Operating Instructions

base control

for Scroll Compressors

Operating Instructions

base

control

for Scroll Compressors

BOGE KOMPRESSOREN

Otto Boge GmbH & Co. KG

Postfach 10 07 13

33507 Bielefeld

Otto-Boge-Straße 1-7

33739 Bielefeld

Tel: +49-520-660-10

Fax: +49-520-660-1200

Email: info@boge.com

Web: www.boge.com

Version: 11 / 2016

No. 596.1454.18

Nominal price: €5.00

BOGE base control for scroll compressors Page I

Table of Contents

Table of Contents

Part 1: About these Operating Instructions

Part 2: Safety

1.1 Who are these Operating Instructions aimed at?........................ 1

1.2 Content of these Instructions........................................................ 1

1.3 Other Important Documents .......................................................... 2

1.4 Guide for Reading........................................................................... 2

Symbols and Typographic Aids ........................................................ 2

Structure of Warning Notices............................................................ 3

2.1 General Safety Information............................................................ 5

Prior to Commissioning and Operation............................................. 5

Intended Use .................................................................................... 5

Reasonably Foreseeable Misuse ..................................................... 5

2.2 Special Safety Information............................................................. 6

Switch Cabinet.................................................................................. 6

Emergency Stop Function / Main Switch .......................................... 6

Changing Parameters / Settings....................................................... 7

Data Security .................................................................................... 7

Damage to the Control Unit .............................................................. 7

2.3 Operator and Personnel................................................................. 7

Personnel Requirements .................................................................. 7

Obligations of the Operator............................................................... 8

Obligations of Personnel................................................................... 8

Part 3: Layout and Function

BOGE base control for scroll compressors Page III

3.1 Operating Principle of the Control ................................................ 9

Basic Tasks of the Control................................................................ 9

Use as a Lower-level Control in the Compressor Network ............... 9

3.2 Layout of the Control Unit ........................................................... 10

LCD Display (1) .............................................................................. 11

"Fault" and "Ready" Indicator Lamps (2 and 3) .............................. 11

Info and Enter Keys (4 and 5)......................................................... 11

On and Off Keys (6 and 7).............................................................. 12

Table of Contents

Part 4: Display and Operation

Part 5: Setting Parameters

Part 6: Troubleshooting

4.1 Description of Display Symbols .................................................. 13

4.2 Description of the Displays and Navigation............................... 14

Main Display ................................................................................... 14

Additional Displays ......................................................................... 16

5.1 Unlocking Code-protected Parameters ...................................... 19

5.2 Changing Individual Parameters................................................. 20

Parameter Codes............................................................................ 20

Compressor Servicing Interval: Restart the Counter / Change the Start

Value............................................................................................... 20

Motor Servicing Interval: Restart the Counter / Change the Start Value

21

Change Target Pressure Values (p

Activating / Deactivating the Auto-Restart Function ....................... 23

Activating / Deactivating the External Output Release ................... 25

Performing Leakage Measurement (without code release) ............ 27

6.1 Message Types ............................................................................. 31

6.2 Processing Messages .................................................................. 31

max

and p

) ........................... 22

min

Part 7: Servicing

6.3 List / Meaning of Message Codes ............................................... 32

6.4 Acknowledging Messages ........................................................... 33

7.1 Cleaning the Display .................................................................... 35

7.2 Updating the Software.................................................................. 35

Page IV BOGE base control for scroll compressors

About these Operating Instructions

1.1 Who are these Operating Instructions aimed at?

Part 1: About these Operating Instructions

1.1 Who are these Operating Instructions aimed at?

These operating instructions are aimed at end customers of BOGE who have

purchased a scroll compressor and wish to operate it using the compressor

base control.

In addition to reading these instructions, the user must meet the following prerequisites in order to ensure professional operation of the control. S/he must:

– have an understanding of the compressor

– have an understanding of the accompanying operating instructions

– be classified as qualified personnel or trained personnel with technical

background knowledge in the field of compressed air technology (see also

"Personnel Requirements", page 7).

1.2 Content of these Instructions

These operating instructions deal exclusively with the functionality, operation

and parametrization of the base control.

The following content and work descriptions do not form part of these operating instructions:

– All safety information on the compressor. This is part of the compressor

operating instructions.

– Work such as electrical commissioning or repairs to the control.

– Work on the control that requires the switch cabinet to be opened, for

example installing updates.

– Work on the compressor and its accessories (e.g. installation or commis-

sioning).

The above-mentioned work must only be carried out by an authorized, qualified electrician or BOGE Service personnel.

BOGE recommends having the control, compressor and accessories set up

and commissioned by BOGE Service personnel. Maintenance and repair work

on the control should also be carried out by BOGE Service personnel.

Should you have any questions about this product, please contact

Product Support on:

Telephone: +49-520-660-1140

If you require Service assistance, please contact BOGE Service on:

Telephone: +49-520-660-1100

BOGE base control for scroll compressors Page 1

About these Operating Instructions

1.3 Other Important Documents

1.3 Other Important Documents

The following documents are required for any work not described in these

operating instructions:

– the compressor operating instructions;

– the operating instructions for the connected accessories.

Pay particular attention to the safety information in this document!

The following pages contain a guide for reading these instructions as well as

information on the design of warning notices.

1.4 Guide for Reading

These operating instructions are designed to help you to operate the compressor control quickly and easily.

