Bosch ACS 611 Original Instructions Manual

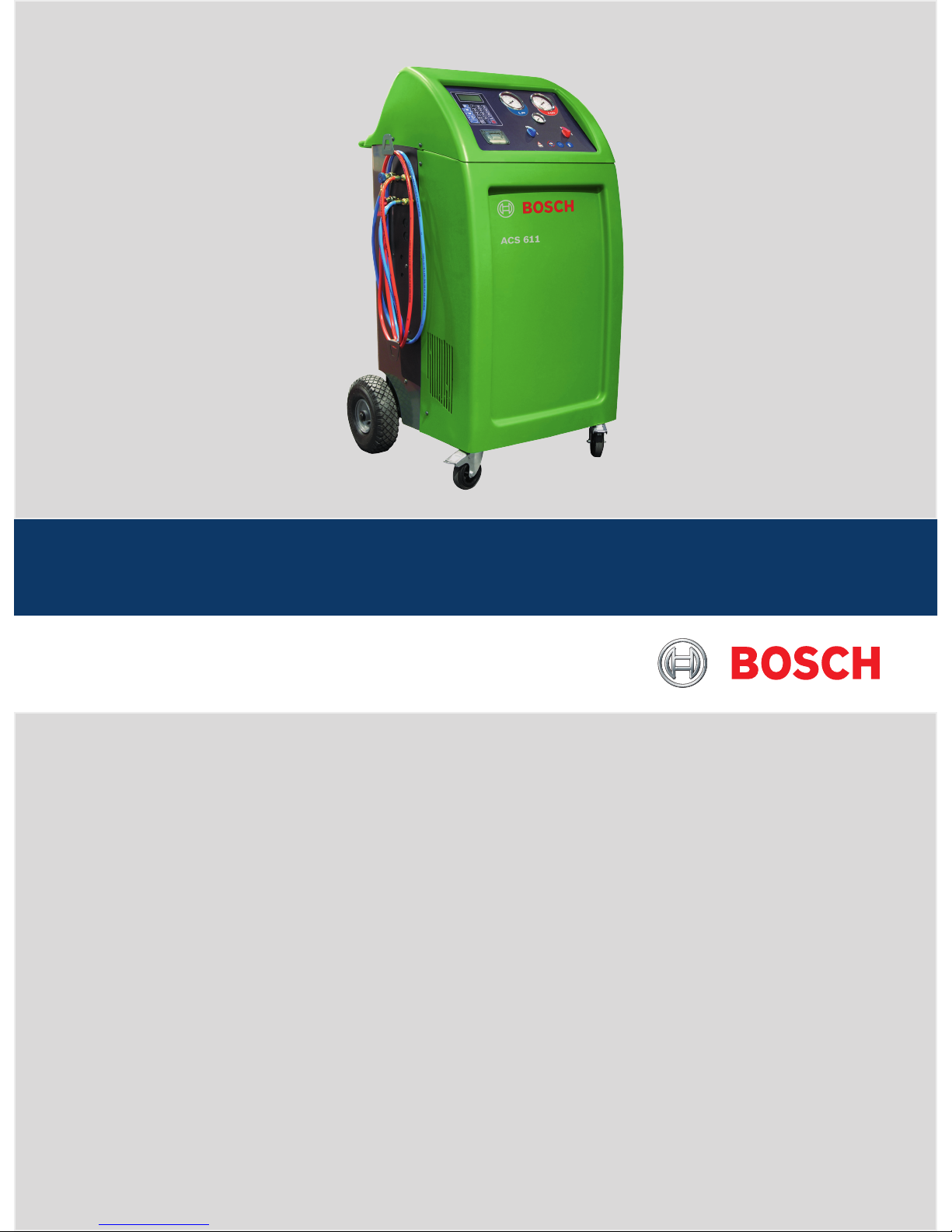

ACS 611

de

Originalbetriebsanleitung

Klimaservicegerät

en

Original instructions

A/C service-unit

fr

Notice originale

Appareil de SAV pour climatiseur

es

Manual original

Aparato de servicios de aire

acondicionado

it

Istruzioni originali

Attrezzatura per assistenza

climatizzatore

sv

Bruksanvisning i original

A/C serviceenhet

nl

Oorspronkelijke gebruiksaanwijzing

Airco-onderhoudsapparaat

pt

Manual original

Aparelho de manutenção de sistemas

de ar condicionado

fi

Alkuperäiset ohjeet

A/C huoltolaite

da

Original brugsanvisning

A/C tjenesten Unit

no

Original driftsinstruks

A/C tjenesten Unit

pl

Oryginalna instrukcja eksploatacji

Urządzenie do obsługi układu

klimatyzacji

cs

Původní návod k používání

Přístroj na servis klimatizací vozidel

tr

Orijinal işletme talimatı

A/C servis ünitesi

ru

Оригинальное руководство по эксплуатации

Подготовка к обслуживанию

S P00 D00 002 2013-04-10

|

Robert Bosch GmbH

32 | ACS 611 |

en

1. Symbols used 34

1.1 In the documentation 34

1.1.1 Warning notices Structure and meaning 34

1.1.2 Symbols in this documentation 34

1.2 On the product 34

2. Important notes 34

2.1 User group 34

2.2 Agreement 34

2.3 Obligation of contractor 35

2.4 Safety regulations 36

2.5 Safety devices 37

3. Product description 38

3.1 Application 38

3.2 Delivery specification 38

3.3 Overview on software texts 38

3.4 Description of unit 39

3.4.1 Selection and function keys 40

3.4.2 Input keys 41

3.4.3 Printer 41

3.4.4 Service flap 41

3.4.5 Scales for

refrigerant, fresh oil and used oil 41

3.4.6 Service hose and service quick-release

coupling 42

3.4.7 Locking brakes 42

3.4.8 Power cord 42

3.4.9 Master switch 42

3.5 Description of function 42

4. Program structure 43

4.1 Calibration and tare 43

4.2 Settings 43

4.3 Repair 43

4.4 Vehicle and customer data 43

4.5 Menu 43

4.6 Manual mode 43

4.7 Automatic mode 43

4.8 Flush (optional) 43

4.9 Enter 43

5. Initial commissioning 44

5.1 Removing transportation packaging 44

5.2 Switching on the ACS 611 44

5.3 Required settings 44

5.3.1 Setting the language 44

5.3.2 Setting the date and time 44

