Bosch 1575A Operating/safety Instructions Manual

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

1575A

For English Parlez-vous français? ¿Habla español?

See page 3 Voir page 9 Ver página 16

Consumer Information

Renseignement des consommateurs

Información para el consumidor

Toll Free Number: Appel gratuit : Número de teléfono gratuito:

1-877-BOSCH99 (1-877-267-2499) http://www.boschtools.com

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

2

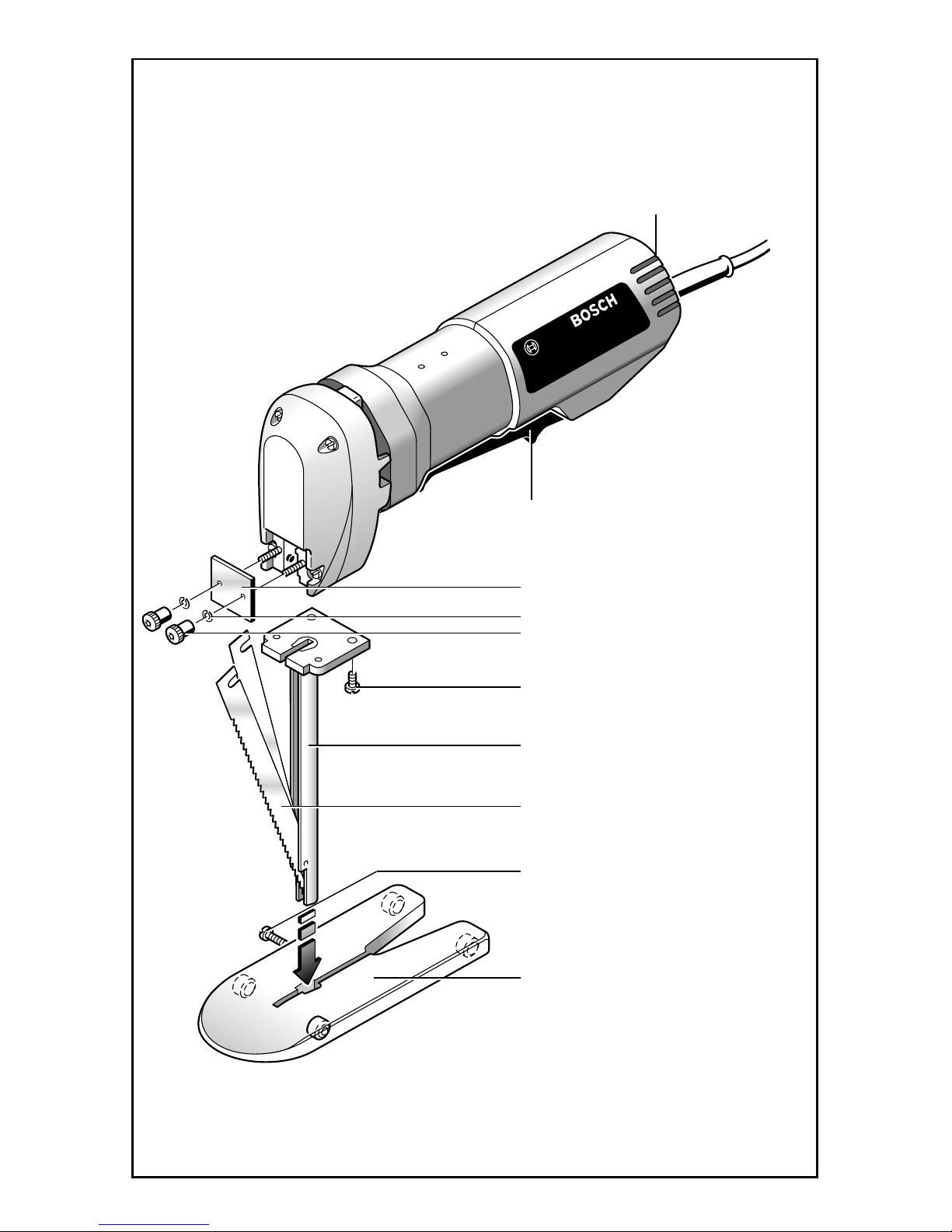

1

2

3

4

9

5

6

7

8

10

3

gases. Motors in these tools normally spark,

and the sparks might ignite fumes.

