Page 1

Yamaha Phazer Boost Capable

EFI Control Box Instructions

Before you begin, please read all the instructions below and check kit contents.

Control Box Kit Contents:

Quality check by:

___1 Control Box

___1 EFI harness

___1 Pressure Transducer

___1 pressure transducer harness

___1 mounting bracket for transducer

___1 battery/jumper connector

___2 velcro strips

IMPORTANT - PRODUCT REGISTRATION: Please register this product online as soon as possible (if you

do not have internet access, please call us at 208-542-4411). It is required that you register this product so you can receive

technical support, warranty claims, and so you can keep informed of product updates.

To register, go to www.boondockers.com, select “SUPPORT” then select “PRODUCT REGISTRATION”. Please

complete the on-line form.

I. Theory of Operation:

The Boondocker Control Box connects between the sled’s ECU (Electronic Control Unit) and the fuel injectors. It does

not reprogram or communicate with the ECU. It only modifies the existing signals sent from the ECU to the fuel injectors.

By modifying only these signals, it is possible to make fuel changes while keeping the stock fuel map. This means the

ECU can still compensate for engine speed, throttle position, barometric pressure, engine temperature, air temperature, etc.

The Control Box can reduce fuel or increase fuel amounts for certain rpm ranges and load conditions. This is done by

changing its fuel adjustment settings by using the buttons and LCD display. As with tuning a carburetor, it is possible to

go too rich or too lean!

Note: Be sure you know how to properly tune an engine before you adjust the fuel settings! Use of an Air/Fuel Guage and

plug readings are highly recommended whe n tuni n g.

IMPORTANT NOTES – READ THIS!

Note1: Never unplug the Control Box when the engine is still running! Electrical damage may result which is not

covered under warranty!

Note 2: We recommend using Dielectric Grease on all connections to help prevent corrosion on the terminals.

Note 3: Avoid exposing the Control Box to environments where static charges may exist. For example, quickly

removing a sled cover from the sled in a dry environment can create a static spark that will damage the box (especially if

the box is mounted up on the handlebars).

Note 4: The Control Box is sealed – do not take it apart or it will no longer be sealed. The Control Box is designed to be

splash-proof. Do not submerge or subject the box to high-pressure spra y. During long periods of non-use it is

recommended that you do not leave the control box exposed to the elements.

Note 5: Always use Resistor Spark Plugs! Non-resistor plugs WILL cause electrical interference with the Control Box.

BoonDocker – 1585 Hollipark Dr. Idaho Falls, ID 83401 – 208-542-4411 / 877-522-7805

www.boondockers.com – email: info@boondockers.com – fax: 208-524-7381

Revised 05-07-07 Page 1 of 16

Page 2

II. Wiring:

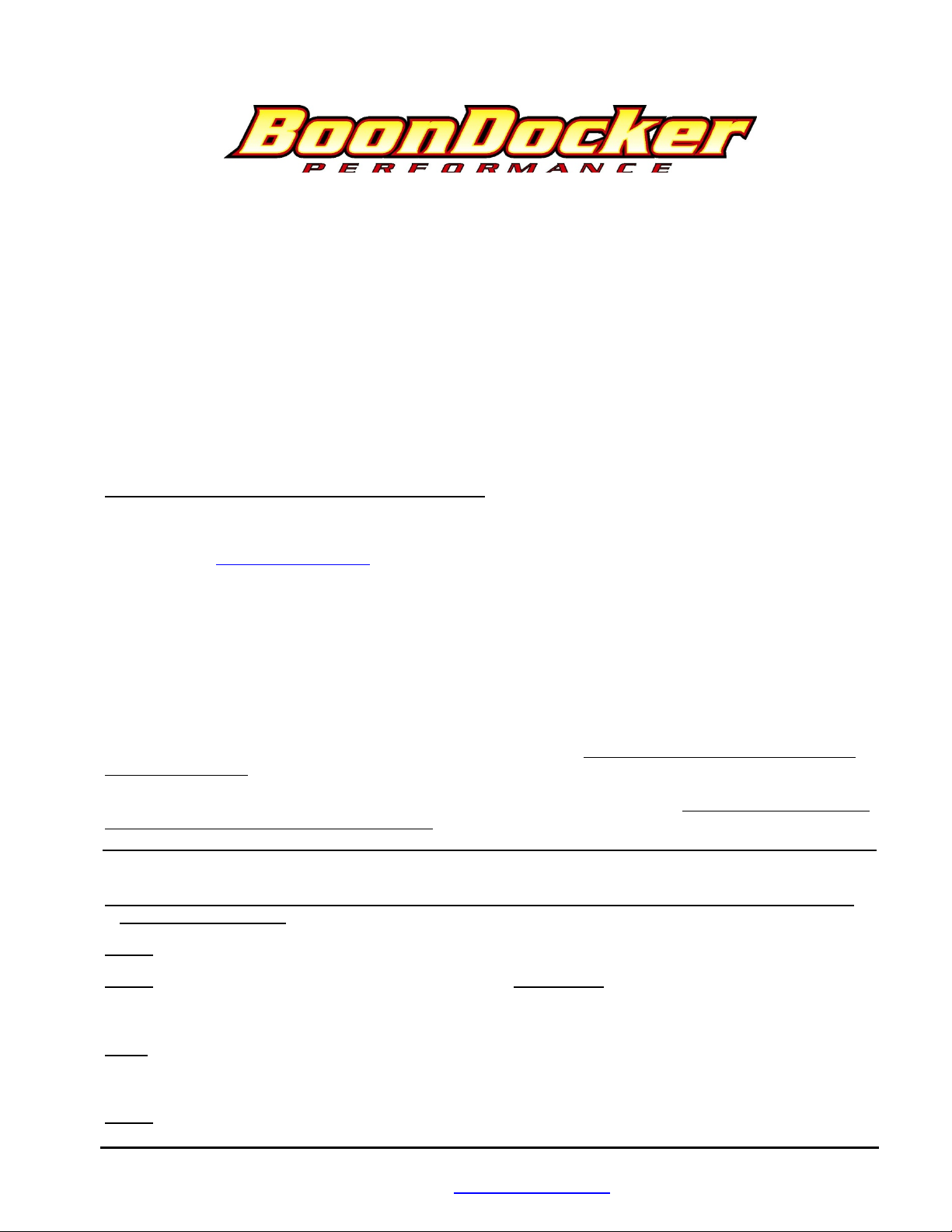

A. EFI Harness

There are two 10-pin connectors at the end of the black cable on the control box. One is for the EFI Harness and the other

is for the optional Nitrous Harness. These two connectors are keyed (male/female) so only the correct harness will fit into

the correct plug-in.

Note: Use Dielectric Grease on all plug

connections to help prevent corrosion on the

terminals.

The EFI harness plugs into the stock sled’s injector

connectors as follows:

1. Disconnect the stock harness connector from

each fuel injector. Note which connector goes

to which injector.

2. Determine where the control box will be

mounted and how the harness will be routed.

Route the harness so the injector connectors end

up near the sled’s fuel injectors.