5.3.3 Set workshop data 45

5.3.4 Enter serial number 45

5.4 Internal Refrigerant cylinder 45

5.4.1 Checking type of connection of

external refrigerant cylinder 45

5.4.2 Filling internal refrigerant cylinder 46

6. A/C service preparation 46

7. Operating instructions 47

7.1 Database 47

7.1.1 Vehicle database 47

7.1.2 Personal database 47

7.1.3 Customer and vehicle data 47

7.2 Service phases 47

7.3 Manual service 48

7.3.1 Filling of refrigerant, fresh

oil and UV dye 48

7.3.2 Recovery 49

7.3.3 Vacuum 49

7.4 Automatic service 49

7.5 Processing 50

8. Troubleshooting 51

8.1 Service prompt 51

8.2 Fault messages 51

9. Diagnosis 52

9.1 Preparatory work 52

9.2 Diagnosis 52

10. ACS 611 settings 53

10.1 Set unit 53

10.2 Set length of service hoses 53

10.3 Contrast 53

10.4 Flush (optional) 53

10.5 Scales for fresh and used oil 53

10.6 UV dye 53

10.7 Service data report 54

10.7.1 Activate/deactivate consumption

R134a report 54

10.7.2 Report printout 54

Contents English

S P00 D00 002 2013-04-10

|

Robert Bosch GmbH

| ACS 611 | 33

en

11. Maintenance 54

11.1 Spare and wearing parts 54

11.2 Maintenance interval 54

11.3 Tare oil scales 55

11.4 Calibration of scales 55

11.4.1 Calibrating internal refrigerant cylinder 55

11.4.2 Fresh oil and used oil scales 55

11.5 Vacuum pump 56

11.5.1 Changing vacuum pump oil 56

11.5.2 Reset of oil change interval 56

11.6 Combo filter 57

11.6.1 Replacement of combo filter 57

11.6.2 Reset filter 57

11.7 Software update 57

11.7.1 irmware 57

11.7.2 Vehicle database 58

11.8 Replacing printer paper 58

12. Disposal 58

12.1 Disposal of electronic parts 58

12.2 Disposal of LCD display 58

12.3 Disposal of refrigerants, UV dye,

lubricants and oils 58

12.4 Disposal of combo filter 58

13. Technical data 59

13.1 ACS 611 59

13.2 Ambient temperature 59

13.3 Electromagnetic compatibility 59

14. Glossary 59

S P00 D00 002 2013-04-10

|

Robert Bosch GmbH

34 | ACS 611 | Symbols used

en

1. Symbols used

1.1 In the documentation

1.1.1 Warning notices - Structure and meaning

Warning notices warn of dangers to the user or people

in the vicinity. Warning notices also indicate the

consequences of the hazard as well as preventive action.

