3296

0 603 296 0 . .

Before use - Read this instruction manual.

Lisez attentivement la présente notice avant l’emploi.

Lea estas instrucciones de manejo antes de la utilización del aparato.

BM 2609931094 6/95 12/14/98, 4:19 PM1

english 4. . . 11

french 12. . . 21

spanish 22. . . 33

BM 2609931094 6/95 12/14/98, 4:19 PM2

1

2 5

3

4

6

87 9

12

10

11 12 13 161514 191817

BM 2609931094 6/95 12/14/98, 4:19 PM3

31

31

Product Data - Planer

Model number 3296

Identification number 0 603 296 0 . .

Planing depth 0 - 3/32" (0 - 2.5mm)

Rabbeting depth 0 - 15/16" (0 - 24mm)

Cutting width 3-1/4"(82mm)

( NOTE: This tool is designed for use with alternating current (AC) only.)

Accessory Listing

Rabbeting depth guide*

Deluxe angle/width fence*

Blade wrench 8mm*

Carbide reversible blade set*

HSS reversible blade conv. kit**

HSS reversible blade set**

Rustic reversible blade conv. kit**

Rustic reversible blade set**

(* = standard equipment)

(** = CAUTION: see section "Special Cutting Applications", before installing or using

these optional blade conv. kits or optional blade sets. )

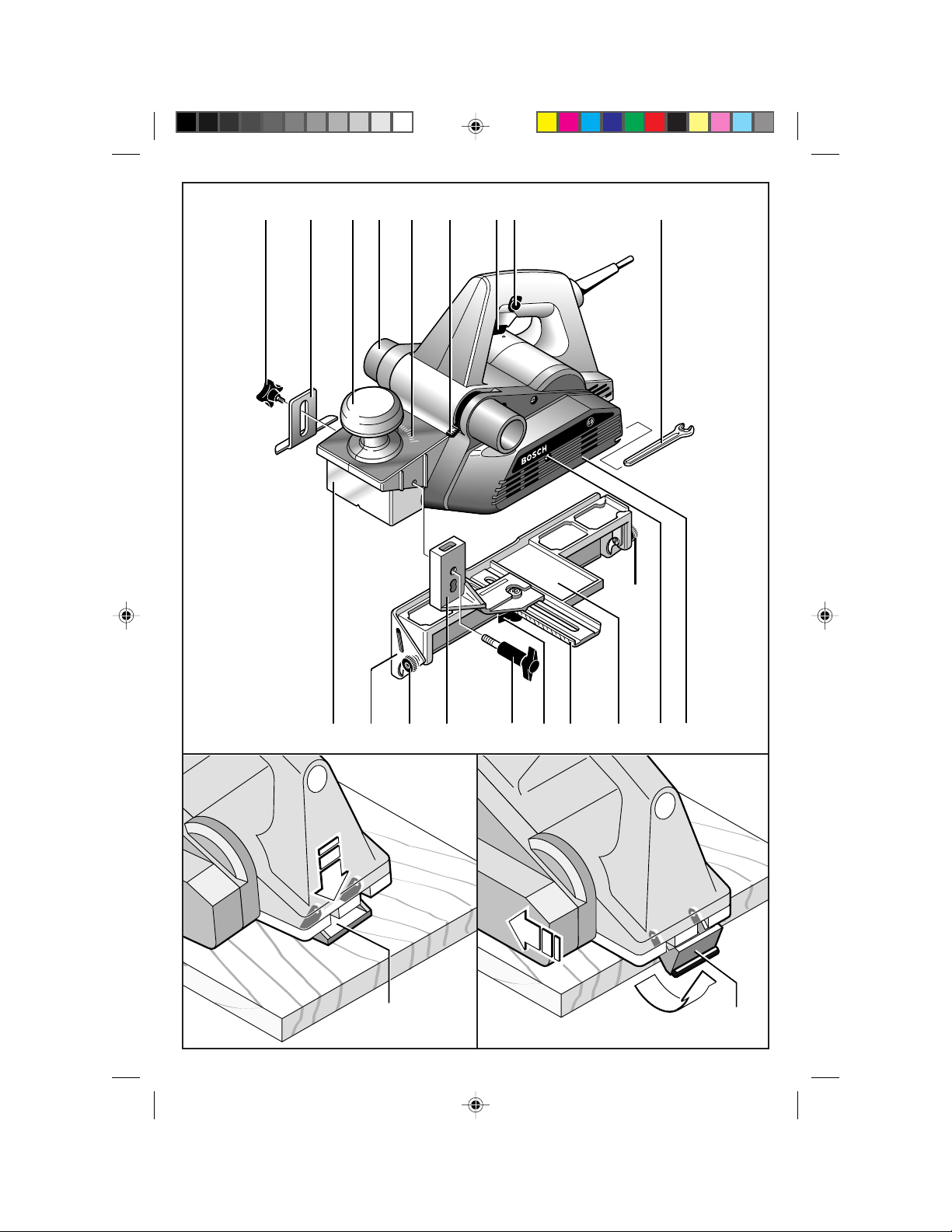

Planer Components

1. Wing knob 12. Round knobs 23. Cutter drum

2. Rabbeting depth stop 13. Guide bracket 24. Planer blades

3. Depth adjustment knob 14. Wing knob 25. Rabbet guard

4. Chip exhaust ports 15. Wing knob 26. Blade holders

5. Depth scale 16. Width scale 27. Blade leveling screws

6. Port selector lever 17. Deluxe angle/width fence 28. Driven pulley

7. Trigger switch 18. Screw 29. Drive belt

8. "Lock-OFF" button 19. Drive belt cover 30. Drive pulley

9. Blade wrench 8mm 20. Chamfer V-groove 31. Tool rest

10. Front shoe 21. Clamping screws

11. Pivot fence 22. Rear shoe

(NOTE: planer components not illustrated on page 2 are illustrated elsewhere in this manual.)

4

BM 2609931094 6/95 12/14/98, 4:19 PM4

WARNING! “READ ALL INSTRUC-

TIONS”. Failure to follow the SAFETY RULES

identified by the BULLET (•) symbols listed

BELOW and other safety precautions, may

result in serious personal injury. Keep these

operating instructions with this product.

GENERAL SAFETY RULES

for all Power Tools

Work Area

• KEEP WORK AREAS CLEAN. Cluttered

areas and benches invite accidents.

• AVOID DANGEROUS ENVIRONMENT.

Don’t use power tools in damp or wet locations.

Do not expose power tools to rain. Keep work

area well lit.

• AVOID GASEOUS AREAS. Do not operate portable electric tools in explosive atmospheres in presence of flammable liquids or

gases. Motors in these tools normally spark,

and the sparks might ignite fumes.

• KEEP CHILDREN AWAY. Do not let

visitors contact tool or extension cord. All

visitors should be kept away from work areas.

Personal Safety

• GUARD AGAINST ELECTRIC SHOCK.

Prevent body contact with grounded surfaces

such as pipes, radiators, ranges and refrigerator

enclosures. Rubber gloves and non-skid footwear are recommended when working outdoors, where damp or wet ground may be

encountered. A Ground Fault Circuit Interrupter protected power line must be used for

these conditions.

• DRESS PROPERLY. Do not wear loose

clothing or jewelry. They can be caught in

moving parts. Wear protective hair covering to

contain long hair.

• USE SAFETY EQUIPMENT. WEAR

SAFETY GOGGLES or glasses with side

shields. Wear hearing protection during extended use of power tools and dust mask for

dusty operations.

• STAY ALERT. USE COMMON SENSE.

Watch what you are doing. Do not operate tool

when you are tired or under influence of drugs.

•

REMOVE ADJUSTING KEYS AND

WRENCHES.

keys and adjusting wrenches are removed from

tool before turning it on.

• AVOID ACCIDENTAL STARTING. Don’t

Form habit of checking to see that

carry plugged in tool with finger on switch. Be

sure the switch is OFF before being plugged in.

• DON’T OVERREACH. Keep proper footing and balance at all times.

• BEFORE CONNECTING THE TOOL to a

power supply (receptacle, outlet, etc.) be sure

the voltage supplied is the same as that specified on the tool’s nameplate. A power supply

with voltage greater than that specified for the

tool can result in serious injury to the user - as

well as damage to the tool. If in doubt, DO NOT

PLUG IN THE TOOL. Using a power supply

with voltage less than the nameplate rating is

harmful to the motor.

“Volts AC” designated tools are for Alternating

Current 50-60 Hz only. “Volts DC” designated

tools are for Direct Current. Do not use AC

designated tools with DC power supply. Do not

use electronic speed controlled tools with DC

power supply.

Tool Use and Care

• DON’T FORCE TOOL. It will do the job

better and safer at the rate for which it was

designed.

• USE RIGHT TOOL. Don’t force small tool

or attachment to do the job of a heavy-duty tool.

Don’t use tool for purpose not intended - for

example; don’t use a circular saw for cutting

tree limbs or logs.

• SECURE WORK. Use clamps or a vise to

hold work. It’s safer than using your hand and

it frees both hands to operate the tool.

• DON’T ABUSE CORD. Never carry tool by

cord or yank it to disconnect from receptacle.

Keep cord from heat, oil, and sharp edges.

Always keep cord away from the spinning

blade, bits or any other moving part while the

tool is in use.

• OUTDOOR USE EXTENSION CORDS.

When tool is used outdoors, use only extension

cords suitable for use outdoors and marked with

suffix W-A (for UL), or W (for CSA). Refer to

section “Extension Cords”, for proper cord use.

• DISCONNECT TOOLS. When not in use,

before servicing, or when changing blades,

bits, cutters, etc.

• STORE IDLE TOOLS. When not in use,

tools should be stored in dry, high or locked up

place - out of the reach of children.

• DO NOT ALTER OR MISUSE TOOL.

These tools are precision built. Any alterations

or modifications not specified is misuse and

BM 2609931094 6/95 12/14/98, 4:19 PM5

5

may result in a dangerous condition.

• THE USE OF ANY ACCESSORIES not

specified in this manual may create a hazard.

• MAINTAIN TOOLS WITH CARE. Keep

tools sharp and clean for better and safer performance. Follow instructions for lubricating and

changing accessories. Inspect tool cords periodically and if damaged, have repaired by authorized service facility. Inspect extension

cords periodically and replace if damaged. Keep

handles dry, clean and free from oil and grease.

• CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part that is

damaged should be carefully checked to determine that it will operate properly and perform

its intended function. Check for alignment of

moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect its operation. A guard or

other part that is damaged should be promptly

and properly repaired or replaced. Have defective switches replaced. Do not use tool if switch

does not turn it on or off.

• ALL REPAIRS, ELECTRICAL OR MECHANICAL, should be attempted only by

trained repairmen. Contact the nearest Bosch

Factory Service Center, or Bosch Authorized

Service Center or other competent repair center. Use only Bosch replacement parts, any

other may create a hazard.

Safety Rules for Planers

• Always start the plane before contacting the

workpiece and never pull the plane backwards

on the workpiece.

• Unplug the power cord before making adjustments or changing/reversing blade sets.

• Make sure the spring operated automatic

retracting rabbet guard returns to blade covering position instantly.

• Do not put fingers or any objects into the chip

ejector or clean out chips while tool is running.

Remove plug from power source if it becomes

necessary to remove chips.

• Before planing, check the workpiece for nails.

If there are nails, either remove or set them well

below intended finished surface.

• Small workpiece must be adequately secured

so that the rotating planer knives will not pick it

up during forward motion of the planer.

• After changing blades, rotate the cutter drum

to make sure blades are not hitting any part of

the blade head housing and the blade locking

screws are tight.

• Wear protective gloves and safety goggles.

• Always hold the tool firmly with both hands.

• Never place the plane down until the blade is

completely at rest.

Double Insulated Tools

• Double Insulation is a design concept

used in electric power tools which eliminates

the need for the three wire grounded power cord

and grounded power supply system. It is a

recognized and approved system by

Underwriter’s Laboratories, CSA and Federal

OSHA authorities.

