Page 1

Room sealed gas continuous flow water heaters

6720808879-00.1V

Optiflow Professional

GWH12/16/20 1 CTD E23/31 F5 L

Installation Manual

Read installation manual prior to installation of this appliance!

Read user manual before putting this unit in operation!

Observe the warnings in the manuals!

The installation location must meet the requirements for sufficient ventilation!

Installation by an authorised person only!

6 720 810 560 (2016/06) AU

Page 2

2 | Index

Index

1 Key to symbols and safety instructions . . . . . . . . . . 3

1.1 Key to symbols . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Safety Information . . . . . . . . . . . . . . . . . . . . . 3

2 Product details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Declaration of Conformity . . . . . . . . . . . . . . 5

2.2 Type overview . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Included Items . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Rating plate . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5 Description of appliance . . . . . . . . . . . . . . . . 5

2.6 Accessory . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.7 Dimensions and minimum clearances . . . . . 6

2.8 Appliance layout . . . . . . . . . . . . . . . . . . . . . . 7

2.9 Electrical wiring diagram . . . . . . . . . . . . . . . 8

2.10 Specification . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.11 Flue accessories . . . . . . . . . . . . . . . . . . . . . 10

2.11.1 Selecting the Right Flue . . . . . . . . . . . . . . . 10

2.11.2 Vertical installation . . . . . . . . . . . . . . . . . . . 12

2.11.3 Horizontal installation . . . . . . . . . . . . . . . . . 12

3 Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Installation (only by an authorised technicians) . 12

4.1 Important information . . . . . . . . . . . . . . . . . 12

4.2 Choice of installation site . . . . . . . . . . . . . . 13

4.2.1 Regulations concerning the installation

site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2.2 Overall flue length of the installation . . . . . 13

4.3 Minimum clearances . . . . . . . . . . . . . . . . . . 13

4.4 Fitting hanging-plate . . . . . . . . . . . . . . . . . . 14

4.5 Installing the appliance . . . . . . . . . . . . . . . . 14

4.6 Water connection . . . . . . . . . . . . . . . . . . . . 14

4.7 Gas connection . . . . . . . . . . . . . . . . . . . . . . 14

4.8 Installation of flue accessories . . . . . . . . . . 15

4.9 Altitude of installation site . . . . . . . . . . . . . 15

4.10 Electrical connection (only by authorised

technicians) . . . . . . . . . . . . . . . . . . . . . . . . 16

4.10.1 Connecting the power cable . . . . . . . . . . . . 16

4.11 Commissioning of the appliance . . . . . . . . 16

4.12 Changing the setpoint limit temperature

(only for 55 °C preset appliances) . . . . . . . 16

4.13 Delivery temperature calibration . . . . . . . . 16

5 Regulating the gas (only for authorised

technicians) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

5.1 Factory settings . . . . . . . . . . . . . . . . . . . . . . 17

5.2 Service function . . . . . . . . . . . . . . . . . . . . . 17

5.3 Adjusting the appliance . . . . . . . . . . . . . . . 17

5.3.1 Access to the test points . . . . . . . . . . . . . . . 17

5.3.2 Adjusting the maximum flow

(Parameter P1) . . . . . . . . . . . . . . . . . . . . . .17

5.3.3 Adjusting the minimum flow

(Parameter P2) . . . . . . . . . . . . . . . . . . . . . .18

5.3.4 Adjusting pressure at the burner

(Parameter P0) . . . . . . . . . . . . . . . . . . . . . .18

5.4 Factory default settings . . . . . . . . . . . . . . . 19

6 Maintenance (only by authorised service

technician) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

6.1 To remove the front panel . . . . . . . . . . . . . 19

6.2 Periodic maintenance . . . . . . . . . . . . . . . . . 20

6.3 Replacement of the fuse (electronic

control unit) . . . . . . . . . . . . . . . . . . . . . . . . .20

6.4 Start-up after completion of maintenance 20

6.5 Safe operation/ risk for prolonged use . . . 20

7 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

8 Environmental considerations . . . . . . . . . . . . . . . . 23

9 Water quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

10 Warranty details . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6 720 810 560 (2016/06) Optiflow Professional

Page 3

Key to symbols and safety instructions | 3

1 Key to symbols and safety instructions

1.1 Key to symbols

Warnings

Warnings in this document are identified by a

warning triangle printed against a grey

background.

Keywords at the start of a warning indicate

the type and seriousness of the ensuing risk

if measures to prevent the risk are not taken.

The following keywords are defined and used in this document:

• NOTICE indicates a situation that could result in damage to

property or equipment.

• CAUTION indicates a situation that could result in minor to

medium injury.

• WARNING indicates a situation that could result in severe

injury or death.

• DANGER indicates a situation that will result in severe

injury or death.

Important information

This symbol indicates important information

where there is no risk to people or property.

Additional symbols

Symbol Explanation

▶ Step in an action sequence

Cross-reference to another part of the document

•List entry

– List entry (second level)

Table 1

1.2 Safety Information

If you smell gas

A gas leak could potentia lly cause an explosion. If you smell gas,

observe the following rules.

▶ Avoid producing flames or sparks:

– Do not smoke, do not use a lighter or strike matches.

– Do not operate any electrical switches or unplug any

equipment.

– Do not use the telephone or ring doorbells.

▶ Turn off the gas supply at the main shut-off valve or at the

gas meter.

▶ Open windows and doors.

▶ Warn your neighbours and leave the building.

▶ Prevent anyone from entering the building.

▶ Stay well away from the building: call the emergency

services and the gas supplier.

If you notice dark combustion gases or sooting:

▶ Isolate the gas supply to the heater.

▶ Notify an authorised technician.

Installation, Assembly and Modifications

Installation, assembly and modifications to the heater must

only be performed by an authorised technician .

Maintenance

▶ The water heater is required to have a service and safety

inspection every two years.

▶ The installer is responsible for the safety and

environmental compatibility of the installation, according

to local regulations.

▶ The Owner/User is responsible for keeping the area around

the water heater free from debris.

▶ Safe access to inspect and service the water heater is the

responsibility of the property owner.

▶ Use only genuine Bosch spare parts.

Explosive and highly flammable material

▶ Do not store or use flammable material (paper, spray cans,

solvents, paints, etc) near the heater.

Combustion air and surrounding air

▶ The combustion air and surrounding air must be free from

corrosive substances.

▶ Do not spray aerosols or use chemicals around the heater

unless heater is disconnected from the power supply.

Risk of damage due to user error

User errors can result in injury and damage to property.

▶ Ensure that children never play with or operate this

appliance.

▶ Ensure that only personnel who can operate this appliance

correctly have access to it.

▶ Refer to the operating and user instructions before

adjusting the water heater.

To be installed and serviced only by an authorised person

The authorised installer is responsible for:

• Correct installation and commissioning of this appliance.

6 720 810 560 (2016/06)Optiflow Professional

Page 4

4 | Key to symbols and safety instructions

• Ensuring the appliance performs to the specifications

stated on the rating label.

• Demonstrating the operation of the appliance to the

customer before leaving.

• Handing the operating instructions to the customer.

THIS APPLIANCE IS NOT SUITABLE FOR POOL OR SPA POOL

APPLICATIONS.