3. There is a left (PTO) and right (MAG) pair of

connectors for each injector (see picture). The

connector pair with the Yellow and Tan wires

go to the MAG side, and the connector pair with the Green and Brown wires go the PTO side.

4. Plug the gray Control Box connector (female) to the sled’s fuel injector, and the black connector to the sled’s gray

injector connector. Do this for both the MAG and PTO sides. The space above each injector is tight – it may help to

rotate the injector 90deg to install the connector, then rotate it back.

Note: Be sure the black harness connectors latch securely to the gray injector connectors. This may require pushing

the latch on the gray connector down over the tab on the black connector. Do not force the connectors – check for

bent pins.

5. Connect the Control Box harness ground eyelet to a bolt on the chassis. A good ground connection is extremely

important!

6. Use zip ties to keep the harness away from moving parts. Use reflective heat tape if the harness must be routed near

hot items such as the exhaust.

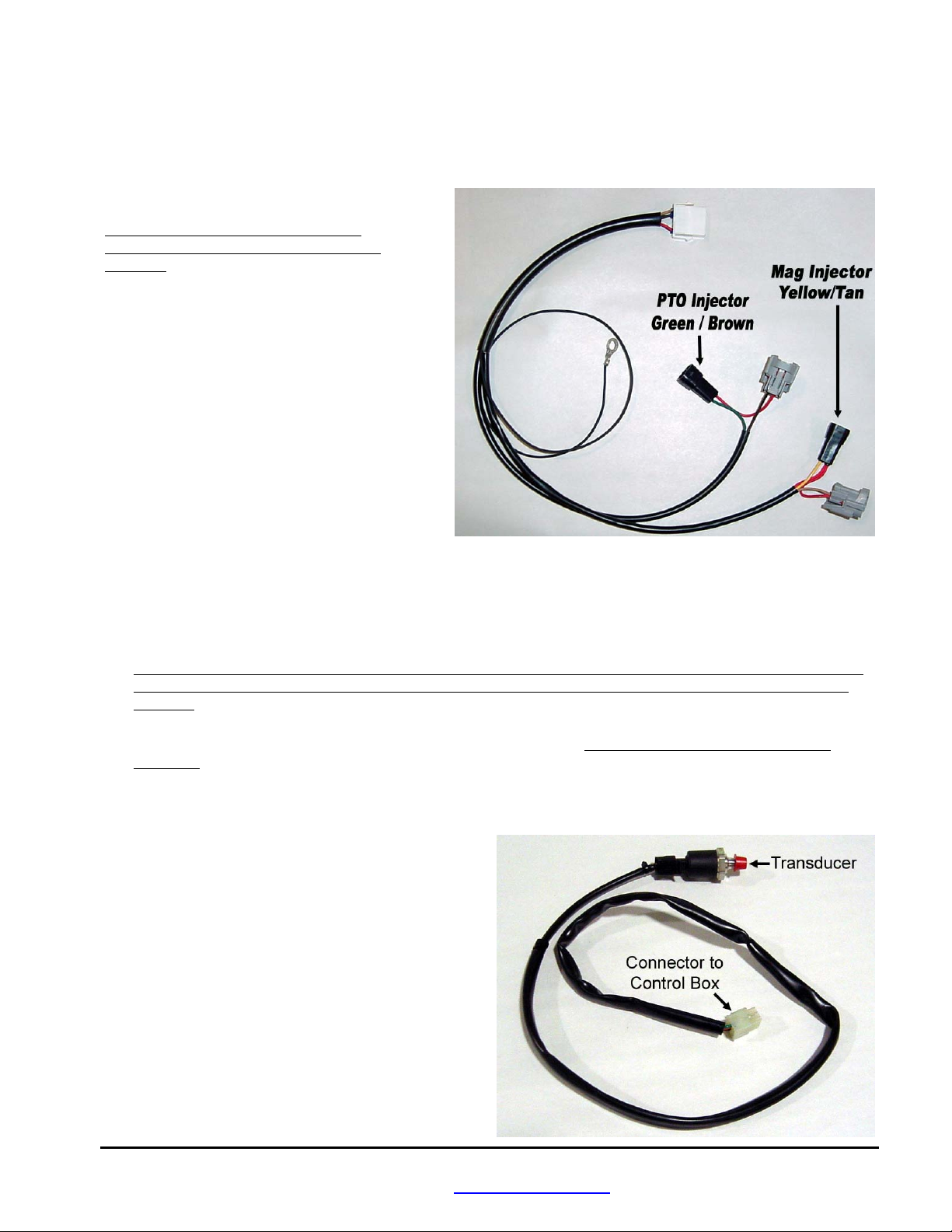

B. Pressure Transducer wiring:

The pressure transducer is used to determine manifold

pressure (vacuum or boost).

1. Connect the pressure transducer so it is Tee’d into

the manifold vacuum line (same hose that goes to

MAP sensor). The pressure transducer can be

mounted to the frame with the supplied mounting

bracket.

2. Plug the transducer connector into the transducer.

3. The white connector from the transducer harness

plugs into the Control Box.

BoonDocker – 1585 Hollipark Dr. Idaho Falls, ID 83401 – 208-542-4411 / 877-522-7805

www.boondockers.com – email: info@boondockers.com – fax: 208-524-7381

Revised 05-07-07 Page 2 of 16

Page 3

C. Jumper/Battery Connector

The jumper can be used in one of the following two ways:

1. A 9-volt battery can be plugged into the jum per and

the jumper can be plugged into the female connector

(pressure transducer connector must be unplugged)

to power the Control Box. This allows the Control

Box to be turned on when the engine is off.

2. If the Control Box is unplugged from the injector

harness, the jumper can be plugged in its place into

the injector harness (9-volt battery is not required).

This bypasses the Control Box to allow the sled’s

ECU to directly drive the injectors. This is for

emergency or diagnostic use only!

III. Control Box Mounting Locations

The Control Box can be mounted under the hood, on the dash, or on the handlebars using the supplied Velcro strips.

Before applying the adhesive strips, thoroughly clean each surface (rubbing alcohol works well). It is also best if each

surface is room temperature.

If the box is mounted under the hood, keep the box away from excess heat (like the exhaust), and away from the ignition

coil.

Note: The Control Box is designed to be splash proof. Do not submerge or subject the box to high-pressure spray.

IV. Control Box Operation

The control box is powered only when the injectors are on which occurs for a few seconds when the key is first turned on

or when the engine is running. Up to 5 different fuel adjustment maps are stored in the box (currently all with zero values).

The box will remember what map was last selected and what its settings are – you do not need to do anything to save a

map when making adjustment (see Fuel Adjustments below).

A. Intro / Startup Screen

When the box is first turned on (by the engine or battery), the Intro screen is displayed. Press any key to go to the main

menu. An example Intro screen display is shown below:

Phazer Turbo

4B5gBD N2O:FIX

In the example shown above, this screen displays the following information:

Phazer Turbo Sled model. This box is designed for the Yamaha Phazer. Boxes for other sleds will

4B5gBD This is the software version of the box. The box can be reprogrammed only by sending

have other lettering.

the box back to Boondocker

N2O: Shows that this Control Box is nitrous capable.

