1615

0 601 615 0 . .

1615EVS

0 601 615 7 . .

Before use - Read this instruction manual.

Lisez attentivement la présente notice avant l'emploi.

Lea estas instrucciones de manejo antes de la utilización del aparato.

BM 3609929671 1/95 12/7/98, 11:56 AM1

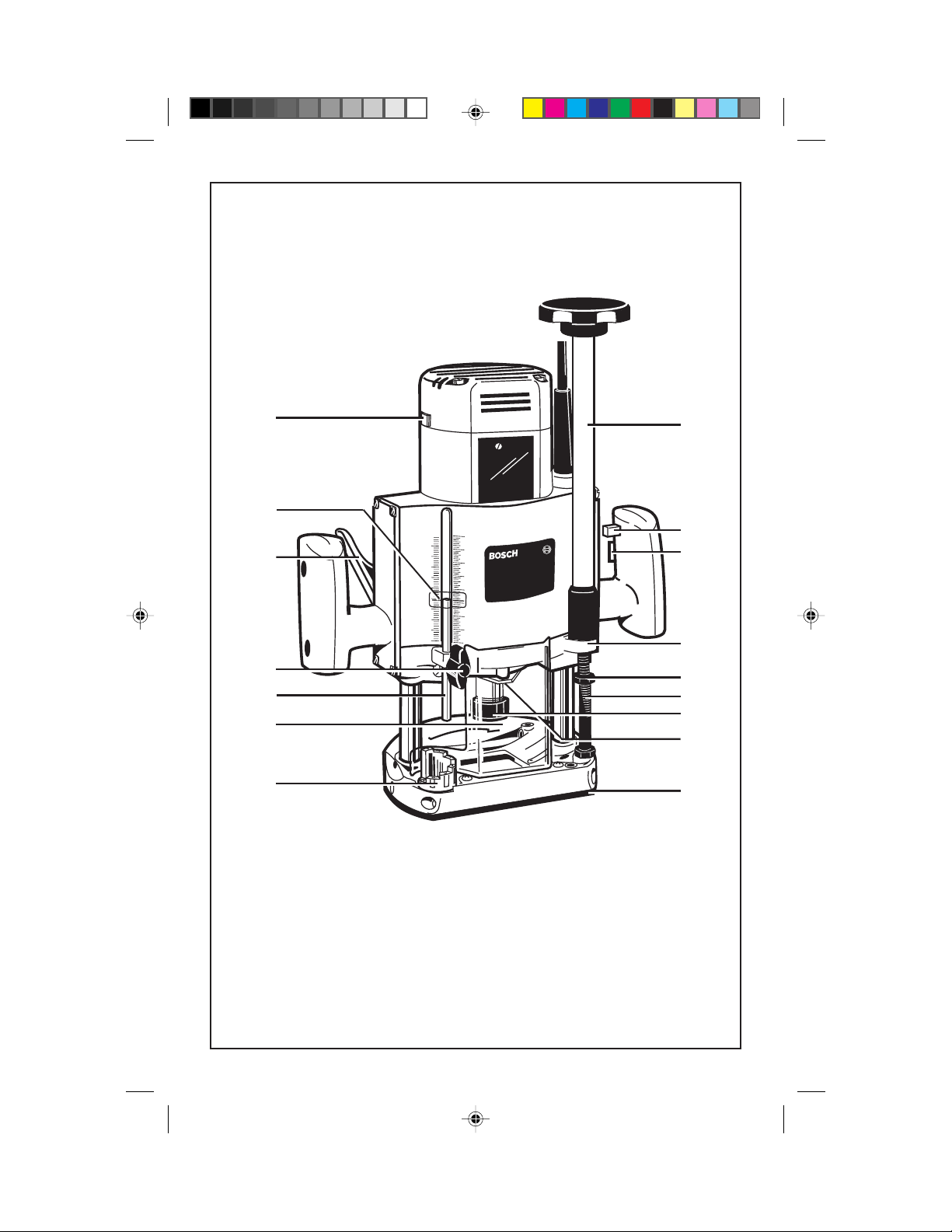

21

13

22

2

11

12

14

3

1

4

6

9

7

10

5

BM 3609929671 1/95 12/7/98, 11:56 AM2

8

2

Product Data - Plunge Router

Model number 1615 1615EVS

Identification number 0 601 615 0 . . 0 601 615 7. .

Collet capacity 1/4", 3/8", 1/2" dia. 1/4", 3/8", 1/2" dia.

Router bit capacity 2-5/8" dia. max. 2-5/8" dia. max.

( NOTE: This tool is designed for use with Alternating Current (AC) only. )

Accessory Listing

1/2 “ Collet Chuck Assy *

3/8 “ Collet Chuck Assy

1/4 “ Collet Chuck Assy*

27 mm Collet Nut Wrench*

Templet Guide Adapter w/2 screws*

Deluxe Router Guide

Steel Case

Fine Adjustment Accessory* *

Vacuum adapter

Vacuum Hose

Hose/Vacuum adaptor

( * = standard equipment )

(* * = standard equipment 1615EVS only)

Router Components

1. Depth indicator rod 12. Trigger switch

2. Depth indicator scale 13. Plunge lock/release lever

3. Depth indicator lock/release knob 14. Cast boss

4. Router base 15. Retaining ring

5. Revolving depth turret 16. Collet

6. Stop nut 17. Collet nut

7. Collet chuck assembly 18. Templet guide adaptor

8. Subbase 19. Templet guide

9. Threaded guide rod 20. Bit

10. Spindle lock 21. Variable speed dial (1615EVS)

11. “Lock-ON” button 22. Fine adjustment accessory (1615EVS)

(NOTE: router components not illustrated on page 2 are illustrated elsewhere in this manual)

3

BM 3609929671 1/95 12/7/98, 11:56 AM3

WARNING! “READ ALL INSTRUC-

TIONS”. Failure to follow the SAFETY RULES

identified by the BULLET (•) symbols listed

BELOW and other safety precautions, may

result in serious personal injury. Keep these

operating instructions with this product.

GENERAL SAFETY RULES

for all Power Tools

Work Area

• KEEP WORK AREAS CLEAN. Cluttered

areas and benches invite accidents.

• AVOID DANGEROUS ENVIRONMENT.

Don’t use power tools in damp or wet locations.

Do not expose power tools to rain. Keep work

area well lit.

• AVOID GASEOUS AREAS. Do not operate portable electric tools in explosive atmospheres in presence of flammable liquids or

gases. Motors in these tools normally spark,

and the sparks might ignite fumes.

• KEEP CHILDREN AWAY. Do not let

visitors contact tool or extension cord. All

visitors should be kept away from work areas.

Personal Safety

• GUARD AGAINST ELECTRIC SHOCK.

Prevent body contact with grounded surfaces

such as pipes, radiators, ranges and refrigerator

enclosures. Rubber gloves and non-skid footwear are recommended when working outdoors, where damp or wet ground may be

encountered. A Ground Fault Circuit Interrupter protected power line must be used for

these conditions.

• DRESS PROPERLY. Do not wear loose

clothing or jewelry. They can be caught in

moving parts. Wear protective hair covering to

contain long hair.

• USE SAFETY EQUIPMENT. WEAR

SAFETY GOGGLES or glasses with side

shields. Wear hearing protection during extended use of power tools and dust mask for

dusty operations.

• STAY ALERT. USE COMMON SENSE.

Watch what you are doing. Do not operate tool

when you are tired or under influence of drugs.

•

REMOVE ADJUSTING KEYS AND

WRENCHES.

keys and adjusting wrenches are removed from

Form habit of checking to see that

tool before turning it on.

• AVOID ACCIDENTAL STARTING. Don’t

carry plugged in tool with finger on switch. Be

sure the switch is OFF before being plugged in.

• DON’T OVERREACH. Keep proper footing and balance at all times.

• BEFORE CONNECTING THE TOOL to a

power supply (receptacle, outlet, etc.) be sure

the voltage supplied is the same as that specified on the tool’s nameplate. A power supply

with voltage greater than that specified for the

tool can result in serious injury to the user - as

well as damage to the tool. If in doubt, DO NOT

PLUG IN THE TOOL. Using a power supply

with voltage less than the nameplate rating is

harmful to the motor.

“Volts AC” designated tools are for Alternating

Current 50-60 Hz only. “Volts DC” designated

tools are for Direct Current. Do not use AC

designated tools with DC power supply. Do not

use electronic speed controlled tools with DC

power supply.

Tool Use and Care

• DON’T FORCE TOOL. It will do the job

better and safer at the rate for which it was

designed.

• USE RIGHT TOOL. Don’t force small tool

or attachment to do the job of a heavy-duty tool.

Don’t use tool for purpose not intended - for

example; don’t use a circular saw for cutting

tree limbs or logs.

• SECURE WORK. Use clamps or a vise to

hold work. It’s safer than using your hand and

it frees both hands to operate the tool.

• DON’T ABUSE CORD. Never carry tool by

cord or yank it to disconnect from receptacle.

Keep cord from heat, oil, and sharp edges.

Always keep cord away from the spinning

blade, bits or any other moving part while the

tool is in use.

• OUTDOOR USE EXTENSION CORDS.

When tool is used outdoors, use only extension

cords suitable for use outdoors and marked with

suffix W-A (for UL), or W (for CSA). Refer to

section “Extension Cords”, for proper cord use.

• DISCONNECT TOOLS. When not in use,

before servicing, or when changing blades,

bits, cutters, etc.

• STORE IDLE TOOLS. When not in use,

tools should be stored in dry, high or locked up

place - out of the reach of children.

4

BM 3609929671 1/95 12/7/98, 11:56 AM4

• DO NOT ALTER OR MISUSE TOOL.

These tools are precision built. Any alterations

or modifications not specified is misuse and

may result in a dangerous condition.

• THE USE OF ANY ACCESSORIES not

specified in this manual may create a hazard.

• MAINTAIN TOOLS WITH CARE. Keep

tools sharp and clean for better and safer performance. Follow instructions for lubricating and

changing accessories. Inspect tool cords periodically and if damaged, have repaired by authorized service facility. Inspect extension

cords periodically and replace if damaged. Keep

handles dry, clean and free from oil and grease.

• CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part that is

damaged should be carefully checked to determine that it will operate properly and perform

its intended function. Check for alignment of

moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect its operation. A guard or

other part that is damaged should be promptly

and properly repaired or replaced. Have defective switches replaced. Do not use tool if switch

does not turn it on or off.

• ALL REPAIRS, ELECTRICAL OR MECHANICAL, should be attempted only by

trained repairmen. Contact the nearest Bosch

Factory Service Center, or Bosch Authorized

Service Center or other competent repair center. Use only Bosch replacement parts, any

other may create a hazard.

Safety Rules for Routers

• If router bit is protruding through the base,

never lay the router down until the motor has

come to a complete standstill.

• Never hold the workpiece in one hand and

the router in other when in use. Always clamp

the material and hold the router securely with

both hands.

• Never use bits that have a cutting diameter

greater than the opening in the base.