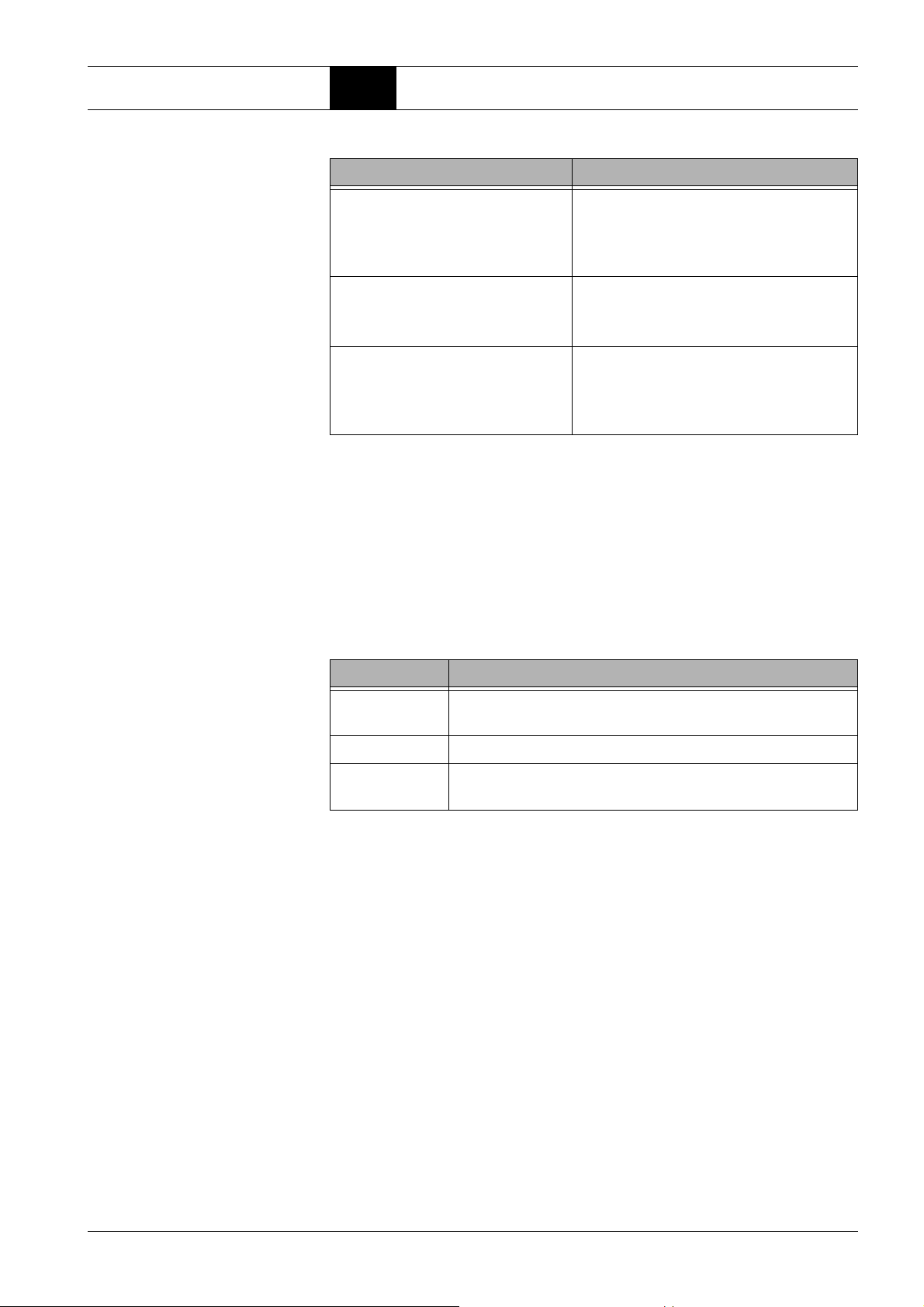

Symbols and Typographic Aids

The following table contains an overview of all the symbols and typographic

aids used to simplify the content:

Symbol

– Information 1

– Information 2

– Information 3

● Action Directions for Use I

Meaning

Setup Mode

In this area, settings can only be

changed if a code has been issued.

Tips and additional information on

optimum operation

Tips and information that help you

to use the control in an optimum

manner are indicated by the symbol

shown.

List

Important information is listed clearly.

Directions for use with one action are

indicated by the symbol shown.

Page 2 BOGE base control for scroll compressors

About these Operating Instructions

1.4 Guide for Reading

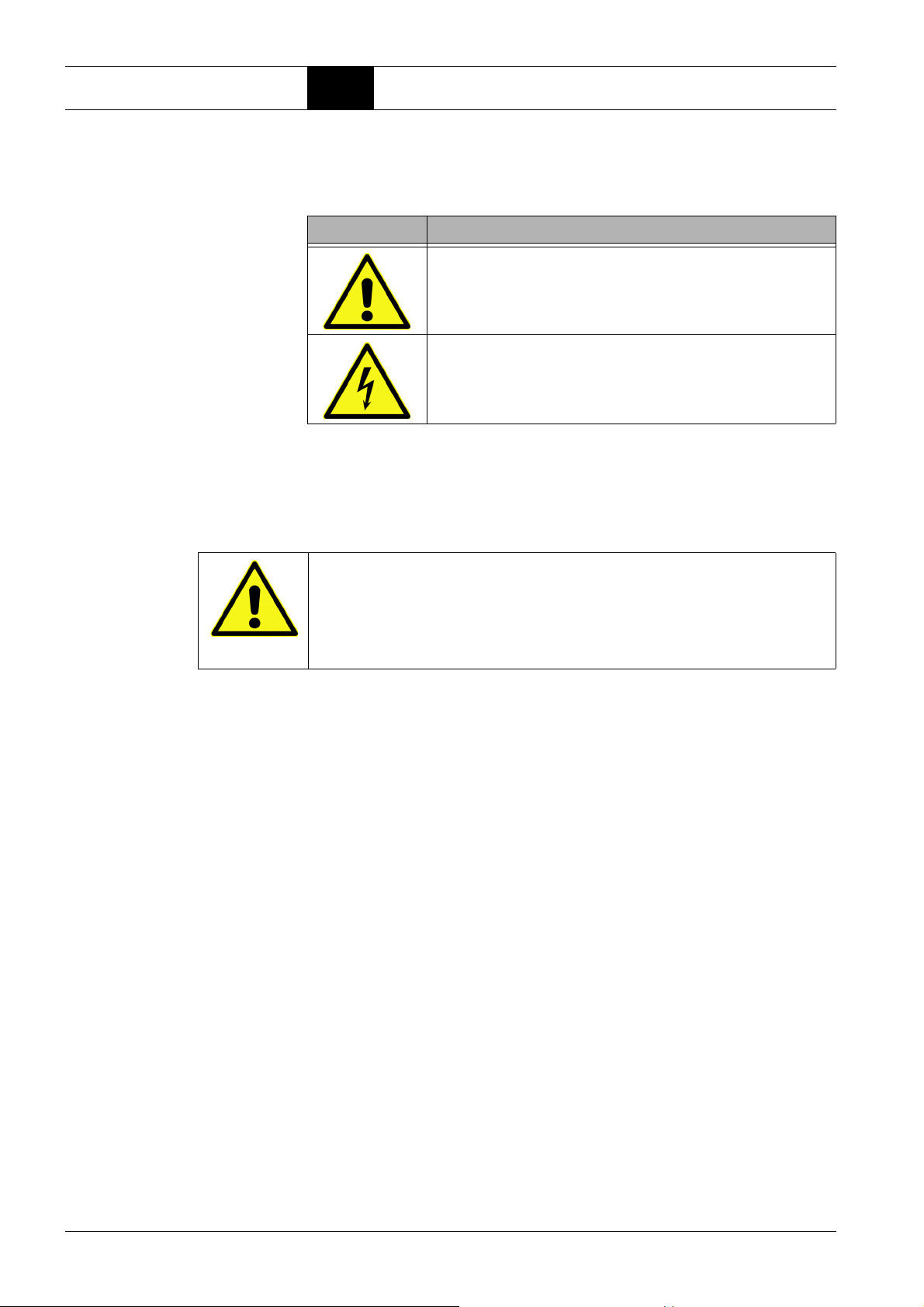

Structure of Warning Notices

Symbol

1. Action 1

2. Action 2

3. Action 3

Result of action Result

(1)

(2)

(3)

Tab. 1.1: Overview of all design elements that simplify the content of these

instructions

The warning notices in these instructions indicate dangers that may occur

when carrying out certain tasks. They also indicate how a dangerous situation

can be avoided. Warning notices follow a fixed structure which is described

below.

