Boekel InSlide Out™

Hybridization Oven

Models

241000 and 241000-2

Operating Instructions

N2400117 Rev. 4 01/2013

CONTENTS

Page

1. Safety .............................................................................................................................. 2

2. Product Information ........................................................................................................ 3

3. Assembly......................................................................................................................... 3

3.1 Unpacking ....................................................................................................................... 3

3.2 Installation....................................................................................................................... 3

4. Operation......................................................................................................................... 3

4.1 Controls and Indicator Lamps (see Figure 1). ................................................................ 3

4.2 Setting the Temperature .................................................................................................. 4

4.3 Loading Tray with Slides ................................................................................................ 4

4.4 Loading Tray into Heating Chamber .............................................................................. 4

4.5 Removing Tray from Heating Chamber ......................................................................... 5

5. Accessories ..................................................................................................................... 5

5.1 Slide Holder .................................................................................................................... 5

6. Fault Diagnosis ............................................................................................................... 6

7. Technical Specifications ................................................................................................. 6

8. Maintenance and Service ................................................................................................ 7

8.1 Cleaning .......................................................................................................................... 7

8.2 Replacement of Fuses ..................................................................................................... 7

9. Warranty ......................................................................................................................... 8

10. Service............................................................................................................................. 8

1

1. Safety

The following symbols marked on the equipment mean:

Caution: Read these operating instructions fully before use and pay particular

attention to sections containing this symbol.

Attention: Suivre attentivement les instructions avant l’usage et prêtez une attention

particulière aux sections comportant ce symbole.

Caution: Surfaces can become hot during use.

Attention: Les surfaces peuvent devenir brûlantes pendent l’usage.

Caution: Risk of electric shock. Before attempting any service to this unit remove

power cord from the rear of the unit.

Attention: Risque électrique! Débrancher la prise arrière de réparer l’appareil.

Always observe the following safety precautions:

• Use only as specified by the operatin g instructions or the intrinsic protection may

be impaired. After transport or storage in humid conditions, dry out the unit

before connecting it to the supply voltage. During drying out the intrinsic

protection may be impaired. Allow unit to dry out for 4 hours minimum.

• Connect only to a power supply with a voltage corresponding to that on the serial

number label.

• Connect only to a power supply that provides a Protective Earth terminal.

• Before moving, disconnect at the power supply socket. Do not remove the plug.

• Do not check the temperature by touch, but instead use the temperature display.

• To reduce the risk of eye injury during high temperature operation, use safety

goggles or spectacles.

• Do not touch surfaces that become hot during high temperature operation.

• To protect from fire and other possible hazards, ensure that the operating

temperature is less than the maximum operating temperature of your sample

material.

• Ensure that the power switch is easily accessible during use.

• If liquid is spilled inside the unit, disconnect it from the power supply and have it

checked by a competent person.

• It is the user’s responsibility to carry out appropriate decontamination if

hazardous material is spilled on or inside the equipment.

• The Power Cord supplied with the unit is the disconnect means.

2

2. Product Information

The InSlide Out Hybridization Oven is designed so its sealed tray maintains a humid

condition for In-Situ Hybridization applications without the need to use sealed cover slips.

Uses include in-situ RNA amplification, reverse transcription reactions and hybridizations,

and immunohistochemical reactions.

The InSlide Out can hold up to twenty standard microscope slides on the standard wire

rack. An optional slide holder can hold up to eighteen standard microscope slides. The

unit has an advanced PID t emperatu re contro ller t hat provid es stable an d accu rate ch amber

temperatures from ambient plus 10˚C to 75˚C. The unit utilizes a sealed tray to create a

humid environment for overnight runs or weekend runs, depending on the operating

temperature.

3. Assembly

3.1 Unpacking

Remove packing materials carefully, and retain for future shipment or storage of the unit.

Inspect for damage. Report all shipping damage to the carrier immediately. Shipping

damage is covered b y the carrier and r epair/replacement for shipping d amages must be

coordinated through the carrier. Complete and return the Warranty Registration Card.

Packs should contain:

• In Slide Out Hybridization Oven

• Power Line Cord

• Operating Instructions

• Tray Assembly (includes tray with gasket installed and lid)

• Frame Assembly (held in place during shipping with corrugated spacer)

• Wire Rack (shipped inside the Tray Assembly)

• Filter Paper

3.2 Installation

Place the InSlide Out on a flat and stable s urface, preferably away from drafts. Fit the

power line cord into the IEC power socket on the rear of the unit. Plug power cord into a

power supply that matches the voltage listed on the serial number label on the rear of the

unit.