• After changing the bits or making any adjustments, make sure the collet nut and any other

adjustment devices are securely tightened before using the router.

• The direction of feeding the router into the

material is very important and it relates to the

direction of bit rotation. When viewing the

router from the top, the bit rotates clockwise.

When the router is located between your body

and the material, the feed direction must be to

the right. If the material is located between your

body and the router, then the feed direction

must be to the left. Feeding the router in the

wrong direction, causes the cutting edge of the

bit to climb out of the work and pull the router

in the direction of this feed.

Double Insulated Tools

• Double Insulation is a design concept

used in electric power tools which eliminates

the need for the three wire grounded power cord

and grounded power supply system. It is a

recognized and approved system by

Underwriter’s Laboratories, CSA and Federal

OSHA authorities.

• Never start the router when the bit is engaged

in the material. The bit’s cutting edge may grab

the material causing the router to get out of

control. Always hold the router with two hands

during start-up. The reaction torque of the

motor can cause the router to twist.

• Always make sure the workpiece is free from

nails and other foreign objects which can cause

the bit and router to jump and damage the bit.

• Always wear safety goggles. If router has a

removable chip deflector, keep it in place when

routing.

• Never touch the router bit or other moving

part during use. After use the router bit is too

hot to be touched by bare hands.

BM 3609929671 1/95 12/7/98, 11:56 AM5

IMPORTANT: Servicing of a tool with

double insulation requires care and knowledge

of the system and should be performed only by

a qualified service technician. WHEN SERVICE IS REQUIRED USE ONLY IDENTICAL REPLACEMENT PARTS.

POLARIZED PLUGS: If your tool is equipped

with a polarized plug (one blade is wider than

the other), this plug will fit in a polarized outlet

only one way. If the plug does not fit fully in the

outlet, reverse the plug. If it still does not fit,

contact a qualified electrician to install the

proper outlet. To reduce the risk of electric

shock do not change the plug in any way.

5

Extension Cords

• Replace damaged cords immediately. Use of

damaged cords can shock, burn or electrocute.

• If an extension cord is necessary, a cord with

adequate size conductors should be used to

prevent excessive voltage drop, loss of power

or overheating. The table below shows the

correct size to use, depending on cord length

and amperage rating on the tool’s nameplate. If

in doubt, use the next heavier gauge. Always

use U.L. and CSA listed extension cords.

Ampere Rating (shown on nameplate)

0- 2.1- 3.5- 5.1- 7.1- 12.1-

2.0 3.4 5.0 7.0 12.0 16.0

25' 18 18 18 18 16 14

50' 18 18 16 16 14 12

75' 18 18 16 14 12 10

100' 18 16 14 12 10

150' 16 14 12 12 Wire Gauge

Cord Length

Note: The smaller the gauge number, the larger

the wire is in the cord.

"SAVE THESE INSTRUCTIONS"

Operating the Tool

Trigger Switch and “Lock-On” Button

Your tool can be turned “ON” or “OFF” by

squeezing or releasing the trigger. Your tool is

also equipped with “Lock-ON” button located

just above the trigger that allows continuous

operation without holding the trigger .

TO LOCK SWITCH ON: Squeeze trigger,

depress button and release trigger.

TO UNLOCK THE SWITCH: Squeeze trigger

and release it without depressing the “LockON” button.

WARNING! if the “Lock-ON” button is con-

tinuously being depressed, the trigger cannot be

released.

WARNING! Hold the tool with both hands

while starting the tool, since torque from the

motor can cause the tool to twist.

Variable Speed with Dial Setting

(1615EVS)

Your router is also equipped with a variable

speed dial 21. The router bit speed can be preset

from 12,000 to maximum nameplate RPM by

rotating the dial to the desired setting. The dial

may be set on or between any of six positions (1

= low through 5 = high). The "Lock-ON"

button may also be used with any setting of the

dial.

The following speeds generally apply, but precise settings are largely determined by

experience with the material being cut. Momentary speed variation is normal when starting

the router until the electronic regulator takes

control.

Dial Setting Material

1-3 Hardwoods, soft plastics,

(12,000 to nonferrous metals,

15,000 RPM) larger diameter router

bits and cutters.

4-5 Softwoods, plastics,

(16,500 to counter tops, smaller

19,000 RPM) diameter router bits and

cutters.

"Soft Start" Feature (1615EVS)

The router is equipped with the "soft start"

feature which gradually increases the starting

speed and torque, reducing the stress that occurs from a high torque start.

Start the tool before applying to work and let

the tool come to full speed before contacting

the workpiece. Lift the tool from the work

before releasing the switch. DO NOT turn the

switch "ON" and "OFF" while the tool is under

load; this will greatly decrease the switch life.

Router Bit Installation and Removal

WARNING! Always disconnect the tool

from the power supply before installing router

bits, accessories or making any adjustments.

Installing a Router Bit

Turn the armature shaft to align the flats with

the spindle lock 10, and push in with thumb to

hold the armature shaft firmly. Next, use the

27mm wrench supplied to loosen the collet

chuck assembly 7 in a counter-clockwise direction (viewed from under the router). Insert the

shank of the router bit into the collet chuck as

6

BM 3609929671 1/95 12/7/98, 11:56 AM6

far as it will go, and then back the shank out until

the cutters are approximately 1/8" to 1/4" away

from the collet nut face. With the bit inserted

and the spindle lock fully engaged, firmly tighten

the collet chuck assembly in a clockwise direction with the 27mm wrench. To avoid damage,

never tighten the collet chuck unless a bit of the

proper shank size is inserted.

and press the lever with the thumb of the left

hand. The motor may then be raised or lowered

to the desired position. The plunge lock/release

lever is spring-loaded, and will hold the router

motor in position when pressure on the lever is

released. When plunging, always apply uniform firm pressure to both handles to avoid

cocking the motor on the posts.

CAUTION! To minimize run-out and ensure

proper gripping, the bit should be inserted into

the collet as far as possible, and never less than

5/8".

CAUTION! Do not use router bits greater

than 2-5/8" in diameter as they will not fit

through the base casting.

Removing the Router Bit

To remove bit, use the spindle lock and wrench

as described above, and turn the collet chuck

assembly 7 in a counter-clockwise direction.

Once the collet chuck assembly is loosened,

continue to turn the collet chuck until it pulls the

collet free from its taper, and the bit can be

removed.

NOTE: The collet chuck is self-extracting; it is

NOT necessary to strike the collet chuck to free

the router bit.

Collet Chuck Care

With the router bit removed, continue to turn

the collet chuck counter-clockwise until it is

free of the shaft. To assure a firm grip, occasionally blow out the collet chuck with compressed air, and clean the taper in the armature

assembly shaft with a tissue or fine brush. The

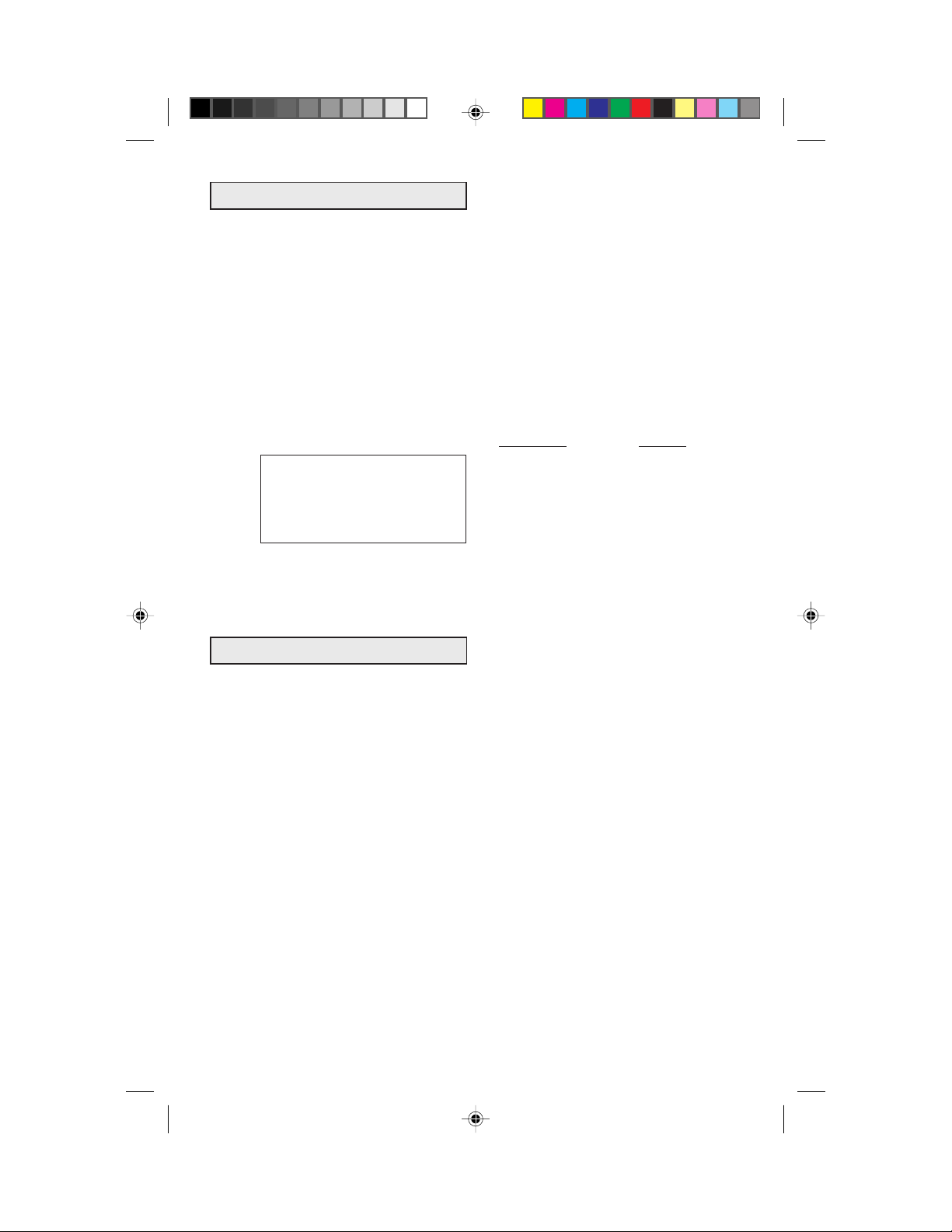

collet chuck is made up of three component

parts as illustrated; check to see that the retaining ring 15 is properly located around the collet

16 and seated in the inner groove of the collet

chuck nut 17 and lightly

thread the collet chuck

back onto the armature

shaft. Replace worn or

damaged collet chucks

immediately.

15

16

7

17

Plunge Lock/Release Lever

To release the plunge lock/release lever 13

grasp the router handles firmly with both hands

Indicator Rod and

Revolving Depth Turret

The depth indicator rod 1 and the revolving

depth turret 5 are used to control cutting depth

as follows;

With the bit installed, gently lower the motor

until the tip of the router bit just contacts the

level surface the router is sitting on. This is the

“zero” position, from which further depth adjustments can be accurately made. To set a

desired depth of cut, rotate depth turret until the

lowest step is aligned with the depth indicator

rod. Loosen depth indicator lock/release knob

3 and lower the depth indicator rod until it

contacts the lowest step of the turret. The reading of the red indicator line along the depth

indicator scale 2 now indicates the point at

which the bit just contacts the work, and is used

as a reference point to set the desired depth of

cut.

