Boonton 4530 Peak Power Meter Service Manual

SERVICE AND CALIBRATION MANUAL

BOONTON ELECTRONICS

4530 SERIES

RF PEAK POWER METER

MODELS 4531 AND 4532

REV DATE 9/14/07

P/N 98405100A

BOONTON ELECTRONICS a WIRELESS TELECOM GROUP COMPANY

25 EASTMANS ROAD ■ PARSIPPANY, NEW JERSEY 07054-0465

TELEPHONE: (973) 386-9696 ■ FAX: (973) 386-9191 ■ E-MAIL: boonton@boonton.com

BOONTON ELECTRONICS a WIRELESS TELECOM GROUP COMPANY

1

CONTENTS

Contents 2

Section 1. 4530 Series Test Procedure 3

Section 2. 4530 Series Calibration Procedure 11

Section 3. 4530 Series Block Diagrams 23

Section 4. 4530 Series Drawings 27

Appendix Entering Data into Boonton Peak and CW Sensors 33

© Copyright 2002-2007 by Boonton Electronics a Wireless Telecom Group Company, Parsippany, NJ,

USA

BOONTON ELECTRONICS a WIRELESS TELECOM GROUP COMPANY

2

Section 1: 4530 Series Test Procedure

Note: The following procedures assume that the technician is familiar with the basic menu operation of the

4530 Series. To select menu items, press the MENU key twice to return to the top-level menu, and then

use the up and down arrows to highlight the desired entry. Once highlighted, the right arrow or Enter key

is used to select that entry. The ESC key aborts a menu entry, and the left arrow moves back one level in

the menu hierarchy. To select a different menu item at the same menu level, simply navigate directly - it is

not necessary to return to the top of the menu hierarchy. If needed, see the 4530 User’s Manual for more

detailed instructions on menu navigation, and a complete chart of the menu tree.

1) TEST SETUP

a. Remove instrument cover by removing four screws on rear and carefully sliding cover off the back

of the instrument.

b. Connect AC line cord to AC mains (90-264Vac, 47-63Hz)

c. Turn ON rear panel power switch.

d. If instrument turns “on” (display lights, fan runs), wait for startup to complete, then press ON/STBY

key on front panel to return the unit to “standby”.

2) TESTING the 24V UNIVERSAL SUPPLY:

a. Locate Universal Power Supply: small (3” x 5” approx) pc board on top of chassis.

b. Verify that supply voltage is 24.0VDC +/-0.5VDC on the output connector (P102) of the power

supply:

P102-4 is GND, P102-2 is +24V

Pin 1 is near P102 reference designator on power supply board.

c. Verify that the AC ripple voltage on the output connector is less than 250mV peak-to-peak.

d. Press the ON/STBY switch on front panel to turn the unit “ON”, and wait 15 seconds for

initialization to complete.

e. Repeat the DC output and AC ripple tests above of the universal power supply.

3) TESTING HOST BOARD POWER SUPPLY

a. Locate the Host CPU Board: large “L” shaped pc board on top of chassis.

b. Verify the main supply voltages at the following testpoints:

TP1 = +15.00VDC +/- 0.25V

TP2 = +7.50 VDC +/-0.25V

TP3 = -15.00 VDC +/-0.25V

TP4 = -7.50 VDC +/-0.25V

TP6 = +5.00 VDC +/-0.25V

BOONTON ELECTRONICS a WIRELESS TELECOM GROUP COMPANY

3

4) TESTING DSP BOARD POWER SUPPLY

a. Locate the DSP Board: large pc board on bottom of chassis

b. Verify the main supply voltages at the following testpoints:

TP2 =+5.00VDC +/-0.25V

TP3 = +15.00 VDC +/- 0.25V

TP4 = +5.00 VDC c +/-0.25V

TP5 = +2.50 VDC +/-0.25V

TP7 = -5.00 VDC +/-0.25V

TP8 = -15.00 VDC +/-0.25V

TP10 = +8.00 VDC +/-0.25V

TP11 = -8.00 VDC +/-0.25V

5) BASIC SYSTEM CHECK AND SETUP

a. Press ON/STBY key on front panel to return to “standby” mode, then after a few seconds press

again to turn back “on” while observing the display.

b. The display should show a start-up screen, the BOONTON logo, and then the main menu of the

4530.

c. Check that the fan is operating and that air flows freely through the fan and filter. The fan should

blow air OUT of instrument, not in. Clean the filter or fan guard if necessary.

d. Press and hold the ESC/Stop key while using the UP and DOWN keys to adjust the LCD contrast.

Contrast should change from full dark to full light. Adjust for best display when viewed from

directly in front of instrument.

e. From front panel controls, select Main Menu > Utilities > Backlight, and set to “OFF”. Verify

that LCD backlight turns off. Set back to “ON” and verify that backlight turns on.

f. From front panel controls, select Main Menu > Utilities > Key Beep, and set to “ON”. Verify that

pressing any key now causes a beep. Set to “OFF” and verify that the key beep is now disabled.

g. From front panel controls, select Main Menu > Utilities > Sys-Tests > Voltages. Verify that all

the voltages read correctly (no errors messages are displayed). The “Cal VDC = 0V” message is

normal, since the calibrator is off. ESC ends the test.

h. From front panel controls, select Main Menu > Utilities > Sys-Tests >DispTest. Observe the

display test and make sure that the fill and clear patterns appear correct and that the fonts are all

readable. ESC ends the test.

i. From front panel controls, select Main Menu > Utilities > Sys-Tests > Keypad. Press each key.

The corresponding key name on the display will go into reverse video. The ESC/Stop key ends

the test so use this key last.