IMPORTANT: Servicing of a tool with

double insulation requires care and knowledge

of the system and should be performed only by

a qualified service technician. WHEN SERVICE IS REQUIRED USE ONLY IDENTICAL REPLACEMENT PARTS.

POLARIZED PLUGS: If your tool is equipped

with a polarized plug (one blade is wider than

the other), this plug will fit in a polarized outlet

only one way. If the plug does not fit fully in the

outlet, reverse the plug. If it still does not fit,

contact a qualified electrician to install the

proper outlet. To reduce the risk of electric

shock do not change the plug in any way.

Extension Cords

• Replace damaged cords immediately. Use of

damaged cords can shock, burn or electrocute.

• If an extension cord is necessary, a cord with

adequate size conductors should be used to

prevent excessive voltage drop, loss of power

or overheating. The table below shows the

correct size to use, depending on cord length

and amperage rating on the tool’s nameplate. If

in doubt, use the next heavier gauge. Always

use U.L. and CSA listed extension cords.

6

BM 2609931094 6/95 12/14/98, 4:19 PM6

Ampere Rating (shown on nameplate)

0- 2.1- 3.5- 5.1- 7.1- 12.1-

2.0 3.4 5.0 7.0 12.0 16.0

25' 18 18 18 18 16 14

50' 18 18 16 16 14 12

75' 18 18 16 14 12 10

100' 18 16 14 12 10

Cord Length

150' 16 14 12 12 Wire Gauge

Note: The smaller the gauge number, the larger

the wire is in the cord.

"SAVE THESE INSTRUCTIONS"

overreach your work surface, or use the planer

in an uncomfortable position. This will extend

the life of your tool, and decrease the risk of

accidents. Remember, safety and good results

depend on sharp, properly adjusted cutting

blades. Keep your planer blades clean and

sharp, and replace or reverse dull blades when

your planer no longer performs smooth, fast

cuts.

Planer Blades

CAUTION! The planer blades are sharp and

fragile and must be handled carefully to avoid

injury to the user or damage to the blades .

Operating the Tool

Trigger "ON/OFF" Switch

WARNING! Hold the tool with both hands

while starting the tool, since torque from the

motor can cause the tool to twist.

To turn tool "ON", depress the "Lock-OFF"

button and squeeze the trigger switch 7. To turn

the tool "OFF", release the trigger switch which

is spring loaded and will return to "OFF" position automatically.

To increase switch life, do not turn switch on

and off while tool is under the load.

Planing Action

Check that the workpiece is held in place securely on your work surface, and standing

comfortably, hold the planer firmly with both

hands. With the planer fully adjusted, place the

front shoe 10 on the workpiece, (be certain that

the cutter drum 23 is not in contact with the

work) and start the planer as described earlier.

With pressure on the front shoe 10, and the

fence against the side of the work (to control the

width or angle,) feed the planer steadily until

the rear shoe 22 fully engages the workpiece.

Now gradually transfer pressure to the rear

shoe, and continue planing to the end of the cut.

Feed the planer at a uniform and reasonable

rate, which does not put excessive strain on the

motor or blades, (do not pull the planer back

over the surface already cut.) Use progressive

cuts until you are near the desired depth, and

then readjust to a light cut for the final pass to

obtain a good surface finish.

Use a smooth, even planing action, and do not

The standard planer blades 24 have two cutting

edges, and may be reversed when one of the

cutting edges becomes dull or chipped. When

reversing or replacing blades, it is generally not

necessary to readjust the blade holders 26. If it

becomes necessary to adjust blade holder, take

planer to a Bosch Factory Service Center. To

avoid imbalance of the cutter drum 23, which

could result in vibration, premature tool wear

and poor work quality, always reverse or

replace blades as a set. Do not attempt to

sharpen used blades.

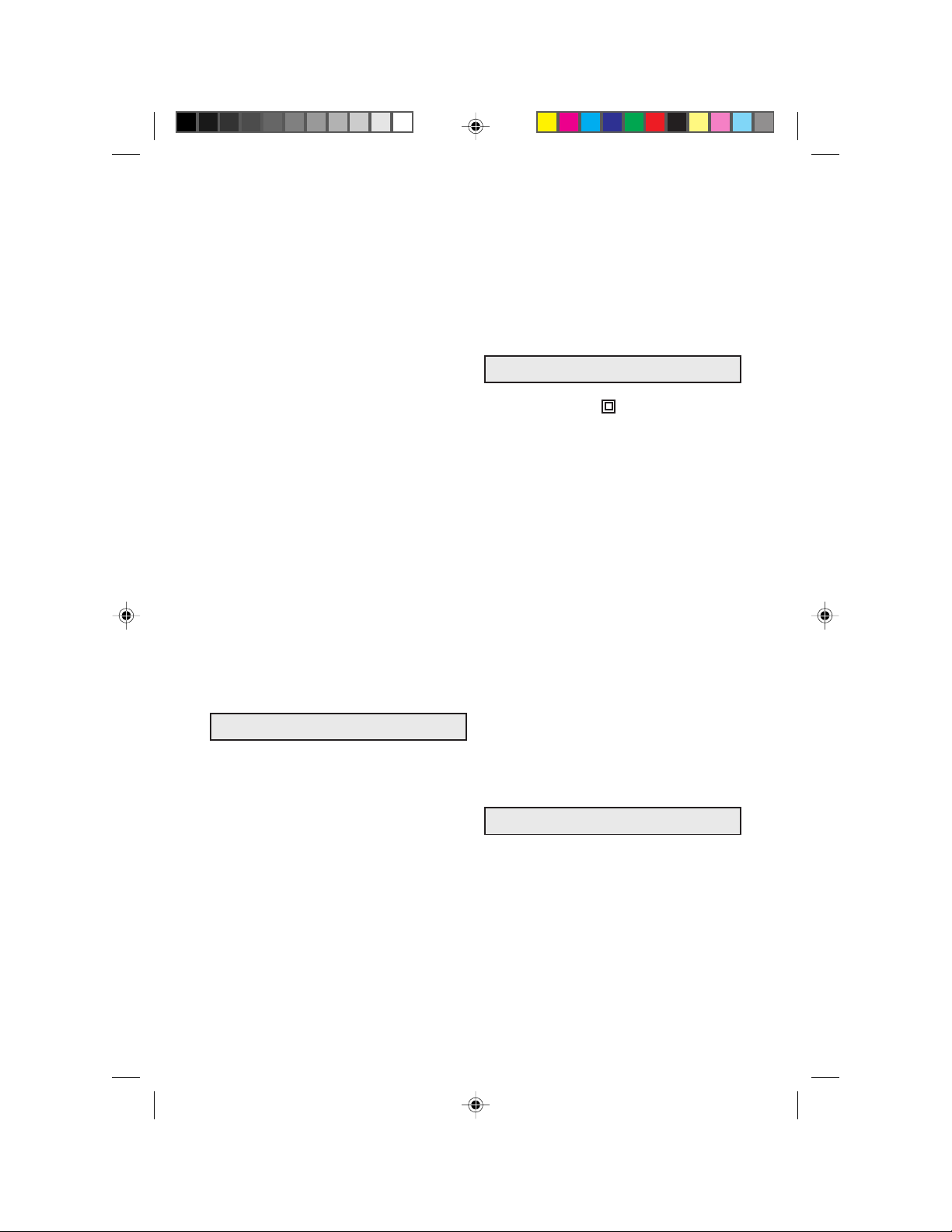

Reversing or Replacing Blades

To reverse or replace the blades loosen the

clamping screws 21 with blade wrench 9. With

the screws

loosened,

20

21

9

25

press the rabbet guard 25

down and slide

the blade

holder 26 and

blades 24

lengthwise out

of the cutter

drum 23, tak-

ing care to

keep your fin-

10

23

2624

gers away

from the sharp

edges of the

blade. Next,

slide the blade

out of the blade

holder. A

piece of wood

may be used

7

22

BM 2609931094 6/95 12/14/98, 4:20 PM7

for this purpose. If the

26 24

blade is

gummed and

difficult to remove, you

may clean the

blade with

mineral spirits, lacquer

thinner or alcohol. Clean all seating surfaces before reinstalling the new blades, as this will ensure an

accurate blade setting and proper tool performance.

Blade Adjustment

Reassembly of the blades and blade holders is

essentially the reverse of the disassembly procedure, but the following points should be

noted. When reinstalling the blades and blade

holders, it is important that the blade holders

rest firmly against the side stop of the cutter

drum 23 (position 1), before it is secured into

place. To ensure an even cut, it is important that

the blades are adjusted so that they align with

the outside edge of the front and rear shoes.

This alignment can be done as follows: place a

straight edge or a piece of wood along the

outside surface of the front shoe 10 and rear

shoe 22, then slide the planer blade 24 to just

contact the straight edge or wood (position 2).

Note that this adjustment must be done by

sliding the blade in its blade holder, and that the

blade holder

10

23

22

must remain

in contact with

the cutter

drum side

1

2

stop. You

may then

tighten the

clamping

screws 21

which secure

the blade holders evenly and alternately for

both blades, and your planer is ready for use.

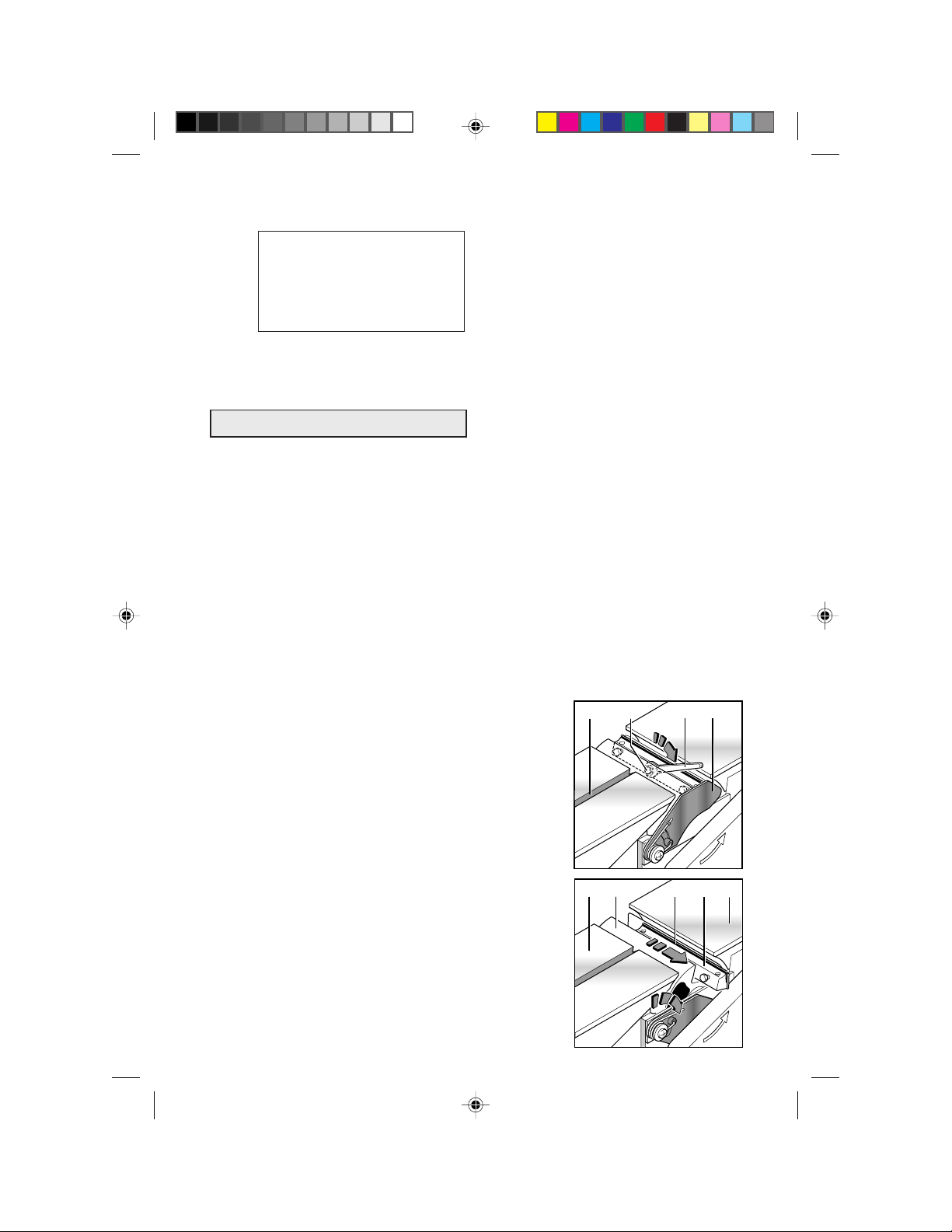

Blade Leveling

The blade leveling screws 27 are factory set

with a fastening compound, and do not require

readjustment or removal under normal circum-

stances. If adjustment is required, it may be

done as follows. First set the front shoe 10 to

the zero "0" position. Next place a straight edge

over the front shoe 10 and rear shoe 22 and

check the height of both ends of the blades.

