Page 1

MAIN →FUEL Stats

MENU Xtra # 5.0

SEL

ETEC Turbo 800 EFC

5B2mBD2p 12.4

When the control box is powered up the Start Up Screen will be displayed.

There are five buttons used to navigate through the Boondocker Control box.

Left Arrow Button

Select (SEL) Button

Right Arrow Button

Up Button

Down Button

Push any button to advance from the Start Up Screen to the Main Menu.

Use the arrow buttons to move the →(cursor), up, down, left or right.

Once the →(cursor) is next the desired menu item press the SEL button to advance to that screen.

Page 2

rpm →

4500 00 00 00 00

rpm →

5500 05 03 00 -05

MAIN →FUEL Stats

MENU Xtra # 5.0

TPS

66 0 99

33

Adjustable Values

05

10

07

11

Note: The adjustable values displayed are only samples, intended to illustrate the manner in

which these values will affect the blending in each region.

00

00

4500

0

5500

6700

RPM

07

10

Applied (TPS) Values

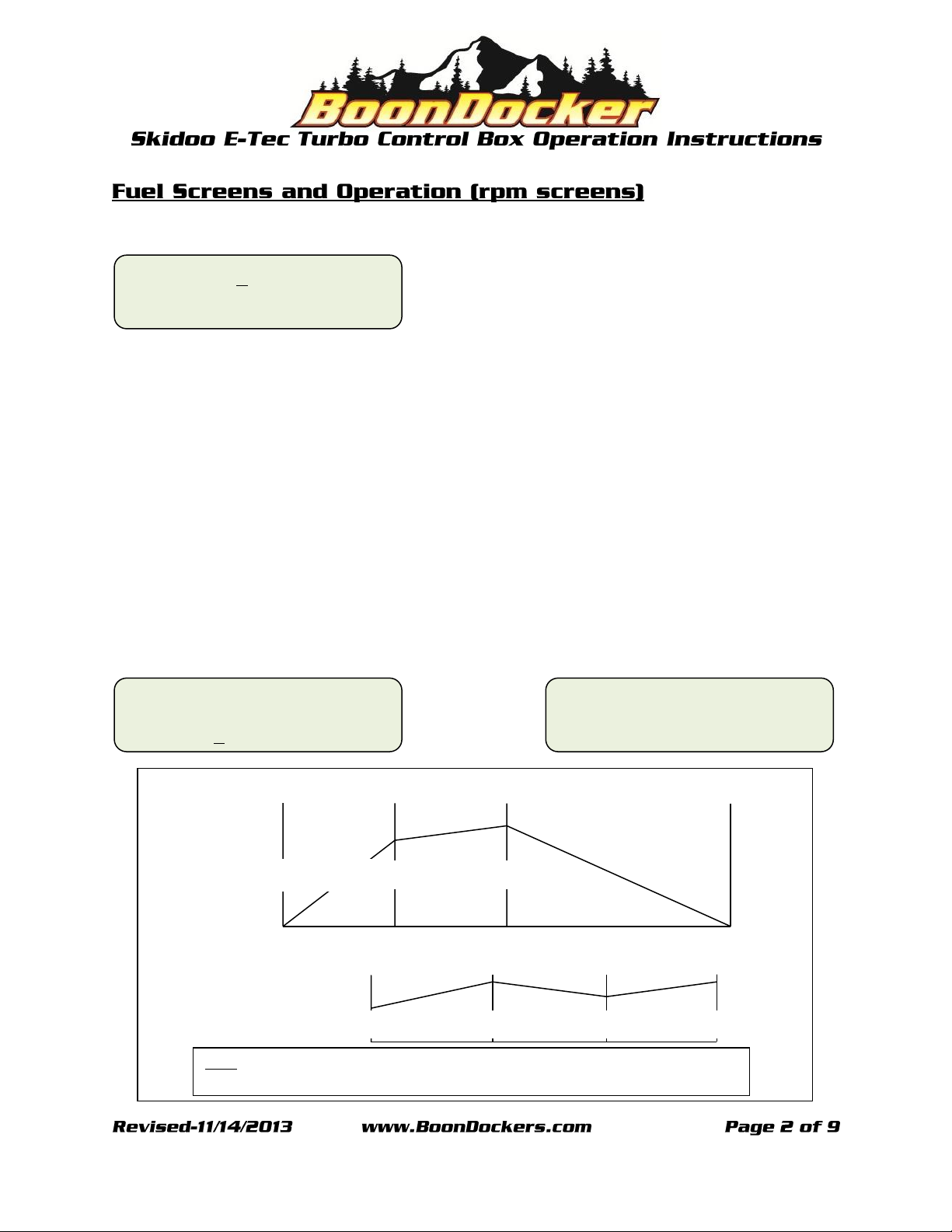

Position the → (cursor) next to “FUEL” and press the SEL button to advance to the first fuel “rpm”

screen.