EXAMPLE: With the bit just contacting the

work surface, depth indicator rod 2 reads 3/4"

with the tip of the rod in contact with the turret.

To achieve a 1/2" depth of cut, loosen knob and

move the rod upward until the red line indicates

1 1/4", and tighten knob. Plunging the router

until the depth rodcontacts the depth turret will

now move the bit into the workpiece 1/2". To be

certain that your settings are accurate, you may

want to make test cuts in scrap material before

beginning work.

It is possible to make progressively deeper cuts

by starting with a higher flat on the depth turret

and rotating the turret to progressively lower

stops until the final cutting depth is reached.

Threaded Guide Rod

The threaded guide rod 9 is fitted with three stop

nuts 6. When not in use, these nuts should be

snugly seated at the top and bottom of the rod so

that they do not interfere with the plunge action.

7

BM 3609929671 1/95 12/7/98, 11:56 AM7

If a shorter stroke is desired, turn the upper stop

7

20

19

8

nut closest to the cast boss 14 on the motor

down to the desired position, and lock in place

by firmly tightening the other upper stop nut

against it. If a fixed depth setting is desired, (no

plunge action) tighten a stop nut on either side

of the boss and the depth of cut will be rigidly

set.

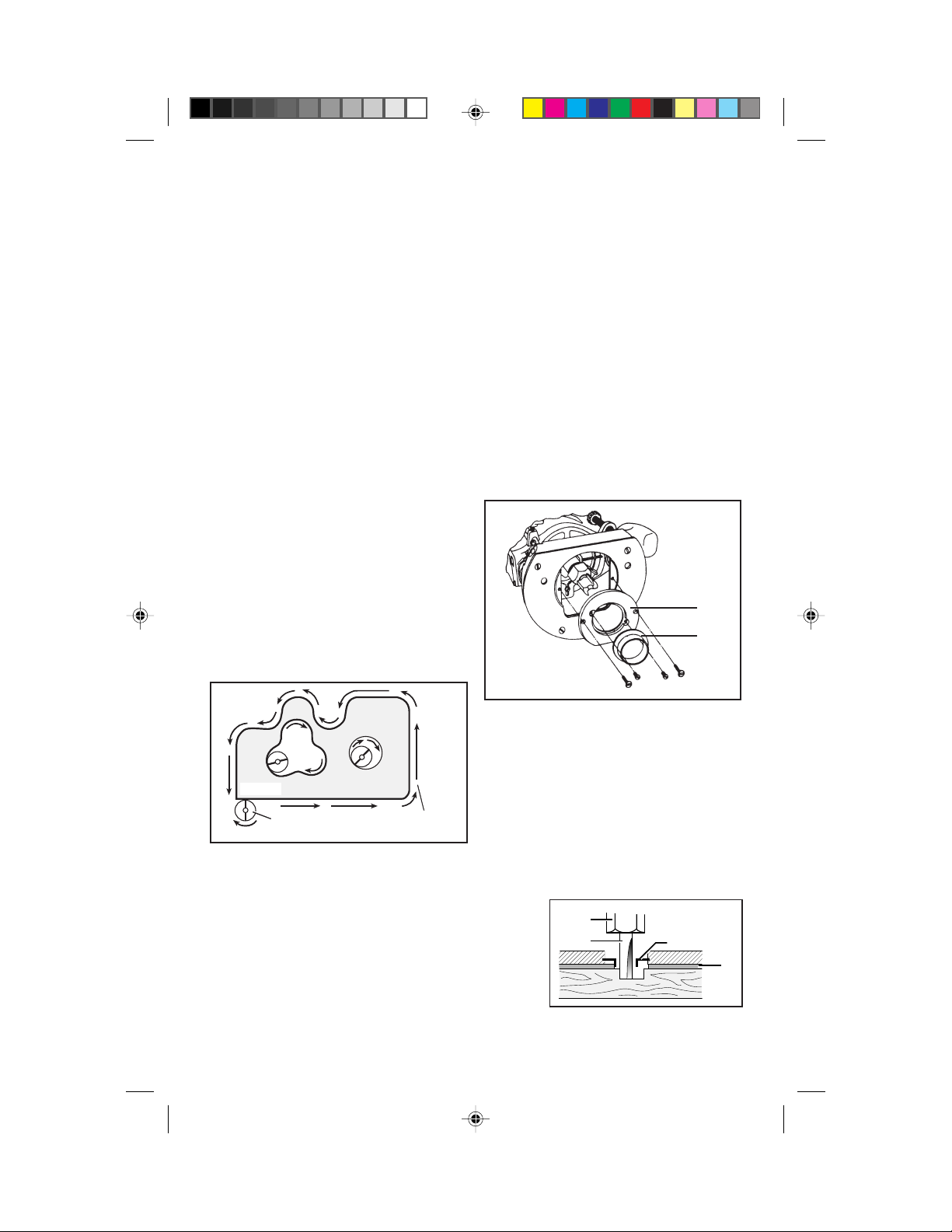

Direction of Feed

The router rotates in a clockwise direction as

viewed from the top. The correct relationship

between direction of bit or cutter rotation and

router feed is shown below. It is very important

to move the router in the proper direction or bit

chatter and rough cutting will be the result.

As an example, to rout a decorative edge on the

front of a table top, you would move the router

from left to right to perform the operation, or

counter-clockwise around the workpiece. If

you were cutting an opening in the center of a

panel, you would feed the router in a clockwise

direction, so that the edge of the opening would

be cut against the rotation of the bit as described, and have a smooth finish. Whenever

you are cutting completely around a workpiece,

it is advisable to cut across the grain first, so any

corner tearout may be smoothed by cutting with

the grain on the second pass.

start the tool when the bit is engaged. Always be

sure the collet nut is tightened securely before

use. Always use bits with the shortest cutting

length necessary to produce the desired cut to

minimize router bit run-out and chatter.

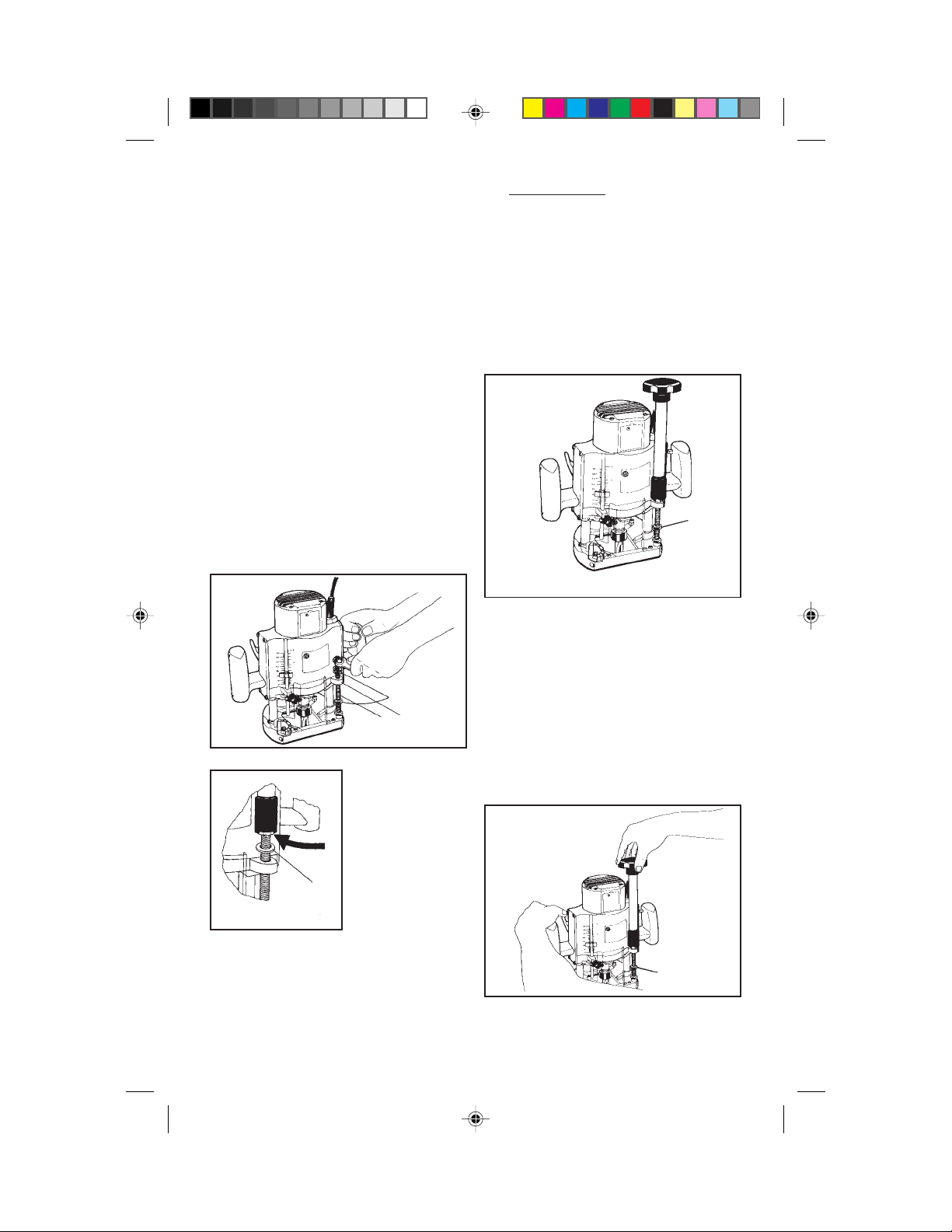

Templet Guides

To use the templet guides 19 that are listed in

the BOSCH catalog, your router is supplied

with a templet guide adaptor 18, which is fastened to the base with the two countersunk

screws provided. Optional templet guides may

be inserted and held in place along their edges

with the two screws provided with the templet

guide. Some templet guides have holes for

mounting, but these holes are not required for

use with the adaptor plate shown, as it grips the

edge of the templet guide.

18

19

Templet guides are used with a number of

accessories which are listed in your BOSCH

catalog. In addition, special templets are easily

prepared for cutting repeated patterns, designs,

WORK

CUTTER

DIRECTION

OF FEED

Rate of Feed

When routing or doing related work in wood

and plastics, the best finishes will result if the

depth of cut and feed rate are regulated to keep

the motor operating at high speed. Feed the

router at a moderate rate. Soft materials generally require a faster feed rate than hard materials.

The router may stall if improperly used or

overloaded. Reduce the feed rate to prevent

possible damage to the tool. Do not attempt to

inlays, and other applications. A templet pattern may be made of plywood, hardboard, metal

or even plastic, and the design can be cut with

a router, jigsaw, or other suitable cutting tool.