Signal Words

The following signal words are used:

Meaning

Directions for Use II

Directions for use with several actions

are numbered and must be carried out

in the specified sequence.

The outcome that will follow an action is indicated by the arrow shown.

Screenshots

The screenshots of the operating unit

display may be divided into areas.

The individual areas are numbered.

Signal Word Meaning

WARNING Warns of dangers to persons that could lead to serious

injury or death.

CAUTION Warns of property damage and data loss

NOTE Warns of faults in the operating sequence /

communication

Tab. 1.2: Signal words

BOGE base control for scroll compressors Page 3

About these Operating Instructions

1.4 Guide for Reading

Warning Signs

The following warning signs are used:

Warning Sign Meaning

Warns of a hazardous area

Warns of life-threatening electrical voltage

Tab. 1.3: Warning signs

Design of Warning Notices

Warning notices are a combination of signal words, warning signs and information. They are structured as follows:

SIGNAL WORD

Type of Danger

Source of the danger and consequences if the warning notice is not observed.

How to avoid the danger.

Page 4 BOGE base control for scroll compressors

Safety 2.1 General Safety Information

Part 2: Safety 2.1 General Safety Information

Prior to Commissioning and Operation

Intended Use

Reasonably Foreseeable Misuse

The following must be observed prior to commissioning and operation of the

base control:

– These instructions must be read thoroughly and understood before com-

missioning / operating the control.

– These instructions must be available at all times at the place of operation

of the control.

– Changes to parameters and settings may only be carried out by authorized,

qualified personnel, see also "Personnel Requirements".

– Work on the control that requires the switch cabinet to be opened may only

be carried out by an authorized, qualified electrician, see also "Personnel

Requirements".

– Prior to initial commissioning of the control unit, check for visible transport

damage.

– Damage to the control that affects safe operation of the machine must be

rectified immediately.

The control is intended exclusively for the correct operation of a BOGE scroll

compressor and its connected accessories.

The control is not suitable for use with other types of compressed air generators or compressors from other manufacturers.

BOGE base control for scroll compressors Page 5

Safety 2.2 Special Safety Information

2.2 Special Safety Information

Switch Cabinet

Emergency Stop Function / Main Switch

The control is housed in a switch cabinet.

The control unit of the control can be found at the front of the switch cabinet.

The control may only be operated via the control unit when the switch cabinet

is closed.

WARNING

Risk of Electric Shock

Live parts are located inside the switch cabinet. There is a risk of electric

shock when the switch cabinet is opened.

Never open the switch cabinet during operation.

Only operate the control when the switch cabinet is closed.

The switch cabinet may only be opened by an authorized and qualified

electrician.

Please note that only settings that can be applied via the control unit of the

control may be changed using these operating instructions.

The emergency stop function serves to avert or prevent a prevailing emergency situation, where such a situation is the result of conduct by individuals

or an event posing an unexpected danger.

The emergency stop function is provided through the main switch. When the

main switch with emergency stop function is pressed, compressor operation

stops immediately and the switch cabinet and control are no longer live.

Dangerous voltage may still be present on the supply terminals even though

the machine is disconnected from the grid.

The main switch is not located on the control unit of the base control; it is instead in a highly visible location on the front of the scroll compressor housing.

Please note:

– Press the main switch to avoid or prevent an emergency situation.

– In normal operation the Off key should be pressed on the control to prop-

erly shut down the compressor.

– In addition, always press the main switch when carrying out inspections

or work on the compressor or switch cabinet.

Page 6 BOGE base control for scroll compressors

Safety 2.3 Operator and Personnel

Changing Parameters / Settings

Data Security

Damage to the Control Unit

The control regulates the compressor using specific parameters / settings.

The individual parameters represent the values that can be used to change

the compressor functions (e.g. switch-on and switch-off pressure) so that the

compressor generates compressed air as required. However, incorrect settings can also lead to operational faults or destruction of the compressor.

CAUTION

Compressor Damage

Changing parameters / operational settings that have an effect on the operation or function of the compressor may damage or destroy the compressor.

Only authorized, qualified personnel may make changes to parameters

or settings.

If in doubt regarding a change to operational settings, contact BOGE

Service.

The base control automatically stores all data – e.g. altered settings – in the

non-volatile memory. The saved data are therefore also available in the event

of a power failure.

All keys on the control unit are operated by tapping on them with a finger. Light

tapping on the interface is sufficient to actuate the keys. Do not use any sharp

or abrasive objects when operating the control unit. BOGE accepts no liability

for damage resulting from improper use.

Personnel Requirements

2.3 Operator and Personnel

Only individuals who are able to carry out the work correctly and reliably and

who meet the following requirements may perform work on the control:

Trained Personnel

Trained personnel are individuals who have been informed in detail by the

operator of the potential dangers concerning the tasks assigned to them and

for whom this training has been documented.

Qualified Personnel

Qualified personnel are individuals who are able to successfully carry out work

assigned to them, recognize potential dangers independently and avoid injury

to individuals or property due to their professional training, knowledge and

experience as well as their knowledge of the relevant regulations.

BOGE base control for scroll compressors Page 7

Safety 2.3 Operator and Personnel

Qualified Electricians

Qualified electricians are individuals who are able to successfully carry out

work assigned to them, recognize potential dangers independently and avoid

injury to individuals or property due to their qualifications, knowledge and experience as well as their knowledge of the relevant regulations.

Prior to descriptions of work requiring specialist knowledge, the requirements that the individual must fulfill in order to be able to carry out the work

described are clearly stated.

Obligations of the Operator

Obligations of Personnel

The operator is subject to the legal obligations concerning occupational safety

and must be familiar with the applicable occupational health and safety regulations. In addition:

– The operator must authorize qualified electricians to carry out work on the

switch cabinet.

– The operator may only provide the key to the switch cabinet to a qualified

electrician who is authorized to carry out work on the switch cabinet.

– The operator must authorize qualified personnel to change parameters or

settings on the control.

