Page 1

Operating/Safety Instructions

Model 335 Plunge Router Attachment

•

Safety

• Assembly

•

Operation

• Service Parts

•

Warranty

2 610 920 458 02/04 Printed in Taiwan

Parlez-vous français?

Voir page 12

¿Habla español?

Vea página 23

P.O. Box 1468

Racine, Wisconsin

1-800-437-3635

http://www.dr emel.com

Dremel brand products are manufactured and sold by the

Dremel Division of Robert Bosch Tool Corporation

Page 2

2

Power Tool Safety Rules

Read and understand all instructions. Failure to follow all instructions listed

below, may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

!

WARNING

Hold tool by insulated gripping surfaces

when performing an operation where the

cutting tool may contact hidden wiring or

its own cord. Contact with a “live” wire will

make exposed metal parts of the tool “live”

and shock the operator. If cutting into existing walls or other blind areas where electrical wiring may exist is unavoidable, disconnect all fuses or circuit breakers feeding this

worksite.

Always make sure the work surface is

free from nails and other foreign objects.

Cutting into a nail can cause the bit and the

tool to jump and damage the bit.

Never hold the workpiece in one hand

and the tool in the other hand when in

use. Never place hands near or below

cutting surface. Clamping the material and

guiding the tool with both hands is safer.

Never place tool with bit protruding

through base on top of bench or work

surface. Lay the tool on its side or retract

the bit before setting on bench or work

surface. Protruding cutting bit may cause

tool to jump.

Always wear safety goggles and dust

mask. Use only in well ventilated area.

Using personal safety devices and working

in safe environment reduces risk of injury.

After changing the bits or making any

adjustments, make sure the collet nut and

any other adjustment devices are securely tightened. Loose adjustment device can

unexpectedly shift, causing loss of control.

Loose rotating components will be violently

thrown.

Never start the tool when the bit is

engaged in the material. The bit cutting

edge may grab the material causing loss of

control of the cutter.

Always hold the tool with two hands during startup. The reaction torque of the

motor can cause the tool to twist.

The direction of feeding the bit into the

material is very important and it relates to

the direction of bit rotation. When viewing the tool from the top, the bit rotates

clockwise. Feed direction of cutting must

be counterclockwise. NOTE: Inside and

outside cuts will require different feed direction. Refer to section on feeding the router.

Feeding the tool in the wrong direction causes the cutting edge of the bit to climb out of

the workpiece and pull the tool in the direction of the feed.

Always use the tool with the router base

securely attached and positioned flat

against material being cut. Having the

base securely positioned on the material

improves the stability and control of your

tool.

Never use dull or damaged bits. Sharp

bits must be handled with care. Damaged

bits can snap during use. Dull bits require

more force to push the tool, possibly causing the bit to break.

Never touch the bit during or immediately

after use. After use, the bit is too hot to be

touched by bare hands.

Never lay the tool down until the motor

has come to complete stop. The spinning

bit can grab the surface and pull the tool out

of your control.

Do not use the tool for drilling purposes.

This tool is not intended to be used with drill

bits.

Never use bits that have a cutting diameter greater than the opening in the base.

Safety Rules for Routers

Make sure to read and understand the Owner’s Manual for your Dremel Rotary Tool

Models 275, 285, 395 & 398.

