Page 1

UNIT COOLERS FOR CO2 SYSTEMS

Technical Guide

Low Prole • Medium Prole • Low Velocity • Center Mount

BNCUCTB

September 2009

www.thecoldstandard.com

Page 2

Table of Contents

Nomenclature .........................................................................................................................................................................................................2

Features & Benets ...............................................................................................................................................................................................

Medium Temperature Overfeed/Recirculation

Low Prole ...................................................................................................................................................................................................4-5

Low Velocity ................................................................................................................................................................................................ 6-7

Medium Prole ...............................................................................................................................................................................................8

Low Temperature DX

Low Prole .................................................................................................................................................................................................9-10

Medium Prole .............................................................................................................................................................................................11

Center Mount ................................................................................................................................................................................................12

3

Nomenclature

Medium Temperature Overfeed / Recirculation

ADT R 065 B K

Model Series Type Capacity Electrical Code Design Revision

ADT = Low Prole Air Defrost, 6 FPI

LET = Low Prole Electric Defrost, 6 FPI

BMA = Medium Prole Air Defrost, 6 FPI

WKA = Low Velocity Center Mount Air

Defrost, 6 FPI

WKE = Low Velocity Center Mount Electric

Defrost, 6 FPI

Low Temperature DX

ADT C 065 B K

Model Series Type Capacity Electrical Code Design Revision

LET = Low Prole Electric Defrost, 6 FPI

LLE = Low Prole Electric Defrost, 4.5 FPI

BML = Medium Prole Electric Defrost, 4.5 FPI

SME = Center Mount Electric Defrost, 6 FPI

2

R = CO2, Medium

Temperature

Overfeed/

Recirculation

C = CO2, Low

Temperature

DX

# x 100 = BTUH AE = 115/1/60

BE = 208-230/

1/60

# x 100 = BTUH AE = 115/1/60

BE = 208-230/

1/60

©2009 Heatcraft Refrigeration Products, LLC

(Varies depending

on model series)

(Varies depending

on model series)

Page 3

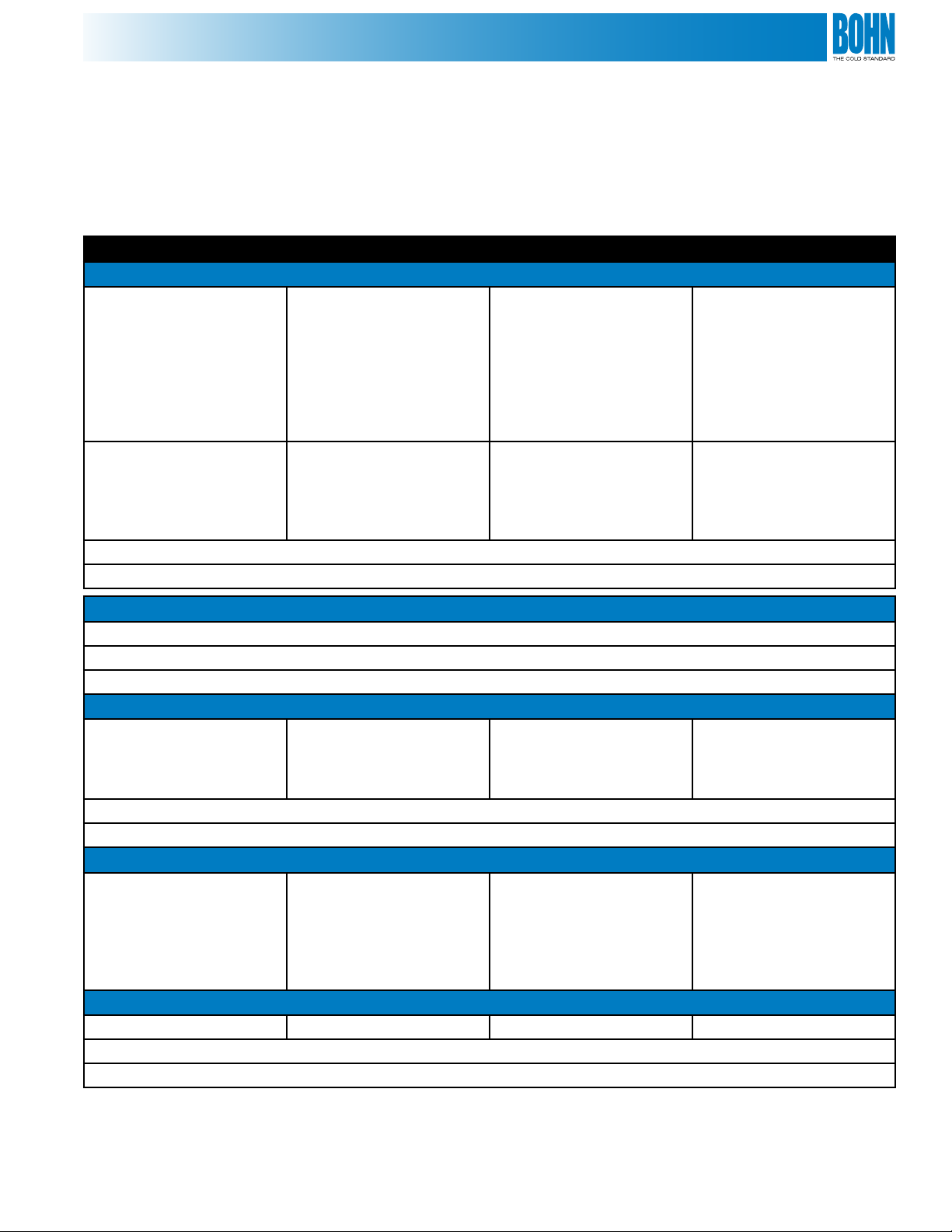

Features & Benefits

The models featured here are specically designed for use with carbon dioxide (CO2) refrigeration systems, which are

optimized for lifecycle climate performance (LCCP). Carbon dioxide refrigeration systems have zero ozone depletion potential

and a very low global warming potential . The evaporators described in this technical guide are UL listed for the US and

Canada and meet NSF standards.

