Page 1

A DIVISION OF LEAR SIEGLER, INC.

AMPLIFIERS

Bogen

Amplifiers are versatile, silicon-transistor

amplifiers designed for professional-quality sound reinforcement requirements. Model CT-35 is rated at 35 watts,

Model CT-60 at 60 watts and CT-100 at 100 watts output.

Four high-impedance microphone inputs are provided,

each convertible for use with low-impedance microphones.

A simple modification converts inputs to low-impedance

unbalanced; balanced inputs require accessory plug-in

transformers. Two mic inputs and one auxiliary input may

be remotely controlled or muted for announcements over

another mic channel. The same two mic inputs may be converted to accept a magnetic source, i.e., turntable or tape

player. Two auxiliary inputs with fader control are provided, as well as a bridging input.

Acousta-Master amplifiers feature the

acoustic equalizer filter circuit, which provides a means of

boosting or attenuating any of five selected frequencies to

suit individual room acoustics. An electronic limiter circuit

provides uniform output regardless of wide variations in the

input level. With this capability, all paging calls can be

transmitted with the same volume and clarity.

An output terminal strip and connectors at the rear of

the amplifier provide standard speaker impedance taps, as

well as connections for

There is also a bridging output for feeding a tape recorder.

Bogen

line input and output connections, remote volume control,

and channel override facilities. Further information is

contained in the Accessories section.

The amplifier operates from a

source. A three-prong line cord provides automatic ground-

ing when connected to a three-wire power outlet. The

power line is protected by a circuit breaker, and the output

transistors by a thermal overload device, which shuts off

the unit when the temperature of the heat sink rises

excessively.

Acousta-Master@ CT Series Public Address

preamp-mixer-

Bogen

built-in

25volt

or

70-volt

balanced lines.

accessories provide the amplifier with telephone

105-125

volt,

50/60

Hz

Models CT

35/60/100

INSTALLATION

UNPACKING

The amplifier was carefully checked before leaving

factory. Inspect shipping container and unit carefully for

indications of improper handling. If the unit has been

damaged, make an immediate claim to distributor from

whom it was purchased. If the amplifier was shipped to

you, notify transportation company without delay and

place your claim.

POWER AND GROUNDING

The ac line cord has a three-prong plug which should be

plugged into a three-wire grounded, 120 volt, 60 Hz outlet.

As it is important to ground the amplifier, where a threewire outlet is not available, use an adapter (e.g., Leviton

No. 5017) and connect the grounding pigtail to the screw

securing the wall plate. If the wall plate screw is not grounded, connect a wire from the GND terminal of the amplifier

to a suitable ground.

AUXILIARY POWER

The auxiliary power receptacle on the rear chassis (see

figure 1) is a three-wire grounded outlet, which can supply

power to accessory sound equipment. When connecting

associated equipment with a three-prong cord, appropriate

grounding is accomplished when the amplifier line cord is

properly grounded.

Use the ON/OFF switch on the phonograph for turning

off a record player connected to the auxiliary receptacle, as

use of the amplifier power switch could cause flats to

develop on the idler wheel of the phonograph.

Be sure that the auxiliary components do

not draw more than 250 watts on the CT35

and CT 60, and 500 watts on the CT1 00.

Prmted in

USA 8104

54-5629-l 4

Page 2

TECHNICAL SPECIFICATIONS

I

POWER OUTPUT (RMS at 1000Hz)

FREQUENCY RESPONSE

REGULATION

HUM & NOISE (below rated output)

SENSITIVITY

OUTPUTS

OUTPUT CONNECTIONS

INPUTS

CONTROLS

FILTERCONTROLACTION ±

COMPRESSION

LINE FUSING

SEMICONDUCTORS

POWER CONSUMPTION

DIMENSIONS

SHIPPING WEIGHT

(for rated output)

MIC, 60

Hi Z MIC, 3 mV; Low Z Bal MIC, 0.3

30 mV; AUX 150

4, 8,

Bridging, 30

500/6OOa telephone line input or output with WMT-i optional accessory.

I

2 Quick disconnect type sockets with plugs provided, in addition to screw-type

terminals, tape/booster jack, and provisions for WMT-1.

I

4 Hi Z MIC inputs, each convertible to Low Z Bal or Unbal MIC; 2 AUX inputs with

fader control; MIC 1

telephone line with optional WMT-1 accessory; 3 inputs for remote volume control.

