Page 1

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

1529B

Consumer Information

Renseignement des consommateurs

Información para el consumidor

Toll Free Number: Appel gratuit : Número de teléfono gratuito:

1-877-BOSCH99 (1-877-267-2499) http://www.boschtools.com.

For English Parlez-vous français? ¿Habla español?

See page 3 Voir page 9 Ver página 16

BM 3609929430 4-04 4/22/04, 9:56 AM1

Page 2

1

2

3

4

5

6

7

BM 3609929430 4-04 4/22/04, 9:56 AM2

8

9

2

Page 3

Product Data - Corrugated Nibbler

Model number 1529B

Identification number 0 601 529 2 . .

Nibbler Capacities:

Material Max. Sheet Thickness

Mild Steel 60,000 PSI up to 18 Ga. (.048")

Most Alum. 36,000 PSI up to .080" (2mm)

Stainless 87,000 PSI up to 20 Ga. (.036")

Accessory Listing

Punch 2 608 639 027

Die 2 608 639 028

Carrying case

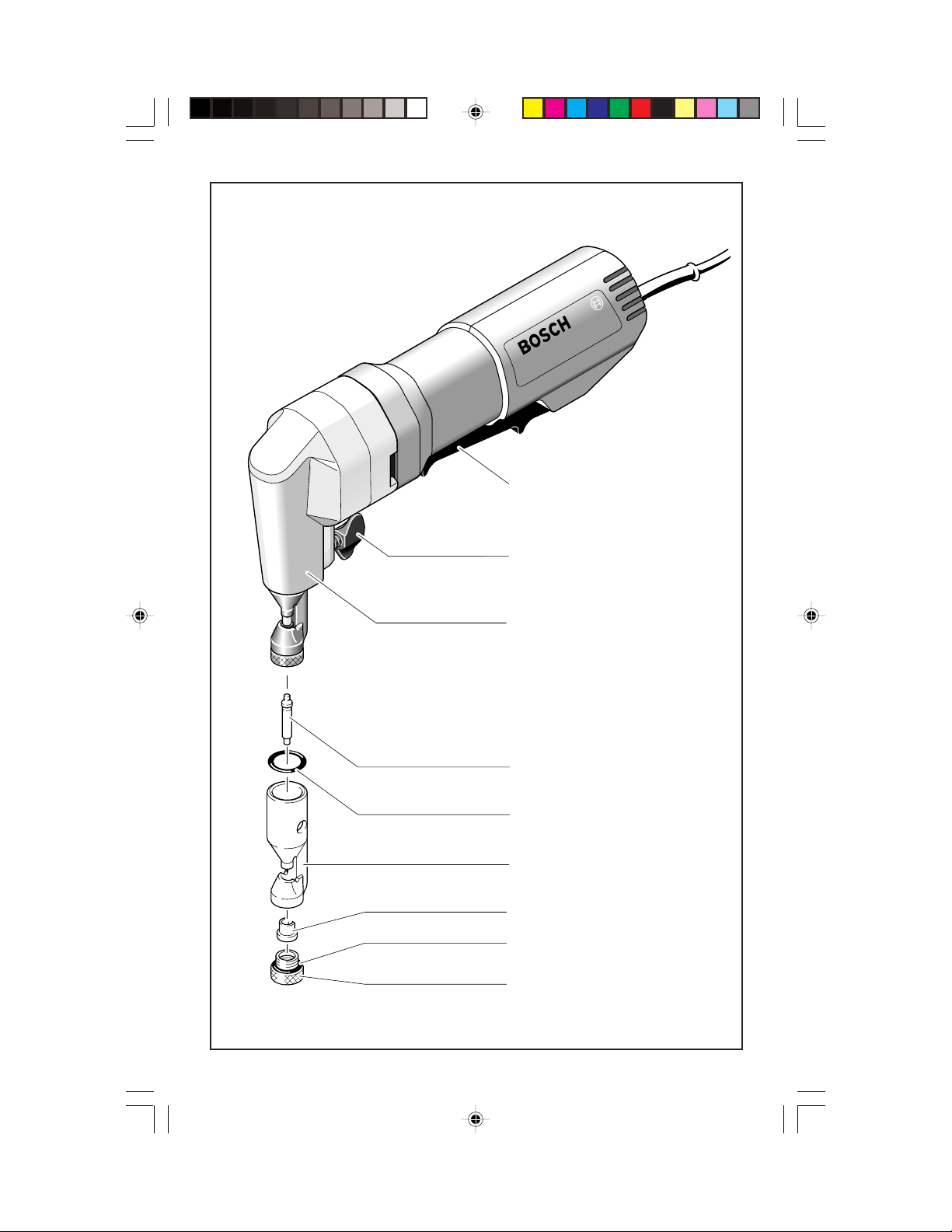

Corrugated Nibbler Components

1. Paddle ON/OFF switch 6. Die holder

2. Wing screw 7. Die

3. Housing 8. Rubber ring

4. Punch 9. Knurled nut

5. Sealing ring

WARNING! “READ ALL INSTRUC-

TIONS”. Failure to follow the SAFETY RULES

identified by the BULLET (•) symbols listed

BELOW and other safety precautions, may

result in serious personal injury. Keep these

operating instructions with this product.

GENERAL SAFETY RULES

for all Power Tools

Work Area

• KEEP WORK AREAS CLEAN. Cluttered

areas and benches invite accidents.

• AVOID DANGEROUS ENVIRONMENT.

Don’t use power tools in damp or wet locations.

Do not expose power tools to rain. Keep work

area well lit.

• AVOID GASEOUS AREAS. Do not operate portable electric tools in explosive atmospheres in presence of flammable liquids or

gases. Motors in these tools normally spark,

BM 3609929430 4-04 4/22/04, 9:56 AM3

and the sparks might ignite fumes.

• KEEP CHILDREN AWAY. Do not let

visitors contact tool or extension cord. All

visitors should be kept away from work areas.

Personal Safety

• GUARD AGAINST ELECTRIC SHOCK.

Prevent body contact with grounded surfaces

such as pipes, radiators, ranges and refrigerator

enclosures. Rubber gloves and non-skid footwear are recommended when working outdoors, where damp or wet ground may be

encountered. A Ground Fault Circuit Interrupter protected power line must be used for

these conditions.

• DRESS PROPERLY. Do not wear loose

clothing or jewelry. They can be caught in

moving parts. Wear protective hair covering to

contain long hair.

• USE SAFETY EQUIPMENT. WEAR

SAFETY GOGGLES or glasses with side

shields. Wear hearing protection during ex-

3

Page 4

tended use of power tools and dust mask for

dusty operations.

• STAY ALERT. USE COMMON SENSE.

Watch what you are doing. Do not operate tool

when you are tired or under influence of drugs.

•

REMOVE ADJUSTING KEYS AND

WRENCHES.

keys and adjusting wrenches are removed from

tool before turning it on.

• AVOID ACCIDENTAL STARTING. Don’t

carry plugged in tool with finger on switch. Be

sure the switch is OFF before being plugged in.

• DON’T OVERREACH. Keep proper footing and balance at all times.

• BEFORE CONNECTING THE TOOL to a

power supply (receptacle, outlet, etc.) be sure

the voltage supplied is the same as that specified on the tool’s nameplate. A power supply

with voltage greater than that specified for the

tool can result in serious injury to the user - as

well as damage to the tool. If in doubt, DO NOT

PLUG IN THE TOOL. Using a power supply

with voltage less than the nameplate rating is

harmful to the motor.

“Volts AC” designated tools are for Alternating

Current 50-60 Hz only. “Volts DC” designated

tools are for Direct Current. Do not use AC

designated tools with DC power supply. Do not

use

electronic speed controlled tools with DC

power supply.

Form habit of checking to see that

Tool Use and Care

• DON’T FORCE TOOL. It will do the job

better and safer at the rate for which it was

designed.

• USE RIGHT TOOL. Don’t force small tool

or attachment to do the job of a heavy-duty tool.

Don’t use tool for purpose not intended - for

example; don’t use a circular saw for cutting

tree limbs or logs.

• SECURE WORK. Use clamps or a vise to

hold work. It’s safer than using your hand and

it frees both hands to operate the tool.

• DON’T ABUSE CORD. Never carry tool by

cord or yank it to disconnect from receptacle.

Keep cord from heat, oil, and sharp edges.

Always keep cord away from the spinning

blade, bits or any other moving part while the

tool is in use.

• OUTDOOR USE EXTENSION CORDS.

When tool is used outdoors, use only extension

cords suitable for use outdoors and marked with

suffix W-A (for UL), or W (for CSA). Refer to

section “Extension Cords”, for proper cord use.

• DISCONNECT TOOLS. When not in use,

before servicing, or when changing blades,

bits, cutters, etc.

• STORE IDLE TOOLS. When not in use,

tools should be stored in dry, high or locked up

place - out of the reach of children.

• DO NOT ALTER OR MISUSE TOOL.

These tools are precision built. Any alterations

or modifications not specified is misuse and

may result in a dangerous condition.

• THE USE OF ANY ACCESSORIES not

specified in this manual may create a hazard.

• MAINTAIN TOOLS WITH CARE. Keep

tools sharp and clean for better and safer performance. Follow instructions for lubricating and

changing accessories. Inspect tool cords periodically and if damaged, have repaired by authorized service facility. Inspect extension

cords periodically and replace if damaged. Keep

handles dry, clean and free from oil and grease.

• CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part that is

damaged should be carefully checked to determine that it will operate properly and perform

its intended function. Check for alignment of

moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect its operation. A guard or

other part that is damaged should be promptly

and properly repaired or replaced. Have defective switches replaced. Do not use tool if switch

does not turn it on or off.