FIX Nitrous pressure regulator type (refer to Nitrous Section for more description)

BoonDocker – 1585 Hollipark Dr. Idaho Falls, ID 83401 – 208-542-4411 / 877-522-7805

www.boondockers.com – email: info@boondockers.com – fax: 208-524-7381

Revised 05-07-07 Page 3 of 16

Page 4

B. Main Menu

The Main Menu is shown below:

Main ÆFuel Stats

Menu N2O Map1U

The current selection is shown by the Right-Arrow and the cursor (underscore below the “F”). Use the arrow keys to

move the cursor. Move the cursor to the desired selection and press the “SEL” key to select the desired menu option from

one of the following:

Fuel Go to the Fuel adjust menus (see Section 1).

Stats Display runtime data, captured data, and recorded maximum data (see Section 3).

N2O Menus for optional Boondocker Nitrous kit (see Chapters VII and IX..).

Map Go to the Map menu (see Section 2)

The current Map number is displayed as “Map1U”. This indicates that map number 1 is being used and it is Unlocked.

1. Fuel Adjust Menus

This selection is used to make fuel adjustments. There are four Fuel adjust screens (examples shown below). The first

screen comes up after selecting Fuel.

Go to the next screen by pressing the “SEL” button. After pressing the “SEL” on the last Fuel adjust screen, you will

return to the Main Menu. Use the Left/Right Arrow keys to switch between settings. Use the Up/Down Arrow keys to

change the settings. Sample Fuel adjust screens are shown below (actual rpm settings and number of screens may be

different for your model).

Fuel screen1:

3000 00 00 00 00

Fuel screen2:

6000 00 00 00 00

Fuel screen3:

8500 00 00 00 00

Fuel screen4:

10K5 00 00 00 00

M1L LO MD HI tr

M1L LO MD HI tr

M1L LO MD HI tr

M1L LO MD HI tr

Fuel screen5: M1L -4 -2 +4 +8

TboL 00 00 00 00

Fuel screen6:

TboH 00 00 00 00

Fuel screen7:

ACEL 00 00 00

M1L 12 16 20 24

M1L AM DR Sens

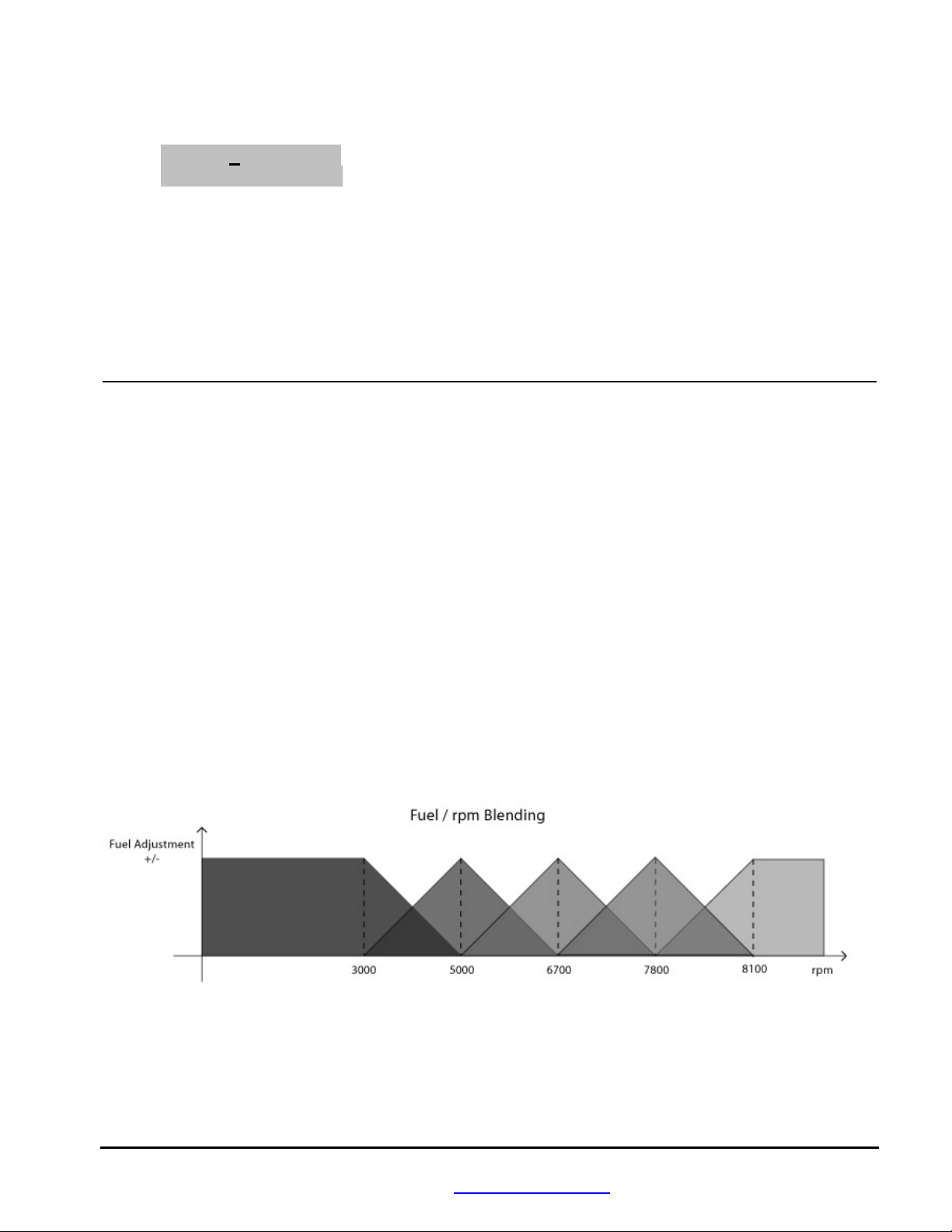

The fuel adjustment rpm ranges are blended as shown in the picture above. This allows for a broader range of adjustments

with fewer steps. Each fuel setting is centered at a particular rpm value, in this example: 3000 , 5000, 6700 , 7800 , 8100rpm.

Each region is blended with the region below and the region above it as shown. For example, if the rpm is at 4000, the

adjustment value will be half the value of the 3000 setting plus half the value of the 5000 setting.

BoonDocker – 1585 Hollipark Dr. Idaho Falls, ID 83401 – 208-542-4411 / 877-522-7805

www.boondockers.com – email: info@boondockers.com – fax: 208-524-7381

Revised 05-07-07 Page 4 of 16

Page 5

1.A Fuel: RPM Adjustments M1L ÆLO MD HI tr

3000 00 00 00 00

M1L This displays current map that is being used – in this case, M1 stands for Map1. Five possible fuel maps can

be used. Each map consists of all your configuration and fuel settings for a particular setup. The “L”

indicates that this map is Locked – this means the settings cannot be changed (the up/down buttons have no

effect). If the map is Unlocked, adjustments can be made to any setting and these changes will be

automatically saved to the selected map. Refer to the Load/Copy sections for more details about how to lock

and unlock individual maps.