4 MIC Volume, AUX 1, AUX 2-fader, MASTER VOLUME, 5 Equalizer Filter Slide

Controls. 1

10

dBB

5 milliseconds attack time, 2 seconds decay time, max. compression 30

I

18

silicon transistors 18 silicon transistors 20silicon

16-3/8”W

(41.6cm x 32.4cmx12.lcm)

19 lbs. (8.6 kg)

CT35

35 watts

dB

for both low and high impedance; AUX 70

mV

16

ohms 8,16

25V CT

7ov 7ov

mV;

Tape, 0.68 V. TAPE/BOOSTER/BRIDGING outputs,

&

Compressor.

variationatthefollowingfrequencies:

0.93 A Hold

2 Zener Diodes; 8 Silicon Diodes (10 in

0.86A, 96W

x

12¾”D

x

I

I

@

less than 2% total harmonic distortion

50Hz to 15kHz ±2dB

4 convertible to MAG input; Bridging input; 500/600 ohm

1 Power Switch.

Resettable Circuit Breaker

4¾”H

CT60

60 watts

2

dB

mV;

Low Z Unbal MIC 0.3 mV; Bridging Input,

ohms

25V

CT

1.65 A Hold 2.5 AHold

120 V AC,

221bs. (9.9 kg)

50/60

1.6A,

170w

16-3/8”W

(41.6cm x

I

I

dB;

Fundamental, 80

I

80Hz,300Hz,1 kHz,3kHz,10kHz.

CTl00)

Hz

x

13 3/4”D

34.9cm

CT100

100 watts

4, 8,,16ohms

25V

7ov

dB

2.9A, 300W

x

4 3/4”H

x 12.lcm)

26 lbs. (11.8 kg)