• KEEP CHILDREN AWAY. Do not let

visitors contact tool or extension cord. All

visitors should be kept away from work areas.

Personal Safety

• GUARD AGAINST ELECTRIC SHOCK.

Prevent body contact with grounded surfaces

such as pipes, radiators, ranges and refrigerator

enclosures. Rubber gloves and non-skid footwear are recommended when working outdoors, where damp or wet ground may be

encountered. A Ground Fault Circuit Interrupter protected power line must be used for

these conditions.

• DRESS PROPERLY. Do not wear loose

clothing or jewelry. They can be caught in

moving parts. Wear protective hair covering to

contain long hair.

• USE SAFETY EQUIPMENT. WEAR

WARNING! “READ ALL INSTRUC-

TIONS”. Failure to follow the SAFETY RULES

identified by the BULLET (•) symbols listed

BELOW and other safety precautions, may

result in serious personal injury. Keep these

operating instructions with this product.

GENERAL SAFETY RULES

for all Power Tools

Work Area

• KEEP WORK AREAS CLEAN. Cluttered

areas and benches invite accidents.

• AVOID DANGEROUS ENVIRONMENT.

Don’t use power tools in damp or wet locations.

Do not expose power tools to rain. Keep work

area well lit.

• AVOID GASEOUS AREAS. Do not operate portable electric tools in explosive atmospheres in presence of flammable liquids or

