Page 1

BNHCUTB

July

2016

3-22 HP CONDENSING UNITS

Technical Guide

Scroll® and Discus® Models

Replaces BN-HCUTB,

September 2015

heatcraftrpd.com

Page 2

TABLE OF CONTENTS

Nomenclature ........................................................................................................................................................................................................................................................2

Standard Features ................................................................................................................................................................................................................................................3

Options ................................................................................................................................................................................................................................................................3-4

Scroll Compressor Models

Performance Data ......................................................................................................................................................................................................................................... 5-12

Medium Temperature ...........................................................................................................................................................................................................................5-8

R-404A/R-507 ...............................................................................................................................................................................................................................................5

R-407A/R-407F

R-407C ............................................................................................................................................................................................................................................................7

R-448A/449A ................................................................................................................................................................................................................................................8

Low Temperature ................................................................................................................................................................................................................................. 9-12

R-404A/R-507 ...............................................................................................................................................................................................................................................9

R-407A/R-407F

R-407C ......................................................................................................................................................................................................................................................... 11

R-448A/449A ............................................................................................................................................................................................................................................ 12

Electrical Data ........................................................................................................................................................................................................................................... 13

Unit Specications................................................................................................................................................................................................................................... 14

Discus Compressor Models

Performance Data .......................................................................................................................................................................................................................................15-24

Medium Temperature ......................................................................................................................................................................................................................15-19

R-404A/R-507 ............................................................................................................................................................................................................................................ 15

R-407A/R-407F

R-407C ......................................................................................................................................................................................................................................................... 17

R-448A/449A ............................................................................................................................................................................................................................................ 18

R-22 ............................................................................................................................................................................................................................................................... 19

Low Temperature ...............................................................................................................................................................................................................................20-24

R-404A/R-507 ............................................................................................................................................................................................................................................ 20

R-407A/R-407F

R-407C ......................................................................................................................................................................................................................................................... 22

R-448A/449A ............................................................................................................................................................................................................................................ 23

R-22 ............................................................................................................................................................................................................................................................... 24

Electrical Data ........................................................................................................................................................................................................................................... 25

Unit Specications................................................................................................................................................................................................................................... 26

Dimensional Diagrams .......................................................................................................................................................................................................................... 27

.............................................................................................................................................................................................................................................6

.......................................................................................................................................................................................................................................... 10

.......................................................................................................................................................................................................................................... 16

.......................................................................................................................................................................................................................................... 21

B

ModelDCompressorTApplication

B = Bohn D = Discus

Z = Scroll

®

®

T = Outdoor

N = Indoor

S = Beacon II

2

0300 = 3HP

0400 = 4HP

™

0500 = 5HP

0501 = 5HP

0600 = 6HP

0601 = 6HP

0650 = 6.5HP

0700 = 7HP

0750 = 7.5HP

Nomenclature

0500

Equiv. HP

0751 = 7.5HP

0800 = 8HP

0860 = 8.5HP

0900 = 9HP

1000 = 10HP

1200 = 12HP

1300 = 13HP

1401 = 14HP

1500 = 15HP

2200 = 22HP

L

Temperature6Refrigerant

M = Med. Temp.

L = Low Temp.

6 = R-404A,

R-507

Scrolls also

compatible

with R-407A,

R-407C, R407F,

R-448A/449A

Discus also

compatible

with R-407A,

R-407C, R407F,

R-448A/449A

©2016 Heatcraft Refrigeration Products, LLC

C

Voltage

C = 208-230/3/60

(200-220/3/50)*

D = 460/3/60

(380-420/3/50)*

E = 575/3/60

*Limited by

compressor

model

Page 3

STANDARD FEATURES

™

• Floating Tube™ coil design

• Suction and discharge vibration eliminators with Copeland Discus® compressors

• Spring mounting with Discus® compressors

• Fixed high and adjustable low pressure switches

• Discharge line check valve with medium and low temperature Copeland Scroll® compressors

• Discharge line thermostat with medium temperature Scroll® compressors

• Liquid injection with low temperature Scroll® compressors

• Manual pumpdown switch

• Refrigeration-duty, ried copper condenser tubing

• Crankcase heater and head pressure valve on all outdoor units

• Sight glass and permanent liquid line lter

Better Performance

• Enhanced grill design gives 25% to 40% increase in free-air area

• Electrical box located out of air stream

• Vertical receiver needs less refrigerant for liquid seal

Faster Access

• Base valve and high & low pressure taps on outside of unit

• Removable grill for access to all serviceable parts

• Improved access to fan motors & components

• Lighter, one-piece top

• Easy-to-view sight glass location

Easier Service

• Better access to components for easier repair

• Compact design allows for better jobsite placement

& installation

• Dual isolation valves on receiver

Greater Reliability

• Floating Tube™ coil design eliminates tube-sheet

leaks

• Pre-bent tubing reduces mechanical joints

• State-of-the-art factory leak-detection ensures

highest quality

OPTIONS

Beacon II™ Refrigeration System

Beacon II™ is a Heatcraft patented, preassembled, factory installed refrigeration system featuring an integrated microcomputer

based electronic control board. The Beacon II™ systems come completely factory installed, wired and tested saving you time and

money.

Beacon II™ oers:

• Complete factory installation, wiring and testing which saves time and money

• Simple eld electrical connections and 24 volt wiring between condensing and evaporator units

• Preset factory superheat allowing the system to run more eciently and reducing future adjustments

• Monitors and controls box temperature, evaporator superheat, condenser fan cycling on two fan units, system status and defrost from outside the box

• Data logging capabilities with Smart Controller

Beacon II™ Smart Controller

Beacon II™ Smart Controller is an optional system monitoring and programming control device.

It allows for adjustments to be made at the push of a button from a conveniently mounted

location. The Beacon II™ Smart Controller also allows you to monitor and make changes to the

refrigeration system via remote connection from anywhere in the world. The Beacon II™ has been updated to allow the user to

make even more precise adjustments than the original Beacon’s Smart Controller. One Smart Controller can program and control

up to four separate condensing units with up to four evaporators on each system. That’s more control in your hands!

™

Beacon II

The Beacon II™ Smart Defrost, available only on the Beacon II™ Smart Controller, enables the

Beacon II™ system to sense frost accumulation and initiates defrost only when it is necessary.

To begin, preset defrost times using the Beacon II™ Smart Controller. At each scheduled defrost

time, Smart Defrost checks system performance to see if a defrost is necessary. If not, it simply

does not defrost, waiting until the next scheduled defrost time.

Smart Defrost

3

Page 4

Smart Defrost Kit™

The Smart Defrost Kit (SDK), available as a factory-installed option is a control module that can reduce the number of defrosts

by up to 40% on a typical commercial refrigeration system. This reduces energy consumption and costs.

Scroll® Compressors

Bohn condensing units are available with Copeland Scroll® compressors. Copeland Scroll®

compressors are hermetically sealed so no service is required. The Scroll’s® ability to handle liquid

refrigerant makes it extremely reliable and, in low temperature applications, liquid injection is

provided to lower discharge temperatures under adverse conditions. Also, nuisance oil safety

trips are eliminated because the Scroll® doesn’t require an oil pressure sensing device.

Electrical Options Mechanical Options

• Smart Defrost Kit™ (SDK)

• Crankcase heater on indoor units

• Mounted fused disconnect

• Fan cycling

• Low ambient kit (Heated & insulated receiver with low

pressure cut-out time delay)

• Defrost timer for air defrost

• Defrost timer & contactor for electric defrost includes

evaporator fan subfusing (Only the large 2 fan units

have evaporator fan sub-fusing included as standard in

the Electric Defrost kit)

• Beacon II™ kits (see Beacon II™ section for details)

• Electric Defrost Fusing (includes evaporator fan fusing on

1 fan and 2 fan units)

• Dual-pressure control*

• Adjustable high pressure control with manual reset*

• Phase-loss monitor*

• Compressor fusing*

• Circuit breaker circuit protection for compressor,

condenser fan and control circuit*

• Head pressure valve on indoor units

• Mounted liquid line solenoid valve

• Replaceable core liquid line lter/drier

• Permanent suction line lter

• Replaceable core suction line lter

• Suction accumulator

• Oil separator

• Bohnguard

• Copper nned coil

• Oversized receiver

• Slanted louver for snowbelt regions (not available with

indoor unit)

• 12" extended legs for snowbelt regions

• Hail guards

• NEMA contactors*

• Compressor unloading (one step)*

™

n protection

* Available on large two-fan cabinet only

4

Page 5

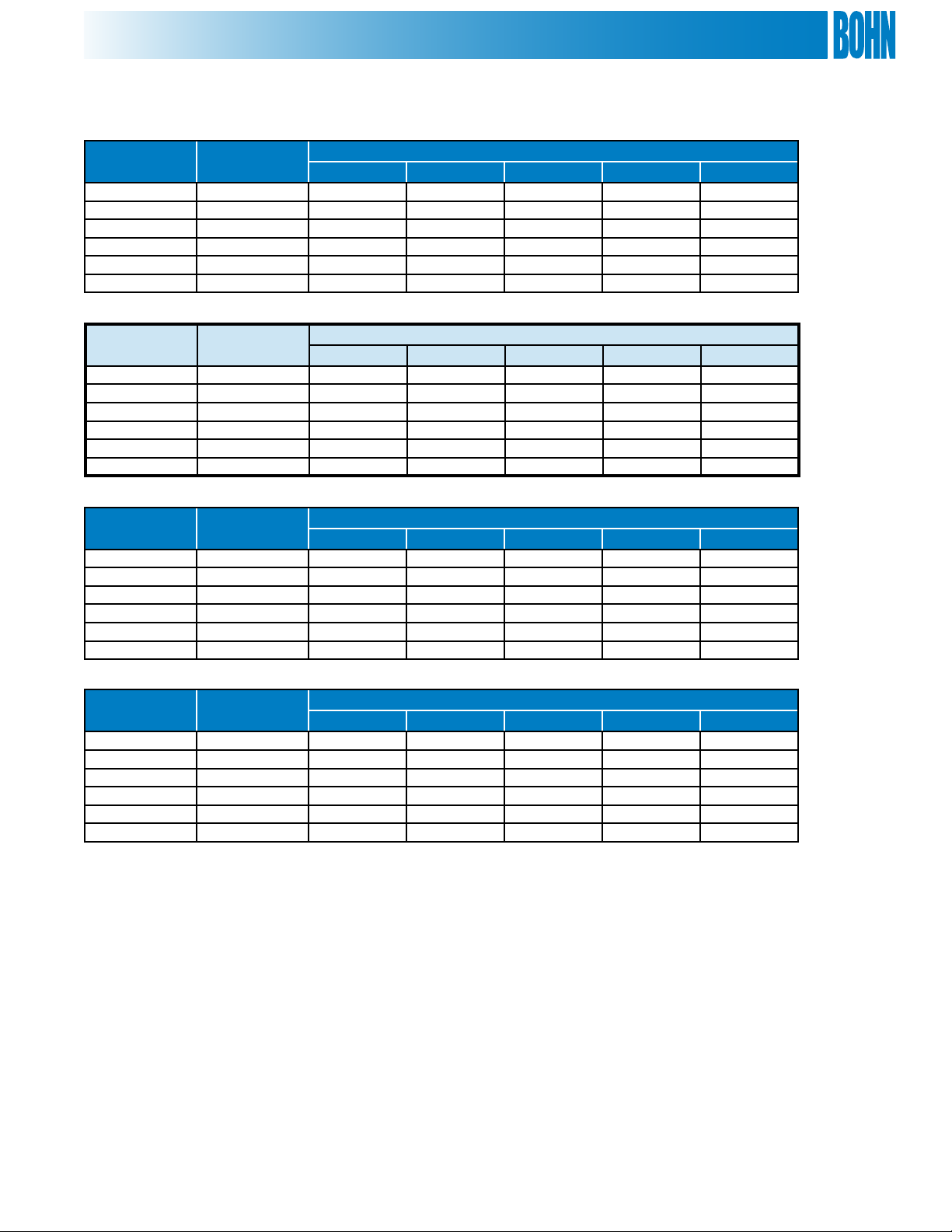

PERFORMANCE DATA

Scroll Compressors - Medium Temperature Applications - R-404A/507

Model Compressor

BZ*0650M6 ZB48KCE 73,820 63,560 58,750 54,140 45,560

BZ*0700M6 ZB58K5E 89,490 78,520 72,930 67,220 55,640

BZ*0750M6 ZB66K5E 101,820 89,790 83,570 77,340 65,010

BZ*0860M6 ZB76K5E 112,460 100,510 94,050 87,480 73,830

BZ*1000M6 ZB95K5E 135,560 121,480 113,480 104,610 89,330

BZ*1401M6 ZB114K5E 163,950 144,760 134,110 124,310 105,470

Model Compressor

BZ*0650M6 ZB48KCE 70,090 60,410 55,880 51,500 43,300

BZ*0700M6 ZB58K5E 85,490 74,920 69,460 63,990 52,860

BZ*0750M6 ZB66K5E 97,640 86,190 80,250 74,290 62,450

BZ*0860M6 ZB76K5E 107,350 96,150 90,090 83,760 71,100

BZ*1000M6 ZB95K5E 129,960 116,720 108,200 100,490 85,340

BZ*1401M6 ZB114K5E 157,320 138,240 128,920 119,450 102,300

Model Compressor

BZ*0650M6 ZB48KCE 66,330 57,210 52,940 48,790 41,030

BZ*0700M6 ZB58K5E 81,120 71,190 66,020 60,830 50,350

BZ*0750M6 ZB66K5E 93,460 82,610 76,960 71,250 59,880

BZ*0860M6 ZB76K5E 102,270 91,950 86,040 80,050 68,040

BZ*1000M6 ZB95K5E 124,400 110,910 104,720 97,380 82,700

BZ*1401M6 ZB114K5E 150,780 132,610 123,660 115,580 97,690

Capacity BTUH @ 90°F Ambient Suction Temperature

40°F 30°F 25°F 20°F 10°F

Capacity BTUH @ 95°F Ambient Suction Temperature

40°F 30°F 25°F 20°F 10°F

Capacity BTUH @ 100°F Ambient Suction Temperature

40°F 30°F 25°F 20°F 10°F

Model Compressor

BZ*0650M6 ZB48KCE — 50,640 46,850 43,140 36,330

BZ*0700M6 ZB58K5E 72,150 63,775 59,100 54,390 44,670

BZ*0750M6 ZB66K5E 84,560 75,430 70,410 65,180 55,210

BZ*0860M6 ZB76K5E — 83,330 78,100 73,030 62,360

BZ*1000M6 ZB95K5E — — 95,780 89,190 75,650

BZ*1401M6 ZB114K5E 137,740 122,370 114,500 106,270 89,670

* = T for Outdoor, N for Indoor, S for Beacon II™

Consult factory on all models for applications above 110°F ambient.

