Bosch 8981 021 140 Assembly Manual

Ergonomic Workstations

Adjustable Height Workstation Kit

Assembly Guide

Installation and Maintenance

Publication Number: 8981 500 300 7/02

Adjustable Height Workstation

2

Table of Contents

Important Safety Information ........................................................................................................................................3

About This Manual ..........................................................................................................................................................5

Technical Data .................................................................................................................................................................6

Application and Function...............................................................................................................................................6

Recommended Tools .....................................................................................................................................................7

Design and Detailed Description ................................................................................................................................8

Parts List............................................................................................................................................................................8

Before You Begin......................................................................................................................................................... 10

Table Top Assembly ....................................................................................................................................................11

Using T-bolts and T-nuts ............................................................................................................................................13

Joining Profiles ..............................................................................................................................................................13

Attaching the Cross Braces ......................................................................................................................................14

Attaching the Table Top ............................................................................................................................................. 15

Control Box Mounting .................................................................................................................................................16

Installing the Cross Brace..........................................................................................................................................17

Mounting Telescoping Acturator Assembly........................................................................................................... 18

Assembling the Base Frame...................................................................................................................................... 20

Mounting Base Frame to the Telescoping Acturators ........................................................................................ 21

Final Assembly ..............................................................................................................................................................22

Operation and Maintenance ...................................................................................................................................... 23

Warranty Information ................................................................................................................................................... 24

Liability ............................................................................................................................................................................24

Environmental Protection ...........................................................................................................................................24

All rights are held by BOSCH REXROTH CORPORATION and

ROBERT BOSCH GMBH, also regarding patent claims. We retain

all powers of disposition, such as for copying and/or for passing-on to

third parties.

We reserve the right to make technical changes at any time

without notice.

Errors and omissions excepted.

© 2002 Bosch Rexroth Corporation

IMPORTANT SAFETY INFORMATION

IMPORTANT: This assembly and operation manual should be reviewed

with all equipment operators as part of your operator training program.

3

SAFETY FIRST!

Important safety information is contained throughout

this manual to alert you to potentially dangerous

situations and help prevent accidental injury and

property damage.

The safety warning symbol above has been included

to warn you of hazards that can hurt or kill you and

others, and/or cause serious damage to the equipment

and other property.

In addition, the following safety alert words are used:

DANGER! Means that you or others will

be seriously or fatally injured if

instructions are not followed.

WARNING! Means that you or others may

be seriously or fatally injured if

instructions are not followed.

Material Hazards:

Some components, such as gearboxes, contain

lubricants or other materials that can represent a

potential health hazard if handled, stored, or disposed

of improperly.

Please contact Bosch for copies of the Material

Safety Data Sheets (MSDS) for the lubricating oil

used in gearboxes and other potentially hazardous

materials.

Review All Safety Information:

Please review the safety information included on

page 4 and throughout this manual with all installers,

operators, and maintenance personnel of this

equipment.

CAUTION! Means that you or others may

be injured if instructions are

not followed.

4

IMPORTANT SAFETY INFORMATION

WARNING!

Please read all assembly, and maintenance instructions

carefully before beginning set-up of the components in

this document.

Where appropriate, warning symbols have been

included in this publication to alert you of potential or

impending danger.

• Be sure to read and observe all safety warnings in

this document as well as those attached to the

individual modules. Failure to do so could result in

potential risks to your health and safety as well as

those around you.

• Covers and guards have been designed to

eliminate pinch points and exposure to moving

components. DO NOT operate the adjustable

height workstation or any machinery with the

guards removed. Serious injury may result!

• All set-up maintenance and repair work should

be performed only by properly trained, qualified

personnel. All operators must be properly trained

in the use of this equipment.

holders, balancers, lights, parts bins and power

strips. Maximum workstation load must not exceed

400 lb (181.5 kg), either centered or distributed.

Exceeding published specifications will result in

premature wear, damage, or failure of the motor,

gearbox, seals and/or other components.