• ALL REPAIRS, ELECTRICAL OR MECHANICAL, should be attempted only by

trained repairmen. Contact the nearest Bosch

Factory Service Center, or Bosch Authorized

Service Center or other competent repair center. Use only Bosch replacement parts, any

other may create a hazard.

Safety Rules for Nibblers

• Always unplug the tool from the power source

before changing accessories or making any

adjustments.

• Always wear safety goggles or eye protection when using this tool.

4

BM 3609929430 4-04 4/22/04, 9:56 AM4

Page 5

• Wear leather gloves to protect hands from

sharp metal edges and safety shoes to protect

feet from sharp metal pieces.

• Periodically check tool fasteners for looseness, tighten as required.

• Do not cut material greater than the rated

capacity of the nibbler.

• Secure the material being cut. Never hold

small pieces in your hand or across legs.

• Do not use dull or damaged punch and dies or

accessories not intended for a nibbler. Replace

worn punches and dies immediately.

• Do not touch punch and die during use of the

nibbler.

• Never place the tool down until the punch has

come to a complete stop.

Some dust created by

power sanding, sawing,

grinding, drilling, and other construction

activities contains chemicals known to cause

cancer, birth defects or other reproductive

harm. Some examples of these chemicals

are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and

other masonry products, and

• Arsenic and chromium from chemically

treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work.

To reduce your exposure to these chemicals:

work in a well ventilated area, and work with

approved safety equipment, such as those dust

masks that are specially designed to filter out

microscopic particles.

a qualified service technician. WHEN SERVICE IS REQUIRED USE ONLY IDENTICAL REPLACEMENT PARTS.

POLARIZED PLUGS: If your tool is equipped

with a polarized plug (one blade is wider than

the other), this plug will fit in a polarized outlet

only one way. If the plug does not fit fully in the

outlet, reverse the plug. If it still does not fit,

contact a qualified electrician to install the

proper outlet. To reduce the risk of electric

shock do not change the plug in any way.

Extension Cords

• Replace damaged cords immediately. Use of

damaged cords can shock, burn or electrocute.

• If an extension cord is necessary, a cord with

adequate size conductors should be used to

prevent excessive voltage drop, loss of power

or overheating. The table below shows the

correct size to use, depending on cord length

and amperage rating on the tool’s nameplate. If

in doubt, use the next heavier gauge. Always

use U.L. and CSA listed extension cords.

Ampere Rating (shown on nameplate)

0- 2.1- 3.5- 5.1- 7.1- 12.1-

2.0 3.4 5.0 7.0 12.0 16.0

25' 18 18 18 18 16 14

50' 18 18 16 16 14 12

75' 18 18 16 14 12 10

100' 18 16 14 12 10

Cord Length

150' 16 14 12 12 Wire Gauge

Note: The smaller the gauge number, the larger

the wire is in the cord.

"SAVE THESE INSTRUCTIONS"

Double Insulated Tools

• Double Insulation is a design concept

used in electric power tools which eliminates

the need for the three wire grounded power cord

and grounded power supply system. It is a

recognized and approved system by

Underwriter’s Laboratories, CSA and Federal

OSHA authorities.

IMPORTANT: Servicing of a tool with

double insulation requires care and knowledge

of the system and should be performed only by

BM 3609929430 4-04 4/22/04, 9:56 AM5

Operating the Tool

General Information

Following a few simple tips will reduce wear on

the tool and the chance of injury to the user.

With the tool unplugged from the power supply

and the ON/OFF Switch 1 in the “OFF” position, become familiar with handling the nibbler

and learning the location of its parts.

5

Page 6

Before running the nibbler, inspect the punch

and die for excessive wear, and replace if necessary.

Do not exceed recommended capacities for this

nibbler. Premature punch and die failure will

occur when the nibbler is under- or over-gaged.

• Never start the nibbler with the punch and die

in contact with the material being cut.

For clean and fast cuts, hold the nibbler so that

the cutting head is at a right angle to the cutting

path, with the body of the tool parallel to the

corrugations. Move the cutting head in and out

of the corrugations, constantly keeping the head

at a right angle to the material being cut.

Feed the nibbler into the work with a minimum

of pressure. Let the nibbler do the work. If the

nibbler doesn’t cut correctly, check for a dull

punch or die. Dulling will be apparent as more

pressure is required to feed the nibbler into the

material. Burrs will also show along the cut

edge. A harder material will dull the punch and

die faster than a soft material.

Always direct the cord toward the rear, and

away from the nibbler. Keep it away from sharp

edges.

Secure or clamp small workpieces to be cut to

prevent slippage.

Always use recommended lubricant for the

material being cut. Lack of lubricant will shorten

punch and die life.

Paddle Switch with “Lock-ON” feature

The Paddle Switch enables the operator to control the switch functions of “ON/OFF” and

“Lock-ON”.

TO SWITCH TOOL “ON”: Squeeze and hold

the paddle lever.

TO SWITCH TOOL “OFF”: Release pressure

on the paddle lever. The switch is spring loaded

and will return to “OFF” position automatically.

The “Lock-ON” feature, incorporated into the

paddle switch, is a convenience for long operations.

TO LOCK SWITCH “ON”: After switch has

been activated, PULL the front portion of the

paddle lever completely BACKWARD and

release pressure on the paddle lever.

TO SWITCH TOOL “OFF”: Squeeze the rear

portion of paddle lever and then release the

paddle lever. The switch is spring loaded and

will return to “OFF” position automatically.

Nibbling to a Scribed Line

or with a Template

Cuts may be executed easily by guiding the

nibbler along a template or a straight edge.

A preboring of 21mm (.827") diameter is required for internal cut-outs.

When cutting, guide the unit with a slight thrust

in the cutting direction. Cutting takes place

during the downward movement of the punch.

The chips are ejected downward through the

knurled nut 9.

Rotating the Die holder

By rotating the die holder 6, cutting can be

preformed at a right angle to the forward axis of

the machine. Loosen the winged screw 2 and turn

the die holder 6 (including the die 7 and knurled

nut 9), to the right or left by 90°. Re-tighten the

winged screw 2. The winged screw must engage

one of the 3 holes in the die holder 6.

Tool Tips

The corrugated nibbler is especially designed

for working with corrugated sheets of both

trapezoidal and rectangular profiles.

Always use both hands to guide the nibbler.

Do not use force; this will lead to premature die

and punch wear.

Before running the nibbler, be sure the punch

and die are properly lubricated. See "Punch and

Die Lubrication" section.

Never start the nibbler with the punch and die in

contact with the material being cut.

Always be sure material is resting on lower die

during operation.

Changing Punches and Dies

CAUTION! Unplug nibbler before changing

punches and dies.

Replacing the punch

Loosen the winged screw 2 and pull the die

holder 6 (including the die 7 and knurled nut 9)

out of the housing 3. Slide the punch 4 sideways

out of the groove and remove downward.

Oil the new punch well, insert into the groove

and center.

6

BM 3609929430 4-04 4/22/04, 9:56 AM6

Page 7

Slide the die holder 6 carefully over the punch

and into the housing 3. Re-tighten the winged

screw 2. The winged screw must engage one of

the holes in the die holder 6.

NOTE: The punch cannot be reground.

Replacing the Die

Unscrew the knurled nut 9 together with the

rubber ring 8 out of the die holder 6 and remove

the die 7. Remove any rust material or cutting

particles that may have collected in the die

holder 6.

Insert a new die 7 paying attention to the alignment of the flat surface on the side. Firmly

tighten the knurled nut 9 against the resistance

of the rubber ring 8.

NOTE: The die cannot be reground.

Punch and Die Lubrication

Proper lubrication is essential to prolong punch

and die life, and is achieved by occasionally

fully submersing the punch and die in a small

container of the proper lubricant.

To further ensure a smooth cut and long punch

life, always lubricate the cutting path with cutting oil. When cutting steel or stainless steel,

lubricate path of cut before starting work. When

cutting aluminum, lubricate path of cut while

making the cut. Since the punch cuts on the

downstroke, the upper side of the cut should be

lubricated.

When cutting steel, use a cutting oil or an SAE

30 weight oil.

When cutting aluminum, a mixture of 7 parts

kerosene and 3 parts turpentine should be used.

Should punch jam, immediately switch off

nibbler, re-lubricate punch and die, and remove

tension from sheet.

WARNING! The use of any accessory or

attachment other than recommended in this

instruction manual or the BOSCH Catalog may

present a risk of personal injury.

mend that all tool service be performed at a

Bosch Factory Service Center.

Tool Lubrication

Your Bosch tool has been properly lubricated

and is ready for use. We recommend, that tools

with gears be regreased with a special gear

lubricant every time the brushes are changed.

Carbon Brushes

The brushes and commutator in your Bosch

tool have been engineered for many hours of

dependable service. To maintain peak efficiency of the motor, we recommend that every

two to six months the brushes be examined.

Only genuine Bosch replacement brushes specially designed for your tool should be used.

Bearings

After about 300-400 hours of operation, or at

every second brush change, the bearings should

be replaced at a Bosch Factory Service Center.

Bearings which become noisy (due to heavy

load or very abrasive material cutting) should

be replaced at once to avoid overheating and

motor failure.

Cleaning

WARNING! To avoid accidents, always

disconnect the tool from the power supply

before cleaning or performing any maintenance.

The tool may be cleaned most effectively with

compressed air. Always wear safety goggles

when cleaning tools with compressed air.

Ventilation openings and switch levers must be

kept clean and free of foreign matter. Do not

attempt to clean by inserting pointed objects

through openings.

CAUTION! Certain cleaning agents and

solvents damage plastic parts. Some of these

are: gasoline, carbon tetrachloride, chlorinated

cleaning solvents, ammonia and household

detergents that contain ammonia.