Capacity BTUH @ 110°F Ambient Suction Temperature

40°F 30°F 25°F 20°F 10°F

5

Page 6

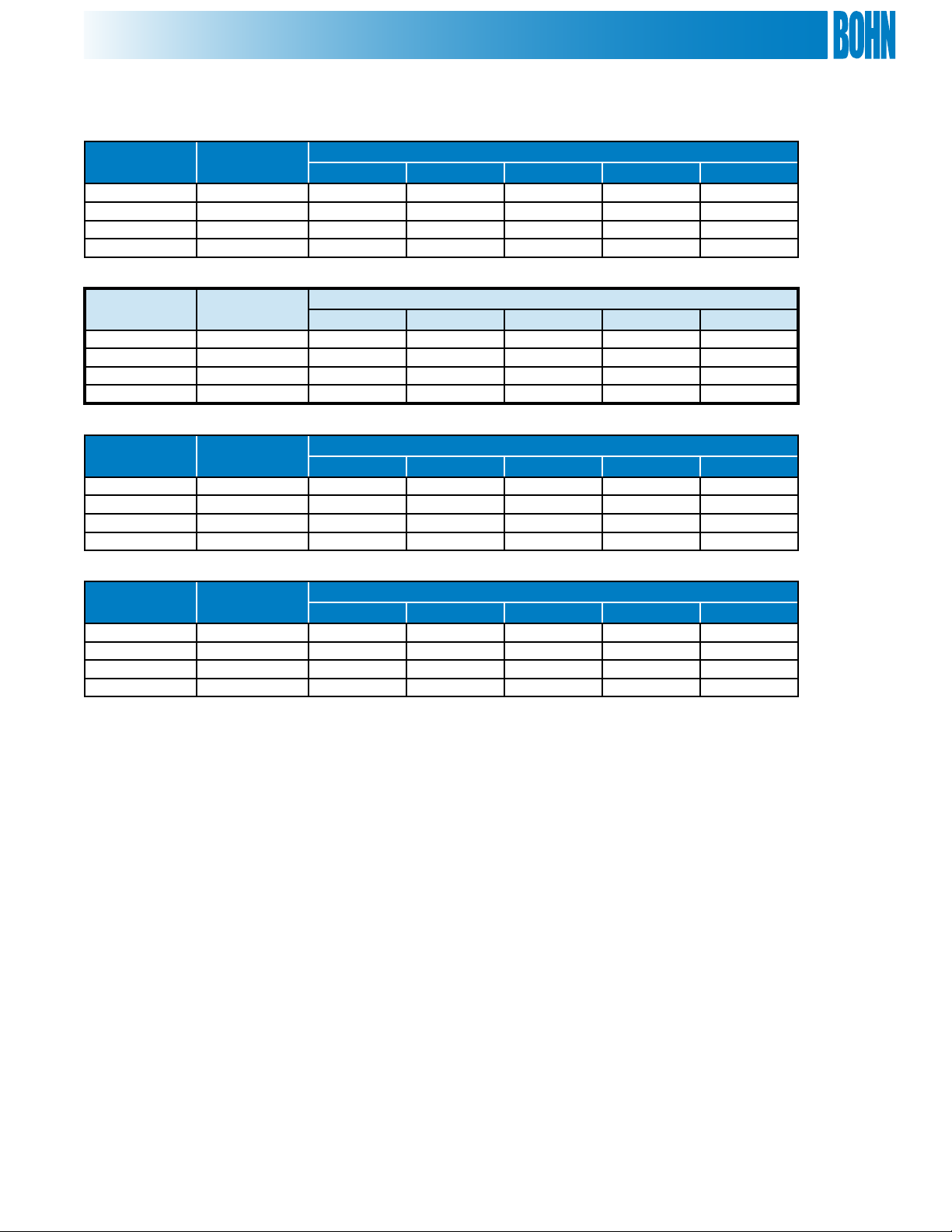

PERFORMANCE DATA

Scroll Compressors - Medium Temperature Applications - R-407A/R-407F

Model Compressor

BZ*0650M6 ZB48KCE

BZ*0700M6 ZB58K5E

BZ*0750M6 ZB66K5E

BZ*0860M6 ZB76K5E

BZ*1000M6 ZB95K5E

BZ*1401M6 ZB114K5E

Model Compressor

BZ*0650M6 ZB48KCE

BZ*0700M6 ZB58K5E

BZ*0750M6 ZB66K5E

BZ*0860M6 ZB76K5E

BZ*1000M6 ZB95K5E

BZ*1401M6 ZB114K5E

Model Compressor

BZ*0650M6 ZB48KCE

BZ*0700M6 ZB58K5E

BZ*0750M6 ZB66K5E

BZ*0860M6 ZB76K5E

BZ*1000M6 ZB95K5E

BZ*1401M6 ZB114K5E

Capacity BTUH @ 90°F Ambient Suction Temperature

40°F 30°F 25°F 20°F 10°F

1

1

1

1

1

1

76,280 64,810 59,180 53,760 43,650

94,040 78,560 71,560 65,120 53,190

106,180 89,280 81,200 73,370 59,070

119,660 101,250 92,710 84,650 69,720

138,870 118,800 108,900 98,680 79,120

176,690 149,530 136,030 122,860 98,640

Capacity BTUH @ 95°F Ambient Suction Temperature

40°F 30°F 25°F 20°F 10°F

1

1

1

1

1

1

72,990 62,040 56,660 51,480 41,790

90,300 75,670 68,980 62,780 51,150

101,900 85,640 77,840 70,340 56,630

114,730 97,420 89,330 81,680 67,300

132,120 112,960 103,490 93,720 75,120

168,950 142,600 129,640 117,320 94,120

Capacity BTUH @ 100°F Ambient Suction Temperature

40°F 30°F 25°F 20°F 10°F

1

1

1

1

1

1

69,610 59,210 54,090 49,150 39,890

86,440 72,640 66,230 60,260 48,810

97,490 81,890 74,430 67,260 54,180

109,720 93,500 85,880 78,600 64,780

- 106,970 97,950 88,700 71,160

161,070 136,150 123,610 111,680 89,430

Model Compressor

BZ*0650M6 ZB48KCE

BZ*0700M6 ZB58K5E

BZ*0750M6 ZB66K5E

BZ*0860M6 ZB76K5E

BZ*1000M6 ZB95K5E

BZ*1401M6 ZB114K5E

*=T for outdoor, N for indoor, S for Beacon IITM

Consult factory on all models for application above 110F ambient

20°F Maximum Superheat

1

R407F not available in 575/3/60.

1

1

1

1

1

1

Capacity BTUH @ 110°F Ambient Suction Temperature

40°F 30°F 25°F 20°F 10°F

- - 48,790 44,360 36,030

78,420 66,130 60,280 54,720 43,760

88,350 74,230 67,380 61,030 49,330

- 85,470 78,740 72,230 59,510

- - - - 63,350

- - - 100,200 80,360

6

Page 7

PERFORMANCE DATA

Scroll Compressors - Medium Temperature Applications - R-407C

Model Compressor

BZ*0650M6 ZB48KCE

1

Capacity BTUH @ 90°F Ambient Suction Temperature

40°F 30°F 25°F 20°F 10°F

69,940 58,290 52,650 47,210 36,960

BZ*0700M6 ZB58K5E 88,220 72,610 65,530 58,920 46,970

BZ*0750M6 ZB66K5E 100,240 82,340 74,230 66,810 53,350

BZ*0860M6 ZB76K5E 114,850 95,240 86,230 77,810 62,880

BZ*1000M6 ZB95K5E 134,540 111,080 100,260 90,240 71,800

BZ*1401M6 ZB114K5E 164,380 136,000 122,780 110,450 88,500

Model Compressor

BZ*0650M6 ZB48KCE

1

Capacity BTUH @ 95°F Ambient Suction Temperature

40°F 30°F 25°F 20°F 10°F

67,400 56,120 50,650 45,350 35,340

BZ*0700M6 ZB58K5E 85,560 70,300 63,350 56,830 45,070

BZ*0750M6 ZB66K5E 97,420 79,930 72,020 64,770 51,600

BZ*0860M6 ZB76K5E 111,440 92,450 83,700 75,540 61,080

BZ*1000M6 ZB95K5E 129,770 106,980 96,480 86,750 68,820

BZ*1401M6 ZB114K5E 159,110 131,570 118,720 106,730 85,360

Model Compressor

BZ*0650M6 ZB48KCE

1

Capacity BTUH @ 100°F Ambient Suction Temperature

40°F 30°F 25°F 20°F 10°F

64,790 53,880 48,560 43,410 33,620

BZ*0700M6 ZB58K5E 82,790 67,750 61,010 54,590 43,010

BZ*0750M6 ZB66K5E 94,500 77,460 69,730 62,650 49,770

BZ*0860M6 ZB76K5E 107,990 89,620 81,160 73,270 59,290

BZ*1000M6 ZB95K5E 124,860 102,820 92,800 83,160 65,740

BZ*1401M6 ZB114K5E 153,690 127,000 114,540 102,900 82,130

Model Compressor

BZ*0650M6 ZB48KCE

1

Capacity BTUH @ 110°F Ambient Suction Temperature

40°F 30°F 25°F 20°F 10°F

- 49,180 44,140 39,290 30,050

BZ*0700M6 ZB58K5E 76,850 62,500 55,940 49,710 38,520

BZ*0750M6 ZB66K5E 88,400 72,270 64,950 58,200 45,950

BZ*0860M6 ZB76K5E - 83,920 76,060 68,700 55,760

BZ*1000M6 ZB95K5E - - 84,740 75,710 59,380

BZ*1401M6 ZB114K5E - 117,570 105,890 94,950 75,410

*=T for outdoor, N for indoor, S for Beacon IITM

Consult factory on all models for application above 110F ambient

20°F Maximum Superheat

1

R407C not available in 575/3/60.

7

Page 8

PERFORMANCE DATA

Scroll Compressors - Medium Temperature Applications - R-448A/R-449A

Model Compressor

BZ*0650M6 ZB48KCE 76,570 64,190 58,380 52,900 43,030

BZ*0700M6 ZB58K5E 93,760 77,070 69,420 62,320 49,780

BZ*0750M6 ZB66K5E 105,840 87,450 78,910 70,970 57,020

BZ*0860M6 ZB76K5E 119,560 99,340 89,900 81,030 65,540

BZ*1000M6 ZB95K5E 142,240 117,890 106,580 96,200 78,060

BZ*1401M6 ZB114K5E 179,600 147,130 132,340 118,830 95,380

Model Compressor

BZ*0650M6 ZB48KCE 73,590 61,760 56,200 50,970 41,580

BZ*0700M6 ZB58K5E 90,490 74,650 67,310 60,510 48,430

BZ*0750M6 ZB66K5E 101,880 84,500 76,400 68,880 55,660

BZ*0860M6 ZB76K5E 115,050 96,060 87,180 78,830 64,280

BZ*1000M6 ZB95K5E 135,810 112,670 101,920 92,070 74,900

BZ*1401M6 ZB114K5E 172,070 141,060 126,930 114,010 91,710

Model Compressor

BZ*0650M6 ZB48KCE 70,760 59,310 54,030 49,070 40,220

BZ*0700M6 ZB58K5E 87,070 72,050 65,070 58,610 47,070

BZ*0750M6 ZB66K5E 97,780 81,440 73,840 66,780 54,420

BZ*0860M6 ZB76K5E 110,380 92,680 84,400 76,650 63,190

BZ*1000M6 ZB95K5E - 107,320 97,160 87,840 71,690

BZ*1401M6 ZB114K5E 164,280 134,800 121,360 109,070 87,970

Capacity BTUH @ 90°F Ambient Suction Temperature

40°F 30°F 25°F 20°F 10°F

Capacity BTUH @ 95°F Ambient Suction Temperature

40°F 30°F 25°F 20°F 10°F

Capacity BTUH @ 100°F Ambient Suction Temperature

40°F 30°F 25°F 20°F 10°F

Model Compressor

BZ*0650M6 ZB48KCE - - 49,850 45,430 37,810

BZ*0700M6 ZB58K5E 79,600 66,300 60,080 54,370 44,140

BZ*0750M6 ZB66K5E 89,050 74,970 68,460 62,470 52,140

BZ*0860M6 ZB76K5E - 85,640 78,710 72,290 61,470

BZ*1000M6 ZB95K5E - - - - 64,880

BZ*1401M6 ZB114K5E - - - 98,900 80,330

NOTES:

*=T for outdoor, N for indoor, S for Beacon II

Consult factory on all models for application above 110F ambient

20°F Maximum Superheat

TM

Capacity BTUH @ 110°F Ambient Suction Temperature

40°F 30°F 25°F 20°F 10°F

8

Page 9

PERFORMANCE DATA

Scroll Compressors - Low Temperature Applications‡ - R-404A/507

Model Compressor

BZ*0750L6 ZF25K4E 40,520 33,850 27,510 21,860 17,230

BZ*1000L6 ZF34K5E 56,860 47,390 38,430 30,240 23,070

BZ*1300L6 ZF41K5E 72,010 59,990 48,700 38,720 30,610

BZ*1500L6 ZF49K5E 80,840 67,610 55,200 44,020 34,860

Model Compressor

BZ*0750L6 ZF25K4E 39,060 32,650 26,540 21,060 16,540

BZ*1000L6 ZF34K5E 54,890 45,630 36,890 28,940 22,050

BZ*1300L6 ZF41K5E 69,440 57,900 47,010 37,330 29,410

BZ*1500L6 ZF49K5E 77,970 65,370 53,282 42,440 33,510

Model Compressor

BZ*0750L6 ZF25K4E 37,590 31,460 25,580 20,260 15,850

BZ*1000L6 ZF34K5E 52,920 43,860 35,350 27,650 21,040

BZ*1300L6 ZF41K5E 66,890 55,810 45,320 35,940 28,220

BZ*1500L6 ZF49K5E 75,050 62,980 51,370 40,870 32,160

Model Compressor

BZ*0750L6 ZF25K4E 34,680 29,090 23,660 18,690 14,490

BZ*1000L6 ZF34K5E 49,010 40,350 32,290 25,080 19,020

BZ*1300L6 ZF41K5E 61,740 51,640 41,950 33,180 26,590

BZ*1500L6 ZF49K5E 69,270 58,270 47,560 37,750 29,470

Capacity BTUH @ 90°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

Capacity BTUH @ 95°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

Capacity BTUH @ 100°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

Capacity BTUH @ 110°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

* = T for Outdoor, N for Indoor, S for Beacon II™

‡ Liquid Injection via DTC is required for operation at Low Temperature Applications

Consult factory on all models for applications above 110°F ambient.