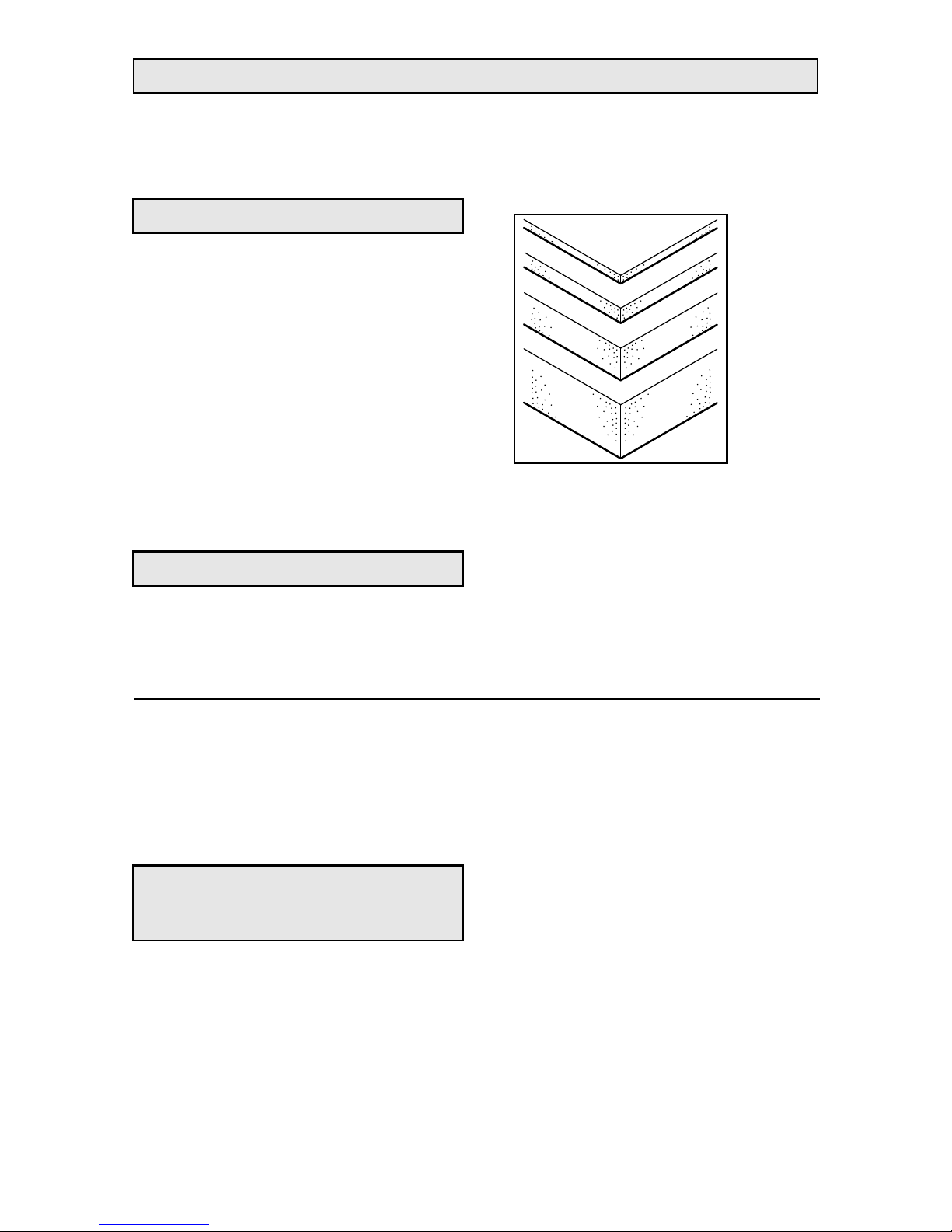

max 200mm

max 130mm

max 70mm

max 300mm

3" blades

5" blades

8" blades

12" blades

cutting depth capacities

9. Lockwasher

10. Air vents

5. Blade guide

6. Blade set

7. Screw

8. Footplate

1. Paddle On/Off switch

2. Face plate

3. Knurled nut

4. Screw

Product Data - Foam Cutter

Model number 1575A

Identification number 0 601 575 1 . .

(NOTE: This tool is designed and sold for use with alternating current (AC) only. )

Accessory Listing

Blade set 3" (70mm)

Blade guide 3" (70mm)

Blade set 5" (130mm)

Blade guide 5" (130mm)

Blade set 8" (200mm)

Blade guide 8" (200mm)

Blade set 12" (300mm)

Blade guide 12" (300mm)

Footplate

Blade sharpener w/whetstone

Metal case

(Standard equipment = motor only. Blades, guides and foot plate must be ordered

separatedly.)

Foam Cutter Components

4

SAFETY GOGGLES or glasses with side

shields. Wear hearing protection during extended use of power tools and dust mask for

dusty operations.

• STAY ALERT. USE COMMON SENSE.

Watch what you are doing. Do not operate tool

when you are tired or under influence of drugs.

•

REMOVE ADJUSTING KEYS AND

WRENCHES.

Form habit of checking to see that

keys and adjusting wrenches are removed from

tool before turning it on.

• AVOID ACCIDENTAL STARTING. Don’t

carry plugged in tool with finger on switch. Be

sure the switch is OFF before being plugged in.

• DON’T OVERREACH. Keep proper footing and balance at all times.

• BEFORE CONNECTING THE TOOL to a

power supply (receptacle, outlet, etc.) be sure

the voltage supplied is the same as that specified on the tool’s nameplate. A power supply

with voltage greater than that specified for the

tool can result in serious injury to the user - as

well as damage to the tool. If in doubt, DO NOT

PLUG IN THE TOOL. Using a power supply

with voltage less than the nameplate rating is

harmful to the motor.

“Volts AC” designated tools are for Alternating

Current 50-60 Hz only. “Volts DC” designated

tools are for Direct Current. Do not use AC

designated tools with DC power supply. Do not

use electronic speed controlled tools with DC

power supply.

Tool Use and Care

• DON’T FORCE TOOL. It will do the job

better and safer at the rate for which it was

designed.

• USE RIGHT TOOL. Don’t force small tool

or attachment to do the job of a heavy-duty tool.

Don’t use tool for purpose not intended - for

example; don’t use a circular saw for cutting

tree limbs or logs.

• SECURE WORK. Use clamps or a vise to

hold work. It’s safer than using your hand and

it frees both hands to operate the tool.