Both ends of the blades should just contact the

straight edge. If the blade edge is not perfectly

parallel with the shoes, you may raise or lower

the blade holder 26. With the clamping screws

21 loosened raise or lower the blade leveling

screws 27,

which will al-

10 27 2226

21

low you to adjust the blade

holder 26 up or

down until the

blade is parallel to the front

and rear shoes.

When this adjustment is

complete, the clamping screws 21 must be

tightened firmly. Be certain that there is no

foreign material between the blades 24, the

blade holders 26 or the cutter drum 23.

These adjustments are critical, and are best

performed by a Bosch Factory Service or Bosch

Authorized Service Center if required, as the

blade leveling screws 27 must again be fastened with the proper chemical fastening compound.

Special Cutting Applications

The planer comes with two carbide reversible

blades. Optional blade sets**, which are listed

on page 3 of this instruction manual, may be

purchased for different applications.

CAUTION! When changing to an optional

blade set you must first purchase and install the

correct blade conversion kit, as listed. The

conversion kits include a different set of blade

holders and one set of optional blades. Once

the conversion kit is installed you may order

replacement blade sets separately. Each time

you change from one style blade set to the next,

you must always change the blade holders also.

The various blade holders and blade sets are not

interchangeable with each other.

8

BM 2609931094 6/95 12/14/98, 4:20 PM8

CAUTION! The motor may stall if improp-

45°

erly used or overloaded. Reduce the pressure

(feed rate) or depth of cut to prevent possible

damage to the tool if the motor labors.

knob 15. Be certain that the flat washer (supplied) is fitted between the bottom of the guide

fence and wing knob 15 or the guide fence is

likely to slip.

Tool Rest

The tool rest 31 swings down to help keep the

blade from coming in contact with the work

surface when plane is not in use.

Adjusting Depth of Cut

Proper cutting depth should be determined according to the hardness, gumminess or moisture content of the material being cut, as well as

the feed rate, and is largely a matter of experience. Start with a light cut and increase the

depth setting if the plane moves freely through

the workpiece with no excessive load on the

motor. Do not change depth of cut while

planing.

The cutting depth is determined by the difference in height between the adjustable front

shoe 10, and the fixed rear shoe 22 of the planer.

As the front shoe is adjusted, it retracts and

exposes the blades 24, which can then remove

the desired amount from the workpiece. The

cutting depth is graduated

from 0 to 2.5mm, and the "0"

indicates the blades are fully

retracted. The planer should

never be set down until the

blades have come to a complete stop.

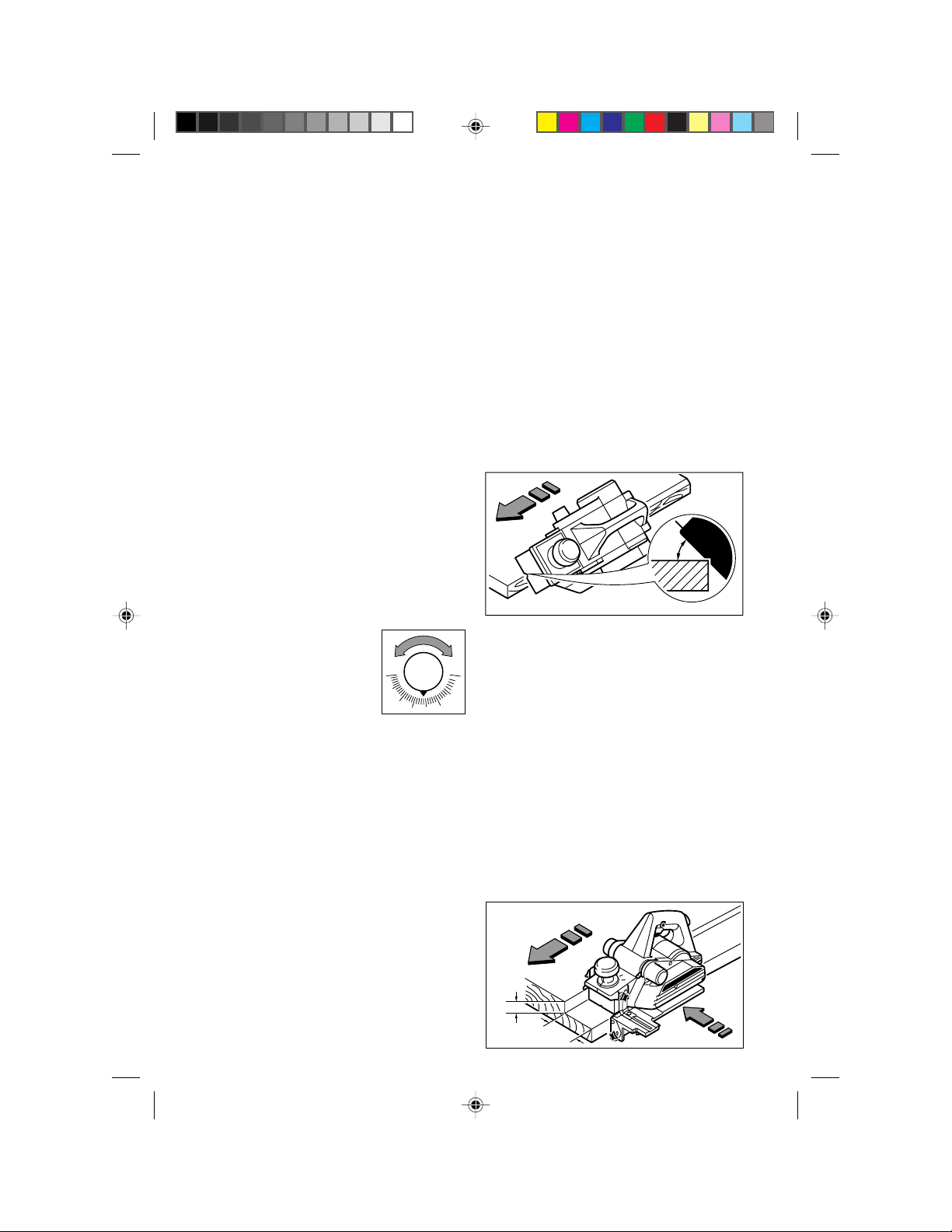

Adjusting depth of cut: Rotate depth adjustment knob 3 until the indicator engages the

detent which indicates the desired cutting depth

on the depth scale 5. Each graduation mark is

equal to .1mm (.004"). The planer may be set

to cut any depth from 0 - 2.5mm (0 - 3/32").

Width Guide Fence

The width guide fence (not illustrated) can be

used to cut various desired widths.

Installing the guide fence: Place the wing knob

14 through the hole in the guide bracket 13 and

screw into the housing. Securely tighten wing

knob 14.

Setting the cutting width: Loosen wing knob 15

and slide the fence along the guide bracket 13 to

the desired position. Securely tighten wing

Deluxe Angle/Width Fence

The optional deluxe angle/width fence 17 can

be used to cut various desired widths, with the

additional capability of guiding the planer on

any angle up to 45 degrees, to allow edge

chamfering.

Installing the angle/width fence: Place the

wing knob 14 through the hole in the guide

bracket 13 and screw into the housing. Securely tighten wing knob 14.

Setting the cutting width: Loosen wing knob

15 and using the width scale 16, slide the fence

17 along the guide bracket 13 to the desired

position. Securely tighten wing knob 15.

Setting the cutting angle: Loosen round knobs

12 and pivot the fence 11 to the desired posi-

tion. Securely tighten round knobs 12.

Note that the adjustable front shoe 10 contains

a chamfer V-groove 20, which will follow the

corner of a workpiece to allow easier handling

when using the deluxe angle/width fence.

Rabbeting Depth Guide

The rabbeting depth guide 2 allows the user to

set any rabbeting depth from 0 to 15/16 inch (0

to 24mm). For best results, it is important that

the blades be properly aligned (See "blade

24mm

max

82mm

max

9

BM 2609931094 6/95 12/14/98, 4:20 PM9

adjustment"). The width of the rabbet is controlled by the width fence. The maximum

cutting width is 3-1/4" (82mm), and the final

depth is achieved by repetitive cutting until the

rabbeting depth guide contacts the workpiece.

Setting the rabbet depth: Loosen wing knob 1

and using the depth scale on the rabbeting depth

guide 2, set the desired rabbet depth. Securely

tighten wing knob 1.

Chip Extraction

The planer comes with a chip exhaust port 4,

which may be used with a chip bag or a shop

vacuum and vacuum connector to keep your

work environment cleaner.

The chip bag or

hose may be attached to either

end of the exhaust port.

Moving the port

selector lever 6

to position 1

(towards front of tool) discharges chips to the

right, while position 2 (towards rear of tool)

discharges chips to the left.

