Bosch ACS 500 Repair Instructions

ACS 500

Repair instructions

en

AC Service Unit

en2 ACS 500

1 689 975 197 (2006-09-22)

Robert Bosch GmbH

en 3ACS 500

Inhalt

1. Important information . . . . . . . . . . . . . . . . . . . . . . . . 4

2. Testing and resources

3. General and component overview

3.1 Overview .........................................................................................4

3.1.1 Electronic compartment ..............................................................

3.1.2 Cold chamber ................................................................................

3.2 Component overview ...................................................................

3.2.1 Valve block .....................................................................................

3.2.2 Processing unit .............................................................................

3.2.3 Actuation circuit board ................................................................

3.2.4 Refrigerant flask ............................................................................

4. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.1 By function and fault messages ................................................ 7

4.2 By symptoms .................................................................................

5. Calibration and customer service menu . . . . . . . 10

5.1 Entering the calibration and customer service menu .........10

5.2 Calibration and customer service menu overview ..............

5.3 Description of calibration and customer service menu

5.3.1 Menu for updating the language database ...........................

5.3.2 Display menu for force and pressure sensor output

voltages .........................................................................................10

5.3.3 Menu for time and date setting ...............................................

5.3.4 Menu for changing language ...................................................

5.3.5 Parameter menu ..........................................................................

5.3.6 Menu for resetting system parameters ..................................

5.3.7 Menu for resetting counters .....................................................

5.3.8 Display menu for all counters ...................................................

5.3.9 Menu for entry of workshop address .....................................

5.3.10 Menu for setting the offset for the filling hoses. ..................

5.3.11 Menu for checking the control/display unit ...........................

5.3.12 Menu for calibration of force and pressure sensors ...........

. . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . 4

10

......10

10

11

11

11

11

11

11

11

11

11

11

6. Calibrating force and pressure sensors . . . . . . . 12

6.1 Calibrating force sensor ............................................................12

6.1.1 Refrigerant scale .........................................................................

6.1.2 Used oil, fresh oil or UV contrast medium scale .................

6.2 Calibrating the pressure sensor ..............................................

12

12

13

7. Updating firmware . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4

5

5

5

6

6

6

8

8. Test

8.1 Control/display unit function test ............................................14

8.2 Checking the pressure switch .................................................

8.3 Check pressure sensor .............................................................

9. Repairs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

9.1 Opening and closing the ACS 500 .......................................15

9.1.1 Electronic compartment ............................................................

9.1.2 Cold chamber ..............................................................................

9.2 Replacing the actuation circuit board ....................................

9.3 Control/display unit ....................................................................

9.3.1 Replacing control/display unit .................................................

9.3.2 Checking control/display unit ..................................................

9.4 Replacing force sensor for refrigerant scale ........................

9.5 Replacing valve block ................................................................

9.6 Replacing the pressure sensor ..............................................

9.7 Replacing the vacuum pump ...................................................

9.8 Replace the preparation unit ...................................................

9.8.1 Removing processing unit .......................................................

9.8.2 Installing the processing unit ..................................................

9.9 Replacing the pressure switch ...............................................

9.10 Replacing force sensors for used oil, fresh oil and UV

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

14

14

15

15

16

17

17

17

17

19

20

21

22

22

22

23

contrast medium scales ........................................................... 24

10. Hose system diagram . . . . . . . . . . . . . . . . . . . . . . . 25

11. Pneumatic circuit diagram

12. Electrical terminal diagram

12.1 General terminal diagram ........................................................27

12.2 Wiring harness terminal diagram ...........................................

12.2.1 Connection to actuation circuit board ..................................

12.2.2 Connection to valve block .......................................................

. . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . 27

28

28

28

Robert Bosch GmbH

1 689 975 197 (2006-09-22)

en

459790-3

HP

LP

10 11

4

1

2

3

5

6

7

8 9

1 2

3

4 5

6

7 8

9

R

1

3

4

a

R

1

3

4

a

U

V

.,

/

a

b

c

d

e

f

j

k

l

m

n

o

t

u

v

w

x

y

z

g

h

i

p

q

r

s

0

C

*

4 ACS 500

1. Important information

Installation and/or repairs may only be carried out by trained

and instructed Robert Bosch GmbH customer service staff

or organizations authorized by Robert Bosch GmbH.

Opening or modification of the units by unauthorized

persons will invalidate all warranty entitlements.

Electrical systems and equipment may only be commissioned

in proper condition (see Testing Technology Information

0108_084 for details). This requirement is met if, after

modification or repair (initial test), it is ensured that the

requirements of the electrical engineering regulations are

adhered to. To verify this tests should be performed, the

type and scope of which should be based on the measures

defined in the electrical engineering regulations (e.g.

in Germany BGV A3). In Germany, the type and scope

of the tests are described in VDE 0701/0702 Part 1. The

corresponding national regulations must be adhered to.

2. Testing and resources

#

General tool for electricians and mechanics

#

Digital multimeter

#

PC or Notebook (Windows 2000, XP)

#

9-pole Sub-D cabel (plug: male/female, wiring: 1:1) for

udating the firmware

#

Pipe sealant with PTFE (e. g. RODI-DOS PTFE from Würth).

