Page 1

by

Body-Solid

®

Assembly Instructions

Page 2

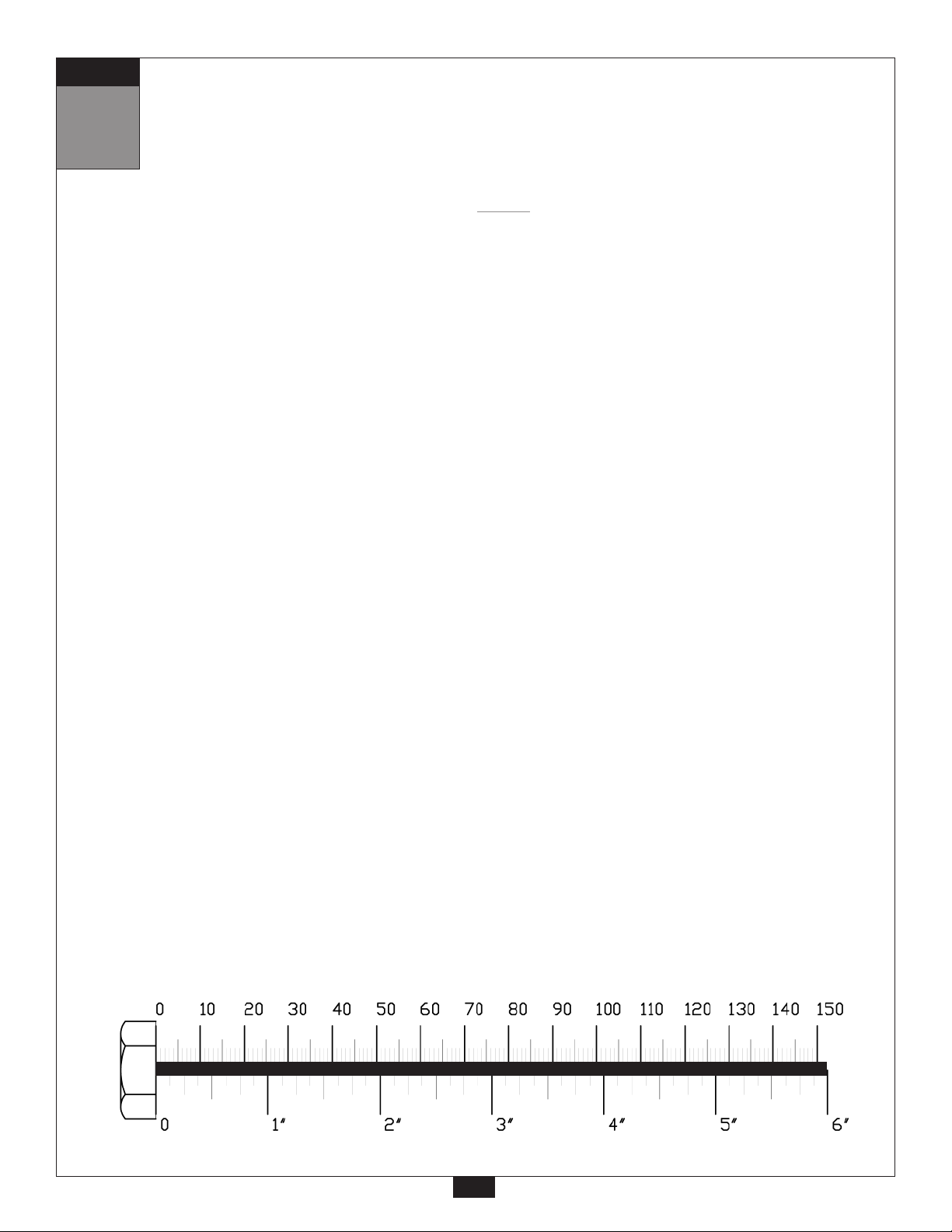

STEP

1

Be careful to assemble all components

in the sequence they are presented.

NOTE:

Finger tighten all hardware in this step. Do Not

A. Attach two Weight Stack Shims (28) to the bottom of Main Base Frame (A), and two Weight

Stack Shims (28) to the bottom of Side Base Frame (B). Also, install two Frame Levelers (25)

to the Main Base Frame (A) as shown.

B. Attach Main Base Frame (A) to Side Base Frame (B) using:

Two 73 (3/8”x 2 3/4” hex head bolt)

Four 94 (3/8” washer)

Two 91 (3/8” nylon lock nut)

C. Attach two Foot Caps (19) to the ends of Front Base Frame (C).

Attach Front Base Frame (C) to the Main Base Frame (A) using:

One 65 (1/2”x 3” hex head bolt)*

Two 93 (1/2” washer)

One 90 (1/2” nylon lock nut)

*NOTE:

Only use one bolt (65) as shown. You will need the other side open for step 5.

wrench tighten until end of step 5.

D. Attach one Foot Cap (19) to one end of Rear Base Frame (D). Leave the other side open,

(depending on which side of the gym you want the low pulley station).* Connect Rear Base

Frame (D) and Rear Vertical Frame (E) to Main Base Frame (A) as shown using:

Two 64 (1/2”x 3 1/4” hex head bolt)

Four 93 (1/2” washer)

Two 90 (1/2” nylon lock nut)

*NOTE:

Depending on how much space you have available, and the configuration of your

room, you can assemble this gym with the low pulley station on either side.

E. Attach End Cap (13) to the top of Rear vertical Frame (E) and Frame Leveler (25) to Rear

Base Frame (D).