6

1

2

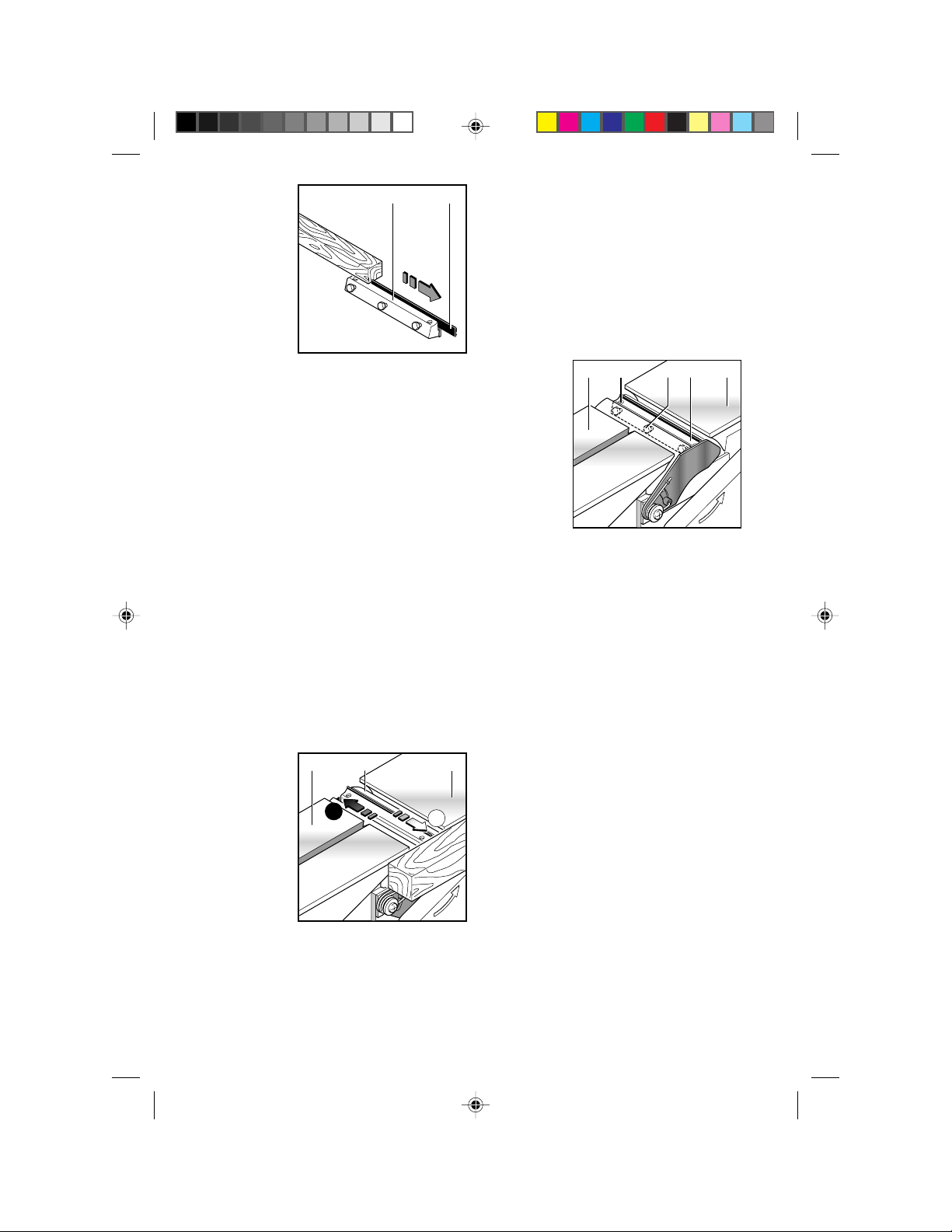

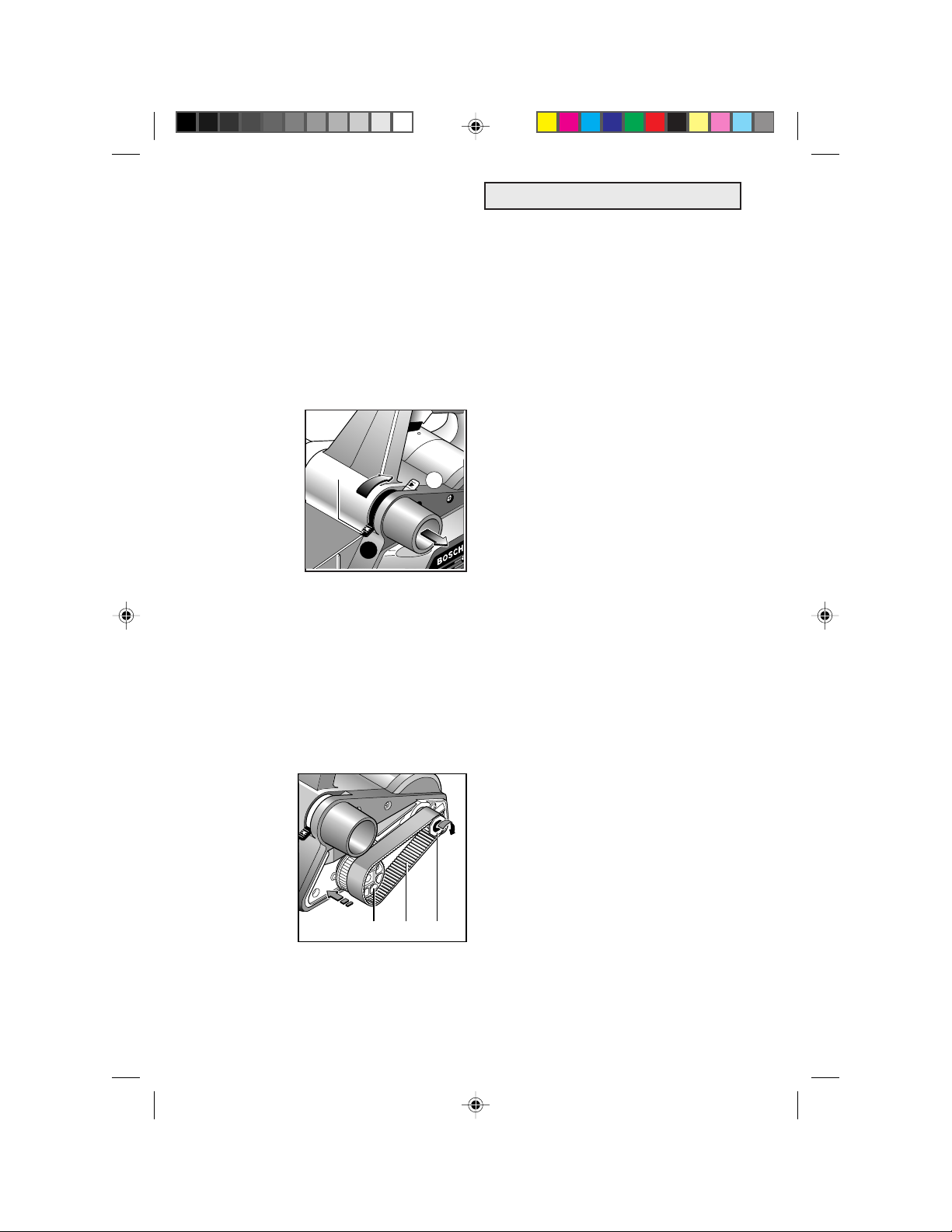

Drive Belt

The drive belt 29 is a normal maintenance part

and should be inspected periodically for wear.

If the drive belt shows signs of drying out,

cracking or tearing, it should be replaced. If the

drive belt will not track properly or comes off

the pulleys it should be replaced.

Installing new

drive belt:

Loosen screw

18 and remove

the drive belt

cover 19. Cut

and remove

the worn drive

belt 29. Before installing

the new drive

belt, clean both pulleys thoroughly. First place

the new drive belt onto the drive pulley 30 then

rotate clockwise while pushing the belt onto the

driven pulley 28. Reinstall the drive belt cover

and securely tighten screw 18.

28

29

30

Maintenance and Service

WARNING! Preventive maintenance per-

formed by unauthorized personnel may result

in misplacing of internal wires and components

which could cause serious hazard. We recommend that all tool service be performed at a

Bosch Factory Service Center.

Tool Lubrication

Your Bosch tool has been properly lubricated

and is ready for use. We recommend, that tools

with gears be regreased with a special gear

lubricant every time the brushes are changed.

Carbon Brushes

The brushes and commutator in your Bosch

tool have been engineered for many hours of

dependable service. To maintain peak efficiency of the motor, we recommend that every

two to six months the brushes be examined.

Only genuine Bosch replacement brushes specially designed for your tool should be used.

Bearings

After about 300-400 hours of operation, or at

every second brush change, the bearings should

be replaced at a Bosch Factory Service Center.

Bearings which become noisy (due to heavy

load or very abrasive material cutting) should

be replaced at once to avoid overheating and

motor failure.

Cleaning

WARNING! To avoid accidents, always

disconnect the tool from the power supply

before cleaning or performing any maintenance.

The tool may be cleaned most effectively with

compressed air. Always wear safety goggles

when cleaning tools with compressed air.

Ventilation openings and switch levers must be

kept clean and free of foreign matter. Do not

attempt to clean by inserting pointed objects

through openings.

CAUTION! Certain cleaning agents and

solvents damage plastic parts. Some of these

are: gasoline, carbon tetrachloride, chlorinated

cleaning solvents, ammonia and household

detergents that contain ammonia.

BM 2609931094 6/95 12/14/98, 4:20 PM10

10

WARRANTY

BOSCH

S-B POWER TOOL COMPANY

LIMITED WARRANTY

S-B Power Tool Company (“Seller”) warrants,

to the original purchaser only, that all BOSCH

portable power tools will be free from defects in

material or workmanship for a period of one (l)

year from date of purchase. SELLER’S SOLE

OBLIGATION AND YOUR EXCLUSIVE

REMEDY under this Limited Warranty and, to

the extent permitted by law, any warranty or

condition implied by law, shall be the repair or

replacement of parts, without charge, which are

defective in material or workmanship and which

have not been misused, carelessly handled, or

misrepaired by persons other than Seller or

Authorized Service Stations. To make a claim

under this Limited Warranty, you must return

the complete portable power tool product, transportation prepaid, to any BOSCH Factory Service Center or Authorized Service Station. A

listing of U.S. BOSCH Factory Service Centers

is packed with each BOSCH Power Tool. For

BOSCH Power Tool Authorized Service Stations, please refer to your phone directory.

THIS LIMITED WARRANTY DOES NOT

APPLY TO ACCESSORY ITEMS SUCH AS

CIRCULAR SAW BLADES, DRILL BITS,

ROUTER BITS, JIGSAW BLADES, SANDING BELTS, GRINDING WHEELS AND

OTHER RELATED ITEMS. ANY IMPLIED

WARRANTIES SHALL BE LIMITED IN

DURATION TO ONE (1) YEAR FROM DATE

OF PURCHASE. SOME STATES IN THE

U.S. DO NOT ALLOW LIMITATIONS ON

HOW LONG AN IMPLIED WARRANTY

LASTS, SO THE ABOVE LIMITATION MAY

NOT APPLY TO YOU. IN NO EVENT

SHALL SELLER BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES (INCLUDING BUT NOT LIMITED

TO LIABILITY FOR LOSS OF PROFITS)

ARISING FROM THE SALE OR USE OF

THIS PRODUCT. SOME STATES IN THE

U.S. DO NOT ALLOW THE EXCLUSION

OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE

ABOVE LIMITATION OR EXCLUSION

MAY NOT APPLY TO YOU. THIS LIMITED WARRANTY GIVES YOU SPECIFIC

LEGAL RIGHTS, AND YOU MAY ALSO

HAVE OTHER RIGHTS WHICH VARY

FROM STATE TO STATE.

BM 2609931094 6/95 12/14/98, 4:20 PM11

S-B Power Tool Company

4300 W. Peterson A venue

Chicago, IL 60646-5999

11

Fiche technique - Raboteuse

Numéro de modèle 3296

Numéro d’identification 0 603 296 0 . .

Profondeur de rabotage 0 - 2,5 mm (0 - 3/32")

Profondeur de rainurage 0 - 24 mm (0 - 15/16")

Largeur de coupe 82 mm (3-1/4")

(REMARQUE : cet outil ne fonctionne qu’au courant alternatif (c.a.).

Accessoires

Guide de profondeur de feuillure*

Guide d’angle/largeur de luxe*

Clé 8 mm pour lame*

Jeu de lames au carbure réversibles*

Kit de conv. de lames HSS réversibles**

Jeu de lames réversibles HSS**

Kit de conv. de lames réversibles rustique**

Jeu de lames réversibles rustique**

(*équipement standard)

(**ATTENTION: voir la rubrique «Cas spéciaux» avant de poser ou d’utiliser les kits

de conv. de lames facultatifs ou jeux de lames facultatifs).

Composants de la raboteuse

1. Bouton à oreilles 12. Boutons ronds 23. Cylindre de coupe

2. Butée de profondeur de feuillure 13. Bride de guide 24. Lames de raboteuse

3. Réglage de la profondeur 14. Bouton à oreilles 25. Protecteur

4. Éjecteurs des copeaux 15. Bouton à oreilles 26. Porte-lames

5. Guide de profondeur 16. Guide de largeur 27. Vis de nivellement de

6. Sélecteur d’éjection 17. Guide d’angle/largeur de luxe 28. Poulie attaquée

7. Gâchette de commande 18. Vis 29. Courroie

8. Bouton de verrouillage 19. Couvercle de courroie lame d’entraînement

9. Clé 8 mm d’entraînement 20. Rainure en V 30. Poulie

10. Semelle avant 21. Vis de fixation d’entraînement

11. Guide de pivotement 22. Semelle arrière 31. Protecteur de lame

(REMARQUE: les composants de la raboteuse qui ne sont pas illustrés à la page 2 le sont ailleurs

dans le présent manuel).

12

BM 2609931094 6/95 12/14/98, 4:20 PM12

AVERTISSEMENT ! «LISEZ

ATTENTIVEMENT TOUTES LES INSTRUCTIONS». Faute d’observer les

RÈGLES DE SÉCURITÉ précédées d’un point

noir (°) et les autres consignes du présent manuel

risque de vous exposer à de graves blessures.

