Page 1

POWER SENSOR

MANUAL

Revision Date: 4/26/11

Manual P/N 98501900M

CD P/N 98501999M

BOONTON ELECTRONICS Email: boonton@boonton.com

25 EASTMANS ROAD Telephone: 973-386-9696

PARSIPPANY, NJ 07054 Fax: 973-386-9191

Web Site: www.boonton.com

Page 2

SAFETY SUMMARY

The following general safety precautions must be observed during all phases of operation and maintenance of this

instrument. Failure to comply with these precautions or with specific warnings elsewhere in this manual violates safety

standards of design, manufacture, and intended use of the instruments. Boonton Electronics Corporation assumes no

liability for the customer's failure to comply with these requirements.

THE INSTRUMENT MUST BE GROUNDED.

T o minimize shock hazard the instrument chassis and cabinet must be connected to an electrical ground. The instrument

is equipped with a three conductor, three prong AC power cable. The power cable must either be plugged into an approved

three-contact electrical outlet or used with a three-contact to a two-contact adapter with the (green) grounding wire firmly

connected to an electrical ground at the power outlet.

DO NOT OPERATE THE INSTRUMENT IN AN EXPLOSIVE ATMOSPHERE.

Do not operate the instrument in the presence of flammable gases or fumes.

KEEP AWAY FROM LIVE CIRCUITS.

Operating personnel must not remove instrument covers. Component replacement and internal adjustments must be made

by qualified maintenance personnel. Do not replace components with the power cable connected. Under certain conditions

dangerous voltages may exist even though the power cable was removed; therefore, always disconnect power and

discharge circuits before touching them.

DO NOT SERVICE OR ADJUST ALONE.

Do not attempt internal service or adjustment unless another person, capable of rendering first aid and resuscitation, is

present.

DO NOT SUBSTITUTE PARTS OR MODIFY INSTRUMENT.

Do not install substitute parts of perform any unauthorized modification of the instrument. Return the instrument to

Boonton Electronics for repair to ensure that the safety features are maintained.

This safety requirement symbol has been adopted by the International Electrotechnical

Commission, Document 66 (Central Office) 3, Paragraph 5.3, which directs that an instrument

be so labeled if, for the correct use of the instrument, it is necessary to refer to the

instruction manual. In this case it is recommended that reference be made to the instruction

manual when connecting the instrument to the proper power source. Verify that the

correct fuse is installed for the power available, and that the switch on the rear panel is set

to the applicable operating voltage.

The CAUTION sign denotes a hazard. It calls attention to an operation procedure,

CAUTION

WARNING

practice, or the like, which, if not correctly performed or adhered to, could result in damage

to or destruction of part or all of the equipment. Do not proceed beyond a CAUTION sign

until the indicated conditions are fully understood and met.

The WARNING sign denotes a hazard. It calls attention to an operation procedure.,

practice, or the like, which, if not correctly performed or adhered to, could result in injury

of loss of life. Do not proceed beyond a warning sign until the indicated conditions are

fully understood and met.

This SAFETY REQUIREMENT symbol has been adopted by the International

Electrotechnical Commission, document 66 (Central Office)3, Paragraph 5.3 which indicates

hazardous voltage may be present in the vicinity of the marking.

Page 3

Contents

w

Paragraph Page

1 Introduction 1

1-1 Overview 1

1-2 Sensor Trade-offs 1

1-3 Calibration and Traceability 3

2 Power Sensor Characteristics 5

3 Power Sensor Uncertainty Factors 17

4Lo

5 Pulsed RF Power 32

6 Calculating Measurement Uncertainty 35

7 Warranty 47

Response 28

and Standing-Wave-Ratio (SWR) Data

5-1 Pulsed RF Power Operation 32

5-2 Pulsed RF Operation Thermocouple Sensors 33

5-3 Pulsed RF Operation Diode Sensors 34

6-1 Measurement Accuracy 35

6-2 Uncertainty Contributions 36

6-3 Discussion of Uncertainty Terms 36

6-4 Sample Uncertainty Calculations 41

Power Sensor Manual i

Page 4

Figures

Figure Page

1-1 Error Due to AM Modulation (Diode Sensor) 2

1-2 Linearity Traceability 3

1-3 Calibration Factor Traceability 4

4-1 Model 51071 Low Frequency Response 28

4-2 Model 51072 Low Frequency Response 28

4-3 Model 51075 Low Frequency Response 29

4-4 Model 51071 SWR Data 29

4-5 Model 51072 SWR Data 29

4-6 Model 51075 SWR Data 30

4-7 Model 51078 SWR Data 30

4-8 Model 51100 SWR Data 30

4-9 Model 51101 SWR Data 31

4-10 Model 51102 SWR Data 31

5-1 Pulsed RF Operation 32

5-2 Pulsed Accuracy for Thermocouple Sensors 33

5-3 Pulsed Accuracy for Diode Sensors 34

Tables

6-1 Mismatch Uncertainty 39

Table Page

2-1 Dual Diode and Thermal Sensor Characteristics 5

2-2 Peak Power Sensor Characteristics 9

2-3 Legacy Diode CW Sensor Characteristics 12

2-4 Legacy Waveguide Sensor Characteristics 14

2-5 Legacy Peak Power Sensor Characteristics 16

3-1 Diode & Thermocouple Power Sensor Calibration Factor 17

Uncertainty Models 51011(4B), 51011-EMC, 51012(4C),

51013(4E), 51015(5E), 51033(6E)

3-1 Diode & Thermocouple Power Sensor Calibration Factor 18

Uncertainty (con't.) Models 51071, 51072, 51075, 51077,

51078, 51079

3-1 Diode & Thermocouple Power Sensor Calibration Factor 19

Uncertainty (con't.) Models 51071A, 51072A, 51075A,

51077A, 51078A, 51079A

ii Power Sensor Manual

Page 5

Tables (con't.)

Table Page

3-1 Diode & Thermocouple Power Sensor Calibration Factor 20

Uncertainty (con't.) Models 51085, 51086, 51087

3-1 Diode & Thermocouple Power Sensor Calibration Factor 21

Uncertainty (con't.) Models 51081, 51100(9E), 51101,

51102, 51200, 51201

3-1 Diode & Thermocouple Power Sensor Calibration Factor 22

Uncertainty (con't.) Models 51300, 51301, 51082

3-2 Peak Power Sensor Calibration Factor Uncertainty 23

Models 56218, 56226, 56318, 56326, 56340, 56418

3-2 Peak Power Sensor Calibration Factor Uncertainty (con't.) 24

Models 56518, 56526, 56540, 56006, 57006

3-2 Peak Power Sensor Calibration Factor Uncertainty (con't.) 25

Models 57318, 57340, 57518, 57540, 58318, 59318

3-2 Peak Power Sensor Calibration Factor Uncertainty (con't.) 26

Model 59340

3-3 Waveguide Sensor Calibration Factor Uncertainty 27

Models 51035(4K), 51036(4KA), 51037(4Q), 51045(4U),

51046(4V), 51047(4W), 51942(WRD-180)

Power Sensor Manual iii

Page 6

Introduction

1-1 Overview

1-2 Sensor T rade-offs

1

The overall performance of a power meter is dependent upon the sensor employed.

Boonton Electronics (Boonton) has addressed this by providing quality power sensors

to meet virtually all applications. Boonton offers a family of sensors with frequency

ranges spanning 10 kHz to 100 GHz and sensitivity from 0.1 nW (-70 dBm) to 25 W (+44

dBm). A choice of Diode or Thermocouple Sensors with 50 or 75 ohms impedances in

Coaxial or W aveguide styles are available.

Both the Thermocouple and Diode Sensors offer unique advantages and limitations.

Thermocouple Sensors measure true RMS power over a dynamic range from 1.0 µW (-30

dBm) to 100 mW (+20 dBm), and therefore, are less sensitive to non-sinusoidal signals

and those signals with high harmonic content. The Thermocouple Sensors also provide

advantages when making pulsed RF measurements with extremely high crest factors.

While the headroom (the difference between the rated maximum input power and burnout

level) for CW (continuous wave) measurements is only a few dB (decibels), Thermocouple

Sensors are very rugged in terms of short duration overload. For example, a sensor that

operates up to 100 mW average power (CW) can handle pulses up to 15 watts for

approximately two microseconds. One of the major limitations to the Thermocouple

Sensor is on the low-end sensitivity. Low-end sensitivity of these sensors is limited by

the efficiency of the thermal conversion. For this reason, the Diode Sensor is used for

requirements below 10 µW (-20 dBm).

CW Diode Sensors provide the best available sensitivity , typically down to 0.1 nW (70 dBm). Boonton Diode Sensors are constructed using balanced diode detectors. The

dual diode configuration offers increased sensitivity as well as harmonic suppression

when compared to a single diode sensor. The only significant drawback to Diode

Sensors is that above the level of approximately 10 µW (-20 dBm), the diodes begin to

deviate substantially from square-law detection. In this region of 10 µW (-20 dBm) to

100 mW (20 dBm), peak detection is predominant and the measurement error due to the

presence of signal harmonics is increased.

The square-law response can be seen in Figure 1-1, where a 100% amplitude modulated

signal is shown to have virtually no effect on the measured power at low levels. Of

course, frequency modulated and phase modulated signals can be measured at any

level, since the envelope of these modulated signals is flat. Frequency shift keyed and

quadrature modulated signals also have flat envelopes and can be measured at any

power level.

Power Sensor Manual 1

Page 7

This non-square-law region may be "shaped" with meter corrections, but only for one

defined waveform, such as a CW signal. By incorporating "shaping", also referred to as

"Linearity Calibration", Boonton offers a dynamic range from 0.1 nW (-70 dBm) to 100

mW (+20 dB) with a single sensor module. For CW measurements, the entire 90 dB

range can be used, however, when dealing with non-sinusoidal and high-harmonic

content signals, the Diode Sensor should be operated only within its square-law region

(10 µW and below).

Although thermal sensors provide a true indication of RMS power for modulated (nonCW) signals, they are of limited use for characterizing the short-term or instantaneous

RF power due to their rather slow response speed. For accurate power measurements of

short pulses or digitally modulated carriers, Boonton has developed a line of wideband

diode sensors called Peak Power Sensors. These sensors are specially designed for

applications where the instantaneous power of an RF signal must be measured with

high accuracy . They are for use with the Boonton Model 4400 peak Power Meter and

the Model 4500 Digital Sampling Power Analyzer. Because the bandwidth of Peak

Power Sensors is higher than most modulated signals (30 MHz or more for some sensor

models), they accurately respond to the instantaneous power envelope of the RF signal,

and the output of the sensor may be fully linearized for any type of signal, whether CW

or modulated. Boonton Peak Power Sensors contain built-in nonvolatile memory that

stores sensor information and frequency correction factors. The linearity correction

factors are automatically generated by the instrument's built-in programmable calibrator.

With the high sensor bandwidth, and frequency and linearity correction applied

continuously by the instrument, it is possible to make many types of measurements on

an RF signal; average (CW) power, peak power , dynamic range, pulse timing, waveform

viewing, and calculation of statistical power distribution functions.

0.9

0.8

0.7

0.6

0.5

0.4

Error (dB)

0.3

0.2

0.1

Square-Law

Region

-30 -20 -10 0 +10 +20

100% AM Modulation

Peak Detecting

Region

10% AM Modulation

3% AM Modulation

Carrier Level

(dBm)

Note: The error shown is the error above and beyond the

normal power increase that results from modulation.

Figure 1-1. Error Due to AM Modulation (Diode Sensor)

2 Power Sensor Manual

Page 8

1-3 Calibration and Traceability

Boonton employs both a linearity calibration as well as a frequency response calibration.

This maximizes the performance of Diode Sensors and corrects the non-linearity on all

ranges.

Linearity calibration can be used to extend the operating range of a Diode Sensor. It can

also be used to correct non-linearity throughout a sensor's dynamic range, either

Thermocouple or Diode. A unique traceability benefit offered is the use of the 30 MHz

working standard. This is used to perform the linearization. This standard is directly

traceable to the 30 MHz piston attenuator maintained at the National Institute of

Standards T echnology (NIST). Refer to Figure 1-2. Linearity T raceability .

