Bosch 940ESNG, 940ESLP Installation Manual

940 ES

INDOOR MODEL

Temperature Modulated with Electronic Ignition

Suitable for heating potable water only and space heating

(Intended for variable flow applications)

940 ES - Natural Gas

940 ES - Liquefied Petroleum (LP) Gas

Warning: If the information in this manual is not

followed exactly, a fire or explosion may result

causing property damage, personal injury or death.

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

Improper installation, adjustment, alteration,

service or maintenance can cause injury or

property damage. Refer to this manual. For

assistance or additional information consult a

qualified installer, service agency or the gas

supplier.

In the Commonwealth of Massachusetts this

product must be installed by a licensed plumber or

gas fitter.

Upon completion of the installation, these

instructions should be handed to the user of the

appliance for future reference.

6 720 644 930 (2010/09) US

What to do if you smell gas

• Close gas valve. Open windows.

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

• Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

Index

Index

1 Warning 3

2 Appliance details 4

2.1 Features 4

2.2 Specifications (Technical data) 5

2.3 Unpacking the heater 6

2.4 General rules to follow for safe operation 7

2.5 Dimensions and Minimum

installation clearances 8

3 Installation instructions 9

3.1 Specialized tools 9

3.2 Introduction 9

3.3 Venting 9

3.4 Combustion air requirements 23

3.5 Proper location for installing your heater 23

3.6 Heater placement and clearances 24

3.7 Mounting installation 24

3.8 Gas piping & connections 25

3.9 Water connections 28

3.10 Water quality 28

3.11 Domestic hot water recirculation 29

3.12 Space heating applications 30

3.13 Measuring gas pressure 32

6 Maintenance and service 37

6.1 Annual maintenance 37

6.2 Winterizing for seasonal use 38

6.3 Mineral scale build-up 38

6.4 Adjusting CO2 39

6.5 Program values 41

6.6 Diagnostic menu 42

7 Troubleshooting 43

7.1 Introduction 43

7.2 Burner do not ignite when hot water

is turned ON 43

7.3 Water is too hot 43

7.4 Water is not hot enough 43

7.5 Low water flow/pressure 44

7.6 Hot water temperature fluctuates at tap 44

7.7 Noisy burner/heater during operation 44

8 Problem solving 46

8.1 Error code diagnostics 46

9 Electrical diagram 50

4 Electrical connections 33

4.1 Electrical power supply 33

4.2 Position of the fuses in control unit 33

5 Operation instructions 34

5.1 Description LCD display 34

5.2 For your safety read before operating

your water heater 35

5.3 Power 35

5.4 Temperature selection 35

5.5 Use of optional remote control accessory

(part no. TSTAT2) 36

5.6 Operation 36

5.7 Reset button 36

5.8 Program button 36

5.9 Locked condition 37

10 Sensor resistance charts 51

11 Functional scheme 53

12 Interior components diagram

and parts list 54

12.1 Interior components 54

12.2 Components diagram 56

13 Protecting the environment 62

14 Limited Warranty 63

2

6 720 644 930

Warning

1 Warning

For your safety

Do not store or use gasoline or other flammable,

combustible or corrosive vapors and liquids in the

vicinity of this or any other appliance.

Warning: Carefully plan where you

install the heater. Correct combustion

air supply and flue pipe installation are

very important. If a gas appliance is not

installed correctly, fatal accidents can

result, such as carbon monoxide

poisoning or fire.

Warning: Exhaust gas must be vented

to outside using stainless steel vent

material suitable for category III vent

systems and temperatures up to 480°F.

Vent piping must be sealed gas-tight to

prevent possibility of flue gas spillage,

carbon monoxide emissions and risk of

fire, resulting in severe personal injury

or death. Approved vent terminators

must be used when penetrating to the

outside.

Warning: The appliance should be

located in an area where leakage of the

heater or connections will not result in

damage to the area adjacent to the

appliance or to lower floors of the

structure. When such locations cannot

be avoided, it is recommended that a

suitable drain pan, adequately drained,

be installed under the appliance. The

pan must not restrict combustion air

flow.

Warning: The maximum inlet gas

pressure must not exceed the value

specified by the manufacturer and the

minimum value listed is for the purpose

of input adjustment.

Warning: If a water heater is installed in

a closed water supply system, such as

one having a backflow preventer in the

cold water supply line, means shall be

provided to control thermal expansion.

Contact the water supplier or local

plumbing inspector on how to control

this situation.

Warning: Place the heater in a location

where water leaks will do NO DAMAGE

to adjacent areas or lower floors.

Warning: Field wiring connections and

electrical grounding must comply with

local codes, or in the absence of local

codes, with the latest edition of the

National Electric Code, ANSI/NFPA 70,

or in Canada, all electrical wiring must

comply with the local codes and the

Canadian Electrical Code, CSA C22.1

Part 1.

Warning: Shock hazard: line voltage is

present. Before servicing the water

heater, unplug power supply cord from

outlet. Failure to do so could result in

severe personal injury or death.

Warning: The heater must be

disconnected from the gas supply

piping system during any pressure

testing of that system at test pressures

equal to or more than 0.5 psig.

Warning: Keep appliance area clear

and free from combustible materials,

gasoline and other flammable vapors

and liquids.

Warning: Do not obstruct the flow of

combustion and ventilation air.

Warning: Precautions must be taken

prior to manually operating the relief

valve to avoid contact with hot water

coming out of the relief valve and to

prevent water damage.

Caution: Label all wires prior to

disconnection when servicing controls.

Wiring errors can result in improper and

dangerous operation.

Verify proper operation after servicing.

6 720 644 930

3

Appliance details

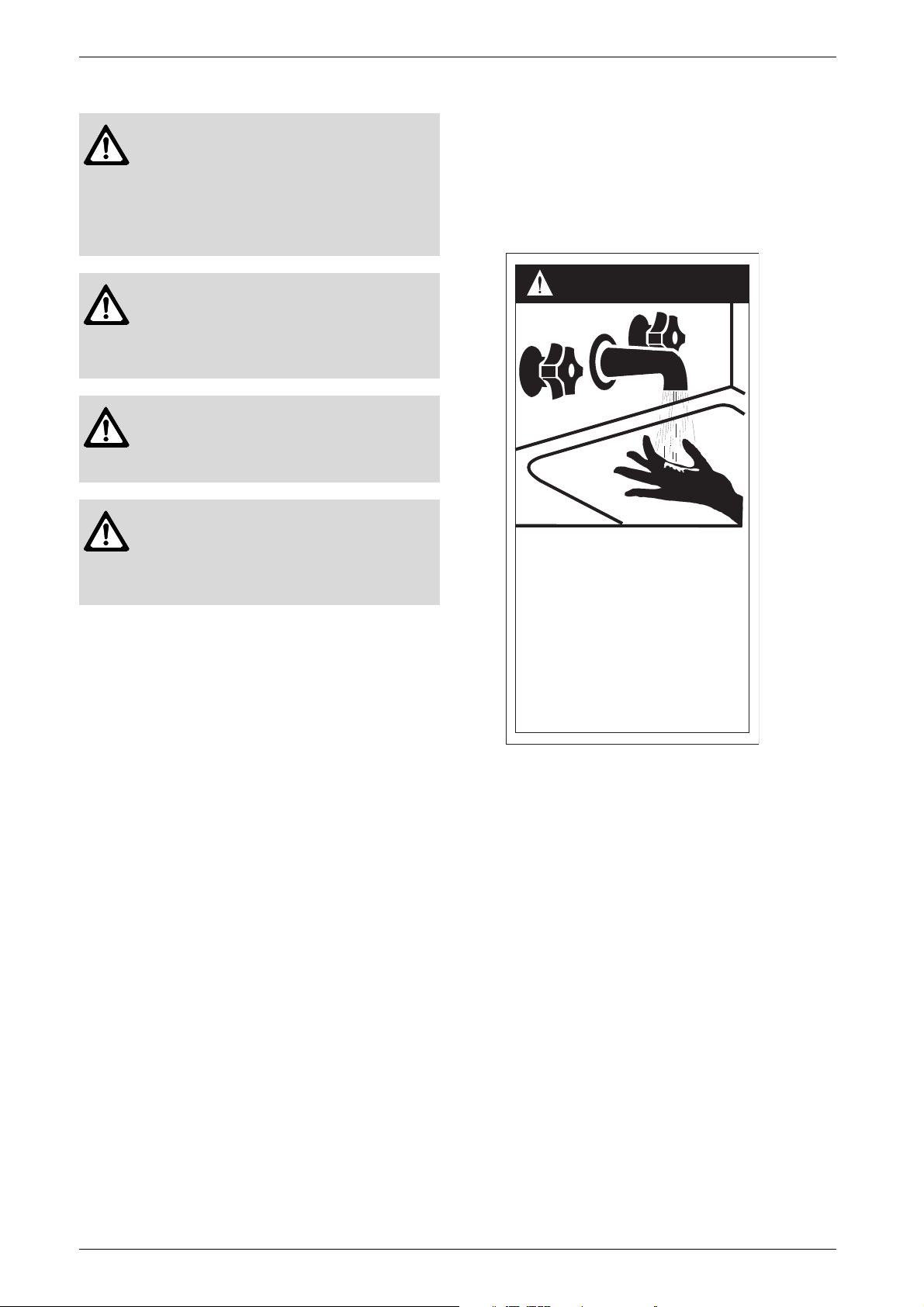

HOT

BURN

D A N G E R

Watertemperatureover125°Fcan

causesevereburnsinstantlyor

deathfromscalds.

Children,disabledandelderlyare

athighestriskofbeingscalded.

Seeinstructionmanualbefore

settingtemperatureatwater

heater.

Feelwaterbeforebathingor

showering.

6720608643-16.1AL

Warning: If a relief valve discharges

periodically, this may be due to thermal

expansion in a closed water supply

system. Contact the water supplier or

local plumbing inspector on how to

correct this situation. Do not plug the

relief valve.

Warning: If the water heater is used in

a space heating application, all piping

and components connected to the

water heater must be suitable for use

with potable water.

Warning: Toxic chemicals, such as

those used for boiler treatment, shall not

be introduced into the potable water

used for space heating.

Warning: A water heater which will be

used to supply potable water shall not

be connected to any heating system or

component(s) previously used with a

nonpotable water heating appliance.

FCC:

This device complies with Part 15 of the FCC rules.

Operation is subject to the following two conditions: (1)

This device may not cause harmful interference, and (2)

this device must accept any interference received,

including interference that may cause undesired operation.

4

Fig. 1

2 Appliance details

2.1 Features

Parts

• Key Pad interface control

• High power pre-mix compact burner with low NOx

emissions

• Modulating Gas Valve with constant gas:air ratio

control

• Modulating water valve for improved comfort and

temperature control.

High quality materials for long working life

• Copper heat exchanger

• High efficiency Ceramat Burner

• Compact space saver: mounts on a wall with a

supplied bracket.

Features

6 720 644 930

Appliance details

i

• Real-time diagnostics for troubleshooting/

informational purposes

• LCD Display with backlight

• On/Off and Temperature control switches

• Reset button

• Program button (Selectable temperature default)

• Failure codes for easy diagnostics and repair

• Easily removable one-piece cover

• Built in freeze prevention.

Note: The freeze prevention kit is designed to provide

protection for the water heater down to approximately

5°F for short term conditions only. It will not protect the

appliance in areas where the temperature is routinely

expected to be below freezing.

- The freeze prevention kit will not protect plumbing out-

side the appliance from freezing. Precautions should be

taken.

Accessories (Bosch part #)

• Optional wireless remote control accessory to

operate with the appliance (TSTAT2)

• Cascading kit (77090003962)

• Outdoor kit (BTOK)

• External water filter (8703305356)

• Gas conversion kit (8719002176)

• Vertical vent kit (ESVVT)

• Concentric vent /air intake kit (ESHCK)

• Horizontal vent kit (4TWHVK3SII)

1)

• Stainless steel bird screen (L2594)

(fits into a 3” PCV fitting - Intake vent).