4. Operation

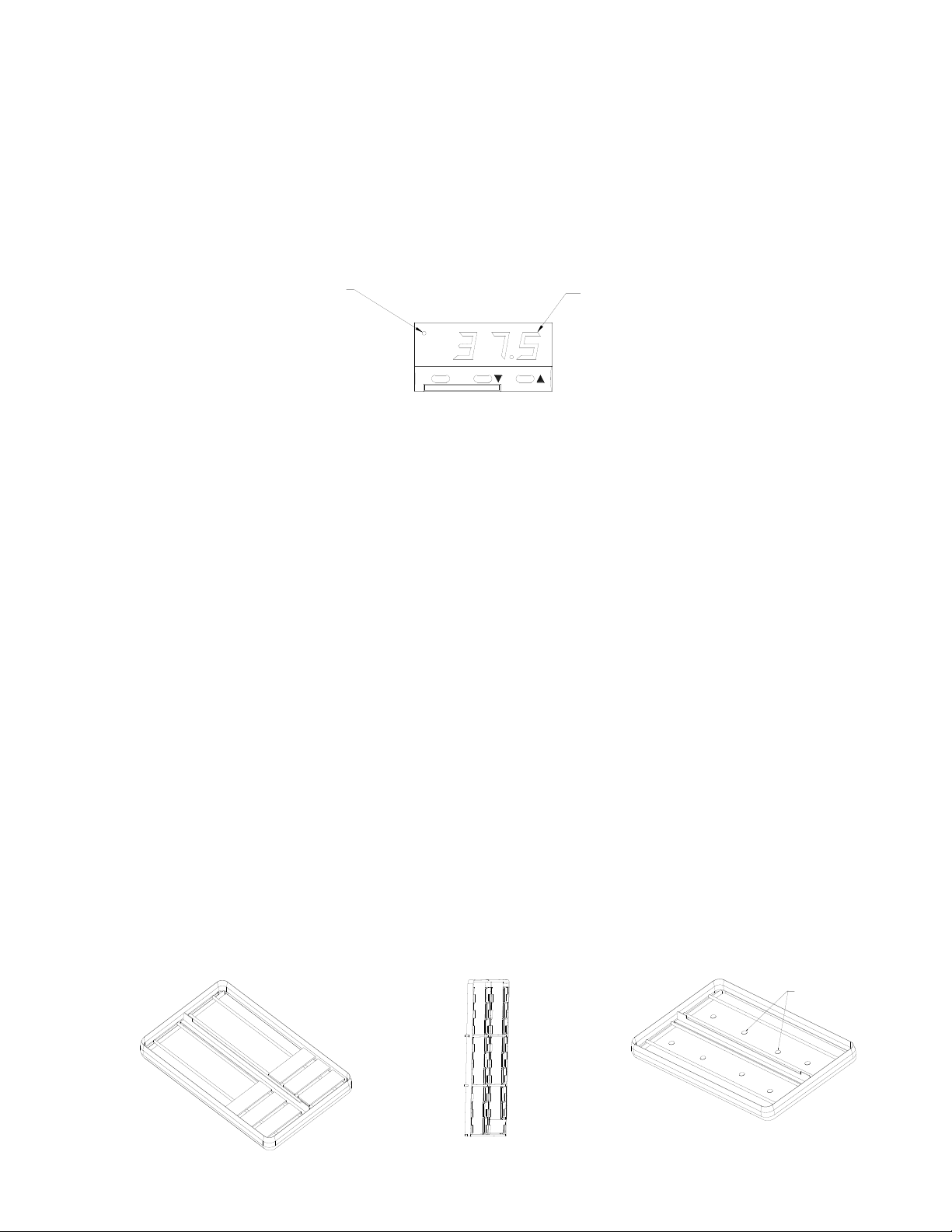

4.1 Controls and Indicator Lamps (see Figure 1)

The Power Switch controls power to the unit.

The temperature display shows the chamber temperature in degrees Celsius.