NIST

Microcalorimeter

0 dBm

Test Set

30 MHz Working

Standard

Linearity Calibration

Meter & Sensor

Piston Attenuator

Figure 1-2. Linearity Traceability

NIST

Fixed

Attenuators

Power Sensor Manual 3

Page 9

Power sensors have response variations (with respect to the reference frequency) at

high frequencies. Calibration factors ranging from ± 3 dB are entered into the

instrument memories at the desired frequencies. Generally, calibration factors are

within ±0.5 dB. These calibration factors must be traceable to the National Institute

of Standards Technology (NIST) to be meaningful. This is accomplished by sending

a standard power sensor (Thermocouple type) to NIST or a certified calibration house

and comparing this standard sensor against each production sensor. The predominant

error term is the uncertainty of the reference sensor, which is typically 2% to 6%,

depending on the frequency. Refer to Figure 1-3. Calibration Factor Traceability.

NIST

Golden Gate

Calibration Labs

Network Analyzer

Calibration Factors &

Figure 1-3. Calibration Factor Traceability

Standard

Sensors

Scalar

Sensor

SWR

4 Power Sensor Manual

Page 10

Power Sensor Characteristics

The power sensor has three primary functions. First the sensor converts the incident

RF or microwave power to an equivalent voltage that can be processed by the power

meter. The sensor must also present to the incident power an impedance which is

closely matched to the transmission system. Finally, the sensor must introduce the

smallest drift and noise possible so as not to disturb the measurement.

Table 2-1 lists the characteristics of the latest line of Continuous Wave (CW) sensors

offered by Boonton. The latest Peak Power sensor characteristics are outlined in Table

2-2. This data should be referenced for all new system requirements.

Table 2-1. Diode and Thermal CW Sensor Characteristics

Model

Impedance Peak Power Drift (typ.)

RF Connector CW Power Frequency SWR 1 Hour RMS

Frequency

Range

Dynamic

Range

(dBm) (GHz) (typical)

(1)

Overload

Rating

WIDE DYNAMIC RANGE DUAL DIODE SENSORS

Maximum SWR Drift and Noise

@ 0 dBm Lowest Range

2

Noise

2 σ

51075 500 kHz -70 to +20 1 W for 1µs to 2 1.15 100 pW 30 pW 60 pW

50 Ω

N(M) to 18 1.40

51077 500 kHz -60 to +30 10 W for 1µs to 4 1.15 2 nW 300 pW 600 pW

50 Ω

GPC-N(M) to 12 1.25

51079 500 kHz -50 to +40 100 W for 1µs to 8 1.20 20 nW 3 nW 6 nW

50 Ω

GPC-N(M) to 18 1.35

51071 10 MHz -70 to +20 1 W for 1µs to 2 1.15 100 pW 30 pW 60 pW

50 Ω

K(M) to 18 1.45

51072 30 MHz -70 to +20 1 W for 1µs to 4 1.25 100 pW 30 pW 60 pW

50 Ω

K(M) to 40 2.00

to 18 GHz

to 18 GHz

to 18 GHz

to 26.5 GHz

to 40 GHz

(2)

(3)

(4)

(2)

(2)

300 mW to 6 1.20

3 W to 8 1.20

to 18 1.35

25 W to 12 1.25

300 mW to 4 1.20

to 26.5 1.50

300 mW to 38 1.65

(6)

(7)

(7)

(7)

(7)

Power Sensor Manual 5

Page 11

5107xA Series of RF Sensors

The “A” series sensors were created to improve production calibration results. These

sensors possess the same customer specifications as the non-A types (i.e.: 51075 and

51075A), however, the utilization of new calibration methods enhances the testing

performance over previous techniques. In doing this, Boonton can provide the customer

with a better product with a higher degree of confidence.

The “A” series sensors utilize “Smart Shaping” technology to characterize the linearity

transfer function. This is accomplished by performing a step calibration to determine the

sensors response to level variations. The shaping characteristics are determined during

the calibration and then the coefficients are stored in the data adapter that is supplied with

the sensor. This provides improved linearity results when used with the 4230A and 5230

line of instruments with software version 5.04 (or later).

Instruments that are equipped with step calibrators such as the 4530 already perform this

function when the Auto Cal process is performed. For these instruments an “A” type

sensor performs the same as a non-“A” type and no discernable difference is realized.

Table 2-1. Diode and Thermal CW Sensor Characteristics (con't.)

Model

Impedance Peak Power Drift (typ.)

RF Connector CW Power Frequency SWR 1 Hour RMS

Frequency

Range

Dynamic

Range

(dBm) (GHz) (typical)

(1)

Overload

Rating

WIDE DYNAMIC RANGE DUAL DIODE SENSORS

Maximum SWR Drift and Noise

@ 0 dBm Lowest Range

Noise

2 σ

51075A 500 kHz -70 to +20 1 W for 1µs to 2 1.15 100 pW 30 pW 60 pW

50 Ω

N(M) to 18 1.40

51077A 500 kHz -60 to +30 10 W for 1µs to 4 1.15 2 nW 300 pW 600 pW

50 Ω

GPC-N(M) to 12 1.25

51079A 500 kHz -50 to +40 100 W for 1µs to 8 1.20 20 nW 3 nW 6 nW

50 Ω

GPC-N(M) to 18 1.35

51071A 10 MHz -70 to +20 1 W for 1µs to 2 1.15 100 pW 30 pW 60 pW

50 Ω

K(M) to 18 1.45

51072A 30 MHz -70 to +20 1 W for 1µs to 4 1.25 100 pW 30 pW 60 pW

50 Ω

K(M) to 40 2.00

to 18 GHz

to 18 GHz

to 18 GHz

to 26.5 GHz

to 40 GHz

(2)

(3)

(4)

(2)

(2)

300 mW to 6 1.20

3 W to 8 1.20

to 18 1.35

25 W to 12 1.25

300 mW to 4 1.20

to 26.5 1.50

300 mW to 38 1.65

(6)

(7)

(7)

(7)

(7)

6 Power Sensor Manual

Page 12

Table 2-1. Diode and Thermal CW Sensor Characteristics (con't.)

Model

Frequency

Range

Dynamic

Range

(1)

Overload

Rating

Impedance Peak Power Drift (typ.)

RF Connector CW Power Frequency SWR 1 Hour RMS

(dBm) (GHz) (typical)

WIDE DYNAMIC RANGE DUAL DIODE SENSORS

Maximum SWR Drift and Noise

@ 0 dBm Lowest Range

Noise

2 σ

51085 500 kHz -30 to +20 1kW for 5µs to 4 1.15 2 uW 500 nW 1 uW

50 Ω

N(M)

to 18 GHz

(2)

5W to 12.4 1.20

(see notes below)

to 18 1.25

(7,10)

51086 0.05 GHz -30 to +20 1 W for 1µs to 18 1.30 2 uW 300 nW 600 nW

50 Ω

K(M)

to 26.5 GHz

(2)

2W to 26.5 1.35

(see notes below)

(7,10)

51087 0.05 GHz -30 to +20 1 W for 1µs to 18 1.30 2 uW 300 nW 600 nW

50 Ω

K(M)

to 40 GHz

(2)

2W to 26.5 1.35

(see notes below)

to 40 1.40

(7,10)

NOTES: For 51085 Peak Power - 1kW peak, 5µs pulse width, 0.25% duty cycle.

For 51085 CW Power - 5W (+37dBm) average to 25°C ambient temperature, derated linearly to 2W (+33dBm) at 85°C.

For 51086 CW Power - 2W (+33dBm) average to 20°C ambient temperature, derated linearly to 1W (+30dBm) at 85°C.

For 51087 CW Power - 2W (+33dBm) average to 20°C ambient temperature, derated linearly to 1W (+30dBm) at 85°C.

Power Sensor Manual 7

Page 13

Table 2-1. Diode and Thermal CW Sensor Characteristics (con't.)

Model

Frequency

Range

Dynamic

(1)

Range

Overload

Rating

Maximum SWR

@ 0 dBm Lowest Range

Impedance Peak Power Drift (typ.) Noise

RF Connector CW Power Frequency SWR 1 Hour RMS 2 σ

(dBm) (GHz) (typical)

THERMOCOUPLE SENSORS

Drift and Noise

51100 (9E) 10 MHz -20 to +20 15 W to 0.03 1.25 200 nW 100 nW 200 nW

50 Ω

N(M)

to 18 GHz

(2)

300 mW to 16 1.18

(8)

to 18 1.28

(5)

51101 100 kHz -20 to +20 15 W to 0.3 1.70 200 nW 100 nW 200 nW

50 Ω

N(M)

to 4.2 GHz

(2)

300 mW to 2 1.35

(8)

to 4.2 1.60

(5)

51102 30 MHz -20 to +20 15 W to 2 1.35 200 nW 100 nW 200 nW

50 Ω

K(M)

to 26.5 GHz

(2)

300 mW to 18 1.40

(8)

to 26.5 1.60

(5)

51200 10 MHz 0 to +37 150 W to 2 1.10 20 µW 10 µW 20 µW

50 Ω

N(M)

to 18 GHz

(2)

10 W to 12.4 1.18

(9)

to 18 1.28

(5)

51201 100 kHz 0 to +37 150 W to 2 1.10 20 µW 10 µW 20 µW

50 Ω

N(M)

to 4.2 GHz

(2)

10 W to 4.2 1.18

(9)

(5)

51300 10 MHz 0 to +44 150 W to 2 1.10 50 µW 25 µW 50 µW

50 Ω

N(M)

to 18 GHz

(2)

50 W to 12.4 1.18

(9)

to 18 1.28

(5)

51301 100 kHz 0 to +44 150 W to 2 1.10 50 µW 25 µW 50 µW

50 Ω

N(M)

to 4.2 GHz

(2)

50 W to 4.2 1.18

(9)

(5)

NOTES: 1) Models 4731, 4732, 4231A, 4232A, 4300, 4531, 4532, 5231, 5232, 5731, 5732

2) Power Linearity Uncertainty at 50 MHz:

<10 dBm: 1% (0.04dB) for 51071, 51072, 51075, 51085, 51086 and 51087 sensors.

10 to 17 dBm: 3% (0.13 dB) for 51071, 51072 and 51075 sensors.

17 to 20 dBm: 6% (0.25 dB) for 51071, 51072 and 51075 sensors.

10 to 20 dBm: 6% (0.25 dB) for 51085, 51086 and 51087 sensors.

30 to 37 dBm: 3% (0.13 dB) for 51078 sensor.

all levels: 1% (0.04dB) for 51100, 51101, 51102, 51200, 51201, 51300 and 51301 sensors.

3) Power Linearity Uncertainty 30/50 MHz for 51077 sensor.

-50 to +20 dBm: 1% (0.04 dB) +20 to +30 dBm: 6% (0.27 dB)

4) Power Linearity Uncertainty 30/50 MHz for 51079 sensor.

-40 to +30 dBm: 1% (0.04 dB) +30 to +40 dBm: 6% (0.25 dB)

5) Temperature influence: 0.01 dB/ºC (0 to 55ºC)

6) Temperature influence: 0.02 dB/ºC ( 0 to 25ºC), 0.01 dB/ºC (25 to 55ºC)

7) Temperature influence: 0.03 dB/ºC (0 to 55ºC)

8) Thermocouple characteristics at 25ºC: Max pulse energy = 30 W µsec/pulse

9) Thermocouple characteristics at 25ºC: Max pulse energy = 300 W µsec/pulse

10) After 2 hour warm-up.