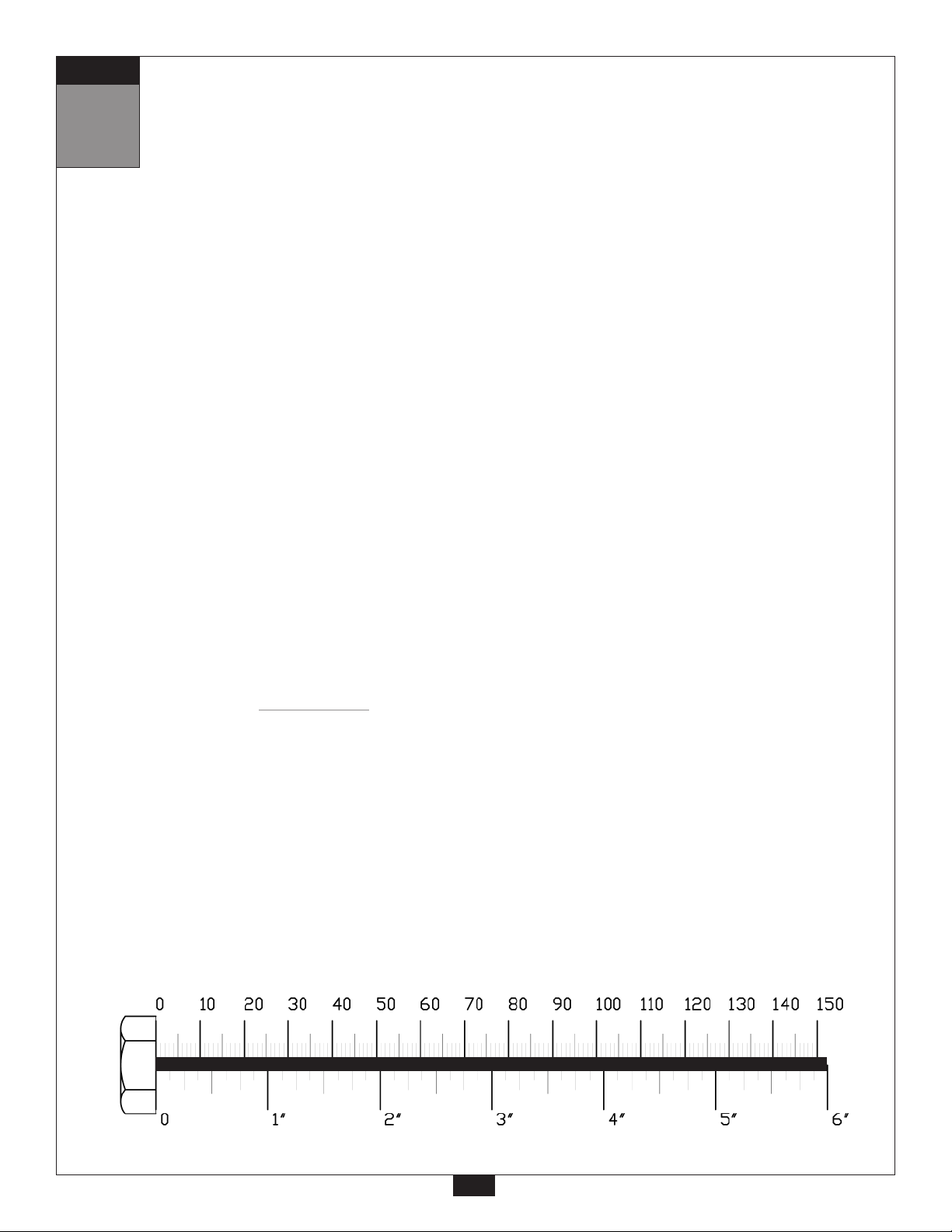

mm

Inch

2

Page 3

STEP

1

3

Page 4

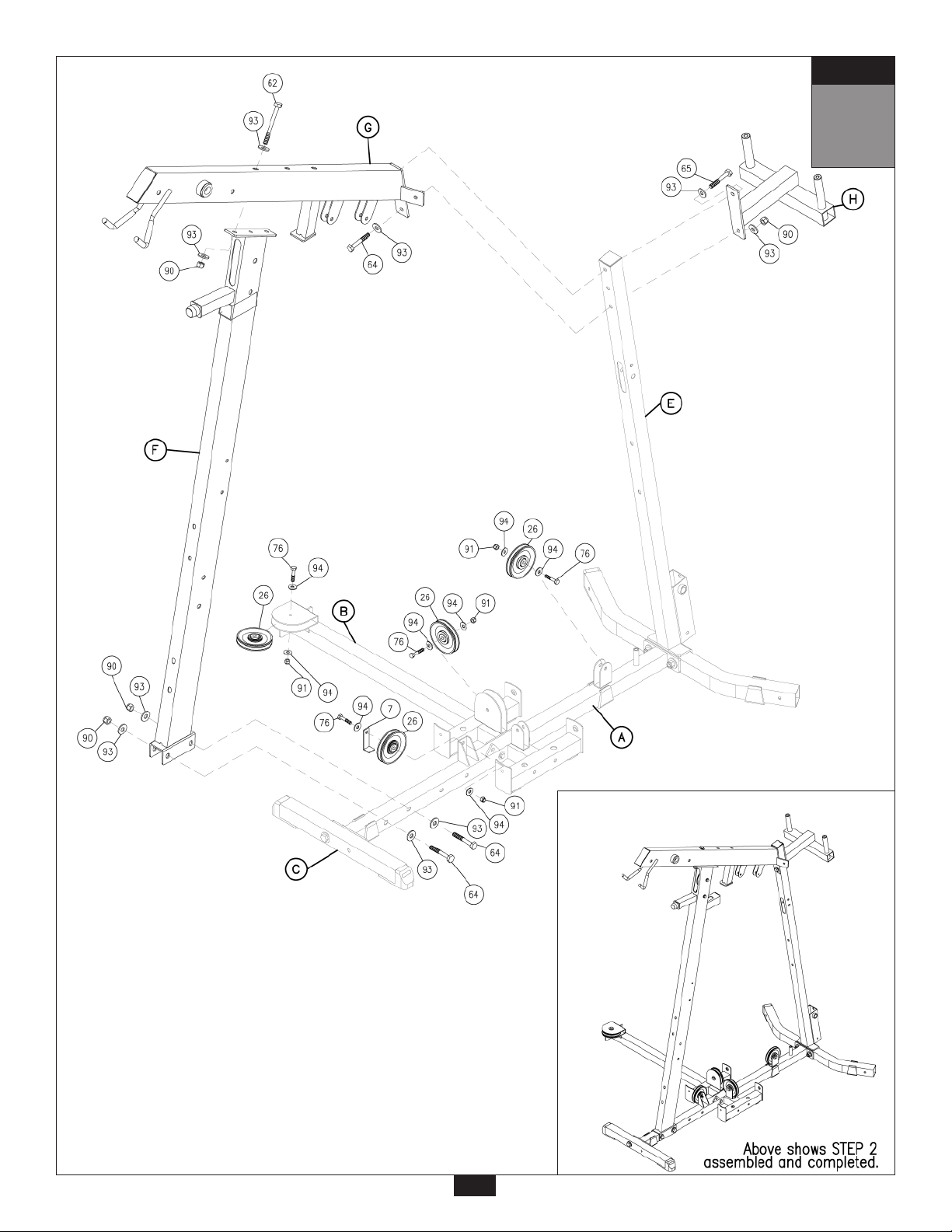

STEP

2

Be careful to assemble all components

in the sequence they are presented.

NOTE:

Finger tighten all hardware in this step. Do Not

A. Attach one Pulley (26) to Main Base Frame (A) and two Pulleys to Side Base Frame (B) as

shown using:

Three 76 (3/8”x 1 3/4” hex head bolt)

Six 94 (3/8” washer)

Three 91 (3/8” nylon lock nut)

B. Attach one Pulley (26) and Pulley Cable Guide (7) to the middle of the Main Base Frame (A)

as shown using

One 76 (3/8”x 1 3/4” hex head bolt)

Two 94 (3/8” washer)

One 91 (3/8” nylon lock nut)

C. Attach Front Vertical Frame (F) to Main Base Frame (A) as shown using:

Two 64 (1/2”x 3 1/4” hex head bolt)

Four 93 (1/2” washer)

Two 90 (1/2” nylon lock nut)

wrench tighten until end of step 5.

D. Attach Top Main Frame (G) to Front Vertical Frame (F) as shown using only one bolt:

One 62 (1/2”x 5” hex head bolt)

Two 93 (1/2” washer)

One 90 (1/2” nylon lock nut)

E. Attach Top Main Frame (G) and Pec Dec Frame (H) to Rear Vertical Frame (E) using:

One 65 (1/2”x 3” hex head bolt)*

One 64 (1/2”x 3 1/4” hex head bolt)

Three 93 (1/2” washer)

One 90 (1/2”nylon lock nut)

*NOTE:

The top bolt (65) goes into an internally threaded nut inside the Top Main Frame (G).

mm

Inch

4

Page 5

STEP

2

5

Page 6

STEP

3

Be careful to assemble all components

in the sequence they are presented.

NOTE:

Finger tighten all hardware in this step. Do Not

A. Place two Weight Stack Risers (55) and two Rubber Donuts (31) onto Main Base Frame (A)

as shown. Slide two Guide Rods (J) through the Rubber Donuts (31), the Weight Stack

Risers (55), and into the Main Base Frame (A).

B. Slide 20 Weight Stack Plates (51) onto the two Guide Rods (J). Make sure the opening in

each weight stack plate, for the Weight Stack Pin (1), is facing outwar

C. Attach Top Plate (8) to Selector Rod (6) using:

One 77 (3/8”x 2” flat allen head)

Slide Top Plate (8) and Selector Rod (6) onto Guide Rods (J).

D. Place two Weight Stack Risers (55) and two Rubber Donuts (31) onto Side Base Frame (B)

as shown. Slide two Guide Rods (J) through the Rubber Donuts (31), the Weight Stack

Risers (55), and into the Side Base Frame (B).

wrench tighten until end of step 5.

d.

E. Slide 20 Weight Stack Plates (51) onto the two Guide Rods (J). Make sure the opening in

each weight stack plate, for the Weight Stack Pin (1), is facing outwar

F. Attach Top Plate (8) to Selector Rod (6) using:

One 77 (3/8”x 2” flat allen head)

Slide Top Plate (8) and Selector Rod (6) onto Guide Rods (J).

G. Slide four Shaft Collars (22) onto the four Guide Rods (J) as shown.*

*NOTE:

Do not tighten the allen screw inside Shaft Collars (22), leave them loose.

≈

d.

mm

Inch

6

Page 7

STEP

3

7

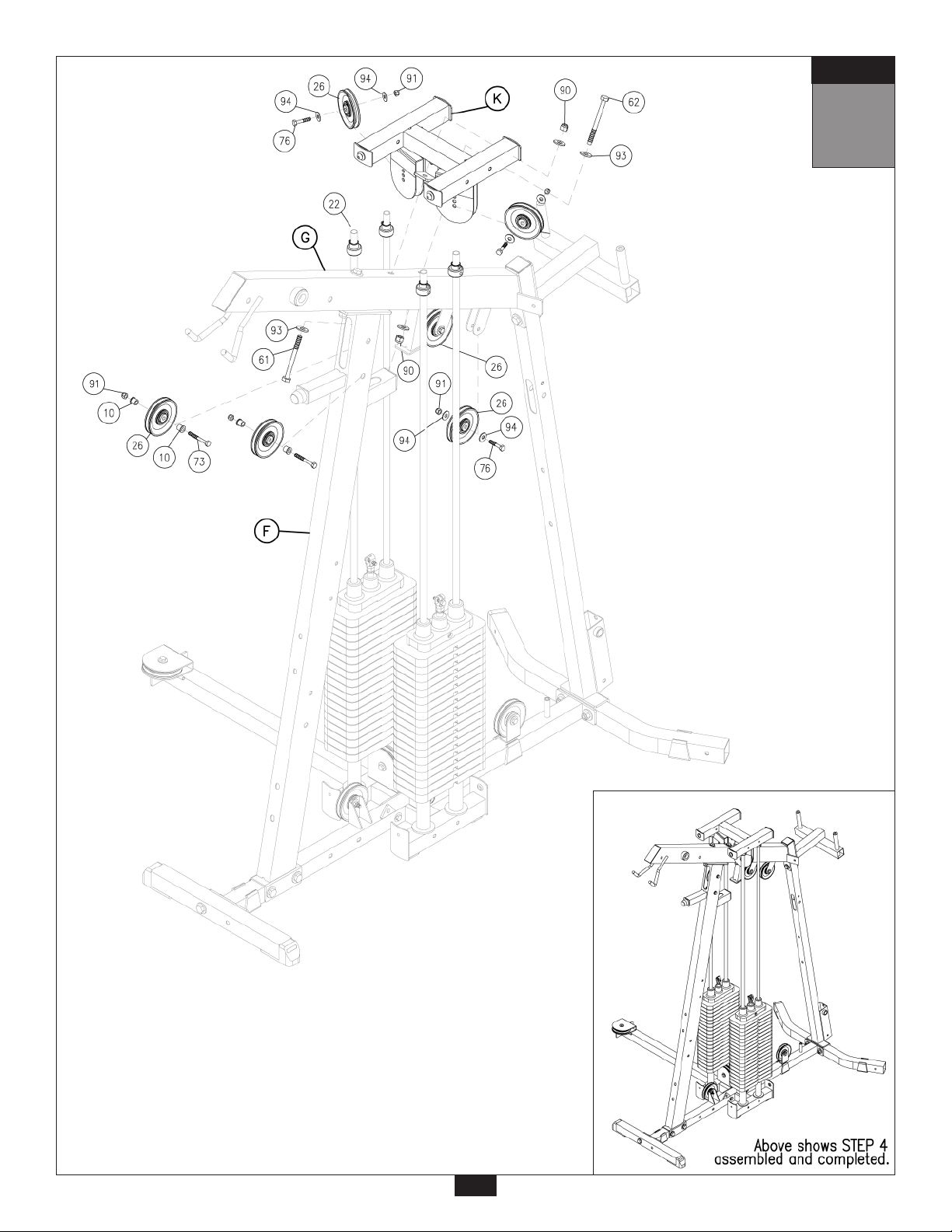

Page 8

STEP

4

Be careful to assemble all components

in the sequence they are presented.

