Page 1

A DIVISION OF LEAR SIEGLER, INC.

UBLIC

The

Bogen

mixer-equalizer-amplifiers, designed for professional-quality

sound systems that once required custom audio equipment. The

CT60B,

rated at 60 watts, and the

output, are comprised of integrated circuits, silicon transistors and

diodes with the latest state-of-the-art active 2/ 3 octave equalization

circuitry.

Four low-impedance, transformer isolated, balanced microphone inputs, (expandable to six with an accessory PMM-2B)

each with individual volume controls, are convertible to highimpedance inputs by rearranging jumpers on the printed circuit

board. A phantom supply for the use of condenser microphones is

built into these units. Professional three-pin female, XLR-type

microphone connectors are provided on the rear panel.

Two auxiliary channels, with an

can be used for inputs from a tuner, tape/cassette player,

phonograph with a ceramic cartridge, or an optional

Multiple Tone Generator.

Built-in microphone precedence, remote volume control,

500/600-ohm line input and output, with accessories, tape and

tape/ booster outputs, amplifier bridging, and connecting amplifiers’ outputs in series are among the many capabilities of these

units.

Ten slide controls, with detented flat positions, allow the

selected frequency equalizer filter circuit to meet individual

installation requirements. Feedback is virtually eliminated, while

intelligibility is greatly improved, and usable power is increased.

A recessed screwdriver-adjustable front panel control for an

electronic compressor circuit is also provided. This circuit

compensates for poor microphone technique or a variety of

announcers, and it eliminates “blasting” in background music

applications.

Screw terminals on the rear panel allow connections to standard

speaker impedance taps, as well as connections for

70-volt balanced lines.

The amplifier operates from a

three-prong line cord provides automatic grounding when

connected to a three-wire grounded power outlet. The power line is

protected by a circuit breaker, and the output transistors by a

thermal overload device, which shuts off the unit when the

temperature of the heat sink rises excessively.

ADDRESS

Models

CT60B

and

CT1OOB

105-125

are versatile

CT100B,

AUXl/

rated at 100 watts

AUX2 fader control

volt, 60 Hz source. A

preamp-

25-volt

TG-4B

and

INSTALLATION

UNPACKING

The amplifier was carefully checked before leaving the factory.

Inspect shipping container and unit carefully for indications of

improper handling. If the unit has been damaged, make an

immediate claim to the distributor from whom it was purchased. If

the amplifier was shipped to you, notify the carrier without delay

and place your claim.

MODELS

CT60B

and CTIOOB

POWER AND GROUNDING

The ac line cord has a three-prong plug which should be plugged

into a three-wire grounded, 120 volt, 60 Hz outlet. As it is

important to ground the amplifier, where a three-wire outlet is not

available, use an adapter (e.g., Leviton No. 5017) and connect the

grounding pigtail to the screw securing the wall plate. If the wall

plate screw is not grounded, connect a wire from the GND

terminal of the amplifier to a suitable ground.

AUXILIARY POWER

CAUTION

Use the ON/OFF switch on a phonograph or

other accessory unit connected to the auxiliary

receptacle, as the power switch on the amplifer

does not control this receptacle.

The auxiliary power receptacle on the rear chassis is a three-wire

grounded outlet which can supply power to accessory equipment

in the sound system. Be sure that the accessory component does

not require more than 300 watts. The power switch does not

control this receptacle.

Associated equipment connected to the auxiliary receptacle

with a three-prong line cord will be grounded, providing the

amplifier line cord has been properly grounded.