• Pipe Cover (PTPCES)

• High temperature kit (7736500074)

• Recess box kit (7736500043)

• Pressure relief valve (FWL-2).

BOSCH is constantly improving its

products, therefore specifications are

subject to change without prior notice.

2.2 Specifications (Technical data)

Approved in US/Canada

Capacity

Maximum flow rate: 7.15 GPM (27 l/min) at a 45°F

(25°C) rise.

Maximum output

160,500 Btu/h (47.0 kW)

Maximum input

199,000 Btu/h (58.3 kW)

Efficiency in %

Thermal efficiency > 82%

Min. Input

19,900 Btu/h (5.8 kW)

Temperature Control

Selection range: 100°F (38°C) - 140°F (60°C)

Default temperature: 122°F (50°C)

Stability: +/- 2°F (+/- 1°C)

Gas Requirement

Gas connection (inches) - ¾”

Inlet gas pressure under operation (with a high hot

water flow rate)*

• Propane: 8” - 13” water column

• Natural Gas: 3.5” - 10.5” water column.

* To measure gas pressure, see Measuring Gas

Pressure, chapter 3.13, page 32.

Water

• Hot water connection (inches) - ¾”

• Cold water connection (inches) - ¾”

• Water valve material: Polymer (PPS) (Polypropylene

Sulfid)

• Minimum water flow: 0.5 gallon/minute (1,9 l/m).

Note: Activation varies with inlet water temperatures

from 0.5 - 1.6 gallon/minute (1,9 - 6.1 l/m).

• Minimum recommended water pressure: 30 PSI

(2.07 bar).

• Minimum well pressure 40 psi, see page 28.

• Connections:

– Bottom of heater

Combustion

• NOx ≤ 40 Ng/J

Joule of heat output).

(Nanograms of NOx (calculated as NO2) per

• CO ≤ 250 ppm (measured)

1) 4TWHVK3S vent kit is compatible with this appliance

but requires the purchase of an additional 12" piece of

straight pipe to meet minimum vent length requirements.

The aluminum flex piping included with this kit is not

permissible for use with this appliance.

6 720 644 930

• CO

level set from factory, see chapter 6.4, page 39.

2

5

Appliance details

i

Dimensions

• Depth (in): 11¼” (286 mm)

7

/

• Width (in): 17

• Height (in): 30½” (775 mm)

• Weight: 67 pounds (30.5 kg).

Gas types

Natural Gas.

LP Gas.

Voltage

120 V AC (60 Hz) nominal

Amperage

Idle - 40 mA

Operation - ≤ 2.5 A

Noise

45 - 65 db (A)

Safety devices

• Flame failure device (ionization flame rod sensor)

• Over heat prevention (temperature limiter)

• Inlet temperature sensor

• Outlet temperature sensor

• Back flow temperature sensor.

Water protection

IP X4 (protection against water drops)

” (452 mm)

8

• 940 ES

• Bracket for wall hanging the heater

• Exhaust vent adaptor (with 4 screws and gasket

provided)

• Combustion air inlet adaptor (with 3 screws and gasket provided)

• Installation manual (manual can be downloaded at

www.boschpro.com)

• Product registration card.

Please complete and return the enclosed product

registration card.

The 940 ES is not approved or designed for:

• Manufactured (mobile) homes, boats or any

mobile installation. (Modular homes are

acceptable for installation).

• Use above 8000 ft A.S.L. altitude (see page 20).

• Outdoor installation without installation of

Outdoor kit (BTOK).

• Applications where inlet water temperature is

higher than 140ºF (60°C). A 3-way valve or

mixing valve must be installed before the

appliance if inlet water temperature exceeds

this limit.

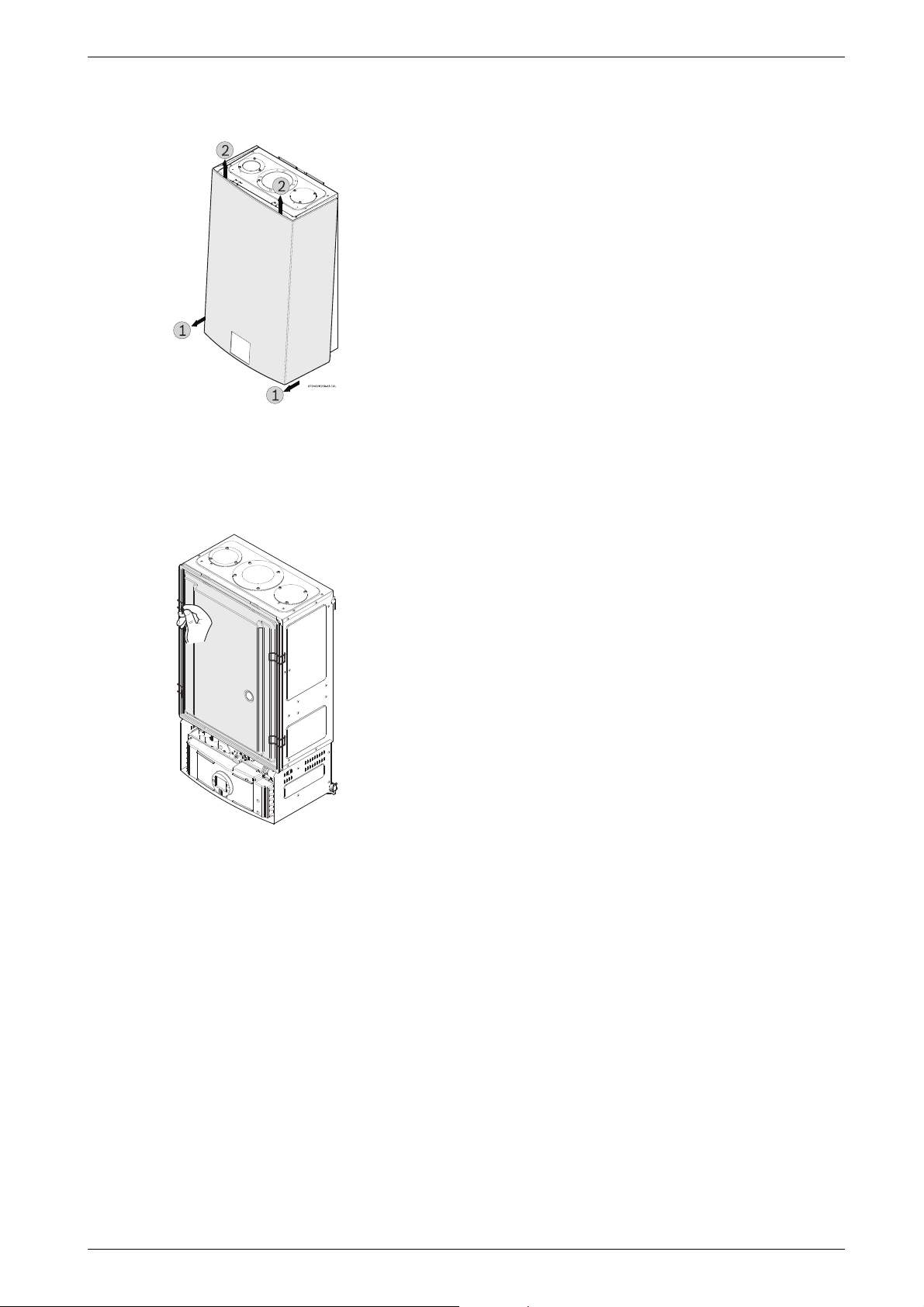

To remove front cover

B Loosen the two Philips head screws located on

bottom rear of cover (see Fig. 3).

If appliance is installed at elevations above

2000ft, refer to Section 3.3.7 Fan speed

adjustment.

2.3 Unpacking the heater

Before installing the unit, be certain you have the

correct heater for your type of Gas: Propane or

Natural Gas. Identification labels are found on the

shipping box, and on the rating plate which is located on

the right side panel of the cover.

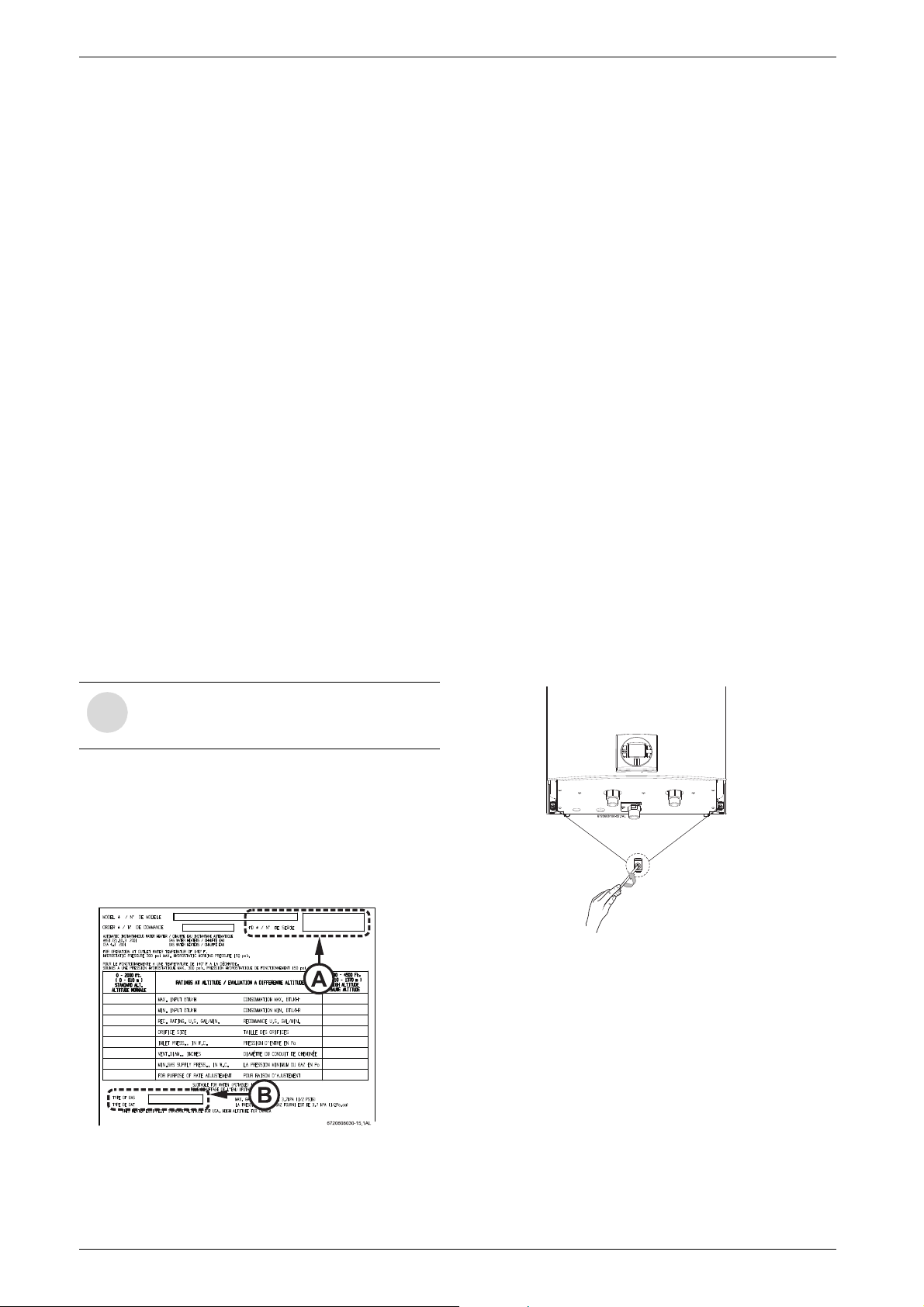

Fig. 2 Rating plate

A Serial number

B Type of gas

Fig. 3 Loosen the two screws

The box includes:

6

6 720 644 930

Appliance details

6720644956-11.1V

B Lift front cover panel upward and remove.

Fig. 4 Remove the front cover

To remove combustion cover (service only)

B Open the four clips and remove the combustion

cover see Fig. 5.