NOTE:

Finger tighten all hardware in this step. Do Not

A. Attach Top Pulley Frame (K) to Top Main Frame (G) and Front Vertical Frame (F) as shown using:

One 61 (1/2”x 5 1/4” hex head bolt)

One 62 (1/2”x 5” hex head bolt)

Four 93 (1/2” washer)

Two 90 (1/2” nylon lock nut)

B. Slide the four Shaft Collars (22) to the top of the four Guide Rods (J).

Insert the top of the Shaft Collars (22) into Top Pulley Frame (K).

Tighten the allen screw in each Shaft Collars (22).

C. Insert two Pulleys (26) into Front Vertical Frame (F) as shown using:

Four 10 (pulley spacer)

Two 73 (3/8”x 2 3/4” hex head bolt)

Two 91 (3/8” nylon lock nut)

wrench tighten until end of step 5.

D. Insert two Pulleys (26) into Top Pulley Frame (K) using:

Two 76 (3/8”x 1 3/4” hex head bolt)

Four 94 (3/8” washer)

Two 91 (3/8” nylon lock nut)

E. Insert two Pulleys (26) into the pulley covers on the Top Main Frame (G) using:

Two 76 (3/8”x 1 3/4” hex head bolt)

Four 94 (3/8” washer)

Two 91 (3/8” nylon lock nut)

mm

Inch

8

Page 9

STEP

4

9

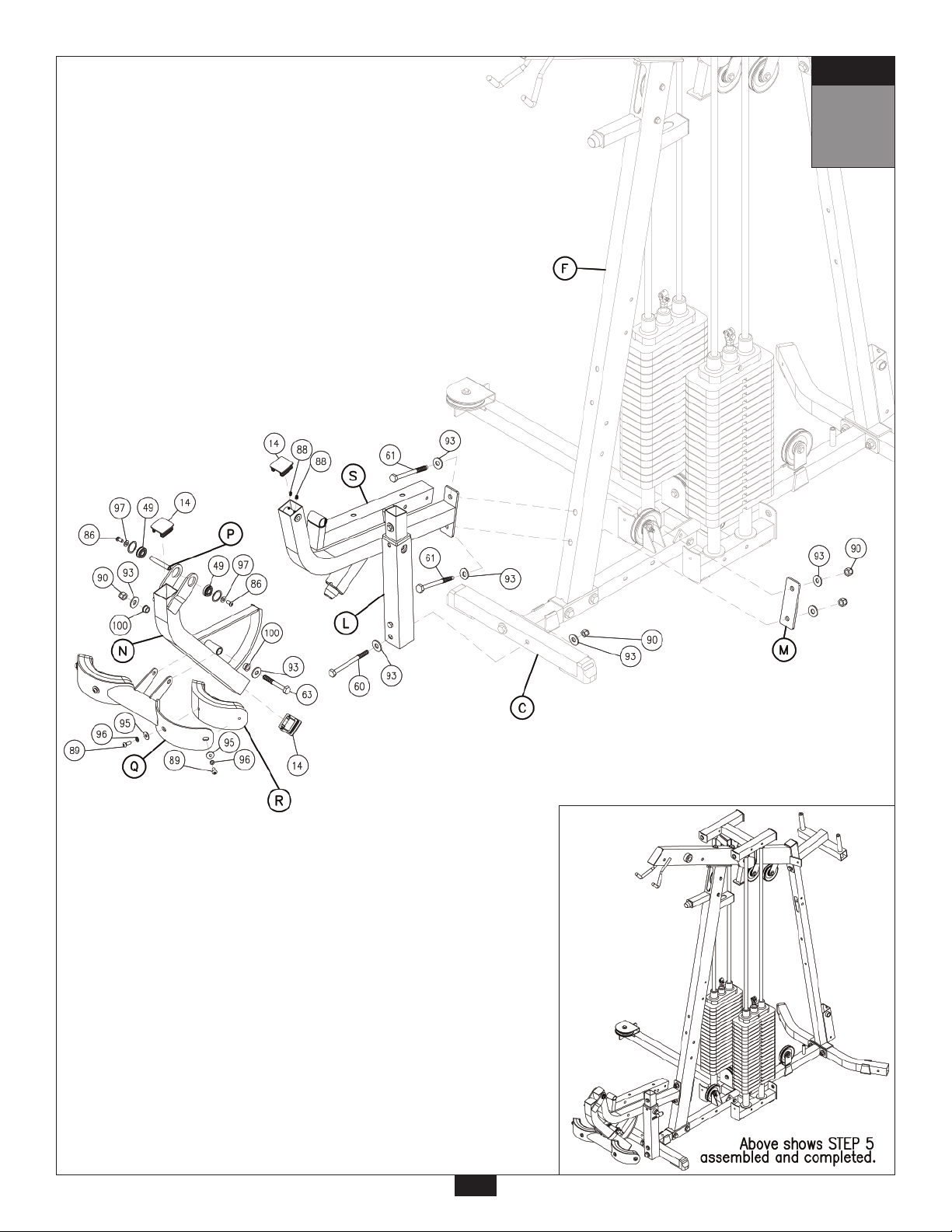

Page 10

STEP

5

Be careful to assemble all components

in the sequence they are presented.

Most of the main frame parts in this step will have RED dots.

NOTE:

LEG EXTENSION SEAT PAD FRAME (S) AND THE LEG EXTENSION FRAME (L) ARE

PRE-ASSEMBLED AS ONE PIECE.

A. Attach Leg Extension Frame (L) and 2”x 6” Plate (M) to Front Vertical Frame (F) using:

Two 61 (1/2”x 5 1/4” hex head bolt)

Four 93 (1/2” washer)

Two 90 (1/2” nylon lock nut)

B. Attach the bottom of Leg Extension Frame (L) to Front Base Frame (C), through the

opening left from step 1 using:

One 60 (1/2”x 5 1/2” hex head bolt)

Two 93 (1/2” washer)

One 90 (1/2” nylon lock nut)

C. Attach Leg Extension Arm (N) to Leg Extension Frame (L) using pre-installed Shaft (P) as

shown. Tighten the two Allen Screws (88) to lock down Shaft (P) in Leg Extension Frame (L).

Attach three End Caps (14) to the top of Leg Extension Frame (L) and each end of the

Leg Extension Arm (N).

D. Attach Leg Extension Pad Holder (Q) to Leg Extension Arm (N) using:

One 63 (1/2”x 3 1/2” hex head bolt)

Two 93 (1/2” washer)

One 90 (1/2” nylon lock nut)

Bronze Bushing (100) was pre-assembled, inside Leg Extension Arm (N).

E. Attach Leg Pads (R) to Leg Extension Pad Holder (Q) using:

Four 89 (5/16”x 3/4” round bolt)*

Four 96 (5/16” spring lock washer)

Four 95 (5/16” washer)

*Do NOT over-tighten these bolts. Tighten these bolts until spring lock washer is flat.

Over - tightening these bolts will cause T - nuts in pads to strip out.

NOTE:

At this point you must make sure that the gym is level, stable and in the right location.

You should now wrench tighten all bolts and nuts on the mainframe unit only.

Do NOT re-tighten any of the pad bolts. Also, leave all pulley bolts finger-tight until

after STEP 20.

mm

Inch

10

Page 11

STEP

5

11

Page 12

STEP

6

Be careful to assemble all components

in the sequence they are presented.

Most of the main frame parts in this step will have RED dots.

A. Attach End Cap (15) onto the front of Leg Extension Seat Pad Frame (S).

B. Insert two Round End Caps (29) into the end of Leg Extension Handles (U). Attach Leg

Extension Handles (U) to Leg Extension Seat Pad Frame (S) using:

Two 72 (3/8”x 3” hex head bolt)

Four 94 (3/8” washer)

Two 91 (3/8” nylon lock nut)

C. Attach Leg Extension Seat Pad (V) to Leg Extension Seat Pad Frame (S) using:

Two 82 (5/16”x 2 3/4” hex head bolt)*

Two 96 (5/16” spring lock washer)

Two 95 (5/16” washer)

*Do NOT over-tighten these bolts. Tighten these bolts until spring lock washer is flat.

Over - tightening these bolts will cause T - nuts in pads to strip out.

D. Slide 4”x 8” Foam Rollers (12) onto Foam Roller Bar (W) and attach to Leg Extension Seat

Pad Frame (S). Hold Foam Rollers (12) in place with 3” Plastic Washer (5) on the inside and

Plastic Roller End Cap (18) on the outside as shown.

Note:

You should now wrench tighten all bolts and nuts in this step.

