Page 1

7170.2

July 2000

Replaces 7170.1

All belt drive models (except 575V) are

Underwriter’s Laboratories, Inc. listed.

Belt Drive Fluid Coolers

Belt Drive Fluid Coolers

Model BFF

Model BFF

Specification Data

Specification Data

Page 2

BOHN DIRECT DRIVE FLUID COOLERS

BOHN DIRECT DRIVE FLUID COOLERS

Belt Drive Fluid Coolers

Multiple fans, carefully matched to the coil surface cover a large

percentage of the face area providing uniform air distribution.

Energy efficient, three phase 1750 RPM motors with drip-proof,

grease lubricated ball bearings. Each motor is inherently

overcurrent protected providing built-in protection against single

phasing. All motors are factory wired with leads marked and

terminated in a single weatherproof junction box on outside of

the unit casing.

Convenient access panels are provided on each fan section for

ease in maintaining fans.

Casing is constructed of heavy gauge aluminum, or galvanized

steel.

Multiple fan sections, each powered by a separate motors, are

separated by a full width baffle to prevent air bypass during fan

cycling.

Motors are positioned within unit casing for weather protection.

Adjustable base provides ease in belt tension adjustment.

Each fan is equipped with heavy duty pillow block ball bearings.

Bearings are supplied with lubrication fittings shown. Fan shafts

are polished steel, precision machined to assure smooth

operation, minimum bearing wear. Shafts are coated with a

corrosion resistant dressing.

Fan guards are constructed of heavy gauge, close meshed, steel

wire zinc plated and iridite dipped to minimize corrosion.

Selection Formulas

Design Load (in BTUH) = GPM * (Ent. Fluid Temp. — Leaving Fluid Temp.) x (Fluid Constant Table 1)

Average Fluid Temperature =

T.D. = Entering Fluid Temperature — Entering Air Temperature

Base Capacity =

1,000 x T.D. x Table 2 Factor x Table 4 Factor

Entering Fluid Temp. + Leaving Fluid Temp.

2

Design Load (in BTUH)

= MBH/˚T.D.

Capacity (Actual) = Capacity (Catalog) x 1,000 x T.D. x Table 2 Factor x Table 4 Factor

PD/F (Actual) = PD/F (Catalog) x Table 3 Factor

2

Page 3

Selection Procedure

Given Conditions:

BOHN DIRECT DRIVE FLUID COOLERS

BOHN DIRECT DRIVE FLUID COOLERS

Belt Drive Unit — BFF 140˚F Entering Fluid Temp.

200 GPM 120˚F Leaving Fluid Temp.

30% Ethylene Glycol Solution 10 Ft. Water Max. P.D.

90˚F Ambient Air Sea Level

Solution:

1.

Calculate Design Load

A. Determine average fluid temperature for factor selection

in Tables 2 and 3.

Average Fluid Temp. =

B. Design Load = 200 x (140—120) x 470 = 1,880,000

2.