Page 3

3

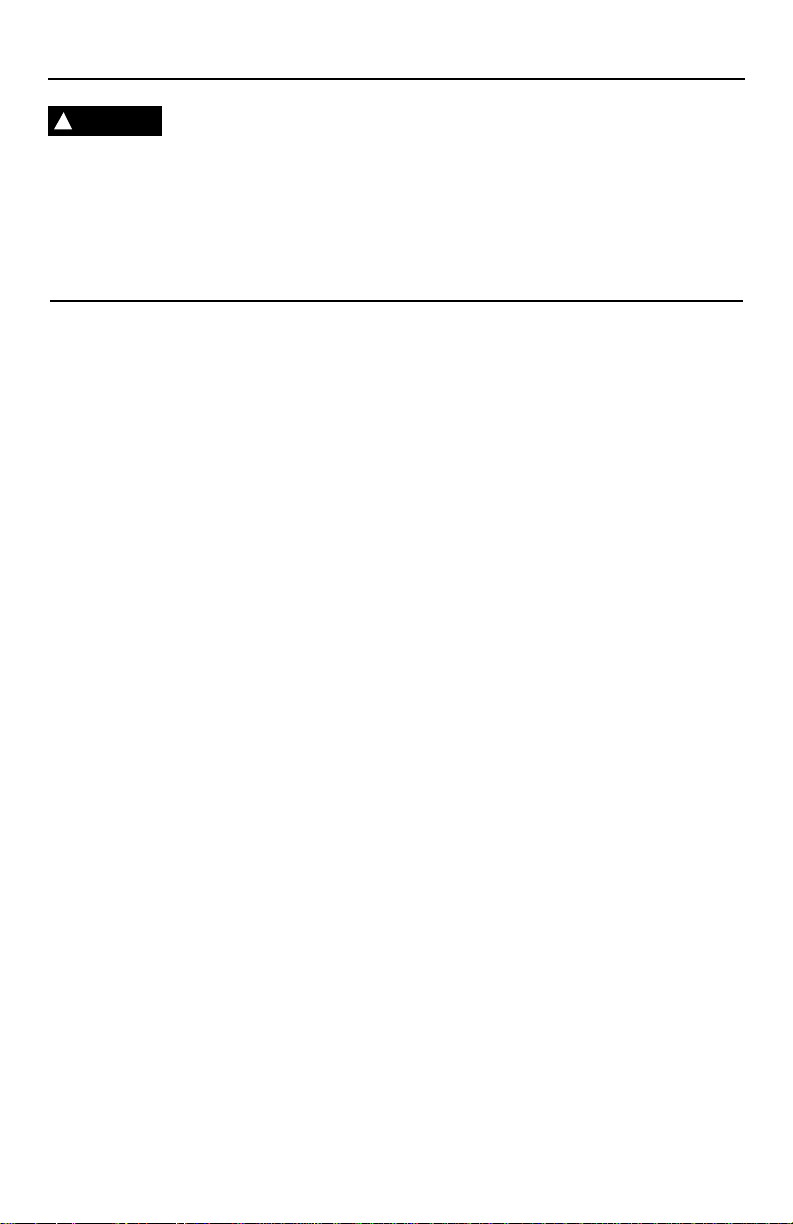

Operating Controls

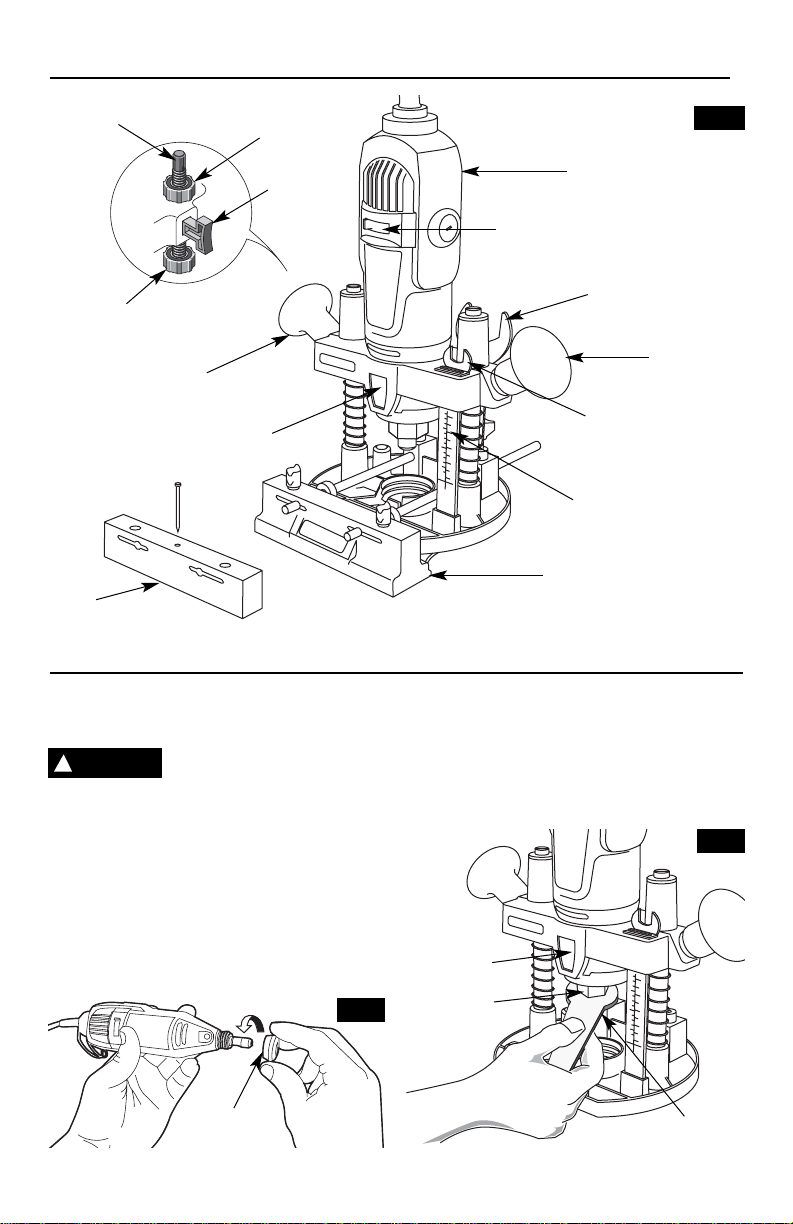

Assembling Plunge Router Attachment to your Tool

ATTACHMENT FOR USE WITH DREMEL

ROTARY TOOL MODELs 275, 285, 395, &

398.

Disconnect the plug from

the power source before

making any assembly, adjustments or

changing accessories. Such preventive

safety measures reduce the risk of starting

the tool accidentally.

1. Remove collet nut, then remove housing

cap from your rotary tool and set housing

cap aside (Fig. 2). The housing cap must

be reinstalled when this attachment is

not used. Once housing cap has been

removed, reassemble the collet nut.

2. Place tool into your router attachment

with the shaft lock button facing forward

as shown (Fig. 3).

3. Thread mounting nut clockwise onto the

threaded portion of your Rotary Tool and

securely tighten with the mounting

wrench provided.

!

WARNING

Shaft Lock

Button

Hand Grip

(turn to lock)

Hand Grip

(stationary)

Speed Control

Depth Scale

(English/Metric)

Dremel

Rotary Tool

Depth Stop

Adjustment

Nut, Upper

Release

Button

Adjustment

Nut, Lower

Shaft Lock

Button

Housing

Cap

Mounting Wrench

& Storage Area

Collet Nut Wrench

Storage Area

(Wrench not included)

Mounting

Wrench

Mounting

Nut

Edge Guide

FIG. 1

FIG. 2

FIG. 3

Circle

Guide

Page 4

4

Operating Instructions

ATTACHMENT FOR USE WITH DREMEL

HIGH SPEED ROTARY TOOL MODELS

275, 285, 395, & 398.

ATTENTION: This attachment will convert

Dremel Rotary Tool to a Plunge Router for

freehand routing, edging, grooving, and

circular cuts. The router attachment comes

assembled ready for freehand or pilot bit

routing.

This Router Attachment is

not intended for use

under a router or saw table.

!

WARNING

Inserting the Router Bit

The router bits are held in the tool by a

collet system. The bit may be installed

before or after the rotary tool is installed

in the attachment.

1. Depress and hold the shaft lock button

while rotating the collet nut and shaft.

Continue to rotate the collet nut and

shaft until the lock engages and holds

the shaft (Fig. 4).

2. Use the wrench from your Dremel Rotary

Tool and turn the collet nut counterclockwise to loosen it.

3. Release the shaft lock button.

4. Insert the router bit into the collet as

deep as possible to ensure proper gripping of the bit and to minimize run out.