Do NOT re-tighten any of the pad bolts or pulley bolts.

mm

Inch

12

Page 13

STEP

6

13

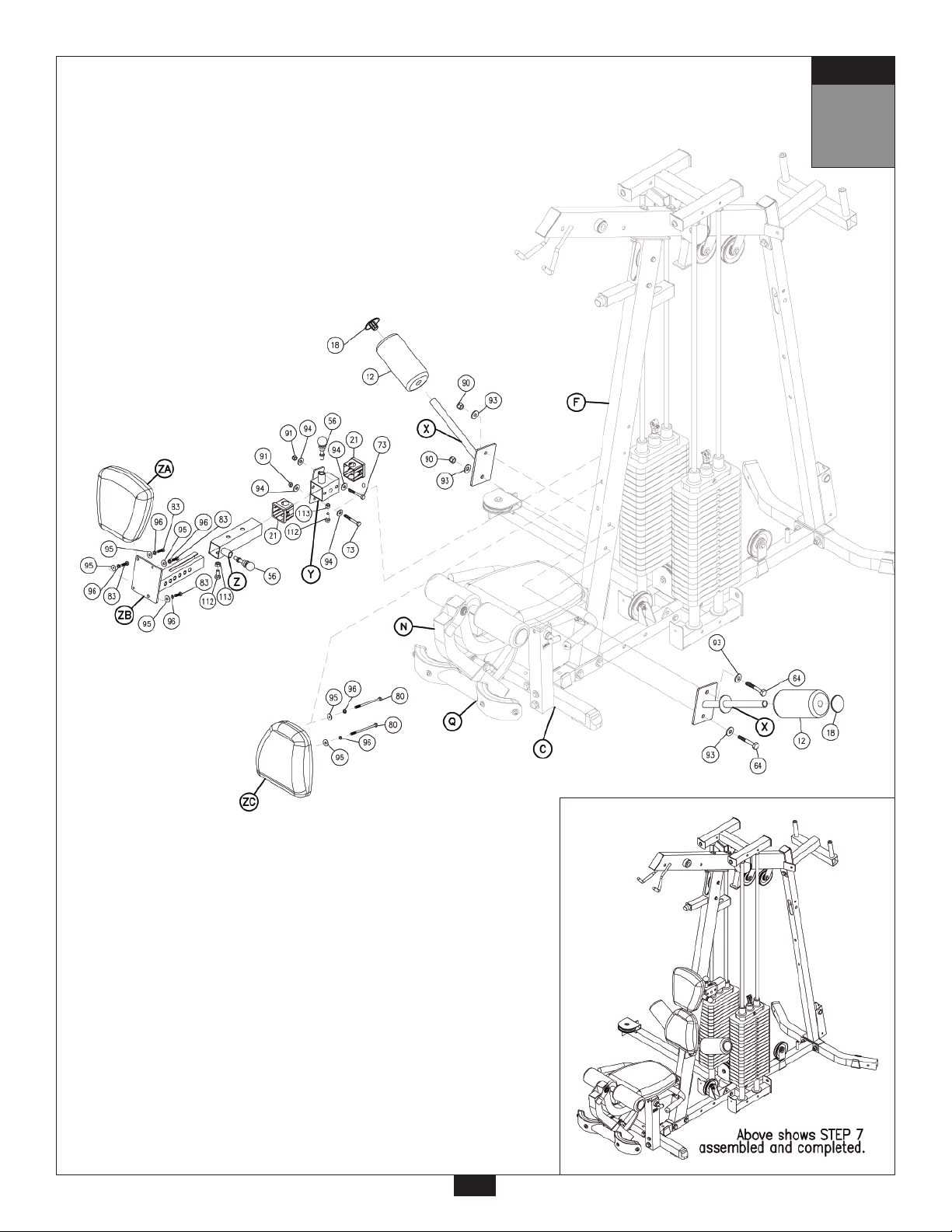

Page 14

STEP

7

Be careful to assemble all components

in the sequence they are presented.

Most of the main frame parts in this step will have RED dots.

A. Attach two Leg Hold Downs (X) to the Front Vertical Frame (F) using:

Two 64 (1/2”x 3 1/4” hex head bolt)

Four 93 (1/2” washer)

Two 90 (1/2” nylon lock nut)

Slide two 4”x 8” Foam Rollers (12) onto the two Leg Hold Downs (X) and hold in place with

two Plastic Roller End Caps (18).

B. Insert two Plastic Bushings (21) into the Back Pad Holder (Y). Connect Back pad Holder (Y)

to the Front Vertical Frame (F) using:

Two 73 (3/8”x 2 3/4” hex head bolt)

Four 94 (3/8” washer)

Two 91 (3/8” nylon lock nut)

C. Slide Back Pad Adjuster (Z) into the Back Pad Holder (Y) and hold in place with Ball Head

Pop Pin (56) and Adjustment Bolt (112). Look inside Back Pad Adjuster (Z) and adjust the

Adjustment Bolt (112) with Lock Nut (113) so that it will stop Back Pad Adjuster (Z) from

sliding out, but will not interfere with Back Pad Insert (ZB) in the next step.

D. Attach Upper Back Pad (ZA) to Back Pad Insert (ZB) using:

Four 83 (5/16”x 1” hex head bolt)*

Four 96 (5/16” spring lock washer)

Four 95 (5/16” washer)

*Do NOT over-tighten these bolts. Tighten these bolts until spring lock washer is flat.

Over - tightening these bolts will cause T - nuts in pads to strip out.

Slide Back Pad Insert (ZB) into Back Pad Adjuster (Z) and hold in place with Ball Head

Pop Pin (56) and Adjustment Bolt (112).

E. Attach Lower Back Pad (ZC) to Front Vertical Frame (F) using:

Two 80 (5/16”x 5” hex head bolt)*

Two 96 (5/16” spring lock washer)

Two 95 (5/16” washer)

*Do NOT over-tighten these bolts. Tighten these bolts until spring lock washer is flat.

Over - tightening these bolts will cause T - nuts in pads to strip out.

Note:

You should now wrench tighten all bolts and nuts in this step.

Do NOT re-tighten any of the pad bolts or pulley bolts.

mm

Inch

14

Page 15

STEP

7

15

Page 16

STEP

8

Be careful to assemble all components

in the sequence they are presented.

Most of the main frame parts in this step will have RED dots.

NOTE:

You will need to loosen two Allen Screws (88) inside Seated Press Arm

Support (AA), in order to remove shaft (AB).

A. Attach Seated Press Arm Support (AA) to Top Main Frame (G) with Shaft (AB).

Tighten Allen Screw (88) in Seated Press Arm Support (AA).

B. Attach two Pulleys (26) to Seated Press Arm Support (AA) using:

Two 76 (3/8”x 1 3/4” hex head bolt)

Four 94 (3/8” washer)

Two 91 (3/8” nylon lock nut)

NOTE:

You will need to loosen two Allen Screws (88), inside Seated Press Arm (AC), in

order to remove shaft (AD).

C. Attach Seated Press Arm (AC) to Seated Press Arm Support (AA) with Shaft (AD).

Tighten two Allen Screws (88) in Seated Press Arm Support (AA) and in Seated

Press Arm (AC).

D. Attach two End Caps (14) to the top of Seated Press Arm Support (AA).

Attach two End Caps (15) to the top of Seated Press Arm (AC).

E. Attach Small Shroud (AE) to Seated Press Arm Support (AA) using:

Four 86 (5/16” x 9/16” round allen head)

Four 97 ( 5/16” washer)

Note:

You should now wrench tighten all bolts and nuts in this step.

Do NOT re-tighten any of the pad bolts or pulley bolts.

mm

Inch

16

Page 17

STEP

8

17

Page 18

STEP

9

Be careful to assemble all components

in the sequence they are presented.

Most of the main frame parts in this step will have

YELLOW dots.

A. Attach three End Caps (13) to the front and sides of Pec Dec Frame (H), and attach Square

Rubber Cap (32) to the top of the Pec Dec Frame (H).

B. Slide Oilite Washer (9), Left Pec Dec Arm (AK) and then the Left Pec Dec Cam (AL) onto

the left side of the Pec Dec Frame (H) as shown, Attach using:

One 59 (1/2”x 1” hex head bolt)

One 93 (1/2” washer)

C. Slide Round End Cap (29) into Left Pec Dec Handle (AM) and attach to the

Left Pec Dec Arm (AK) using:

One 85 (5/16”x 3/4” flat allen head)

One 96 (5/16” spring lock washer)

Note:

Left Pec Dec Handle (AM) should bend out, away from the the gym, as shown.

D. Slide Oilite Washer (9), Right Pec Dec Arm (AP) and then the Right Pec Dec Cam (AQ)

onto the Right side of the Pec Dec Frame (H) as shown, attach using:

One 59 (1/2”x 1” hex head bolt)

One 93 (1/2” washer)

E. Slide Round End Cap (29) into Right Pec Dec Handle (AR) and attach to the

Right Pec Dec Arm (AP) using:

One 85 (5/16”x 3/4” flat allen head)

One 96 (5/16” spring lock washer)

Note:

Right Pec Dec Handle (AR) should bend out, away from the gym, as shown.

F. Attach two Chrome Collars (106) to the top of Left Pec Dec Handle (AM) and Right Pec

Dec Handle (AR) using:

Two 88 (5/16” allen screw) preinstalled

You should now wrench tighten all bolts and nuts in this step.

Do NOT re-tighten any of the pad bolts or pulley bolts.

mm

Inch

18

Page 19

STEP

9

19

Page 20

STEP

10

Be careful to assemble all components

in the sequence they are presented.

Most of the main frame parts in this step will have

YELLOW dots.

A. Slide Plastic Bushing (23) into the receptacle at the bottom of the Rear Vertical Frame (E)

as shown. Attach Hydraulic Seat Adjuster (AU) to the inside of the receptacle at the bottom

of the Rear Vertical Frame (E) using:

One 72 (3/8”x 3” hex head bolt)

Two 94 (3/8” washer)

One 91 (3/8” nylon lock nut)

B. Attach two End Caps (13) to the front and back of Seat Pad Frame (AV).

Slide Seat Pad Frame (AV) into receptacle at the bottom of Rear Vertical Frame (E), and

attach to the top of Hydraulic Seat Adjuster (AU) using:

One 74 (3/8”x 2 1/2”hex head bolt)

Two 94 (3/8” washer)

One 91 (3/8” nylon lock nut)

Insert Pop Pin (48) into the threaded opening in the receptacle at the bottom of the

Rear Vertical Frame (E).

C. Attach Seat Pad (AW) to Seat Pad Frame (AV) using:

Two 82 (5/16”x 2 3/4” hex head bolt)*

Two 96 (5/16” spring lock washer)

Two 95 (5/16” washer)

*Do NOT over-tighten these bolts. Tighten these bolts until spring lock washer is flat.

Over - tightening these bolts will cause T - nuts in pads to strip out.