NOT SUITABLE FOR COMMERCIAL BOOSTING OF A WARM

WATER RECIRCULATION SYSTEM

Regulations

All local by-laws and regulations pertaining to installation and

use of gas appliances must be observed.

This appliance must be installed in accordance with the

manufacturers installation instructions, AS/NZS5601, AS/

NZS3500, and all Local Building & Gas fitting regulations.

The appliance must not be installed outdoors. The appliance is

approved for indoor installation only. Do not install this

appliance with any modification or alteration.

Failure to install this appliance in accordance with these

installation instructions will void the warranty and may create

an unsafe situation.

Installation

DANGER: Explosion Risk!

▶ Always turn off the gas valve before

carrying out any work on components

which carry gas.

DANGER: Appliance malfunction!

This appliance must be installed with no

obstructions to the flue terminal.

▶ Periodic checking of the flue terminal to

ensure no blockage or obstruction of the

openings from plants, debris or insects

must be carried out.

The installation of gas, water, and electrical

supply, and the initial startup are to be

performed by an authorised person.

Not suitable for pool or spa pool applications.

Not suitable for commercial boosting of

warm water recirculation systems.

All gas appliances require adequate air intake

to ensure correct combustion. Insects and

dirt ingress may affect combustion causing

sooting. If you notice sooting from the flue

outlet the unit would require servicing. Pest

and dirt ingress is not covered by the

manufacturers warranty.

Important information

▶ Determine the most appropriate location for the appliance.

Install as close as possible to the most frequently used hot

water outlet.

▶ Ensure the mounting structure is capable of supporting the

weight of the appliance once installed. Secure the heater to

the wall using fixings suitable for the weight of the

appliance and the wall material.

▶ Install gas and water isolation valves as close as possible to

the appliance. Only use a gate valve or full flow ball valve

(fixed mechanism type) for cold water.

▶ Check the cold water supply pressure to ensure it meets

the required supply pressure for the appliance. (see

table 5, page 9).

▶ If inlet water pressure exceeds 800 kPa a pressure limiting

valve (500 kPa) MUST be fitted. The preferable location for

the pressure limiting valve is at the water meter.

▶ Where the pressure limiting valve is less than 3 metres from

the hot water unit, it must be fitted in conjunction with a

cold water expansion valve (700 kPa), between the water

heater and the pressure limiting valve.

▶ Failure to comply with this requirement may void the

warranty.

▶ Refer to AS/NZS5601 for the relevant gas pipe sizing.

▶ After finishing the gas piping system, the pipes must be

thoroughly purged and leak tested. This test must be

performed with the gas isolation valve of the appliance

closed.

▶ Ensure the gas pressure and flow through the regulator are

appropriate for the consumption of the heater (see table 5,

page 9). Refer to AS/NZS5601 and AS3500, for the

relevant pipe size.

Note: Incorrect pipe sizing or gas supply pressure may cause

the appliance to under perform. Service calls for incorrect pipe

sizing and/or gas pressure, will NOT be covered under

warranty.

6 720 810 560 (2016/06) Optiflow Professional

Page 5

Product details | 5

Safety of electrical appliances for domestic use and similar

purposes

The following requirements apply in accordance with EN

60335-1 in order to prevent hazards from occurring when

using electrical appliances:

“This appliance can be used by children of 8 years and older, as

well as by people with reduced physical, sensory or mental

capabilities or lacking in experience and knowledge, if they are

supervised and have been given instruction in the safe use of

the appliance and understand the resulting dangers. Children

must not play with the appliance. Cleaning and user

maintenance must not be performed by children without

supervision.”

“If the power cable is damaged, it must be replaced by the

manufacturer, its customer service department or a similarly

qualified person, so that risks are avoided.”

2 Product details

2.1 Declaration of Conformity

The appliance has been tested and certified to Australia

Standards.

Model GWH12/16/20 1 CTD E23/31 F5 L...

Table 2

2.2 Type overview

GWH 12 1CTDE23 F5 L

GWH 12 1CTDE31 F5 L

GWH 16 1CTDE23 F5 L

GWH 16 1CTDE31 F5 L

GWH 20 1CTDE23 F5 L

GWH 20 1CTDE31 F5 L

Table 3

[GWH] Gas continuous flow water heater

[12] Capacity (l/min)

[1] Generation

[CT] Thermostatic

[D] Digital user interface

[E] Electric ignition

[23] Appliance set for natural gas

[31] Appliance set for Universal LP gas

[F5] Tight chamber

[L] Locked water temperature adjustment

• Appliance documentation

2.4 Rating plate

The rating plate is located on the outside of the appliance, on

the bottom.

The rating plate has the indications on the performance of the

appliance, approval data and the serial number.

2.5 Description of appliance

• Room sealed wall-mounted appliance for internal

installation

• Multifunctional display panel

• Suitable for Natural Gas or Universal LPG

• Electronic ignition

•Water flow sensor

•Water valve

• Temperature sensors for monitoring the temperature of the

incoming and outgoing water of the appliance.

•Safety devices:

–Flame sensor rod

–Thermal fuse

– Hot water temperature sensor

– Electronic control unit

–Air temperature sensor

– Frost protection device

• Electrical connection: 230 V, 50 Hz

2.6 Accessory

• Flue accessories

• Mains remote control (optional).

• Bathroom remote control (optional).

2.3 Included Items

• Gas continuous flow water heater

• Fixing bracket

6 720 810 560 (2016/06)Optiflow Professional

Page 6

6 | Product details

2.7 Dimensions and minimum clearances

Fig. 1 Dimensions (in mm)

Connections

A B C D E Cold Hot Nat. Universal

GWH12 300 570 170 120 107

GWH20 364 570 175 142 137

Table 4 Dimensions (in mm)