Conservez ces instructions à portée de la main.

RÈGLES GÉNÉRALES DE

SÉCURITÉ

pour tous les outils motorisés

Lieu de travail

• TRAVAILLEZ DANS LA PROPRETÉ. Les

endroits et les établis encombrés invitent les

accidents.

• ÉVITEZ LES ENVIRONNEMENTS

DANGEREUX. N’utilisez pas les outils

électriques en lieux humides ou mouillés.

N’exposez pas les outils motorisés à la pluie.

Assurez-vous que l’endroit est adéquatement

éclairé.

• ÉVITEZ LES ENVIRONNEMENTS

GAZEUX. N’utilisez pas les outils électriques

portatifs en atmosphères explosives en présence

de liquides ou de gaz inflammables. Les moteurs

de ces outils émettent normalement des

étincelles qui risquent d’enflammer les vapeurs.

• GARE AUX ENFANTS. Ne permettez pas

aux visiteurs de toucher l’outil ou la rallonge.

Tenez-les à distance raisonnable du lieu de

travail.

Sécurité personnelle

• GARE AUX DÉCHARGES

ÉLECTRIQUES. Évitez tout contact avec les

surfaces mises à la terre telles que tuyaux,

radiateurs, cuisinières et enceintes de

réfrigérateurs. Pour le travail à l’extérieur, par

temps humide ou sur sol mouillé, il est

recommandé de porter des gants en caoutchouc

et des chaussures à semelle antidérapante. Dans

ce cas, vous devez utiliser une prise de courant

protégée par disjoncteur de fuite à la terre.

• PORTEZ DES VÊTEMENTS

CONVENABLES. Ne portez pas de vêtements

amples ni de bijoux car ils risquent de

s’accrocher dans les pièces mobiles. De même,

pour les cheveux longs, nous conseillons le port

d’un serre-tête.

• UTILISEZ L’ÉQUIPEMENT DE

SÉCURITÉ. Portez des lunettes de sécurité ou

lunettes à coques latérales. Portez des protègeoreilles lors des travaux de longue durée et un

masque protecteur si la situation l’exige.

• SOYEZ VIGILANT, FAITES PREUVE DE

DISCERNEMENT. Agissez prudemment.

N’utilisez pas l’outil quand vous êtes fatigué ou

sous l’influence de stupéfiant.

• ENLEVEZ LES CLÉS DE RÉGLAGE ET

AUTRES. Prenez l’habitude de voir à ce qu’elles

soient mises de côté avant de mettre l’outil en

marche.

• ÉVITEZ LA MISE EN MARCHE

ACCIDENTELLE. Ne transportez pas un outil

en marche. Assurez-vous que l’interrupteur est

en position d’arrêt avant de le brancher.

• TRAVAILLEZ AVEC APLOMB. Tenezvous bien d’aplomb et en équilibre en tout

temps.

• AVANT DE BRANCHER L’OUTIL à une

prise de courant, rassurez-vous que la tension

correspond à celle spécifiée sur la plaquette

emblématique de l’outil. Une tension supérieure

à celle recommandée pour l’outil risque de

blesser sérieusement l’utilisateur sans

mentionner l’endommagement de l’outil. NE

BRANCHEZ PAS L’OUTIL à moins que vous

soyez absolument satisfait. Le raccordement à

une source de courant dont la tension est

inférieure à celle indiquée sur la plaquette

endommagera le moteur.

Les outils portant la désignation «AC» ne

s’alimentent que de courant alternatif de 50-60

Hz. Les outils portant la désignation «DC»

s’alimentent de courant continu. N’enfichez

pas d’outils CA à une source d’alimentation c.c.

Ne branchez pas les outils àrégulateur

électronique de vitesse à une source

d’alimentation c.c.

Utilisation et entretien

• N’ABUSEZ PAS DE L’OUTIL. Il est plus

efficace et sûr au régime pour lequel il a été

destiné.

• UTILISEZ L’OUTIL APPROPRIÉ. Ne

forcez pas un petit outil ou un accessoire

àeffectuer le travail d’un de plus grosse taille.

N’utilisez pas l’outil à tort et à travers - par

exemple - n’utilisez pas une scie circulaire pour

tailler les branches d’arbres ou les bûches.

BM 2609931094 6/95 12/14/98, 4:20 PM13

13

• FIXEZ LE MATÉRIAU EN PLACE.

Utilisez des serre-joints ou un étau. C’est

beaucoup plus sûr et vous pouvez manier l’outil

des deux mains.

• N’ABUSEZ PAS DU CORDON. Ne

transportez jamais l’outil par le cordon et ne

tirez jamais sur ce dernier pour le débrancher.

Protégez le cordon de la chaleur, de l’huile et

des bords tranchants. Gardez toujours le cordon à bonne distance de la lame, des accessoires

ou autres pièces mobiles de l’outil en marche.

• CORDONS DE RALLONGE POUR

EXTÉRIEUR. Quand vous utilisez l’outil à

l’extérieur, n’employez que des rallonges

destinées à tel usage et portant les suffixes

d’homologation, soit W-A (pour les UL) soit W

(pour l’ACNOR). Voir le tableau «Dimensions

des rallonges recommandées».

• DÉBRANCHEZ LES OUTILS. Quand ils

ne servent pas; avant l’entretien; avant de

changer les lames, les mèches, les couteaux,

etc.

• RANGEZ LES OUTILS NE SERVANT

PAS. Suivant leur usage, les outils devraient

être rangés dans un endroit sec, élevé ou sous

clé - hors de la portée des enfants.

• NE MODIFIEZ NI ABUSEZ DE L’OUTIL.

Ces outils sont extrêmement précis. Tout

changement ou modification non recommandé

constitue un mésusage risquant d’avoir de graves

répercussions.

• L’USAGE D’ACCESSOIRES AUTRES que

ceux recommandés dans le présent manuel peut

être dangereux.

• TRAITEZ LES OUTILS AVEC SOIN.

Maintenez-les bien propres et bien à point pour

qu’ils fonctionnent en douceur. Observez les

directives concernant le graissage et le

changement des accessoires. Examinez

périodiquement l’état des cordons de l’outil et,

au besoin, confiez-en la réparation à un poste

d’entretien agréé. Examinez périodiquement

l’état des cordons de rallonge et remplacez-les

au besoin. Maintenez les poignées sèches,

propres, sans souillure d’huile et de graisse.

• RECHERCHEZ LES PIÈCES

ENDOMMAGÉES. Avant d’utiliser l’outil,

examinez soigneusement l’état des pièces telles

que le protecteur pour vous assurer qu’elles

fonctionnent correctement. Vérifiez

l’alignement et la liberté de fonctionnement des

pièces mobiles, l’état et le montage des pièces

et toutes autres conditions susceptibles d’affecter

défavorablement le fonctionnement. Il faut

réparer ou remplacer toute pièce ou tout

protecteur dont l’état laisse à désirer. Faites

remplacer tout interrupteur défectueux.

N’utilisez pas un outil dont l’interrupteur ne

fonctionne pas correctement.

• TOUTES LES RÉPARATIONS,

ÉLECTRIQUES OU MÉCANIQUES,

devraient être exécutées par des techniciens

compétents. Confiez-les au centre de serviceusine le plus proche, à un autre centre de service

après-vente Bosch agréé ou, encore, à un poste

d’entretien renommé. Pour vous éviter des

ennuis, exigez toujours les pièces de rechange

Bosch.

Règles de sécurité concernant

la raboteuse

• Prenez soin de toujours mettre l’outil en

marche avant de le poser sur la pièce. De même,

ne le ramenez jamais de l’arrière contre la

pièce.

• Débranchez l’outil de la prise de courant

avant de changer ou d’inverser les lames ou

d’effectuer des réglages.

• Assurez-vous que le capot à ressort retourne

couvrir la lame instantanément.

• N’approchez pas les doigts ni autre objet que

ce soit de l’éjecteur de copeaux ou n’enlevez

pas les copeaux pendant que l’outil est en

marche. Retirez la fiche de la prise de courant

si vous devez enlever les copeaux.

• Avant de raboter, recherchez la présence de

clous dans la pièce. Enlevez les clous ou

enfouissez-les bien au-dessous de la surface

que vous espérez finalement atteindre.

• Il importe de bien assujettir les petites pièces

de sorte que les couteaux de la raboteuse ne

puissent pas les soulever à son passage.

• Suivant le changement des lames, tournez le

cylindre pour vous rassurer qu’elles ne touchent

pas le capot et que leurs vis sont bien serrées.

• Portez des gants et des lunettes de sécurité.

• Tenez toujours fermement l’outil à deux

mains.

• Ne mettez jamais le rabot de côté tant que la

lame ne soit complètement au repos.

14

BM 2609931094 6/95 12/14/98, 4:20 PM14

Outils à double isolation

• La double isolation est utilisée dans les

outils électriques pour éliminer le besoin de

cordon d’alimentation trois fils, dont la prise de

terre, et de dispositif d’alimentation à prise de

terre. Elle est homologuée par l’Underwriter’s

Laboratories, l’ACNOR et l’OSHA.

IMPORTANT : L’entretien d’un outil à

double isolation exige la connaissance du

système et la compétence d’un technicien

qualifié. EN CAS D’ENTRETIEN,

N’UTILISEZ QUE DES PIÈCES DE

RECHANGE IDENTIQUES.

FICHES POLARISÉES. Si votre outil est

équipé d’une fiche polarisée (une lame plus

large que l’autre) elle ne s’enfiche que d’une

manière dans une prise polarisée. Si la fiche

n’entre pas à fond dans la prise, tournez-la d’un

demi-tour. Si elle refuse encore d’entrer,

demandez à un électricien qualifié d’installer

une prise appropriée. Afin de réduire le risque

de choc électrique, ne modifiez la fiche d’aucune

façon.

Rallonges

• Remplacez immédiatement toute rallonge

endommagée. L’utilisation de rallonges

endommagées risque de provoquer un choc

électrique, des brûlures ou l’électrocution.

• En cas de besoin d’une rallonge, utilisez un

cordon de calibre satisfaisant pour éviter toute

chute de tension, perte de courant ou surchauffe.

Le tableau ci-dessous indique le calibre des

rallonges recommandées en fonction de leur

longueur et de l’intensité indiquée sur la

plaquette emblématique de l’outil. En cas de

doute, optez pour le prochain calibre inférieur.

Utilisez toujours des rallonges homologuées

par l’U.L. et l’ACNOR.

Intensité nominale(figurant sur la plaquette emblématique)

0- 2.1- 3.5- 5.1- 7.1- 12.1-

2.0 3.4 5.0 7.0 12.0 16.0

25' 18 18 18 18 16 14

50' 18 18 16 16 14 12

75' 18 18 16 14 12 10

100' 18 16 14 12 10

150' 16 14 12 12 calibre du fil

Longueur de rallonge

REMARQUE: Plus le calibre est petit, plus le

fil est gros.

‹‹CONSERVEZ CES INSTRUCTIONS››

Mode d’emploi

Gâchette de commande

AVERTISSEMENT ! Tenez l’outil à deux

mains à la mise en marche car le couple du

moteur est susceptible de produire une certaine

torsion.

Pour mettre l’outil en marche, appuyez sur le

bouton de verrouillage «Lock-OFF» et serrez la

gâchette de commande 7. Pour mettre l’outil au

repos, relâchez tout simplement la gâchette.

L’interrupteur, qui est à ressort, retournera

automatiquement à la position de repos.

Pour que l’interrupteur dure davantage, évitez

de l’actionner pendant que l’outil est sous charge.

Rabotage

Il importe de bien assujettir la pièce sur l’établi,

de vous tenir bien d’aplomb et de tenir la

raboteuse à deux mains. Une fois la raboteuse

bien ajustée, mettez l’outil en marche et placez

la semelle avant 10 sur le matériau (en vous

assurant que le cylindre de coupe 23 ne touche

pas au matériau), puis mettez la raboteuse en

marche de la façon décrite précédemment. Avec

la pression sur la semelle avant 10 et le guide

bien appuyé contre le côté du matériau pour

contrôler la largeur ou l’angle, avancez

progressivement la raboteuse jusqu’à ce que la

semelle arrière 22 repose sur la pièce. Transférez

alors graduellement la pression sur la semelle

arrière et continuez à raboter normalement.