There are two fuel (rpm) screens. These screens will allow the user to make fueling adjustment

according to RPM only. The values set in these two rpm screens will adjust fueling according to the

corresponding RPM ranges regardless of boost pressure. Each of the fuel screens are labeled with that

screen’s corresponding RPM in the lower left hand corner of the display and have four adjustment

points: 0, 33, 66, and 99. These adjustment points represent a given throttle position (TPS) percentage,

0% being no throttle and 99% being full throttle. The two digit number below each TPS value represents

the amount of fuel that will be added to the given RPM and TPS range. Each of the RPM ranges blend

into each other and taper off to zero as demonstrated in the RPM figure below. Each TPS range blends

to the previous and next adjustment point as demonstrated in the TPS figure below.

To make adjustments, use the left and right arrow buttons to position the →(cursor) next to the

appropriate TPS value and use the up and down buttons to increase or decrease the fuel value.

To advance to the next screen press the SEL button.

0 33 66 99

0 33 66 99

Page 3

psi →

5500 23 18 14 10

psi →

4300 05 05 00 00

psi →

6700 35 23 21 23

psi →

7500 30 26 36 34

psi →

8200 15 25 35 36

Note: The adjustable values displayed are only samples, intended to illustrate the manner in

which these values will affect the blending in each region.