3

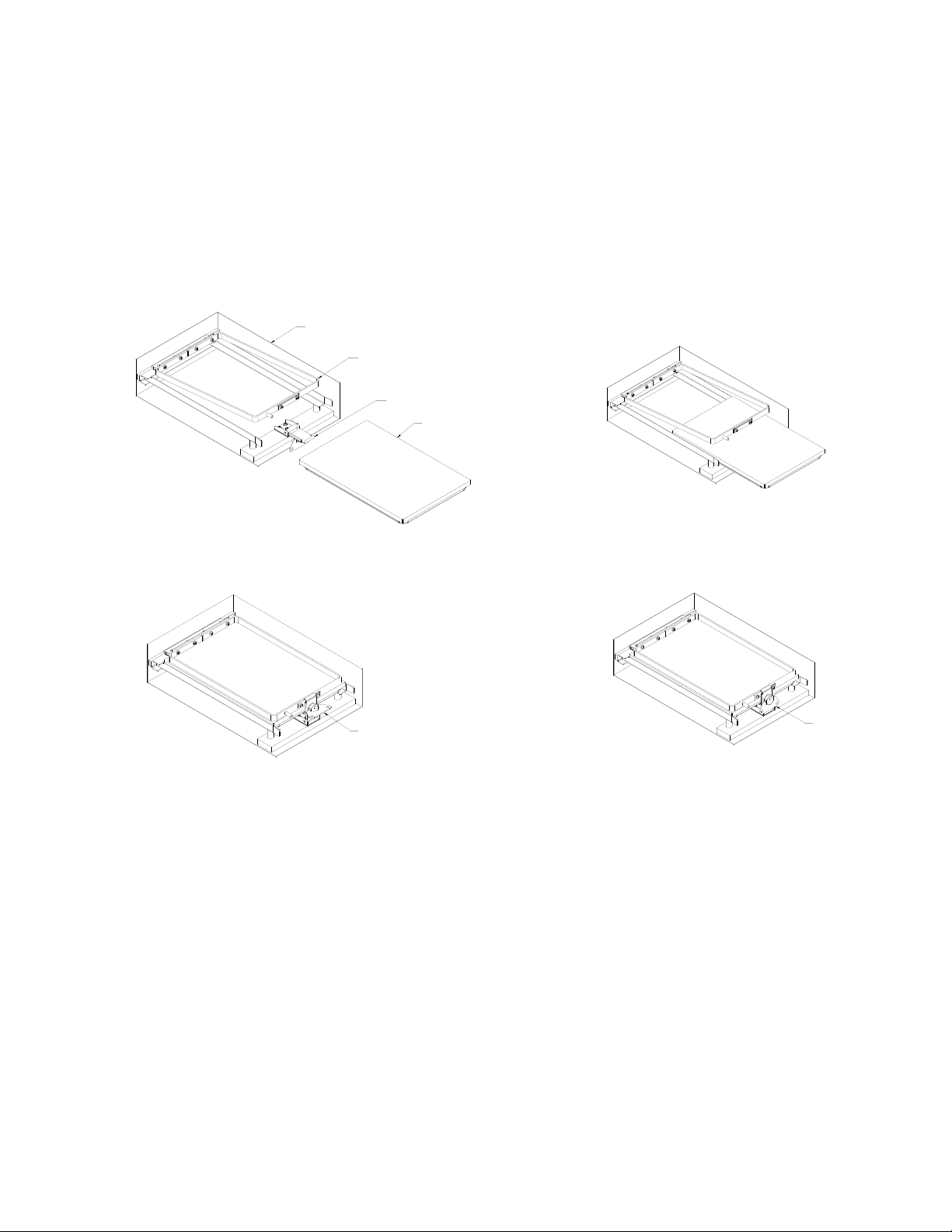

Figure 4

and Filter Paper

Buffer Solution

Figure 2

The heater lamp is on continuously while the Oven is heating up. As the required

Figure 3

temperature is approached, it starts to flash. When the unit is controlling at the set

temperature, the heater lamp flashes intermittently.

Heater

Lamp

4.2 Setting the Temperature

The Temperature Controller has three buttons. When the button on the left ‘*’ is

depressed, it will display the set temperature. When the left button ‘*’ is depressed

simultaneously with the middle button ‘▼’, the set temperature value is lowered. When

the left button ‘*’ is depressed simultaneously with the right button ‘▲’, the set

temperature value is raised. When all buttons are released, the actual chamber

temperature is displayed.

In the event of power loss, the Temperature Controller retains the last set temperature

value.

Temperature

Display

*

Figure 1

4.3 Loading Tray with Slides

The tray with th e standard wire rack can be loaded with up to 20 standard glass slides

(see Figure 2). Using the optional slide holder, up to 18 standard glass slides can be

loaded (see Figure 3). Use your standard protocol to prepare the slides with probe and

buffer. Place filter paper at the bottom of the tray (Whatman* filter paper, Catalog

Number 1823 025, is recommended). To provide humidity during the heating c ycle, add

approximately 2 ml of currently used hybridization solution on the filter paper in the

bottom of the tray (see Figure 4). Do not use water or distilled water. If cover slips are

used, it is not necessary to seal them; the hybridization solution and the sealed tray

maintain a humid environment.