INPUT CONNECTIONS

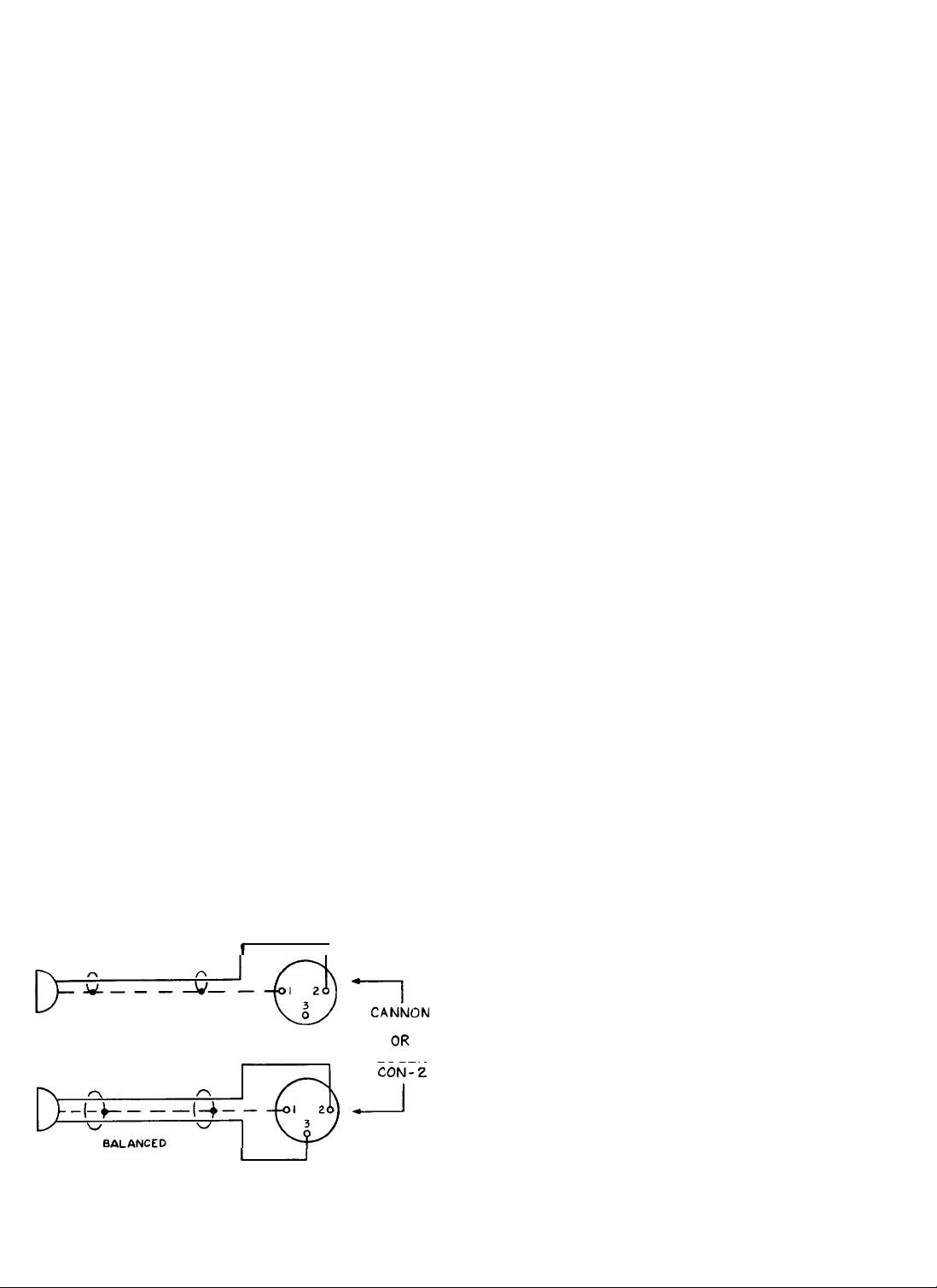

LOW-IMPEDANCE BALANCED MICROPHONES:

amplifier is designed for direct connection of low-impedance

balanced microphones to the MIC input receptacles of the

amplifier. The microphone lead should be a two-conductor

shielded cable terminated in a Cannon XLR312-C or

CON-2 connector, as shown in Figure 1.

CONDENSER MICROPHONES:

as for low-impedance balanced microphones.

HIGH-IMPEDANCE MICROPHONES: The

should be a singleconductor shielded cable under 35 feet in length

and terminated in a Cannon XLR312-C or

connector, as shown in Figure 1. For information regarding the

use of high-impedance microphones, see notes on the schematic

diagram.

MICROPHONE PRECEDENCE: A built-in circuit provides

microphone precedence for special announcements. A customersupplied SPST switch with normally-open contacts is required for

this function. When the contacts are closed, the auxiliary and other

microphone inputs are muted. (See

diagram and related notes.)

Connect in the same manner

microphone lead

Bogen

TSlOl

in the schematic

The

Bogen

CON-2

Printed in USA 8305

54-5751-01

Page 2

Power Output:

RMS

@

1000 Hz

Frequency Response:

Regulation

Line Fusing

full

Sensitivity (for

&

Noise

Hum

(below rated output)

Inputs (impedance)

Outputs (impedance)

Input/Output

Connectors

Controls

Equalizer Filters

Compression

Semi-conductors

Power Source/

Consumption

Dimensions

Shipping Weight

output)

TECHNICAL SPECIFICATIONS

CT100B

100

w @ less than 2%

total harmonic distortion

±2

50 Hz to 15 kHz

2dB

Resettable Circuit Breaker 2.5A

LO-Z balanced MIC, 0.3

LO-Z balanced MIC -55

4 LO-Z balanced dynamic or condenser MIC inputs, each convertible to HI-Z MICs; 2 HI-Z

with optional WMT-1 accessory; remote volume control for all MIC

4,6-8, 16 ohm speaker taps,

25 VCT and 70V balanced 25 VCT and 70V balanced

or unbalanced lines. or unbalanced lines.

Tape and Tape/ Booster, 500/600-ohm line output with WMT-1 optional accessory.

MIC, professional 3-pin audio connectors (female) Cannon XLR313 or Switchcraft C3F

Series; HI-Z standard phono jacks for Tape, Tape/ Booster, Bridging, and optional accessory

WMT-1 output; provision for optional WMT-I input; screw terminals for speaker connections.

10 filters centered at preferred

21 silicon transistors, 10

120

V, 50/60

23 lbs., 12 oz. (10.8 kg.)