#

Cleaning medium (e. g. brake cleaner)

#

Weights for calibration of scale:

−

10 kg

−

200 g

3. General and component overview

3.1 Overview

3.1.1 Electronic compartment

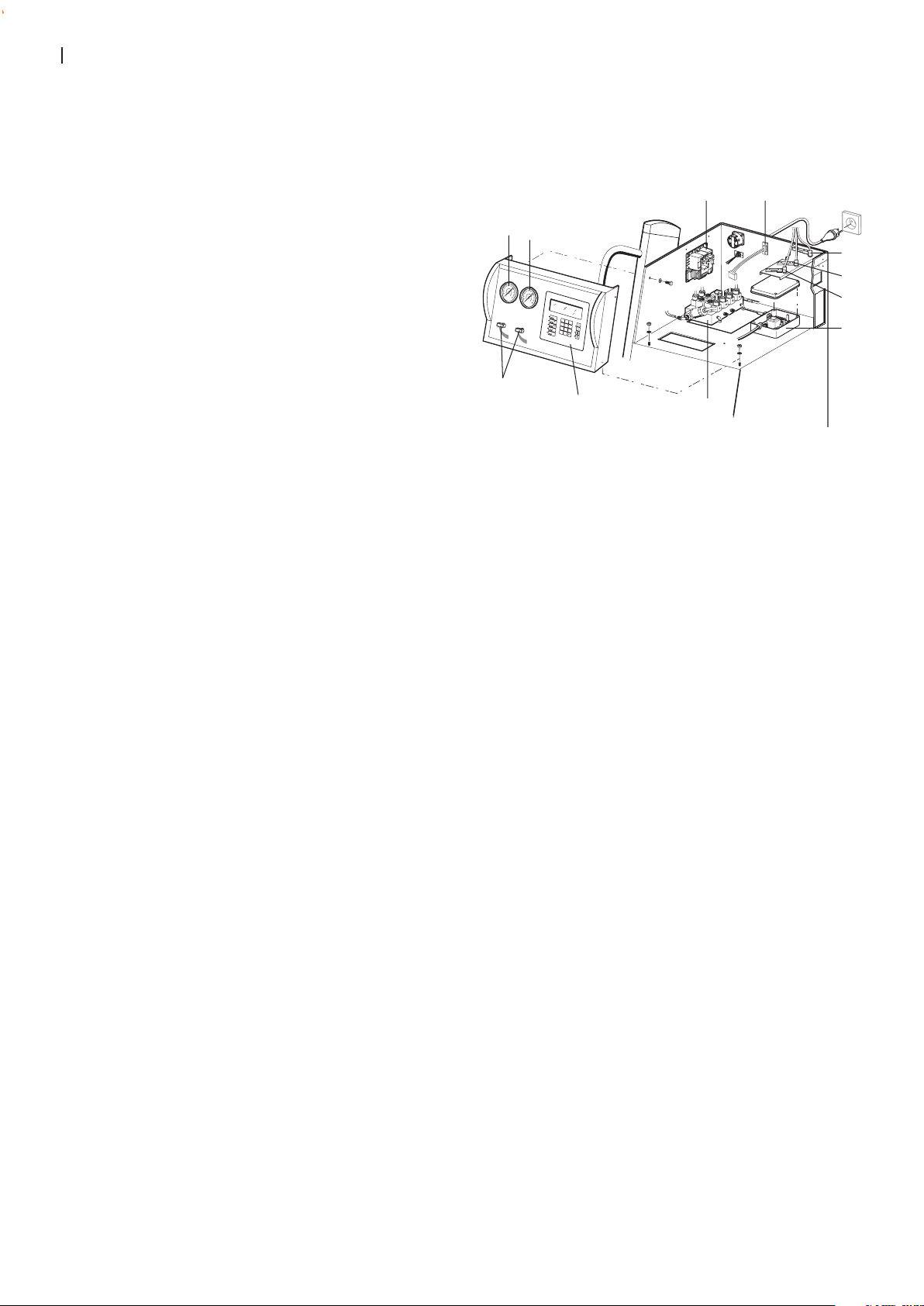

Fig. 1: Component overview in electronic compartment

1. Scale for UV contrast medium tank

2. Scale for used oil tank

3. Scale for fresh oil tank

4. Connection box with actuation circuit board

5. Valve block

6. Control/display unit

7. Low pressure (LP) and high pressure (HP) valve

8. LP manometer

9. HP manometer

10. Printer (accessory)

11. Connection line for firmware and language update

1 689 975 197 (2006-09-22)

