Bosch ACS 255 Original Instructions Manual

ACS 255

en

Original instructions

A/C service unit

Contents English

| ACS 255 | 3 en

1. Symbols used 4

1.1 In the documentation 4

1.1.1 Warning notices - Structure and

meaning 4

1.1.2 Symbols in this documentation 4

1.2 On the product 4

2. User information 5

2.1 User group 5

2.2 Agreement 5

2.3 Obligation of contractor 5

2.4 Safety Instructions 5

2.5 Safety devices 6

3. Product description 7

3.1 Application 7

3.2 Delivery specification 7

3.3 Description of unit 7

3.3.1 Human Machine Interface (HMI) 8

3.3.2 Scale for refrigerant tank 8

3.3.3 Oil bottles 8

3.3.4 Quick couplers 9

3.3.5 Brakes 9

3.3.6 Power cable and master switch 9

3.4 Description of function 9

4. Commissioning 10

4.1 Removing the transport packaging 10

4.2 Before turning on for the first time 10

4.3 Powering on the ACS 255 11

4.4 Changing the system defaults 11

4.5 Filling the internal refrigerant

tank 12

4.6 Viewing system information 12

5. Troubleshooting 13

6. Program description 14

6.1 ACS 255 operating modes 14

6.2 Preparations for A/C service 14

6.3 Configuring the custom database 14

6.3.1 Adding new vehicle details to the

vehicle database 14

6.3.2 Editing vehicle details in the custom

database 14

6.3.3 Deleting vehicle details from the

custom database 14

6.3.4 Viewing custom database information 14

6.3.5 Transferring the custom database

from one ACS 255 to another 14

6.4 Accessing the custom database 14

6.5 Automatic mode 15

6.5.1 Overview of automatic mode 15

6.5.2 Selecting the vehicle from the

custom database 15

6.5.3 Setting custom parameters 15

6.6 Manual mode 15

6.6.1 Overview of manual mode 15

6.6.2 Recovery 16

6.6.3 Vacuuming phase 16

6.6.4 Oil recharge phase 16

6.6.5 Recharge phase 16

6.7 Performing service in manual mode 16

6.8 Additional services 17

6.8.1 Refrigerant top up 17

6.8.2 Hose drain 17

6.8.3 A/C performance test 17

7. Maintenance 18

7.1 Spare and wearing parts 18

7.2 Refilling the refrigerant tank 18

7.3 Service record 18

7.3.1 Viewing the last three vehicle A/C

service reports 18

7.3.2 Last self test 18

7.3.3 Last five errors during vehicle A/C

service 18

7.4 Vacuum pump oil change 18

7.5 Replacing the filter drier 19

7.6 Replacing the inline filters 19

7.7 Self test 20

7.8 Firmware update 20

7.9 Resetting factory settings 20