AUX inputs with fader control;

4 MIC Volume, AUX

10 Equalizer Filter Slide Controls, Compressor Control, Power Switch

1250,2000,3150, and 5000 Hz. Boost/Cut:

5 ms. attack time, 2 s. decay time, max. compression 30 dB

IC’s,

10 diodes 19 silicon transistors, 10

Hz, 2.5A, 300W 120 V,

16 3/8”

W x

13¾”

mV;

HI-Z MIC, 3

dB;

HI-Z MIC -60

l/

AUX 2 - fader, MASTER VOLUME,

IS0

center frequencies of 80, 125, 200, 315,

D x

4¾”

H (41.5 x 34.9 x 12 cm)

dB

500/ 6OO-ohm

total harmonic distortion

Resettable Circuit Breaker

mV;

dB;

8,16

CT6OB

60 w

@

less than 2%

AUX.

0.15V

AUX -70

line input

±12

dB

&

AUX. inputs.

ohm speaker taps,

dB

50/60

Hz,

22 lbs. (10 kg.)

500,

IC’s,

1.6A,

1.6A

800,

10 diodes

170W

1/AUX

AUX

are provided for high-level, high impedance inputs. These may be

used to connect a tuner, tape/cassette player, record player

utilizing a ceramic cartridge, or the input from an accessory

WMT-1 line-matching transformer. (Refer to Accessories Section.)

An input signal of 0.15 volts is required to obtain full output from

the amplifier.

B

.74-2883-01

CF-qTJ

HIGH IMPEDANCE MICROPHONE

LOW IMPEDANCE OR CONDENSER

2 INPUTS: Two auxiliary inputs with a fader control

MICROPHONE

Figure 1

1

u

-

Microphone Cable Connections

I

x,,,?,,

XLR-3-12C

BOGEN

Use singleconductor shielded cable terminated in an RCA

phono plug for connecting an auxiliary component. If hum is

experienced after making connections, run a ground

the chassis of the auxiliary unit and the GND terminal of the

amplifier.

BRIDGING: Two CT-B amplifiers can be bridged together to

double the number of inputs and outputs. Connect a singleconductor shielded cable, terminated in an RCA phono plug at

each end, between the rear panel BRIDGING receptacles of the

two amplifiers. This cable should not exceed 20’in length. If more

than two amplifiers are to be bridged use a

BRIDGING GND ONLY terminals on the rear panel terminal

strip

(TS101)

must also be connected to each other. Any input to

either amplifier will then be fed through and available at the output

of both amplifiers. The amplifiers must each feed separate speaker

systems.

When two amplifiers are bridged together, any

adjustment of the MASTER, COMPRESSION

or Acoustic Equalizer controls in one amplifier

will not affect the output of the other amplifier.

2

wire

“Y”

