Page 1

User’s Guide

52000 Series USB Power Sensor/Meter

Taking performance to a new peak

Page 2

Notices

Disclaimer

Warranty

© BOONTON (A WIRELESS TELECOM GROUP COMPANY) 2006 This

document contains information which is protected by copyright.

Reproduction, adaptation, or translation without prior permission is

prohibited, except as allowed under the copyright laws.

www.boonton.com

The information contained in this document is subject to change

without notice.

BOONTON (A WIRELESS TELECOM GROUP COMPANY) MAKES

NO WARRANTY OF ANY KIND WITH REGARD TO THIS MATERIAL,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Boonton shall not be liable for errors contained herein or for

incidental or consequential damages in connection with the

furnishing, performance, or use of this material.

Refer to the warranty card included with the product. A copy of

the specic warranty terms applicable to your Boonton products

and replacement parts can be obtained from . To request more

information or parts, email sales@boonton.com.

Safety Notices

Before installing and operating these products, please read the safety

statements in “Safety and Specications” on page 61.

2 Introduction

Page 3

User’s Guide

Welcome Thank you for choosing the 52000 Series USB Power

Sensors/Meter and welcome to the Boonton User’s Guide.

This manual will guide you through the following sections:

• Software installation

• Hardware installation

• Using the software

• Getting more from your system

Introduction

The 52000 CW power sensors/meter are a new series of products

which connect directly to a laptop or desktop computer using

a standard USB port, without the need for a stand alone meter.

Measurements from the sensor can be displayed on the laptop or

desktop computer or can be integrated into your test system with a

set of user-dened software functions – supplied as standard.

This guide will take you through the software installation stages.

Then it will outline some typical hardware congurations and how to

get the most from your software. Finally, you will be shown how to

integrate the sensor into your test environment.

Key Features

The key features of the 52000 CW power sensor/meter are:

• Perfect for most Power measurement uses, including:

• Installation and maintenance

• Manufacturing test

• ATE

• Research and Development

• Easy to use software

• Quick conguration

• Flexible set-up and system integration

• Small, compact and rugged

• Multiple sensor support on single PC

• No reference calibration required

• Low cost alternative to tradition power measurements

Boonton 52000 Series 3

Page 4

What you should have

Warranty

User’s Guide

Card

USB

Cable

CD

52000 Sensor

52012 CW Power Sensor

ESD

Earth ground must be connected

Max pwr +23dBm avg, +30dBm peak for 1us +/- 10.0VDC Max.

10MHz - 12.4GHz

10nW - 100mW (-50dBm to 20dBm)

Before you start, please check you have the following items (Refer to

Figure 1 “What you should have” on page 4):

• 52000 CW power sensor (52012 or 52018)

• 6 feet (1.82m) USB cable (USB2-AB-06BK)

• Boonton software CD

• Product warranty card

• This User’s Guide

Figure 1 What you should have

If any of these items are missing or damaged, then please contact

your local representative as soon as possible or refer to “Contacting

Boonton ” on page 59.

4 Introduction

Page 5

Introduction .............................................................................................3

Key Features .............................................................................................3

What you should have ..........................................................................4

Installation Of Software

Install procedure .....................................................................................9

Contents

USB Installation

Driver installation with Windows® XP SP2 .................................. 13

Driver installation with Windows® XP SP1 .................................. 16

Hardware Connections

How to connect your sensor ............................................................ 21

Connection to your PC ...................................................................... 21

Connection to your unit under test (UUT) .................................. 22

Connecting multiple sensors ............................................................ 23

Using The Software

Using the software .............................................................................. 25

Zero your sensor .................................................................................. 26

Making a measurement ..................................................................... 26

Measurements using more than one sensor ............................... 28

How to make a pulse power measurement ................................30

Boonton 52000 Series 5

Page 6

Measuring GSM mobile signals ...................................................... 31

Making a measurement ..................................................................... 32

Measuring power greater than +20dBm (100mW) .................. 33

Measuring an attenuator using relative mode .......................... 34

How to use measurement limts ...................................................... 35

How to use trace mode ..................................................................... 38

Error and status messages ............................................................... 42

Sensor not zeroed ................................................................................ 42

Sensor frequency, offset and duty cycle enabled .......................42

Sensor overload .................................................................................. 43

High limit exceeded ............................................................................ 43

Low limit exceeded .............................................................................44

Zero sensor - temperature change ................................................. 44

Manually entered cal factor ............................................................. 45

Description Of Software

Description of icons ............................................................................ 46

Description of menu options. ........................................................... 47

Enhanced Features

Integrating your power sensor......................................................... 49

Troubleshooting

How to x “No Sensor Connected” problems .............................. 51

No sensor is attached to your PC.................................................... 52

The wrong USB driver has been installed ..................................... 52

The USB cable or USB port are faulty ............................................53

Incorrectly congured USB hub ..................................................... 53

More than one application has been started ..............................54

Unexpected measurements results ............................................... 54

Check status message ........................................................................54

Your sensor is potentially damaged ............................................... 54

Incorrect offset setting ...................................................................... 54

Incorrect measurement settings ................................................... 54

How to identify your PC operating system ................................. 55

Other useful information .................................................................. 56

What is zeroing? .................................................................................. 56

Pulse measurement and setting the duty cycle. ......................... 56

What is a dB? ........................................................................................57

What is a dBm? .................................................................................... 58

Contact And Support

Contacting Boonton ..........................................................................59

Our Website .........................................................................................59

6 Contents

Page 7

Safety And Specications

Safety notices ...................................................................................... 60

EC declaration of conformity ........................................................... 61

WEEE Directive ..................................................................................... 62

Product descriptions and requirements ........................................62

Minimum PC requirements ............................................................... 62

52012 Description ............................................................................... 62

52018 Description ............................................................................... 62

52000 Series Specications ............................................................. 63

Index ........................................................................................................65

Boonton 52000 Series 7

Page 8

This page is intentionally left blank

8 Installation

Page 9

1 Installation Of Software

This chapter provides information about installing the Boonton

power sensor/meter software.

Before you start, please check your PC for software compatibility.

Refer to “Minimum PC requirements” on page 63 for more

information.

Install procedure

To install the Boonton software, follow these steps:

Caution Do not connect any hardware to your PC until you have

installed the Boonton software.

Note If you are using Windows XP SP1, disconnect any LAN

connections. This will prevent your PC automatically downloading

the wrong USB drivers.

Do this Comment

1. Insert the CD into your PC The installation should start automatically.

2. (Optional) If the installation

does not start automatically,

select Start > Run and type

d:\BoontonSensorInstallation.exe

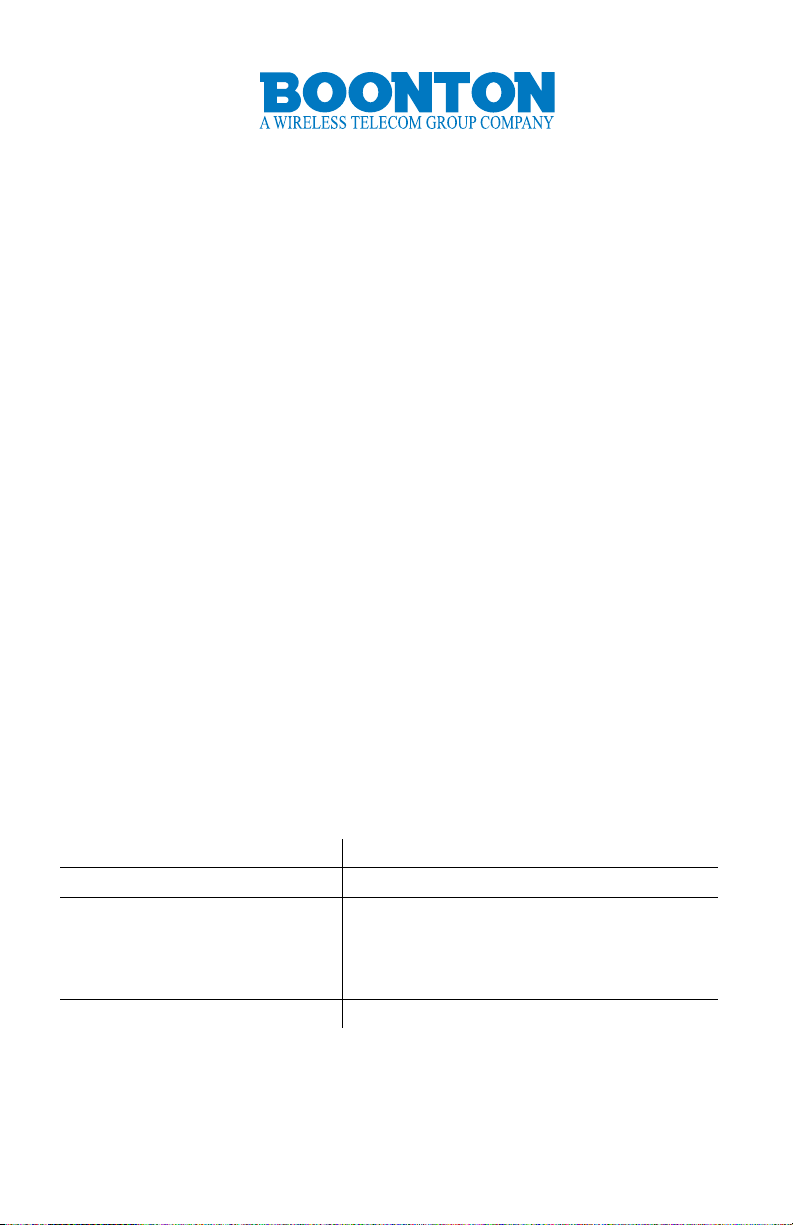

3. Select Continue Refer to Figure 2 on page 10.

Where D:\ is the name of your CD drive.

Boonton 52000 Series 9

Page 10

Figure 2 Start of installation software

4 Check the software matches your sensor types and then select

Continue The sensor part numbers are listed on the side of the sensor.

Refer to Figure 3 on page 10.