LOW VELOCITY LOW PROFILE MEDIUM PROFILE CENTER MOUNT

CABINET

Air moves across the ceiling

Low air velocity helps to

maintain high humidities

and prevent product drying

and weight loss; low sound

makes a comfortable

working environment

Textured aluminum cabinet

for maximum durability

All electrical components factory wired to terminal board and identied, making it easy to eld wire the unit.

Minimal height of the low

prole series makes it ideal

for low ceiling coolers,

allowing for maximum

headroom and more product

storage

Textured aluminum cabinet

design features front access

panels on each side for easy

access to electrical and

refrigeration components

Internal panels are “isolated” which provides for quiet unit operation

Heavy-duty design is ideal

for larger walk-in coolers and

freezers

Textured aluminum cabinet

for maximum durability

in both directions providing

even air distribution

throughout the cooler.

Compact, ceiling mount

design allows for shelving

and storage of product

around walls.

Heavy-guage grained

aluminum cabinet cleans

easily and looks attractive

Wire fan guards with PVC

coating are standard and

provide added durability

Double drain pan eliminates

drain pan swelling and

tapered mounting provides

proper slope for condensate

drainage to one end of the

unit

– – 575 volt units available –

HEATERS AND COIL

Heater/fan control is factory set and wired

Coils are dehydrated and sealed at the factory

Sweat connections to reduce potential for leaks

GUARDS AND MOTORS

Featuring plastic guards and

a motor mount design that

is optimized to minimize

vibration

Energy-ecient EC motors are standard (Totally Enclosed)

Motors plug into wiring harness for easier servicing

Standard molded fan guards

provide excellent air throw

(optional wire fan guard for

diused air pattern)

DRAIN PAN

Optimized drain tting

position

Front hinged drain pan for

easy access

OPTIONS

Available in stainless steel cabinets and/or drain pan

Copper n or coil coating (available for air defrost only)

Wire fan guards with PVC

coating for durability

Double drain pan eliminates

drain pan swelling and

tapered mounting provides

proper slope for condensate

drainage to one end of the

unit

3

Page 4

Medium Temperature Overfeed / Recirculation

Low Profile

Capacities Air Defrost

Capacity Fan Data Fan Motor Data (EC)