Warning notices have the following structure:

Warning

symbol

KEY WORD – Nature and source of hazard!

Consequences of hazard in the event of

failure to observe action and information

given.

¶ Hazard prevention action and information.

The key word indicates the likelihood of occurrence and

the severity of the hazard in the event of non-observance:

Key word Probability of

occurrence

Severity of danger if

instructions not observed

DANGER Immediate impending

danger

Death or severe injury

WARNING Possible impending

danger

Death or severe injury

CAUTION Possible dangerous

situation

Minor injury

1.1.2 Symbols in this documentation

Symbol Designation Explanation

!

Attention Warns about possible property damage.

i

Information Practical hints and other

useful information.

1.

2.

Multi-step

operation

Instruction consisting of several steps.

e

One-step

operation

Instruction consisting of one step.

Intermediate

result

An instruction produces a visible

intermediate result.

"

Final result There is a visible final result on

completion of the instruction.

1.2 On the product

!

Observe all warning notices on products and ensure

they remain legible.

2. Important notes

Before start up, connecting and operating

Bosch products it is absolutely essential

that the operating instructions/owner’s

manual and, in particular, the safety

instructions are studied carefully. By doing so you can

eliminate any uncertainties in handling Bosch products

and thus associated safety risks upfront; something

which is in the interests of your own safety and will

ultimately help avoid damage to the device. When a

Bosch product is handed over to another person, not

only the operating instructions but also the safety

instructions and information on its designated use must

be handed over to the person.

2.1 User group

The product may be used by skilled and instructed

personnel only. Personnel scheduled to be trained,

familiarized, instructed or to take part in a general

training course may only work with the product under

the supervision of an experienced person.

All work conducted on pressurized equipment may be

performed by persons with sufficient knowledge and

experience in the field of refrigeration, cooling systems

and coolants and, also be aware of the risks involved in

the use of pressurized devices.

2.2 Agreement

By using the product you agree to the following regulations:

Copyright

Software and data are the property of

Robert Bosch GmbH or its suppliers and protected

against copying by copyright laws, international

agreements and other national legal regulations.

Copying or selling of data and software or any part

thereof is impermissible and punishable; in the event of

any infringements Bosch reserves the right to proceed

with criminal prosecution and to claim for damages.

¶ Wear safety goggles.

¶ Wear protective gloves.

¶ Protect against dampness and moisture.

S P00 D00 002 2013-04-10

|

Robert Bosch GmbH

Symbols used | ACS 611 | 35

en

2.3 Obligation of contractor

The contractor is obliged to ensure that all measures

geared towards the prevention of accidents, industrial

diseases, labor-related health risks are taken and

measures towards making the workplace fit for people

to work in are carried out.

Specifications for electrical systems (BGV A3)

Electrical engineering in Germany is subject to

the accident prevention regulations of the trade

association "Electrical Plant and Equipment as under

BGV A3 (previously VBG 4)". In all other countries, the

applicable national regulations acts or decrees are to be

adhered to.

Liability

All data in this program is based - where possible - on

manufacturer and importer details. Bosch does not

accept liability for the correctness and completeness of

software and data; liability for damage caused by faulty

software and data is ruled out. Whatever the event,

Bosch liability is restricted to the amount for which the

customer actually pays for this product. This disclaimer

of liability does not apply to damages caused by intent

or gross negligence on the part of Bosch.

Warranty

Any use of non-approved hardware and software will

result in a modification to our product and thus to

exclusion of any liability and warranty, even if the

hardware or software has in the meantime been

removed or deleted.

No changes may be made to our products. Our

products may only be used in combination with original

accessories and original service parts. Failing to do so,

will render null and void all warranty claims.

This product may only be operated using Bosch

approved operating systems. If the product is operated

using an operating system other than the approved one,

then our warranty obligation pursuant to our supply

conditions will be rendered null and void. Furthermore,

we will not be held liable for damage and consequential

damage incurred through the use of a non-approved

operating system.