6 720 810 560 (2016/06) Optiflow Professional

Water Gas

LPG

½“ ½“ ½“ ½“GWH16 364 570 175 142 137

Page 7

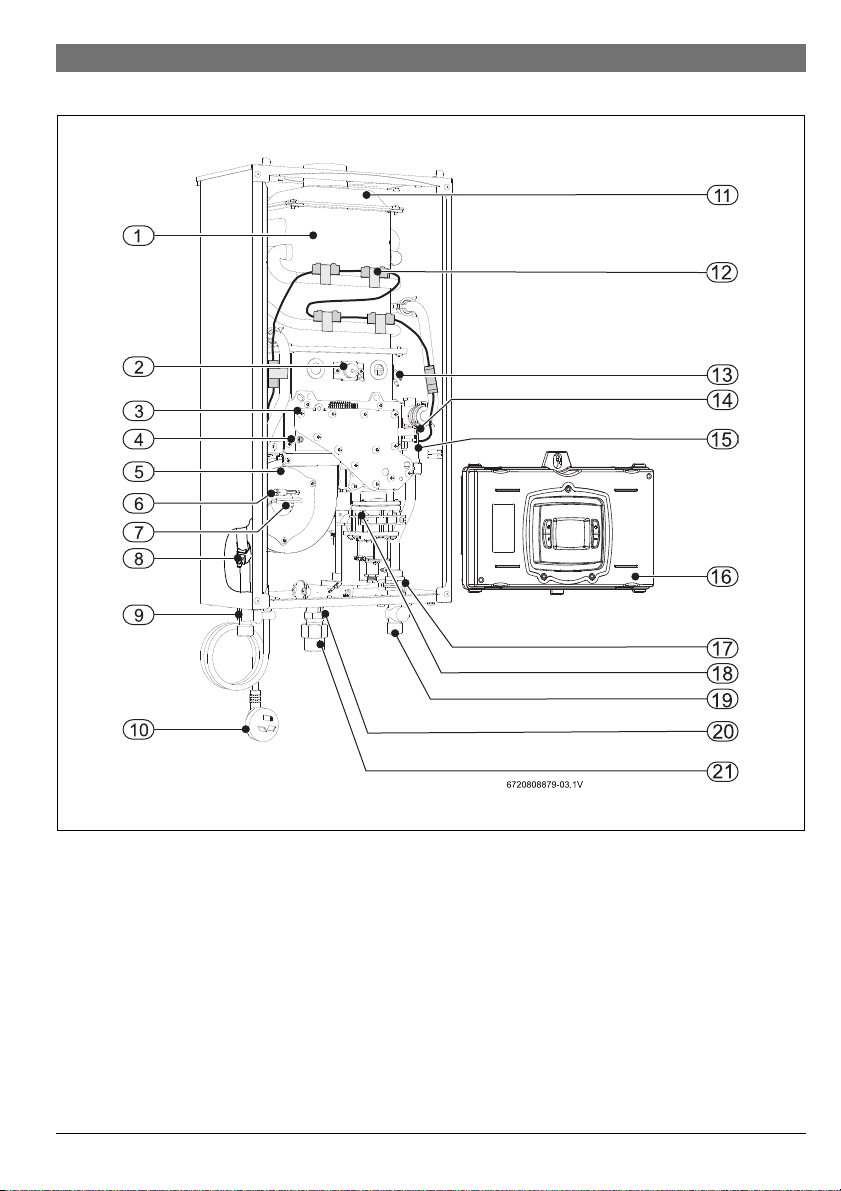

2.8 Appliance layout

Product details | 7

Fig. 2

[1] Heat exchanger

[2] Flame sensor rod

[3] Burner

[4] Air pressure test point

[5] Fan

[6] Air temperature sensor

[7] Thermal fuse

[8] Hot water temperature sensor

[9] Hot water outlet

[10] Power cord and plug

[11] Combustion gas collector

[12] Frost protection device

[13] Ignition electrode

[14] Burner pressure test point

[15] Water flow sensor and Water valve

[16] Electronic control unit

[17] Cold water temperature sensor

[18] Gas shut-off valve

[19] Cold water inlet

[20] Gas pressure test point

[21] Gas inlet

6 720 810 560 (2016/06)Optiflow Professional

Page 8

8 | Product details

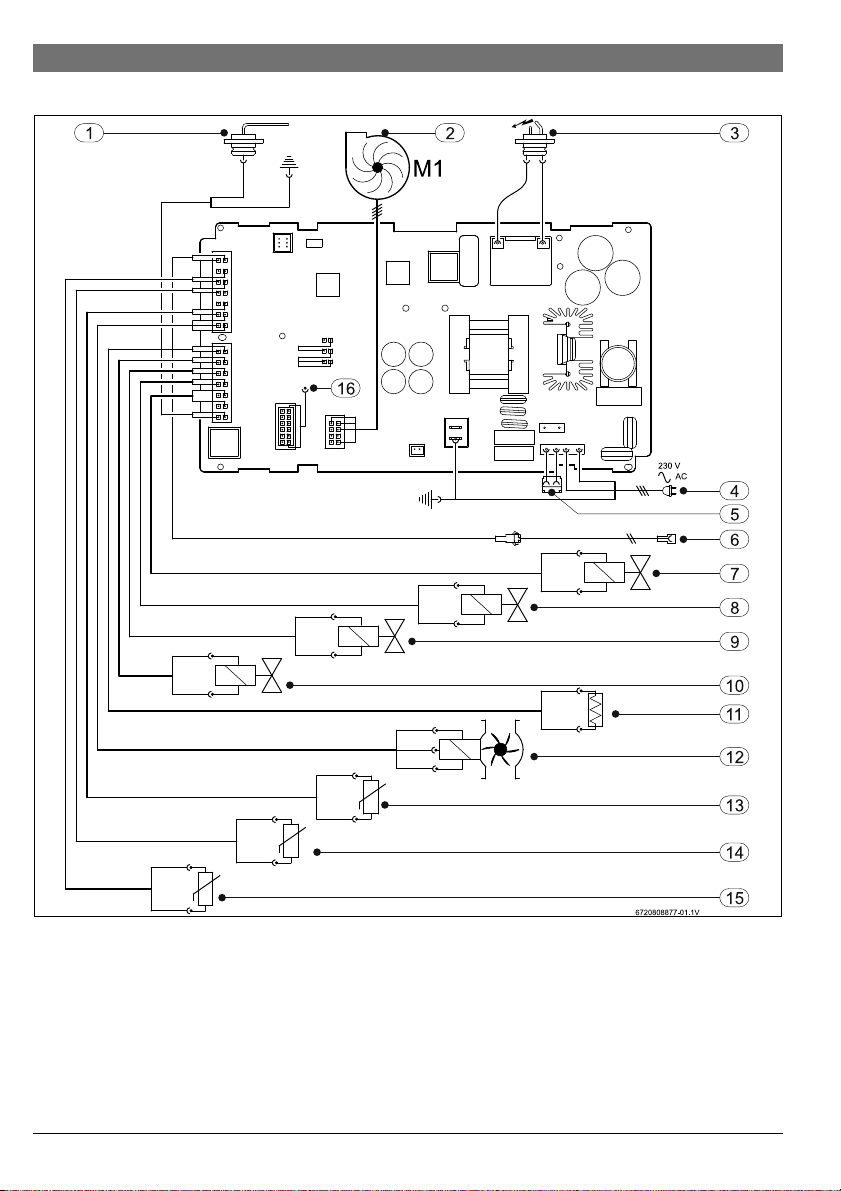

2.9 Electrical wiring diagram

Fig. 3 Electrical diagram

[1] Flame sensor rod

[2] Fan

[3] Ignition electrode

[4] Power supply

[5] Connection for frost protection

[6] Connection for remote control

[7] Modulation electrovalve (gas)

[8] Segmentation electrovalve 1 (gas)

6 720 810 560 (2016/06) Optiflow Professional

[9] Segmentation electrovalve 2 (gas)

[10] Safety electrovalve (gas)

[11] Thermal fuse

[12] Water flow sensor

[13] Air temperature sensor

[14] Hot water temperature sensor

[15] Cold water temperature sensor

[16] Water valve

Page 9

Product details | 9

2.10 Specification

Technical features Units GWH12 GWH16 GWH20

Performance

Nominal Gas Consumption MJ/h 90.0 120.2 149.0

Minimum gas consumption MJ/h 11.9 18.0 18.0

Efficiency at 100% of nominal load % 82.4 82.4 82.4

Gas supply data

Gas supply pressure (flowing)

Natural gas (when operating) kPa 1.13 1.13 1.13

Universal LP gas (when operating) kPa 2.75 2.75 2.75

Water supply data

Maximum permissible pressure (static) kPa 1000 1000 1000

Minimum operating pressure kPa 100 100 100

Start-up flow l/min 2.0 2.0 2.0

Maximum flow, corresponding to a temperature increase of 25 °C l/min 12.0 16.0 20.0

Maximum inlet temperature °C 50 50 50

Electrical circuit

Power supply voltage V

AC

Frequency Hz 50 50 50

Maximum power consumption W 228 228 228

230 230 230

Appliance enclosure rating IPX4D

General data

Weight (unpacked) kg 10 11 12

Height mm 570 570 570

Width mm 300 364 364

Depth mm 170 175 175

Table 5

6 720 810 560 (2016/06)Optiflow Professional

Page 10

10 | Product details

2.11 Flue accessories

Bosch 4000S coaxial flue must be used with

this appliance. Failure to use Bosch 4000S

flue could result in appliance failure.

