Page 1

BM 2609932751 09-09:BM 2609932751 09-09 9/3/09 7:20 AM Page 1

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

1209

1210

1215

Call Toll Free for

Consumer Information

& Service Locations

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

For English Version Version française Versión en español

See page 2 Voir page 11 Ver la página 20

Pour obtenir des informations

et les adresses de nos centres

de service après-vente,

appelez ce numéro gratuit

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

Page 2

BM 2609932751 09-09:BM 2609932751 09-09 9/3/09 7:20 AM Page 2

General Power Tool Safety Warnings

WARNING

!

Read all safety warnings and instructions. Failure to follow the warnings

and instructions may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

The term “power tool” in all of the warnings refers to your mains-operated (corded) power tool

or battery-operated (cordless) power tool.

Work area safety

Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust

or fumes.

Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

Electrical safety

Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

us e a ny adapter pl ug s w ith earthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electric

shock.

Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased risk

of electric shock if your body is earthed or

grounded.

Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

If operating the power tool in damp locations

is unavoidable, use a Ground Fault Circuit

Interrupter (GFCI) protected supply. Use of

an GFCI reduce the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and

us e co mmon sense when operating a

power tool. Do not use a power tool while

you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention

while operating power tools may result in

serious personal injury.

Use personal protective equipment. Always

wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes, hard

hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

Prevent unintentional starting. Ensure the

sw itch is in th e o ff-po sitio n b efore

connecting to power source and / or battery

pa ck, picki ng up or carrying the t ool.

Carrying power tools with your finger on the

switch or energizing power tools that have the

switch on invites accidents.

Remove any adjusting key or wrench before

turning the power tool on. A wrench or a

key left attached to a rotating part of the

power tool may result in personal injury.

Do not overreach. Keep proper footing and

balance at all times. This enables better

co ntrol of the power to ol in unexpe ct ed

situations.

Dress properly. Do not wear loose clothing

or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose

clothes, jewelry or long hair can be caught in

moving parts.

If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce dust-

related hazards.

Power tool use and care

Do not force the power tool . Use the

correct power tool for your application. The

correct power tool will do the job better and

safer at the rate for which it was designed.

Do not use the power tool if the switch does

not turn it on and off. Any power tool that

ca nn ot be co nt ro ll ed wi th th e switc h is

dangerous and must be repaired.

-2-

Page 3

BM 2609932751 09-09:BM 2609932751 09-09 9/3/09 7:20 AM Page 3

isconnect the plug from the power source

D

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment

or binding of moving parts, breakage of

parts and any other condition that may

affect the power tool’s operation. If damaged,

have the power tool repaired before use.

Ma ny accide nt s ar e ca us ed by poorly

maintained power tools.

eep cutting tools sharp and clean. Properly

K

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

Use the power tool, accessories and tool

bits etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the

power tool for operations different from those

intended could result in a hazardous situation.

Have your power tool serviced by a qualified

re pa ir person u sing only identical

replacement parts. This will ensure that the

safety of the power tool is maintained.

Service

Power Tool-Specific Safety Warnings

Safety Warnings Common for

Grinding Operations:

This power tool is intended to function as a

gr inder . Re ad al l safety warnings,

instructions, illustrations and specifications

provided with this power tool. Failure to

follow all instructions listed below may result in

electric shock, fire and/or serious injury.

Operations such as polishing, sanding,

wire brushing and cutting off operations is

not recommended to be performed with

this power tool. Operations for which the

power tool was not designed may create a

hazard and cause personal injury.

Do n ot use accessories whi ch are not

specifically designed and recommended by

the tool manufacturer. Just because the

accessory can be attached to your power tool,

it does not assure safe operation.

The rated speed of the accessory must be

at least eq ual to the ma xi mum spee d

marked on the power tool. Accessories

running faster than their RATED SPEED can

break and fly apart.

The outside diameter and the thickness of

your accessory must be within the capacity

rating of your power tool. Incorrectly sized

accessories cannot be adequately guarded or

controlled.

The arbor size of wheels, flanges, backing

pads or any other accessory must properly

fit the spindle of the power tool. Accessories

wi th arbo r holes tha t do no t match the

mounting hardware of the power tool will run

out of balance, vibrate excessively and may

cause loss of control.

Do not use a damaged accessory. Before

each use inspect the accessory such as

abrasive wheels for ch ips and c rac ks,

backing pad for cracks, tear or excess wear,

wire brush for loose or cracked wires. If

power tool or accessory is dropped, inspect

fo r da mage or install an unda maged

accessory. After inspecting and installing

an accessory, p osition yo ursel f an d

bystanders away from the plane of the

rotating accessory and run the power tool

at maximum no-load speed for one minute.

Damaged accessories will normally break apart

during this test time.

-3-

Page 4

BM 2609932751 09-09:BM 2609932751 09-09 9/3/09 7:20 AM Page 4

ea r perso nal protective equi pment .

W

Depending on application, use face shield,

sa fety go ggles or saf ety gla sses. As

ap propr iate, wea r dust mask, h earin g

protectors, gloves and workshop apron

capable of stoppi ng small abr asive or

workpiece fragments. The eye protection

must be capable of stopping flying debris

generated by various operations. The eye

protection must be capable of stopping flying

debris generated by various operations. The

dust mask or respirator must be capable of

filtrating particles generated by your operation.

Prolonged exposure to high intensity noise may

cause hearing loss.

Keep bystanders a safe distance away from

work area. Anyone entering the work area

must wear personal protective equipment.

Fr agmen ts of wo rkpie ce or of a broke n

accessory may fly away and cause injury

beyond immediate area of operation.

Hold po wer tool by insulated gripping

su rface s only , when performing an

operation where the cutting accessory may

contact hidden wiring or its own cord.

Cutting accessory contacting a “live” wire may

make exposed metal parts of the power tool

“live” and shock the operator.

Position the cord clear of the spinning

accessory. If you lose control, the cord may be

cut or snagged and your hand or arm may be

pulled into the spinning accessory.

Never lay the power tool down until the

accessory has come to a complete stop.

The spinning accessory may grab the surface

and pull the power tool out of your control.

Do not run the power tool while carrying it

at your side. Accidental contact with the

spinning accessory could snag your clothing,

pulling the accessory into your body.

Regularly clean the power tool’s air vents.

The motor’s fan will draw the dust inside the

ho using an d excessive accum ulati on of

powdered metal may cause electrical hazards.

Do no t operate th e po wer tool near

flammable materials. Sparks could ignite

these materials.

Do not use accessories that require liquid

coolants. Using water or other liquid coolants

may result in electrocution or shock.

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or

snagged rotating wheel, backing pad, brush or

any other accessory. Pinching or snagging

causes rapid stalling of the rotating accessory

which in turn causes the uncontrolled power

tool to be forced in the direction opposite of the

accessory’s rotation at the point of the binding.

For example, if an abrasive wheel is snagged

or pinched by the workpiece, the edge of the

wheel that is entering into the pinch point can

dig into the surface of the material causing the

wheel to climb out or kickout. The wheel may

either jump toward or away from the operator,

de pendi ng on direction o f th e wheel’s

movement at the point of pinching. Abrasive

wheels may also break under these conditions.

Kickback is the result of power tool misuse

and/or inc orrect operating procedures or

conditions and can be avoided by taking proper

precautions as given below.

Maintain a firm grip on the power tool and

position your body and arm to allow you to

resist kickback forces. Always use auxiliary

handle, if provided, for maximum control

over kickback or torque reaction during

start-up. The operator can control torque

re actio ns or kickb ack forces, if proper

precautions are taken.

Never place your hand near the rotating

accessory. Accessory may kickback over your

hand.

Do not position your body in the area where

power tool will move if kickback occurs.

Kickback will propel the tool i n direction

opposite to the wheel’s movement at the point

of snagging.

Use special care when working corners,

sh arp edges etc. Avoid bou ncing and

snagging the accessory. Corners, sharp

edges or bouncing have a tendency to snag the

rotating accessory and cause loss of control or

kickback.

Do not attach a saw chain woodcarving

blade or toothed saw blade. Such blades

create frequent kickback and loss of control.

-4-

Page 5

BM 2609932751 09-09:BM 2609932751 09-09 9/3/09 7:20 AM Page 5

Additional Safety Warnings

GFCI and personal protection devices like

electrician’s rubber gloves and footwear will

further enhance your personal safety.

Do not use AC only rated tools with a DC

power supply. While the tool may appear to

work, the electrical components of the AC

rated tool are likely to fail and create a hazard

to the operator.

Keep handles dry, clean and free from oil

and grease. Slippery hands cannot safely

control the power tool.

Use clamps or other practical way to secure

and support the workpie ce to a stable

platform. Holding the work by hand or against

your body is unstable and may lead to loss of

control.

Develop a periodic maintenance schedule

for your tool. When cleaning a tool be

careful not to disassemble any portion of

th e tool sinc e in terna l wi res may be

misplaced or pinched or safety guard return

sp rings may be improperly moun ted.

Certain cleaning agents such as gasoline,

carbon tetrachloride, ammonia, etc. may

damage plastic parts.

Risk of injury to user. The power cord must only

be serviced by a Bosch Factory Service Center

or Autho rized Bosch Service Station.

WARNING

!

drilling, and other construction activities

contains chemicals known to cause cancer,

birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and

other masonry products, and

• Arsenic and chromiu m from chemicallytreated lumber.

Yo ur ri sk from these exposu re s varie s,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals: work in a well ventilated area, and

work with approved safety equipment, such as

those dust masks that are specially designed

to filter out microscopic particles.