Calculate Base Capacity

A. Determine T.D.

T.D. = 140—90 = 50˚F

140 + 120

2

= 130˚F

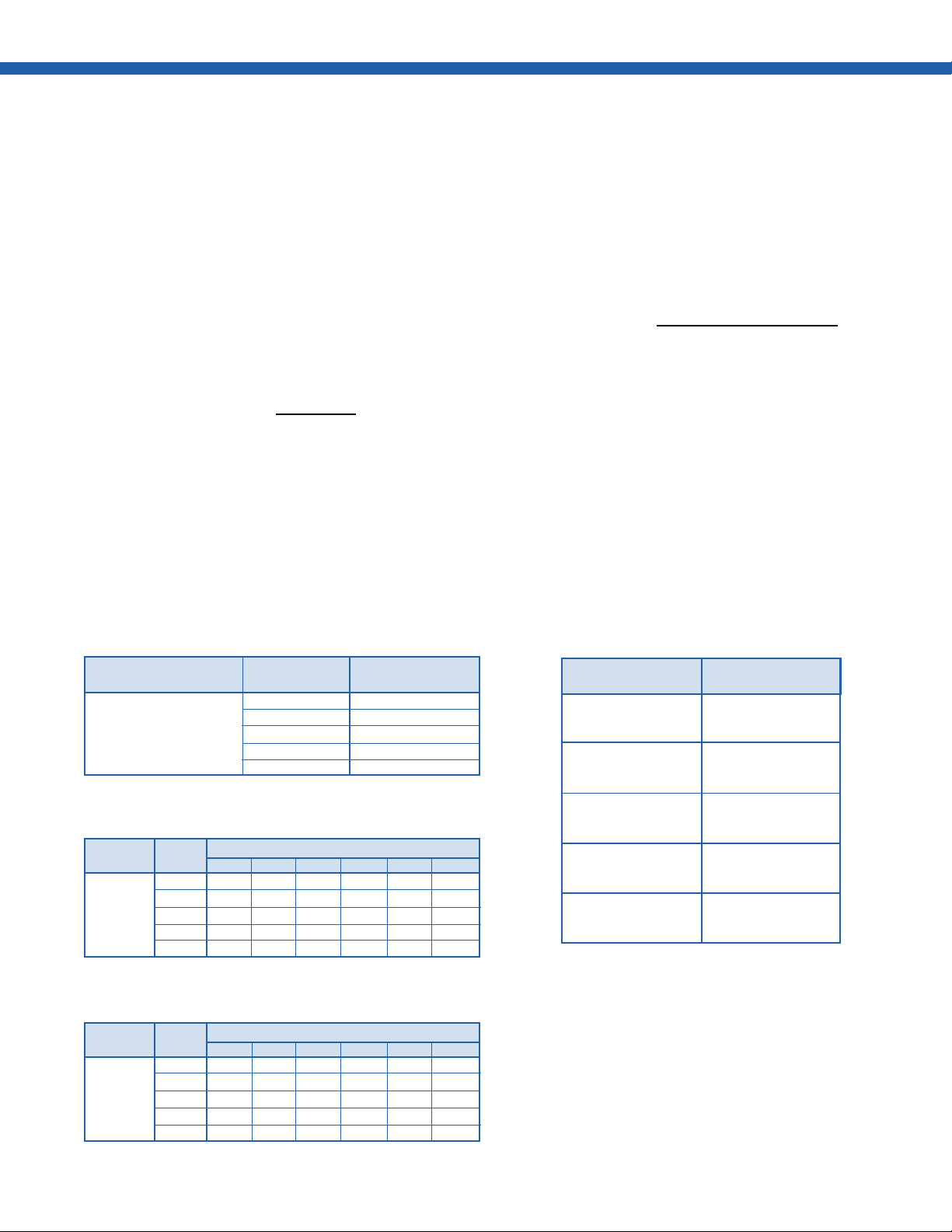

Fluid Cooler Correction Factor Tables

Table 1.

B. Determine Capacity Correction from Table 2

Capacity Correction Factor = 1.032

C. Determine Altitude Correction from Table 4

Altitude Correction Factor = 1.0

D.

Base Capacity =

3. Make selection from capacity tables using given conditions.

Model BFF 096, capacity of 37.57 MBH/˚T.D. meets the

requirements with “C” circuiting.

4. Convert pressure drop of selection to design condition P.D.

6.1 x .950 = 5.8 ft. water pressure drop at design condition.

5. Calculate actual unit rating at design conditions 37.57 x 1,000

x 50 x 1.032 x 1.0 = 1,938,612 BTUH.

1,880,000

1,000 x 50 x 1.032 x 1.0

= 36.43

Table 4. Altitude Correction Factors

% Fluid

Glycol Constant

0 500

Fluid 20 480

Constants 30 470

40 450

50 433

Table 2.

% Average Fluid Temp. (˚F)

Glycol 90 100 110 120 130 140

0 1.079 1.081 1.083 1.086 1.090 1.095

Capacity 20 1.030 1.035 1.042 1.047 1.054 1.058

Correction 30 1.005 1.009 1.012 1.023 1.032 1.034

Factor 40 .928 .943 .960 .984 1.000 1.010

50 .918 .926 .935 .939 .941 .973

Table 3.

% Average Fluid Temp. (˚F)

Glycol 90 100 110 120 130 140

0 .868 .853 .843 .819 .795 .789

Pressure 20 .980 .959 .935 .915 .893 .866

Drop 30 1.055 1.025 1.000 .975 .950 .923

Correction 40 1.120 1.080 1.060 1.034 1.000 .974

50 1.200 1.165 1.128 1.093 1.058 1.024

For average fluid temperatures below 90˚F or above 140˚F, contact the

factory for special application.