DANGER: Install the flue gas pipe so that

there are no leaks.

▶ Non compliance with this requirement

may cause combustion gases to leak

through the appliance installation

compartment and may result in personal

injury or death.

Type Description Reference

AZ369 Vertical Flue Kit (Fixed 1.4m) 7 716 050 071

2.11.1 Selecting the Right Flue

▶ Map your flue configuration.

▶ Check that the configuration, including bends, is within the

maximum flue limits.

▶ Calculate whether a condensate trap is required using

Fig. 4.

▶ Choose the flue kit that best suits your application. The kit

includes the appliance adapter and terminal.

▶ Add any flue lengths, bends, or condensate traps required

for your configuration.

▶ Place your order using the Bosch part numbers shown

below.

Below is a list of accessories. Only use

original accessories.

AZ361 Telescopic Horizontal Flue Kit 500-725mm 7 716 050 063

AZ362 Horizontal Flue Kit (Fixed 0.8m) 7 716 050 064

--- Horizontal Flue Kit w/ Adaptor Ø 60/100 7 736 995 083

Table 6 Flue gas accessories Ø60/100 mm

6 720 810 560 (2016/06) Optiflow Professional

Page 11

Type Description Reference

(A)

10 m

9 m

7 m

6 m

8 m

5 m

4 m

3 m

2 m

1 m

0 m

0°C-5°C-10°C 5°C 10°C 15°C 20°C 25°C

(B)

6720809968-04.3V

--- Flue Elbow Ø 60/100 90° 7 736 995 079

--- Flue Elbow Ø 60/100 45° 7 736 995 071

--- Flue Terminal Extension DN60/100 350mm 7 736 995 059

--- Flue Terminal Extension DN60/100 750 mm 7 736 995 063

--- Flue Terminal Extension DN60/100 1500 mm 7 736 995 067

--- Horizontal Condensate Trap Ø 60/100 7 736 995 087

--- Vertical Flue Condensate Trap Ø 60/100 7 736 995 089

Table 6 Flue gas accessories Ø60/100 mm

Add note on using 100m 2 pce clips.

Product details | 11

Flue condensate collector

We advise using a condensate trap when the flue length and the

lowest average inlet air temperature is likely to result in

condensate forming during operation.

When the intersection of the flue length and lowest average

inlet air temperature is in the white section of the graph, a

condensate trap is required. (See Fig. 4)

Fig. 4

[A] Flue pipe length

[B] Lowest average inlet air temperature

Bosch 4000S flue components

All 4000S coaxial flue components have an internal pipe

diameter of 60 mm and an external pipe diameter of 100 mm.

6 720 810 560 (2016/06)Optiflow Professional

Page 12

12 | Regulations

2.11.2 Vertical installation

Maximum lengths (Lmax)

Lmax

Concentric pipes

GWH12

GWH16

GWH20 10 m

Table 7

2.11.3 Horizontal installation

Maximum lengths (Lmax)

GWH12 8 m

GWH16

GWH20 6 m

Table 8

In case of horizontal flue, ensure that the

installations has a fall of 3°.

Equivalent

lengths (Leq)

Ø

Ø 60/100 45° elbow

Ø 60/100 90° elbow 2 m 0.375 m

Table 9

Accessory Leq Min Length

12 m

Lmax

Concentric pipes

3Regulations

Any local by-laws and regulations pertaining to ins tallation and

use of gas-fired appliances must be observed.

This appliance must be installed in accordance with the

manufacturers installation instructions, AS/NZS5601 and all

Local Building & Gas fitting regulations

It is recommended that sanitary fixtures used for the purpose

of personal hygiene have a temperature limiting device such as

a tempering valve be fitted as per AS3498.

4 Installation (only by an authorised

technicians)

DANGER: Explosion!

▶ Always shut off the gas valve before

carrying out work on gas pipes.

The appliance installation, electrical

connection, gas connection, connection of

the flue system, and the initial start-up, are

operations to be carried out by authorised

technicians only.

NOTICE: Damage to the appliance!

▶ Do not place the device on the floor with

the connections facing downwards as

this may damage the appliance.

Installation in marine environments can lead

to premature corrosion. Premature

corrosion due to the installation environment

would not be covered by warranty.

Not suitable for pool or spa pool applications.

WARNING: Scalding!

This appliance can deliver water exceeding

50 °C.

▶ Please refer to AS/NZS 3500.4 local

requirements and installation

instructions to determine if additional

delivery temperature control is requ ired.

4.1 Important information

▶ Before carrying out the installation, consult the gas supply

company and the standard on gas appliances and

ventilation of rooms.

▶ Install in accordance with AS/NZS5601, AS/NZS3500.4,

NZS5261 and all local building, water and gas fitting

regulations.

6 720 810 560 (2016/06) Optiflow Professional

Page 13

4.2 Choice of installation site

6720817545-09.2V

N

C

J

B

J

A

C

A

K

G

A

H

N

F

J

A

C

K

B

B

B

G

K

H

Flue terminal positions

for water heaters in accordance

with AS/NZ5601

D

D

GM

P

K

E

E

4.2.1 Regulations concerning the installation site

▶ The water heater may not be installed over a heat source.

▶ Comply with the minimum installati on clearances indicated

in fig. 5 and table 10.

▶ Ensure there is a socket for electrical connection near the

water heater and it is easily accessible after the installation

of the water heater.

Location of the appliance

The combined air intake and flue terminal must terminate

outdoors in a well ventilated area away from vegetation and

other obstructions.

In order to prevent corrosion, the combustion air must not

contain any corrosive substances.

Substances classed as corrosion-promoting include

halogenated hydrocarbons containing chlorine and fluorine

compounds. They may be found in solvents, paints, adhesives,

aerosol propellants and household cleaners, for example.

If these conditions cannot be guaranteed, a different site must

be chosen for the appliance.

4.2.2 Overall flue length of the installation

The overall flue length may not exceed the values indicated in

the tables 7 and 8, and must not be less than the values

indicated in table 9 (Min length).

In determining the overall length of the installation, the

equivalent length (Leq) of each accessor y must be considered.

Installation (only by an authorised technicians) | 13

Fig. 5 Minimum distances

[A] Side 1 cm

[B] 40 cm

[C] Front 2 cm

Minimum distances to exhaustion points

In horizontal installations, the first elbow

positioned just at the outlet of the appliance

must not be considered for the purposes of

calculation.

Surface temperature

The maximum surface temperature of the appliance is below

85 °C. No special safety precautions are required with regard

to flammable building materials and cabinetry.