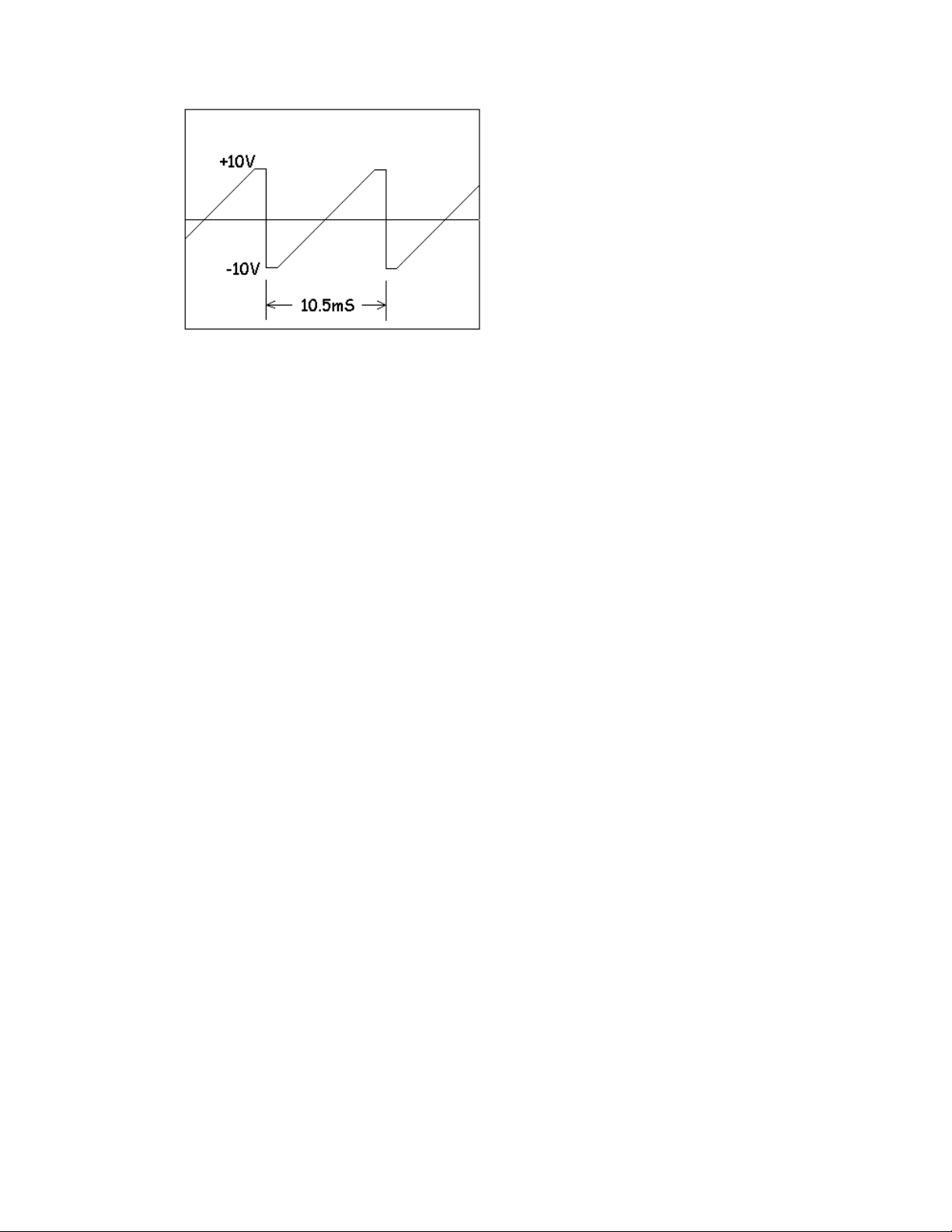

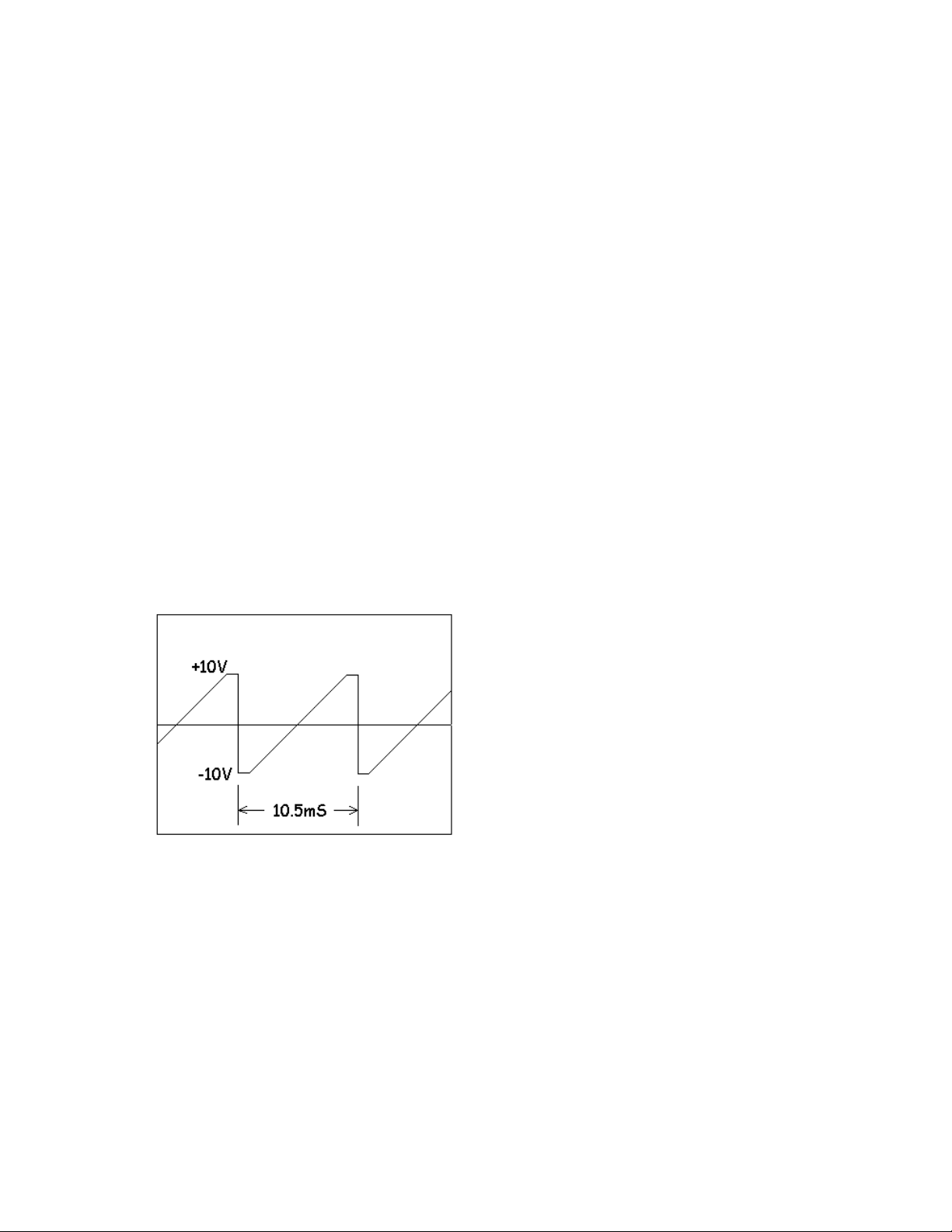

j. From front panel controls, select Main Menu > Utilities > Sys-Tests > Recorder. Monitor the

“Recorder Out” BNC connector on the rear panel using an oscilloscope to verify that the following

waveform is present. Voltages should be within 500mV of values shown, and waveform should

have no large steps or discontinuities. ESC ends the test.

BOONTON ELECTRONICS a WIRELESS TELECOM GROUP COMPANY

4

k. Press and hold the ON/STBY key. Verify that the instrument turns off (enters standby mode)

within 0.5 seconds of key being pressed.

l. Press ON/STBY key again to turn on.

6) SENSOR DETECTION

a. Plug in a CW power sensor into the 4530 “Sensor 1” connector and verify that the 4530 can read

the sensor data (a “reading sensor…” message will be displayed). For two-channel instruments

(Model 4532), repeat for the “Sensor 2” connector.

b. Plug in a Peak power sensor into the 4530 “Sensor 2” connector and verify that the 4530 can read

the sensor data (a “reading sensor…” message will be displayed). For two-channel instruments

(Model 4532), repeat for the “Sensor 2” connector.

7) CHANNEL 1 PEAK ACQUISITION / TRIGGER AND EXTERNAL TRIGGER TESTS

a. Use a 4400/4500 instrument and function generator as a source for a pulsed RF signal and

external trigger signal. A function generator with separate main and TTL outputs such as a BK

Precision Model 3040 is required for these tests. A calibrated oscilloscope will also be needed to

monitor the voltage level.

1. Connect the TTL OUT signal from the function generator to the EXT PULSE input on

the rear panel of the 4400/4500.

2. Connect from the Main Output from the function generator to the EXT TRIGGER

input on the rear panel of the 4530. Using a BNC “T” adapter, also connect this

output to the oscilloscope.

3. Set the function generator’s frequency to 500Hz, and set its main output for a sine

wave.

4. Monitor the sinewave with the oscilloscope, and adjust the function generator’s output

level and offset so the signal has a peak amplitude of +/-4.7V (+/-100mV), and is

symmetrical around 0V.

BOONTON ELECTRONICS a WIRELESS TELECOM GROUP COMPANY

5

5. Set up the 4400/4500 instrument as the source for the pulsed calibrator signal as

follows:

Cal Output On

Set Level: 10.0 dBm.