9

Page 10

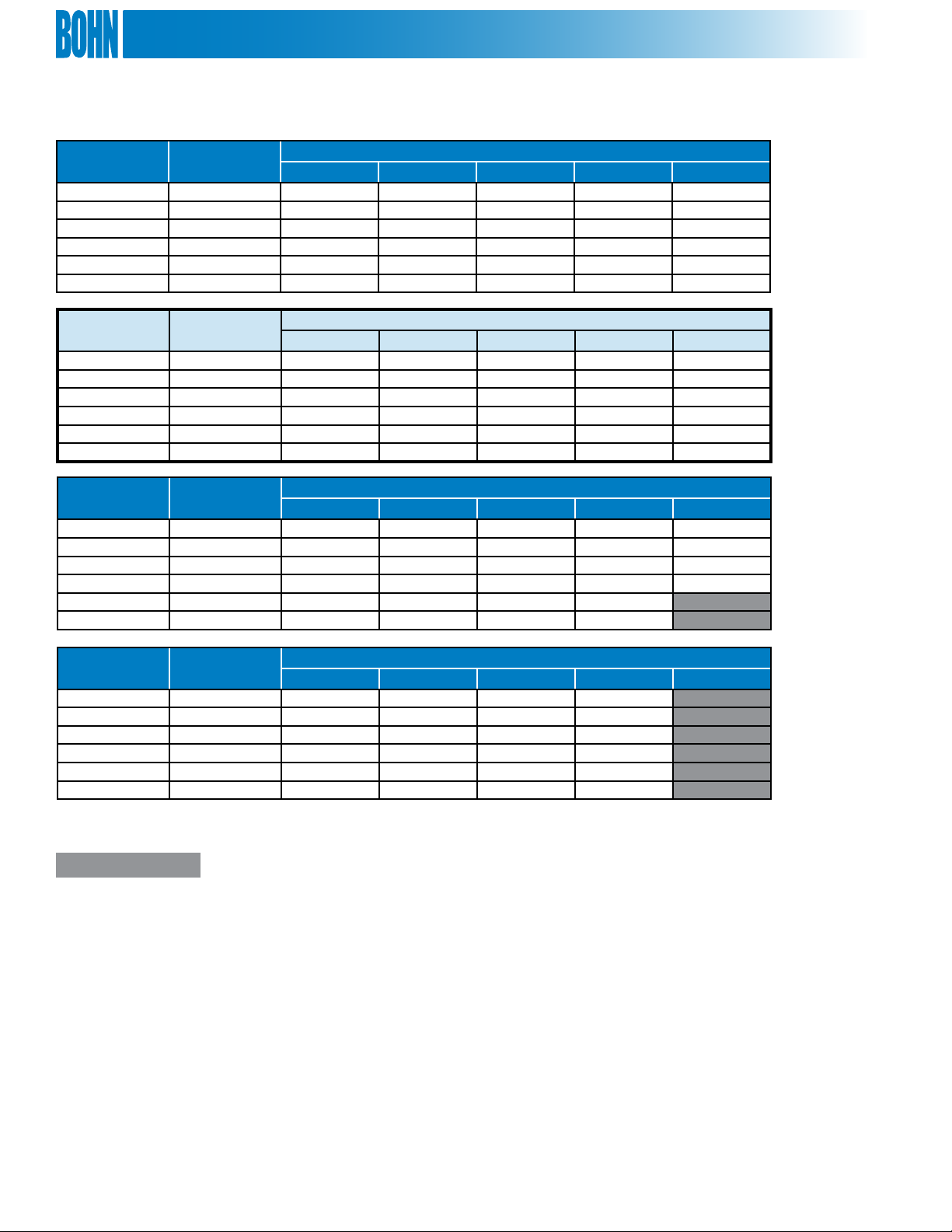

PERFORMANCE DATA

Scroll Compressors - Low Temperature Applications‡ - R-407A/R-407F

Model Compressor

Capacity BTUH @ 90°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

BZ*0750L6 ZF25K4E 39,900 32,130 25,230 19,610 15,600

BZ*1000L6 ZF34K5E

BZ*1300L6 ZF41K5E

BZ*1500L6 ZF49K5E

Model Compressor

3,4

4

3,4

53,090 43,020 33,930 26,280 20,640

67,620 54,560 42,860 33,190 26,110

79,860 64,310 50,410 39,030 31,050

Capacity BTUH @ 95°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

BZ*0750L6 ZF25K4E 38,550 31,020 24,360 18,940 15,120

BZ*1000L6 ZF34K5E

BZ*1300L6 ZF41K5E

BZ*1500L6 ZF49K5E

Model Compressor

3,4

4

3,4

50,960 41,310 32,570 25,220 19,810

65,350 52,700 41,380 32,020 25,180

76,950 61,910 48,500 37,520 29,850

Capacity BTUH @ 100°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

BZ*0750L6 ZF25K4E 37,150 29,880 23,450 18,230 14,580

BZ*1000L6 ZF34K5E

BZ*1300L6 ZF41K5E

BZ*1500L6 ZF49K5E

Model Compressor

3,4

4

3,4

48,730 39,510 31,140 24,090 18,920

63,030 50,770 39,830 30,770 24,170

73,900 59,420 46,490 35,900 28,530

Capacity BTUH @ 110°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

BZ*0750L6 ZF25K4E - - - 16,670 13,350

BZ*1000L6 ZF34K5E

BZ*1300L6 ZF41K5E

BZ*1500L6 ZF49K5E

3,4

4

3,4

- - - - 16,920

57,910 46,620 36,440 28,000 21,840

67,353 54,027 42,087 32,297 25,516

NOTES:

*=T for outdoor, N for indoor, S for Beacon IITM

Consult factory on all models for application above 110F ambient

*Liquid Injection via DTC is required for operation at Low Temperature Application

3

R407F not available in 208-230/3/60

4

R407F not available in 575/3/60

10

Page 11

PERFORMANCE DATA

Scroll Compressors - Low Temperature Applications‡ - R-407C

Model Compressor

BZ*0750L6 ZF25K4E 35,030 27,940 21,760 16,840 13,560

BZ*1000L6 ZF34K5E 47,810 38,290 29,810 22,970 18,330

BZ*1300L6 ZF41K5E 58,800 46,990 36,620 28,310 22,690

BZ*1500L6 ZF49K5E 70,990 56,570 43,920 33,900 27,440

Model Compressor

BZ*0750L6 ZF25K4E 34,050 27,120 21,110 16,350 13,220

BZ*1000L6 ZF34K5E 46,260 37,000 28,770 22,150 17,720

BZ*1300L6 ZF41K5E 57,180 45,640 35,510 27,440 22,010

BZ*1500L6 ZF49K5E 68,900 54,790 42,500 32,740 26,550

Model Compressor

BZ*0750L6 ZF25K4E 33,030 26,270 20,430 15,830 12,850

BZ*1000L6 ZF34K5E 44,620 35,640 27,650 21,270 17,030

BZ*1300L6 ZF41K5E 55,480 44,240 34,330 26,480 21,250

BZ*1500L6 ZF49K5E 66,680 52,920 40,950 31,480 25,540

Model Compressor

BZ*0750L6 ZF25K4E 30,870 24,460 18,960 14,670 11,960

BZ*1000L6 ZF34K5E - - - 19,240 15,370

BZ*1300L6 ZF41K5E 51,840 41,130 31,700 24,270 19,380

BZ*1500L6 ZF49K5E 61,914 48,819 37,493 28,592 23,097

Capacity BTUH @ 90°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

Capacity BTUH @ 95°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

Capacity BTUH @ 100°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

Capacity BTUH @ 110°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

NOTES:

*=T for outdoor, N for indoor, S for Beacon IITM

Consult factory on all models for application above 110F ambient

*Liquid Injection via DTC is required for operation at Low Temperature Application

11

Page 12

PERFORMANCE DATA

Scroll Compressors - Low Temperature Applications - R-448A/R-449A

Model Compressor

BZ*0750L6 ZF25K4E 39,760 31,900 25,200 19,750 15,430

BZ*1000L6 ZF34K5E 50,610 41,060 32,590 25,220 18,840

BZ*1300L6 ZF41K5E 65,040 52,570 41,650 32,300 24,230

BZ*1500L6 ZF49K5E 77,450 62,400 49,340 38,210 28,990

Model Compressor

BZ*0750L6 ZF25K4E 38,390 30,820 24,430 19,260 15,270

BZ*1000L6 ZF34K5E 48,830 39,690 31,570 24,500 18,340

BZ*1300L6 ZF41K5E 63,030 51,010 40,460 31,420 23,620

BZ*1500L6 ZF49K5E 74,920 60,430 47,820 37,100 28,230

Model Compressor

BZ*0750L6 ZF25K4E 37,010 29,750 23,690 18,830 15,180

BZ*1000L6 ZF34K5E 46,980 38,280 30,520 23,740 17,860

BZ*1300L6 ZF41K5E 60,940 49,390 39,240 30,520 23,010

BZ*1500L6 ZF49K5E 72,280 58,370 46,270 35,990 27,470

Capacity BTUH @ 90°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

Capacity BTUH @ 95°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

Capacity BTUH @ 100°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

Model Compressor

BZ*0750L6 ZF25K4E - 27,740 22,330 18,130 15,180

BZ*1000L6 ZF34K5E - 35,310 28,340 22,250 16,950

BZ*1300L6 ZF41K5E 56,550 45,990 36,670 28,670 21,780

BZ*1500L6 ZF49K5E 66,700 54,070 43,040 33,670 25,970

Consult factory on all models for applications above 110°F ambient

Capacity BTUH @ 110°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

12

Page 13

ELECTRICAL DATA

Scroll Compressors - Medium Temperature

™

or Air

Unit

Model

Voltage

Supply

†

Compressor

Condenser

Fan Motor

Beacon II

Defrost

Volts Ph Hz†RLA LRA Qty HP FLA MCA MOPD MCA MOPD Amps Amps MCA MOPD Amps Amps

BZ*0650M6C 208-230 3 60 22.8 164 1 1/3 2.7 31.1 50

BZ*0650M6D 460 3 60 12.2 100 1 1/3 1.9 20 25

BZ*0650M6E1,

BZ*0700M6C 208-230 3 60 30.8 195 2 1/3 5.4 43.9 70

BZ*0700M6D 460 3 60 16.0 95 2 1/3 3.8 23.8 35

BZ*0700M6E

BZ*0750M6C 208-230 3 60 35.3 225 2 1/3 5.4 49.5 80

BZ*0750M6D 460 3 60 15.4 114 2 1/3 3.8 23 35

BZ*0750M6E

BZ*0860M6C 208-230 3 60 38.6 239 2 1/3 5.4 53.6 90

BZ*0860M6D 460 3 60 18.6 125 2 1/3 3.8 27 45

BZ*0860M6E

BZ*1000M6C 208-230 3 60 47.4 350.0 2 1/3 5.4 64.7 110

BZ*1000M6D 460 3 60 22.4 158.0 2 1/3 3.8 31.8 44.8

BZ*1000M6E

BZ*1401M6C 208-230 3 60 56.5 321 2 3/4 8.8 79.4 125 94.4 150 70 (2) 15 100 150 80 (2) 20

BZ*1401M6D 460 3 60 24.4 179 2 3/4 4.4 34.9 50 50 70 40 (1) 15 75 80 60 (2) 15

BZ*1401M6E

* = T for Outdoors, N for Indoors, S for Beacon II™

† = Consult factory for 50Hz applications

‡ = Number of defrost heater contactors in parentheses

^ = Two fan large units have ability for a reduced amp electric defrost kit (low amps). Conrm proper defrost kit prior to ordering or installing.

1

R407F not available in 575/3/60.

2

R407C not available in 575/3/60.

2

575 3 60 9.0 78 1 1/3 1.2 15 20

1

575 3 60 12.2 80 2 1/3 2.4 20 25

1

575 3 60 12.8 80 2 1/3 2.4 20 30

1

575 3 60 13.1 80 2 1/3 2.4 20 30 – – –

1

575 3 60 17.9 125.0 2 1/3 2.4 24.8 35.2

1

575 3 60 20.1 132 2 3/4 3.6 28.7 45 40.7 60 32 (1) 12 60 60 48 (1) 12

Low Amps^ High Amps^

Electric

Defrost

– – – –

– – – –

– – – –

– – – –

– – – –

– – – –

– – – –

– – – –

– – – –

– – – –

– – – –

– – – –

– – – –

– – – –

Def.