Model

ADTR065 6,500 1 650 1/15 0.9 57 0.5 59

ADTR070 7,000 2 1,460 1/15 1.8 114 1.0 118

ADTR090 9,000 2 1,400 1/15 1.8 114 1.0 118

ADTR104 10,400 2 1,400 1/15 1.8 114 1.0 118

ADTR130 13,000 2 1,300 1/15 1.8 114 1.0 118

ADTR156 15,600 3 2,100 1/15 2.7 171 1.5 177

ADTR180 18,000 3 1,950 1/15 2.7 171 1.5 177

ADTR208 20,800 4 2,800 1/15 3.6 228 2.0 236

ADTR260 26,000 5 3,250 1/15 4.5 285 2.5 295

10°F TD

25°F SST

BTUH Amps Watts Amps Watts

No. CFM HP

Capacities Electric Defrost

Capacity Fan Data Fan Motor Data (EC) Defrost Heaters

Model

LETR065 7,475 2 1,400 1/15 1.0 118 1,800 7.8

LETR090 10,350 2 1,300 1/15 1.0 118 1,800 7.8

LETR120 13,800 3 2,100 1/15 1.5 177 2,700 11.7

LETR140 16,100 3 1,950 1/15 1.5 177 2,700 11.7

LETR160 18,400 4 2,600 1/15 2.0 236 3,600 15.7

LETR200 23,000 5 3,250 1/15 2.5 295 4,500 19.6

LETR240 27,600 6 3,900 1/15 3.0 354 5,400 23.5

LETR280 32,200 6 3,900 1/15 3.0 354 5,400 23.5

10°F TD

25°F SST

BTUH Amps Watts Amps

No. CFM HP

115/1/60 208-230/1/60

208-230/1/60

Watts

230/1/60

Physical Data Air & Electric Defrost

Model

ADTR065 1 6 3/8 3/8 3/4 FPT Air 34

ADTR070 2 6 3/8 3/8 3/4 FPT Air 45

ADTR090 2 6 3/8 3/8 3/4 FPT Air 48

ADTR104 2 6 3/8 3/8 3/4 FPT Air 49

ADTR130 2 6 3/8 3/8 3/4 FPT Air 53

ADTR156 3 6 3/8 3/8 3/4 FPT Air 67

ADTR180 3 6 3/8 3/8 3/4 FPT Air 69

ADTR208 4 6 1/2 3/8 3/4 FPT Air 82

ADTR260 5 6 1/2 1/2 3/4 FPT Air 103

LETR065 2 6 3/8 3/8 3/4 FPT Electric 43

LETR090 2 6 3/8 3/8 3/4 FPT Electric 48

LETR120 3 6 3/8 3/8 3/4 FPT Electric 60

LETR140 3 6 3/8 3/8 3/4 FPT Electric 62

LETR160 4 6 3/8 3/8 3/4 FPT Electric 81

LETR200 5 6 1/2 1/2 3/4 FPT Electric 101

LETR240 6 6 1/2 1/2 3/4 FPT Electric 121

LETR280 6 6 1/2 1/2 3/4 FPT Electric 124

No. of

Fans

FPI Coil Inlet Coil Outlet lbs.

Coil Data

Condensate

Drain

Defrost

Type

Approx. Net Wt.

4

Page 5

AIR

FLOW

Outlet

Inlet

Connections

Piping

Connection

End

Inlet

Outlet

3/4" MPT (14 NPS)

19mm

Drain Connection

Electrical

Connection

End

2 7/8"

73mm

1 5/16"

33mm

1 15/16"

49mm

TYP

6 1/8"

156mm

"C" "D"

"A"

6 1/8"

156mm

"B"

1 3/4"

44mm

TYP

13 1/4"

337mm

14 15/16"

379mm

12"

305mm

14 7/8"

378mm

1 3/4"

44mm

3 5/16"

84mm

8 1/8"

206mm

16"

407mm

Medium Temperature Overfeed / Recirculation

Low Profile

Dimensional Diagram Air & Electric Defrost

Dimensional Data Air & Electric Defrost

Dimensions

Model

No. of

Fans

A B C D

in. mm in. mm in. mm in. mm

ADTR065 1 29.50 749 17.25 438 - - - ADTR070 2 45.50 1,156 33.25 845 - - - ADTR090 2 45.50 1,156 33.25 845 - - - ADTR104 2 45.50 1,156 33.25 845 - - - ADTR120 2 45.50 1,156 33.25 845 - - - ADTR130 2 45.50 1,156 33.25 845 - - - ADTR156 3 61.50 1,562 49.25 1,251 - - - ADTR180 3 61.50 1,562 49.25 1,251 - - - ADTR208 4 77.50 1,969 65.25 1,657 - - - ADTR260 5 93.50 2,375 81.25 2,064 48.63 1,235 32.63 829

LETR065 2 45.50 1,156 33.25 845 - - - LETR090 2 45.50 1,156 33.25 845 - - - LETR120 3 61.50 1,562 49.25 1,251 - - - LETR140 3 61.50 1,562 49.25 1,251 - - - LETR160 4 77.50 1,969 65.25 1,657 - - - LETR200 5 93.50 2,375 81.25 2,064 48.63 1,235 32.63 829