Max Power: +20.0 dBm.

Cal Mode Pulse

Pulse Source Ext

Polarity +

b. Connect and Calibrate a peak sensor on channel 1:

1. Plug in a 57518 peak power sensor into the 4530 “Sensor 1” connector.

2. From front panel controls, select Zero/Cal > AutoCal. Use the left-arrow key to select

Sensor 1, and press Enter to begin the autocal. The instrument will take about 1.5

minutes to calibrate the sensor.

c. Use the front panel controls to set the following menu items as needed:

Set Main Menu > Measure to “Run”.

Set Main Menu > Chan 1 > MeasMode to “PulseMode”.

Set Main Menu > Chan 1 > Params > dB Offset to 0.00dB.

Set Main Menu > Chan 1 > Params > Frequency to 1.00GHz.

Set Main Menu > Chan 1 > Params > Video BW to “High”.

Set Main Menu > Chan 1 > Display > Vert Span to 100dB.

Set Main Menu > Chan 1 > Display > Vert Cntr to 0dBm.

Set Main Menu > Trig/Time > Time Span to 5ms.

Set Main Menu > Trig/Time > Trig Pos to “Middle”.

Set Main Menu > Trig/Time > TrigDelay to 0ms.

Set Main Menu > Trig/Time > TrigSlope to “Pos (+)”.

Set Main Menu > Trig/Time > TrigMode to “Norm”.

Set Main Menu > Trig/Time > TrigSrce to “External”.

Set Main Menu > Trig/Time > TrigLevel to 0.0 Volts.

d. Press the Graph key. A square wave should be displayed.

e. Press the Graph key again to bring up the Graph Mode Edit Menu, and press the Right Arrow key

until TrigLvl is highlighted.

f. Press the Up key to increase the trigger level until the square wave disappears or stops updating.

Verify that this occurs at a setting of +4.7 +/- 0.2 Volts.

g. Press the Down key to decrease the trigger level until the square wave disappears or stops

updating. Verify that this occurs at a setting of –4.7 +/- 0.2 Volts.

h. Set Main Menu > Trig/Time > TrigSrce to “Snsr 1”.

i. Set Main Menu > Trig/Time > TrigLevel to 0.0 dBm, and press the Graph key again. The

square wave should again be visible and triggering.

j. Increase the frequency setting on the function generator to 100KHz.

k. Press the Right Arrow key until TimeSpn is highlighted in the Graph Mode Edit Menu, then press

the Up key until the Time Span is set to 50usec. A square wave with sharp edge transitions

should be displayed, although the falling edge may decay slowly near the bottom.

BOONTON ELECTRONICS a WIRELESS TELECOM GROUP COMPANY

6

l. Monitor the VIDEO OUT 1 on the rear panel of the 4530 with the oscilloscope. Verify that the

waveform displayed is a 100kHz squarewave with a peak-to-peak amplitude of 1.7V +/- 0.3V. It is

acceptable for the falling edge to decay slowly near the bottom – similar to the waveform that

displayed on the 4530.

m. Set Main Menu > Chan 1 > Params > Video BW to “Low”, then press the Graph key again.

n. Verify that now a serasoidal waveform (a highly filtered square wave with very slow rise and fall

times) is displayed, which indicates that the sensor correctly switched to low bandwidth mode.

8) CHANNEL 2 PEAK ACQUISITION / TRIGGER TESTS (Model 4532 only)

a. Connect and Calibrate a peak sensor on channel 2:

1. Plug in a 57518 peak power sensor into the 4532 “Sensor 2” connector.

2. From front panel controls, select Zero/Cal > AutoCal. Use the right-arrow key to select

Sensor 2, and press Enter to begin the autocal. The instrument will take about 1.5 minutes to

calibrate the sensor.

b. Use the front panel controls to set the following menu items as needed:

Set Main Menu > Chan 2 > MeasMode to “PulseMode”.