Figure 3 Check sensor part number

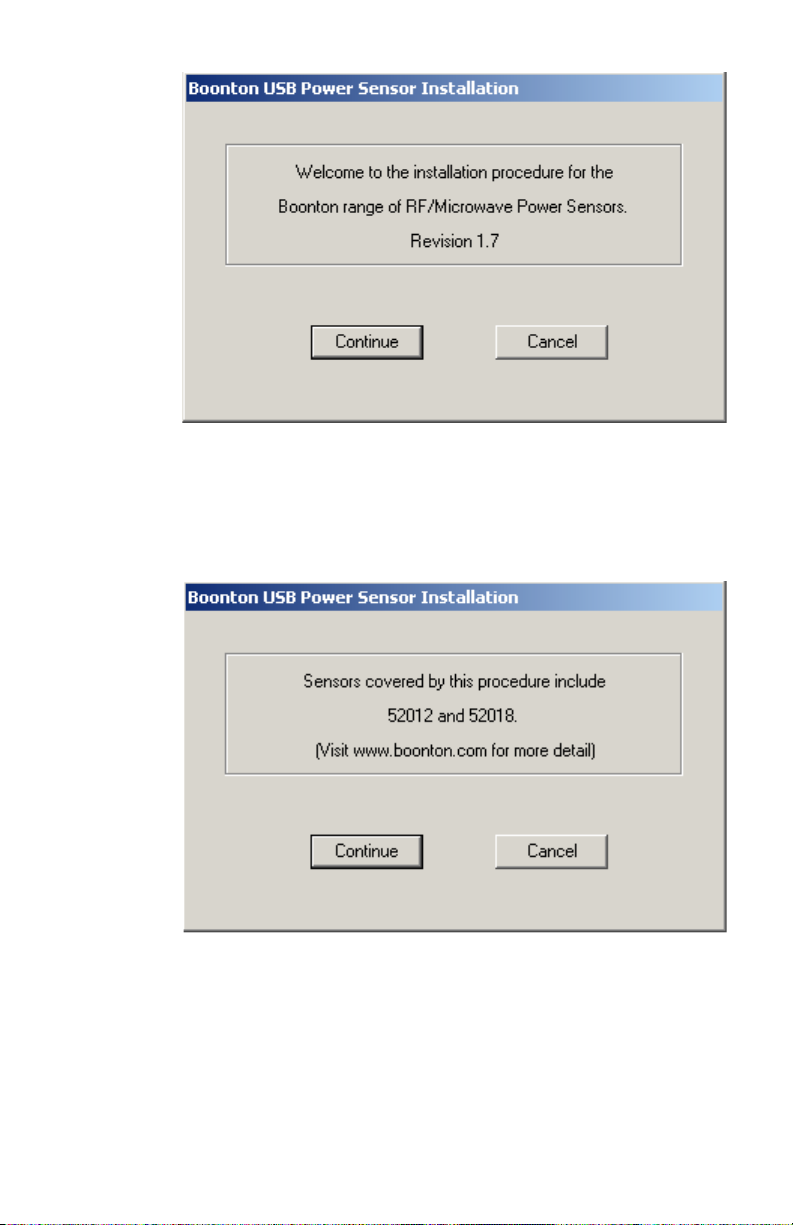

5 Carefully read all of the License Agreement. If you accept the terms

and conditions of the license agreement, enable the Accept option

and then select Continue.

If you have any questions about this agreement, then please contact

us. Refer to Figure 4 on page 11.

10 Software Installation

Page 11

Figure 4 License agreement

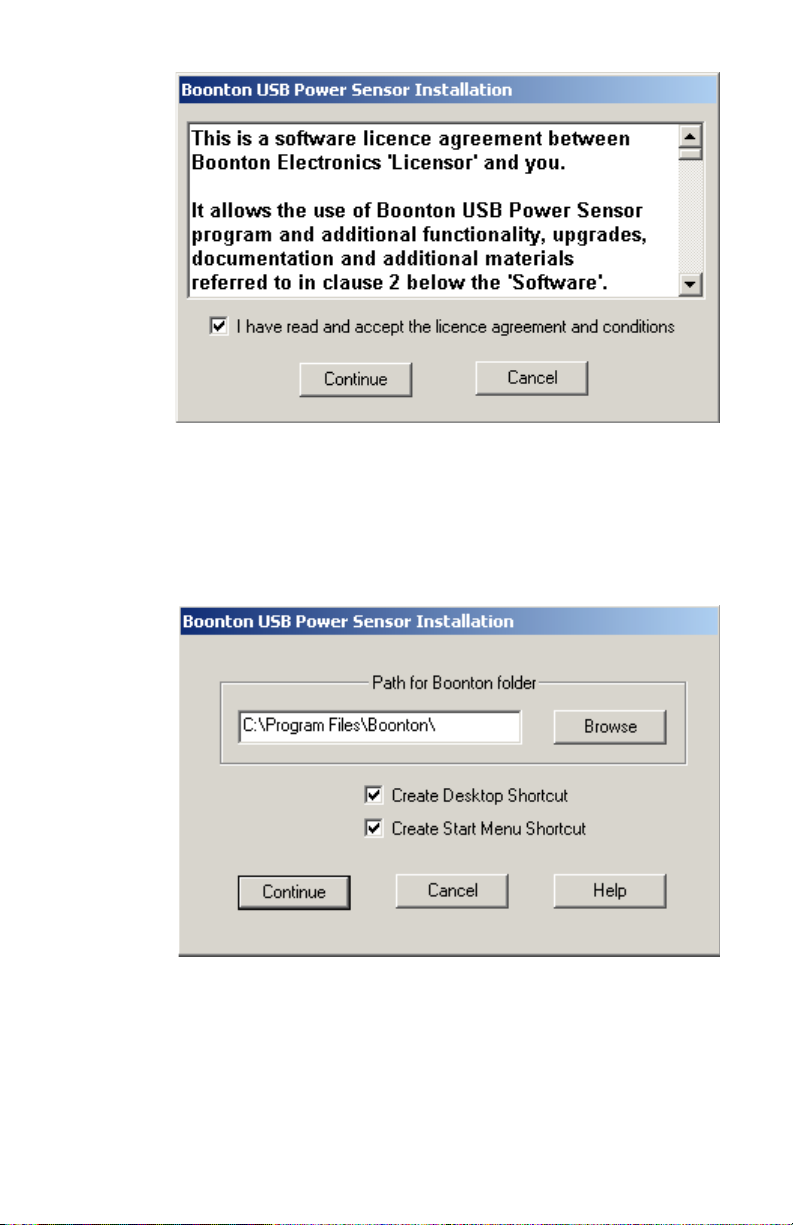

6 Choose the installation location, whether you want a desktop icon

and a shortcut added to your start menu, then select Continue It is

recommended that you use the default installation options.

Refer to Figure 5 on page 11.

Figure 5 Installation location

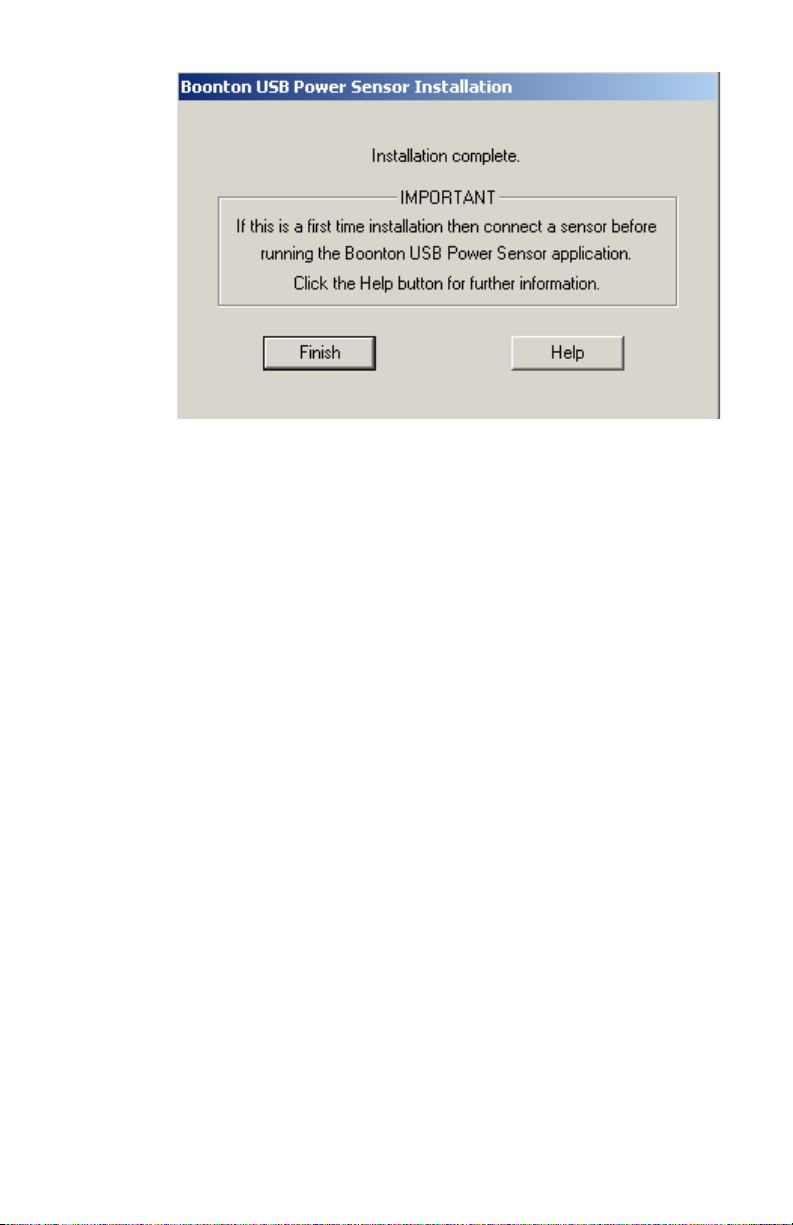

7 Select Finish when the installation has completed

Refer to Figure 6 on page 12.

Boonton 52000 Series 11

Page 12

Figure 6 Installation completed

Note At the end of the installation you are asked to connect your

sensor. Refer to “USB Installation” on page 13 for more information.