8. Decommissioning 21

8.1 Disposal of electronic items 21

8.2 Disposal of LCD display, refrigerants,

lubricants and oils 21

8.3 Disposal of filter drier 21

8.4 Electromagnetic compatibility (EMC) 21

9. Technical data 21

F 002 DG9 432 2014-12-19| Bosch Limited

4 | ACS 255 | Symbols useden

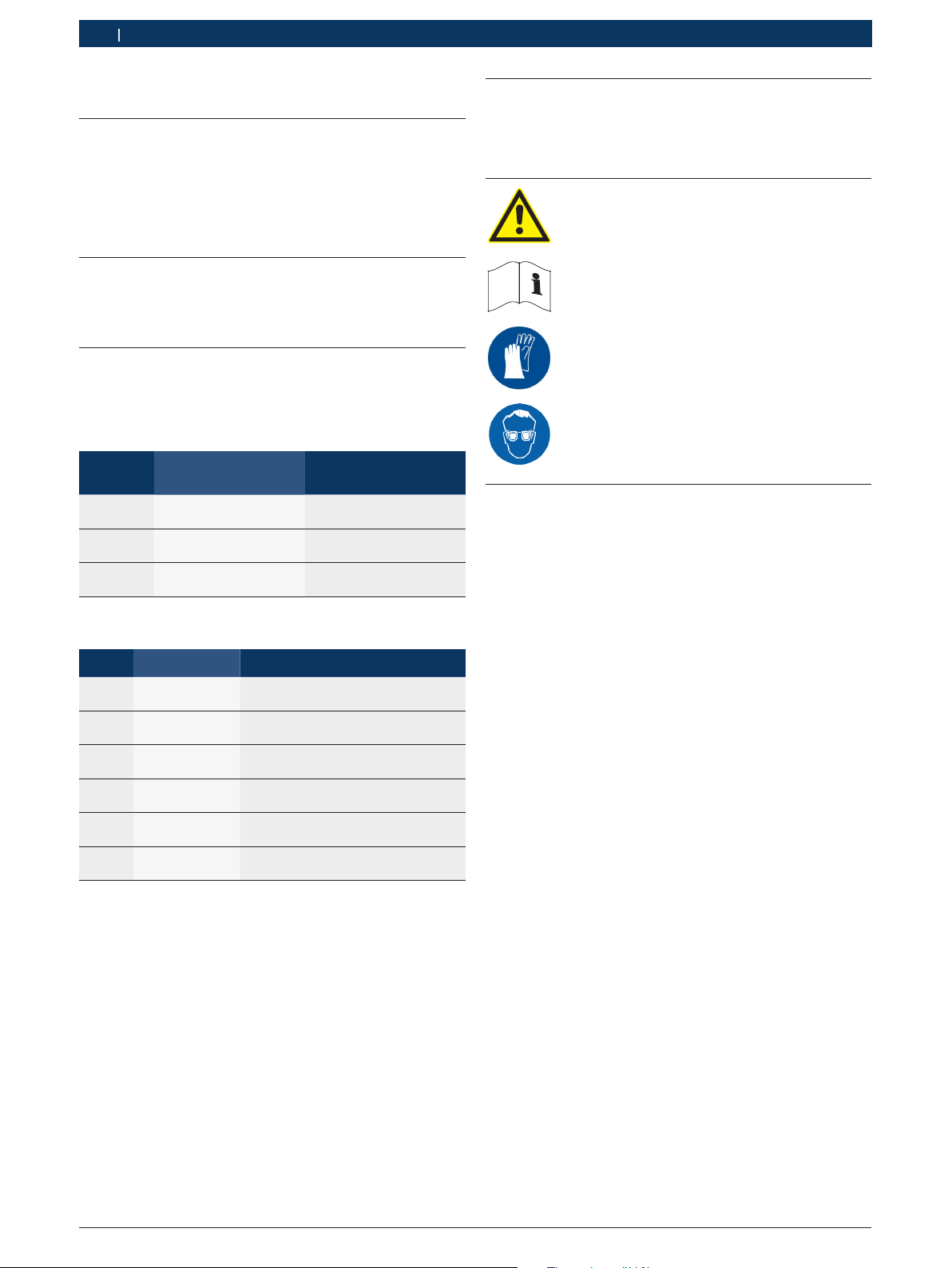

1. Symbols used

1.1 In the documentation

1.1.1 Warning notices - Structure and meaning

Warning notices warn of dangers to the user or people

in the vicinity. Warning notices also indicate the consequences of the hazard as well as preventive action.

Warning notices have the following structure:

Warning

symbol

The key word indicates the likelihood of occurrence and

the severity of the hazard in the event of non-observance:

Key word Probability of

DANGER

WARNING

CAUTION

KEY WORD – Nature and source of hazard!

Consequences of hazard in the event of failure to observe action and information given.

¶ Hazard prevention action and information.

occurrence

Immediate impending

danger

Possible impending

danger

Possible dangerous

situation

Severity of danger if instructions not observed

Death or severe injury

Death or severe injury

Minor injury

1.2 On the product

! Observe all warning notices on products and ensure

they remain legible.

Caution!

Contact with the refrigerant can cause

blindness and severe injuries.

¶ Read this operating manual and all

technical documentation for the used

components.

¶ Wear protective gloves.

¶ Wear protective goggles.

1.1.2 Symbols in this documentation

Symbol Designation Explanation

!

i

1.

2.

e

"

Attention Warns about possible property dam-

Information Practical hints and other useful in-

Multi-step

operation

One-step operation

Intermediate result

Final result There is a visible final result on com-

age.

formation.

Instruction consisting of several

steps.

Instruction consisting of one step.

An instruction produces a visible intermediate result.

pletion of the instruction.

F 002 DG9 432 2014-12-19| Bosch Limited

User information | ACS 255 | 5

en

2. User information

2.1 User group

The product may be used by skilled and instructed

personnel only. Personnel scheduled to be trained, familiarized, instructed or to take part in a general training course may only work with the product under the

supervision of an experienced person.