Some dust created by power

sanding, sawing, grinding,

-5-

Page 6

0

BM 2609932751 09-09:BM 2609932751 09-09 9/3/09 7:20 AM Page 6

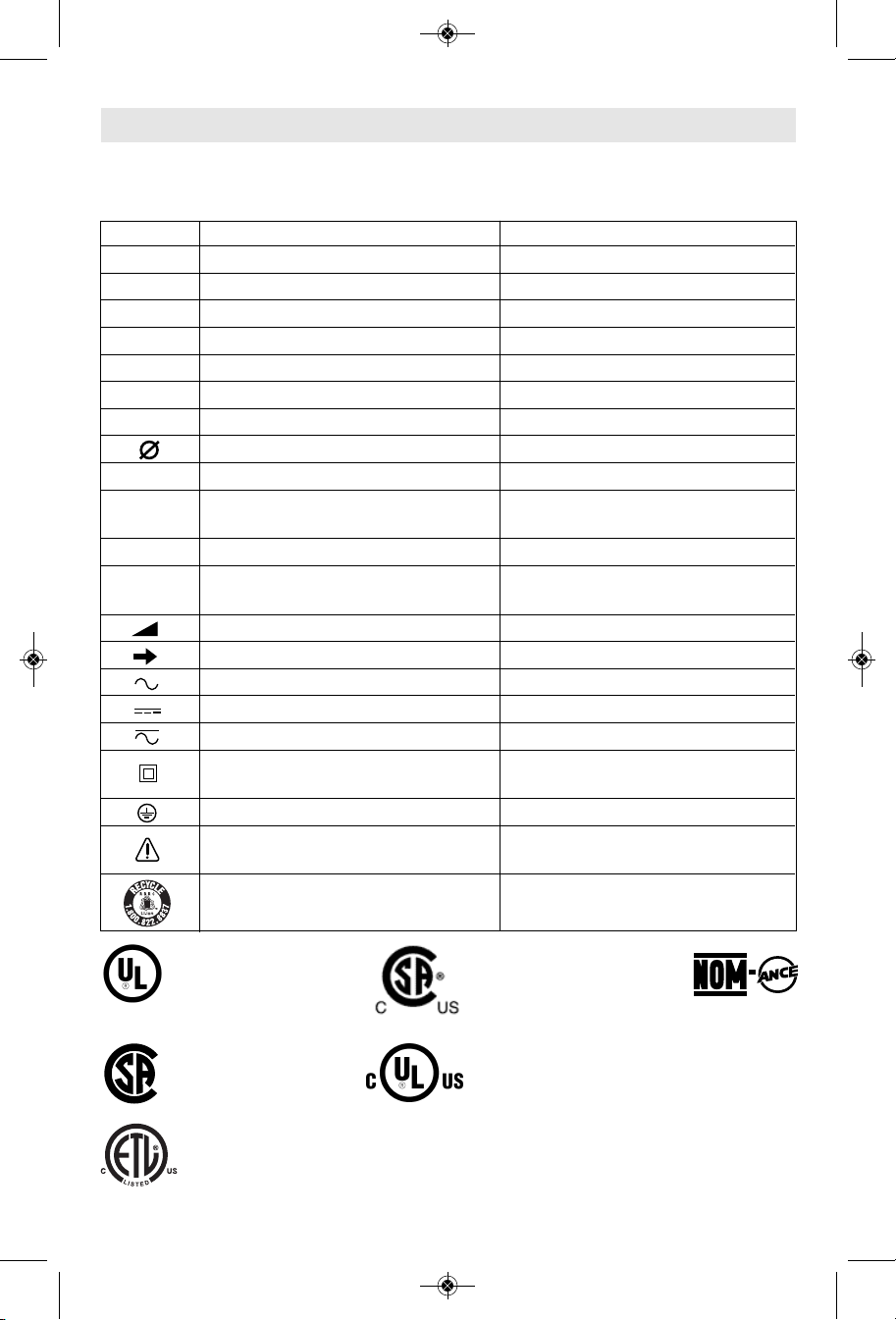

Symbols

MPORTANT: Some of the following symbols may be used on your tool. Please study them

I

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Diameter Size of drill bits, grinding wheels, etc.

n No load speed Rotational speed, at no load

.../min Revolutions or reciprocation per minute Revolutions, strokes, surface speed,

orbits etc. per minute

0 Off position Zero speed, zero torque...

1, 2, 3, ... Selector settings Speed, torque or position settings.

I, II, III, Higher number means greater speed

Infinitely variable selector with off Speed is increasing from 0 setting

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II construction Designates Double Insulated

Construction tools.

Earthing terminal Grounding terminal

Warning symbol Alerts user to warning messages

Li-ion RBRC seal Designates Li-ion battery recycling

program

This symbol designates

that this tool is listed by

Underwriters Laboratories.

This symbol designates

that this tool is listed by

the Canadian Standards

Association.

This symbol designates that this tool is listed by the Intertek Testing

Services, to United States and Canadian Standards.

This symbol designates that

this tool is listed by the

Canadian Standards

Association, to United States

and Canadian Standards.

This symbol designates that

this tool is listed by

Underwriters Laboratories, to

United States and Canadian

Standards.

This symbol

designates

that

this tool

complies

to NOM

Mexican

Standards.

-6-

Page 7

BM 2609932751 09-09:BM 2609932751 09-09 9/3/09 7:20 AM Page 7

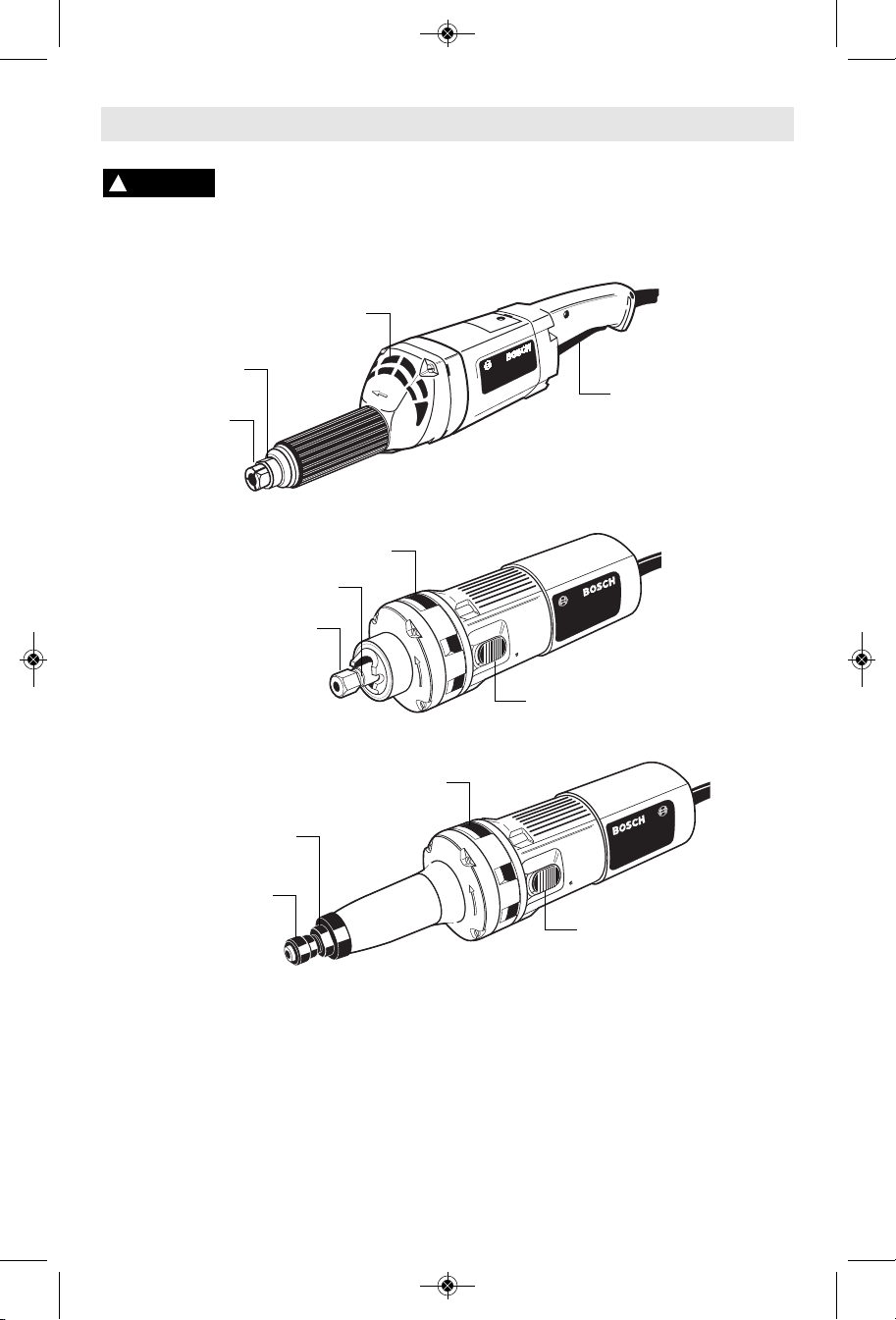

Functional Description and Specifications

WARNING

!

measures reduce the risk of starting the tool accidentally.

