Page 1

INSTRUCTION MANUAL

9240 SERIES

RF VOLTMETER

REV DATE 01/20/2011

MANUAL P/N 98406900A

CD P/N 98406999A

Wireless Telecom Group

25 EASTMANS ROAD, PARSIPPANY, NJ 07054

Telephone: 973-386-9696

Fax: 973-386-9191

Email: boonton@boonton.com

Web:

www.wtcom.com

Page 2

Boonton 9240 Series RF Voltmeter

INSTRUCTION MANUAL, 9240 SERIES RF VOLTMETER

Revision date 01/20/2011

© Copyright in 2005-2011, by BOONTON Electronics, a subsidiary of the Wireless Telecom

Group, Inc.

Parsippany, NJ, USA. All rights reserved.

P/N 98406900A

This manual covers instrument serial numbers: 11001 and higher.

ii

Contents

Page 3

Boonton 9240 Series RF Voltmeter

SAFETY SUMMARY

The following general safety precautions must be observed during all phases of operation and maintenance

of this instrument. Failure to comply with these precautions or with specific warnings elsewhere in this

manual violates safety standards of design, manufacture, and intended use of the instrument. Boonton

Electronics assumes no liability for the customer’s failure to comply with these requirements.

THE INSTRUMENT MUST BE GROUNDED

To minimize shock hazard the instrument chassis and cabinet must be connected to an electrical ground.

The instrument is equipped with a NEMA three conductor, three prong power cable. The power cable must

either be plugged into an approved three-contact electrical outlet or used with a three-contact to a twocontact adapter with the (green) grounding wire firmly connected to an electrical ground in the power

outlet.

DO NOT OPERATE THE INSTRUMENT IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of flammable gases or fumes.

KEEP AWAY FROM LIVE CIRCUITS

Operating personnel must not remove instrument covers. Component replacement and internal adjustments

must be made by qualified maintenance personnel. Do not replace components with the power cable

connected. Under certain conditions dangerous voltages may exist even though the power cable was

removed, therefore; always disconnect power and discharge circuits before touching them.

DO NOT SERVICE OR ADJUST ALONE

Do not attempt internal service or adjustment unless another person, capable or rendering first aid and

resuscitation, is present.

DO NOT SUBSTITUTE PARTS OR MODIFY INSTRUMENT

Do not install substitute parts or perform any unauthorized modifications or the instrument. Return the

instrument to Boonton Electronics for repair to ensure that the safety features are maintained.

Contents

iii

Page 4

Boonton 9240 Series RF Voltmeter

SAFETY SYMBOLS

This safety requirement symbol (located on the rear panel) has been adopted by the

International Electro-technical Commission, Document 66 (Central Office) 3, Paragraph

5.3, which directs that an instrument be so labeled if, for the correct use of the instrument,

it is necessary to refer to the instruction manual. In this case it is recommended that

reference be made to the instruction manual when connecting the instrument to the proper

power source. Verify that the correct fuse is installed for the power available.

The CAUTION symbol denotes a hazard. It calls attention to an operational procedure,

practice or instruction that, if not followed, could result in damage to or destruction of

part or all of the instrument and accessories. Do not proceed beyond a CAUTION symbol

until its conditions are fully understood and met.

The NOTE symbol is used to mark information which should be read. This information

can be very useful to the operating in dealing with the subject covered in this section.

The HINT symbol is used to identify additional comments which are outside of the

normal format of the manual, however can give the user additional information about the

subject.

iv

Contents

Page 5

Boonton 9240 Series RF Voltmeter

1. General Information..............................................................................................1-1

1.1 Organization.......................................................................................................... 1-1

1.2 Description............................................................................................................1-2

1.3 Features................................................................................................................. 1-2

1.4 Accessories ........................................................................................................... 1-5

Standard ............................................................................................................... 1-5

Optional................................................................................................................ 1-5

Optional................................................................................................................ 1-6

Probes................................................................................................................... 1-6

1.5 Models, Options and Configurations .................................................................... 1-6

1.6 Specifications........................................................................................................1-7

VOLTAGE PROBE INPUTS.............................................................................. 1-7

FEATURES .........................................................................................................1-7

MEASUREMENT SYSTEM ..............................................................................1-9

ACCURACY ....................................................................................................... 1-9

EXTERNAL INTERFACES ............................................................................. 1-10

PHYSICAL AND ENVIRONMENTAL CHARACTERISTICS .....................1-11

OTHER CHARACTERISTICS......................................................................... 1-11

REGULATORY CHARACTERISTICS ........................................................... 1-12

2. Installation..............................................................................................................2-1

2.1 Unpacking & Repacking....................................................................................... 2-1

2.2 Power Requirements............................................................................................. 2-2

2.3 Connections ..........................................................................................................2-2

2.4 Preliminary Check ................................................................................................ 2-3

3. Getting Started.......................................................................................................3-1

3.1 Organization.......................................................................................................... 3-1

3.2 Operating Controls, Indicators and Connections.................................................. 3-1

3.3 Operation ..............................................................................................................3-6

3.3.1 Menu Key........................................................................................................ 3-9

3.3.2 Sensor Key.................................................................................................... 3-15

3.3.3 FREQ Key..................................................................................................... 3-17

3.3.4 AVG Key. ..................................................................................................... 3-17

3.3.5 Zero Key (single key press operation).......................................................... 3-18

3.3.6 REL Level Key (single key press operation)................................................ 3-18

4. Operation................................................................................................................4-1

4.1 Zeroing the Instrument..................................................................................... 4-1

4.2 Making Measurements..................................................................................... 4-1

Contents

v

Page 6

Boonton 9240 Series RF Voltmeter

4.3 Overload Limits ............................................................................................... 4-1

4.4 Connection Recommendations ........................................................................4-2

4.5 Low Level Measurements................................................................................ 4-2

4.6 Temperature Effects......................................................................................... 4-3

4.7 Hum, Noise and Spurious Pickup .................................................................... 4-3

4.8 Recorder Output............................................................................................... 4-3

4.9 Correction Curve for Model 952003 50 Ohm Type N Tee Adapter................4-3

4.10 Correction Curve for Model 952007 75 Ohm Type N Tee Adapter................4-3

4.11 RF Power Measurements................................................................................. 4-4

5. Remote Operation..................................................................................................5-1

5.1 GPIB Configuration.............................................................................................. 5-1

5.2 RS-232 Configuration........................................................................................... 5-1

5.3 SCPI Language ..................................................................................................... 5-2

5.3.1 SCPI Structure ...............................................................................................5-2

5.3.2 Long and Short Form Keywords....................................................................5-2

5.3.3 Subsystem Numeric Suffixes......................................................................... 5-2

5.3.4 Colon Keyword Separators............................................................................ 5-3

5.3.5 Command Arguments and Queries................................................................ 5-3

5.3.6 Semicolon Command Separators................................................................... 5-3

5.3.7 Command Terminators .................................................................................. 5-3

5.3.8 9240 Series SCPI Implementation................................................................. 5-3

5.4 Basic Measurement Information........................................................................... 5-5

5.4.1 Service Request.............................................................................................. 5-5

5.5 SCPI Command Reference ................................................................................... 5-6

5.5.1 IEEE 488.2 Commands.................................................................................. 5-6

*CLS .................................................................................................................... 5-6

*ESE ....................................................................................................................5-6

*ESR? ..................................................................................................................5-7

*IDN?................................................................................................................... 5-7

*OPC....................................................................................................................5-7

*OPC? .................................................................................................................. 5-7

*OPT? .................................................................................................................. 5-8

*RST .................................................................................................................... 5-8

*SRE .................................................................................................................... 5-8

*STB? ..................................................................................................................5-9

*TRG.................................................................................................................... 5-9

*TST?................................................................................................................... 5-9

*WAI....................................................................................................................5-9

5.5.2 CALCulate Subsystem................................................................................. 5-10

CALCulate:LIMit:CLEar[:IMMediate]............................................................. 5-10

vi

Contents

Page 7

Boonton 9240 Series RF Voltmeter

CALCulate:LIMit:FAIL?................................................................................... 5-10

CALCulate:LIMit:LOWer[:POWer] ................................................................. 5-10

CALCulate:LIMit:UPPer[:POWer] ................................................................... 5-11

CALCulate:LIMit:LOWer:STATe .................................................................... 5-11

CALCulate:LIMit:UPPer:STATe...................................................................... 5-11

CALCulate:LIMit[:BOTH]:STATe................................................................... 5-11

CALCulate:MATH:ARGA................................................................................5-12

CALCulate:MATH:ARGB................................................................................ 5-12

CALCulate:MATH:DATA? .............................................................................. 5-12

CALCulate:MATH:OPERator........................................................................... 5-12

CALCulate:MODe............................................................................................. 5-12

CALCulate:REFerence:COLLect...................................................................... 5-13

CALCulate:REFerence:DATA.......................................................................... 5-13

CALCulate:REFerence:STATe .........................................................................5-13

CALCulate:STATe ............................................................................................ 5-13

CALCulate:UNITs............................................................................................. 5-13

5.5.3 CALibration Subsystem............................................................................... 5-14

CALibration:ZERO............................................................................................ 5-14

5.5.4 DISPlay Subsystem...................................................................................... 5-15

DISPlay:ACTive[?]............................................................................................5-15

DISPlay:CLEar .................................................................................................. 5-15

DISPlay:LIN:RESolution ..................................................................................5-15

DISPlay:LOG:RESolution................................................................................. 5-15

DISPlay:LABel:MODE ..................................................................................... 5-15

DISPlay:LABel:TEXTA....................................................................................5-16

DISPlay:LABel:TEXTB.................................................................................... 5-16

DISPlay:LABel:TEXTC.................................................................................... 5-16

DISPlay:LABel:TEXTD....................................................................................5-16

