BM 2610925947 6-05 6/10/05 10:35 AM Page 1

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

1644-24

1645-24

Call Toll Free

for Consumer Information

& Service Locations

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

For English

See page 2 Voir page 17 Ver página 32

Pour renseignement des

consommateurs et centres

de service, appelez au

numéro gratuit :

Parlez-vous français?

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

¿Habla español?

BM 2610925947 6-05 6/10/05 10:35 AM Page 2

General Safety Rules

WARNING

!

all of the warnings listed below refers to your mains-operated (corded) power tool or batteryo

perated (cordless) power tool.

Read all instructions. Failure to follow all instructions listed below may

result in electric shock, fire and/or serious injury.

The term “power tool” in

SAVE THESE INSTRUCTIONS

Work area safety

Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust.

tools create sparks which may ignite the dust

or fumes.

Keep children and bystanders away while

operating a power tool.

cause you to lose control.

Distractions can

Power

Electrical safety

Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

use any adapter plugs with earthed

(grounded) power tools.

and matching outlets will reduce risk of

electric shock.

Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators.

is an increased risk of electric shock if your

body is earthed or grounded.

Do not expose power tools to rain or wet

conditions.

increase the risk of electric shock.

Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil,

sharp edges or moving parts.

entangled cords increase the risk of electric

shock.

When operating a power tool outdoors,

use an extension cord suitable for

outdoor use.

outdoor use reduces the risk of electric

shock.

Do not use AC only rated tools with a DC

power supply.

work, the electrical components of the AC

rated tool are likely to fail and create a

hazard to the operator.

Water entering a power tool will

Use of a cord suitable for

While the tool may appear to

Unmodified plugs

There

Damaged or

If operating the power tool in damp

locations is unavoidable a Ground Fault

Circuit Interrupter (GFCI) must be used to

supply the power to your tool.

personal protection devices like electrician’s

rubber gloves and footwear will further

enhance your personal safety.

GFCI and

Personal safety

Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use a power tool while

you are tired or under the influence of

drugs, alcohol or medication.

inattention while operating power tools may

result in serious personal injury.

Use safety equipment. Always wear eye

protection.

mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate

conditions will reduce personal injuries.

Avoid accidental starting. Ensure the

switch is in the off-position before

plugging in.

finger on the switch or plugging in power

tools that have the switch on invites

accidents.

Remove any adjusting key or wrench

before turning the power tool on.

or a key left attached to a rotating part of the

power tool may result in personal injury.

Do not overreach. Keep proper footing

and balance at all times.

better control of the power tool in unexpected

situations.

Dress properly. Do not wear loose

clothing or jewelry. Keep your hair,

clothing and gloves away from moving

parts.

be caught in moving parts.

If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used.

related hazards.

Safety equipment such as dust

Carrying power tools with your

Loose clothes, jewelry or long hair can

Use of these devices can reduce dust-

A moment of

A wrench

This enables

-2-

BM 2610925947 6-05 6/10/05 10:35 AM Page 3

Keep handles dry, clean and free from oil

and grease.

control the power tool.

Slippery hands cannot safely

Power tool use and care

Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job better

and safer at the rate for which it was

designed.

Do not use the power tool if the switch

does not turn it on and off.

that cannot be controlled with the switch is

dangerous and must be repaired.

Disconnect the plug from the power

source and/or the battery pack from the

power tool before making any

adjustments, changing accessories, or

storing power tools.

measures reduce the risk of starting the

power tool accidentally.

Store idle power tools out of the reach of

children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of parts and any other condition

that may affect the power tools operation.

If damaged, have the power tool repaired

before use.

poorly maintained power tools.

Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

Use the power tool, accessories and tool

bits etc., in accordance with these

instructions and in the manner intended

for the particular type of power tool,

taking into account the working

conditions and the work to be performed.

Use of the power tool for operations different

from those intended could result in a

hazardous situation.

Many accidents are caused by

Any power tool

Such preventive safety

Use clamps or other practical way to

secure and support the workpiece to a

stable platform.

or against your body is unstable and may

lead to loss of control.

Holding the work by hand

Battery tool use and care

Recharge only with the charger specified

by the manufacturer.

suitable for one type of battery pack may

create a risk of fire when used with another

battery pack.

Use battery tools only with specifically

designated battery packs.

battery packs may create a risk of injury and

fire.

When battery pack is not in use, keep it

away from other metal objects like paper

clips, coins, keys, nails, screws, or other

small metal objects that can make a

connection from one terminal to another.

Shorting the battery terminals together may

cause burns or a fire.

Under abusive conditions, liquid may be

ejected from the battery, avoid contact. If

contact accidentally occurs, flush with

water. If liquid contacts eyes, additionally

seek medical help.

battery may cause irritation or burns.

Ensure the switch is in the off position

before inserting battery pack.

battery pack into power tools that have the

switch on invites accidents.

A charger that is

Use of any other

Liquid ejected from the

Inserting the

Service

Have your power tool serviced by a

qualified repair person using only identical

replacement parts.

safety of the power tool is maintained.

Develop a periodic maintenance schedule

for your tool. When cleaning a tool be

careful not to disassemble any portion of

the tool since internal wires may be

misplaced or pinched or safety guard

return springs may be improperly

mounted. Certain cleaning agents such as

gasoline, carbon tetrachloride, ammonia, etc.

may damage plastic parts.

This will ensure that the

SAVE THESE INSTRUCTIONS

-3-

BM 2610925947 6-05 6/10/05 10:35 AM Page 4

Safety Rules for Cordless Reciprocating Saws

Hold tool by insulated gripping surfaces

when performing an operation where the

cutting tool may contact hidden wiring.

Contact with a "live" wire will make exposed

metal parts of the tool "live" and shock the

operator.

Do not drill, fasten or break into

existing walls or other blind areas where

electrical wiring may exist. If this situation is

unavoidable, disconnect all fuses or circuit

breakers feeding this worksite.

Keep hands away from cutting area. Do

not reach under the material being cut.

The proximity of the blade to your hand is

hidden from your sight.

Keep hands from between the gear

housing and saw blade clamp (plunger).

The reciprocating blade clamp (blade

plunger) can pinch your fingers.

Do not use dull or damaged blades. Bent

blades can break easily or cause kickback.

Before starting to cut, turn tool "ON" and

allow the blade to come to full speed.

can chatter or vibrate if blade speed is too

slow at beginning of cut and possibly

kickback.

Always wear safety goggles or eye

protection when using this tool. Use a

dust mask or respirator for applications,

which generate dust.

Secure material before cutting. Never

hold it in your hand or across legs.

Tool

Small

or thin material may flex or vibrate with the

blade, causing loss of control.

Make certain all adjusting screws (knobs)

and the blade clamp are tight before

m

aking a cut.

clamps can cause the tool or blade to slip and

loss of control may result.

When removing the blade from the tool

avoid contact with skin and use proper

protective gloves when grasping the blade

or accessory.

prolonged use.

!

WARNING

grinding, drilling, and other construction

activities contains chemicals known to

cause cancer, birth defects or other

reproductive harm. Some examples of

these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement

and other masonry products, and

• Arsenic and chromium from chemicallytreated lumber.

Your risk from these exposures varies,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals: work in a well ventilated area, and

work with approved safety equipment, such

as those dust masks that are specially

designed to filter out microscopic particles.

L

oose adjusting screws and

Accessories may be hot after

Some dust created by

power sanding, sawing,

Battery/Charger

Before using battery charger, read all

instructions and cautionary markings on

(1) battery charger, (2) battery pack, and

(3) product using battery.

Use only the charger which accompanied

your product or direct replacement as

listed in the catalog or this manual.

substitute any other charger.

approved chargers with your product. See

Functional Description and Specifications.

Use only Bosch

Do not

Do not disassemble charger or operate the

charger if it has received a sharp blow,

been dropped or otherwise damaged in

any way. Replace damaged cord or plugs

immediately.

damage may result in electric shock or fire.

Do not recharge battery in damp or wet

environment. Do not expose charger to

rain or snow. If battery case is cracked or

otherwise damaged, do not insert into

charger.

Battery short or fire may result.

