Page 1

Slim Contour Unit Cooler

with Modular Cassette Design

ULA Models

BN-ULA-TB

08/12

Page 2

Table of Contents

Overview ........................................................................................................................................3

Benets & Advantages ................................................................................................................... 3

Value Statements ........................................................................................................................... 4

Nomenclature .................................................................................................................................6

Air Defrost Models

Performance Data.....................................................................................................................6

Fan Motors................................................................................................................................7

Physical Data ............................................................................................................................ 7

Replacement Parts.........................................................................................................................8

Nozzle Selection Tool ..................................................................................................................... 8

Dimensional Information ................................................................................................................9

Notes .............................................................................................................................................. 10

2

Page 3

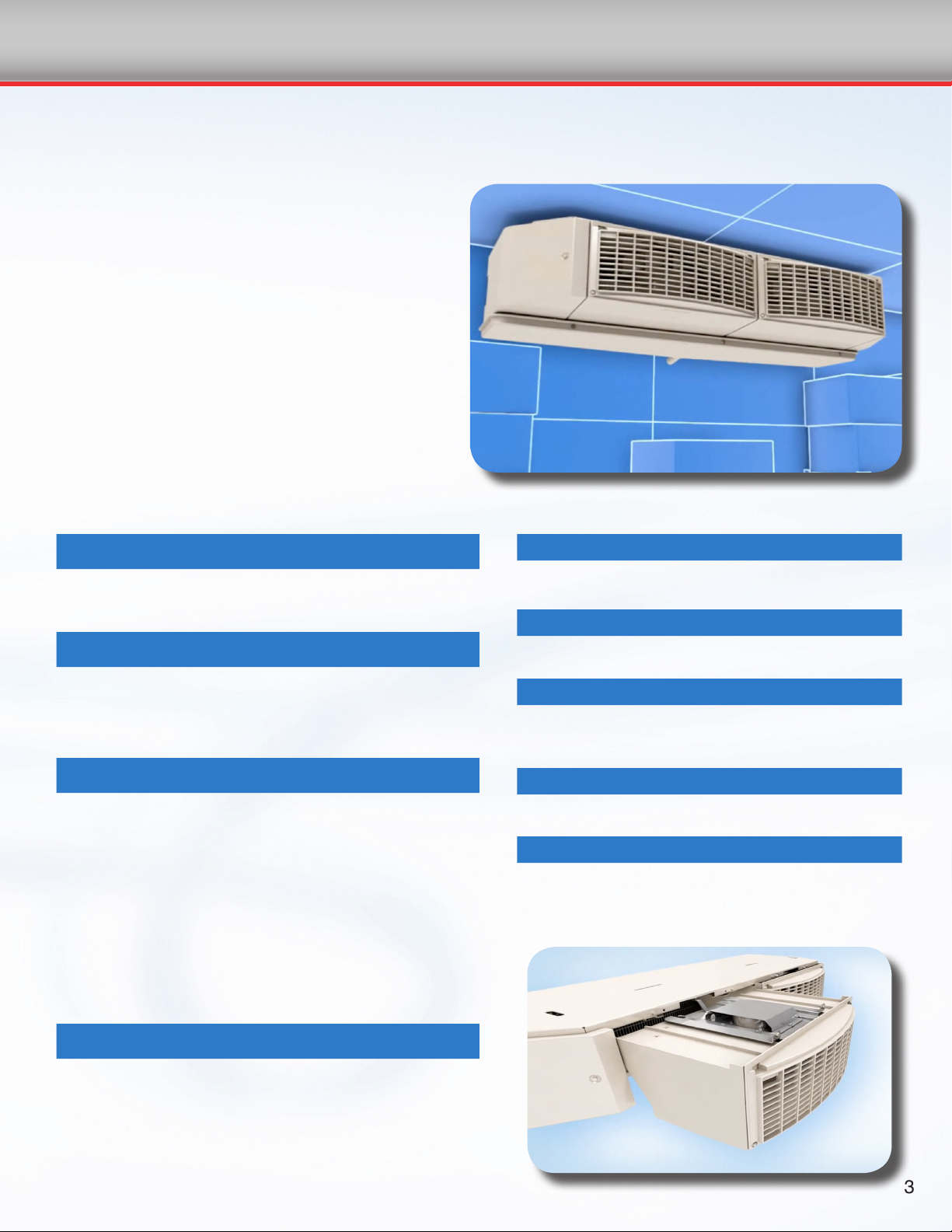

ULA - Slim Contour Unit Cooler

Maximized Storage, Minimized Energy

The Slim Contour, an innovative unit cooler with

space-saving design offers enhanced servicability and

maximum cooling performance for the food service

industry.

