Page 1

Page 2

2

Page 3

Contents

1 INTRODUCTION ........................................................................................... 7

2 SAFETY SUMMARY ..................................................................................... 8

2.1 SYMBOLS ............................................................................................... 8

2.2 DISCLAIMER ......................................................................................... 10

2.3 POWER REQUIREMENTS ................................................................... 11

2.4 PIM 31 SERIES PACKING LIST ............................................................ 12

3 PIM 31 ELEMENTS ..................................................................................... 13

3.1 PIM 31 FR ONT PANEL ......................................................................... 13

3.2 PIM 31 BACK PANEL ............................................................................ 15

4 PRECAUTIONS ........................................................................................... 16

4.1 USING HIGH PERFORMANCE RF ACCESS ORIES ............................ 19

4.2 USING HIGH PERFORMANCE RF CABLE S ........................................ 21

5 POWERING PIM 31 UP/DOWN .................................................................. 22

5.1 Powering UP .......................................................................................... 22

5.2 POWERING DOWN .............................................................................. 23

6 GETTING STARTED ................................................................................... 25

6.1 THE FIRST MEASUREMENT ............................................................... 25

7 PIM 31 OPERATION ................................................................................... 29

7.1.1 Operations Men u Tree .................................................................... 31

7.2 FIELD MODE ......................................................................................... 32

7.2.1 Field Mode Elemen ts ....................................................................... 32

7.2.2 Carrier Entry .................................................................................... 34

7.2.3 Site Entry ......................................................................................... 37

7.2.4 Comments ....................................................................................... 39

7.2.5 History Screen ................................................................................. 40

7.2.6 Data Management ........................................................................... 41

7.2.7 Log Files and Content ..................................................................... 41

7.2.8 Log File Management ...................................................................... 43

7.2.9 Data Copy ....................................................................................... 43

3

Page 4

7.2.10 Data Delete Log Files .................................................................. 44

7.2.11 Data Delete Carrier & Site............................................................ 46

7.3 System Menu ......................................................................................... 47

7.3.2 System Menu Functional Block ....................................................... 49

7.4 Analyzer Mode ....................................................................................... 54

7.4.1 Frequency Mode ............................................................................. 56

7.4.2 Time Mode ...................................................................................... 57

7.4.3 Sweep Mode ................................................................................... 58

8 Pull Down Menus ......................................................................................... 61

8.1 File ......................................................................................................... 62

8.1.1 Start / Stop History Save ................................................................. 62

8.1.2 Screen Capture / Print ..................................................................... 63

8.1.3 Initialize Program ............................................................................ 64

8.1.4 Quit .................................................................................................. 64

8.2 System Management ............................................................................. 65

8.2.1 Self Check ....................................................................................... 65

8.2.2 PIMD Management ......................................................................... 66

9 Remote Application and TCP/IP Setup ........................................................ 67

9.1 Installation and connection setup for remote control: ............................. 67

9.1.1 Install PIM31 Remote Software ....................................................... 67

9.1.2 Known issues that might occur during installation on Windows OS:67

9.1.3 Setting IP address of PIM31 ............................................................ 67

9.1.4 Connecting PIM31 and PC. ............................................................. 68

9.1.5 Setting IP Address of PC ................................................................. 68

9.1.6 Check the network connection status of PIM31 and PC .................. 69

9.2 Using PIM31 Remote Application: ......................................................... 70

9.2.1 Enter IP address and Por t ............................................................... 70

9.2.2 List of remote commands ................................................................ 71

10 PIM31 Reporter Software .......................................................................... 72

10.1 Installation .......................................................................................... 72

10.2 PIM 31 Reporter settings .................................................................... 73

4

Page 5

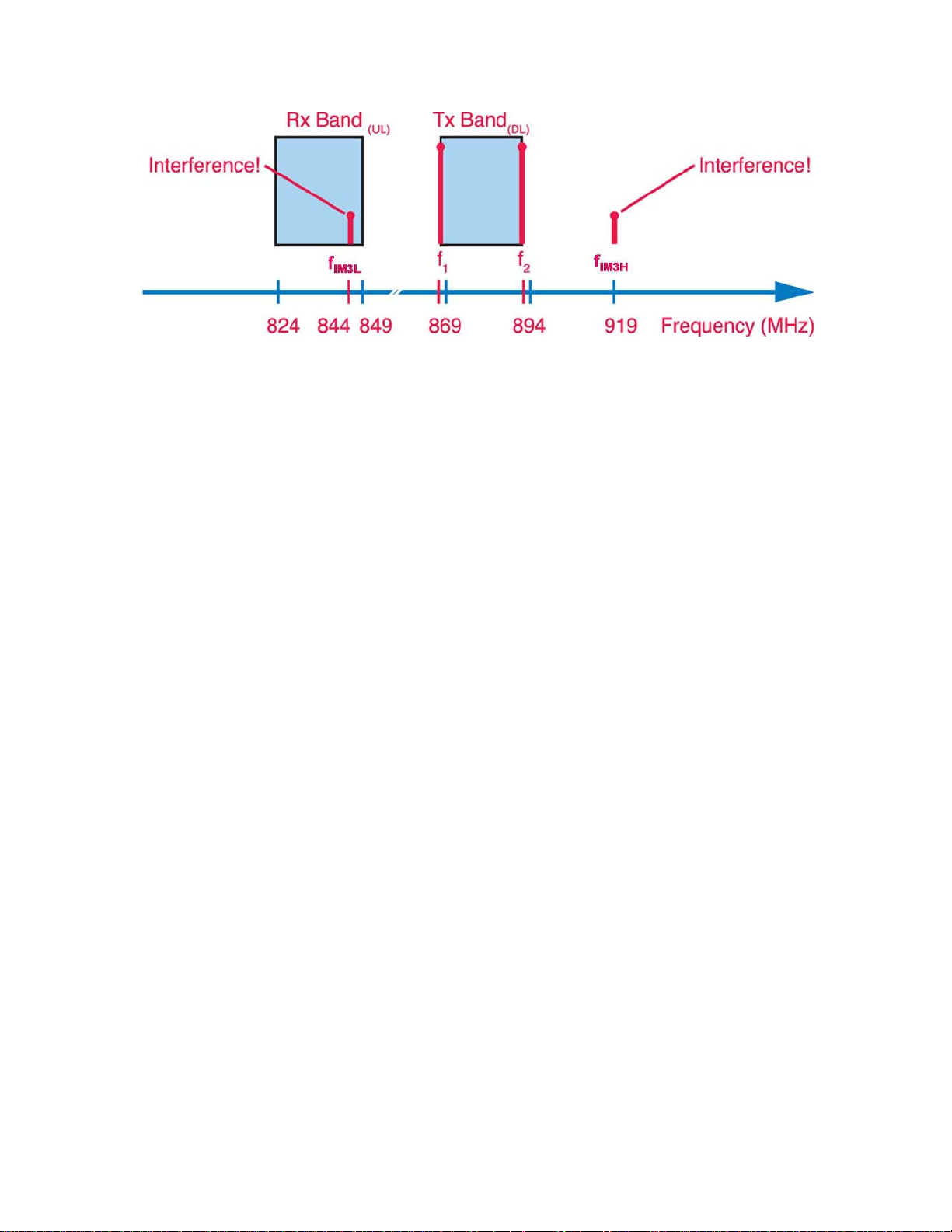

11 What is PIM? ............................................................................................. 77

11.1 What Causes PIM? ............................................................................. 77

11.1.1 Manufacturing & Design ............................................................... 77

11.1.2 Mechanical ................................................................................... 77

11.1.3 Environment ................................................................................. 78

11.2 How to test PIM .................................................................................. 78

12 PIM 31 Technical Information ................................................................... 80

12.1 Tester Types....................................................................................... 80

12.2 Specifications (Data Sheet) ................................................................ 81

12.2.1 Transmitter Specification.............................................................. 81

12.2.2 Receiver Specifications ................................................................ 81

12.2.3 System Specifications .................................................................. 81

12.2.4 Environmental .............................................................................. 82

12.2.5 Dimensions and Weight ............................................................... 82

13 Maintenance ............................................................................................. 83

13.1 Block Diagram .................................................................................... 83

13.2 Performance Check ............................................................................ 84

13.2.1 Testing Analyzer operation status ................................................ 84

13.3 Performance Verification .................................................................... 86

13.3.1 Tx Signal Power Level ................................................................. 86

13.3.2 Tx Signal Frequency .................................................................... 88

13.3.1 Rx Power and Receiving Frequency ............................................ 90

14 Accessories ............................................................................................... 93

Appendix A ......................................................................................................... 94

Warrant y Statement ........................................................................................ 94

Appendix B ......................................................................................................... 96

EC Declaration of Conformity .......................................................................... 96

Appendix C ......................................................................................................... 97

Special Units Packing List ............................................................................... 97

Appendix D ......................................................................................................... 98

PIM31 F07 UL ................................................................................................. 98

5

Page 6

Manual Version Control ...................................................................................... 98

Contact ............................................................................................................. 110

6

Page 7

1 INTRODUCTION

Thank you for choosing a Boonton test system. The PIM31 is a high performance

instrument that allows users to make reliably, highly accurate measurements of

passive intermodulation, in systems and / or components. Our test systems are

built to the highest quality standards. We strive to provide the most reliable, state

of the art test equipment allowing our customers to have the utmost confidence in

the results of their testing. To ensure you can utilize all functions and features of

this test system, we strongly recommend you familiarize yourself with this manual

prior to operating your PIM31 test system. This manual contains valuable

information on the safe operation of the PIM31 test set and a brief technical

background on passive intermodulation.

7

Page 8

2 SAFETY SUMMARY

2.1 SYMBOLS

This safety requirement symbol (located on the rear panel) has

been adopted by the International Electro-technical Commission,

Document 66 (Central Office) 3, Paragraph 5.3, which directs that

an instrument be so labeled if, for the correct use of the instrument,

it is necessary to refer to the instruction manual. In this case it is

recommended that reference be made to the instruction manual

when connecting the instrument to the proper power source. Verify

that the correct fuse is installed for the power available.

The CAUTION symbol denotes a hazard. It calls attention to an

operational procedur e, pract i ce or instr uct i o n that, if not followed,

could result in damage to or destruction of part or all of the

instrument and accessor i es. Do not proce e d beyond a CAUTION

symbol until its conditions are fully understood and met.

The NOTE symbol is used to mark information which should be

read. This information may be very useful to the operation when

with the subject covered in this section.

The HINT symbol is used to identify additional comments which are

outside of the normal format of the manual, however can give the

user additional information about the subject.

8

Page 9

The following general safety precautions must be observed during all phases of

operation and maintenance of the Boonton PIM 31 Passive Intermodulation Test

System. Failure to comply with these precautions or with specific warnings

elsewhere in this manual violates safety standards of design, manufacture, and

intended use of the instrument. Boonton Electronics Corporation assumes no

liability for the customer’s failure to comply with these requirements.

INSTRUMENT MUST BE GROUNDED

To minimize shock hazard, the instrument chassis and cabinet must be

connected to an electrical ground. The instrument is equipped with a

three conductor, three prong AC power cable. The power cable must

either be plugged into an approved three-contact electrical outlet or used

with a three-contact to a two-contact adapter with the (green) grounding

wire firmly connected to an electrical ground at the power outlet.

DO NOT OPERATE THE INSTRUMENT IN AN EXPLOSIVE

ATMOSPHERE

Do not operate the instrument in the presence of flammable gases or

fumes.

KEEP AWAY FROM LIVE CIRCUITS

Operating personnel must not remove instrument covers. Component

replacement and internal adjustments must be made by qualified

maintenance personnel only. Never replace components or operate the

instrument with the covers removed and the power cable connected.

Even with the power cable removed, dangerous voltages may be

present. Always remove all jewelry (rings, watches, etc.) and discharge

circuits before touching them. Never attempt internal service or

adjustment of the test system unless another person, capable of

rendering first aid and resuscitation, is present.

9

Page 10

DO NOT SUBSTITUTE PARTS OR MODIFY INSTRUMENT

Do not substitute parts or perform any unauthorized modification of the

instrument. Return the instrument to Boonton Electronics for repair to

insure that the warranty and safety features are maintained.

NON IONIZING RADIO FREQUENCY RADIATION HAZARD

This device generates Radio Frequency (RF) energy under normal

operation, and should always be operated in accordance with local and

national licensing laws. RF energy in the 700 to 1,000 MHz and 1,800 to

2,200 MHz with a total power of up to 50W Watts or +47 dBm is present

at the test port during testing. The Test Port is to be terminated into a

non radiating 50 ohm load to reduce the risk of RF exposure. Do not

switch RF Power On if Test Port is open or load is unknown.

ELECTRIC SHOCK HAZARD

The device is supplied with 90 to 264 Volt AC. Prior to AC connection

always inspect the power cord and instrument cas e for da mag e. I f

damage is observed, do not use until inspected and repaired by an

authorized Boonton Service center.

2.2 DISCLAIMER

PIM 31 test systems transmit two settable CW RF signals, with a power of up to

25W each, to measure passive intermodulation of components and transmitting

systems.

Wireless Telecom Group and its subsidiaries are under no circumstances

accountable for use of PIM31 test systems not conforming to laws and

regulations of national and local authorities. Customer / user bear the full

responsibility and legal accountability to use PIM31 only in a lawful manner.

10

Page 11

2.3 POWER REQUIREMENTS

Caution

The PIM 31 Series is equipped with a switching power supply that provides

automatic operation from a 90 to 260 volt, 47 to 63 Hz, single-phase, AC power

source. Maximum power consumption is 750W / 750 VA

For bench-top use, choose a clear, uncluttered area. For field use,

choose a dust free environment. Ensure that there is at least 2" of

clearance at the fan air intake on the front panel and bottom vents,

and the exhaust vents on the back panels to allow for proper air

circulation.