Maintenance and Service

WARNING! Preventive maintenance per-

formed by unauthorized personnel may result

in misplacing of internal wires and components

which could cause serious hazard. We recom-

BM 3609929430 4-04 4/22/04, 9:56 AM7

7

Page 8

LIMITED WARRANTY OF BOSCH PORTABLE AND

BENCHTOP POWER TOOLS

Robert Bosch Tool Corporation (“Seller”)

warrants to the original purchaser only, that all

BOSCH portable and benchtop power tools

will be free from defects in material or workmanship for a period of one year from date of

purchase. SELLER’S SOLE OBLIGATION

AND YOUR EXCLUSIVE REMEDY under

this Limited Warranty and, to the extent permitted by law, any warranty or condition implied

by law, shall be the repair or replacement of

parts, without charge, which are defective in

material or workmanship and which have not

been misused, carelessly handled, or misrepaired

by persons other than Seller or Authorized

Service Station. To make a claim under this

Limited Warranty, you must return the

complete portable or benchtop power tool

product, transportation prepaid, to any BOSCH

Factory Service Center or Authorized Service

Station. For Authorized BOSCH Power Tool

Service Stations, please refer to your phone

directory.

THIS LIMITED WARRANTY DOES NOT

APPLY TO ACCESSORY ITEMS SUCH AS

CIRCULAR SAW BLADES, DRILL BITS,

ROUTER BITS, JIGSAW BLADES, SANDING BELTS, GRINDING WHEELS AND

OTHER RELATED ITEMS.

ANY IMPLIED WARRANTIES SHALL BE

LIMITED IN DURATION TO ONE YEAR

FROM DATE OF PURCHASE. SOME

STATES IN THE U.S., SOME CANADIAN

PROVINCES DO NOT ALLOW LIMITA-

TIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

IN NO EVENT SHALL SELLER BE LIABLE

FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES (INCLUDING BUT NOT

LIMITED TO LIABILITY FOR LOSS OF

PROFITS) ARISING FROM THE SALE OR

USE OF THIS PRODUCT. SOME STATES

IN THE U.S. AND SOME CANADIAN PROVINCES DO NOT ALLOW THE EXCLUSION

OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE

ABOVE LIMITATION OR EXCLUSION

MAY NOT APPLY TO YOU.

THIS LIMITED WARRANTY GIVES YOU

SPECIFIC LEGAL RIGHTS, AND YOU MAY

ALSO HAVE OTHER RIGHTS WHICH

VARY FROM STATE TO STATE IN THE

U.S., PROVINCE TO PROVINCE IN

CANADA AND FROM COUNTRY TO

COUNTRY.

THIS LIMITED WARRANTY APPLIES

ONLY TO PORTABLE AND BENCHTOP

ELECTRIC TOOLS SOLD WITHIN THE

UNITED STATES OF AMERICA, CANADA

AND THE COMMONWEALTH OF PUERTO

RICO. FOR WARRANTY COVERAGE

WITHIN OTHER COUNTRIES, CONTACT

YOUR LOCAL BOSCH DEALER OR IMPORTER.

© Robert Bosch Tool Corporation 1800 W. Central Road

Mt. Prospect, IL 60056 -2230

BM 3609929430 4-04 4/22/04, 9:56 AM8

8

Page 9

Données concernant le produit — Grignoteuse de tôles ondulées

Numéro de modèle 1529B

Numéro d’identification 0 601 529 2..

Capacités de la grignoteuse :

Matériau Épaisseur max. de la tôle

Acier doux 60,000 1b/po

La plupart des alum. 36,000 1b/po

Acier inox 87,000 1b/po

2

2

jusqu’à calibre 18 (,048")

2

jusqu’à ,080" (2 mm)

jusqu’à calibre 20 (,036")

Liste des accessoires

Poinçon 2 608 639 027

Filière 2 608 639 028

Étui

Composants de la grignoteuse de tôles ondulées

1. Interrupteur marche/arrêt à palette 6. Porte-filière

2. Vis à oreilles 7. Filière

3. Boîtier 8. Anneau en caoutchouc

4. Poinçon 9. Écrou moleté

5. Anneau d’étanchéité

AVERTISSEMENT ! « LISEZ ATTENTIVEMENT TOUTES LES INSTRUCTIONS ».

Faute d’observer les RÈGLES DE SÉCURITÉ

précédées d’un POINT NOIR (•) et les autres

consignes du présent manuel risque de vous

exposer à de graves blessures. Conservez ces

instructions à portée de la main.

RÈGLES GÉNÉRALES

DE SÉCURITÉ

pour tous les outils motorisés

Lieu de travail

• TRAVAILLEZ DANS LA PROPRETÉ.

Les endroits et les établis encombrés invitent

les accidents.

• ÉVITEZ LES ENVIRONNEMENTS

DANGEREUX. N’utilisez pas les outils

électriques en lieux humides ou mouillés.

N’exposez pas les outils motorisés à la pluie.

Assurez-vous que l’endroit est adéquatement

éclairé.

• ÉVITEZ LES ENVIRONNEMENTS

GAZEUX. N’utilisez pas les outils électriques

portatifs en atmosphères explosives en présence

de liquides ou de gaz inflammables. Les moteurs de ces outils émettent normalement des

étincelles qui risquent d’enflammer les vapeurs.

• GARE AUX ENFANTS. Ne permettez pas

aux visiteurs de toucher à l’outil ou à la rallonge.

Tenez-les à distance raisonnable du lieu de travail.

Sécurité personnelle

• GARE AUX DÉCHARGES ÉLECTRIQUES. Évitez tout contact avec les surfaces

mises à la terre telles que tuyaux, radiateurs,

cuisinières et enceintes de réfrigérateurs. Pour le

travail à l’extérieur, par temps humide ou sur sol

mouillé, il est recommandé de porter des gants en

caoutchouc et des chaussures à semelle antidérapante. Dans ce cas, vous devez utiliser une

prise de courant protégée par disjoncteur de fuite

à la terre.

• PORTEZ DES VÊTEMENTS CONVE-

9

BM 3609929430 4-04 4/22/04, 9:56 AM9

Page 10

NABLES. Ne portez pas de vêtements amples ni

de bijoux car ils risquent de s’accrocher dans les

pièces mobiles. De même, pour les cheveux

longs, nous conseillons le port d’un serre-tête.

• UTILISEZ L’ÉQUIPEMENT DE SÉCURITÉ. PORTEZ DES LUNETTES DE

SÉCURITÉ ou lunettes à coques latérales.

Portez des protège-oreilles lors des travaux de

longue durée et un masque protecteur si la

situation l’exige.

• SOYEZ VIGILANT, FAITES PREUVE

DE DISCERNEMENT. Agissez prudemment.

N’utilisez pas l’outil quand vous êtes fatigué ou

sous l’influence de stupéfiant.

• ENLEVEZ LES CLÉS DE RÉGLAGE

ET AUTRES. Prenez l’habitude de voir à ce

qu’elles soient mises de côté avant de mettre

l’outil en marche.

• ÉVITEZ LA MISE EN MARCHE ACCIDENTELLE. Ne transportez pas un outil

branché avec le doigt appuyé sur l’interrupteur.

Assurez-vous que l’interrupteur est en position

d’arrêt avant de le brancher.

• TRAVAILLEZ AVEC APLOMB. Tenezvous bien d’aplomb et en équilibre en tout

temps.

• AVANT DE BRANCHER L’OUTIL à une

prise de courant, rassurez-vous que la tension

correspond à celle spécifiée sur la plaquette

emblématique de l’outil. Une tension supérieure

à celle recommandée pour l’outil risque de

blesser sérieusement l’utilisateur sans mentionner l’endommagement de l’outil. NE

BRANCHEZ PAS L’OUTIL à moins que vous

soyez absolument satisfait. Le raccordement à

une source de courant dont la tension est

inférieure à celle indiquée sur la plaquette

endommagera le moteur.

Les outils portant la désignation « AC » ne

s’alimentent que de courant alternatif de 50-60

Hz. Les outils portant la désignation « DC »

s’alimentent de courant continu. N’enfichez pas

d’outils c.a. à une source d’alimentation c.c.

Ne branchez pas les outils à régulateur électronique de vitesse à une source d’alimentation c.c.

Utilisation et entretien

• N’ABUSEZ PAS DE L’OUTIL. Il est plus

efficace et sûr au régime pour lequel il a été

destiné.

• UTILISEZ L’OUTIL APPROPRIÉ. Ne

forcez pas un petit outil ou un accessoire à

effectuer le travail d’un de plus grosse taille.

N’utilisez pas l’outil à tort et à travers — par

exemple — n’utilisez pas une scie circulaire

pour tailler les branches d’arbres ou les bûches.

• FIXEZ LE MATÉRIAU EN PLACE. Utilisez des serre-joints ou un étau. C’est beaucoup

plus sûr et vous pouvez manier l’outil des deux

mains.

• N’ABUSEZ PAS DU CORDON. Ne

transportez jamais l’outil par le cordon et ne

tirez jamais sur ce dernier pour le débrancher.

Protégez le cordon de la chaleur, de l’huile et

des bords tranchants. Gardez toujours le cordon

à bonne distance de la lame, des accessoires ou

autres pièces mobiles de l’outil en marche.

• CORDONS DE RALLONGE POUR

EXTÉRIEUR. Quand vous utilisez l’outil à

l’extérieur, n’employez que des rallonges

destinées à tel usage et portant les suffixes

d’homologation, soit W-A (pour les UL) soit W

(pour l’ACNOR). Voir le tableau « Dimensions

des rallonges recommandées ».

• DÉBRANCHEZ LES OUTILS. Quand ils

ne servent pas ; avant l’entretien ; avant de

changer les lames, les mèches, les couteaux et

autres.