dB

CT

transistors

I

I

I

I

INPUT CONNECTIONS

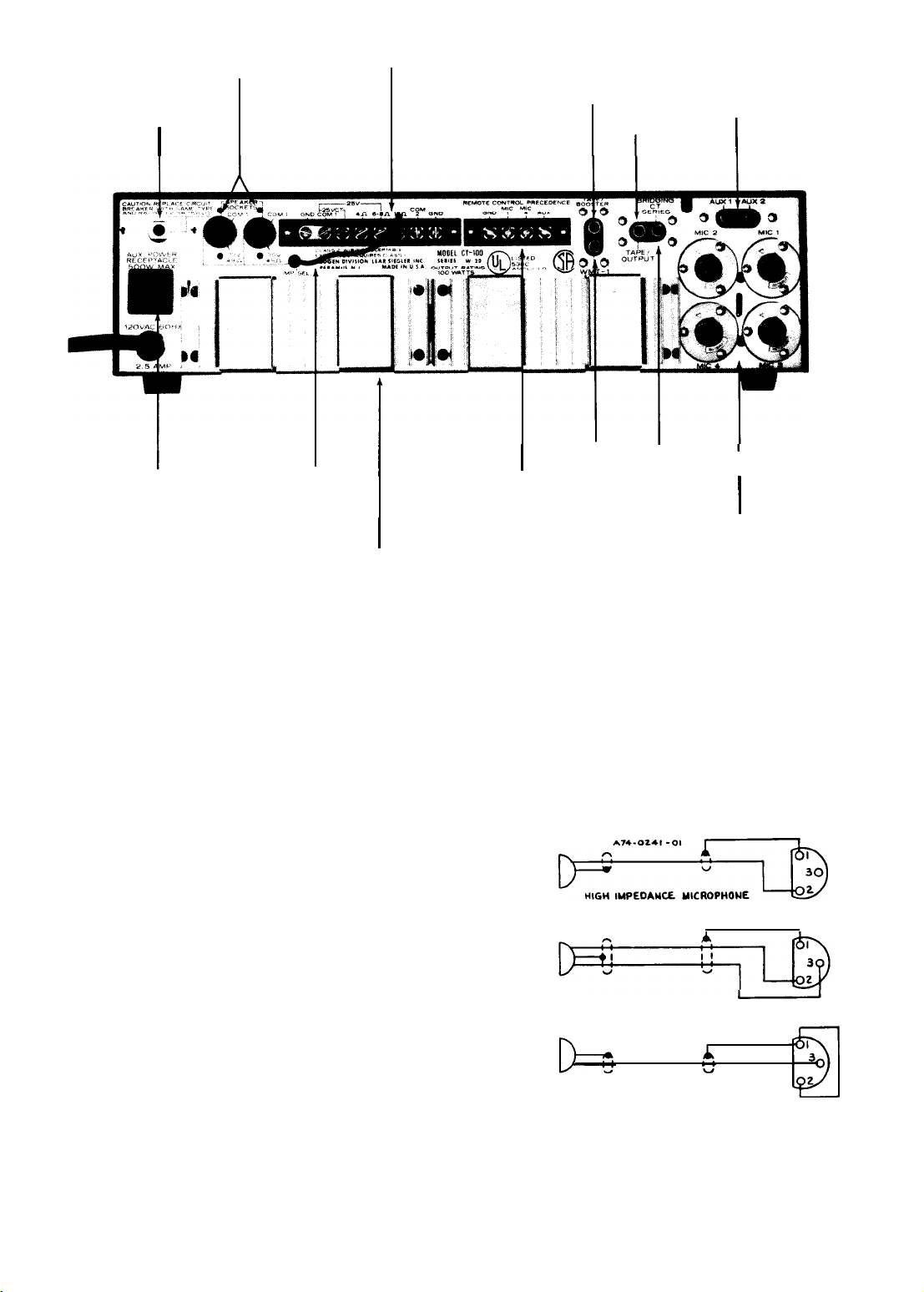

HIGH IMPEDANCE MICROPHONES: The amplifier is

shipped in a configuration for direct connection of high

impedance microphones (50k ohms) to the four MIC input

receptacles of the amplifier. The microphone lead should be

a single-conductor shielded cable under 35 feet long and

terminated in a Cannon XLR-311C connector

No. 85-0124-01) as shown in figure 2.

In the event jumpers on the printed circuit board have

been rearranged and must be returned to the configuration

for direct connection of high impedance microphones,

connect the two jumpers involved as follows: the first

jumper between terminals 11 and 19, and the second

(Bogen

Part

be-

tween 8 and 18. Three jumpers are not involved and are

stored by connecting both ends to an assigned terminal: the

first jumper on terminal 20, the second on 24, and the third

on 25.

BALANCED LOW-IMPEDANCE MICROPHONES:

impedance accessory transformers are required to permit

the amplifier to accept inputs from microphones rated from

50 to 600 ohms. Before connecting microphone, insert

appropriate plug-in transformers and reset jumpers adjacent

to transformer sockets as described in the Accessories

tion. Use a two-conductor shielded cable for the

phone lead, terminated in a Cannon XLR-311C connector,

as shown in figure 3.

-2-

Low-

+

micro

sec-

,

Page 3

CIRCUIT

BREAKER

SPEAKER

SOCKETS

OUTPUT

TERMINALS

TAPE/BOOSTER

TAPE

OUTPUT

AUX

INPUTS

I

AUX

POWER

Note:

Heat sink for Model CT-35

is an aluminum plate.

IMPEDANCE

SELECTOR

I

I

REMOTE/PRECEDENCE

TERMINALS

I

HEAT SINK

Figure 1 - Rear Panel, CT-100

I

I

WMT-1

OUTPUT

I I

BRIDGING

I

I

MIC INPUTS

UNBALANCED LOW IMPEDANCE MICROPHONES:

Jumpers with push-on connector lugs are mounted on the

printed circuit board assembly for use in converting the

MIC input channel circuits. See note 4 on the schematic

diagram, figure 6. To convert MIC 1 and 4 for unbalanced

low impedance use, connect jumper between pins 20 and

2 1; to convert MIC 2 and 3, connect jumper between pins

25 and 26. As shown in figure 2, connect a jumper between

terminals 1 and 2 of the connector and wire microphone to

pin 3 of the plug.

AUXILIARY INPUTS: Two auxiliary inputs are provided

for high-level, high impedance inputs. these may be used to

connect a radio tuner, tape recorder, or turntable utilizing a ceramic cartridge. An input signal of 0.15 volts is

required to obtain full output from the amplifier.

Use single-conductor shielded cable terminated in an

RCA phono plug for connecting auxiliary component. If

hum is experienced after making connections, run a ground

wire between the chassis of the auxiliary unit and the GND

terminal on the amplifier.

BRIDGING: The amplifier may be bridged to a second

Bogen

CT amplifier to double the number of inputs. Connect a single-conductor shielded cable, terminated in an

RCA phono plug at each end, between the rear panel

BRIDGING receptacles of the two amplifiers. Any input to

either amplifier will then be fed through and available at

the output of both amplifiers. The amplifiers must each

feed separate speaker systems.

When two amplifiers are bridged together,

any adjustment of the MASTER, COMPRESSION or Acoustic Equalizer controls in

one amplifier will not affect the output of

the other amplifier.

:

Figure 2

(CONNECTION

LOW IMPEDANCE MICROPHONE

LOW IMPEDANCE MICROPHONE

-

Connecting Microphone Cable Connector

SAME

FOR

BALANCED

UNBALANCED

MAG

PHONO)

XLR-311C

XLR-311C

2

J

XLR-311C

-3-

Page 4

MAG PHONO: The output of a phonograph employing a

magnetic cartridge may be connected to the MIC 1 and 4

receptacles on the rear panel. Use a single-conductor

ed audio cable terminated in a Cannon XLR3

shield-

11C connector as shown in figure 2 (connections same as high impedance mic). A magnetic tape head may also be connected

in this manner.