LETR240 6 109.50 2,781 97.25 2,470 48.63 1,235 48.63 1,235

LETR280 6 109.50 2,781 97.25 2,470 48.63 1,235 48.63 1,235

NOTE: Hanger brackets will accept 3/8"/10 mm threaded rod

5

Page 6

Medium Temperature Overfeed / Recirculation

Low Velocity

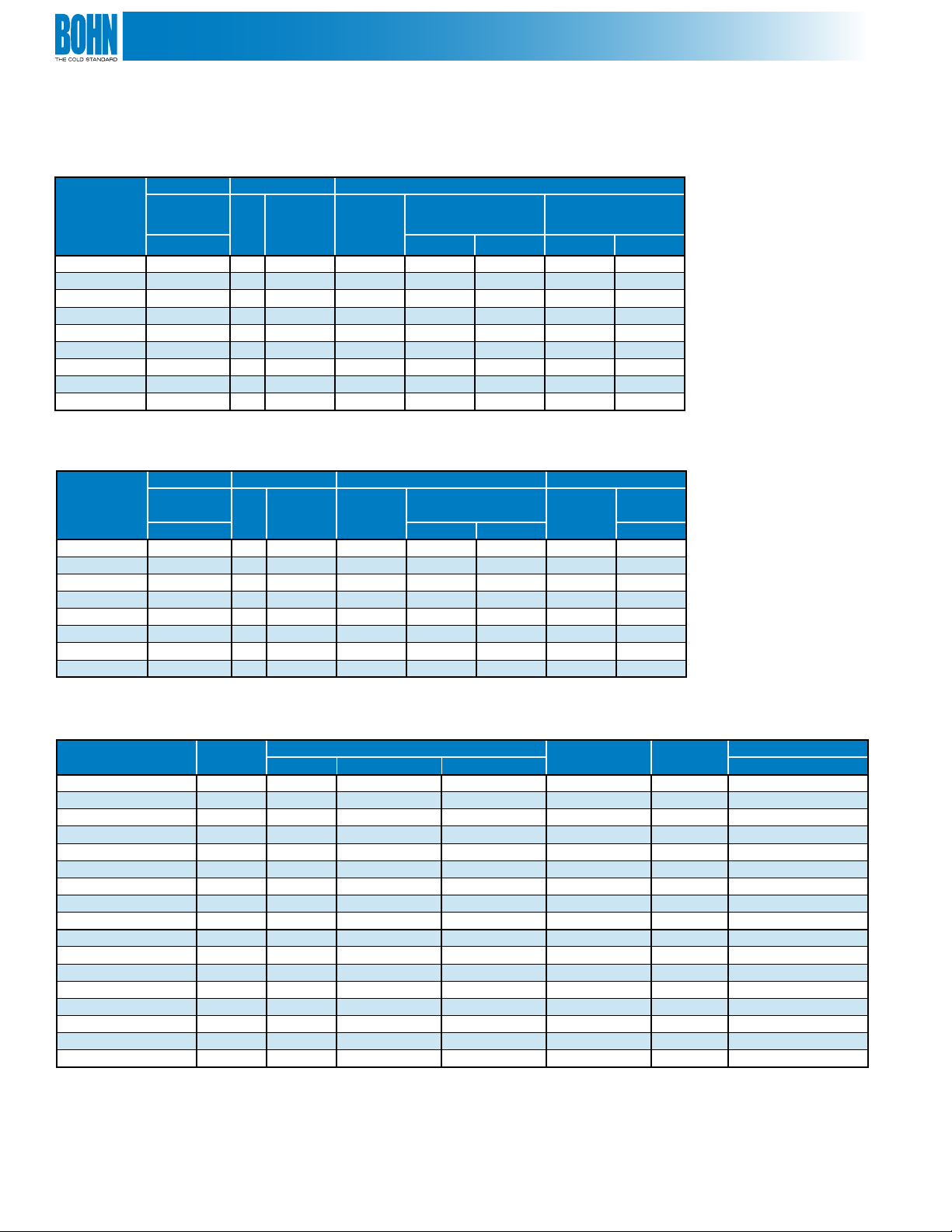

Capacities Air Defrost

Capacity Fan Data Fan Motor Data (EC)

Model

WKAR050 5,000 1 725 1/15 0.9 55 0.5 55

WKAR075 7,500 1 730 1/15 0.9 55 0.5 55

WKAR100 10,000 2 1,450 1/15 1.8 110 1.0 110

WKAR130 13,000 2 1,470 1/15 1.8 110 1.0 110

WKAR155 15,500 2 1,460 1/15 1.8 110 1.0 110

WKAR180 18,000 3 2,130 1/15 2.7 165 1.5 165

WKAR210 21,000 4 2,840 1/15 3.6 220 2.0 220

WKAR270 27,000 4 2,800 1/15 3.6 220 2.0 220

WKAR340 34,000 5 3,500 1/15 4.5 275 2.5 275

Capacities Electric Defrost

Model

WKER050 5,000 1 725 1/15 0.5 55 2,000 8.7

WKER075 7,500 1 730 1/15 0.5 55 2,400 10.5

WKER100 10,000 2 1,450 1/15 1.0 110 2,800 12.2

WKER130 13,000 2 1,470 1/15 1.0 110 4,000 17.4

WKER155 15,500 2 1,460 1/15 1.0 110 4,000 17.4

WKER180 18,000 3 2,130 1/15 1.5 165 4,000 17.4

WKER210 21,000 4 2,840 1/15 2.0 220 5,200 22.6

WKER270 27,000 4 2,800 1/15 2.0 220 5,200 22.6

WKER340 34,000 5 3,500 1/15 2.5 275 7,000 30.4

10°F TD

25°F SST

BTUH Amps Watts Amps Watts

Capacity Fan Data Fan Motor Data (EC) Defrost Heaters

10°F TD

25°F SST

BTUH Amps Watts Amps

No. CFM HP

No. CFM HP

115/1/60 208-230/1/60

208-230/1/60

Watts

230/1/60

Physical Data Air & Electric Defrost

Model

WKAR050 1 6 3/8 3/8 3/4 FPT Air 70

WKAR075 1 6 3/8 3/8 3/4 FPT Air 103

WKAR100 2 6 3/8 3/8 3/4 FPT Air 106

WKAR130 2 6 3/8 3/8 3/4 FPT Air 145

WKAR155 2 6 3/8 3/8 3/4 FPT Air 149

WKAR180 3 6 3/8 3/8 3/4 FPT Air 160

WKAR210 4 6 1/2 3/8 3/4 FPT Air 193

WKAR270 4 6 1/2 1/2 3/4 FPT Air 200

WKAR340 5 6 1/2 1/2 3/4 FPT Air 242

WKER050 1 6 3/8 3/8 3/4 FPT Electric 75

WKER075 1 6 3/8 3/8 3/4 FPT Electric 108

WKER100 2 6 3/8 3/8 3/4 FPT Electric 111

WKER130 2 6 3/8 3/8 3/4 FPT Electric 150

WKER155 2 6 3/8 3/8 3/4 FPT Electric 154

WKER180 3 6 3/8 3/8 3/4 FPT Electric 157

WKER210 4 6 1/2 3/8 3/4 FPT Electric 203

WKER270 4 6 1/2 1/2 3/4 FPT Electric 208

WKER340 5 6 1/2 1/2 3/4 FPT Electric 250

No. of

Fans

FPI Coil Inlet Coil Outlet lbs.

Coil Data

Condensate

Drain

Defrost

Type

6

Approx. Net Wt.