12 Software Installation

Page 13

2 USB Installation

This chapter explains the process for installing and enabling the USB

drivers for your 52000 series CW power sensor/meter. These drivers

are required to enable effective measurement data Transfer.

There are two USB driver installation procedures covered in this

chapter – one for Windows® XP SP1 and the other for Windows® XP

SP2. To identify which operating system you have on your PC, refer to

“How to identify your PC operating system” on page 55.

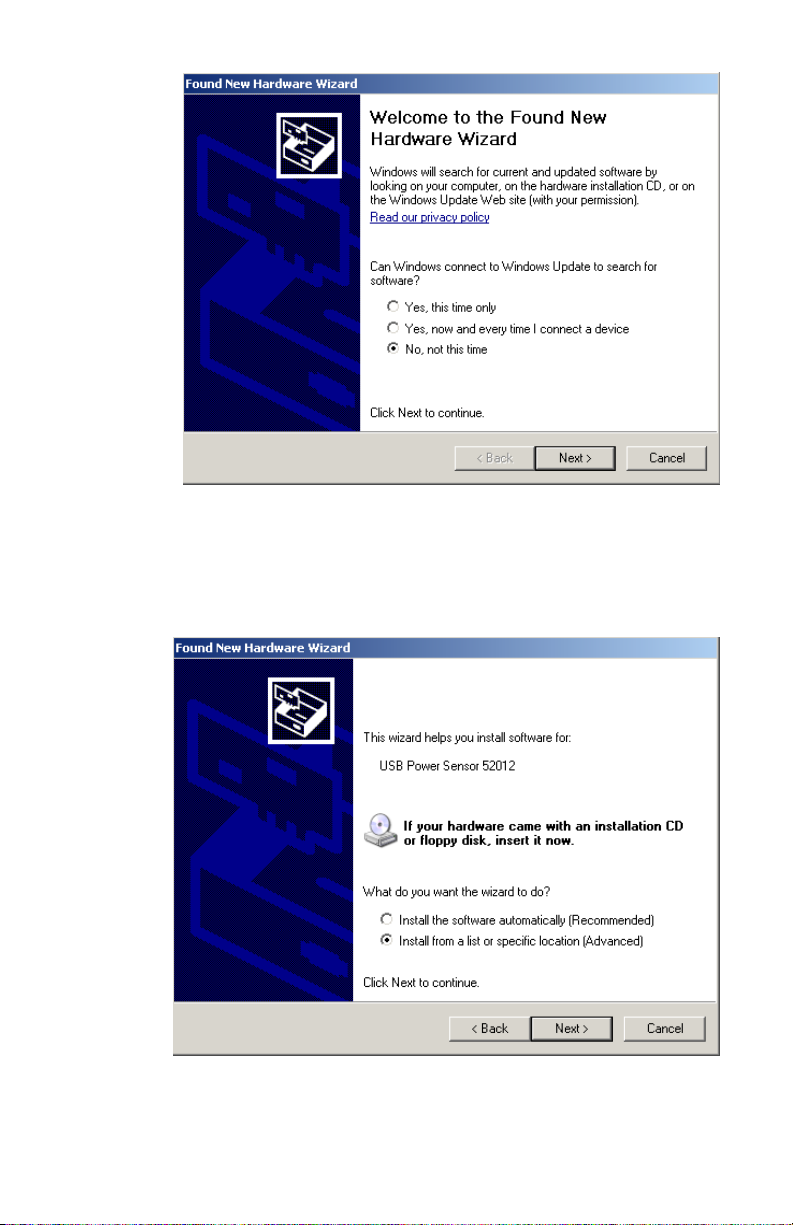

Driver installation with Windows® XP SP2

This section describes how to install and congure your USB drivers

on a PC with Windows® XP and service pack 2 (SP2) operating

system.

Caution Do not connect your sensor and install the USB drivers

unless you have installed the Boonton software. Refer to “Installation

Of Software” on page 9 for more information.

1. Connect your sensor to the USB port of your PC. The Windows

Hardware Wizard starts automatically.

Refer to “How to connect your sensor” on page 21 for more

information.

2. Choose “No not at this time” and select Next.

Refer to Figure 7 on page 14.

Boonton 52000 Series 13

Page 14

Figure 7 Windows hardware installation wizard

3. Choose “Install from a list or specic location (Advanced)” and

select Next.

Refer to Figure 8 on page14.

Figure 8 USB Driver location

14 USB Installation

Page 15

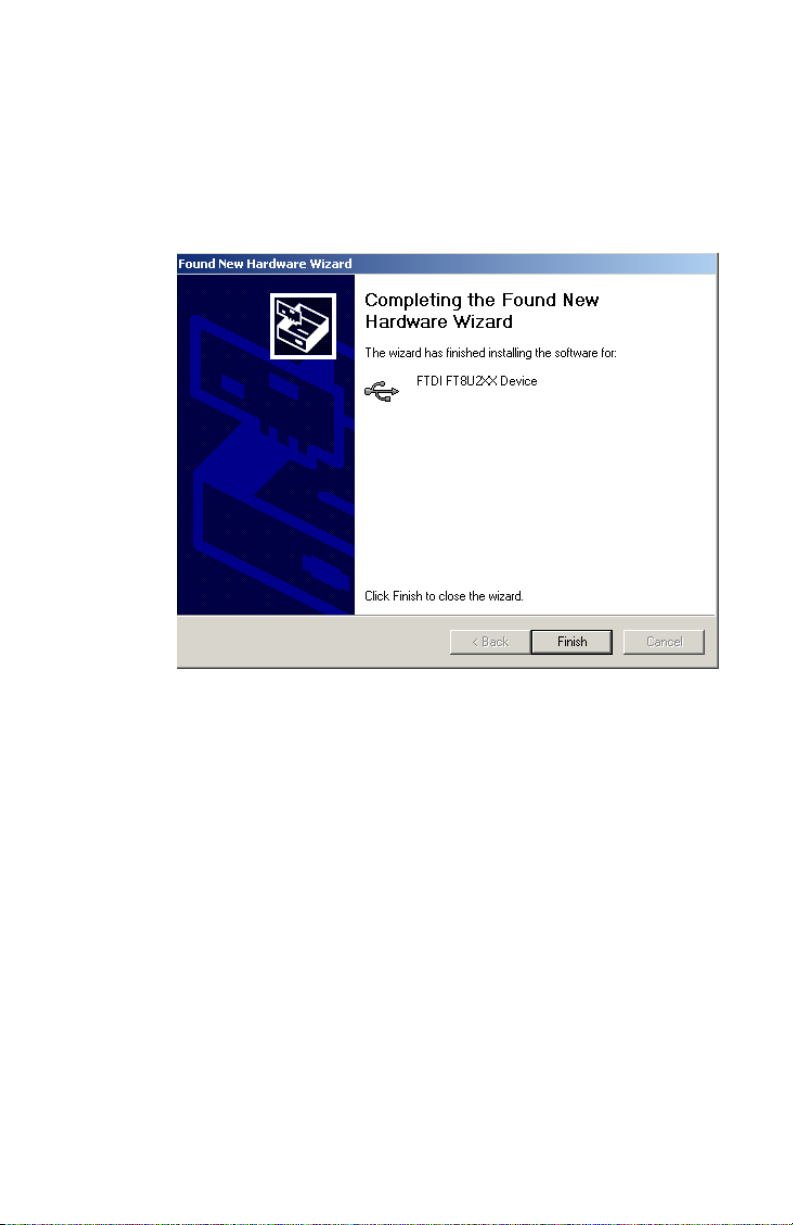

4. Choose “Include this location in the search”.

Refer to Figure 9 on page 15.

Figure 9 Choose the installation location

5. Browse to the following location: C:\ProgramFiles\Boonton\Driver.

If you have changed the default installation location, navigate to the

Boonton installation folder.

6. Select Next.

7. (Optional) During the installation Windows may check the driver

compatibility. Select Continue Anyway. The USB sensor driver is a

valid driver and will not damage your system. Refer to Figure 10 on

page 16.

Boonton 52000 Series 15

Page 16

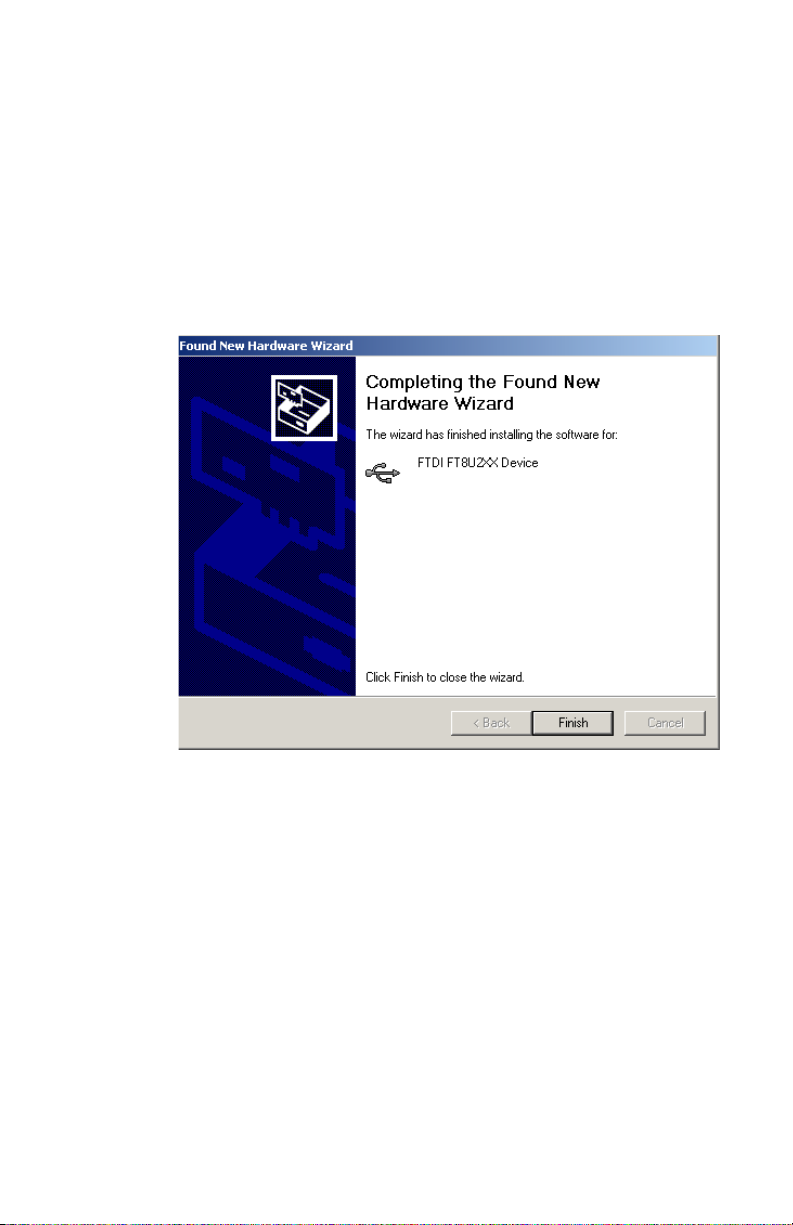

The USB driver that is installed is a generic USB sensor driver and it

is used for a range of USB sensors. The sensor driver installed on your

PC is called FTDI FT8U2XX Device.