• DON’T ABUSE CORD. Never carry tool by

cord or yank it to disconnect from receptacle.

Keep cord from heat, oil, and sharp edges.

Always keep cord away from the spinning

blade, bits or any other moving part while the

tool is in use.

• OUTDOOR USE EXTENSION CORDS.

When tool is used outdoors, use only extension

cords suitable for use outdoors and marked with

suffix W-A (for UL), or W (for CSA). Refer to

section “Extension Cords”, for proper cord use.

• DISCONNECT TOOLS. When not in use,

before servicing, or when changing blades,

bits, cutters, etc.

• STORE IDLE TOOLS. When not in use,

tools should be stored in dry, high or locked up

place - out of the reach of children.

• DO NOT ALTER OR MISUSE TOOL.

These tools are precision built. Any alterations

or modifications not specified is misuse and

may result in a dangerous condition.

• THE USE OF ANY ACCESSORIES not

specified in this manual may create a hazard.

• MAINTAIN TOOLS WITH CARE. Keep

tools sharp and clean for better and safer performance. Follow instructions for lubricating and

changing accessories. Inspect tool cords periodically and if damaged, have repaired by authorized service facility. Inspect extension

cords periodically and replace if damaged. Keep

handles dry, clean and free from oil and grease.

• CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part that is

damaged should be carefully checked to determine that it will operate properly and perform

its intended function. Check for alignment of

moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect its operation. A guard or

other part that is damaged should be promptly

and properly repaired or replaced. Have defective switches replaced. Do not use tool if switch

does not turn it on or off.

• ALL REPAIRS, ELECTRICAL OR MECHANICAL, should be attempted only by

trained repairmen. Contact the nearest Bosch

Factory Service Center, or Bosch Authorized

Service Center or other competent repair center. Use only Bosch replacement parts, any

other may create a hazard.

Foam Cutter Safety Rules

• Always wear proper eye protection and

leather gloves.

• Before running a foam cutter, inspect the

right and left blades for wear. Replace worn

blades immediately.

5

• Never start the foam cutter with the blades

in contact with the workpiece.

• Do not remove the foam cutter from the

workpiece while the blades are moving.

• Never put the foam cutter down until the

motor and blades have come to a complete

standstill.

• Never touch the blades during use.

• Make sure the material being cut is secured

properly.

WARNING! Some dust created by power

sanding, sawing, grinding, drilling, and other

construction activities contains chemicals

known to cause

cancer, birth defects or other reproductive harm.

Some examples of these

chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and

other masonry products, and

• Arsenic and chromium from chemically treated

lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work

in a well ventilated area, and work with

approved safety equipment, such as those dust

masks that are specially designed to filter out

microscopic particles.

Double Insulated Tools

• Double Insulation is a design concept

used in electric power tools which eliminates

the need for the three wire grounded power cord

and grounded power supply system. It is a

recognized and approved system by

Underwriter’s Laboratories, CSA and Federal

OSHA authorities.

IMPORTANT: Servicing of a tool with

double insulation requires care and knowledge

of the system and should be performed only by

a qualified service technician. WHEN SERVICE IS REQUIRED USE ONLY IDENTICAL REPLACEMENT PARTS.

POLARIZED PLUGS: If your tool is equipped

with a polarized plug (one blade is wider than

the other), this plug will fit in a polarized outlet

only one way. If the plug does not fit fully in the

outlet, reverse the plug. If it still does not fit,

contact a qualified electrician to install the

proper outlet. To reduce the risk of electric

shock do not change the plug in any way.

Extension Cords

• Replace damaged cords immediately. Use of

damaged cords can shock, burn or electrocute.

• If an extension cord is necessary, a cord with

adequate size conductors should be used to

prevent excessive voltage drop, loss of power

or overheating. The table below shows the

correct size to use, depending on cord length

and amperage rating on the tool’s nameplate. If

in doubt, use the next heavier gauge. Always

Cord Length

"SAVE THESE INSTRUCTIONS"

Operating the Tool

Paddle Switch with “Lock-ON” feature

The Paddle Switch enables the operator to control the switch functions of “ON/OFF” and

“Lock-ON”.