8 Power Sensor Manual

Page 14

Table 2-2. Peak Power Sensor Characteristics

Model

Impedance

Frequency Power Overload

Range Measurement Rating

Peak Fast Slow

(1)

CW

Peak Power High Low Frequency SWR Peak Power

Rise Time

RF Connector Int. Trigger CW Power Bandwidth Bandwidth CW Power

(GHz) (dBm) (ns) (ns) (GHz)

DUAL DIODE PEAK POWER SENSORS

Sensors below are for use with 4400, 4500, 4400A and 4500A RF Peak Power Meters and

4530 Series RF Power Meter when combined with Model 2530 1 GHz calibrator accessory.

56218 0.03 to 18 -24 to 20 1W for 1us < 150 < 500 to 2 1.15 4 uW

50 Ω

N(M) -10 to 20 to 18 1.25

56318 0.5 to 18 -24 to 20 1W for 1 us

50 Ω

N(M) -10 to 20 to 18 1.34

56326 0.5 to 26.5 -24 to 20 1W for 1 us

50 Ω

K(M) -10 to 20 to 18 1.45

-34 to 20 200 mW (3 MHz) (700 kHz) to 6 1.20 0.4 uW

(3)

(2)

< 15

< 200 to 2 1.15 4 uW

-34 to 20 200 mW (35 MHz) (1.75 MHz) to 16 1.28 0.4 uW

(3)

(2)

< 15

< 200 to 2 1.15 4 uW

-34 to 20 200 mW (35 MHz) (1.75 MHz) to 4 1.20 0.4 uW

(3)

Maximum SWR

@ 0 dBm

to 26.5 1.50

Drift & Noise

56418 0.5 to 18 -34 to 5 1W for 1 us < 30 < 100 to 2 1.15 400 nW

50 Ω

-40 to 5 200 mW (15 MHz) (6 MHz) to 6 1.20 100 nW

N(M) -18 to 5 to 16 1.28

(3)

to 18 1.34

56518 0.5 to 18 -40 to 20 1W for 1 us < 100 < 300 to 2 1.15 400 nW

50 Ω

-50 to 20 200 mW (6 MHz) (1.16 MHz) to 6 1.20 100 nW

N(M) -27 to 20 to 16 1.28

(4)

to 18 1.34

NOTES: 1) Models 4400, 4500, 4400A and 4500A only.

2) Models 4531 and 4532: <20ns, (20MHz).

3) Shaping Error (Linearity Uncertainty), all levels 2.3%

4) Shaping Error (Linearity Uncertainty), all levels 4.0%

Power Sensor Manual 9

Page 15

Table 2-2. Peak Power Sensor Characteristics (con't.)

(2)

(2)

y

p

,

p

p

g

g

Model

Impedance

RF Connector Int. Trigger CW Power Bandwidth Bandwidth CW Power

Frequency Power Overload

Range Measurement Rating

Peak Fast Slow

(1)

CW

(GHz) (dBm) (ns) (ns) (GHz)

Peak Power High Low Frequency SWR Peak Power

Rise Time

DUAL DIODE PEAK POWER SENSORS

Sensors below are for use with 4400, 4500, 4400A, 4500A and 4530.

Compatible with 4530 Series internal 50 MHz calibrator.

Maximum SWR

@ 0 dBm

Drift & Noise

57318 0.5 to 18 -24 to 20 1W for 1 us

50 Ω

N(M) -10 to 20 to 18 1.34

57340 0.1 to 40 -24 to 20 1W for 1 us

50 Ω

K(M) -10 to 20 to 40 2.00

57518 0.1 to 18 -40 to 20 1W for 1 us < 100 < 10 us to 2 1.15 50 nW

50 Ω

N(M) -27 to 20 to 16 1.28

57540 0.1 to 40 -40 to 20 1W for 1 us < 100 < 10 us to 4 1.25 50 nW

50 Ω

K(M) -27 to 20 to 40 2.00

NOTES: 1) Models 4400, 4500, 4400A and 4500A only.

(0.05 to 18) -34 to 20 200 mW (35 MHz) (350 kHz) to 16 1.28 0.4 uW

(3)

(0.03 to 40) -34 to 20 200 mW (35 MHz) (350 kHz) to 38 1.65 0.4 uW

(3)

(0.05 to 18) -50 to 20 200 mW (6 MHz) (350 kHz) to 6 1.20 5 nW

(4)

(0.05 to 40) -50 to 20 200 mW (6 MHz) (350 kHz) to 38 1.65 5 nW

(5)

2) Models 4531 and 4532: <20ns, (20MHz).

3) Shaping Error (Linearity Uncertainty), all levels 2.3%

4) Shaping Error (Linearity Uncertainty), all levels 4.0%

5) Shaping Error (Linearity Uncertainty), all levels 4.7%

< 15

< 15

< 10 us to 2 1.15 4 uW

< 10 us to 4 1.25 4 uW

to 18 1.34

Frequency calibration factors (NIST traceable) and other data are stored within

all the Peak Power Sensors. Linearit

calibrator of the

MODELS 4400

eak power meter.

4500, 4400A and 4500A:

calibration is performed by the built-in

All Peak Power sensors can be used with these models and calibrated with the

internal 1GHz ste

calibrator unless otherwise noted.

MODELS 4531 and 4532:

The Peak Power sensors in the lower group above may be used with these models

and calibrated with the internal 50 MHz ste

calibrator. The sensors on the upper

roup may be used if the Model 2530 1 GHz Accessory Calibrator is used for

calibration.

A five-foot lon

sensor cable is standard. Longer cables are available at a higher

cost. Effective bandwidth is reduced with longer cables.

10 Power Sensor Manual

Page 16

Table 2-2. Peak Power Sensor Characteristics (con't.)

Model

Frequency Power Overload

Range Measurement Rating

Rise Time

Peak Fast Slow

Impedance High BW CW Peak Power High Low Frequency SWR Peak Power

RF Connector Low BW Int. Trigger CW Power Bandwidth Bandwidth CW Power

(GHz) (dBm) (ns) (ns) (GHz)

DUAL DIODE PEAK POWER SENSORS

Sensors below are for use with model 4500B ONLY.

58318 0.5 to 18 -24 to 20 1W for 1 us < 10 na to 2 1.15 4 uW

50 Ω

N(M) -10 to 20 to 18 1.34

Sensors below are for use with models 4500B, 4540 or 4540 w/ 1 GHz calibrator model 2530

59318 0.5 to 18 -24 to 20 1W for 1 us < 10 < 10000 to 2 1.15 4 uW

50 Ω

0.05 to 18 -34 to 20 200 mW (@ 0 dBm) (@ 0 dBm) to 16 1.28 0.4 uW

N(M) -10 to 20 to 18 1.34

59340 0.5 to 40 -24 to 20 1W for 1 us < 10 > 1000 to 4 1.25 4 uW

50 Ω

0.05 to 40 -34 to 20 200 mW (@ 0 dBm) (@ 0 dBm) to 38 1.65 0.4 uW

K(M) -10 to 20 to 40 2.00

-34 to 20 200 mW (@ 0 dBm) to 16 1.28 0.4 uW

(6) (7)

(6) (7)

(6) (7)

Maximum SWR

@ 0 dBm

Drift & Noise

PEAK POWER SENSOR

Sensors below are for use with model 4500B ONLY.

56006 0.5 to 6 -50 to 20 1W for 1 us < 7 na to 6 1.25 10 nW

50 Ω

N(M) -39.9 to 20

Sensors below are for use with models 4500B, 4540 or 4540 w/ 1 GHz calibrator model 2530

57006 0.5 to 6 -50 to 20 1W for 1 us < 7 < 10000 to 6 1.25 10 nW

50 Ω

N(M) -39.9 to 20

NOTES: 6) Shaping Error (Linearity Uncertainty), all levels 2.3%

7) 30 ns minimum Internal Trigger pulse width.

8) Shaping Error (Linearity Uncertainty), all levels 2.3%

9) Minimum Internal Trigger pulse width to be determined.

-60 to 20 200 mW (@ 0 dBm) 1 nW

(8) (9)

-60 to 20 200 mW (@ 0 dBm) (@ 0 dBm) 1 nW

(8) (9)

Power Sensor Manual 11

Page 17

Sensor characteristics of Boonton legacy sensors are presented in tables 2-3 (CW)

and 2-4 (Waveguide). This data is presented for reference only. Contact the sales

department for availability.

Table 2-3. Legacy Diode CW Sensor Characteristics

Model

Impedance

RF Connector CW Power Frequency SWR 1 Hour RMS

Frequency

Range

Dynamic

Range

(1) (3)

(dBm) (GHz)

Overload

Rating

Peak Power Drift (typ.)

DUAL DIODE SENSORS

Maximum SWR Drift and Noise

@ 0 dBm Lowest Range

(2) (5)

(typical)

Noise

2 σ

51011 (EMC)

50 Ω

N(M) to 8 1.40

51011 (4B)

50 Ω

N(M) to 11 1.40

51012 (4C)

75 Ω

N(M)

51012-S/4 100 kHz -60 to +20 1 W for 1µs to 2 1.18 150 pW 65 pW 130 pW

75 Ω

N(M)

51013 (4E)

50 Ω

N(M) to 18 1.70

51015 (5E)

50 Ω

N(M) to 4 1.12

10 kHz -60 to +20 1 W for 1µs to 2 1.12 150 pW 65 pW 130 pW

to 8 GHz 300 mW to 4 1.20

100 kHz -60 to +20 1 W for 1µs to 2 1.12 150 pW 65 pW 130 pW

to 12.4 GHz 300 mW to 4 1.20

to 12.4 1.60

100 kHz -60 to +20 1 W for 1µs to 1 1.18 150 pW 65 pW 130 pW

to 1 GHz 300 mW

to 2 GHz 300 mW

100 kHz -60 to +20 1 W for 1µs to 4 1.30 150 pW 65 pW 130 pW

to 18 GHz 300 mW to 10 1.50

100 kHz -50 to +30 10 W for 1µs to 1 1.07 1.5 nW 0.65 nW 1.3 nW

to 18 GHz 2 W to 2 1.10

to 12.4 1.18

to 18 1.28

51033 (6E)

50 Ω

N(M) to 4 1.12

100 kHz -40 to +33 100 W for 1µs to 1 1.07 15 nW 6.5 nW 13 nW

to 18 GHz 2 W to 2 1.10

to 12.4 1.18

to 18 1.28

12 Power Sensor Manual

Page 18

Table 2-3. Legacy Diode CW Sensor Characteristics (con't.)

Model

Impedance

Frequency

Range

Dynamic

Range

(1)

Overload

Rating

Peak Power Drift (typ.)

RF Connector CW Power Frequency SWR 1 Hour RMS

(dBm) (GHz)

DUAL DIODE SENSORS

Maximum SWR Drift and Noise

@ 0 dBm

(2)

Lowest Range

(typical)

Noise

2 σ

51078 100 kHz -20 to +37 100 W for 1µs to 4 1.15 150 nW 65 nW 130 nW

50 Ω

to 18 GHz

(3) (8)

7 W to 12 1.25

(6)

N(M) to 18 1.40

DC COUPLED SINGLE DIODE SENSORS

51081 1 MHz -30 to +10 200 mW to 0.5 1.04 200 pW 200 pW 400 pW

50 Ω

to 40 GHz

k(M)

51082 40 GHz -30 to +10 200 mW 50 MHz (ref.) 1.04 200 pW 200 pW 400 pW

50 Ω

to 50 GHz

V(M)

NOTES: 1) Applies to all Boonton Power Meters unless otherwise indicated with the exception of Model 4200 and 4200A.

The lower limit of the Dynamic Range for Models 4200 and 4200A does not extend below -60 dBm and the

upper limit is degraded by 10 dB with the exception of sensor Model 51033 where the Dynamic range is -40 to +30 dBm.

2) After two-hour warm-up: High frequency power linearity uncertainty: (worst case) (0.005 x f) dB per dB,

where f is in GHz above +4 dBm for sensors 51011, 51012, 51013 ; above +14 dBm for sensor 51015;

above +24 dBm for sensor 51033

3) Power Linearity Uncertainty at 50 MHz:

<10 dBm: 1% for 51011, 51012, 51013, 51015, and 51033 sensors.

10 to 20 dBm: 1% for 51015 and 51033 sensors; 3% for 51011, 51012 and 51013 sensors.

20 to 33 dBm: 3% for 51015 and 51033 sensors.

30 to 37 dBm: 3% for 51078 sensor.

4) Power Linearity Uncertainty 30/50 MHz. -30 to -10 dBm: 6% (0.27 dB), -10 to +10 dBm: 4% (0.18 dB)

5) Temperature influence: 0.02 dB/ºC ( 0 to 25ºC), 0.01 dB/ºC (25 to 55ºC)

6) Temperature influence: 0.03 dB/ºC (0 to 55ºC)

7) Temperature influence: -30 to -10 dBm: 0.03 dB/ºC, -10 to +10 dBm: 0.01 dB/ºC (0 to 55ºC)

8) Not available on 4200 series.