Patterns must compensate for the distance between the router bit and the templet guide, as the

final workpiece will differ in size from the

templet

pattern by

that

amount,

due to the

cutter position.

8

BM 3609929671 1/95 12/7/98, 11:56 AM8

(1615EVS) RA1001

Fine Adjustment Accessory

Installation and Operating Instructions

The RA1001 fine-adjustment accessory will

allow precise bit height adjustments on Bosch

routers. It is important to note that this accessory restricts the movement of the router motor

on the plunge base and effectively replaces the

normal plunge action with a threaded feed.

CAUTION; Always disconnect the tool from

the power source before installing bits, accessories, or making any adjustments. Never adjust this accessory when the tool is running or

the bit is in contact with the workpiece.

Installation

1. Plunge router down so that boss O on the

motor is not in contact with nuts J on threaded

guide rod I. Remove the 17mm locknut and two

flat nuts J from rod I with a suitable wrench

(Fig. 1).

Fig. 1

J

O

I

Fig. 2

Place washer K over

threaded rod, and reinstall one of the flat

nuts J about 3/8" from

the top of rod I. A

light film of general

purpose grease may

K

be applied to washer

K to help reduce friction (Fig. 2).

will protrude slightly from the cutaway end of

the RA1001 so that the face of the nut (NOT the

RA1001) will contact washer K. Figure 3

shows the RA1001 properly installed. If desired, 17mm nut J below boss O may be used to

lock the router in a fixed depth setting by

tightening it against the opposite side of boss O.

(Note: Keep the nuts you have removed in a

safe place so that they may be reinstalled on

your router if the RA1001 is removed for any

reason.)

Fig. 3

J

Operation

To use the RA1001, depress the plunge release

lever and turn the RA1001 clockwise to lower,

or counterclockwise to raise the bit. (Note that

one full turn of the knob will raise or lower the

bit approximately .060", or 1.5mm.) It is necessary to exert slight downward pressure on the

router handle opposite the RA1001, to avoid

cocking the motor on the posts (Fig. 4).

Fig. 4

2. Place the threaded end of the RA1001 over

the top of rod I and press it down to compress

the spring until the cutaway portion engages nut

J and thread adjuster onto rod. When the

RA1001 is properly installed, the 17mm nut J

BM 3609929671 1/95 12/7/98, 11:56 AM9

J

9

Deluxe Router Guide

For routing operations such as grooving or

dadoing, it is often necessary to guide the tool

in a line parallel to a straight edge. One method

of obtaining a straight cut is to securely clamp

a board or other straightedge to the work surface, and guide the edge of the router sub-base

along this path. It is best to keep the router in one

position as it is moved along the guide, as this

will produce the straightest cut.

The Bosch deluxe router guide is an accessory

that will guide the router parallel to a straight

edge or around a curved surface. The deluxe

router guide is supplied with two rods and a

series of wing nuts and screws to fasten the

guide and adjust its position relative to the bit.

With the guide installed and adjusted, the router

should be fed normally, keeping the guide in

contact with the edge of the workpiece at all

times. The deluxe router guide may also be

positioned under the router base for operations

where a limited amount of bit exposure is desired.

The Bosch deluxe router guide includes a

fine-adjustment mechanism for extra precision,

and removable face plates for guiding the router

along straight or curved surfaces. For proper

operation, please refer to the instructions which

are included with this accessory.

Chip Extraction

Your BOSCH plunge router may be fitted with

a chip extraction attachment to help keep your

work environment cleaner. This attachment

can be used for general routing, and has an

adjustable brush attachment that is especially

well-suited to grooving applications. Please

see your BOSCH Power Tool distributor for

more details about these and other optional

accessories.

WARNING! Use of any accessory not speci-

fied in this manual or the BOSCH catalog for

use with this tool may create a hazard.

Maintenance and Service

WARNING! Preventive maintenance per-

formed by unauthorized personnel may result

in misplacing of internal wires and components

which could cause serious hazard. We recommend that all tool service be performed at a

Bosch Factory Service Center.

Tool Lubrication

Your Bosch tool has been properly lubricated

and is ready for use. We recommend, that tools

with gears be regreased with a special gear

lubricant every time the brushes are changed.

Carbon Brushes

The brushes and commutator in your Bosch

tool have been engineered for many hours of

dependable service. To maintain peak efficiency of the motor, we recommend that every

two to six months the brushes be examined.

Only genuine Bosch replacement brushes specially designed for your tool should be used.

Bearings

After about 300-400 hours of operation, or at

every second brush change, the bearings should

be replaced at a Bosch Factory Service Center.

Bearings which become noisy (due to heavy

load or very abrasive material cutting) should

be replaced at once to avoid overheating and

motor failure.

Cleaning

WARNING! To avoid accidents, always

disconnect the tool from the power supply

before cleaning or performing any maintenance.

The tool may be cleaned most effectively with

compressed air. Always wear safety goggles

when cleaning tools with compressed air.

Ventilation openings and switch levers must be

kept clean and free of foreign matter. Do not

attempt to clean by inserting pointed objects

through openings.

CAUTION! Certain cleaning agents and

solvents damage plastic parts. Some of these

are: gasoline, carbon tetrachloride, chlorinated

cleaning solvents, ammonia and household

detergents that contain ammonia.

BM 3609929671 1/95 12/7/98, 11:56 AM10

10

WARRANTY

BOSCH

S-B POWER TOOL COMPANY

LIMITED WARRANTY

S-B Power Tool Company (“Seller”) warrants,

to the original purchaser only, that all BOSCH

portable power tools will be free from defects in

material or workmanship for a period of one (l)

year from date of purchase. SELLER’S SOLE

OBLIGATION AND YOUR EXCLUSIVE

REMEDY under this Limited Warranty and, to

the extent permitted by law, any warranty or

condition implied by law, shall be the repair or

replacement of parts, without charge, which are

defective in material or workmanship and which

have not been misused, carelessly handled, or

misrepaired by persons other than Seller or

Authorized Service Stations. To make a claim

under this Limited Warranty, you must return

the complete portable power tool product, transportation prepaid, to any BOSCH Factory Service Center or Authorized Service Station. A

listing of U.S. BOSCH Factory Service Centers

is packed with each BOSCH Power Tool. For

BOSCH Power Tool Authorized Service Stations, please refer to your phone directory.

THIS LIMITED WARRANTY DOES NOT

APPLY TO ACCESSORY ITEMS SUCH AS

CIRCULAR SAW BLADES, DRILL BITS,

ROUTER BITS, JIGSAW BLADES, SANDING BELTS, GRINDING WHEELS AND

OTHER RELATED ITEMS. ANY IMPLIED

WARRANTIES SHALL BE LIMITED IN

DURATION TO ONE (1) YEAR FROM DATE

OF PURCHASE. SOME STATES IN THE

U.S. DO NOT ALLOW LIMITATIONS ON

HOW LONG AN IMPLIED WARRANTY

LASTS, SO THE ABOVE LIMITATION

MAY NOT APPLY TO YOU. IN NO EVENT

SHALL SELLER BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES (INCLUDING BUT NOT LIMITED

TO LIABILITY FOR LOSS OR PROFITS)

ARISING FROM THE SALE OR USE OF

THIS PRODUCT. SOME STATES IN THE

U.S. DO NOT ALLOW THE EXCLUSION

OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE

ABOVE LIMITATION OR EXCLUSION

MAY NOT APPLY TO YOU. THIS LIMITED WARRANTY GIVES YOU SPECIFIC

LEGAL RIGHTS, AND YOU MAY ALSO

HAVE OTHER RIGHTS WHICH VARY

FROM STATE TO STATE.

S-B Power Tool Company

4300 W. Peterson Avenue

Chicago, IL 60646-5999

BM 3609929671 1/95 12/7/98, 11:56 AM11

11

Fiche technique - Toupie de coupe en plongée

Numéro de modèle 1615 1615EVS

Numéro d’identification 0 601 615 0.. 0 601 615 7..

Capacité de la douille 1/4", 3/8", 1/2" de diamètre 1/4", 3/8", 1/2" de diamètre

Taille maximale du fer 2-5/8" de diamètre 2-5/8" de diamètre

(REMARQUE: Cet outil ne fonctionne qu’au courant alternatif (c.a.).

Accessoires

Ensemble mandrin-douille 1/2"*

Ensemble mandrin-douille 3/8"

Ensemble mandrin-douille 1/4"*

Clé pour écrou de douille 27 mm*

Adaptateur pour guide de gabarit et 2 vis*

Guide de luxe

Coffret en acier

Accessoire de réglage précis* *

Raccord d’aspirateur

Boyau d’aspirateur

Adaptateur boyau/aspirateur

( * = Équipement standard )

( * * = Équipement standard 1615EVS Seulement )

Composants de la toupie

1. Guide de profondeur

2. Règle de profondeur

3. Bouton de serrage du guide

4. Base

5. Tourelle de profondeur tournante

6. Écrou d’arrêt

7. Ensemble mandrin/douille

8. Embase

9. Tige de guidage filetée

10. Dispositif de verrouillage de l’arbre

11. Bouton de blocage en marche

(REMARQUE: les composants de la toupie qui ne sont pas illustrés à la page 2 le sont ailleurs

dans le présent manuel).

BM 3609929671 1/95 12/7/98, 11:56 AM12

12. Gâchette de commande

13. Levier de réglage en plongée

14. Bossage coulé

15. Anneau de retenue

16. Douille

17. Écrou de douille

18. Adaptateur pour guide de gabarit

19. Guide de gabarit

20. Fer

21. Cadran de vitesse (1615EVS)

22. Accessoire de réglage précis (1615EVS)

12

AVERTISSEMENT ! «LISEZ

ATTENTIVEMENT TOUTES LES INSTRUCTIONS». Faute d’observer les

RÈGLES DE SÉCURITÉ précédées d’un point

noir (°) et les autres consignes du présent manuel

risque de vous exposer à de graves blessures.

Conservez ces instructions à portée de la main.

RÈGLES GÉNÉRALES DE

SÉCURITÉ

pour tous les outils motorisés

Lieu de travail

• TRAVAILLEZ DANS LA PROPRETÉ. Les

endroits et les établis encombrés invitent les

accidents.

• ÉVITEZ LES ENVIRONNEMENTS

DANGEREUX. N’utilisez pas les outils

électriques en lieux humides ou mouillés.

N’exposez pas les outils motorisés à la pluie.

Assurez-vous que l’endroit est adéquatement

éclairé.

• ÉVITEZ LES ENVIRONNEMENTS

GAZEUX. N’utilisez pas les outils électriques

portatifs en atmosphères explosives en présence

de liquides ou de gaz inflammables. Les moteurs

de ces outils émettent normalement des

étincelles qui risquent d’enflammer les vapeurs.

• GARE AUX ENFANTS. Ne permettez pas

aux visiteurs de toucher l’outil ou la rallonge.

Tenez-les à distance raisonnable du lieu de

travail.