Fig. 5 Remove the combustion cover

2.4 General rules to follow for safe

operation

bathrooms, bedrooms and occupied rooms that are

normally kept closed. See chapter

3.3 (page 9

). If the

unit will be installed indoors and use indoor

combustion air, the place where you install the heater

must have enough ventilation. The National Fuel

Gas Code does not allow UNSEALED gas fired

water heater installations in bathrooms,

bedrooms or any occupied rooms normally

kept closed. See chapter

page 23

.

B 4. You must vent your heater. See

9

on VENTING.

3.5, page 23

chapter 3.3, page

and

3.4

B 5. The appliance and its gas connection must be leak

tested before placing the appliance in operation.

The appliance must be isolated from the gas supply

piping system by closing its individual manual gas

shutoff valve (not supplied with heater) during any

pressure testing at pressures in excess of ½ Psig (3.5

kPa).

B 6. Keep water heater area clear and free from

combustibles and flammable liquids. Do not locate

the heater over any material which might burn.

B 7. Correct gas pressure is critical for the proper

operation of this heater. Gas piping must be sized to

provide the required pressure at the maximum output

of the heater, while all the other gas appliances are in

operation. Check with your local gas supplier, and

see the section on connecting the gas supply, see

chapter 3.8

.

B 8. Should overheating occur or the gas supply fail to

shut off, turn off the gas supply at the manual gas shut

off valve, on the gas line. Note: manual gas shutoff

valve is not supplied with the heater but must be field

installed.

B 9. Do not use this appliance if any part has been

underwater. Immediately call a qualified service

technician to inspect the appliance and to replace any

part of the control system and any gas control which

has been underwater.

B

10. Failure to install heater correctly may lead to

unsafe operation and void the warranty.

,

B

1. You must follow these instructions when you install

your heater. In the United States: The installation must

conform with local codes or, in the absence of local

codes, the National Fuel Gas Code ANSI Z223.1/

NFPA 54.

In Canada: The Installation must conform with CGA

B149.(1,2) INSTALLATION CODES and /or local

installation codes.

B 2. Carefully plan where you install the heater. Correct

combustion air supply and vent pipe installation are

very important. If not installed correctly, fatal

accidents can occur, such as carbon monoxide

poisoning or fire.

B 3. When the unit is installed indoors and ROOM

SEALED (twin pipe) it is permitted to be located in

6 720 644 930

7

Appliance details

6720608158-04.2AL

2

3

1

6

5

7

4

res et

P

+

5 ¼"

30 ½"

17 "

7

8

5 ¼"

11 ¼"

2 ¾"

6 ½"

2 "

16

5

5 ¼"

2 "

16

4 "

1

16

6 "

5

16

1

16

5

16

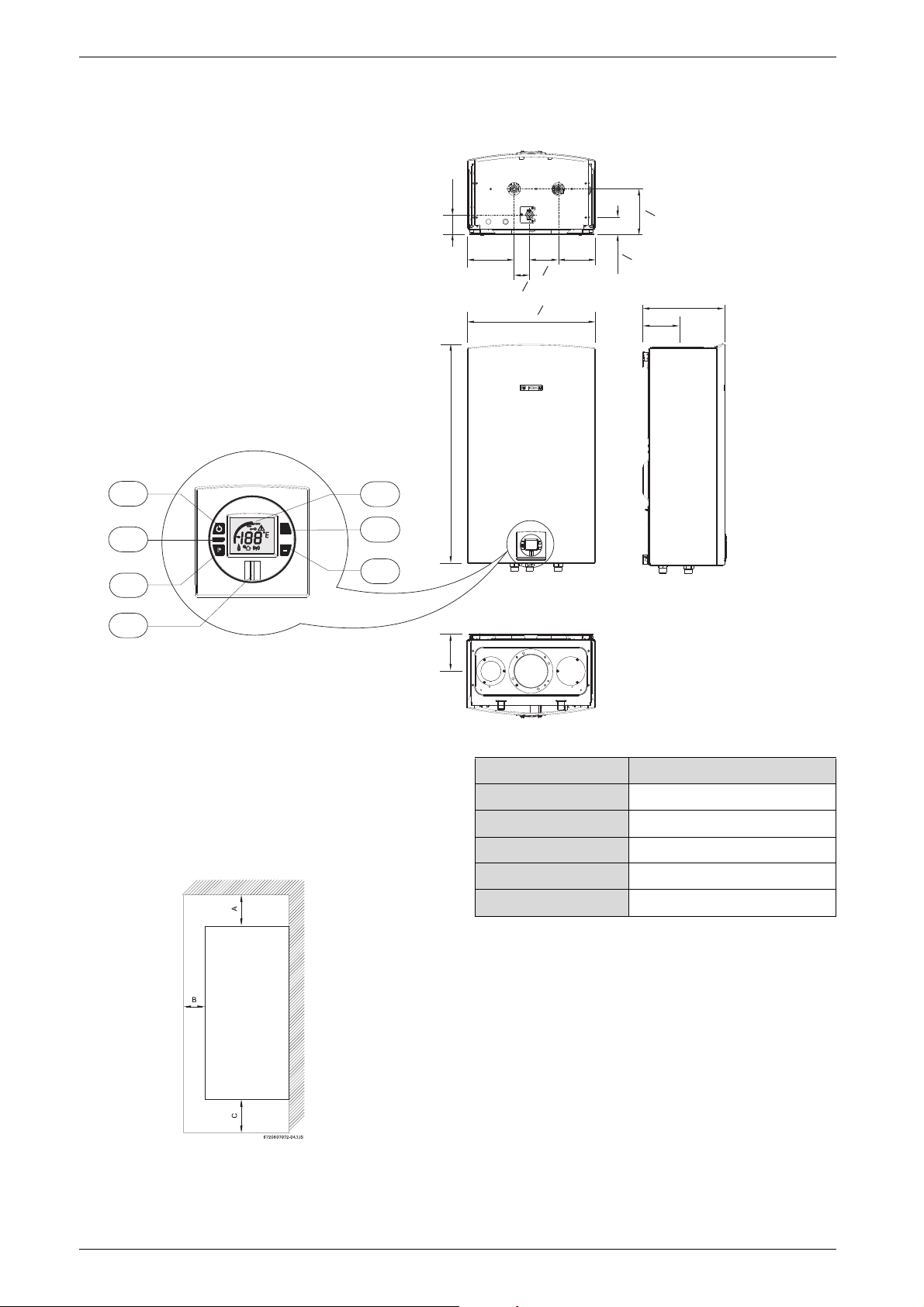

2.5 Dimensions and Minimum installation clearances

Fig. 6 Dimensions

1 On/Off button

2 Reset button

3 Program key

4 Power ON or stand-by LED

5 LCD display

6 Up button

7 Down button

Fig. 7 Minimum clearances

Note: For servicing access, a 2ft clearance to front

cover is recommended.

TOP (A) 12”

FRONT (B) 1”

BACK 0”

SIDES 1”

FLOOR (C) 12”

Table 1 Minimum clearances

Model 940 ES

8

6 720 644 930

3 Installation instructions

i

Installation instructions

3.1 Specialized tools

The following specialized tools may be required for

installation:

• Manometer

• Multi-meter

• Combustion Gas Analyzer.

3.2 Introduction

Please follow these instructions. Failure to follow

instructions may result in:

B Damage or injury.

B Improper operation.

B Loss of warranty.

If you are unable to perform the tasks required to install

this heater properly, please contact a locally licensed

plumber or gas technician.

Common installation practice is to determine the venting/intake system layout and

penetration and then work back to the

heater.

3.3 Venting

Warning: Do not reduce the vent

(exhaust and combustion) pipe sizes

and do not common vent with any other

vented appliance or stove.

Caution: The vent system must be

installed by a qualified installer in

accordance with these instructions. If

improperly installed, a hazardous

condition such as explosion or carbon

monoxide poisoning could result.

Bosch Water Heating will not be

responsible for improperly installed

appliances.

Warning: In areas where outside

temperatures routinely come close to

freezing, sealed combustion operation

is required. Use separate terminations

for combustion and vent, which must be

installed on the same wall or roof

surface, however never facing the

direction of prevailing winds. Failure to

do so may result in heat exchanger

freezing up and bursting. This failure is

not covered under the manufacturer's

warranty.

3.3.1 Vent material

Establish vent clearances that comply with the vent

manufacturer's specifications. In all cases, follow local

codes. See Table 2.

Diam. Material

Exhaust

Vent

3 or 4 inches Sealed single wall stainless steel

(AL29-4C)

Warning: Failure to vent the exhaust

gases to the outside with sealed

stainless steel vent pipe (AL29-4C)

may result in dangerous flue gases

filling the structure in which it is

installed.

Warning: Do not mix vent pipe or

joining methods from different

manufacturers.

Warning: Approved terminators must

be used for inlet and exhaust vent systems to prevent rain from entering the

appliance. Failure to do so may result in

damage to the appliance. This failure is

not covered under the manufacturer’s

warranty.

Intake

Vent

Table 2 Venting Specifications

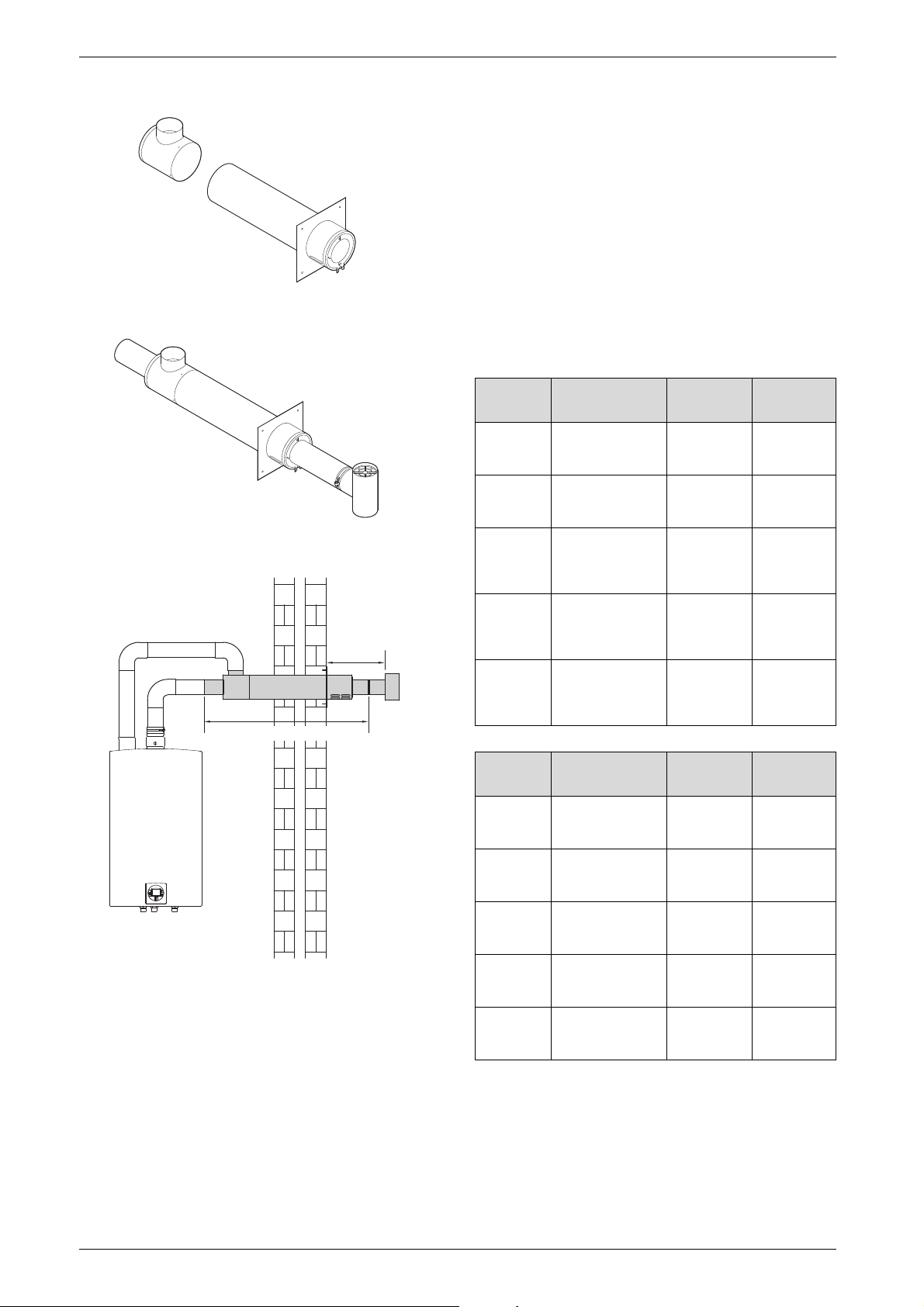

Horizontal venting systems only:

An optional stainless concentric vent/air intake

termination can be used to provide only one penetration

point through the exterior wall (see Fig. 8, 9 & 10). The

concentric vent/air intake kit can be ordered from your

local wholesaler. (Part# ESHCK). Note: Only tee

terminals are approved for use with the

concentric vent/air intake kit (see Table 3). Vent

piping and tee terminal used with kit must be

from the same vent pipe manufacturer. The

appliance can also be installed with separate air

intake and exhaust piping (see Fig. 16 ).