All work conducted on pressurized equipment may be

performed by persons with sufficient knowledge and

experience in using pressurized devices and, also be

aware of the risks involved in the use of pressurized

devices.

2.2 Agreement

Your use of the product means that you accept the following conditions:

Copyright

Software and data are the property of Bosch Limited,

hereafter denoted as Bosch, or its suppliers and are

protected against unauthorized reproduction under

copyright laws, international contracts and other national legal provisions. Copying and selling of data

and software or any other part thereof is prohibited

and punishable by law. In the event of violations,

Bosch Limited reserves the right to proceed with criminal prosecution and to claim for damages.

Liability

All data in this program is based - where possible - on

manufacturer and importer details. Bosch does not accept liability for the correctness and completeness of

software and data; liability for damage caused by faulty

software and data is ruled out. Whatever the event,

Bosch liability is restricted to the amount for which the

customer actually pays for this product. This disclaimer

of liability does not apply to damages caused by intent

or gross negligence on the part of Bosch.

2.3 Obligation of contractor

The contractor is obliged to ensure that all measures

geared towards the prevention of accidents, industrial

diseases, labor-related health risks are taken and measures towards making the workplace fit for people to

work in are carried out.

The contractor is bound to ensure that all electrical

equipment and operating material is set up, modified

and maintained by skilled electricians only or under the

guidance and supervision of a skilled electrician in accordance with electrical engineering principles.

Furthermore, the contractor must ensure that all electrical equipment and operating material is operated in

keeping with electrical engineering principles.

If a piece of electrical equipment or operating material

is found to be defective, i.e. it does not or no longer

complies with electrical engineering principles, the contractor must ensure that the fault is rectified immediately and, in the event that imminent danger exists, also

ensure that the electrical equipment or the electrical

operating material is not used.

2.4 Safety Instructions

All safety instructions are to be read thoroughly before

using the Bosch product and they must be observed.

R Avoid the refrigerant coming into contact with the

skin. The low boiling point of the refrigerant (approximately -30 °C at atmospheric pressure) can cause

frostbite. In case of contact with the skin, remove

wet clothing immediately and rinse the affected area

of skin with plenty of water.

Do not breathe in refrigerant or oil vapors.

The vapors can irritate the eyes and the

breathing passage of the nose. If liquid

refrigerant/oil gets into the eyes, rinse the

eyes thoroughly with water for 15 minutes.

Then, seek medical attention, even if the

eyes do not hurt.

Warranty

Any use of non-approved hardware and software will

result in a modification to our product and thus to

exclusion of any liability and warranty, even if the hardware or software has in the meantime been removed or

deleted. No changes may be made to our products. Our

products may only be used in combination with original

accessories and original service parts. Failing to do so,

will render null and void all warranty claims.

R Before the ACS 255 is connected to the vehicle A/C

system or to an external refrigerant tank, ensure that

the quick couplers do not leak. Use only external

refrigerant tanks that are fitted with safety valves

and approved in accordance with the applicable

standards.

R Before turning off the ACS 255, ensure that all the

service phases are complete. This prevents refrigerant from escaping into the environment.

F 002 DG9 432 2014-12-19| Bosch Limited

6 | ACS 255 | User informationen

Do not use compressed air with R134a.

Some mixtures of air and R134a are highly

flammable at high pressure. These mixtures

are potentially hazardous and can cause

fires or explosions resulting in damage to

property and injury to persons.

R Refrigerant extracted from the vehicle A/C system

might be contaminated with moisture, lubricant, dirt

and traces of other gases.

R The ACS 255 does not have any refrigerant identifier

system. If refrigerants other than R134a are used, it

might lead to contamination.

R R134a is colorless, odorless and heavier than air. It

expels oxygen and can flow into repair pits. If the

refrigerant escapes, there is a risk of suffocation in

poorly ventilated rooms or repair pits.

R R134a may not be used in environments with a risk

of explosion. Fire, naked flames and smoking are

prohibited. No welding or soldering is allowed. High

temperatures and UV radiation can cause R134a to

chemically separate. The resulting products cause

coughs and nausea.

R R134a may not be mixed with other refrigerants.

Mixing refrigerants can cause damage to the vehicle

A/C system.

R The ACS 255 must always be monitored during op-

eration. Do not leave the ACS 255 unattended when

it is switched on.