Page 7

Medium Temperature Overfeed / Recirculation

5 1/2

I

4

L

G

H

ELECTRICAL CONNECTION

(7/8 DIA. KO)

OUTLET

CONNECTION

INLET

CONNECTION

DRAIN

3/4 FPT

15/16

(24

mm)

3/8 DIA

MOUNTING

HOLES

28 13/16

1 1/4

1 1/4

9/16

9/16

26 1/2

E

F

C

D

B

A

(10 mm)

(140 mm)

(22 mm DIA.)

(102 mm)

(673 mm)

(19mm)

(14 mm)

(32 mm)

(32 mm)

(14 mm)

(732mm)

3/4

(19 mm)

Low Velocity

Dimensional Diagram Air & Electric Defrost

Dimensional Data Air & Electric Defrost

Model

WKAR050 1 6-7/8 175 8-7/8 225 4-1/16 103 - - 4-5/8 118 3-1/4 83 1-5/8 41 53-1/2 1,359

WKAR075 1 6-7/8 175 8-7/8 225 4-1/16 103 - - 4-5/8 118 3-1/4 83 1-5/8 41 75-1/2 1,918

WKAR100 2 9-3/8 238 11-3/8 289 6-9/16 167 - - 7-1/8 181 3-1/4 83 1-5/8 41 75-1/2 1,918

WKAR130 2 13-1/8 333 15-1/8 384 10-1/8 257 - - 8-1/2 216 2-11/16 68 1-1/8 29 75-1/2 1,918

WKAR155 2 13-1/8 333 15-1/8 384 10-1/8 257 - - 8-1/2 216 2-11/16 68 1-1/8 29 75-1/2 1,918

WKAR180 3 13-1/8 333 15-1/8 384 10-1/8 257 - - 8-1/2 216 2-11/16 68 1-1/8 29 75-1/2 1,918

WKAR210 4 13-1/8 333 15-1/8 384 10-1/8 257 44 1,118 8-1/2 216 2-11/16 68 1-1/8 29 97-1/2 2,477

WKAR270 4 13-1/8 333 15-1/8 384 10-1/8 257 44 1,118 8-1/2 216 2-11/16 68 1-1/8 29 97-1/2 2,477

WKAR340 5 13-1/8 333 15-1/8 384 10-1/8 257 55 1,397 8-1/2 216 2-11/16 68 1-1/8 29 119-1/2 3,035

WKER050 1 6-7/8 175 8-7/8 225 4-1/16 103 - - 4-5/8 118 3-1/4 83 1-5/8 41 53-1/2 1,359

WKRE075 1 6-7/8 175 8-7/8 225 4-1/16 103 - - 4-5/8 118 3-1/4 83 1-5/8 41 75-1/2 1,918

WKER100 2 9-3/8 238 11-3/8 289 6-9/16 167 - - 7-1/8 181 3-1/4 83 1-5/8 41 75-1/2 1,918

WKER130 2 13-1/8 333 15-1/8 384 10-1/8 257 - - 8-1/2 216 2-11/16 68 1-1/8 29 75-1/2 1,918

WKER155 2 13-1/8 333 15-1/8 384 10-1/8 257 - - 8-1/2 216 2-11/16 68 1-1/8 29 75-1/2 1,918

WKER180 3 13-1/8 333 15-1/8 384 10-1/8 257 - - 8-1/2 216 2-11/16 68 1-1/8 29 75-1/2 1,918

WKER210 4 13-1/8 333 15-1/8 384 10-1/8 257 44 1,118 8-1/2 216 2-11/16 68 1-1/8 29 97-1/2 2,477

WKER270 4 13-1/8 333 15-1/8 384 10-1/8 257 44 1,118 8-1/2 216 2-11/16 68 1-1/8 29 97-1/2 2,477

WKER340 5 13-1/8 333 15-1/8 384 10-1/8 257 55 1,397 8-1/2 216 2-11/16 68 1-1/8 29 119-1/2 3,035

No. of

Fans

A B C D E F G L

in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm

NOTE: 3/8" diameter mounting holes

Dimensions

7

Page 8

Medium Temperature Overfeed / Recirculation

Medium Profile

Capacities Air Defrost

Capacity Fan Data Fan Motor Data (EC)

Model

BMAR130 13,000 1 2,300 1/4 2.8 210 1.4 205

BMAR155 15,500 1 2,200 1/4 2.8 210 1.4 205

BMAR245 24,500 2 4,600 1/4 5.6 420 2.8 410

BMAR300 30,000 2 4,400 1/4 5.6 420 2.8 410

BMAR365 36,500 3 6,900 1/4 8.4 630 4.2 615

BMAR450 45,000 3 6,600 1/4 8.4 630 4.2 615

Physical Data Air Defrost

Model

BMAR130 1 6 3/8 3/8 3/4 FPT Air 115

BMAR155 1 6 3/8 3/8 3/4 FPT Air 123

BMAR245 2 6 1/2 1/2 3/4 FPT Air 134

BMAR300 2 6 1/2 1/2 3/4 FPT Air 148

BMAR365 3 6 1/2 1/2 3/4 FPT Air 200

BMAR450 3 6 5/8 5/8 3/4 FPT Air 227

10°F TD

25°F SST

BTUH Amps Watts Amps Watts

No. of

Fans

No. CFM HP

Coil Data

FPI Coil Inlet Coil Outlet lbs.

115/1/60 208-230/1/60

Condensate

Drain

Defrost

Type

Approx. Net Wt.