Before powering the unit up make sure the instrument does not

show indications of exposure to extensive force like dents, torn off

pieces or loose parts in the case.

11

Page 12

2.4 PIM 31 SERIES PACKING LIST

PIM 31 Series Test Systems are shipped complete and are ready to use upon

receipt.

Note Save the original packing material and container to reship the

instrument, if necessary. If the original materials (or suitable

substitute) are not available, contact Boonton Electronics to

purchase replacements. Store packing materials always in dry

environment. If frequent used in the field with we strongly

recommend purchasing our PIM 31 Transit Case. See chapter

Accessories for ordering information.

Unless otherwise ordered * , your will receive:

• PIM 31 Series Passive Inter mo dulat ion Test System

• Line Cord with 90 deg connector

• USB Mouse

• USB Roll-Up Keyboard

• 2 Connector Savers

• Low PIM Cable 3m (10ft)

• Low PIM Load 50W

• Torque Wrench

* PIM 31 and accessories are available in customized versions / packages. Please refer to

Appendix A for specific package lists.

12

Page 13

3 PIM 31 ELEMENTS

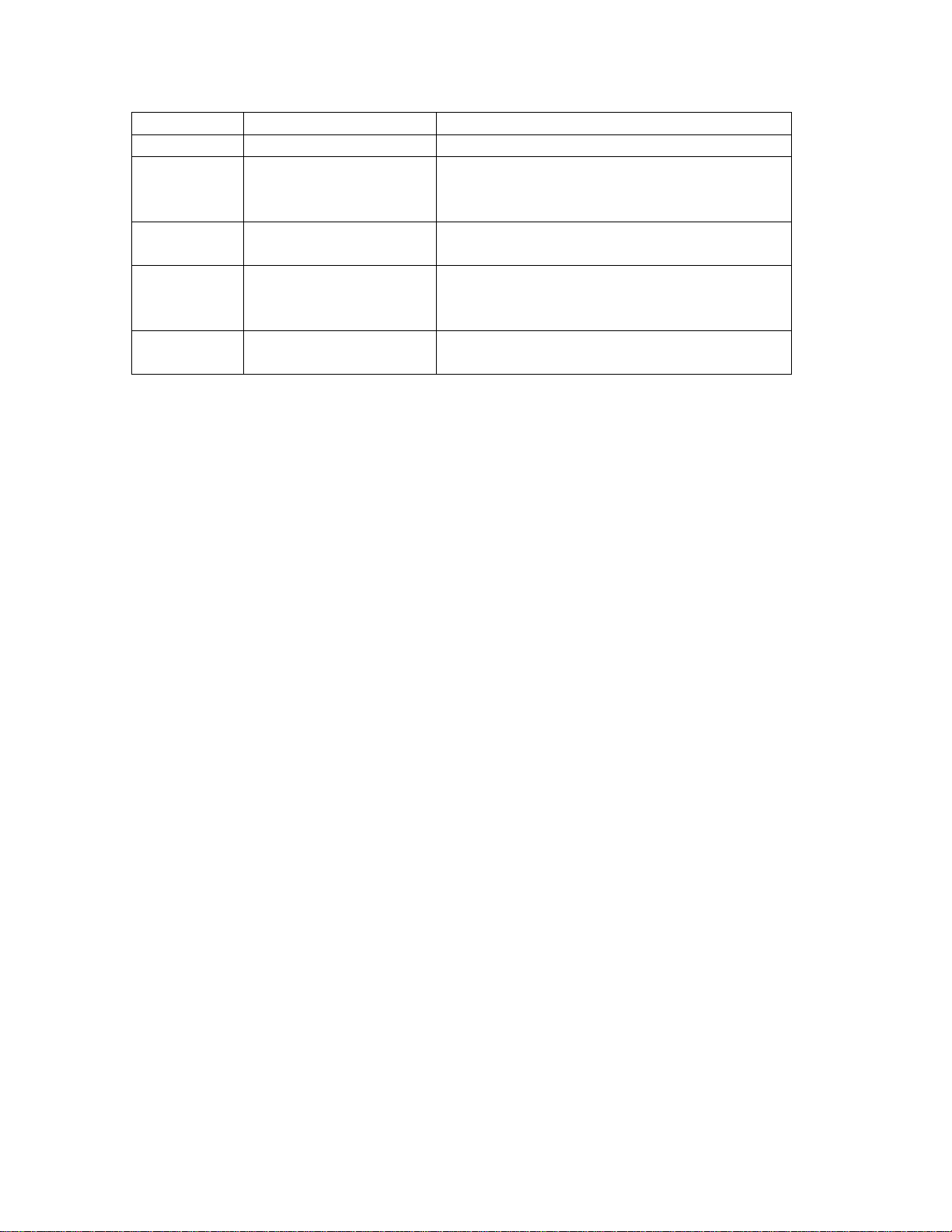

Number

Element

Description

1

Power Switch

Function similar to a PC:

must be in ON Position

2

LAN connector

For factory use only

3

USB Ports (3)

USB Ports for mouse, keyboar d and

Memory Stick

4

RF Port w/ protection

cap

RF Port,

Always use protection cap when PM31

3.1 PIM 31 FRONT PANEL

one short push – PIM31 powers up,

Another short push – controlled power

down

Holding it for 3 second – powers unit

down immediately

See also chapter Powering PIM31

up/down.

Note: Main Power Switch on the back

13

Page 14

is not in use.

5

Audio

Loudspeaker for audio si g nal s

6

Touch Screen

Display

Touch screen display 800x600.

on the screen

7

RF Power On

RF-Power light indicates when RF

Power is present.

8

Front Panel Air

Always allow for proper airflow, prevent

in.

9

Type Label

Provides information about PIM31 Tx/Rx

frequency bands

Never use sharp devices to push buttons

Vents

alien objects or dust from being sucked

14

Page 15

3.2 PIM 31 BACK PANEL

Number

Element

Description

1

Main Power supply

AC Supply: 90-264V, 7 50W / 750VA

Fuse: 4A / 230V or 8A / 110V

2

Main Power Switch

PIM31 contains protection circuitry to control

Button to power the system down.

3

VGA Port

Allows using an external VGA Monitor

4

Communications port

Factory use only

5

10 MHz Reference

out

10 MHz reference output to synchronize

external equipment

6

Air Flow Fan

Always ensure sufficient air flow

7

Air Flow Fan

Always ensure sufficient air flow

use 90 deg connector only

RF Power during operation and during

powering on/off cycles.

After switching Main Power Switch On wait 2

seconds before pushing Front Power Button.

Fans may Briefly run after power off.

Note: Do not use Main Power Switch while

system is in operation mode, vital files may

get corrupted Always use the Front Power

15

Page 16

4 PRECAUTIONS

Caution

Caution

Caution

DO NOT touch RF Connecting parts of components with bare

fingers.

Even the smallest amount of sweat on the conductors can cause

oxidation, which will reduce the performance of the element and

can cause PIM. Elements Included:

• RF Port of PIM31

• Low PIM Cables

• Low PIM Load

• Low PIM Adapters

• All components in the transmitting path of the System under

Test or DUT.

DO NOT switch on RF power without load or antenna attached.

Switching RF power on without termination, results in the full

transmitted energy of the test system being reflected back into the

test system. This can overstress the system cause damage. The

load ensures energy flow from the test system to the load, which

transforms all RF energy into heat.

DO NOT operate the PIM31 in any active systems.

The PIM31 is a very sensitive Test System that allows testing and

analyzing passive RF components. Under no circumstances should

the tester be operated w hen the RF path is active, no outside

carrier signals should be present in the RF path under test. This

includes all active signals even when they are operating in different

frequency bands. Operation with active signals present will cause

serious damage to the i nst r um ent.

16

Page 17

Caution

Caution

Caution

DO NOT connect or disconnect any accessory or component

of the test setup with RF power switched on.

Even at low RF power levels, spark discharge can occur with

sudden energy flow or flow disruption.. Spark discharg e - must be

avoided, because it will alter the surface of the pins and connection

areas. “Burned” surfaces will not only reduce the performance of

the component, but can also cause permanent PIM.

DO NOT operate test system and load without connector

savers.

All connectors wear out when used frequently. Connector savers on

the RF Port and the load port(s). help to prevent costly repairs of

the PIM31 Boonton connector savers offer negligible influence on

measurements. We suggest to always leaving the connector saver

attached to the tester / load to ensure they are always utilized.

Replace them when they wear out, and their performance

deteriorates. For order information please refer to the chapter

accessories.

DO NOT mount components directly on the PIM31.

Always use a cable between PIM31 and DUT. The connector of the

PIM31 is a high quality, high precision element. It is designed to

withstand tangential forces that occur when connector savers or

cables are torqued on with the appropriate force. The RF Port

connector is not designed to support the weight of a component.

17

Page 18

Caution

Caution

DO NOT block air vents.

Due to its high RF output power, PIM31 consumes up to 750W.

This energy has to be disposed. While these test systems have

protection against overheating, it is vital to keep air vents clear of

any obstructions that would prevent or limit the air flow.

Air vent locations

• Front Panel

• Back Panel

• Bottom

Keep clearance at least 15 cm / 6 inches for Front and Back Panel

Vents, and 4cm / 1.5 for the bottom vent.

DO NOT bent cable tighter than 40 cm / 16 inches of diameter.

Caution

Cables that come with the PIM31 offer a combination of high

quality, low PIM, and high reliability. The test cable is a vital piece

of the measurement setup, and a damaged or worn cable will

influence PIM measurements... The structure of Boonton’s PIM

cable offers customer friendly utilization in the field and in the

factory it allows for a bending radius of 20 cm / 8 inches. Tighter

bending will permanently alter the cable structure, which will cause

performance loss and can ca use per m an ent PIM , rend er i ng the

cable unusable. See also chapter: Using the Cable.

DO NOT over-torque the RF Port connector and accessories.

The best performance of RF connectors is achieved when the

connections are made with the correct torque. Too much of a

torque can permanently deform PINs and connections areas, too

little torque can hinder the electron flow, varying the impedance or

in some cases can cause spark discharge. All these effects can

damage the components permanently. To ensure proper

connections always use the torque-wrench that comes standard

with the PIM31.

18

Page 19

Caution

DO NOT use sharp devices at the touch screen.

Users can operate PIM31 test systems but utilizing the touch

screen or via keyboard/mouse. The user interface is designed

specifically for field use; all vital operations can be conveniently

accessed via the touch screen interface. Do not use sharp devices;

they can damage the touch screen. The touch screen, display and

CPU are a single integrated module. In case of service the

complete module has to be exchanged. To prevent costly repairs,

use only your fingers or very dull devices to interact with the

screen.

4.1 USING HIGH PERFORMANCE RF ACCESSORIES

PIM test sets combine very high output power, with extremely sensitive receivers.

Note: The sensitivity of the PIM 31 receiver is many times greater than the

sensitivity of a Base Station. Any unwanted influence generated by poor

performing accessories will reduce the accuracy of the desired measurement. To

ensure quality measurements great care has to be taken; not only for the test

system but also for the cables and accessories. Remember you want to measure

the PIM of the device under test, not a poor performing or worn accessory.

Prevent unnecessary force:

Nearly all RF connectors are designed to allow for manual

connection. To ensure a proper connection, RF connectors should

be manually mated, push in to seat the center pin, then hand

tightened until seated. The torque wrench should only be used to

tighten the last ½ turn or less. Improper connections will cause

performance loss. This includes under torquing and over torquing.

Both, over and under-torquing, result in weak connections which

contribute to PIM. Over tightening may damage the connector and

lead to visible metal fragments in the connector’s surface. All

damaged connectors and connectors savers should be replace

prior to testing.

19

Page 20

Keep Accessories clean:

Dust and dirt may affect test results. Make sure accessories are

stored properly and clean. Please use the protective caps - to keep

the accessories free from contamination. Never use sharp devices

to remove any contamination because scraping can cause metal

chips in the contact areas, which will generate PIM. If any dirt,

corrosion or any other foreign matter needs to be removed use

special RF contact cleaning tabs and / or compress ed air.

Keep Accessories dry:

Even the best plating will wear if accessories are frequently used.

Moisture will cause oxidation. Prevent moisture by using supplied

protective caps and keeping accessories stored properly. Many

connectors are weather sealed to prevent moisture from enteri ng

the contact area. If you discover moisture use RF contact cleaning

tabs and blow dry with compressed air.

Check for wear and tear :

All metal to metal surface subjected to movement will eventually

show the effects of wear and tear. In the case of PIM

measurements the results appear as an increase in PIM level.

Check your accessories frequently to ensure that they are working

properly. Once you have determined that an accessory is no longer

performing as it should, replace it with a new device. When you

received the replacement, dispose of the old one to prevent

accidental reuse. Check chapter on Accessories for ordering

information of spare and replacement accessories. Accessories are

key to accurate PIM measurements. Although properly functioning,

they are also wear and tear items and will need to be replaced.

20

Page 21

4.2 USING HIGH PERFORMANCE RF CABLES

Cables are as vital to proper PIM testing as any of the other accessories are.

Treat them with the appropriate care. All hints listed above for accessories apply

to cables as well. Always use cable caps to protect connectors when the cable is

not in use. The bending radius for the PIM31 cable delivered by Boonton is 20cm

/ 8 inches. To prevent damage, coil cable no tighter than 40 cm / 16 inches in

diameter. A transit case for PIM31 systems is available. This case has dedicated

space for test systems, accessories and also the low PIM cable. For more

information please refer to the chapter on accessories.

“Treat accessories and cables for what they are:

High precision measurement devices”

PIM tests measure the device in the testing path that generates the highest level

of PIM. Worn or malfunctioning accessories lead to inaccurate measurements.