Basic rules

The contractor is bound to ensure that all electrical

equipment and operating material is set up, modified

and maintained by skilled electricians only or under

the guidance and supervision of a skilled electrician in

accordance with electrical engineering principles.

Furthermore, the contractor must ensure that all

electrical equipment and operating material is operated

in keeping with electrical engineering principles.

If a piece of electrical equipment or operating material

is found to be defective, i.e. it does not or no longer

complies with electrical engineering principles, the

contractor must ensure that the fault is rectified

immediately and, in the event that imminent danger

exists, also ensure that the electrical equipment or the

electrical operating material is not used.

Tests (taking Germany as an example):

R The contractor must ensure that all electrical

systems and equipment are tested by a qualified

electrician or under the guidance of a qualified

electrician to ensure they are in proper working

order:

$ Before starting for the first time.

$ After modification or repair before starting for the

first time.

$ At given intervals. Set intervals such as to ensure

that faults that can be expected to occur are

determined in good time.

R The test is to take the electrical engineering

principles relating hereto into account.

R Upon request of the trade association, a test manual

is to be maintained into which specific entries are

made.

S P00 D00 002 2013-04-10

|

Robert Bosch GmbH

36 | ACS 611 | Symbols used

en

2.4 Safety regulations

Always carefully read and observe all the safety

regulations before using the Bosch product.

Avoid all skin contact with the refrigerant.

The low boiling point of the refrigerant

(approx. -30 °C) can lead to frostbites.

Should it nevertheless come into contact

with the skin, remove any moistened clothing

immediately and rinse the affected skin with

copious amounts of water.

R Avoid all skin contact with the UV dye. Should

it nevertheless come into contact with the skin,

remove any moistened clothing immediately and

rinse the affected skin with copious amounts of

water.

R R134a is colorless, has a weak intrinsic odor and

is heavier than air. It displaces oxygen and may

flow into repair pits. Should refrigerant escape

(malfunction), always ensure adequate ventilation

and air extraction (especially in pits). Exit the

workshop.

Never inhale refrigerant, dye and oil vapors.

The vapors can irritate the eyes, nose and

respiratory system. If liquid refrigerant or UV

dye comes into contact with the eyes, rinse

them thoroughly with water for 15 minutes.

Then obtain medical help even if no pain is

felt.

R Never swallow UV dye. If swallowed inadvertently,

never attempt to induce vomiting. Drink copious

amounts of water and obtain medical help.

R Before connecting the ACS 611 to a vehicle air

conditioner or an external refrigerant cylinder, make

sure the quick-release couplings are not leaking.

Only ever use external refrigerant cylinders provided

with safety valves and certified in line with the

applicable standards.

R Before switching off the ACS 611, make sure all

filling and drainage operations have been completed.

This prevents refrigerant escaping into the

environment.

Never use compressed air with R134a.

Certain mixtures of air and R134a are highly

flammable. Such mixtures are a potential

hazard and may lead to fire or explosions

and thus cause damage or injury.

R Refrigerant extracted from a vehicle air conditioner

may be contaminated with moisture, lubricant, dirt

and traces of other gases.

R R134a is not to be used in areas in which there is a

danger of explosion. Fire, naked flames and smoking

are prohibited. Welding and soldering are not

permitted.

R High temperatures and UV radiation may chemically

separate the R134a. The resultant products cause

coughing and nausea.

R R134a is not to be mixed with other refrigerants.

Themixing of refrigerants could damage the vehicle

air conditioner.

If high-voltage components or high-voltage

wires are inappropriately handled, there is a

risk of fatal injury from high voltages and the

possible transmission of current through the

body.

R De-energization is only to be performed by a

qualified electrician, a qualified electrician for

specific tasks (hybrid), or a power systems engineer.

R Work on vehicles with high-voltage components is

only ever to be performed in a safe, de-energized

condition by persons with the minimum qualification

"Trained to perform electrical work".

R Even after deactivating the high-voltage vehicle

electrical system, the high-voltage battery may still

be live.

R The operating condition cannot be established from

any running noise, as the electric machine is silent

when stationary.

R In gear positions "P" and "N" the engine or electric

motor may start spontaneously depending on the

charge of the high-voltage battery.

R Never open or damage high-voltage batteries.

R On accident vehicles, never touch high-voltage

components or exposed high-voltage wires before

deactivating the high-voltage vehicle electrical

system.