Déplacez la raboteuse à allure uniforme et

raisonnable, qui n’imposera pas trop de

contrainte sur le moteur ou les lames et, surtout,

ne ramenez pas la raboteuse sur la surface déjà

rabotée. Effectuez progressivement des coupes

BM 2609931094 6/95 12/14/98, 4:20 PM15

15

de plus en plus profondes jusqu’à ce que vous

approchiez l’épaisseur ou la profondeur désirée,

puis réglez la raboteuse en vue d’une coupe plus

légère qui produira finalement le fini désiré.

Travaillez en douceur, avec aplomb et en tout

confort. Vous prolongerez ainsi la durée utile

de l’outil et vous éviterez le risque d’accidents.

Sachez que la sécurité et la qualité du rabotage

vont de paire avec l’affûtage et le réglage

appropriés des lames. Maintenez donc les

lames propres et affûtées; remplacez ou inversez

les lames émoussées quand le besoin se fait

sentir.

Lames de raboteuse

ATTENTION ! Les lames de la raboteuse

sont coupantes et fragiles et doivent être traitées

délicatement pour éviter de vous blesser et de

les endommager.

Les lames standard 24 ont deux tranchants et

peuvent être inversées si l’un deux devient

émoussé ou entaillé. Généralement, l’inversion

ou le remplacement des lames ne nécessite pas

le réglage des porte-lames 26. Si le réglage du

porte-lames s’avère nécessaire, confiez-vous à

un Centre de service usine Bosch. Évitez le

déséquilibre du cylindre de coupe 23,

déséquilibre qui pourrait causer la vibration,

l’usure prématurée de l’outil et, en conséquence,

la dégradation de la qualité. Remplacez ou

inversez toujours les lames en paire. Ne tentez

pas d’aiguiser les vieilles lames.

Inversion ou remplacement des lames

Pour inverser ou remplacer les lames, desserrez

les vis de fixation 21 au moyen de la clé 9.

Ensuite,

appuyez sur le

20

21

garde 25 et

glissez

longitudinalement

le porte-lames

26 et les lames

24 hors du

cylindre de

coupe 23, en

prenant bien

soin de ne pas vous approcher les doigts des

tranchants de la lame. Glissez la lame hors du

porte-lame. Vous pouvez vous servir d’une

pièce de bois pour déloger la lame. Si la lame

9

25

est gommée ou

difficile à

10

23

2624

enlever, vous

pouvez la

nettoyer

àl’essence

blanche, au

diluant pour

laque ou à

l’alcool.

Nettoyez

également

toutes les sur-

26 24

faces

adjacentes

avant de

reposer les

lames neuves.

Vous vous

assurerez ainsi

que les lames

sont en place

et que l’outil fonctionne correctement.

Réglage des lames

Sauf les quelques points suivants, le remontage

des lames et des porte-lames s’effectue

essentiellement à l’inverse de la pose. Précédant

le serrage, lors de la repose des lames et des

porte-lames, il est important de voir à ce que les

porte-lames appuient fermement contre la butée

latérale du cylindre de coupe 23 (position 1).

Pour assurer une coupe égale, il importe de

régler les lames de sorte qu’elles coïncident

avec le bord extérieur des semelles avant et

arrière. Ce réglage s’accomplit comme suit:

placez une règle ou une pièce de bois le long de

la surface extérieure de la semelle avant 10 et de

la semelle

arrière 22, puis

10

23

glissez les

lames 24 de

sorte qu’elles

1

touchent à

peine à la règle

ou à la pièce

de bois (position 2). Il est à

noter que ce

réglage exige que vous glissiez la lame dans le

porte-lame alors que celui-ci reste appuyé sur la

butée latérale du cylindre de coupe. Vous

16

22

22

2

BM 2609931094 6/95 12/14/98, 4:20 PM16

pouvez ensuite resserrer uniformément les vis

de fixation 21 qui retiennent les porte-lames des

deux lames et votre raboteuse est prête àutiliser.

Nivellement de lames

Les vis de nivellement des lames 27 sont réglées

à l’usine à l’aide d’une pâte de fixation et,

normalement, elles n’ont pas à l’être de nouveau.

En cas de réglage, procédez comme suit. Réglez

d’abord la semelle avant 10 sur le repère «0».

Ensuite, placez une règle sur l’avant de la

semelle avant 10 et la semelle arrière 22, puis

notez la hauteur aux deux extrémités des lames.

Les deux extrémités des lames devraient à peine

toucher à la règle. Si le bord de la lame n’est pas

parfaitement parallèle avec les semelles, vous

pouvez lever

ou baisser le

porte-lame 26.

Les vis de fixation 21

desserrées,

levez ou

baissez les vis

de nivellement

27 de la lame,

ce qui vous

permettra de déplacer le porte-lame 26 jusqu’à

ce que la lame soit parallèle aux semelles avant

et arrière. Suivant le réglage, les vis de fixation

21 doivent être resserrées fermement. Assurezvous qu’aucune matière étrangère n’intervienne

entre les lames 24, les porte-lames 26 et le

cylindre de coupe 23.

Vue l’importance de ces réglages, il est

préférable de les confier à un Centre de service

usine Bosch ou à un centre de réparation Bosch

agréé. D’ailleurs, les filets des vis de nivellement

27 doivent être enduits à nouveau de pâte de

fixation.

10 27 2226

21

Cas spéciaux

La raboteuse est livrée avec deux lames au

carbure réversibles. Cependant, vous pouvez

vous procurer les jeux de lames facultatifs**

dont il est mention à la page 3 du présent

manuel.

ATTENTION ! Si vous optez pour un jeu de

lames facultatif, vous devez d’abord vous procurer l’équipement de conversion approprié.

Les kits de conversion comprennent un différent

jeu de porte-lames et un jeu de lames facultatif.

Quand la raboteuse est équipée du kit de conversion, vous pouvez commander les jeux de

lames de rechange séparément. Chaque fois

que vous changez d’un style de jeu de lames à

un autre, vous devez également changer de

porte-lames. Les divers jeux de lames et portelames ne sont pas interchangeables entre eux.

ATTENTION ! Il est possible que le moteur

cale en cas d’abus ou de surcharge. Réduisez la

pression ou la profondeur de coupe pour éviter

d’endommager l’outil si le moteur force.

Protecteur de lame

Le protecteur de lame 31 s’abaisse pour

empêcher la lame d’entrer en contact avec la

surface de travail lorsque l’outil n’est pas utilisé.

Réglage de la profondeur de coupe

La profondeur de coupe devrait être déterminée

en fonction de la dureté, la viscosité ou

l’humidité du matériau utilisé, aussi bien que de

la vitesse de rabotage, ce qui relève surtout de

l’expérience. Débutez par une coupe légère et

augmentez graduellement le réglage en

profondeur si l’outil se déplace aisément, sans

surcharge sur le moteur. Ne changez surtout

pas le réglage de la profondeur en rabotant.

La profondeur de coupe est la différence en

hauteur entre la semelle avant réglable 10 et la

semelle arrière fixe 22 de la raboteuse. Lors du

réglage de la profondeur, la semelle avant se

rétracte et expose les lames 24 qui peuvent alors

supprimer l’épaisseur désirée de matériau.

L’échelle de la profondeur de coupe est graduée

de 0 à 2,5 mm, le repère «0»

indiquant le retrait total des

lames. Ne posez jamais la

raboteuse sur sa base tant que

les lames ne soient

complètement au repos.

Réglage de la profondeur de coupe: Tournez le

bouton de réglage 3 jusqu’à ce que l’indicateur

engage le cran désignant la profondeur de coupe

désirée sur l’échelle 5. Chaque repère équivaut

à 0,1 mm (0.004"). La raboteuse peut être

réglée àtoute profondeur entre 0 et 2,5 mm (0 et

3/32").

BM 2609931094 6/95 12/14/98, 4:20 PM17

17

Guide de largeur

45°

Le guide de largeur (non illustré) peut servir à

couper diverses largeurs désirées.

Pose du guide de largeur: Introduisez le bouton

à oreilles 14 dans le trou du de la bride 13 du

guide et vissez-le dans le boîtier. Serrez

fermement le bouton 14.

Réglage de la largeur de coupe: Desserrez le

bouton à oreilles 15 et glissez le guide à la

position désirée le long de la bride 13. Serrez

fermement le bouton 15. Assurez-vous d’insérer

la rondelle plate (fournie) entre le fond du guide

et le bouton 15, sinon le guide risque de glisser.

Guide d’angle/largeur de luxe

Le guide d’angle/largeur de luxe 17 facultatif

peut non seulement servir à raboter diverses

largeurs, mais aussi à guider la raboteuse à

n’importe quel angle de moins de 45˚ pour le

chanfreinage des arêtes.

Pose du guide d’angle/largeur: Introduisez le

bouton à oreilles 14 dans le trou de la bride du

guide 13 et vissez-le dans le boîtier. Serrez

fermement le bouton 14.

Réglage de la largeur de coupe: Desserrez le

bouton à oreilles 15 et à l’aide de l’échelle de la

largeur 16, glissez le guide 17 à la position

désirée le long de la bride 13 du guide. Reserrez

fermement le bouton 15.

Réglage de l’angle de coupe: Desserrez les

boutons ronds 12 et pivotez le guide 11 à la

position désirée. Resserrez fermement les

boutons 12.

Notez que la semelle avant réglable 10 renferme

une rainure en V 20 ce qui facilitera l’usage du

guide d’angle/largeur de luxe.

24mm

max

82mm

max

Guide de profondeur de feuillure

Le guide de profondeur de feuillure 2 permet à

l’utilisateur de régler la profondeur de 0 à 24

mm (0 à 15/16"). Pour de meilleurs résultats, il

importe que les lames soient bien alignées (voir

la rubrique «Réglage des lames»). Le réglage

du guide de largeur déterminera la largeur de la

feuillure. La largeur maximale est 82 mm (3-1/

4"). La profondeur finale est réalisée après une

succession de coupes alors que le guide de

profondeur de feuillure finit par s’appuyer contre

la pièce. Réglage en profondeur de la feuillure:

Desserrez le bouton à oreilles 1 et à l’aide de

l’échelle du guide de profondeur de feuillure 2,

réglez le guide à la profondeur désirée. Resserrez

fermement le bouton 1.

Éjection des copeaux

La raboteuse est

équipée d’un

éjecteur de

copeaux 4

auquel vous

6

2

pouvez attacher

un sac ou un

aspirateur pour

assurer la

propreté du tra-

1

vail. Le sac ou

le flexible de l’aspirateur peut être monté à

l’une ou l’autre extrémité de l’éjecteur. Le

réglage du sélecteur 6 à la position 1 (vers

l’avant de l’outil), dirige les copeaux à droite

alors qu’à la position 2 (vers l’arrière de l’outil)

il dirige les copeaux à gauche.

Courroie d’entraînement

Étant donné que l’inspection de la courroie

d’entraînement 29 fait partie de l’entretien nor-

mal, il faudrait y veiller périodiquement. Si la

courroie semble sèche, sur le point de se fissurer

ou de se déchirer, si elle est hors d’alignement

18

BM 2609931094 6/95 12/14/98, 4:20 PM18

ou saute les

poulies, elle

devrait être

remplacée.

Pose de la

courroie de

rechange:

Desserrez la

vis 18 et

enlevez le

couvercle 19

de la courroie. Coupez la courroie 29 usée pour

l’enlever. Avant de poser la courroie de

rechange, nettoyez les deux poulies proprement.

Montez d’abord la courroie neuve sur la poulie

d’entraînement 30, puis tournez en sens horaire

tout en poussant la courroie sur la poulie attaquée

28. Remettez le couvercle de la courroie en

place et serrez fermement la vis 18.

