Page 1

Boondocker Performance www.boondockers.com 208-542-4411 2010 M8 Turbo Kit Instructions

1

Arctic Cat M8 Pump Gas Turbo Install Instructions

Revised 9/30/2010

Page 2

Boondocker Performance www.boondockers.com 208-542-4411 2010 M8 Turbo Kit Instructions

2

Important Information Before Installing This System:

The 2010 -2011 M8 will require a head modification to run pump gas call Boondocker for

more information.

Before you begin your turbo install, read through these instructions to determine if you are

comfortable installing this system. If not please take it to an experienced mechanic for your

install. It is also a good idea to check the kit contents to verify all parts were provided in the kit

before getting started. This install requires time and patience. Do not rush the installation, if you

have any questions on your installation please contact Boondocker tech support at 1-877-522-

7805.

Step 1: Tear Down

Parts Needed: Tools Needed:

None Basic tool set

Air saw

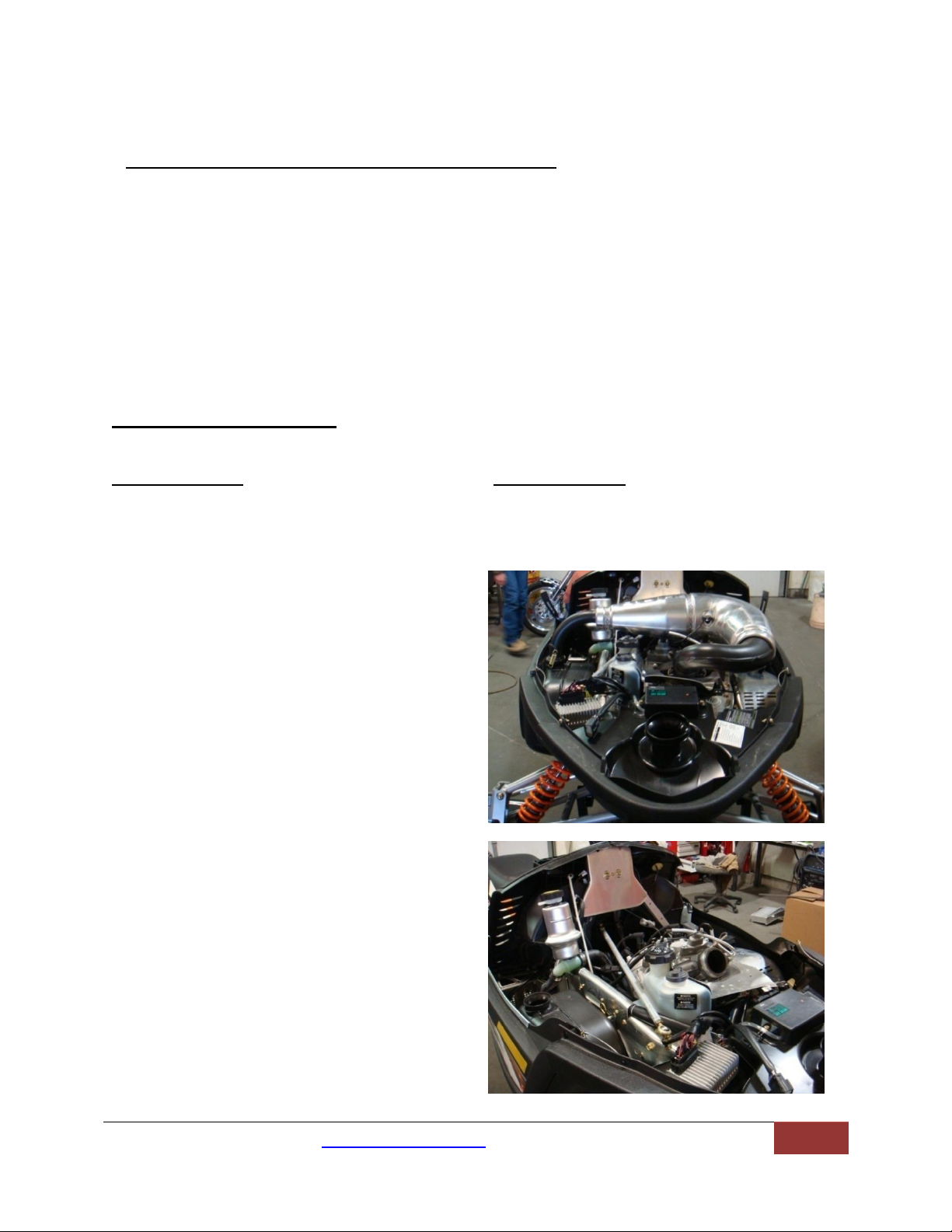

A. Remove hood and side panels

B. Remove pipe and can (remove the

stock rubber mount from the exhaust

can we will need this later).