Htr.‡

Evap.

Fan

–

Electric

Defrost

50 60 40 (1) 15

25.2 35 20 (1) 8

20 25 16 (1) 6.4

63.9 90 48 (1) 20

33.8 45 25 (1) 10

25.6 35 20 (1) 8

69.5 100 48 (1) 20

33 45 25 (1) 10

26.4 35 20 (1) 8

87.5 110 70 (2) 20

43.8 50 35 (1) 13

35 40 28 (1) 10.4

87.5 125 70 (2) 20

44.8 60 35 (1) 13

35.2 50 28 (1) 10.4

Def.

Htr.‡

Evap.

Fan

Scroll Compressors - Low Temperature Applications

or Air

™

Electric

Defrost

Def.

Htr.‡

Beacon II

Defrost

Unit

Voltage

Supply

†

Compressor

Condenser

Fan Motor

Model

Volts

BZ*0750L6C 208-230 3 60 26.9 189.0 1 1/3 2.7 36.4 60 75.0 80 60 (2) 20

BZ*0750L6D 460 3 60 14.1 99.0 1 1/3 1.9 20.0 30 37.5 40 30 (1) 10

BZ*0750L6E 575 3 60 10.3 74.0 1 1/3 1.2 15.0 20 30.0 30 24 (1) 8

BZ*1000L6C3208-230 3 60 39.1 278.0 1 1/3 2.7 51.6 90 75.0 110 60 (2) 20

BZ*1000L6D 460 3 60 18.9 127.0 1 1/3 1.9 25.5 40 37.5 50 30 (1) 10

BZ*1000L6E

BZ*1300L6C 208-230 3 60 47.4 350.0 2 1/3 5.4 64.7 110 87.5 125 70 (2) 20

BZ*1300L6D 460 3 60 23.7 158.0 2 1/3 3.8 33.4 50 46.4 70 35 (1) 13

BZ*1300L6E

BZ*1500L6C3208-230 3 60 49.4 425.0 2 1/3 5.4 67.1 110 87.5 125 70 (2) 20

BZ*1500L6D 460 3 60 21.8 187.0 2 1/3 3.8 31.0 50 44.0 60 35 (1) 13

BZ*1500L6E

* = T for Outdoors, N for Indoors, S for Beacon II™

† = Consult factory for 50Hz applications

‡ = Number of defrost heater contactors in parentheses

3

R407F not available in 208-230/3/60.

4

R407F not available in 575/3/60.

4

4

4

Ph Hz†RLA LRA Qty HP FLA MCA MOPD MCA MOPD Amps Amps

575 3 60 14.4 100.0 1 1/3 1.2 20.0 30 30.0 40 24 (1) 8

575 3 60 17.9 125.0 2 1/3 2.4 24.8 40 35.2 50 28 (1) 10.4

575 3 60 17.6 148.0 2 1/3 2.4 24.4 40 35.0 50 28 (1) 10.4

Evap.

Fan

13

Page 14

UNIT SPECIFICATIONS

Scroll Compressors - Medium Temperature

Unit

Model

BZ*0650M6 ZB48KCE 6.5 1/2 1-1/8 28 52 36-3/4 51-3/4 39-1/4 78 574

BZ*0700M6 ZB58K5E 7.0 5/8 1-3/8 67 78 36-3/4 63-3/4 39-1/4 80 800

BZ*0750M6 ZB66K5E 7.5 5/8 1-3/8 67 78 36-3/4 63-3/4 39-1/4 80 813

BZ*0860M6 ZB76K5E 8.5 5/8 1-3/8 67 78 36-3/4 63-3/4 39-1/4 80 818

BZ*1000M6 ZB95K5E 10.0 5/8 1-3/8 67 78 36-3/4 63-3/4 39-1/4 82 908

BZ*1401M6 ZB114K5E 14.0 7/8 1-5/8 67 78 41-3/4 75-1/8 48-3/4 82 1,235

Compressor

Model

Connections (OD)

HP

Liquid Suction Std Opt Length Width Height (dba)

Refrigerant Line

Rec. Capacity

@90% full (lbs)

Dimensions (inches)

Sound

Data

Net

Wt.

†

(lbs.)

Scroll Compressors - Low Temperature

Unit

Model

BZ*0750L6 ZF25K4E 7.5 1/2 1-1/8 28 52 36-3/4 51-3/4 39-1/4 82 671

BZ*1000L6 ZF34K5E 10.0 1/2 1-1/8 28 52 36-3/4 51-3/4 39-1/4 82 671

BZ*1300L6 ZF41K5E 13.0 5/8 1-3/8 67 78 36-3/4 63-3/4 39-1/4 84 910

BZ*1500L6 ZF49K5E 15.0 5/8 1-3/8 67 78 36-3/4 63-3/4 39-1/4 83 891

* = T for Outdoors, N for Indoors, S for Beacon II™

†

FOR ALL SOUND DATA: Estimate sound pressure values are 5 feet from the unit. For estimating sound pressure from unit at dierent distances, deduct the following

from the unit values: 10 feet deducts 6 dba, 20 feet deducts 12 dba, 40 feet deducts 18 dba. This data is typical of “free eld” conditions for horizontal air cooled

condensing units at the outlet of the discharge air. The actual sound measurements may vary depending on the condensing unit installation. Factors such as

reecting walls, background noise, and mounting conditions may have a signicant inuence on this data.

Compressor

Model

Connections (OD)

HP

Liquid Suction Std Opt Length Width Height (dba)

Refrigerant Line

Rec. Capacity

@90% full (lbs)

Dimensions (inches)

Sound

Data

Net

Wt.

†

(lbs.)

14

Page 15

PERFORMANCE DATA

Discus Compressors - Medium Temperature Applications - R-404A/507

Model Compressor

BD*0500M6 2DC3R53KE 56,550 49,130 41,390 33,780 26,610 20,610

BD*0501M6 2DD3R63KE 64,500 56,160 47,920 39,480 31,490 24,820

BD*0750M6 2DL3R78KE 78,520 68,490 58,930 48,810 39,060 30,850

BD*0751M6 2DA3R89KE 95,540 83,510 71,440 59,380 47,760 37,700

BD*0800M6 3DA3R10ME 111,970 98,210 83,450 69,400 55,730 44,150

BD*1000M6 3DB3R12ME 128,860 114,710 97,920 82,310 62,280 52,260

BD*1200M6 3DF3R15ME 150,790 133,280 116,610 98,100 79,540 63,260

BD*1500M6 3DS3R17ME 176,330 156,910 134,090 112,610 90,910 72,080

Model Compressor

BD*0500M6 2DC3R53KE 53,940 46,880 39,280 32,220 25,330 19,560

BD*0501M6 2DD3R63KE 61,590 53,590 45,530 37,700 30,080 23,810

BD*0750M6 2DL3R78KE 74,990 65,510 56,000 46,750 37,380 29,570

BD*0751M6 2DA3R89KE 90,870 79,960 68,060 56,890 45,670 36,060

BD*0800M6 3DA3R10ME 107,150 94,270 80,170 66,800 53,610 42,460

BD*1000M6 3DB3R12ME 123,170 109,930 93,930 79,060 63,630 50,180

BD*1200M6 3DF3R15ME 144,290 127,640 111,940 94,270 76,300 61,160

BD*1500M6 3DS3R17ME 168,560 150,350 128,610 108,240 87,380 69,470

40°F 30°F 20°F 15°F 0°F -10°F

40°F 30°F 20°F 15°F 0°F -10°F

Capacity BTUH @ 90°F Ambient Suction Temperature

Capacity BTUH @ 95°F Ambient Suction Temperature

Model Compressor

BD*0500M6 2DC3R53KE 51,100 44,590 37,400 30,500 24,070 18,790

BD*0501M6 2DD3R63KE 58,670 51,090 43,640 35,950 28,670 22,710

BD*0750M6 2DL3R78KE 71,410 62,540 53,530 44,690 35,700 28,180

BD*0751M6 2DA3R89KE 86,130 76,400 65,470 54,140 43,490 34,200

BD*0800M6 3DA3R10ME 102,420 90,330 77,330 63,930 51,480 40,620

BD*1000M6 3DB3R12ME 117,590 105,200 90,730 75,350 60,950 47,890

BD*1200M6 3DF3R15ME 137,400 123,360 107,260 89,720 73,200 58,540

BD*1500M6 3DS3R17ME 160,860 143,860 124,130 103,290 83,840 66,530

Model Compressor

BD*0500M6 2DC3R53KE 45,880 40,200 33,670 27,400 21,520 16,540

BD*0501M6 2DD3R63KE 52,820 46,390 39,160 32,270 25,980 20,540

BD*0750M6 2DL3R78KE — 57,070 48,910 40,220 32,500 25,330

BD*0751M6 2DA3R89KE 77,750 69,330 59,180 49,200 39,600 30,540

BD*0800M6 3DA3R10ME 92,590 82,550 70,980 58,770 47,440 36,900

BD*1000M6 3DB3R12ME — 94,900 82,760 68,920 55,900 43,240

BD*1200M6 3DF3R15ME — — 97,720 82,840 67,700 53,680

BD*1500M6 3DS3R17ME 146,980 129,870 113,470 94,610 77,220 60,500

* = T for Outdoor, N for Indoor, S for Beacon II™

Consult factory on all models for applications above 110°F ambient.

40°F 30°F 20°F 15°F 0°F -10°F

40°F 30°F 20°F 15°F 0°F -10°F

Capacity BTUH @ 100°F Ambient Suction Temperature

Capacity BTUH @ 110°F Ambient Suction Temperature

15

Page 16

PERFORMANCE DATA

Discus Compressors - Medium Temperature Applications - R-407A/R-407F

Model Compressor

40°F 30°F 20°F 15°F 0°F

Capacity BTUH @ 90°F Ambient Suction Temperature

1

-10°F

BD*0500M6 2DC3R53KE 59,770 49,180 39,630 35,450 24,910 19,530

BD*0501M6 2DD3R63KE 58,640 48,270 39,060 34,910 24,730 19,680

BD*0750M6 2DL3R78KE 80,650 67,850 56,490 51,290 37,480 29,160

BD*0751M6 2DA3R89KE 98,470 81,920 66,830 60,090 42,490 32,890

BD*0800M6 3DA3R10ME 117,170 98,220 79,980 71,440 49,360 39,000

BD*1000M6 3DB3R12ME 132,530 112,490 92,950 83,540 58,960 47,030

BD*1200M6 3DF3R15ME 147,130 125,260 104,120 93,900 66,740 53,660

BD*1500M6 3DS3R17ME 179,770 152,610 126,210 113,500 79,480 61,450

Model Compressor

40°F 30°F 20°F 15°F 0°F

Capacity BTUH @ 95°F Ambient Suction Temperature

1

-10°F

BD*0500M6 2DC3R53KE 57,140 46,960 37,880 33,800 23,730 18,640

BD*0501M6 2DD3R63KE 56,110 46,160 37,290 33,370 23,680 18,930

BD*0750M6 2DL3R78KE 77,140 64,940 54,090 49,110 35,870 27,900

BD*0751M6 2DA3R89KE 94,310 78,460 64,090 57,560 40,610 31,310

BD*0800M6 3DA3R10ME 111,950 93,910 76,480 68,290 47,070 37,040

BD*1000M6 3DB3R12ME 126,500 107,520 88,910 79,890 56,250 44,690

BD*1200M6 3DF3R15ME 140,150 119,410 99,330 89,590 63,660 51,050

BD*1500M6 3DS3R17ME 171,940 146,250 120,840 108,840 76,060 58,390

1

1

Model Compressor

40°F 30°F 20°F 15°F 0°F

Capacity BTUH @ 100°F Ambient Suction Temperature

1

BD*0500M6 2DC3R53KE 54,510 44,770 36,030 32,170 22,590 17,780

BD*0501M6 2DD3R63KE 53,590 44,080 35,600 31,870 22,670 18,220

BD*0750M6 2DL3R78KE 73,620 62,040 51,680 46,910 34,250 26,610

BD*0751M6 2DA3R89KE 90,140 75,040 61,300 55,020 38,720 29,720

BD*0800M6 3DA3R10ME 106,750 89,820 73,000 65,200 44,770 35,080

BD*1000M6 3DB3R12ME 120,470 102,520 84,820 76,180 53,490 42,300

BD*1200M6 3DF3R15ME 133,220 113,970 94,540 85,270 60,420 48,360

BD*1500M6 3DS3R17ME 164,180 139,940 115,870 104,270 72,600 55,310

Model Compressor

40°F 30°F 20°F 15°F 0°F

Capacity BTUH @ 110°F Ambient Suction Temperature

1

BD*0500M6 2DC3R53KE - - 32,550 29,060 20,430 16,210

BD*0501M6 2DD3R63KE - 39,530 32,010 28,680 20,600 16,820

BD*0750M6 2DL3R78KE - 55,080 45,930 41,670 30,350 23,460

BD*0751M6 2DA3R89KE - 66,130 53,960 48,400 33,820 25,590

BD*0800M6 3DA3R10ME - 77,940 63,410 56,500 38,490 29,670

BD*1000M6 3DB3R12ME - - 72,430 64,870 45,150 35,000

BD*1200M6 3DF3R15ME - - - - 50,110 39,620

BD*1500M6 3DS3R17ME - - - - 61,000 45,050

NOTES:

*=T for outdoor, N for indoor, S for Beacon IITM

Consult factory on all models for application above 110F ambient

-10°F

-10°F

1

1

16

Page 17

PERFORMANCE DATA

Discus Compressors - Medium Temperature Applications - R-407C

Model Compressor

BD*0500M6 2DC3R53KE 56,300 45,410 35,800 31,660 21,590 16,910

BD*0501M6 2DD3R63KE 64,100 51,830 41,100 36,470 25,310 20,180

BD*0750M6 2DL3R78KE 77,640 63,600 51,190 45,640 32,090 25,700

BD*0751M6 2DA3R89KE 92,900 75,590 60,300 53,520 36,780 28,480

BD*0800M6 3DA3R10ME 108,290 90,140 73,320 65,540 45,420 34,780

BD*1000M6 3DB3R12ME 124,480 104,530 85,920 77,180 54,290 41,980

BD*1200M6 3DF3R15ME 140,060 117,980 97,060 87,250 61,300 47,800

BD*1500M6 3DS3R17ME 168,040 141,120 115,850 104,010 72,520 55,220

Model Compressor

BD*0500M6 2DC3R53KE 54,270 43,670 34,340 30,330 20,630 16,190

BD*0501M6 2DD3R63KE 61,840 49,930 39,550 35,040 24,320 19,470

BD*0750M6 2DL3R78KE 74,990 61,410 49,380 44,030 31,050 25,070

BD*0751M6 2DA3R89KE 89,780 73,030 58,140 51,550 35,250 27,170

BD*0800M6 3DA3R10ME 104,490 86,990 70,600 63,080 43,230 32,630

BD*1000M6 3DB3R12ME 120,030 100,830 82,670 74,270 51,740 39,410

BD*1200M6 3DF3R15ME 134,800 113,720 93,250 83,720 58,250 44,820

BD*1500M6 3DS3R17ME 162,280 136,400 111,970 100,460 69,560 52,110

40°F 30°F 20°F 15°F 0°F -10°F

40°F 30°F 20°F 15°F 0°F -10°F

Capacity BTUH @ 90°F Ambient Suction Temperature

Capacity BTUH @ 95°F Ambient Suction Temperature

Model Compressor

BD*0500M6 2DC3R53KE 52,280 41,980 32,920 29,050 19,690 15,500

BD*0501M6 2DD3R63KE 59,620 48,160 38,040 33,660 23,370 18,810

BD*0750M6 2DL3R78KE 72,390 59,250 47,630 42,470 30,070 24,500

BD*0751M6 2DA3R89KE 86,760 70,490 56,010 49,600 33,750 25,890

BD*0800M6 3DA3R10ME 100,690 83,800 67,920 60,510 40,900 30,260

BD*1000M6 3DB3R12ME 115,550 97,020 79,400 71,200 48,900 36,580

BD*1200M6 3DF3R15ME 129,470 109,170 89,300 80,030 55,130 41,640

BD*1500M6 3DS3R17ME 156,510 131,630 107,980 96,760 66,310 48,780

Model Compressor

BD*0500M6 2DC3R53KE 48,430 38,690 30,280 26,620 17,980 14,250

BD*0501M6 2DD3R63KE - 44,590 35,130 31,060 21,630 17,630

BD*0750M6 2DL3R78KE - 55,110 44,300 39,520 28,310 23,540

BD*0751M6 2DA3R89KE 80,820 65,540 51,860 45,810 30,820 23,380

BD*0800M6 3DA3R10ME 93,100 77,440 62,240 55,150 35,860 24,960

BD*1000M6 3DB3R12ME - 89,140 72,590 64,550 42,690 30,180

BD*1200M6 3DF3R15ME - - 81,010 72,170 47,850 35,840

BD*1500M6 3DS3R17ME - 121,890 99,660 88,830 59,210 41,500

NOTES:

*=T for outdoor, N for indoor, S for Beacon IITM

Consult factory on all models for application above 110F ambient

40°F 30°F 20°F 15°F 0°F -10°F

40°F 30°F 20°F 15°F 0°F

Capacity BTUH @ 100°F Ambient Suction Temperature

Capacity BTUH @ 110°F Ambient Suction Temperature

1

-10°F

1

17

Page 18

PERFORMANCE DATA

Discus Compressors - Medium Temperature Applications - R-448A/R-449A

Model Compressor

BD*0500M6 2DC3R53KE 59,110 48,610 39,200 34,980 24,430 19,070

BD*0501M6 2DD3R63KE

BD*0750M6 2DL3R78KE 80,700 67,760 56,190 50,870 36,480 27,690

BD*0751M6 2DA3R89KE 97,210 80,880 66,020 59,250 41,620 32,090

BD*0800M6 3DA3R10ME 115,900 97,520 79,820 71,540 49,730 38,260

BD*1000M6 3DB3R12ME 132,160 112,240 93,070 83,900 59,370 46,290

BD*1200M6 3DF3R15ME 147,590 125,880 104,760 94,750 67,230 53,030

BD*1500M6 3DS3R17ME 179,110 152,030 125,750 113,190 79,310 60,940

Model Compressor

BD*0500M6 2DC3R53KE 56,710 46,590 37,550 33,460 23,330 18,260

BD*0501M6 2DD3R63KE

BD*0750M6 2DL3R78KE 77,500 65,160 54,040 48,910 34,980 26,450

BD*0751M6 2DA3R89KE 93,610 77,830 63,510 56,970 39,950 30,660

BD*0800M6 3DA3R10ME 111,260 93,700 76,660 68,720 47,480 36,160

BD*1000M6 3DB3R12ME 126,730 107,750 89,360 80,520 56,680 43,820

BD*1200M6 3DF3R15ME 141,140 120,490 100,300 90,730 64,230 50,370

BD*1500M6 3DS3R17ME 172,090 146,320 121,140 109,050 76,240 58,260

Model Compressor

BD*0500M6 2DC3R53KE 54,320 44,590 35,850 31,980 22,310 17,480

BD*0501M6 2DD3R63KE

BD*0750M6 2DL3R78KE 74,320 62,530 51,870 46,920 33,460 25,140

BD*0751M6 2DA3R89KE 89,870 74,750 60,990 54,670 38,190 29,220

BD*0800M6 3DA3R10ME 106,630 89,840 73,360 65,800 45,100 33,970

BD*1000M6 3DB3R12ME 121,280 103,190 85,550 77,020 53,940 41,260

BD*1200M6 3DF3R15ME - 115,030 95,780 86,440 61,020 47,610

BD*1500M6 3DS3R17ME 165,050 140,570 116,530 104,900 73,150 55,540

40°F 30°F 20°F 15°F 0°F -10°F

57,910

40°F 30°F 20°F 15°F 0°F -10°F

55,620

40°F 30°F 20°F 15°F 0°F -10°F

53,340

Capacity BTUH @ 90°F Ambient Suction Temperature

47,580 38,440 34,380 24,230 19,220

Capacity BTUH @ 95°F Ambient Suction Temperature

45,690 36,890 32,990 23,280 18,550

Capacity BTUH @ 100°F Ambient Suction Temperature

43,800 35,360 31,620 22,370 17,920

Model Compressor

BD*0500M6 2DC3R53KE 49,590 40,660 32,650 29,100 20,320 16,040

BD*0501M6 2DD3R63KE

BD*0750M6 2DL3R78KE - - 47,500 42,940 30,330 22,490

BD*0751M6 2DA3R89KE 82,330 68,490 55,810 50,010 34,710 26,300

BD*0800M6 3DA3R10ME 97,330 82,070 66,910 59,730 40,220 29,410

BD*1000M6 3DB3R12ME - 93,860 77,740 69,830 48,000 35,890

BD*1200M6 3DF3R15ME - - 86,650 78,100 54,440 41,880

BD*1500M6 3DS3R17ME - - 107,290 96,630 66,990 50,110

Consult factory on all models for applications above 110°F ambient.

40°F 30°F 20°F 15°F 0°F -10°F

48,810

Capacity BTUH @ 110°F Ambient Suction Temperature

40,050 32,380 28,980 20,670 16,780

18

Page 19

PERFORMANCE DATA

Discus Compressors - Medium Temperature Applications - R-22

Model Compressor

BD*0500M6 2DC3R53KE 58,950 49,590 45,060 40,670 32,430

BD*0501M6 2DD3R63KE 66,260 56,150 51,220 46,420 37,360

BD*0750M6 2DL3R78KE 81,780 69,770 64,000 58,450 48,200

BD*0751M6 2DA3R89KE 96,300 81,470 74,510 67,940 56,140

BD*0800M6 3DA3R10ME 116,560 99,580 91,330 83,330 68,320

BD*1000M6 3DB3R12ME 135,700 116,150 106,650 97,430 80,110

BD*1200M6 3DF3R15ME 152,900 130,010 119,030 108,500 89,220

BD*1500M6 3DS3R17ME 180,630 152,650 139,230 126,360 102,810

Model Compressor

BD*0500M6 2DC3R53KE 57,000 47,830 43,380 39,060 30,960

BD*0501M6 2DD3R63KE 64,090 54,200 49,380 44,680 35,800

BD*0750M6 2DL3R78KE 79,200 67,480 61,860 56,450 46,500

BD*0751M6 2DA3R89KE 93,130 78,700 71,930 65,540 54,120

BD*0800M6 3DA3R10ME 113,110 96,520 88,450 80,610 65,890

BD*1000M6 3DB3R12ME 131,720 112,540 103,250 94,230 77,290

BD*1200M6 3DF3R15ME 148,190 125,900 115,210 104,950 86,170

BD*1500M6 3DS3R17ME 174,980 147,820 134,780 122,270 99,390

Capacity BTUH @ 90°F Ambient Suction Temperature

40°F 30°F 25°F 20°F 10°F

Capacity BTUH @ 95°F Ambient Suction Temperature

40°F 30°F 25°F 20°F 10°F

Model Compressor

BD*0500M6 2DC3R53KE 55,050 46,050 41,690 37,460 29,500

BD*0501M6 2DD3R63KE 61,910 52,250 47,530 42,930 34,230

BD*0750M6 2DL3R78KE 76,600 65,190 59,710 54,460 44,800

BD*0751M6 2DA3R89KE 89,960 75,920 69,350 63,150 52,100

BD*0800M6 3DA3R10ME 109,650 93,460 85,570 77,890 63,450

BD*1000M6 3DB3R12ME 127,680 108,940 99,850 91,030 74,450

BD*1200M6 3DF3R15ME 143,480 121,790 111,390 101,400 83,140

BD*1500M6 3DS3R17ME 169,340 142,990 130,340 118,190 95,960

Model Compressor

BD*0500M6 2DC3R53KE 51,130 42,510 38,320 34,240 26,560

BD*0501M6 2DD3R63KE 57,540 48,330 43,820 39,430 31,100

BD*0750M6 2DL3R78KE 71,400 60,590 55,420 50,460 41,400

BD*0751M6 2DA3R89KE 83,620 70,380 64,200 58,380 48,060

BD*0800M6 3DA3R10ME 102,720 87,330 79,800 72,460 58,590

BD*1000M6 3DB3R12ME 119,590 101,740 93,060 84,640 68,800

BD*1200M6 3DF3R15ME — 113,580 103,750 94,320 77,080

BD*1500M6 3DS3R17ME 158,050 133,350 121,460 110,040 89,120

* = T for Outdoor, N for Indoor, S for Beacon II™

Consult factory on all models for applications above 110°F ambient.