Di sc onnect the plug fro m the pow er source bef or e making any

assembly, adjustments or changing accessories. Such preventive safety

Die Grinders

VENTILATION OPENINGS

SPINDLE

COLLET NUT

VENTILATION OPENINGS

SPINDLE

COLLET NUT

PADDLE SWITCH

SWITCH BUTTON

VENTILATION OPENINGS

SPINDLE

COLLET NUT

SWITCH BUTTON

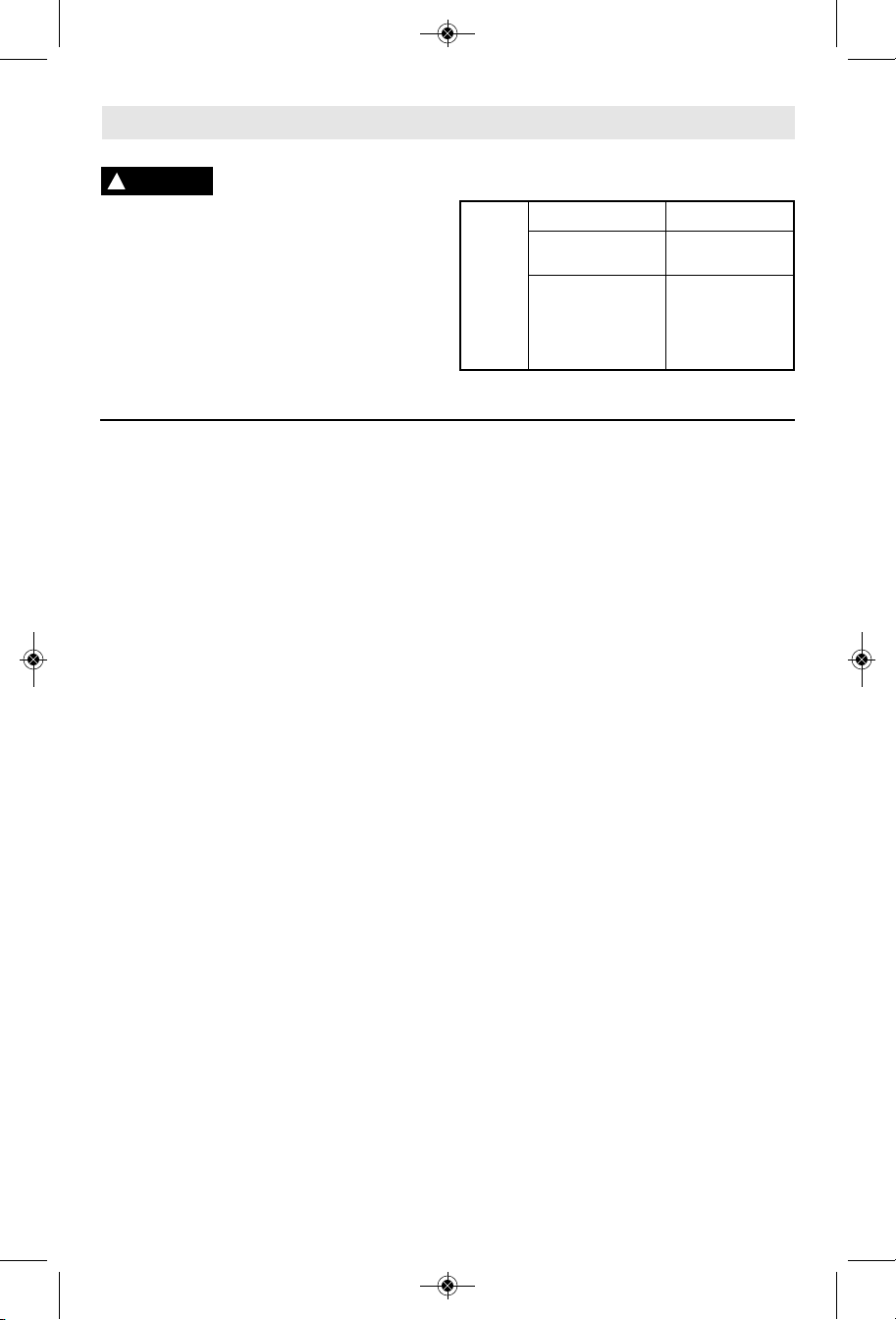

Model number 1209 1210 1215

Collet capacity 1/4" shank 1/8"-1/4" shank 1/8"-1/4" shank

No load speed n

Max. capacity of accessories

Mounted point 2" Dia. 1” Dia. 1" Dia.

NOTE: For tool specifications refer to the nameplate on your tool.

16,000/min n0 27,000/min n0 27,000/min

0

-7-

Page 8

0

0

11

BM 2609932751 09-09:BM 2609932751 09-09 9/3/09 7:20 AM Page 8

Operating Instructions

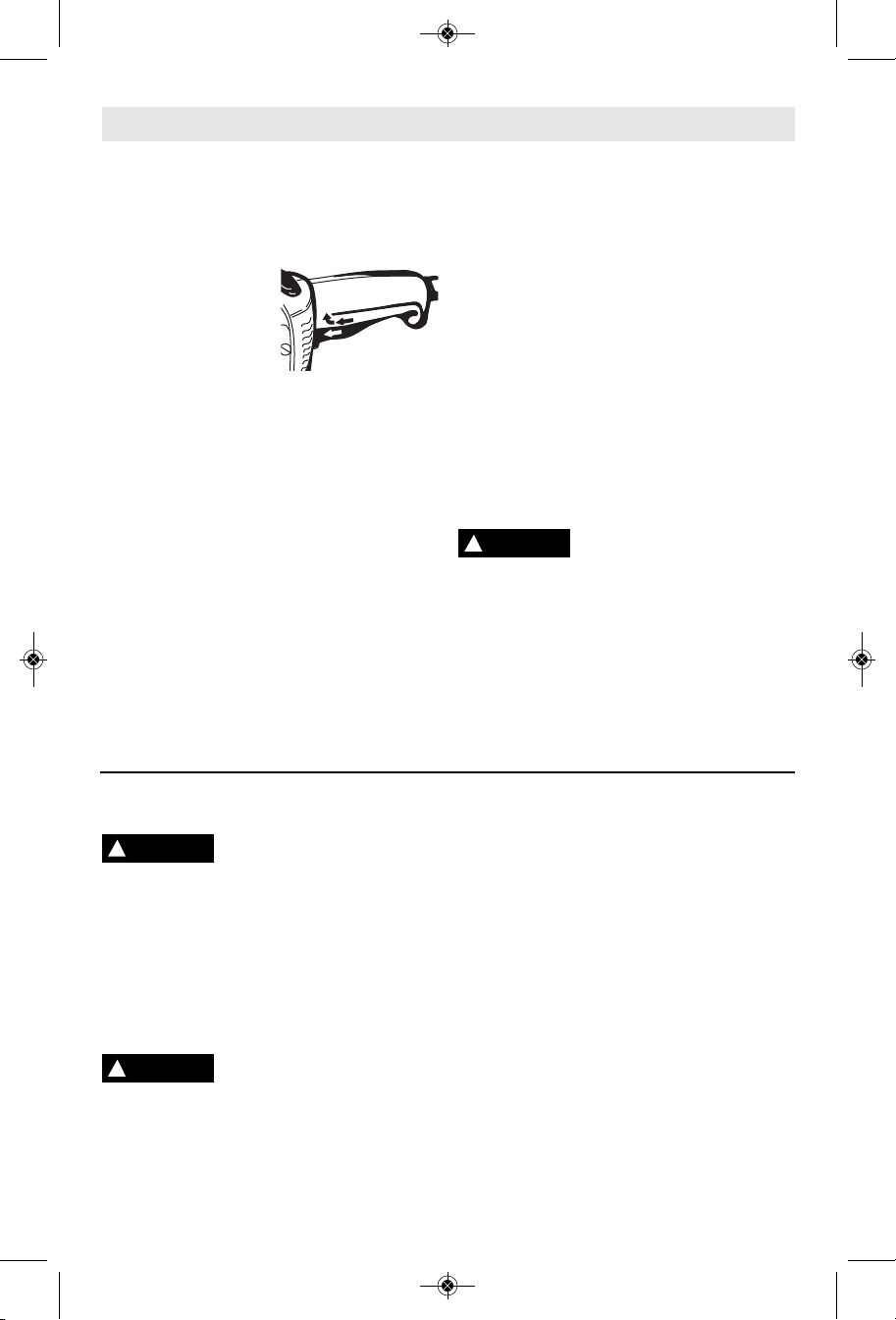

"TRI-CONTROL" PADDLE SWITCH

(Model 1209 only)

The “Tri-Control” Paddle Switch enables the

operator to control the switch functions of

"Lock-OFF", "ON/OFF" and "Lock-ON".

TO UNLOCK SWITCH

AN D TU RN TO OL

"ON": Push paddle lever

FORWARD (toward the

spindle) then squeeze

the paddle lever.

TO SWITCH TOOL "OFF": Release pressure

on paddle lever. The switch is spring loaded

and will return to "OFF" position automatically.

The "Lock-ON" feature, incorporated into the

paddle switch, is a conven ien ce for long

operations.

TO LOCK SWITCH "ON": After paddle switch

ha s be en ac tivated push padd le le ver

completely FORWARD and release paddle

lever.

TO SWITCH TOOL "OFF": Squeeze and then

release paddle lever. The switch is spring

lo aded and will retur n to "OFF" pos ition

automatically.

SLIDE ON-OFF SWITCH WITH LOCK

(Models 1210 & 1215 only)

The tool is switched “ON” by the switch button

located at the side of the motor housing. The

switch can be locked in the “ON” position, a

convenience for long grinding operations.

TO TURN THE TOOL “ON” without locking it,

slide the switch button forward by applying

pressure ONLY at the REAR portion of the

button. When pressure is released the switch

button will snap to “OFF” position.

TO LOCK THE SWITCH “ON”, slide the switch

button forward and press “IN” the FRONT

portion.

TO UNLOCK THE SWITCH, simply press and

release the REAR portion of the button. Switch

is sp ring loaded an d will snap ba ck

automatically.

WARNING

!

Hold the tool with both hands

while starting the tool, since

torque from the motor can cause the tool to

twist.

Start the tool before applying to work and let

the tool come to full speed before contacting

the workpiece. Lift the tool from the work

before releasing the switch. DO NOT turn the

switch “ON” and “OFF” while the tool is under

load; this will greatly decrease the switch life.

SELECTING GRINDING WHEELS

WARNING

!

Before using a grinding wheel,

be certain that its maximum

safe operating speed is not exceeded by the

na meplate speed of t he gri nder. Do not

exceed the recom mended wheel diameter.

Grinding wheels should be carefully selected

in order to use the grinder most efficiently.

Wh ee ls va ry in type of abrasive, bo nd ,

hardness, grit size and structure. The correct

type of wheel to use is determined by the job.

INSTALLING ACCESSORIES

CAUTION

!

Be sure that the diameter of

the shank is the same size as

the inside diameter of the collet.

Models 1209, 1210 & 1215 are equipped with

a 1/4" collet.

1. Place the (22mm) spindle lock wrench that

is provided onto the spindle to prevent the

spindle from rotating.

2. Hold wrench in place and rotate collet nut

counter-clockwise with the (14mm) wrench that

is provided.

3. Insert three fourths of shank of accessory

into the collet, and securely tighten with the

wrench provided.

NOTE: When replacing collets on the model

12 15, loos en the co llet n ut and re move

together with collet 6, then screw in new collet.

Repeat steps 1 and 2 of above and remove

accessory.

(Models 1209 & 1215 only)

REMOVING ACCESSORIES

-8-

Page 9

BM 2609932751 09-09:BM 2609932751 09-09 9/3/09 7:20 AM Page 9

NSTALLING ACCESSORIES

I

1. Insert the locking pin provided into hole in

th e spin dle, t o pr ev ent the sp indle from

rotating.

2. Hold locking pin in place and rotate collet

nut counter-clockwise with the (14mm) wrench

that is provided.

(Model 1210 only)

Maintenance

Service

WARNING

!

orized per so n nel may result in misplacing

of internal wires and components which

could cau se s er ious ha za rd . We

recommend that all tool service be performed

by a Bosch Factory Service Center or Autho rized Bosch Service Station.