Dimensional Diagram Air Defrost

Dimensional Data Air Defrost

Model

BMAR130 1 39-5/16 1,000 30-1/4 770 - - - - - - 4-15/16 125

BMAR155

BMAR245

BMAR300

BMAR365

BMAR450

No. of

Fans

1 39-5/16 1,000 30-1/4 770 - - - - - - 4-15/16 125

2 67-5/16 1,710 58-1/4 1,480 - - - - - - 4-15/16 125

2 67-5/16 1,710 58-1/4 1,480 - - - - - - 4-15/16 125

3 95-5/16 2,420 86-1/4 2,190 - - - - - - 4-15/16 125

3 95-5/16 2,420 86-1/4 2,190 - - - - - - 4-15/16 125

A B C D E F

in. mm in. mm in. mm in. mm in. mm in. mm

NOTE: Hanger brackets will accept up to 1/2"/12 mm threaded rod

Dimensions

8

Page 9

Low Temperature DX

Low Profile

Capacities Electric Defrost, 6 FPI

Capacity Fan Data Fan Motor Data (EC) Defrost Heaters

Model

LETC065 6,500 2 1,400 1/15 1.0 118 1,800 7.8

LETC090 9,000 2 1,300 1/15 1.0 118 1,800 7.8

LETC120 12,000 3 2,100 1/15 1.5 177 2,700 11.7

LETC140 14,000 3 1,950 1/15 1.5 177 2,700 11.7

LETC160 16,000 4 2,600 1/15 2.0 236 3,600 15.7

LETC200 20,000 5 3,250 1/15 2.5 295 4,500 19.6

LETC240 24,000 6 3,900 1/15 3.0 354 5,400 23.5

LETC280 28,000 6 3,900 1/15 3.0 354 5,400 23.5

Capacities Electric Defrost, 4.5 FPI

Model

LLEC080 8,000 2 1,380 1/15 1.0 118 1,800 7.8

LLEC102 10,200 3 2,170 1/15 1.5 177 2,700 11.7

LLEC136 13,600 4 2,760 1/15 2.0 236 3,600 15.7

LLEC170 17,000 5 3,450 1/15 2.5 295 4,500 19.6

LLEC235 23,500 6 4,140 1/15 3.0 354 5,400 23.5

10°F TD

-20°F SST

BTUH Amps Watts Amps

Capacity Fan Data Fan Motor Data (EC) Defrost Heaters

10°F TD

-20°F SST

BTUH Amps Watts Amps

No. CFM HP

No. CFM HP

208-230/1/60

208-230/1/60

Watts

Watts

230/1/60

230/1/60

Physical Data Electric Defrost, 6 & 4.5 FPI

Model

LETC065 2 6 1/2 3/8 3/4 FPT Electric 43

LETC090 2 6 1/2 1/2 3/4 FPT Electric 48

LETC120 3 6 1/2 1/2 3/4 FPT Electric 60

LETC140 3 6 1/2 1/2 3/4 FPT Electric 62

LETC160 4 6 1/2 1/2 3/4 FPT Electric 81

LETC200 5 6 1/2 1/2 3/4 FPT Electric 101

LETC240 6 6 1/2 5/8 3/4 FPT Electric 121

LETC280 6 6 1/2 5/8 3/4 FPT Electric 124

LLEC080 2 4.5 1/2 3/8 3/4 FPT Electric 47

LLEC102 3 4.5 1/2 1/2 3/4 FPT Electric 59

LLEC136 4 4.5 1/2 1/2 3/4 FPT Electric 80

LLEC170 5 4.5 1/2 1/2 3/4 FPT Electric 100

LLEC235 6 4.5 1/2 5/8 3/4 FPT Electric 120

No. of

Fans

FPI Coil Inlet Suction lbs.

Coil Data

Condensate

Drain

Defrost

Type

Approx. Net Wt.