Robert Bosch GmbH

en 5ACS 500

459

786-

4

1

2

3

4

1

3 4 5 6

7 8 9 10 11

12

459790-4

2

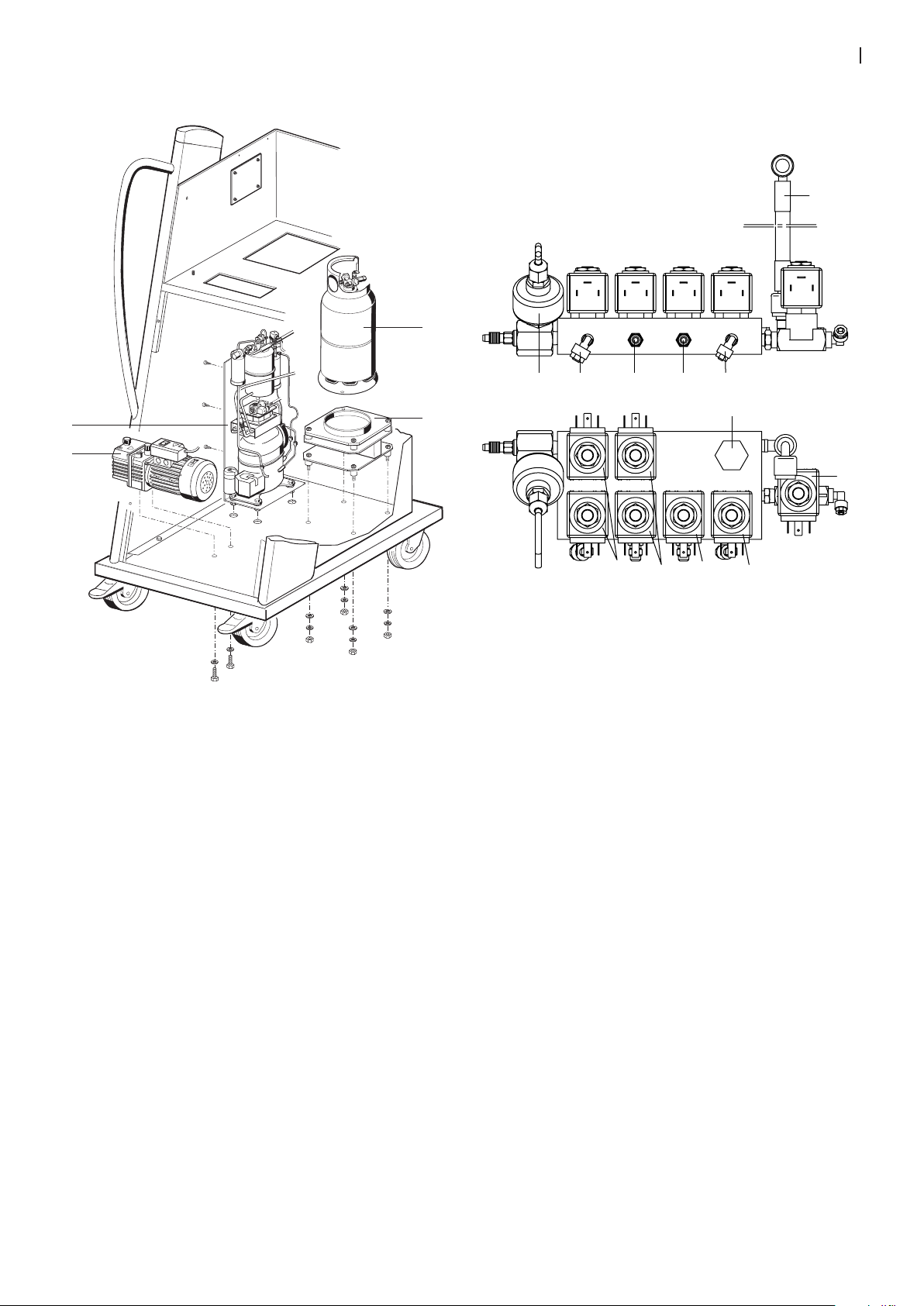

3.1.2 Cold chamber

3.2 Component overview

3.2.1 Valve block

Fig. 3: Valve block overview

1. Hose line for inlet and return

2. Solenoid valve for UV contrast medium injection phase

3. Solenoid valve (OUT L) for oil injection phase

4. Solenoid valve (OUT R) for filling phase

Fig. 2: Component overview in cold chamber

1. Refrigerant flask (reservoir)

2. Scale

3. Vacuum pump

4. Processing unit

5. Solenoid valves (OUT A) for recovery/recycling phase

6. Solenoid valves (OUT B) for vacuum phase

7. Pressure sensor

8. Connection to vacuum pump

9. Connection to processing unit

10. Connection to refrigerant flask

11. Connection to oil separator

12. Non-return valve

Robert Bosch GmbH

1 689 975 197 (2006-09-22)

en

45

97

86

-4

1

2

3

4

5

6

7

8

9

10

11

12

13

PROTECT.