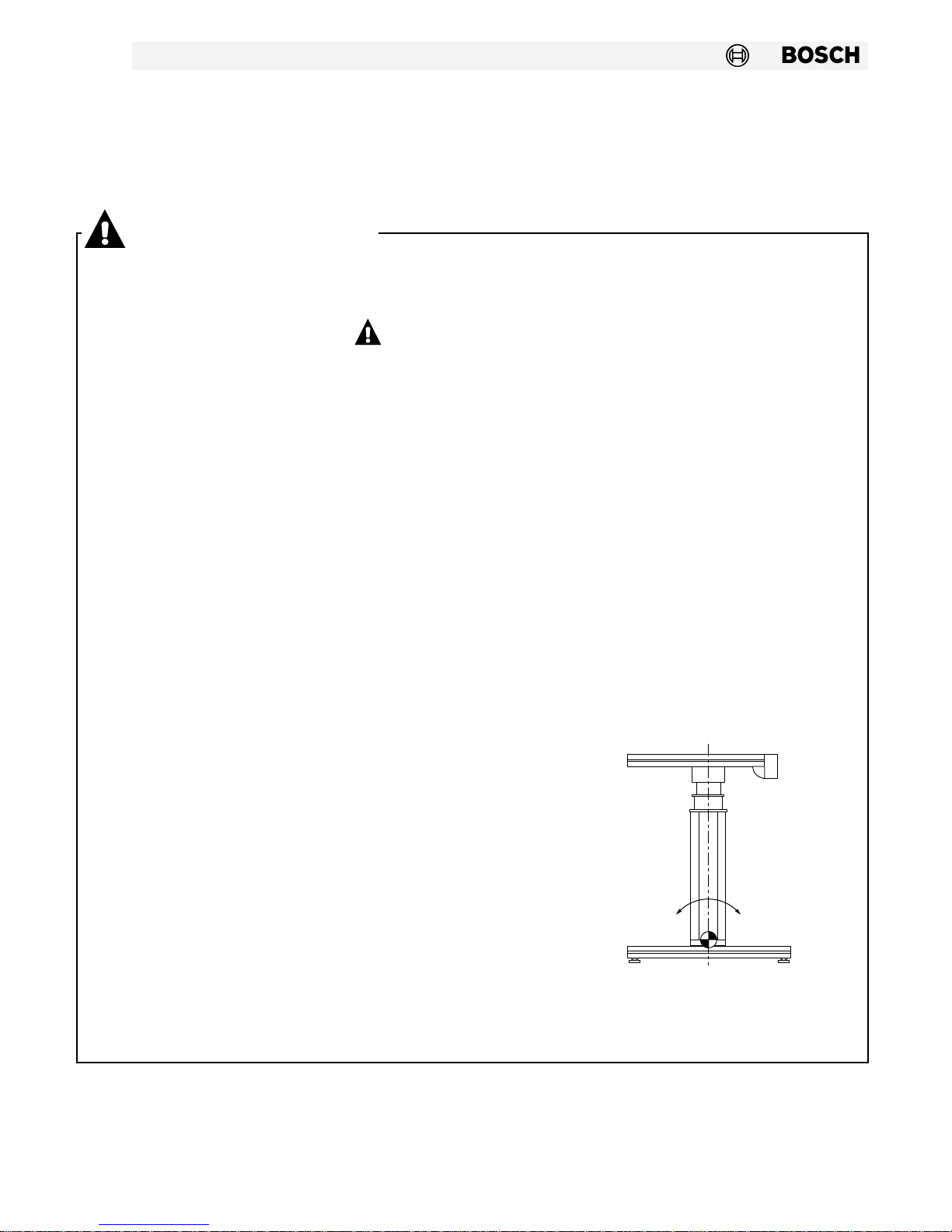

• CAUTION–Tip over hazard! Extension arms with

tool holders and parts bins can present a potential

tip over hazard under certain height and load

conditions. Table tops with overhangs also present

a potential for tip over. Be sure the load is always

centered on the table top. If it is not possible to

center the load, be sure it is evenly distributed

from side to side and front to back. DO NOT sit,

stand or lean on table tops! DO NOT exceed the

maximum allowable moment of 500 Nm as shown

in the diagram below! For maximum stability and

safety Bosch Rexroth recommends anchoring the

workstation to the floor. A number of floor

anchoring options can be found in the Bosch

aluminium structural framing catalog available

through your local distributor.

• Be sure to follow all local, state and federal

regulations when installing electrical devices of

any type

• Unplug the workstation before beginning

maintenance or repair work of any type on the

adjustable height workstation.

• The adjustable height workstation is designed to be

used in assembly operations where ergonomic

considerations dictate the need for a height

adjustable workstation. Table top maximum width is

1400 mm. The minimum width is 1000 mm.

It will accommodate extension arms for tool

SAVE THESE INSTRUCTIONS!