Set Main Menu > Chan 2 > Params > dB Offset to 0.00dB.

Set Main Menu > Chan 2 > Params > Frequency to 1.00GHz.

Set Main Menu > Chan 2 > Params > Video BW to “High”.

Set Main Menu > Chan 2 > Display > Vert Span to 100dB.

Set Main Menu > Chan 2 > Display > Vert Cntr to 0dBm.

Set Main Menu > Trig/Time > Time Span to 5ms.

Set Main Menu > Trig/Time > TrigSrce to “Snsr 2”.

Set Main Menu > Trig/Time > TrigLevel to 0.0 dBm.

c. Press the Graph key.

d. Set the function generator frequency to 500Hz. A square wave should be displayed.

e. Increase the frequency setting on the function generator to 100KHz.

f. Press the Right Arrow key until TimeSpn is highlighted in the Graph Mode Edit Menu, then press

the Up key until the Time Span is set to 50usec. A square wave with sharp edge transitions

should be displayed, although the falling edge may decay slowly near the bottom.

g. Monitor the VIDEO OUT 2 on the rear panel of the 4532 with the oscilloscope. Verify that the

waveform displayed is a 100kHz squarewave with a peak-to-peak amplitude of 1.7V +/- 0.3V. It is

acceptable for the falling edge to decay slowly near the bottom – similar to the waveform that

displayed on the 4530.

h. Set Main Menu > Chan 2 > Params > Video BW to “Low”, then press the Graph key again.

i. Verify that now a serasoidal waveform (a highly filtered square wave with very slow rise and fall

times) is displayed, which indicates that the sensor correctly switched to low bandwidth mode.

BOONTON ELECTRONICS a WIRELESS TELECOM GROUP COMPANY

7

9) CHANNEL 1 CW ACQUISITION TESTS

a. Select internal calibrator and turn on at 0dBm:

Display the Main Menu > Calibratr menu to determine which calibrator is currently selected.

If the bottom line indicates “SelectInt”, then highlight that line and press Enter to select the

internal calibrator. If the bottom line indicates “SelectExt”, then the internal calibrator is

already selected.

Set Main Menu > Calibratr > Int Level to 0.0dBm.

Set Main Menu > Calibratr > Int Signal to “On”.

b. Plug in the CW sensor cable into the 4530 Sensor 1 connector and connect a model 51075 CW

sensor to the 4530 Calibrator.

Set Main Menu > Chan 1 > MeasMode to “CW”.

Set Main Menu > Chan 1 > Params > dB Offset to 0.00dB.

Set Main Menu > Chan 1 > Params > Frequency to 0.05GHz.

Set Main Menu > Chan 1 > Params > Filter to “Auto”.

Set Main Menu > Chan 1 > Params > Range to “Auto”.

c. Zero the sensor:

Press the Zero/CAL key, and press Enter.

Select “Zero Chan”. Press Enter.

The 4530 will perform a sensor fine zero adjustment operation.

Check for any error messages.

d. Perform a Fixed Calibration:

Press the Zero/CAL key.

Select “Fixed Cal”, and press Enter.

The 4530 will perform a fixed 0dBm calibration.

Check for any error messages, then press the Text key.

Channel 1 should display 0.000 dBm +/-0.002dBm.

e. Perform an Auto Calibration:

Press the Zero/CAL key.

Select “Auto Cal”. Press Enter.

The 4530 will perform an automatic sensor power sweep calibration.

Check for any error messages, then press the Text key.

Channel 1 should display 0.000 dBm +-0.002dBm.

10) CHANNEL 2 CW ACQUISITION TESTS (Model 4532 only)

a. Select internal calibrator and turn on at 0dBm:

Display the Main Menu > Calibratr menu to determine which calibrator is currently selected.

If the bottom line indicates “SelectInt”, then highlight that line and press Enter to select the

internal calibrator. If the bottom line indicates “SelectExt”, then the internal calibrator is

already selected.