TO SWITCH TOOL “ON”: Squeeze and hold

the paddle lever.

TO SWITCH TOOL “OFF”: Release pressure

on the paddle lever. The switch is spring loaded

and will return to “OFF” position automatically.

The “Lock-ON” feature, incorporated into the

paddle switch, is a convenience for long operations.

TO LOCK SWITCH “ON”: After switch has

been activated, PULL the front portion of the

paddle lever completely BACKWARD and

release pressure on the paddle lever.

TO SWITCH TOOL “OFF”: Squeeze the rear

portion of paddle lever and then release the

paddle lever. The switch is spring loaded and

will return to “OFF” position automatically.

use U.L. and CSA listed extension cords.

Ampere Rating (shown on nameplate)

0- 2.1- 3.5- 5.1- 7.1- 12.1-

2.0 3.4 5.0 7.0 12.0 16.0

25' 18 18 18 18 16 14

50' 18 18 16 16 14 12

75' 18 18 16 14 12 10

100' 18 16 14 12 10

150' 16 14 12 12 Wire Gauge

Note: The smaller the gauge number, the larger

the wire is in the cord.

6

Tool Tips

Following a few simple tips will reduce wear

on the tool and it will reduce the chance of

injury to the operator. However, these instructions are not intended to teach a novice how to

Blade Installation

The 1575A will cut foam rubber, urethane

foam and other synthetic foams. Its cutting

capacity depends on the length of blades and

guide used.

CAUTION! The foam cutter blades are sharp

and susceptible to bending and must be handled

carefully to avoid injury to user or bending of

the blades.

CAUTION! In order to avoid accidents, always match the blade and blade guide length to

the material to be cut. Never expose any excessive blade length above or below the material.