PRINTER

COMPRESS.PUMP

J2

GND

V +18

GND

V +18

IN PMP

IN CMP

OUT HP

IN 7

IN 1

IN 3

IN 4

IN 6

IN 8

PUMPOUT 1OUT 3OUT 4OUT 6OUT 7OUT 8

LINE IN

200 mA T

F2

TERRA

TERRA

F1

F3

459786_6

1

2

3

5

4

6

7

BU

BN

BU

BN

YE/GN

BU

BN

YE/GN

BU

BN

YE/GN

BU

BN

YE/GN

BU

BN

YE/GN

BU

BN

YE/GN

BU

BN

YE/GN

BU

BN

YE/GN

BU

BN

YE/GN

BU

BN

YE/GN

YE/GN

YE/GN

1

2

3

4

459786_9

6

ACS 500

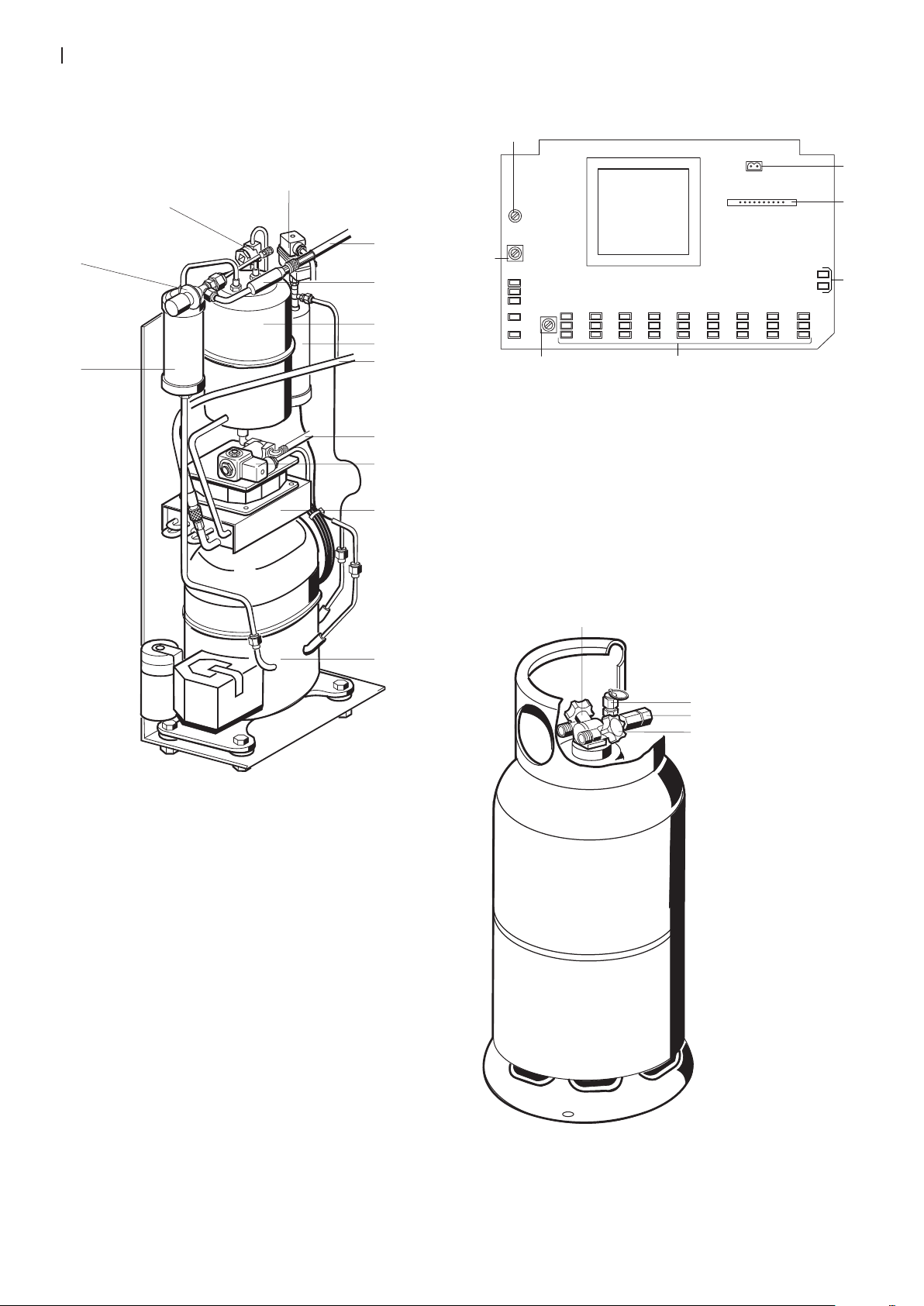

3.2.2 Processing unit

Changing the setting for the expansion valve (item 11)

!

can impair the function of the ACS 500.