R Vehicle A/C service, using the ACS 255, must be pre-

pared and carried out in such a way that the vehicle

A/C circuit is not opened (for example, radiator or

engine removal).

R The ACS 255 should be positioned with all four

wheels on a flat, vibration-free surface to ensure

correct operation of the load sensors. The ACS 255

can be prevented from rolling away by applying the

brake.

R The ACS 255 must always be transported in a verti-

cal position. Do not invert the ACS 255.

R There are no additional safety provisions for protect-

ing the ACS 255 unit against damage in the event of

natural calamities like earthquakes, fires, floods etc.

R Except for maintenance work, do not remove any

pressurized equipment inside the

ACS 255 unit. Adhere to the national laws or regulations for ensuring safety of pressurized equipment.

R We recommend that calibration of load sensors be

done at least once every year. Contact customer

service for calibration of load sensors.

R The ACS 255 must be regularly inspected by service

personnel or the approved authorities to ensure

safety of the unit.

Warning - Risk of frostbite in the event of

refrigerant leakage!

If refrigerant escapes, there is a risk of frostbite to the hands and body.

¶ Wear protective goggles.

¶ Wear protective gloves.

¶ Ensure that the HP and LP hoses are not

damaged.

¶ Ensure that the quick couplers are tightly

fixed to the hoses.

Warning - Risk of frostbite during removal

of service hoses!

If refrigerant escapes, there is a risk of

frostbite to the hands and body.

¶ Carefully disconnect service hoses as all

hoses can contain pressurized

refrigerant.

R Only connect to a properly grounded electrical

outlet.

R Do not attempt to shut off the valves on the R134a

tank when the ACS 255 is in operation.

R For the purposes of safety, it is recommended to use

an Earth Leakage Circuit Breaker (ELCB) with the

following specifications:

Parameter Specification

Rated voltage 230 VAC +/- 10%

Rated frequency 50/60 Hz

Rated current 10 A

Rated trip current 30 mA

Tripping curve C

2.5 Safety devices

R Pressure switch - Switches the compressor off if the

normal operating pressure is exceeded.

R Safety valve: Operates when the design pressure is

exceeded.

R Fuse: Interrupts excessive current flow into the

ACS 255.

F 002 DG9 432 2014-12-19| Bosch Limited

Product description | ACS 255 | 7

1

2

3

en

3. Product description

3.1 Application

The ACS 255 is used to perform the following basic

services for passenger car A/C systems in manual or

automatic mode:

R Refrigerant recovery

R Oil recharge

R Vacuuming and leak tests

R Refrigerant recharge

The ACS 255 should be used with car A/C systems that

use R134a.

