Bolens 244-642-000 User Manual

OWNERS

MANUAL

.75

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

5 and 8 H.P.

LOG SPLITTERS

Model Numbers

244-642-000

244-645-000

24642L

24645L

Important:

Read Safety Rules and

Instructions Carefully

PRINTED IN U.S.A.

Thank you for purchasing an

American buiit product.

FORM NO. 770-3092

(R830628)

INDEX

Operation Practices........................................................ 3

Assembly Instructions .................................................... 5

Operation........................................................................ 8

Maintenance

.................................................................

10

r

limite;d warranty

♦

♦

♦

♦

♦

♦

♦

♦

For one year from the date of original retail purchase, MTD PRODUCTS INC will either

repair or replace, at its option, free of charge, F.O.B. factory or authorized service firm, any

part or parts found to be defective n material or workmanship. Transportation charges for

the movement of any power equipn ent unit or attachment are the responsibility of the pur

chaser. Transportation charges for any parts submitted for replacement under this warran

ty must be paid by the purchaser ur less such return is requested by MTD PRODUCTS INC.

This warranty will not apply to any part which has become inoperative due to misuse, ex

cessive use, accident, neglect, improper maintenance, alterations, or unless the unit has

been operated and maintained in accordance with the instructions furnished. This warran

ty does not apply to the engine, mo or, battery, battery chargeror component parts thereof.

Please refer to the applicable man jfacturer’s warranty on these items.

Off-Season Storage .....................................................11

Illustrated Parts......................................................12, 14

Repair Parts List....................................................13, 14

Parts Information...........................................Back Cover

♦

♦

♦

♦

♦

♦

♦

t

♦

♦

♦

t

This warranty will not apply where the unit has been used commercially.

Warranty service is available throuqh your local authorized service dealer or distributor. If

you do not know the dealer or distri Dutor in your area, please write to the Customer Service

Department of MTD.

The return of a complete unit will r ot be accepted by the factory unless prior written per

mission has been extended by MTD.

This warranty gives you specific kgal rights. You may also have other rights which vary

from state to state.

1.

WARNING I

®c

■'0 PURCHASERS

OF INTERNAL COMBUSTION ENGINE EQUIPPED

MACHINERY OR DEVICES IN THE STATE OF CALIFORNIA

The equipment which you have just purcha; ed does not have a spark arrester. If this equipment is used on

any forest covered land, brush covered land, or grass covered unimproved land in the State of California,

before using on such land, the California la\i/ requires that a spark arrester be provided, in addition, spark

arrester is required by law to be in effec ive working order. The spark arrester must be attached to the

exhaust system and comply with Section 44<^ 2 of the California Public Resources Code.

♦

♦

♦

♦

♦

♦

IMPORTANT

It is suggested that this manual be read in its entirety before attempting to assemble or operate. Keep this manual

^in a safe place for future reference and for ordering replacement parts.

This unit is shipped WITHOUT GASOLINE or 01L. After assembly, see separate engine manual for proper fuel and

engine oil recommendations.

Your log splitter is a precision piece of power equipment, not a plaything. Therefore exercise extreme caution at

all times.

SAFE OPERATION PRACTICES FOR LOG SPLITTERS

TRAINING

1. Know the controls and how to stop quicklyREAD THIS OWNER'S MANUAL.

2. Do not allow children to operate. Do not allow

adults to operate it without proper instruction.

Only persons well acquainted with these rules of

safe operation should be allowed to use your log

splitter.

3. Never use your splitter for any other purpose

than splitting wood. It is designed for this use

only and any other use may cause an injury.

4. Only the operator is to be near your log splitter

during use. Keep all others, including pets, a

minimum of 20 feet away from your work zone.

Flying wood can be hazardous.

Don't step over your splitter when engine is

running. You may trip or accidentally activate

ram if you step over. If you need to get to the

other side, walk around.

PREPARATION

Do not wear loose fitting clothing that could get

1

.

caught on the moving parts.

Do not operate equipment when barefoot or

2.

wearing open sandals. Always wear safety shoes or

heavy boots. A dropped log can seriously injure

your foot.

Check the fuel before starting the engine. Do not

3.

fill the gasoline tank indoors, when the engine is

running, or while the engine is still hot. Wipe off

any spilled gasoline before starting the engine.

Use only in daylight or in good artificial light.

4.

Never operate your splitter on slippery, wet,

5.

muddy, or icy surfaces. Safe footing is essential in

preventing accidents. Never operate your splitter

while attached to a towing vehicle.