9

Page 10

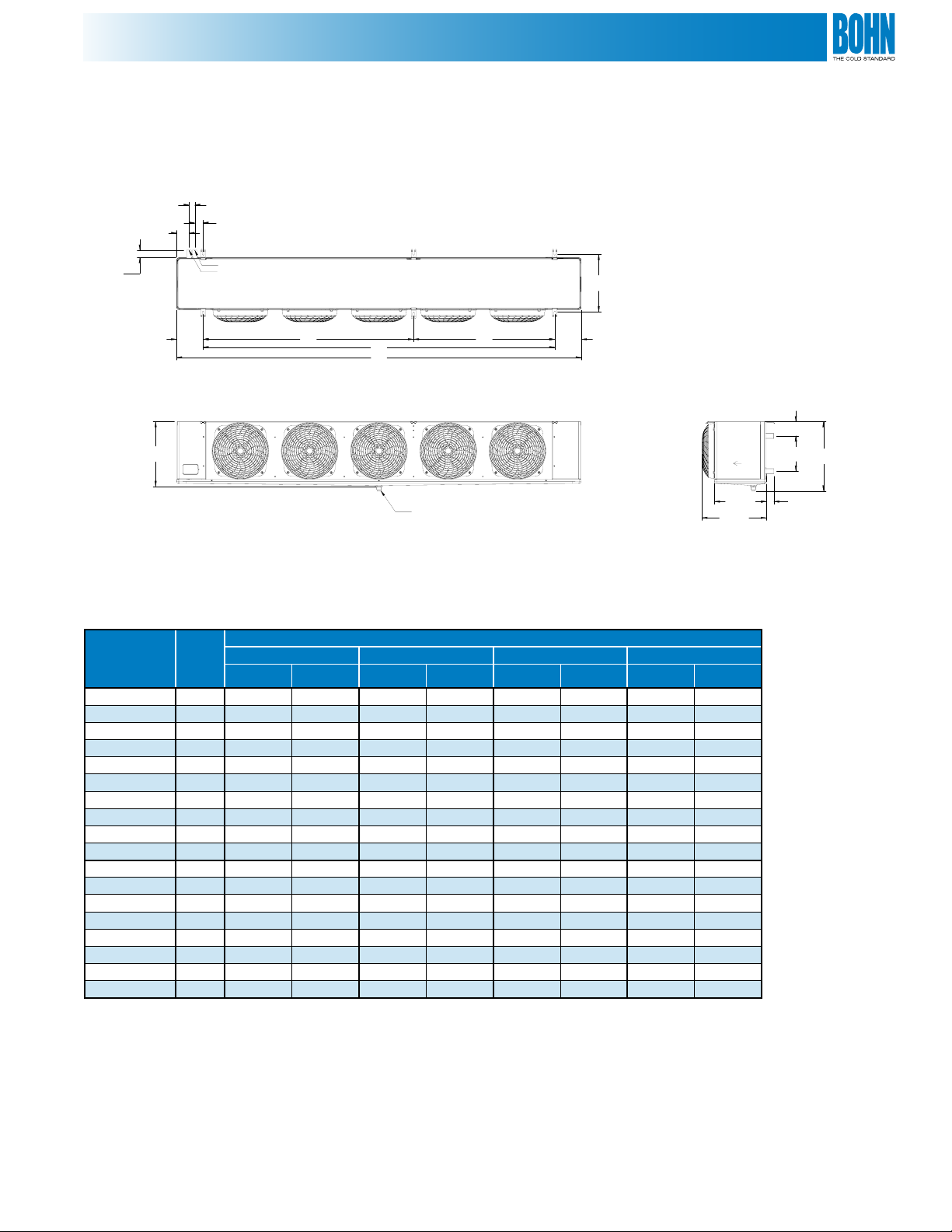

Low Temperature DX

Low Profile

Dimensional Diagram Electric Defrost, 6 & 4.5 FPI

Dimensional Data Electric Defrost, 6 & 4.5 FPI

Model

LETC065 2 45.50 1,156 33.25 845 - - - LETC090 2 45.50 1,156 33.25 845 - - - LETC120 3 61.50 1,562 49.25 1,251 - - - LETC140 3 61.50 1,562 49.25 1,251 - - - LETC160 4 77.50 1,969 65.25 1,657 - - - LETC200 5 93.50 2,375 81.25 2,064 48.63 1,235 32.63 829

LETC240 6 109.50 2,781 97.25 2,470 48.63 1,235 48.63 1,235

LETC280 6 109.50 2,781 97.25 2,470 48.63 1,235 48.63 1,235

LLEC080 2 45.50 1,156 33.25 845 - - - LLEC102 3 61.50 1,562 49.25 1,251 - - - LLEC136 4 77.50 1,969 65.25 1,657 - - - LLEC170 5 93.50 2,375 81.25 2,064 48.63 1,235 32.63 829

LLEC235 6 109.50 2,781 97.25 2,470 48.63 1,235 48.63 1,235

No. of

Fans

A B C D

in. mm in. mm in. mm in. mm

NOTE: Hanger brackets will accept 3/8"/10mm threaded rod

Dimensions

Nozzle Selection Electric Defrost, 6 & 4.5 FPI

Model

LETC065 2 3/16 15 1 N/A

LETC090 2 3/16 15 1 N/A

LETC120 3 3/16 15 2 L 1/3

LETC140 3 3/16 15 2 L 1/3

LETC160 4 3/16 15 2 L 1/2

LETC200 5 3/16 15 3 L 1/2

LETC240 6 3/16 15 3 L 3/4

LETC280 6 3/16 15 3 L 3/4

LLEC080 2 3/16 15 1 N/A

LLEC102 3 3/16 15 1 N/A

LLEC136 4 3/16 15 2 L 1/3

LLEC170 5 3/16 15 2 L 1/2

LLEC235 6 3/16 15 3 L 3/4

No. of

Fans

Distributor Tube (in.) No. of

OD Length

Circuits

CO2 Nozzle

Nozzle selections for Low Temp DX

applications only

Assumptions: 20°F Liquid temperature

-20°F SST

8-15°F TD

10

Page 11

Low Temperature DX

22-3/4"

578 mm

15-1/2"

390 mm

23 -1/4"

590 mm

2-1/2"

64 mm

24"

608 mm

18-7/8"

480 mm

17-1/2"

444 mm

Electrical

Connection

End

Refrigerant

Connection

End

Air

Flow

Medium Profile

Capacities Electric Defrost

Capacity Fan Data Fan Motor Data (EC) Defrost Heaters

Model

BMLC100 10,000 1 2,325 1/4 1.4 275 2,730 11.9

BMLC165 16,500 2 4,900 1/4 2.8 550 5,350 23.3

BMLC220 22,000 2 4,650 1/4 2.8 550 5,350 23.3

BMLC250 25,000 3 7,350 1/4 4.2 825 7,750 33.7

BMLC330 33,000 3 6,975 1/4 4.2 825 7,750 33.7

Physical Data Electric Defrost

Model

BMLC100 1 4.5 1/2 1/2 3/4 FPT Electric 125

BMLC165 2 4.5 1/2 1/2 3/4 FPT Electric 136

BMLC220 2 4.5 1/2 1/2 3/4 FPT Electric 151

BMLC250 3 4.5 1/2 5/8 3/4 FPT Electric 207

BMLC330 3 4.5 1/2 5/8 3/4 FPT Electric 234

Dimensional Diagram Electric Defrost

10°F TD

-20°F SST

BTUH Amps Watts Amps

No. of

Fans

No.