(4)

(4)

to 40 2.00

40 to 50 2.20

(7)

(7)

Power Sensor Manual 13

Page 19

Table 2-4. Legacy Waveguide Sensor Characteristics

Model

Impedance (Ref. Freq.)

RF Connector CW Power Frequency SWR

Frequency

Range

Dynamic

Range

(2)

(dBm) (GHz) (/hr) (typical)

Overload

Rating

WAVEGUIDE SENSORS

Maximum SWR Drift and Noise

@ 0 dBm Lowest Range

Drift

after 2 hr.

RMS

Noise

2 σ

51035 (4K)

WR-42 to 26.5 GHz

UG-595/U

51036 (4KA)

WR-28 to 40 GHz

UG-599/U

51037 (4Q)

WR-22 to 50 GHz

UG-383/U

51045 (4U)

WR-19 to 60 GHz

UG-383/U

51046 (4V)

WR-15 to 75 GHz

UG-385/U

51047 (4W)

WR-10 to 100 GHz

UG-387/U

18 GHz -50 to +10 100 mW 18 to 26.5 1.45 200 pW 60 pW 120 pW

26.5 GHz -50 to +10 100 mW 26.5 to 40 1.45 60 pW 15 pW 30 pW

33 GHz -50 to +10 100 mW 33 to 50 1.45 60 pW 15 pW 30 pW

40 GHz -50 to +10 100 mW 40 to 60 1.45 60 pW 15 pW 30 pW

50 GHz -50 to +10 100 mW 50 to 75 1.45 60 pW 15 pW 30 pW

75 GHz -45 to +10 100 mW 75 to 100 1.45 60 pW 15 pW 30 pW

(1)

(1)

51136 (4Ka)

WR-28 to 40 GHz

(UG-599/U) (33 GHz)

51236 (4Ka)

WR-28 to 40 GHz

(UG-599/U) (33 GHz)

51137 (4Q)

WR-22 to 50 GHz

(UG-383/U) (40 GHz)

51237 (4Q)

WR-22 to 50 GHz

(UG-383/U) (40 GHz)

26.5 -40 to +10 50 mW 26.5 to 40 1.45 100 pW 60 pW 120 pW

26.5 -50 to +10 50 mW 26.5 to 40 1.45 60 pW 15 pW 30 pW

33 -40 to +10 50 mW 33 to 50 1.45 60 pW 15 pW 30 pW

33 -50 to +10 50 mW 33 to 50 1.45 60 pW 15 pW 30 pW

14 Power Sensor Manual

Page 20

Table 2-4. Legacy Waveguide Sensor Characteristics (con't.)

Model

Impedance (Ref. Freq.)

RF Connector CW Power Frequency SWR

Frequency

Range

Dynamic

Range

(2)

(dBm) (GHz) (/hr) (typical)

Overload

Rating

Maximum SWR

@ 0 dBm

Drift

after 2 hr.

WAVEGUIDE SENSORS

51145 (4U) 40 -40 50 mW 40 to 60 1.45 60 pW 15 pW 30 pW

WR-19 to 60 GHz to +10 dBm

(UG-383/U) (50 GHz)

51245 (4U) 40 -50 50 mW 40 to 60 1.45 60 pW 15 pW 30 pW

WR-19 to 60 GHz to +10 dBm

(UG-383/U) (50 GHz)

51146 (4V) 50 -40 50 mW 50 to 75 1.45 60 pW 15 pW 30 pW

WR-15 to 75 GHz to +10 dBm

(UG-385/U) (60 GHz)

51246 (4V) 50 -50 50 mW 50 to 75 1.45 60 pW 15 pW 30 pW

WR-15 to 75 GHz to +10 dBm

(UG-385/U) (60 GHz)

Drift and Noise

Lowest Range

Noise

RMS

2 σ

51147 (4V) 75 -40 50 mW 75 to 100 1.45 60 pW 15 pW 30 pW

WR-10 to 100 GHz to +10 dBm

(UG-387/U) (94 GHz)

51247 (4V) 75 -50 50 mW 75 to 100 1.45 60 pW 15 pW 30 pW

WR-10 to 100 GHz to +10 dBm

(UG-387/U) (94 GHz)

NOTES: 1) -40 to +10 dBm Dynamic Range if used with Model 4200A.

2) Uncertainties:

a) Power Linearity Uncertainty at Reference Frequency: +/- 0.5 dB

b) Cal Factor Uncertainty: +/- 0.6 dB

c) Additional Linearity Uncertainty (referred to -10 dBm): +/- 0.01 dB/dB

Power Sensor Manual 15

Page 21

Sensor characteristics of Boonton legacy Peak Power Sensors are presented in

table 2-5. This data is presented for reference only. Contact the sales department

for availability.

Table 2-5. Legacy Peak Power Sensor Characteristics

Model

Impedance

Frequency Power Overload

Range Measurement Rating

Peak Fast Slow

(1)

CW

Peak Power High Low Frequency SWR Peak Power

Rise Time

RF Connector Int. Trigger CW Power Bandwidth Bandwidth CW Power

(GHz) (dBm) (ns) (ns) (GHz)

DUAL DIODE PEAK POWER SENSORS

Sensors below are for use with 4400, 4500, 4400A and 4500A RF Peak Power Meters and

4530 Series RF Power Meter when combined with Model 2530 1 GHz calibrator accessory.

56218-S2 0.03 to 26.5 -24 to 20 1W for 1 us < 150 < 500 to 2 1.15 4 uW

50 Ω

K(M) -10 to 20 to 18 1.25

56226 0.03 to 26.5 -24 to 20 1W for 1 us < 150 < 500 to 1 1.15 4 uW

50 Ω

K(M) -10 to 20 to 18 1.25

-34 to 20 200 mW (3 MHz) (700 kHz) to 6 1.20 0.4 uW

(3)

-34 to 20 200 mW (3 MHz) (700 kHz) to 6 1.20 0.4 uW

(3)

Maximum SWR

@ 0 dBm

to 26.5 1.50

to 26.5 1.50

Drift & Noise

(2)

56340 0.5 to 40 -24 to 20 1W for 1 us

50 Ω

-34 to 20 200 mW (35 MHz) (1.75 MHz) to 38 1.65 0.4 uW

< 15

< 200 to 4 1.25 4 uW

K(M) -10 to 20 to 40 2.00

(3)

56526 0.5 to 26.5 -40 to 20 1W for 1 us < 100 < 300 to 2 1.15 50 nW

50 Ω

-50 to 20 200 mW (6 MHz) (1.16 MHz) to 4 1.20 5 nW

K(M) -27 to 20 to 18 1.45

(4)

to 26.5 1.50

56540 0.5 to 40 -40 to 20 1W for 1 us < 100 < 300 to 4 1.25 50 nW

50 Ω

-50 to 20 200 mW (6 MHz) (1.16 MHz) to 38 1.65 5 nW

K(M) -27 to 20 to 40 2.00

(4)

NOTES: 1) Models 4400, 4500, 4400A and 4500A only.

2) Models 4531 and 4532: <20ns, (20MHz).

3) Shaping Error (Linearity Uncertainty), all levels 2.3%

4) Shaping Error (Linearity Uncertainty), all levels 4.7%

16 Power Sensor Manual

Page 22

Power Sensor Uncertainty Factors

The uncertainty factors, as a function of frequency for the Diode and Thermocouple,

Peak and Waveguide sensors, are listed in Tables 3-1, 3-2 and 3-3 respectively.

These values represent typical results based on factory test data unless otherwise noted.

The percent (%) column is the sum of all test system uncertainties including mismatch

uncertainties, the uncertainty of the standard sensor and transfer uncertainty which is

traceable to NIST ( National Institute of Standards Technology ). The probable

uncertainty ( % RSS ) is derived by the square root of the sum of the individual

uncertainties squared. % RSS is expressed with a coverage factor of 2 yielding a 95%

confidence level.

Table 3-1. Diode and Thermocouple Power Sensor Calibration Factor Uncertainty

Models 51011(4B), 51011-EMC, 51012(4C), 51013(4E), 51015(5E), 51033(6E)

3

Model

Freq

GHz % % RSS % % RSS % % RSS % % RSS % % RSS % % RSS

0.03 1.9 1.1 1.9 1.1 1.8 1.0 2.0 1.1 2.1 1.2 2.0 1.1

0.1 1.7 0.9 1.7 1.0

0.3 1.6 0.9

0.5 1.6 0.9 2.0 1.1

1 1.7 0.9 1.8 1.0 2.3 1.4 1.7 1.0 1.9 1.0 1.7 0.9

1.5 2.4 1.5

2 1.9 1.1 2.1 1.2 2.4 1.4 1.9 1.1 1.9 1.0 1.8 1.0

3 2.0 1.1 2.4 1.4 2.0 1.2 2.2 1.2 1.9 1.0

4 2.1 1.2 2.6 1.6 2.1 1.2 2.3 1.2 1.9 1.1

5 2.2 1.2 2.8 1.7 2.4 1.4 2.0 1.1 2.0 1.1

6 2.5 1.5 3.1 2.2 2.5 1.6 1.9 1.1 1.9 1.0

7 2.5 1.7 3.2 2.5 2.6 1.9 2.0 1.1 1.7 1.0

8 3.0 2.2 3.7 3.1 3.1 2.3 2.2 1.3 2.0 1.1

9 4.9 4.1 5.3 4.6 2.8 1.7 2.8 1.7

10 5.8 4.8 6.1 5.3 3.4 2.3 3.2 2.1

11 6.1 5.2 6.4 5.5 4.2 2.9 3.3 2.3

12 6.3 5.6 6.3 5.7 3.4 2.2 3.2 2.0

13 6.5 6.3 3.7 2.6 3.4 2.2

14 6.6 6.0 4.0 2.7 3.6 2.3

15 7.7 7.2 3.8 2.6 3.2 2.2

16 7.1 6.4 3.7 2.4 3.3 2.2

17 6.7 6.7 3.5 2.3 2.7 1.5

18 6.4 5.7 4.4 3.1 3.6 2.2

51011 51011-EMC 51012 51013 51015 51033

(4B) (EMC) (4C) (4E) (5E) (6E)

WIDE DYNAMIC RANGE DUAL DIODE SENSORS

(Alias)

Power Sensor Manual 17

Page 23

Table 3-1. Diode and Thermocouple Power Sensor Calibration Factor Uncertainty (con't.)

Models 51071, 51072, 51075, 51077, 51078, 51079

Freq

GHz % % RSS % % RSS % % RSS % % RSS % % RSS % % RSS

51071 51072 51075 51077 51078 51079

Model

WIDE DYNAMIC RANGE DUAL DIODE SENSORS

0.03 1.1 0.8 1.4 1.0 2.0 1.1 2.1 1.2 2.1 1.1 3.3 2.3

1 1.7 1.1 2.0 1.2 1.8 1.0 1.8 1.0 1.8 1.0 3.0 2.2

2 1.7 1.1 2.0 1.1 2.0 1.1 1.9 1.0 3.1 2.2

3 1.8 1.2 2.4 1.4 2.1 1.2 2.3 1.3 1.9 1.1 3.1 2.3

4 1.9 1.2 2.2 1.3 2.1 1.1 2.3 1.3 3.2 2.3

5 2.0 1.3 2.7 1.7 2.4 1.4 2.0 1.1 2.4 1.4 3.2 2.3

6 2.2 1.5 2.5 1.5 2.1 1.2 2.2 1.3 3.2 2.3

7 2.4 1.6 3.4 2.4 2.3 1.5 2.1 1.3 2.4 1.6 2.9 2.2

8 2.6 1.8 2.5 1.6 2.2 1.3 2.6 1.7 3.1 2.2

9 3.7 3.1 5.4 4.9 3.5 2.3 2.9 1.8 3.8 2.6 4.8 4.0

10 3.9 3.4 4.0 2.8 3.3 2.1 3.9 2.6 5.4 4.2

11 3.9 3.7 5.4 5.1 4.3 3.0 3.2 2.2 3.8 2.5 5.5 4.3

12 4.1 3.8 4.4 3.2 4.2 3.0 4.5 3.3 5.2 4.2

13 4.2 3.8 5.7 5.2 3.7 2.6 3.6 2.4 4.5 3.5 5.8 5.2

14 4.2 3.5 3.5 2.3 3.6 2.3 3.8 2.5 6.1 5.3

15 4.3 3.4 5.4 4.4 4.2 2.9 4.3 2.9 4.2 3.0 6.5 5.5

16 4.3 3.4 4.0 2.7 3.9 2.6 4.7 3.4 6.5 5.5

17 4.2 3.1 5.2 3.9 3.3 2.2 3.4 2.2 4.1 3.0 5.7 5.2

18 4.2 3.2 3.8 2.5 3.5 2.1 5.0 3.8 6.2 5.3

19 4.7 3.6 5.0 3.5

20 4.8 3.6

21 5.2 4.0 5.9 4.4

22 5.6 4.3

23 5.7 4.2 6.4 4.7

24 5.8 4.3

25 5.3 3.9 7.1 5.4

26 5.5 4.1

26.5 6.4 4.6

27 7.4 5.2

28 6.5 4.6

29 6.7 4.7

30 6.8 4.8

31 7.0 4.9

32 6.8 4.6

33 6.8 4.7

34 6.0 4.1

35 5.2 3.4

36 4.6 2.9

37 4.3 2.9

38 5.4 3.9

39 6.5 4.9

40 7.0 5.6

18 Power Sensor Manual

Page 24

Table 3-1. Diode and Thermocouple Power Sensor Calibration Factor Uncertainty (con't.)