5.5.5 FETCh Queries ............................................................................................ 5-17

FETCh:CW:VOLTage? ..................................................................................... 5-17

FETCh:KEY?..................................................................................................... 5-17

5.5.6 INITiate and ABORt Commands................................................................. 5-18

ABORt ...............................................................................................................5-18

INITiate:CONTinuous ....................................................................................... 5-18

INITiate[:IMMediate[:ALL]] ............................................................................5-18

5.5.7 MEASure Queries........................................................................................ 5-19

MEASure:POWer? ............................................................................................5-19

MEASure:VOLTage? ........................................................................................ 5-19

5.5.8 MEMory Subsystem .................................................................................... 5-20

MEMory:SNSR:CWRG?................................................................................... 5-20

MEMory:SNSR:INFO? ..................................................................................... 5-20

MEMory:SYS:LOAD........................................................................................ 5-20

MEMory:SYS:STORe ....................................................................................... 5-20

5.5.9 OUTPut Subsystem...................................................................................... 5-21

OUTPut:RECorder:FORCe ...............................................................................5-21

OUTPut:RECorder:MAX .................................................................................. 5-21

Contents

vii

Page 8

Boonton 9240 Series RF Voltmeter

OUTPut:RECorder:MIN.................................................................................... 5-21

OUTPut:RECorder:SOURce .............................................................................5-21

5.5.10 READ Queries ........................................................................................... 5-22

READ:CW:VOLTage? ...................................................................................... 5-22

5.5.11 SENSe Subsystem...................................................................................... 5-23

SENSe:FILTer:STATe ......................................................................................5-23

SENSe:FILTer:TIMe ......................................................................................... 5-23

5.5.12 STATus Commands...................................................................................5-24

STATus:DEVice:CONDition? ..........................................................................5-24

STATus:DEVice:ENABle ................................................................................. 5-24

STATus:DEVice:EVENt? ................................................................................. 5-25

STATus:DEVice:NTRansition .......................................................................... 5-25

STATus:DEVice:PTRansition........................................................................... 5-25

STATus:OPERation:CONDition? ..................................................................... 5-26

STATus:OPERation:ENABle............................................................................ 5-26

STATus:OPERation:EVENt?............................................................................ 5-26

STATus:OPERation:NTRansition..................................................................... 5-27

STATus:OPERation:PTRansition......................................................................5-27

STATus:PRESet ................................................................................................5-27

STATus:QUEStionable:CONDition?................................................................ 5-28

STATus:QUEStionable:ENABle....................................................................... 5-28

STATus:QUEStionable:EVENt?....................................................................... 5-28

STATus:QUEStionable:NTRansition................................................................ 5-29

STATus:QUEStionable:PTRansition ................................................................5-29

STATus:QUEStionable:CALibration:CONDition? ..........................................5-29

STATus:QUEStionable:CALibration:ENABle ................................................. 5-30

STATus:QUEStionable:CALibration:EVENt? .................................................5-30

STATus:QUEStionable:CALibration:NTRansition .......................................... 5-30

STATus:QUEStionable:CALibration:PTRansition........................................... 5-30

5.5.13 SYSTem Subsystem...................................................................................5-31

SYSTem:BEEP[:ENABle] ................................................................................5-31

SYSTem:BEEP:IMMediate............................................................................... 5-31

SYSTem:COMMunicate:GPIB:ADDRess ........................................................ 5-31

SYSTem:COMMunicate:GPIB:EOI..................................................................5-31

SYSTem:COMMunicate:GPIB:LISTen............................................................ 5-31

SYSTem:COMMunicate:GPIB:TALK..............................................................5-32

SYSTem:COMMunicate:SERial:BAUD........................................................... 5-32

SYSTem:COMMunicate:SERial:BITS ............................................................. 5-32

SYSTem:COMMunicate:SERial:PARity.......................................................... 5-32

SYSTem:COMMunicate:SERial:SBITs............................................................ 5-32

SYSTem:ERRor[:NEXT]? ................................................................................5-33

SYSTem:ERRor:CODE?................................................................................... 5-33

SYSTem:ERRor:COUNt? ................................................................................. 5-33

SYSTem:PRESet ...............................................................................................5-33

SYSTem:VERSion?........................................................................................... 5-33

5.5.14 INSTrument:VERSion Commands............................................................ 5-34

viii

Contents

Page 9

Boonton 9240 Series RF Voltmeter

INSTrument:VERSion:FIRMware? ..................................................................5-34

INSTrument:VERSion:FPGA?..........................................................................5-34

5.5.15 SCPI Command Summary......................................................................... 5-35

5.5.16 9230 Emulation GPIB Commands.............................................................5-40

6. Maintenance ...........................................................................................................6-1

6.1 Safety .................................................................................................................... 6-1

6.2 Cleaning ................................................................................................................ 6-1

6.3 Inspection.............................................................................................................. 6-1

6.4 Firmware Upgrade ................................................................................................ 6-1

6.5 Firmware Upgrade Instructions ............................................................................ 6-2

7. Appendix A SCPI Error Messages.......................................................................7-1

7.1 SCPI Error Messages ............................................................................................ 7-1

8. Appendix B Warranty & Repair..........................................................................8-1

Repair Policy................................................................................................................ 8-1

Limited Warranty......................................................................................................... 8-1

Contents

ix

Page 10

Boonton 9240 Series RF Voltmeter

This page intentionally left blank.

x

Contents

Page 11

Boonton 9240 Series RF Voltmeter

1. General Information

This instruction manual provides general information, installation and operating instructions for the Model

9240 Series of RF Voltmeters. The 9240 Series includes single channel Model 9241 and dual channel

Model 9242. The terms 9240 and Model 9240 used throughout this manual refer to both configurations

unless otherwise noted.

1.1 Organization

The manual is organized into seven sections and three Appendices, as follows:

Section 1 - General Information presents summary descriptions of the instrument and its principal

features, accessories and options. Also included are specifications for the instrument.

Section 2 - Installation provides instructions for unpacking the instrument, setting it up for operation,

connecting power and signal cables, and initial power-up.

Section 3 - Getting Started describes the controls and indicators and the initialization of operating

parameters. Several practice exercises are provided to familiarize you with essential setup and control

procedures.

Section 4 - Operation describes the display menus and procedures for operating the instrument locally

from the front panel.

Section 5 - Remote Operation explains the command set and procedures for operating the instrument

remotely over GPIB bus.

Section 6 - Maintenance includes procedures for installing software and verifying fault-free operation.

Section 7 - Appendix A - Error Messages defines the messages that are displayed when errors occur.

Section 8 - Appendix B - Warranty and Repair Policy states the policies governing the return and

replacement of modules and instruments during and after the warranty period.

General Information

1-1

Page 12

Boonton 9240 Series RF Voltmeter

1.2 Description

The Model 9240 is a DSP (digital signal processor) based RF Voltmeter capable of measuring RF voltage

levels from 200 microvolts to 300 volts (probe dependent) over a frequency range from 10 Hz to 2.5 GHz

(probe dependent). The voltage levels can be displayed in V, mV, dBV or dBmV. When the measured

voltage is across a known impedance (5 ohms and 2500 ohms), the calculated power can be displayed in

dBm or dBW.

1.3 Features

• Software. A 32-bit Digital Signal Processor running control software provides display, I/O and

system memory functions for the instrument. Software updates are easily made using either the

GPIB or RS232 interfaces.

• Alphanumeric Display. The alphanumeric LCD provides clear, unambiguous readouts of the

instrument's setup and measurement values. Simultaneous display of both channels is available in

dual channel mode. A bar graph provides a display of the channel's measured value for nulling

and peaking applications.

Figure 1-1. 9240 Series RF Voltmeter

1-2

General Information

Page 13

Boonton 9240 Series RF Voltmeter

• Dual Independent Channels. When equipped with the optional second measurement channel, the

instrument can display two CW signals simultaneously. Each channel is calibrated and all channel

parameters are channel-independent.

• Selectable Ranging. Any of eight measurement ranges, or autoranging, can be selected during

instrument setup. The selection will be held until it is changed, or until the instrument is turned

off. When measuring signals with levels that fall within a narrow range, selecting one specific

instrument range may reduce measurement time. Autoranging is useful if the RF signal level is

unknown, or if RF signals with widely varying levels are to be measured.

• Selectable Filtering. Measurement speed and display stability can be optimized through the use of

selectable filtering. Filter times can be adjusted up to 20 seconds maximum in 50 millisecond

increments.

• Zeroing. Automatic zeroing (nulling of offsets for the voltage probe and input channel) is done

independently on each range to eliminate zero carryovers.

• Wide Frequency Range. The calibrated frequency range of the instrument is determined by the

probe model used. The 952001B standard RF Probe provides calibrated measurementsfrom 10

kHz to 1.2 GHz with usable indications beyond 4 GHz. The optional 952016 low frequency RF

Probe provides calibrated response from 10 Hz to 100 MHz.

• Calibration Storage. Shaping and calibration data for each probe is contained in EEPROM within

its 951090 Sensor Data Adapter. When the probe with its Data Adapter is plugged into the 9240

RF Voltmeter, the shaping and calibration data is downloaded and applied to the measurement

automatically. It is not necessary to enter any data manually. Existing voltage probes can be used

with the 9240 by loading a blank Data Adapter with calibration data. No further calibration of the

probe is needed.

• Voltage Range. The 9240 uses three internal hardware ranges to achieve a dynamic range of 90

dB. The input levels can range from less than 200 microvolts to 10 volts. Display resolution is

selectable to 0.001 dB. Using the appropriate 100:1 Voltage Divider accessory, the voltage range

can be extended to 300 Volts. For the 952001 RF Probe, use adapter Model 952005 to extend the

voltage range to 300 V over a frequency range of 10 kHz to 20 MHz. The 100:1 divider cannot be

used with the 952009 (50 ohm) RF Sensor. For the purpose of compatibility with previous models

and preexisting calibration procedures, the input range is divided into 8 virtual ranges which

correspond to previous practice.