Remember you want to measure the PIM level for the RF path or device under

test, not a worn accessory or test cable. Inspect your accessories and cables

prior to each use, and treat them as part of a high precision me asurement

device.

21

Page 22

5 POWERING PIM 31 UP/DOWN

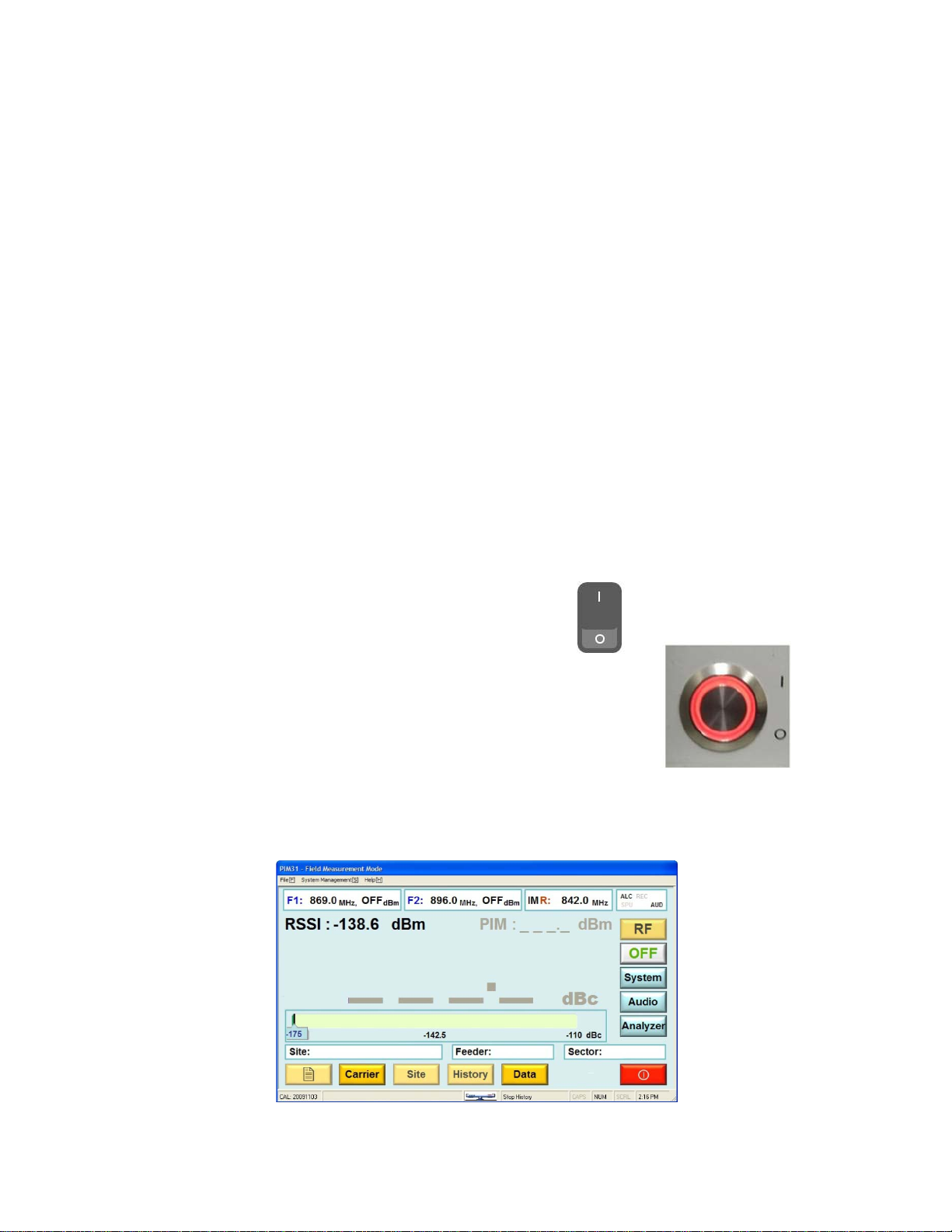

5.1 Powering UP

PIM 31 test systems power up in a similar fashion to a desktop PC. However,

there is one exception: significant RF power has to be controlled and managed..

For this reason PIM 31 series test systems contain a protection system to protect

the hardware, e.g. prevents unusual on/and off cycles ( e.g. 3 cycles per

second). When used normally, the user will not even recognize that these

protective mechanisms are working.

Preparations for powering up:

Ensure that the main outlet has pr oper gr ou nding.

Connect the correct power cable to the tester

Connect the power cable to the main outlet

• Switch on the PIM31 main power switch at

the backside of the unit. Allow for a short

delay before switching on front power

button. (This will allow protection circuitry

to enable all PIM 31 modules).

• Push Start Button briefly at the front panel.

The system will boot up automatically and show the user interface in the Field

Mode.

22

Page 23

Caution

Caution

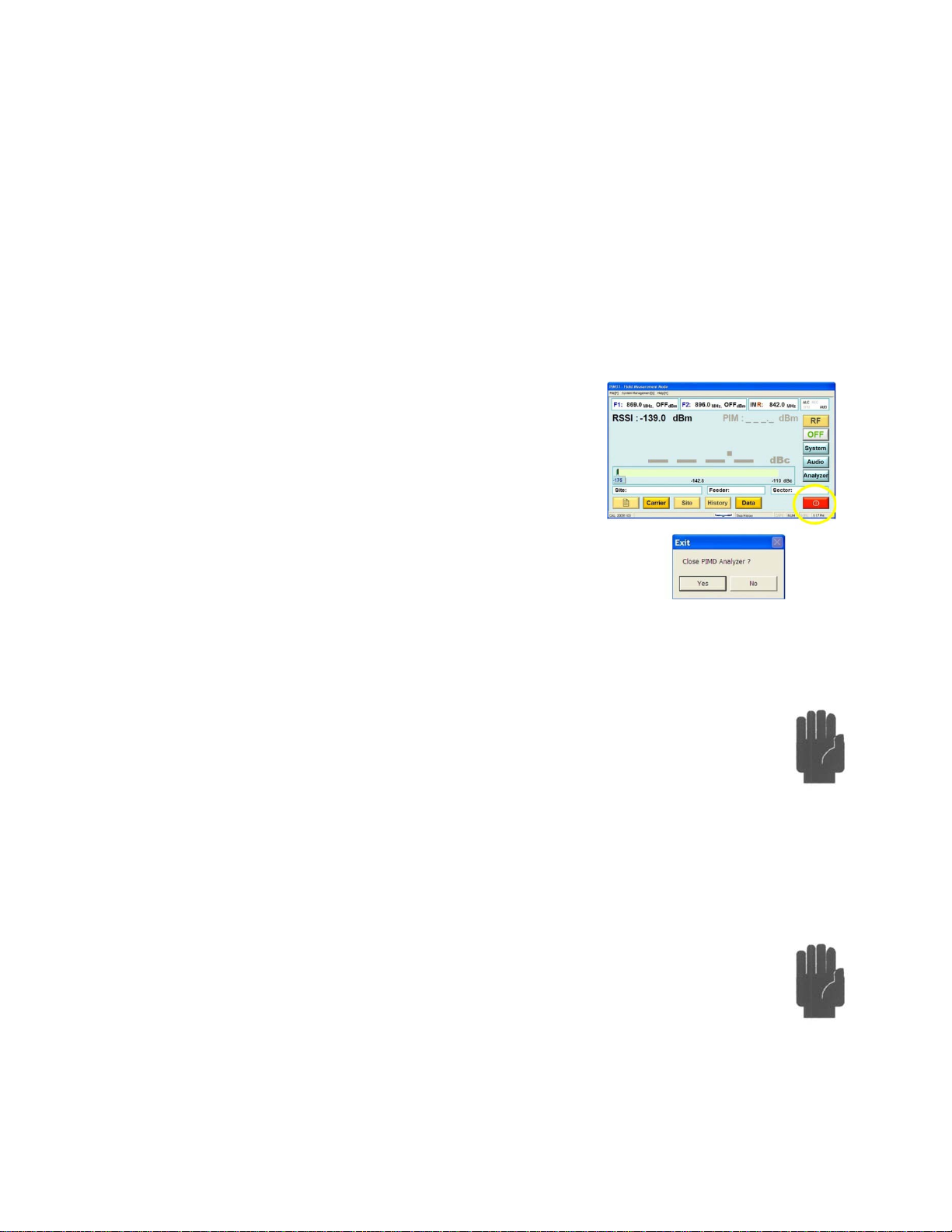

5.2 POWERING DOWN

PIM31 can be powered down in different ways listed below. It is not

recommended to power down simply by “Pulling the plug” or

switching off the Main Switch on the back panel.

Exiting

The proper way is to Exit the UI is by pressing the

red exit button. This will generate an exit pop up.

Respond to the pop-up menu’s choice Yes / NO to

power the system down or not. This method ensures

the RF is switched off properly, all UI and computer

processes are terminated in an orderly fashion, and

data files are closed.

Forced Termination

Holding the Start Button on the front panel for 3 seconds generates a soft

reset. RF is switched off, and all vital files will be closed and stored. In

this mode, the urgency to power off the unit trumps handling and closing

all files. Some information, e.g. log data may be lost.

Main Switch

When not following the proper shutdown sequence and using the Main

switch on the back to terminate power it is likely that files get corrupted,

and the test system may be harmed.

Note: Cooling fans may become operational after the main switch is

placed in the off position until discharge of all internal capacitors is complete;

typically within 5 seconds

23

Page 24

Caution

“Pulling the Plug”

This “method” should be avoided under all circumstances. It can

damage the hardware and corrupt files. This “method” is

especially critical if the RF port is still connected to a grounded

system under test. Residual discharges may flow via RF Ground /

Shield. With the main connector no longer plugged in, ground

connection is also disrupted.

24

Page 25

6 GETTING STARTED

Before starting to measure components with PIM31 systems, users are urged to

familiarize themselves with the precautions (Don’ts) in the chapter below.

Improper operation and handling can cause bodily harm or damage the

instrument.

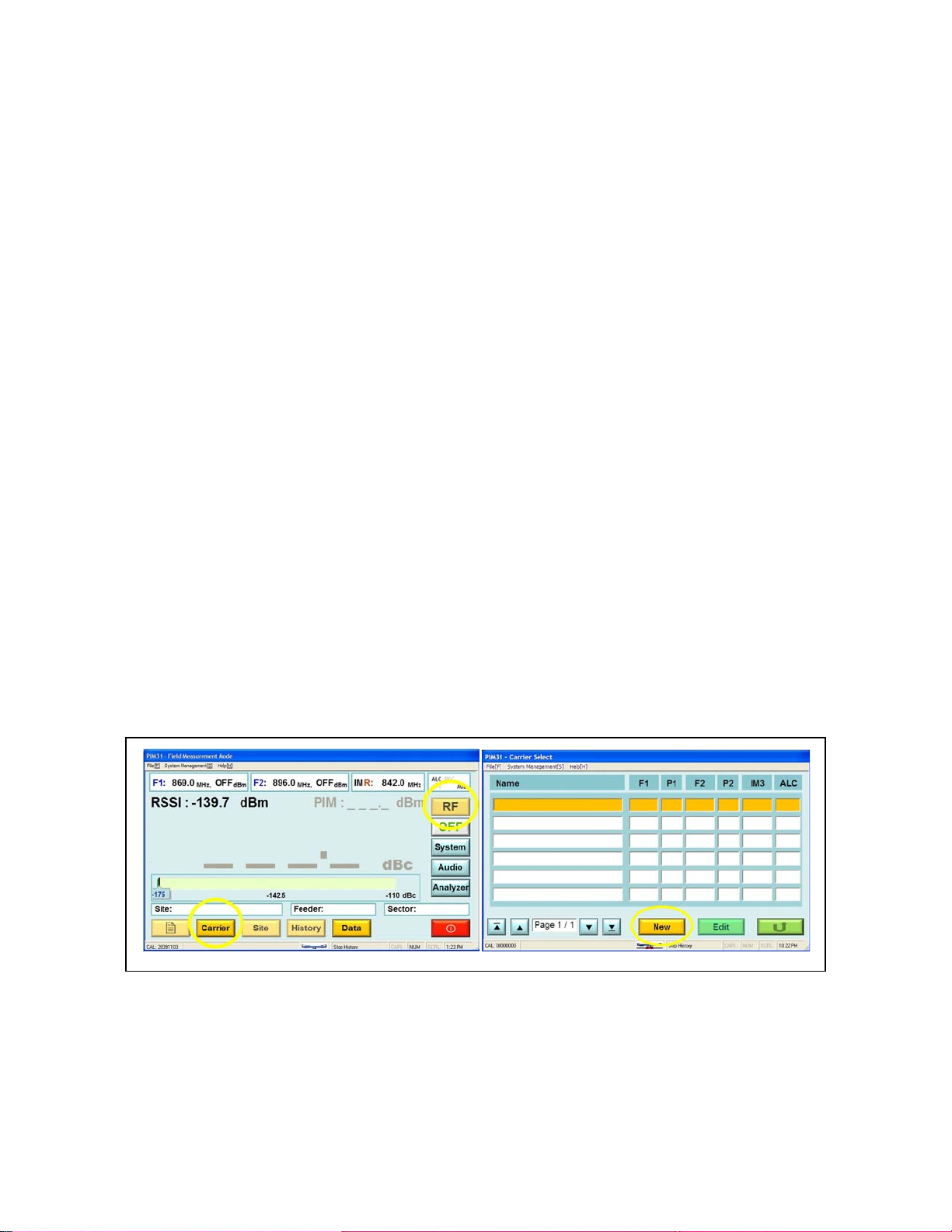

6.1 THE FIRST MEASUREMENT

Preparations:

• Mount connector saver to RF Port and Load (if not already mounted)

• Connect Low PIM cable to Test system (Note: always connect the test

cable to the instrument prior to connecting to the DUT)

• Connect Load to cable.