3 or 4 inches Sealed PVC or any other rigid pipe

6 720 644 930

9

Installation instructions

6720608782-09.1Av

6720608782-10.1Av

12"

6720608782-11.1Av

3” stainless steel pipe

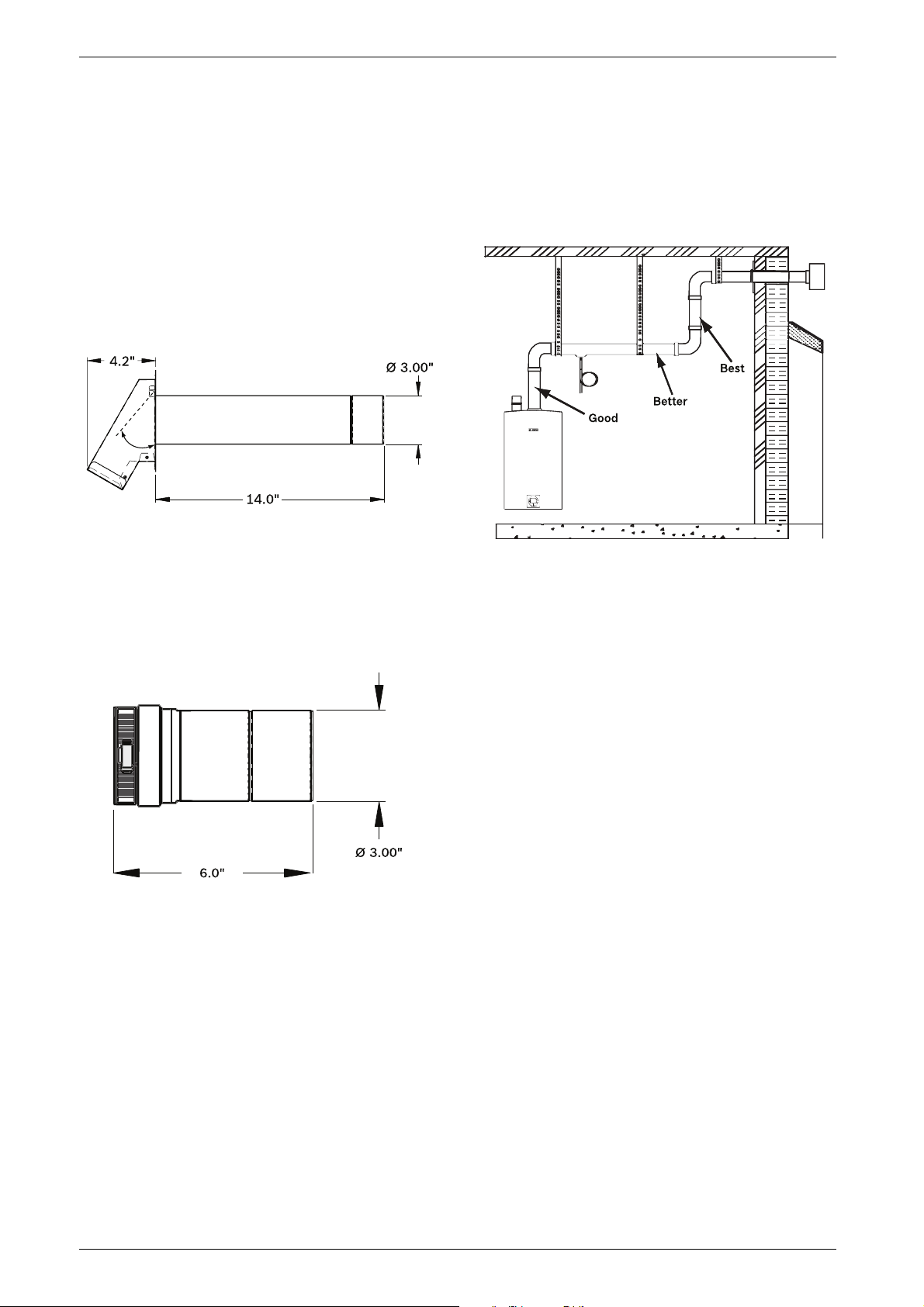

Fig. 8 Concentric kit part # ESHCK

structure. There must be no sections of vent pipe

exposed to the outdoors other than the termination.

Note: Listed thimbles or collars are necessary where

venting passes through wall and ceiling partitions. If the

vent system passes through combustible areas where

the vent clearance requirements cannot be maintained,

it is permissible to chase straight sections of sealed 3

inch single wall vent through 4 inch (or greater) Type-B

vent. The distance to combustibles using this chase

technique is 1 inch. Note: Type-B vent must never be

used as the actual exhaust vent system for the

appliance, as it is not gas tight and illegal for use with

this appliance. This will create a serious health hazard

and void the warranty.

Fig. 9 Concentric kit vent assembly

3”

VENTING

3"

90° elbow

3" Tee

Terminal

3”

Horizontal

Terminal

3" horiz.

terminal

with damper

3” Vertical

Terminal

Z flex Protech Heat Fab

2SVEEWCF0390 FSELB9003 9314

2SVSTTF03 FSTT3 9390TEE

2SVSTB03 FSTB3 N/A

2SVSHTD03 N/A N/A

2SVSRCF03 FSRC3 5300CI

Table 3 3" Terminator Part Numbers

4”

VENTING

4"

90° elbow

Z flex Protech Heat Fab

2SVEEWCF0490 FSELB9004 9414

Fig. 10 Concentric kit installation

3.3.2 Venting Specifications

Install appliance as close to point of vent termination as

possible. The exhaust piping must vent directly to the

outside of the structure.

Horizontal sections of vent must pitch upward towards

termination ¼" for every foot of horizontal length, to

prevent the pooling of condensate, and be supported at

4 foot intervals with overhead hangers.

Exception: horizontal run between last elbow and

termination must pitch down to termination 1/4" per

foot. Note: For horizontal terminations, venting must

terminate once it penetrates to the outside of the

10

4" Tee

Terminal

4”

Horizontal

Terminal

4" horiz.

terminal

with damper

4"

vertical

terminal

2SVSTTF04 FSTT4 9490TEE

2SVSTB04 FSTB4 N/A

2SVSHTD04 FSRC4 5400CI

2SVSRCF04 N/A N/A

Table 4 4" Terminator Part Numbers

For specific questions concerning vent material, specifications, usage or installation, please contact the vent

manufacturer directly.

6 720 644 930

Installation instructions

i

Company Contact info

Z-flex www.z-flex.com

800-654-5600

ProTech Industries www.protechinfo.com

800-766-3473

Heat-Fab www.heatfab.com

800-772-0739

Table 5 Vent manufacturers

Condensate drain requirements

An external condensate drain (not supplied with the

heater) must be installed under the following

conditions:

• All vertical terminating vent installations.

• Horizontal terminating vent installations where the

total linear vent length is greater than 10 feet (3.1 m)

for 3" and 5 feet (1.5 m) for 4".

• Vent installations where any section of the exhaust

vent pipe passes through an unconditioned space.

Twin pipe termination clearances

The minimum clearance between exhaust vent and

combustion air inlet terminations for twin pipe

penetration is 3 feet.

Use of elbows

It is recommended to limit the amount of elbows used in

the exhaust and combustion air piping to reduce friction

in the air flow. The following lists the maximum amount

of 90° elbows allowed in either the exhaust or combustion air piping:

90° elbows

3"

Venting

4"

Venting

Max number of elbows 5 7

Table 7

Two 45° elbows are equal to one 90°

elbow. Any combination of 45° and

90° elbows may be used in the vent

system as long as the combination

does not exceed the maximum listed

in table 7 above.

Minimum combustion air and exhaust pipe

length

The minimum exhaust pipe length is 1 foot (0.3m) of

straight vent pipe. The minimum combustion air pipe

length is one 90° elbow.

Maximum combustion air and exhaust pipe

length

The following tables display the maximum allowable

straight pipe lengths for combustion air and exhaust

piping with consideration to the number of elbows

used. Reduce the equivalent length for each elbow

used from the maximum allowable length.

Venting Maximum

allowable

Exhaust

pipe length

3"

4"

28.5 ft 28.5 ft 2.5 ft 1.25 ft

61.25 ft 61.25 ft 1.25 ft .75 ft

Maximum

allowable

Combustio

n air pipe

length

Elbow

Equivalency

90° 45°

Table 6 Maximum Allowable Exhaust and Combustion

Air Lengths

6 720 644 930

11

Installation instructions

i

i

i

i

Calculation example for 3" venting:

Exhaust

System used Concentric

Number of 90° elbows needed: 1

Number of 45° elbows needed: 2

Table 8

Calculation of example

Max. length 28.5’

90° elbow reduction - 2.5’

sub-total = 26’

45° elbow reduction - 2.5’

Total = 23.5’

Table 9

For this example, the maximum allowable

exhaust pipe length is 23.5 feet.

Calculation example for 4" venting:

Exhaust

System used Twin pipe

Number of 90° elbows needed: 2

Number of 45° elbows needed: 2

Table 12

Calculation of example

Max. length 61.25’

90° elbow reduction - 2.5’

sub-total = 58.75’

45° elbow reduction - 1.5’

Total = 57.25’

Table 13

For this example, the maximum allowable

exhaust pipe length is 57.25 feet.

Combustion air

System used Concentric

Number of 90° elbows needed: 2

Number of 45° elbows needed: 1

Table 10

Calculation of example

Max. length 28.5’

90° elbow reduction - 5’

sub-total = 23.5’

45° elbow reduction - 1.25’

Total = 22.25’

Table 11

For this example, the maximum allowable

combustion air pipe length is 22.25 feet.

Combustion air

System used Twin pipe

Number of 90° elbows needed: 1

Number of 45° elbows needed: 2

Table 14

Calculation of example

Max. length 61.25’

90° elbow reduction - 1.25’

sub-total = 60’

45° elbow reduction - 1.5’

Total = 58.5’

Table 15

For this example, the maximum allowable

combustion air pipe length is 58.5 feet.