Revised 9/30/2010

Page 3

BoonDocker Performance www.boondockers.com 208-542-4411 2010 M8 Turbo Kit Instructions

3

C. Remove Y pipe and heat shield. Note: If

you are installing EGT’s now would be the

time to weld on the EGT bungs. Be sure to

mount them 2 ½” from the flange.

D. Remove airbox from nose cone and

remove the plastic boot that connects to

the throttle bodies.

E. Remove the temp sensor from the airbox

and set it aside, you will need this later in

the install.

F. Remove right hand step panel and reverse

beeper.

G. Cut and remove this portion of bulk head

using an air saw, if you do not have an

airsaw you can work this piece loose with

a pair of pliers.

Page 4

BoonDocker Performance www.boondockers.com 208-542-4411 2010 M8 Turbo Kit Instructions

4

Step 2: Mounting The Airbox and ECU

Drill here

Parts Needed: Tools Needed:

2- Machined rings/o-rings installed Drill with 5/16 drill bit

Air temp sensor (removed from stock airbox) Basic tool set

Boondocker airbox Assembly lube

2- self tapping sheet metal screws Silicone

5/16 x ¾” bolt with lock washer

2- Rubber ECU mounts

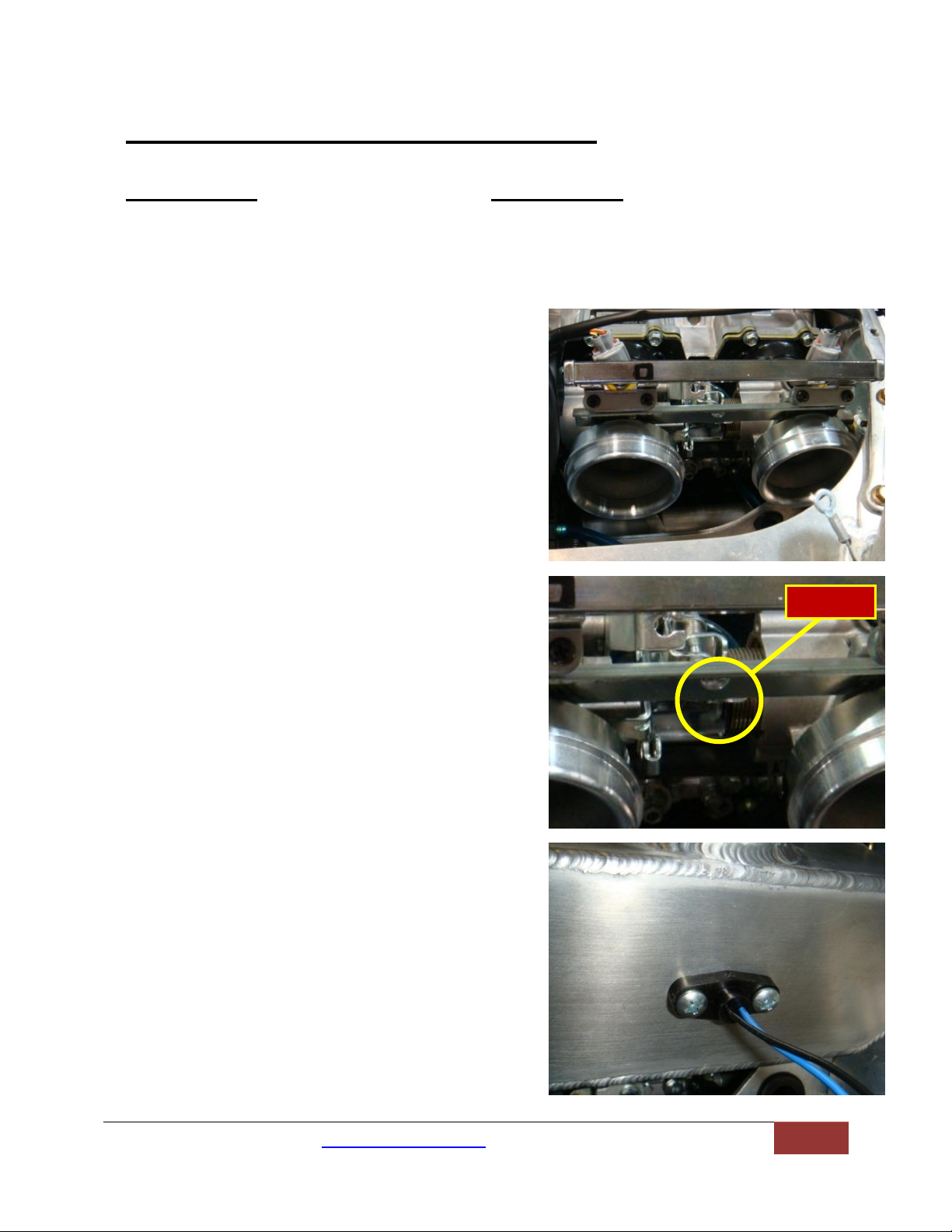

A. Lubricate the o-rings on the machined rings, this

will help ensure a good o-ring seat. Install the

rings to the throttle bodies as shown.

B. Insert the airbox over the machined rings. Mark

and drill a 5/16” hole in the throttle body

support for the airbox mount.

C. Use silicone around the factory temp sensor to

help seal this connection. Be sure not to get any

silicone on the sensor itself. Install the sensor in

the predrilled hole in Boondocker airbox using

the provided self tapping screws.

Page 5

BoonDocker Performance www.boondockers.com 208-542-4411 2010 M8 Turbo Kit Instructions