To provide the necessary equalization for magnetic

phono and tape head inputs, the Berg terminal jumpers on

the printed circuit board must be connected as indicated in

note 3 on the schematic diagram. Connect a jumper between pins 21 and 22 and between pins 23 and 24.

OUTPUT CONNECTIONS

SPEAKERS: For installations where speakers will be con-

nected permanently, output connections are available on

the terminal strip at the rear of the amplifier for 4, 8, and

16 ohm speakers and

made for an unbalanced line or for a balanced line with or

without center-tap grounding. Make speaker line connections

as shown in Table 1.

Impedance indicated in Table

speaker sockets on the rear panel. Two quick-disconnect

plugs (Bogen 85-0147-01) are furnished with the amplifier

to make connections to these sockets. Wiring of the speaker

output plug is shown in figure 3. When the speaker sockets

are used, connect the wired plug to either socket. For

balanced. 4, 8, 16 ohms

impedance selector lead to the speaker system impedance

terminal, and leave the link connected between COM

GND terminals. A balanced output is available by removing the

link.

For 70 volt constant voltage systems, see Table 1. For

detailed information see installation manual No.

furnished with the amplifier.

To minimize shock hazard, Class I wiring as

defined in local building codes should be

used for 70-volt outputs. All other outputs

may use Class 2 wiring.

CONNECTING AMPLIFIERS IN SERIES: Pairs of Bogen

CT amplifiers of the same power rating can be connected in

series to effectively double the power output into the same

speakers. See figure 4 for connection diagram. Be certain to

remove the link between

2.

25volt

lines. Connections may be

1

is also available at two

and 25-volt

operation, attach the

COM 1 and GND of amplifier No.

FOR 70V

OPERATlON

un-

1

and

54-5001,

Connect a single conductor shielded cable, terminated in

an RCA phono plug at each end, between the rear panel

BRIDGING receptacles of both amplifiers. This assures that

any input will have equal amplification.

AMPLIFIER 1

GND

COMI

25VCT

AMPLIFIER 1

GND COM 1

A74-2031-01

l6n

CT60 AND CT

GND

ALL UNITS

AMPLIFIER 2

GND COM 1

AMPLIFIER 2

COMl

25VCT

1

100

L+25V

b

16n

Figure 4 - Connecting Amplifiers in Series

Both amplifier tone and master volume controls must be

at the same setting to assure that each amplifier will share

the load equally.

TAPE/BOOSTER OUTPUT: The amplifier may be used to

drive a tape recorder or a booster amplifier. Connect a

patch cord with an RCA phono plug from the TAPE/

BOOSTER jack on the rear panel of the amplifier to the

input of the tape recorder or booster amplifier. The output

at this jack is controlled by the amplifier’s volume and

equalization controls.

TAPE OUTPUT: A tape recorder may also be driven from

the TAPE OUTPUT jack on the amplifier. In this case, the

output is not subject to the master volume and equalization

settings of the amplifier and is controlled at the tape

recorder. A patch cord terminated in an RCA phono plug is

connected between the TAPE OUTPUT jack on the amplifier and the input of the tape recorder.

WMT-1 OUTPUT: This receptacle is used to accommodate

a Bogen accessory which provides connections to a

600-ohm telephone line.

500/

zil-J=

FOR 25V OPERATION

OR SELECTED IMPEDANCES

3c---1-

-!

Figure 3-Speaker Output Plug Wiring

ACOUSTIC EQUALIZER: The Acoustic Equalizer permits

you to “tune” the amplifier to the room in which the

sound system is used, so that the amplifier will operate at a

substantially higher output before acoustic feedback occurs. Five slide controls, located on the front panel, boost

or attenuate the output at five selected frequencies-80 Hz,

300 Hz, 1 KHz, 3

kHz,

and 10

kHz.

Varrying room acoustics or microphone placement may cause feedback or howling at or near some of these frequencies. If so, feedback can

be greatly attenuated by setting the slide control for that

particular frequency as described below.

-4-

Page 5

TARI

F

1-f-U

._I__ . __.. _.

ITPI IT

CONNECTIONS

Models

CT35 & CT100

All models

All

All

All

*Also see text under “Output Connections”

ROOM EQUALIZATION: With speakers connected and

Speaker Line

4S2

Unbalanced

4n

Balanced

8n

Unbalanced

8n

Balanced

16n Unbalanced

16n

Balanced

25V Unbalanced

25V Balanced

25V Balanced, CT gnd.