D. Attach Back Pad (AX) to Rear Vertical Frame (E) using:

Two 82 (5/16”x 2 3/4” hex head bolt)*

Two 96 (5/16” spring lock washer)

Two 95 (5/16” washer)

*Do NOT over-tighten these bolts. Tighten these bolts until spring lock washer is flat.

Over - tightening these bolts will cause T - nuts in pads to strip out.

Note:

You should now wrench tighten all bolts and nuts in this step.

Do NOT re-tighten any of the pad bolts or pulley bolts.

mm

Inch

20

Page 21

STEP

10

21

Page 22

STEP

11

Be careful to assemble all components

in the sequence they are presented.

A. Attach two End Caps (13) to the ends of the Low Pulley Frame (AY). Connect Low Pulley

Frame (AY) to the Main Base Frame (A) using:

One 98 (3/8” washer)

One 87 (3/8” x 5/8” round allen head)

B. Attach Foot Brace (AZ) to the open side of Rear Base Frame (D) using:

One 73 (3/8”x 2 3/4” hex head bolt)

Two 94 (3/8” washer)

One 91 (3/8” nylon lock nut)

C. Attach two End Caps (16) and Grip Tape (33) to Foot Brace (AZ) as shown.

D. Attach Pulley (26) to Low Pulley Frame (AY) using:

One 76 (3/8”x 1 3/4” hex head bolt)

Two 94 (3/8” washer)

One 91(3/8” nylon lock nut)

Note:

You should now wrench tighten all bolts and nuts in this step.

Do NOT re-tighten any of the pad bolts or pulley bolts.

mm

Inch

22

Page 23

STEP

11

23

Page 24

STEP

12

Be careful to assemble all components

in the sequence they are presented.

Most of the main frame parts in this step will have BLUE dots.

A. Attach Leg Press Support (BA) to Main Base Frame (A) using:

Two 73 (3/8”x 2 3/4” hex head bolt)

Four 94 (3/8” washer)

Two 91 (3/8” nylon lock nut)

B. Attach Leg Press Main Frame (BB) to Leg Press Support (BA) using:

Four 73 (3/8”x 2 3/4” hex head bolt)

Eight 94 (3/8” washer)

Four 91 (3/8” nylon lock nut)

C. Attach Leg Press Main Frame (BB) to Side Base Frame (B) using:

Two 73 (3/8”x 2 3/4” hex head bolt)

Four 94 (3/8” washer)

Two 91 (3/8” nylon lock nut)

D. Attach End Cap (15) to the top of Leg Press Main Frame (BB).

Attach two Frame Levelers (25) to the bottom of Leg Press Main Frame (BB).

Attach Pulley (26) to Leg Press Main Frame (BB) using:

One 76 (3/8”x 1 3/4” hex head bolt)

Two 94 (3/8” washer)

One 91 (3/8” nylon lock nut)

E. Attach two Foot Caps (20) to each end of the Leg Press Front (BC).

Attach Leg Press Front (BC) to the front of Leg Press Main Frame (BB) using:

Two 65 (1/2”x 3” hex head bolt)

Four 93 (1/2” washer)

Two 90 (1/2” nylon lock nut)

Note:

You should now wrench tighten all bolts and nuts in this step.

Do NOT re-tighten any of the pad bolts or pulley bolts.

mm

Inch

24

Page 25

STEP

12

25

Page 26

STEP

13

Be careful to assemble all components

in the sequence they are presented.

Most of the main frame parts in this step will have BLUE dots.

A. Slide two Pillow Block Bearings (45) onto lower shaft on Main Leg Press Pivot (BD) and leave

allen screws loose.

NOTE:

Allen screws should both be on the inside.

B. Attach two Pillow Block Bearings (45) to the plate at the front of Leg Press Frame (BB)

using:

Four 66 (1/2”x 1 3/4” hex head bolt)

Eight 93 (1/2” Washer)

Four 90 (1/2” nylon lock nut)

C. Attach Front Leg Press Pivot (BE) and Shaft (BF) to Leg Press Frame (BB)

as shown using:

Two 41 (leg press oilite bushing)

Two 90 (1/2” nylon lock nut)

D. Attach Foot Plate T-frame (BG) and Shaft (BF) to Front Leg Press Pivot (BE)

as shown using:

Two 41 (leg press oilite bushing)

Two 90 (1/2” nylon lock nut)

E. Attach Foot Plate T-frame (BG) and Shaft (BF) to Main Leg Press Pivot (BD)

as shown using:

Two 41 (leg press oilite bushing)

Two 90 (1/2” nylon lock nut)

F. Attach Foot Plate (BR) to Foot Plate T-frame (BG) using:

Two 64 (1/2”x 3 1/4” hex head bolt)

Four 93 (1/2” washer)

Two 90 (1/2” nylon lock nut)

Attach three End Caps (14) to each side of Foot Plate (BR) and front of

Foot Plate T-frame (BG).

Note:

You should now wrench tighten all bolts and nuts in this step.

Do NOT re-tighten any of the pad bolts or pulley bolts.

mm

Inch

26

Page 27

STEP

13

There are two small allen set screws

in each Pillow Block Bearings (45).

For best alignment of this system

you should loosen all

before installing the Pillow Block Bearings (45).

The last and final step of the

assembly process is to

wrench tighten all of these allen

set screws in all the Pillow Block Bearings (45).

allen set screws

27

Page 28

STEP

14

Be careful to assemble all components

in the sequence they are presented.

Most of the main frame parts in this step will have BLUE dots.

A. Slide Round End Cap (29) onto Leg Press Handles (BH).

Attach Leg Press Handles (BH) onto Leg Press Frame (BB) using:

Two 71 (3/8”x 3 1/4” hex head bolt)

Four 94 (3/8” washer)

Two 91 (3/8” nylon lock nut)

B. Attach two Seat Pad Flange (BL) to Leg Press Frame (BB) using:

One 70 (3/8”x 3 1/2” hex head bolt)

Two 94 (3/8” washer)

One 91 (3/8” nylon lock nut)

C. Attach Leg Press Seat Pad (BM) to the two Seat Pad Flange (BL) using:

Two 83 (5/16”x 1” hex head bolt)*

Two 96 (5/16” spring lock washer)

Two 95 (5/16” washer)

*Do NOT over-tighten these bolts. Tighten these bolts until spring lock washer is flat.

Over - tightening these bolts will cause T - nuts in pads to strip out.

D. Attach Leg Press Seat Pad (BM) to Leg Press Frame (BB) using:

One 81 (5/16”x 3 1/4” hex head bolt)*

One 96 (5/16” spring lock washer)

One 95 (5/16” washer)

*Do NOT over-tighten this bolt. Tighten this bolt until spring lock washer is flat.

Over - tightening this bolt will cause T - nut in pad to strip out.

E. Slide Plastic Bushing (23) into Leg Press Frame (BB).

Slide Leg Press Back Pad Frame (BP) into Plastic Bushing (23) and hold in place with

T-Shaped Pop Pin (48).

Attach End Cap (14) to the bottom of Leg Press Back Pad Frame (BP).

F. Attach Leg Press Back Pad (BQ) to Leg Press Back Pad Frame (BP) using:

Four 83 (5/16”x 1” hex head bolt)*

Four 96 (5/16” spring lock washer)

Four 95 (5/16” washer)

*Do NOT over-tighten these bolts. Tighten these bolts until spring lock washer is flat.

Over - tightening these bolts will cause T - nuts in pads to strip out.

Note:

You should now wrench tighten all bolts and nuts in this step.

Do NOT re-tighten any of the pad bolts or pulley bolts.

mm

Inch

28

Page 29

STEP

14

29

Page 30

STEP

15

Be careful to assemble all components

in the sequence they are presented.

NOTE:

All pulleys are the 4 1/4” diameter Pulleys (26), except where noted.

Lat Pulldown Cable (36)

Ball Stop End

Metal Ball End

3840 mm

A. Start at the front of the gym. Insert metal ball end of the Lat Pulldown Cable (36) into Top

Main Frame (G), through the frame and out through the second opening. Pull entire length

of Cable (36) all the way through. Install Pulley (A1) into the first opening, and Pulley (A2)

into the second opening. Be sure that Cable (36) rides on top of these pulleys. Install each

pulley using:

One 73 (3/8”x 2 3/4” hex head bolt)

Two 10 (pulley spacer)

One 91 (3/8” nylon lock nut)

B. Remove Pulley (A3), route Cable (36) inside pulley housing as shown, and re-install

Pulley (A3).

C. Remove Pulley (A4), route Cable (36) around Pulley (A4) as shown, and re-install Pulley (A4).

D. Remove Pulley (A5), route Cable (36) inside pulley housing as shown, and reinstall

Pulley (A5).

E. Route Cable (36) over Pulley (A6). Route Cable (36) down through opening in the small arm

sticking out of the Front Vertical Frame (F). Pull entire length of Cable (36) through.

F. Route Cable (36) through the Double Pulley Holder (130) as shown and install Pulley (A7)

using:

One 76 (3/8”x 1 3/4” hex head bolt)

Two 94 (3/8” washer)

One 91 (3/8” nylon lock nut)

12’ 6”

G. Route Cable (36) up and over Pulley (A8)* and then down toward weight stack.

*Note:

Leave the bolt going through Pulley (A8) hand tight until the end of Cable

Adjustments in Step 21.

H. Remove Bolt (56) from Selector Rod Top Bolt (52), slide Cable (36) through Selector Rod Top

Bolt (52). Attach Cable End Shaft (135) and tighten Allen Screw (136).

Pull Cable (36) tight, so Cable End Shaft (135) fits inside Selector Rod Top Bolt (52).

Reinstall Bolt (56) in Selector Rod Top Bolt (52).

mm

Inch

30

Page 31

Start at high pulley station by

inserting the Metal Ball End here.

STEP

15

Lat Pulldown

Cable

!

Selector Rod Top Bolt (52) must be threaded a

minimum of 1/2” into the Selector Rod (6), and Jam

Nut (54) tightened securely against spring lock

washer (53) to ensure proper connection. Check the

Jam Nut (54) once a week to make sure it is tight.