Do not insert the bit so far that bit flutes

touch the collet or collet nut to avoid

chipping or cracking the bit.

NOTE: Never place the tool with bit

protruding through base on top of bench or

work surface. Lay the tool on its side or

retract the bit before setting on bench or

work surface. Protruding cutting bit may

cause tool to jump.

5. Re-engage the shaft lock button and

tighten the collet nut; first by hand, then

using the wrench until bit is held securely.

Shaft Lock

Button

Collet Nut

Wrench

Collet Nut

Base

FIG. 4

Page 5

5

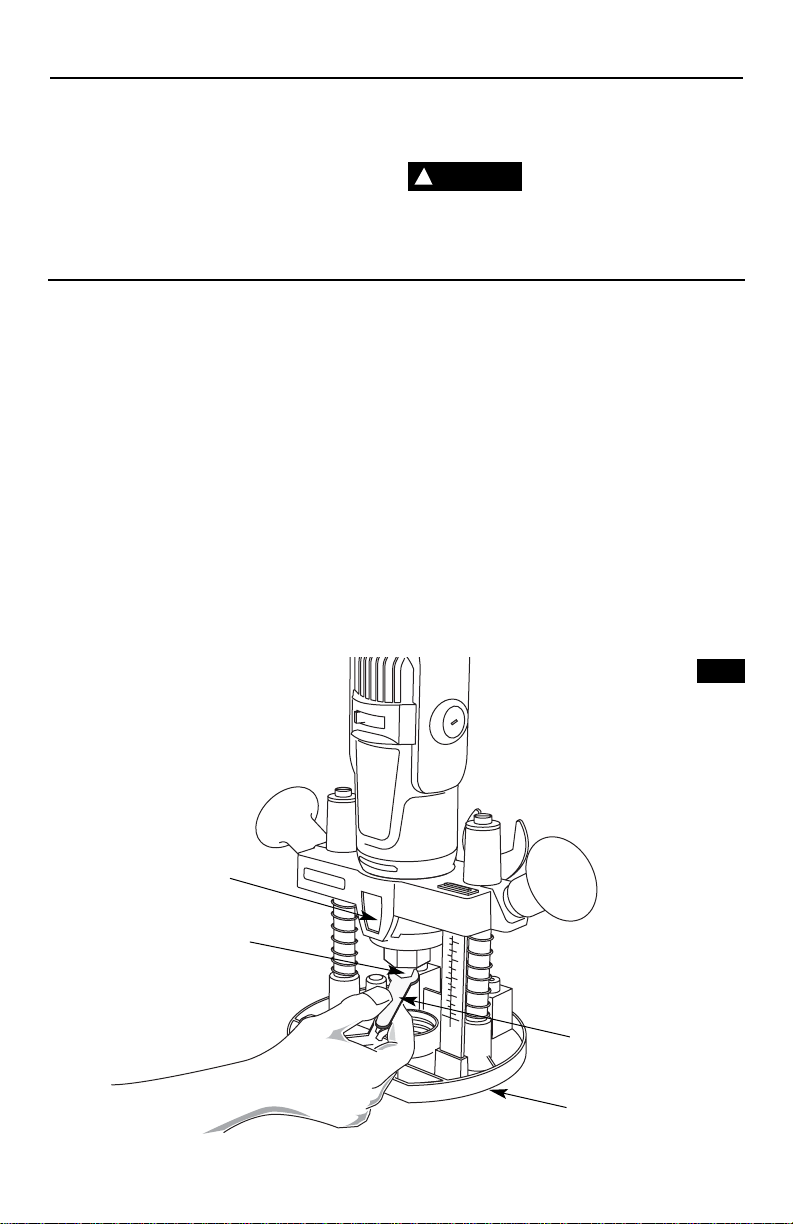

Adjusting Routing Depth

NOTE: When making deep cuts, especially

plunge cuts away from the edge of the workpiece, it is recommended to make several

successive cuts progressively deeper using

the depth adjustment and depth scale rather

than making one single deep cut.

The depth limiter can be adjusted for two

depths.

1. Place your Dremel Rotary Tool and Router

assembly on the workpiece.