• True RMS Response. The waveform response of the RF voltage probe is true RMS for voltages

below 30 mV. This characteristic provides accurate measurements for all types of waveforms with

levels up to 30 mV or 3 V with the appropriate 100:1 Voltage Divider. The waveform response of

the probe gradually changes to a peak detecting response above 30 mV. Computer generated

shaping allows the instrument to display RMS readings above 30 mV. This is valid for nearly

sinusoidal waveforms. For modulated signals, accurate results can be obtained at high levels if the

modulation envelope is relatively flat, (e.g. FM, QPSK). For other modulation types (e.g. Am,

Pulse, CDMA), accurate results can be obtained below 30 mV. The equivalent peak sinewave

voltage can be displayed. It is 1.414 times the RMS voltage and 3.01 dB grater than the reading in

decibel units.

• Low Noise. The 9240 has been designed and constructed to minimize noise from all sources. A

line filter and RF tight enclosure reject outside interference. The probe cables are a special low

noise design; vigorous flexing causes only minor disturbances, even on low level measurements

Non-microphonic probes are used to lessen probe sensitivity to shock and vibration.

General Information

1-3

Page 14

Boonton 9240 Series RF Voltmeter

• Simple Instrument Setup and Operation. The front panel conductive rubber keypad provides

access to menus which control instrument operation. The MENU key selects channel, setup and

diagnostic menus. The <SENSOR> key selects sensor related function. The <AVG> key selects

filter time averaging controls. Setting the filter time to zero will select the auto-filter mode. This

selects an appropriate filter time without operator intervention. The <REF LEVEL> key is used

for making relative measurements in dBr or percent. The values for these parameters are displayed

and can be adjusted by using the arrow and enter keys.

• One key press operations. To provide for ease of use operation of the instrument functions that

are used often, they can be performed with a single push of a button. Common operations such as

Zeroing the channel calibration and setting a Reference Level can be done simply by pressing the

<Zero> and <REF Level> key respectively.

Zero – When measuring low level signals it is important to zero the channel prior to measuring

the signal. When the Active Channel is measuring levels below approximately -50 dBm,

depressing the <Zero> key will use the measured reading as the zero offset. This allows for fast

zeroing of the channel so that the needed measurement can be performed faster.

The Zero sub-menu can be displayed by first pressing the Menu key followed by the <Zero> key.

From there the user chooses the channel to perform a zeroing operation on.

REF Level – Often relative measurements are required especially when measuring system gains

and losses. One key press of the <Ref Level> key makes this job easier and faster to perform.

Simply connect the active channel’s sensor to the input signal of the system under test. Press the

<Ref Level> key and the reference level is set! Next, connect the sensor to the system output and

read the gain or loss directly from the reference level measurement.

The REF Level sub-menu can be displayed by first pressing the <Menu> key followed by the

<REF Level> key. From there the user may LOAD or SET the reference level on either channel.

• Chart Recorder Output. A 0 to 10 volt dc output, proportional to the measurement values is

available for application to a chart recorder. The Recorder Output is selectable to track either

channel 1, channel 2 or the active channel. The Chart Recorder Output is a BNC connector located

on the rear panel.

• Flexible Remote Control. All instrument functions except power on/off can be controlled remotely

via the standard GPIB bus interface or RS232 connection. Setup of interface parameters is menu

driven; front panel indicators keep the user informed of bus activity. Remote control programming

is performed using industry-standard SCPI programming syntax. The 9230 emulation mode is

provided for users that prefer back compatibility with legacy Boonton products such as the 9230

series line of RF Voltmeters.

• Stored Configurations. For applications in which the same instrument configurations are used

repeatedly, up to 10 complete setups can be stored and recalled.

• HIGH/LOW Limit Alarms. The ALARM function provides a means to monitor the power level in

each channel independently. When the ALARM is "ON" (enabled) the level on the channel is

continuously compared with the HI and LO Limit values. The 9240 sets indicator flags (up and

down arrows) on the channel display when the limit values are exceeded. There are 4 status bits in

the Operation Condition register byte which, when unmasked, can be used to request service over

the IEEE-488 interface bus when the selected alarm condition occurs. Note that choosing

overlapping limit conditions is not an error, but may result in confusing alarm indications.

1-4

General Information

Page 15

Boonton 9240 Series RF Voltmeter

1.4 Accessories

Optional 9240 accessories that can be ordered from Boonton Electronics. A Sensor Data Adapter for each

channel installed along with the AC power cord is supplied with the instrument. One or more Boonton

952000 series RF Voltage Probes is required and must be ordered separately. Probes are available with

accessory kits and are sold separately. Additional available accessories are summarized in Table 1-1.

Table 1-1 Accessories for the 9240 Series

Selection Part Number Description

Standard

95109101A Data Adapter with 5 ft (1.27 m) cable

56810400A Line Cord (US)

98601300x* Manual CD, Boonton Measurement Instruments (CD-ROM)

(x* - denotes revision level)

Optional

952063 Standard RF Probe Kit, 10 kHz to 1.2 GHz

Includes: 952001 RF Probe

95200201B 50 Ohm BNC(F) Adapter

95200401A Probe tip

95200501A 100:1 Voltage Divider

41-2A Probe Cable, 5 ft (1.5m)

952064 Low Frequency Probe Kit, 10 Hz to 100 MHz

Includes: 952016 Low Frequency RF Probe

95200201B 50 Ohm BNC(F) Adapter

95200401A Probe tip

95205801A 100:1 Voltage Divider

95201101A 50 Ohm Accessory Kit for 952001B RF Probe.

Includes: 95200301A 50 Ohm Type N Tee Adapter.

95200501A Model 91-7C 100:1 Voltage Divider.

95200801B Unterminated BNC Adapter (Female).

95201301A Accessory Case.

95202801A Model 91-15A 50 Ohm Termination.

95201201A 75 Ohm Accessory Kit for 952001B RF Probe.

Includes: 95200501A Model 91-7C 100:1 Voltage Divider.

95200701A 75 Ohm Tee Adapter.

95200801B Unterminated BNC Adapter (Female).

95201301A Accessory Case.

95202901A Model 91-15A/1 75 Ohm Termination.

95201202A 75 Ohm Accessory Kit for 952001B Rf Probe.

Includes: 95200701A

95200801B

95201301A

91-15A/1

95202801A Model 91-15A 50 Ohm Termination.

95202901A Model 91-15A/1 75 Ohm Termination.

95200301A 50 Ohm Type N Tee Adapter.

95200501A Model 91-7C 100:1 Voltage Divider.

95200601B 75 Ohm BNC Adapter for use up to 500 MHz.

95200701A 75 Ohm Type N Tee Adapter.

95200801B Unterminated BNC Adapter (Female).

General Information

1-5

Page 16

Boonton 9240 Series RF Voltmeter

Table 1-1 Accessories for the 9240 Series (continued)

Selection Part Number Description

Optional

545504000 Fuse, 0.5A 250V

95401501A Rack Mounting Kit

95403001A Rack Mounting Kit (Brackets only)

95403003A Rack Mounting Kit (Brackets with handles)

95109102A Data Adapter with 10 ft (2.54 m) cable

95109103A Data Adapter with 20 ft (5.05 m) cable

95109104A Data Adapter with 50 ft (12.7 m) cable

95109105A Data Adapter with 100 ft (25.4 m) cable

95109001A Voltage Probe Data Adapter – with connector for 41-2A cable

41-2A Voltage Probe Cable – 5ft (1.27 m)

41-2A/10 Voltage Probe Cable – 10ft (2.54 m)

41-2A/20 Voltage Probe Cable – 20ft (5.05 m)

41-2A/50 Voltage Probe Cable – 50ft (12.7 m)

41-2A/100 Voltage Probe Cable – 100ft (25.4 m)

95004701A F/F Adapter, 41-2A (for connecting Model 41-2A cables end to end)

95004901A Bulkhead Connector F/F, 41-2A (for connecting Model 41-2A cables

end to end)

95201301A Accessory Case.

98406900A Instruction Manual 9240 Series, English (Printed w/binder)

Probes

952001 RF Probe - 10 kHz to 1.2 GHz

952016 Low Frequency RF Probe - 10 Hz to 100 MHz

1.5 Models, Options and Configurations

Model 9241. One measurement channel; channel input connector located on the front panel.

Model 9242. Two measurement channels; channel input connectors located on the front panel.

Opt -01. Rear Panel Channel input(s).

Opt -30. Warranty option: Extend factory warranty to 3 years

Option designations are appended to the instrument’s base model number. For example, Model 9242-01

would be a two-channel instrument with channel input connectors all on the rear panel.

Specials. Custom configurations have –S/n appended to the model number, where n is a unique number.

1-6

General Information

Page 17

Boonton 9240 Series RF Voltmeter

1.6 Specifications

Performance specifications for the 9240 Series are listed in Table 1-2.

