14

13

12

11

3.2.2 Human Machine Interface (HMI)

1

2

3

4

5

6

Fig. 4: ACS 751/651 HMI module

1 HP gauge

2 Status and warning light

3 LP gauge

4 LCD

5 Input keys

6 Selection and function keys

7 Printer

7

459898_21Nkv

10

8

9

Fig. 3: General overview

1 High pressure gauge

2 Low pressure gauge

3 Pressure manifold

4 Air purge manifold

5 Temperature sensor

6 Refrigerant cylinder

7 Oil separator

8 Compressor

9 Fan

10 Used oil bottle

11 Fresh oil bottle

12 Vacuum pump

13 UV dye bottle

14 Keypad

15 LCD

1 689 975 223 2013-10-21| Robert Bosch GmbH

Description | ACS 751/651 | 7ACS 751/651 | 7 | 7 en

459898_9Nkv

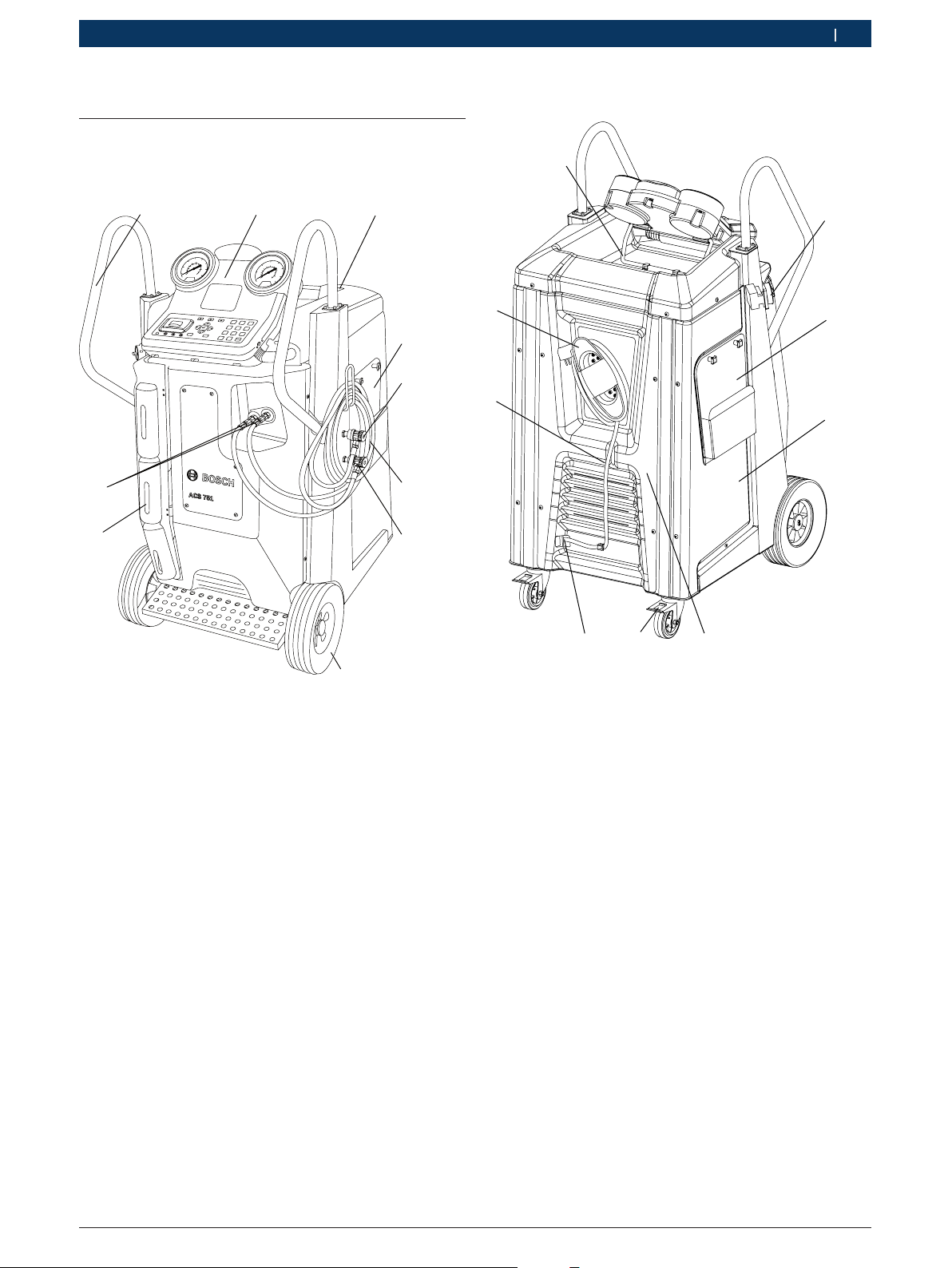

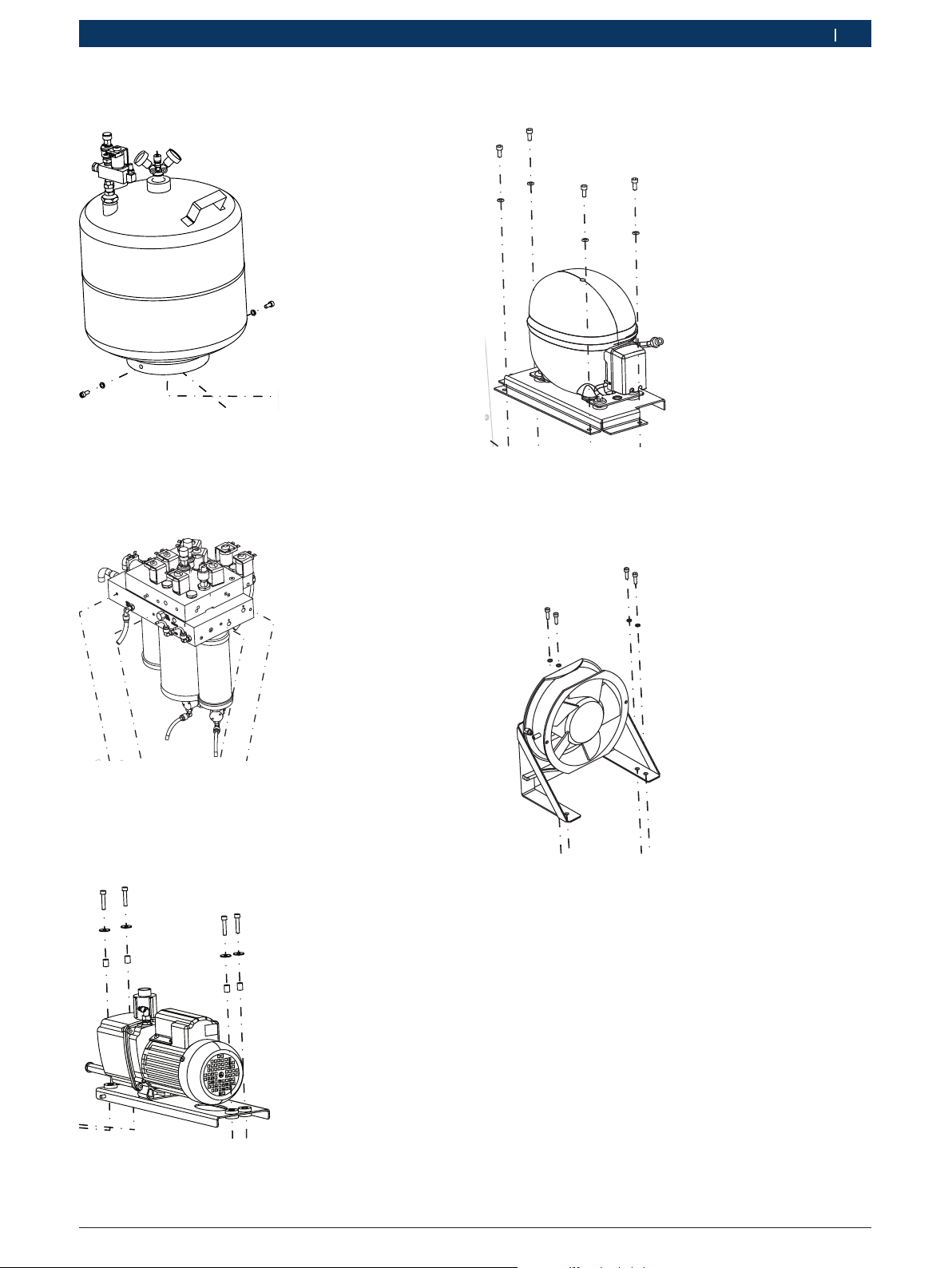

3.2.3 Refrigerant cylinder

Fig. 5: Refrigerant cylinder overview

3.2.4 Pressure manifold

3.2.6 Compressor

Fig. 8: Compressor overview