Set Main Menu > Calibratr > Int Level to 0.0dBm.

Set Main Menu > Calibratr > Int Signal to “On”.

BOONTON ELECTRONICS a WIRELESS TELECOM GROUP COMPANY

8

b. Plug in the CW sensor cable into the 4530 Sensor 2 connector and connect a model 51075 CW

sensor to the 4530 Calibrator.

Set Main Menu > Chan 2 > MeasMode to “CW”.

Set Main Menu > Chan 2 > Params > dB Offset to 0.00dB.

Set Main Menu > Chan 2 > Params > Frequency to 0.05GHz.

Set Main Menu > Chan 2 > Params > Filter to “Auto”.

Set Main Menu > Chan 1 > Params > Range to “Auto”.

c. Zero the sensor:

Press the Zero/CAL key.

Select “Zero Chan”. Press Enter.

The 4530 will perform a sensor fine zero adjustment operation.

Check for any error messages.

d. Perform a Fixed Calibration:

Press the Zero/CAL key.

Select “Fixed Cal”, and press Enter.

The 4530 will perform a fixed 0dBm calibration.

Check for any error messages, then press the Text key.

Channel 2 should display 0.000 dBm +/-0.002dBm.

e. Perform an Auto Calibration:

Press the Zero/CAL key.

Select “Auto Cal”. Press Enter.

The 4530 will perform an automatic sensor power sweep calibration.

Check for any error messages, then press the Text key.

Channel 2 should display 0.000 dBm +-0.002dBm.

11) CHANNEL 1 PEAK ACQUISITION TESTS

a. Select internal calibrator and turn on at 0dBm:

Display the Main Menu > Calibratr menu to determine which calibrator is currently selected.

If the bottom line indicates “SelectInt”, then highlight that line and press Enter to select the

internal calibrator. If the bottom line indicates “SelectExt”, then the internal calibrator is

already selected.

Set Main Menu > Calibratr > Int Level to 0.0dBm.

Set Main Menu > Calibratr > Int Signal to “On”.

b. Connect a model 57318, 57518, 56218 to the 4530 “Sensor 1” connector using a peak sensor

cable, and connect the sensor to the instrument’s 50MHz calibrator connector.

Set Main Menu > Chan 1 > MeasMode to “Modulated”.

Set Main Menu > Chan 1 > Params > dB Offset to 0.00dB.

Set Main Menu > Chan 2 > Params > Video BW to “Low”.

Set Main Menu > Chan 1 > Params > Frequency to 0.05GHz.

Set Main Menu > Chan 1 > Params > Filter to “Auto”.

c. Perform an Auto Calibration:

Press the Zero/CAL key.

Select “Auto Cal”. Press Enter.

The 4530 will perform an automatic sensor power sweep calibration.

Check for any error messages, then press the Text key.

Channel 1 should display 0.000 dBm +-0.005dBm.

BOONTON ELECTRONICS a WIRELESS TELECOM GROUP COMPANY

9

12) CHANNEL 2 PEAK ACQUISITION TESTS (Model 4532 only)

a. Select internal calibrator and turn on at 0dBm:

Display the Main Menu > Calibratr menu to determine which calibrator is currently selected.

If the bottom line indicates “SelectInt”, then highlight that line and press Enter to select the

internal calibrator. If the bottom line indicates “SelectExt”, then the internal calibrator is

already selected.

Set Main Menu > Calibratr > Int Level to 0.0dBm.

Set Main Menu > Calibratr > Int Signal to “On”.

b. Connect a model 57318, 57518, 56218 to the 4530 “Sensor 2” connector using a peak sensor

cable, and connect the sensor to the instrument’s 50MHz calibrator connector.

Set Main Menu > Chan 2 > MeasMode to “Modulated”.

Set Main Menu > Chan 2 > Params > dB Offset to 0.00dB.