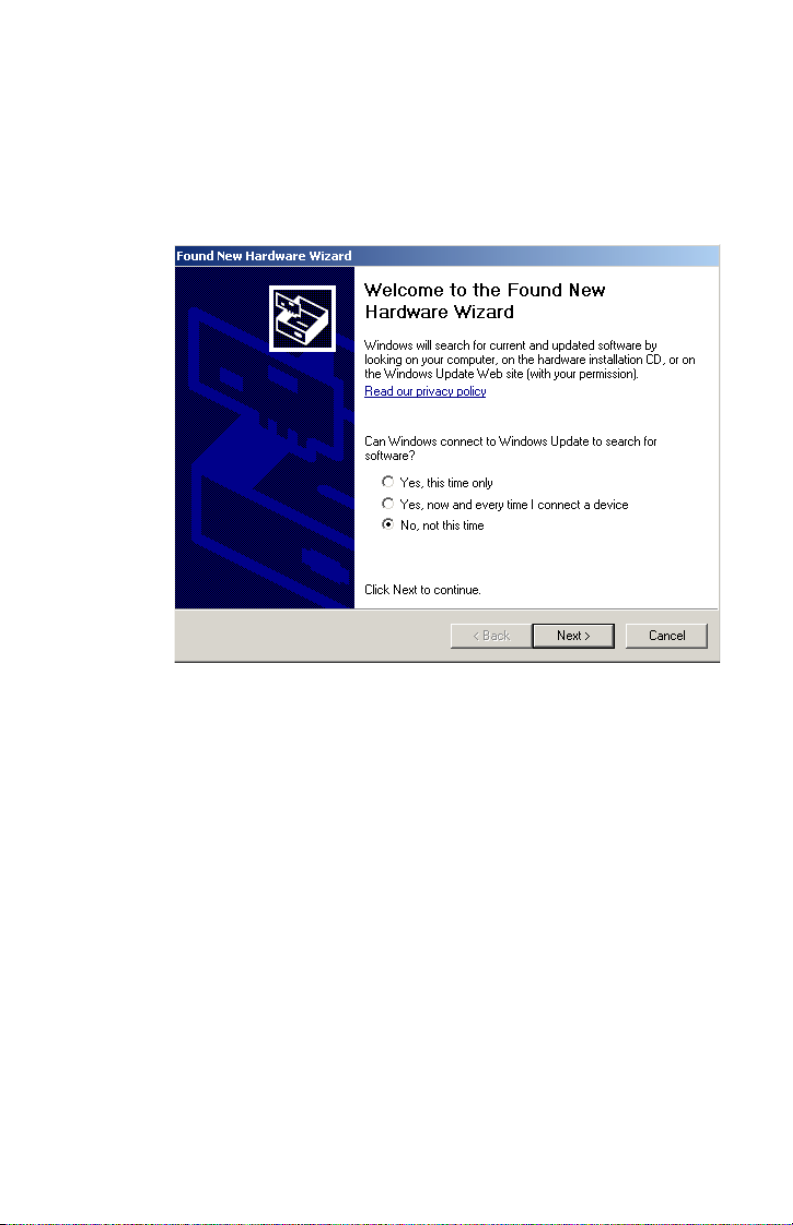

Driver installation with Windows® XP SP1

Figure 10 Continue Anyway with installation

8. The driver will now be installed.

9. Select Finish when the driver installation is complete. Windows

will now conrm it has identied the USB sensor hardware.

This section describes how to install and congure your USB drivers

on a PC with Windows® XP and service pack 1 (SP1) operating

system.

Caution Disconnect any LAN connections to the PC. Windows® XP

SP1 does not provide exible USB driver installation. The operating

system rst attempts to obtain the USB driver from an external

source. This external driver does not provide a working connection

with your sensor.

16 USB Installation

Page 17

1. Connect your sensor to the USB port of your PC. The Windows

Hardware Wizard starts automatically. Refer to “How to connect your

sensor” on page 21 for more information.

2. Choose “No not at this time” and select Next. Refer to Figure 7 on

page 14.

Figure 11 Windows hardware installation wizard

3. Choose “Install from a list or specic location(Advanced)” and

select Next.

Refer to Figure 8 on page14

Boonton 52000 Series 17

Page 18

Figure 12 USB Driver location

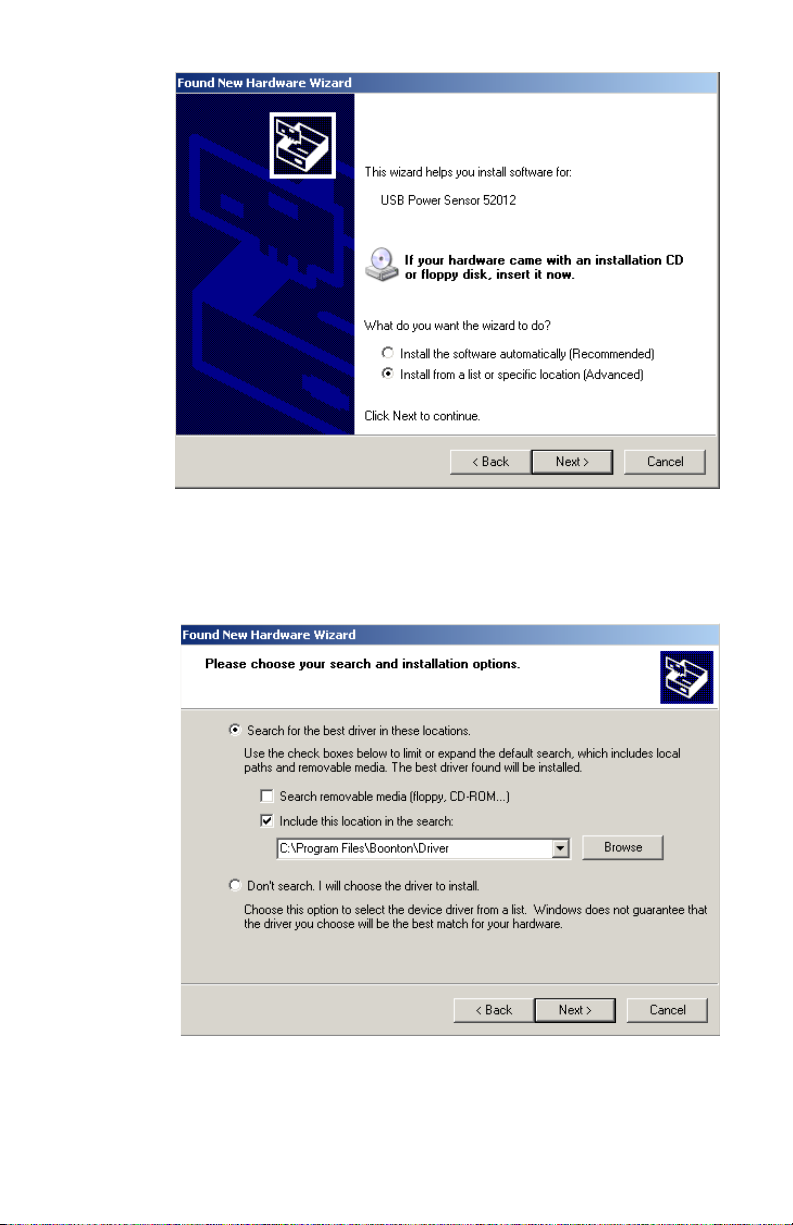

4. Choose “Include this location in the search”.

Refer to Figure 9 on page15.

Figure 13 Choose the installation location

18 USB Installation

Page 19

5. Browse to the following location: C:\ProgramFiles\Boonton\Driver.

If you have changed the default installation location, navigate to the

Boonton installation folder.

6. Select Next.

7. (Optional) During the installation Windows may check the driver

compatibility. Select Continue Anyway. The USB sensor driver is a

valid driver and will not damage your system.

Refer to Figure 10 on page 16.

Figure 14 Continue Anyway with installation

8. The driver will now be installed.

9. Select Finish when the driver installation is complete Windows will

now conrm it has identied the USB sensor hardware.

Reconnect your LAN connection.

The USB driver that is installed is a generic USB sensor driver and it

is used for a range ofUSB sensors. The sensor driver installed on your

PC is called FTDI FT8U2XX Device. If this is not the driver installed on

your PC, refer to “How to x “No Sensor Connected” problems” on

page 51 for more information.

Boonton 52000 Series 19

Page 20

This page is intentionally left blank

20 USB Installation

Page 21

3 Hardware Connections

USB Cable

Your PC

52000 Sensor

52012 CW Power Sensor

ESD

Earth ground must be connected

Max pwr +23dBm avg, +30dBm peak for 1us +/- 10.0VDC Max.