Personnel are subject to the legal obligations concerning occupational safety

and must be familiar with the applicable occupational health and safety regulations. In addition:

– Personnel must have read these instructions thoroughly before commis-

sioning / operating the control.

– The same applies to the instructions for the compressor and accessories.

– For all work requiring specific qualifications, personnel must be authorized

by the operator to carry out such work in line with these instructions.

Page 8 BOGE base control for scroll compressors

Layout and Function 3.1 Operating Principle of the Control

Part 3: Layout and Function

Basic Tasks of the Control

Use as a Lower-level

Control in the Compressor Network

3.1 Operating Principle of the Control

The compressor control is the central control element of the compressor system.

The compressor control with switch cabinet is integrated in the compressor

housing and connected directly to the compressor. This means that it is ready

for operation as soon as the compressor is connected to the power supply.

The first essential task carried out by the control is the monitoring of all com-

pressor system functions. Information on compressor operation can be called

up and checked on the control display. This includes data on the current operating status of the compressor or servicing intervals (see Part 4: Display and

Operation, page 13 ff.).

The second essential task carried out by the control is the efficient regulation

of the compressor for tailored use. To do this, compressor parameters can

be set via the control. These are required for the compressor to generate compressed air according to individual requirements. This includes parameters

for setting the pressure to be generated (see Part 5: Setting Parameters,

page 19 ff.).

The BOGE base control can be connected to the master control of

a compressor network via a Modbus interface module. The lower-level

control then operates according to the instructions of the master control.

It must also be parameterized to suit the master control.

BOGE base control for scroll compressors Page 9

Layout and Function 3.2 Layout of the Control Unit

(4)

(5)

(3)

(1)

(2)

(6)

(7)

3.2 Layout of the Control Unit

The control unit of the base control is structured as follows:

Fig. 3.1: base control – Control Unit

Both display and control elements can be found on the control unit.

Display Elements:

– LCD display (1)

– Indicator lamp – Fault (2)

– Indicator lamp – Ready (3)

Control Elements:

– Info key (4)

– Enter key (5)

– On key (6)

– Off key (7)

The individual elements and their functions are explained in more detail below.

Page 10 BOGE base control for scroll compressors

Layout and Function 3.2 Layout of the Control Unit

LCD Display (1)

"Fault" and "Ready" Indicator Lamps (2 and 3)

Info and Enter Keys (4 and 5)

The control display provides an overview of the individual functions of the control and allows you to monitor compressor operation, apply settings and correct these if necessary.

LED Designation Meaning

Fault

(red)

Ready

(green)

Tab. 3.1: Meaning of the Indicator Lamps

The user can navigate between the individual displays and apply settings or

changes to parameters using the Info and Enter keys:

Key Designation Function

Info key

– Flashing: the control is signaling a fault.

– Rapid flashing: the control is signaling

a warning / maintenance message.

– Lights up: the compressor is ready for operation.

– To switch between the displays for calling up various

pieces of information that can be issued by the control.

– To change a value.

Enter key

Tab. 3.2: Functions of the Info and Enter keys

– To edit values.

– To confirm a setting.

BOGE base control for scroll compressors Page 11

Layout and Function 3.2 Layout of the Control Unit

On and Off Keys (6 and 7)

The compressor can be turned on and off directly via the On and Off keys:

Key Designation Function

On key

Off key

Tab. 3.3: Functions of the On and Off keys

The On and Off key functions are only used to operate the compressor.

To switch off the control completely, the compressor must be disconnected

from the grid. This is because the compressor supplies power to the control.

– To switch on the compressor.

(If the network pressure is greater than the lower switch-on

pressure of the compressor, the compressor remains in

standby when the On key is pressed.)

– To switch off the compressor.

– To acknowledge a network failure (unless the Auto-

Restart function is activated).

Page 12 BOGE base control for scroll compressors

Display and Operation 4.1 Description of Display Symbols

Part 4: Display and Operation

Display Symbol Name (display it appears in) Meaning

Three-digit, Seven-segment Display

Pressure

bar/psi

Three-digit, Seven-segment Display

Temperature

°F

4.1 Description of Display Symbols

Symbols that may appear on the display are described in the table below:

Network pressure display

(main display)

Parametrization

(parameter setting displays)

Network pressure display p

(main display)

Final compression

temperature

(main display)

OFF (main display) or motor

(motor servicing interval)

This symbol indicates that the value displayed on the right

(see 3rd row of this table) is the current network pressure.

This symbol indicates that the user is currently in parametrization mode and is able to change a parameter value.

Current network pressure in bar/psi with a decimal point

n

between the 2nd and 3rd digit.

Current final compression temperature in degrees

Fahrenheit.

The circle symbol has two functions depending on which

display it appears:

1. The compressor is switched off.

2. For motor servicing interval.

Standby / ready

(main display)

Load run (main display) Output phase

Total running time

(operating hours / compressor

servicing interval / motor

servicing interval)

Servicing

(Main display flashing / compressor servicing interval /

motor servicing interval)

Auto-Restart

(Main display / function check

of display elements)

External output release Remote output release activated (e.g. by master control).

Tab. 4.1: Description of Display Symbols

The compressor is ready for operation.

The symbol indicates that the value shown above

is the total operating time of the compressor in hours.

Measurement starts after initial commissioning.

Information on current servicing or servicing that is due.

Auto-Restart function activated:

Automatic restart enabled after power failure (by parametrization).

BOGE base control for scroll compressors Page 13

Display and Operation 4.2 Description of the Displays and Navigation

4.2 Description of the Displays and Navigation

The numerous monitoring and control options of the base control are visualized in various displays on the control. The meaning of these displays is

explained below. An explanation is also given as to how the user can navigate

to the individual displays.

Main Display

Operating / Control Element Display / Action Operation / Explanation

Activated simultaneously:

Indicator lamp – Fault (red)

Indicator lamp – Ready (green)

Following the standard function check of the display elements when turning on

the supply voltage of the compressor (see description in row 1 of the following

table), the main display appears on the control. The symbols in the main display change depending on the operating status of the compressor. The various symbols that appear on the main display are described in the next table.

Function check of the

display elements

Main display after switching

on the supply voltage /

pressing the main switch

– After switching on the supply voltage and

pressing the main switch, all display elements of the control unit that can be activated appear at the same time, and both

indicator lamps come on.

– If standby was not saved (no Auto-Restart),

this status must first be ended by pressing

the Off key before the compressor can

be switched on.

– Otherwise, the Auto-Restart symbol at

the bottom right starts flashing, disappears

automatically after a set time and the compressor is ready for operation again without

pressing any keys.

The main display appears automatically after

the power failure phase has ended (as described under function check of the display elements).