Incorrect reassembly or

-4-

BM 2610925947 6-05 6/10/05 10:35 AM Page 5

C

harge only Bosch approved rechargeable

batteries.

Specifications. Other types of batteries may

burst causing personal injury and damage.

Charge battery pack in temperatures

above +40 degrees F (4 degrees C) and

below +105 degrees F (41 degrees C).

Store tool and battery pack in locations

where temperatures do not go below 40

degrees F (4 degrees C) or will no exceed

120 degrees F (49 degrees C). Allow

battery pack to return to room temperature

before attempting to charge.

important to prevent serious damage to the

battery cells.

Battery leakage may occur under extreme

usage or temperature conditions. Avoid

See Functional Description and

This is

Battery Care

WARNING

!

away from metal objects.

protect terminals from shorting

place batteries in a tool box or pocket with

nails, screws, keys, etc. Fire or injury may

result.

When batteries are not in

tool or charger, keep them

For example, to

DO NOT

c

ontact with skin and eyes.

liquid is caustic and could cause chemical

burns to tissues. If liquid comes in contact

with skin, wash quickly with soap and water,

then with lemon juice or vinegar. If the liquid

contacts your eyes, flush them with water for

a minimum of 10 minutes and seek medical

attention.

Place charger on flat non-flammable

surfaces and away from flammable

materials when re-charging battery pack.

The charger and battery pack heat during

charging. Carpeting and other heat insulating

surfaces block proper air circulation which

may cause overheating of the charger and

battery pack. If smoke or melting of the case

are observed unplug the charger immediately

and do not use the battery pack or charger.

WARNING

!

tool or charger, always place protective

cap onto end of battery pack.

cap, guards against terminal shorting.

DO NOT PUT BATTERIES INTO FIRE OR

EXPOSE TO HIGH HEAT.

explode.

To prevent fire or injury

when batteries are not in

T

he battery

Protective

They may

Battery Disposal

!

WARNING

remove any component projecting from

the battery terminals.

result. Prior to disposal, protect exposed

terminals with heavy insulating tape to

prevent shorting.

NICKEL-CADMIUM BATTERIES

If equipped with a nickel-cadmium battery, the

battery must be collected, recycled or

disposed of in an environmentally sound

manner.

industry program to collect and recycle these

batteries at the end of their useful life, when

Do not attempt to disassemble the battery or

Fire or injury may

“The EPA certified RBRC

Battery Recycling Seal on the

nickel-cadmium (Ni-Cd)

battery indicates Robert

Bosch Tool Corporation is

voluntarily participating in an

taken out of service in the United States or

Canada. The RBRC program provides a

convenient alterative to placing used Ni-Cd

batteries into the trash or the municipal waste

stream, which may be illegal in your area.

Please call 1-800-8-BATTERY for information

on Ni-Cd battery recycling and disposal

bans/restrictions in your area, or return your

batteries to a Skil/Bosch/Dremel Service

Center for recycling. Robert Bosch Tool

Corporation’s involvement in this program is

part of our commitment to preserving our

environment and conserving our natural

resources.”

NICKEL-METAL HYDRIDE BATTERIES

If equipped with a nickel-metal hydride

battery, the battery can be disposed of in a

municipal solid waste stream.

-5-

A

0

A

A

0

A

BM 2610925947 6-05 6/10/05 10:35 AM Page 6

Symbols

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min

s Seconds Time

n

0

.../min Revolutions or reciprocation per minute Revolutions, strokes, surface speed,

0 Off position Zero speed, zero torque...

1, 2, 3, ... Selector settings Speed, torque or position settings.

I, II, III, Higher number means greater speed

Minutes Time

Diameter Size of drill bits, grinding wheels, etc.

No load speed Rotational speed, at no load

orbits etc. per minute

Infinitely variable selector with off Speed is increasing from 0 setting

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II construction Designates Double Insulated

Construction tools.

Earthing terminal Grounding terminal

Warning symbol Alerts user to warning messages

Ni-Cad RBRC seal Designates Ni-Cad battery recycling

program

This symbol designates

that this tool is listed by

Underwriters Laboratories.

This symbol designates

that this tool is listed by

the Canadian Standards

Association.

This symbol designates

that this tool is listed to

Canadian Standards by

Underwriters Laboratories.

This symbol designates that

this tool is listed by

Underwriters Laboratories,

and listed to Canadian

Standards by Underwriters

Laboratories.

This symbol

designates

that

this tool

complies

to NOM

Mexican

Standards.

-6-

BM 2610925947 6-05 6/10/05 10:35 AM Page 7

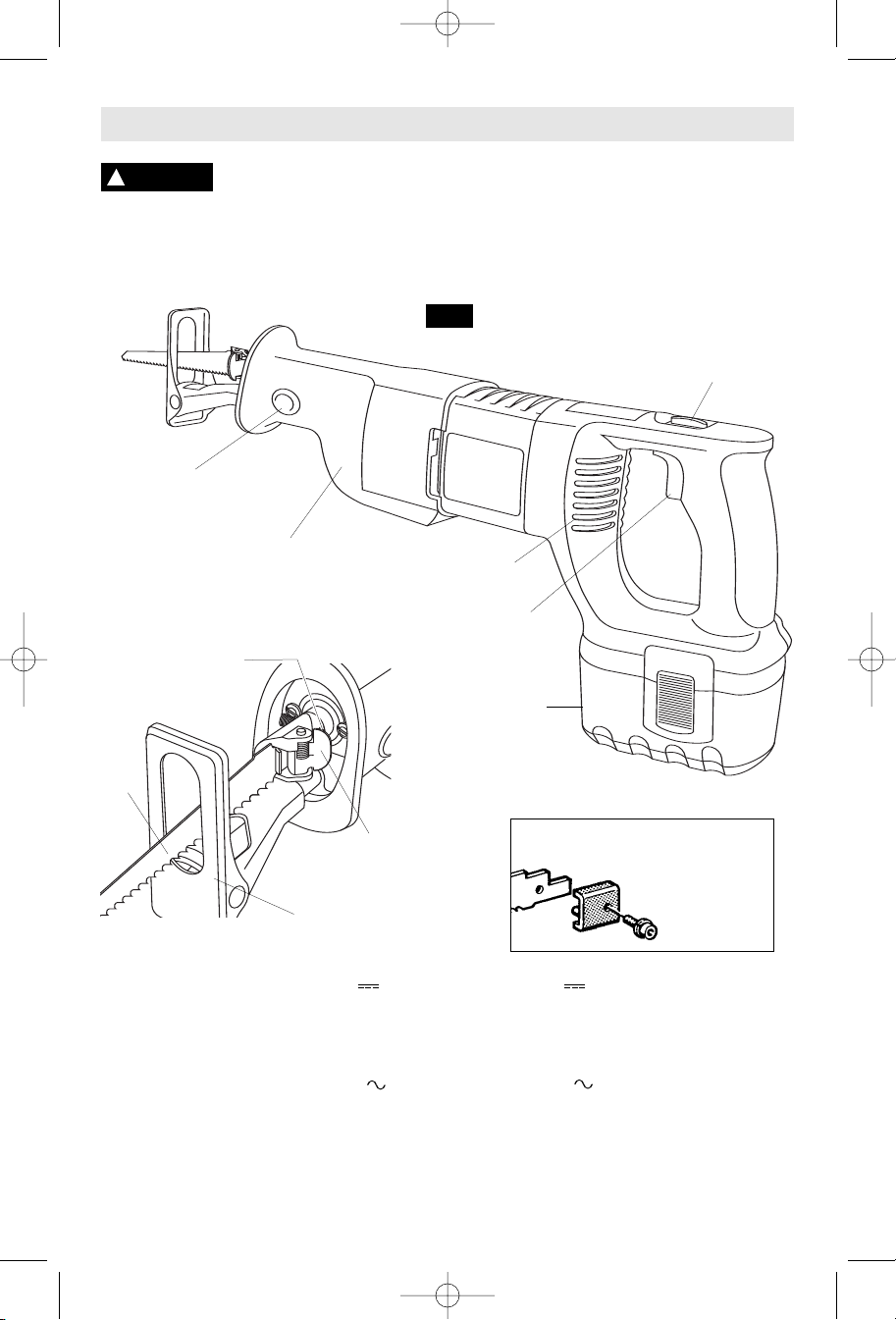

Functional Description and Specifications

WARNING

!