▶ Ensure that local building codes and regulations are

followed.

4.3 Minimum clearances

Consider the following limitations when determining the

installation location:

▶ Maximum length of the power cord.

▶ Allowances for service work while considering the

minimum distances indicated in fig. 6.

Fig. 6 Minimum flue clearances

6 720 810 560 (2016/06)Optiflow Professional

Page 14

14 | Installation (only by an authorised technicians)

Item Min.clea-

rance (mm)

A Below eaves, balconies and other

300

projections

B From the ground, above a balcony or other

surface

1)

C From a return wall or external corn er

300

1)

300

D From a gas meter (GM) 1000

E From an electricity meter or fuse box (P)

2)

500

F From a drain pipe or soil pipe 75

G Horizontally from any building structure 1)

500

or obstruction facing a terminal

H From any other flue terminal, cowl, or

combustion air intake

1)

300

J Horizontally from an openable window, door, non-

mechanical air inlet, or any other opening into a building

with the exception of sub-floor ventilation:

Appliances up to 150 MJ/h input

Appliances over 150 MJ/h input up to 200

MJ/h input

1)

K From a mechanical air inlet, including a spa

1)

300

300

1000

blower

N Vertically below an openable window, non-mechanical air

inlet, or any other opening into a building with the

exception of sub-floor ventilation:

Appliances over 50 MJ/h input and up to

1000

150 MJ/h input

Appliances over 150 MJ/h input 1500

Table 10

1) unless appliance is certified for closer installation

2) Prohibited area below electricity meter or fuse box extends

to ground level

4.4 Fitting hanging-plate

Before fitting the hanging-plate, ensure that

the water, gas, and flue connections can be

installed in this area.

No special wall protection is necessary. The wall has to be

capable of supporting the weight of the appliance.

▶ Find a suitable location.

▶ Drill the required holes.

▶ Fix the hanging plate using appropriate fixings (not

supplied).

4.5 Installing the appliance

NOTICE: The appliance may be damaged if

dirt is allowed to enter via the gas or water

connections.

▶ Purge the pipes to eliminate

possible foreign bodies.

▶ Remove the appliance from the packaging.

▶ Check that all the items indicated are included (section

2.3).

▶ Remove the covers from the gas and water connections.

▶ Check that the gas type available matches that shown on

the sticker on the front of appliance, and on its dataplate.

CAUTION:

▶ Never support or balance the water

heater on the water and gas

connections.

Packaging materials can be recycled.

4.6 Water connection

▶ Identify the cold and hot water pipe to avoid possible cross

connection.

▶ Install a pressure reducing valve if required. It's preferable

to install this valve close to the water meter.

▶ Complete the cold (fig. 2. [18]) and hot (fig. 2, [8]) water

connections.

4.7 Gas connection

DANGER:

Non-compliance with applicable legal

standards may cause, material damage,

personal injury, or even death.

The gas connection to the water heater must comply with the

AS/NZS5601.

▶ First ensure that the water heater corresponds to the gas

type available.

▶ Fit a gas isolation valve on the gas supply line as close as

possible to the appliance.

▶ After installation of the gas supply line, thorough purging

and a tightness test must be carried out.

6 720 810 560 (2016/06) Optiflow Professional

Page 15

Size gas supply as per AS/NZS5601.

Incorrect gas pipe sizing will not be covered

by the warranty.

4.8 Installation of flue accessories

The instructions in the respective manual mu st be followed for

the installation of the accessories.

DANGER: Install the flue gas pipe so that

there are no leaks!

▶ Non compliance with this requirement

may cause combustion gases to leak

through the appliance case and may

result in personal injury or death.

CAUTION:

Ensure that the flue is installed to the

requirements of AS/NZS5601.

▶ Once the connection of the flue is completed, ensure that

the seal is air tight.

Flue configuration

Bosch 4000S supplied flue must be used with these

appliances.

Cutting coaxial flue to length

When cutting flue to length please ensure that:

• All cuts are made on the male end of each flue component.

• The cuts are square (not on an angle) so that a complete

seal can be achieved on installation.

• The burrs are removed from the cut lengths of flue. If burrs

are not removed they may damage the internal seals in the

flue.

Maximum distance to the facade

In case of horizontal flue termination:

▶ Ensure that the distance between the end of the inlet air

pipe and the facade is no greater than 30 mm (Fig. 7).

Installation (only by an authorised technicians) | 15

Fig. 7 Dimensions

4.9 Altitude of installation site

To en sur e c or re ct o pe ra ti on o f t he ap pli an ce , a t al ti tu de s ab ov e

500m, the altitude setting must be adjusted.

▶ Enter the Service function (section 5.2).

Display will show “P2”.

▶ Press until the display shows “P4”.

▶ Press the button .

Display will show “E”.

▶ Press until the display shows “AS”.

▶ Press the button .

Display will show “1”.

▶ Press the button or and select the altitude of the

installation site according with table below.

Display Altitude

1 < 500 m

2 500 m - 1 000 m

3 1 000 m - 1 500 m

4 1 500 m - 2 000 m

5 2 000 m - 2 500 m

6 > 2500 m

Table 11

6 720 810 560 (2016/06)Optiflow Professional

Page 16

16 | Installation (only by an authorised technicians)

4.10 Electrical connection (only by authorised technicians)

DANGER: Due to electric shock!

▶ Before carrying out work on electrical

components, disconnect the power

supply (230 V AC) (by isolating switch

and removing the power plug from the

electrical socket) secure against

unintentional reconnection.

All the regulating, control and safety devices in the appliance

are factory supplied already connected and ready to operate.

4.10.1 Connecting the power cable

The electrical connection must be done in

accordance with AS/NZS3000.

If the power cable is damaged, it must be

replaced with a Bosch supplied spare part.

▶ Connect the power cable to a power socket.

4.11 Commissioning of the appliance

▶ Open the gas and water isolation valves and check the

tightness of all the connections.

When a hot water tap is turned on, the movement of water

through the flow sensor (fig. 2, [15]) sends a signal to the

control box. This signal triggers the following actions:

• The fan to start working.

• The ignition sequence and the gas valve (fig. 2, [18])

delivers gas to the burner.

• The burner ignites. Initially only a part of the burner is lit.

• The flame sensor rod (fig. 2, [2]) detects the flame.

• The temperature of the water is checked automatically by

the sensors. The appliance adjusts the gas flow and water

flow to achieve the temperature selected.

• Depending on the output required, the rest of the burner

will ignite.

Safety shut-down when the safety time is exceeded

If the appliance does not maintain a flame within the safety

interval stipulated, a safety shut-off is carried out.

Air in the gas supply line may cause a delay or difficulty when

igniting.

If the ignition attempt is unsuccessful after a period of time, the

safety devices block the op eration of the appliance, and air will

have to be purged from the circuit.

Safety shut-down due to an excessively high water temperature

The electronic control unit detects the temperature of the

water through the thermistor placed at the hot water outlet. If

the appliance detects an excessive temperature, a safety

shutoff will occur.

Safety shut-off due to incorrect flue conditions

If the appliance detects an incorrect flue condition, a safety

shut-off will occur.

Re-start after a safety shut-off

To put the appliance back into operation after a safety shut-off:

▶ Close all hot water taps.