Allowable Moment=

500 Nm Maximum

About this manual

5

The manual is divided into the following sections to

make it easier to use:

• Technical Data – Provides the most important

technical specifications.

• Application and Function – Gives general

information about the Adjustable Height

Workstation.

• Design and Detailed Description – Supplies an

overview of the modules that make up the

Adjustable Height Workstation. This section will

familiarize you with the modules individual

components.

• Assembly – Lists step-by-step assembly

instructions for the Adjustable Height Workstation.

• Operation – provides valuable operating

information.

• Maintenance – None required over life of unit.

If this module was ordered as CE compliant, please

contact our applications engineering department for

a copy of the latest manufacturer's CE declaration, if

required for your records.

6

Technical Data

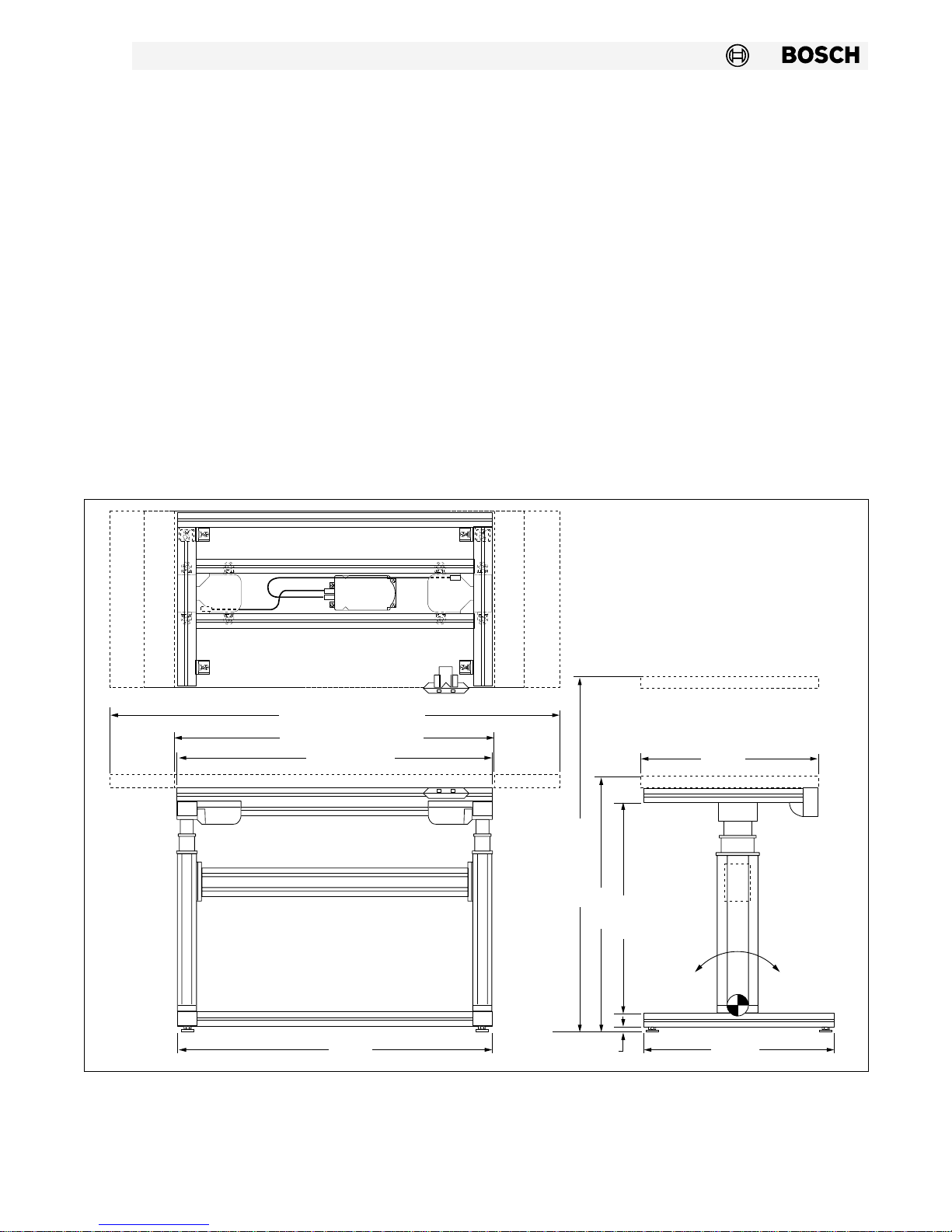

Functional dimensions for the Adjustable Height Table

Frame Kit are shown in Figure 1 below.