Altitude

(Feet) Factor

0 1.000

500 0.993

1000 0.986

1500 0.974

2000 0.963

2500 0.953

3000 0.944

3500 0.935

4000 0.927

4500 0.919

5000 0.911

5500 0.903

6000 0.895

6500 0.887

7000 0.880

3

Page 4

BOHN DIRECT DRIVE FLUID COOLERS

BOHN DIRECT DRIVE FLUID COOLERS

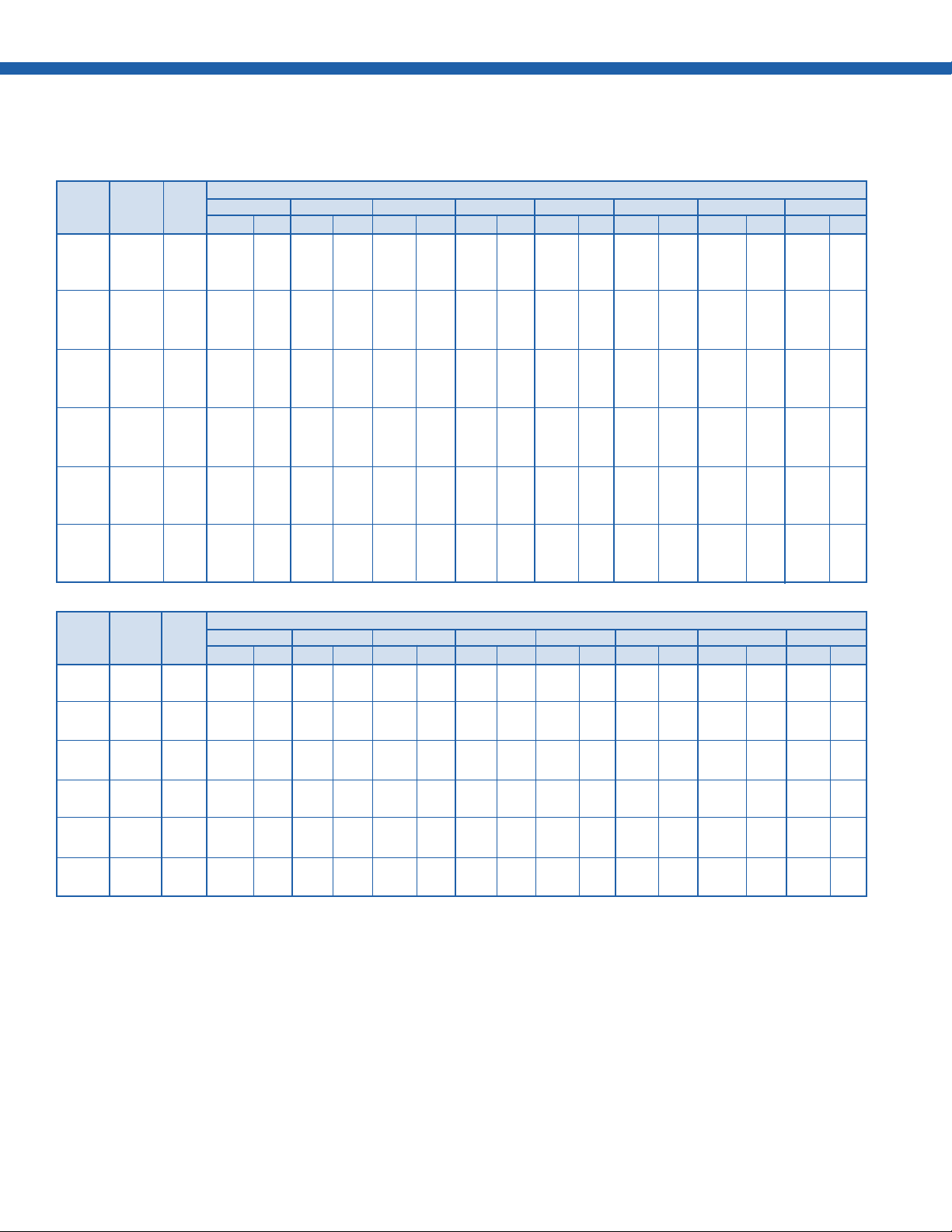

Capacity Ratings Belt Drive Fluid Coolers

Table 5A. MBH/˚T.D. — 40% Glycol — Average Fluid Temperature 130˚F (Sizes 045 - 062)

GPM

BFF Conn. Coil 30 40 50 60 70 80 90 100

Size Loc. Circ. MBH PDF MBH PDF MBH PDF MBH PDF MBH PDF MBH PDF MBH PDF MBH PDF

SE A 10.90 3.3 13.11 5.4 14.57 8.0 15.82 11.0 16.82 14.3 17.64 18.1

045 SE B 13.99 2.9 15.31 3.9 16.10 5.2 16.92 6.5 17.61 8.0 18.20 9.6

OE C 16.46 2.8 17.21 3.5 17.51 4.2

SE A 11.40 3.3 13.93 5.4 15.65 8.0 17.14 11.0 18.34 14.4 19.34 18.2

050 SE B 14.97 2.9 16.54 4.0 17.49 5.2 18.48 6.5 19.32 8.0 20.04 9.7

OE C 17.92 2.8 18.83 3.5 19.20 4.2

SE A 11.67 3.3 14.35 5.4 16.47 8.0 17.83 11.0 19.15 14.4 20.23 18.2

054 SE B 15.49 2.9 17.18 4.0 18.56 5.2 19.29 6.5 20.21 8.0 20.99 9.7

OE C 18.68 2.8 19.67 3.5 20.08 4.2

SE A 11.60 3.3 14.30 5.4 16.46 8.0 17.90 11.0 19.30 14.4 20.47 18.2

057 SE B 15.50 2.9 17.25 4.0 18.70 5.2 19.52 6.6 20.51 8.1 21.38 9.7

OE C 18.90 2.8 19.96 3.5 20.43 4.2

SE A 14.89 3.4 17.24 5.1 19.11 7.0 20.27 9.2 21.44 11.6 22.40 14.2 23.21 17.1