10MHz - 12.4GHz

10nW - 100mW (-50dBm to 20dBm)

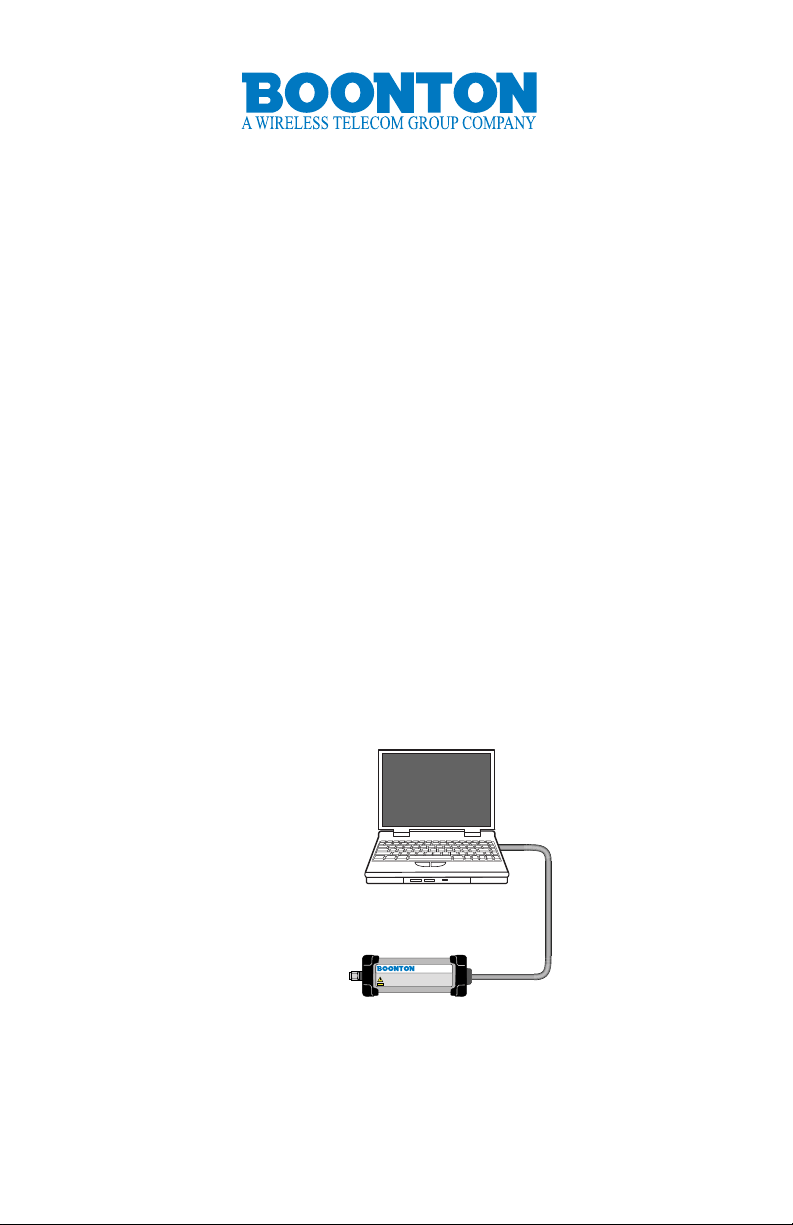

This chapter provides an overview of how to connect your 52000 CW

power sensor/meter in your test environment.

How to connect your sensor

The section describes some typical connection congurations.

Connection to your PC

Connection to your PC is through a USB cable (supplied with

your sensor). The 52000 series CW Power sensor/meter is USB 2.0

compatible. It is recommended that you use the USB cable supplied

with your sensor. Refer to Figure 15 “Sensor to PC connection” on

page 21 for a diagram of the sensor and PC connection.

Figure 15 Sensor to PC connection

The maximum recommended connection length is 5m.

Boonton 52000 Series 21

Page 22

Connection to your unit under test (UUT)

Unit Under Test (UUT)

Test signal source

Your PC

USB

Cable

Signal cable

52012 CW Power Sensor

ESD

Earth ground must be connected

Max pwr +23dBm avg, +30dBm peak for 1us +/- 10.0VDC Max.

10MHz - 12.4GHz

10nW - 100mW (-50dBm to 20dBm)

The 52000 series CW power sensor/meter has a standard SMA-m

connection port.

The recommended torque for the SMA-m connection is 5 lbs/in (0.5 Nm).

Refer to Figure 16 “Typical sensor to UUT connection” on page 22 for

a diagram of the sensor connection.

Figure 16 Typical sensor to UUT connection

Caution Do not turn the body of the sensor when connecting the

sensor to a unit under test (UUT). To avoid internal sensor damage,

connect and disconnect the sensor by turning the metal nut only.

Caution Ensure that you do not apply any excessive force on the

sensor once it has been connected.

22 Hardware Connections

Page 23

Connecting multiple sensors

Your PC

Test signal source

USB

Hub

Units

Under Test (UUT)

USB

Cables

USB

Cables

Signal cables

52000 Sensors

52012 CW Power Sensor

ESD

Earth ground must be connected

Max pwr +23dBm avg, +30dBm peak for 1us +/- 10.0VDC Max.

10MHz - 12.4GHz

10nW - 100mW (-50dBm to 20dBm)

52012 CW Power Sensor

ESD

Earth ground must be connected

Max pwr +23dBm avg, +30dBm peak for 1us +/- 10.0VDC Max.

10MHz - 12.4GHz

10nW - 100mW (-50dBm to 20dBm)

52012 CW Power Sensor

ESD

Earth ground must be connected

Max pwr +23dBm avg, +30dBm peak for 1us +/- 10.0VDC Max.

10MHz - 12.4GHz

10nW - 100mW (-50dBm to 20dBm)

52012 CW Power Sensor

ESD

Earth ground must be connected

Max pwr +23dBm avg, +30dBm peak for 1us +/- 10.0VDC Max.

10MHz - 12.4GHz

10nW - 100mW (-50dBm to 20dBm)

It is possible to connect and monitor multiple sensors. The number

of sensors you can connect to your PC depends on your system

conguration. For example, you may chose to use a USB hub

interface. If this is the case, then carefully read the USB hub

manufacturer’s instructions when connecting and conguring

external USB devices.

Refer to Figure 17 “A typical multiple sensor conguration” on page

23 for a diagram of a typical multiple sensor conguration.

Figure 17 A typical multiple sensor conguration

Boonton 52000 Series 23

Page 24

This page is intentionally left blank

24 Hardware Connections

Page 25

4 Using The Software

This chapter describes how to use the Boonton software when

making typical power measurements. It also provides a description of

the user interface and key features of the software.

Using the software

Once you have installed the software, congured your USB drivers

and connected your hardware, you are ready to make measurements

using the Boonton software.

If you chose the default installation, you should have an icon on your

desktop for the test software. Double-click on this icon to start the

application. Refer to Figure 18 for an example start-up interface.

Figure 18 Default start-up interface

Boonton 52000 Series 25

Page 26

When the software is started, measurement results are displayed

right away. However you are reminded that you should zero the

sensor. Zero your sensor On the right side of the user interface you

are reminded that the sensor is not zeroed. For more information on

zeroing your sensor, refer to “What is zeroing?” on page 56. Use the

following procedure to zero your measurement sensor:

Making a measurement

The following procedure outlines a typical measurement procedure.

Do this Comment

1. With the sensor still connected, select the zero icon .

Or select Measurement > Zero Sensor

2. Conrm you wish to zero the sensor, select OK.

Ensure no power is being applied to the sensor during this process.

3. Wait until the zeroing is completed.

When the zero process is complete, the reminder is removed from the

user interface.

Do this Comment

1. Zero the sensor.

Refer to “Zero your sensor” on page 26.

2. Open the measurement control panel. Select the control panel icon

or select Measurement > ControlPanel.

Refer to Figure 19 on page 27.

26 Using the Software

Page 27

Figure 19 Control panel

3. Choose Log Power from the measurement mode section of the

control panel dialog box.

Top left corner of the dialog box.

Figure 20 Log power

4. Enter the desired measurement frequency.

Figure 21 Set frequency

Boonton 52000 Series 27

Page 28

5. Choose Use Table in the calibration factor section of the control

dialog box. This uses the sensor’s internal calibration table.

Refer to Figure 22 on page 28.

Figure 22 Use table

6. Select Apply and Close the measurement control panel.

Figure 23 Apply button

7. Enable the unit under test (UUT) providing a signal to the sensor.

8. The power measurement is displayed.

For denitions of dB and dBm, refer to “What is a dB?” on page 57

and “What is a dBm?” on page 58.

Measurements using more than one sensor

It is possible to make multiple measurements using multiple USB

sensors and multiple instances of the sensor software. Start the Boonton

software for each sensor connected to your PC. Follow this procedure:

28 Using the Software

Page 29

1. Connect all your sensors to your PC.

2. Double-click on the desktop icon for the Boonton software.

3. To identify which sensor you are connected to, match the serial

number on the display with the serial number on the sensor. Refer to

Figure 24 on page 29.

Figure 24 Sensor serial number identication

4. Congure your measurement software. Refer to “Making a

measurement” on page 26.

5. Again, double-click on the desktop icon for the Boonton software

and start another application.

6. Identify the sensor and congure your measurement.

7. Repeat this process (steps 2-4) for each sensor attached to your PC.

Boonton 52000 Series 29

Page 30

How to make a pulse power measurement

The following procedure outlines how to set up and make a pulse

power measurement. For more information on pulse power

measurement refer to “Pulse measurement and setting the duty

cycle” on page 56.

1. Open the application.

2. Zero your sensor.

Refer to “Zero your sensor” on page 26.

3. Open the measurement control panel. Select the control panel icon

or select Measurement > Control Panel.

4. Enable the duty cycle option and set the duty cycle percentage.

Refer to Figure 25 on page 30.

Figure 25 Setting the duty cycle

5. Set the Calibration Factor.

6. Select Apply.

The pulse repetition rate should be above 200 Hz for the internal

averaging to be effective. Below this PRF the reading will vary. The

duty cycle feature may be used down to about 1%. The peak power

limit of the sensor should be strictly adhered to. Refer to gure 26

on page 31 for more information.