3000 This is the RPM Region for the fuel adjustments on this screen. For this example, this screen’s adjustments

will be centered at 3000rpm. There are usually 5rpm regions (some boxes with special programming will have

additional regions). The effect of the 3000rpm setting tapers off until 5000rpm as shown in the picture above,

while the effect of the 5000rpm setting is ramping up. The other regions work similar to this.

LO This adjustment is for Low load conditions. This will affect throttle settings from approximately 0 up to 1/3.

For rpm region 3000, this adjustment will affect idle. For other rpm regions, this will affect deceleration and

light-load cruising conditions.

MD This adjustment is for Medium (mid-range) load conditions. This will affect throttle settings from

approximately 1/3 up to 2/3.

HI This adjustment is for High load conditions. This will affect throttle settings from approximately 2/3 to full

open.

Note 1: Each number is equal to about 1/2% of the total available fuel. The maximum available fuel will vary

with each engine as well as with elevation and air temperature.

Note 2: It is possible to max the injector (duty cycle > 100%) before the adjustment setting is maxed! Pay careful

attention to EGT’s, O2 readings, and fuel pressure when run ning with engine mods that require a lot of additional

fuel!

tr This adjustment is to Trim the PTO cylinder (left-side cylinder when sitting on the sled). This is used to add

or subtract fuel on the left side if fine-tuning is desired. The LO adjustment is not affected by the Trim value –

trim is only used for the MD and HI settings. It is best to tune the right (mag) cylinder first then make

adjustments to the left (PTO) cylinder if necessary. If more than a small amount of adjustment is required

(greater than plus or minus 7), check for other problems first (such as incorrect harness connections to the PTO

cylinder).

1.B Fuel: Boost Adjustments

Screen 6 (Turbo Low Boost)

M1U -4 -2 +4 +8

This menu adjusts the fuel according to the pressure transducer. Fuel can be added or subtracted as follows:

-4: fuel adjustment when pressure is below -2 in Hg (normal idle)

-2: fuel adjustment when pressure is between -2 and 0 in Hg

+4: fuel adjustment is centered at 4 psi. If pressure is below 4, fuel is blended with -2 setting. If pressure is above 4,

+8: fuel adjustment is centered at 8 psi. If pressure is below 8, fuel is blended with 4 setting. If pressure is above 8,

Screen 7 (Turbo High Boost)

12: fuel adjustment is centered at 12 psi. If pressure is below 12, fuel is blended with 8 setting. If pressure is above

TboL 00 00 00 00

fuel is blended with +8 setting.

fuel is blended with 12 setting.

M1U 12 16 20 24

TboH 00 00 00 00

12, fuel is blended with 16 setting.

BoonDocker – 1585 Hollipark Dr. Idaho Falls, ID 83401 – 208-542-4411 / 877-522-7805

www.boondockers.com – email: info@boondockers.com – fax: 208-524-7381

Revised 05-07-07 Page 5 of 16

Page 6

16: fuel adjustment is centered at 16 psi. If pressure is below 16, fuel is blended with 12 setting. If pressure is

above 16, fuel is blended with 20 setting.

20: fuel adjustment is centered at 20 psi. If pressure is below 20, fuel is blended with 16 setting.

24: fuel adjustment is centered at 24 psi. If pressure is below 24, fuel is blended with 20 setting. If pressure goes

above 24psi, fuel is kept at this setting.

1.C Fuel: Accel Pump Adjustments M1L ÆAM DR Sens

ACEL 00 00 00 .

AM

Amount of fuel to be added/subtracted during acceleration

DR Duration in engine cycles to make acceleration adjustment

Sens Accelerator pump Sensitivity. Larger values are Less sensitive (throttle must be moved more). Value of

Zero will cause accelerator pump to always be on! Typical values are between 5 and 20.

2. Map / Setup Menus

From the Main Menu, select Map1U to go to the Map Menu (shown below). This screen is used to

Load/Copy/Lock/Unlock saved “maps” that contain fuel and N2O settings. Five maps can be used (Map1-Map5).

Lock ULock StUp

ÆLoad Copy Quit

2.1 Map: Load

When a new map is loaded, the current adjustment settings will be changed to the values from that map. To load a

new Map, first move the cursor to select Load and press “SEL”. The following Load/Lock Menu will be

displayed:

Load 1 2 3 4 5→Q

Lock L U U U U Q

Load 1-5 Selects which map to load

Lock L = Locked, U = Unlocked, applied to the map number the L or U is under

Q Quits this menu

Use the Up/Down and Left/Right Arrow keys to move the cursor around. To load a new map, move the cursor to

the desired map number and press “SEL.” The map will be loaded and the Main Menu will be displayed. When a

map is loaded, the Mx (x is the map number) that is displayed in the Main and Fuel menus will show the loaded

map number as a reminder.

To quickly Lock or Unlock maps, move the cursor down to the Lock row, place the cursor under the L or U by the

desired map number, and press “SEL” to change a U (Unlocked) to an L (Locked) or vice versa.

Select Q to Quit and return to the Main Menu.

2.2 Map: Copy

To copy a map, first select Copy from the Map Menu. The following Copy/Lock Menu will be displayed:

Copy 1 2 3 4 5→Q

Lock L U U U U Q

Copy 1-5 Selects which map to copy the current map TO

Lock L = Locked, U = Unlocked

Q Quits this menu

This screen is used to save the CURRENT fuel adjustment map TO one of five available map locations. The map

that is being copied TO must be Unlocked – otherwise a message will be displayed telling you that the map you

selected cannot be overwritten.

BoonDocker – 1585 Hollipark Dr. Idaho Falls, ID 83401 – 208-542-4411 / 877-522-7805

www.boondockers.com – email: info@boondockers.com – fax: 208-524-7381

Revised 05-07-07 Page 6 of 16

Page 7

Note: When a map is copied, the Control Box will load the map copied TO to be the new current map.

Use the Up/Down and Left/Right Arrow keys to move the cursor to the map number you want to copy TO and

press “SEL”. The following confirmation message will be displayed:

Overwrite Map A

With Map B? YÆN

“A” represents the map copied TO and “B” represents the current map to be copied FROM. If this is exactly what

you intend, use the Left Arrow to underscore “Y” and press “SEL”. Then the current map will be loaded into the

selected map number, the selected map number will become the current map, and the Control Box will return to the

Main Menu.

To quickly Lock or Unlock maps, move the cursor down to the Lock row, place the cursor under the L or U by the

desired map number, and press “SEL” to change a U (Unlocked) to an L (Locked) or vice versa.

Select Q to Quit and return to the Main Menu.

2.3 Map – Lock and ULock

Either Lock or ULock (UnLock) can be selected from the Map Menu to quickly lock or unlock the current map.

Move the cursor to the desired selection and press “SEL”. The box will return to the Main Menu and the current

map will be locked or unlocked when SEL is pressed.

2.4 Map – StUp (if Shown)

Refer to the Advanced Mode Instructions

3. Stats Menus

This Control Box has a new feature that allows real-time data to be displayed and captured. This feature can be useful for

tuning or for diagnostic purposes.