3.2.7 Fan

Fig. 6: Pressure manifold overview

3.2.5 Vacuum pump

Fig. 7: Vacuum pump overview

Fig. 9: Fan overview

1 689 975 223 2013-10-21| Robert Bosch GmbH

8 | ACS 751/651 | Descriptionen

1

1

2

3

4

5

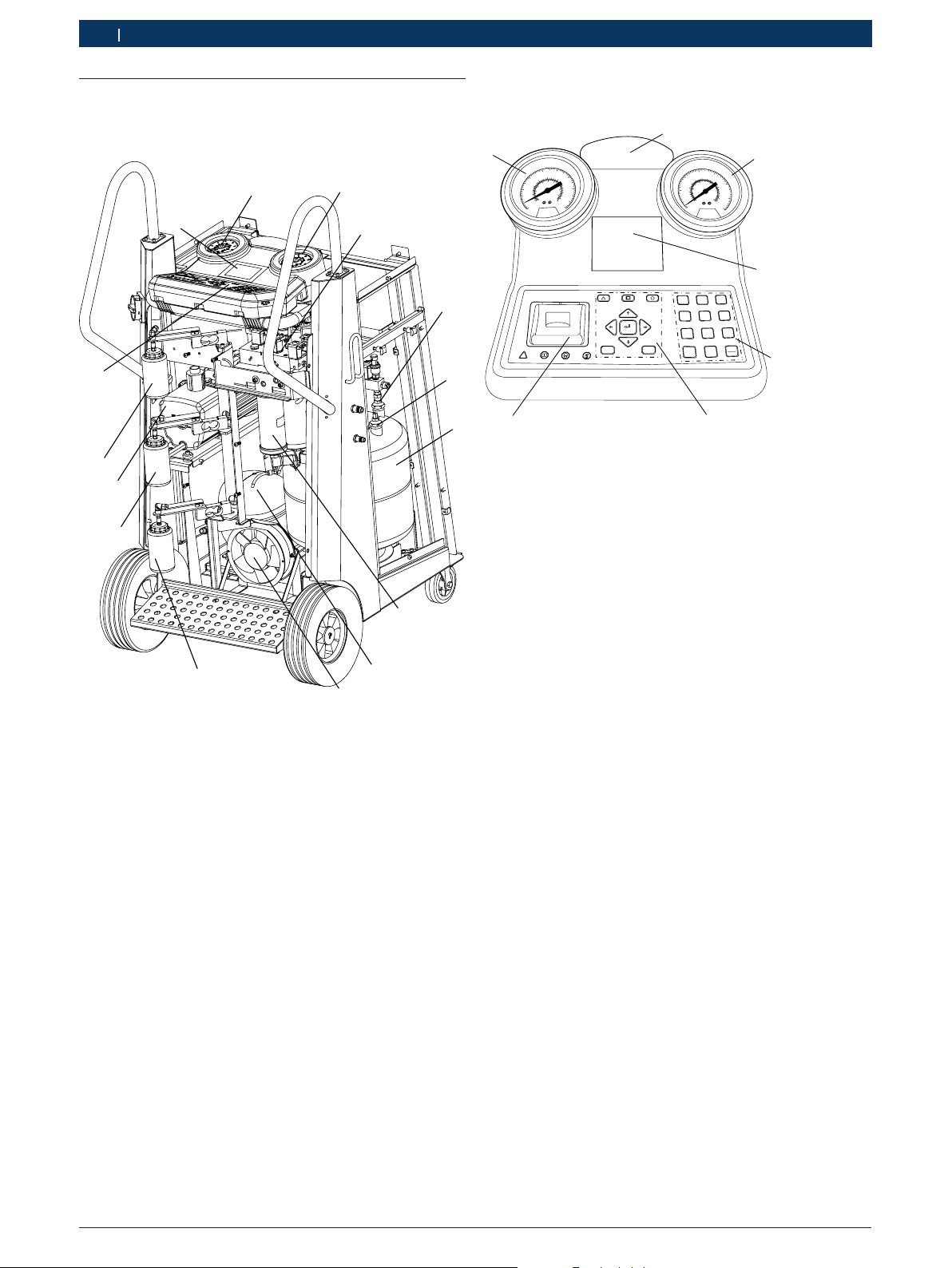

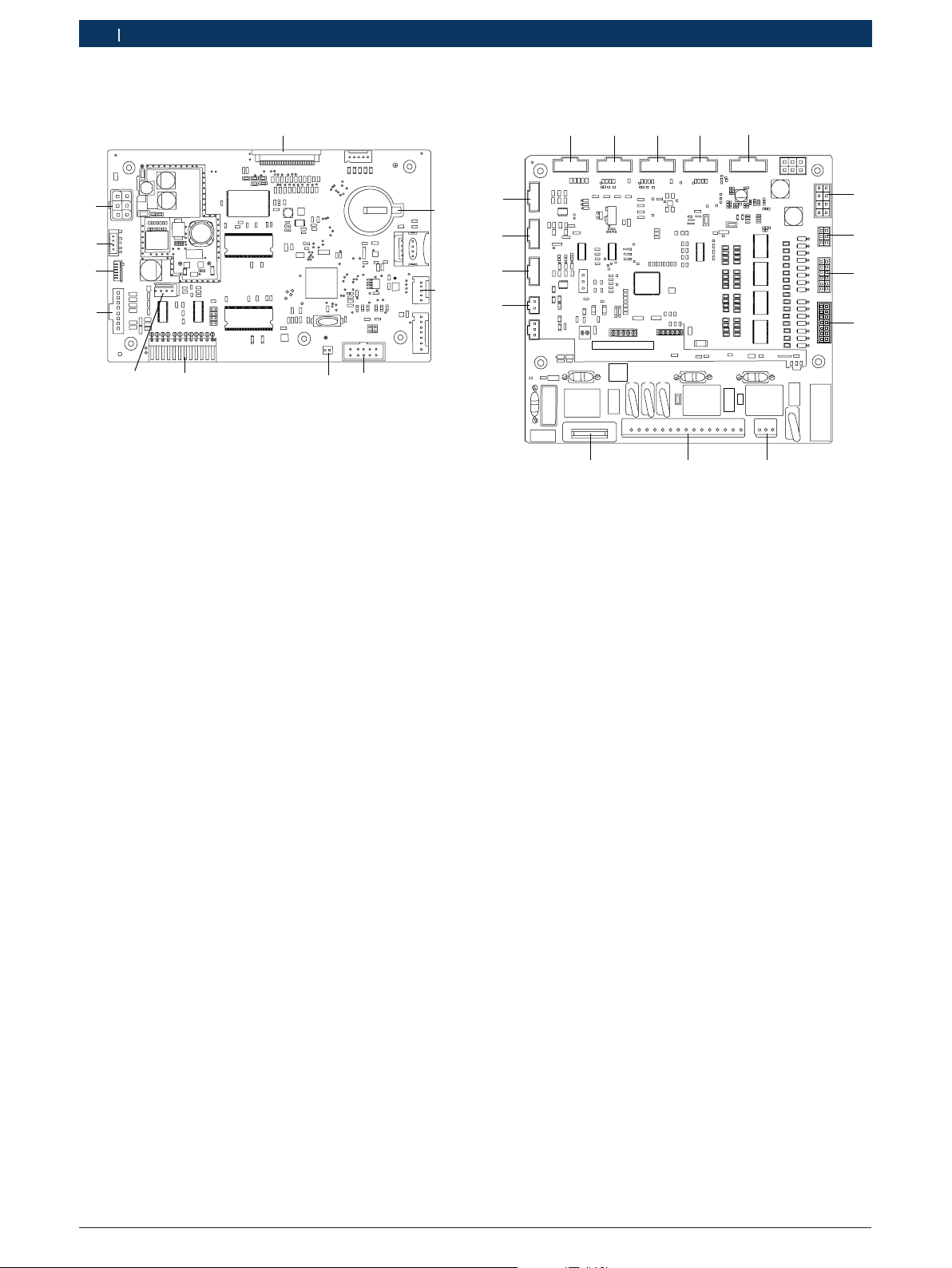

3.2.8 Human Machine Interface board (main board)

11

2

10

9

3

8

459898_29Nkv

7

Fig. 10: HMI Board (main board)