adapter. The

between

Page 3

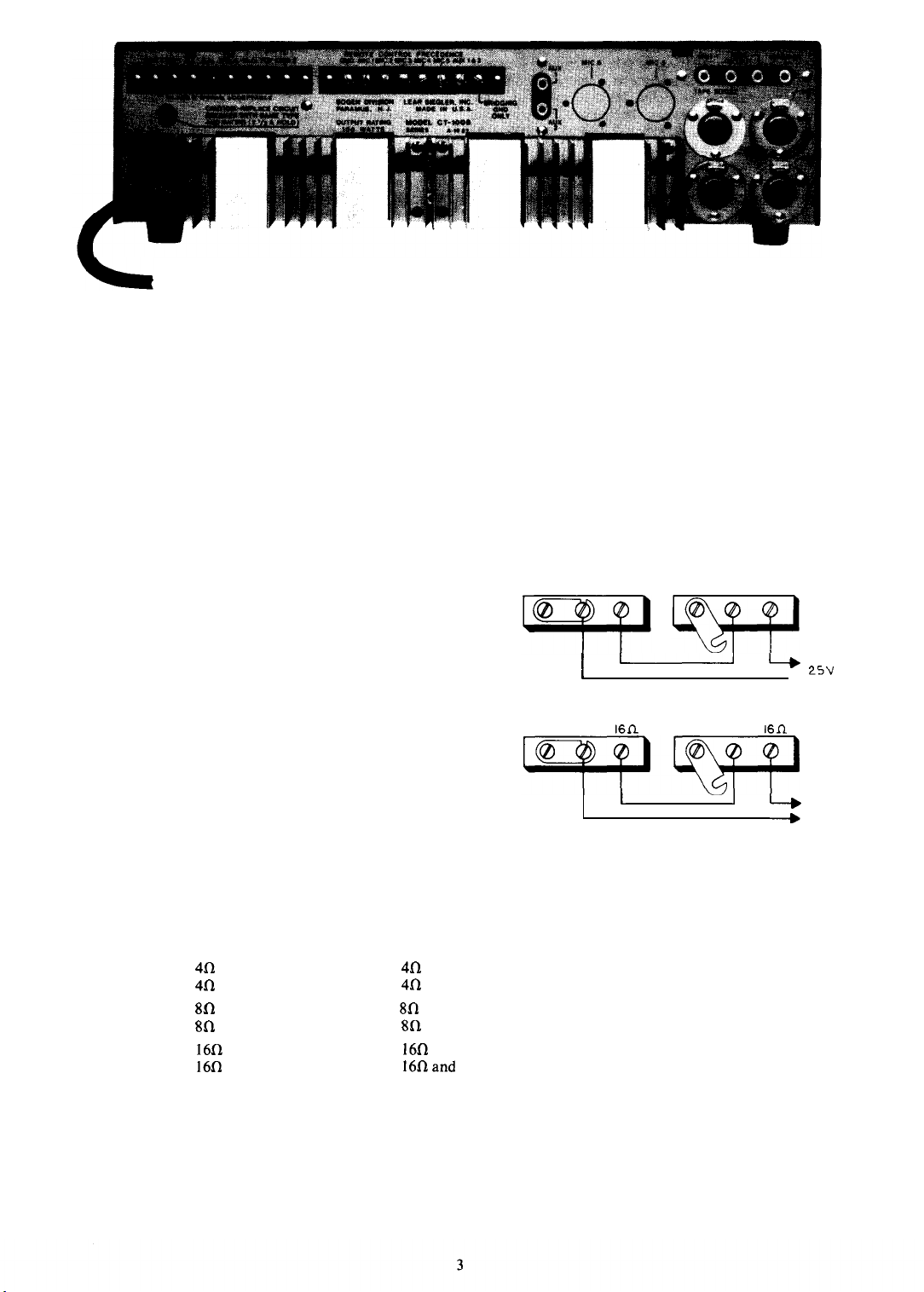

Figure 2 -Rear Panel,

CT100B

OUTPUT CONNECTIONS

SPEAKERS: Output connections are available on the rear panel

terminal strip for 4 (CT-lOOB), 8,16-ohm speakers, 25 volt centertapped and 70 volt lines. Connections necessary are listed in Table

I. Class 2 wiring may be used.

For detailed information see Installation Manual No. 54-5001

furnished with the amplifiers.

TAPE OUTPUT: A tape recorder may also be driven from the

TAPE OUTPUT jack on the amplifier. In this case, the output is

not subject to the master volume and equalization settings of the

amplifier and is controlled at the tape recorder. A patch cord

terminated in an RCA phono plug is connected between the TAPE

OUTPUT jack

BOOSTER OUTPUT: The amplifier may be used to drive a

booster amplifier. Connect a patch cord with an RCA phono plug

from the BOOSTER jack on the rear pane1 of the amplifier to the

high impedence input of the booster amplifier. The output at this

jack is controlled by the amplifier’s volume and equalization

controls.

WMT-1 OUTPUT: This receptacle is used to accommodate a

Bogen

accessory which provides connections to a 500/600-ohm

telephone line. (Refer to Accessories Section).

on the amplifier and the input of the tape recorder.

CONNECTING AMPLIFIERS IN SERIES

Pairs of the same amplifier models can be connected in series to

effectively double the power output into the same loadline, as well

as increase the input capacity. See Figure 3 for connection

diagram. Be certain to remove the link between COM and GND of

amplifier No. 2.

Tone and master volume controls of both amplifiers should be

at the same setting to assure that each amplifier will share the load

equally.

Connect a single conductor shielded cable, terminated in an

RCA phono plug at each end, between the rear panel BRIDGING

receptacles and BRIDGING GND terminal of both amplifiers.

This assures that any input will have equal amplification.

AMPLIFIER I

GND COM

AMPLIFIER

GND COM

A74-2031-01

25VCT

’

I

I

CT60B OR

1

161l

1 I

CT60B

Figure 3- Connecting Like Amplifiers in Series

AMPLIFIER 2

GND COM

CT100B

AMPLIFIER 2

GND COM

OR

CT100B

25VCT

I

“r

\I

L3”

16fl

L_t

7ov

TABLE 1

Models

CTlOOB

Both models

Both models

Both models

Both models

*Also see text under “Output Connections”

Speaker Line

4fI Unbalanced

4fl

Balanced

8fI Unbalanced

80

Balanced

16fI

Unbalanced

16fI

Balanced

25V Unbalanced

25V Balanced

25V Balanced, CT gnd.

70V Unbalanced

70V Balanced

-

OUTPUT CONNECTIONS

Terminal Connections*

4n

and COM 1

4fl

and COM

8fl

and COM 1

8G and COM 1

16fI

and COM 1

16fIaand

COM

25V and COM 1

25V and COM

25V and COM 1

1

1

1

Close link between COM 1 and GND

Open link between COM

Close link between COM

Open link between COM 1 and GND

Close link between COM 1 and GND

Open link between COM 1 and GND

Close link between COM

Open link between COM 1 and GND

Connect jumper between 25V CT and GND

Open link between COM 1 and GND

70V and COM 2

70V and COM 2

Add jumper between COM 2 and GND

No jumper required

Other Connections

1

and GND

1

and GND

1

and GND

Page 4

ACOUSTIC EQUALIZER:

to “tune” the amplifier to the room in which the sound system is

used, so that the amplifier will operate at a substantially higher

output before acoustic feedback occurs. Ten slide controls, located

on the front panel, boost or attenuate the output at preferred IS0

center frequencies-80,

and 5000 Hz-to compensate for varying room acoustics.