3.1 Stats: RUN/CAPTURE

Selecting Stats from the Main Menu will first display the following screen with real “Run-time” data (current

conditions):

Run 35/40 10.2NA

5500 MD █ █ █ 10

st

line

1

Run “Run” indicates display is in Run mode. If in capture mode, “Cap” will be displayed.

35 Input duty cycle in percent

40 Output duty cycle in percent

10.2 Current Boost Pressure

N If “N” displayed, Nitrous is on

A If “A” displayed, Accelerator Pump Fuel adjustment is on

2nd line

5500

MD Engine Load. LO, MD, or HI will be displayed.

█ █ █ These bars are a graphic display of LO, MD, or HI as shown below:

LO

HI █ █ █ █ █ █

10 Current Fuel Adjustment

RPM (note, if the engine is shut off, the last recorded RPM may be displayed)

MD █ █ █

BoonDocker – 1585 Hollipark Dr. Idaho Falls, ID 83401 – 208-542-4411 / 877-522-7805

www.boondockers.com – email: info@boondockers.com – fax: 208-524-7381

Revised 05-07-07 Page 7 of 16

Page 8

Run/Capture mode:

Left-Arrow button : Sets Capture Mode, “Cap” will be displayed and the current data will be frozen on the

display. The capture occurs on the display when the button is released (data will continue to

be captured if the button is held down). It will stay in capture mode (data will remain frozen)

until the Right-Arrow is pressed to return to Run mode or until the Control Box is repowered. If the Stats menu is re-entered before the engine is shut off and the box is in

Capture mode, the last captured data will be displayed.

Right-Arrow button: Clears capture mode (captured data will be lost!) and sets Run mode

displayed and real-time data will be displayed. Note:

configured to Capture the Status screen Press SEL to go to the next screen: Stats: MAX.

The Button Mode can also be

. “Run” will be

3.2 Stats: MAX

Any button press from the Run screen will go to the next Stats screen which is the Max screen, displaying max

RPM, Duty Cycle In from the sled’s ECU, and Duty Cycle Out to the injectors.

MAX:DCIn/Out Clr.

5500 35/45 YÆN.

MAX: 5500 Max rpm

DCIn 35 Max Duty Cycle Input from sled’s ECU.

DCOut 45 Max Duty Cycle Output to the injectors.

These max values will be saved when the box is shut off so they will remain the next time this screen is displayed

even if the box is re-powered. Peak values or “spikes” are filtered by finding the average during a certain timewindow. Therefore, a maximum must be held for at least 1 second to be recorded and displayed properly.

Use the arrow keys to move the cursor between Y and N. Pressing SEL when the cursor is on Y will clear the max

values. Pressing SEL when the cursor is on N takes you to the next screen: Stats: N2O/TPS.

3.3 Stats: PSI

This menu displays nitrous and TPS information.

PSI MAX Peak Clr.

12.2 13.4 YÆN.

MAX 12.2 This is the average maximum boost amount measured in psi. The boost is averaged during a 1

second window in order to filter out boost spikes. This value should be very close to the actual

sustained boost. If the display shows “XX.X”, the boost value has exceeded the valid range.

Peak 13.4 This is the peak boost value. This is usually higher than the Max boost value by 1 to 2 psi due

to spikes on the boost pressure. If the display shows “XX.X”, the boost value has exceeded the

valid range.

Clr Y N Selecting Y will clear the save PSI Max/Peak values. Use any arrow key to select Y or N.

Pressing “SEL” takes you to the Main Menu.

VI. EFI Tuning Suggestions

Each Fuel adjustment setting goes from –99 to 127. Positive numbers add fuel and negative numbers subtract fuel. The

Control Box will not prevent a lean burndown! You must take the proper tuning steps the same as if you were tuning a

carburetor.

The maximum is set to 127. This does not mean you have an effective range all the way to 127 – you will likely max out

the injector before this setting is reached. Your usable adjustment range (max value) is dependent on how long the ECU

already has the injector on. This will vary depending on rpm, throttle setting, temps, and can be different from sled to sled

even of the same model. There is no direct relation

BoonDocker – 1585 Hollipark Dr. Idaho Falls, ID 83401 – 208-542-4411 / 877-522-7805

www.boondockers.com – email: info@boondockers.com – fax: 208-524-7381

Revised 05-07-07 Page 8 of 16

Page 9

Exhaust Gas Temperature gauges can be an effective tuning tool, but they are not a substitute for reading spark plugs and

piston wash and feeling how the engine runs. Use EGTs only as a backup to verify what you see. They can be misleading

under certain conditions and safe readings can vary greatly from engine to engine depending on such things as probe

placement, fuel, timing, pipe design, porting, etc.

Tuning tips:

Important: Find the settings where your motor runs rich before you decide to go lean!

1. Tune with the engine and pipe at operating temperature. The sled’s ECU will make adjustments as the engine

warms up – you might think the engine needs leaner settings then later realize you are too lean once the engine

warms up.

2. Use the Load/Save Map feature to quickly change and compare fuel settings when testing. This can also be

useful for riding under different conditions. For example, changing elevations or temperatures may require

different adjustments if the stock ECU does not compensate properly for your modifications. For drag racing,

you might want to run richer settings for longer distances than you would for short distances.

3. One method for finding out where a fuel adjustment setting is effective, greatly increase only that setting. Run the

engine to find out when it suddenly becomes too rich – this is where that setting is effective. Be careful – you can

easily flood the motor, especially with LO load or low rpm settings. If this happens, to restart the engine you may

have to pull several times with the throttle held wide open.

4. The Stats Capture feature can be used to determine RPM, and if the load setting is LO, MD, or HI. The nitrous

button can be configured to capture these stats (see nitrous configuration section below). From the Main Menu,

select N2O, set Btn to CAP. Whenever the button is pressed, the Stats : Capture screen will be displayed. The

current stats will be captured when the button is released

N2O Menu in “Capture” mode:

.

Fuel TPS RPM Btn

040 OFF OFFÆCAP

5. The nitrous handlebar button can be used to add or subtract a preset amount of fuel for interactive tuning purposes

(see nitrous configuration section below). From the Main Menu, select N2O, set RPM and TPS to OFF, set Btn

to TUN and adjust the fuel number as desired for the test (see example menu screen below). When the nitrous

button is pressed, this amount of fuel will be added or subtracted immediately from the current settings for all

rpms and all loads.

N2O Menu in “TUNE” mode:

Fuel TPS RPM Btn

040 OFF OFFÆTUN

Also consider the following:

A/F Mixture Generally EGT’s get hotter as the motor gets lean, but too lean and the temps can actually drop! It’s like

turning the oxygen up too high on a torch – as oxygen is added, the flame gets hotter to a certain point,

then gradually cools off until it becomes extinguished from too much oxygen.

Detonation Detonation often requires an experienced tuner to detect – in most instances it cannot be heard or

noticed. Careful examination of the piston and sparkplug are required. Watch for melted sparkplug

electrodes, speckling on the sparkplug insulator, or shiny or gray flakes on the electrode which could be

melted aluminum from the piston. If possible, watch the crown of the piston (near exhaust port) for a

pitted or sand-blasted look. EGT’s can sometimes read low during detonation – heat is going into the

cylinder and piston instead of out the pipe.