CFM HP

Coil Data

FPI Coil Inlet Suction lbs.

208-230/1/60

Watts

Condensate

Drain

230/1/60

Defrost

Approx. Net Wt.

Type

Dimensional Data Electric Defrost

Models

BMLC100 1 39-5/16 1,000 30-1/4 770 - - - - - - 4-15/16 125

BMLC165 2 67-5/16 1,710 58-1/4 1,480 - - - - - - 4-15/16 125

BMLC220 2 67-5/16 1,710 58-1/4 1,480 - - - - - - 4-15/16 125

BMLC250 3 95-5/16 2,420 86-1/4 2,190 - - - - - - 4-15/16 125

BMLC330 3 95-5/16 2,420 86-1/4 2,190 - - - - - - 4-15/16 125

NOTE: Hanger brackets will accept 1/2"/12 mm threaded rod

Nozzle Selection Electric Defrost

Model

BMLC100 1 3/16 21-1/2 2 L 1/4

BMLC165 2 3/16 21-1/2 2 L 1/2

BMLC220 2 3/16 21-1/2 3 L 3/4

BMLC250 3 3/16 21-1/2 3 L 3/4

BMLC330 3 3/16 21-1/2 4 L 1

No. of

Fans

No. of

Fans

A B C D E F

in. mm in. mm in. mm in. mm in. mm in. mm

Distributor Tube (in.)

OD Length

No. of

Circuits

Dimensions

CO

2

Nozzle

Nozzle selections for Low Temp DX

applications only

Assumptions: 20°F Liquid temperature

-20°F SST

8-15°F TD

11

Page 12

Low Temperature DX

3/8" DIA. MTG. HOLES

ELECTRICAL

CONNECTION

(OPPOSITE SIDE)

REFRIGERANT

CONNECTION

(OPPOSITE SIDE)

DRAIN

AIR OUT AIR OUT

AIR IN

REFRIGERANT

CONNECTION

AIR IN

7-9/16"

192 mm

8-5/8"

219 mm

28-13/16"

732 mm

3/5"

31 mm

3/5"

31 mm

6-7/8"

175 mm

L

27-5/8"

702 mm

5-1/2"

140 mm

2-7/8"

71 mm

5-3/4"

146 mm

22"

560 mm

10-1/4"

261 mm

11-3/4"

299 mm

22"

560 mm

3-13/16"

97 mm

Center Mount

Capacities Electric Defrost

Capacity Fan Data

Model

10˚F TD

-20˚F SST

No. CFM

BTUH

SMEC090 9,000 3 1,950

SMEC130 13,000 3 1,830

SMEC174 17,400 4 2,440

Physical Data Electric Defrost

Model No. of Fans

FPI Inlet OD Suction OD lbs.

SMEC090 3 6 1/2 1/2 3/4 FPT Electric 160

SMEC130 3 6 1/2 1/2 3/4 FPT Electric 174

SMEC174 4 6 1/2 1/2 3/4 FPT Electric 218

Coil Data

Dimensional Diagram Electric Defrost

Fan Motor Data (EC) Defrost Heaters

HP

208-230/1/60 230/1/60

Amps Watts Amps Watts

1/15 1.5 165 10.5 2400

1/15 1.5 165 15.7 3600

1/15 2.0 220 20.9 4800

Condensate

Defrost

Drain

Type

Approx.

Net Wt.

Dimensional Data Electric Defrost

Nozzle Selection Electric Defrost

12

Model No. of Fans

Dimensions (in.)

L

SMEC090 3 75-1/2

SMEC130 3 75-1/2

SMEC174 4 97-1/2

Model

No. of

Fans

Distributor Tube (in.)

OD Length

No. of

Circuits

CO

Nozzle

SMEC090 3 3/16 18 2 L 1/4

SMEC130 3 3/16 18 2 L 1/3

SMEC174 4 3/16 18 2 L 1/2

2

Nozzle selections for Low Temp DX

applications only

Assumptions: 20°F Liquid temperature

-20°F SST

8-15°F TD

Page 13

Notes

13

Page 14

Notes

14

Page 15

Notes

15

Page 16

For more information on Bohn refrigeration products, contact

your sales representative or visit us at www.thecoldstandard.com.

A Brand of Heatcraft Refrigeration Products, LLC

2175 West Park Place Blvd. • Stone Mountain, GA • 30087

800.537.7775

www.thecoldstandard.com

Since product improvement is a continuing eort, we reserve the right to

make changes in specications without notice.

BN-CUCTB-0909 | Version 000

Loading...

Loading...