The Slim Contour unit cooler is ideal for applications

where maximizing storage capacity in a walk-in cooler

is critical. At less than 11 inches in height, this unit

cooler has a 30% reduction in unit height compared to

traditional unit coolers in the market today.

The unit comes standard with energy efcient EC

(Electronically Commutated) motors, and can be paired

with the Heatcraft Beacon II™ Refrigeration System for

further energy efciency.

Benets & Advantages

Reduced Prole for Added Walk-In Storage

Unit Height of Less Than 11 Inches

• Lower unit height allows for improved storage space.

Reduced Drain Line Height

Straight Drain Line Design

• Minimal drain line height increases product storage.

• Reduced risk of drain line damage.

Ease of Service

Removable, Modular Fan Cassettes

• Allows for easy access to all components for cleaning.

• Serviceable outside of cooler in a warmer environment.

Removable Fan Guard

• Easily removed, attached with two screws.

• Made from durable polymer that is dishwasher safe.

Features

Application

• Air Defrost/Medium temperature walk-in cooler

Coil

• Refrigeration optimized small diameter coil

pattern.

Air Mover

• Energy efcient EC motors standard.

• Curved centrifugal fan for optimal air ow.

Cabinet

• Hybrid design of metal and a high grade polymer.

Options

• Heatcraft Beacon II™ Refrigeration System

• Mounted Solenoid Valve

• Mounted Thermostatic Expansion Valve (TXV)

Mechanical and Electrical Access on Same Side

• Allows for easier unit service.

Energy Efciency & Substantiality

Energy Efcient Motors

• EC Motors come standard on all ULA models.

Optimized Coil for Reduced Refrigerant Charge

• Up to a 40% reduction in refrigerant charge.