Timing Timing can affect the pipe temperature. Generally if the ignition is retarded, more heat will build up in

the pipe. Too much advance may drop EGT temps, but increase cylinder temps.

BoonDocker – 1585 Hollipark Dr. Idaho Falls, ID 83401 – 208-542-4411 / 877-522-7805

www.boondockers.com – email: info@boondockers.com – fax: 208-524-7381

Revised 05-07-07 Page 9 of 16

Page 10

Fuel Different fuels have different densities and other characteristics which can affect your mixture and fuel

requirements. Oxygenated fuel will run leaner. Octane rating is important for highly modified motors.

Lean spots Sometimes a motor runs hot at certain rpms and throttle positions (usually in its mid-range) no matter

what. The fuel adjustment settings can be used to richen this up, but the engine may quickly become

too rich and run erratic. Under light load conditions you can sometimes get away with running hot for

short periods of time. Under such conditions it is best to vary the throttle position often and not stay at

one throttle setting for long durations.

VII. Nitrous Tuning (for optional Boondocker Nitrous kit)

Note: Be sure to make non-nitrous (RPM-based) tuning adjustments first. Once the nitrous tuning procedure has been

done, any changes to the RPM fuel settings may affect nitrous fuel delivery. If this occurs, the nitrous tuning steps will

need to be done again.

On the startup screen (displayed when first powered on), note the message in the lower right-hand corner.

ADJ – Configured for a nitrous system using an Adjustable or Fixed N2O pressure regulator.

Note: Do not use ADJ mode for Control Boxes programmed with Boost capabilities.

FIX – Configured for a nitrous system using a Fixed N2O pressure regulator.

Be sure that this description matches your actual nitrous system. Some internal settings and some user menus and settings

are affected by this configuration. Do not attempt to run a Non-regulated nitrous setup with the Control Box in ADJ

mode or a Regulated nitrous setup in NON mode! Please call Boondocker if your setting is incorrect. If you do not

have nitrous capability, then this configuration does not matter.

The fuel adjustment setting in the N2O menu is used to control how much fuel is added during nitrous use. The nitrous

pressure transducer input is used to automatically scale the fuel adjustment up or down from this base setting according to

nitrous pressure. However, you still must go through the nitrous tuning procedure before you can safely use nitrous.

The steps below should be performed with a full nitrous bottle. On systems without a nitrous pressure regulator, make sure

the bottle is at proper operating temperature (70-90deg F) and pressure (700-1000psi). Make sure the engine is at normal

operating temperature.

Do not exceed 2 seconds of nitrous use until the fuel adjustment is complete and correct.

Æ040 OFF OFF N2O

Æ040 OFF OFF N2O

Æ050 000

NON – Configured for a nitrous system that is Non-regulated.

Warning: Only adjust the control Box settings according to the steps below. The best way to tune an

engine is with the use of an oxygen sensor and gauge (available from Boondocker). This adjustment

process should only be performed by an experienced tuner. If you are not an experienced tuner, find

someone who is. Remember, safety first!

1. First configure the nitrous system for Button use. The next chapter will describe different ways to configure your

system for nitrous activation, but we’re going to shortcut that for now.

Select N2O from the Main Menu, move the cursor so it is under Btn and press the Up Arrow until N2O. Press

“SEL” to return you to the Main Menu. Select N2O from the Main Menu again. Look at the N2O Menu to be

sure that TPS and RPM are turned OFF.

N2O Menu for Button Activation for initial Nitrous Tuning:

Fuel TPS RPM Btn

2. Select N2O from the Main Menu.

Fuel TPS RPM Btn

Select Fuel. The following screen will appear:

N2O Fuel Delay

BoonDocker – 1585 Hollipark Dr. Idaho Falls, ID 83401 – 208-542-4411 / 877-522-7805

www.boondockers.com – email: info@boondockers.com – fax: 208-524-7381

Revised 05-07-07 Page 10 of 16

Page 11

Increase the nitrous Fuel adjustment setting until you notice a drop in the power increase when using nitrous.

Oxygen, EGT, and rpm readings can be used to help determine when you are too rich. Be sure you have reached

this point before proceeding. Note this adjustment setting.

3. Only after step 2 or 3 is complete, start reducing the Fuel setting. Continue reducing the Fuel setting until a

maximum power increase is obtained. Again, note oxygen, EGT, and rpm readings, and do not exceed 2 seconds

of nitrous use which is just sufficient to get a good reading. A useful technique is to accelerate, allow rpm to

stabilize, apply nitrous, and notice maximum rpm, and if available, O2, and EGT readings.

If the Fuel is reduced but no power increase is noticed from the previous setting, this means you are lean. Note this

adjustment setting.

4. Increase the Fuel setting back to where it was before no additional power increase was noted in step 4. This

setting should be somewhere between the rich and lean settings. It is best to stay on the rich side.

5. After this adjustment is made, if the engine does not run perfectly smooth when using nitrous, do not use it! If the

exhaust note does not sound clean, the cause is likely detonation, which can quickly destroy the engine. Use

higher octane fuel, add more ignition retard, reduce the engine’s compression, or reduce the amount of nitrous

(see instructions for changing nozzles) before using nitrous again.

Note 1: The RPM and Nitrous fuel adjustments are summed. Therefore, any changes made to RPM fuel settings will

affect the quantity of fuel delivered for nitrous. Therefore, for example, if the 7800 HI fuel setting is decreased

by X amount, you need to increase the nitrous fuel setting by X amount in order to get the same total fuel delivery

for nitrous.

Note 2: After initial tuning, any new performance enhancements to your engine will require re-tuning the EFI and nitrous

fuel delivery.

Note 3: All nitrous fuel settings are stored in the same map as the RPM settings. All changes you make become part of

the current map. The current map number is shown in the Main Menu.

VIII. N2O System Configuration

A. N2O Configuration Options

There are seven ways to configure nitrous activation using one of more of the following inputs: button, throttle position

(requires installation of Boondocker TPS kit), and rpm range. A brief description for each configuration is given below.

More details can be found in sections B and C.

1. Button only: Pressing the momentary button activates the nitrous and releasing the button turns it off. The

button can be configured to activate the nitrous regardless of TPS or RPM conditions.

2. TPS (Throttle Position Sensor) only: When the throttle is pressed beyond a point set by the user, nitrous is

activated. Nitrous is deactivated when the throttle returns to a point below the chosen threshold.

3. TPS and RPM: When the RPM and TPS are within a range set by the user, nitrous will activate. Nitrous will

turn off when the throttle is decreased (TPS is below the adjustable threshold) or when the RPM is out of the

selected range (lower than Min or higher than Max).

4. Button (N2O) or TPS: The handlebar button can be used in combination with the TPS. In this way, either the

throttle or the button can activate the nitrous. The button will always activate nitrous regardless of the TPS

condition.

5. Button (N2O) or TPS and RPM: The handlebar button can be used in combination with the TPS and RPM

range. In this way, either the throttle/RPM or the button can activate the nitrous. The button will always activate

nitrous regardless of the TPS and RPM conditions.