1 Connection to LCD

2 Coin battery CR2032

3 Connection to USB host (for firmware update)

4 Connection to LED

5 Connection to buzzer

6 Connection to keypad

7 Debug - Common port

8 I/O board communication port

9 Connection to printer data

10 Connection to printer power

11 Power from I/O Board

45 6

3.2.9 I/O board

16

15

14

13

ACS-NP-IO-C-0030

12 11 10

Fig. 11: I/O Board

1,2,3,4 Connections to scales

5 Connection to HMI board

6 Power to HMI

7 Power from SMPS

8,9 Connection to solenoid valves

10 Connection to safety pressure switch

11 Connection to SMPS, Fan, Vacuum pump and compressor

12 Fuse

13 Connection to temperature sensor

14,15,16 Connection to pressure sensors

6

7

8

9

459898_28Nkv

1 689 975 223 2013-10-21| Robert Bosch GmbH

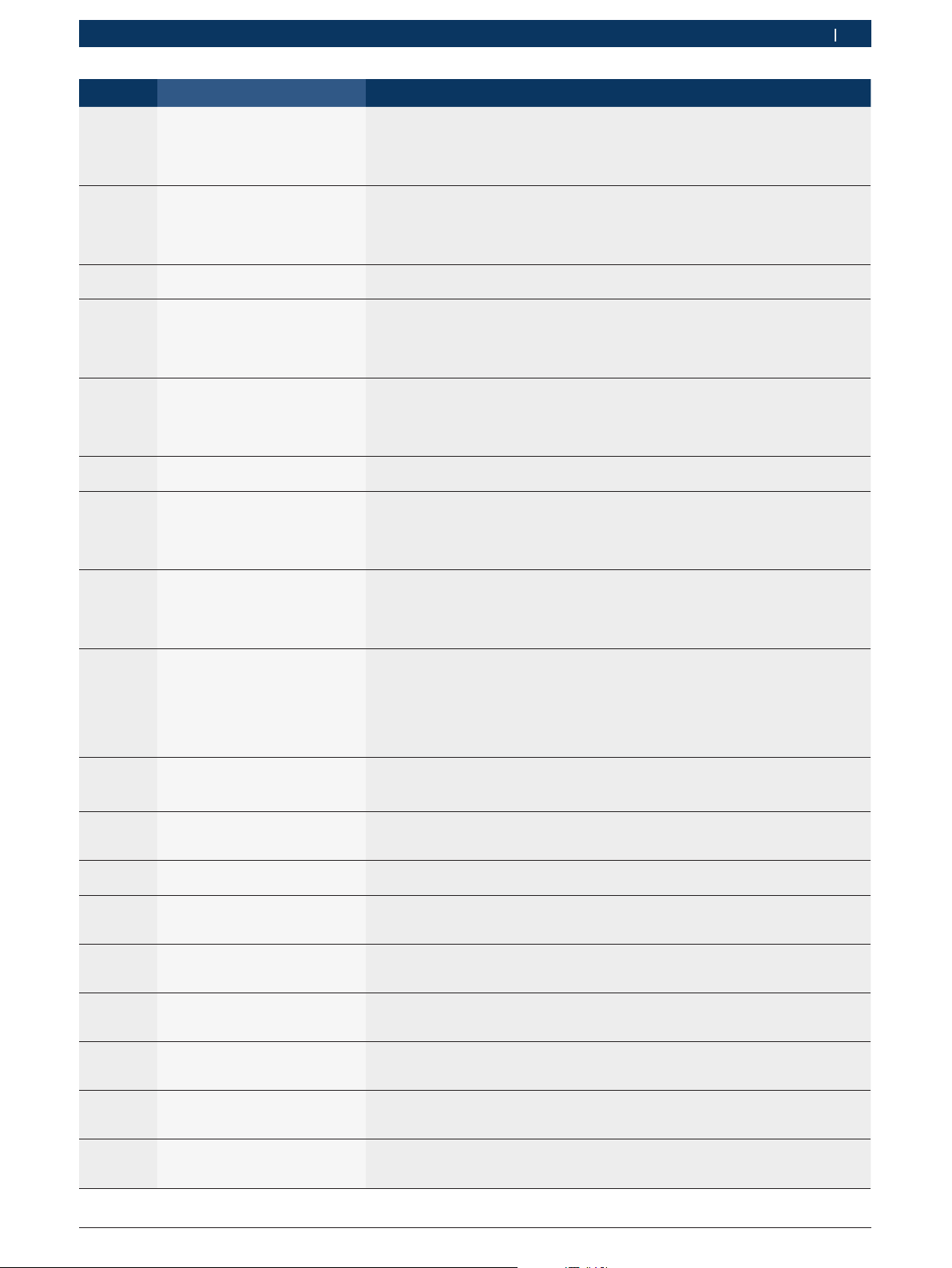

4. Troubleshooting

4.1 By status messages

Error code Messages Actions

1001 RECOVERY

Service Timeout

1002 RECOVERY

High pressure shutdown

1003 RECOVERY

Used Oil bottle full

1004 RECOVERY

Refrigerant cylinder full

1005 RECOVERY

Used Oil Bottle Not Found

2001 VACUUMING

High Pressure in vehicle. Perform Recovery

2002 VACUUMING

Leak detected

3001 OIL RECHARGE

Service Timeout

3002 OIL RECHARGE

High pressure in vehicle - Perform Recovery?

3003 OIL RECHARGE

High pressure in vehicle - Perform Vacuuming?

3004 OIL RECHARGE

Insufficient Oil Quantity

3006 OIL RECHARGE

Fresh oil Bottle Not Found

4001 UV DYE RECHARGE

Service Timeout

4002 UV DYE RECHARGE

High pressure in vehicle - Perform Recovery?

4003 UV DYE RECHARGE

High pressure in vehicle - Perform Vacuuming

4004 UV DYE RECHARGE

Insufficient UV Dye quantity

4006 UV DYE RECHARGE

UV DYE Bottle Not Found

5001 R134a RECHARGE

Service Timeout

5002 R134a RECHARGE

Insufficient R134a quantity