059 SE B 19.35 2.9 20.61 3.7 21.65 4.5 22.13 5.4

OE C 21.61 2.7

SE A 11.92 3.3 14.83 5.4 17.22 8.0 18.83 11.0 20.40 14.5 21.73 18.3

062 SE B 16.17 2.9 18.11 4.0 19.74 5.2 20.66 6.6 21.78 8.1 22.76 9.7

OE C 19.96 2.8 21.16 3.5 21.69 4.2

GPM

BFF Conn. Coil 120 140 160 180 200 250 300 350

Size Loc. Circ. MBH PDF MBH PDF MBH PDF MBH PDF MBH PDF MBH PDF MBH PDF MBH PDF

045 SE B 19.14 13.3 19.86 17.4 20.43 22.0

OE C 18.48 5.7 19.24 7.5 19.85 9.5 20.34 11.7 20.75 14.1 21.53 20.9

050 SE B 21.19 13.3 22.08 17.4 22.79 22.0

OE C 20.39 5.8 21.32 7.6 22.06 9.5 22.68 11.7 23.19 14.1 24.16 20.9

054 SE B 22.25 13.3 23.22 17.4 23.99 22.0

OE C 21.37 5.8 22.38 7.6 23.20 9.6 23.86 11.8 24.42 14.1 25.47 20.9

057 SE B 22.80 13.3 23.91 17.5 24.82 22.1

OE C 21.87 5.8 23.01 7.6 23.94 9.6 24.72 11.8 25.38 14.2 26.65 20.9

059 SE B 23.45 7.5 24.46 9.8 25.24 12.4 25.87 15.2

OE C 23.06 3.7 23.72 4.8 24.54 6.1 25.21 7.4 25.76 9.0 26.79 13.2

062 SE B 24.38 13.3 25.66 17.5 26.70 22.1

Connection Locations: SE = Same End

OE C 23.31 5.8 24.62 7.6 25.69 9.6 26.58 11.8 27.34 14.2 28.80 21.0

OE = Opposite End

4

Page 5

BOHN DIRECT DRIVE FLUID COOLERS

BOHN DIRECT DRIVE FLUID COOLERS

Capacity Ratings Belt Drive Fluid Coolers

Table 5B. MBH/˚T.D. — 40% Glycol — Average Fluid Temperature 130˚F (Sizes 065 - 114)