3.2.3 Actuation circuit board

Fig. 5: Actuation circuit board overview

1. Printer power supply (accessory)

2. Control/display unit connection

3. Pressure switch power supply

4. ACS component power supply

5. Fuse F3 (10 AT) for mains connection

6. Fuse F2 (10 AT) for mains connection

7. Fuse F1 (200 mAT) for 12 Volt supply.

Fig. 4: Processing unit component overview

1. Inlet hose for processing system

2. Coarse filter

3. Moisture and oil separator

4. Oil separator

5. Inlet hose for refrigerant flask

6. Inlet hose for used oil tank

7. Solenoid valve (OUT S) for oil drain

8. Condenser with fan

9. Compressor

10. Filter and driver cartridge

11. Expansion valve

12. Non-return valve

13. Pressure switch

3.2.4 Refrigerant flask

Fig. 6: Refrigerant flask component overview

1. Safety valve (overpressure)

1 689 975 197 (2006-09-22)

2. Safety valve (for non-compressible gases)

3. LP fitting connection

4. HP fitting connection

Robert Bosch GmbH

ACS 500

4. Troubleshooting

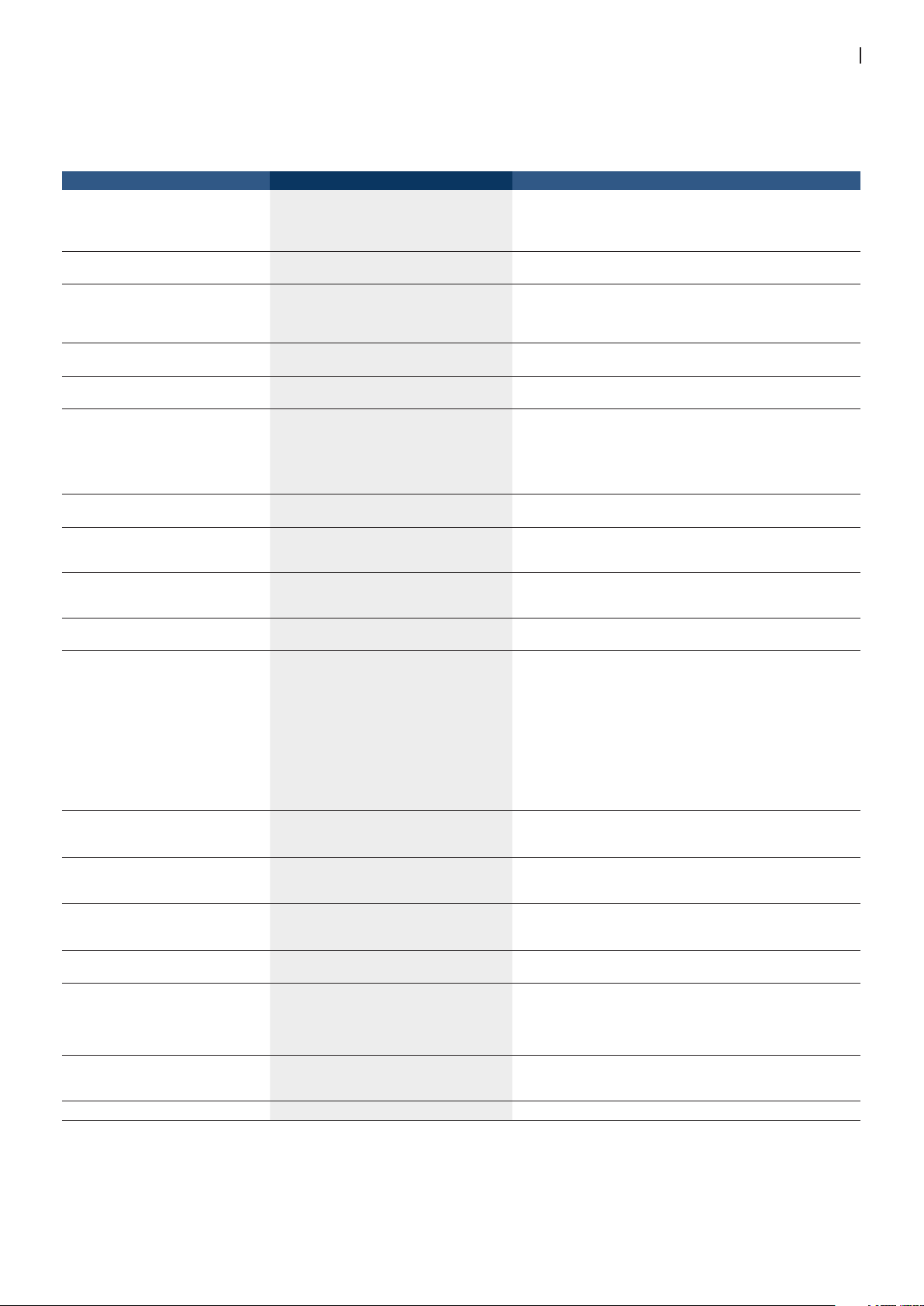

4.1 By function and fault messages

Message Description Problem solving

Change filter.

Change vacuum pump.

Not enough R134a.

Please refill.

Used oil bottle full!

Not enough oil.

Please refill.

Not enough UV.

Please refill.

Internal pressure too high! Overpressure in refrigerant flask.

Printer failure! No paper loaded.

Internal tank full. Maximum permissible filling weight (10

Warning! Internal tank full. Refrigerant flask weight limit reached.

A/C system on

high pressure.

Recovery phase timeout. Maximum permissible time (240 min)

A/C system leaking! Pressure increase during pressure loss

Vacuum failure. Limit value of 100 mbar not reached

Vacuum not reached! The pressure in the vehicle A/C system

Calibration fault! Error in calibration of scale or scale de-

External tank empty or closed valve!