Models 51071A, 51072A, 51075A, 51077A, 51078A, 51079A

Freq

GHz % % RSS % % RSS % % RSS % % RSS % % RSS % % RSS

51071A 51072A 51075A 51077A 51078A 51079A

Model

WIDE DYNAMIC RANGE DUAL DIODE SENSORS

0.03 1.1 0.8 1.4 1.0 2.0 1.1 2.1 1.2 2.1 1.1 3.3 2.3

1 1.7 1.1 2.0 1.2 1.8 1.0 1.8 1.0 1.8 1.0 3.0 2.2

2 1.7 1.1 2.0 1.1 2.0 1.1 1.9 1.0 3.1 2.2

3 1.8 1.2 2.4 1.4 2.1 1.2 2.3 1.3 1.9 1.1 3.1 2.3

4 1.9 1.2 2.2 1.3 2.1 1.1 2.3 1.3 3.2 2.3

5 2.0 1.3 2.7 1.7 2.4 1.4 2.0 1.1 2.4 1.4 3.2 2.3

6 2.2 1.5 2.5 1.5 2.1 1.2 2.2 1.3 3.2 2.3

7 2.4 1.6 3.4 2.4 2.3 1.5 2.1 1.3 2.4 1.6 2.9 2.2

8 2.6 1.8 2.5 1.6 2.2 1.3 2.6 1.7 3.1 2.2

9 3.7 3.1 5.4 4.9 3.5 2.3 2.9 1.8 3.8 2.6 4.8 4.0

10 3.9 3.4 4.0 2.8 3.3 2.1 3.9 2.6 5.4 4.2

11 3.9 3.7 5.4 5.1 4.3 3.0 3.2 2.2 3.8 2.5 5.5 4.3

12 4.1 3.8 4.4 3.2 4.2 3.0 4.5 3.3 5.2 4.2

13 4.2 3.8 5.7 5.2 3.7 2.6 3.6 2.4 4.5 3.5 5.8 5.2

14 4.2 3.5 3.5 2.3 3.6 2.3 3.8 2.5 6.1 5.3

15 4.3 3.4 5.4 4.4 4.2 2.9 4.3 2.9 4.2 3.0 6.5 5.5

16 4.3 3.4 4.0 2.7 3.9 2.6 4.7 3.4 6.5 5.5

17 4.2 3.1 5.2 3.9 3.3 2.2 3.4 2.2 4.1 3.0 5.7 5.2

18 4.2 3.2 3.8 2.5 3.5 2.1 5.0 3.8 6.2 5.3

19 4.7 3.6 5.0 3.5

20 4.8 3.6

21 5.2 4.0 5.9 4.4

22 5.6 4.3

23 5.7 4.2 6.4 4.7

24 5.8 4.3

25 5.3 3.9 7.1 5.4

26 5.5 4.1

26.5 6.4 4.6

27 7.4 5.2

28 6.5 4.6

29 6.7 4.7

30 6.8 4.8

31 7.0 4.9

32 6.8 4.6

33 6.8 4.7

34 6.0 4.1

35 5.2 3.4

36 4.6 2.9

37 4.3 2.9

38 5.4 3.9

39 6.5 4.9

40 7.0 5.6

Power Sensor Manual 19

Page 25

Table 3-1. Diode and Thermocouple Power Sensor Calibration Factor Uncertainty (con't.)

Models 51085, 51086, 51087

Freq

GHz % % RSS % % RSS % % RSS % % RSS % % RSS % % RSS

51085 51086 51087

Model

WIDE DYNAMIC RANGE DUAL DIODE SENSORS

0.03 2.0 1.1 1.1 0.8 1.4 1.0

1 1.8 1.0 1.7 1.1 2.0 1.2

2 2.0 1.1 1.7 1.1

3 2.1 1.2 1.8 1.2 2.4 1.4

4 2.2 1.3 1.9 1.2

5 2.4 1.4 2.0 1.3 2.7 1.7

6 2.5 1.5 2.2 1.5

7 2.3 1.5 2.4 1.6 3.4 2.4

8 2.5 1.6 2.6 1.8

9 3.5 2.3 3.7 3.1 5.4 4.9

10 4.0 2.8 3.9 3.4

11 4.3 3.0 3.9 3.7 5.4 5.1

12 4.4 3.2 4.1 3.8

13 3.7 2.6 4.2 3.8 5.7 5.2

14 3.5 2.3 4.2 3.5

15 4.2 2.9 4.3 3.4 5.4 4.4

16 4.0 2.7 4.3 3.4

17 3.3 2.2 4.2 3.1 5.2 3.9

18 3.8 2.5 4.2 3.2

19 4.7 3.6 5.0 3.5

20 4.8 3.6

21 5.2 4.0 5.9 4.4

22 5.6 4.3

23 5.7 4.2 6.4 4.7

24 5.8 4.3

25 5.3 3.9 7.1 5.4

26 5.5 4.1

26.5 6.4 4.6

27 7.4 5.2

28 6.5 4.6

29 6.7 4.7

30 6.8 4.8

31 7.0 4.9

32 6.8 4.6

33 6.8 4.7

34 6.0 4.1

35 5.2 3.4

36 4.6 2.9

37 4.3 2.9

38 5.4 3.9

39 6.5 4.9

40 7.0 5.6

20 Power Sensor Manual

Page 26

Table 3-1. Diode and Thermocouple Power Sensor Calibration Factor Uncertainty (con't.)

Models 51081, 51100(9E), 51101, 51102, 51200, 51201

Model

Freq

GHz % % RSS % % RSS % % RSS % % RSS % % RSS % % RSS

51081 51100 51101 51102 51200 51201

(9E)

(Alias)

DIODE AND THERMOCOUPLE SENSORS

0.03 1.4 0.9 2.4 1.3 2.0 1.1 1.4 1.1 2.5 1.4 2.6 1.5

1 2.1 1.2 1.7 0.9 1.8 1.0 1.6 1.1 1.7 1.0 2.3 1.4

2 1.8 1.0 2.0 1.1 1.6 1.1 1.9 1.0 2.4 1.4

3 2.2 1.3 1.9 1.0 2.4 1.4 1.6 1.1 1.9 1.0 3.0 2.1

4 2.3 1.3 2.6 1.6 1.6 1.1 2.3 1.3 3.1 2.1

5 2.2 1.3 2.3 1.3 1.7 1.1 2.3 1.3

6 2.3 1.3 1.7 1.1 2.3 1.3

7 2.6 1.5 2.3 1.4 1.7 1.1 2.3 1.5

8 2.6 1.6 1.8 1.1 2.6 1.6

9 3.1 2.0 3.3 2.1 1.9 1.2 3.2 2.0

10 3.5 2.3 1.9 1.2 3.5 2.3

11 3.3 2.4 3.8 2.6 2.0 1.4 3.8 2.5

12 3.3 2.1 2.3 1.6 3.4 2.2

13 3.8 2.9 3.1 1.9 2.6 1.8 3.2 2.1

14 3.6 2.4 2.8 1.9 3.6 2.4

15 4.9 3.9 3.8 2.6 2.7 1.7 3.8 2.6

16 4.2 2.8 2.6 1.6 4.1 2.8

17 5.7 4.5 3.4 2.2 3.6 2.4 3.4 2.2

18 4.4 3.1 4.5 3.4 4.1 2.8

19 6.5 5.4 5.2 4.1

20 4.9 3.7

21 7.2 6.1 4.3 3.0

22 4.6 3.3

23 7.2 5.7 4.8 3.4

24 5.6 4.0

25 7.0 5.3 6.1 4.6

26 6.4 4.8

26.5 6.7 4.7

27 8.9 6.6

28 8.1 6.3

29 8.2 6.4

30 8.3 6.5

31 8.8 7.2

32 9.3 7.7

33 10.0 8.4

34 9.7 8.6

35 9.4 8.4

36 9.1 8.7

37 8.4 8.3

38 8.5 8.1

39 9.0 8.2

40 8.6 7.7

Power Sensor Manual 21

Page 27

Table 3-1. Diode and Thermocouple Power Sensor Calibration Factor Uncertainty (con't.)

Models 51300, 51301, 51082

Freq

GHz % % RSS % % RSS GHz % % RSS

51300 51301 51082

Model

Freq

Model

THERMOCOUPLE DIODE

0.03 2.5 1.4 2.4 1.3 0.05 2.0 1.4

1 1.7 1.0 2.9 2.0 40 10.6 11.1

2 1.9 1.0 2.7 1.7 41 10.3 10.5

3 1.9 1.0 2.6 1.6 42 10.9 10.8

4 2.3 1.3 2.9 1.9 43 10.9 10.1

5 2.3 1.3 44 10.1 8.1

6 2.3 1.3 45 10.7 9.0

7 2.3 1.5 46 10.5 8.8

8 2.6 1.6 47 9.1 7.4

9 3.2 2.0 48 7.7 6.1

10 3.5 2.3 49 10.3 9.3

11 3.8 2.5 50 13.5 11.7

12 3.4 2.2

13 3.2 2.1

14 3.6 2.4

15 3.8 2.6

16 4.1 2.8

17 3.4 2.2

18 4.1 2.8

Denotes legacy sensors. For reference only. Not for new designs.