12

6 720 644 930

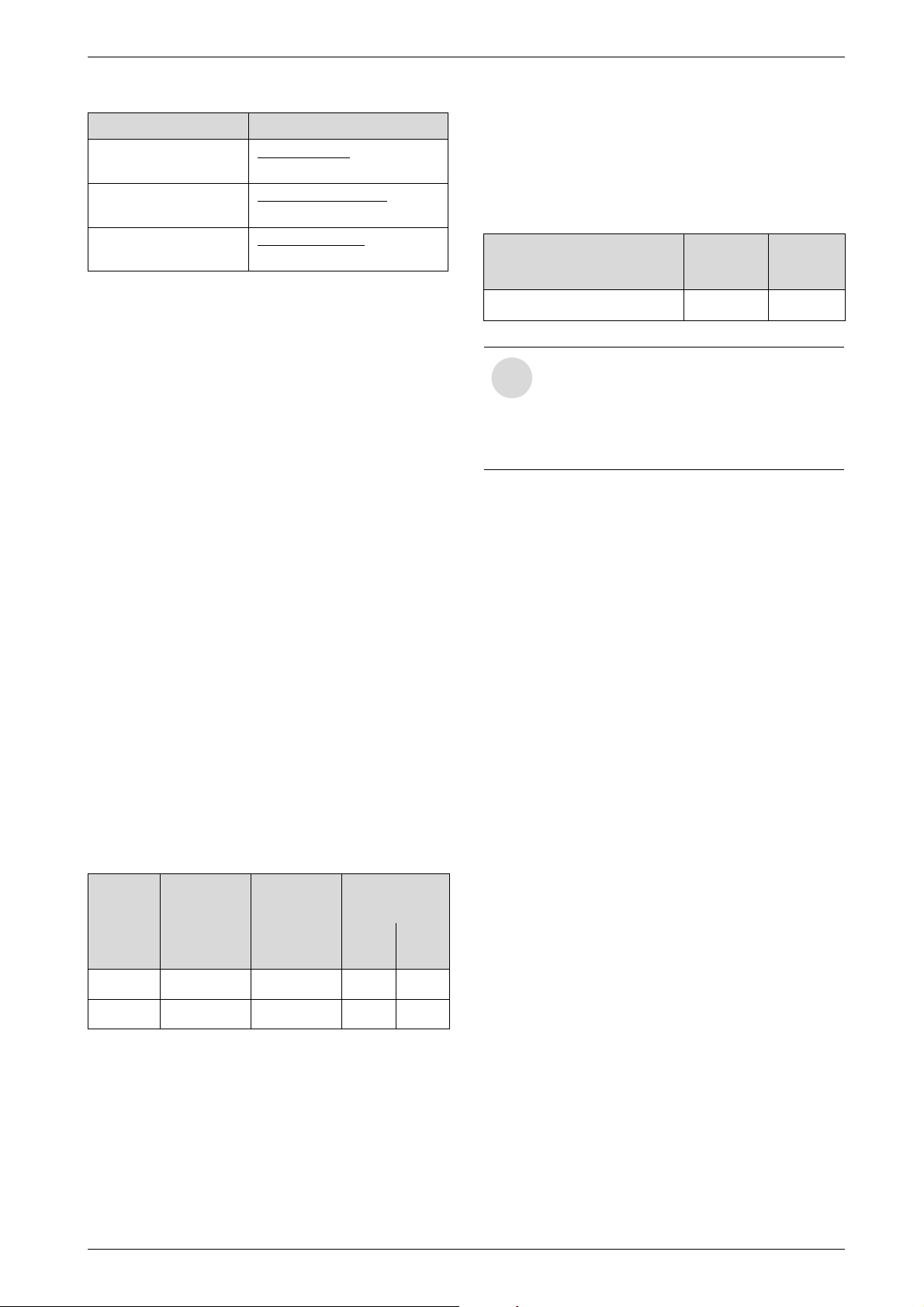

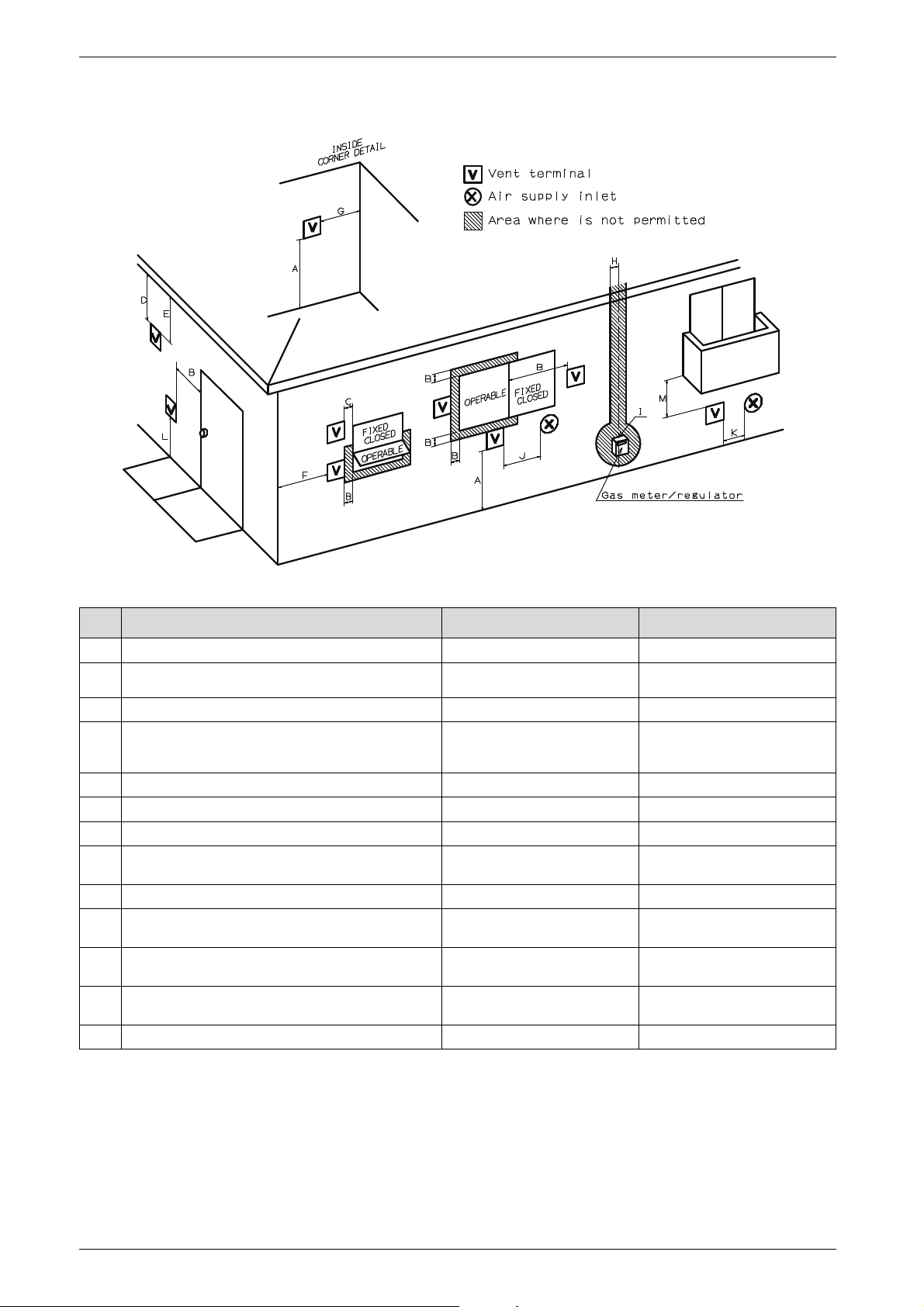

Required direct vent terminal clearances (twin pipe / concentric penetration)

6720608836-23.1Av

Installation instructions

Fig. 11

Canadian installations

A Clearance above grade, veranda, porch, deck or balcony 12 in. 12 in.

B Clearance to window or door that may be opened 36 in. 12 in.

C Clearance to permanently closed window * *

D Vertical clearance to ventilated soffit located above the vent

terminator within a horizontal distance of 2 feet (61cm) from the

center line of the terminator

E Clearance to unventilated soffit * *

F Clearance to outside corner * *

G Clearance to inside corner * *

H Clearance to each side of center line extended above meter/

regulator assembly

I Clearance to service regulator vent outlet 36 in. *

J Clearance to non-mechanical air supply inlet to building or the

combustion air inlet to any other application

K Clearance to mechanical air supply inlet 72 in. 36 in. above if within 10 feet

L Clearance above paved sidewalk or paved driveway located on

public property

M Clearance under veranda, porch deck or balcony 12 in.

36 in. within a height 15 feet above

meter/ regulator assembly

* *

36 in. 12 in.

3)

84 in.

4)

1)

U.S. installations

*

horizontally

*

*

2)

Table 16

1) In accordance with the current CSA B149.1 Natural Gas and Propane Installation Code

2) In accordance with the current ANSI Z223.1 / NFPA 54 National Fuel Gas Code

3) A vent shall not terminate directly above a sidewalk or paved driveway that is located between two single family dwellings and serves both dwellings.

4) Permitted only if veranda, porch, deck or balcony is fully open on a minimum of two sides beneath the floor.

* For clearances not specified in ANSI Z223.1 / NFPA 54 or CSA-B149.1, one of the following shall be indicated:

a) A minimum clearance value determined by testing in accordance with section 2.20, or;

b) A reference to the following footnote:

“Clearance in accordance with local installation codes and the requirements of the gas supplier.”

6 720 644 930

13

Installation instructions

6720608836-23.1Av

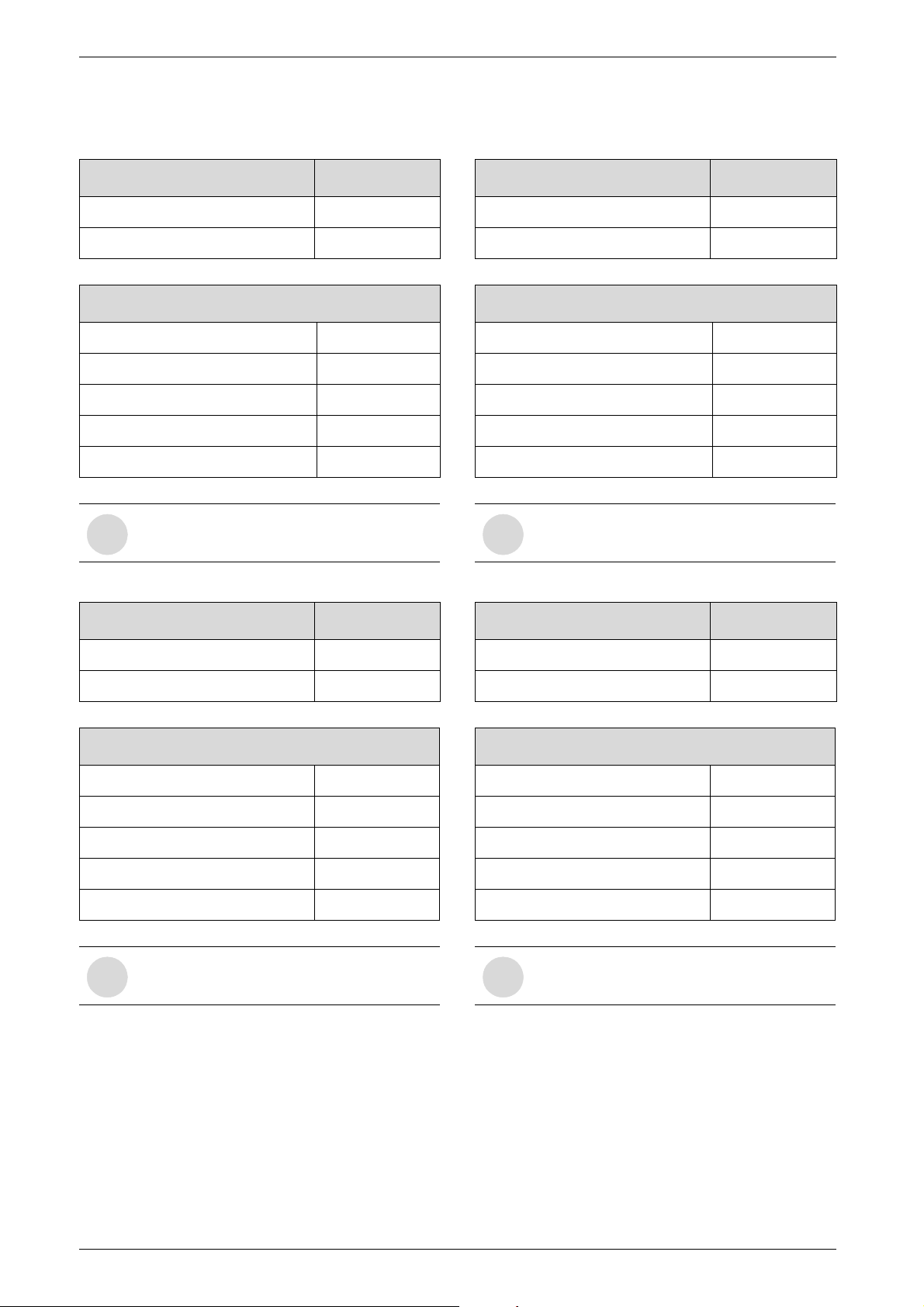

Required other than direct vent terminal clearances (single pipe penetration)

Fig. 12

Canadian installations

A Clearance above grade, veranda, porch, deck or balcony 12 in. 12 in.