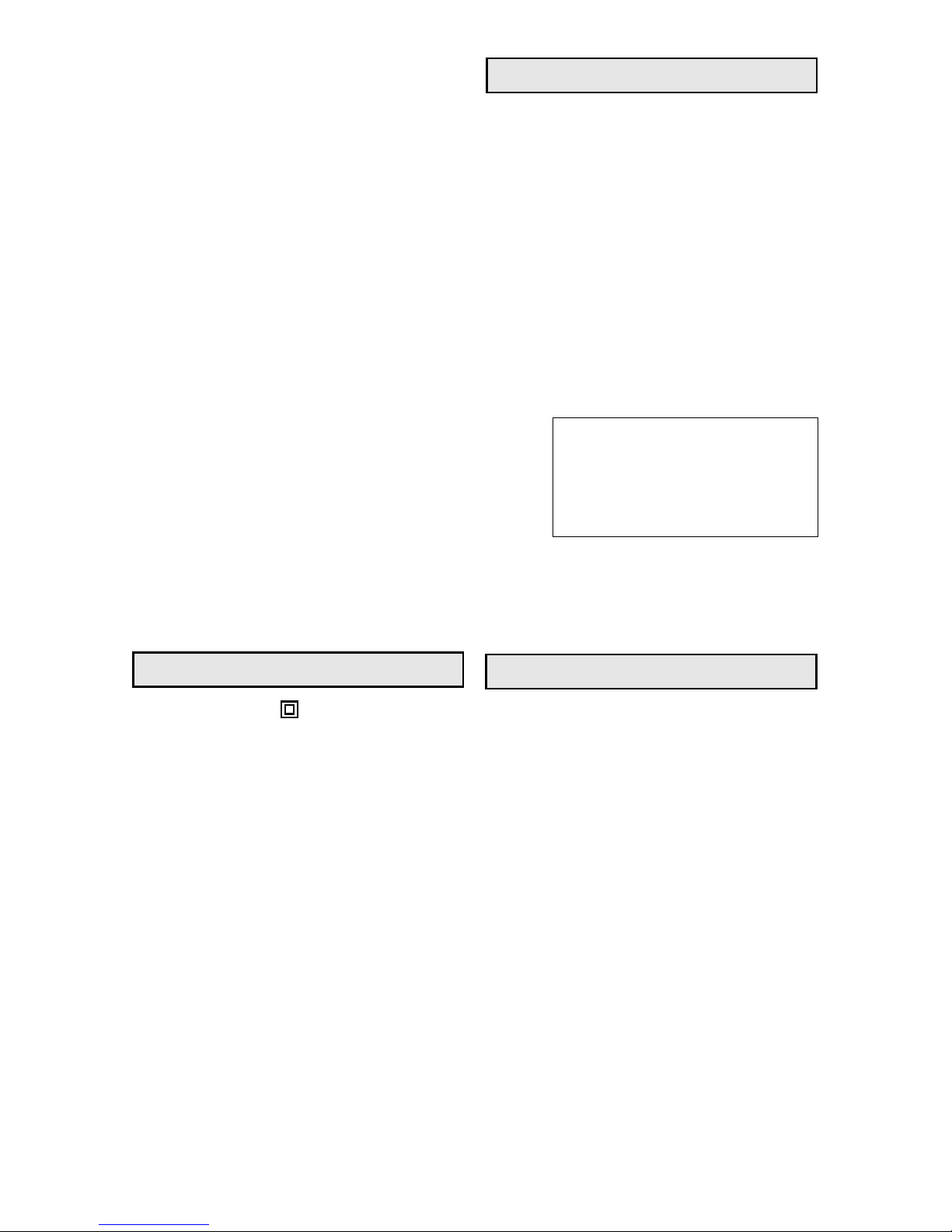

Installing and changing

the blades: Remove

screws 4, knurled nuts 3,

lockwashers 9 and face

plate 2 from the tool. Install the blade guide 5

with the slot towards the

front of the tool, being

sure to align the locating pins in the corresponding holes. Install screws 4 and securely

tighten. Insert the lightly lubricated blades 6

into the blades guide 5 so that the vertical slots

in the bottom of the

blades drop over the pin

in the bottom of the blade

guide 5. Align the horizontal slots at the top of

the blades with the drive

pins in the bottom of the

gear box and slide the

blades in until recessed slightly. Install face

plate 2, lockwashers 9, and securely tighten

knurled nuts 3.