WARNING

!

31

Page 32

STEP

16

Be careful to assemble all components

in the sequence they are presented.

NOTE:

All pulleys are the 4 1/4” diameter Pulleys (26), except where noted.

Leg Extension Cable (37)

Stamped Eye End

2635mm 8’ 7”

Short Cable (40)

Stamped Eye End

Stamped Eye End

Chain End

520mm

A. Attach either stamped eye end of Leg Extension Cable (37) to Leg Extension Arm (N) using:

One 84 (5/16”x 1 1/2” flat allen head)

Two 4 (3/4” steel bushing)

One 2 (1/2” steel sleeve)

One 92 (5/16” nylon lock nut)

B. Route Cable (37) under Pulley (B1) and up toward Double Pulley Holder (52).

C. Route Cable (37) Inside the bottom portion of Double Pulley Holder (132) as shown, and

install Pulley (B2) using:

One 76 (3/8”x 1 3/4” hex head bolt)

Two 94 (3/8” washer)

One 91 (3/8” nylon lock nut)

D. Attach stamped eye end of Short Cable (40) to Cable (37) using a Snap Link (43). Attach

the chain end of Cable (40) to the Main Base Frame (A) using another Snap Link (43).

1’ 8 1/2”

mm

Inch

32

Page 33

STEP

16

Short Cable

Leg Extension Cable

33

Page 34

STEP

17

Be careful to assemble all components

in the sequence they are presented.

NOTE:

All pulleys are the 4 1/4” diameter Pulleys (26), except where noted.

Pec Dec Cable (38)

Metal Ball End

Metal Ball End

1890mm

A. Attach metal ball end of Pec Dec Cable (38) to Right Pec Dec Cam (AQ) and route under

Top Main Frame (G).

B. Attach the other ball end of Cable (38) to Left Pec Dec Cam (AL).

C. Attach Pulley (C1) to flange on Top Main Frame (G) behind Right Pec Dec Cam (AQ) using:

One 76 (3/8”x 1 3/4” hex head bolt)

One 7 (pulley cable guide)

Two 94 (3/8” washer)

One 91 (3/8” nylon lock nut)

Route Pec Dec Cable (38) over Pulley (C1).

D. Attach Pulley (C2) to flange on Top Main Frame (G) behind Left Pec Dec Cam (AL) using:

One 76 (3/8”x 1 3/4” hex head bolt)

One 7 (pulley cable guide)

Two 94 (3/8” washer)

One 91 (3/8” nylon lock nut)

Route Pec Dec Cable (38) over Pulley (C2).

E. Hang Pec Dec Pulley Holder (131) on Pec Dec Cable (38) as shown and install

Pulley (C3) using:

One 76 (3/8”x 1 3/4” hex head Bolt)

Two 94 (3/8” washer)

One 91 (3/8” nylon lock nut)

6’ 2 1/2”

mm

Inch

34

Page 35

Pec Dec Cable

STEP

17

35

Page 36

STEP

18

Be careful to assemble all components

in the sequence they are presented.

NOTE:

All pulleys are the 4 1/4” diameter Pulleys (26), except where noted.

Ab Crunch Cable (39)

Ball Stop End

Chain End

1545mm

A. Insert chain end of the Ab Crunch Cable (39) into the opening above Back Pad (AX),

and pull entire length through.

NOTE:

You will now need the 3” diameter Pulley (27), for the next step.

B. Insert 3” Pulley (27) into the Rear Vertical Frame (E) under Cable (39) using:

Two 10 (pulley spacer)

One 73 (3/8”x 2 3/4” hex head bolt)

One 91 (3/8” nylon lock nut)

C. Attach chain end of Cable (39) to the bottom of Pec Dec Pulley Holder (131).

D. Hang Pulley (D2) from on Cable (39) as shown using two Pulley Plates (132) and:

One 76 (3/8”x 1 3/4” hex head bolt)

Two 94 (3/8” washer)

One 91 (3/8” nylon lock nut)

5’ 1”

mm

Inch

36

Page 37

STEP

18

Ab Crunch Cable

37

Page 38

STEP

19

Be careful to assemble all components

in the sequence they are presented.

NOTE:

All pulleys are the 4 1/4” diameter Pulleys (26), except where noted.

Low Pulley Cable (35)

Ball Stop End

4060mm 13’ 3 1/2”

A. Insert metal ball end of Low Pulley Cable (35) at Low Pulley Frame (AY). Insert metal ball end

of Cable (35) under

B. Route Cable (35) over

using:

One 76 (3/8”x 1 3/4” hex head bolt)

Two 94 (3/8” washer)

One 91 (3/8” nylon lock nut)

C. Route Cable (35) under Pulley (E3).

D. Route Cable (35) over

E. Route Cable (35) through Pulley Holder With Hook (133) as shown. Install Pulley (E6) using:

One 76 (3/8”x 1 3/4” hex head bolt)

Two 94 (3/8” washer)

One 91 (3/8” nylon lock nut)

F. Remove Pulley (E7) from pulley housing. Insert Cable (35) into pulley housing as shown and

reinstall Pulley (E7).*

Pulley (E1).

Pulley (E2), and attach Pulley (E2) to the bottom of Pulley Plates (132)

Pulleys (E4) and (E5).

Metal Ball End

*Note:

Leave the bolt going through Pulley (E7) hand tight until the end of Cable

Adjustments in Step 21.

G. Remove Bolt (56) from Selector Rod Top Bolt (52), slide Cable (35) through Selector Rod Top

Bolt (52). Attach Cable End Shaft (135) and tighten Allen Screw (136).

Pull Cable (36) tight, so Cable End Shaft (135) fits inside Selector Rod Top Bolt (52).

Reinstall Bolt (56) in Selector Rod Top Bolt (52).

mm

Inch

38

Page 39

STEP

19

Low Pulley Cable

Low Pulley

Cable

!

Selector Rod Top Bolt (52) must be threaded a

minimum of 1/2” into the Selector Rod (6), and Jam

Nut (54) tightened securely against spring lock

washer (53) to ensure proper connection. Check the

Jam Nut (54) once a week to make sure it is tight.

WARNING

!

39

Page 40

STEP

20

Be careful to assemble all components

in the sequence they are presented.

NOTE:

All pulleys are the 4 1/4” diameter Pulleys (26), except where noted.

Leg Press Cable (34)

Chain EndStamped Eye End

4270mm 14’

A. Attach the chain end of Leg Press Cable (34) to Leg Press Frame (BB) with Snap Link (43).

B. Route Cable (34) into the top of pulley housing in Leg Press Pivot (BD) as shown and

install Pulley (F1) using:

One 75 (3/8”x 2” hex head bolt)

Two 94 (3/8” washer)

One 91 (3/8” nylon lock nut)

C. Route Cable (34) over Pulley (F2) as shown.

D. Route Cable (34) back into the bottom of pulley housing in Leg Press Pivot (BD) and install

Cable (34) over

One 75 (3/8”x 2” hex head bolt)

Two 94 (3/8” washer)

One 91 (3/8” nylon lock nut)

E. Route Cable (34) through the opening in the support column of Leg Press Frame (BB).

Pull entire length of Cable (34) through.

Route Cable (34) around Pulley (F4) as shown and toward Pulley (F5).

F. Route Cable (34) under

Attach Cable (34) to Pulley Holder With Hook (133).

Note:

You should now wrench tighten all bolts and nuts.

Except the pad bolts, Never re-tighten any pad bolts.

Pulley (F3) using:

Pulley (F5) and up to the bottom of Pulley Holder With Hook (133).

mm

Inch

40

Page 41

STEP

20

Leg Press Cable

41

Page 42

STEP

21

NOW IS THE TIME TO MAKE ALL NECESSARY

CABLE ADJUSTMENTS

After cable installation is complete you must check all cables for proper tension. Obvious signs that

cable tension problems exist include:

c Top Plates (8) do not rest directly on the top weight stack plates.

c The holes in the Selector Bar (6) do not line up with the holes in the Weight Stack Plates.

c Cable(s) are sloppy and there is no resistance from the weight stack for the first few

inches of the exercise.

There are TEN areas for cable adjustment on the G9S:

A TWO Selector Rod Top Bolts (52)

B THREE Rubber Stops (42)

C THREE Adjustable Chains on cables (34), (39), (40).

D TWO Adjustments in pulley housing on Top Pulley Frame (K)

SEE NOTE 1 AND NOTE 2 ON PAGE 43.

If there is too much tension, and the Top Plate (8) is not resting directly on the top weight stack plate:

1st.- Turn and tighten the Rubber Stop (B).

2nd.- Move Snap Link (C) to add a link.

3rd.- Move pulley down to a lower hole in pulley housing on Top Pulley Frame (K).

If there is to much play or excessive slack:

1st.- Turn and loosen the Rubber Stop (B).

2nd.- Move Snap Link (C) to minus a link.

3rd.- Move Pulley up to a higher hole in pulley housing on Top Pulley Frame (K).

4th.- Screw the Selector Bar Top Bolt (52) farther into the Selector Bar (6) of the Weight Stack.

NOTE:

Cables should be inspected daily and adjusted periodically to ensure safe and

smooth operation.

NOTE:

After cable adjustment is complete, go back and tighten two bolts in pulley

housing on Top Pulley Frame (K).

mm

Inch

42

Page 43

B. Rubber Stop (42)

Tighten

NOTE 1

Before beginning final cable

adjustments, be sure that both of

these pulley housings butt-up as

close as possible to the welded

stops on the frame pieces.

STEP

21

Selector Rod Top Bolt

Lock Nut

! !

WARNING

Selector Rod Top Bolt (52) Must be threaded a

minimum of a 1/2” into the Selector Rod(6), and

Lock Nut (54) tightened securely to ensure

proper connection.