Always wear safety glasses or goggles while oper

6.

ating your log splitter. A piece of splitting log

could fly off and hit your eyes.

Both ends of each log must be cut square. This

7.

will prevent the log from flying out of the splitter

while under pressure.

OPERATION

1. Do not change the engine governor settings or

overspeed the engine. Excessive engine speeds are

dangerous.

2. Never place hands or feet between log and split

ting wedge or between log and ram during forward

or reverse stroke. To do so may result in crushed

or amputated fingers or toes, or worse, you may

lose an arm or foot.

3. If the equipment should start to vibrate abnor

mally, stop the engine and check immediately for

the cause. Vibration is generally a warning of

trouble.

4. When cleaning, repairing or inspecting, make

certain all moving parts have stopped. Disconnect

the spark plug wire, and keep the wire away from

the plug to prevent accidental starting.

5. Handle gasoline with care. It is highly flammable.

A. Use approved gasoline container.

B. Never remove cap or add gasoline to a running

or hot engine or fill fuel tank indoors. Wipe

up spilled gasoline.

C. Don't run engine in an enclosed area. Ex

haust gases contain carbon monoxide. This

odorless gas can be deadly when inhaled.

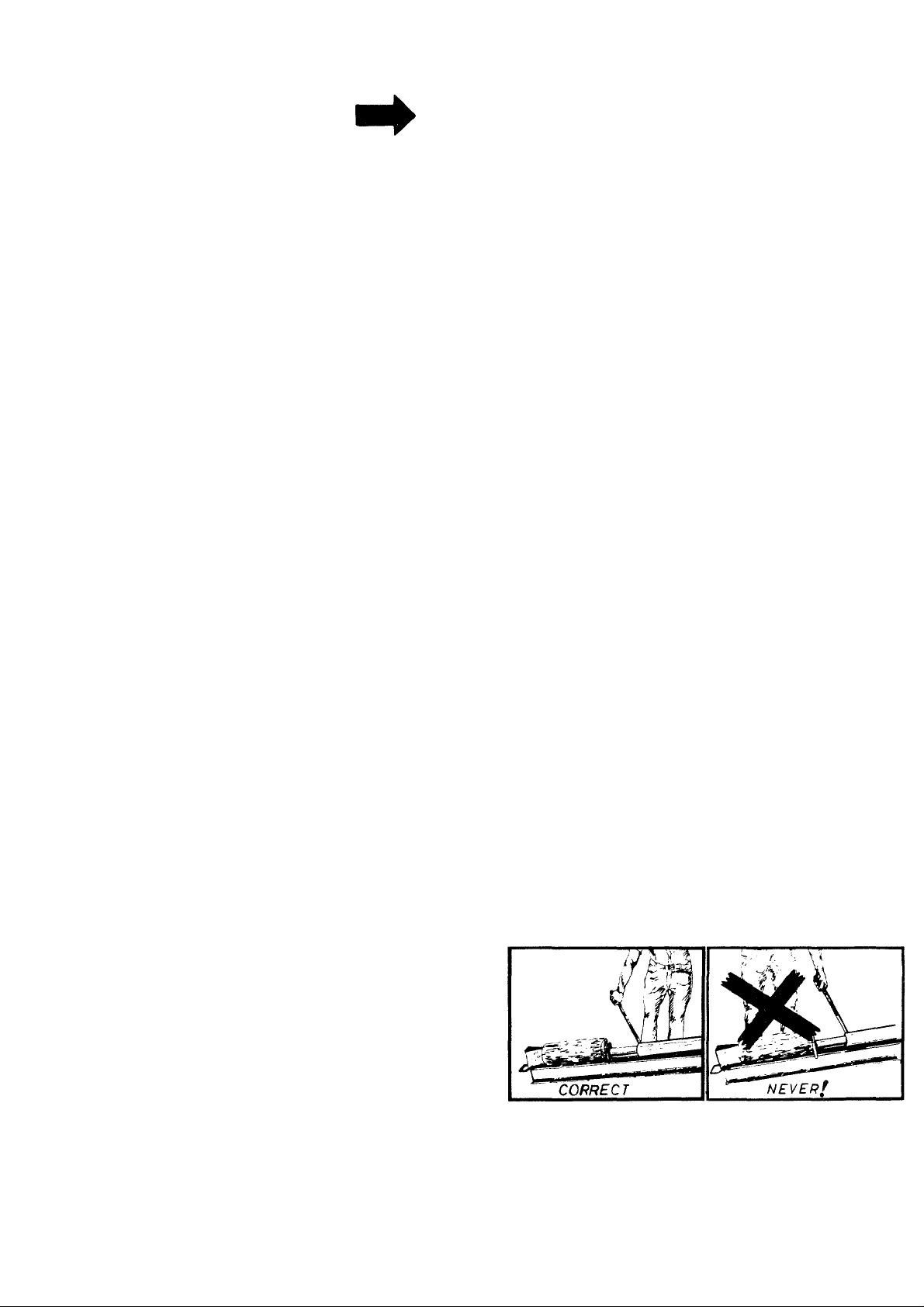

6. Always operate the log splitter from the engine

side of the beam.

Stand behind the ram when operating. See drawings.

7. Be careful not to touch the muffler after the

engine has been running. It is HOT.

8. Never try to split two logs on top of each other.

One may fly out and injure you.

9. Never attempt to split wood across the grain.

Some types of wood may burst or fly oit of

your splitter and result in injury to you or a

bystander.

10. Never leave your log splitter unattended wit i the

engine running. Shut off the engine if yoi are

leaving your splitter, even for a short period of

of time. Someone could accidentally activati the

ram and be injured.

11. Only use your hand to operate the ram or co itrol

lever. Never use your foot or a rope or any c ther

extension device. This could result in your irabil