Capacity BTUH @ 100°F Ambient Suction Temperature

40°F 30°F 25°F 20°F 10°F

Capacity BTUH @ 110°F Ambient Suction Temperature

40°F 30°F 25°F 20°F 10°F

19

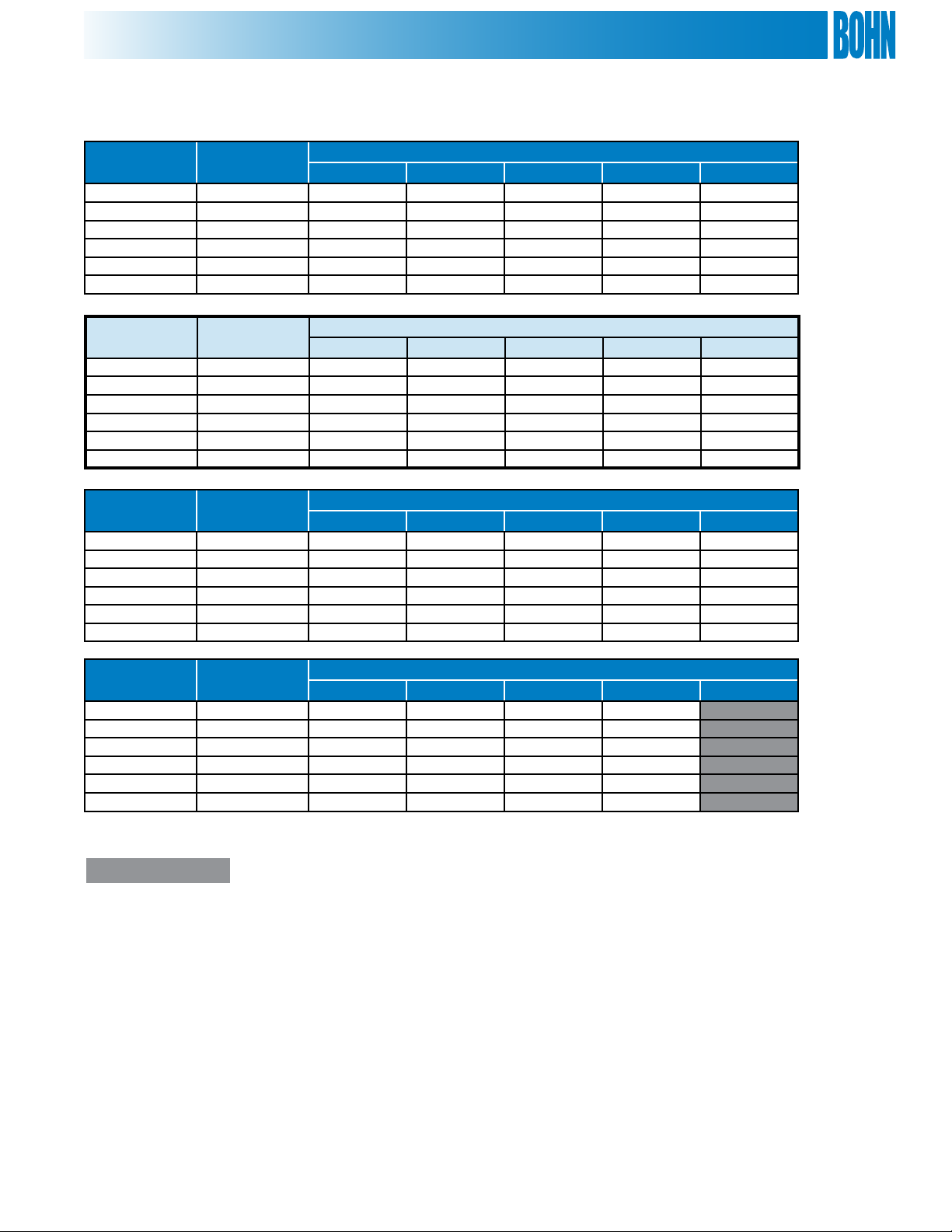

Page 20

PERFORMANCE DATA

Discus Compressors - Low Temperature Applications - R-404A/507

Model Compressor

BD*0300L6 2DF3F16KE 33,130 26,750 20,750 15,530 11,470

BD*0400L6 2DL3F20KE 38,320 31,200 24,500 18,590 13,820

BD*0600L6 2DB3F25KE 44,920 36,970 29,340 22,440 16,730

BD*0601L6 3DA3F28KE 49,300 40,810 32,530 25,110 19,140

BD*0750L6 3DB3F33KE 57,490 47,800 38,230 29,550 22,550

BD*0900L6 3DF3F40KE 75,860 62,020 49,030 37,670 28,660

BD*1000L6 3DS3F46KE 82,110 67,850 54,240 42,040 31,990

BD*1200L6 4DBNF54KE 102,010 82,180 65,110 49,920 35,600

BD*1500L6 4DHNF63KE 112,860 93,820 75,470 58,730 44,520

BD*2200L6 4DJNF76KE 128,840 108,680 88,210 68,690 51,450

Model Compressor

BD*0300L6 2DF3F16KE 31,390 25,320 19,560 14,500 10,490

BD*0400L6 2DL3F20KE 36,470 29,620 23,140 17,400 12,750

BD*0600L6 2DB3F25KE 42,830 35,160 27,770 21,070 15,490

BD*0601L6 3DA3F28KE 47,060 38,920 30,940 23,710 17,830

BD*0750L6 3DB3F33KE 54,880 45,630 36,410 27,960 21,030

BD*0900L6 3DF3F40KE 72,600 59,280 46,730 35,680 26,850

BD*1000L6 3DS3F46KE 78,620 64,870 51,680 39,780 29,910

BD*1200L6 4DBNF54KE 97,660 78,720 62,240 47,360 33,140

BD*1500L6 4DHNF63KE 107,630 89,380 71,720 55,530 41,710

BD*2200L6 4DJNF76KE 122,150 103,010 83,410 64,540 47,660

Capacity BTUH @ 90°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

Capacity BTUH @ 95°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

Model Compressor

BD*0300L6 2DF3F16KE 29,220 23,560 18,380 13,470 9,520

BD*0400L6 2DL3F20KE 34,630 28,040 21,790 16,220 11,690

BD*0600L6 2DB3F25KE 40,730 33,360 26,210 19,700 14,260

BD*0601L6 3DA3F28KE 44,820 37,050 29,370 22,330 16,530

BD*0750L6 3DB3F33KE 52,280 43,470 34,600 26,380 19,520

BD*0900L6 3DF3F40KE 69,350 56,570 44,440 33,700 25,050

BD*1000L6 3DS3F46KE 75,150 61,900 49,130 37,540 27,840

BD*1200L6 4DBNF54KE 93,200 75,170 59,250 44,710 30,580

BD*1500L6 4DHNF63KE 102,420 84,970 67,990 52,350 38,930

BD*2200L6 4DJNF76KE 115,500 97,380 78,650 60,410 43,880

Model Compressor

BD*0300L6 2DF3F16KE 26,200 21,060 16,040 11,440 7,580

BD*0400L6 2DL3F20KE 30,970 24,900 19,100 13,890 9,590

BD*0600L6 2DB3F25KE 36,590 29,780 23,110 16,990 11,800

BD*0601L6 3DA3F28KE 40,390 33,350 26,250 19,610 13,960

BD*0750L6 3DB3F33KE 47,130 39,210 31,040 23,260 16,540

BD*0900L6 3DF3F40KE 62,910 51,180 39,920 29,810 21,490

BD*1000L6 3DS3F46KE 68,260 56,030 44,090 33,100 23,740

BD*1200L6 4DBNF54KE — 67,750 52,970 39,060 25,160

BD*1500L6 4DHNF63KE 92,110 76,230 60,620 46,070 33,400

BD*2200L6 4DJNF76KE 102,320 86,230 69,210 52,230 36,370

* = T for Outdoor, N for Indoor, S for Beacon II™

Consult factory on all models for applications above 110°F ambient.

Capacity BTUH @ 100°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

Capacity BTUH @ 110°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

20

Page 21

PERFORMANCE DATA

Discus Compressors - Low Temperature Application - R407A/F - Demand Cooling is required for all applications

Model Compressor

BD*0300L6 2DF3F16KE 29,980 22,800 16,980 12,140 7,910

BD*0400L6 2DL3F20KE 34,480 26,930 20,080 14,150 9,260

BD*0600L6 2DB3F25KE 40,990 32,150 24,390 17,780 11,920

BD*0601L6 3DA3F28KE 45,510 35,740 27,170 19,750 13,160

BD*0750L6 3DB3F33KE 54,450 43,290 33,440 24,740 16,550

BD*0900L6 3DF3F40KE 71,740 55,720 42,040 30,480 20,250

BD*1000L6 3DS3F46KE 77,140 60,040 45,440 33,000 21,940

BD*1200L6 4DBNF54KE 94,930 74,510 55,850 39,630 26,000

BD*1500L6 4DHNF63KE 106,130 84,970 65,370 48,000 33,280

BD*2200L6 4DJNF76KE 129,550 101,830 77,650 58,030 44,020

Model Compressor

BD*0300L6 2DF3F16KE 28,550 21,690 16,100 11,420 7,320

BD*0400L6 2DL3F20KE 32,910 25,650 19,060 13,350 8,660

BD*0600L6 2DB3F25KE 39,200 30,670 23,190 16,850 11,270

BD*0601L6 3DA3F28KE 43,330 33,930 25,600 18,430 12,000

BD*0750L6 3DB3F33KE 52,000 41,190 31,570 23,160 15,200

BD*0900L6 3DF3F40KE 68,460 53,010 39,760 28,510 18,520

BD*1000L6 3DS3F46KE 73,400 57,100 42,940 30,840 20,040

BD*1200L6 4DBNF54KE 90,430 70,860 52,920 37,160 23,900

BD*1500L6 4DHNF63KE 101,270 81,010 62,150 45,370 31,110

BD*2200L6 4DJNF76KE 123,260 96,720 73,420 54,940 42,000

Capacity BTUH @ 90°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

Capacity BTUH @ 95°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

Model Compressor

BD*0300L6 2DF3F16KE 27,210 20,580 15,220 10,710 6,730

BD*0400L6 2DL3F20KE 31,300 24,340 18,040 12,560 8,090

BD*0600L6 2DB3F25KE 37,370 29,170 22,000 15,910 10,640

BD*0601L6 3DA3F28KE 41,130 32,100 24,060 17,110 10,810

BD*0750L6 3DB3F33KE 49,530 39,080 29,720 21,550 13,830

BD*0900L6 3DF3F40KE 65,150 50,240 37,510 26,520 16,760

BD*1000L6 3DS3F46KE 69,940 54,010 40,410 28,650 18,110

BD*1200L6 4DBNF54KE 85,980 67,130 49,840 34,570 21,680

BD*1500L6 4DHNF63KE 96,410 77,040 58,860 42,670 28,860

BD*2200L6 4DJNF76KE 117,030 91,540 69,250 51,760 39,900

Model Compressor

BD*0300L6 2DF3F16KE 24,410 18,430 13,490 9,320 5,590

BD*0400L6 2DL3F20KE 27,990 21,660 15,950 10,990 6,990

BD*0600L6 2DB3F25KE 33,590 26,050 19,580 14,110 9,460

BD*0601L6 3DA3F28KE - 28,500 20,930 14,420 8,450

BD*0750L6 3DB3F33KE - 34,780 25,970 18,270 11,000

BD*0900L6 3DF3F40KE 58,490 44,710 32,820 22,460 13,160

BD*1000L6 3DS3F46KE 62,530 48,050 35,350 24,210 14,170

BD*1200L6 4DBNF54KE 76,880 59,350 43,360 29,100 16,920

BD*1500L6 4DHNF63KE 86,660 68,890 52,210 37,230 24,230

BD*2200L6 4DJNF76KE 104,420 81,040 60,730 45,310 35,370

NOTES:

*=T for outdoor, N for indoor, S for Beacon IITM

Consult factory on all models for application above 110F ambient

Capacity BTUH @ 100°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

Capacity BTUH @ 110°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

21

Page 22

PERFORMANCE DATA

“Discus Compressors - Low Temperature Application - R407C - Demand Cooling is required for all applications

Model Compressor

Capacity BTUH @ 90°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

BD*0300L6 2DF3F16KE 25,980 19,650 14,550 10,450 6,920

BD*0400L6 2DL3F20KE 30,090 23,360 17,380 12,240 8,100

BD*0600L6 2DB3F25KE 36,370 28,190 21,320 15,460 10,390

BD*0601L6 3DA3F28KE 40,930 31,700 23,570 16,740 11,140

BD*0750L6 3DB3F33KE 48,600 38,040 28,810 20,930 14,240

BD*0900L6 3DF3F40KE 62,490 48,390 36,150 25,500 16,460

BD*1000L6 3DS3F46KE 67,050 51,940 38,830 27,580 18,130

BD*1200L6 4DBNF54KE

1

83,370 63,270 46,440 32,540 21,260

BD*1500L6 4DHNF63KE 93,900 72,420 54,470 39,590 27,260

BD*2200L6 4DJNF76KE 108,590 83,380 63,440 47,290 32,590

Model Compressor

Capacity BTUH @ 95°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

BD*0300L6 2DF3F16KE 24,950 18,850 13,920 9,900 6,370

BD*0400L6 2DL3F20KE 28,970 22,430 16,620 11,580 7,500

BD*0600L6 2DB3F25KE 35,050 27,100 20,380 14,640 9,680

BD*0601L6 3DA3F28KE 39,130 30,210 22,320 15,660 10,180

BD*0750L6 3DB3F33KE 46,660 36,290 27,240 19,520 12,990

BD*0900L6 3DF3F40KE 60,160 46,330 34,250 23,920 15,340

BD*1000L6 3DS3F46KE 64,430 49,730 36,920 25,980 16,860

BD*1200L6 4DBNF54KE

1

79,890 60,420 43,980 30,470 19,430

BD*1500L6 4DHNF63KE 90,070 69,220 51,790 37,310 25,310

BD*2200L6 4DJNF76KE 104,240 80,160 60,910 45,140 30,710

Model Compressor

Capacity BTUH @ 100°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

BD*0300L6 2DF3F16KE 23,910 18,030 13,230 9,280 5,740

BD*0400L6 2DL3F20KE 27,800 21,460 15,780 10,870 6,840

BD*0600L6 2DB3F25KE 33,590 25,920 19,350 13,730 8,850

BD*0601L6 3DA3F28KE 37,260 28,640 21,000 14,510 9,160

BD*0750L6 3DB3F33KE 44,730 34,530 25,660 18,090 11,690

BD*0900L6 3DF3F40KE 57,830 44,120 32,250 22,300 14,140

BD*1000L6 3DS3F46KE 61,610 47,260 34,920 24,300 15,510

BD*1200L6 4DBNF54KE

1

76,350 57,450 41,430 28,260 17,450

BD*1500L6 4DHNF63KE 86,160 65,920 49,030 34,940 23,260

BD*2200L6 4DJNF76KE 99,760 76,700 58,110 42,810 28,690

Model Compressor

Capacity BTUH @ 110°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

BD*0300L6 2DF3F16KE 21,810 16,290 11,700 7,810 3,920

BD*0400L6 2DL3F20KE 25,190 19,260 13,860 9,160 4,460

BD*0600L6 2DB3F25KE 30,430 23,150 16,950 11,590 6,870

BD*0601L6 3DA3F28KE 33,440 25,320 18,120 12,020 6,910

BD*0750L6 3DB3F33KE 40,870 31,020 22,330 15,040 8,870

BD*0900L6 3DF3F40KE 52,820 39,540 28,130 18,850 11,550

BD*1000L6 3DS3F46KE 55,610 42,210 30,460 20,630 12,520

BD*1200L6 4DBNF54KE

1

68,850 51,140 35,990 23,440 13,170

BD*1500L6 4DHNF63KE 78,000 59,180 43,150 29,920 18,830

BD*2200L6 4DJNF76KE 89,910 68,740 51,650 37,180 23,760

NOTES:

*=T for outdoor, N for indoor, S for Beacon IITM

Consult factory on all models for application above 110F ambient

1

R407C not available in 575/3/60

22

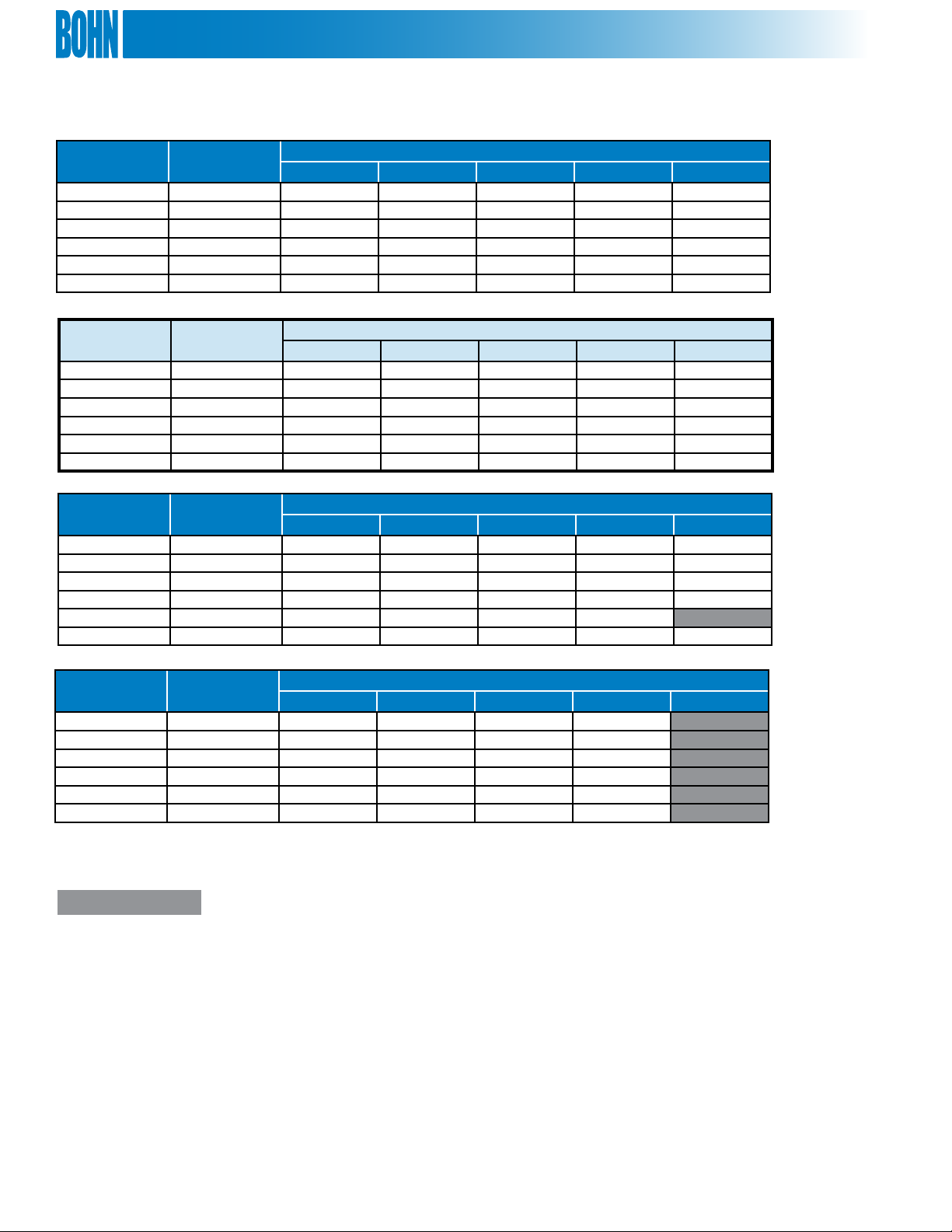

Page 23

PERFORMANCE DATA

Discus Compressors - Low Temperature Application - R448A/R449A - Demand Cooling is required for all applications

Model Compressor

BD*0300L6 2DF3F16KE 29,550 22,360 16,600 12,020 8,260

BD*0400L6 2DL3F20KE 34,150 26,490 19,700 14,040 9,720

BD*0600L6 2DB3F25KE 40,760 31,740 24,090 17,590 11,610

BD*0601L6 3DA3F28KE 45,660 35,530 26,850 19,820 14,490

BD*0750L6 3DB3F33KE 54,580 43,020 33,090 24,750 17,340

BD*0900L6 3DF3F40KE 71,130 54,890 41,380 30,310 21,160

BD*1000L6 3DS3F46KE 76,710 59,360 44,790 32,840 22,910

BD*1200L6 4DBNF54KE

BD*1500L6 4DHNF63KE 105,260 83,710 64,220 47,840 35,090

BD*2200L6 4DJNF76KE 128,480 100,480 77,000 56,810 37,610

5

Model Compressor

BD*0300L6 2DF3F16KE 28,290 21,330 15,780 11,330 7,660

BD*0400L6 2DL3F20KE 32,710 25,310 18,760 13,280 9,110

BD*0600L6 2DB3F25KE 39,140 30,400 22,950 16,630 10,800

BD*0601L6 3DA3F28KE 43,600 33,830 25,380 18,590 13,400

BD*0750L6 3DB3F33KE 52,320 41,070 31,370 23,220 15,960

BD*0900L6 3DF3F40KE 68,110 52,370 39,230 28,410 19,370

BD*1000L6 3DS3F46KE 73,390 56,560 42,420 30,760 20,950

BD*1200L6 4DBNF54KE

BD*1500L6 4DHNF63KE 100,790 80,080 61,220 45,360 32,960

BD*2200L6 4DJNF76KE 123,000 95,860 72,960 53,220 34,360

5

Capacity BTUH @ 90°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

93,640 73,070 54,700 39,300 27,090

Capacity BTUH @ 95°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

89,620 69,740 51,970 36,930 24,950

Model Compressor

BD*0300L6 2DF3F16KE 27,010 20,300 14,960 10,650 7,060

BD*0400L6 2DL3F20KE 31,220 24,100 17,800 12,520 8,520

BD*0600L6 2DB3F25KE 37,470 29,040 21,820 15,680 10,010

BD*0601L6 3DA3F28KE 41,530 32,110 23,920 17,350 12,300

BD*0750L6 3DB3F33KE 50,020 39,100 29,630 21,670 14,540

BD*0900L6 3DF3F40KE 65,070 49,820 37,060 26,480 17,570

BD*1000L6 3DS3F46KE 70,070 53,860 40,090 28,650 18,990

BD*1200L6 4DBNF54KE

BD*1500L6 4DHNF63KE 96,280 76,390 58,170 42,820 30,780

BD*2200L6 4DJNF76KE 117,490 91,210 68,890 49,570 30,960

5

Model Compressor

BD*0300L6 2DF3F16KE 24,410 18,300 13,350 9,320 5,900

BD*0400L6 2DL3F20KE 28,120 21,620 15,860 11,020 7,390

BD*0600L6 2DB3F25KE 34,100 26,230 19,560 13,830 8,520

BD*0601L6 3DA3F28KE - 28,690 21,030 14,850 10,050

BD*0750L6 3DB3F33KE - 35,100 26,120 18,510 11,700

BD*0900L6 3DF3F40KE 58,880 44,680 32,660 22,560 13,940

BD*1000L6 3DS3F46KE 63,260 48,180 35,270 24,360 15,020

BD*1200L6 4DBNF54KE

BD*1500L6 4DHNF63KE 87,200 68,800 51,950 37,630 26,260

BD*2200L6 4DJNF76KE 106,470 81,860 60,680 42,240 24,270

5

Capacity BTUH @ 100°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

85,560 66,270 49,090 34,440 22,660

Capacity BTUH @ 110°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

77,030 59,130 42,990 29,140 17,850

NOTES:

*=T for outdoor, N for indoor, S for Beacon IITM

Consult factory on all models for application above 110F ambient

23

Page 24

PERFORMANCE DATA

Discus Compressors - Low Temperature Applications† - R-22

Model Compressor

BD*0300L6 2DF3F16KE 30,290 23,370 17,270 12,330 8,890

BD*0400L6 2DL3F20KE 34,790 27,220 20,500 14,820 10,400

BD*0600L6 2DB3F25KE 41,490 32,700 24,910 18,330 13,080

BD*0601L6 3DA3F28KE 45,920 36,390 27,740 20,430 15,020

BD*0750L6 3DB3F33KE 54,910 44,060 34,180 25,680 18,800

BD*0900L6 3DF3F40KE 70,480 55,750 42,730 31,600 22,450

BD*1000L6 3DS3F46KE 75,470 59,800 45,880 33,960 25,450

BD*1200L6 4DBNF54KE 96,760 74,360 55,420 39,430 25,800

BD*1500L6 4DHNF63KE 104,910 83,500 64,300 47,760 34,500

BD*2200L6 4DJNF76KE 121,160 96,420 74,190 55,290 40,940

Model Compressor

BD*0300L6 2DF3F16KE 28,840 22,160 16,240 11,420 8,030

BD*0400L6 2DL3F20KE 33,310 25,870 19,290 13,760 9,490

BD*0600L6 2DB3F25KE 39,830 31,180 23,540 17,120 12,250

BD*0601L6 3DA3F28KE 44,070 34,760 26,290 19,090 13,570

BD*0750L6 3DB3F33KE 52,700 42,060 32,340 23,960 17,490

BD*0900L6 3DF3F40KE 67,890 53,290 40,440 29,540 21,020

BD*1000L6 3DS3F46KE 72,700 57,230 43,500 31,830 22,500

BD*1200L6 4DBNF54KE 93,080 71,170 52,620 36,980 23,670

BD*1500L6 4DHNF63KE 100,880 79,760 60,820 44,520 31,460

BD*2200L6 4DJNF76KE 116,660 92,430 70,610 52,030 37,530

Capacity BTUH @ 90°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

Capacity BTUH @ 95°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

Model Compressor

BD*0300L6 2DF3F16KE 27,390 20,950 15,220 10,510 7,160

BD*0400L6 2DL3F20KE 31,830 24,530 18,090 12,690 8,570

BD*0600L6 2DB3F25KE 38,180 29,660 22,170 15,920 11,120

BD*0601L6 3DA3F28KE 42,230 33,140 24,840 17,750 12,260

BD*0750L6 3DB3F33KE 50,480 40,050 30,500 22,230 15,640

BD*0900L6 3DF3F40KE 65,300 50,830 38,160 27,490 19,090

BD*1000L6 3DS3F46KE 69,940 54,660 41,140 29,690 20,640

BD*1200L6 4DBNF54KE 89,180 67,790 49,680 34,400 21,460

BD*1500L6 4DHNF63KE 96,860 76,020 57,340 41,270 28,450

BD*2200L6 4DJNF76KE 112,170 88,450 67,050 48,770 34,470

Model Compressor

BD*0300L6 2DF3F16KE 24,490 18,530 13,170 8,710 5,420

BD*0400L6 2DL3F20KE 28,870 21,840 15,680 10,560 6,730

BD*0600L6 2DB3F25KE 34,860 26,630 19,440 13,510 9,070

BD*0601L6 3DA3F28KE 38,530 29,890 21,930 15,040 9,630

BD*0750L6 3DB3F33KE 46,050 36,040 26,820 18,770 12,290

BD*0900L6 3DF3F40KE 60,130 45,910 33,580 23,360 15,560

BD*1000L6 3DS3F46KE 64,430 49,510 36,420 25,420 16,910

BD*1200L6 4DBNF54KE — 60,560 43,360 28,940 —

BD*1500L6 4DHNF63KE 88,840 68,570 50,390 34,760 22,410

BD*2200L6 4DJNF76KE 103,220 80,520 59,930 42,230 28,350

* = T for Outdoor, N for Indoor, S for Beacon II™

† Demand Cooling is required for operation at Low Temperature Applications

Consult factory on all models for applications above 110°F ambient.

Capacity BTUH @ 100°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

Capacity BTUH @ 110°F Ambient Suction Temperature

0°F -10°F -20°F -30°F -40°F

24

Page 25

ELECTRICAL DATA

Discus Compressor Models - Medium Temperature

or Air

™

Beacon II

Defrost

Unit

Voltage

Supply

†

Compressor

Condenser

Fan Motor

Model

Volts Ph Hz†RLA LRA Qty HP FLA MCA MOPD MCA MOPD Amps Amps MCA MOPD Amps Amps

BD*0500M6C 208-230 3 60 20 120 1 1/3 2.7 27.7 45

BD*0500M6D 460 3 60 9.4 60 1 1/3 1.9 15 20

BD*0500M6E 575 3 60 6.9 49 1 1/3 1.2 15 15

BD*0501M6C 208-230 3 60 20 120 1 1/3 2.7 27.7 45

BD*0501M6D 460 3 60 9.4 60 1 1/3 1.9 15 20

BD*0501M6E 575 3 60 7.1 49 1 1/3 1.2 15 15

BD*0750M6C 208-230 3 60 28.3 169 1 1/3 2.7 38.1 60

BD*0750M6D 460 3 60 12.4 85 1 1/3 1.9 20 25

BD*0750M6E 575 3 60 11.9 67 1 1/3 1.2 20 25

BD*0751M6C 208-230 3 60 28.7 169 2 1/3 5.4 41.3 70

BD*0751M6D 460 3 60 12.6 85 2 1/3 3.8 20 30

BD*0751M6E 575 3 60 11.9 67 2 1/3 2.4 20 25

BD*0800M6C 208-230 3 60 36.8 215 2 1/3 5.4 51.4 80

BD*0800M6D 460 3 60 17.9 106 2 1/3 3.8 26.2 40

BD*0800M6E 575 3 60 14.7 84 2 1/3 2.4 20.8 35

BD*1000M6C 208-230 3 60 39.1 215 2 1/3 5.4 54.3 90

BD*1000M6D 460 3 60 17.9 106 2 1/3 3.8 26.2 40

BD*1000M6E 575 3 60 14.8 84 2 1/3 2.4 20.9 35

BD*1200M6C 208-230 3 60 43.2 275 2 1/3 5.4 59.4 100

BD*1200M6D 460 3 60 21.2 138 2 1/3 3.8 30.2 50

BD*1500M6C 208-230 3 60 53.5 275 2 3/4 8.8 75.7 125 90.7 125 70 (2) 15 100 125 80 (2) 20

BD*1500M6D 460 3 60 26 138 2 3/4 4.4 36.9 60 51.9 70 40 (1) 15 75 80 60 (2) 15

BD*1500M6E 575 3 60 21.2 110 2 3/4 3.6 30 50 42 60 32 (1) 12 60 60 48 (1) 12

Low Amps^ High Amps^

Electric

Defrost

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

Def.