• RANGEZ LES OUTILS NE SERVANT

PAS. Suivant leur usage, les outils devraient

être rangés dans un endroit sec, élevé ou sous

clé — hors de la portée des enfants.

• NE MODIFIEZ NI ABUSEZ DE L’OUTIL.

Ces outils sont extrêmement précis. Tout

changement ou modification non recommandé

constitue un mésusage risquant d’avoir de

graves répercussions.

• L’USAGE D’ACCESSOIRES AUTRES

que ceux recommandés dans le présent manuel

peut être dangereux.

• TRAITEZ LES OUTILS AVEC SOIN.

Maintenez-les bien propres et bien à point pour

qu’ils fonctionnent en douceur. Observez les

directives concernant le graissage et le changement des accessoires. Examinez périodiquement l’état des cordons de l’outil et, au besoin,

confiez-en la réparation à un poste d’entretien

agréé. Examinez périodiquement l’état des cordons de rallonge et remplacez-les au besoin.

Maintenez les poignées sèches, propres, sans

souillure d’huile et de graisse.

• RECHERCHEZ LES PIÈCES ENDOM-

BM 3609929430 4-04 4/22/04, 9:56 AM10

10

Page 11

MAGÉES. Avant d’utiliser l’outil, examinez

soigneusement l’état des pièces telles que le

protecteur pour vous assurer qu’elles fonctionnent correctement. Vérifiez l’alignement et

la liberté de fonctionnement des pièces mobiles, l’état et le montage des pièces et toutes

autres conditions susceptibles d’affecter défavorablement le fonctionnement. Il faut réparer ou

remplacer toute pièce ou tout protecteur dont

l’état laisse à désirer. Faites remplacer tout

interrupteur défectueux. N’utilisez pas un outil

dont l’interrupteur ne fonctionne pas correctement.

• TOUTES LES RÉPARATIONS, ÉLECTRIQUES OU MÉCANIQUES, devraient être

exécutées par des techniciens compétents.

Confiez-les au centre de service-usine Bosch le

plus proche, à tout autre centre de service aprèsvente Bosch agréé ou, encore, à un poste d’entretien renommé. Pour vous éviter des ennuis,

exigez toujours les pièces de rechange Bosch.

Règles de sécurité

pour grignoteuses

• Débranchez toujours l’outil de la source de

courant avant de changer les accessoires ou de

procéder à quelque réglage que ce soit.

• Portez toujours des lunettes de sécurité ou

une protection oculaire en utilisant cet outil.

• Portez des gants en cuir pour vous protéger

les mains contre les arêtes métalliques vives

ainsi que des chaussures de sécurité pour vous

protéger les pieds contre les pièces métalliques

affilées.

• Vérifiez périodiquement les attaches de l’outil

pour vous assurer qu’elles sont bien serrées et

serrez au besoin.

• Ne coupez pas de matériaux plus grands que

ce que le permet la grignoteuse.

• Assujettissez le matériau à couper. Ne tenez

jamais les petites pièces dans votre main ou sur

vos jambes.

• N’utilisez pas un poinçon et des matrices

émoussés ou abîmés ou des accessoires non

prévus pour une grignoteuse. Remplacez

immédiatement les poinçons et les matrices

usés.

• Ne touchez pas le poinçon et la matrice

pendant que vous utilisez la grignoteuse.

• Ne posez jamais l’outil avant que le poinçon

ne se soit complètement arrêté.

Les travaux à la machine

tel que ponçage, sciage,

meulage, perçage et autres travaux du

bâtiment peuvent créer des poussières

contenant des produits chimiques qui sont

des causes reconnues de cancer, de malformation congénitale ou d’autres problèmes

reproductifs. Ces produits chimiques sont,

par exemple :

• Le plomb provenant des peintures à base de

plomb,

• Les cristaux de silices provenant des briques

et du ciment et d’autres produits de maçonnerie,

et

• L’arsenic et le chrome provenant des bois

traités chimiquement.

Le niveau de risque dû à cette exposition varie

avec la fréquence de ces types de travaux. Pour

réduire l’exposition à ces produits chimiques,

il faut travailler dans un lieu bien ventilé et

porter un équipement de sécurité approprié tel

que certains masques à poussière conçus

spécialement pour filtrer les particules

microscopiques.

Double isolation

• La double isolation est utilisée dans les

outils électriques pour éliminer le besoin de

cordon d’alimentation avec prise de terre et

de dispositif d’alimentation à prise de terre.

Elle est homologuée par l’Underwriter’s Laboratories, l’ACNOR et l’OSHA.

IMPORTANT : L’entretien d’un outil à double

isolation exige la connaissance du système et la

compétence d’un technicien qualifié. EN CAS

D’ENTRETIEN, N’UTILISEZ QUE DES

PIÈCES DE RECHANGE IDENTIQUES.

FICHES POLARISÉES

équipé d’une fiche polarisée (une lame plus

large que l’autre) elle ne s’enfiche que d’une

manière dans une prise polarisée. Si la fiche

n’entre pas à fond dans la prise, tournez-la d’un

demi-tour. Si elle refuse encore d’entrer, demandez à un électricien qualifié d’installer une prise

appropriée. Ne modifiez la fiche d’aucune façon.

: Si votre outil est

BM 3609929430 4-04 4/22/04, 9:56 AM11

11

Page 12

Rallonges

• Remplacez immédiatement toute rallonge

endommagée. L’utilisation de rallonges endommagées risque de provoquer un choc

électrique, des brûlures ou l’électrocution.

• En cas de besoin d’une rallonge, utilisez un

cordon de calibre satisfaisant pour éviter toute

chute de tension, perte de courant ou surchauffe.

Le tableau ci-contre indique le calibre des

rallonges recommandées en fonction de leur

longueur et de l’intensité indiquée sur la plaque

du constructeur de l’outil. En cas de doute,

optez pour le prochain calibre inférieur. Utilisez

toujours des rallonges homologuées par l’U.L.

et l’ACNOR.

(indiquée sur la plaquette emblématique)

0- 2,1- 3,5- 5,1- 7,1- 12,12,0 3,4 5,0 7,0 12,0 16,0

25' 18 18 18 18 16 14

50' 18 18 16 16 14 12

75' 18 18 16 14 12 10

100' 18 16 14 12 10

150' 16 14 12 12 Calibre du fil

Longueur du cordon

Intensité nominale

Remarque : Plus le calibre est petit, plus le

fil est gros.

« CONSERVEZ CES INSTRUCTIONS »

Mode d’emploi

Informations générales

L’observance de quelques conseils simples

réduira l’usure sur l’outil et les possibilités de

blessures pour l’utilisateur.

L’outil étant débranché de la source de courant

et l’interrupteur MARCHE/ARRÊT 1 étant à

la position d’ARRÊT, familiarisez-vous avec

le maniement de la grignoteuse et apprenez

l’emplacement de ses pièces.

Avant de mettre la grignoteuse en marche,

inspectez le poinçon et la matrice pour y relever

une usure excessive et remplacez au besoin.

Ne dépassez pas les capacités recommandées

pour cette grignoteuse. L’utilisation de la grignoteuse en dehors de sa plage de fonctionnement

provoquera une défaillance prématurée du

poinçon et de la matrice.

• Ne mettez jamais la grignoteuse en marche

avec le poinçon et la matrice en contact avec le

matériau à couper.

Pour des coupes nettes et rapides, tenez la

grignoteuse de manière à ce que la tête de coupe

soit à angle droit par rapport à la trajectoire de

coupe, le corps de l’outil étant parallèle aux

ondulations. Déplacez la tête de coupe dans et

hors des ondulations, en gardant constamment

la tête à angle droit par rapport au matériau à

couper.

Avancez la grignoteuse dans l’ouvrage en

exerçant une pression minimale. Laissez la

grignoteuse faire le travail. Si la grignoteuse ne

coupe pas correctement, vérifiez si le poinçon

ou la matrice sont émoussés. L’émoussement

sera évident à mesure qu’une pression plus

grande sera requise pour faire avancer la grignoteuse dans le matériau. Des bavures apparaîtront également le long du bord de

coupe. Un matériau plus dur émoussera le

poinçon et la matrice plus rapidement qu’un

matériau doux.

Dirigez toujours le cordon vers l’arrière et à

l’écart de la grignoteuse. Tenez-le à l’écart des

arêtes vives.

Fixez ou serrez les petits ouvrages à couper

pour les empêcher de glisser.

Utilisez toujours le lubrifiant recommandé

pour le matériau à couper. L’absence de lubrifiant réduira la durée du poinçon et de la matrice.

Interrupteur à palette avec dispositif de

blocage en marche

L’interrupteur à palette permet à l’opérateur de

contrôler les fonctions de mise en marche et à

l’arrêt ainsi que de blocage en marche.

POUR METTRE L’OUTIL EN MARCHE :

Pressez et tenez le levier à palette.

POUR METTRE L’OUTIL À L’ARRÊT :

Relâchez la pression sur le levier à palette.

L’interrupteur est à ressort et reviendra

automatiquement à la position d’arrêt.

Le dispositif de blocage en marche, incorporé

dans l’interrupteur à palette, est commode pour

l’utilisation prolongée.

POUR BLOQUER L’INTERRUPTEUR EN

MARCHE : Une fois l’interrupteur actionné,

TIREZ la partie avant du levier à palette

complètement VERS L’ARRIÈRE et relâchez

la pression sur le levier à palette.

12

BM 3609929430 4-04 4/22/04, 9:56 AM12

Page 13

POUR METTRE L’OUTIL À L’ARRÊT :

Pressez la partie arrière du levier à palette, puis

relâchez le levier à palette. L’interrupteur est à

ressort et reviendra automatiquement à la position d’arrêt.