BFF Conn. Coil 30 40 50 60 70 80 90 100

Size Loc. Circ. MBH PDF MBH PDF MBH PDF MBH PDF MBH PDF MBH PDF MBH PDF MBH PDF

065 SE B 16.63 2.9 18.80 4.0 20.45 5.2 21.45 6.6 22.66 8.1 23.72 9.7

069 SE B 17.61 4.1 19.71 5.7 21.47 7.4 22.60 9.3 23.80 11.5 24.83 13.8

073 SE B 21.45 2.9 23.14 3.7 24.60 4.5 25.34 5.5

081 SE B 19.01 4.1 21.59 5.7 23.80 7.4 25.27 9.4 26.83 11.5 28.19 13.9

086 SE B 18.90 4.1 21.50 5.7 23.75 7.4 25.30 9.4 26.93 11.5 28.37 13.9

088

096

097 SE B 19.89 4.1 22.86 5.7 25.49 7.5 27.34 9.4 29.30 11.6 31.05 13.9

101 SE B 26.26 2.9 28.82 3.7 31.09 4.6 33.08 5.5

106

111

114 SE B 27.14 3.0 29.98 3.7 32.53 4.6 34.83 5.5

SE A 12.13 3.3 15.20 5.4 17.74 8.1 19.47 11.1 21.17 14.5 22.61 18.3

OE C 20.69 2.9 21.98 3.5 22.56 4.2

OE A 15.57 5.3 18.15 7.8 20.03 10.7 21.73 14.1 23.15 17.8 24.35 21.8

OE C 20.52 3.2 22.00 4.0 23.27 4.9 23.97 5.9

SE A 15.76 3.5 18.69 5.1 20.99 7.0 22.59 9.2 24.21 11.6 25.60 14.3 26.80 17.2

OE C 24.64 2.7

OE A 16.53 5.3 19.62 7.9 21.97 10.8 24.12 14.1 25.96 17.9 27.54 21.9

OE C 22.64 3.2 24.51 4.0 26.14 5.0 27.07 6.0

OE A 16.42 5.3 19.49 7.9 21.86 10.8 24.06 14.1 25.97 17.9 27.63 21.9

OE C 22.62 3.2 24.55 4.0 26.25 5.0 27.26 6.0

SE A 19.40 2.3 22.24 3.2 24.68 4.2 26.77 5.3 28.57 6.5 29.68 7.8

OE B 25.59 2.6 27.40 3.1 28.97 3.8

SE A 19.82 2.3 22.86 3.2 25.52 4.2 27.83 5.3 29.86 6.5 31.17 7.8

OE B 26.58 2.6 28.60 3.2 30.38 3.8

OE A 17.06 5.3 20.50 7.9 23.55 10.9 25.84 14.2 28.11 17.9 30.13 22.0

OE C 24.20 3.2 26.47 4.0 28.49 4.8 29.72 6.0

OE A 20.82 2.9 24.15 4.0 27.09 5.2 29.68 6.5 31.96 8.0 33.95 9.7

OE C 31.51 2.5

SE A 20.27 2.3 23.54 3.2 26.45 4.2 29.05 5.3 31.36 6.5 33.41 7.8

OE B 27.71 2.6 30.00 3.2 32.04 3.8

SE A 20.74 3.0 24.01 4.2 26.89 5.4 29.43 6.9 31.67 8.4 33.64 10.1

OE B 25.87 2.6 28.39 3.3 30.61 4.1 32.58 4.9

OE A 21.23 2.9 24.78 4.0 27.98 5.2 30.87 6.6 33.46 8.1 35.77 9.7

OE C 33.11 2.5

GPM

BFF Conn. Coil 120 140 160 180 200 250 300 350

Size Loc. Circ. MBH PDF MBH PDF MBH PDF MBH PDF MBH PDF MBH PDF MBH PDF MBH PDF

065

069

073

081

086

088 OE B 31.53 5.2 32.96 6.8 34.48 8.6 35.72 10.5 36.74 12.7 38.67 18.8

096 OE B 33.34 5.2 35.05 6.8 36.87 8.6 38.37 10.6 39.63 12.7 42.02 18.8

097

101 SE B 36.41 7.6 38.44 9.9 40.49 12.5 42.18 15.3 43.59 18.4

106 OE B 35.51 5.2 37.61 6.8 39.83 8.6 41.69 10.6 43.28 `12.7 36.36 18.8

111 OE B 35.89 6.7 38.00 8.8 40.08 11.1 41.81 13.7 43.27 16.4

114 SE B 38.75 7.6 41.26 9.9 43.80 12.5 45.92 15.4 47.73 18.5

Connection Locations: SE = Same End

SE B 25.48 13.4 26.87 17.5 28.00 22.1

OE C 24.32 5.8 25.73 7.6 26.89 9.6 27.86 11.8 28.68 14.2 30.27 21.0

SE B 26.52 19.0

OE C 25.67 8.1 27.00 10.7 28.08 13.5 28.96 16.6 29.70 19.9

SE B 27.29 7.5 28.84 9.8 30.08 12.4 31.10 15.3 31.95 18.4

OE C 26.74 3.8 27.77 4.8 29.05 6.1 30.10 7.5 30.99 9.0 32.70 13.3 33.91 18.3

SE B 30.43 19.1

OE C 29.31 8.2 31.08 10.7 32.53 13.5 33.72 16.6 34.72 20.0

SE B 30.80 19.1

OE C 29.65 8.2 31.60 10.7 33.21 13.5 34.56 16.7 35.71 20.0

SE A 32.09 10.7

SE C 29.23 2.5 31.37 3.3 33.07 4.1 34.46 5.1 35.00 6.1 37.09 9.1 38.57 12.5 39.67 16.4

SE A 33.98 10.7

SE C 30.77 2.5 33.23 3.3 35.24 4.2 36.89 4.1 37.57 6.1 40.12 9.1 41.96 12.5 43.35 16.4

SE B 34.02 19.2

OE C 32.62 8.2 35.01 10.8 37.00 13.6 38.68 16.7 40.11 20.1

OE A 36.73 13.3

OE C 34.88 3.4 37.56 4.5 39.14 5.6 40.85 6.9 42.30 8.3 45.06 12.3 47.01 16.9

SE A 36.23 10.8 38.94 14.1 41.16 17.8 43.01 21.9

SE C 32.60 2.5 35.50 3.3 37.91 4.2 39.93 5.1 40.80 6.2 44.01 9.1 46.37 12.5 48.19 16.4

SE A 36.46 13.9

SE C 33.60 3.2 36.34 4.2 38.57 5.3 40.44 6.5 41.37 7.9 44.28 11.6 46.39 16.0

OE A 39.72 13.3 42.22 17.4 44.77 22.0

OE C 37.03 3.4 40.24 4.5 42.21 5.6 44.34 6.9 46.16 8.3 49.72 12.3 52.29 17.0

OE = Opposite End

GPM

5

Page 6

BOHN DIRECT DRIVE FLUID COOLERS

BOHN DIRECT DRIVE FLUID COOLERS

Capacity Ratings Belt Drive Fluid Coolers

Table 5C. MBH/˚T.D. — 40% Glycol — Average Fluid Temperature 130˚F (Sizes 121 - 228)