Your Bosch tool has been properly lubricated

and is ready to use. It is recommended that

tools with gears be regreased with a special

gear lubricant at every brush change.

The brushes and commutator in your tool

have been engineered for many hours of

dependa bl e servic e. To maint ai n peak

efficiency of the motor, we recommend every

two to six months the brush es be examined.

Only genuine Bosch replace ment brushes

specially designed for your tool should be

used.

After about 300-400 hours of operation, or at

every second brush change, the bearings

Pr eventiv e mainte nance

perform ed by u nauth-

TOOL LUBRICATION

CARBON BRUSHES

BEARINGS

. Insert three fourths of shank of accessory

3

into the collet, and securely tighten with the

wrench provided.

Repeat steps 1 and 2 of above and remove

accessory.

should be replaced at Bosch Factory Service

Center or Au thorized Bosch Service Station.

Bearings which become noisy (due to heavy

load or very abrasive material cut ting) should

be replaced at once to avoid overheating or

motor failure.

REMOVING ACCESSORIES

Cleaning

WARNING

!

th e p ow er su pp ly be fo re cl ea ni ng or

performing any main tenance. The tool may

be cleaned most effectively with compressed

dry air. Always wear safety gog gles when

cleaning tools with compressed air.

Ventilation openings and switch levers must

be kept clean and free of foreign matter. Do

not at tempt to clean by inserti ng point ed

objects through openings.

CAUTION

!

plastic parts. Some of these are: gasoline,

carbon tetrachlo ride, chlo rinated cleaning

solvent s, ammon ia and h ou se ho ld

detergents that contain ammonia.

To avoid accidents always

dis connect the tool from

Ce rtain cl eaning age nts

and so l vents damag e

-9-

Page 10

BM 2609932751 09-09:BM 2609932751 09-09 9/3/09 7:20 AM Page 10

Accessories

ECOMMENDED SIZES OF EXTENSION CORDS

!

WARNING

If an ext en si on co rd is

necessa ry , a cord with

adequate size conductors that is capable

of carrying the current necessary for your

tool mu st be used. This wi ll pr ev en t

excessive voltage drop, loss of power or

overheating. Grounded tools must use 3-wire

extension cords that have 3-prong plugs and

receptacles.

NOTE: The smaller the gauge number, the

heav i er the cord.

Model number 1209 1210 1215

Wrench (22mm) * NA NA

Wrench (14mm) * NA NA

Shaft lock pin

Rubber tool rest NA *. NA

R

20 VOLT ALTERNATING CURRENT TOOLS

1

3-6

-8

6

-10

8

10-12

12-16

Cord Size in A.W.G.

Cord Length in Feet

25 50 100 150 15 30 60 120

8 16 16 14 0.75 0.75 1.5 2.5

1

18 16 14 12 0.75 1.0 2.5 4.0

18 16 14 12 0.75 1.0 2.5 4.0

6 16 14 12 1.0 2.5 4.0 —

1

4 12 —— ————

1

Tool’s

Ampere

Rating

Wire Sizes in mm

Cord Length in Meters

2

(*= standard equipment)

-10-

Page 11

BM 2609932751 09-09:BM 2609932751 09-09 9/3/09 7:20 AM Page 11

Avertissements généraux concernant la sécurité des outils électroportatifs

!

AVERTISSEMENT

choc électrique, d'incendie et/ou de blessures corporelles graves.

Veuillez lire tous les avertissements et toutes les consignes de sécurité. Si l'on

n'observe pas ces avertissements et ces consignes de sécurité, il existe un risque de

CONSERVEZ TOUS LES AVERTISSEMENTS ET TOUTES LES CONSIGNES

DE SÉCURITÉ POUR RÉFÉRENCE FUTURE.

Dans tous les avertissements, le terme « outil électroportatif » se rapporte à des outils branchés sur le secteur (avec

fil) ou à des outils alimentés par piles (sans fil).

Sécurité du lieu de travail

Maintenez le lieu de travail propre et bien éclairé.

Les risques d’accident sont plus élevés quand on

travaille dans un endroit encombré ou sombre.

N’utilisez pas d’outils électroportatifs dans des

atmosphères explosives, comme par exemple en

présence de gaz, de poussières ou de liquides

inflammables. Les outils électroportatifs produisent

des étincelles qui risquent d’enflammer les poussières

ou les vapeurs.

Éloignez les enfants et les visiteurs quand vous vous

servez d’un outil électroportatif. Vous risquez une

perte de contrôle si on vous distrait.

Sécurité électrique

Les fiches des outils électroportatifs doivent

correspondre à la prise. Il ne faut absolument jamais

modifier la fiche. N’utilisez pas d’adaptateur de prise

avec des outils électroportatifs munis d’une fiche de

terre. Le risque de choc électrique est moindre si on

utilise une fiche non modifiée sur une prise qui lui

correspond.

Évitez tout contact du corps avec des surfaces reliées

à la terre tels que tuyaux, radiateurs, gazinières ou

réfrigérateurs. Le risque de choc électrique augmente

si votre corps est relié à la terre.

N’exposez pas les outils électroportatifs à la pluie ou

à l’humidité. Si de l’eau pénètre dans un outil

électroportatif, le risque de choc électrique augmente.

Ne maltraitez pas le cordon. Ne vous en servez

jamais pour transporter l’outil électroportatif, pour le

tirer ou pour le débrancher. Éloignez le cordon de la

chaleur, des huiles, des arêtes coupantes ou des

pièces mobiles. Les cordons abîmés ou emmêlés

augmentent les risques de choc électrique.

Si vous utilisez un outil électroportatif à l’extérieur,

employez une rallonge conçue pour l’extérieur. Ces

rallonges sont faites pour l’extérieur et réduisent le

risque de choc électrique.

S'il est absolument nécessaire d'utiliser l'outil

électroportatif dans un endroit humide, utilisez une

alimentation protégée par un disjoncteur de fuite de

terre (GFCI). L'utilisation d'un disjoncteur GFCI réduit

les risques de choc électrique.

Restez concentré, faites attention à ce que vous

faites, et servez-vous de votre bon sens lorsque vous

utilisez un outil électroportatif. N'employez pas

d’outils électroportatifs quand vous êtes fatigué ou

sous l’emprise de drogues, d’alcool ou de

médicaments. Quand on utilise des outils

électroportatifs, il suffit d’un moment d’inattention pour

causer des blessures corporelles graves.

Utilisez des équipements de sécurité personnelle.

Portez toujours une protection oculaire. Le port

d'équipements de sécurité tels que des masques

antipoussières, des chaussures de sécurité

antidérapantes, des casques de chantier et des

protecteurs d'oreilles dans des conditions appropriées

réduira le risque de blessure corporelle.

Évitez les démarrages intempestifs. Assurez-vous que

l'interrupteur est dans la position arrêt (Off) avant de

brancher l'outil dans une prise de courant et/ou un

bloc-piles, de le ramasser ou de le transporter. Le

transport d'un outil électroportatif avec le doigt sur la

gâchette ou le branchement de cet outil quand

l'interrupteur est en position de marche (ON) est une

invite aux accidents.

Enlevez toutes les clés de réglage avant de mettre

l’outil électroportatif en marche. Si on laisse une clé

sur une pièce tournante de l’outil électroportatif, il y a

risque de blessure corporelle.

Ne vous penchez pas. Conservez toujours une bonne

assise et un bon équilibre. Ceci vous permettra de

mieux maîtriser l’outil électroportatif dans des situations

inattendues.

Habillez-vous de manière appropriée. Ne portez pas

de vêtements amples ou de bijoux. Attachez les

cheveux longs. N’approchez pas les cheveux, les

vêtements ou les gants des pièces en mouvement.

Les vêtements amples, les bijoux ou les cheveux longs

risquent d’être happés par les pièces en mouvement.

Si l’outil est muni de dispositifs permettant le

raccordement d’un système d’aspiration et de

collecte des poussières, assurez-vous que ces

dispositifs sont raccordés et utilisés correctement.

L'utilisation d'un dépoussiéreur peut réduire les

dangers associés à l'accumulation de poussière.

Sécurité personnelle

-11-

Page 12

BM 2609932751 09-09:BM 2609932751 09-09 9/3/09 7:20 AM Page 12

Utilisation et entretien des outils

électroportatifs

Ne forcez pas sur l’outil électroportatif. Utilisez l’outil

électroportatif qui convient à la tâche à effectuer.

L’outil qui convient à la tâche fait un meilleur travail et

est plus sûr à la vitesse pour lequel il a été conçu.

Ne vous servez pas de l’outil électroportatif si son

interrupteur ne parvient pas à le mettre en marche ou

à l’arrêter. Tout outil électroportatif qui ne peut pas

être commandé par son interrupteur est dangereux et

doit être réparé.

Débranchez la fiche de la prise ou enlevez le bloc-pile

de l’outil électroportatif avant tout réglage,

changement d’accessoires ou avant de ranger l’outil

électroportatif. De telles mesures de sécurité

préventive réduisent le risque de démarrage intempestif

de l’outil électroportatif.

Rangez les outils électroportatifs dont vous ne vous

servez pas hors de portée des enfants et ne permettez

pas à des personnes qui ne connaissent pas l’outil

électroportatif ou qui ignorent ces consignes de s’en

servir. Les outils électroportatifs sont dangereux dans

les mains d’utilisateurs inexpérimentés.

Entretenez les outils électroportatifs. Vérifiez que les

pièces mobiles sont alignées correctement et ne

coincent pas. Vérifiez qu’il n’y a pas de pièces

cassées ou d’autre circonstance qui risquent

d’affecter le fonctionnement de l’outil électroportatif.

Si l’outil est abîmé, faites-le réparer avant de

l’utiliser. De nombreux accidents sont causés par des

outils électroportatifs mal entretenus.

Maintenez les outils coupants affûtés et propres. Les

outils coupants entretenus correctement et dotés de

bords tranchants affûtés sont moins susceptibles de

coincer et sont plus faciles à maîtriser.

Utilisez l'outil électroportatif, les accessoires et les

embouts d'outil, etc. conformément à ces instructions,

en tenant compte des conditions de travail et des

travaux à réaliser. L'emploi d’outils électroportatifs

pour des tâches différentes de celles pour lesquelles ils

ont été prévus peut résulter en une situation dangereuse.

Entretien

Faites réparer votre outil électroportatif par un agent

de service qualifié n’utilisant que des pièces de

rechange identiques. Ceci assure que la sécurité de

l’outil électroportatif est préservée.