ity to stop your splitter quickly enough and

cause an injury.

12. Only operate your splitter on the level ground and

not on the side of a hill. It could tip, or ro ling

logs or poor footing could cause an accicent.

This also prevents the spillage of gas from the

tank.

MAINTENANCE and STORAGE

1. Don't operate your splitter in poor mech; nical

condition or when in need of repair.

2. Keep all nuts, bolts, screws, hose clamp: and

hydraulic fittings tight to be sure equipment is

in safe working condition.

3. Replace all damaged or worn parts such as hy

draulic hoses and fittings immediately with man

ufacturer approved replacement parts.

4.

Never store the equipment with gasoline in the

tank inside of a building where fumes may reach

an open flame or spark. Allow the engine to cool

before storing in any enclosure.

To reduce fire hazard keep engine free of grass,

5.

leaves, wood chips, excessive grease and oil.

The hydraulic system of your log splitter re

6.

quires the careful inspection along with the

mechanical parts. Be sure to replace frayed,

kinked, cracked or otherwise damaged hydraulic

components.

Fluid escaping from a very small hole can almost

7.

be invisible. Do not check for leaks with your

hand. Escaping fluid under pressure can have

sufficient force to penetrate skin, causing serious

personal injury. Leaks can be located by passing

a piece of cardboard or wood over the suspected

leak and look for discoloration.

Should it become necessary to loosen or remove

8.

any hydraulic fitting or line, be sure to relieve

all pressure by shutting off the engine and moving

the control handle back and forth several times.

Don't remove the cap from the hydraulic tank or

9.

reservoir while your log splitter is running. Hot

oil under pressure could cause injury.

10. Never store outside without a waterproof cover.

Rain will cause rust on the inside of the cylinder.

CAUTION

THIS UNIT SHOULD NOT BE TOWED ON ANY

STREET, HIGHWAY OR PUBLIC ROAD. ANY

LICENSING NE EDED TO COMPLY WITH THE

EXISTING FECERAL, LOCAL OR STATE VEH

ICLE REQUIREMENTS IS THE SOLE RESPONSI

BILITY OF THE PURCHASER.