Microphone placement may also cause feedback or howling at

or near some of these frequencies. If so, feedback can be greatly

attenuated by setting the slidecontrolfor that particular frequency,

as described below.

The Acoustic Equalizer permits you

125,200,315,500,800,

1250,2000,3150

ACOUSTIC EQUALIZER FILTER ADJUSTMENT

MICROPHONE SOURCE:

The following adjustments of the slide filter controls will permit

“tuning” the system so that the output level is substantially higher

before acoustic feedback (“squeal” or “ringing”) occurs.

1. Set MIC controls and MASTER control to zero (counter-

clockwise).

2.

Set all slide controls to center (flat) position, with speakers

connected to the amplifier and microphone(s) in normal operating

location(s).

3. Turn the appropriate MIC volume control half-way up,

leaving the three other MIC volume controls at zero.

4.

Advance MASTER control slowly until feedback (“ringing”

or “squeal”) is heard.

5. If the feedback sound is high-pitched, one of the five high

frequency filter controls-800 Hz to 5 KHz-will be most effective

low-end

in its elimination. Likewise, a

low frequency filter.

6.

Individually, move each filter control

position to bottom and back to center while listening for change of

feedback. The control which eliminates feedback with the least

movement should then be moved down only as far as is necessary

to eliminate the feedback.

7. Having eliminated the first feedback condition, slowly

increase the MASTER control until feedback is heard again.

Repeat the procedures of steps

8.

If the position of the microphone is changed or if additional

microphones are used some adjustment to these controls may be

necessary.

9.

Output level, reduced because of attenuating one frequency,

may be partly restored by boosting the adjacent frequency filter

control toward maximum.

If feedback

be used to improve the voice quality and intelligibility of the paging system. In most cases, the 80

Hzcontrol should

while the 2 KHz, 3150 Hz and 5 KHz should be

moved to ward maximum for improved response.

Each system, depending on the speakers

room acoustics, will require some experimentation with the controls for optimum results.

10.

Note and record the settings of the individual filter controls

and the MASTER control. These settings are generally applicable

to all four MIC input channels. Rubber washers (supplied) can be

placed on the slide controls to avoid accidental movement. To do

so, pull the slide control knobs off the shafts, insert the rubber

washers, and replace the knobs securely.

is not a problem, the controls should

be placed

tone will be controlled by a

slowly

from the center

5,6.

in

minimum

position

used and

COMPRESSOR LIMITER: The COMPRESSION control

(which is screwdriver-adjustable through the front panel-to

avoid tampering) is used to provide relatively uniform output from

the amplifier, regardless of variations in the input levels. This is

particularly important in speech applications, where a microphone

may be used by a number of people with varying voices and

microphone techniques. It is also useful for musical programs,

particularly when handling background music.

The COMPRESSION control is turned clockwise to reduce the

output range for a given variation in input range. Turn the control

counterclockwise to increase the output range. To remove

compression and restore the normal full range of the amplifier,

turn the control fully counterclockwise.

To determine the optimum setting of the COMPRESSION

control for speech applications, proceed as indicated below. (For

music, the setting will generally be lower than for speech.)

Set the COMPRESSION control fully counterclockwise. Set

the MASTER volume control to the highest level likely to be

required. Use a level setting that will permit you to pick up clearly

spoken inputs in a low voice at a distance of three feet on axis from

the microphone. However, do not set the volume level so high as to

produce feedback or howling.

Then, speaking in a loud voice directly into the microphone,

turn the COMPRESSION control clockwise to the point where

the output of the amplifier is reduced to the same level as obtained

above. The MASTER control can be used to vary the overall

volume without upsetting the COMPRESSION adjustments.

OPERATION

POWER: This switch applies power to the amplifier. It does not

control any associated equipment which may be connected to the

auxiliary power receptacle on the rear panel. The POWER

indicator lamp will go on to show that power has been applied to

the unit.

MIC

VOLUME: The four individual MIC volume controls are

used to adjust the level of each microphone input channel. The

control is turned clockwise (to the higher numbers) to increase the

volume and counterclockwise to reduce it.

AUX VOLUME:

either of the two auxiliary inputs and it controls the volume of the

selected auxiliary input. To select the AUX 1 input, rotate the

control counterclockwise past the center position. Turning this

control counterclockwise to the higher numbers increases the

AUX 1 volume. To select the AUX 2 input, rotate the control

clockwise past the center position. Turn the control more clockwise to increase the AUX 2 volume.

If the auxiliary input is not to be used, set the control to the

center position. The center position is indicated when the triangle

on the control knob coincides with the vertical line between the

AUX 1 and AUX 2 designations.

MASTER: This control is used to regulate the overall volume of

the amplifier, which may include the mixed output of two or more

input channels. To set this control, rotate it to the center position,

then set the individual MIC and AUX controls to the highest level

likely to be used and consistent with the operation of the limiter

compressor. Adjust the MASTER control to the desired listening

level for the mixed output.