BoonDocker – 1585 Hollipark Dr. Idaho Falls, ID 83401 – 208-542-4411 / 877-522-7805

www.boondockers.com – email: info@boondockers.com – fax: 208-524-7381

Revised 05-07-07 Page 11 of 16

Page 12

6. Button (ARM) and TPS: The nitrous button input on the Control Box can be used to quickly arm and disarm

nitrous capability. When armed (button input is on), the system can be configured to activate with TPS.

Optionally, the handlebar button, which is momentary (only activated while pressed), can be replaced with a

toggle, rocker, or slide switch so it remains in the on or off position (when not pressed).

7. Button (ARM) and TPS and RPM: Same as option 6 above except with RPM capability. When armed (button

input is on), the system can be configured to activate with TPS and RPM.

B. N2O Configuration Procedure

Note: All nitrous configuration settings are stored in the same map as the EFI settings. All changes you make become

part of the current map. The current map number is shown in the Main Menu.

From the Main Menu, select the N2O option. Below is a description of this menu:

Fuel TPS RPM Btn

Æ040 OFF OFF OFF

Fuel 040

Fuel setting during nitrous activation

TPS OFF Shows TPS mode is OFF or displays TPS trigger value

RPM OFF Shows whether RPM mode is ON or OFF

Btn OFF Displays button mode (described in detail below)

Fuel: The nitrous fuel adjustment tuning procedure is described above in section VIII.

N2O Fuel Delay

Æ050 000

Descritpion of N2O Fuel menu for NON / FIX mode:

050 N2O fuel setting. Amount is centered at 1000psi, if bottle pressure is lower, actual fuel

delivered will be reduced, if bottle pressure is higher, actual fuel delivered will be higher.

Delay 000 Delay in number of engine cycles from when nitrous is activated to when fuel is delivered.

Use this feature to reduce any bog that occurs due to fuel being delivered before nitrous

arrives in the engine.

TPS: To select throttle-position triggering, move the cursor until it is under TPS and press “SEL”, Up or Down

Arrow. The following screen will appear:

TPS N2O on if

ÆOFF TPS > 200

TPS OFF Shows TPS mode is OFF.

200 TPS threshold value.

Under TPS, press the Up or Down Arrow to toggle the TPS mode ON or OFF.

Move the cursor right to the 200 setting, then use the Up and Down Arrows to select the trigger level. This

Press the “SEL” button to return to the Main Menu.

number is set to near 200 at the factory. You can adjust it from 50 to 248.

RPM: To select rpm triggering, move the cursor right until it is under RPM and press “SEL”, Up or Down Arrow.

The following screen will appear:

. RPM Min Max

OFF← 5050 7550

BoonDocker – 1585 Hollipark Dr. Idaho Falls, ID 83401 – 208-542-4411 / 877-522-7805

www.boondockers.com – email: info@boondockers.com – fax: 208-524-7381

Revised 05-07-07 Page 12 of 16

Page 13

RPM OFF Shows RPM mode is OFF.

5050 Min RPM threshold

7550 Max RPM threshold

Under RPM, press the up or down button to turn this mode ON or OFF.

Move the cursor right to adjust the Minimum RPM (nitrous will be on above this level) and the Maximum

RPM (nitrous will turn off above this level).

Note: To use this mode, TPS must also be ON and the TPS trigger threshold set.

Press the “SEL” button to return to the Main Menu.

BTN: To select the button mode, move the cursor right until it is under Btn. Press the up or down key to select

between the following five possible modes. The screen will change to the following:

OFF: Description: Btn

Button Off :ÆOFF

This mode disables the handlebar button.

N2O: Description: Btn

N2O + Fuel :ÆN2O

This mode adds nitrous and fuel when the button is pressed. When the button is pressed, nitrous will be

activated regardless of the TPS or RPM settings.

TUN: Description: Btn

Fuel only :ÆTUN

When the handlebar button is pressed in TUN mode, only fuel is added. This is used to experiment

with fuel addition and subtraction while riding. Press the button at a certain rpm or under a certain load

to see whether your addition or subtraction is beneficial. This cannot be used in combination with N2O

operation. Be sure TPS and RPM triggering are OFF when using this feature.

CAP: Description: Btn

StatCapture:ÆCAP

In CAP mode, the handlebar button is used to capture current data. When pressed, the Stats Capture

screen will be displayed and the data will be frozen when the button is released. After a capture,

pressing the Right-Arrow button will erase the captured data and return to Run Mode.

ARM: Description: Btn

On for N2O :ÆARM

By using a pushbutton (momentary), toggle, rocker, or slide switch connected to the button input, the

nitrous system can be armed or disarmed. When the switch is closed the system is armed and ready.

Then, depending upon other configuration settings, either the TPS or RPM with TPS can activate the

nitrous system. When the switch is open, the system is disarmed so neither TPS nor RPM will result

in nitrous activation.

Nitrous activation idea: One way to use the button for nitrous activation and to have the RPM limiting feature

(to prevent hitting the rev-limiter), set Btn to ARM, TPS to ON (with a low threshold), and RPM to ON (with

desired Min/Max settings).

Press the Left or Right Arrow to return to the N2O menu or push the “SEL” button to return to the Main

Menu.

BoonDocker – 1585 Hollipark Dr. Idaho Falls, ID 83401 – 208-542-4411 / 877-522-7805

www.boondockers.com – email: info@boondockers.com – fax: 208-524-7381

Revised 05-07-07 Page 13 of 16

Page 14

C. N2O Configuration Examples

The following are examples of settings to achieve the various nitrous triggering configurations described in Section A

above:

1. Button only: Activate nitrous

only when the button is pressed.

2. TPS only: Activate nitrous only

when the Throttle is pressed

beyond a set level.

3. TPS and RPM only: Activate

nitrous only when the Throttle is

pressed beyond a set level AND

when RPMs are with a certain

range.

Fuel TPS RPM Btn

040 OFF OFFÆN2O

Fuel TPS RPM Btn

040Æ200 OFF OFF

Fuel TPS RPM Btn

040 200ÆON OFF

Set: TPS to OFF, RPM to OFF, and Btn to

N2O.

Set: TPS to ON (set the TPS threshold to the

desired level), RPM to OFF, Btn to OFF.

Set: TPS to ON (set TPS threshold to desired

level), RPM to ON (set Min/Max to

desired levels), Btn to OFF.

4. Button (N2O) or TPS: Activate

nitrous when button is pressed or

when Throttle is pressed beyond a

set level.

Fuel TPS RPM Btn

040 200 OFFÆN2O

Set: TPS to ON (set TPS threshold to desired

level), RPM to OFF, and Btn to N2O.

5. Button (N2O) or TPS and RPM:

Activate nitrous when button is

pressed or when Throttle is

pressed beyond a set level AND

the RPMs are within a certain

range.

Fuel TPS RPM Btn

040 200 ON ÆN2O

Set: TPS to ON (set TPS threshold to desired

level), RPM to ON (set Min/Max values),

and Btn to N2O.