3.2 Delivery specification

Description

ACS 255

Hose - HP

Hose - LP

Quick coupler - HP

Quick coupler - LP

Can assembly - Used oil

Can assembly - Fresh oil

Operating instructions

Adapter for filling internal refrigerant tank

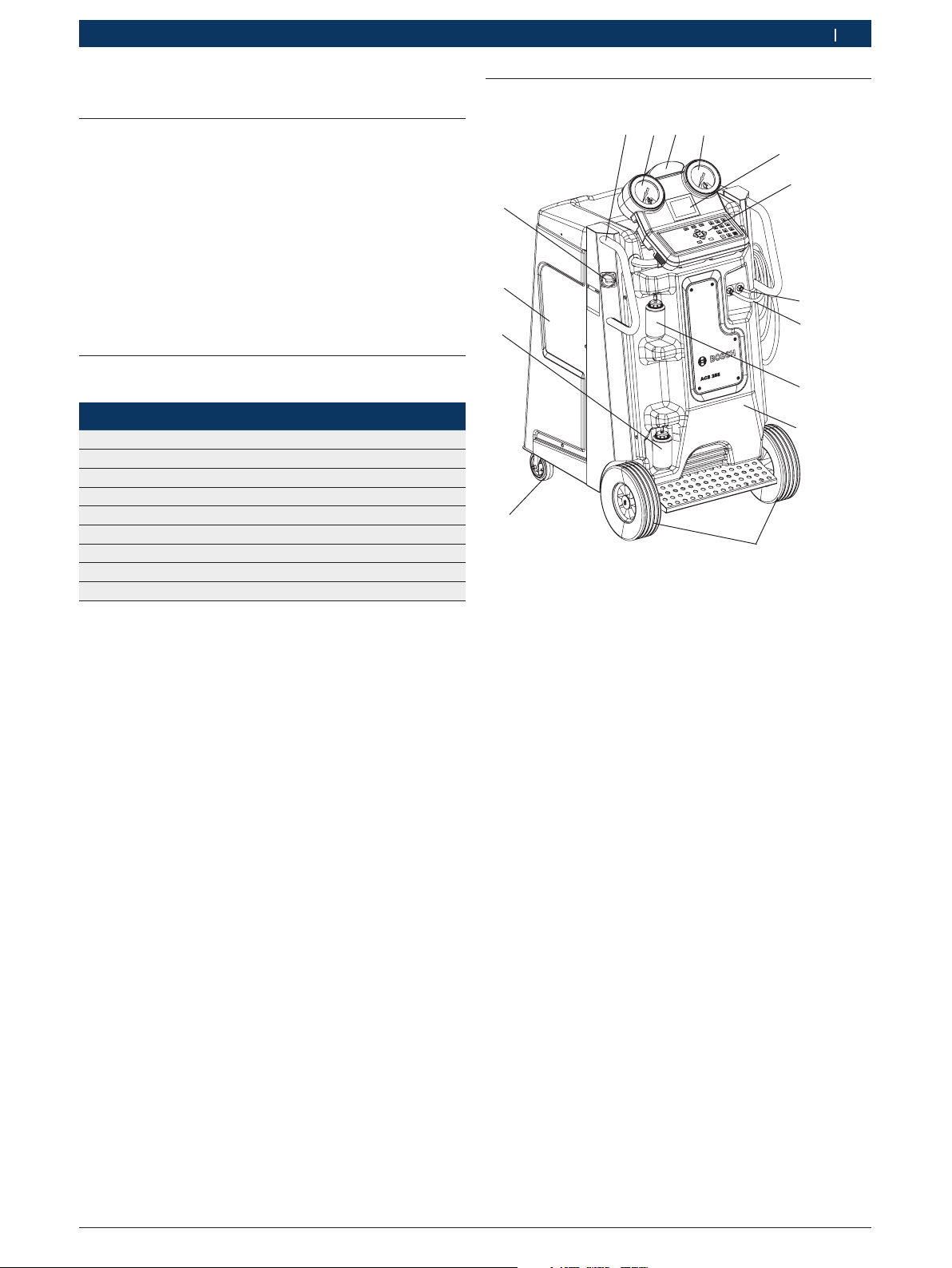

3.3 Description of unit

15

14

13

459897_159Nkv

12

Fig. 1: Front view

1 Handle (x 2)

2 HP gauge

3 Status and warning light

4 LP gauge

5 LCD

6 Keypad

7 LP hose

8 HP hose

9 Fresh oil bottle

10 Front panel

11 Front wheels

12 Rear wheel (x 2)

13 Used oil bottle

14 Left-hand side panel

15 Master switch

4

5

6

7

8

9

10

11

F 002 DG9 432 2014-12-19| Bosch Limited

8 | ACS 255 | Product descriptionen

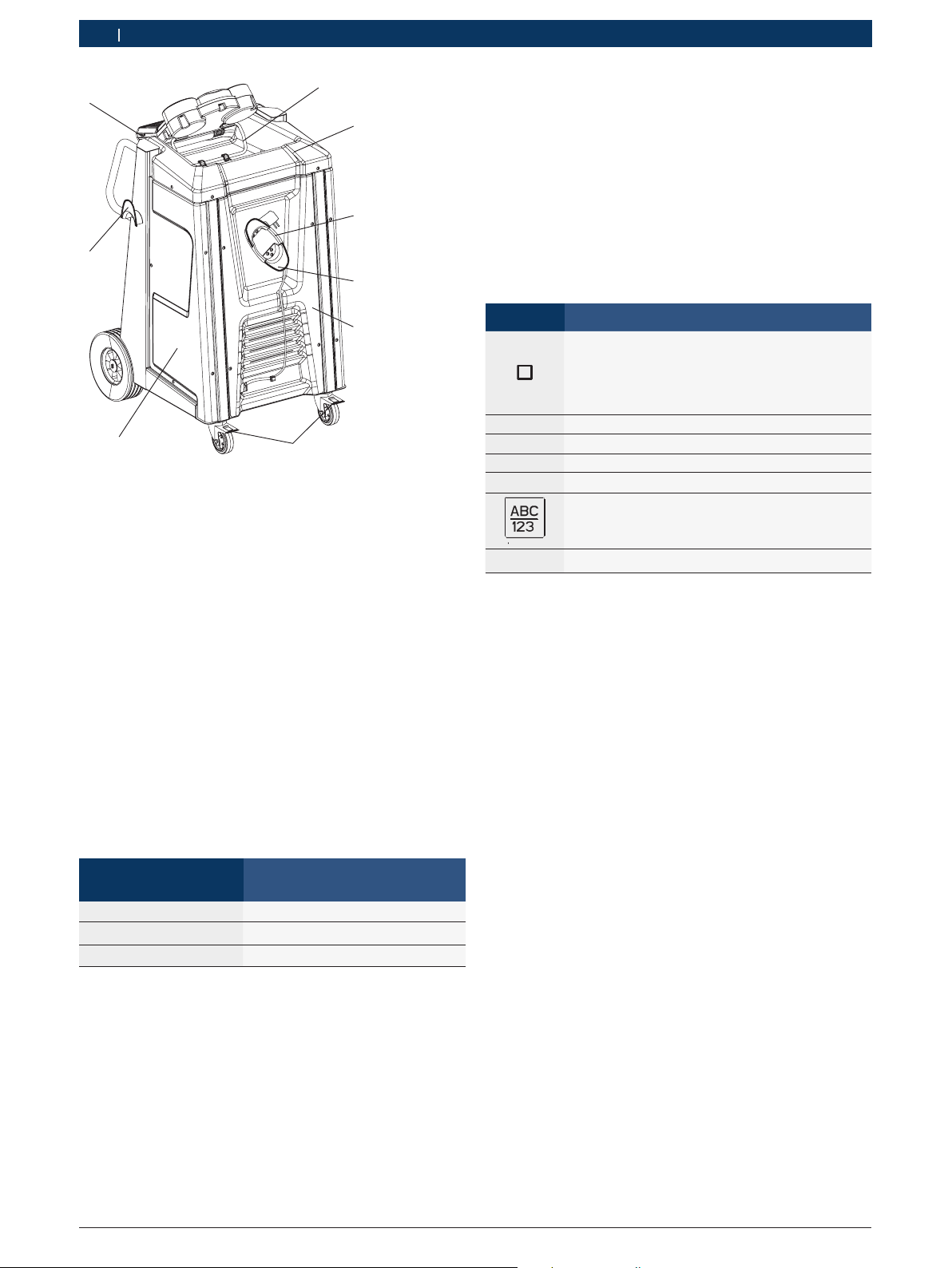

1

9

2

3

8

4

459897_112Nkv

7

Fig. 2: Rear view

1 HMI support

2 Painel superior

3 Power cable

4 Cable holder

5 Rear panel

6 Brakes

7 Right-hand side panel

8 Hose holder

9 USB port

6

5

3.3.1 Human Machine Interface (HMI)

The HMI consists of:

R Pressure gauges - The pressure during the service is

displayed on the gauges.

R Status and warning lights - The status of service

and disruptions during service are indicated by the

status and warning light.

R Keypad - The selection of service menu options and

service parameters can be done via the keypad. The

alphanumeric input keys can be used to enter letters

and special characters in input fields. In an input

field, pressing a key several times in succession

displays all the characters it can be used for (upper

case letters, special characters).

i The alphabetical entries can be made in upper case

only.

Keys Description

c

o or u Navigate up or down

v or z

E

C

Function keys,

The function keys are assigned various functions in the ACS 255 software. The functions of

the keys are specified in the soft key bar of the

ACS 255 software.

Navigate right or left

Enter

Clear

Switch between numeric and alphabetical entry

Display system information

i

R USB port - Firmware updates can be performed by

plugging the USB disk into the USB port.

3.3.2 Scale for refrigerant tank

The quantity of refrigerant charged into the vehicle A/C

system is controlled by a scale mounted beneath the

refrigerant tank.

3.3.3 Oil bottles

! Do not apply excessive force while detaching or at-

taching the oil bottles.

Color indicated by the

status and warning light

Red Error/Warning

Blinking green Service in progress

Static green Service complete

Status of service

R LCD - The menu options and status of service are

displayed on the LCD.

F 002 DG9 432 2014-12-19| Bosch Limited

Loading...

Loading...