Sécurité personnelle

• GARE AUX DÉCHARGES

ÉLECTRIQUES. Évitez tout contact avec les

surfaces mises à la terre telles que tuyaux,

radiateurs, cuisinières et enceintes de

réfrigérateurs. Pour le travail à l’extérieur, par

temps humide ou sur sol mouillé, il est

recommandé de porter des gants en caoutchouc

et des chaussures à semelle antidérapante. Dans

ce cas, vous devez utiliser une prise de courant

protégée par disjoncteur de fuite à la terre.

• PORTEZ DES VÊTEMENTS

CONVENABLES. Ne portez pas de vêtements

amples ni de bijoux car ils risquent de

s’accrocher dans les pièces mobiles. De même,

pour les cheveux longs, nous conseillons le port

d’un serre-tête.

• UTILISEZ L’ÉQUIPEMENT DE

SÉCURITÉ. Portez des lunettes de sécurité ou

lunettes à coques latérales. Portez des protègeoreilles lors des travaux de longue durée et un

masque protecteur si la situation l’exige.

• SOYEZ VIGILANT, FAITES PREUVE DE

DISCERNEMENT. Agissez prudemment.

N’utilisez pas l’outil quand vous êtes fatigué ou

sous l’influence de stupéfiant.

• ENLEVEZ LES CLÉS DE RÉGLAGE ET

AUTRES. Prenez l’habitude de voir à ce qu’elles

soient mises de côté avant de mettre l’outil en

marche.

• ÉVITEZ LA MISE EN MARCHE

ACCIDENTELLE. Ne transportez pas un outil

en marche. Assurez-vous que l’interrupteur est

en position d’arrêt avant de le brancher.

• TRAVAILLEZ AVEC APLOMB. Tenezvous bien d’aplomb et en équilibre en tout

temps.

• AVANT DE BRANCHER L’OUTIL à une

prise de courant, rassurez-vous que la tension

correspond à celle spécifiée sur la plaquette

emblématique de l’outil. Une tension supérieure

à celle recommandée pour l’outil risque de

blesser sérieusement l’utilisateur sans

mentionner l’endommagement de l’outil. NE

BRANCHEZ PAS L’OUTIL à moins que vous

soyez absolument satisfait. Le raccordement à

une source de courant dont la tension est

inférieure à celle indiquée sur la plaquette

endommagera le moteur.

Les outils portant la désignation «AC» ne

s’alimentent que de courant alternatif de 50-60

Hz. Les outils portant la désignation «DC»

s’alimentent de courant continu. N’enfichez

pas d’outils CA à une source d’alimentation c.c.

Ne branchez pas les outils àrégulateur

électronique de vitesse à une source

d’alimentation c.c.

Utilisation et entretien

• N’ABUSEZ PAS DE L’OUTIL. Il est plus

efficace et sûr au régime pour lequel il a été

destiné.

• UTILISEZ L’OUTIL APPROPRIÉ. Ne

forcez pas un petit outil ou un accessoire

àeffectuer le travail d’un de plus grosse taille.

N’utilisez pas l’outil à tort et à travers - par

exemple - n’utilisez pas une scie circulaire pour

tailler les branches d’arbres ou les bûches.

• FIXEZ LE MATÉRIAU EN PLACE.

13

BM 3609929671 1/95 12/7/98, 11:56 AM13

Utilisez des serre-joints ou un étau. C’est

beaucoup plus sûr et vous pouvez manier l’outil

des deux mains.

• N’ABUSEZ PAS DU CORDON. Ne

transportez jamais l’outil par le cordon et ne

tirez jamais sur ce dernier pour le débrancher.

Protégez le cordon de la chaleur, de l’huile et

des bords tranchants. Gardez toujours le cordon à bonne distance de la lame, des accessoires

ou autres pièces mobiles de l’outil en marche.

• CORDONS DE RALLONGE POUR

EXTÉRIEUR. Quand vous utilisez l’outil à

l’extérieur, n’employez que des rallonges

destinées à tel usage et portant les suffixes

d’homologation, soit W-A (pour les UL) soit W

(pour l’ACNOR). Voir le tableau «Dimensions

des rallonges recommandées».

• DÉBRANCHEZ LES OUTILS. Quand ils

ne servent pas; avant l’entretien; avant de

changer les lames, les mèches, les couteaux,

etc.

• RANGEZ LES OUTILS NE SERVANT

PAS. Suivant leur usage, les outils devraient

être rangés dans un endroit sec, élevé ou sous

clé - hors de la portée des enfants.

• NE MODIFIEZ NI ABUSEZ DE L’OUTIL.

Ces outils sont extrêmement précis. Tout

changement ou modification non recommandé

constitue un mésusage risquant d’avoir de graves

répercussions.

• L’USAGE D’ACCESSOIRES AUTRES que

ceux recommandés dans le présent manuel peut

être dangereux.

• TRAITEZ LES OUTILS AVEC SOIN.

Maintenez-les bien propres et bien à point pour

qu’ils fonctionnent en douceur. Observez les

directives concernant le graissage et le

changement des accessoires. Examinez

périodiquement l’état des cordons de l’outil et,

au besoin, confiez-en la réparation à un poste

d’entretien agréé. Examinez périodiquement

l’état des cordons de rallonge et remplacez-les

au besoin. Maintenez les poignées sèches,

propres, sans souillure d’huile et de graisse.

• RECHERCHEZ LES PIÈCES

ENDOMMAGÉES. Avant d’utiliser l’outil,

examinez soigneusement l’état des pièces telles

que le protecteur pour vous assurer qu’elles

fonctionnent correctement. Vérifiez

l’alignement et la liberté de fonctionnement des

pièces mobiles, l’état et le montage des pièces

et toutes autres conditions susceptibles d’affecter

défavorablement le fonctionnement. Il faut

réparer ou remplacer toute pièce ou tout

protecteur dont l’état laisse à désirer. Faites

remplacer tout interrupteur défectueux.

N’utilisez pas un outil dont l’interrupteur ne

fonctionne pas correctement.

• TOUTES LES RÉPARATIONS,

ÉLECTRIQUES OU MÉCANIQUES,

devraient être exécutées par des techniciens

compétents. Confiez-les au centre de serviceusine le plus proche, à un autre centre de service

après-vente Bosch agréé ou, encore, à un poste

d’entretien renommé. Pour vous éviter des

ennuis, exigez toujours les pièces de rechange

Bosch.

Règles de sécurité concernant

les toupies

• Ne mettez jamais la toupie en marche alors

que le fer est enfoui dans le matériau. Le

tranchant du fer peut gripper dans le matériau

rendant la toupie incontrôlable. Tenez toujours

la toupie à deux mains au moment de la mettre

en marche. Le couple du moteur de la toupie

peut donner un contrecoup.

• Assurez-vous toujours qu’aucun clou et autres

obstacles semblables ne soient enfouis dans la

pièce, car ils peuvent faire sauter la toupie et le

fer et abîmer ce dernier.

• Portez toujours des lunettes de sécurité. Si la

toupie est équipée d’un sac à copeaux amovible,

assurez-vous qu’il est en place.

• Évitez de toucher au fer ou autre pièce mobile de la toupie pendant l’usage. Même après

l’usage, le fer prend assez de temps à se refroidir.

• Ne posez jamais la toupie de côté tant que le

moteur ne soit totalement au repos, si le fer fait

saillie par rapport à la base.

• Ne tenez jamais le matériau d’une main et la

toupie en marche de l’autre. Il importe de bien

assujettir le matériau et de tenir fermement la

toupie à deux mains.

• N’utilisez jamais des fers dont le diamètre de

coupe est supérieur à celui de l’ouverture

pratiquée dans la base.

• Après le remplacement des fers ou un réglage

quelconque, assurez-vous que l’écrou de la

douille et les autres dispositifs d’assemblage

soient fermement serrés avant de mettre la

toupie en marche.

• Le sens de déplacement de la toupie dans le

14

BM 3609929671 1/95 12/7/98, 11:56 AM14

matériau est très important et il se rapporte au

sens de rotation du fer. En regardant du dessus

de la toupie, le fer tourne dans le sens des

aiguilles d’une montre. Lorsque la toupie se

trouve entre l’utilisateur et le matériau, le sens

de déplacement doit être vers la droite. Par

contre, si le matériau se trouve entre l’utilisateur

et la toupie, le sens de déplacement doit être

vers la gauche. Le déplacement dans le mauvais

sens forcera le tranchant du fer à grimper hors

du matériau entraînant la toupie dans le même

sens.

Outils à double isolation

• La double isolation est utilisée dans les

outils électriques pour éliminer le besoin de

cordon d’alimentation trois fils, dont la prise de

terre, et de dispositif d’alimentation à prise de

terre. Elle est homologuée par l’Underwriter’s

Laboratories, l’ACNOR et l’OSHA.

rallonges recommandées en fonction de leur

longueur et de l’intensité indiquée sur la

plaquette emblématique de l’outil. En cas de

doute, optez pour le prochain calibre inférieur.

Utilisez toujours des rallonges homologuées

par l’U.L. et l’ACNOR.

Intensité nominale(figurant sur la plaquette emblématique)

0- 2.1- 3.5- 5.1- 7.1- 12.1-

2.0 3.4 5.0 7.0 12.0 16.0

25' 18 18 18 18 16 14

50' 18 18 16 16 14 12

75' 18 18 16 14 12 10

100' 18 16 14 12 10

150' 16 14 12 12 calibre du fil

Longueur de rallonge

REMARQUE : Plus le calibre est petit, plus le

fil est gros.

‹‹CONSERVEZ CES INSTRUCTIONS››

IMPORTANT : L’entretien d’un outil à

double isolation exige la connaissance du

système et la compétence d’un technicien

qualifié. EN CAS D’ENTRETIEN,

N’UTILISEZ QUE DES PIÈCES DE

RECHANGE IDENTIQUES.

FICHES POLARISÉES. Si votre outil est

équipé d’une fiche polarisée (une lame plus

large que l’autre) elle ne s’enfiche que d’une

manière dans une prise polarisée. Si la fiche

n’entre pas à fond dans la prise, tournez-la d’un

demi-tour. Si elle refuse encore d’entrer,

demandez à un électricien qualifié d’installer

une prise appropriée. Afin de réduire le risque

de choc électrique, ne modifiez la fiche d’aucune

façon.

Rallonges

• Remplacez immédiatement toute rallonge

endommagée. L’utilisation de rallonges

endommagées risque de provoquer un choc

électrique, des brûlures ou l’électrocution.

• En cas de besoin d’une rallonge, utilisez un

cordon de calibre satisfaisant pour éviter toute

chute de tension, perte de courant ou surchauffe.

Le tableau ci-dessous indique le calibre des

Mode d’emploi

Gâchette de commande et bouton de

blocage en marche

Votre outil peut être mis en marche ou au repos

à l’enfoncement ou au relâchement de la

gâchette. Il est aussi équipé, juste au-dessus de

la gâchette, d’un bouton de blocage en marche

qui maintient l’interrupteur sous tension sans

avoir à appuyer sur la gâchette de commande.