The following information is shown on the main

display:

– The network pressure symbol p

played at the top left (manometer 21).

– The current value for the network pressure

is displayed to the right in bar/psi.

– The current value for the final compression

temperature is displayed on the far right.

– The circle symbol indicates that the com-

pressor is currently switched off.

is dis-

n

To switch on the

compressor

1 Indicator lamp – Ready (green)

Page 14 BOGE base control for scroll compressors

● Press the On key .

The pressure control function is acti-

vated.

If no fault is reported, the green indicator

lamp lights up (compressor is ready for

operation).

Display and Operation 4.2 Description of the Displays and Navigation

Operating / Control Element Display / Action Operation / Explanation

Load run The pressure control starts the motor if the net-

work pressure falls below the switch-on pressure p

required. The load run symbol

on the display. The compressor delivers compressed air.

Standby / ready If the network pressure reaches the set switch-

off pressure p

off. The standby / ready symbol is shown on

the display.

; in other words, compressed air is

min

, the control switches the motor

max

is shown

1 Indicator lamp – Fault (red)

Tab. 4.2: Description of the Main Display

To switch off the compressor

● Press the Off key .

The compressor is switched off.

The pressure control function is

deactivated.

The O symbol appears on the display.

The green indicator lamp goes out.

Fault If the control registers a fault, the compressor

is automatically switched off immediately. The

"Fault" indicator lamp flashes. At the same time,

a number flashes on the display to the right of

the network pressure value:

This number is a fault code, which is assigned

to a specific cause (see "List / Meaning of Message Codes", page 32).

BOGE base control for scroll compressors Page 15

Display and Operation 4.2 Description of the Displays and Navigation

Additional Displays

Display View / Meaning Display Operation / Explanation

means: 124 h total running time

means: 500 h until next compressor servicing

means: 1000 h until next motor servicing

Additional displays can be called up on the control from the main display using

the Info key . The meaning of these displays is described in the table below.

Operating hours ● Press the Info key (on the main dis-

play).

The "Operating hours" display appears,

together with the total running time symbol.

The seven-segment display shows the

total operating hours counter in hours.

Compressor servicing

interval

Motor servicing interval ● Press the Info key three times (from the

● Press the Info key twice (from the main

display).

The "Compressor servicing interval"

display appears, together with the

servicing and total running time symbols.

The seven-segment display shows the

servicing countdown counter in hours.

main display).

The "Motor servicing interval" display

appears, together with the circle symbol

O (stands for motor here) and the servicing and total running time symbols.

The seven-segment display shows the

servicing countdown counter in hours.

Single leakage

measurement

Continuous leakage

measurement

● Press the Info key four times (from the

main display).

The "Single leakage measurement"

display appears, indicated by the letters

LE.

The seven-segment display shows the

value for the load run hours per year

caused by leakage.

● Press the Info key five times (from the

main display).

The "Continuous leakage measure-

ment" display appears, indicated by the

letters Lc or LC.

The seven-segment display shows the

value for the load run hours per year

caused by leakage.

If the letters LC are displayed, continu-

ous measurement has already been

carried out for over a week.

Page 16 BOGE base control for scroll compressors

Display and Operation 4.2 Description of the Displays and Navigation

means: p

means: p

= 10.0 bar

max

= 9.0 bar

min

Upper target pressure value

(switch-off pressure p

max

)

Lower target pressure value

(switch-on pressure p

min

)

Function check of the display elements

● Press the Info key six times (from the

main display).

The "Upper target pressure value" dis-

play appears, indicated by a bar/psi at

the top edge of the display.

The seven-segment display shows the

set value for the network pressure.

If this is reached, the control switches

the compressor off automatically.

● Press the Info key seven times (from

the main display).

The "Lower target pressure value" dis-

play appears, indicated by a bar/psi at

the bottom edge of the display.

The seven-segment display shows the

set value for the network pressure.

If this is reached, the control switches

the compressor on automatically.

● Press the Info key eight times (from the

main display).

All display elements that can be acti-

vated appear on the control unit at the

same time, and both indicator lamps

come on.

Activated simultaneously:

Indicator lamp – Fault (red)

Indicator lamp – Ready (green)

means software version 0001 (the first digit (4)

stands for scroll compressor software)

Irrespective of the display that was last called up: If no keys are pressed on

the control unit for five minutes, the main display reappears automatically.

Software version ● Press the Info key nine times (from the

main display).

The "Software version" display appears.

The seven-segment display shows the

version number of the control software.

● Press the Info key again.

The main display appears again.

If no keys are pressed on the control unit for

five minutes, the main display appears automatically.

BOGE base control for scroll compressors Page 17

Setting Parameters 5.1 Unlocking Code-protected Parameters

Part 5: Setting Parameters

5.1 Unlocking Code-protected Parameters

The operation of the compressor can be modified by applying parameters

via the control, so that the compressor can generate compressed air on site

according to individual requirements. To prevent unintentional changes to preset parameter values, operational parameters are code-protected. These

parameters must be unlocked before they can be changed. The same

unlocking procedure is always followed:

CAUTION

Compressor Damage

Changing parameters / operational settings that have an effect on the

operation or function of the compressor may damage or destroy the

compressor.

Only authorized, qualified personnel may make changes to parameters

or settings.

If in doubt regarding a change to operational settings, contact BOGE

Service.

1. Call up the main display of the control.

2. Press the Info key nine times.

The "Software version" display appears.

3. Press the Enter key .

The parametrization symbol appears on the left of the display followed

by three 0 digits, the left of which flashes.

The flashing 0 can be changed.

4. Press the Info key until the correct first digit of the desired code

(see following page) is displayed.

5. Press the Enter key .

The first digit is set and no longer flashes.

The middle 0 flashes.

This digit can now be changed.

6. Press the Info key until the correct second digit of the desired code

(see following page) is displayed.

7. Press the Enter key .

The second digit is set and no longer flashes.

The third 0 flashes.

This digit can now be changed.

8. Press the Info key until the correct last digit of the desired code

(see following page) is displayed.

9. Press the Enter key .

Depending on the code set, the display via which the code-protected

parameter can be changed appears.

If an invalid code is entered, the main display appears on the control.

BOGE base control for scroll compressors Page 19

Setting Parameters 5.2 Changing Individual Parameters

5.2 Changing Individual Parameters

The required codes, description and step-by-step alteration of the individual

parameters are covered in this section.

