Page 1

2011-12 Ski-Doo 800 R E-Tec

Turbo Kit Installaon Instrucons

The BoonDocker E-Tec turbo is a Race Gas only kit at this me. We recommend a minimum of 100 octane

non-ethanol fuel or higher depending on boost levels and elevaon.

Addional informaon and updates on BoonDocker products may be available on the following sites.

• www.boondockers.com

• www.youtube.com/boondockerusa

• www.facebook.com/boondockerperformance

BoonDocker tollfree: 877-522-7805 local: 208-542-4411 fax: 208-524-7381 www.boondockers.com 1

Page 2

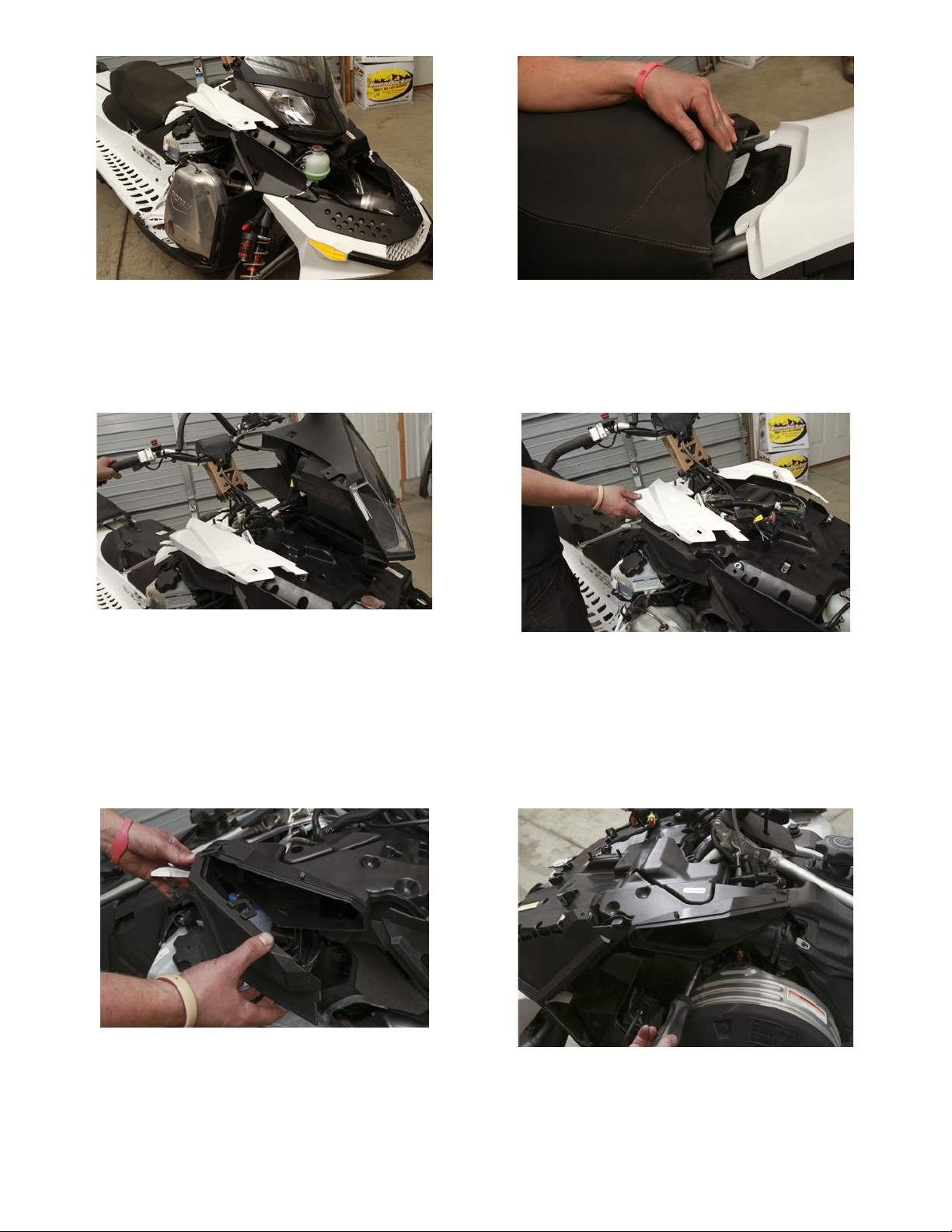

1. Remove both side panels and hood.

2. Remove the seat by liing up on the white plasc lever under the front and pulling the seat rearward.

3. Remove the torx bolts holding on the headlight /

gauge cluster. Disconnect the wiring harnesses hooked

to the headlights and gauge. Remove headlight and

gauge cluster.

5. Remove air intake screens from each side of the air

box plenum. Be careful to not damage the clips when

removing.

4. Remove the torx bolts holding the tank cowl to the air

box plenum, remove the gas cap nut, remove gas cap

and remove tank cowl.

6. Remove the hose clamp holding the air box plenum

to the intake ute.

BoonDocker tollfree: 877-522-7805 local: 208-542-4411 fax: 208-524-7381 www.boondockers.com 2