30 Using the Software

Page 31

pulse pe riod

on time

time

pulse power

average

power

duty cycle =

on time

pulse period

100%

1

p.r.f. =

pulse period

average power =

on time

pulse power

x

x

pulse period

Watts

Figure 26 Typical RF burst

Measuring GSM mobile signals

GSM mobile signals are usually present for a single time-slot per

frame, that is, for approximately one eighth of the time, since there

are eight time slots per frame.

The mobile transmitter is active for slightly less than this time because

the transmitter has around three ‘tail’ bits to ramp up and down in

power, and 8.25 guard bits where the transmitter is silent. This means

that the transmitter is inactive for 11.25 bits out of 156.25.

That is for roughly (156.25 - 11.25) / 156.25 = 0.928 of a time slot.

The duty cycle of the transmitter is then 12.5% * 0.928 = 11.6%.

Refer to Figure 27 on page 32.

Note This measurement example is based on the 51012 sensor.

Boonton 52000 Series 31

Page 32

8 1

2

3 4

5

6 7 8

1

TB3Data

57

57

Data

Training

26

f

1

f

1

TB

3

GB

8.25

1 TDMA frame (4.615 ms)

1 timeslot (0.577 ms)

TB = Tail Bits

f = Flag

GB = Guard Band

Figure 27 GSM TDMA structure and normal burst

In some cases, when the modulation is GPRS, multiple time slots are

used. The correct duty cycle can be found by multiplying 11.6% by

the number of active time-slots.

Making a measurement

Follow this procedure:

1. Start the application.

2. zero the sensor.

Refer to “Zero your sensor” on page 26.

3. Open the measurement control panel. Select the control panel icon

or select Measurement > Control Panel.

4. Enable the duty cycle option and set the duty cycle percentage to

11.6%.

5. Select Apply.

The sensor will read the GSM phone power in the active part of the

time slot with reasonable accuracy.

32 Using the Software

Page 33

Measuring power greater than +20dBm (100mW)

The offset facility is useful when an attenuator or amplier is used

ahead of the sensor.

For example, if a 10.00 dB attenuator could be placed before the

sensor to measure powers up to +30dBm (1 Watt).

Caution Do not apply more than +20dBm directly to the sensor. This

level of power will damage the sensor.

1. Connect the sensor and open the application.

Refer to “Making a measurement” on page 32.

2. Zero the sensor.

Refer to “Zero your sensor” on page 26.

3. Set the measurement frequency.

This is set in the measurement control panel.

4. Insert the RF attenuator in front of the sensor. The power reading

decreases by the attenuation value.

5. In the measurement control panel, enable ‘Measurement Offset

(dB)’ and enter the value of the attenuator.

A positive number for attenuation, negative for gain.

6. The power reading will now increase by the value entered. This

counteracts the decrease in the displayed reading caused by the

attenuator. The offset value also appears on the application software.

7. The sensor and attenuator now measure from -40 dBm to +30 dBm.

Refer to Figure 28 on page 34.

Boonton 52000 Series 33

Page 34

Figure 28 Sensor conguration using an attenuator

10dB

PAD

+30 dBm

Offset

52012 CW Power Sensor

ESD

Earth ground must be connected

Max pwr +23dBm avg, +30dBm peak for 1us +/- 10.0VDC Max.

10MHz - 12.4GHz

10nW - 100mW (-50dBm to 20dBm)

Measuring an attenuator using relative mode

Use relative mode to measure an attenuator, similar to the type

used when measuring power greater than +20dBm. The process is as

follows:

1. Connect the sensor and open the application.

Refer to “Making a measurement” on page 32.

2. Zero the sensor.

Refer to “Zero your sensor” on page 26.

3. Set the measurement frequency.

This is set in the measurement control panel.

4. Connect the sensor to a signal generator and attenuator.

Set the signal generator level so that it will not damage to sensor,

even without the attenuator.

5. In the measurement panel, enable relative measurement mode.

Refer to Figure 29 on page 35.

34 Using the Software

Page 35

Figure 29 Enable relative measurement mode

6. Select the Set button.

The display should be 0.000 dB.

7. Remove the attenuator and reconnect the sensor to signal

generator.

8. The sensor now reads the value of the attenuator, in dB, at the

measurement frequency.

9. This value may be entered in the measurement offset.

How to use measurement limits

The limit facility is useful for placing a guard band around a

measurement.

For example, if the output from a device is +3dBm and must stay

within 1dB of that level, then the limits facility can be used to warn

you if the output rises above 4dBm or falls below 2dBm. Follow this

procedure:

1. Connect the sensor and open the application.

Refer to “Making a measurement” on page 32.

2. Zero the sensor.

Refer to “Zero your sensor” on page 26.

Boonton 52000 Series 35

Page 36

3. Set the measurement frequency. This is set in the measurement

control panel.

4. In the measurment control panel, enable the limits options.

Refer to Figure 30 on page 36.

Figure 30 Setting measurement limits

5. Set the Low (dB) limit to 2dBm.

6. Set the High (dB) limit to 4dBm These limit settings are shown on

the status area of the user interface.

If the level drops below 2dBm then a low limit warning message will

appear. Refer to Figure 31 on page 37.

36 Using the Software

Page 37

Figure 31 Low limits warning message

If the level rise above 4dBm then a high limit warning message will

appear. Refer to Figure 32 on page 37.

Figure 32 High limit warning message

Boonton 52000 Series 37

Page 38

How to use trace mode

The trace facility is useful for plotting the level being measured by

the sensor over a period of time.

To congure a trace, open the trace control dialog box. Select the

trace icon or select Tools > Trace...

The trace is congured as follows:

1. Set the number of samples.

This is the number of samples to be taken for the trace.

2. Set the sample period.

This is the time between the plotted points. Refer to Figure 33 on

page 38.

Figure 33 Trace control dialog box

3. Set the plot type.

Power linear (watts) or power log (dBm).

38 Using the Software

Page 39

4. Set the plot scaling to Auto.

The Y-axis is automatically scaled to suit the Min and Max values

associated with the level being plotted.

5. (Optional) Disable plot scaling.

The Y-axis uses the entered Min and Max values.

6. Set temperature display, enable the sensor option.

The temperature is displayed with a red trace.

7. (Optional) Enable the Auto Scale option.

The Y-axis is automatically scaled to suit the Min and Max

temperature values. If auto scaling is not selected, then Min and Max

values for the temperature Y-axis can be entered into the Min and

Max boxes.

8. Select Start to begin the real-time trace.

Refer to Figure 34 on page 39.

Figure 34 Typical trace with temperature

While the trace is drawing, the scaling can be altered by selecting

the settings icon or selecting Trace > Settings on the menu bar. Also,

the trace can be stopped by selecting the stop icon or selecting Trace

> Stop on the menu bar. Refer to Figure 35 on page 40.

Boonton 52000 Series 39

Page 40

Figure 35 Trace controls dialog box

When the trace is complete, markers for making X and Y

measurements can be turned on by selecting the markers icon or

selecting Trace > Markers in the menu bar. Refer to Figure 36 on

page 40.

40 Using the Software

Page 41

Figure 36 Trace markers

The displayed trace can be saved by selecting the File > Save Trace in

the trace control dialog box. A trace can be recalled by selecting File

> Recall Trace. The raw data used todraw the trace can be saved in a

le by selecting the Save Data icon.

To exit trace mode select the exit icon or select Trace > Exit.

Note Do not select the window close icon at the top right of the

application to exit

the trace feature as this closes the whole application. Instead select

the close icon .

Boonton 52000 Series 41

Page 42

Error and status messages

The right side of the users interface displays a series of warnings and

status messages. These are described as follows:

Sensor not zeroed

This message is displayed when the application rst detects a sensor

or the sensor needs to be re-zeroed. Refer to “Zero your sensor” on

page 26 for more information. Refer to Figure 37 on page 42.

Sensor frequency, offset and duty cycle enabled

These message let you know your measurement frequency setting. It

also shows if offset has been enable along with the duty cycle. Refer

to Figure 37 on page 42.

Figure 37 Frequency, Offset and Duty Cycle messages

42 Using the Software

Page 43

Sensor overload

This warning message indicates a sensor overload. Refer to Figure 38

on page 43.

Figure 38 Sensor overload warning message

High limit exceeded

This warning message tells you when you have exceeded the high

measurement limit you have set in the measurement control panel.

When you see this warning message, reduce the power being tested.

Refer to Figure 39 on page 43.

Figure 39 High limit warning

Boonton 52000 Series 43

Page 44

Low limit exceeded

This warning message tells you when you have exceeded the low

measurement limit you have set in the measurement control panel.

When you see this warning message, increase the power being

tested.Refer to Figure 40 on page 44.

Figure 40 Low limit warning

Zero sensor - temperature change

When the temperature of the sensor is too great for the reliable

measurement to be made, the zero sensor and temperature warning

message is displayed. Refer to Figure 41 on page 44.

Figure 41 Zero shift warning

44 Using the Software

Page 45

Manually entered cal factor

When you have entered a cal table, the entries are displayed on the

user interface. Refer to on page 45.

Figure 42 Manually entered cal table

Boonton 52000 Series 45

Page 46

5 Description of Software

Icon Description

Opens the control panel.

Starts the zero sensor process.

Sets the sensor frequency.

Changes the display between dBm nW.

Changes the display between numerical or numerical with graphical data

display to just a graphical display.

Changes the number of decimal places being displayed.

Opens the trace setting dialog box.

Saves the current data.

Recalls (Open) saved data.

Opens the application help.

Description of icons

The following section describes the basic software features. For more

information on the software and menu options, refer to the online

help in the application.

The icons, along the top of the application, are used for accessing the

most common tasks. The icons are used as follows:

46 Description of Software

Page 47

Description of menu options

The following describes the menu options from the application.

File Menu

Save Setup

Allows current setup to be saved to a simple text le.

Recall Setup

Allows a previous setup to be recalled.

Firmware download

Lets you update the rmware revision of the sensor.

Exit

Exits the application.

Measurement Menu

Control Panel

The control panel is used for setting most of the user interface

components and key measurement factors. The control panel is

divided into areas for conguring your measurement environment.

Zero Sensor

This performs a sensor zeroing process and will remove any offsets

before making a measurement. This function should be carried out

typically for values less than -35dBm. Refer to “What is zeroing?” on

page 56 for more information.