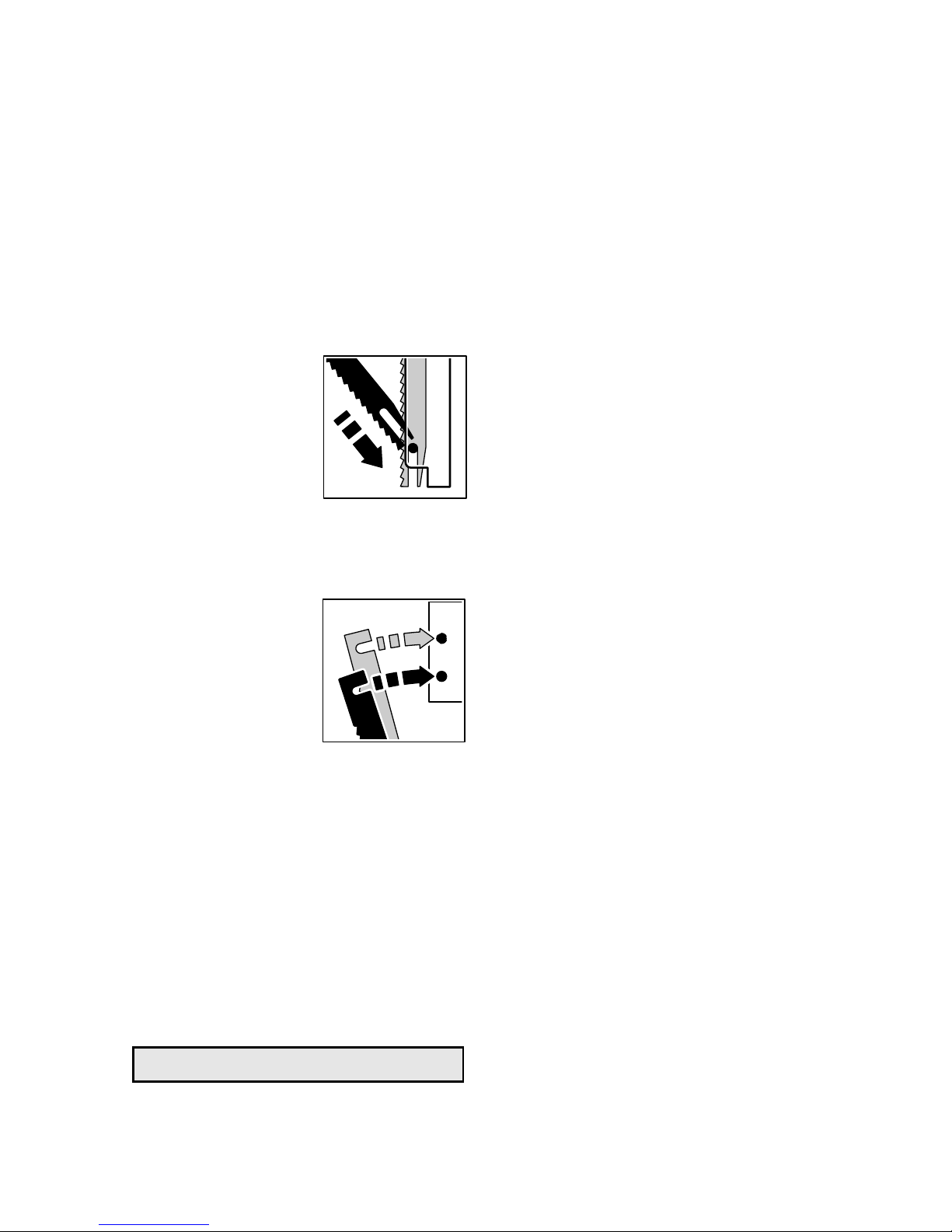

Footplate Installation

The 1575A may be used with or without the

foot plate 8, which facilitates guiding the saw

and enables sharp corners to be cut. The foot

plate may be removed when cutting random

shapes.

Installing the footplate: Press the foot plate 8

into the blades guide 5. Tighten foot plate onto

blade guide using locking screw 7.

operate this tool. If you are not familiar with

the operation of this tool, it is best to obtain

instruction from a skilled user, or take a class

at a local junior or community college.

With the tool unplugged from the power supply and the on/off switch 1 in the "OFF"

position, please become familiar with handling the foam cutter and learning the location

of the foam cutter's component parts that are

listed on page three of this manual.

Before running the foam cutter, inspect the

blades for excessive wear, and replace if necessary.

For clean and fast cuts, hold the tool so that the

cutting head is at a right angle (90º) to the

material being cut. Feeding the tool into the

work with a minimum of pressure reduces

output considerably as well as the cutting life

of the blades.

When making cut-outs, remove the footplate

and pierce a hole through the material for the

blades with a knife or scissors.

If the foam cutter does not cut correctly, check

for dull blades. Denser materials will dull the

blades faster than less dense materials. Dulling

will be apparent as more pressure is required to

feed and cut into the material.

Blades can be easily re-sharpened by means of

the blades sharpener with whetstone available

as an optional accessory.

When cutting precise blanks, and especially

when cutting soft foam and similar materials,

feed the foam cutter slowly. Don't stretch or

press materials excessively when cutting.

The blades and blade guide must be cleaned at

regular intervals (approx. every 8-10 operating hours). It is advisable to clean them using

benzine. Before installing new or sharpened

blades, lightly oil the blade guide 5.

7

Bearings

After about 300-400 hours of operation, or at

every second brush change, the bearings should

be replaced at a Bosch Factory Service Center.

Bearings which become noisy (due to heavy

load or very abrasive material cutting) should

be replaced at once to avoid overheating and

motor failure.

Cleaning

WARNING! To avoid accidents, always

disconnect the tool from the power supply

before cleaning or performing any maintenance.