Grignotage sur une ligne tracée ou à

l’aide d’un gabarit

Les coupes peuvent être réalisées facilement en

guidant la grignoteuse le long d’un gabarit ou

d’un bord droit. Un préperçage de 21 mm

(0,827") de diamètre est requis pour les

découpages internes. En coupant, guidez l’unité

avec une légère poussée dans la direction de

coupe. La coupe a lieu durant le mouvement

vers le bas du poinçon. Les éclats sont éjectés

vers le bas à travers l’écrou moleté 9.

Rotation du porte-filière

En tournant le porte-filière 6, on peut couper à

angle droit par rapport à l’axe avant de la

machine. Desserrez la vis à oreilles 2 et tournez

le porte-filière 6 (y compris la filière 7 et l’écrou

moleté 9) vers la droite ou la gauche, de 90°.

Resserrez la vis à oreilles 2. La vis à oreilles doit

engager un des trois trous du porte-filière 6.

Conseils pratiques

La grignoteuse de tôles ondulées est conçue

spécialement pour le travail des tôles ondulées

de profil trapézoïdal et rectangulaire.

Servez-vous toujours de vos deux mains pour

guider la grignoteuse.

Ne forcez pas, ce qui provoquerait une usure

prématurée de la matrice et du poinçon.

Avant de mettre la grignoteuse en marche,

assurez-vous que le poinçon et la matrice sont

bien lubrifiés. Reportez-vous à la section

« Lubrification du poinçon et de la matrice ».

Ne mettez jamais la grignoteuse en marche

alors que le poinçon et la matrice sont en contact

avec le matériau à couper.

Assurez-vous toujours que le matériau repose

sur la matrice inférieure durant le fonctionnement.

Remplacement des poinçons

et des filières

ATTENTION ! Débranchez la grignoteuse

avant de changer les poinçons et les filières.

Remplacement du poinçon

Desserrez la vis à oreilles 2 et tirez le portefilière 6 (y compris la filière 7 et l’écrou moleté

9) hors du boîtier 3. Faites glisser le poinçon 4

latéralement hors de la rainure et retirez vers le

bas.

Huilez le nouveau poinçon adéquatement,

insérez dans la rainure et centrez.

Faites glisser le porte-filière 6 soigneusement

par-dessus le poinçon et dans le boîtier 3.

Resserrez la vis à oreilles 2. La vis à oreilles doit

engager l’un des trous du porte-filière 6.

REMARQUE : Le poinçon ne peut être

remeulé.

Remplacement de la filière

Dévissez l’écrou moleté 9 avec l’anneau en

caoutchouc 8 hors du porte-filière 6 et retirez la

filière 7. Enlevez toute rouille ou particule de

coupe qui peut s’être déposée dans le portefilière 6.

Insérez une nouvelle filière 7 en accordant une

attention particulière à l’alignement de la surface plate sur le côté. Serrez fermement l’écrou

moleté 9 contre la résistance de l’anneau en

caoutchouc 8.

REMARQUE : La filière ne peut être

remeulée.

Lubrification du poinçon

et de la matrice

Une lubrification appropriée est essentielle pour

prolonger la durée du poinçon et de la matrice,

et cette lubrification se fait en immergeant

complètement à l’occasion le poinçon et la

matrice dans un petit récipient contenant le

lubrifiant approprié.

Pour mieux assurer une coupe régulière et

prolonger la durée du poinçon, lubrifiez toujours

la trajectoire de coupe à l’aide d’huile de coupe.

Pour couper l’acier ou l’acier inoxydable,

lubrifiez la trajectoire de coupe avant de commencer le travail. Pour couper l’aluminium,

lubrifiez la trajectoire de coupe tout en pratiquant

la coupe. Étant donné que le poinçon coupe sur

la course descendante, le côté supérieur de la

coupe doit être lubrifié.

BM 3609929430 4-04 4/22/04, 9:56 AM13

13

Page 14

Pour couper l’acier, utilisez une huile de coupe

ou une huile SAE 30.

Pour couper l’aluminium, un mélange de 7

parties de kérosène et de 3 parties de térébenthine doit être utilisé.

Au cas où le poinçon se gripperait, mettez

immédiatement la grignoteuse à l’arrêt, relubrifiez le poinçon et la matrice, et délestez la

tension de la tôle.

AVERTISSEMENT ! L’utilisation de tout

accessoire autre que ceux recommandés dans

ce manuel d’instructions ou dans le catalogue

BOSCH peut présenter un risque de blessures.

Maintenance et entretien

Roulements

Après environ 300 à 400 heures d’utilisation,

ou à tous les deux remplacements des balais, il

faudrait confier le remplacement des roulements

à un centre de service-usine Bosch. Les roulements qui sont devenus bruyants (à cause de

sciage de matériaux très abrasifs ou de durs

efforts) devraient être remplacés à l’instant

pour éviter la surchauffe et la défaillance du

moteur.

Nettoyage

AVERTISSEMENT ! Pour éviter le risque

d’accidents, débranchez toujours l’outil de la

prise de courant avant de procéder au nettoyage

ou à l’entretien. Vous pouvez très bien le nettoyer

à l’air comprimé. Dans ce cas, portez toujours

des lunettes de sécurité.

AVERTISSEMENT ! L’entretien préventif

par des personnes non autorisées peut être

dangereux. Il est recommandé que l’entretien et

la réparation de nos outils soient confiés à un

centre de service-usine Bosch.

Graissage de l’outil

Votre outil Bosch a été convenablement graissé

et est prêt à utiliser. Il est recommandé que les

outils à engrenages soient regraissés avec une

graisse spéciale à l’occasion de tout remplacement de balais.

Balais de charbon

Les balais et le collecteur de votre outil ont été

conçus pour donner plusieurs heures de fonctionnement sans aléas. Pour maintenir le moteur

en forme, nous recommandons d’examiner les

balais tous les deux à six mois. Vous ne devriez

utiliser que les balais de rechange d’origine

Bosch qui conviennent spécialement à votre

outil.

Les prises d’air et les leviers d’interrupteur

doivent être maintenus propres et exempts de

corps étrangers. Ne tentez pas de les nettoyer

en insérant des objets pointus à travers les

ouvertures.

AVERTISSEMENT ! Certains produits de

nettoyage et dissolvants dont la gazoline, le

tétrachlorure de carbone, les nettoyeurs chlorés,

l’ammoniaque et les détergents ménagers contenant de l’ammoniaque peuvent abîmer les

pièces en plastique.

BM 3609929430 4-04 4/22/04, 9:56 AM14

14

Page 15

GARANTIE LIMITÉE DES OUTILS ÉLECTRIQUES

PORTATIFS ET D'ÉTABLI BOSCH

Robert Bosch Tool Corporation (le « vendeur »)

garantit à l'acheteur initial seulement que tous

les outils électriques portatifs et d'établi BOSCH

seront exempts de vices de matériaux ou

d'exécution pendant une période d'un an depuis

la date d'achat. LA SEULE OBLIGATION DU

VENDEUR ET LE SEUL RECOURS DE

L’ACHETEUR sous la présente garantie

limitée, et en autant que la loi le permette sous

toute garantie ou condition implicite qui en

découlerait, sera l’obligation de remplacer ou

réparer gratuitement les pièces défectueuses

matériellement ou comme fabrication, pourvu

que lesdites défectuosités ne soient pas

attribuables à un usage abusif ou à quelque

réparation bricolée par quelqu’un d’autre que le

vendeur ou le personnel d’une station-service

agréée. Pour présenter une réclamation en vertu

de cette garantie limitée, vous devez renvoyer

l'outil électrique portatif ou d'établi complet,

port payé, à tout centre de service agréé ou

centre de service usine. Veuillez consulter

votre annuaire téléphonique pour les adresses.

LA PRÉSENTE GARANTIE NE

S’APPLIQUE PAS AUX ACCESSOIRES

TELS QUE LAMES DE SCIES

CIRCULAIRES, MÈCHES DE PERCEUSES,

FERS DE TOUPIES, LAMES DE SCIES

SAUTEUSES, COURROIES DE PONÇAGE,

MEULES ET AUTRES ARTICLES DU

GENRE.

TOUTE GARANTIE IMPLICITE SERA

LIMITÉE COMME DURÉE À UN AN À

COMPTER DE LA DATE D’ACHAT.

CERTAINS ÉTATS AMÉRICAINS,

CERTAINES PROVINCES CANADIENNES

N’ADMETTANT PAS LE PRINCIPE DE LA

LIMITATION DE LA DURÉE DES

GARANTIES IMPLICITES, IL EST

POSSIBLE QUE LES LIMITATIONS CIDESSUS NE S’APPLIQUENT PAS À VOTRE

CAS.

EN AUCUN CAS LE VENDEUR NE

SAURAIT ÊTRE TENU POUR

RESPONSABLE DES INCIDENTS OU

DOMMAGES INDIRECTS (INCLUANT,

MAIS NE SE LIMITANT PAS AUX PERTES

DE PROFITS) CONSÉCUTIFS À LA VENTE

OU L’USAGE DE CE PRODUIT. CERTAINS

ÉTATS AMÉRICAINS ET CERTAINES

PROVINCES CANADIENNES

N’ADMETTANT PAS LE PRINCIPE DE LA

LIMITATION NI L’EXCLUSION DES

DOMMAGES INDIRECTS ET

CONSÉQUENTIELS, IL EST POSSIBLE

QUE LES LIMITATIONS OU EXCLUSIONS

CI-DESSUS NE S’APPLIQUENT PAS À

VOTRE CAS.

LA PRÉSENTE GARANTIE VOUS

ACCORDE DES DROITS BIEN

DÉTERMINÉS, Y COMPRIS

POSSIBLEMENT CERTAINS DROITS

VARIABLES DANS LES DIFFÉRENTS

ÉTATS AMÉRICAINS, PROVINCES

CANADIENNES.