Preset

Resets all your congured measurements back to the factory default

settings.

Tools Menu

Trace

Opens the trace control dialog box. Congure and start your trace

from this dialog box.

Stats

This opens the statistics conguration dialog box. From this dialog

box you can setup and draw a snap-shot bar chart of your results.

Boonton 52000 Series 47

Page 48

Calculators

Help Menu

This menu option gives you access to three useful microwave

calculators.

These are:

• VSWR Mismatch

• Parameters

• Power Units Converter

The VSWR Mismatch calculator and the Parameter calculator have

help les which describe their operation.

USB Power Sensor Help

Opens the application help which provides detailed descriptions of

the features being used. Help on the measurement control panel is

displayed when you select the help button in the dialog box.

Sensor Details

Provides information about the detected sensor being used by the

application. This includes the rmware and serial number of the

sensor.

About…

This provides information about the revision of the application you

are using.

48 Description of Software

Page 49

6 Enhanced Features

This chapter outlines the advanced capabilities of the 52000 series

CW power sensor/meter software.There are brief outlines and

descriptions of how the software can be integrated into other test

environments such as C++, Agilent VEE and National Instruments® NI.

Refer to the programming reference guide for more details . An

electronic version is included on your Boonton CD.

Integrating your power sensor

The following section details how to integrate the Boonton software

into your test environment.

A library of function calls provides a simple, but powerful interface

between your application software and sensor hardware. All the

function calls are contained in a dynamic link library (DLL).

To use the library, the following three les are required:

• USB Sensor Lib.dll

• USB Sensor.Lib.lib

• USB Sensor.h

These les can be found on the installation CD. The latest versions

can be downloaded free of charge from the Boonton website www.

boonton.com

Boonton 52000 Series 49

Page 50

The le USB Sensor Lib.dll can reside in the same directory as your

application executable le, or in a path known to your application

executable le.

The le USB Sensor Lib.lib must reside in a path known to the linker

that will link to your application.

The le USB Sensor.h contains denitions required by the USB Sensor

function calls and must reside in a path known to the compiler that

will compile your source code.

50 Enhanced Features

Page 51

7 Troubleshooting

This chapter explains how to x some typical software and hardware

conguration issues that you may have encountered. It also provides

some technical background information that can help you better

understand your test environment.

How to x “No Sensor Connected” problems

When you start your Boonton software application you can get the

following condition message displayed - “No Sensor Connected”,

refer to Figure 43 on page 51.

Figure 43 No sensor connected warning

This can be the result of one of the following issues:

• No sensor is attached to your PC (refer to page 52)

• The wrong USB driver has been installed (refer to page 52)

• The USB cable or USB port are faulty (refer to page 53)

• Incorrectly congured USB hub (refer to page 53)

• More than one application has been started (refer to page 54)

The following procedures will help you correct these problems:

Boonton 52000 Series 51

Page 52

No sensor is attached to your PC

Check all cable connections from your PC to your sensor. A connector

may have been loosened and may not be making adequate contact.

This is especially important when using multiple sensor

congurations.

The wrong USB driver has been installed

If the wrong USB driver has been installed then there will be no

consistent communication between your sensor and PC. Use the

following procedure to identify the installed driver

.

This procedure applies to Windows® XP operating system.

1. On your PC, select Start > Control Panel.

2. Double-click on System.

This opens the System Properties dialog box.

3. Select the Hardware tab.

4. Select the Device Manager button.

This opens the Device Manager dialog box.

5. Expand the list of Universal Serial Bus controllers

Click the ‘plus’ symbol to expand the list.

6. If the correct driver has been installed you should see the

following item listed - FTDI FT8U2XX Device

Refer to Figure 43 on page 52.

Figure 44 Correct USB driver conguration

52 Troubleshooting

Page 53

If this is NOT the driver listed in your Device Manager, then use the

following procedure to remove the installed driver and congure the

correct driver:

The USB cable or USB port are faulty

In the event of a faulty cable or port, try the following solutions:

• Replace the cable with another high standard USB cable.

• Use another USB port on your PC. If you only have one port on your

PC, connect another USB device to the suspected port (for example a

mouse or printer) and verify device recognition.

Incorrectly congured USB hub

Some USB hub devices require custom driver installation. If the driver

installation procedures are not followed correctly some, or all the

ports provided by the hub, may not be seen by your PC. Carefully

read your USB hub manufacturer’s instructions on driver installation

and conguration. If you are not sure the fault is with the USB hub,

try connecting a sensor directly to your PC and verify connection

using the application. Do this Comment

1. Disconnect any sensors connected to your PC.

2. On your PC, select Start > Control Panel.

3. Double-click on Add or Remove Programs.

4. Locate and select the FTDI COM driver listed.

5. Select the Change/Remove button. This removes the USB driver.

6. When the driver has been removed, close the Add or Remove

Programs dialog box.

7. Close the Control Panel.

8. To install the correct USB, refer to “USB Installation” on page 13.

Boonton 52000 Series 53

Page 54

More than one application has been started

It is possible to start multiple instances of the application software.

The rst time the application is started it checks the available USB

ports for a recognised sensor. If the application is started again, but

you only have one sensor connected, then the application will report

a “No Sensor Connected” error.

Check your PC Taskbar for any minimised applications.

Unexpected measurements results

If you suspect that you are getting unexpected measurements, then

use the following procedures to correct the potential fault:

• Check the status messages displayed on the right-side of the application

• Your sensor is potentially damaged

• Incorrect offset setting

• Incorrect measurement settings

Check status messages

The status messages on the right-side of the applcaition provide

infroamtion about your measurement settings and any possible limits

errors. Refer to “Error and status messages” on page 42.

Your sensor is potentially damaged

If you suspect that your sensor is damaged, then connect a known

signal source and verify that the sensor is measuring that source

correctly. If this, or any of the other procedures do not correct the

fault then contact your local representative for more information.

Incorrect offset setting

If you have made the wrong measurement offset setting in

the measurement control panel, then you may see incorrect

measurements.

Incorrect measurement settings

Check that you have set all the right settings in the measurement

control panel. Refer to “Using the software” on page 25 for more

information. If you are not sure what settings you have set, select

Measurement > Preset to return the sensor measurement settings to

the factory default settings.

54 Troubleshooting

Page 55

How to identify your PC operating system

Your operating system

Installed service pack

The procedure for installing USB drivers differs slightly depending on

which version of operating system you have on your PC. Follow this

procedure to identify your operating system.

Do this Comment

1. On your PC, select Start.

2. Highlight and right-click on My Computer.

3. Select Properties from the pop-up menu. This opens the System

Properties dialog box.

4. Select the General tab. Refer to Figure 45 on page 55.

Figure 45 How to identify your operating system Your operating

system Installed service pack

Boonton 52000 Series 55

Page 56

Other useful information

The following sections provide some useful information about power

measurement and your USB sensor.

What is zeroing?

Zeroing is a measurement process that ensures that the sensor

indicates as close as possible to 0 watts when no power is applied.

This ensures that the sensor gives the best possible linearity.

Due to the very low voltages that are measured by the analogue to

digital converter in the sensor, some averaging is necessary and the

process takes about eleven seconds. The zero should be re-measured

periodically for best accuracy at low power levels. It should also be

re-measured after connecting the sensor directly to equipment that

is at a signicantly different temperature than the sensor, when the

sensor has reached operating temperature.

It is only necessary to re-zero if the power indicated when no power

is applied to the sensor is worse than -55 dBm. A poor zero affects

lower power measurements more than larger ones. Excessive zeroing

in automatic measurement programs is not recommended as it can

signicantly increase program run times.

Pulse measurement and setting the duty cycle

The duty cycle facility is used to measure the ‘pulse power’. This is the

power measurement while an RF burst is present, when the signal is

a gated burst of a sinusoidal RF signal - for example a radar pulse.

The sensor is calibrated to measure average power, and provided the

pulse repetition rate is sufciently high, a measurement of the pulse

power can be obtained from the average power.

Certain assumptions are made about the RF burst, and these must be

met if the measurement is to be accurate. The burst is assumed to be

either on or off, in other words it does not take a nite time to ramp

up or down.

The ramp up and down times should be small in relation to the

on time of the signal generator. The burst is also assumed to have

constant amplitude when on. The amplitude does not ring, droop

or overshoot. If the pulse does not have these attributes, then the

accuracy of the result is not valid.

56 Other Information

Page 57

The RF in the burst is also assumed to be un-modulated. If it were

amplitude modulated, for example, then the measurements would

be likely to vary with time as the modulation and the voltage

measurement made in the power meter would not be synchronized.

Constant amplitude modes of modulation like phase or frequency

modulation are permissible.

What is a dB?

The dBm and dB are common units occurring in power

measurements. ‘dB’ is short for decibel. The dB is a method of

describing the ratio of two powers over a very wide range and is

dened as:

The table below gives some power ratios and their equivalent dB

values:

Power ratio dB

0.001 -30.00

0.01 -20.00

0.1 -10.00

0.25 -6.02

0.5 -3.01

1 0

2 3.01

4 6.02

10 10.00

100 20.00

1000 30.00

Boonton 52000 Series 57

Page 58

What is a dBm?

When one of the powers is dened, again for convenience, as 1mW,

then the related unit, abbreviated to ‘dBm’, is described as follows.

The table below gives some powers and their equivalent dBm values:

Power dBm

1 μW -30.00

10 μW -20.00

100 μW -10.00

0.25 mW -6.02

0.5 mW -3.01

1 mW 0

2 mW 3.01

4 mW 6.02

10 mW 10.00

100 mW 20.00

1 W 30.00

58 Other Information

Page 59

8 Contact and Support

This chapter provides information about Boonton. It tells you how to

get in touch and what to do if you are having problems or need more

information about other products.

Contacting Boonton

To contact Boonton please contact your local representative or use

the following e-mail address:

boonton@boonton.com

Our Website

The Boonton website provides up to date product information and news.

www.boonton.com

Boonton 52000 Series 59

Page 60

9 Safety and Specications

This chapter provides information about the 52000 Series CW power

sensor/meter safety compliance and sensor specications.