BFF Conn. Coil 30 40 50 60 70 80 90 100

Size Loc. Circ. MBH PDF MBH PDF MBH PDF MBH PDF MBH PDF MBH PDF MBH PDF MBH PDF

121

136 SE B 26.08 2.9 29.86 3.8 33.37 4.9 36.61 6.0 39.60 7.2

139

145 OE B 28.82 3.2 32.05 4.1 35.00 5.0 37.67 6.0

151 SE B 26.41 2.9 30.36 3.9 34.08 4.9 37.57 6.0 40.83 7.2

159 OE B 29.28 3.2 32.67 4.1 35.81 5.0 38.68 6.1

167 OE B 26.08 2.9 29.85 3.8 33.34 4.8 36.57 6.0 39.54 7.2

179 OE B 29.79 3.2 33.39 4.1 36.74 5.0 39.87 6.1

182 OE B 26.33 2.9 30.21 3.8 33.85 4.9 37.24 6.0 40.39 7.2

200 SE B 23.07 3.1 27.53 4.3 31.87 5.6 36.06 7.1 40.08 8.8 43.90 10.6

209 OE B 26.60 2.9 30.62 3.8 34.42 4.9 38.00 6.0 41.37 7.2

228 SE B 23.14 3.1 27.66 4.3 32.08 5.6 36.38 7.1 40.54 8.8 44.55 10.6

SE A 21.04 3.0 24.45 4.2 27.52 5.4 30.25 6.9 32.70 8.5 34.87 10.2

OE B 26.47 2.6 29.18 3.3 31.59 4.1 33.75 4.9

OE A 22.54 3.7 26.64 5.2 30.50 6.8 34.09 8.6 37.41 10.6 40.45 12.7

OE C 37.98 3.2

SE A 21.44 3.0 25.07 4.2 28.40 5.5 31.42 6.9 34.17 8.5 36.66 10.2

OE B 27.34 2.6 30.31 3.3 33.00 4.1 35.45 4.9

SE A 22.21 3.7 26.11 5.1 29.72 6.7 33.02 8.5 36.03 10.4 38.76 12.6

SE C 35.14 2.9

OE A 22.71 3.8 26.94 5.2 30.97 6.8 34.77 8.6 38.35 10.6 41.68 12.7

OE C 39.19 3.2

SE A 22.38 3.7 26.40 5.1 30.15 6.7 33.63 8.5 36.84 10.5 39.79 12.6

SE C 36.07 2.9

SE A 18.30 3.0 22.62 4.4 26.72 6.1 30.57 8.0 34.14 10.1 37.44 12.4 40.47 14.9

SE C 34.35 2.8 37.27 3.4

SE A 22.57 3.7 26.71 5.1 30.63 6.7 34.32 8.5 37.77 10.5 40.98 12.6

SE C 37.19 2.9

SE A 18.36 3.0 22.74 4.4 26.93 6.1 30.90 8.0 34.62 10.1 38.10 12.4 41.32 15.0

SE C 35.02 2.8 38.10 3.4

OE A 18.65 3.7 23.24 5.5 27.76 7.6 32.16 9.9 36.42 12.6 40.52 15.5 44.42 18.7

OE C 31.12 2.5 35.21 3.2 39.12 3.9 42.84 4.7

SE A 18.43 3.0 22.88 4.4 27.16 6.1 31.26 8.0 35.16 10.1 38.84 12.4 42.29 15.0

SE C 35.79 2.8 39.06 3.4

OE A 18.67 3.7 23.29 5.5 27.85 7.6 32.33 9.9 36.69 12.6 40.93 15.5 45.02 18.7

OE C 35.60 3.2 39.65 3.9 43.55 4.7

GPM

BFF Conn. Coil 120 140 160 180 200 250 300 350

Size Loc. Circ. MBH PDF MBH PDF MBH PDF MBH PDF MBH PDF MBH PDF MBH PDF MBH PDF

121 OE B 37.43 6.7 39.84 8.8 42.22 11.1 44.22 13.7 45.92 16.5

136 SE B 44.84 9.9 48.56 13.0 52.10 16.4 55.10 20.1

139 OE B 39.72 6.8 42.64 8.9 45.52 11.2 47.98 13.7 50.11 16.5

145 OE B 42.39 8.3 45.57 10.9 48.64 13.7 51.23 16.9 53.43 20.3

151 SE B 46.69 9.9 51.03 13.0 55.20 16.4 58.81 20.2

159 OE B 43.76 8.3 47.42 10.9 50.89 13.8 53.86 16.9

167

179 OE B 45.48 8.3 49.67 10.9 53.68 13.8 57.16 16.9 60.21 20.4

182 OE B 46.03 9.9 50.32 12.9 54.33 16.3 57.80 20.1

200 SE B 50.98 14.5 56.78 19.0

209 OE B 47.49 9.9 52.29 13.0 56.82 16.4 60.79 20.1

228

Connection Locations: SE = Same End OE = Opposite End

SE A 38.05 14.0

SE C 34.95 3.2 38.01 4.2 40.54 5.3 42.67 6.5 43.78 7.9 47.17 11.6 49.67 16.0

OE A 45.24 17.5

OE C 43.12 4.4 47.45 5.8 51.10 7.3 53.36 9.0 55.89 10.8 60.84 16.0

SE A 40.42 14.0 43.89 18.3

SE C 36.98 3.2 40.55 4.2 43.57 5.3 46.16 6.6 47.57 7.9 51.82 11.7 55.02 16.0 57.51 21.0

SE A 42.97 17.3

SE C 39.75 3.9 43.59 5.2 46.80 6.5 49.52 8.0 51.08 9.6 55.41 14.2 58.57 19.5

OE A 47.11 17.5

OE C 44.90 4.4 49.82 5.8 54.09 7.4 56.85 9.0 59.93 10.9 66.10 16.0 70.69 22.0

SE A 44.45 17.3

SE C 41.07 3.9 45.29 5.2 48.88 6.5 51.96 8.0 53.80 9.6 58.84 14.2 62.59 19.6

OE B 44.77 9.9 48.67 12.9 52.28 16.3 55.37 20.0

SE C 43.42 4.7 46.78 6.1 50.49 7.7 53.67 9.5 55.70 11.4 60.92 16.8 64.78 23.1

SE A 46.20 17.3

SE C 42.65 4.0 47.37 5.2 51.47 6.5 55.05 8.0 57.26 9.7 63.31 14.3 67.91 19.6

SE A 46.65 20.6

SE C 43.60 4.7 48.33 6.1 52.42 7.7 55.97 9.5 58.29 11.4 64.25 16.8 68.74 23.1

OE A 51.29 25.7

OE C 49.70 6.5 55.81 8.5 61.22 10.7 65.25 13.2 69.31 15.8 77.54 23.4

SE A 48.12 20.6

SE C 45.00 4.7 50.20 6.1 54.76 7.7 58.79 9.5 61.51 11.4 68.49 16.9

SE B 52.08 14.6 58.44 19.1

OE C 50.85 6.5 57.48 8.5 63.47 10.8 68.10 13.2 72.77 15.9 82.50 23.4

GPM

6

Page 7

Optional Accessories

BOHN DIRECT DRIVE FLUID COOLERS

BOHN DIRECT DRIVE FLUID COOLERS

Optional Cooling Coils

The standard coil construction and fin pattern is compatible with

most system environments. Where the fluid cooler is subject to

a contaminated or corrosive airstream, special coils may be

required. A vailable for these applications are coils with wider fin

spacing for easier cleaning, coils Heresite® coated to reduce

corrosion (up through 169" long cabinet), polyester painted fins

for salt atmosphere protection (BOHNGUARD®), and copper fin/

copper tube coils for all models.

Extended Lube Lines

Available on belt drive units, extended lube lines are factory

installed with external grease fittings to make lubrication routine.

Low Ambient Operation

Fan Control

Fan control is an automatic operation to control the leaving fluid

temperature by cycling fans off in sequence. Each fan section,

with the exception of the number one cell, operates under the

control of an individual thermostat which senses leaving fluid

temperature. As the fluid temperature drops below the set point

of each thermostat, that fan section cycles off. The number one

fan section remains on at the full fan cycling. Cooler capacity

drops to the approximate capacity percentages shown in the table

below.