5003 R134a RECHARGE

Recharge Failed - Check Hoses

R Check for blockage in the vehicle A/C system.

R Check for functionality of pressure sensor (PTA).

R Check for compressor connections.

R Check if internal parts of the manifold have blockage.

R Check for blockage in the vehicle A/C system.

R Check for high pressure switch connection.

R Empty the used oil bottle.

R Perform scale reset.

R Check for used oil bottle scale.

R Weight limit reached. Reduce quantity of refrig-

erant in internal refrigerant cylinder.

R Scale is defective. Replace the scale.

R Check for used oil bottle scale.

R Check if the used oil bottle is disconnected. If the bot-

tle is disconnected, connect the bottle.

R Check the used oil bottle scale.

The pressure is greater than 1400 mbar while vacuuming

R Press "Yes" to continue the recovery.

R Press "No" to abort the operation.

Leakage detected in the vehicle A/C system. Repair the vehicle A/C system.

R Check the oil scale.

R Check for blockage on the oil charge solenoid path.

The pressure is greater than 1400 mbar while recharging.

R Press "Yes" to continue the recovery.

R Press "No" to abort the operation.

The pressure is greater than 1400 mbar while recharging.

R Press "Yes" to continue the recovery.

R Press "No" to abort the operation.

R Oil quantity is less than 30 ml. Refill the oil.

R Reset the fresh oil bottle scale

R Check the fresh oil bottle scale..

R Check if the fresh oil bottle is disconnected. If the bot-

tle is disconnected, connect the bottle.

R Check the oil bottle scale.

R Check for blockage on the oil charge solenoid path.

R Check for blockage in the hoses.

R Check the oil scale.

R Replace the scale.

The pressure is greater than 1400 mbar while recharging.

R Press "Yes" to continue the recovery.