BLOCAGE DE L’INTERRUPTEUR EN

MARCHE: appuyez sur la gâchette, enfoncez

le bouton et relâchez la gâchette.

DÉBLOCAGE DE L’INTERRUPTEUR:

appuyez sur la gâchette et relâchez-la sans

toucher au bouton de blocage en marche.

AVERTISSEMENT ! Le relâchement de

la gâchette est impossible si le bouton de blocage

en marche est maintenu enfoncé.

AVERTISSEMENT ! Tenez l’outil à deux

mains au départ car le couple du moteur peut le

faire tourner sur lui-même.

Variateur de vitesse à cadran

Votre toupie est aussi dotée d’un variateur de

15

BM 3609929671 1/95 12/7/98, 11:56 AM15

vitesse à cadran 21. Au moyen du cadran, vous

pouvez prérégler la vitesse du fer depuis 12

000 tr/mn jusqu’au régime maximal spécifié

sur la plaquette de l’outil. Le cadran peut être

réglé sur ou entre n’importe lequel des six

régimes (depuis 1 = le plus bas jusqu’à 5 = le

plus élevé). Le bouton de blocage en marche

peut être utilisé sur tous les réglages du cadran.

En général, les régimes suivants sont

recommandés, mais l’expérience avec le

matériau utilisé peut dicter des réglages

différents. La variation momentanée du régime

est normale à la mise en marche de la toupie

jusqu’à ce que le régulateur électronique prenne

charge.

le pouce pour immobiliser l’arbre en place.

Ensuite, au moyen de la clé 27 mm fournie,

desserrez l’ensemble mandrin-douille 7 dans le

sens contraire de celui des aiguilles d’une montre

(vu du dessous de la toupie). Introduisez la tige

du fer à fond dans la douille du mandrin, puis

retirez la tige jusqu’à ce que les couteaux soient

environ entre 1/8" et 1/4" de la face de l’écrou

de la douille. Une fois le fer en place et le

dispositif de verrouillage de l’arbre solidement

engagé, serrez fermement l’ensemble mandrindouille dans le sens des aiguilles d’une montre

avec la clé de 27 mm. Pour éviter le risque

d’endommagement, ne serrez jamais le mandrin

sans qu’un fer à tige de taille convenable y soit

inséré.

Réglage du cadran Matériau

1-3 Bois durs, plastiques

(12 000 - mous, métaux non-ferreux,

15 000 tr/mn) fers et couteaux de toupie

de plus grand diamètre

4-5 Bois mous, plastiques,

(16 500 - comptoirs, fers et

19 000 tr/mn) couteaux de toupie

de plus petit diamètre

Démarrage en douceur

La toupie est dotée d’un dispositif de démarrage

en douceur qui assure l’augmentation graduelle

de la vitesse et du couple, réduisant ainsi la

tension qui accompagne le lancement à couple

élevé.

Mettez l’outil en marche et attendez qu’il

atteigne la vitesse maximale avant de le poser

sur la pièce. De même, soulevez-le avant d’en

relâcher l’interrupteur. Pour prolonger la durée

de l’interrupteur, évitez de le mettre sous tension et hors tension pendant que l’outil est à

l’oeuvre.

Pose et dépose des fers

AVERTISSEMENT ! Débranchez toujours

l’outil de la source d’alimentation avant de

changer les fers, les accessoires ou d’effectuer

des réglages.

Pose d’un fer

Tournez l’arbre pour aligner les plats avec le

dispositif de verrouillage 10, puis poussez avec

MISE EN GARDE ! Pour minimiser le

risque d’excentricité et assurer le serrage

approprié, le fer devrait être enfoncé aussi loin

que possible dans la douille, jamais moins que

5/8".

MISE EN GARDE ! N’utilisez pas des fers

de diamètre supérieur à 2-5/8" car ils ne

passeraient pas dans l’ouverture de la base.

Dépose du fer

Pour déposer le fer, servez-vous du dispositif de

verrouillage de l’arbre et de la clé, comme il est

décrit précédemment et tourner l’ensemble

mandrin-douille 7 dans le sens contraire de

celui des aiguilles d’une montre. Quand

l’ensemble mandrin-douille est desserré,

continuez de tourner jusqu’à ce que la douille se

déloge du cône et que vous puissiez retirer le

fer.

REMARQUE : L’extraction de l’ensemble

mandrin-douille s’accomplit sans effort; il n’est

PAS nécessaire de frapper le mandrin pour

déloger le fer.

Soin de l’ensemble mandrin-douille

Quand le fer est enlevé, continuez de tourner

l’ensemble mandrin-douille dans le sens

contraire de celui des aiguilles d’une montre

jusqu’à ce qu’il se détache de l’arbre. Pour

assurer un serrage adéquat, nettoyez

occasionnellement l’ensemble à l’air comprimé

et nettoyez le cône de l’arbre avec un chiffon ou

une brosse douce. Comme le montre

16

BM 3609929671 1/95 12/7/98, 11:56 AM16

l’illustration,

l’ensemble mandrindouille est constitué de

trois éléments.

Assurez-vous que

l’anneau de retenue 15

est bien en place autour

de la douille 16, à fond

dans la rainure intérieure de l’écrou 17 de la

douille, puis vissez légèrement l’ensemble

mandrin-douille sur l’arbre. Remplacez les

ensembles mandrin-douille usés ou

endommagés immédiatement.

15

16

7

17

Levier de réglage de la plongée

Pour desserrer le levier de réglage en plongée

13, saisissez fermement les poignées de la toupie

des deux mains et, avec le pouce de la main

gauche, appuyez sur le levier. Le moteur peut

être alors réglé à la hauteur désirée. Étant donné

qu’il est à ressort, le levier maintiendra le moteur

en place au relâchement. Lors de la coupe en

plongée, appuyez toujours fermement à force

égale sur les deux poignées pour éviter d’incliner

le moteur sur les poteaux.

Guide de profondeur et tourelle

tournante

Le guide de profondeur 1 et la tourelle tournante

5 servent à régler la profondeur de coupe comme

suit:

Le fer en place, abaissez délicatement le moteur

jusqu’à ce que la pointe du fer affleure à peine

la surface sur laquelle la toupie repose. C’est en

effet le «point mort» à partir duquel il est

possible d’effectuer d’autres réglages avec

précision. Pour obtenir la profondeur de coupe

désirée, tournez la tourelle de profondeur jusqu’à

ce que le plus bas gradin soit vis-à-vis le guide

de profondeur. Desserrez le bouton de serrage

du guide 3 et baissez le guide jusqu’à ce qu’il

touche au plus bas gradin de la tourelle. La

valeur à la ligne rouge, le long de la règle de

profondeur 2, représente effectivement le point

auquel le fer effleure à peine la surface du

matériau et cette valeur est utilisée à titre de

référence pour réaliser la profondeur de coupe

désirée.

EXEMPLE : Le fer touchant à peine la surface

du matériau, le guide de profondeur 2 enregistre

3/4" alors que la pointe du guide appuie sur la

tourelle. Pour réaliser une coupe de 1/2" de

profondeur, desserrez le bouton et remontez le

guide jusqu’à ce que la ligne rouge indique 1-1/

4", puis resserrez le bouton. Le fait de plonger

la toupie jusqu’à ce que le guide de profondeur

appuie sur la tourelle permettra d’enfouir le fer

1/2" dans la pièce. Pour vous rassurer que vos

réglages sont exacts, vous auriez intérêt à faire

l’essai dans des retailles au préalable.

Il est possible d’exécuter des coupes

progressivement plus profondes en commençant

par un gradin plus élevé et en tournant

graduellement la tourelle vers des gradins

inférieurs jusqu’à ce vous atteigniez la

profondeur de coupe désirée.

Tige de guidage filetée

La tige de guidage filetée 9 est dotée de trois

écrous d’arrêt 6. Quand ils ne servent pas, ces

écrous devraient être serrés au haut et au bas de

la tige, de sorte qu’ils ne nuisent d’aucune

façon. Si vous désirez raccourcir la course,

tournez l’écrou d’arrêt supérieur le plus proche

du bossage coulé 14 vers le bas à la position

voulue et immobilisez-le fermement en place

en serrant l’autre écrou d’arrêt supérieur sur lui.

Si vous désirez un réglage fixe (sans plongée),

serrez un écrou d’arrêt de chaque côté du

bossage.

Déplacement de la toupie

Vue du dessus, la toupie tourne dans le sens des

aiguilles d’une montre. La correcte relation

entre le sens de rotation du fer ou du couteau et

celui du déplacement de la toupie est la suivante.

Il importe de diriger la toupie dans le sens

approprié, car autrement le fer broute et produit

une coupe plutôt grossière.

Par exemple, pour exécuter une coupe décorative

dans le bord avant d’un dessus de table, vous

déplaceriez la toupie de gauche à droite ou dans

le sens contraire de celui des aiguilles d’une

montre autour de la pièce. Pour tailler une

ouverture dans le centre d’un panneau, vous

déplaceriez la toupie dans le sens des aiguilles

d’une montre, de sorte que le bord de l’ouverture

soit taillé contre la rotation du fer, tel qu’il est

décrit, et présente un fini doux. Dans le cas de

17

BM 3609929671 1/95 12/7/98, 11:56 AM17

coupe tout le tour d’une pièce, il est préférable

7

20

19

8

de couper contre les fibres d’abord, de sorte que

le déchirement des coins puisse être adouci en

repassant dans le sens des fibres ensuite.

WORK

DIRECTION

CUTTER

COUTEAU

SENS DE

OF FEED

DÉPLACEMENT

Vitesse de déplacement

Vous obtiendrez de meilleurs résultats dans le

bois ou les plastiques, si la profondeur de coupe

et la vitesse de déplacement que vous choisissez

favorisent le fonctionnement à régime élevé du

moteur. Travaillez à vitesse modérée.

Normalement, les matériaux mous exigent une

vitesse plus rapide que les matériaux durs.

Le mésusage ou la surcharge peut caler le

moteur. Ralentissez pour éviter tout

endommagement de l’outil. Ne tentez pas de

mettre l’outil en marche alors que le fer est

enfoui. Assurez-vous toujours que l’écrou de la

douille est fermement serré avant l’usage. Pour

minimiser l’excentricité ou le broutage du fer,

utilisez toujours des fers dont la longueur exigée

pour effectuer la coupe désirée est la plus courte.

Guides de gabarit

Pour utiliser les guides de gabarit figurant dans

le catalogue BOSCH, votre toupie est

accompagnée d’un adaptateur 18 pour guides

de gabarit qui s’attache à la base au moyen des

deux vis à tête conique fournies. Les guides de

gabarit facultatifs peuvent être introduits et

maintenus en place le long de leurs rebords par

les deux vis qui les accompagnent. Certains

guides de gabarit sont pourvus de trous

d’assemblage, mais ceux-ci ne sont pas

nécessaires lors de l’usage avec l’adaptateur

montré, puisqu’il capte le bord du guide.

Les guides de gabarit sont utilisés de concert

avec une foule d’accessoires figurant dans votre

catalogue BOSCH. De plus, il est facile de

fabriquer des gabarits spéciaux pour la coupe

répétitive de patrons, dessins, modèles et autres.