Table 1-2 9240 Series Performance Specifications

(Specifications are subject to change without notice)

VOLTAGE PROBE INPUTS

Frequency Range: 10 Hz to 1.2 GHz

Voltage Range: 200 µV to 10V

Dynamic Range: 90 dB

Waveform response: RMS to 30mV, calibrated in RMS of a sinewave above 30mV

(RMS to 10V and 700MHz with 100:1 divider)

Crest Factor: Direct Input: Level 300uV 1mV 3mV 10mV 30mV

CF 140 42 14 4.2 1.4

With Divider: Level 30mV 100mV 300mV 1V 3V

CF 140 42 14 4.2 1.4

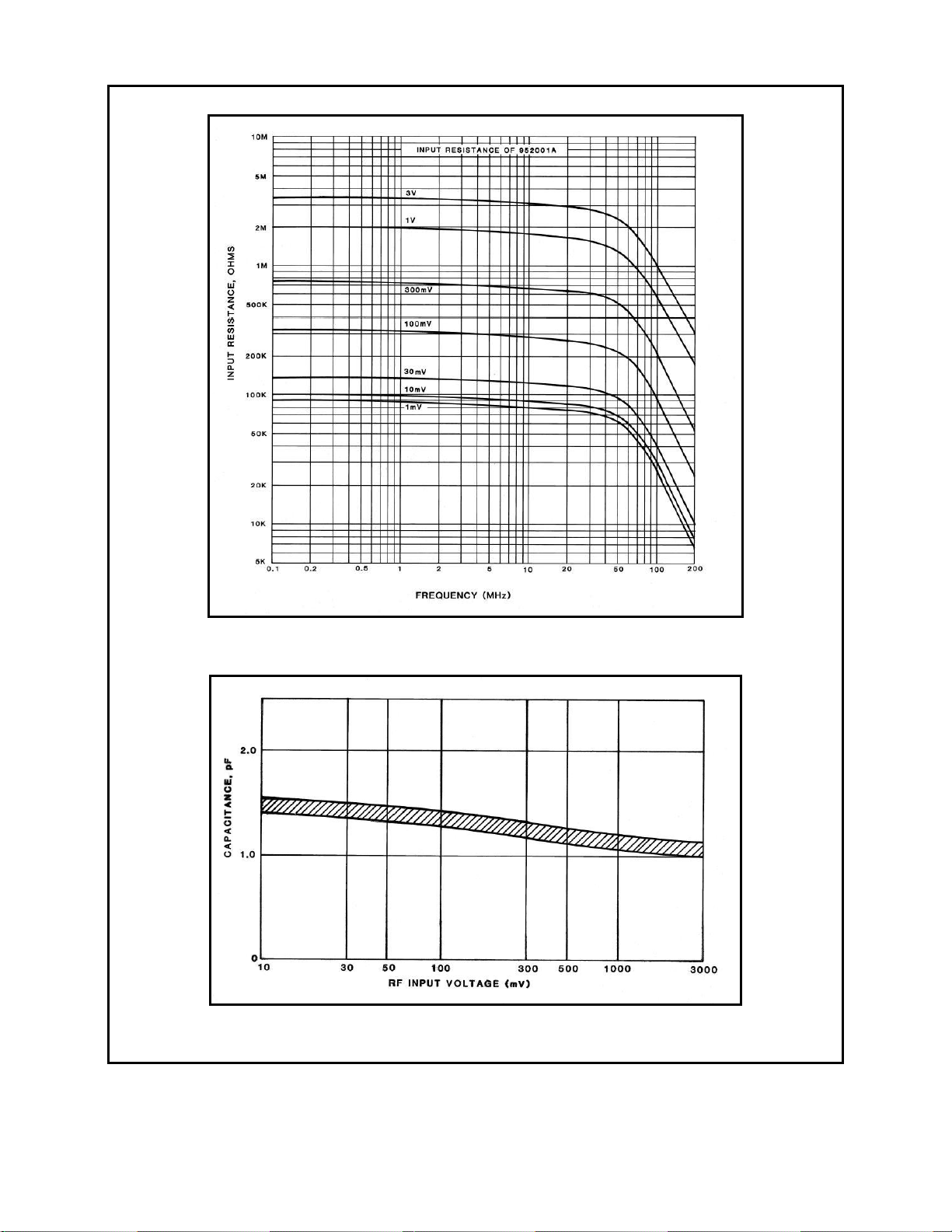

Input Impedance: Refer to Figure 1-2

Maximum AC Input: 10V

Maximum DC Input: 200V

FEATURES

Display: Menu-driven 20 character x 4 line LCD

Display Units: VOLTS, dBV, dBmV, dBµV, dBnV, WATTS, dBW, dBm

dBnW, dBr, %

2

(

Z

Impedance: Any selected reference value from 5 to 2500 Ω

o

Peak Display: 1.414 times Voltage display or 3.01 dB added to dB display

Display Resolution: 0.001 dB or 5 digits (in Volts mode)

Display Offset: -99.99 dB to +99.99 dB in 0.01 dB steps

Limiting: Individual high and low limit thresholds, -99.99 dB to +99.99 dB

Ranging: Manual (8 ranges) or autoranging

Filtering: Filter times to 20.00 seconds in 0.05 second increments

Zeroing: Automatic function; calculates, stores, and applies zero corrections to

each range

Reference Level: -99.99 dB to +99.99 dB in 0.01 dB steps for dBr measurements

may be express in % in linear mode.

Recorder Ouput: For linear voltage readout, 10V full scale proportional to indicated

voltage over each decade. Ranging occurs at 10% of full scale. For

decibel readouts, scale factor is 1V per 10dB change over the entire

dynamic range.

0dBm = 1mW calculated from V

1

(

1

Voltage Probe dependant )

2

, dBµW,

2

/Zo where Zo is the selected reference impedance)

General Information

1-7

Page 18

Boonton 9240 Series RF Voltmeter

INPUT RESISTANCE VS. FREQUENCY,

MODEL 952001B RF PROBE

INPUT CAPACITANCE VS. INPUT VOLTAGE,

MODEL 952001B RF PROBE

Figure 1-2. Input Impedance

1-8

General Information

Page 19

Boonton 9240 Series RF Voltmeter

Table 1-2 9240 Series Performance Specifications (continued)

MEASUREMENT SYSTEM

Voltage Probe Inputs: One or two measurement channels.

Measurement Technique: 24 bit Sigma-delta A/D converter per channel.

ACCURACY

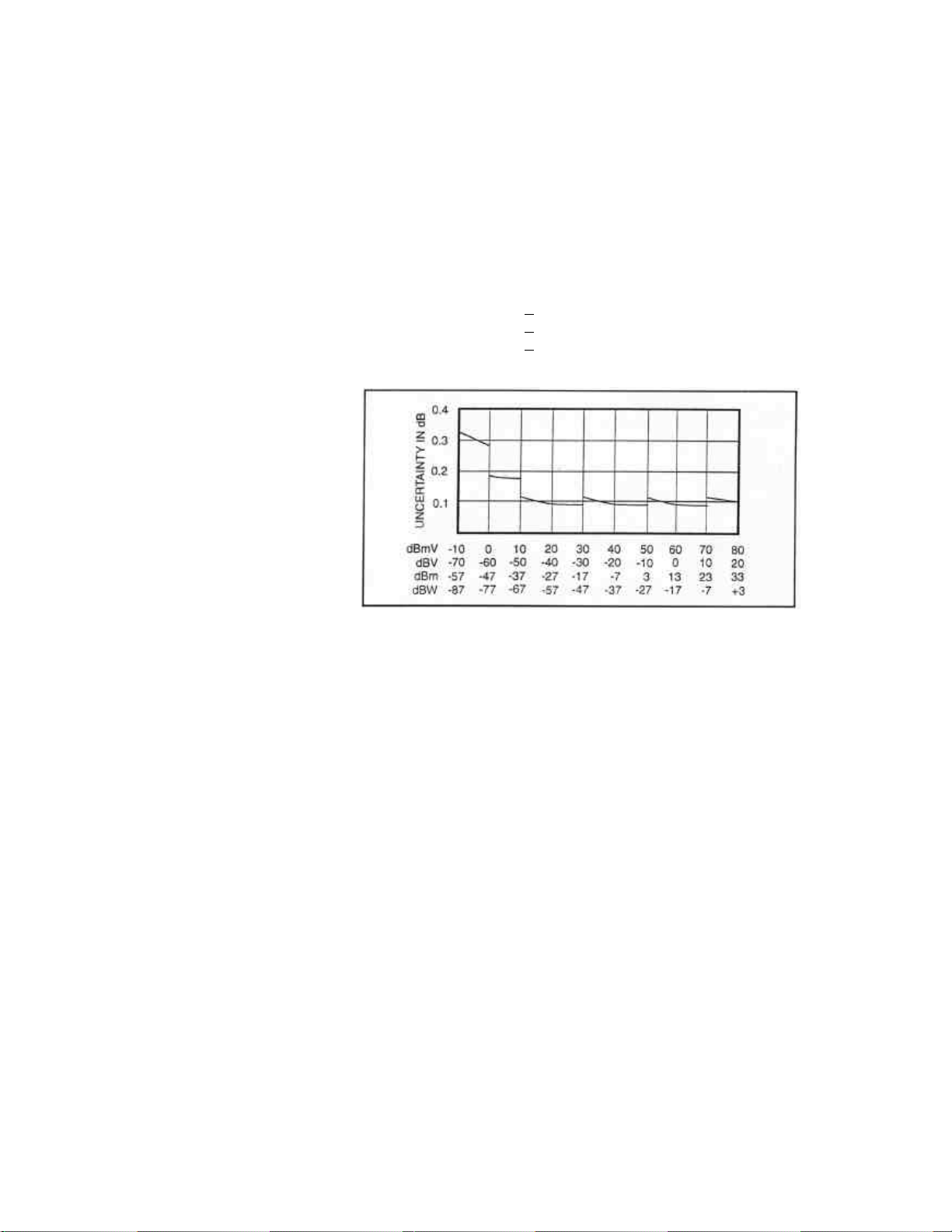

Basic Uncertainty : 3 mV – 10 V 1% rdg

1 mV – 3 mV 2% rdg

0.2 mV – 1mV 3% rdg

For dBv, dBmv, dBm, dBW

+ 1 count

+ 2 counts

+ 3 counts

Model 9240 Uncertainy vs. Input Level

For dBV, dBmV, dBm and dBW

Frequency Effect: Model 952001B Probe with Model 952002 50Ω

Model 952003 Tee Adapter.