Disconnect battery pack from tool or place the switch in the locked

or off position before making any assembly, adjustments or

changing accessories

tool accidentally.

FOOTPLATE

RELEASE BUTTON

RUBBER BOOT

BLADE

CLAMP SET

SCREW

. Such preventive safety measures reduce the risk of starting the

Cordless Reciprocating Saw

FIG. 1

STROKE LENGTH/

LOCK-OFF SWITCH

AIR VENTS

VARIABLE

SPEED

TRIGGER

BATTERY

PACK

SAW

BLADE

BLADE CLAMP

RELEASE LEVER

ADJUSTABLE

FOOTPLATE

BASIC BLADE

CLAMP

(Optional)

Model Number 1644-24 1645-24

Voltage Rating

18 V

24 V

Stroke Length(s) 3/4”, 1 1/4” (19mm, 32mm) 3/4”, 1 1/4” (19mm, 32mm)

Strokes Per Minute n

0-2,300/min n00-2,300/min

0

Charger BC003, 4, 6, & BC016 BC004, 6, & BC016

BC130 & BC230 BC130 & BC230

Voltage rating 120 V 60 Hz 120 V 60 Hz

Battery pack BAT025 & BAT026 BAT030 & BAT031

BAT160 thru BAT189 BAT240 thru BAT299

BC006 charger requires 12 V DC input

NOTE: ONLY USE CHARGERS LISTED ABOVE

-7-

BM 2610925947 6-05 6/10/05 10:35 AM Page 8

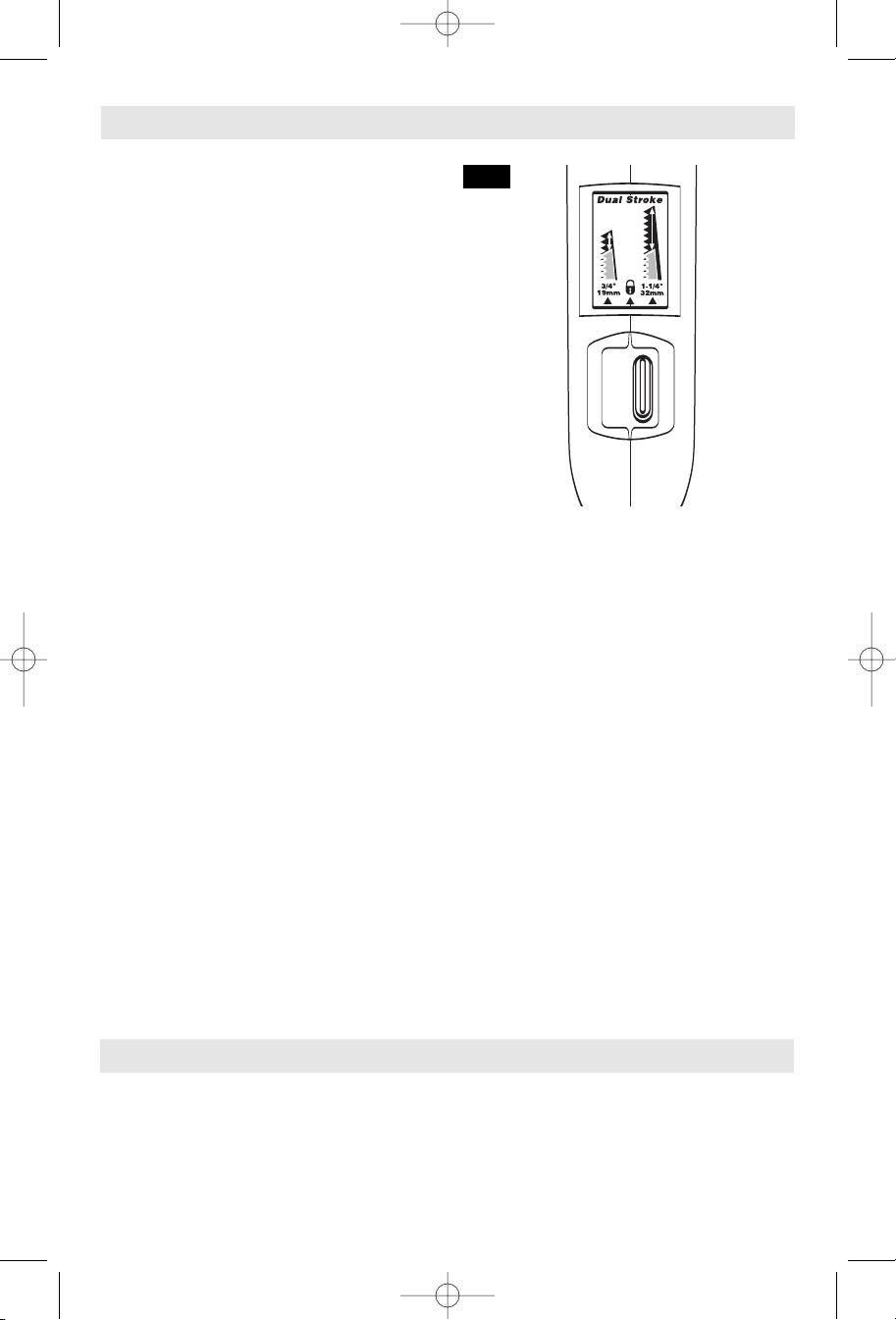

Operating Instructions

STROKE LENGTH/LOCK-OFF SWITCH

Your tool is equipped with a dual stroke-length

/ lock-off switch located on the top of the saw.

This lever is designed for choosing the stroke

length and for locking the trigger in the "OFF"

position to help prevent accidental starts and

accidental battery discharge. The tool should

be at a complete stop before changing stroke

lengths. For the 3/4" (19 mm) stroke, move

the switch to the far left. For the 1-1/4" (32

mm) stroke, move the switch to the far right.

To activate the trigger lock, move the switch to

the center position (Fig 2).

The 1-1/4" (32 mm) stroke is useful for fast,

aggressive cutting, especially in wood.

The 3/4" (19 mm) stroke offers a wide

variety of benefits:

• Reduced vibration of workpiece when

cutting thin or fragile workpiece materials,

such as sheet metal, thin plywood, or

plaster-and-lath walls.

• Reduced depth-of-cut and blade projection

beyond the far edge of the workpiece, such

as when cutting into a wall or when cutting

a pipe that runs along a wall.

• Easier pocket/plunge cutting.

• Precise starts of cuts.

• Increased pulling power (like a drill has

more torque in low gear).*

• Less heat from lower blade travel speed,

thus longer blade life.*

*These characteristics are especially

beneficial when cutting metal.

BRAKE

When the trigger switch is released it activates

the brake to stop the saw quickly. This is

especially useful when making repetitive cuts.

FIG. 2

VARIABLE SPEED CONTROLLED

TRIGGER SWITCH

Your tool is equipped with a variable speed

controlled trigger switch. The tool can be

turned "ON" or "OFF" by squeezing or

releasing the trigger. The blade plunger

stroke rate can be adjusted from the minimum

to maximum nameplate stroke rate by the

pressure you apply to the trigger. Apply more

pressure to increase the speed and release

pressure to decrease speed.

Higher speed settings are generally used for

fast cutting or when softer cutting materials

such as wood, composite materials, and

plastics. Slower speed settings are generally

used when precision is required or when

cutting harder materials. Materials typically cut

using slower speeds include sheet metal,

conduit, and pipe.

Preparing the Saw

BLADE SELECTION

No one blade can be efficient on all cutting

jobs. Different materials require specially

designed blades. Since your reciprocating

saw can cut so many materials, many types of

BOSCH blades are available. Be sure to use

the proper blade to insure proper cutting

performance.