2. Turn the upper adjustment nut upward

and turn the lower adjustment nut downward so depth stop is free to move (Fig. 5).

3. Loosen the locking hand grip (Fig. 6).

Slowly lower the tool until the router bit

just touches the workpiece.

4. Tighten the locking hand grip to lock the

tool in place.

5. Press and hold the release button so

depth stop touches the router base.

1st Routing Depth

6. Turn the depth stop upwards so that

measurement X equals the first desired

routing depth (Fig. 7).

NOTE: 1 turn equals .06" (1.5 mm)

7. Turn the upper adjustment nut down

snug against the router frame.

2nd Routing Depth

8. Turn the depth stop upwards so that

measurement X equals the second

desired routing depth. Make sure upper

adjustment nut turns with the depth stop,

so it rises away from router frame (Fig. 8).

9. Turn the lower adjustment nut up snug

against the router frame.

NOTE: The upper adjustment nut must

remain stationary when tightening the lower

adjustment nut.

1

X

X

X

X

Upper

Adjustment

Nut

Lower

Adjustment

Nut

Hand

Grip

FIG. 5

FIG. 6

Release

Button

FIG. 7

Depth

Stop

Upper

Adjustment

Nut

Depth

Stop

Lower

Adjustment

Nut

Depth

Stop

FIG. 8

Page 6

6

10.Press the release button to select the 1st

or 2nd routing depth (Fig. 9).

NOTE: The adjustment of each routing

depth should be checked with a trial cut and

re-adjusted as necessary.

When routing is complete, loosen the hand

grip and return the router to the top position.

Feeding the Router

If the router is hard to control, heats up,

runs very slowly or leaves an imperfect cut,

consider these causes:

• Wrong direction of feed – hard to control.

• Feeding too fast – overloads motor.

• Dull bit – overloads motor.

• Cut too large for one pass – overloads

motor.

• Feeding too slow – leaves friction burns

on the workpiece.

Feed smoothly and steadily (do not force).

You will soon learn how the router sounds

and feels when it is working best.

Rate Of Feed

When routing or doing related work in wood

and plastics, the best finishes will result if

the depth of cut and feed rate are regulated

to keep the motor operating at high speed.

Feed the router at a moderate rate. Soft

materials require a faster feed rate than hard

materials.

The router may stall if improperly used or

overloaded. Reduce the feed rate to prevent

possible damage to the tool. Always be sure

the collet nut is tightened securely before

use. Always use router bits with the shortest

cutting length necessary to produce the

desired cut. This will minimize router bit runout and chatter.

Edge Forming

When edge forming, always use piloted or

bearing bits. The lower portion of a pilot

tipped bit is a shaft with no cutting edges.

Bearing guide bits have a ball bearing to

pilot the bit.

The pilot slides along the edge of the work

as the rotating blades make the cut, making

decorative edges. The edge on which the

pilot slides should be perfectly smooth since

any irregularities are transferred to the

shaped surface.

When routing a workpiece that requires edge

forming on the endgrain, always rout the

endgrain edge before routing the edges that

follow the grain. This minimizes the possibility of damage from any blowout at the end of

the endgrain.

Router Feed Direction

The router spindle turns in a clockwise

direction when viewed from above. For best

control and quality of cut, feed the tool into

the workpiece in the direction that the bit will

tend to pull itself into the wood. Incorrect

feed direction will cause the bit to try and

climb over the wood.

Feed the tool in direction shown here. If cutting around the edge of a square piece,

move the tool in a counterclockwise direction. If routing the inside surface as shown,

move in a clockwise direction (Fig. 10).

NOTE: Feed direction is extremely important

when using a pilot bit freehand on the edge

of a workpiece.

Release button

FIG. 9

Router Feed direction

Bit Rotation

Work

Rout

End

Grains

First

FIG. 10

Page 7

7

Assembling the Edge Guide

For edge guide use, assemble guide rods into

tool holder assembly and secure using (2)

#10-24 square nuts and (2) guide rod knobs

(Fig. 11).