At this point the RF Button is visible but inactive. Power levels and the

frequencies of the carrier signals must be set in or der to act i v at e the RF button.

To do so, pushing the “Carrier” button displays a list of Carrier signal settings.

Since this is the first boot up, the list is empty. To enter carrier parameters, push

“New” at the Carrier Select screen. Now we can enter a Carrier name,

frequencies and power levels. With growing list of carriers, meaningful carrier

25

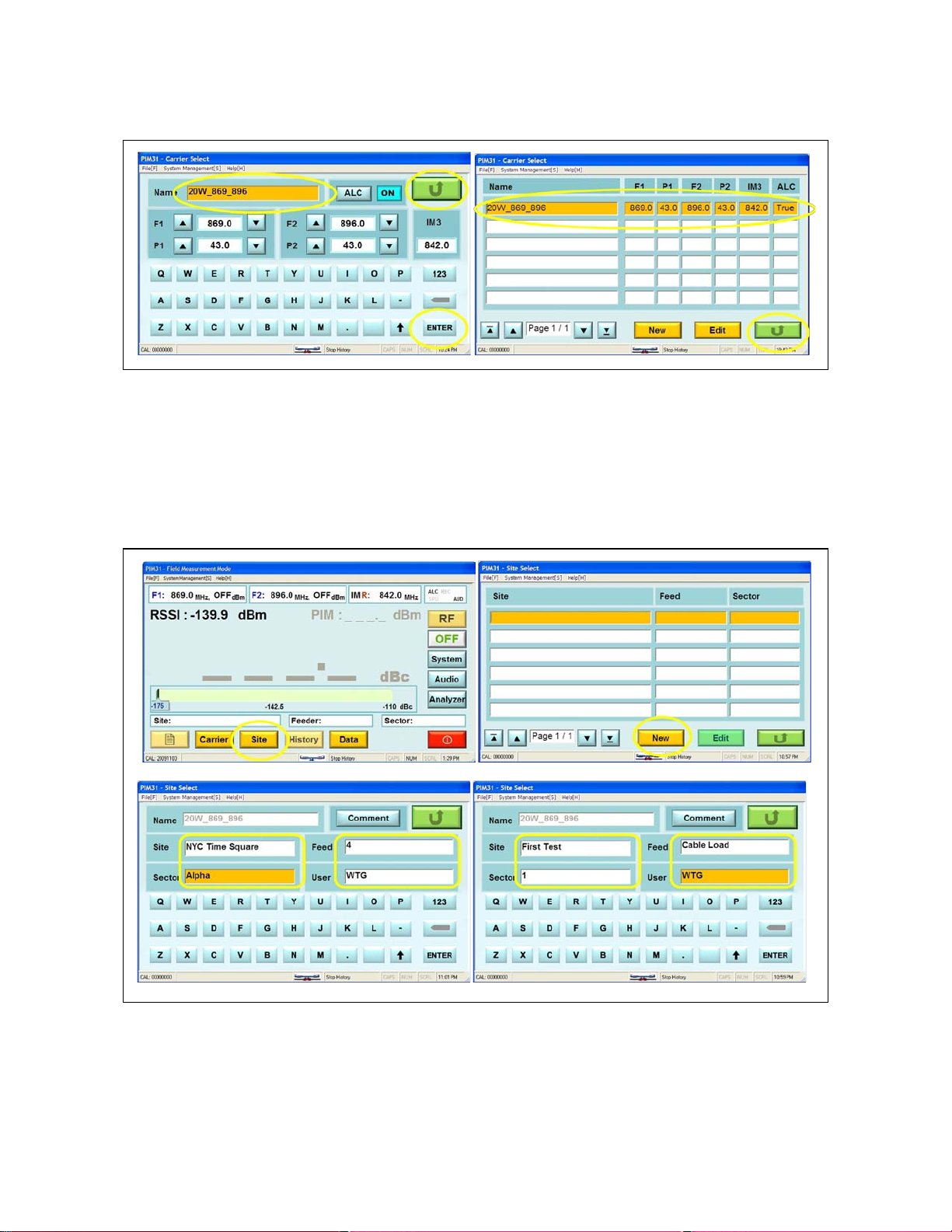

Page 26

names help to recognize the settings: Example 20W_869_896 means: power of

the signals is 20W, and the frequencies used are 869 MHz and 896MHz.Every

entry or change needs to be confirmed by pushing the “Enter” button. Once our

entries are complete, we return to the previous screen, “Carrier List” by pushing

the green Return button. The list shows now a carrier entry. By pushing the

Green return button we come back to the Field Mode screen.

26

Page 27

PIM 31 test systems provide not only accurate PIM analysis, they also allow

users to log data that is specific to a particular test setup or particular base

station site. At a later point, measurements can be recalled for comparison and to

analyze if the performance has changed. This particular information has to be

entered as well. The process is similar to the Carrier entry, except this time we

push the “Site” button. As with the carrier, the system lists all available Sites (or

Tests). Since we have not entered a Site the list is still empty.

Note: Site information is linked to particular Carriers. If a different Carrier

is selected the associated list of Sites (Tests) corresponds to Sites that

were entered under this Carrier.

Now we can enter detailed base station or measurement setup information. Once

completed, we return to the initial Field Mode Screen. The selected Site (Test)

information is now visible in the appropriate fields and the RF Button is now

active.

27

Page 28

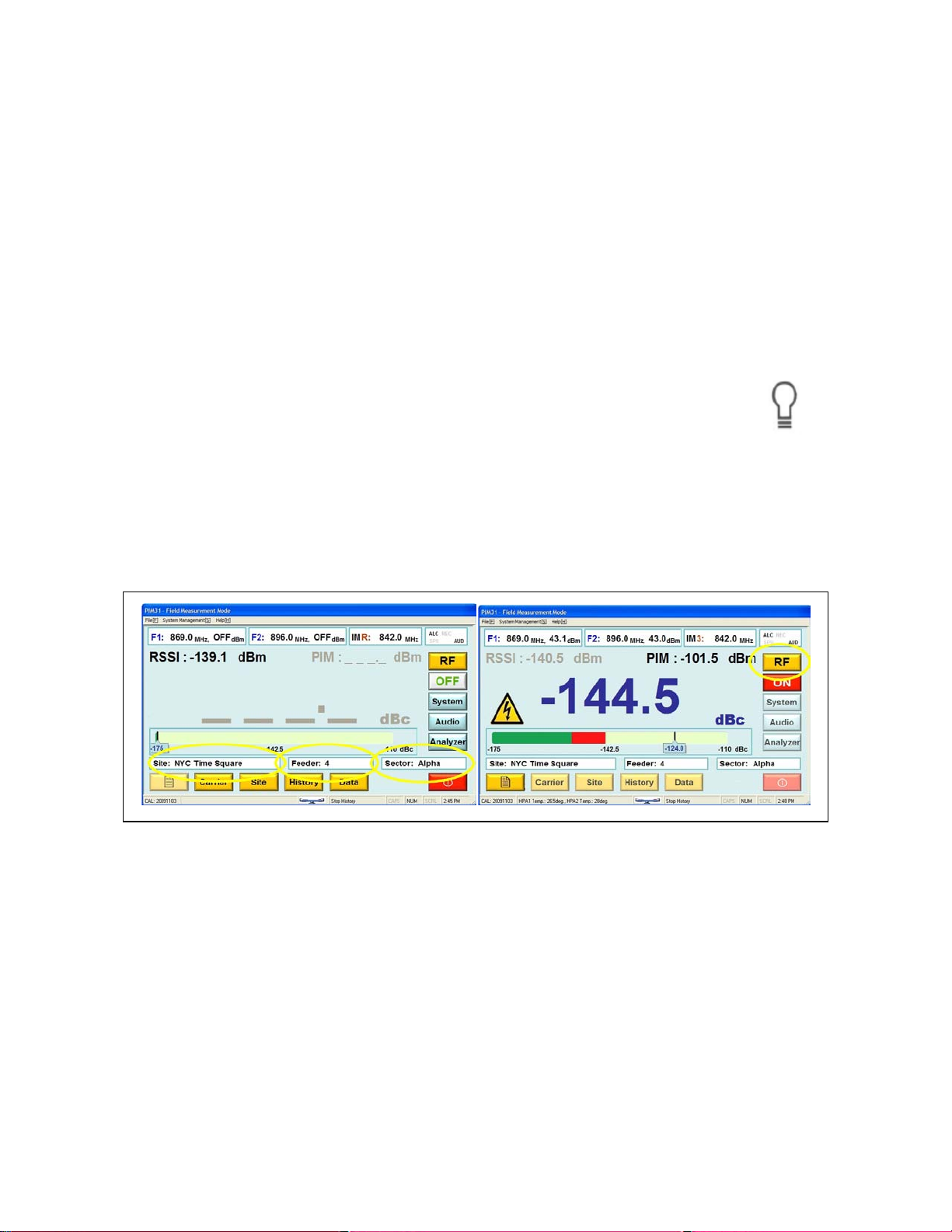

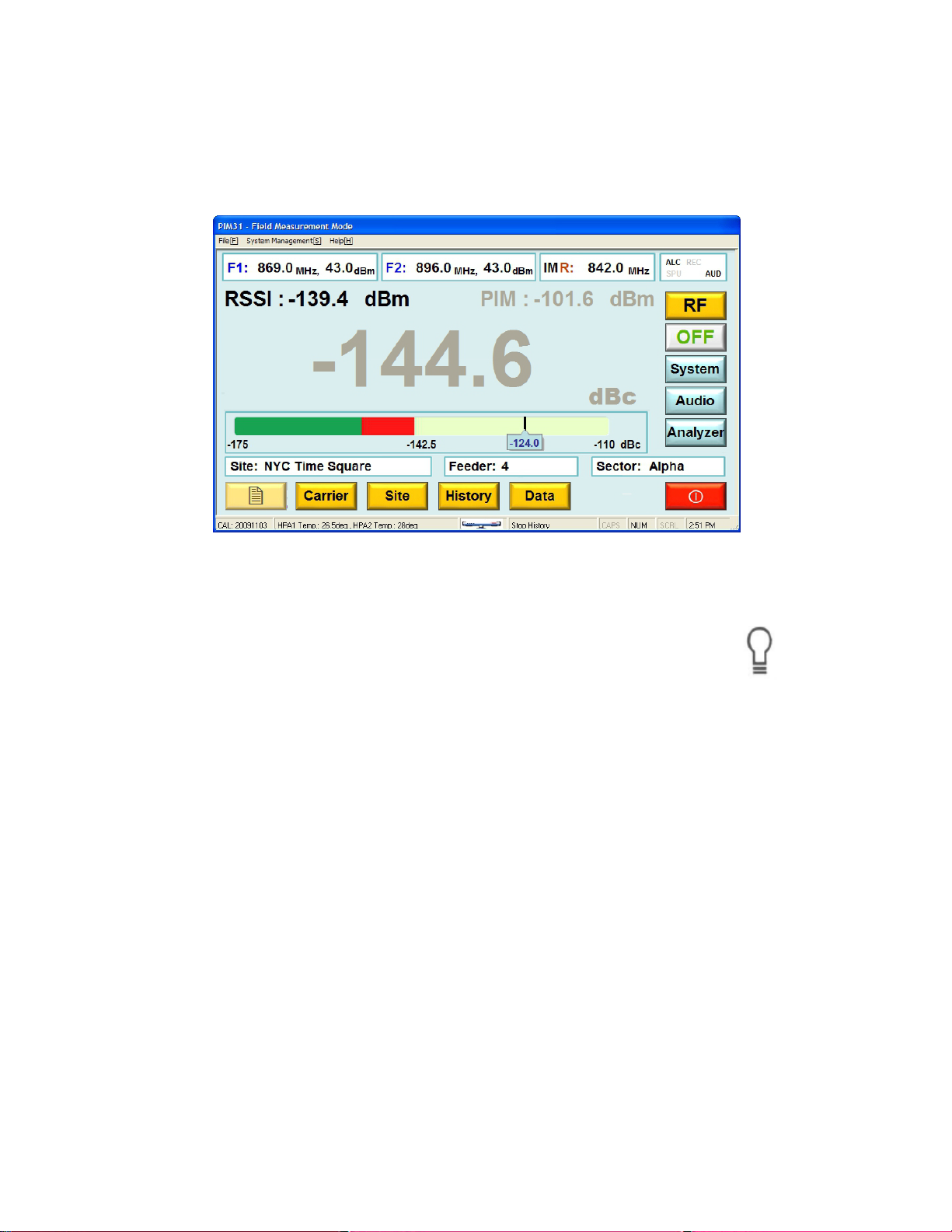

By pressing the RF Button, the system initializes, and starts measuring PIM. A

second push of the RF button stops measurements and transmission of RF

signal carriers. The last PIM reading is held and shown in grey.

Note: PIM 31 test systems switch RF Power off after 30mins (default).

Other cycles or “Always On” can be selected. For more information

refer to chapter System Menu.

28

Page 29

7 PIM 31 OPERATION

PIM31 Test Systems were developed to measure and analyze PIM data of RFcomponents, cables, or complete RF systems.

Operation Modes for Different Applications: Field Mode / Analyzer Mode

Depending on the application, the users’ requirements will be different. The main

task at a base station site is to quickly analyze the RF Path, and document the

measurements. If unacceptable PIM levels are detected the PIM31 can be used

to identify and pin-point problematic components. When testing base stations,

typically, the frequency and power settings of the test equipment are site specific.