R Press "No" to abort the operation.

The pressure is greater than 800 mbar while recharging.

R Press "Yes" to continue the vacuuming.

R Press "No" to abort the operation.

R UV dye quantity is less than 30 ml. Fill the UV dye bottle.

R Reset the UV dye bottle scale.

R Check the UV dye scale.

R Check for blockage on the oil charge solenoid path

R Check if the UV dye bottle is disconnected. If the bot-

tle is disconnected, connect the bottle.

R Check for blockage on the oil charge solenoid path.

R Check for blockage in the ACS 751/651.

R Check if quick couplers are open.

R Check for blockage in the hoses.

Fill the internal refrigerant cylinder.

R Check if HP and LP quick couplers are open.

R Check if the HP and LP service hoses are blocked.

R Check for blockage in the hoses

Troubleshooting | ACS 751/651 | 9ACS 751/651 | 9 | 9 en

1 689 975 223 2013-10-21| Robert Bosch GmbH

10 | ACS 751/651 | Troubleshootingen

Error code Messages Actions

5004 R134a RECHARGE

High Pressure shutdown

5005 R134a RECHARGE

Refrigerant Cylinder Full

5006 R134a RECHARGE

High Pressure in Vehicle - Perform Recovery?

5007 R134a RECHARGE

High pressure in vehicle - Perform Vacuuming

7100 Safety Switch

High pressure shutdown

7102 PSA

Sensor Connection Failed

7202 PST

Sensor Connection Failed

7302 PSV

Sensor Connection Failed

7402 Tank Temperature

Sensor Connection Failed

7403 Tank Temperature

Sensor Connection Failed

7501 R134a

Timeout

7502 R134a

Sensor Connection Failed

7503 R134a

Sensor Connection Failed

7601 UV Dye

Timeout

R Check the connection to high pressure switch

R Check if the connection to the blue valve on the cylinder is open.

R Check for blockage in the blue hose

R Weight limit reached.

R Reduce quantity of refrigerant in internal refrigerant cylinder.

R Scale is defective. Replace the scale.

R Press "Yes" to perform recharge.

R Press "No" to abort the operation.

R Press "Yes" to perform vacuuming.

R Press "No" to abort the operation.

R Allow the unit to cool for 30 minutes and switch on the unit. Try re-

covery/hose drain. Check if the blue knob on the internal refrigerant tank is closed. Open the blue knob If it is closed.

R Check if the electrical connections to the pressure switch are disconnected.

R Check if there is blockage in the discharge tube/manifold/blue hose be-

tween the tank and valve block. Rectify if there is leakage.

R In debug mode switch on CX and check if compressor is functioning.

R Temporarily interchange the PSA and PSV cable connection at the sen-

sor side. If the error is still with PSA sensor, then replace the top block.

R Check the electrical continuity of the sensor cable including connector at both

ends for each individual wires. If continuity test fails, then change the cable.

R Change the I/O board.

R Temporarily interchange the PST and PSV cable connection at the sen-

sor side. If the error is still with PST sensor, then replace the top block.

R Check the electrical continuity of the sensor cable including connector at both

ends for each individual wires. If continuity test fails, then change the cable.

R Change the I/O board.

R Temporarily interchange the PSV and PSA cable connection at the sen-

sor side. If the error is still with PSV sensor, then replace the top block.

R Check the electrical continuity of the sensor cable including connector at both

ends for each individual wires. If continuity test fails, then change the cable.

R Change the I/O board.

R Check the electrical continuity of the sensor ca-

ble including connector at both ends.

R Measure the resistance across two terminals of the temper-

ature sensor. If the measured resistance is found to be infinity or zero, change the temperature sensor.

R Replace the I/O board.

R Check the electrical continuity of the sensor ca-

ble including connector at both ends.

R Measure the resistance across two terminals of the temper-

ature sensor. If the measured resistance is found to be infinity or zero, change the temperature sensor.

R Replace the I/O board.

Replace the I/O board.

R Measure the resistance across:

- Red-Black

- Green-White

If any of the two measurement shows inifinite resistance, change the load sensor.

R Change the I/O board.

R Measure the resistance across

- Red-Black

- Green-White

If any of the two measurement shows inifinite resistance, change the load sensor.

R Change the I/O board.

Replace the I/O board.