Parameter Codes

Compressor Servicing Interval: Restart the Counter / Change the Start Value

Below is a table containing a list of codes that the user can use to change the

individual parameters:

Code Parameter function Page

111 Setting the compressor servicing interval and restarting the counter 20

222 Setting the motor servicing interval and restarting the counter 21

360 Changing the target pressure values (switch-off / switch-on pressure)

(p

/ p

min

)

max

134 Activating / deactivating the Auto-Restart function 23

210 Activating / deactivating the external output release 25

Tab. 5.1: Codes and Editable Parameters

This function is used to signal in advance the pending servicing of the compressor. The hours until the next compressor servicing interval count down

from a start value (remaining hours). When the value reaches 0, the control

outputs a maintenance message. After servicing, the countdown counter must

be manually reset to the start value.

To restart and reset the countdown counter to the start value until the next

compressor servicing interval:

1. Unlock the code-protected parameters for the compressor servicing interval using code 111, as described under "Unlocking Code-protected

Parameters" on page 19.

The current start value for the countdown counter flashes on the seven-

segment display.

2. Press the Enter key .

The main display reappears on the control.

The servicing interval countdown counter has been reset to the start

value and restarted.

22

CAUTION

Compressor Damage

If the servicing interval countdown counter is not restarted, urgently

required servicing work can be overlooked.

After all servicing work, the respective countdown counter must be

manually reset to the start value.

The start value for the remaining hours can be changed. To reset / change

the start value of the countdown counter until the next compressor servicing

interval:

Page 20 BOGE base control for scroll compressors

Setting Parameters 5.2 Changing Individual Parameters

1. Unlock the code-protected parameters for the compressor servicing inter-

val using code 111, as described under "Unlocking Code-protected

Parameters" on page 19.

The current start value for the countdown counter flashes on the seven-

segment display.

2. Press the Info key until the desired value is displayed.

3. Press the Enter key .

The main display reappears on the control.

The previous value is overwritten.

The changed value is set.

CAUTION

Compressor Damage

If the maximum start value (21,000 h) is set, the countdown counter stops

and the compressor servicing interval function is deactivated, meaning that

urgently required servicing work may be overlooked.

Please consult BOGE Product Support prior to setting the highest value.

Motor Servicing Interval: Restart the Counter /

Change the Start Value

This function is used to signal in advance the pending servicing of the motor.

The hours until the next motor servicing interval count down from a start value

(remaining hours). When the value reaches 0, the control outputs a maintenance message. After servicing, the countdown counter must be manually

reset to the start value.

To restart and reset the countdown counter to the start value until the next

motor servicing interval:

1. Unlock the code-protected parameters for the motor servicing interval

using code 222, as described under "Unlocking Code-protected Param-

eters" on page 19.

The current start value for the countdown counter flashes on the seven-

segment display.

2. Press the Enter key .

The main display reappears on the control.

The servicing interval countdown counter has been reset to the start

value and restarted.

CAUTION

Compressor Damage

If the servicing interval countdown counter is not restarted, urgently

required servicing work can be overlooked.

After all servicing work, the respective countdown counter must be

manually reset to the start value.

BOGE base control for scroll compressors Page 21

Setting Parameters 5.2 Changing Individual Parameters

The start value for the remaining hours can be changed. To reset / change

the start value of the countdown counter until the next motor servicing interval:

1. Unlock the code-protected parameters for the motor servicing interval

using code 222, as described under "Unlocking Code-protected Param-

eters" on page 19.

The current start value for the countdown counter flashes on the seven-

segment display.

2. Press the Info key until the desired value is displayed.

3. Press the Enter key .

The main display reappears on the control.

The previous value is overwritten.

The changed value is set.

CAUTION

Compressor Damage

If the maximum start value (30,000 h) is set, the countdown counter stops

and the motor servicing interval function is deactivated, meaning that

urgently required servicing work may be overlooked.

Please consult BOGE Product Support prior to setting the highest value.

Change Target Pressure

Values (p

and p

max

min

)

This parameter can be used to change the target pressure values.

The p

value defines the switch-off pressure of the compressor. If the

max

network pressure reaches this value during an output phase, the control

switches off the compressor automatically.

The p

value defines the switch-on pressure of the compressor. If the

min

network pressure falls below this value, the control switches the compressor

on automatically.

To change the p

max

and p

target pressure values:

min

1. Unlock the code-protected parameters for the target pressure values using

code 360, as described under "Unlocking Code-protected Parameters"

on page 19.

The currently valid upper target pressure value (p

) flashes in the

max

seven-segment display.

2. Press the Info key until the desired p

value is displayed.

max

3. Press the Enter key .

The currently valid lower target pressure value (p

) flashes in the

min

seven-segment display.

The previous p

value has been overwritten.

max

The changed value is set.

4. Press the Info key until the desired p

value is displayed.

min

Page 22 BOGE base control for scroll compressors

Setting Parameters 5.2 Changing Individual Parameters

5. Press the Enter key .

The main display reappears on the control.

The previous p

The changed value is set.

value has been overwritten.

min

Activating / Deactivating

the Auto-Restart Function

If changes are made to these pressure values, the p

value is automati-

min

cally held or brought outside any applicable minimum hysteresis range.

The p

value must not be set below a model-specific minimum value.

min

This parameter can be used to automatically restore the on-off status of the

compressor with a set delay after a power failure.

If the compressor was switched on prior to the power failure, the set delay time

counts down after the voltage supply has been restored. Once the countdown

is complete, the compressor automatically returns to the standby / ready state.

The pressure control is active and the compressor starts generating compressed air again as necessary.

WARNING

Risk of injury due to automatic restart

When automatic restart (Auto-Restart) is activated, the compressor will

start automatically following a power failure.

Prerequisite: the network pressure is lower than the set switch-on pressure

When Auto-Restart is activated, never carry out work on the machine

after a power failure without disconnecting the compressor from the grid.

All safety covers must be in place when restoring the power supply.

To activate / deactivate the Auto-Restart function:

1. Unlock the code-protected parameters for the Auto-Restart function using

code 134, as described under "Unlocking Code-protected Parameters"

on page 19.

The display for setting the Auto-Restart function appears with the

"deactivated" selection option.

Fig. 5.1: Auto-Restart display – deactivated

The flashing line at the top right means: no Auto-Restart.

BOGE base control for scroll compressors Page 23

Setting Parameters 5.2 Changing Individual Parameters

2. Press the Info key .

The display for setting the Auto-Restart function appears with the "acti-

vated" selection option.

Fig. 5.2: Auto-Restart display – activated

The flashing curve at the top right means: Auto-Restart.

You can toggle between display 5.1 (deactivated) and 5.2 (activated) by

pressing the Info key .

Once "Auto-Restart" or "no Auto-Restart" has been selected by calling up the

corresponding display (Fig. 5.1 or 5.2):

3. Press the Enter key :

If the "Auto-Restart deactivated" display has been selected:

The main display appears again.

The Auto-Restart function is deactivated.