▶ Reset the appliance by switching it off at the socket and

unplugging the cord.

4.12 Changing the setpoint limit temperature (only for 55 °C preset appliances)

The maximum temperature is preset to 55 °C. If required it can

be increased to 60 °C or 70 °C.

▶ Enter the Service function (section 5.2).

Display will show "P2".

▶ Press until the display shows "P4".

▶ Press the button .

Display will show "E".

▶ Press until the display shows "SL".

▶ Press the button .

Display will show "55"

▶ Press until the display shows "60" or “70”.

▶ Press the button for 3 seconds.

The value flashes to confirm the new setpoint limit.

4.13 Delivery temperature calibration

If the delivery temperature at the closest hot water outlet to the

appliance does not match the setpoint it can be adjusted as

follows:

▶ Enter the Service function (section 5.2).

Display will show "P2".

▶ Press until the display shows "P4".

▶ Press the button .

Display will show "E".

▶ Press until the display shows "SC".

▶ Press the button .

Display will show "0"

▶ Press or to adjust the delivery temperature as

required.

The setpoint can be adjusted between -5 °C and +5 °C.

6 720 810 560 (2016/06) Optiflow Professional

Page 17

Regulating the gas (only for authorised technicians) | 17

A

B

-

+

6720804089-11.1V

▶ Press the button for 3 seconds.

The value flashes to confirm the new setpoint limit.

Calibration example

Setpoint Water temp. at tap Calibration

50 °C 48 °C +2 °C

Table 12

5 Regulating the gas (only for authorised

technicians)

5.1 Factory settings

The data plate on the each appliance will show the factory

setting of that appliance.

Natural gas

The appliance must not be operated if the

dynamic connection pressure is less than

1.13 kPa or greater than 2.75 kPa.

Universal LPG

The appliance must not be operated if the

dynamic connection pressure is less than

2.5 kPa or greater than 4.5 kPa.

DANGER:

▶ The operations described below must only

be carried out by an authorised service

technician.

5.2 Service function

Accessing the service function

▶ Press and hold down at the same time , ,and

for 3 seconds.

Fig. 8 Service function

The display will show "P2".

The service function is now activated.

5.3 Adjusting the appliance

5.3.1 Access to the test points

▶ Remove the front of the appliance.

Fig. 9

[A] Air pressure test point

[B] Gas pressure test point

5.3.2 Adjusting the maximum flow (Parameter P1)

▶ Turn on the appliance using the ON/OFF button.

▶ Loosen the test point screw of the gas pressure test

point.[B]

▶ Connect the pressure gauge connection "+" to the gas

pressure test point [B].

6 720 810 560 (2016/06)Optiflow Professional

Page 18

18 | Regulating the gas (only for authorised technicians)

▶ Loosen the test point screw of the air pressure test

point.[A]

▶ Connect the negative "-" side of the pressure gauge to the

air pressure test point.[A]

▶ Press until the display shows "P1".

▶ Press the button .

Display will show "E".

▶ Press until the display shows "L1".

▶ Press the button .

The appliance is now ready for adjustment of the maximum

gas flow.

▶ Open a hot water tap.

▶ Press or until the pressure gauge shows the

value indicated in tab. 13.

If it is not possible to reach the differential

pressure value:

▶ Adjust the pressure in the burner

(section 5.3.4) and repeat the

procedure for adjusting maximum flow.

▶ Press for 3 seconds.

The displayed value flashes as a sign of confirmation.

▶Press .

Display will show "L1".

▶ Close the hot water tap.

▶ Press until the display shows "E".

▶ Press the button .

Display will show "P1".

The adjustment of the maximum gas flow is complete.

5.3.3 Adjusting the minimum flow (Parameter P2)

▶ Press until the display shows "P2".

▶ Press the button .

Display will show "E".

▶ Press until the display shows "L2".

▶ Press the button .

▶ Open a hot water tap.

The appliance is now ready for adjustment of the minimum

gas flow.

▶ Press or until the pressure gauge shows the

value indicated in tab. 13.

If it is not possible to reach the differential

pressure value:

▶ Adjust the pressure in the burner

(section 5.3.4) and repeat the

procedure for adjusting minimum flow.

▶ Press for 3 seconds.

The displayed value flashes as a sign of confirmation.

▶ Press .

Display will show "L2".

▶ Close the hot water tap.

▶ Press until the display shows "E".

▶ Press the button .

Display will show "P2".

▶ Simultaneously press the , and for 3

seconds.

Display will show the temperature selected.

▶ Disconnect the pressure gauge from the test points [A] and

[B].

▶ Tighten the shutter screws of the test points [A] and [B].

The adjustment of the minimum gas flow is complete.

Natural gas H Universal

LP gas

Øinjector

Dynamic

connection

pressure

(kPa)

Burner

pressure

(kPa) - P0

Differential

pressure of

the burner

MAX (kPa) P1

Differential

pressure of

the burner

MIN (kPa) P2

GWH12

GWH16

GWH20

GWH12

GWH16

GWH20

GWH12

GWH16

GWH20

GWH12

GWH16

GWH20

GWH12

GWH16

GWH20

1.7 1.3

2.0 + 1.7 1.5 + 1.3

1.13 2.75

0.12

0.46 - 0.50 0.63 - 0.67

0.37 - 0.41 0.63 - 0.67

0.33 - 0.37 0.44 - 0.49

0.05 - 0.08 0.05 - 0.08

0.05 - 0.07 0.05 - 0.07

0.04 - 0.08 0.05 - 0.08

Table 13 Pressure of the burner

5.3.4 Adjusting pressure at the burner (Parameter P0)

Burner pressure adjustment is only required

if “L1” and “L2” cannot be achieved

according to table 13.

6 720 810 560 (2016/06) Optiflow Professional

Page 19

▶ Enter the service mode by pressing and holding down the

, , and buttons simultaneously for 3

seconds (section 5.2).

Display will show "P2".

▶ Press until the display shows "P0".

▶ Press the button .

▶ Open a hot water tap.

With the pressure gauge connected, let the value measured

stabilise.

▶ Press or until the pressure gauge shows the

value indicated in tab. 13.

▶ Press for 3 seconds.

The displayed value flashes as a sign of confirmation.

▶ Press to exit this function.

Display will show "P0".

▶ Close the hot water tap.

The adjustment of the burner pressure is complete.

5.4 Factory default settings

▶ Enter the service mode by pressing and holding down the

, , and buttons simultaneously for 3

seconds (section 5.2).

Display will show "P2".

▶ Press until the display shows "P4".

▶ Press the button .

Display will show “E”.

▶ Press until the display shows "rP".

▶ Press the button .

Display will show "P1"

▶ Press for 3 seconds.

The displayed value flashes as a sign of confirmation.

▶Press .

Display will show "P1"

▶ Press until the display shows "P2".

▶ Press the button for 3 seconds.

The displayed value flashes as a sign of confirmation.

▶Press .

Factory default settings are now restored.

Maintenance (only by authorised service technician) | 19

6 Maintenanc e (only by authorised service

technician)

Bosch recommend that to maintain optimum performance

from this appliance, servicing should be carried out by suitably

licensed persons at intervals not greater than two (2) years.

Maintenance must only be performed by an

authorised service technician.

DANGER: Due to electric shock!