Focus lies on quick measurement and documentation of data. PIM31 test

systems provide this easy to use functionality in the Field Mode. All base station

test parameters can be stored in the PIM31 test system, including feeder and

sector information. By selecting the base station, the user is ready to go. For

preventive maintenance it can be very helpful to compare actual with historical

data, which the PIM31 offers this as well. Measurements can be stored in the

system as .log files. Whenever data are logged, the log field stores

measurements, test system settings, and even complete information of the base

station. The operator can view the historical data of a base station at any time

and analyze if readings have changed compared to historical measurements.

29

Page 30

Similar conditions apply when components are tested. The instrument settings do

not change, but for quality reasons every measurement has to be documented.

For measuring RF Components, the Field Mode is a very comfortable and

efficient

If more detailed information about the DUT is required, it can be accessed by

using the Analyzer Mode of the PIM31 test system. In this mode the user can

analyze multiple intermodulation products at the same time (Frequency Mode),

can record graphical traces over a longer time period (Time Mode) and can

frequency sweep DUTs (Sweep Mode) to ensure it performs within the complete

frequency band within specification.

The following chapters Field Mode and Analyzer Mode provide more detailed

information.

30

Page 31

7.1.1 Operations Menu Tree

PIM 31 Test systems are designed to provide an efficient workflow. The Menu

Tree shows the overall menu structure of the PIM31.

31

Page 32

7.2 FIELD MODE

Element

Name

Description / Display

A

File Menue

Pull down Menu, choices:

See also chapter Pull-down Menus

B

Carrier Field:F1

Shows Frequency (MHz) and Power level(dBm) of first

carrier signal.

C

System management

Pull down Menu, choices:

See also chapter Pull-down Menus

E

Carrier Field:F2

Frequency (MHz) and Power level(dBm) of second

carrier signal.

F

PIM Value dBm

Measured PIM value numerically in dBm. Displays last

value after RF Power is turned off.

G

IM Frequency

Frequency (MHz) if strongest IM signal in the receiving

band and indicates which IM it is (3,5,7,9,11,13 or 15).

H

Status Indicator Field

Shows status and activities of PIMM31:

ALC – Automatic Level Control

7.2.1 Field Mode Elements

The following chapter desc ribes the Display elements of the F ield Mode screen.

“Quit”, same function as Exit Button

“Self Test”, tests PIM 31 functionality with RF ON and

OFF

32

Page 33

AUD – Audio On

REC –Data Recording

SPU – Soft Power Up

I

RSSI

RSSI (Received Signal Strength Indication) in dBm.

-130dBm.

J

PIM Value dBc

Measured PIM value numerically in dBc. The unit dBc

Displays last value after RF power is turned off

K

Voltage at the RF-port can reach up t 50V.

L

Bar Graph PIM

Graphical display of PIM measurement. Range is:

M

Display fields (3)

Detailed Information of selected Site (e.g. Base Station

20W_Combiner_Test”

N

RF On / Off Switch

One Push switched RF ON,

Carrier Select and Site Select

O

RF Indicator light

Indicates when RF-power is ON

P

See Chapter System Menu for further information

Q

Audio On/Off

Audio Signal when measurement passes green/red

threshold of Bar Graph

R

For more information see chapter Analyzer Mode

S

EXIT

Triggers Power down sequence.

Active only when RF-power is OFF.

T

see chapters Data and System Menu

U

Carrier

Opens Carrier Select screen.

Active only when RF-Power is OFF

V

Site

Opens Site Select screen.

Active only when RF-Power is OFF

W

History

Opens Site History screen

Active only when RF-Power is OFF

X

Data

Opens Data menu (copy log files, delete log files, sites

External signals at the receiving frequency / frequencies

may disturb PIM measurements. For accurate PIM

measurements RSSI should always be below

describes a measurement relative to the carriers, in this

case the carrier signals transmitted by the test system.

Voltage Warning Warning Sign appears when RF Power is switched on.

indicator

Site, Feeder, Sector

System Opens System menu.

Analyzer Opens Analyzer Menu

Record In single mode (default), log measurement and system

-175dBc (start green bar) to -110dBc (end red bar).

Default threshold green/red is -153dBc. See System

Menu for further information.

Location), and Site specific information like Feeder line

and antenna sector.

Also often used to describe test setup, e.g. “Site:

Second push switches RF ON.

The button is only active if Carrier parameters have

been set and Site information is available.

For further information see menus:

data of current measurement.

In auto mode, start/stop for recording continuous log

sequences.

For further information on recorded data and auto mode

For more information see chapter Carrier Select:

For more information see chapter Site Carrier:

For more information see chapter Site Carrier:

33

Page 34

and carriers)

For more information see chapter Data

Active only when RF-Power is OFF

7.2.2 Carrier Entry

Carrier Signal settings specify the frequencies of the transmitting RF signals and

their power level. Site information allows to a) specify the tested site in detail or

to specify component tests more closely. All settings entered with Carrier signals

or Site/Test information are recorded when measurement data is logged, this

allows for detailed analysis after a series of tests has been completed.

Furthermore settings and vital measurements are stored in the system so that

historical data related to site information can be viewed for comparison, e.g. if

systems are deteriorating. For more information on this see chapter “History

Screen”.

Carrier Select

Once carriers have been stored in the system, they can be easily recalled. The

screenshot shows a list of 2 carriers with related information on transmit

frequencies and power levels.

34

Page 35

Element

Name

Description / Display

A

Carrier

Carrier specific information on frequencies and

power levels stored in the PIM31.

B

Selected Carrier

The yellow background indicates the carrier that is

selected and will be used for test after pressing

Return

C

Page Indicator &

If more than 6 different carrier signals are stored in

Carriers are selected by clicking / tapping them.

D

New

Opens Edit Carrier screen without carrier name.

cannot be changed (only deleted) at a later time.

E

Edit

Opens Carrier Edit screen, allowing the

modification of frequencies or power levels.

F

Return

Returns to previous screen.

Jump arrows

PIM 31 Carrier Edit

the PIM31, the current page and number of pages

are shown.

Inner arrows: One page jumps in both directions

Outer arrows: Jump to Pos1 or End of list

Note: Once the carrier name has been entered, it

35

Page 36

Element

Name

Description / Display

A

Carrier 1

Parameter

Sets power level and frequency of carrier signal 1:

by pushing the Enter button (I)

B

Carrier Name

When entering new carrier information, the cursor

The name will be stored by pushing “Enter” (I)

C

Carrier 2

Sets power level and frequency of Carrier Signal 2:

by pushing “Enter” (I)

D

ALC

Auto Level Control – for utmost accuracy it is

For more information see chapter “System Menu”.

E

Return

Returns to previous site.

F

IM

Automatically calculates and displays the next IM

product that lies in the receiving band of the PIM31

G

123 / ABC

Toggles the touch screen keyboard between

characters and numeric.

H

Delete

Deletes last character / character to the left of the

cursor

I

Enter

Entries are stored in the system when the “Enter”

button is pressed

J

Keyboard

Keyboard, toggles between characters and

numeric

K

Space

Space

L

Capitals

Upper case entries

Note: when entering this field a numeric keyboard

is displayed. A new or changed value is accepted

is set to this field and marked orange for editing.

Parameter

Note: when entering this field a numeric keyboard

is displayed. A new or changed value is accepted

recommended to set ALC to ON (default).

Note: When using an external keyboard do not use commas in

names or descriptions. Log Data is stored in a CSV (Commaseparated value) text form. Commas in the description will mix up

fields that are assigned for particular values, relevant e.g. when

importing data in a spreadsheet or database. The touch screen

keyboard does not offer commas for entry.

36

Page 37

7.2.3 Site Entry

Element

Name

Description / Display

A

Site

Sites, with information on feeder and sector stored

in the PIM31.

B

Selected Site

The yellow background indicates that this site is

selected and will be used for data logging.

C

Page Indicator &

If more than 6 different sites are stored in the

Sites are selected by clicking / tapping them.

D

New

Opens Edit Site screen without site name.

cannot be changed (only deleted) at a later time.

E

Edit

Opens Site Edit screen, allowing the modification

of site related infor mation.

F

Return

Returns to previous screen.

As with Carriers, Sites (or Tests) and linked information can be stored in the

memory of the PIM31. Once Sites have been stored in the system, they can be

easily recalled. The screenshot shows a list of 4 Sites with related information on

feeder and sector.

Jump arrows

PIM31, the current page and number of pages are

shown.

Inner arrows: One page jumps in both directions

Outer arrows: Jump to Pos1 or End of list

Note: Once the site name has been entered, it

37

Page 38

PIM 31 Site Edit

Element

Name

Description / Display

A

Carrier Name

Carrier signal to which site information is related to.

B

Comment

Allows additional entries related to the Site or Test.

C

Site / Test Name

Site / test name

“Enter” (J)

D

Sector

Additional information (Sector)

“Enter” (J)

E

Return

Returns to previous site.

F

Feed

Additional information (Feeder)

“Enter” (J)

G

User

Additional information (User)

“Enter” (J)

H

123 / ABC

Toggles the touch screen keyboard between

characters and numeric.

I

Delete

Deletes last character / character to the left of the

cursor

J

Enter

Entries are stored in the system when the Enter

button is pressed

New or changed entries are stored by pushing

New or changed entries are stored by pushing

New or changed entries are stored by pushing

New or changed entries are stored by pushing

38

Page 39

K

Keyboard

Keyboard, toggles between characters and

numeric

L

Space

Space

M

Capitals

Upper case entries

Name

Carrier 1

PIM 31 – Site Information - Comment

Site Info

123

More

Site

Info

Feeder Alpha shows sporadic PIM values up to - 83.5 dBc. High RSSI

readings.

ENTER

A

B

C

D

E

F JG H

I

K

L

M

N

O PTQ R

S

U

V

W

X

Y

Z

.

-

Note: When using an external keyboard do not use commas in

names or descriptions. Log Data is stored in a CSV (Commaseparated value) text form. Commas in the description will mix up

fields that are assigned for particular values, relevant e.g. when

importing data in a spreadsheet or database. The touch screen

keyboard does not offer commas for entr y.

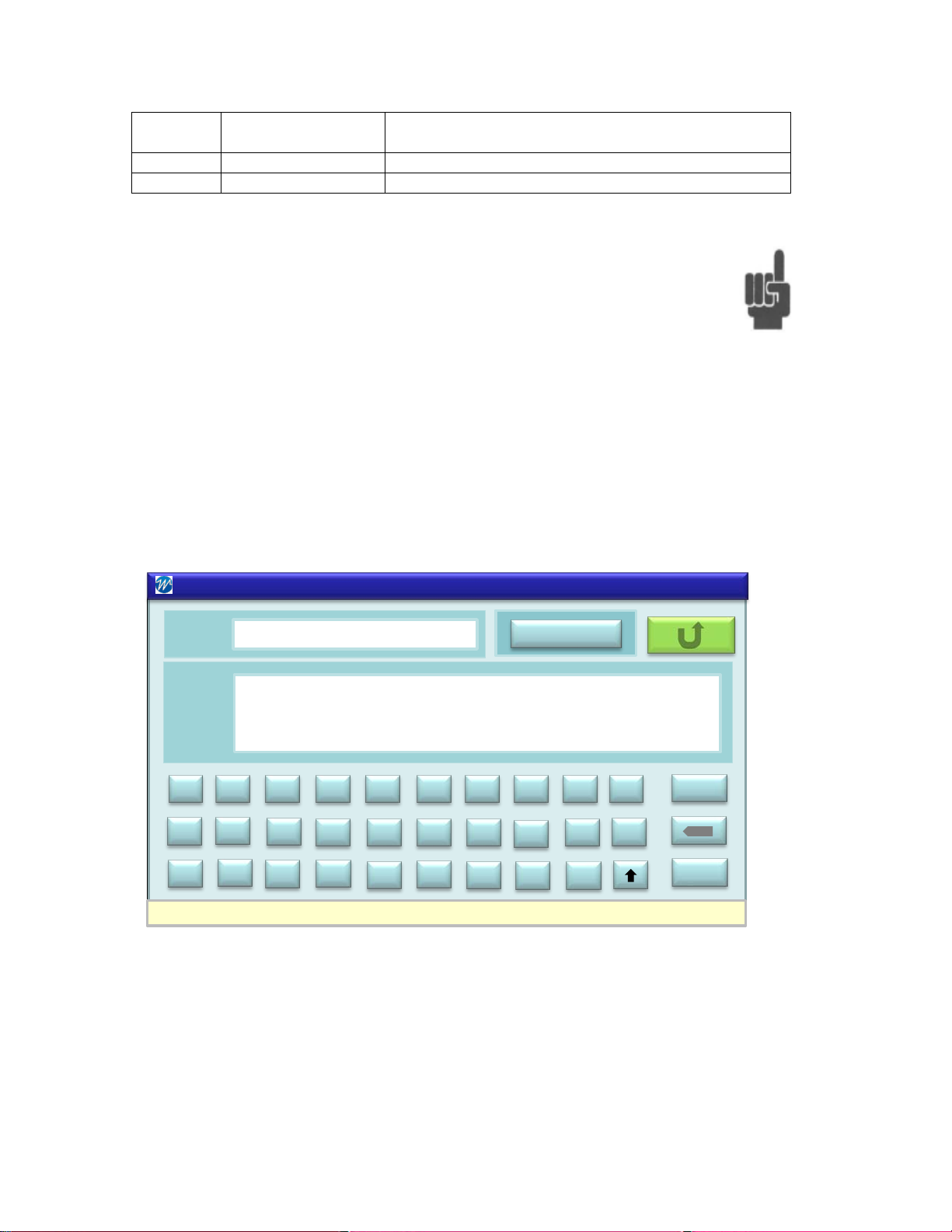

7.2.4 Comments

Site information allows users to add comments that provide further information

about the Site or the Test. Comments are not stored in the log file.