This control serves a two-fold purpose. It selects

4

Page 5

ACCESSORIES

CAUTION

The installation of internal accessories requires

the removal of the cover, which presents an

electrical shock hazard. For this reason, these

accessories should be installed by

technicians only.

PMM-2B

MICROPHONE MODULE: The

Microphone Module is a preamplifier designed to provide two

additional microphone channels for the amplifier. Each preamplifier channel has its own volume control and will accommodate either low-impedance balanced or high-impedance

microphones. These added channels have all the characteristics of

the basic channels, and the same accessories are applicable to

them, except that provision for remote control, and precedence is

made on one of the two additional inputs.

The Model PMM-2B mounts through the front panel of the

CT-B amplifiers. Holes are incorporated in the front panel of the

amplifiers to receive the control shafts of the PMM-2B unit.

To install the PMM-2B in the amplifier:

1.

Remove the four screws on each side of the amplifier cover

and lift it away from the chassis.

2.

Remove the plug buttons on the front panel of the amplifier

where the Volume Controls for MIC

inserted.

3. Open accessory bag furnished with the PMM-2B.

4.

Two metal brackets are furnished to support the rear of the

preamplifier circuit board assembly. Note two predrilled holes

and locator holes in the chassis directly below and at the rear of the

circuit board assembly. Turn the chassis on one side. Position one

bracket, locating tongue into locating hole in chassis. Secure with

machine screws and nuts supplied. Repeat this procedure with the

other bracket. Turn the chassis right side up.

Before installing the circuit board assembly, note that the

PMM-2B is shipped for low-impedance microphone inputs. For

high impedance microphone input connections, see Note 3 on the

schematic diagram.

5. Use a screwdriver to pry out two knockouts at the rear

panel of amplifier chassis.

6.

Remove the push-on lugs from the PMM-2B printed circuit

board (pins 1 through 6). Guide the orange cable through the

MIC 6 opening on the rear panel and the yellow cable through the

MIC 5 opening; reconnect the push-on lugs to pins 1 through 6.

The following table lists correct connections.

Color

MIC 6 (Orange Cable)

Red

Black

White

MIC 5 (Yellow Cable)

Black

Red

White

7.A .047

disc capacitor is attached to the MIC 5 microphone

connector. Remove the loose end of the wire from the sleeve on the

yellow cable and connect it to the ground lug on the tie strip

directly below MIC 6 connector.

8. Using the six mounting screws provided, secure the micro-

phone connectors to the rear panel with the PUSH tabs at the top

(same position as MIC 1 and MIC 2).

9. A brown wire is connected to pin 10 on the PMM-2B

printed circuit board. Connect the other end of this wire to the

terminal lug inside the rear panel, corresponding to the screw

terminal marked MIC 5 PRECEDENCE on the rear panel.

10. Insert the four-wire Molex plug into the four-prong male

socket

Jl

on the amplifier’s main printed circuit board. Note that

the four-wire plug can be inserted one way only. Do not twist or

turn.

qualifed

Bogen

PMM-2B

5

and MIC 6 are to be

PMM-2B

Term. No.

1

2

3

5

4

6

-

WMT-1

MOUNT

0

FRONT

Figure 4

A74-2923-01

Mounting Holes for WMT-1

-

ING

HOLES

11. Install the PMM-2B, component side down, inserting

control shafts and bushings through holes in front panel. Run up

two hex nuts over bushings of control shafts.

12. Press the control knobs onto the flatted volume control

shafts. Replace the amplifier cover, using the original screws

provided.

WMT-1 LINE-MATCHING TRANSFORMER:

The

Bogen

WMT-1 line-matching transformer provides an impedance match

between the amplifier and a 0 level, 500/600-ohm line. This may be

a telephone line connected to the switchboard for internal paging

or used with a wired music system. No soldering is required to

connect the WMT-1 to the amplifier.

To connect the input from a balanced 500/600-ohm telephone

line, remove the amplifier cover and mount the WMT-1 using the

mounting holes provided on the chassis (see Figure 4). Connect the

input line to the three-screw terminal board on the WMT-1.

Connect the phono plug on the WMT-1 cable to the AUX 1 or

AUX 2 jack on the rear of the amplifier. If these jacks are being

used for other sound inputs, the WMT-1 may be connected to one

of the MIC inputs. In order to do this, the WMT-1 wiring must be

modified as described in the instruction sheet supplied with the

WMT-1.

To connect the amplifier output to a 500/600-ohm telephone

line, remove the amplifier cover and mount the WMT-1 using the

mounting holes provided in the chassis (see Figure 4). Connect the

500/600-ohm line to the three-screw terminal board on the

WMT-1. Connect the phono plug on the WMT-1 cable to the

WMT-1 (OUTPUT) jack (next to the BOOSTER jack) on the rear

of the amplifier.

RVC-2B

RVC-2B to the Remote Control/ Precedence terminal

REMOTE VOLUME CONTROL: Connect the

(TSlOl)

on

the rear of the amplifier. Connect one lead from the accessory to

the appropriate MIC or AUX terminal and the other lead to

GND. Complete installation instructions are supplied with the

RVC-2B accessory.