B Clearance to window or door that may be opened 36 in. 4 feet below or to side of opening;

C Clearance to permanently closed window * *

D Vertical clearance to ventilated soffit located above the vent

terminator within a horizontal distance of 2 feet (61cm) from the

center line of the terminator

E Clearance to unventilated soffit * *

F Clearance to outside corner * *

G Clearance to inside corner * *

H Clearance to each side of center line extended above meter/

regulator assembly

I Clearance to service regulator vent outlet 36 in. *

J Clearance to non-mechanical air supply inlet to building or the

combustion air inlet to any other application

K Clearance to mechanical air supply inlet 72 in. 36 in. above if within 10 feet

L Clearance above paved sidewalk or paved driveway located on

public property

M Clearance under veranda, porch deck or balcony 12 in.

36 in. within a height 15 feet above

meter/ regulator assembly

* *

36 in. 4 feet below or to side of opening;

3)

84 in.

4)

1)

U.S. installations

1 foot above opening

*

1 foot above opening

horizontally

84 in.

*

2)

Table 17

1) In accordance with the current CSA B149.1 Natural Gas and Propane Installation Code

2) In accordance with the current ANSI Z223.1 / NFPA 54 National Fuel Gas Code

3) A vent shall not terminate directly above a sidewalk or paved driveway that is located between two single family dwellings and serves both dwellings.

4) Permitted only if veranda, porch, deck or balcony is fully open on a minimum of two sides beneath the floor.

* For clearances not specified in ANSI Z223.1 / NFPA 54 or CSA-B149.1, one of the following shall be indicated:

a) A minimum clearance value determined by testing in accordance with section 2.20, or;

b) A reference to the following footnote:

“Clearance in accordance with local installation codes and the requirements of the gas supplier.”

14

6 720 644 930

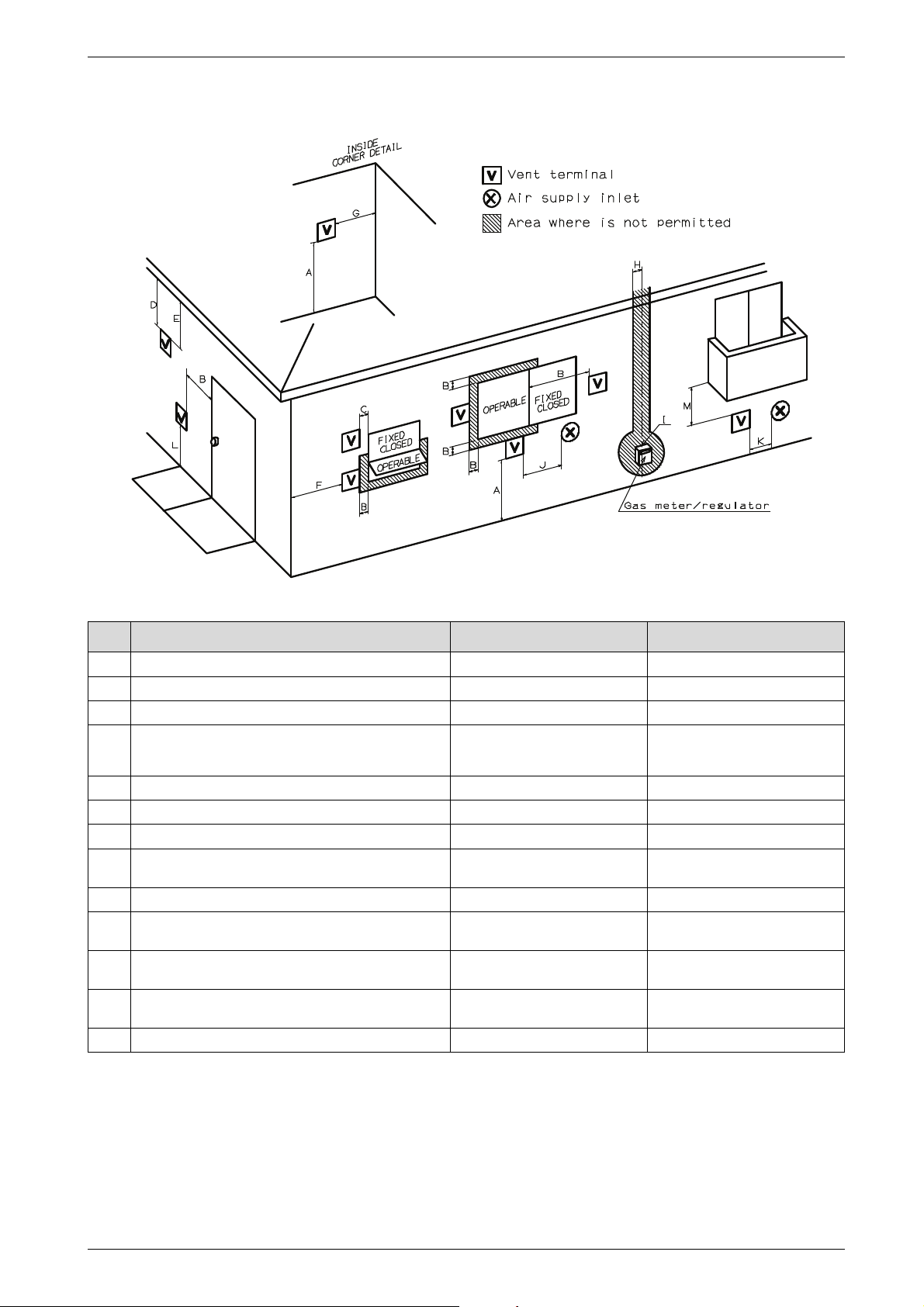

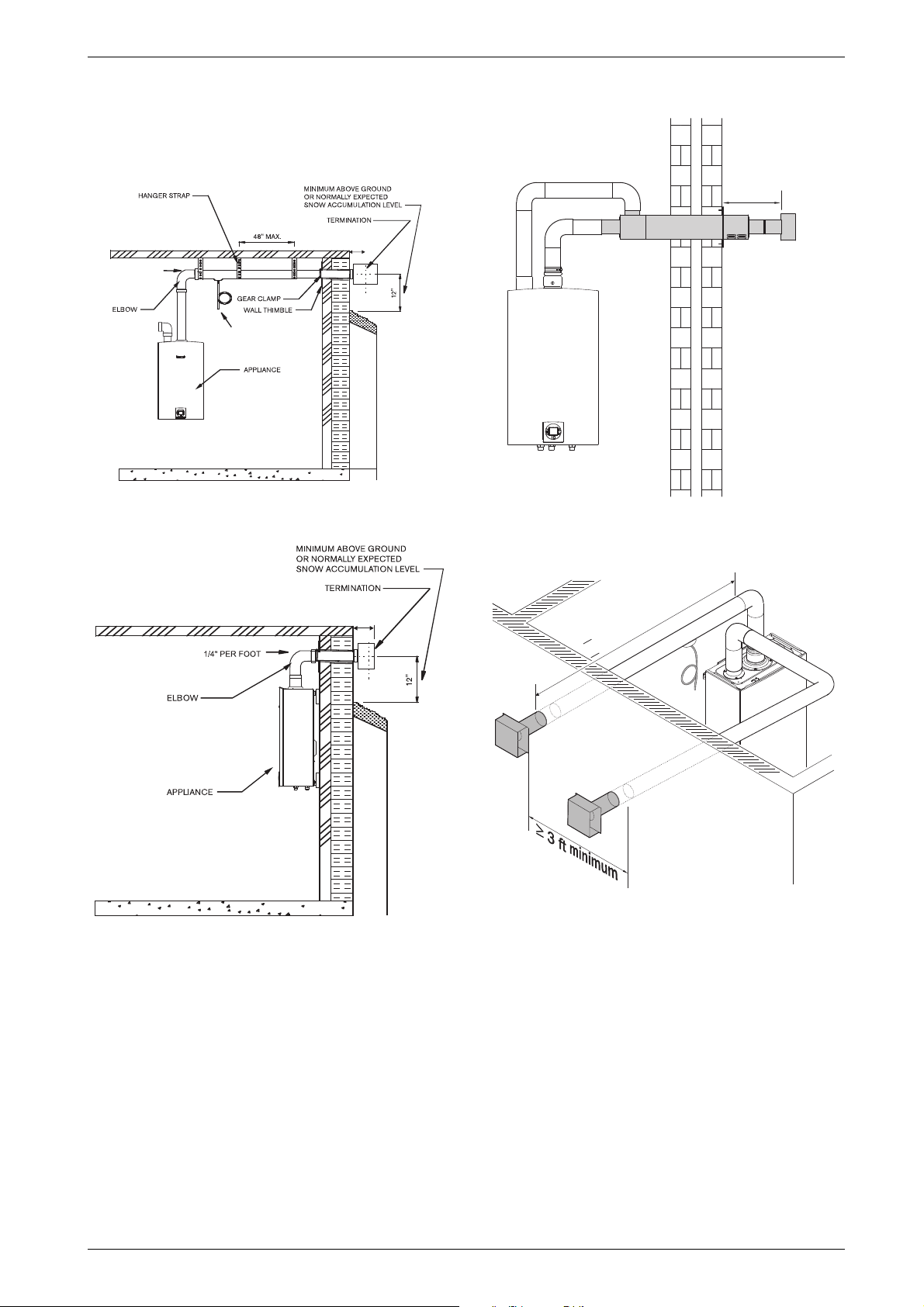

3.3.3 Venting configuration examples

4"

6720608542-02.2AL

HORIZONTAL RUN

1/4" PERFOOT

DOWN TO

TERMINATOR.

CONDENSATE

DRAIN

4"

HORIZONTAL RUN

DOWN TO

TERMINATOR.

SIDE

OF

WATER

HEATER

NOTE:

MINIMUM1FT OF

STRAIGHT VENT PIPE

REQUIRED

6720608542-10.1V

12"

6720608782-11.2V

6720608542-05.3V

<

<

26ft with 3"venting

60ft with 4"venting

Below are approved examples of horizontal

venting installations.

Installation instructions

Fig. 13 Horizontal side wall venting installation (single

pipe penetration)

Fig. 14 Horizontal venting installation (combustion air

piping not shown)

Warning: Single pipe penetration should be used in

non-freezing climates only!

Important:

Note: Pitch horizontal runs down toward the heater,

except horizontal run between last elbow and termination which must slope down to termination 1/4" per

foot.

Note: For horizontal terminations, venting must

terminate once it penetrates to the outside of the

structure. There must be no sections of vent pipe

exposed to the outdoors.