39

Page 40

7.2.5 History Screen

Element

Name

Description / Display

A

Site

Site (test) information including Site name, Feeder,

and Sector

B

Log Data Set

Shows historical information of measurement:

levels and RSSI

C

Log Data Set

As in A. The cursor is just for visually aiding the

user.

D

Page Indicator &

If more than 6 different sets of log data are stored

Outer arrows: Jump to Pos1 or End of list

E

Return

Returns to previous site.

Log data is stored in the test system memory whenever the REC button is

pushed. Log data stores the measurements, tester settings, and site related

information. With this capability operators can view historic information of specific

sites, allowing them to compare current and former measurements and analyze if

their performance has chang ed over time..

Jump arrows

Date, Time, PIM reading, Frequencies, Power

in the PIM31, the current page and number of

pages are shown.

Inner arrows: One page jumps in both directions

40

Page 41

7.2.6 Data Management

The following chapter desc ribes the Data Menu and Data structure.

Recording / Record - Button

PIM31 can store measurement data manually (default) or automatically with

predetermined intervals. When the “Record” button in the “Field Mode” screen is

pushed, the system stores one data set in a log file. The recorded measure men t

data is stored in a log fil e. This file is stored in ASCII text format with CSV

structure. (Comma -Separated Values), allowing convenient importing of log data

into databases or spreadsheet applications.

For more information about Automatic Mode refer to chapter “System Menu”.

Note: While it is theoretically possible to enter commas in descriptive

fields like Carrier Name, Site, Feeder and Sector, it is strongly

suggested to refrain from such practice. In a CSV structure, text after

the comma will be taken as new value when importing into a database

or spreadsheet which will mix up field assignments. Important

information will be at an incorrect location.

7.2.7 Log Files and Content

With PIM31 firmware versions 1.2 and later, log file names are a combination of

Carrier, Site, Feeder, Sector, Date and Time. This way every log data file is

absolutely unique and allows for easy identification:

PIM31_SITE_FEEDER_SECTOR_YYYYMMDD_HHMMSS.log

Previous firmware versions used the nome ncl atur e:

PIM31_YYYYMMDD_HHMMSS.log

Log files are stored in the directory C:/PIM 31 /History

Users do not need to access this directory directly since the data features of

PIM31 test system offer a convenient way to extract and copy the data.

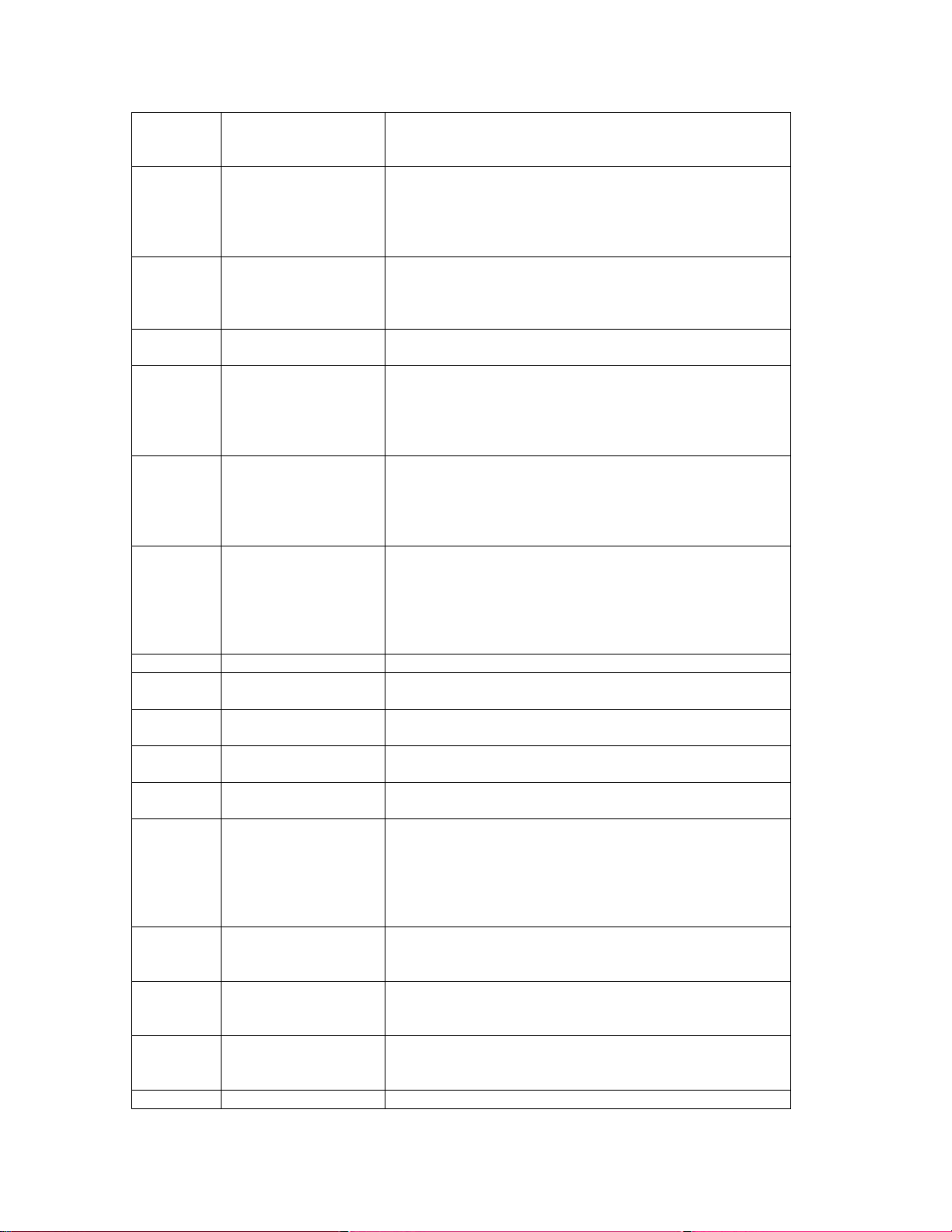

Information stored in log files is listed in the table below.

41

Page 42

Content (comma separated)

Variable

Format

Description

Date

YYYYMMDD

Time

HHMMSS

PIM (dBc)

-XXX.X

Signed Field

PIM (dBm)

-XXX.X

Signed Field

RSSI (dBm)

-XXX.X

Signed Field

F1 (MHz)

XXXX.X

Frequency 1 in MHz

F2 (MHz)

XXXX.X

Frequency 2 in MHz

IM 3 (MHz)

XXXX.X

IM3 Frequency in MHz

F1 (dBm)

XX.X

F1 Power level in dBm

F2 (dBm)

XX.X

F1 Power Level in dBm

IM3 Bandwidth (Hz)

XXXXX

IM 3 Bandwidth in Hz

PIM 31 Type

XXX

Example: “F03”

Model

String - 40 Characters max

Serial Number

String - 40 Characters max

Serial number of test system

HW Version

String - 40 Characters max

Hardware version

SW Version

String - 40 Characters max

Software version installed

OS Version

String - 40 Characters max

Operating system

Carrier

String - 70 Characters max

Carrier name

Site Name

String - 70 Characters max

Site / Test description

Feeder

String - 40 Characters max

Feeder description

User

String - 70 Characters max

User name / Initials

“Wireless Telecom Group”

String

For internal use

“PIM 31 Data Log”

String

For internal use

Cal date

YYYYMMDD

Date of Last Calibration

CHKSUM

XXX

For future use

SECTOR

String - 40 Characters max

Sector description.

BarGraph_RG

-XXX

Value of Bar Graph green /red

threshold (–dBc).

RFON

String:

RF On time in seconds,

120m,180m or “Always On”

RECINTRV

String

Lists Recording interval time

and units or “OFF”

ALC

String - 3 Characters max

“ON” or “OFF”

Added with firmware version 1.2 and later.

1m,2m,5m,10m,20m,30m,60m,

42

Page 43

7.2.8 Log File Management

Element

Name

Description / Display

A

Copy location

Drive, directory and file name of the merged log data

file.

B

when related log data are erased.

All measurements are stored in separate log files. When transferring files to an

external drive (e.g. memory stick), all log data is merged into one file for ease of

importing into databases and spreadsheets.

Default drive directory and file name of the merged log data-sets is:

D:\Site Info\PIM31_Site_all.log

The default setting can be overwritten when specific locations or filenames are

required (requires keyboard).

7.2.9 Data Copy

Data copies selected log files to one merged log file at a particular directory.

Erase Yes/No Selects if log files are to be deleted after files have been

copied.

Note: Historical site information is no longer available

43

Page 44

Default: No

C

Site

Allows copying of log data from a specific Site or all

Sites the PIM 31 contains. Specific Sites can be

Default: Specific

D

History

Allows copying of log data recorded at specific dates

Default: Today

E

Copy

Executes copy process

F

Site

Opens Site Selection screen.

to Data Menu after Return

G

Advanced

Opens Data Delete menu (allows deletion of log data

without copying)

H

Default

Sets default values

I

Return

Returns to previous site.

selected via the Site Button

Selection: Specific, All

Selection: Today, Specific, All, Date, Period

Date or Period require entry in YY/MM/DD format.

Press enter to store setting

Marked Site on Site Selection screen will be transferred

7.2.10 Data Delete Log Files

The Data Delete Menu allows the user to delete specific log files or all log files. In

this mode the data is not copied before it is deleted so extreme care need to be

taken because with lost log files, historical data of related sites is no long er

available.

44

Page 45

Element

Name

Description / Display

A

Carrier

Selection to erase log data of a specific Carrier, All

Default: None

B

Site

Selection to erase log data of a specific Site, all sites or

Default: None

C

History

Allows deletion of log data recorded at specific dates

Default: Today

D

Delete

Executes deletion

E

transferred to Data Delete Menu after Return

F

to Data Delete Menu after Return

G

Advanced

Opens Data Carrier & Site Delete menu

H

Default

Sets default values

I

Return

Returns to Data Copy site.

Carriers or none.

Specific Carriers can be selected via the Carrier button

Selection: None, Specific, All

none.

Specific Sites can be selected via the Site button

Selection: None, Specific, All

Selection: Today, Specific, All, Date, Period

Date or Period require entry in YY/MM/DD format.

Press enter to store setting

Carrier Opens Carrier Selection screen.

Marked Carrier on Carrier Selection screen will be

Site Opens Site Selection screen.

Marked Site on site Selection screen will be transferred

45

Page 46

7.2.11 Data Delete Carrier & Site

Element

Name

Description / Display

A

Carrier

Selection to erase a specific Carrier, All Carriers or

Default: None

B

Site

Selection to erase a specific Site, all sites or none.

Default: None

C

Sites Only

Selection of only Sites are erased or both Sites and

Default: Sites only

D

Delete

Executes deletion of Sites / Sites & Carriers (all settings

and data will be lost)

E

Carrier

Opens Carrier Selection screen.

Return

This Menu allows users to delete Sites and/or Carriers. After the

deletion process, all Carrier and/or Site related settings and data,

including log data, will be erased.

none.

Specific Carriers can be selected via the Carrier button

Selection: None, Specific, All

Specific Sites can be selected via the Site button

Selection: None, Specific, All

Sites & Carriers

Carriers.

Selection: Sites only, Sites & Carriers

Marked Carrier on Carrier Selection screen will be

transferred to Data Site & Carries Delete Menu after

46

Page 47

F

Site

Opens Site Selection screen.

Marked Site on site Selection screen will be transferred

to Data Site & Carrier Delete Menu after Return

G

Default

Sets default values

H

Return

Returns to Data Copy site.

7.3 System Menu

The System Menu provides information about the PIM31 test system. Information

shown includes software version, hardware version, and memory space available

for log data. This menu allows users to modify the default settings of the PIM31.

The need to modifying basic settings may be required during regular testing.

Advanced settings should only be modified by advanced operators since they

influence how the PIM31 measures PIM.

System Information and Buttons

Note: This screenshot has been taken form a PIM31 S W Simulator running on a

PC, therefore some values are displayed as 0s

47

Page 48

Element

Name

Description / Display

A

Model

Model type of PIMI31. .

B

TX Frequencies

Transmitting frequency range, tester type

dependent

C

RX Frequencies

Receiving frequency range, tester type dependent

D

SW Version

Software Version of PIM31

E

HW Version

Hardware version of PIM31

F

Operation System

Operation system and service pack used

G

Free Space

Memory space available for data logging.

H

Cal Date

Calibration Date of PIM31

I

Serial Number

Serial number of PIM 31:

J

Basic / Advanced

Toggles between Basic mode and Advanced

information.

K

Default

Sets default values.

L

Return

Returns to previous site.

mode:

Basic mode: RF On Time, REC Interval

Advanced mode: Access to all settings

See chapter System Function Block for detailed

48

Page 49

7.3.1.1 PIM 31 Memory Space

PIM 31 Passive intermodulation test systems come with a total of

5.75 GB of user accessible memory. This memory is used to store

log data and site setup information. The average size of a Log data

set is 250 Bytes. With a drive segmentation of 512 Byte per block,

PIM 31 test systems can store more than 11 Million data sets.

7.3.2 System Menu Functional Block

7.3.2.1 RF ON TIME

By default, PIM 31 test systems will switch RF

power off after 30mins. This prevents

unnecessary transmission of RF power if the

system has been left on unintended.

RF-ON periods: 1m, 2m, 5m, 10m, 20m, 60m, 120m, 360m or “Always On”.

Default: 30min

49

Page 50

7.3.2.2 REC Interval

PIM 31 test systems record measurements

whenever the Record button is pushed. Multiple

pushes create multiple, corresponding individual

log files. If measurements need to be analyzed

over a longer of time, PIM 31 test systems can

record log data automatically by setting the REC

interval to a value other than “OFF”, which will

record data automatically at the interval entered.

When RF power is activated in the Field mode

screen pressing the Record once starts

recording, the second push stops recording.