Frequency mV dBV, dBmV, dBm, dBW

1 MHz (cal freq) 0 0

10 kHz – 100 MHz 1% rdg 0.09 dB

100 MHz – 1 GHz 3% rdg 0.27 dB

1 GHz – 1.2 GHz 7% rdg 0.63 dB

SWR: 1.05 to 300 MHz, 1.10 to 1 GHz, 1.15 to 1.2 GHz

BNC Adapter or

Model 952016 Low Frequency Probe with Model 952002 50Ω

BNC Adapter.

Frequency mV dBV, dBmV, dBm, dBW

1 MHz (cal freq) 0 0

50 Hz - 20 MHz 1% rdg 0.09 dB

20 Hz - 50 Hz 2% rdg 0.17 dB

10 Hz - 100 MHz 5% rdg 0.45 dB

SWR: 1.05 to 100 MHz

General Information

1-9

Page 20

Boonton 9240 Series RF Voltmeter

Table 1-2 9240 Series Performance Specifications (continued)

Frequency Effect: Model 952016 Low Frequency Probe with Model 952058

100:1 Divider.

Frequency mV dBV, dBmV, dBm, dBW

1 MHz (cal freq) 0 0

1MHz - 20 MHz 5% rdg 0.45 dB

50 Hz - 1 MHz 3.5% rdg 0.31 dB

20 Hz - 50 Hz 4.5% rdg 0.40 dB

10 Hz - 20 Hz 7.5% rdg 0.68 dB

Model 952001B Probe with Model 952006 75Ω BNC Adapter.

1 MHz (cal freq) 0 0

10 kHz - 100 mHz 1% rdg 0.09 dB

100MHz - 300 MHz 3% rdg 0.27 dB

300 MHz -500 MHz 6% rdg 0.54 dB

Frequency mV dBV, dBmV, dBm, dBW

SWR: 1.05 to 150 MHz, 1.10 to 300 MHz, 1.20 to 500 MHz

Model 952001B Probe with Model 952007 75Ω Tee Adapter.

Frequency mV dBV, dBmV, dBm, dBW

1 MHz (cal freq) 0 0

10 kHz - 100 MHz 1% rdg 0.09 dB

100 MHz - 700 MHz 3% rdg 0.27 dB

700 MHz - 1 GHz 7% rdg 0.63 dB

SWR: 1.05 to 150 MHz, 1.10 to 750 MHz, 1.25 to 1 GHz

Temperature Effect: Model 952001B Voltage Probe at 10 kHz to 1.2 GHz.

mV dBV, dBmV, dBm, dBW

Temp °C Inst Probe Inst Probe

21 – 25 0 0 0 0

18 – 30 0 1% rdg 0 0.09 dB

10 - 40 1% rdg 3% rdg 0.09 dB 0.26 dB

0 - 55 2% rdg 7% rdg 0.18 dB 0.63 dB

EXTERNAL INTERFACES

Remote Control: Complies with IEEE-488.1 and SCPI version 1993.

GPIB: Implements AH1, SH1, T6, LE0, SR1, RL1, PP0, DC1, DT1, C0, and E1.

RS232: Type-D connector, 9 pins.

Inputs: Front or Rear panel sensor connector; rear panel IEEE-488 connector

and RS-232 connector.

1-10

General Information

Page 21

Boonton 9240 Series RF Voltmeter

Table 1-2 9240 Series Performance Specifications (continued)

EXTERNAL INTERFACES

Outputs Front panel or optional Rear panel CAL OUT connector, 50 MHz, 100

mW max; rear panel recorder BNC connector, 9.09 kilohm impedance, 0

to 10 volts into 1 megohm (may be operated into 1 kilohm for 1V fs).

PHYSICAL AND ENVIRONMENTAL CHARACTERISTICS

Case Dimensions: 8.26W x 3.48H x 13.5D inches (21.0 x 8.9 x 34.3 cm), Half-rack width, 2U

height

Weight: 5 lbs (2.3kg)

Power Requirements: 90 to 264 VAC, 47 to 63 Hz, (25VA) maximum.

Operating Temperature

Storage Temperature

Humidity

Altitude

Shock

Vibration

2

: 95% maximum, non-condensing

2

: Operation up to 15,000 feet

2

: Withstands ±30G, in X, Y, and Z axes

2

: Withstands 2G

( 2 as per MIL-PRF-28800F )

OTHER CHARACTERISTICS

Display: Dot matrix 80 character LCD module (4 lines by 20 characters)

Keyboard: 11 Key conductive rubber

Processor: 32-bit Digital Signal Processor

Panel setup storage: Can save and recall 10 complete “user” setups.

2

: 0 to 55 °C

2

: -30 to +60 °C

General Information

1-11

Page 22

Boonton 9240 Series RF Voltmeter

Table 1-2 9240 Series Performance Specifications (continued)

REGULATORY CHARACTERISTICS

CE Mark: Full compliance with the following European Union directives and standards:

Safety: Low Voltage Directive 2006/95/EC

IEC 61010 – 1 : 2001 (2

EMC: Electromagnetic Compatibility Directive 2004/108/EC

IEC 61000-3-2: 2000 Limits for harmonic current emissions

IEC 61000-3-3: 2002 Limitation of voltage changes, voltage

fluctuations and flicker

IEC 61000-4-2: 2001 Electrostatic discharge immunity test

IEC 61000-4-3: 2002 Radiated, radio-frequency, electromagnetic

IEC 61000-4-4: 2004 Electrical fast transient/burst immunity test

IEC 61000-4-5: 2001 Surge immunity test

IEC 61000-4-6: 2003 Immunity to conducted disturbances,

IEC 61000-4-11: 2004 Voltage dips, short interruptions and voltage

variations immunity test

EN 61326-1: 2006 Electrical equipment for measurement,

RoHS: RoHS Directive 2002/95/EC

Construction: Manufactured to the intent of MIL-T28800E, Type III, Class 5, Style E

nd

Edition); EN 61010 – 1 : 2001 (2

field immunity test

induced by radio frequency fields.

control and laboratory use – EMC

requirements - Part 1: General requirements

nd

Edition)

1-12

General Information

Page 23

Boonton 9240 Series RF Voltmeter

2. Installation

This section contains unpacking and repacking instructions, power requirements, connection descriptions and preliminary

checkout procedures.

2.1 Unpacking & Repacking

The 9240 Series is shipped complete and is ready to use upon receipt. Figure 2-1 shows you the various pieces included in

the packaging and the order in which they are loaded into the container. Actual details may vary from the illustration.

Note Save the packing material and container to ship the instrument, if necessary. If the original materials (or

suitable substitute) are not available, contact Boonton Electronics to purchase replacements. Store materials

in a dry environment. Refer to the Physical and Environmental Specifications in Table 1-2 for further

information.

Figure 2-1. Packaging Diagram

Installation

2-1

Page 24

Boonton 9240 Series RF Voltmeter

Table 2-1 9240 Series Packing List

INSTRUMENT (See also Table 1-1)

9240 Series RF Voltmeter

Line Cord

Boonton Instruction Manual CD

PROBE(S) (packaged separately)

Voltage Probe(s)

Data Adapter/Cable(s)

For bench-top use, choose a clear, uncluttered area. Ensure that there is at least 2" of clearance at the exhaust vents on the

side panels. Pull-down feet are located on the bottom of the instrument. Rack mounting instructions are provided with the

optional rack mount kit.

2.2 Power Requirements

The 9240 Series is equipped with a switching power supply that provides automatic operation from a 90 to 260 volt, 47 to 63

Hz, single-phase, AC power source. Maximum power consumption is 15W and 25VA. For metric fuse sizes, use the metric

fuse kit supplied. Connect the power cord supplied with the instrument to the power receptacle on the rear panel. See Figure

3-2.

Caution Before connecting the instrument to the power source, make certain that a 0.5-ampere time delay fuse (type

T) is installed in the fuse holder on the rear panel.

Before removing the instrument cover for any reason, position the input module power switch to off (0 =

OFF; 1 = ON) and disconnect the power cord.

2.3 Connections

Probe(s) Connect the RF Voltage Probe that covers the frequency range of the measurement to the CHANNEL 1

connector on the front (Standard) or rear (Optional) panel, as follows. Connect the probe to the supplied

Data Adapter/Cable combo. Connect the Data Adapter to the CHANNEL 1 Input, holding the red mark on

the adapter connector up. For two-channel measurements, use the same procedures to connect the second

probe to the CHANNEL 2 input.

Recorder If a recorder is to be used to record measurement data, connect the recorder to the recorder BEC connector

on the rear panel. Output impedance is 9.06 kilohms, and the output voltage range is 0 to 10 volts dc.

Remote If the instrument is to be operated remotely using the GPIB (IEEE-488) bus, connect the instrument to the

bus using the rear panel GPIB connector and appropriate cable. For RS-232 control, the rear panel 9 pin

RS-232 connector should be used. In most cases, it will be necessary to configure the interface used via

the Menu > SETUP > IEEE or Menu > SETUP > RS232 menus.