*Whatman is a trademark of Whatman International Ltd.

4

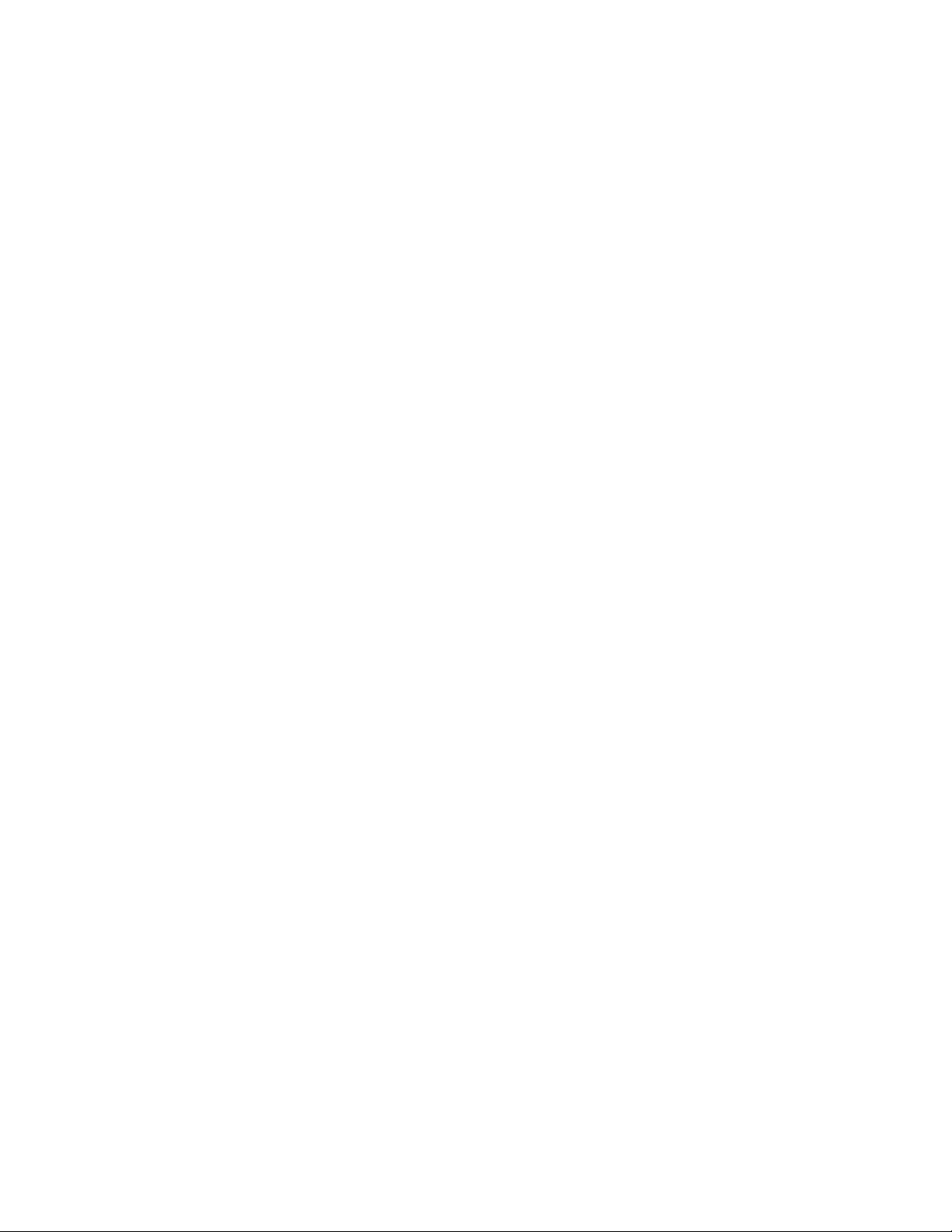

4.4 Loading Tray into Heating Chamber

Once the Tray Assembly is loaded and the slides prepared, the tray can be loaded into the

heating chamber. Open the main door, lift the frame, pivot the latch forward (see Figure

5), and slide the Tray Assembly into the Frame Assembly until it is fully seated against

the rear of the Frame Assembly (see Figure 6). Rotate the latch into a vertical position

and position the latch over the keeper on the frame, then rotate the Latch Handle 180˚

clockwise (see Fi gure 7). R otate the Latch Handle down (see Figure 8). Cl ose the main

door.