MODEL TG-4B MULTIPLE TONE GENERATOR:

TG4B

Multiple Tone Generator is capable of generating four

Model

distinct signals: pulsed tone, slow whoop, repeating chime, and

steady tone. Each of these four signals may be applied continuously

or limited to a double burst (single burst only of the steady tone)

for alarm signalling or pre-anouncement. Signals are triggered by

an external device that provides a contact closure. Both tone level

and pitch are adjustable. May be powered from 15-26 VDC

source, or use optional

Bogen PRS-40

Power Supply for 120 VAC

operation.

5

Page 6

MODEL RPK-33A RACK PANEL: The

designed to mount the CT-B amplifiers in a standard 19” sound

rack. Instructions are furnished with the RPK-33A.

CON-2

MICROPHONE CONNECTOR:

a 3-pin male microphone connector, similar to the Cannon

XLR-3-12C or the Switchcraft A3M. The

the PMM-2B microphone connectors are designed to accept mic

inputs with these terminations.

RPK-33A rack panel is

The Bogen CON-2 is

CT60B, CT100B

and

use a heat sink (such as a small alligator clip) between the

component and the source of heat. Unless you are experienced in

the removal of IC micromodules, do not attempt to remove them

since excessive heat can damage an IC and/ or the printed circuit

board. If you are certain that an IC is defective, the easiest method

of removal is to cut the leads off close to the component and

unsolder the leads individually. If you are not certain an IC is

defective, the use of a low-wattage, vacuum-type desoldering tool

(such as Ungar Type 7800) is advised.

TP SERIES TUNERS: The

provide FM/ AM or FM/ AM/ FM-Stereo reception of superior

signal quality with precise tuning indicators. Output jacks permit

connection to an amplifier and/ or a tape recorder. Rack mounting

kits are also available for these units.

Bogen

TP Series solid-state tuners

MAINTENANCE

CAUTION

There

are no user replaceable parts within the

unit. Have all internal servicing done by a

qualified technician.

CIRCUIT BREAKER

If the circuit breaker opens, the ac power lamp will go out and

the amplifier will have no output, but there will be power at the

AUX POWER receptacle at the rear panel. Set the ac power

switch to off and

breaker to reset it. Return the ac power switch to on. If the breaker

trips again, do not attempt to reset it but have the trouble

investigated by a qualified technician.

THERMAL BREAKER

If the thermal breaker opens, there will be no audio output but

the ac power lamp will remain on. Wait approximately two

minutes for the breaker to reset. If the breaker resets and then

opens again, investigate the cause of the temperature overload.

This may be due to improper connections at the output terminals

or to excessive environmental heat with inadequate ventilation.

The thermal breaker will open when the temperature at the output

transistor heat sink reaches 105” C

REMOVING PC BOARD FOR SERVICING

To remove the PC board:

1. Remove all knobs and nuts from the front panel controls.

2. Remove four PK screws from the slide control mounting

bracket (inside the front panel).

3. Remove two PK screws at either end (toward the front) of

the PC board.

4.

Disengage the four nylon standoffs that support the rear of

the PC board by raising the board gently with one finger while

depressing the standoff locking tab with a screwdriver blade or

small pliers.

5. Lift the rear portion of the PC board so as to clear the

adjacent components and guide it toward the rear of the unit for

removal.

REPLACING COMPONENTS

Improper soldering may damage components or

the printed circuit board, and such damage can

void the warranty.

Many semiconductor components are soldered in place to

ensure maximum reliability. When soldering transistors or diodes,

momentarily

CAUTION

depress the red button on the circuit

(221°

F) on all models.

REPLACING TRANSISTORS

CAUTION

AN transistors are soldered to ensure maximum

reliability. When soldering leads, use a heat sink

(such as a small alligator clip) between the

transistor and the source of heat.

When replacing the driver transistors, press a small screwdriver

blade into the side of the

clip. Draw the clip and screwdriver off the metal tab on the driver

transistor. Reverse the procedure to install the clip on the

replacement transistor. Since the U-clip heat sink is a spring clip,

avoid spreading the jaws too wide.

When replacing the output transistors, clean all foreign matter

from the heat sink, insulator, and transistor. Brush a light coating

of silicon compound, such as Dow Corning No. 340, to completely

cover both surfaces of the insulator (Part No.

the insulator between the heat

Use the original transistor mounting hardware to mount the

replacement transistor.

U-clip

heat sink to spread the jaws of the

sink and

the replacement transistor.

16-9278-01).

Place

BOGEN SERVICE

We are interested in your Bogen amplifier for as long as you

have it. If trouble ever develops with your unit, please do not

hesitate to ask our advice or assistance. Information can be

obtained by writing to Service Department, Bogen Division/ Lear

Siegler, Inc., PO. Box 500, Paramus, New Jersey 07652.