On peut fabriquer un patron à partir d’une pièce

de contreplaqué, d’agglomérés, de métal ou

même de plastique; le dessin peut être découpé

à l’aide d’une toupie, scie sauteuse ou autre

outil convenable. Les patrons doivent prendre

en considération la distance entre le fer et le

guide de gabarit, étant donné que la dimension

finale

différera

d’autant,

en raison

de la position du

fer.

Instructions de pose et D’utilisation

De L’accessoire de Réglage de

Précision RA1001 (1615EVS)

L’accessoire de réglage de précision RA1001

permet des réglages précis de la hauteur des

mèches sur les toupies Bosch. Il convient de

noter que cet accessoire restreint le mouvement

du moteur de la toupie sur la base de plongée et

remplace efficacement l’action normale de

plongée par une alimentation filetée.

AVERTISSEMENT : Débranchez toujours

l’outil de la prise de courant avant de poser des

mèches ou des accessoires, ou d’effectuer quel-

18

19

que réglage que ce soit. Ne réglez jamais cet

accessoire pendant que l’outil est en marche ou

que la mèche est en contact avec le matériau.

Pose

1. Plongez la toupie vers le bas de manière à ce

18

BM 3609929671 1/95 12/7/98, 11:56 AM18

que l’ergot O sur le moteur ne soit pas en

contact avec les écrous J sur la tige de guidage

filetée I. Retirez le contre-écrou de 17 mm et

deux écrous plats J de la tige I à l’aide d’une clé

adéquate (fig. 1).

Fig. 1

J

O

I

Fig. 2

Placez la rondelle K

par-dessus la tige

filetée et reposez l’un

des écrous plats J à

environ 3/8" depuis

le dessus de la tige I.

Une mince pellicule

K

de graisse d’usage

général peut être

appliquée sur la

rondelle K pour aider à réduire la friction (fig.

2).

Fig. 3

J

Fonctionnement

Pour utiliser le RA1001, appuyez sur le levier

de dégagement de plongée et tournez le RA1001

en sens horaire pour baisser, ou en sens antihoraire pour lever la mèche. (Il convient de

remarquer qu’un tour complet du bouton lèvera

ou baissera la mèche d’environ 0,060" ou

1,5 mm.) Il faut exercer une légère pression

vers le bas sur la poignée de la toupie en sens

opposé au RA1001 de manière à éviter de

basculer le moteur de côté sur les montants

(fig. 4).

Fig. 4

2. Placez l’extrémité filetée du RA1001 pardessus la partie supérieure de la tige I et pressezla vers le bas de manière à comprimer le ressort

jusqu’à ce que la partie découpée engage l’écrou

J et filetez le régleur sur la tige. Lorsque le

RA1001 est posé adéquatement, l’écrou J de 17

mm fait légèrement saillie depuis l’extrémité

découpée du RA1001 de manière à ce que la

face de l’écrou (NON le RA1001) vienne en

contact avec la rondelle K. La figure 3 montre

le RA1001 posé adéquatement. Si désiré, l’écrou

J de 17 mm sous l’ergot O peut être employé

pour verrouiller la toupie à un réglage fixe de

profondeur en le serrant contre le côté opposé

de l’ergot O.

(Remarque : Conservez les écrous déposés en

lieu sûr de manière à pouvoir les réinstaller sur

la toupie si le RA1001 est déposé pour quelque

motif que ce soit.)

BM 3609929671 1/95 12/7/98, 11:56 AM19

J

Guide de luxe

Pour les travaux à la toupie tels que le rainurage,

on doit souvent guider l’outil dans un plan

parallèle à une règle. Une façon d’exécuter une

coupe droite est d’assujettir à la surface du

matériau, au moyen de serres, une planche ou

autre règle et de diriger le bord de l’embase de

la toupie le long de ce guide de coupe. Pour de

meilleurs résultats, il est recommandé de

maintenir la toupie dans la même position alors

que vous la déplacez le long du guide.

19

Le guide de luxe Bosch est un accessoire qui

permet de maintenir la toupie parallèle à une

surface rectiligne ou curviligne. Le guide de

luxe est accompagné de deux tiges et d’un

nombre d’écrous à ailettes et de vis de fixation

et de réglage. Le guide en place et bien réglé,

déplacez la toupie normalement en le maintenant

en contact avec le bord de la pièce en tout temps.

De même, le guide de luxe peut être fixé audessous de la base de la toupie lorsque vous ne

désirez exposer le fer que partiellement. Le

guide de luxe Bosch comprend un mécanisme

de réglage précis et des plateaux amovibles

pour guider la toupie le long des surfaces

rectilignes et curvilignes. Le mode d’emploi

est inclus avec l’accessoire.

Extraction des copeaux

Vous pouvez équiper votre toupie BOSCH d’un

extracteur de copeaux qui permet de travailler

dans la propreté. Cet accessoire, qui sert au

toupillage général, comporte une brosse réglable

qui convient surtout aux travaux de rainurage.

Pour tous les détails sur les accessoires

facultatifs, consultez votre distributeur d’outils

motorisés BOSCH.

AVERTISSEMENT ! L’emploi

d’accessoires autres que ceux recommandés

dans le présent manuel ou dans le catalogue

BOSCH peut être dangereux.

Maintenance et entretien

AVERTISSEMENT ! L’entretien préventif

prodigué par des personnes non autorisées peut

être dangereux. Il est recommandé de confier

l’entretien et la réparation de l’outil à un centre

de service-usine Bosch.

Balais de charbon

Les balais et le collecteur de votre outil Bosch

ont été conçus pour donner plusieurs heures de

fonctionnement sans aléas. Pour maintenir le

moteur en pleine forme, nous recommandons

d’examiner les balais tous les deux à six mois.

Vous ne devriez exiger que les balais de rechange

d’origine Bosch qui conviennent spécialement

à votre outil.

Roulements

Après environ 300 à 400 heures d’utilisation,

ou à tous les deux remplacements des balais, il

faudrait confier le remplacement des roulements

à un centre de service-usine Bosch. Les

roulements qui sont devenus bruyants (à la suite

d’usage dans des matériaux très abrasifs ou de

durs efforts) devraient être remplacés à l’instant

pour éviter la surchauffe et la défaillance du

moteur.

Nettoyage

AVERTISSEMENT ! Pour éviter le risque

d’accidents, débranchez toujours l’outil de la

prise de courant avant de procéder au nettoyage

ou à l’entretien. Vous pouvez très bien le

nettoyer à l’air comprimé. Dans ce cas, portez

toujours des lunettes de sécurité.

Gardez les prises d’air et les interrupteurs propres

et libres de saletés. N’essayez pas de les nettoyer

en introduisant des objets pointus dans leurs

ouvertures.

MISE EN GARDE ! Certains produits de

nettoyage et dissolvants dont la gazoline, le

tétrachlorure de carbone, les nettoyeurs chlorés,

l’ammoniaque et les détergents ménagers

contenant de l’ammoniaque peuvent abîmer les

pièces en plastique.

Graissage de l’outil

Votre outil Bosch a été convenablement graissé

et est prêt à utiliser. Il est recommandé que les

outils à engrenages soient regraissés avec une

graisse spéciale à l’occasion de tout

remplacement de balais.

BM 3609929671 1/95 12/7/98, 11:56 AM20

20

GARANTIE

GARANTIE LIMITÉE

BOSCH

S-B POWER TOOL COMPANY

TELS QUE LAMES DE SCIES

CIRCULAIRES, MÈCHES DE PERCEUSES,

FERS DE TOUPIES, LAMES DE SCIES

SAUTEUSES, COURROIES DE PONÇAGE,

MEULES ET AUTRES ARTICLES DU

GENRE.

S-B Power Tool Company («Vendeur») garantit

à l’acheteur originel d’outils électriques portatifs

Bosch (et uniquement à celui-ci) que lesdits

outils sont et resteront exempts de vices matériels

et de fabrication pendant un (1) an àcompter de

la date d’achat. LA SEULE OBLIGATION

DU VENDEUR ET LE SEUL RECOURS DE

L’ACHETEUR sous la présente garantie

limitée, et en autant que la loi le permette sous

toute garantie ou condition implicite qui en

découlerait, sera l’obligation de remplacer ou

réparer gratuitement les pièces défectueuses

matériellement ou comme fabrication, pourvu

que lesdites défectuosités ne soient pas

attribuables à un usage abusif ou à quelque

réparation bricolée par quelqu’un d’autre que le

vendeur ou le personnel d’une station-service

agréée. En cas de réclamation sous la présente

garantie limitée, l’acheteur est tenu de renvoyer

l’outil électrique portatif complet en port payé

à un centre de service-usine Bosch ou une

station-service agréée. Une liste des centres de

service-usine américains accompagne chaque

outil électrique Bosch. Veuillez consulter votre

annuaire téléphonique pour les adresses.

LA PRÉSENTE GARANTIE NE

S’APPLIQUE PAS AUX ACCESSOIRES

TOUTE GARANTIE IMPLICITE SERA

LIMITÉE COMME DURÉE À UN (1) AN À

COMPTER DE LA DATE D’ACHAT.

CERTAINS ÉTATS AMÉRICAINS

N’ADMETTANT PAS LE PRINCIPE DE LA

LIMITATION DE LA DURÉE DES

GARANTIES IMPLICITES, IL EST POSSIBLE QUE LES LIMITATIONS CI-DESSUS

NE S’APPLIQUENT PAS À VOTRE CAS.

EN AUCUN CAS LE VENDEUR NE

SAURAIT ÊTRE TENU POUR

RESPONSABLE DES INCIDENTS OU

DOMMAGES INDIRECTS (INCLUANT,

MAIS NE SE LIMITANT PAS AUX PERTES

DE PROFITS) CONSÉCUTIFS À LA VENTE

OU L’USAGE DE CE PRODUIT. CERTAINS

ÉTATS AMÉRICAINS N’ADMETTANT

PAS LE PRINCIPE DE LA LIMITATION NI

L’EXCLUSION DES DOMMAGES

INDIRECTS ET CONSÉQUENTIELS, IL EST

POSSIBLE QUE LES LIMITATIONS OU

EXCLUSIONS CI-DESSUS NE

S’APPLIQUENT PAS À VOTRE CAS.

LA PRÉSENTE GARANTIE VOUS

ACCORDE DES DROITS BIEN

DÉTERMINÉS, Y COMPRIS

POSSIBLEMENT CERTAINS DROITS

VARIABLES DANS LES DIFFÉRENTS

ÉTATS.

S-B Power Tool Company

4300 W. Peterson Avenue

Chicago, IL 60646-5999

BM 3609929671 1/95 12/7/98, 11:56 AM21

21

Datos del producto - Fresadora de descenso vertical

Modelo número 1615 1615EVS

Número de identificación 0 601 615 0.. 0 601 615 7..

Capacidad del portaherramienta 1/4", 3/8", 1/2" de diám. 1/4", 3/8", 1/2" de diám.