70V Unbalanced

70V Balanced

Terminal Connections

4n

and COM 1

4n and COM

8n

and COM 1

8n

and COM 1

160

and COM 1

16n

and COM 1

25V and COM 1

25V and COM 1

25V and COM 1

Pins 2 and 3

Pins 2 and 3

one microphone in normal operating location, turn amplifier on and proceed as follows:

1. Connect microphone to appropriate MIC input of

amplifier.

2. Set all five acoustic filter controls to zero (center

position).

3. Turn MIC volume control half-way up and the three

other MIC volume controls to zero.

4. Advance MASTER volume control slowly until

feedback is heard.

5. Note the frequency of the feedback tone, and determine which of the five selected frequencies on the

Acoustic Equalizer is closest to it.

6. Move the control determined in Step 5, above,

down toward minimum until feedback disappears.

7. Advance MASTER control again and note whether

feedback is heard at another frequency.

8. Adjust the appropriate filter controls until this

feedback disappears.

9. Continue to advance MASTER control and adjust

individual filter controls until MASTER control is at maximum setting, consistent with a stable output without

feedback at any frequency.

10. Output level reduced because of attenuating one

frequency may be partly restored by boosting the adjacent

frequency filter control toward maximum.

If feedback is nor a problem, the controls

should be used to improve the voice quality

and intelligibility of the paging system. In

most cases, the 10

should be placed in minimum position while

the 300 Hz, 1

moved toward maximum for improved

presence.

speakers used and room acoustics, will require someexperimentation with the controls

for optimum results.

Each system, depending on the

kHz

and 80 Hz controls

kHz

and 3

kHz

should be

*

Close link between COM 1 and GND

1

Open link between COM 1 and GND

Close link between COM 1 and GND

Other Connections

Open link between COM 1 and GND

Close link between COM 1 and GND

Open link between COM 1 and GND

1

Close link between COM

Open link between COM 1 and GND

Connect jumper between 25V CT and GND

Open link between COM 1 and

and GND

GND

Connect impedance selector to COM 2

Connect jumper between COM 2 and

Connect impedance selector to COM 2

GND

11. Note and record the settings of the individual filter

controls and the MASTER control. These settings are

generally applicable to all four MIC input channels, if the

microphone remains in the same position.

12. If the position of the microphone is changed or

additional microphones are used, some adjustment in the

feedback controls may be necessary.

COMPRESSOR LIMITER: The COMPRESSION control is

used to provide relatively uniform output from the amplifier regardless of variations in the input levels. This is

particularly important in speech applications, where a

microphone may be used by a number of people with

varying voices and microphone techniques. It is also useful

for musical programs, particularly when handling background music.

The COMPRESSION control is turned clockwise to the

higher numbers to reduce the output range for a given

variation in input range. Turn the control counter-clockwise

to lower numbers to increase the output range. To remove

compression and restore the normal full range of the

amplifier, turn the control fully counter-clockwise to zero.

To determine the optimum setting of the COMPRESSION control for speech applications, proceed as indicated

below. For music, the setting will generally be lower than

for speech.

Set the COMPRESSION control fully counter-clockwise

to zero position. Set the MASTER volume control to the

highest level likely to be required. Use a level setting’that

will permit you to pick up clearly spoken inputs in a low

voice at a distance of three feet on axis from the microphone. However, do not set the volume level so high as to

produce feedback or howling.

Then, speaking in a loud voice directly into the microphone, turn the COMPRESSION control clockwise to the

point where the output of the amplifier is reduced to the

same level as obtained above. The MASTER control can be

used to vary the over-all volume without upsetting the

COMPRESSION adjustments.

-5-

Page 6

MIC VOLUME: The four individual MIC volume controls

are used to adjust the level of each microphone input

channel. The control is turned clockwise (to the higher

numbers) to increase the volume and counterclockwise to

reduce it.

AUX VOLUME: This control serves a two-fold purpose. It

selects either of the two auxiliary inputs and it controls the

volume’ of the selected auxiliary input. To select the AUX 1

input, rotate the control counterclockwise past the center

position. Turning this control counter-clockwise to the

higher numbers increases the AUX 1 volume. To select the

AUX 2 input, rotate the control clockwise past the center

position. Turn the control more clockwise to increase the

AUX 2 volume.

If the auxiliary input is not to be used, set the control to

the center position. The center position is indicated when

the triangle on the control knob coincides with the vertical

line between the AUX 1 and AUX 2 designations.