If the "Auto-Restart activated" display has been selected:

The display for setting the delay time appears:

Fig. 5.3: Auto-Restart display – delay time

The number of seconds for the delay time flashes on the seven-seg-

ment display.

4. Press the Info key until the desired value is displayed.

Page 24 BOGE base control for scroll compressors

Setting Parameters 5.2 Changing Individual Parameters

5. Press the Enter key .

The main display reappears on the control with the symbol for activated

Auto-Restart at the bottom right.

The Auto-Restart function is activated.

The last value displayed for the delay time is applied.

Activating / Deactivating the External Output Release

If the compressor output is to be enabled by an output release device (a master control), the control must be set as follows:

1. Unlock the code-protected parameters for the external output release using

code 210, as described under "Unlocking Code-protected Parameters"

on page 19.

The display for setting the external output release appears with the

"deactivated" selection option.

Fig. 5.4: External output release display – deactivated

The flashing square at the top means: no external output release.

2. Press the Info key .

The display for setting the external output release appears with the

"activated" selection option.

Fig. 5.5: External output release display – activated

The flashing lines on the seven-segment display mean: external output

release.

You can toggle between display 5.4 (deactivated) and 5.5 (activated) by

pressing the Info key .

BOGE base control for scroll compressors Page 25

Setting Parameters 5.2 Changing Individual Parameters

Once "External output release" or "No external output release" has been

selected by calling up the corresponding display (Fig. 5.4 or 5.5):

3. Press the Enter key :

If the "External output release deactivated" display has been selected:

The main display appears again.

External output release is deactivated.

The compressed air generation is regulated exclusively by the inte-

grated compressor control.

If the "External output release activated" display has been selected:

The display for setting the first output release mode appears:

Fig. 5.6: External output release display – output release mode 1

Output Release Mode 1

If the external output release is to be activated, one of two different output

release modes must be selected.

The following applies in release output mode 1 in spite of the external output

release: If the actual network pressure falls below the set switch-on pressure

(p

) of the control, the control enables the compressor output independently

min

(without release from the master control) in order to prevent a complete loss

of pressure. At the same time, message 18 (warning) is output. If the switchoff pressure (p

) is exceeded, the control switches off the compressor auto-

max

matically and outputs message 20 (warning). This mode is recommended as

additional security against a complete loss of pressure (e.g. in hospitals).

4. Press the Info key .

The display for setting the second output release mode appears:

Fig. 5.7: External output release display – output release mode 2

Page 26 BOGE base control for scroll compressors

Setting Parameters 5.2 Changing Individual Parameters

Output Release Mode 2

The following applies in output release mode 2: If the actual network pressure

falls below the set switch-on pressure (p

does not respond. Only when the master control issues an output release does

the base control start the compressor. A drop in network pressure to below p

is therefore possible. The control also switches off the compressor automatically in this mode if the switch-off pressure (p

message is output. The external control is only followed once more when the

pressure drops to the switch-on pressure (p

This mode is recommended if a drop in pressure is desired or the generation

of compressed air is not required for specific periods of time (e.g. at night or at

the weekend).

You can toggle between display 5.6 (mode 1) and 5.7 (mode 2) by pressing

the Info key .

Once output release mode 1 or output release mode 2 has been selected by

calling up the corresponding display (Fig. 5.6 or 5.7):

5. Press the Enter key .

The main display reappears on the control with the symbol for the acti-

vated external output release at the bottom in the center.

External output release is activated.

The compressed air generation is regulated by the master control.

) of the control, the base control

min

) is exceeded, however no

max

).

min

min

Performing Leakage Measurement (without code release)

This function is used to record the energy loss caused by leaks in the compressed air network.

The control measures the duration of compressor load runs in time phases,

during which compressed air is not normally generated, for example overnight.

For an exact calculation, compressed air generation must be stopped for at

least six hours, during which time the compressor must be in the "standby /

ready" operating status. In the event of a possible drop in pressure to below

the set switch-on pressure (p

) – caused by leaks in the compressed air

min

network – the compressor automatically switches to load run to compensate

for the pressure loss. The duration of these load runs can be recorded using

the leakage measurement function and extrapolated to an annual value.

Leakages can therefore be recorded in numerical form, allowing the additional

costs incurred as a result of the energy loss to be calculated with ease. There

are two types of leakage measurement: Single measurement (LE) and

continuous measurement (Lc / LC).

During single measurement, a single measurement is taken over six hours

to calculate the number of hours spent in load run throughout the year as

a result of leaks in the compressed air network.

The start of the measurement is delayed, i.e. once the function has been

activated, the actual measurement does not start for another six hours.

The advantage of this is that the leakage measurement function can be

activated in the late afternoon, meaning that measurement will start in the

late evening and run overnight.

BOGE base control for scroll compressors Page 27

Setting Parameters 5.2 Changing Individual Parameters

Unlike continuous measurement, single measurement can also be used if

several compressors are in operation in the same compressor network.

Once single measurement has been started for each compressor, all the

individual values can be read from the compressor controls and added

together when the six hour measurement is complete. The total value

represents the number of hours that would be spent in load run throughout the

year as a result of leaks.

During continuous leakage measurement, load run values are continuous-

ly calculated in six hour cycles over a period of one week.

The measurement begins automatically when the control is started, however

it can be restarted manually at any time. Unlike single leakage measurement,

continuous measurement can also be manually started during daily production. The measurement starts immediately once the function has been activated. The first value calculated after a six hour period will probably be false,

since the compressed air generated as part of the normal functioning of the

system will be added to the possible leak-related load run. However, it is likely

that no compressed air will be generated during the next value measurement.

The value obtained purely as a result of leakage will thus be smaller than the

first value. The control always displays the smallest value of all measurements

taken during a period of one week. This will eliminate the possibility of normal

production load runs falsifying the results.

Once the smallest value has been output for the week, continuous measurement starts for the next week, at the end of which the smallest value will again

be output.

A code is not required to start leakage measurement.

Starting Single Measurement

Single measurement starts six hours after this setting has been activated.

Ensure that:

– No compressed air is generated during the measurement as part of normal

operation of the system (for at least six hours).

– The compressor has been set to standby / ready by the control and the

green LED on the control is lit.

– (If "external output release" is activated) the external output release can

neither be disabled manually nor locked using the switch clock.

To start single measurement:

1. Call up the main display of the control.

2. Press the Info key four times.

The "Single leakage measurement" display appears (see page 16).

Page 28 BOGE base control for scroll compressors

Setting Parameters 5.2 Changing Individual Parameters

3. Press the Enter key .

The number 9999 appears on the display and single measurement

starts in six hours.

In twelve hours, the measurement value for the single measurement will

be displayed. The value will be stored until a new measurement is performed.