Capacidad para brocas de fresadora 2-5/8" de diám. máx. 2-5/8" de diám. máx.

(NOTA: Esta herramienta está diseñada para uso con corriente alterna (AC) únicamente. )

Lista de accesorios

Ensamblaje del mandril portaherramienta de 1/2"*

Ensamblaje del mandril portaherramienta de 3/8"

Ensamblaje del mandril portaherramienta de 1/4"*

Llave para la tuerca del portaherramienta de 27 mm*

Adaptador de guías de plantilla con 2 tornillos*

Guía de lujo para fresadoras

Caja de acero

Accesorio de ajuste fino* *

Adaptador de aspiración

Manguera de aspiración

Adaptador de manguera/aspiración

( * = equipo estándar )

( * * = equipo estándar 1615EVS unicamente)

Componentes de la fresadora

1. Varilla indicadora de profundidad

2. Escala indicadora de profundidad

3. Pomo de fijación/liberación

del indicador de profundidad

4. Base de la fresadora

5. Torreta giratoria de profundidad

6. Tuerca de tope

7. Ensamblaje del mandril portaherramienta

8. Subbase

9. Varilla de guía roscada

10. Cierre del husillo

11. Botón de “Fijación en ON”

(NOTA: los componentes de la fresadora que no están ilustrados en la página 2 están

ilustrados en otra parte de este manual)

BM 3609929671 1/95 12/7/98, 11:56 AM22

12. Interruptor gatillo

13. Palanca de fijación/liberación

del descenso vertical

14. Saliente fundido

15. Anilla de retención

16. Portaherramienta

17. Tuerca del portaherramienta

18. Adaptador de guías de plantilla

19. Guía de plantilla

20. Broca

21. Dial de velocidad variable (1615EVS)

22. Accesorio de ajuste fino (1615EVS)

22

!ADVERTENCIA! “LEA TODAS LAS

INSTRUCCIONES”. El incumplimiento de

las NORMAS DE SEGURIDAD identificadas

por el símbolo del PUNTO NEGRO (°) que se

indican y otras precauciones de seguridad puede

dar lugar a lesiones personales graves. Conserve estas instrucciones de funcionamiento

con este producto.

NORMAS GENERALES DE

SEGURIDAD

para todas las herramientas

mecánicas

Area de trabajo

• MANTENGA LIMPIAS LAS AREAS DE

TRABAJO. Las áreas y mesas desordenadas

invitan a que se produzcan accidentes.

• EVITE LOS ENTORNOS PELIGROSOS.

No utilice herramientas mecánicas en lugares

húmedos o mojados. No exponga las

herramientas mecánicas a la lluvia. Mantenga

el área de trabajo bien iluminada.

• EVITE LAS AREAS CON PRESENCIA

DE GASES. No utilice herramientas eléctricas

portátiles en atmósferas explosivas en presencia

de líquidos o gases inflamables. Los motores

de estas herramientas normalmente producen

chispas y las chispas pueden dar lugar a la

ignición de vapores.

• MANTENGA ALEJADOS A LOS NIÑOS.

No permita que los visitantes toquen las

herramientas o el cordón de extensión. Todos

los visitantes deben mantenerse alejados del

área de trabajo.

Seguridad personal

• PROTEJASE CONTRA LAS SACUDIDAS

ELECTRICAS. Evite el contacto del cuerpo

con las superficies conectadas a tierra tales

como tuberías, radiadores o cocinas y

refrigeradores. Se recomiendan guantes de

caucho y calzado antideslizante cuando se

trabaja a la intemperie, donde se puede encontrar

terreno húmedo o mojado. En estas condiciones

se debe utilizar una línea de energía protegida

con un Interruptor de circuito para fallos a

tierra.

• VISTASE ADECUADAMENTE. No se

ponga ropa suelta ni joyas. Pueden quedar

atrapadas en las piezas móviles. Use cubiertas

protectoras para el pelo a fin de sujetar el pelo

largo.

• UTILICE EQUIPO DE SEGURIDAD. USE

GAFAS DE SEGURIDAD o lentes con

protectores laterales. Utilice protección en los

oídos cuando use las herramientas mecánicas

mucho rato y una máscara contra el polvo para

operaciones que generan polvo.

• MANTENGASE ALERTA. USE EL

SENTIDO COMUN. Fíjese en lo que está

haciendo. No utilice la herramienta cuando está

cansado o bajo la influencia de medicamentos.

• QUITE LAS LLAVES DE AJUSTE Y LAS

LLAVES DE TUERCA. Forme el hábito de

asegurarse de que las llaves de ajuste y de tuerca

se han quitado de la herramienta antes de

encenderla.

• EVITE EL ARRANQUE ACCIDENTAL.

No lleve la herramienta enchufada con el dedo

en el interruptor. Asegúrese de que el interruptor

está en la posición OFF (desconectado) antes de

enchufar.

• NO INTENTE ALCANZAR DEMASIADO

LEJOS. Mantenga una posición y un equilibrio

adecuados en todo momento.

• ANTES DE CONECTAR LA

HERRAMIENTA a una fuente de energía (caja

tomacorriente, tomacorriente, etc.), asegúrese

de que el voltaje suministrado es el mismo que

el que se indica en la placa del fabricante de la

herramienta. Una fuente de energía con un

voltaje superior al especificado para la

herramienta puede ocasionar graves lesiones al

usuario — así como daños a la herramienta. En

caso de duda, NO ENCHUFE LA

HERRAMIENTA. La utilización de una fuente

de energía con un voltaje inferior a la capacidad

nominal indicada en la placa del fabricante es

perjudicial para el motor.

Las herramientas designadas “VOLTS AC”

son para corriente alterna de 50-60 Hz solamente.

Las herramientas designadas “VOLTS DC”

son para corriente continua. No utilice

herramientas designadas AC con una fuente de

energía DC. No utilice herramientas de

velocidad controlada electrónicamente con una

fuente de energía DC.

Utilización y cuidado de las

herramientas

• NO FUERCE LA HERRAMIENTA. La

23

BM 3609929671 1/95 12/7/98, 11:56 AM23

herramienta trabajará mejor y con más seguridad

a la capacidad para la cual fue diseñada.

• UTILICE LA HERRAMIENTA

ADECUADA. No fuerce una herramienta

pequeña o un accesorio pequeño a realizar el

trabajo de una herramienta pesada. No utilice la

herramienta para funciones para las cuales no

fue diseñada — por ejemplo, no use una sierra

circular para cortar ramas o troncos de árboles.

• FIJE LA PIEZA DE TRABAJO. Utilice

abrazaderas o un tornillo de carpintero para

sujetar la pieza de trabajo. Es más seguro que

utilizar la mano y libera ambas manos para

manejar la herramienta.

• NO ABUSE DEL CORDON. Nunca lleve la

herramienta por el cordón ni tire de él para

desconectarlo del tomacorriente. Proteja el

cordón del calor, el aceite y los bordes afilados.

Mantenga siempre el cordón alejado de la hoja

cuando esté girando, de las brocas o de cualquier

otra pieza móvil durante la utilización de la

herramienta.

• A LA INTEMPERIE, UTILICE

CORDONES DE EXTENSION. Cuando la

herramienta se utiliza a la intemperie, use

únicamente cordones de extensión adecuados

para la utilización a la intemperie y marcados

con el sufijo W-A (para UL) o W (para la CSA).

Consulte la sección “Cordones de extensión”

para la utilización del cordón adecuado.

• DESCONECTE LAS HERRAMIENTAS.

Cuando no se estén utilizando, antes del servicio

de ajustes y reparaciones o al cambiar hojas,

brocas, cortadores, etc.

• GUARDE LAS HERRAMIENTAS QUE

NO ESTA USANDO. Cuando las herramientas

no se estén utilizando, deberán guardarse en un

lugar seco, alto o con cierre — fuera del alcance

de los niños.

• NO ALTERE NI HAGA USO

INCORRECTO DE LA HERRAMIENTA.

Estas herramientas están fabricadas con

precisión. Cualquier alteración o modificación

no especificada constituye un uso incorrecto y

puede dar lugar a una situación peligrosa.

• LA UTILIZACION DE CUALQUIER

ACCESORIO no especificado en este manual

puede constituir un peligro.

• MANTENGA LAS HERRAMIENTAS

CON CUIDADO. Conserve las herramientas

afiladas y limpias para que funcionen mejor y

con más seguridad. Siga las instrucciones de

lubricación y de cambio de accesorios.

Inspeccione periódicamente los cordones de las

herramientas y si están dañados hágalos reparar

por un centro de servicio autorizado.

Inspeccione periódicamente los cordones de

extensión y sustitúyalos si están dañados.

Mantenga los mangos secos, limpios y libres de

aceite y grasa.

• REVISE LAS PIEZAS DAÑADAS. Antes

de volver a utilizar la herramienta, una

protección u otra pieza que esté dañada deberá

revisarse cuidadosamente para determinar que

funcionará adecuadamente y que realizará la

función para la cual está diseñada. Verifique la

alineación de las piezas móviles, el atascamiento

de las piezas móviles, la ruptura de piezas, el

montaje y cualquier otra situación que pueda

afectar su funcionamiento. Un protector o

cualquier otra pieza que presenta daños se debe

reparar o sustituir inmediata y adecuadamente.

Haga que cambien los interruptores defectuosos.

No utilice la herramienta si el interruptor no la

enciende y apaga.

• TODAS LAS REPARACIONES,

ELECTRICAS O MECANICAS, deben ser

realizadas únicamente por técnicos de reparación

capacitados. Póngase en contacto con el Centro

de servicio de fábrica Bosch más próximo o con

el Centro de servicio Bosch autorizado más

próximo o con otro centro de reparaciones

competente. Utilice piezas de repuesto Bosch

únicamente, cualquier otra puede constituir un

peligro.

Normas de seguridad para

fresadoras

• Nunca arranque la fresadora cuando la broca

está encajada en el material. El borde de corte

de la broca puede engancharse en el material,

haciendo que la fresadora se descontrole. Sujete

siempre la fresadora con las dos manos durante

el arranque. El par de reacción del motor puede

hacer que la fresadora se tuerza.

• Asegúrese siempre de que la pieza de trabajo

no tiene clavos ni otros objetos extraños que

pueden hacer que la broca y la fresadora salten

y que la broca se dañe.

• Use siempre gafas de seguridad. Si la

fresadora tiene un deflector de virutas removible,

manténgalo puesto en su sitio al fresar.

24

BM 3609929671 1/95 12/7/98, 11:56 AM24

• Nunca toque la broca de la fresadora ni

ninguna otra pieza móvil durante la utilización.

Después de la utilización, la broca de la fresadora

está demasiado caliente para tocarla con las

manos desnudas.

• Si la broca de la fresadora sobresale de la

base, nunca deje la fresadora en ningún sitio

hasta que el motor se haya detenido por

completo.

• Nunca tenga la pieza de trabajo en una mano

y la fresadora en la otra durante la utilización.

Fije siempre con abrazaderas el material y agarre

la fresadora firmemente con las dos manos.