MASTER: This control is used to regulate the overall

volume of the amplifier, which may include the mixed out-

put of two or more input channels. To set this control,

rotate it to *maximum clockwise position, then set the

individual MIC and AUX controls to the highest level likely

to be used and consistent with the operation of the limiter

compressor. Adjust the MASTER control to the desired

listening level for the mixed output.

POWER: This switch applies power to the amplifier. It will

also turn on any associated equipment which may be

connected to the auxiliary power receptacle on the rear

panel. The POWER indicator lamp will go on to show that

power has been applied to the unit.

8. Change jumper connections as indicated in the table

below.

9. At preamplifier board A2, install low impedance

transformer(s) in 9-pin socket(s). XI is for MIC 4 input; X2

is for MIC 3 input.

10. Use spring clip(s) to secure transformer(s) in

socket(s).

11. Change jumper connection as indicated in the table

below.

Transformer

Plugged

MIC 1 Conversion

MIC 2 Conversion

MIC 3 Conversion

MIC

using two screws at the rear, two nuts over the control

shafts, and the two control knobs. Replace cover.

in for:

4 Conversion

12. Mount preamplifier board Al on the amplifier,

Remove

Reconnect

Jumper between: Jumper between

Pins 8 &18

Pins11&19

Pins11&19

Pins8&18

Pins7&9

Pinsl0&12

Pins

lO& 12

Pins7&9

ACCESSORIES

The installation of accessory transformers requires the removal of the cover, which presents an electrical shock hazard. For this

reason, these accessories must be installed

only by a qualified technician.

MIC INPUT TRANSFORMERS: Bogen

TM5OOA

convert the input impedance of the amplifier to that of a low-

impedance microphone. Model TM200A accommodates

ohm mics, and the

for use with high-impedance microphones. To convert any

of the microphone inputs to balanced low-impedance use,

refer to figure

cover (1).

socket(s). XI is for MIC 1 input; X2 is for MIC 2 input.

socket(s).

plug-in transformer accessories are designed to

TM5OOA

The Acousta-Master CT amplifiers are furnished ready

5

and proceed as follows:

1. Remove four screws on each side of cover and the

2. Remove two knobs (2).

3. Remove two nuts (3).

4. Remove two screws (4).

5. Remove preamplifier board Al. Turn board over.

6. Install low impedance transformer(s) in 9-pin

7. Use spring clip(s) to secure transformer(s) in

500/600-ohm microphones.

TM2OOA

and

200-

Figure 5 - Installing Low-Impedance MIC Input Transformers

LVP-1 AND

accessory which provides microphone precedence over the

MIC or AUX channel to which the accessory is connected.

The LVP-1 may be used with the MIC 1, MIC 4 and AUX

channel, and a separate accessory is required for each

channel.

The LVP-1 unit is also used in conjunction with the

Model RVC-2A accessory to provide remote volume control

of these channels. The RVC-2A will control the output

level at distances up to 2000 feet from the amplifier.

RVC-2A

UNITS: The Bogen LVP-1 is a plug-in

-6-

Page 7

MIC PRECEDENCE: The MIC 1 and MIC 4 input channels

as well as the AUX channel may be remotely controlled by

installing the LVP-1 accessory. Plug the accessory into the

appropriate LVP-1 accessory socket on the Preamplifier

Board Assembly, after removing the amplifier cover as previously described. The MIC 1 socket is on the top preamp

board (Al), MIC 4 socket is on the bottom board

the AUX socket is on the main component board

(A2),

(A3).

and

Connections are made from an external switch to the

appropriate MIC 1, MIC 4 or AUX terminal and to GND

terminal on the REMOTE CONTROL PRECEDENCE strip

on the rear panel. The switch on the paging microphone may

be used for this purpose, if it has a normally open pair of

contacts for the precedence function, as on the Shure 450

microphone. Otherwise, an external single-pole,

singlethrow switch may be installed near the microphone. When

the switch contacts are closed, the controlled channel is

muted. For detailed information on MIC precedence

connections, see the instruction sheet furnished with the

LVP-1

accessory.

REMOTE VOLUME CONTROL: Plug an LVP-1 accessory

into each channel to be remotely controlled, as described

above. Connect the

RVC-2A

remote volume control to the

REMOTE CONTROL PRECEDENCE terminal strip TSlOl

on the rear panel of the amplifier. Connect one lead from

the accessory to the appropriate MIC 1, MIC 4 or AUX

terminal and the other lead to GND.

After connecting the

RVC-2A,

turn its control knob fully

clockwise and the volume control for the appropriate

amplifier channel counter-clockwise. Advance the volume

control on the amplifier to the loudest position likely to be

used or to the point where feedback begins. Reduce the

output level at the RVC-2A control to the desired level, and

adjust the control as necessary during operation.