CETTE GARANTIE LIMITÉE NE

S'APPLIQUE QU'AUX OUTILS

ÉLECTRIQUES PORTATIFS ET D'ÉTABLI

VENDUS AUX ÉTATS-UNIS D'AMÉRIQUE,

AU CANADA ET AU COMMONWEALTH

DE PORTO RICO.POUR COUVERTURE DE

GARANTIE DANS LES AUTRES PAYS,

CONTACTEZ VOTRE IMPORTATEUR OU

REVENDEUR BOSCH LOCAL.

Exportado por: Robert Bosch Tool Corporation

Mt. Prospect, IL 60056 -2230, E.U.A.

BM 3609929430 4-04 4/22/04, 9:56 AM15

15

Page 16

Datos del producto — Recortadora de chapa corrugada

Modelo número 1529B

Número de identificación 0 601 529 2..

Capacidad de la recortadora de chapa:

Material Grosor máximo de chapa

Acero suave 60,000 PSI hasta Calibre 18 (.048")

Casi todo el alum. 36,000 PSI hasta .080" (2mm)

Acero inoxidable 87,000 PSI hasta Calibre 20 (.036")

Lista de accesorios

Punzón 2 608 639 027

Troquel 2 608 639 028

Estuche de transporte

Componentes de la recortadora de chapa corrugada

1. Interruptor de paleta “ON/OFF” 5. Anilla de sellado

(de encendido y apagado) 6. Portatroquel

2. Tornillo de mariposa 7. Troquel

3. Caja protectora 8. Anilla de goma

4. Punzón 9. Tuerca estriada

!ADVERTENCIA! “LEA TODAS LAS

INSTRUCCIONES”. El incumplimiento de

las NORMAS DE SEGURIDAD identificadas

por los símbolos del PUNTO NEGRO (•) que

se indican A CONTINUACION y otras precauciones de seguridad puede dar lugar a

lesiones personales graves. Conserve estas

instrucciones de funcionamiento con este

producto.

NORMAS GENERALES

DE SEGURIDAD

para todas las herramientas mecánicas

Area de trabajo

• MANTENGA LIMPIAS LAS AREAS DE

TRABAJO. Las áreas y mesas desordenadas

invitan a que se produzcan accidentes.

• EVITE LOS ENTORNOS PELIGROSOS.

No utilice herramientas mecánicas en lugares

húmedos o mojados. No exponga las herramientas mecánicas a la lluvia. Mantenga el área

de trabajo bien iluminada.

• EVITE LAS AREAS DE GASES. No utilice herramientas eléctricas portátiles en atmósferas explosivas en presencia de líquidos o

gases inflamables. Los motores de estas herramientas normalmente producen chispas y las

chispas pueden dar lugar a la ignición de vapores.

• MANTENGA ALEJADOS A LOS NIÑOS.

No permita que los visitantes toquen las

herramientas o el cordón de extensión. Todos

los visitantes deben mantenerse alejados del

área de trabajo.

Seguridad personal

• PROTEJASE CONTRA LAS SACUDIDAS ELECTRICAS. Evite el contacto del

cuerpo con las superficies conectadas a tierra

tales como tuberías, radiadores, cocinas y refrigeradores. Se recomiendan guantes de caucho

y calzado antideslizante cuando se trabaja a la

intemperie, donde se puede encontrar terreno

húmedo o mojado. En estas condiciones se

debe utilizar una línea de energía protegida

con un Interruptor de circuito para fallos de la

conexión a tierra.

16

BM 3609929430 4-04 4/22/04, 9:56 AM16

Page 17

• VISTASE ADECUADAMENTE. No se

ponga ropa suelta ni joyas. Pueden quedar atrapadas en las piezas móviles. Use cubiertas

protectoras para el pelo a fin de sujetar el pelo

largo.

• UTILICE EQUIPO DE SEGURIDAD.

USE GAFAS DE SEGURIDAD o lentes con

protectores laterales. Utilice protección en los

oídos cuando use las herramientas mecánicas

mucho rato y una máscara contra el polvo para

operaciones que generan polvo.

• MANTENGASE ALERTA. USE EL SENTIDO COMUN. Fíjese en lo que está haciendo.

No utilice la herramienta cuando está cansado o

bajo la influencia de medicamentos.

• QUITE LAS LLAVES DE AJUSTE Y

LAS LLAVES DE TUERCA. Forme el hábito

de asegurarse de que las llaves de ajuste y de

tuerca se han quitado de la herramienta antes de

encenderla.

• EVITE EL ARRANQUE ACCIDENTAL.

No lleve la herramienta enchufada con el dedo

en el interruptor. Asegúrese de que el interruptor

está en la posición OFF (desconectado) antes de

enchufar.

• NO INTENTE ALCANZAR DEMASIADO LEJOS. Mantenga una posición y un

equilibrio adecuados en todo momento.

• ANTES DE CONECTAR LA HERRAMIENTA a una fuente de energía (caja tomacorriente, tomacorriente, etc.), asegúrese de

que el voltaje suministrado es el mismo que el

que se indica en la placa del fabricante de la

herramienta. Una fuente de energía con un

voltaje superior al especificado para la

herramienta puede ocasionar graves lesiones al

usuario — así como daños a la herramienta. En

caso de duda, NO ENCHUFE LA HERRAMIENTA. La utilización de una fuente de

energía con un voltaje inferior a la capacidad

nominal indicada en la placa del fabricante es

perjudicial para el motor.

Las herramientas designadas “Volts AC” son

para corriente alterna de 50-60 Hz solamente.

Las herramientas designadas “Volts DC” son

para corriente continua. No utilice herramientas designadas AC con una fuente de energía

DC. No utilice herramientas de velocidad

controlada electrónicamente con una fuente de

energía DC.

Utilización y cuidado de las

herramientas

• NO FUERCE LA HERRAMIENTA. La

herramienta trabajará mejor y con más seguridad

a la capacidad para la cual fue diseñada.

• UTILICE LA HERRAMIENTA ADECUADA. No fuerce una herramienta pequeña

o un accesorio pequeño a realizar el trabajo de

una herramienta pesada. No utilice la herramienta para funciones para las cuales no fue

diseñada — por ejemplo, no use una sierra

circular para cortar ramas o troncos de árboles.

• FIJE LA PIEZA DE TRABAJO. Utilice

abrazaderas o un tornillo de carpintero para

sujetar la pieza de trabajo. Es más seguro que

utilizar la mano y libera ambas manos para

manejar la herramienta.

• NO ABUSE DEL CORDON. Nunca lleve la

herramienta por el cordón ni tire de él para

desconectarlo del tomacorriente. Proteja el

cordón del calor, el aceite y los bordes afilados.

Mantenga siempre el cordón alejado de la hoja

cuando esté girando, de las brocas o de cualquier

otra pieza móvil durante la utilización de la

herramienta.

• UTILICE CORDONES DE EXTENSION

PARA USO A LA INTEMPERIE. Cuando la

herramienta se utiliza a la intemperie, use

únicamente cordones de extensión adecuados

para la utilización a la intemperie y marcados

con el sufijo W-A (para UL) o W (para la CSA).

Consulte la sección “Cordones de extensión”

para la utilización del cordón adecuado.

• DESCONECTE LAS HERRAMIENTAS.

Cuando no se estén utilizando, antes del servicio

de ajustes y reparaciones o al cambiar hojas,

brocas, cortadores, etc.

• GUARDE LAS HERRAMIENTAS QUE

NO ESTA USANDO. Cuando las herramientas

no se estén utilizando, deberán guardarse en un

lugar seco, alto o con cierre — fuera del alcance

de los niños.

• NO ALTERE NI HAGA USO INCORRECTO DE LA HERRAMIENTA. Estas

herramientas están fabricadas con precisión.

Cualquier alteración o modificación no especificada constituye un uso incorrecto y puede

dar lugar a una situación peligrosa.

• LA UTILIZACION DE CUALQUIER

ACCESORIO no especificado en este manual

puede constituir un peligro.

• MANTENGA LAS HERRAMIENTAS

BM 3609929430 4-04 4/22/04, 9:56 AM17

17

Page 18

CON CUIDADO. Conserve las herramientas

afiladas y limpias para que funcionen mejor y

con más seguridad. Siga las instrucciones de

lubricación y de cambio de accesorios. Inspeccione periódicamente los cordones de las

herramientas y si están dañados hágalos reparar

por un centro de servicio autorizado. Inspeccione periódicamente los cordones de extensión

y sustitúyalos si están dañados. Mantenga los

mangos secos, limpios y libres de aceite y grasa.

• REVISE LAS PIEZAS DAÑADAS. Antes

de volver a utilizar la herramienta, una protección u otra pieza que esté dañada deberá

revisarse cuidadosamente para determinar que

funcionará adecuadamente y que realizará la

función para la cual está diseñada. Verifique la

alineación de las piezas móviles, la sujeción de

las piezas móviles, la ruptura de piezas, el

montaje y cualquier otra situación que pueda

afectar su funcionamiento. Un protector o

cualquier otra pieza que presenta daños se debe

reparar o sustituir inmediata y adecuadamente.

Haga que cambien los interruptores defectuosos. No utilice la herramienta si el interruptor

no la enciende o apaga.

• TODAS LAS REPARACIONES, ELECTRICAS O MECANICAS, deben ser realizadas únicamente por técnicos de reparación

capacitados. Póngase en contacto con el Centro

de servicio de fábrica Bosch más próximo o con

el Centro de servicio Bosch autorizado más

próximo o con otro centro de reparaciones competente. Utilice piezas de repuesto Bosch únicamente, cualquier otra puede constituir un peligro.

Normas de seguridad para

recortadoras de chapa

nominal de la recortadora de chapa.