Connection Manifold Kit

This field installed kit converts the standard dual circuit cooler

(direct drive models and belt drive models) to one having a single

inlet and outlet connection.

Sealtite Wiring

Sealtite wiring is watertight, flexible conduit and fittings for fan

motors. It is factory installed and replaces the standard THW

wiring.

NOTE: The standard fan control packages use individual

thermostats to cycle fans. This method of control will allow leaving

fluid temperatures to fluctuate between fan cycling points. For

applications requiring precise fluid temperature control during

all periods of operation, contact the factory applications

department.

Multiple Contactor Fan Cycling:

Consists of a factory mounted and wired, weatherproofed

enclosure containing starting contactors (with holding coils) and

thermostat(s) with sensing bulb strapped to coil outlet header.

Specify control voltage on order: 24V, 115V or 208-230V

available.

The fan control thermostats must be field adjusted to meet design

requirements. The maximum temperature setting for the standard

control thermostat is 100˚F. For applications requiring precise

fluid temperature control during all periods of operation, contact

the factory applications department.

Table 6. Capacity at Maximum Fan Control

One Fan Cell Operating

Table 7. Belt Drive Fluid Cooler Volume in Gallons

BFF Volume BFF Volume BFF Volume

Unit Gallons Unit Gallons Unit Gallons

045 19.3 086 26.3 139 43.1

050 19.3 088 33.7 145 52.5

054 19.3 096 33.7 151 52.9

057 19.3 097 26.3 159 52.5

059 24.3 101 41.1 167 62.0

062 19.3 106 26.3 179 52.5

065 19.3 111 43.1 182 62.0

069 26.3 114 41.1 200 76.4

073 24.3 121 43.1 209 62.0

081 26.3 136 52.9 228 76.4

Fans % Total

Available Capacity

2 55%

3 40%

4 33%

5 28%

6 25%

7

Page 8

BOHN DIRECT DRIVE FLUID COOLERS

BOHN DIRECT DRIVE FLUID COOLERS

Physical / Dimensional Data

Diagram 1.Dimensional Diagram for models BFF 45-228

8

Page 9

BOHN DIRECT DRIVE FLUID COOLERS

BOHN DIRECT DRIVE FLUID COOLERS

Dimensional and Physical Data

Table 8A. Dimensions

BFF Dimensions 48" Fans

Size A D E F G J K L M R S Y Qty. RPM CFM

045 114 110 --- ---- 315/82113/

5

050 114 110 --- ---- 31

054 114 110 --- ---- 31

/82113/

5

/82113/

057 114 110 --- ---- 315/82113/

1

/

059 114 110 --- ---- 30

062 114 110 --- ---- 31

065 114 110 --- ---- 31

069 169 165 82 83 31

073 114 110 --- --- 30

4

5

/82113/

5

/82113/

5

/82113/

1

/

4

081 169 165 82 83 315/82113/

5

086 169 165 82 83 31

088 169 165 82 83 30

096 169 165 82 83 30

097 169 165 82 83 31

101 169 165 82 83 28

/82113/

1

/42113/162113/16421/4421/461/2115/

1

/42113/162113/16421/4421/461/2115/

5

/82113/

7

/82113/162113/16421/4421/4615/

106 169 165 82 83 301/42113/162113/16421/4421/461/2115/

1

111 224 220 109

114 169 165 82 83 28

121 224 220 109

136 224 220 109

139 224 220 109

/21101/2301/42113/162113/16421/4421/4611/

7

1

/21101/2301/42113/162113/16421/4421/4611/

1

/21101/2287/82113/162113/16421/4421/4615/

1

/21101/2301/42113/162113/16421/4421/4611/

/82113/162113/16421/4421/4615/

145 279 275 821/21101/2301/42113/162113/16421/4421/4615/

1

151 224 220 109

159 279 275 82

167 334 330 109

179 279 275 82

182 334 330 109

200 334 330 1091/21101/2299/

209 334 330 109

228 334 330 109

/21101/2287/82113/162113/16421/4421/4615/

1

/21101/2301/42113/162113/16421/4421/4615/

1

/21101/2301/42113/162113/16421/4421/4615/

1

/21101/2301/42113/162113/16421/4421/4615/

1

/21101/2301/42113/162113/16421/4421/4615/

1

/21101/2301/42113/162113/16421/4421/4615/

1

/21101/2299/

16

16

16

225/

225/

237/16417/16417/

16

237/16417/16417/

16

237/16417/16417/

16

237/16417/16417/

8

237/163913/163513/1661/2115/

16

237/16417/16417/

16

237/16417/16417/

16

237/16417/163913/1661/2115/

8

237/163913/163513/1661/2115/

16

237/16417/163913/1661/2115/

16

237/16417/163913/1661/2115/

16

237/16417/163913/1661/2115/

16

16

16

16

16

16

61/2115/

61/2115/

61/2115/

61/2115/

61/2115/

61/2115/

2113/162113/16421/4421/4615/

2113/162113/16421/4421/4615/

16

--- 2 415 32,800

16

--- 2 470 35,000

16

--- 2 470 34,400

16

--- 2 600 51,200

16

--- 2 470 31,200

16

--- 2 600 50,100

16

--- 2 600 48,200

16

--- 3 415 44,000

16

--- 2 600 49,200

16

--- 3 470 51,600

16