5

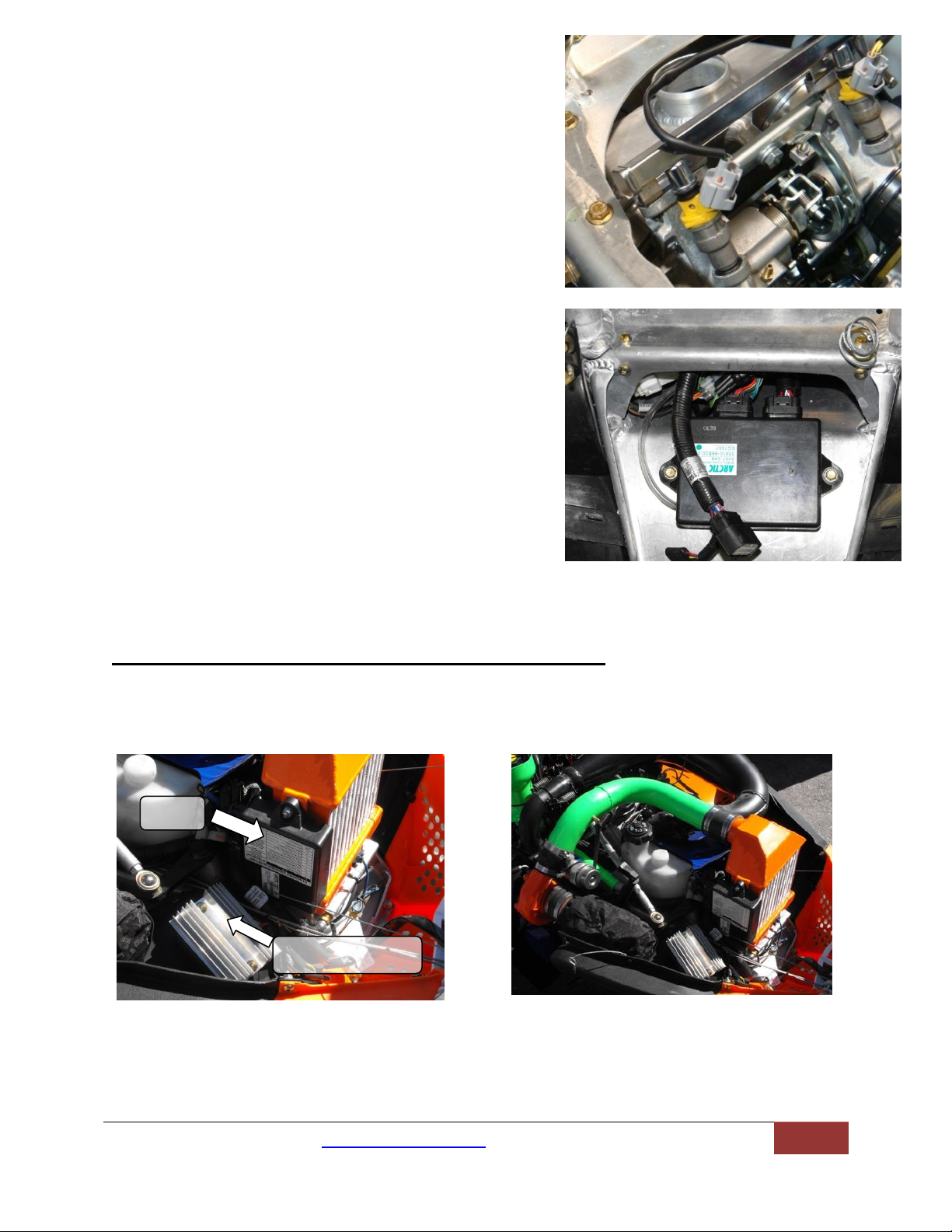

D. Reroute the ECU Harness. Be sure the harness

Voltage regulator

ECU

does not rub on the chassis, this can cause a short

in the wiring,

E. Install the Boondocker airbox and fasten it using

the provided 5/16 x ¾” bolt with lock washer.

F. Relocate the ECU as shown in the picture. Be sure

to mount the ECU far enough forward so that the

connectors plug in without hitting the bulkhead.

Use the factory bolts, and the provided rubber

ECU mounts in between the ECU and bulkhead to

dampen the vibration.(DO NOT

OVERTIGHTEN)

Installing Intercooler (in place of Airbox)

Follow step A-E for Airbox. Relocate the ECU to the side of the Intercooler and re locate the

voltage regulator (see pictures). For wiring fan see Step 6 section B

Page 6

BoonDocker Performance www.boondockers.com 208-542-4411 2010 M8 Turbo Kit Instructions

6

Step 3: Install the Air Density Advantage Kit:

Parts Needed; Tools Needed:

ADA kit bag w/ instructions Basic tool set

Step 4: Installing the Control Box (See Control Box

Instuctions):

Parts Needed: Tools Needed:

Control Box w/instructions Basic tool set

Step 5: Muffler

Parts Needed: Tools Needed:

Muffler Basic tool set

5- 8mm x 25mm Allen head bolts 3” hole saw

Spring tab Die grinder

¼” x ½” bolt with lock nut 2 ¼” hole saw

Muffler support with rubber bumper

2- Aluminum rivets

4- Gold exhaust springs

Turbo oil tank assembly

12” of heat tape

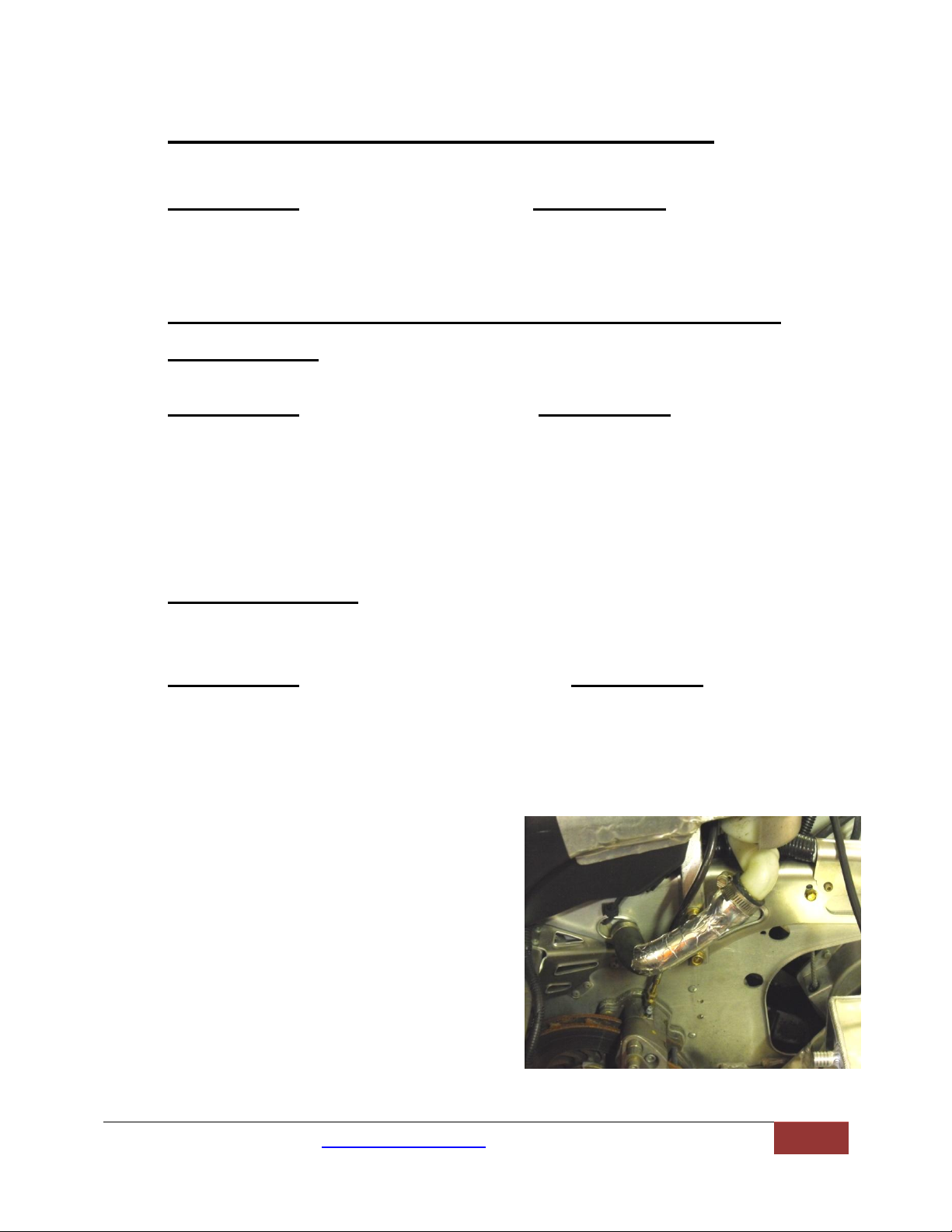

A. Using the provided 12” piece of heat tape.

Wrap the coolant line as shown in picture.

Page 7

BoonDocker Performance www.boondockers.com 208-542-4411 2010 M8 Turbo Kit Instructions

7

B. Using a 3” hole saw make the first cut as shown in picture.

Be sure to trim here for best fit

3”

1 7/8”

Hole center

C. Using a 2 ¼” hole saw make this first cut as shown

D. NOTE: You will have to do additional trimming in the holes to get the muffler to fit, use a die

grinder for this step (see below). You can now fit the muffler inside the foot rest.

Page 8

BoonDocker Performance www.boondockers.com 208-542-4411 2010 M8 Turbo Kit Instructions

8

E. From the inside of the footrest find the center row in the vertical hole pattern and the

hole in the very bottom of the horizontal pattern. Install the spring tab here using the ¼”

x ½” bolt with lock nut as shown in picture.

F. Trim the hole pattern on the front of the foot rest count 6 holes up on the middle vertical

hole pattern and 5 holes up on the right vertical hole pattern. Fasten the muffler support

bumper here using the 2 aluminum rivets as shown in picture.

G. Trim 3 rounded spots on the foot rest as shown and mount the reverse beeper.

H. Place a bead of high temp silicone around the muffler flange as shown, reinstall to turbo.

I. Install the 5 hole muffler flange to the turbo exhaust housing using the 5- 8mm x25mm

Allen heat bolts. Install the 4 gold springs as shown.

.