Refill phase timeout. Maximum permissible time for filling the

External tank empty! External flask for filling is empty.

Maintenance interval reached. Carry

out maintenance and reset counter (see

Operating instructions 1 689 979 953,

Section 7).

Insufficient refrigerant in internal refrigerant flask.

Overpressure in path after compressor.

Printer defective.

kg) of refrigerant flask reached.

Absolute pressure in vehicle A/C system

is greater than 1.6 bar

for evacuation of vehicle A/C system reached.

measurement (leak test) in vacuum phase.

10 minutes after start of vacuum phase.

is too high for oil or UV contrast medium injection.

fective.

Attempt to fill internal flask failed.

vehicle A/C system reached.

None

Top up refrigerant flask.

•

Control/display unit is defective. Replace control/display unit.

•

Empty used oil tank.

•

Force sensor for used oil scale is defective. Replace

•

force sensor.

Control/display unit is defective. Replace control/display unit.

•

Top up oil tank.•

Top up UV tank.•

Open shut-off valves and cocks on internal refrigerant flask.

•

Turn off ACS 500 and wait for 30 minutes. Then restart

•

the recovery/recycling phase.

Check non-return valve in inlet hose for internal refrige-

•

rant flask.

Check pressure switch.

•

Load new printer paper roll.

•

Replace printer.

•

Reduce quantity of refrigerant in refrigerant flask.

•

Check refrigerant scale with calibrating weight. Recali-

•

brate scale.

Reduce quantity of refrigerant in refrigerant flask.

•

Check refrigerant scale with calibrating weight. Recali-

•

brate scale.

Start and carry out recovery/recycling phase

Read pressure on manometer.

Pressure is present:

•

Solenoid valves for recovery/recycling phase do not

open:

Check solenoid valves.

$

Check solenoid valve actuation.

$

No pressure present:

•

Vehicle A/C system not tight

or

leak in processing unit

Scan connections for leakage.

$

Check solenoid valve for oil drain.

$

Check vehicle A/C system for leaks.

•

Check connections and condition of filling hoses.

•

Check connections and condition of quick release couplings.

•

Check vehicle A/C system for leaks.

•

Check connections and condition of filling hoses.

•

Check connections and condition of quick release couplings.

•

Start vacuum phase.

•

Check vehicle A/C system for leaks.

•

Recalibrate scale.

•

Replace scale.

•

Use full external flask.

•

Open low pressure (LP) and high pressure (HP) valve

•

Open valve cocks on refrigerant flask.

•

Check fill quantity in refrigerant flask and top up if neces-

•

sary.

Open low pressure (LP) and high pressure (HP) valve

•

Open valve cocks on refrigerant flask.

•

Check fill quantity in refrigerant flask and top up if necessary.

•

Obtain new flask with refrigerant.•

en 7

Robert Bosch GmbH

1 689 975 197 (2006-09-22)