The minimum height is nominal since the position of

the height adjustment studs and thickness of the table

top will effect this dimension.

The table frame is constructed of 6063 T6 aluminum

profile. It is clear anodized to give a professional

finished appearance.

The Adjustable Height Table Frame Kit is powered by

two 110 VAC, 60 Hz motors. The telescoping actuators

have a maximum adjustment range of 500 mm, and will

support a maximum load of 400 lb (181.5 kg).

Application and Function

The Adjustable Height Table Frame Kit is used in

assembly operations where ergonomic considerations

dictate the need for height adjustability.

Height adjustment is accomplished with simple pushbutton up/down control supplied with the unit. 110

VAC motors inside the telescoping actuators supply

the power for the height adjustment. The two motors

are synchronized electronically by a control module

also supplied with the unit.

Figure 1

Table Top Max. 1400mm

Table Top Min. 1000mm

Frame 990mm

595mm

Max. 1302mm

15mm

802mm

640mm

555mm

500 Nm

Maximum

Moment

595mm

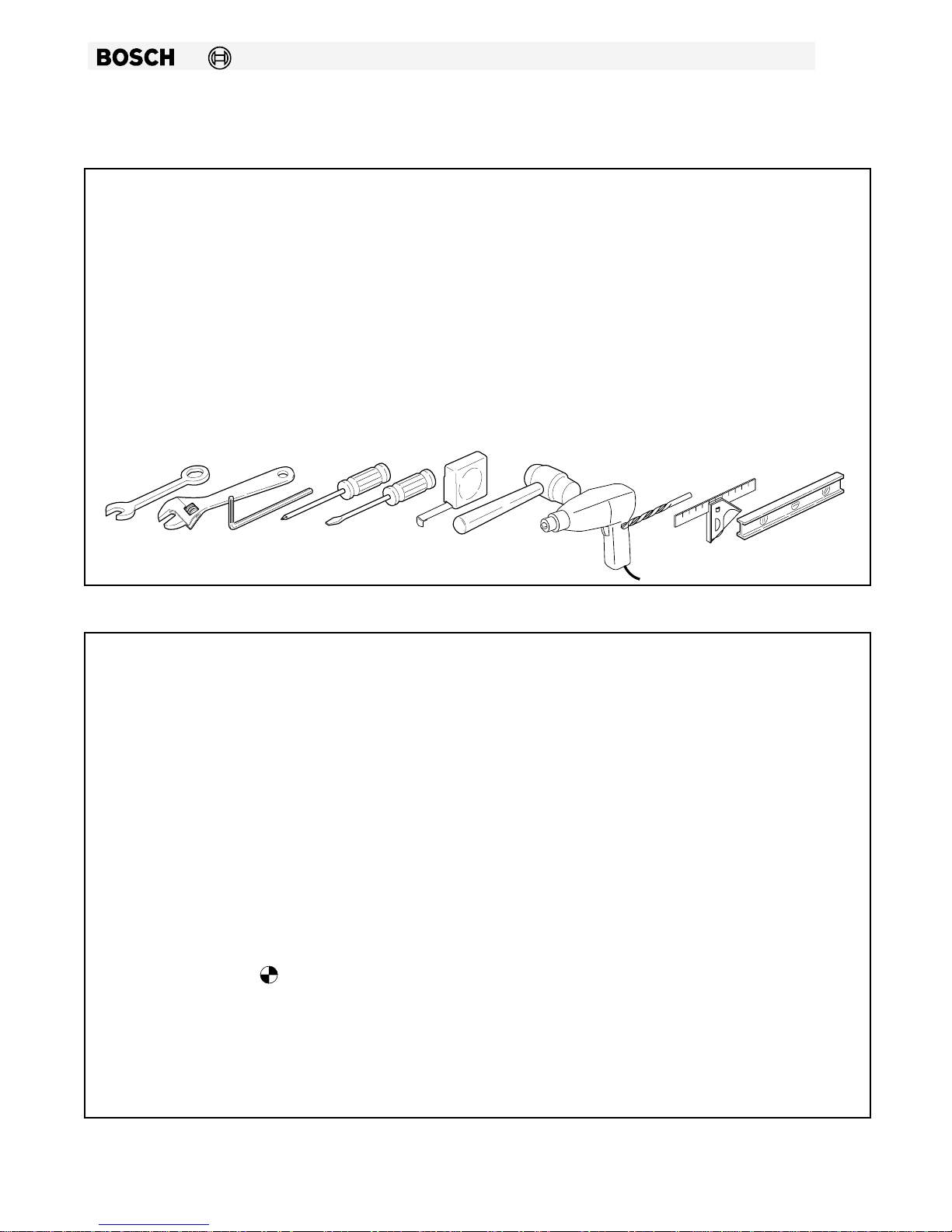

Recommended Tools

The following tools are recommended to assemble the Adjustable Height Table Frame Kit:

7

1 13 mm and 19 mm combination wrench

1 5, 6, 8, and 10 mm allen wrenchs

1 flat tip screwdriver

1 electric drill

1 soft faced mallet

1 adjustable wrench

1 #1 and #2 phillips screwdriver

1 tape measure

1 square

1 2 mm and 3 mm drill bits for drilling pilot holes

in the table top.

1 level

Specifications

Adjustable Height Workstation Kit Part Number........................................................................... 8981 021 140

Frame Height.................................................................................................................. 802 – 1302 mm Adjustable

Frame Width................................................................................................................................. 990 mm (38.976 in)

Table Top Width.....................................................................................................1000 mm min. – 1400 mm max.

Frame Depth................................................................................................................................. 595 mm (23.425 in)

Maximum Load, Centered .............................................................................................................. 400 lb (181.5 kg)

Maximum Load, Distributed ........................................................................................................... 400 lb (181.5 kg)

Maximum Moment @

Shipping Weight W/Out Table Top:

Carton 1 – Telescoping Actuators and Components ...........................................................40.5 lb (18.4 kg)

Carton 2 – Frame Components..................................................................................................45.5 lb (20.7 kg)

....................................................................................................................500 Nm (Static)

8

Design and Detailed Description

The Adjustable Height Table Frame Kit contains all of

the components necessary to build an electric lift

height adjustable table frame. The lift mechanism

consist of two motors synchronized with an electrotonic

control. The frame components are made from extruded

aluminum profiles. Tabletops are sold separately and

include 4 mounting screws and flatwashers.

Parts List

Item No. Qty. Part Number Description

1 2 8981 992 026/870 Profile, 45x45 –/–

2 1 3842 990 644/867 Profile, 45x45 D17/D17

3 2 8981 021 266 Profile, 45x60 W/S12x30 screws

4 2 8981 021 148 Profile W/Inserts, P45x60H

5 1 8981 021 147 Profile, 45x90H D17/D17 SPCL

6 1 8981 021 145 Profile, 45x90L D9.5/D9.5 SPCL

7 2 8981 021 127 Telescoping Actuator (TMA) with 8–Hex Nuts

8 2 8981 021 129 Plate, Mounting

9 2 3842 500 923 Bolt Connector Kit, 90 mm

10 2 3842 500 921 Bolt Connector Kit, 45 mm

11 16 3842 197 091 T-bolt

12 16 3842 345 081 M8 Flange Nut

13 8 3842 242 493 T-Nut, 10mm, M8

14 16 2910 131 238 Screw, DIN 7984-M8x16-8.8-CZ

15 4 3842 513 560 Economy Leveling Stud, M12

16 2 2915 051 119 Nut, ISO4036-M-12

17 4 3842 502 387 WS58N12 Washer, Lock (Zinc)

18 4 2910 141 350 Screw, DIN 912-M12x50-8.8-CZ

19 8 2910 141 207 Screw, DIN 912-M6x35-8.8-CZ

20 8 3842 502 384 WS58N6 Washer, Lock (Zinc)

21 4 2910 611 014 3.5x22-CH-CA screw (DIN7981-ST)

22 4 8981 021 193 Rectangular Nut

23 8 3842 523 537 Plastic Adapter, 8mm to 10mm

24 8 3842 515 473 Adjustable Angle Gusset

25 10 3842 523 558 Gusset, 45x45

26 6 3842 523 563 Round Cover Cap, 45x45

27 6 3842 515 122 End Cap, 45x60 H Black

28 2 3842 511 783 End Cap, 45x90 H Black

29 1 8981 021 190 Control Box

30 1 8981 021 192 Switch W/Mounting Bracket

31 4 3842 506 739 Cable Carrier, 10mm

Not shown 4 8981 010 500 Cable Tie, Black 8.0 x 0.1 in

Not Shown 2 8981 021 191 Cable

Not Shown 1 8981 500 290 Layout Template

Loading...

Loading...