Avertissements spécifiques à la sécurité des outils électroportatifs

Avertissements habituels concernant la

sécurité des opérations de rectification:

Cet outil électroportatif a été conçu pour fonctionner

comme un outil de rectification. Veuillez lire toute la

documentation relative à la sécurité qui a été fournie

avec cet outil électroportatif, notamment, les

avertissements, les consignes, les illustrations et les

spécifications. Si l'on n'observe pas toutes les

consignes indiquées ci-dessous, il existe un risque de

choc électrique, d'incendie et/ou de blessures

corporelles graves.

Cet outil électroportatif n'est pas recommandé pour le

polissage, de ponçage, de brossage métallique ou de

tronçonnage. L'usage de l'outil au cours de travaux

pour lesquels il n'a pas été conçu risque de présenter

un danger et de causer des blessures corporelles.

N'utilisez pas d'accessoires qui n'ont pas été

spécifiquement conçus et recommandés par le

fabricant de l'outil. Le simple fait qu'un accessoire

puisse être attaché à votre outil électroportatif ne

garantit pas un fonctionnement sans danger.

La vitesse nominale de l'accessoire doit être au

moins égale à la vitesse maximum indiquée sur

l'outil électroportatif. Les accessoires que l'on fait

tourner à une vitesse supérieure à leur VITESSE

NOMINALE peuvent se casser et voler en éclats.

Le diamètre externe et l'épaisseur de votre

accessoire doivent être dans les limites de capacité

de votre outil électroportatif. Des accessoires de la

mauvaise taille ne peuvent pas être adéquatement

protégés ou contrôlés.

Les arbres des meules, des brides, des disques

d'appui ou de tous les autres accessoires doivent être

d'une taille qui leur permet d'être ajustés

correctement sur la broche de l'outil électroportatif.

Les accessoires qui ont des orifices d'arbre n'étant pas

compatibles avec la quincaillerie de montage de l'outil

électroportatif seront déséquilibrés, vibreront de

manière excessive et risquent de causer une perte de

contrôle.

N'utilisez pas d'accessoires endommagés. Inspectez

vos accessoires avant chaque utilisation : vérifiez par

exemple que votre meule abrasive n'est ni fêlée, ni

ébréchée, que votre disque d'appui n'est ni fêlé, ni

déchiré, ni trop usé et que votre brosse métallique ne

contient pas de fils cassés ou détachés. Si vous

laissez tomber l'outil ou l'accessoire, vérifiez que ce

dernier n'est pas endommagé ou remplacez-le par un

accessoire en bon état. Après l'inspection et

l'installation d'un accessoire, tenez-vous à distance

du plan de l'accessoire en mouvement et demandez à

toute personne présente de faire de même, et faites

fonctionner l'outil à sa vitesse à vide maximale

-12-

Page 13

BM 2609932751 09-09:BM 2609932751 09-09 9/3/09 7:20 AM Page 13

pendant une minute. Si un accessoire est endommagé,

il se cassera habituellement en plusieurs morceaux

pendant cette période de test.

Portez des équipements de protection personnelle.

Suivant le travail effectué, portez un masque de

protection, des lunettes à coques ou des lunettes de

sécurité. S'il y a lieu, portez un masque

antipoussières, des dispositifs de protection de l'ouïe,

des gants et un tablier d'atelier capable d'arrêter des

petits fragments abrasifs ou des fragments de la

pièce. Les dispositifs de protection des yeux doivent

pouvoir arrêter des débris volants produits par diverses

opérations. Le masque antipoussières ou le respirateur

doit être capable de filtrer des particules générées par

votre travail. Une exposition prolongée à un bruit de

haute intensité peut entraîner une perte de l'ouïe.

Gardez toute personne présente à une distance sûre

de l'aire de travail. Toute personne qui entre dans

l'aire de travail doit porter des équipements de

protection personnelle. Des fragments d'une pièce ou

d'un accessoire peuvent être projetés et causer des

blessures au-delà de l'aire d'opération immédiate.

Tenez l'outil électroportatif exclusivement au niveau

de ses surfaces de préhension isolées quand vous

réalisez une opération au cours de laquelle

l'accessoire de coupe risque d'entrer en contact avec

des fils électriques dissimulés ou avec son propre

cordon d'alimentation. Quand un accessoire de coupe

entre en contact avec un fil « sous tension », cela peut

mettre des parties métalliques exposées de l'outil

électroportatif « sous tension » et électrocuter

l'utilisateur.

Positionnez le cordon hors de la trajectoire de

l'accessoire en mouvement. Si vous perdez contrôle de

l'outil, le cordon d'alimentation risque d'être coupé ou de

s'accrocher et votre main ou votre bras risque d'être tiré

jusqu'à ce qu'il entre en contact avec l'accessoire en

mouvement.

Ne posez jamais l'outil électroportatif tant que

l'accessoire n'a pas complètement cessé de tourner.

L'accessoire en mouvement risque d'accrocher la

surface sur laquelle il est posé et de vous faire perdre

contrôle de l'outil.

Ne laissez pas l'outil électroportatif en marche quand

vous le portez sur le côté. Un contact accidentel avec

l'accessoire en mouvement risquerait d'accrocher vos

vêtements et d'attirer l'accessoire vers votre corps.

Nettoyez régulièrement les prises d'air de l'outil

électroportatif. Le ventilateur du moteur attirera de la

poussière à l'intérieur du boîtier de l'outil et une

accumulation excessive de poudre métallique risque de

causer des dangers électriques.

Ne faites pas fonctionner l'outil électroportatif à

proximité de matériaux inflammables. Des étincelles

pourraient enflammer ces matériaux.

N'utilisez pas d'accessoires qui exigent des liquides

de refroidissement. L'utilisation d'eau ou d'autres

liquides de refroidissement peut entraîner une

électrocution ou un choc électrique.

Avertissements sur les rebonds et effets

associés

L'effet de rebond est une réaction soudaine au

pincement ou à l'accrochage d'une meule, d'un disque

d'appui, d'une brosse ou de tout autre accessoire

pivotant. Un tel pincement ou accrochage fait

rapidement caler l'accessoire en mouvement, ce qui

force l'outil électroportatif hors de contrôle à aller dans la

direction opposée à celle de la rotation de l'accessoire à

l'emplacement du blocage.

Par exemple, si une meule abrasive est accrochée ou

pincée par la pièce, le bord de la meule à l'emplacement

du pinçage peut creuser la surface du matériau et forcer

la meule à se « hisser » sur la pièce ou à être éjectée. La

meule peut alors sauter soit en direction de l'utilisateur,

soit dans la direction opposée, en fonction de la direction

du mouvement de la meule à l'emplacement du

pincement. Les meules abrasives peuvent également se

briser dans de telles conditions.

Les rebonds résultent d'une mauvaise utilisation de

l'outil électroportatif et/ou de procédures ou de

conditions d'utilisation incorrectes, et ils peuvent être

évités en prenant les précautions nécessaires indiquées

ci-dessous :

Maintenez une prise ferme sur l'outil électroportatif et

positionnez votre bras et le reste de votre corps de

façon à vous permettre de résister aux forces de

rebond. Utilisez toujours la poignée auxiliaire, quand

elle vous a été fournie, pour un contrôle maximum du

rebond ou de la réaction de couple qui se produit

pendant la mise en marche de l'outil. L'utilisateur peut

contrôler les réactions de couple ou les forces de rebond

en prenant les précautions nécessaires.

Ne placez jamais votre main à proximité de

l'accessoire en mouvement. L'accessoire risquerait de

rebondir sur votre main.

Ne vous placez jamais dans la zone où l'outil

électroportatif se dirigerait si un rebond se produisait.

L'effet de rebond projetterait l'outil dans la direction

opposée à celle du mouvement de la meule à

l'emplacement de l'accrochage.

Faites particulièrement attention quand vous travaillez

des coins ou des arêtes tranchantes, etc. Évitez de

faire rebondir ou d'accrocher l'accessoire. Les coins,

les arêtes tranchantes et les rebondissements ont

tendance à faire accrocher l'accessoire en mouvement et

à entraîner une perte de contrôle ou un rebond.

Ne fixez pas une lame à sculpter le bois de chaîne

coupante ou une lame de scie dentée sur l'outil. De

telles lames causent fréquemment des rebonds et des

pertes de contrôle.

-13-

Page 14

BM 2609932751 09-09:BM 2609932751 09-09 9/3/09 7:20 AM Page 14

Avertissements supplémentaires concernant la sécurité

L’emploi d’un GFCI et de dispositifs de protection

personnelle tels que gants et chaussures d’électricien en

caoutchouc améliorent votre sécurité personnelle.

N’utilisez pas un outil conçu uniquement pour le C.A.

sur une alimentation en C.C. Même si l’outil semble

fonctionner, les composants électriques d’un outil prévu

pour le C.A. tomberont probablement en panne et

risquent de créer un danger pour l’utilisateur.

Maintenez les poignées sèches et exemptes d’huile et

de graisse. On ne pas maîtriser un outil électroportatif

en toute sécurité quand on a les mains glissantes.

Utilisez des brides ou d’autres moyens pratiques de

brider ou de supporter la pièce sur une plate-forme

stable. Tenir la pièce à la main ou contre le corps est

instable et risque de résulter en une perte de contrôle.

Créez un agenda d’entretien périodique pour votre

outil. Quand vous nettoyez un outil, faites attention de

n’en démonter aucune pièce car il est toujours

possible de mal remonter ou de pincer les fils

internes ou de remonter incorrectement les ressorts

de rappel des capots de protection. Certains agents de

nettoyage tels que l’essence, le tétrachlorure de

carbone, l’ammoniaque, etc. risquent d’abîmer les

plastiques.

Risque de blessure pour l'utilisateur. Le cordon

d'alimentation électrique ne doit être réparé que par un

Centre de service usine de Bosch ou par une Station

service agréée de Bosch.

!

AVERTISSEMENT

meulage, perçage et autres travaux du bâtiment

peuvent créer des poussières contenant des produits

chimiques qui sont des causes reconnues de cancer,

de malformation congénitale ou d’autres problèmes

reproductifs. Ces produits chimiques sont, par

exemple :

• Le plomb provenant des peintures à base de plomb,

• Les cristaux de silices provenant des briques et du

ciment et d’autres produits de maçonnerie, et

• L’arsenic et le chrome provenant des bois traités

chimiquement.