Safety notices

Please careful read the following information:

WARNING A WARNING denotes a hazard. A WARNING that is not

followed and adhered to could result in injury or loss of life. Do not

proceed beyond the WARNING note until you have carefully read and

understood the note.

Caution A CAUTION denotes a hazard. A CAUTION that is not

followed and adhered to could result in partial or complete damage

of your equipment.

Do not proceed beyond the CAUTION note until you have carefully

read and understood the note.

Note A NOTE draws your attention to a procedure or additional

information that, if followed correctly, can prevent mis-use of the

your equipment. It also points out additional information that can

help you get more from your system.

60 Safety & Specications

Page 61

Boonton 52000 Series 61

Page 62

WEEE Directive

Boonton will undertake a “take back” policy for all sensor products

no longer t for purpose and dispose of the said products under the

European WEEE directive.

Please contact Boonton for more details, refer to “Contacting

Boonton”on page 59.

Product descriptions and requirements

The 52000 series CW power sensor/meter descriptions and PC

specications are as follows:

Minimum PC requirements

Your minimum recommended PC specications are:

PIII Windows XP SP2

256 RAM

600 MHz

USB Port (1.0 or greater)

CD Drive

52012 Description

• 52012 USB power sensor

• Frequency range: 10MHz to 12.4GHz

• Amplitude range: -50dBm to +20dBm

• RF input connector SMA male

52018 Description

• 52018 USB power sensor

• Frequency range: 10MHz to 18.5GHz

• Amplitude range: -50dBm to +20dBm

• RF input connector SMA male

62 Safety & Specications

.

Page 63

52012

Frequency 10MHz to 12.4GHz

Measurement range -50 to +20dBm CW

Operating Temperature 0 to 50 deg C

Shock 25G, 11 ms

Vibration 15G, 100 to 2000Hz

Linearity error 25 +/- 5 deg C +/-0.27 dB; -40dBm to +10dBm;

Cal factor error 25 +/- 5 deg C +/-0.24 dB; 10 MHz to 50 MHz

Linearity variation 25 +/- 25 deg C +/-0.29 dB; 50MHz to12.4GHz

Cal factor variation 25 +/- 25 deg C +/-0.29 dB; greater than or equal to 50 MHz

Zero set +/-1.2 nW

Noise 0.12 nW RMS

Input SWR - max 1.26:1 = 12.4 GHz 1.26:1 = 18.5 GHz

Measurement Speed: -50 to -35 dBm 8 measurements per sec.

-35 to -20 dBm 33 measurements per sec.

-20 to +20 dBm 50 measurements per sec.

Max input power (damage level) 200mW CW (+23dBm)

Connector type SMA (m)

Connectivity USB 2.0 (cable length up to 5m)

USB power supply current Approx. 50mA

Sensor Cable Length (std) 76” (193 cm)

Dimensions (max) H x W x L 1.34” x 1.69” x 4.92” (34 x 43 x 125 (mm)

Weight 0.18lb (83 grams)

Specications include expanded uncertainty of measurement stated as the standard uncertainty of

measurement multiplied by the coverage factor k=2 which corresponds to a coverage probability of

approximately 95% for abnormal distribution.

greater than or equal to 50 MHz

+/-0.49 dB; +10dBm to +20dBm;

greater than or equal to 50 MHz

+/-0.28 dB; -40dBm to +10dBm; less than 50 MHz

+/-0.95 dB; +10dBm to +20dBm; less than 50 MHz

+/-0.19 dB; 50MHz to 4.5GHz

+/-0.23 dB; 4.5GHz to 8.5GHz

+/-0.32 dB; 8.5GHz to 12.4GHz

+/-0.47 dB; 10 MHz to 50MHz

+/-0.44 dB; less than 50 MHz

Boonton 52000 Series 63

Page 64

52018

Frequency 10MHz to 18.5GHz

Measurement range -50 to +20dBm CW

Operating Temperature 0 to 50 deg C

Shock 25G, 11 ms

Vibration 15G, 100 to 2000Hz

Linearity error +/-0.27 dB; -40dBm to +10dBm;

Cal factor error 25 +/- 5 deg C +/-0.24 dB; 10 MHz to 50MHz

Linearity variation 25 +/- 25 deg C +/-0.35 dB; 50MHz to18.5GHz

Cal factor variation 25 +/- 25 deg C +/-0.32 dB; greater than or equal to 50 MHz

Zero set +/-1.8 nW

Noise 0.15 nW RMS

Input SWR - max 1.26:1 = 18.5 GHz

Measurement Speed: -50 to -35 dBm

-35 to -20 dBm

-20 to +20 dBm 50 measurements per sec

Max input power (damage level) 200mW CW (+23dBm)

Connector type SMA (m)

Connectivity USB 2.0 (cable length up to 5m)

USB power supply current Approx. 50mA

Sensor Cable Length (std) 76” (193 cm)

Dimensions (max) H x W x L 1.34” x 1.69” x 4.92” (34 x 43 x 125 (mm)

Weight 0.18lb (83 grams)

Specications include expanded uncertainty of measurement stated as the standard uncertainty of

measurement multiplied by the coverage factor k=2 which corresponds to a coverage probability of

approximately 95% for abnormal distribution.

greater than or equal to 50 MHz

+/-0.49 dB; +10dBm to +20dBm;

greater than or equal to 50 MHz

+/-0.28 dB; -40dBm to +10dBm; less than 50 MHz

+/-0.95 dB; +10dBm to +20dBm; less than 50MHz

+/-0.19 dB; 50MHz to 4.5GHz

+/-0.23 dB; 4.5GHz to 8.5GHz

+/-0.32 dB; 8.5GHz to 12.4GHz

+/-0.38 dB; 12.4GHz to18.5GHz

+/-0.47 dB; 10 MHz to 50MHz

+/-0.44 dB; less than 50 MHz

8 measurements per sec.

33 measurements per sec.

64 Safety & Specications

Page 65

Index

A

Attenuator .......................................................................................................... 33

C

cautions ............................................................................................................... 60

compliance ......................................................................................................... 60

connecting multiple sensors ........................................................................ 23

connection torque ........................................................................................... 22

contact Boonton .............................................................................................. 59

contents of your system ...................................................................................4

D

dB ......................................................................................................................... 57

dBm ..................................................................................................................... 58

declaration of conformity ..............................................................................61

driver

windows XP SP1 .............................................................................................. 16

windows XP SP2 .............................................................................................. 13

duty cycle .....................................................................................30, 31, 32, 56

E

embedding software ....................................................................................... 49

enhanced features .......................................................................................... 49

error messages ................................................................................................. 42

extra features ................................................................................................... 49

F

le menu ............................................................................................................ 47

forced zero ........................................................................................................ 44

G

GPRS measurement ........................................................................................ 32

GSM phone measurement ............................................................................ 32

GSM signal measurement ..............................................................................31

H

hardware conguration ..................................................................................21

Boonton 52000 Series 65

Page 66

help menu .......................................................................................................... 48

high limit ........................................................................................................... 43

high limit exceeded ........................................................................................ 43

I

icons .................................................................................................................... 46

identify operating system ............................................................................. 55

install USB drivers ........................................................................................... 13

installed USB driver ........................................................................................ 16

installing software ............................................................................................. 9

introduction ......................................................................................................... 3

K

key features ..........................................................................................................3

L

license agreement ............................................................................................10

low limit exceeded .......................................................................................... 44

M

make a measurement ..................................................................................... 26

manual cal factors .......................................................................................... 45

measure GSM signal ........................................................................................31

measure power greater than +20dBm ...................................................... 33

measure pulse power ..................................................................................... 30

measure using more than one sensor ....................................................... 28

measurement menu ........................................................................................ 47

measurement offset .......................................................................................33

measurement procedure ................................................................................ 26

menu

le ........................................................................................................................ 47

help ...................................................................................................................... 48

measurement .................................................................................................... 47

tools .................................................................................................................... 47

menu options .................................................................................................... 47

multiple sensor connection .......................................................................... 23

multiple sensors ............................................................................................... 28

N

no sensor connected ........................................................................................51

notes ................................................................................................................... 62

O

offset measurement .......................................................................................33

operating system identication .................................................................. 55

overloaded sensor ...........................................................................................43

P

PC specications ............................................................................................. 62

procedure for installing software .................................................................. 9

programming guide ........................................................................................ 49

66 Index

Page 67

pulse measurement ..................................................................................30, 56

R

return products ................................................................................................ 62

S

safety notices ................................................................................................... 60

sensor driver installation ............................................................................... 13

sensor overload ................................................................................................ 43

sensor to your UUT connection ................................................................... 22

sensor zero ........................................................................................................ 26

serial number .................................................................................................... 29

software

how to use ......................................................................................................... 25

software installation .........................................................................................9

software license agreement ..........................................................................10

software menus ............................................................................................... 46

52012 Specications ...................................................................................... 63

52018 specications ...................................................................................... 64

start-up screen ................................................................................................. 25

status messages ............................................................................................... 42

system integration .......................................................................................... 49

T

tools menu ....................................................................................................... 47

torque for connection .................................................................................... 22

troubleshooting ................................................................................................51

U

unit under test (UUT) .....................................................................................22

USB connection ................................................................................................21

USB driver installation ................................................................................... 13

USB driver problems ....................................................................................... 52

using the software .......................................................................................... 25

UUT connection ............................................................................................... 22

W

warnings ............................................................................................................ 60

website ............................................................................................................... 59

WEEE directive ................................................................................................. 62

welcome ................................................................................................................3

What is dB ......................................................................................................... 57

What is dBm ..................................................................................................... 58

Windows XP installation ............................................................................... 13

wrong USB driver ............................................................................................ 52

Z

zero sensor 26

zeroing what is it ............................................................................................ 56

Boonton 52000 Series 67

Page 68

Boonton Electronics

25 Eastmans Rd.

Parsippany, NJ 07054

U.S.A

Tel. +1 973 386 9696

Fax. +1 973 386 9191

boonton@boonton.com

www.boonton.com

© Copyright 2006

Boonton Electronics (A

Wireless Telecom Group

Company). All rights reserved.

Loading...

Loading...