28

29

30

Maintenance et entretien

AVERTISSEMENT! L’entretien préventif

prodigué par des personnes non autorisées peut

être dangereux. Il est recommandé de confier

l’entretien et la réparation de l’outil à un centre

de service-usine Bosch.

à un centre de service-usine Bosch. Les

roulements qui sont devenus bruyants (à la suite

d’usage dans des matériaux très abrasifs ou de

durs efforts) devraient être remplacés à l’instant

pour éviter la surchauffe et la défaillance du

moteur.

Nettoyage

AVERTISSEMENT! Pour éviter le risque

d’accidents, débranchez toujours l’outil de la

prise de courant avant de procéder au nettoyage

ou à l’entretien. Vous pouvez très bien le

nettoyer à l’air comprimé. Dans ce cas, portez

toujours des lunettes de sécurité.

Gardez les prises d’air et les interrupteurs propres

et libres de saletés. N’essayez pas de les nettoyer

en introduisant des objets pointus dans leurs

ouvertures.

MISE EN GARDE! Certains produits de

nettoyage et dissolvants dont la gazoline, le

tétrachlorure de carbone, les nettoyeurs chlorés,

l’ammoniaque et les détergents ménagers

contenant de l’ammoniaque peuvent abîmer les

pièces en plastique.

Graissage de l’outil

Votre outil Bosch a été convenablement graissé

et est prêt à utiliser. Il est recommandé que les

outils à engrenages soient regraissés avec une

graisse spéciale à l’occasion de tout

remplacement de balais.

Balais de charbon

Les balais et le collecteur de votre outil Bosch

ont été conçus pour donner plusieurs heures de

fonctionnement sans aléas. Pour maintenir le

moteur en pleine forme, nous recommandons

d’examiner les balais tous les deux à six mois.

Vous ne devriez exiger que les balais de rechange

d’origine Bosch qui conviennent spécialement

à votre outil.

Roulements

Après environ 300 à 400 heures d’utilisation,

ou à tous les deux remplacements des balais, il

faudrait confier le remplacement des roulements

BM 2609931094 6/95 12/14/98, 4:20 PM19

19

GARANTIE

GARANTIE LIMITÉE

BOSCH

S-B POWER TOOL COMPANY

S-B Power Tool Company («Vendeur») garantit

à l’acheteur originel d’outils électriques portatifs

Bosch (et uniquement à celui-ci) que lesdits

outils sont et resteront exempts de vices matériels

et de fabrication pendant un (1) an àcompter de

la date d’achat. LA SEULE OBLIGATION

DU VENDEUR ET LE SEUL RECOURS DE

L’ACHETEUR sous la présente garantie

limitée, et en autant que la loi le permette sous

toute garantie ou condition implicite qui en

découlerait, sera l’obligation de remplacer ou

réparer gratuitement les pièces défectueuses

matériellement ou comme fabrication, pourvu

que lesdites défectuosités ne soient pas

attribuables à un usage abusif ou à quelque

réparation bricolée par quelqu’un d’autre que le

vendeur ou le personnel d’une station-service

agréée. En cas de réclamation sous la présente

garantie limitée, l’acheteur est tenu de renvoyer

l’outil électrique portatif complet en port payé

à un centre de service-usine Bosch ou une

station-service agréée. Une liste des centres de

service-usine américains accompagne chaque

outil électrique Bosch. Veuillez consulter votre

annuaire téléphonique pour les adresses.

LA PRÉSENTE GARANTIE NE

S’APPLIQUE PAS AUX ACCESSOIRES

TELS QUE LAMES DE SCIES

CIRCULAIRES, MÈCHES DE PERCEUSES,

FERS DE TOUPIES, LAMES DE SCIES

SAUTEUSES, COURROIES DE PONÇAGE,

MEULES ET AUTRES ARTICLES DU

GENRE.

TOUTE GARANTIE IMPLICITE SERA

LIMITÉE COMME DURÉE À UN (1) AN À

COMPTER DE LA DATE D’ACHAT.

CERTAINS ÉTATS AMÉRICAINS

N’ADMETTANT PAS LE PRINCIPE DE LA

LIMITATION DE LA DURÉE DES

GARANTIES IMPLICITES, IL EST POSSIBLE QUE LES LIMITATIONS CI-DESSUS

NE S’APPLIQUENT PAS À VOTRE CAS.

EN AUCUN CAS LE VENDEUR NE

SAURAIT ÊTRE TENU POUR

RESPONSABLE DES INCIDENTS OU

DOMMAGES INDIRECTS (INCLUANT,

MAIS NE SE LIMITANT PAS AUX PERTES

DE PROFITS) CONSÉCUTIFS À LA VENTE

OU L’USAGE DE CE PRODUIT. CERTAINS

ÉTATS AMÉRICAINS N’ADMETTANT

PAS LE PRINCIPE DE LA LIMITATION NI

L’EXCLUSION DES DOMMAGES

INDIRECTS ET CONSÉQUENTIELS, IL EST

POSSIBLE QUE LES LIMITATIONS OU

EXCLUSIONS CI-DESSUS NE

S’APPLIQUENT PAS À VOTRE CAS.

LA PRÉSENTE GARANTIE VOUS

ACCORDE DES DROITS BIEN

DÉTERMINÉS, Y COMPRIS

POSSIBLEMENT CERTAINS DROITS

VARIABLES DANS LES DIFFÉRENTS

ÉTATS.

S-B Power Tool Company

4300 W. Peterson Avenue

Chicago, IL 60646-5999

BM 2609931094 6/95 12/14/98, 4:20 PM20

20

Datos del producto - Cepillo

Modelo número 3296

Número de identificación 0 603 296 0 . .

Profundidad de cepillado 0 - 3/32" (0 - 2.5mm)

Profundidad de rebajado 0 - 15/16" (0 - 24mm)

Ancho de corte 3-1/4" (82mm)

(NOTA: Esta herramienta está diseñada para uso con corriente alterna (AC) únicamente.)

Lista de accesorios

Guía de profundidad de rebajado*

Tope de ángulo/ancho de lujo*

Llave para hojas 8mm*

Juego de hojas de carburo reversibles*

Equipo de conv. de hojas reversibles HSS**

Juego de hojas reversibles HSS**

Equipo de conv. de hojas reversibles rústicas**

Juego de hojas reversibles rústicas**

(* = equipo estándar)

(** =

PRECAUCION: vea la sección “Aplicaciones de corte especiales” antes de instalar o

utilizar los equipos de conv. de hojas opcionales o los juegos de hojas opcionales.)

Componentes del cepillo

1. Botón de mariposa 12.Pomos redondos 23. Tambor cortador

2 Tope de profundidad de rebajado 13.Soporte guía 24.Hojas del cepillo

3. Pomo de ajuste de profundidad 14. Botón de mariposa 25.Protector de rebajado

4. Orificios de expulsión de virutas 15.Botón de mariposa 26.Soportes de las hojas

5. Escala de profundidad 16. Escala de ancho 27.Tornillo de nivelación

6. Palanca selectora de orificio 17.Tope de ángulo/ancho de lujo de las hojas

7. Interruptor gatillo 18.Tornillo 28. Polea impulsada

8. Botón de “Fijación en OFF” 19.Cubierta de la correa de transmisión 29. Correa de transmisión

9. Llave para hojas 8mm 20. Ranura en V para biselar 30.Polea motriz

10. Base delantera 21.Tornillos de fijación 31. Descanso de la

11. Tope pivote 22. Base trasera herramienta

(NOTA: Los componentes del cepillo que no están ilustrados en la página 2 están ilustrados

en otra parte de este manual.)

21

BM 2609931094 6/95 12/14/98, 4:20 PM21

!ADVERTENCIA! “LEA TODAS LAS

INSTRUCCIONES”. El incumplimiento de

las NORMAS DE SEGURIDAD identificadas

por el símbolo del PUNTO NEGRO (°) que se

indican y otras precauciones de seguridad puede

dar lugar a lesiones personales graves. Conserve estas instrucciones de funcionamiento

con este producto.

NORMAS GENERALES DE

SEGURIDAD

para todas las herramientas

mecánicas

Area de trabajo

• MANTENGA LIMPIAS LAS AREAS DE

TRABAJO. Las áreas y mesas desordenadas

invitan a que se produzcan accidentes.

• EVITE LOS ENTORNOS PELIGROSOS.

No utilice herramientas mecánicas en lugares

húmedos o mojados. No exponga las

herramientas mecánicas a la lluvia. Mantenga

el área de trabajo bien iluminada.

• EVITE LAS AREAS CON PRESENCIA

DE GASES. No utilice herramientas eléctricas

portátiles en atmósferas explosivas en presencia

de líquidos o gases inflamables. Los motores

de estas herramientas normalmente producen

chispas y las chispas pueden dar lugar a la

ignición de vapores.

• MANTENGA ALEJADOS A LOS NIÑOS.

No permita que los visitantes toquen las

herramientas o el cordón de extensión. Todos

los visitantes deben mantenerse alejados del

área de trabajo.

Seguridad personal

• PROTEJASE CONTRA LAS SACUDIDAS

ELECTRICAS. Evite el contacto del cuerpo

con las superficies conectadas a tierra tales

como tuberías, radiadores o cocinas y

refrigeradores. Se recomiendan guantes de

caucho y calzado antideslizante cuando se

trabaja a la intemperie, donde se puede encontrar

terreno húmedo o mojado. En estas condiciones

se debe utilizar una línea de energía protegida

con un Interruptor de circuito para fallos a

tierra.

• VISTASE ADECUADAMENTE. No se

ponga ropa suelta ni joyas. Pueden quedar

atrapadas en las piezas móviles. Use cubiertas

protectoras para el pelo a fin de sujetar el pelo

largo.

• UTILICE EQUIPO DE SEGURIDAD. USE

GAFAS DE SEGURIDAD o lentes con

protectores laterales. Utilice protección en los

oídos cuando use las herramientas mecánicas

mucho rato y una máscara contra el polvo para

operaciones que generan polvo.

• MANTENGASE ALERTA. USE EL

SENTIDO COMUN. Fíjese en lo que está

haciendo. No utilice la herramienta cuando está

cansado o bajo la influencia de medicamentos.

• QUITE LAS LLAVES DE AJUSTE Y LAS

LLAVES DE TUERCA. Forme el hábito de

asegurarse de que las llaves de ajuste y de tuerca

se han quitado de la herramienta antes de

encenderla.

• EVITE EL ARRANQUE ACCIDENTAL.

No lleve la herramienta enchufada con el dedo

en el interruptor. Asegúrese de que el interruptor

está en la posición OFF (desconectado) antes de

enchufar.

• NO INTENTE ALCANZAR DEMASIADO

LEJOS. Mantenga una posición y un equilibrio

adecuados en todo momento.

• ANTES DE CONECTAR LA

HERRAMIENTA a una fuente de energía (caja

tomacorriente, tomacorriente, etc.), asegúrese

de que el voltaje suministrado es el mismo que

el que se indica en la placa del fabricante de la

herramienta. Una fuente de energía con un

voltaje superior al especificado para la

herramienta puede ocasionar graves lesiones al

usuario — así como daños a la herramienta. En

caso de duda, NO ENCHUFE LA

HERRAMIENTA. La utilización de una fuente

de energía con un voltaje inferior a la capacidad

nominal indicada en la placa del fabricante es

perjudicial para el motor.

Las herramientas designadas “VOLTS AC”

son para corriente alterna de 50-60 Hz solamente.

Las herramientas designadas “VOLTS DC”

son para corriente continua. No utilice

herramientas designadas AC con una fuente de

energía DC. No utilice herramientas de

velocidad controlada electrónicamente con una

fuente de energía DC.

22

BM 2609931094 6/95 12/14/98, 4:20 PM22

Utilización y cuidado de las

herramientas

• NO FUERCE LA HERRAMIENTA. La

herramienta trabajará mejor y con más seguridad

a la capacidad para la cual fue diseñada.