The Status Indicator field will show the REC

symbol lit during recording. If RF power is

switched off during recording, data logging stops.

REC Intervals: 1s, 2s, 5s, 10s, 20s, 30s, 1m, 2m, 5m, 10m, 15m, 30m, 1h, 2h,

5h, 12h, 24h and “OFF”,

Default: OFF

50

Page 51

7.3.2.3 Filter BW

Advanced Mode Only.

Default filter bandwidth of the PIM31 receiver is

1.2 kHz; which is the optimized setting for best

performance. Increasing bandwidth opens the

receiver, allowing to “see” if signals are present

close to the receiving signal frequencies. If

Change of Filter Bandwidth effects all IM

frequencies that fall in the receiving range of the PIM31.Decreasing the filter

bandwidth allows to eliminate unwanted signals very close to the receiving signal

frequencies. Possibl e Filter BW settings are:

Filer BW: 300Hz, 600Hz, 1.2kHz, 2.4kHz,5kHz,10kHz, 12kHz, 15kHz ,25kHz

50kHz

Default:1.2 KHz

Note: Varying filter bandwidth influences the amount of RF energy

measured by the PIM31 receiver.

Wider Filter BW measurement values increase

(lower negative number),

Tighter Filter BW measurement values decrease (higher negative

numbers).

7.3.2.4 SPU Time

Advanced Mode Only.

SPU (Soft Power-Up) gradually ramps up the

RF output power, starti ng from 20d Bm , to the

actual power level. When the PIM31 amplifiers

switch the RF Power on, the full power is

practically immediately present at the RF Port.

Depending on the DUT, this can sometimes cause strong reflections. Antennas

which are directly (only with a short cable) connected to the RF port of the PIM31

51

Page 52

are prone to such reflections. If the returned energy is too high, PIM31 will switch

off to protect its hardware. A remedy is to simply increasing RF power gradually.

SPU Time: Increments 1s, Settings range 0sec to 60sec

Default: 0s

Example: With a power setting for 43dBm and SPU of 10s it takes 10 seconds to

ramp RF power up from 20dBm to 43dBm

Note: PIM31 starts measuring immediately after RF power is present at

the RF Port. During the period power is ramping up, PIM

measurements are lower than the ones at the final power level.

Remember, PIM is measured in dBc – power relative to the carrier:

Lower carrier power equals lower PIM readings.

To ensure users do not misinterpret a “good” reading during power

ramp-up, a blinking “SPU” marker is shown during the time. Measurements

should not be considered valid when the red SPU indicator is flashing. Please

wait for this indicator to disappear before considering the measurement valid.

52

Page 53

7.3.2.5 BAR Graph G/R

Advanced Mode Only

The Bar Graph’s green/red threshold is -153dBc

by default. The switch from green to red is an

optical indicator if a DUT is within limits or if it

exceeds them. PIM measurement values higher

than the set threshold can

provide an audible indicator.

Obviously Audio has to be

switched on in the Field Mode

screen. Maxhold is an important

feature which holds the

maximum value during PIM

measurements. In this example

the maxhold value is -147 dBc.

Bar Graph g/r: -60dBc to 180dBc in 1dB increments

Default: -153 dBc

7.3.2.6 Precision Tx Levels

Advanced Mode Only

ALC (Auto Level Control) provides an extra

boost of Tx Signal accuracy. When measuring

PIM, two RF carrier signals are combined and

transmitted into a passive RF component (DUT). Depending on its quality, the

DUT generates more or less intermodulation energy. For best measurement

accuracy the injected signals should closely match their power levels. With ALC:

ON, the PIM31 will synchronize these power levels perfectly. Increased accuracy

costs a bit more time. Setting Tx power levels with will 0.05 to 0.2 sec longer than

with ALC: OFF. With the exception of high volume production, this additional time

is not an issue, so it is recommended to always leave ALC ON.

53

Page 54

Default: ON

7.4 Analyzer Mode

The Analyzer Mode of the PM 31 offers more possibilities to analyze PIM

measurements. It contains of 3 Sub modes:

• Frequency

• Time

• Sweep

The Analyzer mode is selected by pressing the Analyzer button

while in the Field Mode Screen. Returning to field mode is

possible by pressing the return button. RF Power needs to be

OFF

Frequency and power values can be set directly without utilizing Carrier or Site

information. For larger display we recommend to use an external monitor.

As in the Field Mode, the Analyzer Mode allows to log data over a period of time.

In this mode only the settings and measurement values are recorded. The

analyzer mode allows taking screenshots. This is helpful due to the graphic

display and measurement trac es. Anal yzing an image often reveals mor e det ai l s

than analyzing numeric values.

For more information on data logging and screen shots see chapter “Pull-Down

menus”.

54

Page 55

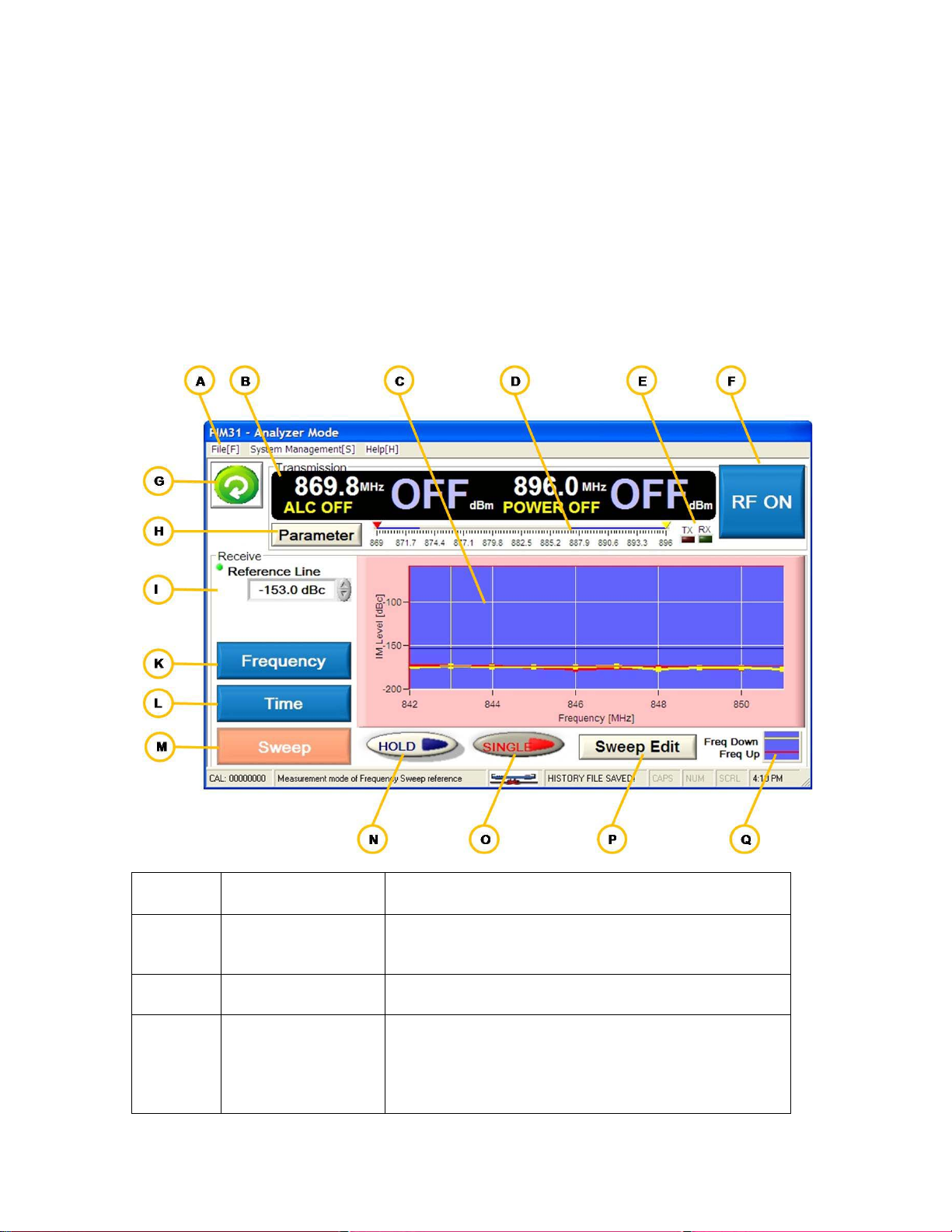

Element

Name

Description / Display

A

Pull-Down menu

Allows Screenshots, data logging, and self test. For

more information refer to chapter Pull-Down

menus.

B

Carrier display

Carrier signal information: Frequencies, Power

levels

C

Graphical display

Shows up to 4 IM signals as a vertical bar. Position

screen and drawing it to the desired location

D

Zoom Out

Allows modification of the range from -60 t o -200

resolution.

E

Tx/Rx

Shows internal communication activity to modules.

F

RF Power Button

Switches RF Power ON / OFF

power OFF.

G

Return

Brings PM 31 back to Field Mode. Works only

when RF Power is OFF

H

Parameter Setting

Allows modification of frequencies and power

Works only with RF Power OFF

on the x-axis indicates frequency and length

indicates power level. Color of the bars refers to

the colors of the numeric displays (N-Q).

The graphical display is floating, meaning the

center area can be moved for better convenience

and visibility of important display information.

Moving by touching grid part of the display and the

dBc to -100 to 200dBc, which provides a better

The Button inscription shows what happens if the

button is pushed. In the shown screenshot RF

power is ON, the next button push will switch RF

levels used in Analyzer Time and Frequency mode.

55

Page 56

I

Reference Line

Moves reference line for audible indication of

measurements that exceed the limit. Same as

Range -60 to -200 dBc

J

Reference IM

Selects if particular IM products (faster) or All IM

show up to 4 IM signals at the same time.

K

Frequency

Graphic Display Frequency mode: IM signals

frequency. Signal colors relate to numeric display

L

Time

Graphic display – Time Mode: IM signals shown as

over time. Signal color relates to numeric display

M

Sweep

Graphic display Sweep mode. Signals are “swept”

over a range to test wide frequency range

N

Numeric field 1

Strongest IM Signal in the receiver band

frequency

O

Numeric field 2

Second strongest IM Signal in the receiver band

frequency

P

Numeric field 3

Third strongest IM Signal in the receiver band

frequency

Q

Numeric field 4

Forth strongest IM Signal in the receiver band

frequency

Green/Red threshold of Bar graph in field mode.

products (more comprehensive) that fall into the

receiving band of the PIM31. The test system can

shown as vertical bar, indicating power and

moving horizontal line, indicating power (changes)

Information shown: Power (dBc & dBm) and IM

Information shown: Power (dBc & dBm) and IM

Information shown: Power (dBc & dBm) and IM

Information shown: Power (dBc & dBm) and IM

7.4.1 Frequency Mode

In Frequency mode IM products are displayed as vertical bars, where the

positions indicate the frequencies and the length the power level. Up to 4 signals

can be shown at the same time. Different colors are used when more IM

products are shown. PIM products are also shown numerically, where the colors

of the bars correlates with the colors of the 4 numeric displays.

56

Page 57

7.4.2 Time Mode

In Time mode IM products are displayed as a horizontally moving line, where the

position indicates the power level over the time. This display is very helpful to test

immediate PIM variations, like loose connections. Any change is immediately

visible. Time mode shows a 10 seconds window, but more information up to 10

minutes may be recorded. Move past traces to the window by touching, holding

and drawing it to right until the wanted information is appears.

The screenshot shows two IM signals IM3 and IM5 With -149.0 dBc IM3 exceeds

the reference limit of -153.0 dBc. IM5 measured -176.8 dBc. Frequency

information of the IM signals is provided in the numeric displays. In this example

(M3 is 846.5 MHz and IM5 824.0 MHz.

57

Page 58

7.4.3 Sweep Mode

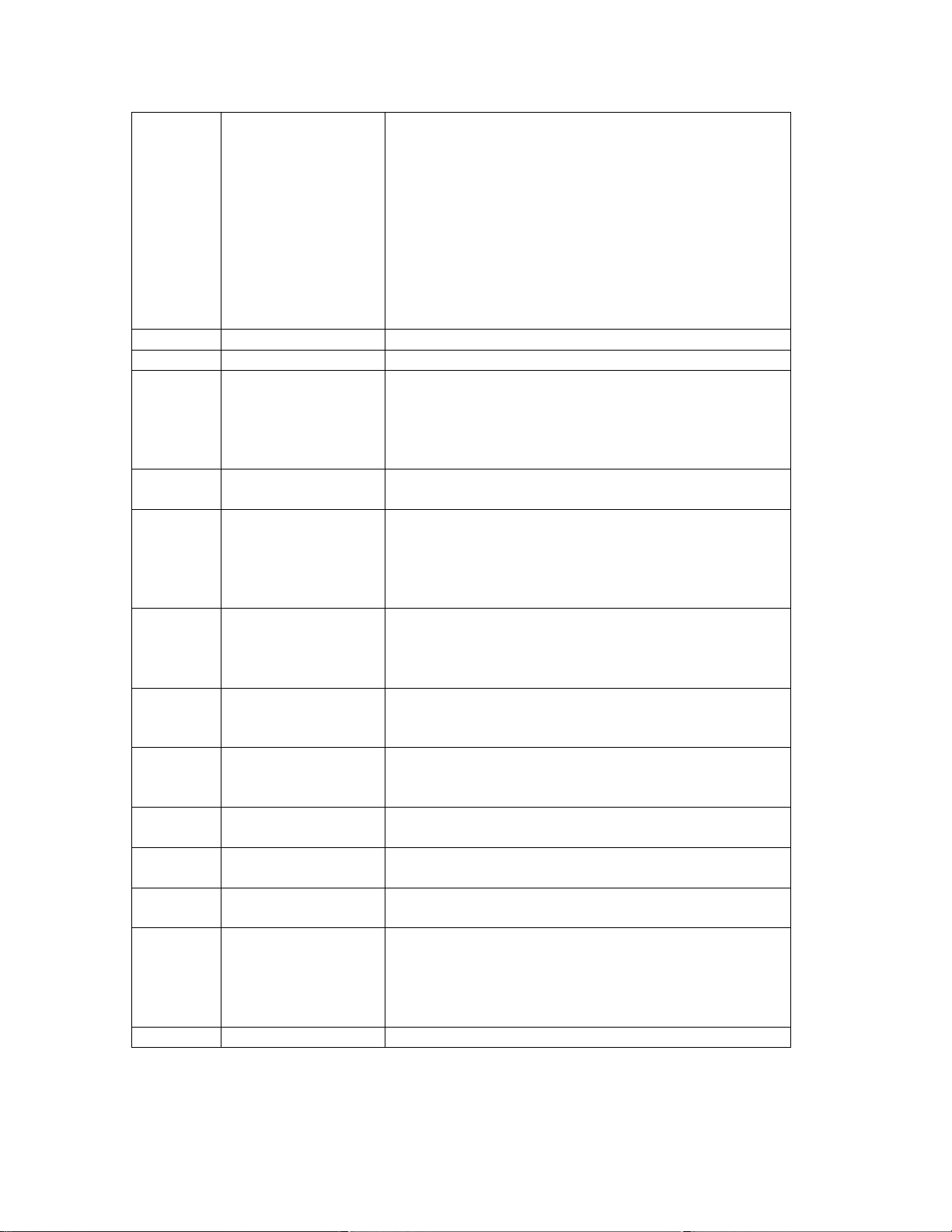

Element

Name

Description / Display

A

Pull-Down menu

Allows Screenshots, data logging, and self test. For

menus”.