When communicating with us, give the model number and

series designation of your unit. Describe the difficulty encountered

and the effects each operating control has upon the symptoms of

trouble. Include details on electrical connections to associated

equipment, and list such equipment. When we receive this

information, we will send you service information if the trouble

appears to be simple. If the trouble requires servicing, we shall send

you the name and address of the nearest Bogen authorized service

agency to which you can send your unit for repairs.

When shipping your unit, pack the amplifier well, using the

original shipping carton or a similar container and filler material

to prevent damage in transit. Send the unit, fully insured and

prepaid, via UPS or any responsible carrier. The unit will be

promptly repaired and returned to you collect.

REPLACEMENT PARTS

Most components used in the amplifier are standard parts

available through reputable parts suppliers. The parts listed here

may be obtained from

directly from the factory. When ordering a part, specify a part

number, the model of the unit, and give the series designation,

which is a letter followed by numbers, printed on the chassis. For

parts on circuit boards, also give the component board assembly

number, which begins with “45”.

When replacing transistors, use those made by the specified

manufacturers. Transistors from other suppliers may not be

satisfactory. Certain resistors must be Allen-Bradley products.

These are designated by “AB” on the schematic diagram.

Bogen

distributors, service agencies or

6

Page 7

Page 8

Page 9

Ref. No. Part No.

45-7176-05

C18,81-83 79-008-046

C28,3

I

79-008-049

C34,7

1

79-008-058

c35

C29,36,73

C56

C61

C63

C65,66,75

C68

C70

C80

CR1,2,4-6

CR3

ICI-5

IC6-8

IC9

IC10

Ql-l0, 12,

QlY

Q13

Ql4

Q16

Q17 96-5356-0 1

R53,55-57777-001-808

Rlll

R140 77-001-812

79-008-057

79-008-033

781104-l 50

79-120-005

79-008-044

79-008-062

78404-l 52

79-119-001

79-119-015

96-5333-01

96-5344-08

96-5436-O

96-5488-O

96-5437-O

96-5489-0

96-5213-01 96-5 176-O

96-5298-01

96-5283-01

96-5357-01

77-007-003

Description

P.

C. Board

P. C. Board Assembly

Cap., Elect.,

Cap., Elect.,

Cap., Elect.,

Cap., Elect.,

Cap., Elect.,

Cap., Dura Mica, 680pF

Cap., Elect., Low Leakage,

Cap., Elect.,

Cap., Elect.,

Cap., Dura Mica, 820pF

Cap., Elect., 470µF 63V

Cap., Elect.,

Diode, 400 prv

Zener Diode,

I. C., HllF3

1

I. C., LM348N

1

I. C., MC78L24CP

1

1. C., LF356N

1

Transistor,

1

Transistor, MPS6518

Transistor,

Transistor, MPS-A55

Transistor, 2SD389P/2SD313D/

TIP3lA

Transistor, 2SB512P/2SB507D/

TIP32A

Control, 1 megohm

Trimpot, 50kilohms

Control, 200 kilohms

22µF 35V

5OOµF

lOµF,

50µF 5OV

2.2µF

1OOOµF

lOOµF,

33OOµF

@

3OV,

2N5089

SPSl910

35V

50V

16V

35V

50V

63V

1

A

2W

2.2µF

50V

Ref. No. Part No.

Rl49,152 76-107-096

T1-4

-

ClOl-104

Cl06

CBlOl 94-0023-05

CB102 94-0014-07

4101,102 96-5385-01

QlOl-104

R201

R202,203 76-116-003

R202,

204-20676-l 16-003

R207

R80-89 77-001-826

SW101 8 l-009-035

TlOl 83-809-000

T102

83-058-000

85-1287-01

70-93

13-O

96-5241-01

79-509-052

79-509-053

94-0023-08

96-5397-01

96-5385-01

96-5397-01

77-001-825

75-742-101

83-814-010

83-423-000

83424-000

14-9088-01

03-0670-0

03-0671-0l

03-0628-03 Slide Control Knob (Black)

1

Description

.82

Resistor,

Mic Input Transformer

4-Point Header

1

Heat Sink Clip

Chassis

Diode, 300 prv

Cap., Elect.,

Cap., Elect.,

Circuit Breaker,

Circuit Breaker,

Thermal Breaker,

Transistor,

Transistor,

Transistor,

Transistor,

Control,

Resistor,

Resistor,

Resistor, 100 ohms, 7W

Slide Control, 50 kilohms

Lighted Rocker Switch,

Power Transformer

Power Transformer (CTlOOB)

Output Transformer

Output Transformer (CTlOOB)

Foot

Knob (O-10)

Knob (5-O-5)

ohms, 2W

@

3A

2OOOµF

3000µF

1.6A (CT60B)

2.5A (CT100B)

105°

2N3055H

2N3055

Solitron

2N3055H

2N3055

Solitron (CTlOOB)

2 megohm

.27

ohms, 7W

.27

ohms, 7W (CTlOOB)

75V

(CT60B)

75V (CTlOOB)

C

RCA, or

(CT60B)

RCA, or

(CT60B)

lOA,

(CT60B)

(CT60B)

SPST

Loading...

Loading...