Square nut will slide in slots above the guide

rods. Guide rod knobs are assembled from

the top through holes down through nuts, and

against the rods. Fasten edge guide to guide

rods using edge guide knobs, and hex head

nuts.

Locate hex head nuts underneath edge guide

and fasten with edge guide knob on top

surface of edge guide. Slide edge guide

assembly on guide rods as shown. Set edge

guide at desired distance from cutter and

tighten edge guide knobs. (See Fig. 11 )

Edge guide is used for shaping edges, cutting rabbets, dadoes, mortise, tongues,

grooves, slots, and chamfers. Remember to

feed so the cutter tends to pull the edge

guide against the wood. A consistent feed

rate gives a smooth cut.

In general, several shallow cuts should be

used when a deep groove is desired.

Maximum depth of cut will vary depending

on material used. Do not over feed to an

amount that the motor is noticeably slowed.

Square Nuts

Circle Guide

Edge Guide

Finishing Nail

Edge Guide Knob

Guide Rods

Hex Head Nuts

Guide Rod Knob

Depth Adjustment

Screw

FIG. 11

Tool Lubrication

Periodic cleaning and lubrication of guide

posts will keep plunge action smooth.

Depress and lock plunge router and evenly

apply a light lubricant (i.e. petroleum jelly,

cooking oil) to upper portion of guide posts.

Page 8

8

Installation

1. Install the edge guide to the plunge

router mounting blocks (Fig. 12).

2. Place parallel guide against work surface

with router bit in desired position.

3. Tighten thumbscrews.

Routing with Edge Guide

Slide the flattened side of the edge guide

along the work surface.

Edge Guide

Routing Arcs and Circles

1 Remove the edge guide and attach the

circle guide bracket to the guide rods

(Fig. 13).

2. Use the finishing nail provided as a compass point. Set the circle guide for the

desired radius.

3. Place the nail through the hole in the

guide and place the nail at the center of

the desired radius to be cut.

Edge

Guide

Mounting

Blocks

Edge

Guide

Finishing

Nail

FIG. 12

FIG. 13

Page 9

9

Templates

Using template patterns lets you duplicate

designs or letters uniformly time after time.

This technique requires the use of a guide

bushing.

GUIDE BUSHINGS

The guide bushing shown in (Fig. 14), is

essentially a plate with a collar which is inserted into the hole in base as shown, and

secured by threading a bushing plug on top of

the guide bushing. The guide bushing rides

along the edge of the template while the

router bit, protruding below, cuts into the

work.

ATTENTION: Be sure the thickness of the

template is the same or larger than the length

of bushing protruding below the base.

Do not use a bit that may touch the inside of

the collar. Select a bit that is at least 1/16"

less in diameter.

In addition, special templates are easily prepared for cutting repeated patterns, special

designs, inlays, and other applications. A

template pattern may be made of plywood,

hardboard, metal or even plastic, and the

design can be cut with a router, jigsaw, or

other suitable cutting tool.

Remember that the pattern will have to be

made to compensate for the distance

between the router bit and the guide bushing

(the “offset”), as the final workpiece will

differ in size from the template pattern by

that amount, due to the bit position (Fig. 15).

FREEHAND ROUTING

Many effects are gained by using the router

freehand with a small diameter bit. Usually the

craftsman pencils the outline or script he

desires onto the work and uses the pencil line

as a guide.

Collet Nut

Workpiece

Router Bit

Offset

Guide Bushing

Templete

Pattern

FIG. 15

Base

Bushing

Plug

Guide

Bushing

Base

FIG. 14

Page 10

10

Ref. Part Description

No. No.

1 2610920042 Spring (2)

2 2610920041 Guide Post. (2)

3 2610913432 Depth Marker

4 2610920044 Guide Plate Assy.

5 1603501018 Knurled Thumbscrew

6 2603345015 Adjusting Nut (2)

7 2604511008 Compression Spring

8 2602305044 Detent Pin

9 2610918203 Hand Grip

10 2610918204 Handle Cap

11 2610918206 Handle Cap

12 2916011884 Plain Washer (2)

13 2910011191 Cheese Head Screws (2)

14 2610358149 Nut (2)

Ref. Part Description

No. No.