2-2

Installation

Page 25

Boonton 9240 Series RF Voltmeter

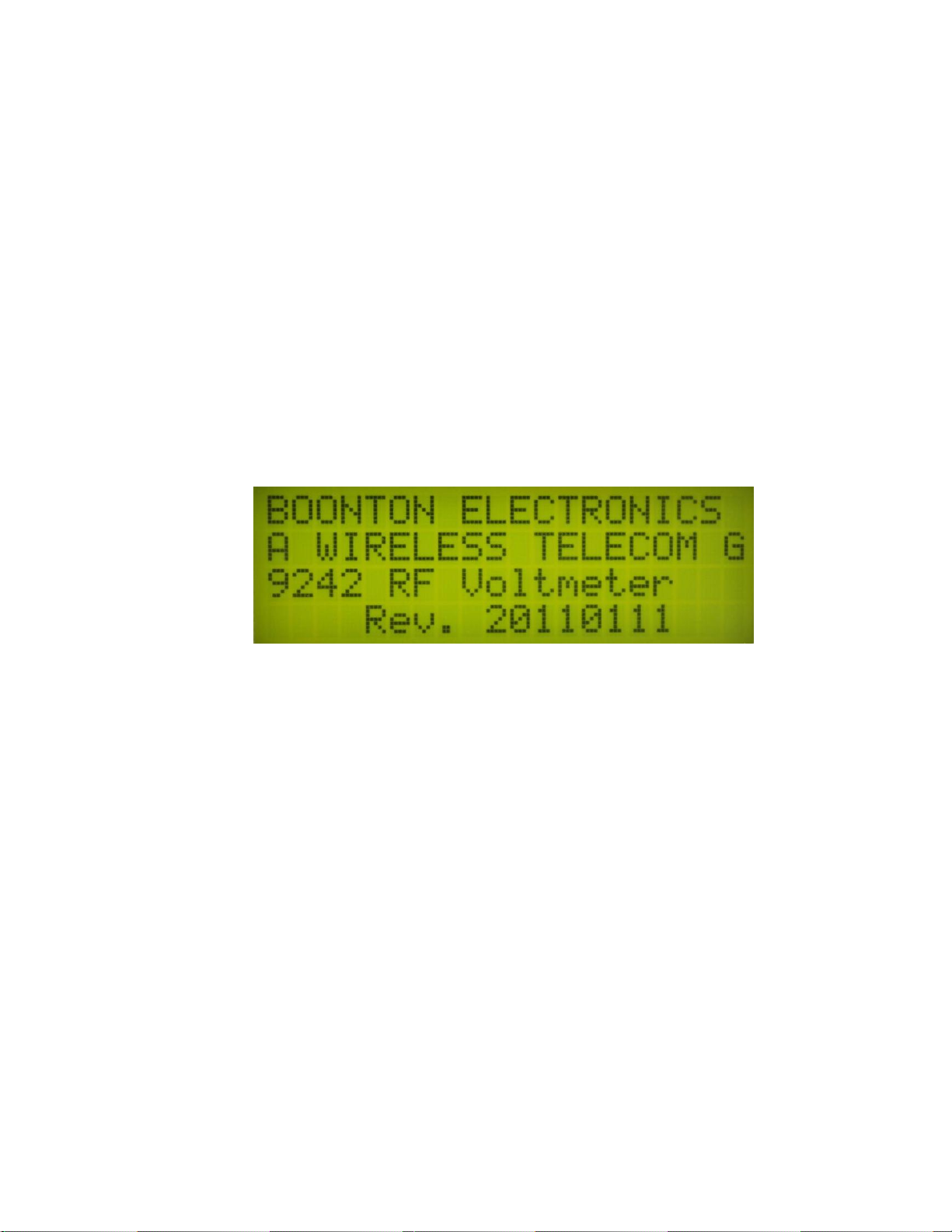

2.4 Preliminary Check

The following preliminary check verifies that the instrument is operational and has the correct software installed. It should

be performed before the instrument is placed into service. To perform the preliminary check, proceed as follows:

1. Connect the AC (mains) power cord to a suitable AC power source; 90 to 264 volts AC, 47 to 63 Hz, with a

capacity in excess of 75 W. The power supply will automatically adjust to voltages within this range.

2. Attach the probe Data Adapter(s) to the front panel CHANNEL connector(s).

3. Set the POWER switch to the ON (1) position.

4. Verify that "BOONTON ELECTRONICS, 9242 RF Voltmeter, Rev. XXXXXXXX" is momentarily displayed

where XXXXXXXX represents the revision code. (Note: Model number 9241 display for single channel

instruments.) While the sign-on screen is displayed the phrase “ A WIRELESS TELECOM GROUP

COMPANY” is scrolled along the second line.

5. Verify that the measurement display showing "CH 1" only for Model 9241 or "CH 1" and "CH 2" for Model

9242. Other data on the display will depend upon previous settings.

6. Press the <MENU> key and select DIAGNOSTICS with the down arrow key. Press <ENTER>. Verify the

following sub-menu:

RTN

SELFTEST <

SWITCHES

RECORDER

7. Press <Enter> to execute the self-test. The items tested are as follows:

PROCESSOR

SRAM MEMORY

EEPROM

Each test will display the OK message if passed. When the test is completed the menu will reappear.

Figure 2-2. Typical Power-On Display

Installation

2-3

Page 26

Boonton 9240 Series RF Voltmeter

8. Use the <Down Arrow> key to move the "<" cursor to SWITCHES and press <ENTER>. Press each

front panel key, avoiding <MENU> until last. Each key press will result in an identifying message;

<MENU> will exit the test and return to the MENU.

9. Use the <Down Arrow> key to select RECORDER and press <ENTER>. This test will sequentially

send a DC voltage in 1 volt steps to the recorder output BNC connector on the rear panel. The test

will continue until <MENU> is pressed. Use a DC voltmeter to verify correct operation.

10. Press <MENU> to return to the measurement display.

11. Press the <Sensor> key and verify that the RF Voltage Probe serial number(s) appear under the

channel heading(s). An active channel with no sensor installed will report a table number.

12. Press the <AVG> key and verify that the filter time and number of samples appear for each active

channel.

13. Press the <Menu> key followed by the <Zero/Cal> key and select ZERO function for the active

channel. Verify the ZERO operation completes successfully.

14. Repeat steps 13 for channel 2 if installed.

15. Connect a GPIB controller to the Model 9240. Verify that the instrument can be addressed to Listen at

its IEEE bus address, and set to Remote. The display must show the correct status on the bottom line

of the display. For message passing, the line terminators for the controller and the Model 9240 must

be compatible for both Listen and Talk. Use <Menu> <SETUP> <IEEE> to set address and

terminators for the 9240. Address the Model 9240 to Listen/Remote and send the command "*IDN?"

EOL. Then address the Model 9240 to Talk (controller to listen) and verify that the correct

identification string is returned. For example using SCPI emulation the ID string returned would be as

follows;

BOONTON ELECTRONICS, 9242, 11002, 20110111

16. Connect a dumb terminal or PC serial terminal to the Model 9240. Use a null modem if the terminal is

wired as DCE. For message communication to take place, the parameters of the serial connection and

message strings must agree between the terminal and the Model 9240. Use <Menu> <SETUP> <RS232> to set parameters for the 9240. Send the command or "*IDN?" EOL and verify that the correct

identification string is returned.

2-4

Installation

Page 27

Boonton 9240 Series RF Voltmeter

3. Getting Started

This chapter will introduce the user to the 9240 Series. The chapter will identify objects on the front and rear panels, identify

display organization, list the initial configuration of the instrument after reset, and provide practice exercises for front panel

operation. For additional information you should see Chapter 4 "Operation."

3.1 Organization

Subsection 3.2 Operating Controls, Indicators and Connections identifies the control features and connections on the front

and rear panels.

Subsection 3.3 Operation identifies the front panel keys, their functions and the menu structure while describing the various

display modes.

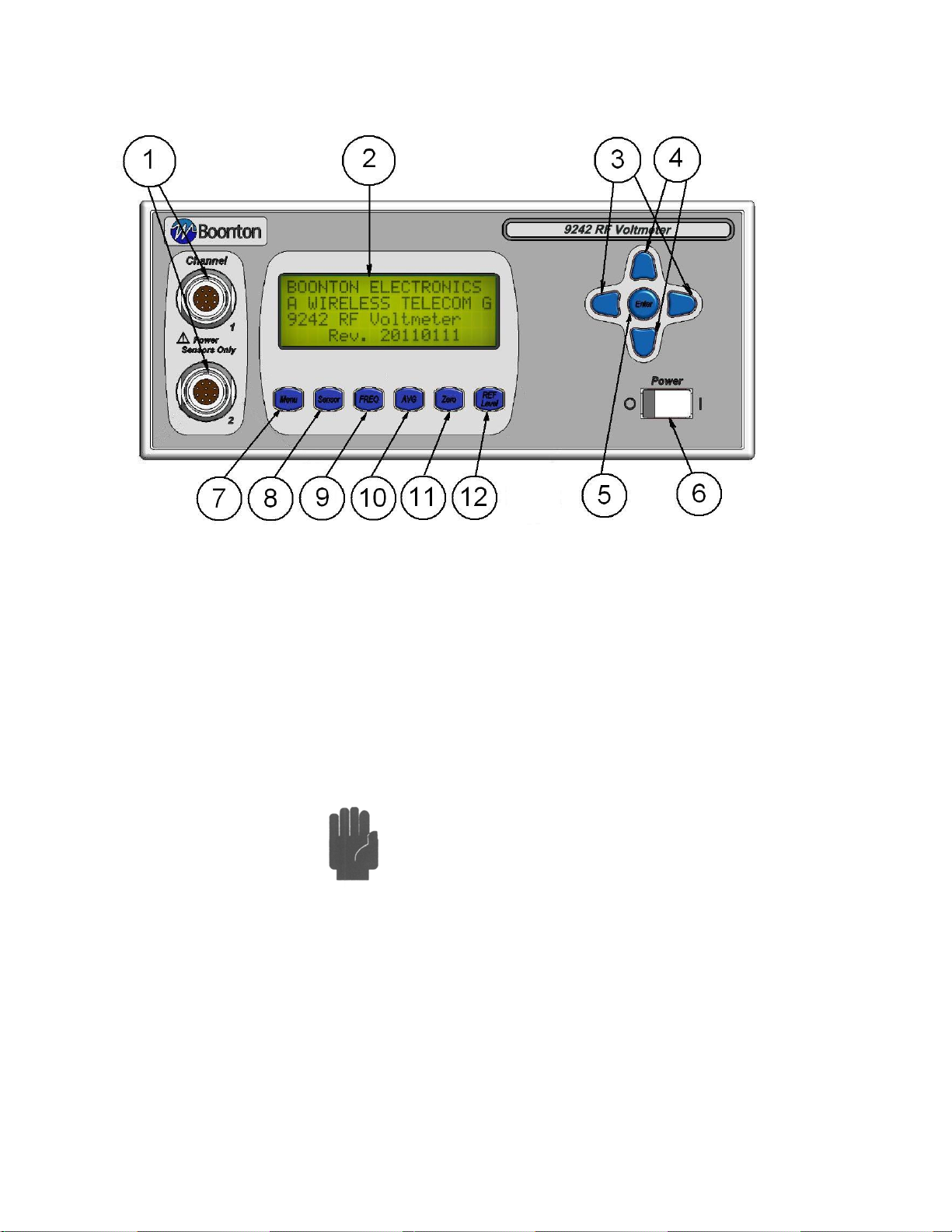

3.2 Operating Controls, Indicators and Connections

Figures 3-1 and 3-2 illustrate the controls, indicators and connectors on the front and rear panels, respectively, of the standard

instrument. Refer to Table 3-1 for a description of each of the illustrated items. Connectors indicated by an asterisk (*) may

be front or rear-mounted, depending on the option selected. The function and operation of all controls, indicators and

connectors are the same on the standard and optional models.