-8-

BM 2610925947 6-05 6/10/05 10:35 AM Page 9

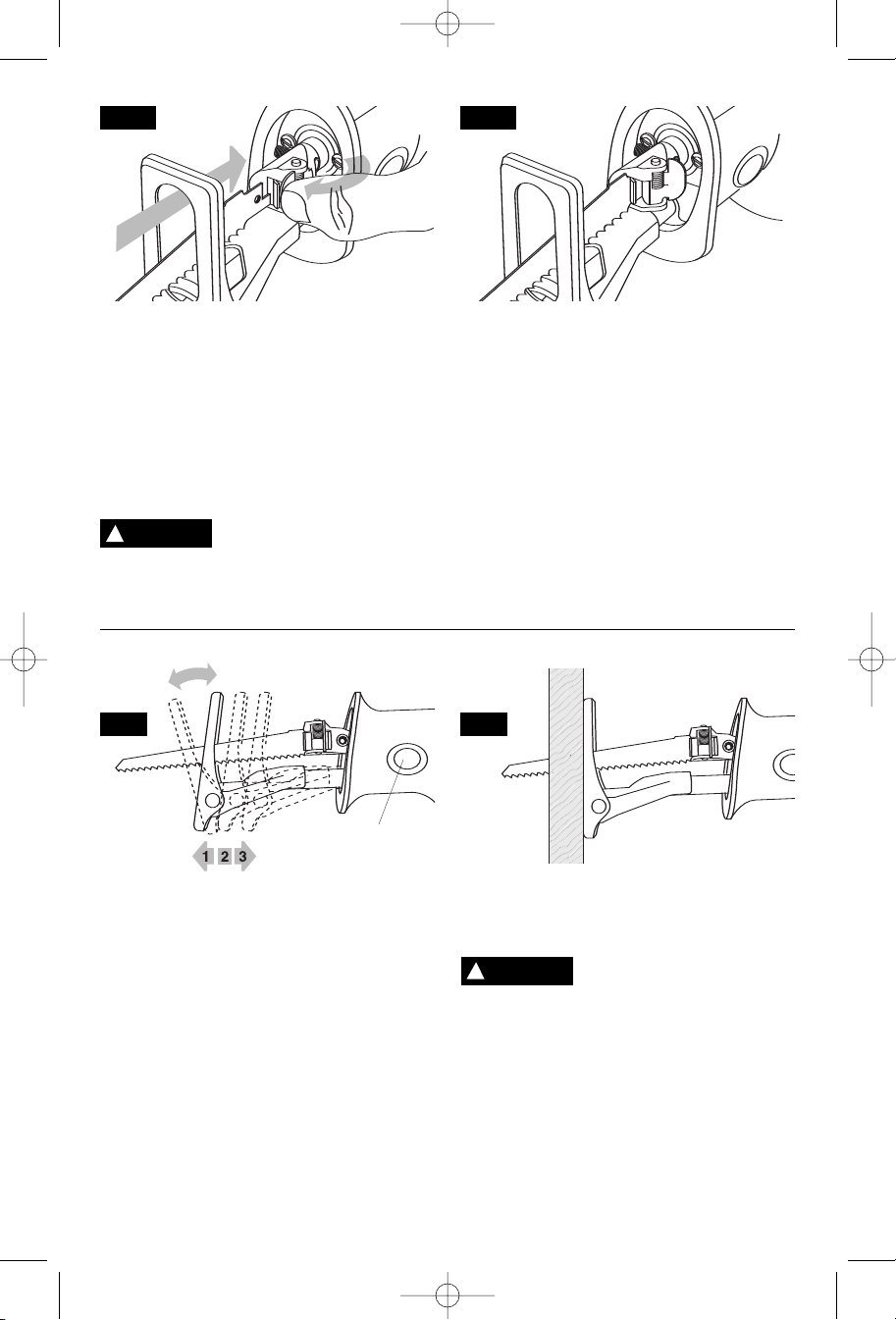

FIG. 3

Simply press the release lever forward to open

the tool-less clamp; insert the blade until it

stops and release the lever (Fig. 3). The

spring-loaded mechanism will lock the clamp

against the blade (Fig. 4). Push in and pull out

on the blade to be sure the pin in the clamp

housing goes through the hole in the blade to

hold the blade securely. The blade may be

inserted with the teeth facing down or up.

!

the footplate for the entire stroke length. Do

not use specialty blades that are very short or

INSTALLING A BLADE

WARNING

Make sure that the front end

of the blade extends through

(a)

FIG. 4

those with a significant cant. Blade must not

contact footplate. A blade which is too short or

canted could jam inside the foot and snap.

NOTE: If you require a basic (Allen wrench)

blade clamp for any reason (extra thick

blades, very thin blades, etc.) an optional

basic blade clamp kit is sold separately. It

contains a clamp, Allen wrench, screw and

lock washer. To use the basic clamp, remove

the tool-less clamp assembly by unscrewing

the setscrew that holds it onto the draw bar.

Then assemble the basic clamp with the

screw and lock washer provided (Fig. 1).

FIG. 5

(b)

FOOTPLATE ADJUSTMENT

The footplate tilts in order to keep as much of

its surface in contact with the work surface

Fig. 5 (a).

The footplate assembly can also be locked

into one of three projection positions to

optimize blade life and/or to reduce blade

protrusion beyond the end of the footplate,

such as when cutting into large diameter pipe

or into walls. To adjust the footplate position,

simply push the footplate release button and

move the footplate into the desired position.

The locking mechanism is spring-loaded to

lock into one of the 3 positions on the footplate

assembly. If the footplate is pulled out so far

that a notch shows at the other end of the

FOOTPLATE

RELEASE BUTTON

FIG. 6

shaft, the footplate assembly is extended too

far out, and must be retracted to the one of

the 3 positions Fig. 5 (b).

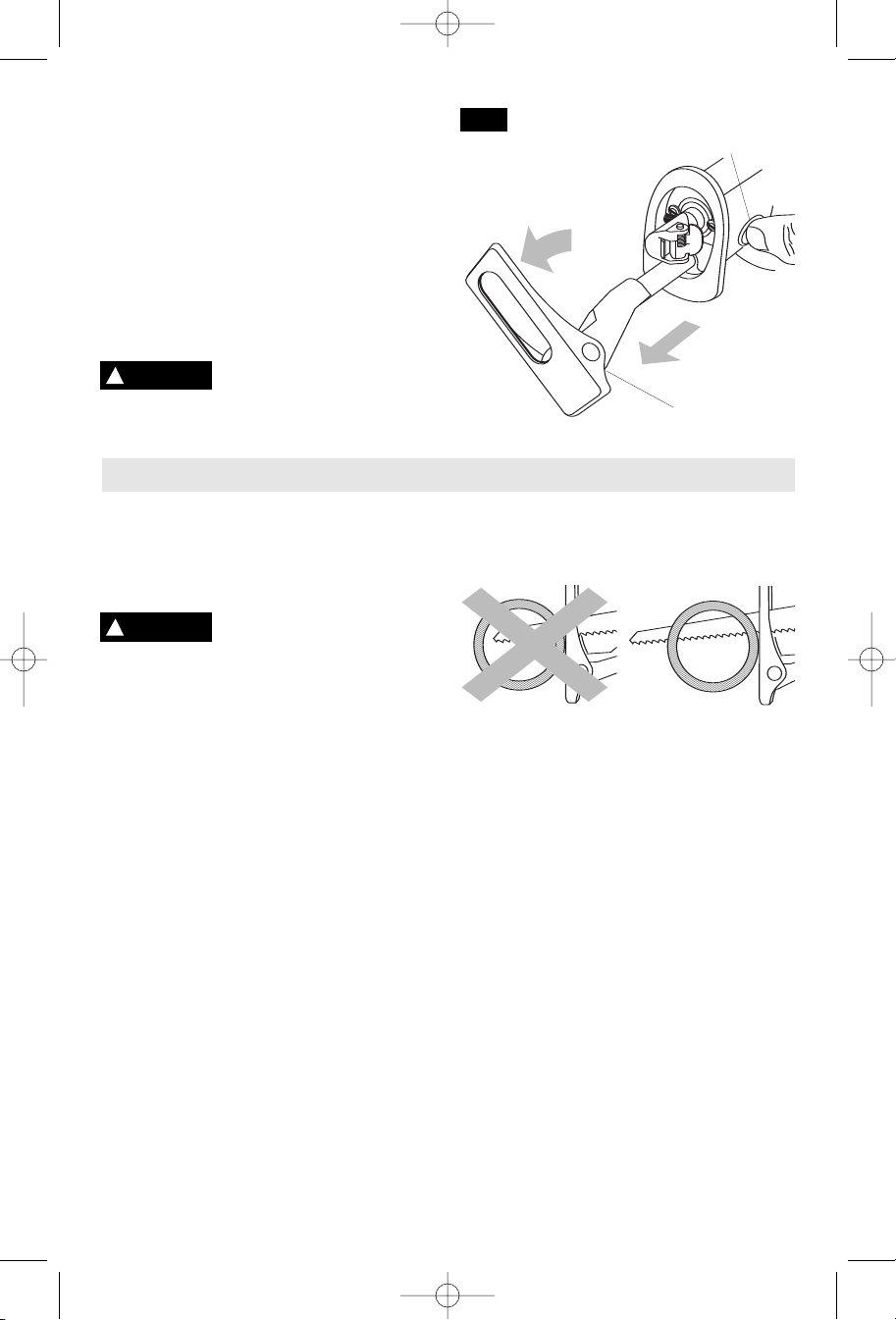

!