Heated

Chamber

Frame

Assembly

Latch

Tray

Assembly

Figure 6

Figure 5

(Tray partially inserted)

Latch

Handle

Figure 7

(Fully inserted and locked)

4.5 Removing Tray from Heating Chamber

Extreme care must be used when removing the tray due to the potentially high

temperature. It may be necessary to use gloves when removing the tray. To remove the

tray from the Heating Chamber, open the main door, lift the Latch Handle up and rotate it

180˚ in a counter clockwise direction. Rotate the latch down, lift the frame up and

carefully slide the Tray Assembly out.

5. Accessories

5.1 Slide Holder – Catalog Number C2403765

This slide holder is made from polycarbonate and will hold 18 standard glass slides.

5

Latch

Handle

Figure 8

(Ready to close main door)

6. Fault Diagnosis

Symptom

Possible Cause

Action Required

1. Unit does not operate

a. Unit not switched on

a. Switch on

2. Chamber temperature does

a. Actual temperature is

a. Check set temperature

3. Temperature continues to

a. Actual temperature is

a. Check set temperature

4. Slides dry out during

a. Gasket not sealing

a. Replace Tray and Gasket

tighten Latch

not rise when expected

rise when not expected

heating cycle

b. Unit not plugged into

power supply

c. Fuses blown

d. Power supply failure

higher than set

temperature

b. Temperature control

circuit fault

lower than set temperature

b. Temperature control

circuit fault

b. Lid bent

c. Insufficient buffer placed

in bottom of tray

d. Latch not fully engaged

b. Plug in, switch on

c. Replace fuses per 8.2

d. Check that other electrical

appliances on the same

circuit are working

b. Have unit checked by

competent person

b. Have unit checked by

competent person

Assembly

b. Repl ace Lid

c. Place more buffer in

bottom of tray

d. Re-install Tray Assembly

into chamber and re-

7. Technical Specifications

This equipment is intended for indoor use and will meet its performance figures within the

ambient temperature range of 10°C to 35°C, with maximum relative humidity of 80% (noncondensing). Installation Category II (transient voltages). Pollution Degree 2 in accordance

with IEC 664. Suitable for operation at altitudes of up to 6500 feet.

6

Specifications:

Temperature Range: (Ambient +10°C) to 75°C

Setting Range: 0°C to 75°C

Stability: +/- 0.2°C

Overall Accuracy: +/- 0.5°C at 65°C

Temperature Display Resolution: 0.1°C

Supply Voltage Range: 115V +/- 10%, 1.35A, 60 Hz

230V +/- 10%, 0.67A, 50/60 Hz

Power Rating: Model 241000: 155W

Model 241000-2: 155W

Heating Rate: Ambient to 50°C within 20 minutes

8. Maintenance and Service

All Boekel laboratory products are designed to comply with IEC1010-1. No routine

maintenance is required.

8.1 Cleaning

Disengage power cord prior to cleaning. If a spill occurs, use appropriate clean up

procedures as required for radiation or biohazard control. The outer casing may be

cleaned with water and a damp cloth. Do not submerge or immerse the InSlide Out in

water. Before using an y cleanin g or decontamination method except those recommended

by the manufacturer, users should check that the proposed method would not damage the

equipment.

7

8.2 Replacement of Fuses

There are two supply fuses located in the fuse drawer. To replace the fuses:

• Disconnect the unit from the power supply.

• Remove the plug from the socket in the back of the unit.

• Pull back on the fuse drawer (see Figure 11).

• Pull out the fuse drawer.

• Check and replace with the correct fuses if necessary. The fuses must be

5mm x 20mm quick acting, rated 250V.

Model 241000: -2AF

Model 241000-2: -1AF

• Push the fuse drawer back in. Reconnect unit to the power supply.

Fuse

Drawer

Figure 11

9. Warranty

When used in laboratory conditions and according to these operating instructions, Boekel

warrants this product to be free of defective material and workmanship for a period of two

years from the date o f manufacture. The liabili ty of Boekel for any defectiv e equipment

during the warrant y period shall be limited to the repair of such equipment or replacement

thereof without charge for parts or labor.

10. Service

A Returned Goods Authorization (RGA) number must be obtained before any Boekel

products are returned for any reason. A Decontamination Notice must be completed,

signed by the user, and returned to Boekel Scientific prior to receiving the RGA number.

Please be sure to mark the outside of the return goods package with this RGA number to

ensure prompt handling.

Boekel Scientific

855 Pennsylvania Blvd.

Feasterville, PA 19053

PHONE: (215) 396-8200 or (800) 336-6929

FAX: (215) 396-8264

e-mail: boekel-info@boekelsci.com

website: www.boekelsci.com

8

Loading...

Loading...