TPS

66 0 99

33

Adjustable Values

05

10

07

11

RPM

5500

4300

7500

6700

8200

05

07

10

11

12

Applied (TPS) Values

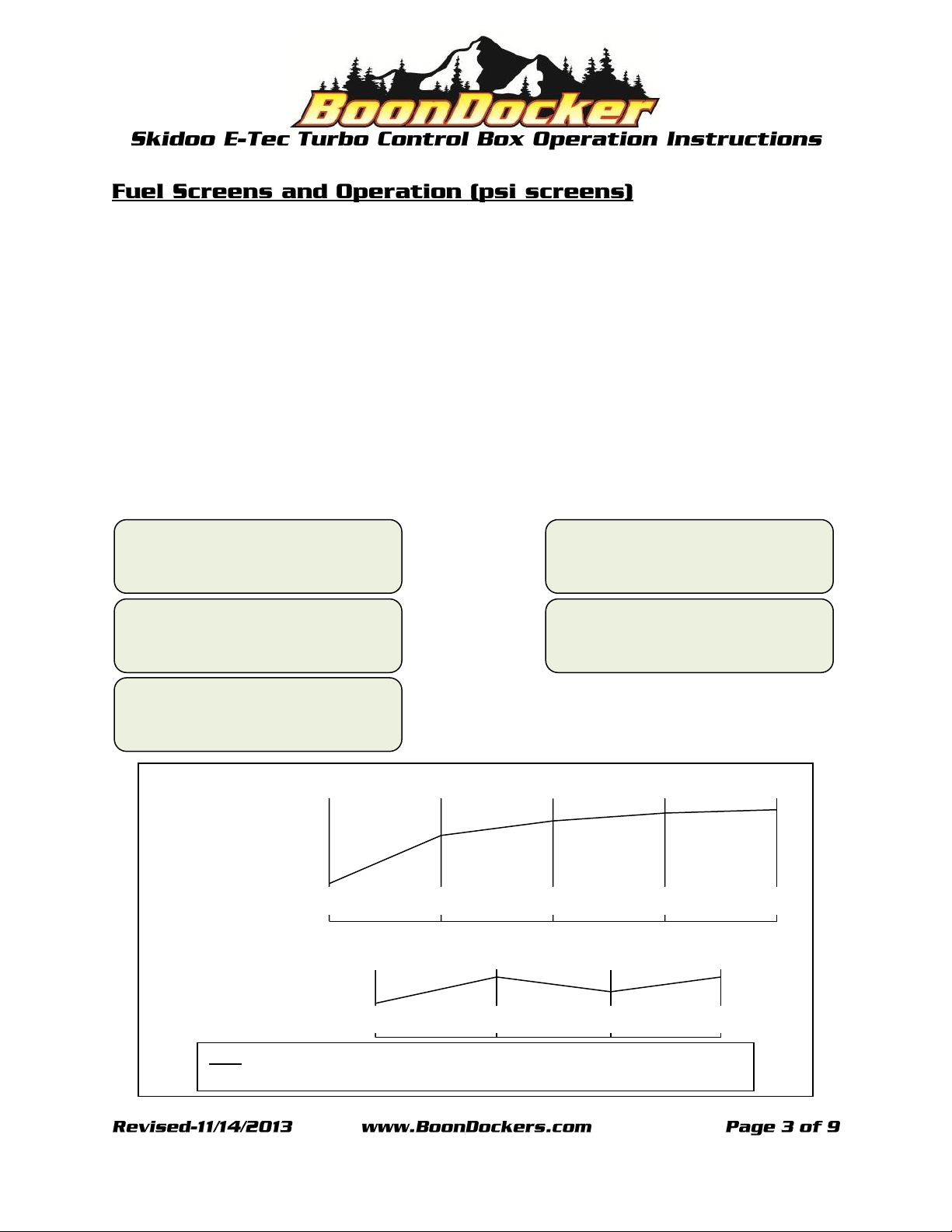

There are five fuel (psi) screens. These screens allow the user to make fueling adjustments for boost.

Each of the fuel screens are labeled with that screens corresponding RPM in the lower left hand corner

of the display and has four adjustment points 0, 33, 66, and 99. These adjustment points represent a

given throttle position (TPS) percentage, 0% being no throttle and 99% being full throttle. The adjustable

two digit numbers below each TPS value represents the amount of fuel that will be added to the given

RPM and TPS range. The values set in these psi screens will adjust fueling according to the

corresponding RPM and TPS ranges while automatically factoring in boost pressure. Each of the RPM

ranges blend into each other as demonstrated in the RPM figure below. Each TPS range blends to the

previous and next adjustment point as demonstrated in the TPS figure below.

To make adjustments, use the left and right arrow buttons to position the →(cursor) next to the

appropriate TPS value and use the up and down buttons to increase or decrease the fuel value.

To advance to the next screen press the SEL button.

0 33 66 99

0 33 66 99

0 33 66 99

0 33 66 99

0 33 66 99

Page 4

RPM →AF DR Sens

ACEL 00 00 08

Note: (The ACEL feature is useful for precise tuning, and if misused can create a wide range of tuning

issues. ACEL adjustment should only be made after all other tuning parameters have been properly

adjusted. ACEL adjustments should only be made by persons with an in-depth knowledge of tuning and

Boondocker control box use.)

The ACEL feature is an electronic accelerator pump that can be used to add fuel according to throttle

movement. When the throttle position is advanced (opened) the ACEL is activated.

Sensitivity (Sens): The set sensitivity determines how far or fast the throttle position should be advanced

before the ACEL is activated. The value set below SN will determine the sensitivity, 01 being the most

sensitive and 10 being the least sensitive, 00 being on all of the time.

Amount (AF): The set amount determines the amount of fuel that will be added when the ACEL is

activated.

Duration (DR): The set duration determines the amount of time (number of engine cycles) the ACEL

feature will add fuel each time the ACEL is activated.

DCEL is basically the same thing as ACEL only it will add/subtract fuel when it senses the throttle being

let off.

Page 5

MAIN FUEL Stats

MENU →Xtra # 5.0

FUEL PSI RPM Btn

→000 OFF OFF Tst

PSI Xtra on if

→OFF PSI < 4.6

RPM Min Max

OFF← 3900 5950

The extra (Xtra) screen contains features that can be used to add fuel when the adjustable specified

parameters for PSI and RPM are met. Auxiliary button parameters can also be adjusted in the Xtra

screen.

Position the → (cursor) next to Xtra and press the SEL button to advance to the extra screen.

The adjusted FUEL value will determine the amount of fuel that will be added when the auxiliary button

is pushed if button is set to TUN. Note: To adjust parameters position the → (cursor) below the desired

parameter, FUEL, PSI or RPM or Btn and press select.

The PSI or RPM parameter can be turned on or off using the up and down arrow buttons with the

→ (cursor) positioned next to the (OFF/ON) below PSI or RPM.

When the PSI Xtra is ON fuel will be added only when the boost pressure is less than the adjusted value.

To adjust the less than PSI value use the up and down arrow buttons with the →(cursor) next to the PSI

adjustable value.