MODEL WMT-1 TELEPHONE LINE TRANSFORMER:

The

Bogen

Model WMT-1 input/output matching trans-

former is an accessory which has been designed especially

for matching either inputs from or outputs to a 500/600ohm line. As an input matching transformer, it may be used

with the

Bogen

amplifier for distributing background music

or a page which has been transmitted over leased telephone

lines. The accessory also functions as an output matching

transformer in feeding special program material over a

500/600-ohm telephone line for transmission to a local

broadcast studio.

MAINTENANCE

Some servicing procedures require removal

of the cover or bottom plate, as described

previously.

parts inside the amplifier enclosure. Have all

interior servicing done by a qualified technician.

BOGEN

SERVICE

We are interested in your

you have it. If trouble ever develops with your unit, please

do not hesitate to ask our advice or assistance. Information

can be obtained by writing to Service Department,

Division/Lear Siegler, Inc., P.O. Box 500, Paramus, New

Jersey 07652.

When communicating with us, give the model number

and series designation of your unit. Describe the difficulty

encountered and the effects each operating control has

upon the symptoms of trouble. Include details on electrical

connections to associated equipment, and list such equipment. When we receive this information, we will send you

service information if the trouble appears to be simple. If

the trouble requires servicing, we shall send you the name

and address of the nearest

to which you can send your unit for repairs.

When shipping your unit, pack it well, using the original

shipping carton or a similar container and filler material, to

prevent damage in transit. Remove any plug-in transformers

from the PC board before shipping. Send the unit fully insured and prepaid. The unit will be promptly repaired and

returned to you express collect.

CIRCUIT BREAKER

The power line is protected by a circuit breaker, which

shuts off the power and turns off the POWER indicator in

case of overload. The breaker is reset by pressing in the red

reset button located on the rear panel. If the amplifier shuts

off again after resetting the breaker, make no further

attempt to operate the equipment. Call a serviceman to

locate the cause of the trouble.

There are no user-serviceable

Bogen

amplifier for as long as

Bogen

authorized service agency

Bogen

MODEL LPC/4A PHONO PLAYER TOP: The Model

LPC-4A is a three-speed, ac-operated phono player top

designed for mounting on the amplifier. The phono player

is furnished complete with all necessary mounting hard-

ware, and only a screwdriver is required to install it on the

amplifier. A tone arm housing a dual-stylus flip-over

cartridge for standard or 78 rpm records is furnished with

the unit.

MODEL RPK-33A RACK PANEL: The RPK-33A rack

panel is designed to mount the CT amplifiers in a standard

19” sound rack. Instructions are furnished with the

RPK-

33A instruction sheet.

MODEL LK-12 LOCKING PLATE: Equipped with a lock

and 2 keys. Fully conceals the control panel to prevent

Bogen

tampering with the controls of a

amplifier.

THERMAL BREAKER

The output transistors are protected by a thermal over-

load device, which shuts off the unit when the temperature

of the unit rises excessively. When the unit is shut off by the

thermal overload device, the POWER indicator on the front

panel remains on. Check the output transistors and replace

defective transistors as indicated below.

REPLACING TRANSISTORS

When replacing the driver transistors, press a small screwdriver blade into the side of the U-clip heat sink to spread

the jaws of the clip. Draw the clip and screwdriver off the

metal tab on the driver transistor. Reverse the procedure to

install the clip on the replacement transistor. Since the

U-clip heat sink is a spring clip, avoid spreading the jaws too

wide.

-9-

Page 8

When replacing the output transistors, clean all foreign

matter from the heat sink, insulator, and transistor. Brush a

generous amount of silicon compound such as Dow Corning

No. 340 to completely cover both surfaces of the insulator

(Part No. 16-9278-01). Place the insulator between the heat

sink and the replacement transistor. Use the original transistor mounting hardware to mount the replacement transis-

tor.

The above procedure may require some dismantling of

the heat sink. It is therefore important to also clean the

contact surface of the thermal breaker and to apply the

silicon compound to the thermal breaker before reassembling the heat sink. Make certain the thermal breaker makes

firm contact with the heat sink.

REPLACEMENT PARTS

Most components used in the amplifier are standard

parts available through reputable parts suppliers. The parts

listed here may be obtained from Bogen distributors,

service agencies or directly from the factory. When ordering

a part, specify a part number, the model of the unit, and

give the series designation, which is a letter followed by

numbers, printed on the chassis. For parts on circuit

boards, also give the component board assembly number,

which begins with “45”.

When replacing transistors, use those made by the

specified manufacturers. Transistors from other suppliers

may not be satisfactory. Certain resistors must be

Bradley products. These are designated by “AB” on the

schematic diagram.