• Fije el material que se esté cortando. Nunca

tenga piezas pequeñas en la mano ni sobre las

piernas.

• No use un punzón y troqueles desafilados o

dañados, o accesorios que no estén diseñados

para una recortadora de chapa. Cambie los

punzones y troqueles desgastados inmediatamente.

• No toque el punzón y el troquel durante la

utilización de la recortadora de chapa.

• Nunca deje la herramienta en ningún sitio

hasta que el punzón se haya detenido por completo.

Cierto polvo generado

por el lijado, aserrado,

amolado y taladrado mecánicos, y por otras

actividades de construcción, contiene agentes

químicos que se sabe que causan cáncer,

defectos de nacimiento u otros daños sobre la

reproducción. Algunos ejemplos de estos

agentes químicos son:

• Plomo de pinturas a base de plomo,

• Sílice cristalina de ladrillos y cemento y otros

productos de mampostería, y

• Arsénico y cromo de madera tratada

químicamente.

Su riesgo por causa de estas exposiciones varía,

dependiendo de con cuánta frecuencia realice

este tipo de trabajo. Para reducir su exposición

a estos agentes químicos: trabaje en un área

bien ventilada y trabaje con equipo de seguridad

aprobado, como por ejemplo máscaras antipolvo

que estén diseñadas especialmente para impedir

mediante filtración el paso de partículas

microscópicas.

• Desenchufe siempre la herramienta de la

fuente de energía antes de cambiar accesorios o

realizar ajustes.

• Use siempre gafas de seguridad o protección

de los ojos al utilizar esta herramienta.

• Use guantes de cuero para protegerse las

manos contra los bordes metálicos afilados y

zapatos de seguridad para protegerse los pies

contra pedazos de metal afilados.

• Compruebe periódicamente las piezas de

fijación de la herramienta para ver si están

flojas y apriételas según se requiera.

• No corte material más grande que la capacidad

BM 3609929430 4-04 4/22/04, 9:56 AM18

Herramientas con

aislamiento doble

• El aislamiento doble es un concepto de

diseño utilizado en las herramientas mecánicas

eléctricas que elimina la necesidad de un cable

de energía de tres hilos conectado a tierra y de

un sistema de fuente de energía conectado a

tierra. Es un sistema reconocido y aprobado por

Underwriter’s Laboratories, la CSA y las

autoridades federales de la OSHA.

IMPORTANTE: El servicio de ajustes y

reparaciones de una herramienta con aislamien-

18

Page 19

to doble requiere cuidado y conocimiento del

sistema y deberá ser realizado únicamente por

un técnico de servicio competente. CUANDO

SE REQUIERA SERVICIO DE AJUSTES Y

REPARACIONES, UTILICE UNICAMENTE PIEZAS DE REPUESTO IDENTICAS.

ENCHUFES POLARIZADOS. Si su herramienta está equipada con un enchufe polarizado

(una terminal es más ancha que la otra), este

enchufe entrará en un tomacorriente polarizado

solamente de una manera. Si el enchufe no entra

por completo en el tomacorriente, déle la vuelta.

Si sigue sin entrar, póngase en contacto con un

electricista competente para instalar el tomacorriente adecuado. Para reducir el riesgo de

sacudidas eléctricas, no haga ningún tipo de

cambio en el enchufe.

Cordones de extensión

• Sustituya los cordones dañados inmediatamente. La utilización de cordones dañados

puede causar “shock”, quemar o electrocutar.

• Si se necesita un cordón de extensión, se

debe utilizar un cordón con conductores de

tamaño adecuado para prevenir caídas de tensión

excesivas, pérdidas de potencia o sobrecalentamiento. La tabla que se presenta a continuación muestra el tamaño correcto a utilizar, según

la longitud del cordón y la capacidad nominal

en amperios indicada en la placa del fabricante

de la herramienta. En caso de duda, utilice la

medida más gruesa siguiente. Utilice siempre

cordones de extensión catalogados por U.L. y

la CSA.

Capacidad nominal en amperios

(mostrada en la placa del fabricante)

0- 2.1- 3.5- 5.1- 7.1- 12.1-

2.0 3.4 5.0 7.0 12.0 16.0

25' 18 18 18 18 16 14

50' 18 18 16 16 14 12

75' 18 18 16 14 12 10

100' 18 16 14 12 10

150' 16 14 12 12

Longitud del cordón

Nota: Cuanto más pequeño es el número de

calibre, más grueso es el cordón.

“CONSERVE ESTAS INSTRUCCIONES”

calibre de

alambre

Funcionamiento de la

herramienta

Información general

El seguir unos cuantos consejos sencillos

reducirá el desgaste de la herramienta y la

posibilidad de lesiones del usuario.

Con la herramienta desenchufada de la fuente

de energía y el interruptor “ON/OFF” (de encendido y apagado) 1 en la posición “OFF”

(apagado), familiarícese con el manejo de la

recortadora de chapa y apréndase la ubicación

de sus partes.

Antes de poner en marcha la recortadora de

chapa, inspeccione el punzón y el troquel para

ver si se ha producido un desgaste excesivo y

cámbielos si es necesario.

No exceda la capacidad recomendada para esta

recortadora de chapa. El fallo prematuro del

punzón y del troquel se producirá cuando la

recortadora de chapa se utiliza para material de

un calibre inferior o superior al recomendado.

• Nunca arranque la recortadora de chapa con

el punzón y el troquel en contacto con el material que se esté cortando.

Para lograr cortes mejor hechos y rápidos, sujete

la recortadora de chapa de manera que la cabeza

de corte se encuentre en ángulo recto respecto

a la trayectoria de corte, con el cuerpo de la

herramienta paralelo a las corrugaciones. Mueva

la cabeza de corte hacia adentro y hacia afuera

de las corrugaciones, manteniendo constantemente la cabeza en ángulo recto respecto al

material que se esté cortando.

Haga avanzar la recortadora de chapa por la

pieza de trabajo con una presión mínima. Deje

que la herramienta haga el trabajo. Si la

recortadora de chapa no corta correctamente,

compruebe si el punzón o el troquel están desafilados. El desafilado será evidente cuando se

requiera más presión para hacer avanzar la

recortadora de chapa por el material. También

aparecerán rebabas a lo largo del borde cortado.

Un material más duro desafilará el punzón y el

troquel más deprisa que un material blando.

Dirija siempre el cordón hacia la parte posterior

y alejándose de la recortadora de chapa. Manténgalo alejado de bordes afilados.

Fije o sujete con abrazadera las piezas de trabajo

BM 3609929430 4-04 4/22/04, 9:56 AM19

19

Page 20

pequeñas que se van a cortar para evitar que se

produzca resbalamiento.

Use siempre un lubricante recomendado para el

material que se esté cortando. La falta de lubricante reducirá la vida del punzón y del troquel.

Interruptor de paleta con dispositivo de

“Fijación en ON”

El interruptor de paleta permite al operador

controlar las funciones del interruptor de “ON/

OFF” (de encendido y apagado) y de “Fijación

en ON”.

PARA ENCENDER LA HERRAMIENTA

(POSICION “ON”): Apriete y sujete la palanca

de paleta.

PARA APAGAR LA HERRAMIENTA

(POSICION “OFF”): Reduzca la presión sobre

la palanca de paleta. El interruptor está activado

por resorte y volverá a la posición “OFF”

(apagado) automáticamente.

El dispositivo de “Fijación en ON”, incorporado

al interruptor de paleta, es práctico para

operaciones prolongadas.

PARA FIJAR EL INTERRUPTOR EN “ON”

(ENCENDIDO): Después de que se haya

activado el interruptor, TIRE de la parte

delantera de la palanca de paleta completamente

HACIA ATRAS y deje de presionar la palanca

de paleta.

PARA APAGAR LA HERRAMIENTA

(POSICION “OFF”): Apriete la parte de atrás

de la palanca de paleta y luego suelte la palanca

de paleta. El interruptor está activado por resorte

y volverá a la posición “OFF” (apagado)

automáticamente.

Giro del portatroquel

Al girar el portatroquel 6, el corte se puede

realizar a un ángulo recto respecto al eje

delantero de la máquina. Afloje el tornillo de

mariposa 2 y gire el portatroquel 6 (incluyendo

el troquel 7 y la tuerca estriada 9) hacia la

derecha o hacia la izquierda 90°. Vuelva a

apretar el tornillo de mariposa 2. El tornillo de

mariposa debe acoplarse en uno de los 3 agujeros

del portatroquel 6.

Consejos para la herramienta

La recortadora de chapa corrugada está diseñada especialmente para trabajar con chapas

corrugadas de perfiles tanto trapezoidales como

rectangulares.

Use siempre ambas manos para guiar la recortadora de chapa.

No ejerza fuerza; esto llevará a un desgaste

prematuro del troquel y del punzón.

Antes de hacer funcionar la recortadora de

chapa, asegúrese de que el punzón y el troquel

estén lubricados adecuadamente. Vea la sección

“Lubricación del punzón y del troquel”.

Nunca arranque la recortadora de chapa con el

punzón y el troquel en contacto con el material

que se esté cortando.

Asegúrese siempre de que el material esté

apoyado en el troquel inferior durante la operación.

Cambio de punzones y troqueles

¡PRECAUCION! Desenchufe la recortadora

de chapa antes de cambiar los punzones y los

troqueles.

Recorte de chapa siguiendo una línea

marcada o con una plantilla

Los cortes se pueden realizar fácilmente guiando

la recortadora de chapa a lo largo de una plantilla

o de una regla recta.

Se requiere un diámetro de perforación previa

de 21mm (0.827") para cortes internos.

Al cortar, guíe la unidad con un ligero empuje

en el sentido de corte. El corte tiene lugar

durante el movimiento del punzón hacia abajo.