Getting Started

3-1

Page 28

Boonton 9240 Series RF Voltmeter

Figure 3-1. Standard 9240 Series RF Voltmeter - Front Panel

Table 3-1 Operating Controls, Indicators and Connections

Reference #

Front Rear Nomenclature Function

1 1 Channel Inputs One or two Channel inputs are located on the front, or optionally on the rear

panel of the instrument. These are 10-pin precision connectors designed to accept

only Boonton RF Voltage Probes.

2 Display Screen LCD readout of the measurements and user interface for editing of the

instrument's operating parameters.

Caution Do not attempt to connect anything other than a

Boonton Voltage Probe and Data Adapter to the Channel inputs! The

Channel inputs are not measurement terminals and cannot be used for

other than the intended purpose.

3-2

Getting Started

Page 29

Boonton 9240 Series RF Voltmeter

Table 3-1 Operating Controls, Indicators and Connections

Reference #

(continued)

Front Rear Nomenclature Function

3 ◄ and ► Keys In entry mode, pressing ◄advances the cursor to the left. In the measurement

mode of operation pressing the ◄ key sets the Active channel to Linear

measurement units (Volts, %). In entry mode, pressing ►advances the cursor to

the right. In the measurement mode of operation pressing the ►key sets the

Active channel to Log measurement units (dBm, dBr).

4 ▲ and ▼ Keys Used for incrementing or decrementing numeric parameters, selecting from lists,

or scrolling through multi-line displays. In the measurement mode of operation

pressing the ▲ key moves the Active Channel cursor up on the display. For

example if the active channel is set to 2, pressing the ▲key will cause channel 1

to be the active channel. Pressing the ▼ key moves the Active Channel cursor

down on the display. If the active channel is set to 1, pressing the ▼ key will

cause channel 2 to be the active channel.

5 Enter Key In entry mode, initiates the procedure to change a parameter. In parameter entry

mode, terminates the current command and changes the parameter to the last

displayed value. In the measurement mode, display the active channels

CHANNEL menu.

6 Power Switch Turns the instrument off and on.

7 <Menu> Key Displays and allows editing of the instrument's operating parameters. Returns

instrument to local mode when operating in the bus remote mode. Escapes back

to measurement screen from any menu.

8 <Sensor> Key Displays the serial number of the installed probes and allows for editing of the

Voltage Probe parameters.

9 <FREQ> Key Selects the operating frequency display. NOTE: The probes are not provided with

frequency calibration factors. Changing this parameter has no affect on the

measurement.

10 <AVG> Key Selects the filter averaging display for the measurement value.

11 <Zero > Key One Key Press Operation. When measuring low level signals it is important to

zero the channel prior to measuring the signal. When the Active Channel is

measuring levels below approximately -50 dBm, depressing the <Zero > key will

use the measured reading as the zero offset. This allows for fast zeroing of the

most sensitive range of the channel so that the needed measurement can be

performed faster.

The Zero menu can be displayed by first pressing the <Menu> key followed by

the <Zero > key. From there the user chooses the the channel to perform a Zero

operation on.

Getting Started

3-3

Page 30

Boonton 9240 Series RF Voltmeter

Table 3-1 Operating Controls, Indicators and Connections (continued)

Reference #

Front Rear Nomenclature Function

12 <REF Level> Key Often relative measurements are required especially when measuring system gains

and losses. One key press of the Ref/Level key makes this easier and faster to

perform. Simply connect the active channel’s probe to the input signal of the system

under test. Press the Ref/Level key and the reference level is set! Next connect the

probe to the system output and read the gain or loss directly from the reference level

measurement.

The REF Level menu can be displayed by first pressing the <Menu> key followed

by the <REF Level> key. From there the user may LOAD or SET the reference

level on either channel.

13 Recorder Provides a DC voltage proportional to the measured values for use by an external

recorder.

14 RS232 9-pin D-sub connector for connecting the voltmeter to the remote control Serial

Bus. Communication parameters can be configured through the <SETUP <RS232>

menu.

15 GPIB 24-pin GPIB (IEEE-488) connector for connecting the voltmeter to the remote

control General Purpose Instrument Bus. GPIB parameters can be configured

through the <SETUP <IEEE> menu.

16 AC Line Input A multi-function power input module is used to house the AC line input, main

power switch, and safety fuse. The module accepts a standard AC line cord,

included with the voltmeter. The power switch is used to shut off main instrument

power. The safety fuse may also be accessed once the line cord is removed. The

instrument’s power supply accepts 90 to 264VAC, so no line voltage selection

switch is necessary.

Caution Replace fuse only with specified type and rating:

0.5 A-T (time delay type), 250VAC

3-4

Getting Started

Page 31

Boonton 9240 Series RF Voltmeter

Figure 3-2. 9240 Series - Rear Panel

(Shown without optional rear panel connectors not installed)

Getting Started

3-5

Page 32

Boonton 9240 Series RF Voltmeter

3.3 Operation

The Model 9240 can be configured for operation via the six switches on the front panel;

<Menu> <Sensor> <FREQ> <AVG> <Zero>

(

Pressing a key will bring the instrument to the next submenu. A flow chart of the instrument’s command structure is

shown in figure 3-5. The <Menu> key serves as an ESCAPE key to cancel the current operation from any point and return

to the measurement screen.

To change a value , use the arrow keys to position the cursor to the desired parameter. Press the <Enter> key and then use

the up/down arrow keys to scroll through the parameter list. When a number is to be entered, use the left/right arrow keys

to position the cursor under the number that is to be changed, then use the up/down arrow keys to increment/decrement

the number. Holding the up/down arrow key will initiate repeat mode to allow rapid movement through the selection.

Within a submenu, the ∧ ∨ indicators are displayed in the upper right potion of the display when the current screen has

additional information that can be obtained by scrolling with the up/down arrow keys. Three conditions are possible:

1. ∧ Use the up arrow key to scroll the screen upward for additional information.

2. ∨ Use the down arrow key to scroll the screen downward for additional information.

3. ∧ ∨ Use the up/down arrown keys to scoll the screen upward/downward for additional information.

Additonal freatures introduced in the 9240 are the ‘single key press operation’ for the <Zero> and <REF Level> keys. See

section 3.3.5 and 3.3.6 for further details. Also the arrow keys and the <Enter> key have special functions while

measurements are displayed.

Arrow keys group. Selection of the Active Channel and the channel’s measurement units may be accomplished by use of

the arrow keys while in the measurement mode of operation.

Up Arrow key. Moves the Active Channel cursor up on the display. For example if the active channel is set to 2, pressing

the <Up Arrow> key will cause channel 1 to be the active channel.

Down Arrow key. Moves the Active Channel cursor down on the display. For example if the active channel is set to 1,

pressing the <Down Arrow> key will cause channel 2 to be the active channel.

Left Arrow key. Pressing this key sets the Active Channel to Linear measurement units (Volts, %).

Right Arrow key. Pressing this key sets the Active Channel to Log measurement units (dBm, dBr).

Enter key. When in the measurement mode of operation pressing the <Enter> key causes the instrument to drop down

into the CHANNELS menu using the Active Channel as a pointer to the associated channels menu. This provides faster

settings of channel parameters such as units, resolution, duty cycle, offset, range, alarm setting and limits.

1

single key press operation)

1

<REF Level>

1

3-6

Getting Started

Page 33

Boonton 9240 Series RF Voltmeter

A

M M M M M L ± D D D D D D U U U U

C

( B A R G R A P H )

A

M M M M M L ± D D D D D D U U U U

C

( B A R G R A P H )

A

M M M M M L ± D D D D D D U U U U

C

( B A R G R A P H )

DUAL CHANNEL

SINGLE CHANNEL

P

∆

K

P

∆

K

P

∆

K

KEY:

L "="

M M M M M "=" CH1, CH2, CH1+2, CH1/2

U U U U "=" V, mV, nW, uW, mW, kW, MW,dBm,

dBnW, dBuW, dBnV, dBuV, dBmV, dBV

A

M M M M M L ± D D D D D D U U U U

C

( B A R G R A P H )

A

M M M M M L ± D D D D D D U U U U

C

R E M L S N T L K S R Q

KEY:

LSN

TLK

SRQ

D

A

C

"=" Active Channel pointer

Figure 3-3. Measurement Display, Local Mode

REM

Figure 3-4. Measurement Display, Remote Mode

"=" 0 through 9 or a decimal point

"="

"="

"="

"="

∧ , ∨

Ω (indicating power measurement relative

ZØ)

Remote mode enabled

Listener addressed

Talker addressed

Service Request activated

(alarm mode)

P

∆

K

P

∆

K

Getting Started

3-7

Page 34

Boonton 9240 Series RF Voltmeter

Figure 3-5. Model 9240, Command Set

Last Menu Operation. In keeping with minimum key stokes to perform a function repeatedly, the control program can

remember the last menu the user was at prior to returning to the measurement display. In doing this submenu functions can be

quickly selected and parameters changed getting the user back to the measurement display faster.