Set Main Menu > Chan 2 > Params > Video BW to “Low”.

Set Main Menu > Chan 2 > Params > Frequency to 0.05GHz.

Set Main Menu > Chan 2 > Params > Filter to “Auto”.

c. Perform an Auto Calibration:

Press the Zero/CAL key.

Select “Auto Cal”. Press Enter.

The 4530 will perform an automatic sensor power sweep calibration.

Check for any error messages, then press the Text key.

Channel 2 should display 0.000 dBm +-0.005dBm.

BOONTON ELECTRONICS a WIRELESS TELECOM GROUP COMPANY

10

Section 2: 4530 Series Calibration Procedure

Note: The following procedures assume that the technician is familiar with the basic menu operation of the

4530 Series. To select menu items, press the MENU key twice to return to the top-level menu, and then

use the up and down arrows to highlight the desired entry. Once highlighted, the right arrow or Enter key

is used to select that entry. The ESC key aborts a menu entry, and the left arrow moves back one level in

the menu hierarchy. To select a different menu item at the same menu level, simply navigate directly - it is

not necessary to return to the top of the menu hierarchy. If needed, see the 4530 User’s Manual for more

detailed instructions on menu navigation, and a complete chart of the menu tree.

Required Test Equipment:

BOONTON Model 2520 RF Calibrator.

BOONTON Model 2510 DC Range Calibrator.

BOONTON Model 4530 RF Power Meter.

BOONTON Model 51075 CW Power Sensor and its Data Adapter.

Murata Eire TZBX Special Trim Cap tool or equivalent (0.047" Square Ceramic Tip)

Jewelers Screw driver for pots R81, R82 (0.125” blade)

HP8761A RF coaxial Switch

4 90 degree Male to Female Type N adapters

2 Straight Male to Male Type N adapters

DC power supply (12-15vdc) and switch control of your own design.

Oscilloscope with 1 Megohm (min) input impedance

Spectrum Analyzer with 50 ohm input impedance

50 ohm, 1 Watt precision termination (dummy load)

NOTE: When removing or inserting a sensor or data adapter into the 4530, you will

notice that the instrument reacts to these events. Pause a moment to allow the 4530

time to perform its house keeping. This will prevent some unpredictable behavior.

In the unlikely event that unpredictable or improper behavior is noticed, the

instrument should be restarted by cycling AC power.

BOONTON ELECTRONICS a WIRELESS TELECOM GROUP COMPANY

11

1) BASIC SYSTEM CHECK AND SETUP

a. Turn ON rear panel power switch

b. Press ON/STBY key on front panel.

c. The display should show a start-up screen, the BOONTON logo, and then the main menu of the 4530.

Check that the fan is operating. If the menu is not shown, press the Menu key.

d. Press and hold the ESC/Stop key while using the UP and DOWN keys to adjust the display contrast.

e. Select Main Menu > Utilities > SystemInf. Note the software version date. This is useful when

contacting Boonton Engineering. Software update instructions are available at

http://www.boonton.com/upgrade.htm

f. Verify proper operation of the following:

Select Main Menu > Utilities > Backlight – backlight should turn on or off

Select Main Menu > Utilities > Key Beep – key beep should be audible or silent

Select Main Menu > Utilities > Sys-Tests > Voltages – all voltages should be within 0.5V of

nominal.

Select Main Menu > Utilities > Sys-Tests > Disp Test – check for abnormal pixels or bad display

Select Main Menu > Utilities > Sys-Tests > Keypad – check for response from each key; ESC

ends test.

g. Select Main Menu > Utilities > Sys-Tests > Recorder and monitor the signal on the Recorder Out

BNC connector on the rear panel using an oscilloscope. The waveform should be approximately as

shown below:

h. Press and hold the ON/STBY key. The instrument should turn off.

BOONTON ELECTRONICS a WIRELESS TELECOM GROUP COMPANY

12

Loading...

Loading...