43

NOTE 2

Check lock nut

weekly to be

sure it is tight

and locked on

to the Selector

Rod.

Page 44

STEP

22

Be careful to assemble all components

in the sequence they are presented.

SEE NOTE 1on page 45:

A. Apply weight stack numbers to weight stack Top Plate (8) and each Weight Stack Plate

as shown.

SEE NOTE 2 on page 45: Note the shape of each shroud for proper placement.

B. Weight Stack Shroud (CA) is pre-assembled with Shroud Insert (CB).

Attach Weight Stack Shroud (CA) to the side of the weight stack as shown.

Bolt onto Side Base Frame (B) and Top Pulley Frame (K) using:

Two 87 (3/8” x 5/8” round allen head)

Two 98 (3/8” washer)

C. Attach Weight Stack Shroud (CC) to the other side of this weight stack using:

Two 87 (3/8” x 5/8” round allen head)

Two 98 (3/8” washer)

D. Weight Stack Shroud (CD) is pre-assembled with Shroud Insert (CE).

Attach Weight Stack Shroud (CD) to the side of the weight stack as shown.

Bolt onto Main Base Frame (A) and Top Pulley Frame (K) Using:

Two 87 (3/8” x 5/8” round allen head)

Two 98 (3/8” washer)

E. Attach Weight Stack Shroud (CF) to the other side of this weight stack using:

Two 87 (3/8” x 5/8” round allen head)

Two 98 (3/8” washer)

mm

Inch

44

Page 45

NOTE 1

Apply weight stack numbers to the Weight

Stack Plates (51). Start at the Top Plate (8) with

the number 1, and the first plate should be

number 2. The following Weight Stack Plates

(51) should be numbered in sequential order

down through the stack.

STEP

2” flat side3/4” flat side

22

3/4” flat side

NOTE 2

This is the top view of the four Weight Stack Shrouds. Note the

shape of each shroud for proper placement.

45

Page 46

G9S Parts List

KEY# QTY PART# DESCRIPTION

A

B

C

D

E

F

G

H

J

K

L

M

N

P

Q

S

T

U

W

X

Y

Z

ZB

AA

AB

AC

AD

AK

AL

AM

AP

AQ

AR

AU

AV

AY

AZ

1

1

1

1

1

1

1

1

4

1

1

1

1

1

1

1

1

2

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

JG9SMBF-A

JG9SSBF-B

JG9SFBF-C

JG9SRBF-D

JG9SRVF-E

JG9SFVF-F

JG9STMF-G

JG9SPDF-H

JG9SGR-J

JG9STPF-K

JG9SLEF-L

JG9SP-M

JG9SLEA-N

JG9SS-P

JG9SLEPH-Q

JG9SLESPF-S

JG9SHSA-T

JG9SLEH-U

JG9SFRB-W

JG9SLHD-X

JG9SBPH-Y

JG9SBPA-Z

JG9SBPI-ZB

JG9SSPAS-AA

JG9SS-AB

JG9SSPA-AC

JG9SS-AD

JG9SLPDA-AK

JG9SLPDC-AL

JG9SLPDH-AM

JG9SRPDA-AP

JG9SRPDC-AQ

JG9SRPDH-AR

JG9SHSA-AU

JG9SPDSF-AV

JG9SLRF-AY

JG9SFB-AZ

MAIN BASE FRAME

SIDE BASE FRAME

FRONT BASE FRAME

REAR BASE FRAME

REAR VERTICAL FRAME

FRONT VERTICAL FRAME

TOP MAIN FRAME

PEC DEC FRAME

GUIDE ROD

TOP PULLEY FRAME

LEG EXTENSION FRAME

2”X 6” PLATE

LEG EXTENSION ARM

2” SHAFT

LEG EXTENSION PAD HOLDER

LEG EXTENSION SEAT PAD FRAME

HYDRAULIC SEAT ADJUSTER (PRE-INSTALLED)

LEG EXTENSION HANDLES

FOAM ROLLER BAR

LEG HOLD DOWN

BACK PAD HOLDER

BACK PAD ADJUSTER

BACK PAD INSERT

SEATED PRESS ARM SUPPORT

9” SHAFT

SEATED PRESS ARMS

11 3/4” SHAFT

LEFT PEC DEC ARM

LEFT PEC DEC CAM

LEFT PEC DEC HANDLE

RIGHT PEC DEC ARM

RIGHT PEC DEC CAM

RIGHT PEC DEC HANDLE

HYDRAULIC SEAT ADJUSTER

PEC DEC SEAT FRAME

LOW PULLEY FRAME

FOOT BRACE

Part numbers are required when ordering parts.

46

Page 47

G9S Parts List

KEY# QTY PART# DESCRIPTION

(continued)

BA

BB

BC

BD

BE

BF

BG

BH

BL

BP

BR

1

1

1

1

1

3

1

2

2

1

1

JG9SLPC-BA

JGPSLPF-BB

JG9SLPF-BC

JG9SLPP-BD

JG9SFLPP-BE

JG9SS-BF

JG9SFPTF-BG

JG9SLPH-BH

JG9SSPF-BL

JG9SLPBF-BP

JG9SFP-BR

LEG PRESS CONNECTION

LEG PRESS FRAME

LEG PRESS FRONT

LEG PRESS PIVOT

FRONT LEG PRESS PIVOT

3” SHAFT

FOOT PLATE T-FRAME

LEG PRESS HANDLES

SEAT PAD FLANGE

LEG PRESS BACK PAD FRAME

FOOT PLATE

Shroud List

KEY# QTY PART# DESCRIPTION

AE

CA

CB

CC

CD

CE

CF

1

1

1

1

1

1

1

JG9SSPHS-AE

JG9SWSS-CA

JG9SSI-CB

JG9SWSS-CC

JG9SWSS-CD

JG9SSI-CE

JG9SWSS-CF

SEATED PRESS HINGE SHROUD

WEIGHT STACK SHROUD

SHROUD INSERT

WEIGHT STACK SHROUD

WEIGHT STACK SHROUD

SHROUD INSERT

WEIGHT STACK SHROUD

Pads List

KEY# QTY PART# DESCRIPTION

R

V

ZA

ZC

AW

AX

BM

BQ

2

1

1

1

1

1

1

1

JG9SLP-R

JG9SLESP-V

JG9SUBP-ZA

JG9SLBP-ZC

JG9SPDSP-AW

JG9SPDBP-AX

JG9SLPSP-BM

JG9SLPBP-BQ

LEG PAD

LEG EXTENSION SEAT PAD

UPPER BACK PAD

LOWER BACK PAD

PEC DEC SEAT PAD

PEC DEC BACK PAD

LEG PRESS SEAT PAD

LEG PRESS BACK PAD

Part numbers are required when ordering parts.

47

Page 48

G9S Hardware List

KEY# QTY PART# DESCRIPTION

1

2

3

4

5

6

7

8

9

10

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

41

42

43

45

47

48

49

50

51

52

53

54

55

56

57

59

2

1

1

2

2

2

3

2

2

10

4

5

13

4

2

1

4

3

2

2

4

3

2

5

26

1

4

10

2

4

1

2

6

3

7

2

1

3

2

2

40

2

2

2

4

2

1

2

JPIN4.25

JSS.5

JSCH.18

JSB.75X.5

JPW31

JSR20

JPCG31

JTP10

JBW1.37X1

JPS.56X.37

JFOAM48

JPEC22X.56

JPEC22X.75

JPEC12

JPEC24

JFHC.37

JPFREC2.5

JFC221.8

JFC222.5

JPB222

JSC1.37X.75

JPB226.5

JBEC2

JFL22

JPP4.25W.75

JPP3W.62

JWSS22

JREC1.5

JRP2450

JRD2.25

JSRC22

JGT5.5

JBB.87X.37

JRS1.5

JSNAP3

JPBB1LP

JRFPG3700

JTSPP3

JBB.87X.37

JBHPP5.5

JSP10

JSRTB.5

JSLW.5

JLN.5

JWSR4.87

JBHPP313

JBHPP311

JHEX121FTB

WEIGHT STACK PIN 4 1/4”L X 7/16”W

STEEL SLEEVE 1/2” OD X 5/16” ID X 3/4”L

STEEL CHAIN 3/16”

STEEL BUSHING 3/4” OD X 1/2” ID X 5/16”W

PLASTIC WASHER 3” OD X 1” ID

SELECTOR ROD (20 selector holes)

PULLEY CABLE GUIDE 3” L X 1”W

TOP PLATE (10 lbs.)

OILITE WASHER 1 3/8” OD X 1” ID (35mm X 25mm)

PULLEY SPACER 9/16” OD X 3/8” ID X 5/8” L (15mm X 9mm X 17mm)

FOAM ROLLER 4” X 8”

PLASTIC END CAP 2” X 2” (9/16” THICK)

PLASTIC END CAP 2” X 2” (3/4” THICK)

PLASTIC END CAP 1” X 2”

PLASTIC END CAP 2” X 4”

FRAME HOLE CAP 3/8” (round)

PLASTIC ROLLER END CAP 2.5” OD X 1” ID

FOOT CAP 2” X 2” (1.8” THICK)

FOOT CAP 2” X 2” (2.5” THICK)

PLASTIC BUSHING 2” X 2” (2” LONG)

SHAFT COLLAR 1 3/8” OD 3/4 ID 1.5” L

PLASTIC BUSHING 2” X 2” (6 1/2” LONG)

PLASTIC BALL-END CAP 2”

FRAME LEVELER 2”X 2”

PLASTIC PULLEY 4 1/4” X 3/4” WIDE

PLASTIC PULLEY 3” X 5/8” WIDE

WEIGHT STACK SHIMS 2” X 2”

ROUND END CAP 1 1/2”

RUBBER PAD

RUBBER DONUT 2 1/2”

SQUARE RUBBER CAP 2” X 2”

GRIP TAPE 5 1/2” X 3 3/4”

OILITE BUSHING 7/8” OD X 3/8” ID (22mm X 11mm leg press)

RUBBER STOP 1 1/2”

SNAP LINK

PILLOW BLOCK BEARING 1” ID

RUBBER FOOT PLATE GUARD-PREINSTALLED

T-SHAPED POP PIN 3” L

OILITE BUSHING 7/8” OD X 3/8” ID (22mm X 11mm leg extension)

BALL HEAD POP PIN 5.5”L (pec dec)

WEIGHT STACK PLATE 10lbs.