WARNING

It will cause the footplate to release from the

desired settings and you may lose control and

be injured.

To reduce the risk of injury, be sure the blade

extends beyond the footplate and all the way

through the workpiece throughout the stroke.

Blades may shatter if the blade hits the

footplate or hits the work at an angle that is

nearly head-on (Fig. 6).

Do not push the footplate

release button while sawing.

-9-

BM 2610925947 6-05 6/10/05 10:35 AM Page 10

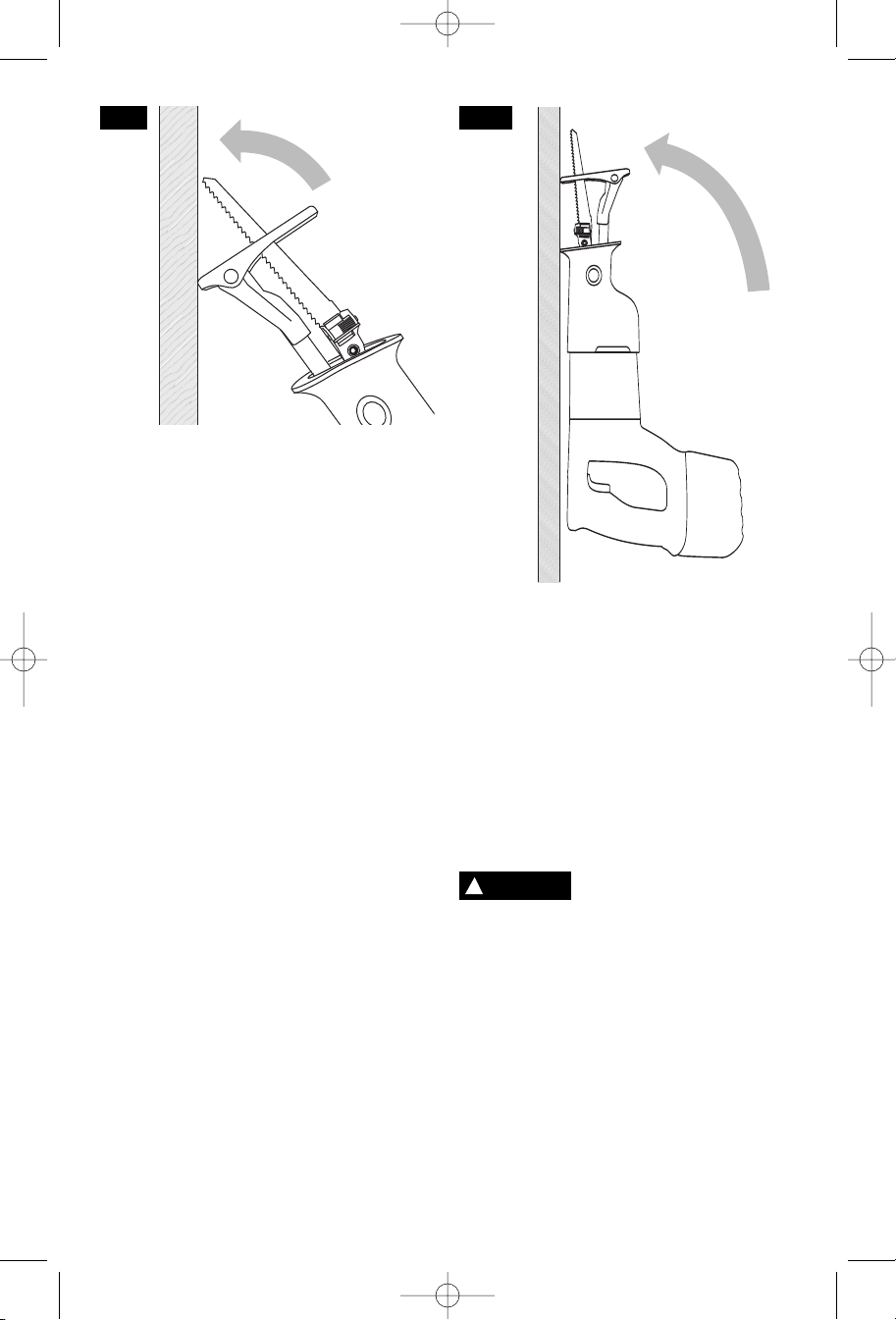

To remove the footplate assembly for

servicing (Fig. 7):

1. Remove the blade.

2. Press and hold footplate release button in.

3. Pull the footplate assembly out as far as it

will go.

4. Rotate it clockwise (as viewed from the

back of the saw) about 90 degrees until it

releases.

5. Pull footplate assembly completely out.

To re-insert, reverse this process.

!

WARNING

the footplate will cause instability, expose the

blade, and may damage the spindle.

Always use tool with the

footplate. Using tool without

Using the Saw

1. Securely clamp the work.

2. Mark the line of cut and grasp the tool with

one hand on the handle and the other

placed on the insulated rubber boot over

the front housing.

!

WARNING

housing. If you saw into a blind area where

live wiring exists, you may be shocked or

electrocuted.

3. Keep the saw footplate firmly against the

work to minimize counter-force (jumping)

and vibration.

4. Squeeze the trigger to start the tool. Let the

saw reach full speed before starting the cut.

Guide the saw so that the blade will move

along the marked line.

Following a few simple tips will reduce the

wear on the workpiece, the tool and the

operator.

1. Blades cut on the draw or back stroke. On

fine work, such as paneling, fiberglass, etc.,

place the good side of workpiece facing

down.

2. Use the correct saw blade for the material

being cut and keep extra blades on hand to

use when others become dull. Replace

cracked or bent blades immediately.

3. Select the appropriate stroke length and

footplate projection settings, as well as the

appropriate cutting speed.

4. To reduce the risk of injury, be sure the

blade always extends beyond the footplate

Always operate the saw with

the insulated boot on the front

SAWING TIPS

FIG. 7

and work throughout the stroke. Blades

may shatter if the front on the blade hits the

work and/or the footplate.

WRONG RIGHT

5. When cutting metal:

- Use the 3/4” (19 mm) stroke length to

achieve (less vibration, less heat, and

longer blade life).

- Apply a lubricant for easier, smoother,

faster cutting and longer blade life.

- For non-ferrous metals, aluminum,

bronze or brass, use a stick wax on the

blade.

- For ferrous metals, iron and steel, use

machine or cutting oil along the surface

to be cut.

6. When cutting thin metal, "sandwich" the

material between two pieces of scrap wood.

Clamp or put in a bench vise. One piece of

lumber on top of the metal can be used with

adequate clamping. Place your cut lines or

design on the wood. Use the 3/4" (19 mm)

stroke for reduced vibration in the material.

7.

Don’t force the cutting. Let the saw and

blade do the work.

FOOTPLATE

RELEASE

BUTTON

FOOTPLATE

ASSEMBLY

-10-

BM 2610925947 6-05 6/10/05 10:35 AM Page 11

FIG. 8 FIG. 9

The reciprocating saw can be used to make

plunge cuts into softer material, (for example,

wood or light building materials for walls),

without a starting hole (Fig. 8).