ASSEMBLY INSTRUCTIONS

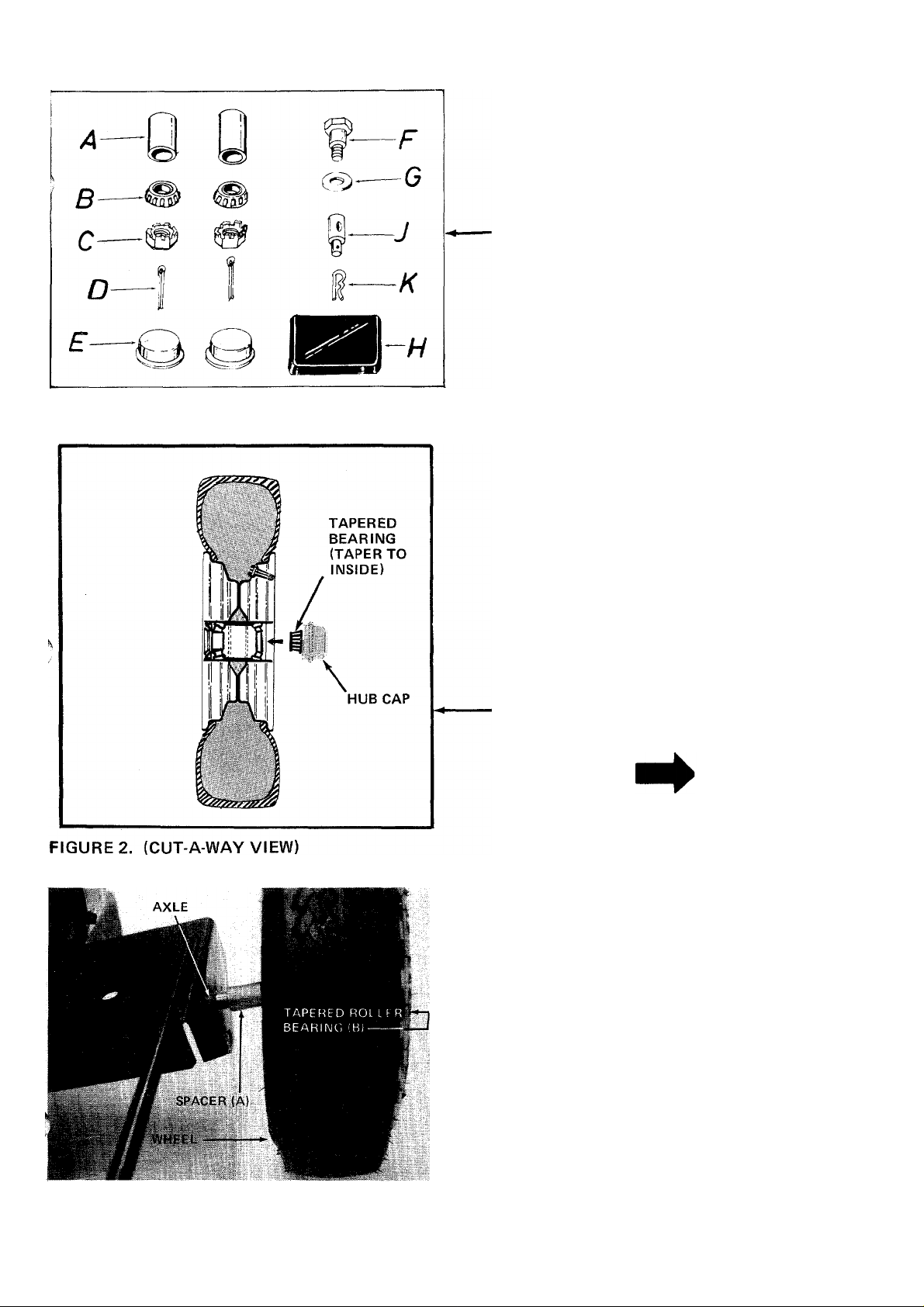

CONTENTS OF HARDWARE PACK (See Figure 1):

(A) (2) Spacers

(B) (2) Tapered Roller Bearings

(C) (2) Hex Castle Nuts 3/4-16 Thread

(D) (2) Cotter Pins

(E) (2) Hubcaps

(F) (1) Shoulder Bolt

(G) (1) Flat Washer

(H) (1) Automotive Grease

(I) (1) Tow Hitch and Stand (Not Shown - See

Figure?)

(J) (1) Ferrule

(K) (1) Hairpin Cotter

FIGURE 1.

TOOLS REQUIRED:

(1) Raw H ide or Plastic Hammer

1-1/8" Wrench or Adjustable Wrench

(1)

3/4" Wrench

(1)

Pipe Wrench

(1)

OTHER MATERIALS NEEDED:

(A) One gallon of regular grade gasoline (for engine)

1-1/2 pints of SAE 30or 10W-30oil (for engine)

(B)

Approximately 2-1/2 gallons of Dexron II auto

(C)

matic transmission fluid. (May be obtained at

your local service station or auto parts store.)

Funnel

(E)

Pipe Sealant

(F)

1. Pack the tapered roller bearings with automotive

grease.

•NOTE

Do not put any grease in the hub caps.

FIGURE 3.

, 2. Place one spacer (A) on axle, then one wheel and

tapered roller bearing (B). See figures 2 and 3.

Loading...

Loading...