Le niveau de risque dû à cette exposition varie avec la

fréquence de ces types de travaux. Pour réduire

l’exposition à ces produits chimiques, il faut travailler

dans un lieu bien ventilé et porter un équipement de

sécurité approprié tel que certains masques à poussière

conçus spécialement pour filtrer les particules

microscopiques.

Les travaux à la machine

tel que ponçage, sciage,

-14-

Page 15

0

BM 2609932751 09-09:BM 2609932751 09-09 9/3/09 7:20 AM Page 15

Symboles

IMPORTANT : Certains des symboles suivants peuvent être utilisés sur votre outil. Veuillez les étudier et apprendre

leur signification. Une interprétation appropriée de ces symboles vous permettra d'utiliser l'outil de façon plus

efficace et plus sûre.

Symbole Nom Désignation/Explication

V Volts Tension (potentielle)

A Ampères Courant

Hz Hertz Fréquence (cycles par seconde)

W Watt Puissance

kg Kilogrammes Poids

min Minutes Temps

s Secondes Temps

Diamètre Taille des mèches de perceuse, meules,

etc.

n Vitesse à vide Vitesse de rotation, à vide

.../min Tours ou mouvement alternatif par Tours, coups, vitesse en surface, orbites,

minute etc., par minute

0 Position d'arrêt Vitesse zéro, couple zéro ...

1, 2, 3, ... Réglages du sélecteur Réglages de vitesse, de couple ou de

l, ll, lll, ... position. Un nombre plus élevé signifie

une vitesse plus grande

Sélecteur variable à l'infini avec arrêt La vitesse augmente depuis le réglage 0

Flèche Action dans la direction de la flèche

Courant alternatif Type ou caractéristique du courant

Courant continu Type ou caractéristique du courant

Courant alternatif Type ou caractéristique du courant

ou continu

Construction classe II Désigne des outils construits avec double

isolation

Borne de terre Borne de mise à la terre

Symbole d'avertissement Alerte l'utilisateur aux messages

d'avertissement.

Sceau Li-ion RBRC Désigne le programme de recyclage des piles

Li-ion.

Ce symbole signifie que cet

outil est approuvé par

Underwriters Laboratories.

Ce symbole signifie que cet

outil est approuvé par

l'Association canadienne

de normalisation.

Ce symbole signifie que cet outil est approuvé par Intertek Testing

Services selon les normes des États-Unis et du Canada

Ce symbole signifie que cet outil

est approuvé par l'Association

canadienne de normalisation

selon les normes des États-Unis

et du Canada.

Ce symbole signifie que cet outil

est approuvé par Underwriters

Laboratories selon les normes

des États-Unis et du Canada.

Ce symbole

signifie que

cet outil se

conforme aux

normes

mexicaines

NOM.

-15-

Page 16

BM 2609932751 09-09:BM 2609932751 09-09 9/3/09 7:20 AM Page 16

Description fonctionnelle et spécifications

!

AVERTISSEMENT

préventive réduisent le risque d'une mise en marche accidentelle de l'outil.

Débranchez la fiche de la prise de courant avant d'effectuer quelque assemblage

ou réglage que ce soit ou de changer les accessoires. Ces mesures de sécurité

Rectifieuses de matrices

PRISES D’AIR

ARBRE

ÉCROU DE LA

DOUILLE

PRISES D’AIR

ARBRE

ÉCROU DE LA

DOUILLE

BOUTON DE

L’INTERRUPTEUR

INTERRUPTEUR

A PALETTE

PRISES D’AIR

ARBRE

ÉCROU DE LA

DOUILLE

Numéro de modèle 1209 1210 1215

Capacité de la douille queue 1/4 po 1/4 po-1/8 po 1/4 po-1/8 po

Régime à vide n

Capacité max. des accessoires

Pointe montée 2 po diam. 1 po diam. 1 po diam.

REMARQUE : Pour spécifications de l'outil, reportez-vous à la plaque signalétique de votre outil.

16,000/min n0 27,000/min n0 27,000/min

0

BOUTON DE

L’INTERRUPTEUR

-16-

Page 17

0

0

11

BM 2609932751 09-09:BM 2609932751 09-09 9/3/09 7:20 AM Page 17

Consignes de fonctionnement

INTERRUPTEUR E PALETTE «TROIS REGLAGES»

(modèle 1209 seulement)

L’interrupteur à palette permet à l’utilisateur de choisir

entre trois réglages: «déverrouillage», «marche/arrêt»

et «verrouillage».

PO UR DÉVERROUI LLER

L’ INTERRUPTEUR ET

ME TTRE L’OUTI L EN

MA RCHE : Déplacez la

palette vers l’AVANT (vers

l’ arbre), puis serrez la

palette.

POUR METTRE L’OUTIL AU REPOS: Relâchez la

palette. L’interrupteur, qui est àressort, retournera

automatiquement à la position d’arrêt.

La fonction de verrouillage, in corporée dans

l’interrupteur à palette, est très pratique lors de longs

travaux.

PO UR VERROUI LLER L’INTER RUPTEUR SO US

TENSION : Après que l’interrupteur est mis sous

te nsion, DÉPLACE Z la palette totalement ver s

l’AVANT, puis relâchez-la.

POUR METTRE L’OUTIL AU REPOS : Serrez la palette,

puis relâchez-la. L’interrupteur, qui est à ressort,

retournera automatiquement à la position d’arrêt.

INTERRUPTEUR A COULISSE AVEC

BLOCAGE EN MARCHE

(modèles 1210 et 1215 seulement)

L’outil se met en marche à l’aide du bouton

d’interrupteur situé sur le côté du carter du moteur.

L’interrupteur peut être bloqué en position de marche,

fonction commode pour les longues opérations de

rectification.

Pour mettre l’outil en marche sans le verrouiller, glissez

l’interrupteur vers l’avant en appuyant SEULEMENT sur

la partie ARRIÈRE du bouton. Au relâchement, le

bouton retournera à la position d’arrêt.

POUR BLOQUER L’INTERRUPTEUR EN MARCHE,

glissez l’interrupteur vers l’avant et appuyez sur la

partie AVANT du bouton.

POUR DÉBLOQUER L’INTERRUPTEUR, appuyez

simplement sur la partie ARRIÈRE du bouton et

relâchez-le aussitôt. Étant donné que l’interrupteur est à

ressort, il reviendra automatiquement.

!

AVERTISSEMENT

Tenez l’outil à deux mains à

la mise en marche car le

couple du moteur peut transmettre une certaine

torsion.

Mettez l’outil en marche avant de le poser sur la pièce.

De même, sou levez-le avant d’en relâcher

l’interrupteur. Pour prolonger la durée de l’interrupteur,

évitez de le mettre sous tension et hors tension

pendant que l’outil est à l’oeuvre.

CHOIX DES MEULES

!

AVERTISSEMENT

Avant d’utiliser une meule,

assurez-vous que la vitesse

maximale de rotation qu’elle peut at teindre, sans

compromettre la sécurité de fonctionnement, n’est pas

inférieure à la vitesse en marche libre figurant sur la

plaquette emblé matique de l’outil. Ne choisissez pas

des meules de diamètre supérieur à celui recommandé.

Pour de meilleurs résultats, choisissez les meules

soigneusement. Les meules diffèrent de plusieurs

façons : granulométrie, composition, dureté, taille des

particules et structure. Le choix de la meule est dicté par

le type de travail à réaliser.

POSE DES ACCESSOIRES

!

MISE EN GARDE

Assurez-vous que le

diamètre de la tige est

identique au diamètre intérieur de la douille.

Les modèles 1209, 1210 et 1215 sont pourvus d’une

douille de 1/4 po.

(modèles 1209 et 1215 seulement)

1. Placez la clé de blocage d’arbre (22 mm) fournie sur

l’arbre pour empêcher l’arbre de tourner.

2. Tenez la clé en place et faites tourner l’écrou de

douille en sens anti-horaire à l’aide de la clé (14 mm)

fournie.

3. Insérez les trois quarts de la tige de l’accessoire

dans la douille, et serrez fermement à l’aide de la clé

fournie. REMARQUE : En remettant les douilles en

place sur le modèle 1215, desserrez l’écrou de la

douille et retirez concurremment avec la douille, vissez

ensuite la nouvelle douille.

DEPOSE DES ACCESSOIRES

Répétez les étapes 1 et 2 ci-dessus pour déposer

l’accessoire.

-17-

Page 18

BM 2609932751 09-09:BM 2609932751 09-09 9/3/09 7:20 AM Page 18

POSE DES ACCESSOIRES

1. Insérez la cheville de blocage fournie dans le trou de

l’arbre, afin d’empêcher l’arbre de tourner.

2. Tenez la cheville de blocage en place et tournez

l’écrou de douille en sens anti-horaire à l’aide de la clé

de 14 mm fournie.

(modèle 1210 seulement)

Entretien

Service

!

AVERTISSEMENT

personnels non autorisés peut résulter en mauvais

placement de fils internes ou de pièces, ce qui peut

présenter un danger grave. Nous vous conseillons de

faire faire tout l’entretien par un centre de service

d’usine Bosch ou une station service agréée Bosch.

Votre outil Bosch a été lubrifié correctement en usine

et il est prêt à l’utilisation. Nous vous conseillons de

re-graisser les outils qui comportent des engrenages

avec un lubrifiant à engrenages spécial à chaque fois

que vous changez les balais.

Les balais (ou charbons) et le collecteur de votre outil

ont été conçus pour apporter de nombreuses heures

de fonctionnement fiable. Pour maintenir le

rendement du moteur à son maximum, nous vous

conseillons de contrôler les balais tous les deux à six

mois. Il ne faut utiliser que des balais de rechange

Bosch d’origine et conçus pour votre outil.

Après environ 300 à 400 heures de fonctionnement ou

tous les deux changements de balais, il est conseillé

LUBRIFICATION DE L’OUTIL

BALAIS OU CHARBONS

Tout entretien préventif

effectué par des

PALIERS

3. Insérez les trois quarts de la tige de l’accessoire

dans la douille, et serrez fermement à l’aide de la clé

fournie.

Répétez les étapes 1 et 2 ci-dessus pour déposer

l’accessoire.

de faire remplacer les paliers par un centre de service

d’usine Bosch ou une station service agréée Bosch. Si

les paliers commencent à faire du bruit (à cause de

surcharges importantes ou du toupillage de matériaux

très abrasifs) il faut les faire remplacer immédiatement

pour éviter la surchauffe ou une panne de moteur.