• UTILICE LA HERRAMIENTA

ADECUADA. No fuerce una herramienta

pequeña o un accesorio pequeño a realizar el

trabajo de una herramienta pesada. No utilice la

herramienta para funciones para las cuales no

fue diseñada — por ejemplo, no use una sierra

circular para cortar ramas o troncos de árboles.

• FIJE LA PIEZA DE TRABAJO. Utilice

abrazaderas o un tornillo de carpintero para

sujetar la pieza de trabajo. Es más seguro que

utilizar la mano y libera ambas manos para

manejar la herramienta.

• NO ABUSE DEL CORDON. Nunca lleve la

herramienta por el cordón ni tire de él para

desconectarlo del tomacorriente. Proteja el

cordón del calor, el aceite y los bordes afilados.

Mantenga siempre el cordón alejado de la hoja

cuando esté girando, de las brocas o de cualquier

otra pieza móvil durante la utilización de la

herramienta.

• A LA INTEMPERIE, UTILICE

CORDONES DE EXTENSION. Cuando la

herramienta se utiliza a la intemperie, use

únicamente cordones de extensión adecuados

para la utilización a la intemperie y marcados

con el sufijo W-A (para UL) o W (para la CSA).

Consulte la sección “Cordones de extensión”

para la utilización del cordón adecuado.

• DESCONECTE LAS HERRAMIENTAS.

Cuando no se estén utilizando, antes del servicio

de ajustes y reparaciones o al cambiar hojas,

brocas, cortadores, etc.

• GUARDE LAS HERRAMIENTAS QUE

NO ESTA USANDO. Cuando las herramientas

no se estén utilizando, deberán guardarse en un

lugar seco, alto o con cierre — fuera del alcance

de los niños.

• NO ALTERE NI HAGA USO

INCORRECTO DE LA HERRAMIENTA.

Estas herramientas están fabricadas con

precisión. Cualquier alteración o modificación

no especificada constituye un uso incorrecto y

puede dar lugar a una situación peligrosa.

• LA UTILIZACION DE CUALQUIER

ACCESORIO no especificado en este manual

puede constituir un peligro.

• MANTENGA LAS HERRAMIENTAS

CON CUIDADO. Conserve las herramientas

afiladas y limpias para que funcionen mejor y

con más seguridad. Siga las instrucciones de

lubricación y de cambio de accesorios.

Inspeccione periódicamente los cordones de las

herramientas y si están dañados hágalos reparar

por un centro de servicio autorizado.

Inspeccione periódicamente los cordones de

extensión y sustitúyalos si están dañados.

Mantenga los mangos secos, limpios y libres de

aceite y grasa.

• REVISE LAS PIEZAS DAÑADAS. Antes

de volver a utilizar la herramienta, una

protección u otra pieza que esté dañada deberá

revisarse cuidadosamente para determinar que

funcionará adecuadamente y que realizará la

función para la cual está diseñada. Verifique la

alineación de las piezas móviles, el atascamiento

de las piezas móviles, la ruptura de piezas, el

montaje y cualquier otra situación que pueda

afectar su funcionamiento. Un protector o

cualquier otra pieza que presenta daños se debe

reparar o sustituir inmediata y adecuadamente.

Haga que cambien los interruptores defectuosos.

No utilice la herramienta si el interruptor no la

enciende y apaga.

• TODAS LAS REPARACIONES,

ELECTRICAS O MECANICAS, deben ser

realizadas únicamente por técnicos de reparación

capacitados. Póngase en contacto con el Centro

de servicio de fábrica Bosch más próximo o con

el Centro de servicio Bosch autorizado más

próximo o con otro centro de reparaciones

competente. Utilice piezas de repuesto Bosch

únicamente, cualquier otra puede constituir un

peligro.

Normas de seguridad para

cepillos

• Arranque siempre el cepillo antes de que éste

entre en contacto con la pieza de trabajo y nunca

tire del cepillo hacia atrás sobre la pieza de

trabajo.

• Desenchufe el cordón de energía antes de

realizar ajustes o de cambiar/invertir los juegos

de hojas.

• Asegúrese de que el protector de rebajado

retráctil automático accionado por resorte vuelve

a la posición de cobertura de la hoja

instantáneamente.

23

BM 2609931094 6/95 12/14/98, 4:20 PM23

• No ponga los dedos ni ningún objeto dentro

del eyector de virutas ni limpie las virutas

mientras la herramienta está funcionando. Saque

el enchufe de la fuente de energía si se hace

necesario quitar virutas.

• Antes de cepillar, compruebe si hay clavos

en la pieza de trabajo. Si hay clavos, quítelos o

colóquelos de manera que queden

completamente por debajo de la superficie

acabada proyectada.

• Hay que fijar adecuadamente las piezas de

trabajo pequeñas para que las cuchillas giratorias

del cepillo no las levanten durante el movimiento

hacia adelante del cepillo.

• Después de cambiar las hojas, gire el tambor

cortador para asegurarse de que las hojas no

tocan ninguna parte de la caja protectora de las

cabezas de las hojas y de que los tornillos de

fijación de las hojas están bien apretados.

• Use guantes protectores y gafas de seguridad.

• Sujete siempre la herramienta firmemente

con las dos manos.

• Nunca apoye el cepillo hasta que la hoja se

haya detenido por completo.

ENCHUFES POLARIZADOS: Si su

herramienta está equipada con un enchufe

polarizado (una terminal es más ancha que la

otra), este enchufe entrará en un tomacorriente

polarizado solamente de una manera. Si el

enchufe no entra por completo en el

tomacorriente, déle la vuelta. Si sigue sin

entrar, póngase en contacto con un electricista

competente para instalar el tomacorriente

adecuado. Para reducir el riesgo de sacudidas

eléctricas, no haga ningún tipo de cambio en el

enchufe.

Herramientas con aislamiento

doble

• El aislamiento doble es un concepto de

diseño utilizado en las herramientas mecánicas

eléctricas que elimina la necesidad de un cable

de energía de tres hilos conectado a tierra y de

un sistema de fuente de energía conectado a

tierra. Es un sistema reconocido y aprobado por

Underwriter’s Laboratories, la CSA y las

autoridades federales de la OSHA.

IMPORTANTE: El servicio de ajustes y

reparaciones de una herramienta con aislamiento

doble requiere cuidado y conocimiento del

sistema y deberá ser realizado únicamente por

un técnico de servicio competente. CUANDO

SE REQUIERA SERVICIO DE AJUSTES Y

REPARACIONES, UTILICE UNICAMENTE

PIEZAS DE REPUESTO IDENTICAS.

ENCHUFES POLARIZADOS: Si su

herramienta está equipada con un enchufe

polarizado (una terminal es más ancha que la

otra), el enchufe entrará en un tomacorriente

polarizado solamente de una manera. Si el

enchufe no entra por completo en el

tomacorriente, déle la vuelta. Si sigue sin

entrar, póngase en contacto con un electricista

competente para instalar el tomacorriente

adecuado. Para reducir el riesgo de sacudidas

eléctricas, no modifique el enchufe de ninguna

manera.

Cordones de extensión

• Sustituya los cordones dañados

inmediatamente. La utilización de cordones

dañados puede causar sacudidas, quemar o

electrocutar.

• Si se necesita un cordón de extensión, se debe

utilizar un cordón con conductores de tamaño

adecuado para prevenir caídas de tensión

excesivas, pérdidas de potencia o

sobrecalentamiento. La tabla siguiente muestra

el tamaño correcto a utilizar, según la longitud

del cordón y la capacidad nominal en amperios

indicada en la placa del fabricante de la

herramienta. En caso de duda, utilice la medida

más gruesa siguiente. Utilice siempre cordones

de extensión catalogados por U.L. y la CSA.

Capacidad nominal en amperios

(mostrada en la placa del fabricante)

0- 2.1- 3.5- 5.1- 7.1- 12.1-

2.0 3.4 5.0 7.0 12.0 16.0

25' 18 18 18 18 16 14

50' 18 18 16 16 14 12

75' 18 18 16 14 12 10

100' 18 16 14 12 10

150' 16 14 12 12 calibre de cable

Longitud del cordón

Nota: Cuanto más pequeño es el número de

calibre, más grueso es el cable en el cordón.

"CONSERVE ESTAS INSTRUCCIONES"

24

BM 2609931094 6/95 12/14/98, 4:20 PM24

Funcionamiento de la

herramienta

Interruptor gatillo “ON/OFF” (de

encendido y apagado)

¡ADVERTENCIA! Agarre la herramienta

con las dos manos cuando arranque la

herramienta, ya que el par de fuerzas del motor

puede hacer que la herramienta se tuerza.

Para encender la herramienta (posición “ON”),

oprima el botón de “Fijación en OFF” y apriete

el interruptor gatillo 7. Para apagar la

herramienta (posición “OFF”), suelte el

interruptor gatillo que está accionado por resorte

y volverá a la posición “OFF” automáticamente.

Para prolongar la vida del interruptor, no

encienda ni apague el interruptor cuando la

herramienta esté sometida a carga.

Acción de cepillado

Compruebe que la pieza de trabajo está sujeta

en su sitio de manera segura sobre la superficie

de trabajo y, situado cómodamente de pie, sujete

el cepillo firmemente con ambas manos. Con el

cepillo completamente ajustado, arranque el

cepillo y coloque la base delantera 10 sobre la

pieza de trabajo (asegúrese de que el tambor

cortador 23 no está en contacto con la pieza de

trabajo), y arranque el cepillo tal como se ha

descrito anteriormente. Con presión sobre la

base delantera 10 y con el tope apoyado en el

lado de la pieza de trabajo para controlar el

ancho o el ángulo, aplique el cepillo firmemente

hasta que la base trasera 22 entre en contacto

con la pieza de trabajo. Ahora, transfiera la

presión gradualmente a la base trasera y continúe

cepillando hasta el final del corte. Haga avanzar

el cepillo a una velocidad uniforme y razonable,

que no someta a un esfuerzo excesivo al motor

o a las hojas, y no tire del cepillo hacia atrás

sobre la superficie ya cortada. Use cortes

progresivamente más profundos hasta que esté

cerca de la profundidad deseada y luego reajuste

a un corte ligero para la pasada final a fin de

obtener un buen acabado de la superficie.

Utilice una acción de cepillado suave y uniforme,

y no intente alcanzar demasiado lejos sobre la

superficie de trabajo ni utilizar el cepillo en una

posición incómoda. Esto prolongará la vida de

la herramienta y disminuirá el riesgo de

accidentes. Recuerde, la seguridad y los buenos

resultados dependen de que las hojas de corte

estén afiladas y ajustadas adecuadamente.

Mantenga las hojas del cepillo limpias y afiladas,

y cambie o invierta las hojas desafiladas cuando

el cepillo ya no realice cortes lisos y rápidos.

Hojas del cepillo

¡PRECAUCION! Las hojas del cepillo son

afiladas y frágiles y se deben manejar

cuidadosamente para evitar lesiones al usuario

o daños a las hojas.

Las hojas estándar del cepillo 24 tienen dos

filos para cortar y se pueden invertir cuando uno

de los filos para cortar se desafila o se mella. Al

invertir o cambiar las hojas, generalmente no es

necesario reajustar los soportes de las hojas 26.

Si se hace necesario ajustar el soporte de las

hojas, lleve el cepillo a un Centro de servicio de

fábrica Bosch. Para evitar el desequilibrio del

tambor cortador 23, lo cual podría dar lugar a

vibración, desgaste prematuro de la herramienta

y trabajo de mala calidad, invierta o cambie

siempre el juego de hojas completo. No intente

afilar hojas usadas.

Inversión o cambio de las hojas

Para invertir o cambiar las hojas, afloje los

tornillos de fijación 21 con la llave para hojas 9.

Con los tornillos aflojados,

oprima el protector de

rebajado 25

hacia abajo y

deslice el

soporte de las

hojas 26 y las

hojas 24 longitudinalmente para que

salgan del

tambor

cortador 23,

teniendo

cuidado de

mantener los

dedos alejados

de los bordes

afilados de la

20

10

21

23

9

25

2624

22

BM 2609931094 6/95 12/14/98, 4:20 PM25