▶ Always isolate the electrical power to

the appliance (by turning off the power

point and removing the power plug from

the electrical socket) before carrying

out any work on electrical parts.

▶ Your appliance should only be attended to by a Bosch

service technician. To locate your nearest service provider,

call: AU 1300 30 70 37, NZ 080054 33 52.

▶ Only use Bosch supplied replacement parts.

6.1 To remove the front panel

▶ Remove the bezel around the display from the appliance by

gently levering it off with a screwdriver. (fig. 10, [1]).

▶ Loosen the 3 fixing screws from around the display and 2

front panel fixing screws from the underside of the

appliance (fig. 10, [2]).

Fig. 10 Remove the front

▶ Remove the front by lifting forwards and upwards.

6 720 810 560 (2016/06)Optiflow Professional

Page 20

20 | Maintenance (only by authorised service technician)

6.2 Periodic maintenance

Functional check

▶ Check the correct operation of all the safety, regulation and

verification elements.

Heat exchanger

▶ If the heat exchanger is showing signed of sooting:

– Remove the heat exchanger.

– Clean by applying a jet of water in the lengthw ise

direction of the fins.

NOTICE: Damage to the appliance.

Damage to the heat exchanger.

▶ Do not apply a jet that is too strong or

aimed in a direction other than that

indicated.

▶ If the soot is not removed use a stiff brush to carefully clean

the fins.

▶ Regions with average/high water hardness: descale the

inside of the heat exchanger and the connection pipes by

using a diluted solution of hydrochloric acid or white

vinegar.

▶ When reinstalling the heat exchanger replace the o-rings

and seals.

Burner

▶ Inspect the burner and clean it if necessary.

If cleaning is required:

▶ Dismantle the burner.

▶ Use a brush to clean the surface of the burner elements.

▶ Use a jet of air to blow the burner elements.

Water filter

▶ Close the cold water inlet isolation valve.

▶ Loosen the cold water pipe.

▶ Carefully remove the water filter.

▶ Replace with a new water filter.

6.3 Replacement of the fuse (electronic control unit)

▶ Loosen the fixing screw of the electronic control unit

▶ Release all the connections to the electronic control unit

▶ Open the electronic control unit

▶ Replace the fuse located in the corner of the circuit board.

6.4 Start-up after completion of maintenance

▶ Re-tighten all of the connections.

▶ Check the burner pressure.

▶ Check air tightness of the flue circuit with the front cover

fitted.

▶ Check that there are no gas or water leaks.

6.5 Safe operation/ risk for prolonged use

Prolonged use power wear some elements may cause gas leaks

and transhipment of products of combustion.

Preventively should:

▶ Make a visual inspection of the ma intenance intervals to the

following elements:

– Electrical contact of security sensor

–Fan

–Gas valve

–Combustion chamber

In case of corrosion visible:

▶ Call the intervention of a qualified contractor.

6 720 810 560 (2016/06) Optiflow Professional

Page 21

Troubleshooting | 21

7Troubleshooting

Fitting, maintenance and repair must only be carried out by authorised technicians. The following table describes the possible

solutions.

Display Description Possible solution

A0 Cold and hot water temperature sensor damaged. ▶ Check temperature sensor and associated

A1 Temperature inside the water heater housing is high

A4 Faulty air temperature sensor. ▶ Call an authorised service technician.

A7 Faulty hot water outlet temperature sensor. ▶ Check temperature sensor and associated

A9 Hot water outlet temperature sensor is not fitted

C7 Faulty fan. ▶ Check if the fan is properly connected to

CA Water flow above maximum specified value. ▶ Check incoming water pressure.

CF

C1

E0 Failure of control module ▶ Unplug the electrical connection for 10

E1 Hot water temperature sensor detects overheating. ▶ Let the appliance cool and try again.

E2 Faulty inlet water temperature sensor. ▶ Call an authorised service technician.

Table 14

(heat exchanger calcified or sooted).

properly.

Low incoming gas pressure.

Blocked flue gas outlet.

Air flow insufficient for start-up.

connections.

▶ If the problem persists, call an authorised

service technician.

▶ The appliance automatically regulates its

performance to avoid overheating.

▶ If the problem persists, call an authorised

service technician.

connections.

▶ If the problem persists, call an authorised

service technician.

▶ Check temperature sensor and associated

connections.

▶ If the problem persists, call an authorised

service technician.

ECU.

▶ If the problem persists, call an authorised

service technician.

▶ Install a pressure limiting valve if necessary.

▶ Remove dirt or any other impediment from

the flue terminal and/or pipe.

▶ Press the reset button.

If the problem persists, call an authorised

service technician.

seconds.

▶ Reconnect and restart the appliance.

▶ If the problem persists, call an authorised

service technician.

If the problem persists, call an authorised

service technician.

6 720 810 560 (2016/06)Optiflow Professional

Page 22

22 | Troubleshooting

Display Description Possible solution

E4 Air temperature sensor detects overheating (leaking

combustion products inside the combustion

chamber).

▶ Switch off at the power point and remove

the plug from the electrical socket.

▶ Do not try to Restart the appliance.

▶ Call a service agent immediately.

E9 Activated thermal fuse. ▶ Call an authorised service technician.

EA Flame not detected. ▶ Check that the gas to the appliance has not

been turned off.

▶ Unplug the electrical connection for 10

seconds.

▶ Reconnect and restart the appliance.

▶ If the problem persists, call an authorised

service technician.

EC Failure ionization during operation ▶ Check type of gas.

▶ Check gas pressure.

▶ Check the ignition system.

▶ Check the output of combustion gases and

remove dirt or other impediment to good

extraction.

EE Modulating solenoid valve disconnected. ▶ Check solenoid connections.

▶ If the problem persists, call an authorised

service technician.

EF Wrong gas connected. ▶ Call an authorised service technician.

F7 A flame is detected although the appliance is

switched off.

▶ Unplug the electrical connection for 10

seconds.

▶ Reconnect and restart the appliance.

▶ If the problem persists, call an authorised

service technician.

F9 Safety Solenoid valve disconnected. ▶ Call an authorised service technician.

FA Fault in the gas control valve. ▶ Call an authorised service technician.

FC Buttons stuck in a “pressed” position for more than

30 seconds.

▶ Release the button.

▶ If the problem persists, call an authorised

service technician.

With indication,

but without existence of

solar thermal system.

With indication

and water temperature

low.

The temperature selected is lower than the minimum

power that the appliance supplies.

High incoming water temperatures, or low flow rate

can create this occurrence.

▶ Increase the hot water flow.

-or-

▶ Select a higher temperature.

▶ If the problem persists:

▶ Call an authorised service technician.

Appliance is making a resonance noise (vibration). ▶ Call an authorised service technician.

Table 14

Note: breakdowns diagnosed by the water heater through an indication in the LCD panel result in the blocking of the appliance for

safety reasons. Once the problem is solved, you have to press the on/off button for > 3 seconds to restart the appliance.

To locate your nearest service agent, call: AU 1300 30 70 37, NZ 0800 54 33 52.

6 720 810 560 (2016/06) Optiflow Professional

Page 23

Environmental considerations | 23

8 Environmental considerations

Environmental protection is a fundamental corporate strategy

of the Bosch Group.