MODULAR

CASSETTE DESIGN

3

Page 4

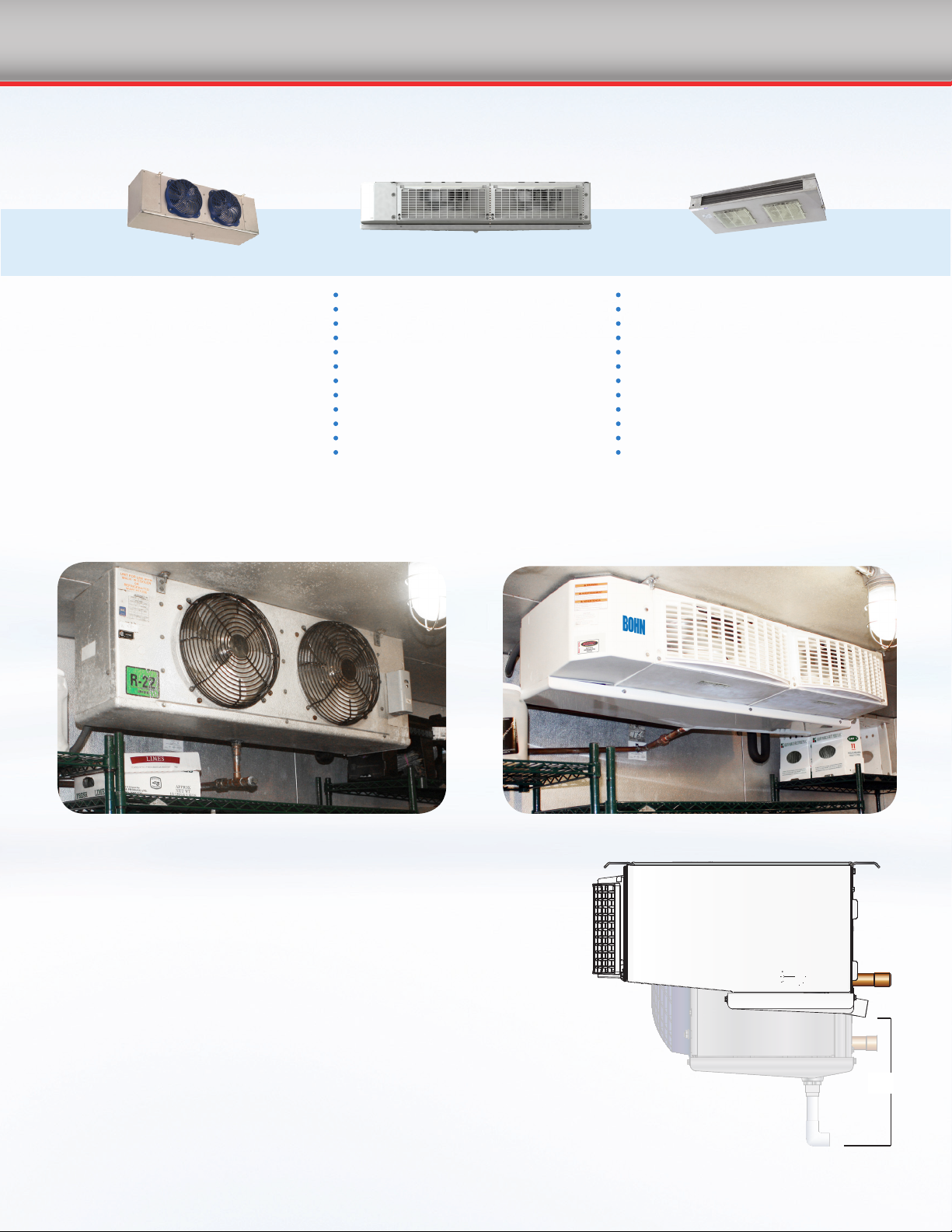

Heatcraft Unit Cooler Portfolio

10”

Low Prole

The industry standard for walk-in

cooler applications.

Offering the broadest capacity range,

from 4,000 to 37,000 BTUH, the

low prole unit cooler is designed

for maximum air ow and cooling

capacity inside a walk-in cooler.

More Space Where You Need It Most

Slim Contour Center Mount

Optimized for air defrost (medium

temperature) applications, the Slim

Contour unit cooler is ideally suited

for installations where storage space

is critical and a higher pull down

capability is desired.

Available in air or electric defrost,

ideal for tight storage situations

because they are ceiling mount and

have a height of less than 9” allowing

for maximum headroom in a cooler.

The center mount design provides

a moderated, evenly distributed air

ow throughout the box.

Before

THE CHALLENGE

• Traditional unit coolers take up valuable space within a walk-in cooler.

The drain line also extends another 6” beneath the unit; making it prone

to damage and further reducing storage space.

• Servicing the unit is also a challenge as the coil and drain pan cannot

be easily accessed for cleaning.

THE SOLUTION

• The Slim Contour unit cooler is optimized for applications where space,

performance, and serviceability cannot be compromised.

• The low 11” height, coupled with modular, removable fan cassettes

and a low drain line height maximize storage space while improving

serviceability.

4

After

Page 5

The Most Servicable Unit Cooler Available

The Slim Contour units are a hybrid design, made from high strength polymer housings and metal, fans

are modular and are easily removed to expose the coil and drain pan for easy cleaning.

Modular, removable air mover cassette

• Allows for easy access to components for cleaning.

• Modular cassettes allows for service in warmer environments.

Removable fan guards

• Fan guards are easily removed and easily cleaned.

• Made from durable polymer that is dishwasher safe.

Mechanical and electrical service access on same side

EA SY SE RVIC E

ACCESS

• Allows for easier and faster service and installation with access to all critical

electrical and mechanical components on one side.

Exceptional Cooling Performance

The Slim Contour features a capacity range that mirrors that of the existing unit coolers in the Heatcraft unit cooler portfolio.

Only 1-3 Fan units shown. Center Mount Available in 1-5 Fans & Low Prole Available in 1-6 fan models.

5

Page 6

Nomenclature

UL A 041 A E A

Model Series Defrost Type Capacity Electrical Code Motor Code

Design

Revision

UL = Slim

Contour

A = Air Defrost # x 100 = BTUH

Performance Data - 50 Hz⁺ / 60 Hz

Capacity Fan Data

Model

ULA041AEA 4,100 1,201 1 530 900

ULA050AEA 5,000 1,464 1 530 900

ULA072AEA 7,200 2,109 2 1,090 1,852

ULA100AEA 10,000 2,929 2 1,090 1,852

ULA132AEA 13,200 3,866 3 1,675 2,846

ULA153AEA 15,300 4,481 3 1,675 2,846

ULA041BEA 4,100 1,201 1 530 900

ULA050BEA 5,000 1,464 1 530 900

ULA072BEA 7,200 2,109 2 1,090 1,852

ULA100BEA 10,000 2,929 2 1,090 1,852

ULA132BEA 13,200 3,866 3 1,675 2,846

ULA153BEA 15,300 4,481 3 1,675 2,846

10 F TD

25 F SST

BTUH Watts

6 C TD

-4 C SST

A = 115v/1/60Hz

B = 208-230v/1/60Hz

No. CFM m

E = EC Motor

3

H

⁺For EC motors, use 60 Hz capacity and airflow values (Units with EC motors operating at 50 Hz will not see a reduction in

performance due to the electronic control of the motor)