Htr.‡

Evap.

Fan

Electric

Defrost

50 60 40 (1) 15

25 30 20 (1) 8

20 20 16 (1) 6.4

50 60 40 (1) 15

25 30 20 (1) 8

20 20 16 (1) 6.4

60 80 48 (1) 20

31.3 35 25 (1) 10

25 35 20 (1) 8

61.3 90 48 (1) 20

31.3 40 25 (1) 10

25.3 35 20 (1) 8

87.5 100 70 (2) 20

43.8 50 35 (1) 13

35 45 28 (1) 10.4

87.5 110 70 (2) 20

43.8 50 35 (1) 13

35 45 28 (1) 10.4

87.5 110 70 (2) 20

43.8 60 35 (1) 13

Def.

Htr.‡

Evap.

Fan

Discus Compressor Models - Low Temperature

or Air

MOPD

™

Beacon II

Defrost

Unit

Voltage

Supply

†

Compressor

Condenser

Fan Motor

Model

Volts Ph Hz†RLA LRA Qty HP FLA MCA

BD*0300L6C 208-230 3 60 14.4 102 1 1/3 2.7 20.6 35

BD*0300L6D 460 3 60 7.1 52 1 1/3 1.9 15 15

BD*0300L6E 575 3 60 6 41 1 1/3 1.2 15 15

BD*0400L6C 208-230 3 60 23.6 161 1 1/3 2.7 32.2 50

BD*0400L6D 460 3 60 9.2 60 1 1/3 1.9 15 20

BD*0400L6E 575 3 60 6.9 49 1 1/3 1.2 15 15

BD*0600L6C 208-230 3 60 25.3 161 1 1/3 2.7 34.4 50

BD*0600L6D 460 3 60 11.9 80 1 1/3 1.9 20 25

BD*0600L6E 575 3 60 8.6 63 1 1/3 1.2 15 20

BD*0601L6C 208-230 3 60 24 150 1 1/3 2.7 32.7 50

BD*0601L6D 460 3 60 10.8 77 1 1/3 1.9 20 25

BD*0601L6E 575 3 60 9.4 62 1 1/3 1.2 15 20

BD*0750L6C 208-230 3 60 27.6 161 1 1/3 2.7 37.2 60

BD*0750L6D 460 3 60 14.1 83 1 1/3 1.9 20 30

BD*0750L6E 575 3 60 9.9 67 1 1/3 1.2 15 20

BD*0900L6C 208-230 3 60 33.2 215 2 1/3 5.4 46.9 80

BD*0900L6D 460 3 60 15 106 2 1/3 3.8 22.6 35

BD*0900L6E 575 3 60 14.1 84 2 1/3 2.4 20 30

BD*1000L6C 208-230 3 60 37.2 215 2 1/3 5.4 51.9 80

BD*1000L6D 460 3 60 16.7 106 2 1/3 3.8 24.6 40

BD*1000L6E 575 3 60 14.6 84 2 1/3 2.4 20.6 35

BD*1200L6C 208-230 3 60 46 220 2 3/4 8.8 66.3 110 81.3 125 40 (1) 15 87.5 125 70 (2) 20

BD*1200L6D 460 3 60 23 110 2 3/4 4.4 33.2 50 48.2 70 25 (1) 15 50 70 40 (1) 15

BD*1200L6E

BD*1500L6C 208-230 3 60 47.2 278 2 3/4 8.8 67.8 110 82.8 125 48 (1) 15 92.8 125 70 (2) 25

BD*1500L6D 460 3 60 23.6 139 2 3/4 4.4 33.9 50 48.9 70 25 (1) 15 50 70 40 (1) 15

BD*1500L6E 575 3 60 18.8 113 2 3/4 3.6 27.1 45 39.1 50 20 (1) 12 40 50 32 (1) 12

BD*2200L6C 208-230 3 60 57.7 278 2 3/4 8.8 80.9 125 95.9 150 48 (1) 15 105.9 150 70 (2) 25

BD*2200L6D 460 3 60 28.8 139 2 3/4 4.4 40.5 60 55.5 80 25 (1) 15 60 80 48 (1) 15

BD*2200L6E 575 3 60 21.7 113 2 3/4 3.6 30.7 50 42.7 60 20 (1) 12 47.5 60 38 (1) 12

* = T for Outdoors, N for Indoors, S for Beacon II™

† = Consult factory for 50Hz applications

‡ = Number of defrost heater contactors in parentheses

^ = Two fan large units have ability for a reduced amp electric defrost kit (low amps). Conrm proper defrost kit prior to ordering or installing.

5

R407C not available in 575/3/60.

5

575 3 60 15.6 106 2 3/4 3.6 23.1 35 35.1 50 20 (1) 12 40 50 32 (1) 12

Low Amps^ High Amps^

Electric

Defrost

MCA

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

— — — —

Def.

Htr.‡

MOPD

Amps Amps MCA

Evap.

Fan

Electric

Defrost

MOPD

50 50 40 (1) 15

25 25 20 (1) 8

20 20 16 (1) 6.4

60 70 48 (1) 15

31.3 35 25 (1) 8

25 25 20 (1) 6.4

75 80 60 (2) 20

37.5 40 30 (1) 10

30 30 24 (1) 8

75 80 60 (2) 20

37.5 40 30 (1) 10

30 30 24 (1) 8

75 80 60 (2) 20

37.5 40 30 (1) 10

30 30 24 (1) 8

87.5 100 70 (2) 20

43.8 50 35 (1) 13

35 40 28 (1) 10.4

87.5 100 70 (2) 20

43.8 50 35 (1) 13

35 45 28 (1) 10.4

Def.

Htr.‡

Amps Amps

Evap.

Fan

25

Page 26

UNIT SPECIFICATIONS

Discus Compressors - Medium Temperature

Unit

Model

BD*0500M6 2DC3R53KE 5.0 1/2 1-1/8 28 52 36-3/4 51-3/4 39-1/4 78 751

BD*0501M6 2DD3R63KE 5.0 1/2 1-1/8 28 52 36-3/4 51-3/4 39-1/4 78 751

BD*0750M6 2DL3R78KE 7.5 1/2 1-1/8 28 52 36-3/4 51-3/4 39-1/4 78 761

BD*0751M6 2DA3R89KE 7.5 5/8 1-3/8 67 78 36-3/4 63-3/4 39-1/4 82 985

BD*0800M6 3DA3R10ME 8.0 5/8 1-3/8 67 78 36-3/4 63-3/4 39-1/4 82 1,020

BD*1000M6 3DB3R12ME 10.0 5/8 1-3/8 67 78 36-3/4 63-3/4 39-1/4 82 1,045

BD*1200M6 3DF3R15ME 12.0 5/8 1-3/8 67 78 36-3/4 63-3/4 39-1/4 82 1,065

BD*1500M6 3DS3R17ME 15.0 7/8 1-5/8 87 98 41-3/4 75-1/8 48-3/4 81 1,182

Compressor

Model

Connections (OD)

HP

Liquid Suction Std Opt Length Width Height (dba)

Refrigerant Line

Rec. Capacity

@90% full (lbs)

Dimensions (inches)

Sound

Data

Net

Wt.

†

(lbs.)

Discus Compressors - Low Temperature

Unit

Model

BD*0300L6 2DF3F16KE 3.0 1/2 1-1/8 28 52 36-3/4 51-3/4 39-1/4 78 737

BD*0400L6 2DL3F20KE 4.0 1/2 1-1/8 28 52 36-3/4 51-3/4 39-1/4 78 741

BD*0600L6 2DB3F25KE 6.0 1/2 1-1/8 28 52 36-3/4 51-3/4 39-1/4 78 751

BD*0601L6 3DA3F28KE 6.0 1/2 1-1/8 28 52 36-3/4 51-3/4 39-1/4 81 781

BD*0750L6 3DB3F33KE 7.5 1/2 1-1/8 28 52 36-3/4 51-3/4 39-1/4 81 805

BD*0900L6 3DF3F40KE 9.0 5/8 1-3/8 67 78 36-3/4 63-3/4 39-1/4 82 1,030

BD*1000L6 3DS3F46KE 10.0 5/8 1-3/8 67 78 36-3/4 63-3/4 39-1/4 82 1,035

BD*1200L6 4DBNF54KE 12.0 7/8 1-5/8 67 87 41-3/4 75-1/8 48-3/4 82 1,199

BD*1500L6 4DHNF63KE 15.0 7/8 1-5/8 67 87 41-3/4 75-1/8 48-3/4 82 1,234

BD*2200L6 4DJNF76KE 22.0 7/8 1-5/8 87 98 41-3/4 75-1/8 48-3/4 82 1,224

* = T for Outdoors, N for Indoors, S for Beacon II™

†

FOR ALL SOUND DATA: Estimate sound pressure values are 5 feet from the unit. For estimating sound pressure from unit at dierent distances, deduct the following

from the unit values: 10 feet deducts 6 dba, 20 feet deducts 12 dba, 40 feet deducts 18 dba. This data is typical of “free eld” conditions for horizontal air cooled

condensing units at the outlet of the discharge air. The actual sound measurements may vary depending on the condensing unit installation. Factors such as

reecting walls, background noise, and mounting conditions may have a signicant inuence on this data.

Compressor

Model

Connections (OD)

HP

Liquid Suction Std Opt Length Width Height (dba)

Refrigerant Line

Rec. Capacity

@90% full (lbs)

Dimensions (inches)

Sound

Data

Net

Wt.

†

(lbs.)

26

Page 27

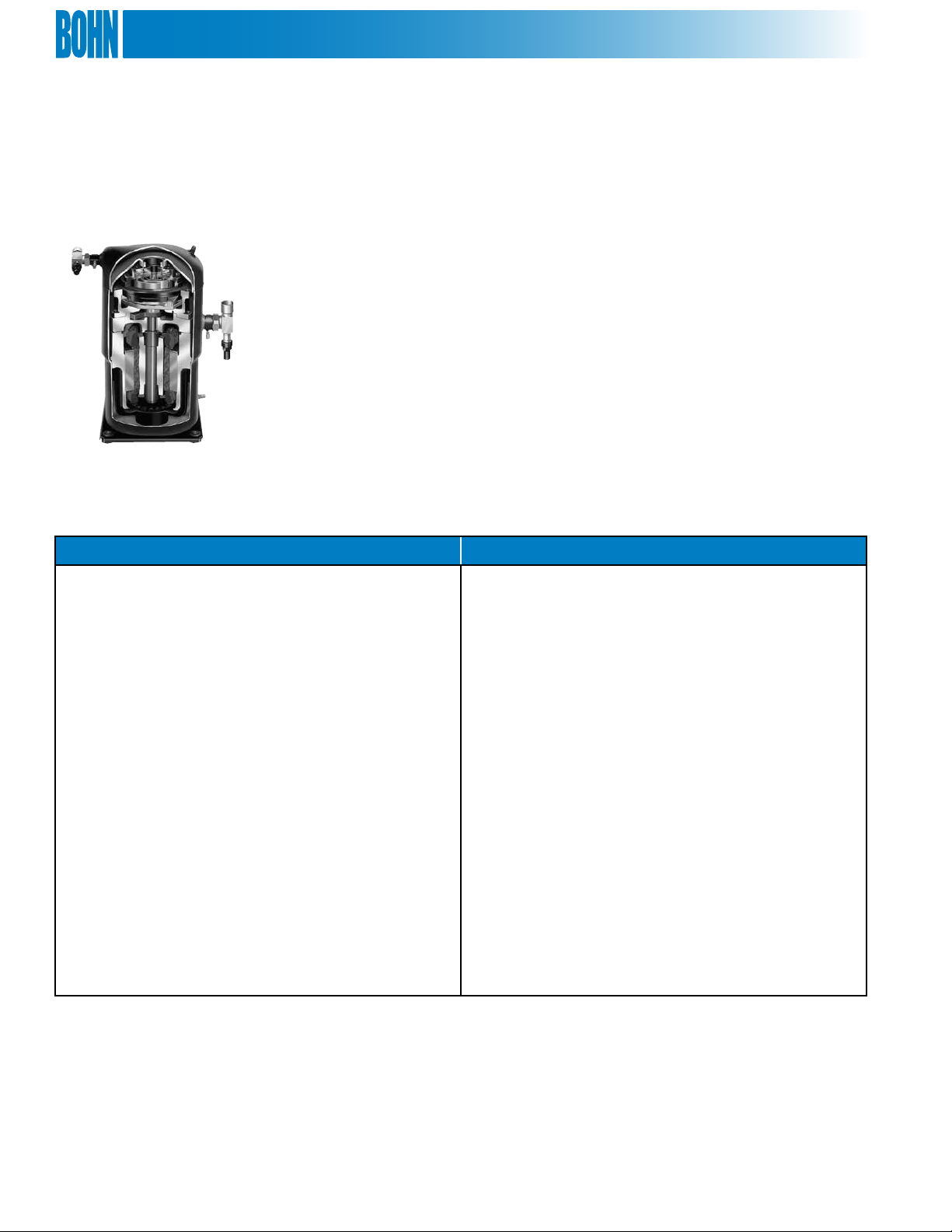

DIMENSIONAL DIAGRAMS

One Fan Condenser

Two Fan Condenser

Large Two Fan Condenser

LEFT SIDE

FRONT

Length

Height

Width

27

Page 28

For more information on Bohn refrigeration products, contact

your sales representative or visit us at heatcraftrpd.com.

A Brand of Heatcraft Refrigeration Products LLC

2175 West Park Place Blvd. • Stone Mountain, GA • 30087

(800) 537-7775

heatcraftrpd.com

BNHCUTB

July 2016

Since product improvement is a continuing eort, we reserve the right to

make changes in specications without notice.

Loading...

Loading...