DEPOSE DES ACCESSOIRES

Nettoyage

!

AVERTISSEMENT

l’outil avant de le nettoyer ou de l’entretenir. Le

meilleur moyen de nettoyer l’outil est d’utiliser de l’air

comprimé sec. Il faut toujours porter des lunettes de

protection quand on utilise de l’air comprimé.

Les ouïes de ventilation et les leviers de l’interrupteur

doivent rester propres et exempts de corps étrangers.

Ne tentez pas de les nettoyer en enfonçant des objets

pointus dans les orifices.

!

MISE EN GARDE

dissolvants abîment les pièces en plastique. Parmi

ceux-ci se trouvent: l’essence, le tétrachlorure de

carbone, les dissolvants de nettoyage chlorés,

l’ammoniaque ainsi que les détergents domestiques

qui en contiennent.

Pour éviter les accidents, il

faut toujours débrancher

Certains agents de

nettoyages et certains

-18-

Page 19

BM 2609932751 09-09:BM 2609932751 09-09 9/3/09 7:20 AM Page 19

Accessoires

!

AVERTISSEMENT

Si un cordon de rallonge

s'avère nécessaire, vous

devez utiliser un cordon avec conducteurs de

dimension adéquate pouvant porter le courant

nécessaire à votre outil. Ceci préviendra une chute

excessive de tension, une perte de courant ou une

surchauffe. Les outils mis à la terre doivent utiliser des

cordons de rallonge trifilaires pourvus de fiches à trois

broches ainsi que des prises à trois broches.

REMARQUE : Plus le calibre est petit, plus le fil est gros.

DIMENSIONS DE RALLONGES RECOMMANDÉES

OUTILS 120 VOLTS COURANT ALTERNATIF

Intensité

ominale

n

de l’outil

3-6

6-8

-10

8

10-12

12-16

Calibre A.W.G.

ongueur en pieds

L

5 50 100 150 15 30 60 120

2

18 16 16 14 0,75 0,75 1,5 2,5

18 16 14 12 0,75 1,0 2,5 4,0

8 16 14 12 0,75 1,0 2,5 4,0

1

16 16 14 12 1,0 2,5 4,0 —

14 12 —— ————

Calibre en mm

ongueur en mètres

L

Numéro de modèle 1209 1210 1215

(22mm) Clé * S/O S/O

(14mm) Clé * S/O S/O

Cheville de blocage d’arbre

Porte-outil en caoutchouc S/O *. S/O

(* = équipement de série)

2

-19-

Page 20

BM 2609932751 09-09:BM 2609932751 09-09 9/3/09 7:20 AM Page 20

Advertencias generales de seguridad para herramientas mecánicas

!

ADVERTENCIA

Lea todas las advertencias de seguridad e instrucciones. Si no se siguen las advertencias e

instrucciones, el resultado podría ser sacudidas eléctricas, incendio y/o lesiones graves.

GUARDE TODAS LAS ADVERTENCIAS E INSTRUCCIONES

PARA REFERENCIA FUTURA

La expresión “herramienta mecánica” en todas las advertencias se refiere a su herramienta mecánica alimentada por

la red eléctrica (herramienta alámbrica) o su herramienta mecánica alimentada por baterías (herramienta

inalámbrica).

Seguridad del área de trabajo

Mantenga el área de trabajo limpia y bien iluminada.

Las áreas desordenadas u oscuras invitan a que se

produzcan accidentes.

No utilice herramientas mecánicas en atmósferas

explosivas, como por ejemplo en presencia de

líquidos, gases o polvos inflamables. Las

herramientas mecánicas generan chispas que pueden

incendiar el polvo o los vapores.

Mantenga alejados a los niños y a las personas que

estén presentes mientras esté utilizando una

herramienta mecánica. Las distracciones pueden

hacerle perder el control de la herramienta.

Seguridad eléctrica

Los enchufes de las herramientas mecánicas deben

coincidir con el tomacorriente. No modifique nunca el

enchufe de ningún modo. No use enchufes

adaptadores con herramientas mecánicas conectadas

a tierra (puestas a tierra). Los enchufes no

modificados y los tomacorrientes coincidentes

reducirán el riesgo de sacudidas eléctricas.

Evite el contacto del cuerpo con las superficies

conectadas o puestas a tierra, tales como tuberías,

radiadores, estufas y refrigeradores. Hay un aumento

del riesgo de sacudidas eléctricas si el cuerpo del

operador se conecta o pone a tierra.

No exponga las herramientas mecánicas a la lluvia o

a condiciones mojadas. La entrada de agua en una

herramienta mecánica aumentará el riesgo de que se

produzcan sacudidas eléctricas.

No maltrate el cordón de energía. No use nunca el

cordón para transportar la herramienta mecánica,

tirar de ella o desenchufarla. Mantenga el cordón

alejado del calor, el aceite, los bordes afilados o las

piezas móviles. Los cordones dañados o enganchados

aumentan el riesgo de que se produzcan sacudidas

eléctricas.

Cuando utilice una herramienta mecánica en el

exterior, use un cordón de extensión adecuado para

uso a la intemperie. La utilización de un cordón

adecuado para uso a la intemperie reduce el riesgo de

que se produzcan sacudidas eléctricas.

Si es inevitable utilizar una herramienta mecánica en

un lugar húmedo, utilice una fuente de energía

protegida por un interruptor de circuito accionado por

corriente de pérdida a tierra (GFCI). El uso de un GFCI

reduce el riesgo de sacudidas eléctricas.

Seguridad personal

Manténgase alerta, fíjese en lo que está haciendo y

use el sentido común cuando esté utilizando una

herramienta mecánica. No use una herramienta

mecánica cuando esté cansado o bajo la influencia de

drogas, alcohol o medicamentos. Un momento de

distracción mientras esté utilizando herramientas

mecánicas podría causar lesiones corporales graves.

Use equipo de protección personal. Use siempre

protección de los ojos. El equipo de protección, como

por ejemplo una máscara antipolvo, calzado de

seguridad antideslizante, casco o protección de oídos,

utilizado para las condiciones apropiadas, reducirá las

lesiones corporales.

Evite el arranque accidental. Asegúrese de que el

interruptor esté en la posición de apagado antes de

conectar la herramienta a la fuente de energía y / o al

paquete de batería, levantar la herramienta o

transportarla. Transportar herramientas mecánicas con

un dedo en el interruptor o encender herramientas

mecánicas que tengan el interruptor en la posición de

encendido invita a que se produzcan accidentes.

Quite todas las llaves de ajuste o de tuerca antes de

encender la herramienta mecánica. Una llave de

tuerca o de ajuste que se deje colocada en una pieza

giratoria de la herramienta mecánica podría causar

lesiones corporales.

No intente alcanzar demasiado lejos. Mantenga un

apoyo de los pies y un equilibrio apropiados en todo

momento. Esto permite controlar mejor la herramienta

mecánica en situaciones inesperadas.

Vístase adecuadamente. No use ropa holgada ni

alhajas holgadas. Mantenga el pelo, la ropa y los

guantes alejados de las piezas móviles. La ropa

holgada, las alhajas holgadas o el pelo largo pueden

quedar atrapados en las piezas móviles.

Si se proporcionan dispositivos para la conexión de

instalaciones de extracción y recolección de polvo,

asegúrese de que dichas instalaciones estén

conectadas y se usen correctamente. El uso de

dispositivos de recolección de polvo puede reducir los

peligros relacionados con el polvo.

-20-

Page 21

BM 2609932751 09-09:BM 2609932751 09-09 9/3/09 7:20 AM Page 21

Uso y cuidado de las herramientas

mecánicas

No fuerce la herramienta mecánica. Use la

herramienta mecánica correcta para la aplicación que

desee realizar. La herramienta mecánica correcta hará

el trabajo mejor y con más seguridad a la capacidad

nominal para la que fue diseñada.

No use la herramienta mecánica si el interruptor no la

enciende y apaga. Toda herramienta mecánica que no

se pueda controlar con el interruptor es peligrosa y

debe ser reparada.

Desconecte el enchufe de la fuente de energía y/o el

paquete de batería de la herramienta mecánica antes

de hacer cualquier ajuste, cambiar accesorios o

almacenar herramientas mecánicas. Dichas medidas

preventivas de seguridad reducen el riesgo de arrancar

accidentalmente la herramienta mecánica.

Guarde las herramientas que no esté usando fuera

del alcance de los niños y no deje que personas que

no estén familiarizadas con la herramienta mecánica

o con estas instrucciones utilicen la herramienta. Las

herramientas mecánicas son peligrosas en manos de

usuarios que no hayan recibido capacitación.

Mantenga las herramientas mecánicas. Compruebe si

hay piezas móviles desalineadas o que se atoran, si

hay piezas rotas y si existe cualquier otra situación

que podría afectar el funcionamiento de la

herramienta mecánica. Si la herramienta mecánica

está dañada, haga que la reparen antes de usarla.

Muchos accidentes son causados por herramientas

mecánicas mantenidas deficientemente.

Mantenga las herramientas de corte afiladas y

limpias. Es menos probable que las herramientas de

corte mantenidas apropiadamente, con bordes de corte

afilados, se atoren, y dichas herramientas son más

fáciles de controlar.

Utilice la herramienta mecánica, los accesorios, las

brocas de la herramienta, etc., de acuerdo con estas

instrucciones, teniendo en cuenta las condiciones de

trabajo y el trabajo que se vaya a realizar. El uso de la

herramienta mecánica para operaciones distintas a

aquéllas para las que fue diseñada podría causar una

situación peligrosa.

Servicio de ajustes y reparaciones

Haga que su herramienta mecánica reciba servicio de

un técnico de reparaciones calificado, utilizando

únicamente piezas de repuesto idénticas. Esto

asegurará que se mantenga la seguridad de la

herramienta mecánica.

Advertencias de seguridad específicas para herramientas mecánicas

Advertencias de seguridad comunes para las

operaciones de amolado:

Esta herramienta mecánica está diseñada para

funcionar como amoladora. Lea todas las

advertencias de seguridad, instrucciones,

ilustraciones y especificaciones suministradas con

esta herramienta mecánica. Si no se siguen todas las

instrucciones que se indican a continuación, el

resultado podría ser descargas eléctricas, incendio y/o

lesiones graves.