Fig. 15 Horizontal venting installation (concentric

penetration)

Fig. 16 Horizontal twin pipe penetration

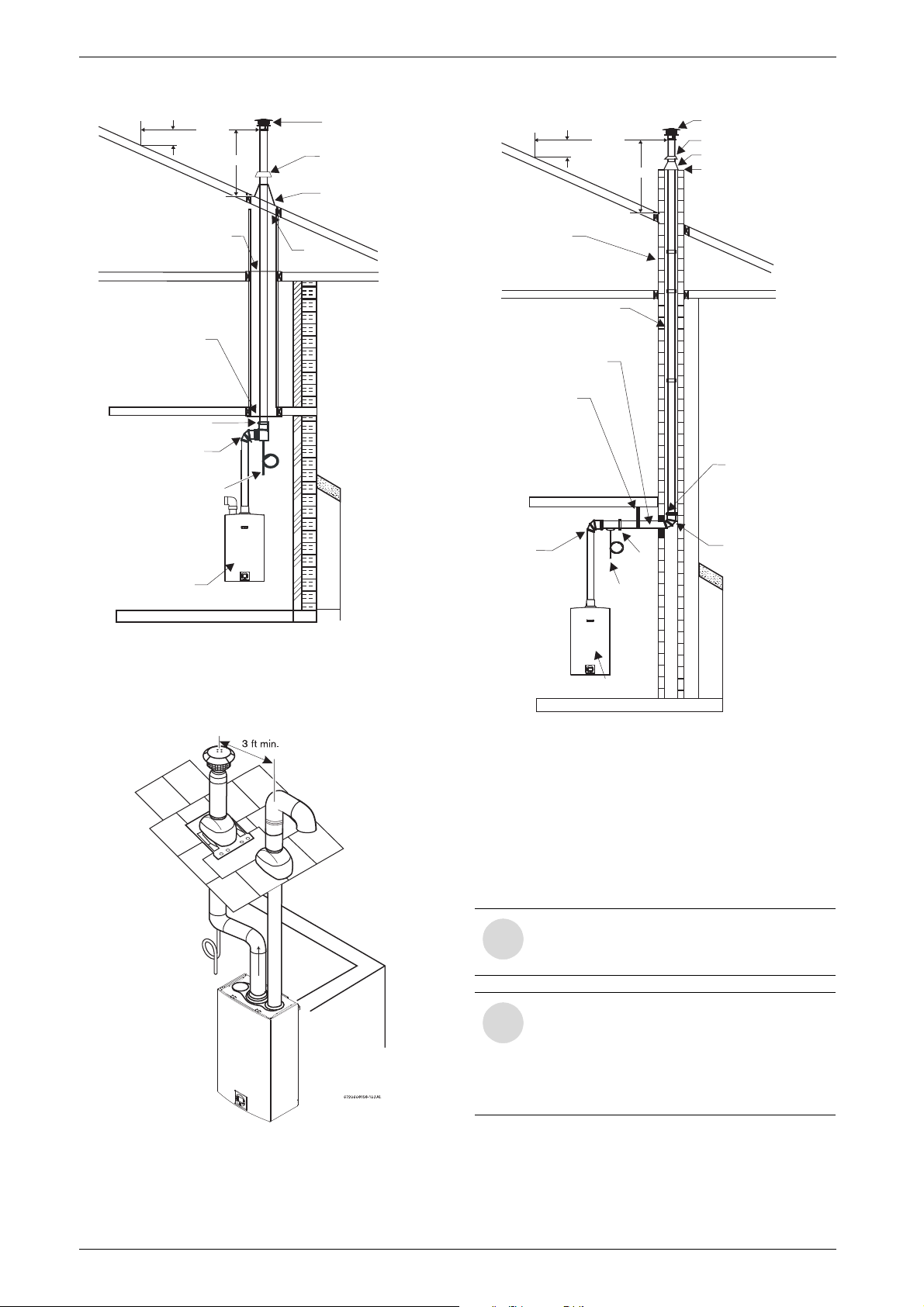

Below are approved examples of vertical venting

installations.

Important:

Note: Pitch horizontal runs down toward the heater,

1/4" per foot.

6 720 644 930

15

Installation instructions

FIRESTOP SUPPORT

ELBOW

APPLIANCE

HOSE

CLAMP

RAINCAP

STORMCOLLAR

FLASHING

FIRESTOP SUPPORT

4"MIN.

AIRSPACE

6720608158-91.2Av

CONDENSATE

DRAIN

2'MIN.

10'MIN.

3'MIN.

i

i

CHIMNEY

MORTAR

HANGERSTRAP

HORIZONTAL RUN

1/4"RISE/FT

ELBOW

APPLIANCE

MAY BEINSULATED

IFNECESSARY

6720608158-14.2AL

HOSE

CLAMP

ELBOW

RAINCAP

STORMCOLLAR

SILICONESEAL

FLASHING

CONDENSATE

DRAIN

2'MIN.

10'MIN.

3'MIN.

Fig. 17 Vertical venting installation (single pipe pene-

tration)

Warning: Single pipe penetration should be used

in non-freezing climates only!

Fig. 18 Vertical venting installation (twin pipe penetra-

tion)

Fig. 19 Vertical venting installation - Masonry Chim-

ney (combustion air piping not shown)

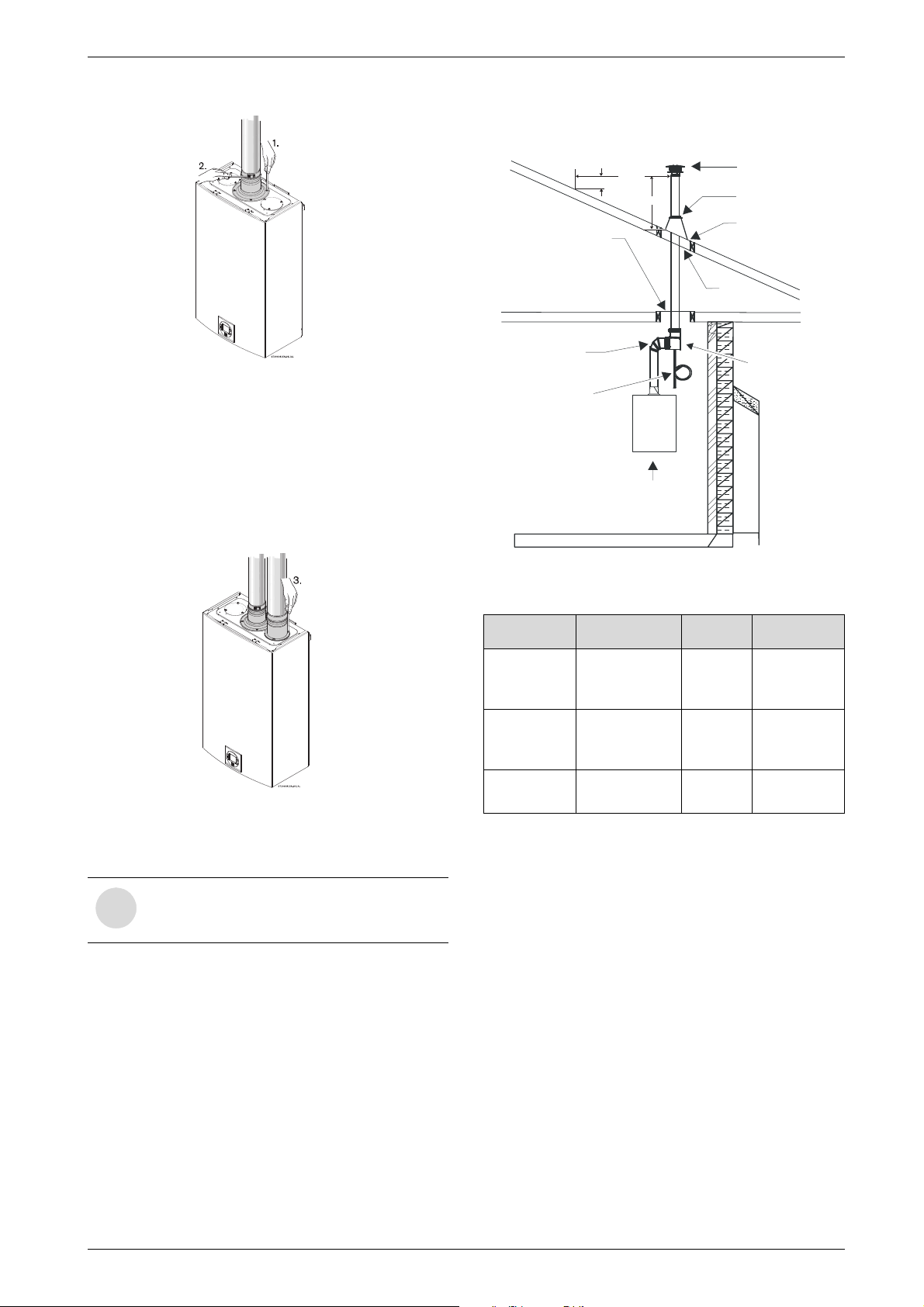

3.3.4 Vent connections

B Attach the flue gas exhaust accessory (8 705 504

151) to the top of the unit (position 1) using the 4

screws and gasket provided. Fully insert stainless

steel vent pipe 1.5” minimum into the accessory and

tighten the clamp (position 2).

If using the 4” vent, a 3” to 4” increaser is

required immediately off the top of the

heater.

NOTE: Vent pipe must be completely vertical when inserting or gasket inside exhaust accessory can become displaced.

Exhaust accessory can be removed with

vent pipe attached to check gasket position.

16

6 720 644 930

Fig. 20

i

RAIN CAP

STORM COLLAR

FLASHING

4" MIN.

AIR SPACE

CONDENSATE

APPLIANCE

6720608782-04.2Av

ELBOW

FIRESTOP SUPPORT

DRAIN TRAP

TO DRAIN - DISPOSE

OF CONDENSATE

ACCORDING TO

LOCAL CODES

DRAIN TEE

2'MIN.

10'MIN.

3'MIN.

B Attach the combustion air inlet accessory (8 705

504 154) to the top of the unit (position 3) using the

3 screws and gasket provided, and install air intake

pipe over the accessory. NOTE: The appliance has

the option to mount the combustion air inlet accessory on the top right or on the top left side of the

heater. The combustion air inlet that is not used must

be kept sealed.

Installation instructions

any point.

5. Dispose of condensate according to local codes.

Fig. 21

B Ensure that exhaust vent pipe is fully inserted in collar

3.3.5 Condensate drain installation

Note: Do not install condensate drain in areas where it

may freeze.

1. Install condensate drain as close to heater as possi-

ble.

2. Use 3/8" ID high temperature silicone tube to con-

nect to condensate drain port. Do not use copper piping for any portion of the condensate drain.

3. Form a condensate trap by means of a 3" loop par-

tially filled with water.

4. To increase the tube length, connect to end of the

high temperature silicone tubing with vinyl tubing, PVC

or CPVC pipe. Do not reduce the internal diameter at

to enable proper connection.

Exhaust venting must be 3" or 4" sealed

single wall stainless steel (AL29-4C) vent

pipe.

Fig. 22 Condensate drain installation (combustion air

piping not shown)

3" Venting Z-flex ProTech Heat Fab

90°

Condensate

Drain Tee

Horizontal

Condensate

Drain

Condensate

Drain Tube

2SVEVWCF03 FST3 &

FSDF3

2SVEDWCF03 FSHDT3 9321

2SVEDTK24 N/A 7000TUBE

93PPLSTEE

Table 18 Approved Condensate Drain Part Numbers

3.3.6 Freeze prevention

In cold climates, components of a tankless water heater

can freeze and burst from negative draft. A leading

cause of negative draft is combustion appliances in the

building not being supplied with sufficient combustion

air. A wood stove or furnace can pull its combustion air

from the water heater‘s vent pipe, allowing the cold

incoming air to freeze the cold water in the heat

exchanger. Supplying more combustion air for all combustion appliances is the solution. A HVAC specialist

should be consulted to design solutions for providing

more combustion air.

Listed below are additional measures designed to further limit backdraft in extreme conditions assuming all

other possible causes have been addressed.

6 720 644 930

17

Installation instructions

6720608542-07.1V

6720608542-08.1V

6720608542-06.1V

Solution One

The Z-flex vent termination hood is the preferred option

for limiting backdraft under the following conditions

(see Fig. 23):

• The vent hood is only to be used in the exhaust vent

piping.

• The vent hood can only be used for horizontal terminations.

• The vent hood is able to meet the required clearances outlined in the venting section of the water

heater‘s installation manual.

Fig. 23 Part nr. 2SVSHTD03 for 3" venting

Part nr. 2SVSHTD04 for 4" venting

Solution Two

If the required clearances of the Zflex termination hood

cannot be met, the Zflex damper is the preferred alternative (see Fig. 24).