Page 3

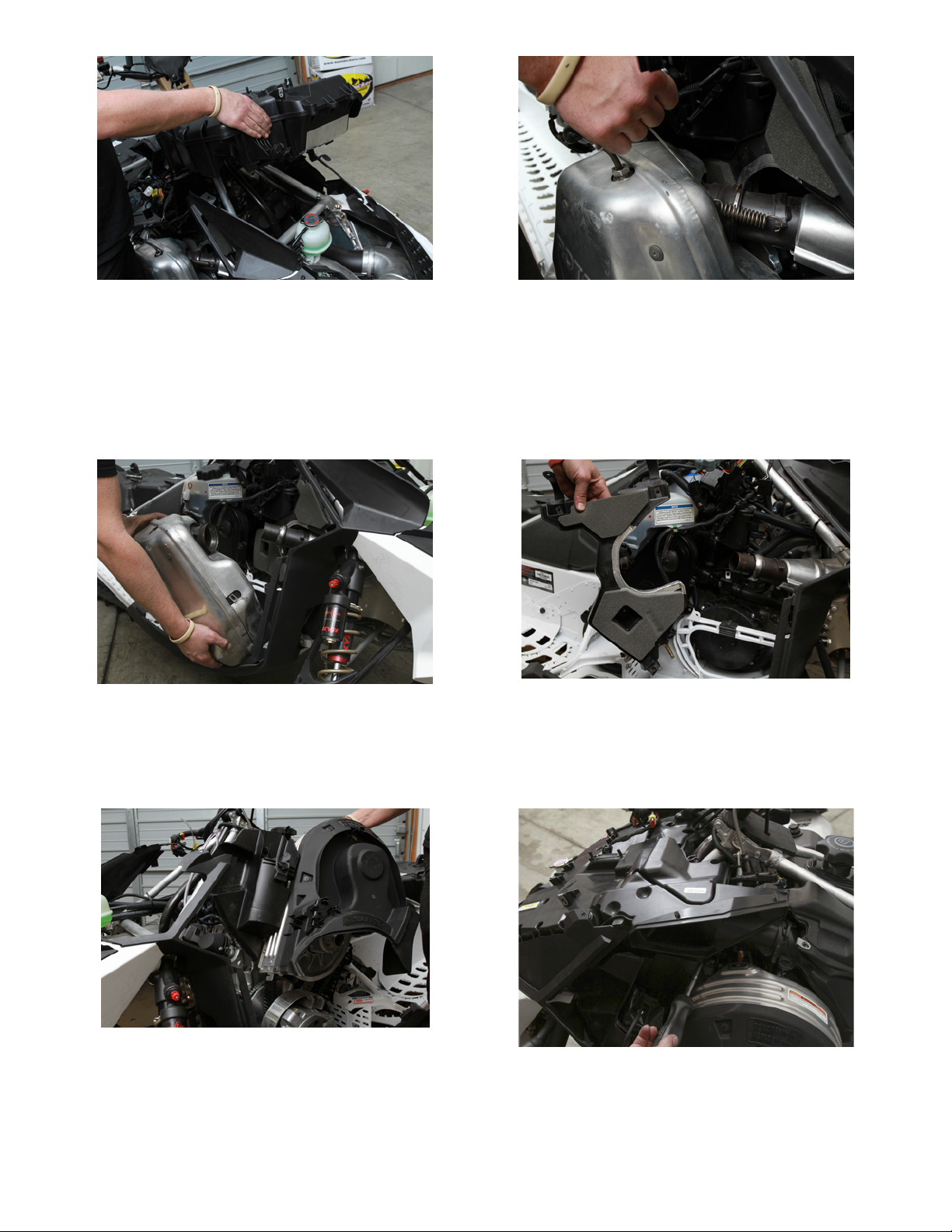

7. Remove coolant bole from airbox plenum, remove

velcro holding plenum to the chassis and remove the

air box plenum from the machine.

8. Using a spring puller remove the two springs holding

the silencer to the expansion chamber and the two

springs holding the silencer to the chassis.

9. Remove the exhaust temp sensor from the top of the

silencer and remove the silencer from the chassis.

11. Remove belt gaurd. 12. Disconnect sensor and twist the intake ute to re-

BoonDocker tollfree: 877-522-7805 local: 208-542-4411 fax: 208-524-7381 www.boondockers.com 3

10. Remove the exhaust noise shield.

move.

Page 4

13. Remove air box by sliding it vercally o the throle

body adaptor plate.

14. Remove clamps and remove throle body adaptor

plate from the throle bodies.

15. Remove the throle bodies and reed cages. Install

the included half reeds on top of the factory reeds.

The half-reeds with sloed holes install on the

matching inside reeds and the standard hole halfreeds on the matching outer reeds.

17. Connect the Control Box Injector harness to the

stock coil connectors. Similar to the TPS connecon

in step 15 these connectors plug inline. It does not

maer which of the two coil connectors on the CB

INJ harness plug to the stock Coil connectors. They

can be connected either way.

16. Connect the Control Box ADA harness to the Throle

Posion Sensor (TPS) on the mag end of the throle

bodies. The factory connector should be removed

and the harness plugged inline.

18. Install the Power Adaptor cable to the machine. Bolt