22 Power Sensor Manual

Page 28

Table 3-2. Peak Power Sensor Calibration Factor Uncertainty

Models 56218, 56226, 56318, 56326, 56340, 56418

Freq

GHz % % RSS % % RSS % % RSS % % RSS % % RSS % % RSS

56218 56226 56318 56326 56340 56418

Model

DUAL DIODE PEAK POWER SENSORS

0.03 2.0 1.2 2.9 2.9

0.5 1.7 1.1 2.9 2.9 1.6 1.1 2.4 1.6 2.2 1.5 1.7 1.1

1 1.8 1.2 3.4 3.0 1.5 0.9 1.8 1.1 1.7 1.1 1.6 1.0

2 2.2 1.5 3.4 3.0 2.0 1.3 2.1 1.4 1.9 1.2 2.0 1.4

3 2.3 1.6 3.7 3.3 2.1 1.5 2.2 1.5 2.1 1.4 2.1 1.5

4 2.1 1.4 3.7 3.3 2.0 1.3 2.4 1.6 2.2 1.5 2.1 1.4

5 2.4 1.6 3.7 3.3 2.4 1.6 2.4 1.7 2.3 1.6 2.4 1.7

6 2.1 1.5 3.7 3.3 2.2 1.5 2.5 1.8 2.4 1.7 2.2 1.5

7 1.6 1.1 3.8 3.3 1.6 1.1 2.5 1.8 2.6 2.0 1.7 1.1

8 1.7 1.1 3.8 3.3 1.6 1.0 2.5 1.7 2.8 2.2 1.8 1.2

9 2.6 1.7 5.5 5.6 2.4 1.6 3.2 2.6 4.1 3.6 2.7 1.8

10 3.3 2.4 5.5 5.6 3.2 2.3 3.2 2.6 4.1 3.8 3.3 2.4

11 3.4 2.5 5.3 5.6 3.5 2.6 3.3 2.8 4.1 4.0 3.5 2.6

12 3.0 2.1 5.4 5.6 3.2 2.3 3.4 2.9 4.2 3.9 3.4 2.5

13 2.8 2.0 5.6 5.6 2.9 2.0 3.6 3.0 4.3 3.9 3.2 2.4

14 3.2 2.3 5.8 5.6 3.3 2.4 3.8 3.0 4.6 4.1 3.3 2.4

15 3.1 2.3 5.9 5.7 3.4 2.5 3.8 2.9 4.8 4.1 3.5 2.7

16 3.8 2.8 6.1 5.7 3.8 2.8 3.8 2.8 4.9 4.2 3.9 2.9

17 3.1 2.3 6.2 5.7 3.5 2.8 3.8 2.7 5.0 4.2 3.3 2.5

18 3.4 2.4 6.3 5.7 3.9 2.9 4.2 3.1 5.1 4.2 3.8 2.8

19 8.5 8.6 5.0 3.9 5.8 5.0

20 8.6 8.6 5.3 4.3 6.3 5.6

21 8.7 8.6 5.4 4.3 6.7 5.9

22 9.0 8.7 5.3 4.1 6.8 5.8

23 9.2 8.8 5.3 3.9 6.6 5.4

24 9.5 8.9 5.3 3.8 6.3 4.9

25 9.6 8.9 5.1 3.7 6.3 4.9

26 9.8 9.0 5.4 3.9 6.4 4.9

26.5 10.3 9.1 6.3 4.5

27 7.4 5.6

28 6.9 5.4

29 6.9 5.3

30 6.8 5.2

31 6.9 5.3

32 6.8 5.1

33 7.2 5.5

34 6.6 5.1

35 5.8 4.4

36 5.3 4.2

37 4.9 4.1

38 5.6 4.7

39 7.9 7.3

40 9.4 9.3

Power Sensor Manual 23

Page 29

Table 3-2. Peak Power Sensor Calibration Factor Uncertainty (con't.)

Models 56518, 56526, 56540, 56006, 57006

Freq

GHz % % RSS % % RSS % % RSS % % RSS % % RSS

56518 56526 56540 56006

Model

(1)

57006

(1)

DUAL DIODE PEAK POWER SENSORS

0.5 1.2 0.8 2.3 1.6 2.2 1.5 2.8 1.4 2.8 1.4

1 1.3 0.8 1.7 1.1 1.6 1.1 2.8 1.4 2.8 1.4

2 1.6 1.0 1.9 1.2 1.8 1.2 2.8 1.4 2.8 1.4

3 1.7 1.1 2.0 1.3 2.0 1.3 3.0 1.5 3.0 1.5

4 1.6 1.0 2.0 1.3 2.2 1.5 3.3 1.5 3.3 1.5

5 2.0 1.2 2.1 1.4 2.3 1.6 3.4 1.5 3.4 1.5

6 2.1 1.4 2.2 1.4 2.4 1.7 3.3 1.5 3.3 1.5

7 1.8 1.2 2.2 1.4 2.7 2.0

8 1.9 1.2 2.4 1.6 2.9 2.2

9 2.6 1.8 3.2 2.5 4.1 3.6

10 2.9 2.1 3.3 2.7 4.2 3.8

11 3.7 2.7 3.5 3.0 4.3 4.1

12 3.7 2.8 3.5 3.1 4.3 4.2

13 3.1 2.2 3.7 3.0 4.5 4.2

14 3.4 2.5 3.6 2.8 4.7 4.2

15 3.6 2.6 3.5 2.4 4.9 4.3

16 3.8 2.8 3.7 2.6 5.1 4.4

17 3.6 2.9 4.0 2.9 5.1 4.2

18 3.7 2.6 4.2 3.2 5.2 4.3

19 5.1 4.0 5.9 5.0

20 5.8 4.9 6.2 5.4

21 6.2 5.2 6.3 5.4

22 5.8 4.5 6.1 5.0

23 5.1 3.7 6.1 4.8

24 5.3 3.9 6.3 4.9

25 5.6 4.1 6.0 4.5

26 6.6 5.1 5.8 4.3

26.5 7.6 5.8 6.2 4.4

27 6.7 4.9

28 6.4 4.8

29 6.6 5.0

30 6.7 5.0

31 7.1 5.5

32 7.2 5.6

33 7.2 5.6

34 6.2 4.8

35 5.6 4.3

36 5.2 4.0

37 4.8 4.0

38 5.5 4.5

39 7.0 6.1

40 8.1 7.6

24 Power Sensor Manual

Page 30

Table 3-2. Peak Power Sensor Calibration Factor Uncertainty (con't.)

Models 57318, 57340, 57518, 57540, 58318, 59318

Freq

GHz % % RSS % % RSS % % RSS % % RSS % % RSS % % RSS

57318 57340 57518

Model

57540 58318

(1)

59318

(1)

DUAL DIODE PEAK POWER SENSORS

0.5 1.6 1.1 2.5 1.7 1.6 1.0 2.3 1.5 3.4 1.4 3.4 1.4

1 1.7 1.1 1.9 1.3 1.7 1.1 1.7 1.1 3.4 1.4 3.4 1.4

2 2.0 1.3 2.0 1.3 2.1 1.5 1.8 1.2 3.4 1.4 3.4 1.4

3 2.1 1.5 2.2 1.5 2.2 1.5 2.0 1.3 3.6 1.4 3.6 1.4

4 2.0 1.3 2.4 1.7 2.0 1.3 2.2 1.5 3.8 1.5 3.8 1.5

5 2.2 1.5 2.5 1.8 2.4 1.7 2.3 1.5 3.9 1.5 3.9 1.5

6 2.3 1.7 2.7 2.0 2.2 1.5 2.4 1.6 4.0 1.5 4.0 1.5

7 1.9 1.4 3.0 2.3 1.6 1.1 2.7 1.9 4.0 1.5 4.0 1.5

8 1.9 1.2 3.2 2.6 1.7 1.1 2.9 2.2 4.2 1.6 4.2 1.6

9 2.5 1.7 4.7 4.4 2.5 1.7 4.2 3.8 3.9 1.5 3.9 1.5

10 3.2 2.4 4.8 4.7 3.1 2.2 4.4 4.1 3.7 1.5 3.7 1.5

11 3.6 2.6 4.9 5.0 3.3 2.5 4.5 4.4 4.3 1.6 4.3 1.6

12 3.1 2.2 4.9 5.0 3.3 2.4 4.5 4.4 4.6 1.7 4.6 1.7

13 2.8 1.9 5.1 5.0 3.2 2.5 4.7 4.4 4.1 1.6 4.1 1.6

14 3.5 2.6 5.3 5.0 3.5 2.7 5.0 4.5 3.9 1.5 3.9 1.5

15 3.8 2.8 5.1 4.6 3.4 2.5 5.0 4.4 4.3 1.6 4.3 1.6

16 3.8 2.8 4.9 4.1 4.1 3.0 4.8 4.0 4.5 1.7 4.5 1.7

17 3.2 2.4 4.6 3.7 3.3 2.5 4.7 3.7 4.1 1.6 4.1 1.6

18 3.5 2.5 4.5 3.5 3.4 2.4 4.7 3.7 4.2 1.6 4.2 1.6

19 4.7 3.6 5.2 4.2

20 4.9 3.7 5.4 4.4

21 5.3 4.2 5.7 4.6

22 5.9 4.6 6.0 4.8

23 6.1 4.8 6.3 5.0

24 6.3 4.8 6.6 5.2

25 6.3 4.8 6.3 4.9

26 6.5 5.0 6.6 5.2

26.5 6.9 5.1 7.1 5.2

27 7.4 5.6 7.6 5.8

28 6.6 5.1 6.8 5.3

29 6.4 4.8 6.7 5.1

30 6.3 4.7 6.7 5.0

31 6.5 4.9 6.8 5.1

32 6.9 5.3 6.7 5.0

33 7.3 5.6 6.7 5.0

34 6.6 5.1 6.1 4.7

35 6.5 5.3 5.9 4.6

36 5.7 4.7 5.5 4.5

37 4.9 4.3 5.3 4.6

38 5.6 4.7 6.4 5.7

39 6.4 5.4 8.0 7.5

40 6.6 5.6 8.4 7.9

NOTES: 1) Uncertainty derived in part from the sensor SWR specification applied to a Tegam test system.

Denotes legacy sensors. For reference only. Not for new designs.

Power Sensor Manual 25

Page 31

Table 3-2. Peak Power Sensor Calibration Factor Uncertainty (con't.)

Models 59340

Freq

GHz % % RSS % % RSS % % RSS % % RSS % % RSS % % RSS

59340

Model

DUAL DIODE PEAK POWER SENSORS

0.5 2.5 1.7

1 1.9 1.3

2 2.0 1.3

3 2.2 1.5

4 2.4 1.7

5 2.5 1.8

6 2.7 2.0

7 3.0 2.3

8 3.2 2.6

9 4.7 4.4

10 4.8 4.7

11 4.9 5.0

12 4.9 5.0

13 5.1 5.0

14 5.3 5.0

15 5.1 4.6

16 4.9 4.1

17 4.6 3.7

18 4.5 3.5

19 4.7 3.6

20 4.9 3.7

21 5.3 4.2

22 5.9 4.6

23 6.1 4.8

24 6.3 4.8

25 6.3 4.8

26 6.5 5.0

26.5 6.9 5.1

27 7.4 5.6

28 6.6 5.1

29 6.4 4.8

30 6.3 4.7

31 6.5 4.9

32 6.9 5.3

33 7.3 5.6

34 6.6 5.1

35 6.5 5.3

36 5.7 4.7

37 4.9 4.3

38 5.6 4.7

39 6.4 5.4

40 6.6 5.6

26 Power Sensor Manual

Page 32

Table 3-3. Waveguide Sensor Calibration Factor Uncertainty

Models 51035(4K), 51036(4KA), 51037(4Q), 51045(4U), 51046(4V), 51047(4W), 51942(WRD-180)

Reference at Reference Over Sensor

Model

(Alias)

Frequency Frequency Bandwidth

GHz

% % RSS % % RSS

W A V E G U I D E S E N S O R S

51035

(4K)

51036

(4KA)

51037

(4Q)

51045

(4U)

51046

(4V)

51047

(4W)

51942

(WRD-180)

22

33

40

40

60

94

33

6565

6 5 10 7

10 6 13 7

10 6 13 8

12 6 13 9

12 9 13 11

6 5 10 7

Denotes legacy sensors. For reference only. Not for new designs.

Power Sensor Manual 27

Page 33

Low Frequency Response and

28

Standing-Wave-Ratio (SWR) Data

The typical performance data that follows is not guaranteed, however, it represents a

large number of production units processed. Therefore, it is a good guideline for user

expectations. The worst case specifications are quite conservative in accordance with

Boonton's general policy.

Detailed SWR data is supplied with each sensor unit shipped against a customer order

to give the user specific information required to properly evaluate errors in a particular

application. Please consult the factory for optional units with more stringent

specifications.