1. Mark the line to be cut clearly on the work.

2. Adjust the footplate position or change

3. Set the stroke length selector switch to the

4. Set the tool with the bottom edge of the

5. Place the tip of the blade (not running) on

6. Tilt the saw back so that the blade clears

7. Squeeze the trigger switch and carefully tilt

8.

9.

10. Continue sawing as needed.

POCKET/PLUNGE CUTS

blades as necessary.

3/4" (19 mm) stroke length.

footplate firmly against the material.

the line to be cut.

the work.

the tool forward to engage the moving saw

blade into the material.

After the blade penetrates through the work,

stop the saw and position it so that the front

of the footplate rests firmly against the

work.

Chose the appropriate stroke length for the

material, 3/4" (19 mm) or 1-1/4" (32 mm)

To make plunge cutting easier, use a heavy

gauge blade, install the blade with the teeth

facing upward, and hold the saw upside down

as shown (Fig. 9).

Do not plunge cut in metal surfaces.

In thick materials and in harder materials,

such as metal, plunge cutting should not be

attempted. Such materials can be cut with the

recip saw only by starting the cut from the

edge of the material or from a hole drilled all

the way through the material that is large

enough to fit the saw blade.

!

WARNING

may create a hazard.

NOTES:

The use of any accessories

not specified in this manual

-11-

BM 2610925947 6-05 6/10/05 10:35 AM Page 12

RELEASING AND INSERTING BATTERY PACK

Release battery pack from tool by pressing on

both sides of the battery release tabs and pull

downwards. Before inserting battery pack,

remove protective cap from battery pack.

To insert battery, align battery and slide

IMPORTANT CHARGING NOTES

1. The battery pack accepts only about 80% of

its maximum capacity with its first few charge

cycles. However, after the first few charge

cycles, the battery will charge to full capacity.

2. The charger was designed to fast charge

the battery only when the battery temperature

is between 40˚F (4˚C) and 105˚F (41˚C).

3. A substantial drop in operating time per

charge may mean that the battery pack is

nearing the end of its life and should be

replaced.

4. If you anticipate long periods (i.e. a month

or more) of non-use of your tool, it is best to

run your tool down until it is fully discharged

before storing your battery pack. After a long

period of storage, the capacity at first recharge

will be lower. Normal capacity will be restored

in two or three charge/discharge cycles.

battery pack into tool until it locks into

position. Do not force.

Remember to unplug charger during storage

period.

5. If battery does not charge properly:

in some other electrical device.

light switch which turns power “off” when lights

are turned off.

Clean with cotton swab and alcohol if

necessary.

take or send tool, battery pack and charger to

your local Bosch Service Center. See “Tools,

Electric” in the Yellow Pages for names and

addresses.

Note: Use of chargers or battery packs not

sold by Bosch will void the warranty.

a. Check for voltage at outlet by plugging

b. Check to see if outlet is connected to a

c. Check battery pack terminals for dirt.