the ground connector to the stock ground point on

the footwell. Plug the spade connector into the fuse

holder on the oil tank.

BoonDocker tollfree: 877-522-7805 local: 208-542-4411 fax: 208-524-7381 www.boondockers.com 4

Page 5

19. Plug the BoonDocker Power Harness into the Power

Adaptor and run the harness behind the fuel tank

next to the throle bodies. Run all the the previously

installed harnesses to the front of the chassis inline

with the factory harness are shown above.

20. Install the throle body adaptors onto the throle

bodies with keeper tabs. The tabs should be installed

on the throle bodies 180 degrees apart at approximately clock posions 10 and 4.

21. Install the Torque Tubes onto the throle body adaptors and connect the the auxilliary injector connectors

from the Injector Harness into the auxilliary injectors.

23. Remove the center coolant line from the coolant reservior bole and re-route to inside coolant barb on

the turbo. Install the outside turbo coolant line onto

the center ng on the coolant bole. Ensure that

the coolant line roung is clear of the pipe and other

hazards.

22. Install the Torque Tube Y-Pipe onto the Torque Tubes.

24. Before installing the turbo mount the Boost Solenoid

to the plasc bracket between the coolant lines.

BoonDocker tollfree: 877-522-7805 local: 208-542-4411 fax: 208-524-7381 www.boondockers.com 5

Page 6

25. Bolt the turbo exhaust outlet to the turbo housing.

26. Install the rubber bumpers from the original silencer

on to the turbo assembly. Check that the other stock

silencer rubber mount is aached to the chassis.