The tool may be cleaned most effectively with

compressed air. Always wear safety goggles

when cleaning tools with compressed air.

Ventilation openings and switch levers must be

kept clean and free of foreign matter. Do not

attempt to clean by inserting pointed objects

through openings.

CAUTION! Certain cleaning agents and

solvents damage plastic parts. Some of these

are: gasoline, carbon tetrachloride, chlorinated

cleaning solvents, ammonia and household

detergents that contain ammonia.

Maintenance and Service

WARNING! Preventive maintenance per-

formed by unauthorized personnel may result

in misplacing of internal wires and components

which could cause serious hazard. We recommend that all tool service be performed at a

Bosch Factory Service Center.

Tool Lubrication

Your Bosch tool has been properly lubricated

and is ready for use. We recommend, that tools

with gears be regreased with a special gear

lubricant every time the brushes are changed.

Carbon Brushes

The brushes and commutator in your Bosch

tool have been engineered for many hours of

dependable service. To maintain peak efficiency of the motor, we recommend that every

two to six months the brushes be examined.

Only genuine Bosch replacement brushes specially designed for your tool should be used.

8

© Robert Bosch Tool Corporation 1800 W. Central Road

Mt. Prospect, IL 60056 -2230

WARRANTY

LIMITED WARRANTY OF

BOSCH PORTABLE AND

BENCHTOP

POWER TOOLS

Robert Bosch Tool Corporation (“Seller”)

warrants to the original purchaser only, that all

BOSCH portable and benchtop power tools

will be free from defects in material or workmanship for a period of one year from date of

purchase. SELLER’S SOLE OBLIGATION

AND YOUR EXCLUSIVE REMEDY under

this Limited Warranty and, to the extent permitted by law, any warranty or condition implied

by law, shall be the repair or replacement of

parts, without charge, which are defective in

material or workmanship and which have not

been misused, carelessly handled, or misrepaired

by persons other than Seller or Authorized

Service Station. To make a claim under this

Limited Warranty, you must return the

complete portable or benchtop power tool

product, transportation prepaid, to any BOSCH

Factory Service Center or Authorized Service

Station. For Authorized BOSCH Power Tool

Service Stations, please refer to your phone

directory.

THIS LIMITED WARRANTY DOES NOT

APPLY TO ACCESSORY ITEMS SUCH AS

CIRCULAR SAW BLADES, DRILL BITS,

ROUTER BITS, JIGSAW BLADES, SANDING BELTS, GRINDING WHEELS AND

OTHER RELATED ITEMS.

ANY IMPLIED WARRANTIES SHALL BE

LIMITED IN DURATION TO ONE YEAR

FROM DATE OF PURCHASE. SOME

STATES IN THE U.S., SOME CANADIAN

PROVINCES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

IN NO EVENT SHALL SELLER BE LIABLE

FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES (INCLUDING BUT NOT

LIMITED TO LIABILITY FOR LOSS OF

PROFITS) ARISING FROM THE SALE OR

USE OF THIS PRODUCT. SOME STATES

IN THE U.S. AND SOME CANADIAN PROVINCES DO NOT ALLOW THE EXCLUSION

OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE

ABOVE LIMITATION OR EXCLUSION

MAY NOT APPLY TO YOU.

THIS LIMITED WARRANTY GIVES YOU

SPECIFIC LEGAL RIGHTS, AND YOU MAY

ALSO HAVE OTHER RIGHTS WHICH

VARY FROM STATE TO STATE IN THE

U.S., PROVINCE TO PROVINCE IN

CANADA AND FROM COUNTRY TO

COUNTRY.

THIS LIMITED WARRANTY APPLIES

ONLY TO PORTABLE AND BENCHTOP

ELECTRIC TOOLS SOLD WITHIN THE

UNITED STATES OF AMERICA, CANADA

AND THE COMMONWEALTH OF PUERTO

RICO. FOR WARRANTY COVERAGE

WITHIN OTHER COUNTRIES, CONTACT

YOUR LOCAL BOSCH DEALER OR IMPORTER.

Loading...

Loading...