d. If you still do not get proper charging,

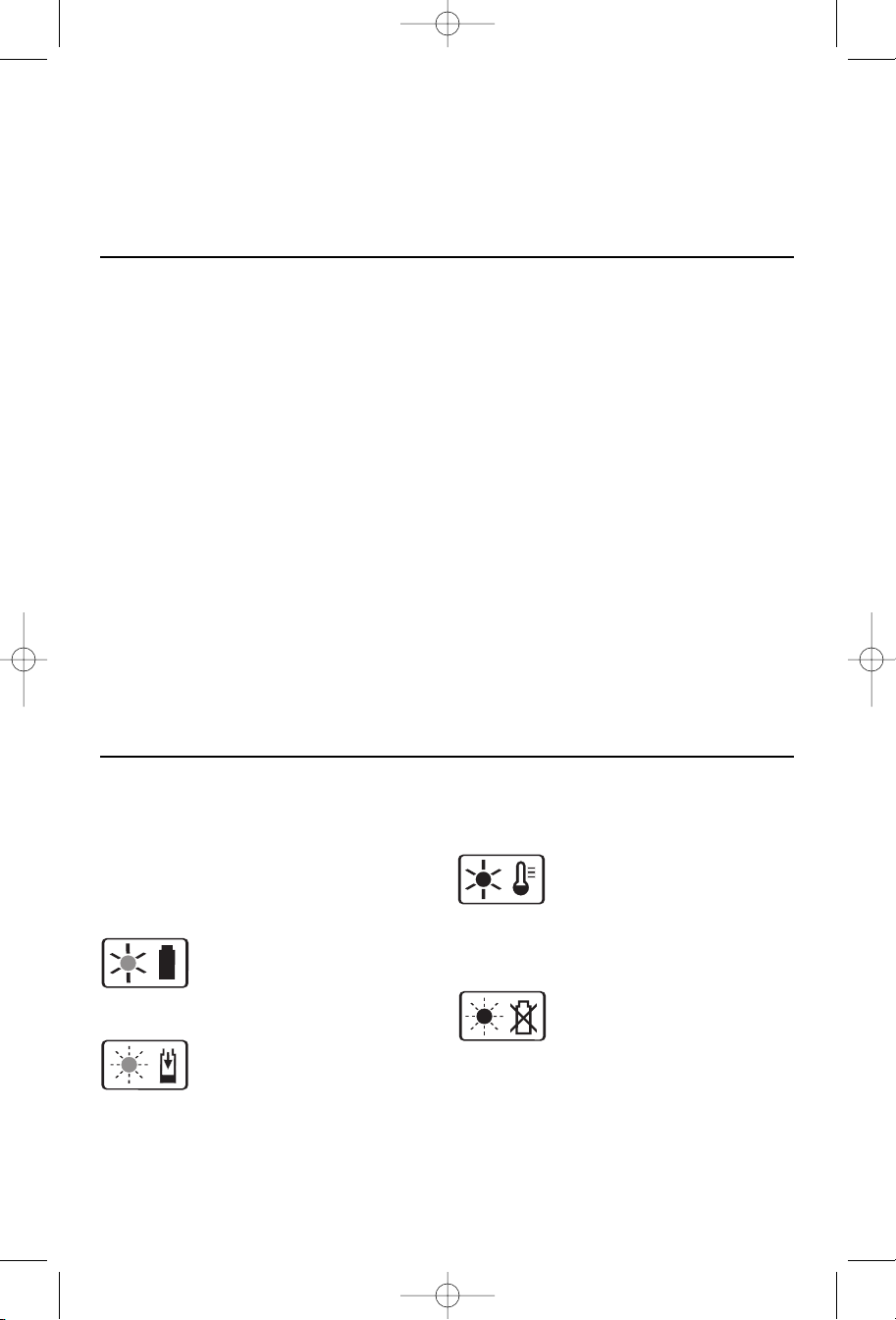

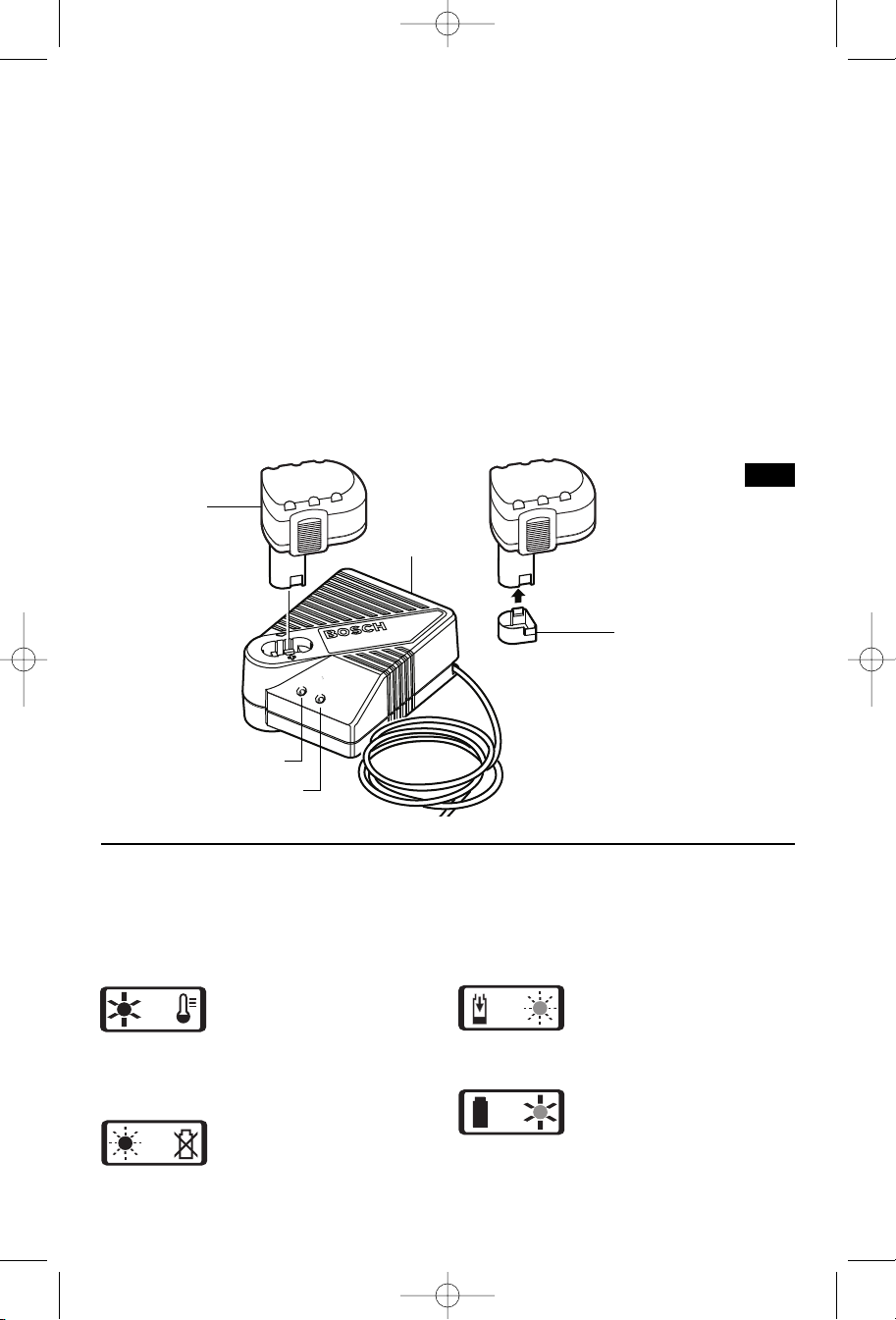

CHARGING BATTERY PACK (30 MINUTE SINGLE BAY-BC130)

INDICATORS, SYMBOLS AND MEANING

If the indicator lights are “OFF”, the charger

is not receiving power from power supply

outlet.

If the green indicator light is

“ON”, the charger is plugged in

but the battery pack is not

inserted, or the battery pack is fully charged

and is being trickle charged.

If the green indicator light is

“BLINKING”, the battery pack is

being fast-charged. Fastcharging will automatically stop when the

battery pack is fully charged.

If the red indicator light is “ON”,

the battery pack is too hot or

cold for fast-charging. The

charger will switch to trickle charge, until a

suitable temperature is reached, at which

time the charger will switch automatically to

fast-charging.

If the red indicator light is

“BLINKING”, the battery pack

cannot accept a charge or the

contacts of the charger or battery pack are

contaminated. Clean the contacts of the

charger or battery pack only as directed in

these operating instructions or those

supplied with your tool or battery pack.

-12-

BM 2610925947 6-05 6/10/05 10:35 AM Page 13

Plug charger cord into your standard power

outlet. Before inserting battery pack, remove

protective cap, then insert battery pack into

charger (Fig. 10).

T

he charger’s green indicator light will begin to

“BLINK”. This indicates that the battery is

receiving a fast charge. Fast-charging will

automatically stop when the battery pack is

fully charged.

When the indicator light stops “BLINKING”

(and becomes a steady green light) fast

charging is complete.

The battery pack may be used even though

the light may still be blinking. The light may

require more time to stop blinking depending

on temperature. When you begin the charging

process of the battery pack, a steady red light

BATTERY

PACK

CHARGER

could also mean the battery pack is too hot or

too cold.

The purpose of the green light is to indicate

that the battery pack is fast-charging. It does

not indicate the exact point of full charge. The

light will stop blinking in less time if the battery

p

ack was not completely discharged.

When charging several batteries in sequence,

the charge time may slightly increase.

When the battery pack is fully charged,

unplug the charger (unless you're charging

another battery pack) and slip the battery

pack back into the tool.

To prevent fire or injury when batteries are

not in tool or charger, always place protective

cap onto end of battery pack.

FIG. 10

PROTECTIVE

CAP

RED LIGHT

GREEN LIGHT

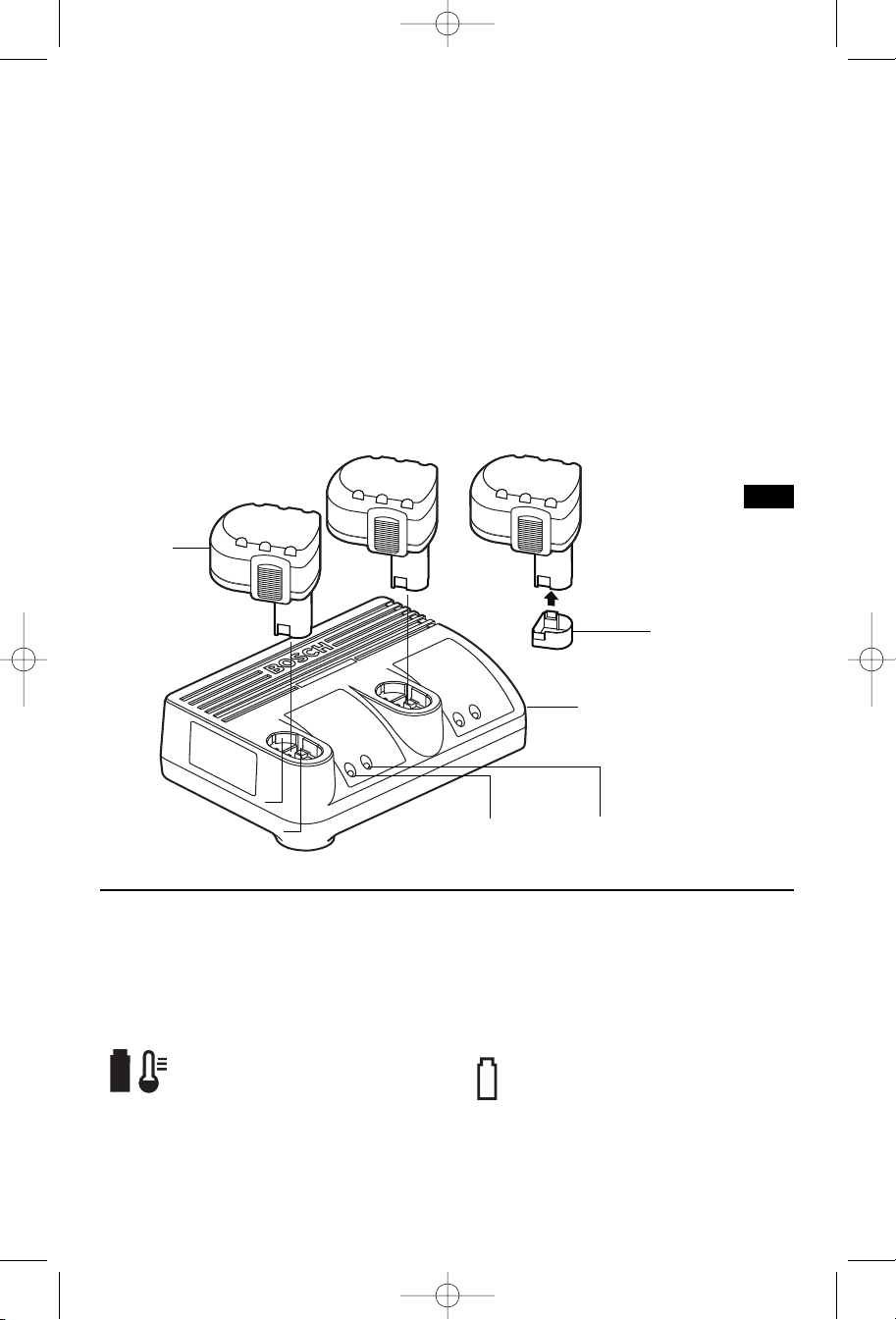

CHARGING BATTERY PACK (30 MINUTE DUAL BAY-BC230)

INDICATORS, SYMBOLS AND MEANING

If the indicator lights are “OFF”, the charger

is not receiving power from power supply

outlet.