--- 3 600 76,800

16

--- 3 470 46,800

16

--- 3 545 54,300

16

--- 3 600 72,300

16

27/

16

--- 3 545 58,800

16

--- 3 600 66,000

16

23/

16

--- 4 470 72,000

16

27/

16

--- 3 600 67,600

16

23/

16

--- 4 545 78,000

16

27/

16

--- 4 545 82,400

16

23/

16

--- 4 600 99,200

16

27/

16

821/

2

5 470 81,500

16

27/

16

--- 4 600 100,400

16

27/

16

821/

2

5 545 94,000

16

27/

16

110 6 470 101,400

16

27/

16

821/

2

5 600 114,500

16

27/

16

110 6 545 117,000

16

27/

16

110 6 545 123,600

16

27/

16

110 6 600 142,200

16

27/

16

110 6 600 150,600

9

Page 10

BOHN DIRECT DRIVE FLUID COOLERS

BOHN DIRECT DRIVE FLUID COOLERS

Table 8B. Physical Data

Motors Internal Approximate

BFF Full Load Amps (Three Phase) Volume Dry Weight

Size HP 208V 230V 460V Gallons (Lbs.)

045 11/

050 2 13.4 13.2 6.6 19.3 1340

054 2 13.4 13.2 6.6 19.3 1380

057 5 29.2 26.4 13.2 19.3 1370

059 2 13.4 13.2 6.6 24.3 1540

062 5 29.2 26.4 13.2 19.3 1420

065 5 29.2 26.4 13.2 19.3 1450

069 1

073 5 29.2 26.4 13.2 24.3 1610

081 2 20.1 19.8 9.9 26.3 2110

086 5 43.8 39.6 19.8 26.3 2095

088 2 20.1 19.8 9.9 33.7 2335

096 3 27.9 25.2 12.6 33.7 2380

097 5 43.8 39.6 19.8 26.3 2395

101 3 27.9 25.2 12.6 41.1 2460

106 5 43.8 39.6 19.8 26.3 2440

111 2 26.8 26.4 13.2 43.1 2910

114 5 43.8 39.6 19.8 41.1 2580

121 3 37.2 33.6 16.8 43.1 2970

136 3 37.2 33.6 16.8 52.9 3370

139 5 58.4 52.8 26.4 43.1 3050

145 2 33.5 33.0 16.5 52.5 3850

151 5 58.4 52.8 26.4 52.9 3450

159 3 46.5 42.0 21.0 52.5 3900

167 2 40.2 39.6 19.8 62.0 4525

179 5 73.0 66.0 33.0 52.5 3950

182 3 55.8 50.4 25.2 62.0 4575

200 3 55.8 50.4 25.2 76.4 4995

209 5 87.6 79.2 39.6 62.0 4695

228 5 87.6 79.2 39.6 76.4 5115

2

1

/

2

11.0 10.0 5.0 19.3 1280

16.5 15.0 7.5 26.3 1960

10

Page 11

Engineering Specifications

BOHN DIRECT DRIVE FLUID COOLERS

BOHN DIRECT DRIVE FLUID COOLERS

Unit Cabinet -

Casings shall be constructed of heavy gauge corrosion resistant

aluminum, or galvanized steel, thoroughly reinforced with bolted

gussets. Full width baffles shall divide the individual fan sections.

Motor access panels shall be provided in each fan section.

Cabinet mounting frames and mounting legs shall be constructed

of heavy galvanized steel. The legs shall be shipped with the

unit for field installations.

Coil -

Coil shall be constructed of plate type, die formed, aluminum

fins mechanically bonded to copper tubes; fins shall employ full

height, self-spacing collars which completely cover tube surface.

Coil shall be pressure and leak tested at 425 PSIG air under

warm water, evacuated, dehydrated and sealed with caps on

connections.

Fans -

Fans, each driven by its own motor, shall be selected to cover a

large percentage of the coil face area. Fans shall be statically

and dynamically balanced before shipment. Low tip speeds shall

provide quiet operation.

Fan Motors -

Motors shall be NEMA type “T” frame, open drop-proof with

grease lubricated ball bearings. They shall be thermally protected

against burnout, and may be started by a single contactor. Motors

shall be factory wired with leads marked and terminated in a

weatherproof junction box located on the outside of the unit. They

shall be positioned within unit casing for weather protection.

Adjustable motor mount bases and large, easy access motor

compartment panels. Available in 208V, 230V, 460V and 575V,

three phase 60 Hz. models: and 200V, 380V and 415V, three

phase 50 Hz. models.

Fan Guards -

Guards shall be constructed of heavy gauge, close meshed steel

wire that is zinc plated and iridite dipped to prevent corrosion.

U.L. Listing -

All 60 Hz. models (except 575V) shall be U.L. listed.

Drives & Bearings -

Each fan shall be equipped with a heavy duty , weather protected,

pillow block bearing with lubricating fitting accessible through

the motor access panel. Fan shafts shall be polished steel,

precision machined and coated with corrosion resistant dressing.

V-belt and cast iron drive pulleys shall be matched for heavy

duty continuous operation.

11

Page 12

Bohn is a product line of

Heatcraft Refrigeration Products

2175 W. Park Place Blvd.

Stone Mountain, GA 30087 • (770) 465-5600 • Fax: (770) 465-5990

Visit our web site at

www.heatcraftrpd.com

for technical literature online.

Loading...

Loading...