S P00 D00 002 2013-04-10

|

Robert Bosch GmbH

Symbols used | ACS 611 | 37

en

R The ACS 611 must be constantly monitored when

in operation. Never leave the ACS 611 unattended

when in operation.

R The vehicle A/C service using the ACS 611 must

be prepared and implemented so that the vehicle

air conditioner circuit does not have to be opened

(forexample by removing the radiator or engine).

R Position the ACS 611 on all four wheels on a flat,

vibration-proof surface so that proper operation

ofthe scales is guaranteed.

R The ACS 611 can be secured in position by locking

the brake.

R The ACS 611 must always be transported in its

operating position. Never lay the ACS 611 on its

side, as oil could then escape from the vacuum

pump, or the built-in compressor could be damaged.

R There are no additional safety systems for protecting

the ACS 611 against damage resulting from natural

catastrophes.

R Never remove any components from inside the

ACS 611 except for maintenance or repair purposes.

R Observe the pertinent legal regulations or directives

to ensure safe handling of pressurized devices.

R We recommend calibrating the scales and pressure

sensors at least once per year. Contact customer

service for calibrating the scales of the internal

refrigerant cylinder.

R Never perform any maintenance work which is not

expressly recommended in this manual. Contact

customer service if components have to be replaced

other than in the course of maintenance work.

R ACS 611 must be connected to a properly grounded

electrical connection.

R If damage to the ACS 611 is established, terminate

usage immediately and contact customer service.

R The service hoses and quick-release couplings

must be regularly checked for wear and replaced

ifdamaged.

R The ACS 611 must be operated in an environment

corresponding to the directive BGR 157 with respect

to the exchange of air.

R Observe local laws or directives so as to ensure the

safety of the pressurized device.

R For safety reasons it is advisable to use a residual

current operated circuit breaker (rccb) with the

following specifications:

Parameters Specification

Rated voltage

230 VAC ± 10 %

Rated frequency

50/60 Hz

Rated current 230 VAC 6,3 A

Rated tripping current

30 mA

Tripping switch

C

2.5 Safety devices

Description Operation

Pressure switch Switches the compressor off if the normal

operating pressure is exceeded.

Safety valve The safety valve opens if the design

pressure is exceeded.

Fuse

Interrupts the power supply if overcurrent

is applied to the ACS 611.

Vents

The ACS 611 is provided with vents in

the bottom of the housing to ensure the

exchange of air even when switched off.

S P00 D00 002 2013-04-10

|

Robert Bosch GmbH

38 | ACS 611 | Product description

en

3. Product description

3.1 Application

ACS 611 is suitable for vehicles with conventional

combustion engines (PAG oil) as well as for hybrid

and electric vehicles (POE oil). ACS 611 features all

functions necessary for the air conditioning service of

vehicles.

! ACS 611 can be operated with either PAG or POE

oil. Mixing the oils causes damage to the vehicle

air conditioning system. For this reason, the oil

types must not be changed after the first vehicle air

conditioning service.

The following functions can be implemented:

R Refrigerant removal by suction and filling.

R Refrigerant processing.

R Vacuum creation.

R Addition of oil.

R Addition of UV dye.

R Flushing.

! The ACS 611 is only to be operated with R134a

refrigerant. The ACS 611 is not to be used for service

work on vehicles with air conditioning systems

employing refrigerants other than R134a, as this will

cause damage. Check the type of refrigerant used in

the vehicle air conditioner prior to A/C service.

3.2 Delivery specification

Description Order number

ACS 611 –

Safety goggles

–

Protective gloves

–

Original instructions

SP00D00002

External refrigerant cylinder adapter set

big

small

SP00100019

SP00100080

1)

Pre-assembled.

3.3 Overview on software texts

Software Orig. operating instructions

UV DYE

UV dye

HOSES LENGTH

Service hose length

TANK

Internal refrigerant cylinder

IN OIL Fresh oil

OIL OUT Used oil

HOSES

Service hoses

SELECT PORTS

Vehicle air-conditioning system

service connection (service quick-

release coupling)