en

8

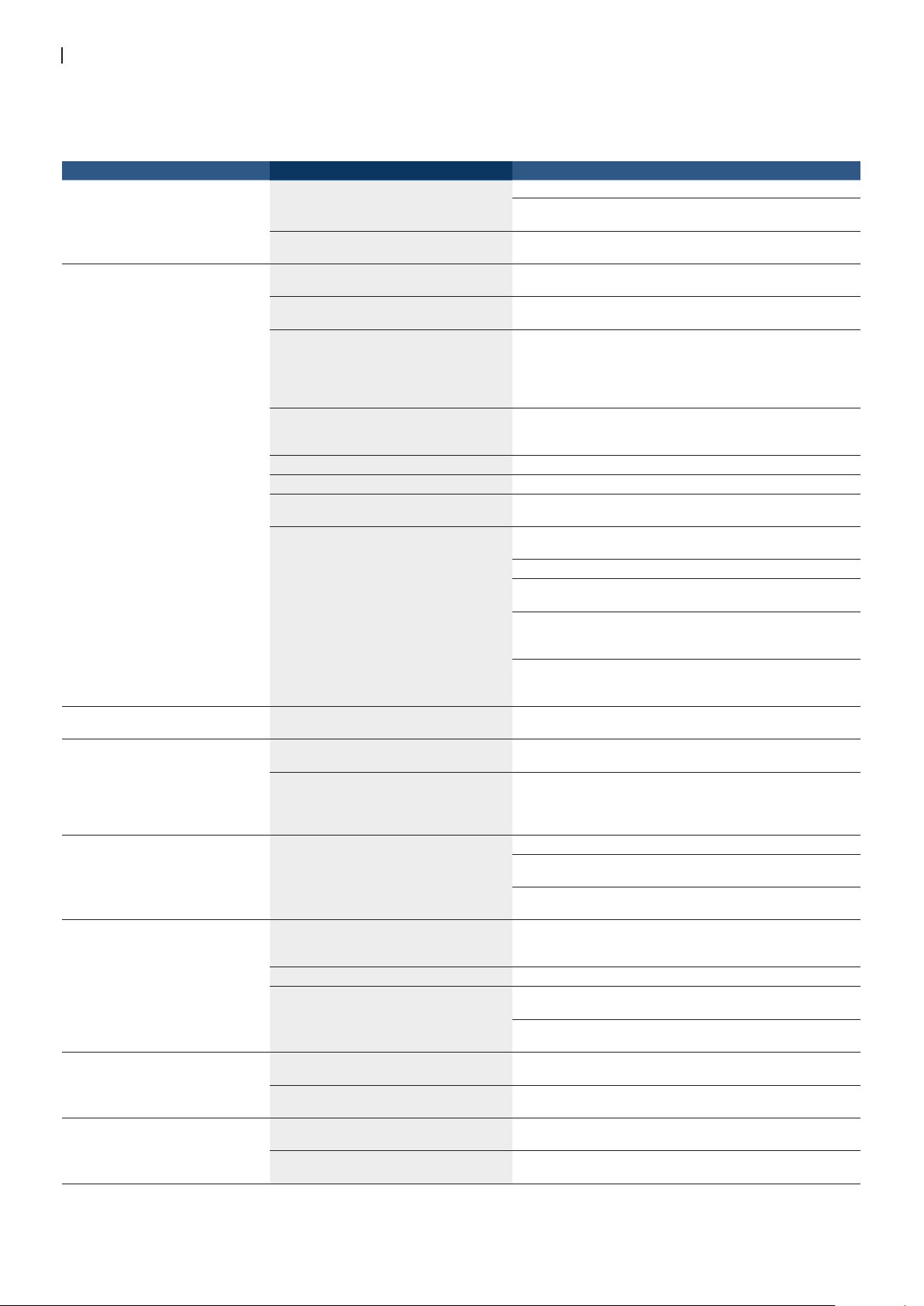

4.2 By symptoms

Error pattern Cause Troubleshooting and correction

The digital display does not

light up.

The recovery and recycling phase

is slow or does not run at all.

The recovery and recycling phase

ends prematurely or not at all.

The gauge pressure rises after the

recovery and recycling phase.

The vacuum phase does not start. The vacuum pump does not start. Check fuses F2 and F3 on the control PCB.

The leakage test at the end of the

vacuum phase failed.

Filling in the filling phase is very

slow or is interrupted before the

set quantity has been filled.

The quantity filled does not match

the set amount.

Power supply interrupted. Check mains input voltage.

Check fuse F1 on the control printed circuit board.

Replace defective fuse.

The control / display unit or the control

printed circuit board is defective.

Wrong working position of the external

refrigerant cylinder when filling.

Low pressure valve and/or high pressure

valve is/are closed.

Flow in the hose lines may be faulty. Check external and hose lines, whether the sealing rings

Excess pressure in internal refrigerant

cylinder.

Compressor defective. Replace processing unit.

Filter and drier cartridge is saturated. Replace the filter and drier cartridge.

Ice in expansion valve due to aspirated

water.

Do not switch OUT A solenoid valves. Check relay on the control printed circuit board. If the re-

Incorrectly calibrated or faulty pressure

sensor.

Valve pistons for the recovery and recycling phase are leaking.

The valve pistons for the filling phase

are leaking.

Duration of the vacuum phase is too

short.

Leaking vehicle air conditioning system. Repair the vehicle's air conditioning system.

ACS is leaking internally. Check external filling hoses and their connections

Insufficient refrigerant in the internal refrigerant container.

Pressure in the internal refrigerant cylinder is too low.

Scale is not calibrated. Check scale with a known weight. If the value does not

Mechanical malfunction in the scale

movement.

Replace the control / display unit or control printed circuit

board.

Correct the working position of the external refrigerant cylinder (see operating instructions).

Open the valve in question.

have become deformed due to tightening of the hose lines,

thereby possibly blocking the flow of the refrigerant. Carefully loosen hose lines and tighten them again by hand. Replace misshapen seals if necessary.

Reduce pressure in the internal refrigerant cylinder by pulling the metal ring on the safety valve for excess pressure

(see Chap. 3.2.4, Item 1).

Heat expansion valve and replace all refrigerant from the

ACS with fresh refrigerant.

lay has blown, replace the control printed circuit board.

Check electrical connection to the solenoid valves.

Check connecting lines to the solenoid valves for continuity. Replace defective connecting line.

Connecting lines to the solenoid valves have been

swapped. Check connection against connection diagram /

wiring harness (see Chap. 12.2).

Connecting lines to control printed circuit board have

been swapped. Check connection against connection diagram / wiring harness (see Chap. 12.2).

Check pressure sensor (see Chap. 8.3).

Check condition (contamination, wear) of the valve pistons

in the valve block.

Caution: Close the shutoff valve on the internal refriger-

ant cylinder before testing.

Check condition (contamination, wear) of the valve pistons

in the valve block.

Check relay on the control printed circuit board. If the relay has blown, replace the control printed circuit board.

The vacuum pump is mechanically blocked. Replace vacuum pump.

Vacuum phase duration: approx. 30 min. for vehicles

(for larger systems, e.g. commercial vehicles, set a corre

spondingly longer vacuum time).