B

Carrier display

Carrier signal information: Frequencies, Power

levels

C

Graphical display

Shows two traces (red / yellow) of an IM product

b) sweeping highest frequency carrier signal

IM products in linear environment are frequency independent. Many passive

components show a frequency response that is less linear or strongly frequency

dependent. The sweep mode increments / decrements carrier signals by 1 MHz.

covering a Tx range that results in a sweep of the complete Rx frequency range.

Any deviations of PIM measurements that are frequency dependent are

immediately visible.

more information refer to chapter “Pull-Down

that are generated by

a) sweeping the lowest frequency upwards – red

trace and after that

58

Page 59

downwards –yellow trace.

Increments are 1 MHz

screen and drawing it to the desired location

D

TX Range

Shows Range of up-sweep and down-sweep..

E

Tx/Rx

Shows internal communication activity to modules.

F

RF Power Button

Switches RF Power ON / OFF

power ON.

G

Return

Brings PM 31 back to Field Mode. Works only

when RF Power is OFF

H

Parameter Setting

To set power levels for the sweep cycles:

(P) sets frequency ranges.

I

Reference Line

Moves reference line for audible indication of

Range -60 to -200 dBc

K

Frequency

Graphic Display Frequency mode: IM signals

frequency. Signal colors relate to numeric display

L

Time

Graphic display – Time Mode: IM signals shown as

over time. Signal color relates to numeric display

M

Sweep

Graphic display Sweep mode. Signals are “swept”

over a range to test wide frequency range

N

Hold

Hold Off blue, On red. While sweeping,

measurement can be held immediately.

O

Single

Single Off –Blue, On -red. Determines if a single

sweep or continuous sweeps are measured.

P

100ms, range 10ms to 2000ms)

Q

Freq Up/Down

Only for visualization of Tx sweep ranges

IM signals as a vertical bar. Position on the x-axis

indicates frequency and length indicates power

level. Color of the bars refers to the colors of the

numeric displays (N-Q).

The graphical display is floating, meaning the

center area can be moved for better convenience

and visibility of important display information.

Moving by touching grid part of the display and the

The Button inscription shows what happens if the

button is pushed. In the shown screenshot RF

power is OFF, the next button push will switch RF

Menu comes up only with RF Power OFF

Note: frequency setting in the parameter menu is

not relevant for sweep measurements. Sweep Edit

Sweep Edit

measurements that exceed the limit. Same as

Green/Red threshold of Bar graph in field mode.

shown as vertical bar, indicating power and

moving horizontal line, indicating power (changes)

Opens Sweep Edit menu, allowing to set:

End of Lower Tx range, Start of Higher Tx range,

Selection of measured IM (in case more than one

are in the range), sweep increment time (default

59

Page 60

Element

Name

Description / Display

A

Reference IM

Allows selection of IM product (in case more than

one are in the swept range)

B

generate

C

Freq 2 Sweep

Start frequency of down-sweep

generate

D

Sweep Cycle

Time between setting and measurement of

increments

E

Set

Stores settings and returns to Analyzer Sweep

Mode

Freq 1 Sweep

Start Frequency of up-sweep

Default: lowest Tx frequency the tester can

Default: lowest Tx frequency the tester can

Note: Sweep mode requires setting the power levels (Parameter

button) and also to define the sweep frequency range (Sweep Edit

Button).

60

Page 61

8 Pull Down Menus

Field

Mode

Analyzer

Mode

File

Start History Save

X

Stop History Save

X

X X

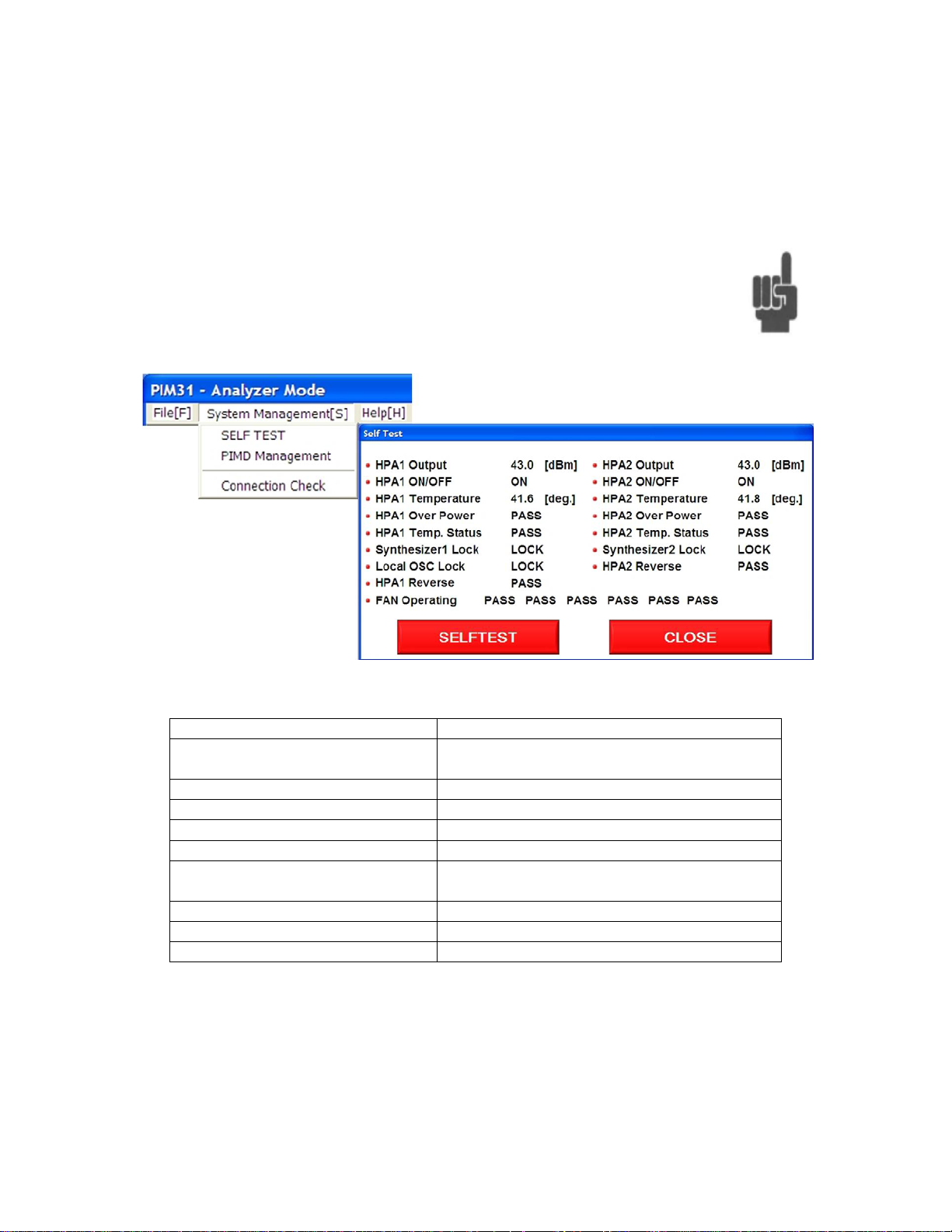

System Management

Self Test

X

X

PIMD management

X

Connection check *

Help

Contact information

X

X

Pull down Menus offer additional features and allow users to set some system

parameters. They allow also performing a self test of the PIM31 test system.

Three Pull-Down menus are available:

• File

o Start History Save

o Stop History Save

o Screen Capture

o Initialize Program

o Quit

• System Management

o Self Test

o PIMD management

o Connection check *

Field Mode offers a subset of Pull-Down menus, Analyzer mode offers all of

them. The features available in field mode

Screen Capture

Initialize Program

Quit

X

X

*Connection check is for factory use only.

61

Page 62

8.1 File

8.1.1 Start / Stop History Save

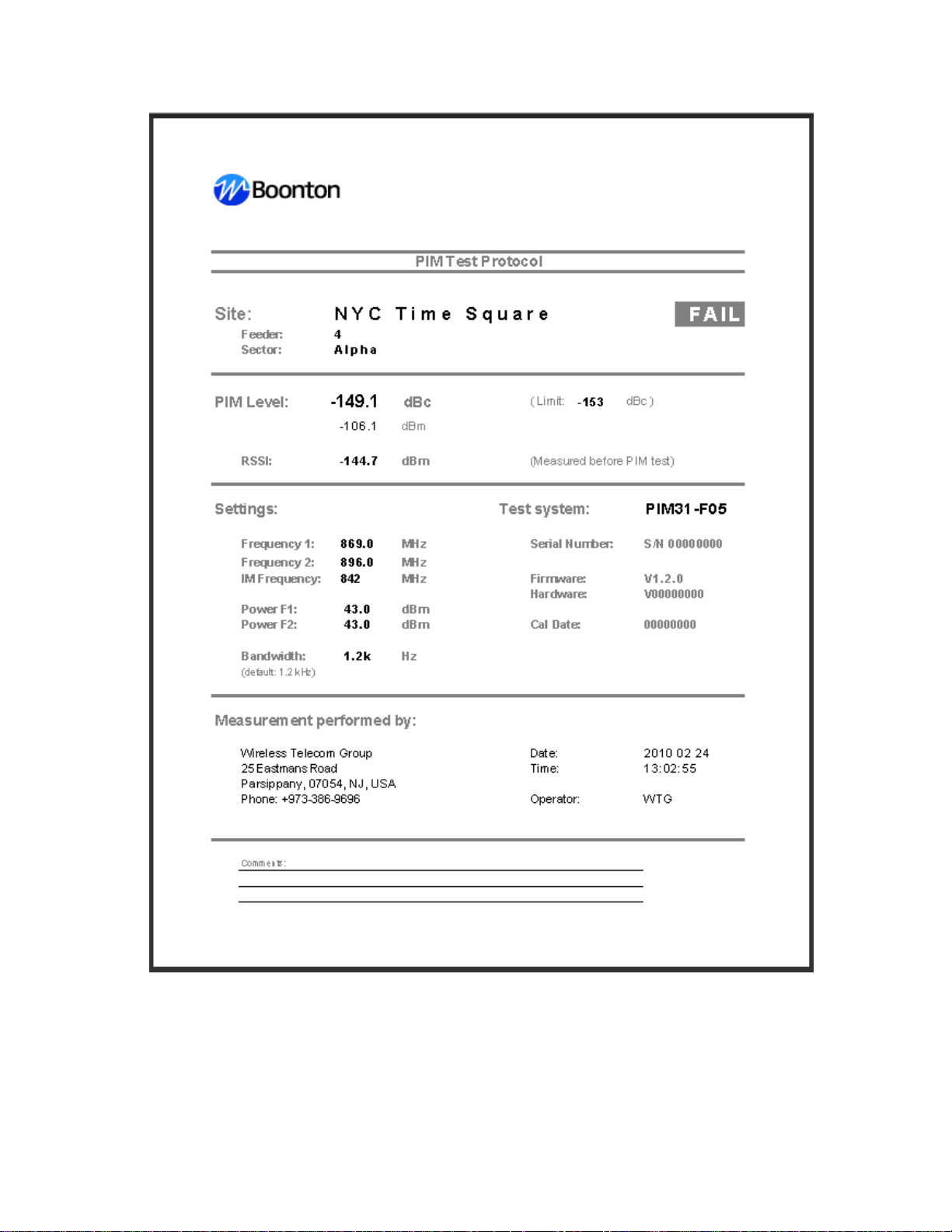

This feature allows users to log measurements over a period of time in Analyzer

mode. The log files are stored in TSV (Tab Separated Value) ASCII text format.

Values listed are:

Date, Time, Carrier1 (MHz), Carrier2 (MHz), Output Level1 (dBm), Output Level2

(dBm), Offset (dB), ALC On/Off, Screen Mode, IM Number (Order), IM

Frequency (MHz), IM Measure(dBc), Direction, Measure Mode/Pass IM

Level/decision

Note: PIM 31 does not support Offset, Measure Mode/Pass and IM