CHANGE OIL

Vacuum pump

S P00 D00 002 2013-04-10

|

Robert Bosch GmbH

Product description | ACS 611 | 39

en

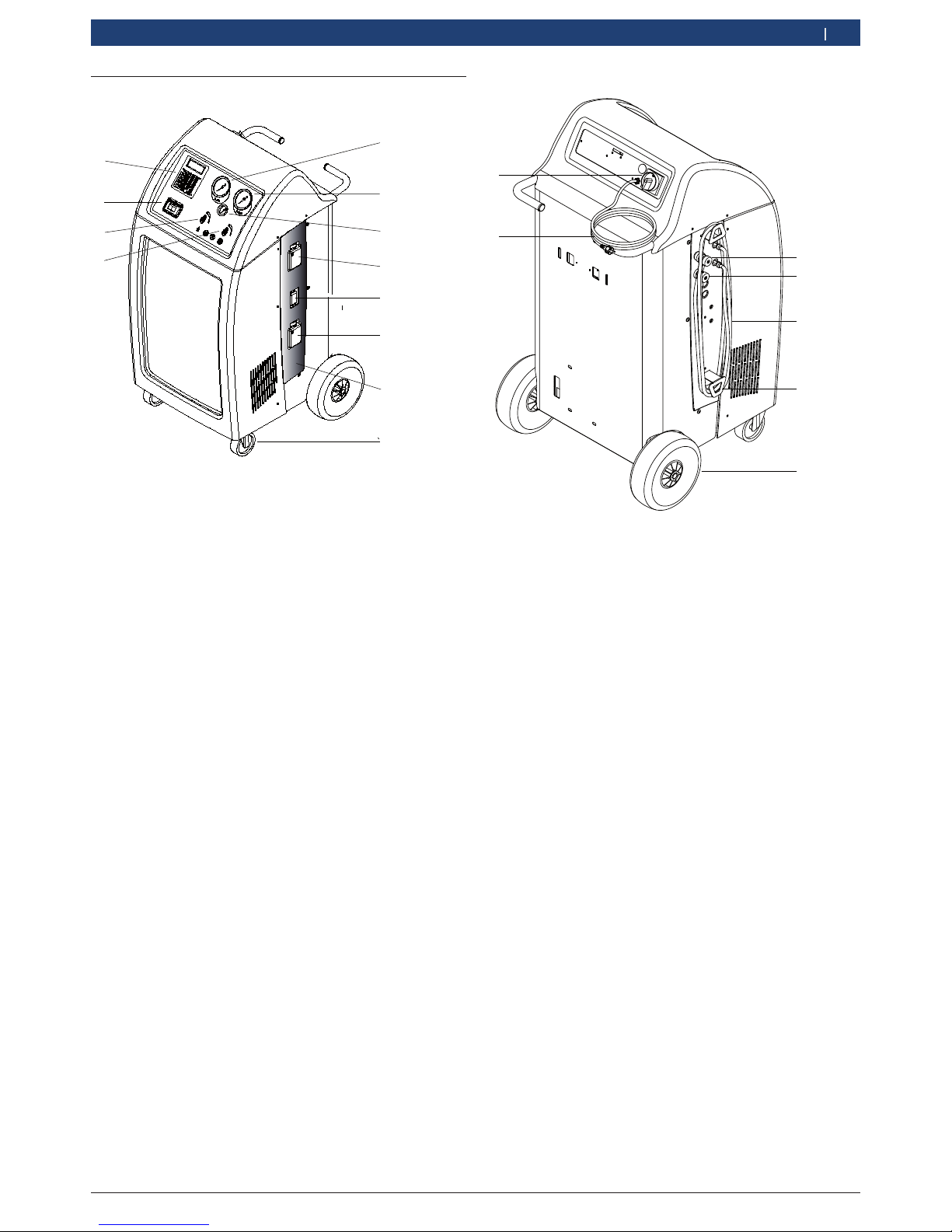

1

5

4

3

2

6

7

Fig. 2: Rear

1 Service quick-release coupling (high pressure)

2 Service quick-release coupling (low pressure)

3 Service hose (2,5m/5m)1)

4 Service hose mount

5 Rear wheels

6 Master switch

7 Power cord (socket)

1)

Depending on version ordered

3.4 Description of unit

4

6

5

1

2

3

8

7

9

10

12

11

Fig. 1: Front view

1 Valve high pressure (hp)

2 Valve low pressure (lp)

3 Printer

4 Display and control panel

5 Gauge low pressure (lp)

6 Gauge high pressure (hp)

7 Pressure gauge of internal refrigerant cylinder

8 Fresh oil bottle

9 UV dye bottle

10 Used oil bottle

11 Cover

12 Front wheels with locking brake

Loading...

Loading...