SELECTOR ROD TOP BOLT 1/2” X 2” FULL THREAD

SPRING LOCK WASHER 1/2”

JAM NUT 1/2”

WEIGHT STACK RISERS 4 7/8”L

BALL HEAD POP PIN 3 13/16” L (back support)

BALL HEAD POP PIN 3 11/16” L (seated press)

HEX HEAD BOLT 1/2”X 1” FULL THREAD

Part numbers are required when ordering parts.

48

Page 49

G9S Hardware

KEY# QTY PART# DESCRIPTION

(continued)

60

61

62

63

64

65

66

70

71

72

73

74

75

76

77

78

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

101

102

103

104

105

106

107

108

112

113

114

115

135

136

1

JHEX.5X5.5PTB

3

JHEX.5X5.25PTB

2

JHEX.5X5PTB

1

JHEX.5X3.5PTB

9

JHEX.5X3.25PTB

4

JHEX.5X3PTB

4

JHEX.5X1.75FTB

1

JHEX.37X3.5PTB

2

JHEX.37X3.25PTB

3

JHEX.37X3PTB

18

JHEX.37X2.75PTB

1

JHEX.37X2.5PTB

2

JHEX.37X2PTB

21

JHEX.37X1.75PTB

2

JFAH.37X2FTB

2

JHEX.37X.87FTB

2

JHEX.31X5PTB

1

JHEX.31X3.25PTB

6

JHEX.31X2.75FTB

10

JHEX.31X1FTB

1

JFAH.31X1.5FTB

4

JFAH.31X.75FTB

6

JRAH.31X.56FTB

9

JRAH.37X.62FTB

14

JAS.31X.31FT

4

JRAH.31X.75FTB

21

JNLN.5

50

JNLN.37

1

JNLN.31

43

JWFLT.5

90

JWFLT.37

23

JWFLT.31

23

JWSW.31

4

JWFLT.31

9

JWFLT.37

4

JAS.19X.19

2

JCEC1.37X1

2

JRR1.5X1.25

2

JBB1.75X1

2

JBB.87x.62

2

JCC1.43X1

12

JBB1.75X1

2

JACN.19

2

JHEX.37X1FTB

2

JLN.37

2

JSB1.75X1

2

JRR1.75X1.5

2

JCES

2

JAS

HEX HEAD BOLT 1/2” X 5 1/2” PARTIAL THREAD

HEX HEAD BOLT 1/2” X 5 1/4” PARTIAL THREAD

HEX HEAD BOLT 1/2” X 5” PARTIAL THREAD

HEX HEAD BOLT 1/2” X 3 1/2” PARTIAL THREAD

HEX HEAD BOLT 1/2” X 3 1/4” PARTIAL THREAD

HEX HEAD BOLT 1/2” X 3” PARTIAL THREAD

HEX HEAD BOLT 1/2” X 1 3/4” FULL THREAD

HEX HEAD BOLT 3/8” X 3 1/2” PARTIAL THREAD

HEX HEAD BOLT 3/8” X 3 1/4” PARTIAL THREAD

HEX HEAD BOLT 3/8” X 3” PARTIAL THREAD

HEX HEAD BOLT 3/8” X 2 3/4” PARTIAL THREAD

HEX HEAD BOLT 3/8” X 2 1/2” PARTIAL THREAD

HEX HEAD BOLT 3/8” X 2” PARTIAL THREAD

HEX HEAD BOLT 3/8” X 1 3/4” PARTIAL THREAD

FLAT ALLEN HEAD 3/8” X 2” FULL THREAD

HEX HEAD BOLT 3/8” X 7/8” FULL THREAD

HEX HEAD BOLT 5/16” X 5” PARTIAL THREAD

HEX HEAD BOLT 5/16” X 3 1/4” PARTIAL THREAD

HEX HEAD BOLT 5/16” X 2 3/4” FULL THREAD

HEX HEAD BOLT 5/16” X 1” FULL THREAD

FLAT ALLEN HEAD 5/16” X 1 1/2” FULL THREAD

FLAT ALLEN HEAD 5/16” X 3/4” FULL THREAD

ROUND ALLEN HEAD 5/16” X 9/16” FULL THREAD (8mmX15mm)

ROUND ALLEN HEAD 3/8” X 5/8” FULL THREAD (10mmX16mm)

ALLEN SCREW 5/16” X 5/16” FULL THREAD

ROUND ALLEN HEAD 5/16” X 3/4” FULL THREAD

NYLON LOCK NUT 1/2”

NYLON LOCK NUT 3/8”

NYLON LOCK NUT 5/16”

WASHER 1/2”

WASHER 3/8”

WASHER 5/16”

SPRING LOCK WASHER 5/16”

WASHER 5/16” (8mm shrouds)

WASHER 3/8” (10mm shrouds)

ALLEN SCREW 3/16” X 3/16” -PREINSTALLED

CHROME END CAP 1 3/8”OD X 1”ID X 3/4”L- PREINSTALLED

RETAINING RING 1 1/2” OD X 1 1/4”ID (leg ext)-PREINSTALLED

OILITE BUSHING 1 3/4”OD 1”ID - PREINSTALLED (seated press)

OILITE BUSHING 7/8”OD 5/8”ID - PREINSTALLED (low row)

CHROME COLLAR 1 7/16” OD X 1” ID

OILITE BUSHING 1 3/4”OD 1”ID - PREINSTALLED (pec dec)

ACORN CAP NUT 3/16” ID - PREINSTALLED

HEX HEAD BOLT 3/8” X 1” FULL THREAD (adjustment bolt)

LOCK NUT 3/8”

STEEL BUSHING 1 3/4”OD 1” ID - PREINSTALLED (seated press)

RETAINING RING - 1 3/4”OD 1” ID -PREINSTALLED (seated press)

CABLE END SHAFT 3/4” L

ALLEN SCREW 1/8” X 1/4”(4mm X 8mm)

Part numbers are required when ordering parts.

49

Page 50

Cable List

KEY# QTY PART# DESCRIPTION

34

35

36

37

38

39

40

1

1

1

1

1

1

1

JLPC4270

JLRC4060

JLPC3840

JLEC2635

JPDC1890

JACC1545

JSC520

LEG PRESS CABLE 4270 mm(14’)

LOW PULLEY CABLE 4060 mm(13’ 3 1/2”)

LAT PULLDOWN CABLE 3840 mm(12’ 6”)

LEG EXTENSION CABLE 2635 mm(8’ 7”)

PEC DEC CABLE 1890 mm(6’ 2 1/2”)

AB CRUNCH CABLE 1545 mm(5’ 1”)

SHORT CABLE 520 mm(1’ 8 1/2”)

Pulley Holder List

KEY# QTY PART# DESCRIPTION

130

131

132

133

1

1

2

1

JG9SDPH

JG9SPDPH

JG9SPP

JG9SPHWH

DOUBLE PULLEY HOLDER

PEC DEC PULLEY HOLDER

PULLEY PLATE

PULLEY HOLDER WITH HOOK

Accessories List

KEY# QTY PART# DESCRIPTION

120

121

122

123

124

125

126

127

128

POSTER

PAINT

1

1

1

1

2

2

2

2

4

1

1

JG9SLB

JG9SLRB

JG9SAS

JG9SACH

JFG18

JFG8.37

JFG17.25

JFG24

JFG17

G9SPOSTER

TUP-G

LAT BAR

LOW ROW BAR

ANKLE STRAP

AB CRUNCH HARNESS

FOAM GRIP 1 1/2” OD X 18” L -PREINSTALLED

FOAM GRIP 1 1/2” OD X 8 3/8” L -PREINSTALLED

FOAM GRIP 1 1/2” OD X 17 1/4” L -PREINSTALLED

FOAM GRIP 1 1/2” OD X 24” L -PREINSTALLED

FOAM GRIP 1 1/2” OD X 17” L -PREINSTALLED

WORK OUT POSTER

TOUCH UP PAINT - GRAY

Part numbers are required when ordering parts.

50

Page 51

Obtaining Service

Please retain this Owner’s Manual for future reference. When ordering parts you must use the part number and description

from this Owner’s Manual. Use only Body-Solid replacement parts when servicing this machine. Failure to do so will void

your warranty and could result in personal injury.

For more information about product operation or service, check out the official Body-Solid website at www.bodysolid.com

or contact an authorized Body-Solid dealer or a Body-Solid factory authorized service company or contact Body-Solid

customer service at one of the following:

Toll Free: 1-800-833-1227

Phone: 1-708-427-3555

Fax: 1-708-427-3556

E-mail: service@bodysolid.com

Or write to: Body-Solid, Inc.

Service Department

1900 S. Des Plaines Ave.

Forest Park, IL 60130 USA

Ordering replacement parts

When ordering replacement parts, please have the following information available:

1. Model number: G9S

2. Date of purchase: ________________________________________

3. Name of dealer: ________________________________________

__________________________________________________________

4. Dealer location: ________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

5. Part numbers (see pages 46-51):____________________________

__________________________________________________________

6. Description of part:_________________________________________

__________________________________________________________

__________________________________________________________

51

Page 52

EXPLODED VIEW

DIAGRAM

G9S

52

Page 53

© Copyright 2003. Body-Solid. All rights reserved. Body-Solid reserves the right to change design and specifications when we feel it will improve the product.

Body-Solid machines maintain several patented and patent pending features and designs. All rights reserved on all design patents and utility patents.

53

Loading...

Loading...