(e. g. are seals present?).

Check condition (contamination, wear) of the valve pistons

in the valve block.

Fill internal refrigerant cylinder with fresh refrigerant.

Optimum amount: approx. 7 kg.

Fill internal refrigerant cylinder with fresh refrigerant.

Optimum pressure: approx. 6-7 bar.

match, calibrate the scale (see Chap. 9.4.2).

Check whether the movement of the scale and the refriger-

ant cylinder is blocked mechanically by other components.

ACS 500

-

1 689 975 197 (2006-09-22)

Robert Bosch GmbH

ACS 500

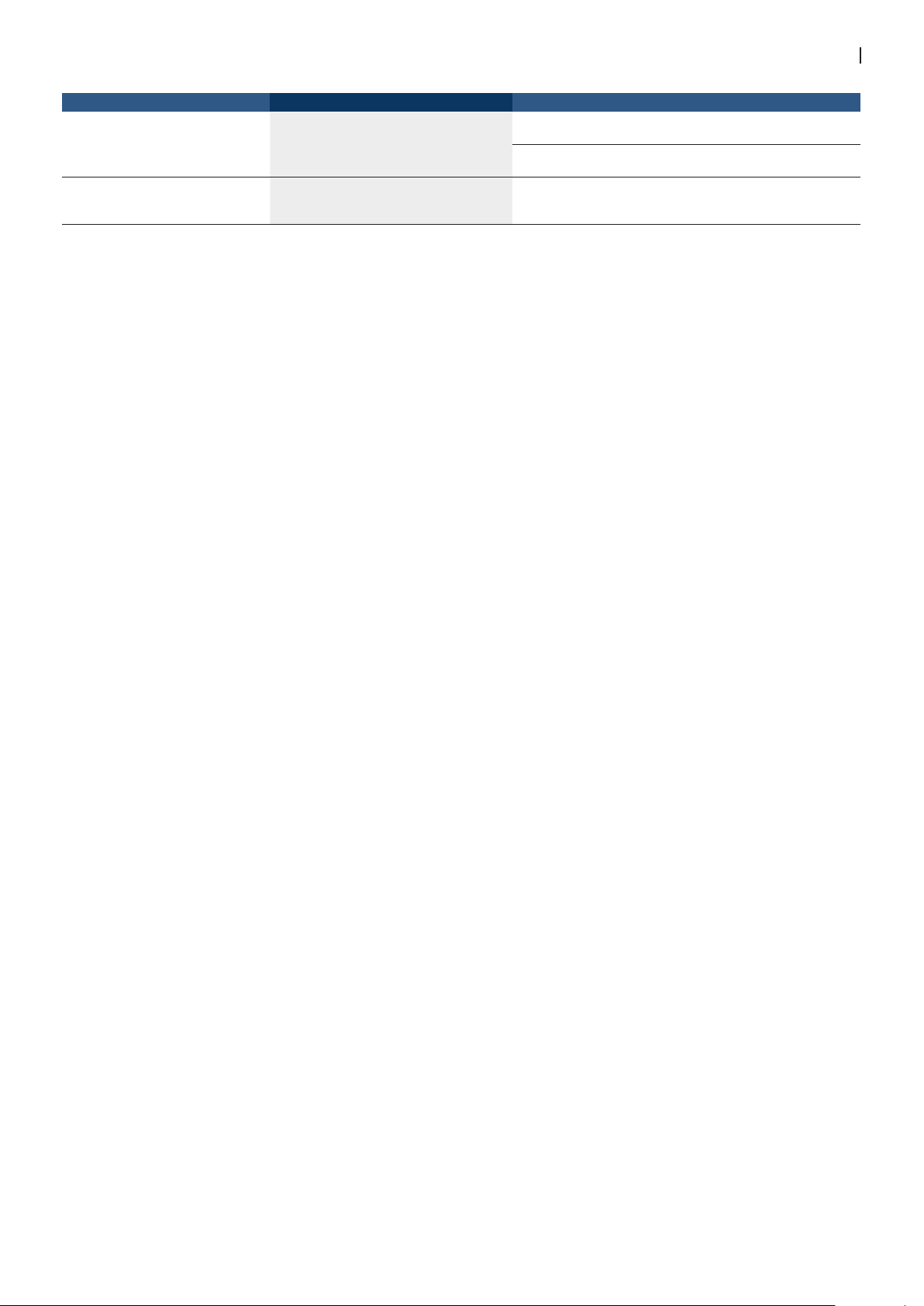

Error pattern Cause Troubleshooting and correction

Compressor will not start. Power supply interrupted. Check fuses F2 and F3 on control PCB. Replace defective

White smoke escapes from the

vacuum pump.

Aspirated ambient air. Inspect the vehicle air conditioning system and ACS for

fuse.

Check relay on the control printed circuit board. If the re-

lay has blown, replace the control printed circuit board.

leaks and repair. Small quantities of smoke in the first minutes of the vacuum phase are permitted.

en 9

Robert Bosch GmbH

1 689 975 197 (2006-09-22)

Loading...

Loading...