When the RPM Xtra is ON, fuel will be added only when engine rpm is between the minimum and

maximum adjusted values. To adjust the RPM minimum and maximum use the up and down arrow

buttons with the →(cursor) next to the Min or Max adjustable value.

Note: (The Xtra PSI feature has to be turned on for this function to be activated.)

Page 6

Description: Btn

Test AuxInj: → Tst

Description: Btn

Button +HP: → +HP

Description: Btn

Fuel only : → TUN

Description: Btn

StatCapture: → CAP

There are four functions that can be assigned to an auxiliary button. Tst, +HP, TUN, and CAP. To assign a

function to the auxiliary button position the →(cursor) below Btn and use the up down arrow buttons to

toggle to the desired option.

Test (Tst): When set to Tst the auxiliary button can be used to test the auxiliary injectors. With the

engine idling if the auxiliary button is pushed the auxiliary injectors will spray, usually over fueling the

engine and causing the engine to die. Note: (To test injectors individually the opposite injector should be

unplugged while performing test.)

Plus Horse Power (+HP): When set to +HP the auxiliary button can be used to momentarily add a

designated amount of boost. The designated amount of boost can be adjusted in the Boost screen (see

page 8 for more details).

Tune (TUN): When set to TUN the auxiliary button can be used to momentarily add fuel through the

Auxiliary injectors. The amount of fuel added is determined by the value set below FUEL when Btn is set

to TUN. Note: (Btn must be set to tune to access this adjustment. See page 5 for more details.)

Capture (CAP): When set to CAP the auxiliary button can be used to capture statistics in the Stats

screens. With the engine running when the auxiliary button is pushed statistics will be captured in the

Stats Cp Screens (see Stats screen on page 7 for more details).

Page 7

MAIN FUEL →Stats

MENU Xtra # 5.0

Run 00% 0.0

0000 tps99 00F°

Cp1 00% 0.0

0000 tps99 00F°

MAX Inj%DC Clr

0000 00 →Y N

MAX PSI Temp Clr

0.0 00 →Y N

Statistics (Stats) screens display information that can be very useful.

Position the → (cursor) next to “Stats” and press the SEL button to advance to the extra screen

Run screen: The Run screen displays live information when the engine is running. Auxiliary injector duty

cycle percentage, boost pressure (upper right), engine rpm (lower left), TPS percentage (lower middle)

and charge air temperature °F (lower right).

Capture (Cp) screens: Press the up or down arrow button when on the Run screen to display the ten

capture screens 0,1,2,3,4,5,6,7,8, and 9 (Press the right arrow button to return to the Run Screen). When

Btn is set to CAP in the Xtra menu, a capture series can be started with the engine running by pushing

the auxiliary button. When the button is pushed the capture feature is armed, when the button is

released a statistics screen will be recorded every 7 engine cycles and can be reviewed in the Cp screens.

Maximum (MAX) Screens: There are two MAX screens. The first MAX screen displays maximum rpm, and

auxiliary injector duty cycle. The second MAX screen displays maximum boost pressure (PSI) and charge

air temperature (Temp). To clear MAX screens position the →(cursor) next to (Y) and press the SEL

button.

Page 8

MAIN FUEL Stats

MENU Xtra →# 5.0

Psi Btn

5.0← 2.0

Position the → (cursor) next to # and press the SEL button to advance to the boost screen.

Boost screen: The boost screen has two adjustable values: Psi and Btn. The Psi value can be set to the

desired boost pressure. Once the desired boost pressure has been set, the Boondocker control box will

automatically adjust boost for changes in atmospheric pressure such as changes in elevation. Note: (The

minimum achievable boost pressure will be dependent on the waste gate actuator.)

Button (Btn): The value set below Btn is the amount of boost that can be momentarily added by pushing

the auxiliary button, when Btn is set to +HP in the Xtra menu (see page 6 for more details).

Page 9

Boost Solenoid Installation

Install the boost solenoid in a pressure line between the air box (or charge tube) and wastegate

actuator. Attach the metal port of the solenoid with a 3/16” hose to the air box (or charge tube) fitting

(see the figure below). Connect the right-angle port of the solenoid with a 3/16” hose to the wastegate

actuator. Attach a short length of hose to the third port and point it downward so that it won’t get

water in it. This is the actuator vent hose. Attach the solenoid so that it is supported. Use small zip ties

to secure the hoses to the ports.

Loading...

Loading...