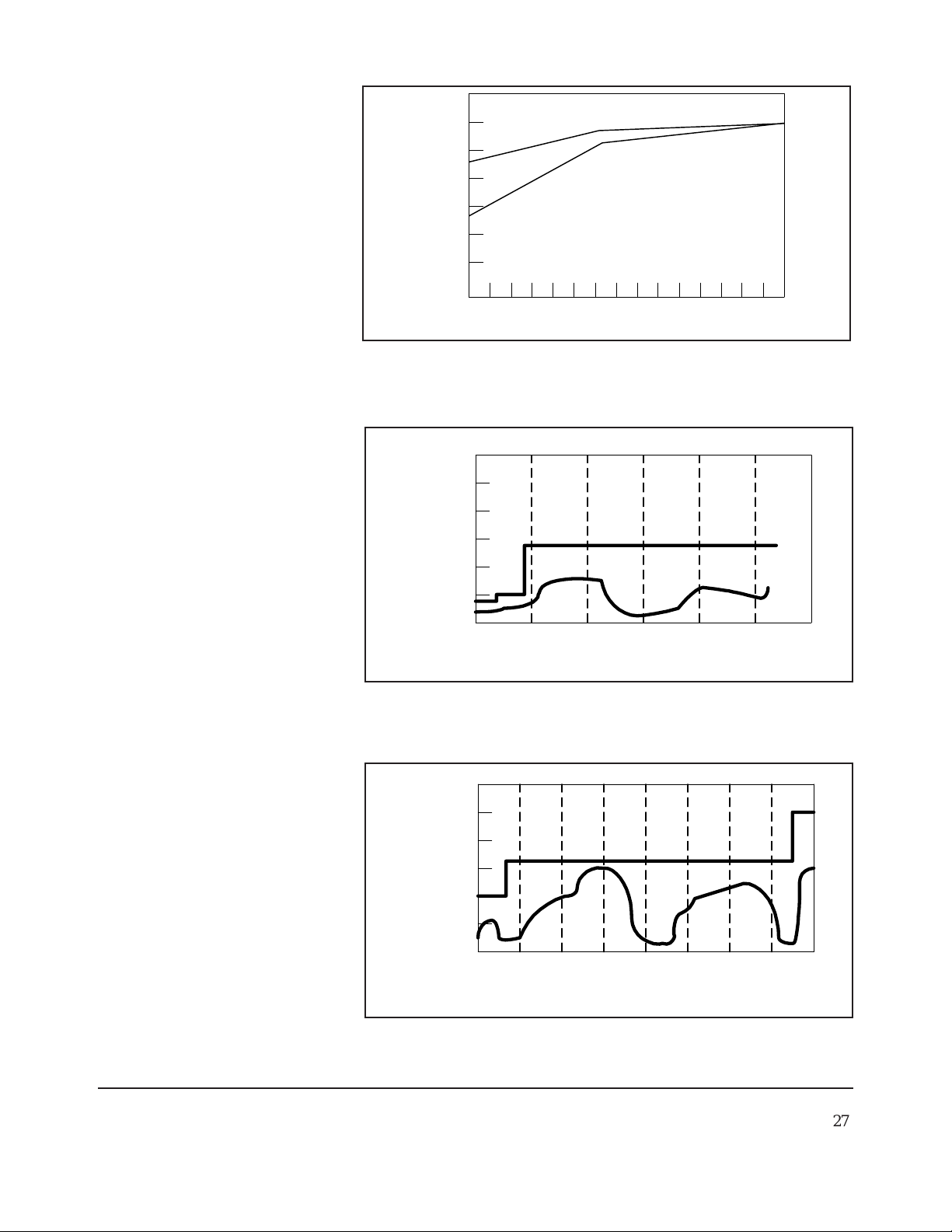

The typical low frequency response for three sensor models are shown in Figures 4-1

through 4-3. Figures 4-4 through 4-10 represent SWR Data.

4

0

-1

-2

-3

-4

Response (dB)

-5

Figure 4-1. Model 51071 Low Frequency Response

-1

-2

-3

-4

Response (dB)

-5

0 dBm

-40 dBm

150

Frequency (MHz)

0

0 dBm

-40 dBm

10

150

Figure 4-2. Model 51072 Low Frequency Response

26 Power Sensor Manual

10

Frequency (MHz)

Page 34

0.0

29

-0.5

0 dBm

-1.0

-1.5

-2.0

Response (dB)

-2.5

0.1 10.3

-40 dBm

Frequency (MHz)

Figure 4-3. Model 51075 Low Frequency Response

2.0

1.8

1.6

1.4

SWR

1.2

1.0

51510 20 25

Spec

Frequency

(GHz)

Figure 4-4. Model 51071 SWR Data

2.0

1.8

1.6

1.4

SWR

1.2

1.0

51510 20 25

Frequency

Spec

3530

(GHz)

Figure 4-5. Model 51072 SWR Data

Power Sensor Manual 27

Page 35

2.0

30

1.8

1.6

1.4

SWR

1.2

1.0

51510 20 25

Spec

Frequency

(GHz)

Figure 4-6. Model 51075 SWR Data

2.0

1.8

1.6

1.4

SWR

1.2

Spec

1.0

51510 20 25

Frequency

(GHz)

Figure 4-7. Model 51078 SWR Data

2.0

1.8

1.6

1.4

SWR

1.2

1.0

51510 20 25

Spec

Frequency

(GHz)

Figure 4-8. Model 51100 SWR Data

28 Power Sensor Manual

Page 36

2.0

31

1.8

1.6

1.4

SWR

1.2

1.0

13245

Spec

Frequency

(GHz)

Figure 4-9. Model 51101 SWR Data

2.0

1.8

1.6

1.4

SWR

1.2

Spec

1.0

51510 20 25

Frequency

(GHz)

Figure 4-10. Model 51102 SWR Data

Power Sensor Manual 29

Page 37

Pulsed RF Power

32

5-1 Pulsed RF Power Operation

Although this manual discusses power sensors used with average responding power

meters, for rectangular pulsed RF signals, pulse power can be calculated from average

power if the duty cycle of the reoccurring pulse is known. The duty cycle can be found

by dividing the pulse width (T) by the period of the repetition frequency or by

multiplying the pulse width times the repetition frequency as shown in Figure 5-1.

5

P

P

P

p

avg

Duty Cycle =

P

p

=

Duty Cycle

1

=

T

r

f

T

Figure 5-1. Pulsed RF Operation

r

P

avg

T

T

r

t

This technique is valid for the entire dynamic range of Thermocouple Sensors and

allows very high pulse powers to be measured. For Diode Sensors, this technique is

valid only within the square-law region of the diodes.

30 Power Sensor Manual

Page 38

5-2 Pulsed RF Operation Thermocouple Sensors

33

Figure 5-2 shows the regions of valid duty cycle and pulse power that apply to the

Thermal Sensors. As the duty cycle decreases, the average power decreases for a

given pulse power and the noise becomes a limitation. Also, there is a pulse power

overload limitation. No matter how short the duty cycle is, this overload limitation

applies. Lastly, the average power cannot be exceeded (there is some headroom between

the measurement limitation and the burnout level of the sensor).

Since the detection process in Thermal Sensors is heat, Thermal Sensors can handle

pulse powers that are two orders of a magnitude larger than their maximum average

power. This makes them ideal for this application. The minimum pulse repetition

frequency for the Thermal Sensors is approximately 100 Hz.

30

Valid

20

measurement

region

Average

overload

limitation

(300mW)

Upper

measurement

limitation

(100mW Avg Power)

RMS Noise = 100 nW @ 4.8 sec filter

10

<0.1 dB

<0.2 dB

0

-10

Pulse Power (dBm)

Operation in this

-20

region not valid

<0.3 dB

Notes:

1

For 51200 and 51300 sensors,

add 20 dB to vertical axis. For

51201 and 51301 sensors, add

24 dB to vertical axis.

2

These accuracy figures are to

be added to the standard CW

accuracy figures.

-30

.001

.01 .1 1 10 100

Duty Cycle (%)

Figure 5-2. Pulsed Accuracy for Thermocouple Sensors

Power Sensor Manual 31

Page 39

5-3 Pulsed RF Operation Diode Sensors

34

Figure 5-3 shows the valid operating region for the Diode Sensors. As with Thermal

Sensors, the bottom end measurement is limited by noise, getting worse as the duty

cycle decreases. At the top end, the limitation is on pulse power because even a very

short pulse will charge up the detecting capacitors. The burnout level for Diode Sensors

is the same for the pulsed and CW waveforms. The minimum pulse repetition frequency

is 10 kHz.

0

-10

-20

-30

-40

Pulse Power (dBm)

-50

-60

<0.5 dB

Notes:

1

For 51015, 51016 and 51078

sensors, add 10, 20 and 30 dB

to the vertical axis respectively.

2

For 10 second filtering, drop

this line by 3 dB.

3

These figures are to be added

to the standard CW accuracy

figures.

Operation in this

region not valid

.001

.01 .1 1 10 100

<0.2 dB

<0.1 dB

222

RMS Noise = 65pW @ 2.8 sec filter

Duty Cycle (%)

Figure 5-3. Pulsed Accuracy for Diode Sensors

32 Power Sensor Manual

Page 40

Calculating Measurement Uncertainty

11

35

6-1 Introduction

This Section has been extracted from the 4530 manual since it provides examples using CW

and Peak Power sensors. As such, in calculating Power Measurement Uncertainty ,

specifications for the 4530 are used. If one of Boonton's other Power Meters are in use,

refer to its Instruction Manual for Instrument Uncertainty and Calibrator Uncertainty.

The 4530 Series includes a precision internal RF reference calibrator that is traceable to the

National Institute for Standards and Technology (NIST). When the instrument is maintained

according to the factory recommended one year calibration cycle, the calibrator enables you

to make highly precise measurements of CW and modulated signals. The error analyses in

this chapter assumes that the power meter is being maintained correctly and is within its valid

calibration period.

Measurement uncertainties are attributable to the instrument, calibrator, sensor, and impedance

mismatch between the sensor and the device under test (DUT). Individual independent

contributions from each of these sources are combined mathematically to quantify the upper

error bound and probable error. The probable error is obtained by combining the linear

(percent) sources on a root-sum-of-squares (RSS) basis.

6

Note that uncertainty figures for individual components may be provided given in either

percent or dB. The following formulas may be used to convert between the two units:

= (10(UdB/10) - 1) * 100 and UdB = 10 * Log10(1 + (U% / 100))

U

%

Section 6-2 outlines all the parameters that contribute to the power measurement uncertainty

followed by a discussion on the method and calculations used to express the uncertainty.

Section 6-3 continues discussing each of the uncertainty terms in more detail while presenting

some of their values.

Section 6-4 provides Power Measurement Uncertainty calculation examples for both CW and

Peak Power sensors with complete Uncertainty Budgets.

References used in the Power Measurement Uncertainty analysis are:

1. “ISO Guide to the Expression of Uncertainty in Measurement,”

Organization for Standardization, Geneva, Switzerland,

ISBN 92-67-10188-9, 1995.

2. “U.S. Guide to the Expression of Uncertainty in Measurement",

National Conference of Standards Laboratories, Boulder, CO 80301, 1996.

ANSI/NCSL Z540-2-1996,

`

Power Sensor Manual 33

Page 41

U

N

36

6-2 Uncertainty Contributions

The total measurement uncertainty is calculated by combining the following terms:

1. Instrument Uncertainty

2. Calibrator Level Uncertainty

3. Calibrator Mismatch Uncertainty

4. Source Mismatch Uncertainty

5. Sensor Shaping Error

6. Sensor Temperature Coefficient

7. Sensor Noise

8. Sensor Zero Drift

9. Sensor Calibration Factor Uncertainty

The formula for worst-case measurement uncertainty is:

U

WorstCase

where

through UNrepresent each of the worst-case uncertainty terms.

1

The worst-case approach is a very conservative method where the extreme condition of each

individual uncertainty is added to one another. If the individual uncertainties are independent

of one another, the probability of all being at the extreme condition is small. For this reason,

these uncertainties are usually combined using the RSS method. RSS is an abbreviation for

“root-sum-of-squares”. In this method, each uncertainty is squared, added to one another, and

the square root of the summation is calculated resulting in the Combined Standard Uncertainty.

The formula is:

= ( U

U

C

where U1 through UN represent normalized uncertainty based on the uncertainty's probaility

distribution. This calculation yields what is commonly refered to as the combined standard

uncertainty with a level of confidence of approximately 68%.

To gain higher levels of confidence an Expanded Uncertainty is often employed. Using a

coverage factor of 2 ( 2 * U

of approximately 95%.

6-3 Discussion of Uncertainty Terms

= U1 + U2 + U3 + U4 + ... U

2

2

2

1

+ U

+ U

2

3

) will provide an Expanded Uncertainty with a confidence level

C

+ U

2

+ ... U

4

N

2

0.5

)

Following is a discussion of each term, its definition, and how it is calculated.