If the red indicator light is

“ON”, the battery pack is too

hot or cold for fast-charging.

The charger will switch to trickle charge, until

a suitable temperature is reached, at which

time the charger will switch automatically to

fast-charging.

If the red indicator light is

“BLINKING”, the battery pack

cannot accept a charge or

the contacts of the charger or battery pack

are contaminated. Clean the contacts of the

charger or battery pack only as directed in

these operating instructions or those

supplied with your tool or battery pack.

If the green indicator light is

“BLINKING”, the battery pack

is being fast-charged. Fastcharging will automatically stop when the

battery pack is fully charged.

If the green indicator light is

“ON”, the charger is plugged

in but the battery pack is not

inserted, or the battery pack is fully charged

and is being trickle charged.

-13-

BM 2610925947 6-05 6/10/05 10:35 AM Page 14

Plug charger cord into your standard power

outlet. Before inserting battery pack, remove

protective cap, then insert battery pack into

charger (Fig. 11).

The charger’s green indicator light will begin to

“BLINK”. This indicates that the battery is

receiving a fast charge. Fast-charging will

automatically stop when the battery pack is

fully charged.

When the indicator light stops “BLINKING”

(and becomes a steady green light) fast

charging is complete.

The battery pack may be used even though

the light may still be blinking. The light may

require more time to stop blinking depending

on temperature. When you begin the

charging process of the battery pack, a

BATTERY

PACK

steady red light could also mean the battery

pack is too hot or too cold.

The purpose of the green light is to indicate

that the battery pack is fast-charging. It does

not indicate the exact point of full charge.

The light will stop blinking in less time if the

battery pack was not completely discharged.

When charging several batteries in

sequence, the charge time may slightly

increase.

When the battery pack is fully charged,

unplug the charger (unless you're charging

another battery pack) and slip the battery

pack back into the tool.

To prevent fire or injury when batteries are

not in tool or charger, always place protective

cap onto end of battery pack.

FIG. 11

PROTECTIVE

CAP

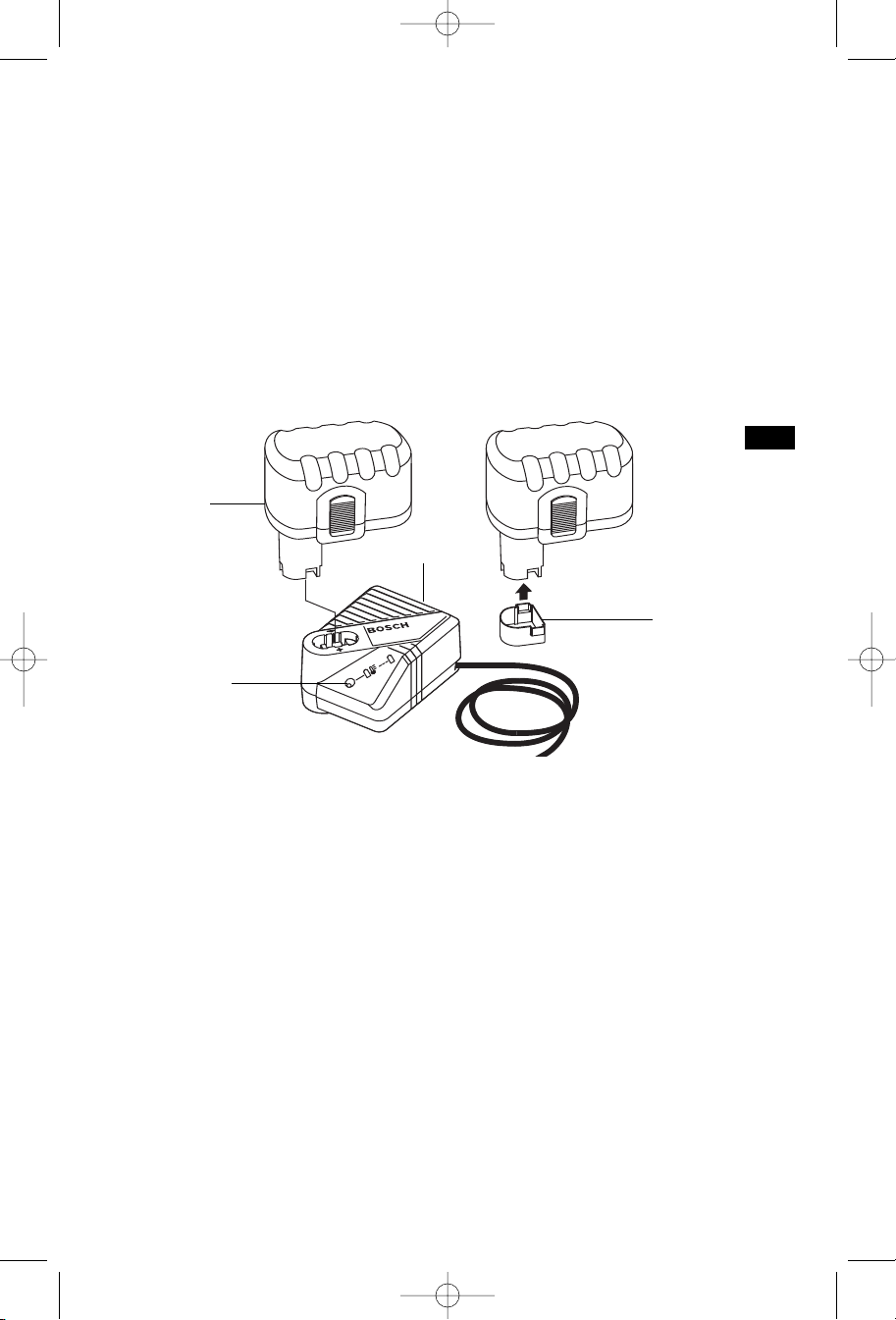

CHARGING BATTERY PACK (1 HOUR CHARGER)

INDICATORS, SYMBOLS AND MEANING

If the indicator lights are “OFF”, the charger

is not receiving power from power supply

outlet.

If the green indicator light is “ON”,

the charger is plugged in but the

battery pack is not inserted, or the

battery pack is fully charged and is being

trickle charged, or the battery pack is too hot

or cold for fast-charging. The charger will

CHARGER

RED LIGHT

GREEN LIGHT

switch to trickle charge, until a suitable

temperature is reached, at which time the

charger will switch automatically to fastcharging.

If the green indicator light is

“BLINKING”, the battery pack is

being fast-charged. Fast-charging

will automatically stop when the battery pack

is fully charged.

-14-

BM 2610925947 6-05 6/10/05 10:35 AM Page 15

CHARGING BATTERY PACK (1 HOUR CHARGER)

Plug charger cord into your standard power

outlet. Before inserting battery pack, remove

p

rotective cap, then insert battery pack into

c

harger (Fig. 12).

The charger’s green indicator will begin to

“

BLINK”. This indicates that the battery is

receiving a fast charge. Fast-charging will

automatically stop when the battery pack is

fully charged.

When the indicator light stops “BLINKING”

(and becomes a steady green light) fast

charging is complete.

When you begin the charging process of the

mean the battery pack is too hot or too cold.

The purpose of the light is to indicate that the

battery pack is fast-charging. It does not

indicate the exact point of full charge. The

light will stop blinking in less time if the

b

attery pack was not completely discharged.

When the battery pack is fully charged,

unplug the charger (unless you're charging

another battery pack) and slip the battery

pack back into the tool handle.

To prevent fire or injury when batteries are

not in tool or charger, always place protective

cap onto end of battery pack.

battery pack, a steady green light could also

BATTERY

PACK

CHARGER

FIG. 12

INDICATOR

LIGHT

PROTECTIVE

CAP

-15-

Loading...

Loading...