15 2610920043 Pressure Spindle

16 2610917203 Edge Guide

17 2610920879 Base plate Assy.

18 2610917207 Mounting Wrench

19 2610917208 Guide Rod (2)

20 2615294964 Square Nut (2)

21 2610915483 Nut (2)

22 2610914826 Circle Guide

23 2610914825 Clamp Screw #6-32 (4)

24 2615294965 Nail

25 2610920984 Bushing Plug

26 2610920985 Guide Bushing 15/16"

27 2610920986 Guide Bushing 5/8"

Dremel Parts Diagram

1

2

3

4

5

9

10

11

12

12

13

13

14

15

17

19

8

7

6

6

22

23

23

23

24

20

21

16

18

26

27

25

Page 11

11

Your Dremel product is warranted against defective material or workmanship for a period of

one year from date of purchase. In the event of a failure of a product to conform to this

written warranty, please take the following action:

1. DO NOT return your product to the place of purchase.

2. Carefully package the product by itself, with no other items, and return it, freight prepaid,

along with:

A. A copy of your dated proof of purchase (please keep a copy for yourself).

B. A written statement about the nature of the problem.

C. Your name, address and phone number to:

We recommend that the package be insured against loss or in transit damage for which we

cannot be responsible.

This warranty applies only to the original registered purchaser. DAMAGE TO THE PRODUCT

RESULTING FROM TAMPERING, ACCIDENT, ABUSE, NEGLIGENCE, UNAUTHORIZED

REPAIRS OR ALTERATIONS, UNAPPROVED ATTACHMENTS OR OTHER CAUSES UNRELATED TO PROBLEMS WITH MATERIAL OR WORKMANSHIP ARE NOT COVERED BY

THIS WARRANTY.

No employee, agent, dealer or other person is authorized to give any warranties on behalf of

Dremel. If Dremel inspection shows that the problem was caused by problems with material

or workmanship within the limitations of the warranty, Dremel will repair or replace the product free of charge and return product prepaid. Repairs made necessary by normal wear or

abuse, or repair for product outside the warranty period, if they can be made, will be charged

at regular factory prices.

DREMEL MAKES NO OTHER WARRANTY OF ANY KIND WHATEVER, EXPRESSED OR

IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE WHICH EXCEED THE ABOVE MENTIONED OBLIGATION ARE

HEREBY DISCLAIMED BY DREMEL AND EXCLUDED FROM THIS LIMITED WARRANTY.

This warranty gives you specific legal rights and you may also have other rights which vary

from state to state. The obligation of the warrantor is solely to repair or replace the product.

The warrantor is not liable for any incidental or consequential damages due to any such

alleged defect. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitations or exclusion may not apply to you.

For prices and warranty fulfillment in the continental United States, contact your local Dremel

distributor .

Exportado por: Robert Bosch Tool Corporation Mt. Prospect, IL 60056 -2230, E.U.A.

Importado en México por: Robert Bosch, S.A. de C.V., Calle Robert Bosch No. 405,

Zona Industrial, Toluca, Edo. de México, C.P. 50070, Tel. (722) 2792300

Dremel Limited Warranty

UNITED STATES

Dremel Service Center

4915 Twenty-First Street

Racine, Wisconsin 53406

Dremel Service Center

4631 E. Sunny Dunes

Palm Springs, CA 92264

OUTSIDE CONTINENTAL

UNITED STATES

See your local distributor or write

to Dremel, 4915 Twenty-First

Street, Racine, Wisconsin 53406

CANADA

Clinique d’ Outillage M.P.

3075 Boul, Hamel, Suite 107

Quebec City, Quebec G1P 4C6

Giles Tool Agencies

6520 Lawrence Avenue, East

Scarborough, Ontario M1C4A7

Service d’Outlis ACM

2071 Victoria Street

St. Lambert, Quebec J4S 1H1

Westcoast Tool

Unit 2-285 East First Avenue

Vancouver, B.C. V5T 1A8

Loading...

Loading...