Page 9

BoonDocker Performance www.boondockers.com 208-542-4411 2010 M8 Turbo Kit Instructions

9

J. Turn the sled on its side and install the heat deflector plate as shown in picture, fasten

Install rubber grommet from

stock exhaust.

using the factory bolts

Step 6: Turbo/Oil Tank

Assembly Installations

Parts Needed: Tools Needed:

Turbo/Oil Tank Assembly Basic Tool Kit

A. Mount the oil tank/ turbo assembly to the sled using the stock exhaust can mounts as

shown in picture.

Page 10

BoonDocker Performance www.boondockers.com 208-542-4411 2010 M8 Turbo Kit Instructions

10

B. Wiring your oil pump. Use the Voltage Regulator Power Adapter (supplied in the kit,

see picture), plug in between the chassis harness and voltage regulator (see picture). If

you have an Intercooler with fan you will connect here also.

Step 7: Installing Water Lines

Parts Needed: Tools Needed:

2-Banjo style water fittings 1 @ 17” 1 @ 19’’ Basic tool set

2- Bolts for Banjo fittings 4- Copper washers

1-¼” x ¼” barbed fitting

T20 torx head bit.

A. To route the water lines tilt the sled on its side

and remove the belly plate using a T20 torx head

bit.

B. Locate the factory water line that runs from the

throttle bodies to the back of the motor. Pinch the

factory water line with a pair of vise grips or

other clamping pliers and remove the factory

clamp Note: you may have to rotate the clamp to

gain access to

The worm drive fastener on the hose clamp.

Page 11

BoonDocker Performance www.boondockers.com 208-542-4411 2010 M8 Turbo Kit Instructions

11

C. Connect the 19” water line on the turbo charger

to the back of the motor and fasten with the

factory clamp

D. Trim the protective plastic cover right before the

clamp. We will use this later.

E. Route the 17” water line from the turbo to the

stock water line that you just pinched off. Trim

the factory water line to proper length and

connect the factory water line to the 17” turbo

water line using the supplied ¼” barb and fasten

with the 2 #4 hose clamps provided in the kit (as

shown in picture).

\

C. Install the piece of trimmed plastic sleeving on

the upper side of the water line, this will keep

the hose from rubbing on any sharp edges (see

picture).

Page 12

BoonDocker Performance www.boondockers.com 208-542-4411 2010 M8 Turbo Kit Instructions

12

Step:8 Fuel System

Parts Needed: Tools Needed:

Fuel regulator fitting Basic tool set

2- 1/8” NPT x 1/8” PTC 90 Vise

41” of 1/8” poly line Drill w/ 5/16” drill bit

Bulkhead fitting with 1/8” push to connect Nut driver

5/16 nylon lock nut

1/4 “ flat washer

4- 8” cable zip ties

7” of clear 3/16” tubing

Boondocker airbox

A. Disconnect and remove the electrical connector, fuel

line, brass fitting and the nut shown in picture, then

remove the factory fuel pump from the gas tank.

B. Locate the brass fuel regulator fitting and using a

9/16” socket press the fitting on the stock fuel

regulator using a vise as shown in picture.

C. Thread the 1/8 push to connect 90 into the copper

cap as shown in picture

D. Reinstall the fuel pump in gas tank.

E. Find a flat surface on the fuel tank to mount the

bulkhead fitting. Drill a 5/16” hole and install the

bulkhead union in gas tank. Fasten the bulkhead

fitting using the provided 5/16 lock nut and ¼” tighten using a nut driver. IMPORTANT:

Do not over tighten this fitting it will break.

Page 13

BoonDocker Performance www.boondockers.com 208-542-4411 2010 M8 Turbo Kit Instructions

13

F. Install the 90 degree push to connect fitting in

the air box as shown

G. Locate the 41” of 1/8” black poly and route the

poly line to the bulkhead fitting following the

throttle cable as shown. Insert the 7” of clear

tubing onto the poly line as shown and connect

to airbox. Note: be sure to avoid sharp edges,

possible melting and kinking the 3/16” hose.

H. Push the poly line through the bulkhead fitting

and connect it to the fitting on the copper cap we

installed in part C.

Page 14

BoonDocker Performance www.boondockers.com 208-542-4411 2010 M8 Turbo Kit Instructions

14

Step 9:Exhaust Pipe

Parts Needed: Tools Needed:

Air saw or band saw

4- 8mm non Nylon lock nuts Welder

Stock pipe Basic tool kit

Boondocker turbo inlet Grinder or sand paper

4- 8mm x 25mm bolts

A. Remove stock heat shield from pipe.

B. Cut the exhaust pipe right before the weld as

shown in picture. You will also need to grind

about 1.5” inches off the factory weld of the

pipe as shown in picture.