1 689 975 223 2013-10-21| Robert Bosch GmbH

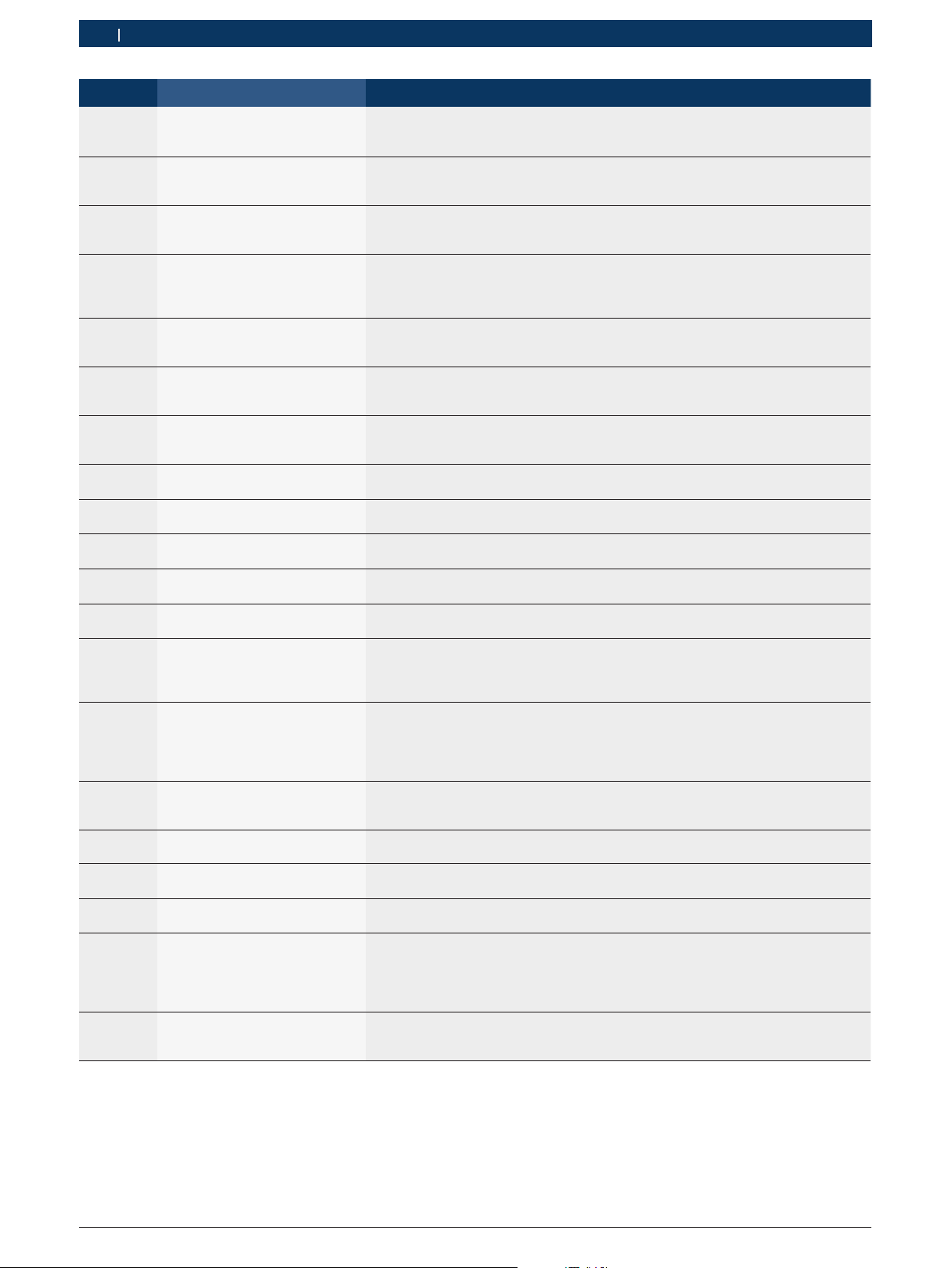

Error code Messages Actions

7602 UV Dye

Sensor Connection Failed

7603 UV Dye

Sensor Connection Failed

7701 Fresh Oil

Timeout

7702 Fresh Oil

Sensor Connection Failed

7703 Fresh Oil

Sensor Connection Failed

7801 Used Oil

Timeout

7802 Used Oil

Sensor Connection Failed

7803 Used Oil

Sensor Connection Failed

7804 Used Oil

Invalid Range

8000 SYSTEM ERROR

Retry Operation. Contact techsupport if problem persists

9001 FIRMWARE UPDATE Retry Op-

eration. Contact tech-support if problem persists.

9201 SYSTEM ERROR

No USB detected

9203 SYSTEM ERROR Retry Op-

eration. Contact tech-support if problem persists.

9204 SYSTEM ERROR Retry Op-

eration. Contact tech-support if problem persists.

9205 SYSTEM ERROR Retry Op-

eration. Contact tech-support if problem persists

9206 SYSTEM ERROR Retry Op-

eration. Contact tech-support if problem persists

9207 SYSTEM ERROR Retry Op-

eration. Contact tech-support if problem persists

9208 SYSTEM ERROR Retry Op-

eration. Contact tech-support if problem persists

R Measure the resistance across

- Red-Black

- Green-White

If any of the two measurement shows inifinite resistance, change the load sensor.

R Change the I/O board.

R Measure the resistance across:

- Red-Black

- Green-White

If any of the two measurement shows inifinite resistance, change the load sensor.

R Change the I/O board.

Replace the I/O board.

R Measure the resistance across:

- Red-Black

- Green-White

If any of the two measurement shows inifinite resistance, change the load sensor.

R Change the I/O board.

R Measure the resistance across

- Red-Black

- Green-White

If any of the two measurement shows inifinite resistance, change the load sensor.