• To allow accessibility, damper must not be installed

in an enclosed section of vent pipe.

• Do not install damper in unconditioned spaces (e.g.

attics) Condensation can build up while the heater is

running which can later freeze and potentially block

the flapper.

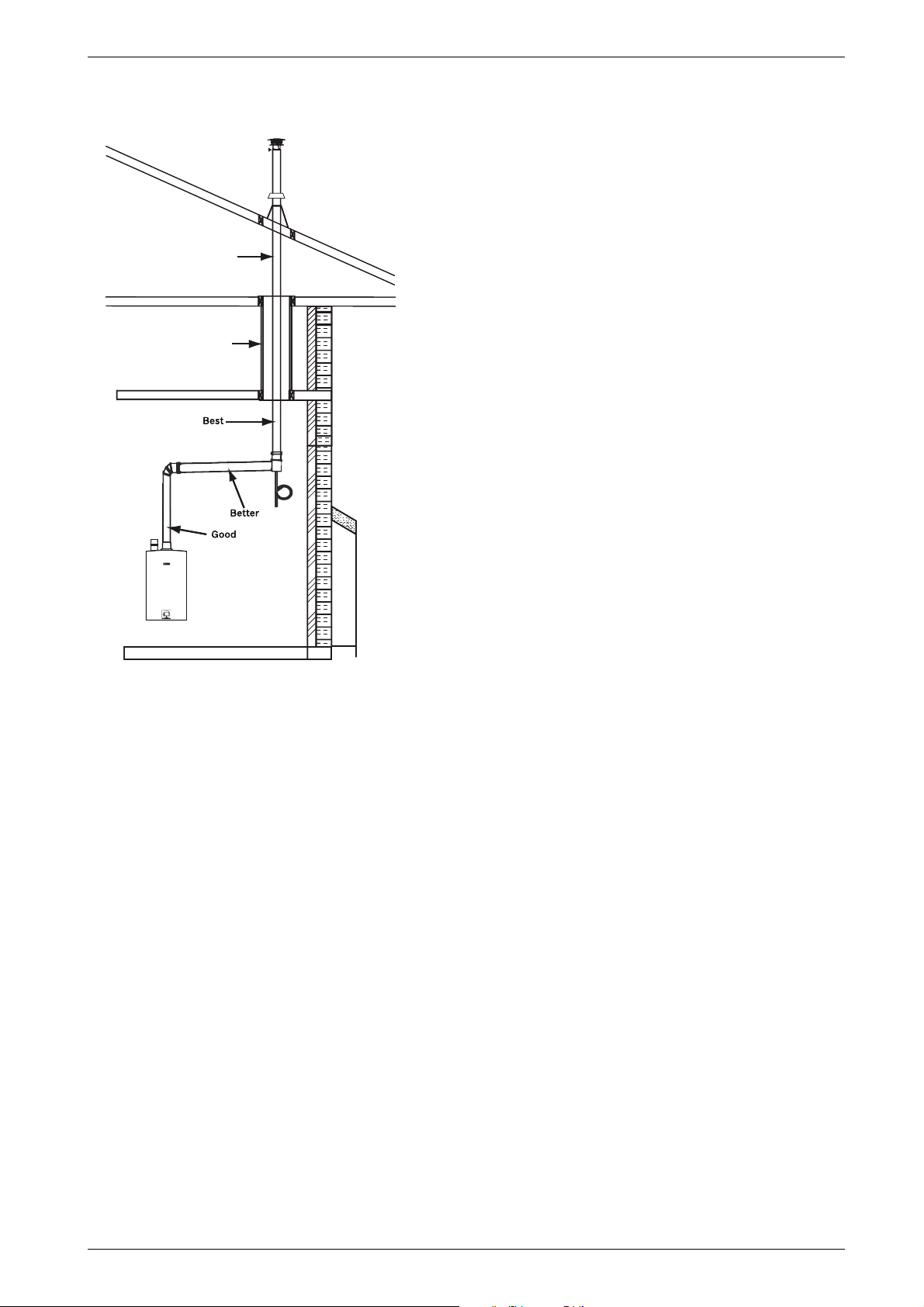

Fig. 25 Combustion air piping not shown for clarity

purposes

Good - Vertical directly on top of the heater.

Better - Closer to the termination horizontally installed in a condi-

tioned space.

Best - Closer to the termination vertically installed in a conditioned

space.

Fig. 24 Part nr. 2ZVBP03 for 3" venting

Part nr. 2ZVBP04 for 4" venting

Installation

For these solutions to be effective, the internal flapper

must be 100% closed when the water heater is not running. Refer to Fig. 25 and 26 for preferred installation

positions in the vent system.

If using the Zflex damper:

• Ensure directional arrow on damper label faces in the

same direction as exhaust flow.

• If installed horizontally, the axis must be horizontal or

slightly pitched up towards termination to ensure

damper closes 100% when heater is not running.

18

6 720 644 930

Installation instructions

Preferreddamperpositionforverticalterminations

Unconditioned

space.Donot

installdamper.

Enclosedvent

pipe.Donot

installdamper.

6720608542-09.1V

3.3.7 Fan speed adjustment

IMPORTANT! Installation adjustment:

After installing the water heater, the fan speed values for

minimum power (P2) and maximum power (P1) may

need adjustment due to variations in altitude and vent

pipe length.

Failure to make necessary adjustments to fan speed

values may result in improper operation of the

appliance.

First calculate the total equivalent vent length. This is

the straight pipe length of both exhaust and combustion

air plus the number of elbows used. To determine the

length equivalency of each elbow refer to table 6.

Use the equivalent vent length value to determine the

appropriate fan speed values found in Table 19 and

20. Refer to page 21 on how to adjust the fan speeds

if an adjustment is necessary. After changing fan speed

values, proceed to section 6.4 to confirm CO2 values

are within specified ranges.

Fig. 26 Combustion air piping not shown for clarity

purposes

Good - Vertical directly on top of the heater.

Better - Closer to the termination horizontally installed in a condi-

tioned space.

Best - Closer to the termination vertically installed in a conditioned

space.

6 720 644 930

19

Installation instructions

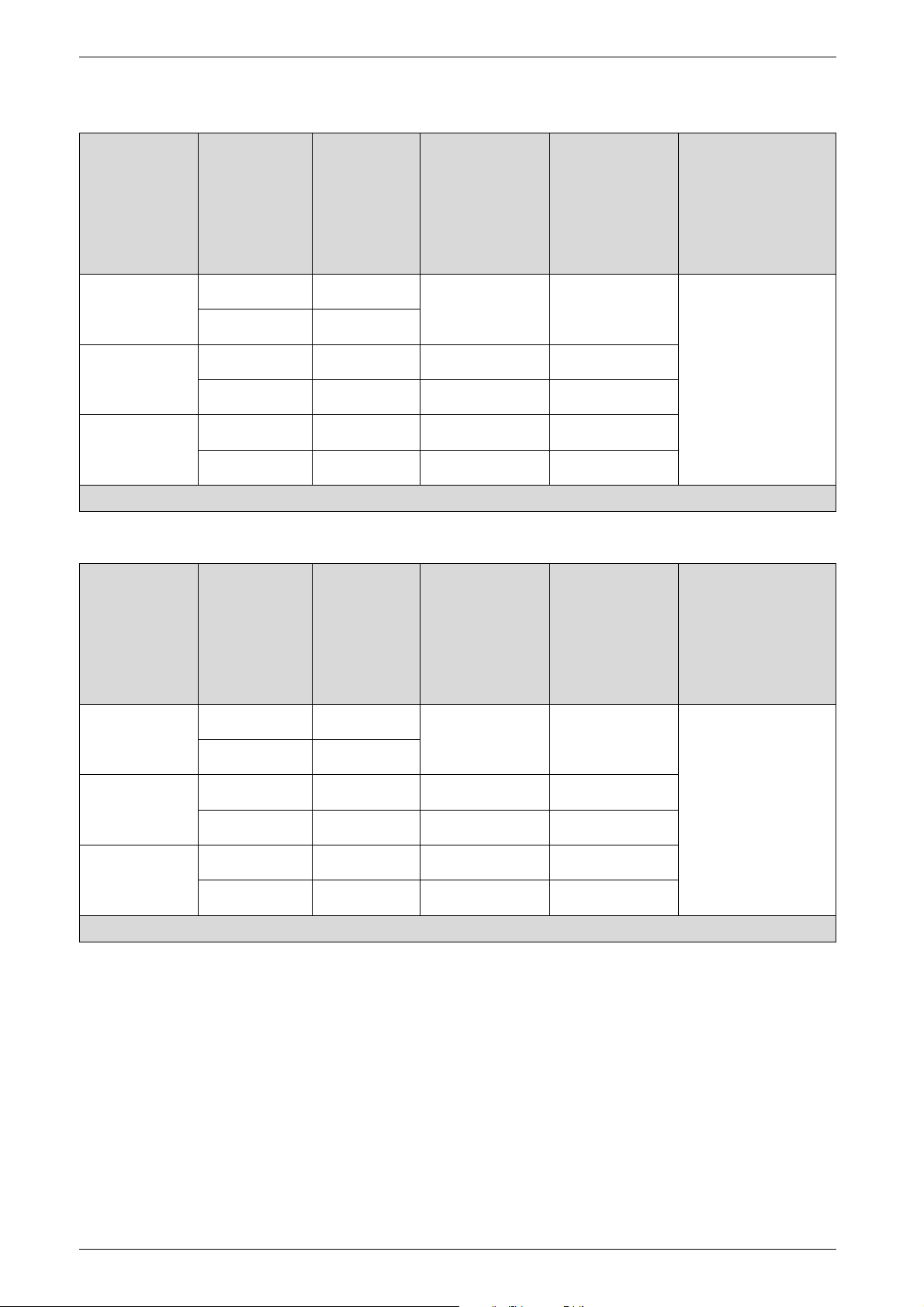

Fan speed adjustment

Natural Gas Liquid propane

Altitude

(above sea

level)

0 - 2000 ft

(0 - 610 m)

2000 - 4500 ft

(610 - 1372 m)

4500 - 8000 ft

(1372 - 2439 m)

Total

equivalent

vent length

3.5 - 32 ft

33 - 57 ft

1)

Minimum

power fan

speed (P2)

7

8

Maximum

power fan speed

(P1)

No

modification required

Maximum

power fan speed

modification required

3.5 - 32 ft 8* 48* 47*

33 - 57 ft 8* 49* 48*

3.5 - 32 ft 9* 49*

33 - 57 ft 9* 50* 49*

(P1)

* Above 2000 ft, CO2 levels must be checked with a combustion gas analyzer, see section

Table 19 Fan speed adjustment for 3" piping

1) Full equivalent length (inlet + outlet piping + fittings)

Natural Gas Liquid propane

Altitude

(above sea

level)

Total

equivalent

vent length

1)

Minimum

power fan

speed (P2)

Maximum

power fan speed

(P1)

Maximum

power fan speed

(P1)

No

48*

6.4

For operation at elevations

above 2,000 ft (610 m) the

equipment ratings shall be

reduced at the rate of 4% for

each 1,000 ft (305 m) above sea

for instructions.

level

0 - 2000 ft

(0 - 610 m)

2000 - 4500 ft

(610 - 1372 m)

4500 - 8000 ft

(1372 - 2439 m)

2.25 - 59 ft

60 - 122.5 ft

2.25 - 59 ft 8* 48* 47*

60 - 122.5 ft 8* 49* 48*

2.25 - 59 ft 9* 49*

60 - 122.5 ft 9* 50* 49*

7

8

No

modification required

modification required

* Above 2000 ft, CO2 levels must be checked with a combustion gas analyzer, see section

Table 20 Fan speed adjustment for 4" piping

1) Full equivalent length (inlet + outlet piping + fittings)

No

48*

6.4

For operation at elevations

above 2,000 ft (610 m) the

equipment ratings shall be

reduced at the rate of 4% for

each 1,000 ft (305 m) above sea

for instructions.

level

20

6 720 644 930

Loading...

Loading...