Ref. No. Part No.

A3 45-9813-01

C3,19

C5, 17,18879-008-057

Cl5

C25

c29 79-008-058

c31

CRl,

CR3 96-5344-04

CR4

CR5 96-5202-01

Ll-3 95-5 162-01

L4 95-5 163-01

&4,6-8

:;

79-008-049

79-504-032

79-l 12-001

79-008-062

2, 6696-5333-01

96-5344-02

95-5164-01 96-5213-01

96-5346-01

96-5 96-5298-01 176-01

Q10 96-5283-01

Q11

96-5357-01

Q12 96-5356-01

Rl

R23 77-00 l-709

R32 77-001-722

R48 75-842-561

R65, 69 76-107-096

R67, 68 76-116-003

77-001-712

Description

PC board assembly

Capacitor, electrolytic,

Capacitor, electrolytic, 50µF, 50V

Capacitor, tantalum, 2.2µF, 15V

Capacitor, electrolytic,

Capacitor, electrolytic,

Capacitor, Electrolytic, 1

Diode, 400 piv

Diode, zener, 18V, 2W

Diode, zener, 12V, 2W

HVR3

Inductor,

Inductor,

Inductor, 1

Transistor,

Transistor, BC 239C

Transistor, MPS-65 18

Transistor, SPS-1910

Transistor, MPS-A55

Transistor, 2SD-389 (P)

/2SD313D/TIP31A

Transistor,

/2SB507D/TIP32A

Control, aux vol., 2

C.T.

Control,

Control, master vol., 10

kilohm

Resistor, 560 ohm, 3W

Resistor, .82 ohm, 2W

Resistor, .27 ohm, 7W

150µH

50µH

5µH

2N5089

2SB-5

comp.,

@

1 A

or

12 (P)

megohm

50 kilohm

500µF,

500µF,

l0µF,

OOµF,

Allen-

35V

75V

50V

50V

Schem. Ref. Part No.

Chassis electrical components

Cl06

Cl07

CBlOl

CB-102

CR-101, 102 96-5241-01

CR-103, 104 96-5333-01

1101

QlOl-106

RlOl-105

R108

R109,

110

SW101

TlOl

T102

Al, A2

C4,13

Q1,2

Rl,

2,

15,1676-147-126 Resistor,4.7 ohm,

R14,25

79-509-05 1

79-509-052

79-509-053

79-509-O 15

79-509-O 17

79-509-O 19

94-00 17-04

94-00 17-09

94-00 17-15

94-00 14-07

94-0302-05

96-5385-01

96-5397-01

77-001-723

75-741-101

76-116-003

81-003-057

81-003-053

83-805-000

83-804-000

83-803-000

83-422-000

83-423-000

83-424-000

Pre-amp board components

45-7082-01 PC board assembly

79-008-05

96-5213-01

96-5346-01

77-001-711 Control,1 megohm

Mechanical components

03-0628-02 Control,anti-feedback

03-0593-01 Control,aux 1, 2 vol.

03-0641-01 Control,mic 1, 2 vol.

03-0592-01 Control,master vol.,

Description

Cap, electrolytic,

75V (CT-35)

Cap, electrolytic,

75v (CT-60)

Cap, electrolytic,

75V

(CT-l00)

Cap, electrolytic,

5OV

(CT-35)

Cap, electrolytic,

5ov (CT-60)

Cap, electrolytic,

50V

(CT-l00)

Circuit breaker,

(CT-35)

Circuit breaker, 1.65A hold

(CT-60)

Circuit breaker,

(CT-l 00)

Thermal breaker, 105°C

Diode, 300 piv

Diode, 400 piv

Pilot lamp assembly

Transistor,

(CT-35,60)

Transistor, 2N3055 Solitron

(CT-l 00)

Control, slide, 500 kilohm __

Resistor, 100 ohm, 7W

Resistor, .27 ohm, 7W

(CT-l 00)

Switch, ac, 3A

Switch, ac, 6A

Transformer, power (CT-35)

Transformer, power (CT-60)

Transformer, power

Transformer, output (CT-35)

Transformer, output (CT-60)

Transformer, output

1

Cap,electrolytic,

Transistor,

Transistor, BC 239C

mic

3,4

1500µF,

2000µF,

3000µF,

750µF,

1500µF,

2500µF,

.93A

2.5A

@

3A

@ 1A

2N3055H

(CT-35,60)

(CT-l00)

25µF,

2N5089

hold

hold

RCA

(CT-l00)

(CT-l00)

35V

or

1/2W

comp.,

Page 9

Page 10

Loading...

Loading...