Esta herramienta mecánica no se recomienda para

pulir, lijadora, cepillo de alambre o herramienta

recortadora. Las operaciones para las cuales la

herramienta mecánica no fue diseñada pueden crear un

peligro y causar lesiones corporales.

No utilice accesorios que no estén diseñados y

recomendados específicamente por el fabricante de

la herramienta. Sólo porque el accesorio se pueda

instalar en su herramienta mecánica, eso no garantiza

una operación segura.

La velocidad nominal del accesorio debe ser al

menos igual a la velocidad marcada en la

herramienta mecánica. Los accesorios que funcionen

más rápidamente que su VELOCIDAD NOMINAL se

pueden romper y salir despedidos.

El diámetro exterior y el grosor de su accesorio deben

estar dentro de la capacidad nominal de su

herramienta mecánica. Los accesorios de tamaño

incorrecto no se pueden proteger ni controlar

adecuadamente.

El tamaño del eje portaherramienta de las ruedas de

amolar, las pestañas, las zapatas de soporte o

cualquier otro accesorio debe encajar

apropiadamente en el husillo de la herramienta

mecánica. Los accesorios con agujeros de eje

portaherramienta que no coincidan con los herrajes de

montaje de la herramienta mecánica funcionarán

desequilibrados, vibrarán excesivamente y podrían

causar pérdida de control.

No utilice un accesorio que esté dañado. Antes de

cada uso, inspeccione el accesorio, como por ejemplo

las ruedas abrasivas para comprobar si tienen

picaduras y grietas, la zapata de soporte para

comprobar si tiene grietas, desgarraduras o desgaste

excesivo, y el cepillo de alambre para comprobar si

hay alambres flojos o agrietados. Si la herramienta

mecánica o el accesorio se cae, realice una

inspección para comprobar si se ha dañado o instale

un accesorio que no esté dañado. Después de

inspeccionar e instalar un accesorio, posiciónese

-21-

Page 22

BM 2609932751 09-09:BM 2609932751 09-09 9/3/09 7:20 AM Page 22

usted y posicione a las personas que estén presentes

alejados del plano del accesorio que gira y haga

funcionar la herramienta mecánica a la máxima

velocidad sin carga durante un minuto. Normalmente,

los accesorios dañados se romperán en pedazos

durante este tiempo de prueba.

Utilice equipo de protección personal. Dependiendo

de la aplicación, use una careta, anteojos de

seguridad o lentes de seguridad. Según sea

apropiado, use una máscara antipolvo, protectores de

la audición, guantes y un delantal de taller capaz de

detener pequeños fragmentos de abrasivo o de la

pieza de trabajo. La protección de los ojos debe ser

capaz de detener los residuos que salgan despedidos al

ser generados por diversas operaciones. La máscara

antipolvo o el respirador debe ser capaz de filtrar las

partículas generadas por la operación que usted realice.

La exposición prolongada a ruido de alta intensidad

puede causar pérdida de audición.

Mantenga a las personas presentes a una distancia

segura del área de trabajo. Toda persona que entre al

área de trabajo debe usar equipo de protección

personal. Los fragmentos de la pieza de trabajo o de un

accesorio roto pueden salir despedidos y causar

lesiones más allá del área inmediata de operación.

Agarre la herramienta mecánica solamente por las

superficies de agarre con aislamiento cuando realice

una operación en la que el accesorio de corte pueda

entrar en contacto con cables ocultos o su propio

cordón de energía. Si un accesorio de corte entra en

contacto con un cable “con corriente”, eso puede hacer

que las partes metálicas de la herramienta mecánica que

estén al descubierto “lleven corriente” y causen

descargas eléctricas al operador.

Posicione el cordón de energía alejado del accesorio

que gira. Si usted pierde el control, el cordón de energía

puede resultar cortado o enganchado y la mano o el

brazo del operador puede ser arrastrado hasta el

accesorio que gira.

No deje nunca la herramienta mecánica en ningún

lugar hasta que el accesorio se haya detenido por

completo. El accesorio que gira se puede enganchar en

la superficie y tirar de la herramienta mecánica hasta

hacer que usted pierda el control.

No haga funcionar la herramienta mecánica mientras

la lleva a su lado. El contacto accidental con el

accesorio que gira podría enganchar la ropa del

operador y tirar del accesorio hacia su cuerpo.

Limpie regularmente las aberturas de ventilación de

la herramienta mecánica. El ventilador del motor

absorberá el polvo al interior de la carcasa y la

acumulación excesiva de metal en polvo puede causar

peligros eléctricos.

No utilice la herramienta mecánica cerca de

materiales inflamables. Las chispas podrían incendiar

estos materiales.

No utilice accesorios que requieran enfriadores

líquidos. La utilización de agua u otros enfriadores

líquidos puede causar electrocución o descargas

eléctricas.

Retroceso y advertencias relacionadas

El retroceso es una reacción repentina a una rueda que

gira, una zapata de soporte, un cepillo o cualquier otro

accesorio que resulte pellizcado o enganchado. El

pellizcamiento o el enganche causan una parada rápida

del accesorio que gira, lo cual a su vez hace que la

herramienta mecánica descontrolada sea forzada en

sentido opuesto al de rotación del accesorio en el punto

del atoramiento.

Por ejemplo, si la pieza de trabajo engancha o pellizca

una rueda abrasiva, el borde de la rueda que esté

entrando en el punto de pellizcamiento puede penetrar

en la superficie del material, haciendo que la rueda se

salga del corte o experimente retroceso. La rueda puede

saltar hacia el operador o alejándose de éste,

dependiendo del sentido de movimiento de dicha rueda

en el punto de pellizcamiento. Las ruedas abrasivas

también se pueden romper en estas condiciones.

El retroceso es el resultado de la utilización indebida de

la herramienta mecánica y/o de procedimientos o

condiciones de operación incorrectos, y se puede evitar

tomando las precauciones apropiadas que se indican a

continuación.

Mantenga un agarre firme de la herramienta

mecánica y posicione el cuerpo y el brazo para

permitir que usted resista las fuerzas de retroceso.

Utilice siempre el mango auxiliar, si se suministra,

para tener el máximo control sobre el retroceso o la

reacción de fuerza de torsión durante el arranque. El

operador puede controlar las reacciones de fuerza de

torsión o las fuerzas de retroceso, si se toman las

precauciones apropiadas.

No coloque nunca la mano cerca del accesorio que

gira. El accesorio puede experimentar retroceso sobre la

mano.

No ubique el cuerpo en el área donde la herramienta

mecánica se moverá si se produce retroceso. El

retroceso propulsará la herramienta en sentido contrario

al del movimiento de la rueda en el punto de enganche.

Tenga cuidado especial cuando trabaje en esquinas,

bordes afilados, etc. Evite hacer rebotar y enganchar

el accesorio. Las esquinas, los bordes afilados o los

rebotes tienen tendencia a enganchar el accesorio que

gira y causar pérdida de control o retroceso.

No instale una hoja de cadena de sierra para tallar

madera ni una hoja con dientes de sierra. Dichas hojas

generan retroceso y pérdida de control frecuentes.

-22-

Page 23

BM 2609932751 09-09:BM 2609932751 09-09 9/3/09 7:20 AM Page 23

Advertencias de seguridad adicionales

Un GFCI y los dispositivos de protección personal,

como guantes de goma y calzado de goma de

electricista, mejorarán más su seguridad personal.

No use herramientas mecánicas con capacidad

nominal solamente para CA con una fuente de

energía de CC. Aunque pueda parecer que la

herramienta funciona correctamente, es probable que

los componentes eléctricos de la herramienta con

capacidad nominal para CA fallen y creen un peligro

para el operador.

Mantenga los mangos secos, limpios y libres de

aceite y grasa. Las manos resbalosas no pueden

controlar de modo seguro la herramienta mecánica.

Use abrazaderas u otro modo práctico de sujetar y

soportar la pieza de trabajo en una plataforma

estable. Si se sujeta la pieza de trabajo con la mano o

contra el cuerpo, se crea una situación inestable que

podría causar pérdida de control.

Desarrolle un programa de mantenimiento periódico

de la herramienta. Cuando limpie una herramienta,

tenga cuidado de no desmontar ninguna de sus

partes, ya que los cables internos podrían reubicarse

incorrectamente o pellizcarse, o los resortes de

retorno de los protectores de seguridad podrían

montarse incorrectamente. Ciertos agentes de

limpieza, tales como gasolina, tetracloruro de carbono,

amoníaco, etc., podrían dañar las piezas de plástico.

Riesgo de lesiones para el usuario. El cordón de energía

debe recibir servicio de ajustes y reparaciones

solamente por un Centro de Servicio de Fábrica Bosch o

una Estación de Servicio Bosch Autorizada.

!

ADVERTENCIA

taladrado mecánicos, y por otras actividades de

construcción, contiene agentes químicos que se sabe

que causan cáncer, defectos de nacimiento u otros

daños sobre la reproducción. Algunos ejemplos de

estos agentes químicos son:

• Plomo de pinturas a base de plomo,

• Sílice cristalina de ladrillos y cemento y otros

productos de mampostería, y

• Arsénico y cromo de madera tratada químicamente.

Su riesgo por causa de estas exposiciones varía,

dependiendo de con cuánta frecuencia realice este tipo

de trabajo. Para reducir su exposición a estos agentes

químicos: trabaje en un área bien ventilada y trabaje con

equipo de seguridad aprobado, como por ejemplo

máscaras antipolvo que estén diseñadas especialmente

para impedir mediante filtración el paso de partículas

microscópicas.

Cierto polvo generado por el

lijado, aserrado, amolado y

-23-

Page 24

0

BM 2609932751 09-09:BM 2609932751 09-09 9/3/09 7:20 AM Page 24

Símbolos

IMPORTANTE: Es posible que algunos de los símbolos siguientes se usen en su herramienta. Por favor,

estúdielos y aprenda su significado. La interpretación adecuada de estos símbolos le permitirá utilizar la

herramienta mejor y con más seguridad.

Símbolo Nombre Designación/explicación

V Volt Tensión (potencial)

A Ampere Corriente

Hz Hertz Frecuencia (ciclos por segundo)

W Watt Potencia

kg Kilogramo Peso

min Minuto Tiempo

s Segundo Tiempo

Diámetro Tamaño de las brocas taladradoras,

muelas, etc