6. Button (ARM) and TPS:

Activate nitrous when button

input is on (armed) AND Throttle

is pressed beyond a set level.

7. Button (ARM) and TPS and

RPM: Activate nitrous when

button input is on (armed) AND

Throttle is pressed beyond a set

level AND the RPMs are within a

certain range.

Fuel TPS RPM Btn

040 200 OFFÆARM

Fuel TPS RPM Btn

040 200 ON ÆARM

Set: TPS to ON (set TPS threshold to desired

level), RPM to OFF, and Btn to ARM.

Set: TPS to ON (set TPS threshold to desired

level), RPM to ON (set Min/Max values),

and Btn to ARM.

IX. Control Box Troubleshooting

Stuck Button

When the Control Box is first turned on, all buttons are checked to verify that a button is not stuck on. If a button is

detected to be on during power up, the button will be disabled and the following message will be displayed until

another button is pressed. To verify if a button really is stuck on, re-power the box without pressing any buttons.

Button is Stuck!

Note: A common problem is a bad ground connection on the sled causing the box to keep resetting itself. If a button

is being pressed when this occurs, the “button stuck” message will be displayed. Start the sled without pressing a

button and see if the message goes away. If it is not present, start looking for a disconnected ground on the sled (see

Other Issues below).

BoonDocker – 1585 Hollipark Dr. Idaho Falls, ID 83401 – 208-542-4411 / 877-522-7805

www.boondockers.com – email: info@boondockers.com – fax: 208-524-7381

Revised 05-07-07 Page 14 of 16

Page 15

If a button really is stuck on, the Control Box can still function and adjust fuel properly. The Control Box can be sent

back to Boondocker to be serviced.

Injector Fault

The Control Box monitors the signals from the sled’s ECU. If it detects signals on one set of wires but not the other, it

will detect a fault on that injector and display one of the two error messages.

MAG Inj. Fault! Missing or bad signal detected on the MAG side injector (yellow or tan wire).

PTO Inj. Fault! Missing or bad signal detected on the PTO side injector (green or brown wire).

xxx Inj. Fault! This means a previous injector fault has occurred which has not yet been

cleared.

If any of these conditions occur, the Control Box will still function and it will still try to make fuel adjustments,

the intermittent injector connection will need to be fixed. Contact Boondocker to determine if the Control Box and

harness need to be sent back to be inspected or serviced.

Note: Injector errors that occur infrequently can be ignored since they are likely caused by sporadic electrical noise

but

.

Other Issues

Engine runs erratically:

1. Verify that the ground on the sled’s harness has a good connection to the chassis.

2. Verify that the EFI Harness Ground Wire has a good connection.

3. Verify that all wiring is in good condition and that the wires have not pulled out of the terminals. To verify this,

look inside each connector and verify that the terminal pins are all at the same height. If a terminal is starting to

back out, it will appear to be lower in the connector, or the seal on the back-side will be protruding out farther

than the rest.

4. Unplug the EFI harness and plug original harness back into the injectors and verify that the sled runs OK.

5. If problem only occurs with Control Box plugged in, change all fuel adjustment settings to 0 and see if problem

persists.

6. Verify that the Control Box does not reset itself when the sled is running by doing the following:

a. When the sled is first powered up, change the menu screen on the Control Box to one of the fuel adjust

screens.

b. Run the sled.

c. Before sh utting off the sled, verify that the screen is still on the same menu selection.

d. If the startup screen is displayed (showing version number etc.), the box has reset itself. This is likely

7. If necessary, the voltage supply to the box can be verified using a voltmeter. Probe from the Mag-side gray

connector on the EFI harness where two red wires go to one connector terminal. Insert a small thin wire such as a

paperclip or a small probe tip between the connector and the rubber seal in order to make contact with the terminal

inside. Place the positive voltmeter probe here. Place the negative voltmeter probe on chassis ground. At idle the

DC voltage should read around 12-14V.

Rough Idle: Idle adjustments are much more sensitive than other adjustments since the injectors are on for a

LCD is dim: If you are using a 9 volt battery to power the box when the sled is not running, your battery v oltage

caused by bad voltage to the box due to an intermittent connection.

very short duration. You may not be able to adjust your 3000 LO settings by very much.

is getting low – replace your battery. Extreme hot or cold temperatures may cause the LCD to not

display properly.

BoonDocker – 1585 Hollipark Dr. Idaho Falls, ID 83401 – 208-542-4411 / 877-522-7805

www.boondockers.com – email: info@boondockers.com – fax: 208-524-7381

Revised 05-07-07 Page 15 of 16

Page 16

LCD display is slow: Cold weather conditions can make the LCD respond very slowly. The Control Box will still

function OK. You can locate the box under the hood in order to provide heat so the LCD will

Moisture on LCD: Condensation is normal if the Control Box is quickly moved from a cold to a warm environment.

Check Engine light: Make sure the wires in the EFI harness are correct and check for a bad connection in the wiring

display quicker.

In some cases, the Control Box enclosure may no longer be sealing properly. If such problems

persist, contact Boondocker to determine if resealing the box is necessary.

harness. Recheck all connectors and be sure each is completely latched. Also inspect each wire to

make sure there are no frayed, broken, or melted wires. Look at the seals on the back of each

connector – if a pin has backed out, its wire seal will be protruding out of the connector more than

the rest.

X. Fuel Octane Recommendations

The octane your engine needs depends on many variables such as air density (elevation/temp), engine compression ratio,

camshaft timing, and ignition timing. The table below is provided as a general guideline only – your engine requirements

may be different.

Note:

When using pump gas, be aware that the fuel quality can vary and has been known to be less than that shown on the

pump! We recommend you obtain fuel from a known source and/or mix with race gas if in doubt.

Boost Æ 8lbs 10lbs 12lbs 14lbs 16lbs

Comp.

Ratio Æ

0 ft

2500 ft

5000 ft

8000 ft

octane shown is determined by (R+M)/2

x = not recommended when using stock injectors and fuel pump

11.8:1 9.0:1 11.8:1 9.0:1 11.8:1 9.0:1 11.8:1 9.0:1 11.8:1 9.0:1

95 93 100 95 105 100 x x x x

93 92 98 94 103 98 108 103 x x

92 91 97 92 102 97 107 102 112 107

91 91 95 91 100 95 105 100 110 105

XI. Warranty, Terms & Conditions

Returned Goods – No merchandise will be accepted without prior approval. A RMA number (Return Merchandise

Authorization) provided by Boondocker is required before a return will be accepted. A 20% handling and restocking

charge will be applied to returned merchandise. No unauthorized returns will be accepted.

Limited Warranty – Boondocker warrants its product to the original purchaser against workmanship defects for a p eriod

of 90 days, commencing from the date of product delivery to the Consumer.

Maximum Liability – The maximum liability of Boondocker in connection with this warranty shall not under any

circumstances exceed the price of the product claimed to be defective.

BoonDocker – 1585 Hollipark Dr. Idaho Falls, ID 83401 – 208-542-4411 / 877-522-7805

www.boondockers.com – email: info@boondockers.com – fax: 208-524-7381

Revised 05-07-07 Page 16 of 16

Loading...

Loading...