Instrument Uncertainty. This term represents the amplification and digitization uncertainty

in the power meter, as well as internal component temperature drift. In most cases, this is very

small, since absolute errors in the circuitry are calibrated out by the AutoCal process. The

instrument uncertainty is 0.20% for the 4530 Series. (Refer to the Instruction Manual of the

instrument in use for instrument uncertainty.)

34 Power Sensor Manual

Page 42

Calibrator Level Uncertainty. This term is the uncertainty in the calibrator’s output level for

37

a given setting for calibrators that are maintained in calibrated condition. The figure is a

calibrator specification which depends upon the output level:

50MHz Calibrator Level Uncertainty:

At 0 dBm: ± 0.055 dB (1.27%)

+20 to -39 dBm: ± 0.075 dB (1.74%)

-40 to -60 dBm: ± 0.105 dB (2.45%)

1GHz Calibrator Level Uncertainty:

± (0.065 dB (1.51%) at 0 dBm + 0.03 dB (0.69%) per 5 dB from 0 dBm)

The value to use for calibration level uncertainty depends upon the sensor calibration

technique used. If AutoCal was performed, the calibrator’s uncertainty at the measurement

power level should be used. For sensors calibrated with FixedCal, the calibrator is only used

as a single-level source, and you should use the calibrator’s uncertainty at the FixedCal level,

(0dBm, for most sensors). This may make FixedCal seem more accurate than AutoCal at

some levels, but this is usually more than offset by the reduction in shaping error afforded by

the AutoCal technique. (Refer to the Instruction Manual of the instrument in use for

calibrator level uncertainty.)

Calibrator Mismatch Uncertainty. This term is the mismatch error caused by impedance

differences between the calibrator output and the sensor’s termination. It is calculated from

the reflection coefficients of the calibrator (D

) and sensor (D

CAL

) at the calibration

SNSR

frequency with the following equation:

Calibrator Mismatch Uncertainty = ±2 * D

CAL

* D

SNSR

* 100 %

The calibrator reflection coefficient is a calibrator specification:

Internal Calibrator Reflection Coefficient (D

External 2530 Calibrator Reflection Coefficient (D

The sensor reflection coefficient, D

is frequency dependent, and may be looked up in

SNSR

): 0.024 (at 50MHz)

CAL

): 0.091 (at 1GHz)

CAL

Section 2 of this manual. (Refer to the Instruction Manual of the instrument in use for

calibrator SWR specifications.)

Source Mismatch Uncertainty. This term is the mismatch error caused by impedance

differences between the measurement source output and the sensor’s termination. It is

calculated from the reflection coefficients of the source (D

) and sensor (D

SRCE

SNSR

) at

the measurement frequency with the following equation:

Source Mismatch Uncertainty = ±2 * D

SRCE

* D

SNSR

* 100 %

The source reflection coefficient is a characteristic of the RF source under test. If only the

SWR of the source is known, its reflection coefficient may be calculated from the source

SWR using the following equation:

Source Reflection Coefficient (D

) = (SWR - 1) / (SWR + 1)

SRCE

Power Sensor Manual 35

Page 43

The sensor reflection coefficient, D

38

is frequency dependent, and can be referenced in

SNSR

Section 2 of this manual. For most measurements, this is the single largest error term, and care

should be used to ensure the best possible match between source and sensor. Figure 6-1. plots

Mismatch Uncertainty based on known values of both source and sensor SWR.

Sensor Shaping Error. This term is sometimes called "linearity error", and is the residual

non-linearity in the measurement after an AutoCal has been performed to characterize the

"transfer function" of the sensor (the relationship between applied RF power, and sensor

output, or shaping). Calibration is performed at discrete level steps and is extended to all

levels. Generally, sensor shaping error is close to zero at the autocal points, and increases in

between due to imperfections in the curve-fitting algorithm.

An additional component of sensor shaping error is due to the fact that the sensor's transfer

function may not be identical at all frequencies. The published shaping error includes terms

to account for these deviations. If your measurement frequency is close to your AutoCal

frequency, it is probably acceptable to use a value lower than the published uncertainty in your

calculations.

For CW sensors using the fixed-cal method of calibrating, the shaping error is higher because

it relies upon stored "shaping coefficients" from a factory calibration to describe the shape of

the transfer function, rather than a transfer calibration using a precision power reference at the

current time and temperature. For this reason, use of the AutoCal method is recommended for

CW sensors rather than simply performing a FixedCal. The shaping error for CW sensors

using the FixedCal calibration method is listed as part of the "Sensor Characteristics"

outlined in Section 2 of this manual. If the AutoCal calibration method is used with a CW

sensor, a fixed value of 1.0% may be used for all signal levels.

All peak power sensors use the AutoCal method only. The sensor shaping error for peak

sensors is also listed in Section 2 of this manual.

Sensor Temperature Coefficient. This term is the error which occurs when the sensor's

temperature has changed significantly from the temperature at which the sensor was AutoCal'd.

This condition is detected by the Model 4530 and a "temperature drift" message warns the

operator to recalibrate the sensor for drift exceeding ± 4 °C on non-temperature compensated

peak sensors.

Temperature compensated peak sensors have a much smaller temperature coefficient, and a

much larger temperature deviation, ± 30 °C is permitted before a warning is issued. For these

sensors, the maximum uncertainty due to temperature drift from the autocal temperature is:

Temperature Error = ± 0.04dB (0.93%) + 0.003dB (0.069%) / °C

Note that the first term of this equation is constant, while the second term (0.069%) must be

multiplied by the number of degrees that the sensor temperature has drifted from the AutoCal

temperature.

CW sensors have no built-in temperature detectors, so it is up to the user to determine the

temperature change from AutoCal temperature. Temperature drift for CW sensors is

determined by the temperature coefficient of the sensor. This figure is 0.01dB (0.23%) per

degreeC for the 51075 and many other CW sensors. Refer to Section 2 for the exact figure to

36 Power Sensor Manual

Page 44

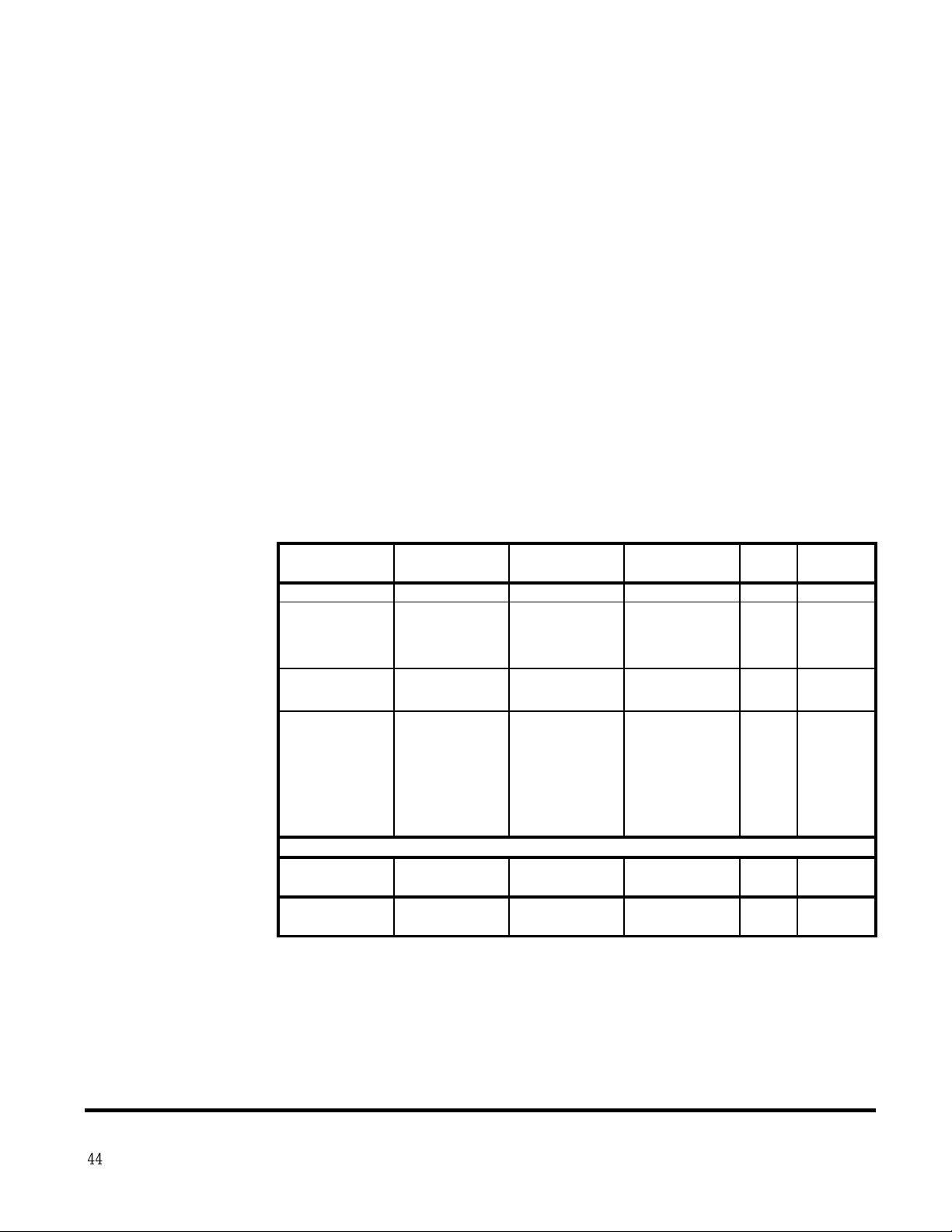

Mismatch Uncertainty

39

SWR -1 Relative Power Uncertainty

p =

SWR +1 P.U. = (1 +/- p p )

L

S

p = Source SWR

Where p = Load SWR

L

S

Chart

Figure 6-1. Mismatch Uncertainty

Power Sensor Manual 37

Page 45

use. Sensor temperature drift uncertainty may be assumed to be zero for sensors operating

40

exactly at the calibration temperature.

Sensor Noise. The noise contribution to pulse measurements depends on the number of

samples averaged to produce the power reading, which is set by the "averaging" menu setting.

For continuous measurements with CW sensors, or peak sensors in modulated mode, it

depends on the integration time of the measurement, which is set by the "filter" menu setting.

In general, increasing filtering or averaging reduces measurement noise. Sensor noise is

typically expressed as an absolute power level. The uncertainty due to noise depends upon the

ratio of the noise to the signal power being measured. The following expression is used to

calculate uncertainty due to noise:

Noise Error = ± Sensor Noise (in watts) / Signal Power (in watts) * 100 %

The noise rating of a particular power sensor may be found in Section 2 of this manual. It may

be necessary to adjust the sensor noise for more or less filtering or averaging, depending upon

the application. As a general rule (within a decade of the datasheet point), noise is inversely

proportional to the filter time or averaging used. Noise error is usually insignificant when

measuring at high levels (25dB or more above the sensor's minimum power rating).

Sensor Zero Drift. Zero drift is the long-term change in the zero-power reading that is not a

random, noise component. Increasing filter or averaging will not reduce zero drift. For lowlevel measurements, this can be controlled by zeroing the meter just before performing the

measurement. Zero drift is typically expressed as an absolute power level, and its error

contribution may be calculated with the following formula:

Zero Drift Error = ± Sensor Zero Drift (in watts) / Signal Power (in watts) *100 %

The zero drift rating of a particular power sensor may be found in Section 2 of this manual.

Zero drift error is usually insignificant when measuring at high levels (25dB or more above the

sensor's minimum power rating). The drift specification usually indicates a time interval such

as one hour. If the time since performing a sensor Zero or AutoCal is very short, the zero

drift is greatly reduced

Sensor Calibration Factor Uncertainty. Sensor frequency calibration factors ("calfactors")

are used to correct for sensor frequency response deviations. These calfactors are characterized during factory calibration of each sensor by measuring its output at a series of test

frequencies spanning its full operating range, and storing the ratio of the actual applied power

to the measured power at each frequency. This ratio is called a calfactor. During measurement

operation, the power reading is multiplied by the calfactor for the current measurement

frequency to correct the reading for a flat response.

The sensor calfactor uncertainty is due to uncertainties encountered while performing this

frequency calibration (due to both standards uncertainty, and measurement uncertainty), and is

different for each frequency. Both worst case and RSS uncertainties are provided for the