27. Install the turbo assemblly into the chassis ensuring

that the exhaust exits through the bellypan and the

turbo bracket hangs on the chassis correctly.

29. Bolt exhaust inlet to turbo charger and secure to expansion chamber using supplied exhaust springs.

28. Install the stock probe into the exhaust outlet.

30. Cut fuel line between fuel lter and voice coils. Install

barbed T coming from auxilliary fuel injectors inline.

Install Rave Check Valves as per instrucons on page 9

BoonDocker tollfree: 877-522-7805 local: 208-542-4411 fax: 208-524-7381 www.boondockers.com 6

Page 7

31. Install supplied sheet metal gauge cluster bracket to

frame diagonals using supplied hose clamps.

32. Install the intercooler into the chassis by securing it to

the chassis crossbar using the supplied hose clamps.

33. Install the charge tube between the turbo and intercooler using the supllied silicone tubes and clamps.

35. Install the coolant bole relocator bracket to the

PTO side chassis diagonal. Secure the coolant bole

to the bracket and secure the bracket to the chassis

using the suppied hose clamps.

34. Connect the two pin rubber connector on the fan to

the Power Harness.

36. Install the intercooler torque tube between the

intercooler and Torque Tube Y. Connect using the

supplied silicone tubes and secure using the supplied hose clamps.

BoonDocker tollfree: 877-522-7805 local: 208-542-4411 fax: 208-524-7381 www.boondockers.com 7

Page 8

37. Install the air lter onto the turbo inlet and secure using the supplied hose clamps.

38. Re-assemble the stock plascs in the reverse order of

how they were remove.

39. Remove the foam from the inside of the hood so that

the intercooler fan has room to clear.

41. Install supplied clutching components.

42. 8 oz of BoonDocker T2C Turbo Oil should be poured

into the fuel tank everyme it is lled. This extra oil

will compensate for the addional fuel being injected

by the auxilliary injectors.

43. It is recommended to change the turbo oil and lter

every 300 miles or when the oil becomes discolored.

BoonDocker oers a Turbo Oil Service Kit that includes

new oil, lter and clamps.

40. Fill the turbo tank with T2C oil. Remove the top turbo

oil line, start the machine to verify oil ow to the turbo. Reconnect the oil line.

FUEL

The BoonDocker E-Tec turbo is a Race Gas only kit at this

me. We recommend a minimum of 100 octane non-ethanol fuel or higher depending on boost levels and elevaon.

BoonDocker tollfree: 877-522-7805 local: 208-542-4411 fax: 208-524-7381 www.boondockers.com 8

Page 9

• • • • • • • • • • •• • • • •• • • • • •• • •• • •

RAVE VALVE CHECK VALVE INSTALLATION

1. Red and Black check valve assembly with

3/16” plastic vacuum T and hose.

3. Blue check valve assembly with 3/16” plastic

vacuum T and hose. Note flow direction of

check valve.

2. Install red and black check valve assembly to

the metal (chrome) port on the RAVE valve

solenoid, and reconnect the clear RAVE valve

hose to the red and black check valve assembly.

4. Cut the hose to the RAVE valves before

RAVE valves, install blue check valve assembly

into RAVE valve hose . Do not do not connect

anything to open end of the blue check valve.

BoonDocker tollfree: 877-522-7805 local: 208-542-4411 fax: 208-524-7381 www.boondockers.com 9

Page 10

Injector Harness

Aux Injectors

EBC Harness

Push-to-Pass Button

Oil Pump

sel

008

CB Capture Button

Boost Solenoid

ADA Harness

Temp Sensor

Power Harness

TPS

Stock Coils

BoonDocker tollfree: 877-522-7805 local: 208-542-4411 fax: 208-524-7381 www.boondockers.com 10

Loading...

Loading...