The quality of our products, their efficiency and environmental

safety are all of equal importance to us and all environmental

protection legislation and regulations are strictly observed.

We use the best possible technology and materials for

protecting the environment taking into account economic

considerations.

Packaging

We participate in the recycling programmes of the countries in

which our products are sold to ensure optimum recycling.

All of our packaging materials are environmentally friendly and

can be recycled.

Used appliances

Used appliances contain valuable materials that should be

recycled.

The various assemblies can be easily dismantled and synthetic

materials are marked accordingly. Assemblies can therefore be

sorted by composition and passed on for recycling or disposal.

9 Water quality

All Bosch water heating appliances are constructed from high

quality materials and components and all are certified for

compliance with relevant parts of Australian and New Zealand

gas, electrical and water standards.

Whilst Bosch water heaters are warranted against defects, the

warranty is conditional upon correct installation and use, in

accordance with detailed instructions provided with the

heater. In the case of the water supplied to the heater, it is

important that the water quality be of an acceptable standard.

The water quality limits/parameters listed in water quality table

are considered acceptable and generally, Australian and New

Zealand suburban water supplies fall within these limits/

parameters.

In areas of Australia and New Zealand where water may be

supplied, either fully or partly, from bores, artesian wells or

similar, one or more of the important limits may well be

exceeded and the heater could, therefore, be at risk of failure.

Where uncertainty exists concerning water quality, intending

appliance users should seek a water analysis from the water

supplying authority and in cases where it is established that the

water supply does not meet the quality requirements of the

water quality table, the Bosch warranty would not apply.

Water quality table

Maximum levels

Index(LSI)

(langelier)

pH

6.5-9.0 +0.4 to -1.0

Table 15

Saturation

at 65 °C

Total

200

mg/l

Hardness

Chlorides

250

mg/l

Iron

Sodium

180

mg/l1 mg/l

6 720 810 560 (2016/06)Optiflow Professional

Page 24

24 | Warranty details

10 Warranty details

Robert Bosch (Australia) Pty Ltd (Bosch) Manufacturer's Warranty (Applicable for purchases from 1 January 2012)

All Bosch hot water units are carefully checked, tested and

subject to stringent quality controls.

1. Warranty

Bosch offers, at its option, to repair or exchange this Bosch hot

water unit or the relevant part listed in clause 2 below at no

charge, if it becomes faulty or defective in manufacture or

materials during the warranty period also stated in clause 2.

This warranty is offered in addition to any other rights or

remedies held by a consumer at law.

2. Warranty periods & coverage (a) Domestic applications: 3 years (parts and labour)

(b) Heat exchangers used in domestic applications: 12 years

(parts only)

(c) Commercial applications: 12 months (parts and labour)

(d) Heat exchangers used in commercial applications: 12

months (part and labour)

All warranty periods commence on the date of purchase of the

hot water unit by the end-user. However, where the date of

purchase by the end-user is more than 24 months after the

date of manufacture, all warranty periods will automatically

commence 24 months after the date of manufacture.

3. Warranty exclusions

This warranty is VOID if any damage to or failure of the hot

water unit is caused wholly or partly by:

(a) faulty installation

(b) neglect, misuse, accidental or non-accidental damage,

failure to follow instructions

(c) use of the unit for purposes other than which it was

designed or approved

(d) unauthorised repairs or alterations to the unit without

Bosch's consent

(e) use of unauthorised parts and accessories without Bosch's

consent

(f) use of non-potable water or bore wate r in the hot water unit

(see product instructions for further details)

(g) continued use after a fault becomes known or apparent.

This warranty DOES NOT include:

(a) costs of consumables or accessories

(b) wear and tear, normal or scheduled maintenance

(c) to the extent permitted by law, any damage to property,

personal injury, direct or indirect loss, con sequential losses or

other expenses

(d) changes in the condition or operational qualities of the hot

water unit due to incorrect storage or mounting or due to

climatic, environmental or other influences.

NOTE: Any service call costs incurred by the owner or user of

the hot water unit for any matter not covered by the terms of

this warranty will not be reimbursed by Bosch, even if those

costs are incurred during the warranty period. If the hot water

unit is located outside the usual operating area of a Bosch

service agent, the agent's travel, freight or similar costs are not

covered by this warranty and must be paid by the ow ner or user

of the hot water unit.

4. Warranty conditions (a) Proof of purchase may be required. (b) The hot water unit must be installed by an authorised and

licensed installer.

(c) Proof may be required of the date of installation and correct

commissioning of the hot water unit has been carried out to

Bosch's satisfaction (such as a certificate of compliance).

(d) Repair or replacement of the hot water unit or any parts

under this warranty does not lengthen or renew the warranty

period.

(e) This warranty is not transferable and is only offered to the

original purchaser of the hot water unit.

(f) No employee or agent of Bosch is authorised to amend the

terms of this warranty.

(g) This warranty only applies to Bosch hot water units

purchased from an authorised reseller and installed in Australia

or New Zealand.

(g) To the extent that any condition or warranty implied by law

is excludable, such condition or warranty is excluded.

5. How to lodge a warranty claim and warranty procedure (a) Warranty claims must be made with the Bosch Customer

Contact Centre (Australia: ph 1300 307 037; New Zealand: ph

0800 543 352). Please be ready to provide the model and

serial numbers, date of installation, purchase details and a full

description of the problem. Warranty claims must be made

before the end of the warranty period.

(b) All warranty service calls must co nducted by an authorised

Bosch service agent.

(c) Invoices for attendance and repair of a hot water unit by

third parties not authorised by Bosch will not be accepted for

payment by Bosch.

6. Privacy Act 1988 (Cth)

A customer's personal information collected during warranty

claims may be used for the provision of customer support, for

the provision of information about products and services and

for other marketing activities undertaken by Bosch and its

Bosch Service Agents who are authorised to carry out warrant y

repairs on behalf of Bosch (Purpose). Bosch is committed to

protecting the privacy of its cus tomers' personal information. It

will act in compliance with the National Privacy Principles and

6 720 810 560 (2016/06) Optiflow Professional

Page 25

Privacy Act 1988 (Cth). Bosch will not forward customers'

personal information to third parties other than for the

Purpose. A customer can object at any time to the use of their

personal information for the Purpose. Bosch will ce ase to use a

customer's personal information accordingly if an objection is

made.

7. Bosch contact details

If you have any questions about this warranty or to lodge a

warranty claim, please contact:

Robert Bosch (Australia) Pty Ltd

1555 Centre Road, Clayton, Victoria 3168

Tel: Australia: 1300 307 037

Tel: New Zealand: 0800 543 352

IMPORTANT NOTE FOR AUSTRALIAN CONSUMERS

Our goods come with guarantees that cannot be excluded

under the Australian Consumer Law. You are entitled to a

replacement or refund for a major failure and for compensation

for any other reasonably foreseeable loss or damage. You are

also entitled to have the goods repaired or replaced if the goods

fail to be of acceptable quality and the failure does not amount

to a major failure.

Warranty details | 25

6 720 810 560 (2016/06)Optiflow Professional

Page 26

26 |

Notes

6 720 810 560 (2016/06) Optiflow Professional

Page 27

Notes

| 27

6 720 810 560 (2016/06)Optiflow Professional

Page 28

6720810560

Loading...

Loading...