For example, suppose the user steps through a series of voltage levels while manually changing ranges. Pressing the <Enter>

key in the measurement mode brings up the Active CHANNEL Menu. To hold a measurement range press the <Down Arrow>

key until the cursor is pointing RANGE. Pressing <Enter> allows this parameter to be set to the desired range. In this example

the voltage measured will vary from -35 dBm to -25 dBm (Z

then pressing <Enter> sets the range. Ressing the <Menu> key at this time returns to the measurement display. As the voltage

is increased it reaches the overrange limit and the “-HIGH-“ message is displayed. At this point prenting the <Enter> key

returns the user to the previous CHANNL Menu item, in this case RANGE. The user can now edit the range parameter and

return quickly to the measurement display, simplifying the ease of use.

In this example multiple key strokes were eliminated from previous instrument implementations cutting down time on

instrument configuration providing the user expedient results.

Once in a submenu, the previous menu can always be reached by depressing the <Up Arrow> until RTN or escape to the

parent menu using the <Left Arrow> key. If the user exits out to the measurement screen by this method, pressing the <Menu>

key will bring up the top level menu.

= 50) in 1 dB steps. So the initial range setting is set to range 2

0

3-8

Getting Started

Page 35

Boonton 9240 Series RF Voltmeter

3.3.1 Menu Key.

The instrument's, CHANNELS, SETUP, REPORT and DIAGNOSTIC functions are accessed when the <Menu> key is

pressed (see Figure 3-6). Using the up/down arrow keys, the cursor can be positioned to select from the four submenus.

Channel Menu. An example of the display for the Channels menu is shown in Figure 3-7. Although the figure shows twelve

lines, the instrument can only display four at a time. Therefore, it will be necessary to use the up/down arrow keys to sequence

through the commands. When viewing the commands, the instrument will retain the first line as a header and use the next

three lines to scroll through the remaining commands.

Table 3-2 gives a description of the commands available from the Channels menu. The associated parameters, and factory

default settings are also given.

Setup Menu. An example of the display for the Setup menu is shown in Figure 3-8. It will be necessary to use the up/down

arrow keys to sequence through the commands since there are more than four lines of information to be displayed. When

sequencing through the commands, the instrument will retain the first line as a header and use the next three lines to scroll

through the command list.

R T N

C H A N N E L S <

S E T U P

R E P O R T

D I A G N O S T I C S

Figure 3-6. Main Menu Display

R T N C H # V O L T

U N I T S > V O L T S

R E S X X X X X

B A R O N

M O D E

R A N G E A U T O

A L A R M O F F

H I L I M I T 9 9 . 9 9

L O L I M I T - 9 9 . 9 9

Z 0 5 0 . 0 0

P E A K O F F

X 1 0 0 O F F

Figure 3-7. Channels Menu Display

Getting Started

3-9

Page 36

Boonton 9240 Series RF Voltmeter

Table 3-2 CHANNEL MENU Functions

Function Description Parameters Defaults

RTN Returns the instrument to the n/a

previous menu.

UNITS Units used for measurement dBm, WATTS dBm

display.

RES Display resolution X.X, X.XX, X.XXX dBm or/ X.XX

XXX, XXXX, XXXXX Watts

BAR Enables the bar graph on the ON, OFF ON

measurement display.

MODE Sets the display mode for CH2,CH1+2, CH1/2 CH2

channel 2; only available when OFF

two channels are installed. The

units for sum and ratio modes

track the units selected for

channel 2.

RANGE Selects and hols the instrument’s AUTO, 0,1,2,3,4,5,7 AUTO

measurement range. If

repetitive measurements are to

be made over a narrow range of

levels, selecting the appropriate

instrument range may speed

measurements.

ALARM Enables alarm mode; the ∨ or ON, OFF OFF

∧ symbol is displayed before

the channel mode designator on

the measurement display to

indicate when the upper or

lower threshold limit is

Exceeded.

HI LIMIT Upper threshold limit for the -99.99 to 99.99 99.99

alarm function.

LO LIMIT Lower threshold limit for the -99.99 to 99.99 -99.99

alarm function.

ZØ Characteristic impedance used to 5 to 2500 Ohms 50 Ohms

calculate power.

PEAK Displays sinewave peak instead of ON, OFF OFF

RMS.

Equal to a factor of 1.414 or +3dB.

X100 Used with 100:1 divider accessory ON, OFF OFF

3-10

Getting Started

Page 37

Boonton 9240 Series RF Voltmeter

R T N

R E C A L L > 1

S A V E 2

P O W E R U P D E F A U L T

K E Y B E E P O F F

I E E E

R S 2 3 2

R E C C H A N C H 1

L I N E F R E Q

I N S T R C A L

Figure 3-8. Setup Menu Display

Table 3-3 SETUP MENU Functions

Function Description Parameters Defaults

RTN Returns the instrument to the n/a

previous menu.

RECALL Recalls one of ten user DEFAULT, 1-10, DEFAULT

defined instrument SANITIZE

configurations or the factory

setup.

1

SANITIZE initializes all program locations to DEFAULT settings

SAVE Saves the current instrument 1-10 1

configuration to one of ten

non-volatile memory

locations.

POWER-UP Instructs the instrument to power-up DEFAULT, 1-10 DEFAULT

to the specified configuration.

KEY BEEP Turns on/off the key beep. ON, OFF OFF

IEEE Brings the instrument to the see table 3-5 n/a

IEEE menu.

RS232 Brings the instrument to the see table 3-6 n/a

RS-232 menu.

LINEFREQ Select line (mains) frequency. 50Hz, 60Hz n/a

INSTR CAL Refer to Service Manual. n/a n/a

1

Getting Started

3-11

Page 38

Boonton 9240 Series RF Voltmeter

IEEE Menu. The IEEE submenu is used to configure the Model 9240 for communications over the GPIB. An example of the

menu is shown in Figure 3-9 and the description of the commands, parameters and factory defaults is given in Table 3-4.

R T N

A D D R E S S > 1 3

E M U L A T I O N S C P I

E O S L S T N C R L F

E O S T A L K E R C R L F

E O I O N

S R Q M A S K 0

Figure 3-9. IEEE Menu Display

Table 3-4 IEEE MENU Functions

Function Description Parameters Defaults

RTN Returns the instrument to the n/a

previous menu.

ADDRESS GPIB address assigned to the 0 to 30 n/a

instrument.

EMULATION GPIB emulation mode. SCPI, 437B, 438A, 4230 SCPI

EOS LSTN End of string indicator for LF, CR, CRLF, NONE LF

received messages. Where:

LF = Line Feed

CR = Carriage Return

CRLF = Carriage Return

and Line Feed

EOS TALKER End of string character sent LF, CR, CRLF, NONE LF

with transmitted messages.

EOI Enables/disables the end or ON, OFF OFF

identify hardware control line.

SRQ MASK Service request interrupt mask. 0 to 255 0

See Section 5.5.1 *STB? for bit Where:

descriptions. 255 enables all interrupts

3-12

Getting Started

Page 39

Boonton 9240 Series RF Voltmeter

RS232 Menu. The RS232 menu is used to configure the Model 9240 for serial communications over the RS-232 bus. An

example of the submenu is shown in Figure 3-10 and an explanation of the commands, parameters and factory defaults is

given in Table 3-5.

R T N

B A U D R A T E > 3 8 4 0 0

D A T A B I T S 8

S T O P B I T S 1

P A R I T Y N O N E

E O S L S T N L F

E O S T A L K E R C R L F

S R Q M A S K 0

Figure 3-10. RS232 Menu Display

Table 3-5 RS232 MENU Functions

Function Description Parameters Defaults

RTN Returns the instrument to the n/a

previous menu.

BAUD RATE Rate at which data is 300, 600, 1200, 2400, 4800, 38400

transferred over the bus. 9600, 19200, 38400, 57600,

115200

DATA BITS Number of data bits in a message. 7, 8 8

STOP BITS Number of stop bits in a message. 1, 2 1

PARITY Parity bit mode in a message. ODD, EVEN, NONE NONE

EOS LSTN End of string indicator for LF, CR, CRLF, NONE LF

received messages. Where:

LF = Line Feed

CR = Carriage Return

CRLF = Carriage Return

and Line Feed

EOS TALKER End of string character sent LF, CR, CRLF, NONE CRLF

with transmitted messages.

SRQ MASK Service request interrupt mask. 0 to 255 0

See Table 4-7 for bit Where:

descriptions. 255 enables all interrupts

Getting Started

3-13

Page 40

Boonton 9240 Series RF Voltmeter

REPORT Display. The REPORT menu item displays the versions of the firmware and FPGA image installed in the

instrument. The SCPI specification compliance version is also displayed in this report. This display is for informational

purposes only and does not support any editing of the data. The REPORT display is shown in Figure 3-11.

V E R S I O N

F I R M W A R E 2 0 1 0 0 7 1 1

F P G A 1 . 1 8

S C P I 1 9 9 0

Figure 3-11. Report Display

Diagnostics Menu. The Model 9240 can be directed to perform self-tests from the diagnostics menu. The Diagnostics menu is

shown in Figure 3-12 and a description of each command is given in Table 3-6.

R T N

S E L F T E S T <

S W I T C H E S

R E C O R D E R

Figure 3-12. Diagnostics Display

Table 3-6 DIAGNOSTICS MENU Functions

Function Description Parameters Defaults

RTN Returns the instrument to the n/a n/a

previous menu.

SELF TEST Instructs the instrument to n/a n/a

perform internal diagnostics

and the display test.