Should a power failure occur after the measurement has started, the

number 9980 appears on the display. In this case, the measurement

must be repeated at a later time.

If the compressor is no longer on standby at any point during the

measurement, the number 9990 appears on the display. The compressor

has been switched off, meaning that the energy loss caused by leaks

cannot be recorded correctly. In this case, the measurement must also be

repeated at a later time. Measures must also be taken to prevent the

compressor from being switched off during the new measurement.

Starting Continuous Measurement

Continuous leakage measurement starts immediately. Ensure that:

– No compressed air is generated as a result of the normal functioning of the

system for a continuous period of at least 12 hours at some point over the

following days.

– The compressor has been set to standby / ready by the control and the

green LED on the control is lit.

To start continuous measurement manually:

1. Call up the main display of the control.

2. Press the Info key five times.

The "Continuous leakage measurement" display appears (see page 16).

3. Press the Enter key .

Lc 9999 appears on the display.

Continuous measurement starts immediately.

After the 12 hour period (during which no compressed air was gener-

ated as part of the normal functioning of the system) has passed, a valid

measurement value is displayed.

The control always stores the smallest value. The control searches for the

smallest value again (as a background process) on a weekly basis. This

means that after another week has passed, a higher value may be displayed compared to the previous week if the smallest measured value has

increased during this time. Thus, an increase in the number of leaks in the

compressed air network can also be recorded.

Power failures during a measurement are not displayed as a sequence of

digits, since new values are produced every six hours and a failure during

one measurement does not prevent values from being output for the following measurement.

BOGE base control for scroll compressors Page 29

Troubleshooting 6.1 Message Types

+

Part 6: Troubleshoot-

6.1 Message Types

ing

Two types of message may appear:

No. Message Type Meaning Visualization / Display of the Message Type

1. Warning / maintenance message

2. Fault message The control is signaling a fault.

A warning has been issued or servicing

work must be carried out.

The compressor is still operational.

The compressor is switched off.

Tab. 6.1: Message Types

The "Fault" indicator lamp is flashing

rapidly. The wrench symbol is

flashing on the main display.

Pressing the Info key displays

the message code.

The "Fault" indicator lamp flashes

and a message code is shown on

the main display.

6.2 Processing Messages

The following procedure is recommended when an event occurs that causes

one of the message types to appear:

1. Determine / narrow down the cause of the message using the table below,

which contains a list of messages and message codes.

2. If necessary, have the fault rectified by BOGE Service personnel.

CAUTION

Compressor Damage

Arranging to have faults and problems rectified (including maintenance

and repair work) by unauthorized or unqualified personnel may damage or

destroy the compressor.

Faults and problems may only be rectified by authorized and qualified

personnel or BOGE Service personnel.

If in doubt, contact BOGE Service.

3. Acknowledge the message (see page 33).

As soon as the cause has been rectified successfully and the message

acknowledged, the compressor should be operational again without

restrictions.

BOGE base control for scroll compressors Page 31

Troubleshooting 6.3 List / Meaning of Message Codes

6.3 List / Meaning of Message Codes

The table below is used to narrow down the causes of messages so that potential faults and problems during compressor operation can be prevented or

rectified quickly.

It contains a list of message codes that may be issued by the base control.

Each message code has a specific cause. The causes of the messages are

specified in the table next to the codes, along with possible corrective measures.

If in doubt, BOGE recommends contacting BOGE Product Support in the

event of warnings, maintenance messages or faults.

You can contact BOGE Product Support on:

Telephone: +49-520-660-1140

Type Code Message / Cause Corrective Measures

First

then

1 Final compression temperature Lower ambient temperature by venting.

2 Motor overtemperature

10 Motor servicing due Have the component serviced by BOGE Service personnel. *

11 Compressor servicing due Have the component serviced by BOGE Service personnel. *

14 (Intake) temperature too low Increase ambient temperature at the installation site.

15 Suction regulation

16 Network pressure sensor

18 Fault on an external control

Have the motor and pressure generation of the compressor

checked by BOGE Service personnel.

Have the suction regulator checked and if necessary replaced

by authorized, qualified personnel or BOGE Service personnel.

Have the network pressure sensor replaced by BOGE Service

personnel.

– Have the control settings in the master / slave parametri-

zation checked and if necessary corrected by authorized,

qualified personnel.

– Have the master control checked for proper functioning

and if necessary replaced by BOGE Service personnel.

– Have the cabling between the controls checked by an

authorized, qualified electrician.

– Too many motor switching cycles caused by interruptions

in the electrical supply. If necessary, have the compres-

19 Power failures too frequent

Page 32 BOGE base control for scroll compressors

sor checked by BOGE Service personnel.

– Have the power supply checked by an authorized, quali-

fied electrician.

Troubleshooting 6.4 Acknowledging Messages

Type Code Message / Cause Corrective Measures

– Have the control settings in the master / slave parametri-

zation checked and if necessary corrected by authorized,

qualified personnel.

20 Continuous contact of an external control

– Have the master control checked for proper functioning

by BOGE Service personnel.

– Check messages on the master control and if necessary

carry out fault rectification.

25 Incorrect calibration data

27 Control unit On key does not open

29 Control unit Enter key does not open

Tab. 6.2: List / Meaning of Message Codes

Key to Table:

: Maintenance message

: Warning message

: Fault message

First then : First warning message, then fault message

* After servicing work, the respective countdown counter must be manually reset to the start value.

Have the control unit of the control checked and if necessary

replaced by BOGE Service personnel.

Have the control unit of the control checked and if necessary

replaced by BOGE Service personnel.

Have the control unit of the control checked and if necessary

replaced by BOGE Service personnel.

6.4 Acknowledging Messages

Once the cause of a message has been found and rectified, the message must

be acknowledged via the control unit to ensure that the compressor can be

operated again without restrictions. A message is acknowledged as follows:

1. The message view can be called up using the Info key .

2. Press the Enter key .

The main display reappears on the control.

The "Fault" indicator lamp goes out.

The "Ready" indicator lamp goes out.

The event has been acknowledged.

The compressor is operational again without restrictions

BOGE base control for scroll compressors Page 33

.

Servicing 7.1 Cleaning the Display

Part 7: Servicing 7.1 Cleaning the Display

Use a slightly damp cloth to clean the display, but make sure the cloth is not

too wet. If the display is more heavily soiled, add some commercial cleaning

agent to the cloth.

7.2 Updating the Software

Updates for the control software are performed by BOGE Service personnel.

The description for performing updates is therefore not part of these operating

instructions.

If the software is updated, inform BOGE Service personnel of any changes in

the function of the control.

BOGE base control for scroll compressors Page 35

Loading...

Loading...