6

Page 7

Fan Motors

EC Motors

Model

ULA041 1 1/15 1.0 72 .5 72 15 20

ULA050 1 1/15 1.0 72 .5 72 15 20

ULA072 2 1/15 2.0 144 1.0 144 15 20

ULA100 2 1/15 2.0 144 1.0 144 15 20

ULA132 3 1/15 3.0 216 1.5 216 15 20

ULA153 3 1/15 3.0 216 1.5 216 15 20

No. of

Fans

HP

115/1/60 208-230/1/60

Amps Watts Amps Watts

MCA MOPD

Physical Data

Model

ULA041 1 7 1/2” 5/8” 3/4” Air 33

ULA050 1 7 1/2” 7/8” 3/4” Air 33

ULA072 2 7 1/2” 7/8” 3/4” Air 64

ULA100 2 7 1/2” 7/8” 3/4” Air 64

ULA132 3 7 1/2” 7/8” 3/4” Air 93

ULA153 3 7 1/2” 7/8” 3/4” Air 93

No. of

Fans

FPI Coil Inlet

Coil Data

Coil

Outlet

Condensate

Drain

(MPS)

Defrost

Type

Approx. Weight

(lbs)

NET

7

Page 8

Replacement Parts

Right source. Right parts. Right now.

InterLink™ Commercial Refrigeration Parts by Heatcraft Worldwide Refrigeration is your link to a complete line of dependable and

certied commercial refrigeration parts, accessories and innovative electronic controls for all Heatcraft equipment. With InterLink, we

provide our wholesalers with a comprehensive selection of product solutions and innovative technologies for the installed customer

base. And every product is built to ensure the same high performance standards with which all Heatcraft Worldwide Refrigeration

brands are built — backed by a dedicated team to serve every customer need, delivering at the best lead times in the industry.

Dependable. Versatile. Courteous.

Finally, one simple source for all your replacement needs from a brand you can trust.

For parts, please contact (800) 686-7278 or visit heatcraftrpd.com

Non-Model Specic Replacement Parts List

Commercial Refrigeration Parts

by Heatcraft Worldwide Refrigeration

Air Mover

115/1/60 Hz 208-230/1/60 Hz

Cassette

Housing

Fan Guard Service Panel Side Panel

25321401 25321501 89955201 37001101 89955501 35217401

Model Specic

Replacement Parts List

No. of Fans Drain Pan

1 55563201

2 55563301

3 55563401

Nozzle Selection Tool

Model No. of Fans

ULA041 1 5/32 10 3 L - 1/3 L - 1/4

ULA050 1 5/32 10 4 L - 1/3 L - 1/4

ULA072 2 5/32 10 4 L - 1/2 L - 1/3

ULA100 2 5/32 10 8 L - 3/4 L - 1/2

Distributor Tube (in.)

No. of Circuits R-404a R-22

OD Length

ULA132 3 5/32 10 6 L - 1 L - 3/4

ULA153 3 5/32 10 8 L - 1 L - 3/4

8

Page 9

Dimensional Information

Side Dimensions Detail A - Dimensions

Air Flow

Non-Model Specic Dimensions

1.81

10.73

11.35

5.45

2.69

1.44

8.43

8.61

0.875 X 1.125 KO

Back Panel Elect.

Access

8.83

Suction

Connection

Model Specic Dimensions

One Fan Model Dimensions Two Fan Model Dimensions

15.56

2.00

19.93

5.55

Suction

Connection

see detail A

Liquid

Connection

see detail A

4.45

0.875 X 1.125 KO

2.06

Top Panel Elect. Access

2.84

31.13

.99

22.30

Drain Pan Fitting

Connection

18.70

1.307.52

2.85

2.02

21.93

19.91

7.52

5.55

26.06

Suction

Connection

see detail A

Liquid

Connection

see detail A

Three Fan Model Dimensions

36.56

21.06

16.50

Drain Pan Fitting

Connection

43.25

2.85

2.02

19.91

5.55

7.52

Suction

Connection

see detail A

Liquid

Connection

see detail A

52.13

Route Liquid Line

thru 0.875 hole

**FIELD SUPPLY**

43.30

Drain Pan Fitting

Connection

18.70

1.30

21.93

1.30

18.70

21.80

9

Page 10

Notes

10

Page 11

Notes

11

Page 12

2175 West Park Place Blvd. · Stone Mountain, GA 30087

Phone: 800.537.7775 · Fax: 770.465.5900

heatcraftrpd.com

BN-ULA-TB

08/12

Loading...

Loading...