C. Sand the end of the pipe and the inlet for a

clean weld on the pipe

D. Bolt the turbo inlet to the exhaust housing on

the turbo as shown using the provided 8mm

bolts and nuts Note: the exhaust housing side of

the turbo should still be loose, this will allow

you to rotate the housing as needed to fit the

exhaust pipe.

Page 15

BoonDocker Performance www.boondockers.com 208-542-4411 2010 M8 Turbo Kit Instructions

15

E. Reinstall the bottom heat shield on the pipe and

install the exhaust pipe as shown in picture Be

sure to spring the pipe in place to ensure proper

placement (use factory springs).

F. We are now ready to weld the inlet to the exhaust

pipe. Either mark the inlet and pipe with a

permanent marker and remove pipe to tack and

weld, or If you plan on tacking the inlet to the pipe

on the sled, be sure to disconnect the ECU failure

to follow this step will result in damage to your

ECU. Remove pipe and finish the weld.

NOTE: Do not reinstall the exhaust pipe until you

complete step 9.

Page 16

BoonDocker Performance www.boondockers.com 208-542-4411 2010 M8 Turbo Kit Instructions

16

Step 10: Exhaust Pipe Final Install

Parts Needed: Tools Needed:

Air saw or band saw

4- High tension exhaust spring Basic tool kit

4- 8mm x 25mm bolts Spring tool

4- 8mm top lock nuts Black high temp spray paint

4 Hole exhaust gasket (packaged in turbo box)

Exhaust Pipe with heat shield

Factory heat shield

A. For a cleaner look, paint the welded inlet on the

exhaust pipe with a black high temp spray paint.

B. Reinstall the factory heat shield on exhaust pipe.

C. Using an air saw or band saw trim the exhaust heat

shield as shown in picture

D. Reinstall the heat shield to the sled

E. To save you a headache install the 2 high tension

exhaust springs on the right side of the pipe first,

this allows you to use the exhaust pipe to torque the

springs instead of a spring puller. Be sure to install

the short hook onto the pipe side and the long side

of the spring to the Y pipe.

F. Be sure to add the 4-hole gasket on the turbo side

of the pipe. Fasten this connection using the

provided 8mm bolts with lock nuts.

G. Install the remaining high tension exhaust springs

Page 17

BoonDocker Performance www.boondockers.com 208-542-4411 2010 M8 Turbo Kit Instructions

17

Step 12: Charge Tube ( If Intercooler kit same process)

Parts Needed: Tools Needed:

2” x 3” black silicone Basic tool set

2” x 2” black silicone

4- Size 32 hose clamps

6.5” of 3/16” hose

2- 4” zip ties

A. Install 2” x 2” black silicone to the Boondocker

airbox and loosely place 2 size 32 hose clamps over

the silicone.

B. Install 2” x 3” black silicone to the turbo charger

and loosely place 2 size 32 hose clamps over the

silicone.

C. Insert the charge tube into the 2 silicone pieces as

shown

D. Tighten all 4 size 32 hose clamps

E. Route the 6.5” piece of 3/16” tubing from the

actuator to the barbed fitting on the charge tube.

F. Zip tie these 2 connections.

Page 18

BoonDocker Performance www.boondockers.com 208-542-4411 2010 M8 Turbo Kit Instructions

18

Step 13: Final Touches

Parts Needed: Tools Needed:

Snorkel filter Basic tool set

Oil tube w/dipstick Assembly lube

A. Fill oil tank with 16oz of synthetic 2 stroke

engine oil IMPORTANT: start the sled to

make sure the oil pump is working before

installing it to the turbo.

B. Install the oil hose to the top of the turbo as

shown

C. Clean up and zip tie all hoses.

D. Using the provided size 48 hose clamp, fasten

the snorkel filter to the turbo inlet as shown.

E. Well you did it, good job. Replace the hood

and side panels, oh yeah, and don’t forget to

hold on!!! Thanks for choosing Boondocker

Performance Products.

Loading...

Loading...