R Change the I/O board.

Replace the I/O board.

R Measure the resistance across:

- Red-Black

- Green-White

If any of the two measurement shows inifinite resistance, change the load sensor.

R Change the I/O board.

R Measure the resistance across:

- Red-Black

- Green-White

If any of the two measurement shows inifinite resistance, change the load sensor.

R Change the I/O board.

R Allow the unit to cool for 30 minutes and switch on the unit. Try re-

covery/hose drain. Check if the blue knob on the internal refrigerant tank is closed. Open the blue knob If it is closed.

R Check if the electrical connections to the pressure switch are disconnected.

R Check if there is blockage in the discharge tube/manifold/blue hose be-

tween the tank and valve block. Rectify if there is leakage.

R In debug mode switch on CX and check if compressor is functioning.

Check the cable connection between the HMI board and the I/O board.

or

Replace the HMI board.

R Check the HMI board.

R Check the USB connection.

R Replace the HMI board.

Check if the USB disk is connected to the USB port.

R Check the HMI board.

R Check the USB connection.

R Replace the HMI board.

R Check the HMI board.

R Check the USB connection.

R Replace the HMI board.

R Check the HMI board.

R Check the USB connection.

R Replace the HMI board.

R Check the HMI board.

R Check the USB connection.

R Replace the HMI board.

R Check the HMI board.

R Check the USB connection.

R Replace the HMI board.

R Check the HMI board.

R Check the USB connection.

R Replace the HMI board.

Troubleshooting | ACS 751/651 | 11ACS 751/651 | 11 | 11 en

1 689 975 223 2013-10-21| Robert Bosch GmbH

12 | ACS 751/651 | Troubleshootingen

Error code Messages Actions

9209 SYSTEM ERROR Retry Op-

eration. Contact tech-support if problem persists

920A SYSTEM ERROR Retry Op-

eration. Contact tech-support if problem persists

920B SYSTEM ERROR Retry Op-

eration. Contact tech-support if problem persists

920C SYSTEM ERROR Retry Op-

eration. Contact tech-support if problem persists

R Check the HMI board.

R Check the USB connection.

R Replace the HMI board.

R Check the HMI board.

R Check the USB connection.

R Replace the HMI board.

R Check the HMI board.

R Check the USB connection.

R Replace the HMI board.

R Check the HMI board.

R Check the USB connection.

R Replace the HMI board.

920D SYSTEM ERROR Retry Op-

eration. Contact tech-support if problem persists

920E SYSTEM ERROR Retry Op-

eration. Contact tech-support if problem persists

920F SYSTEM ERROR Retry Op-

eration. Contact tech-support if problem persists

9300 SELF TEST FAILED

View Detail?

9400 RTC Failed Replace the HMI board.

9600 PRINTER

Out of paper

A101 INTERNAL BOTTLE FILL

Service Timeout

A102 INTERNAL BOTTLE FILL

Used Oil bottle full

A103 INTERNAL BOTTLE FILL Re-

frigerant Cylinder Full

A104 INTERNAL BOTTLE FILL

High Pressure shutdown

A105 INTERNAL BOTTLE FILL

Low Pressure - Check external cylinder valve

A202 SHORT FLUSHING

Service timeout

A203 SHORT FLUSHING

Insufficient R134a quantity

A204 SHORT FLUSHING

Leak Detected

A205 SHORT FLUSHING

High Pressure shutdown

R Check the HMI board.

R Check the USB connection.

R Replace the HMI board.

R Check the HMI board.

R Check the USB connection.

R Replace the HMI board.

R Check the HMI board.

R Check the USB connection.

R Replace the HMI board.

Press "Yes" to view details. Press "No" to continue.

R Check if paper roll is present in the printer. If not, insert paper roll.

To order printer paper, use the order number F 002 DG1 450.

R Check for blockage in ACS 751/651.

R Check R134a scale.

Check if the used oil bottle is full. If the bottle is full, empty the bottle.

R Weight limit reached. Reduce quantity of refriger-

ant in the internal refrigerant cylinder.

R Refrigerant cylinder scale is defective. Replace the scale.

R Check for blockage in the vehicle A/C system.

R Check the connection to the high pressure switch.

R Check if the connection to the blue valve on the cylinder is open.

R Check for blockage in the blue hose.

R Check if the valve on the external cylinder is open.

R Check if R134a is available in the external cylinder.

R Check for blockage in the ACS 651/751.

Fill the internal refrigerant cylinder.

Repair the vehicle A/C system or part under flushing.

R Check for blockage in the vehicle A/C system.

R Check the connection to the high pressure switch.

R Check if the connection to the blue valve on the cylinder is open.

R Check for blockage in the blue hose.

A206 SHORT FLUSHING

High Pressure in vehicle. Perform Recovery?

1 689 975 223 2013-10-21| Robert Bosch GmbH

The pressure is greater than 1400 mbar while vacuuming Press "Yes"

to continue the recovery. Press "No" to abort the operation.

Loading...

Loading...