Las virutas se expulsan hacia abajo a través de

la tuerca estriada 9.

BM 3609929430 4-04 4/22/04, 9:56 AM20

Cambio del punzón

Afloje el tornillo de mariposa 2 y tire del

portatroquel 6 (incluyendo el troquel 7 y la

tuerca estriada 9) hasta sacarlo de la caja

protectora 3.

Deslice el punzón 4 lateralmente hacia afuera

de la ranura y quítelo hacia bajo.

Aceite bien el nuevo punzón, introdúzcalo en la

ranura y céntrelo.

Deslice el portatroquel 6 cuidadosamente sobre

el punzón y hacia el interior de la caja protectora

3. Vuelva a apretar el tornillo de mariposa 2. El

20

Page 21

tornillo de mariposa debe acoplarse en uno de

los agujeros del portatroquel 6.

NOTA: El punzón no se puede reamolar.

Cambio del troquel

Desenrosque la tuerca estriada 9 junto con la

anilla de goma 8 hasta sacarla del portatroquel

6 y quite el troquel 7. Quite todo el material

oxidado o todas las partículas resultantes del

corte que se puedan haber acumulado en el

portatroquel 6.

Introduzca un nuevo troquel 7 prestando

atención a la alineación de la superficie plana

sobre el lado. Apriete firmemente la tuerca

estriada 9 contra la resistencia de la anilla de

goma 8.

NOTA: El troquel no se puede reamolar.

Mantenimiento y servicio

¡ADVERTENCIA! El mantenimiento pre-

ventivo realizado por personal no autorizado

pude dar lugar a la colocación incorrecta de

cables y componentes internos que podría

constituir un peligro serio. Recomendamos

que todo el servicio de las herramientas sea

realizado en un Centro de servicio de fábrica

Bosch.

Lubricación de las herramientas

Su herramienta Bosch ha sido lubricada adecuadamente y está lista para la utilización.

Recomendamos que las herramientas con

engranajes se vuelvan a engrasar con un

lubricante especial para engranajes cada vez

que se cambien las escobillas.

Lubricación del punzón y del troquel

La lubricación adecuada es esencial para

prolongar la vida del punzón y del troquel, y se

logra sumergiendo ocasionalmente por completo el punzón y el troquel en un pequeño

recipiente que contenga el lubricante adecuado.

Para asegurase más de que se logre un corte

suave y una larga vida del punzón, lubrique

siempre la trayectoria de corte con aceite para

cortar. Al cortar acero o acero inoxidable,

lubrique la trayectoria de corte antes de

comenzar a trabajar. Al cortar aluminio, lubrique

la trayectoria de corte mientras realiza el corte.

Como el punzón corta en la carrera descendente,

se debe lubricar el lado superior del corte.

Al cortar acero, use un aceite para cortar o un

aceite de viscosidad SAE 30.

Al cortar aluminio se debe usar una mezcla de

7 partes de queroseno y 3 partes de trementina.

Si el punzón se atasca, apague la recortadora de

chapa inmediatamente, relubrique el punzón y

el troquel y quite la tensión de la chapa.

¡ADVERTENCIA! El uso de cualquier accesorio o aditamento que no esté recomendado

en este manual de instrucciones o en el catálogo BOSCH puede constituir riesgo de lesiones

personales.

Escobillas de carbón

Las escobillas y el conmutador de su herramienta Bosch han sido diseñados para muchas

horas de servicio fiable. Para mantener un

rendimiento óptimo del motor, recomendamos

que se examinen las escobillas cada dos a seis

meses. Sólo se deben utilizar escobillas de

repuesto Bosch genuinas diseñadas especialmente para su herramienta.

Rodamientos

Después de 300-400 horas de funcionamiento o

después de cada segundo cambio de escobillas,

los rodamientos deben cambiarse en un Centro

de servicio de fábrica Bosch. Los rodamientos

que se vuelvan ruidosos (debido a una carga

pesada o al corte de materiales muy abrasivos)

deben ser sustituidos inmediatamente para evitar el sobrecalentamiento y el fallo del motor.

Limpieza

¡ADVERTENCIA! Para evitar accidentes,

desconecte siempre la herramienta de la fuente

de energía antes de la limpieza o de la realización de cualquier mantenimiento. La herramienta se puede limpiar más eficazmente con

aire comprimido. Use gafas de seguridad

siempre que limpie herramientas con aire

comprimido.

BM 3609929430 4-04 4/22/04, 9:56 AM21

21

Page 22

Las aberturas de ventilación y las palancas de

interruptor se deben mantener limpias y libres

de materias extrañas. No intente limpiar

introduciendo objetos puntiagudos a través de

las aberturas.

¡PRECAUCION! Ciertos agentes de limpieza

y disolventes dañan las piezas de plástico.

Algunos de estos son: gasolina, tetracloruro de

carbono, disolventes de limpieza clorados,

amoníaco y detergentes domésticos que contienen amoníaco.

BM 3609929430 4-04 4/22/04, 9:56 AM22

22

Page 23

GARANTIA LIMITADA PARA HERRAMIENTAS MECANICAS

PORTATILES Y PARA TABLERO DE BANCO BOSCH

Robert Bosch Tool Corporation ("el Vendedor")

garantiza, únicamente al comprador original,

que todas las herramientas mecánicas portátiles

y para tablero de banco BOSCH estarán libres

de defectos de material o de fabricación durante

un período de un año a partir de la fecha de

compra. LA UNICA OBLIGACION DEL

VENDEDOR Y EL RECURSO EXCLUSIVO

QUE USTED TIENE bajo esta Garantía

Limitada y, hasta donde la ley lo permita, bajo

cualquier garantía o condición implícita por

ley, consistirá en la reparación o sustitución sin

costo de las piezas que presenten defectos de

material o de fabricación y que no hayan sido

utilizadas incorrectamente, manejadas

descuidadamente o reparadas incorrectamente

por personas que no sean el Vendedor o una

Estación de servicio autorizada. Para efectuar

una reclamación bajo esta Garantía Limitada,

usted debe devolver el producto, que consiste

en la herramienta mecánica portátil o para tablero

de banco completa, con el transporte pagado, a

cualquier Centro de servicio de fábrica o

Estación de servicio autorizada. Para Estaciones

de servicio autorizadas de herramientas

mecánicas BOSCH, por favor, consulte el

directorio telefónico.

ESTA GARANTIA LIMITADA NO SE

APLICA A ARTICULOS ACCESORIOS

TALES COMO HOJAS PARA SIERRAS

CIRCULARES, BROCAS PARA

TALADROS, BROCAS PARA

FRESADORAS, HOJAS PARA SIERRAS DE

VAIVEN, CORREAS PARA LIJAR,

RUEDAS DE AMOLAR Y OTROS

ARTICULOS RELACIONADOS.

TODAS LAS GARANTIAS IMPLICITAS

TENDRAN UNA DURACION LIMITADA

A UN AÑO A PARTIR DE LA FECHA DE

COMPRA. ALGUNOS ESTADOS DE LOS

EE.UU., ALGUNAS PROVINCIAS

CANADIENSES NO PERMITEN

LIMITACIONES EN CUANTO A LA

DURACION DE UNA GARANTIA

IMPLICITA, POR LO QUE ES POSIBLE QUE

LA LIMITACION ANTERIOR NO SEA

APLICABLE EN EL CASO DE USTED.

EL VENDEDOR NO SERA RESPONSABLE

EN NINGUN CASO DE NINGUN DAÑO

INCIDENTAL O EMERGENTE

(INCLUYENDO PERO NO LIMITADO A

RESPONSABILIDAD POR PERDIDA DE

BENEFICIOS) QUE SE PRODUZCA COMO

CONSECUENCIA DE LA VENTA O

UTILIZACION DE ESTE PRODUCTO.

ALGUNOS ESTADOS DE LOS EE.UU. Y

ALGUNAS PROVINCIAS CANADIENSES

NO PERMITEN LA EXCLUSION O

LIMITACION DE LOS DAÑOS

INCIDENTALES O EMERGENTES, POR LO

QUE ES POSIBLE QUE LA LIMITACION O

EXCLUSION ANTERIOR NO SEA

APLICABLE EN EL CASO DE USTED.

ESTA GARANTIA LIMITADA LE

CONFIERE A USTED DERECHOS LEGALES ESPECIFICOS Y ES POSIBLE QUE

USTED TAMBIEN TENGA OTROS

DERECHOS QUE VARIAN DE ESTADO A

ESTADO EN LOS EE.UU., DE PROVINCIA

A PROVINCIA EN CANADA.

ESTA GARANTIA LIMITADA SE APLICA

SOLAMENTE A HERRAMIENTAS

ELECTRICAS PORTATILES Y PARA

TABLERO DE BANCO VENDIDAS EN LOS

ESTADOS UNIDOS DE AMERICA,

CANADA Y EL ESTADO LIBRE

ASOCIADO DE PUERTO RICO. PARA

COBERTURA DE GARANTIA EN OTROS

PAISES, PONGASE EN CONTACTO CON

SU DISTRIBUIDOR O IMPORTADOR LOCAL DE BOSCH.

Importado en México por: Robert Bosch, S.A. de C.V.,

Calle Robert Bosch No. 405, Zona Industrial,

Toluca, Edo. de México, C.P. 50070, Tel. (722) 2792300

BM 3609929430 4-04 4/22/04, 9:56 AM23

23

Page 24

© Robert Bosch Tool Corporation

1800 W. Central Road

Mt. Prospect, IL 60056 -2230

3 609 929 430 4/04

Printed in Federal Republic of Germany - Imprimé en République Fédérale d’Allemagne

BM 3609929430 4-04 4/22/04, 9:56 AM24

Loading...

Loading...