Page 1

Table of Contents

Total Body Workout DVD . . . . . . . . . . . . . p. 2

Reference Drawings . . . . . . . . . . . . . . . . . p. 3

Safety Instructions . . . . . . . . . . . . . . . . . . p. 4

Before You Begin . . . . . . . . . . . . . . . . . . . p. 5

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . p. 6

Safety Guidelines . . . . . . . . . . . . . . . . . . . p. 7

Preparations . . . . . . . . . . . . . . . . . . . . . . . p. 8

Assembly Instructions . . . . . . . . . . . . p. 9-27

Cable Installations . . . . . . . . . . . . . . p. 28-37

Shroud Installation . . . . . . . . . . . . . . p. 40-41

Cable Adjustments . . . . . . . . . . . . . . p. 38-39

Adjustments . . . . . . . . . . . . . . . . . . . p. 42-45

Warning, Safety & Maintenance . . . . p. 46-47

Maintenance Schedule . . . . . . . . . . .p. 48-49

Phrases, Terms, Tips & Guidelines . . p. 50-51

Nutrition . . . . . . . . . . . . . . . . . . . . . . . . . p. 52

Exercise Prescription . . . . . . . . . . . . . . . p. 53

Training Tips . . . . . . . . . . . . . . . . . . . . . . p. 54

Common Training Mistakes . . . . . . . . . . p. 55

Setting Up Your Personal Program . . . . p. 56

Determine Your Training Method . . . . . . p. 57

Exercise Tips . . . . . . . . . . . . . . . . . . . . . . p. 58

Anatomy Chart . . . . . . . . . . . . . . . . . . . . p. 59

Fitness Goals . . . . . . . . . . . . . . . . . . . . . p. 60

Exercise Logs . . . . . . . . . . . . . . . . . . p. 61-63

Stretching & Flexibility . . . . . . . . . . . . . . p. 64

Stretching: Warm-Up / Cool-Down . p. 65-69

Workout/Exercises . . . . . . . . . . . . . . p. 70-75

Signs of Overtraining . . . . . . . . . . . . . . . p. 76

Weight Ratios . . . . . . . . . . . . . . . . . . . . . p. 77

Obtaining Service . . . . . . . . . . . . . . . . . . p. 79

Mainframe Parts List . . . . . . . . . . . . p. 80-81

Hardware Parts List . . . . . . . . . . . . . p. 82-85

Hardware Diagrams . . . . . . . . . . . . . p. 86-88

Exploded View Diagram . . . . . . . . . . p. 89-90

Body-Solid

®

Assembly Instructions

&

OWNER’S MANUAL

Page 2

Total Body Workout DVD

Follow the lead of international fitness presenter

Geoff Bagshaw as he guides you step by step through

a total health and conditioning program. Includes

thorough explanations and demonstrations of over 50

exercises targeting all major muscle groups. The

Body-Solid Total Body Workout is a “must have” for

anyone truly serious about in-home training.

Also includes:

l Complete stretching routine

l Importance of cardio training

l Body-Solid company profile

Body-Solid

Total Body Workout DVD

2

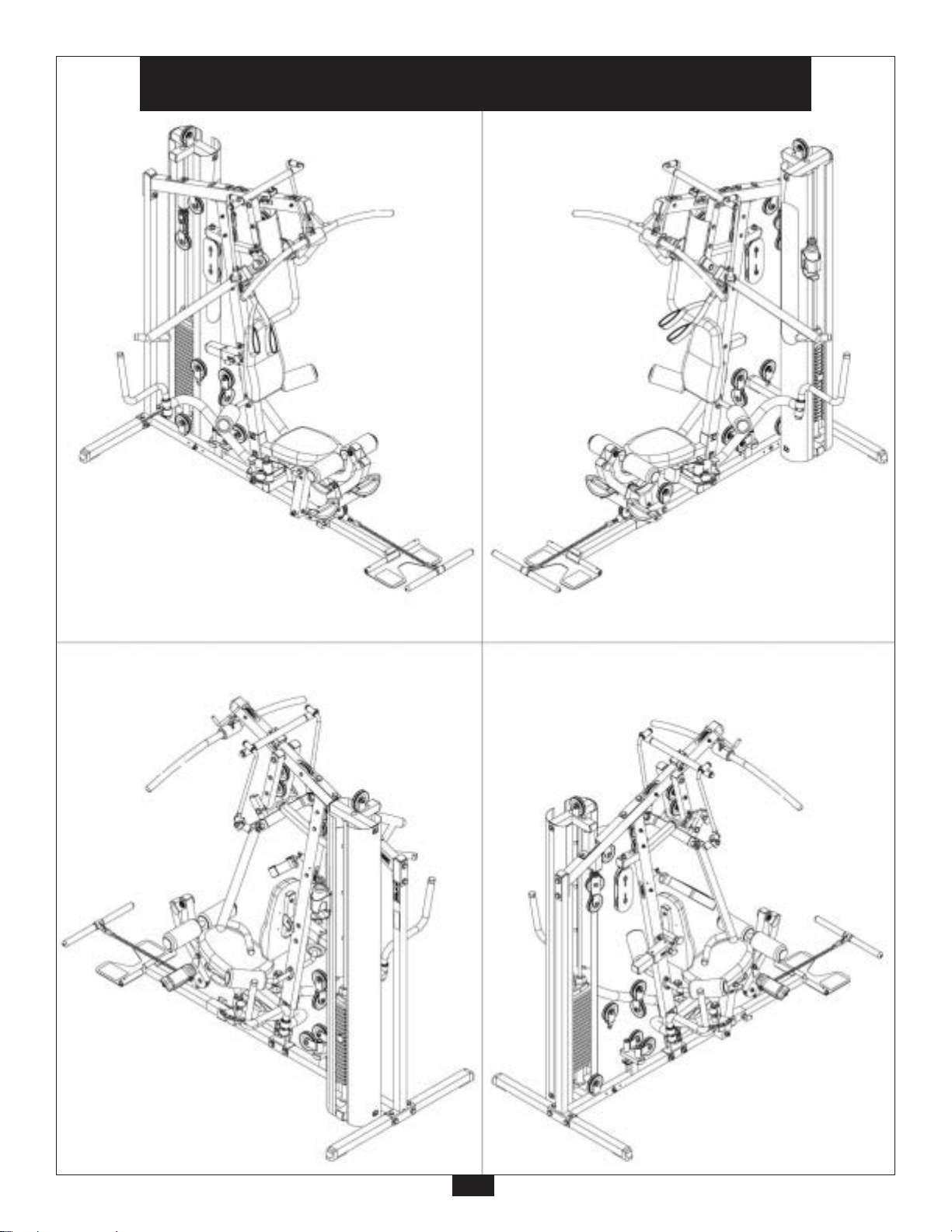

Page 3

G6B

Reference Drawings

3

Page 4

Important Safety Instructions

Before beginning any fitness program, you should obtain a complete physical examination from your physician.

Il est conseille de subir un examen medical complet avant d’entreprendre tout programme d’exercise.

Si vous avez des etourdissements ou des faiblesses, arretez les exercices immediatement.

Antes de comenzar cualquier pr

When using exercise equipment, you

should always take basic precautions,

including the following:

Read all instructions before using the G6B. These

•

instructions are written to ensure your safety and to

protect the unit.

Do not allow childr

•

Use the equipment only for its intended purpose as

•

described in this guide. Do not use accessory

attachments that are not recommended by the

manufacturer. Such attachments might cause injuries.

Wear proper exercise clothing and shoes for your

•

workout, no loose clothing.

Use care when getting on or off the unit.

•

Do not overexert yourself or work to exhaustion.

•

If you feel any pain or abnormal symptoms, stop your

•

workout immediately and consult your physician.

Never operate unit when it has been dropped or

•

damaged. Return the equipment to a service center

for examination and repair.

Never drop or insert objects into any opening in the

•

equipment.

Always check the unit and its cables before each

•

use. Make sure that all fasteners and cables are

secure and in good working condition.

Do not use the equipment outdoors or near water.

•

Personal Safety During Assembly

It is strongly recommended that a qualified dealer

•

assemble the equipment.

Before beginning assembly, please take the time to

•

read the instructions thoroughly.

Read each step in the assembly instructions and

•

follow the steps in sequence. Do not skip ahead. If

you skip ahead, you may learn later that you have to

disassemble components and that you may have

damaged the equipment.

Assemble and operate the G6B on a solid, level

•

surface. Locate the unit a few feet from the walls or

furniture to provide easy access.

en on or near the equipment.

ogramma de ejercicios, deberias tener un examen fisico con su doctor.

Assistance is required.

The G6B is designed for your enjoyment. By

following these precautions and using common

sense, you will have many safe and pleasurable hours

of healthful exercise with your Body-Solid G6B.

After assembly, you should check all functions to

ensure correct operation. If you experience problems,

first recheck the assembly instructions to locate any

possible errors made during assembly. If you are unable

to correct the problem, call the dealer from whom

you purchased the machine or call 1-800-833-1227

for the dealer nearest you.

Obtaining Service

Please use this Owner’s Manual to make sure that all

par

ts have been included in your shipment. When

ordering parts, you must use the par

description from this Owner’s Manual. Use only

Body-Solid replacement parts when servicing this

machine. Failure to do so will void your warranty and

could result in personal injury.

For information about product operation or service,

check out the official Body-Solid website at

www.bodysolid.com or contact an authorized

Body-Solid dealer or a Body-Solid factory-authorized

service company or contact Body-Solid customer

service at one of the following:

Toll Free: 1-800-556-3113

Phone: 1-708-427-3555 ext. 5

Fax: 1-708-427-3598

E-mail: service@bodysolid.com

Or write to: Body-Solid, Inc.

Retain this Owner’s Manual for future

r

eference. Part numbers ar

ordering parts.

Service Department

1900 S. Des Plaines Ave.

Forest Park, IL 60130 USA

t number and

e required when

4

Page 5

Before You Begin

Thank you for purchasing the G6B. This gym is part of the Body-Solid line of quality strength training

machines, which let you target specific muscle groups to achieve better muscle tone and overall body

conditioning. To maximize your use of the equipment please study this Owner’s Manual thoroughly.

Unpacking the Equipment

The G6B is carefully tested and inspected before

shipment. Body-Solid ships the unit in several pie

that require assembly. Ask for assistance during the

assembly process.

Carefully unpack the boxes and lay the pieces on

the floor near the area where you plan to use the

equipment.

ces

Be careful to assemble all components in the

sequence presented in this guide.

If any items are missing, contact the dealer from whom

you purchased the unit or call 1-800-833-1227 for

the dealer nearest you.

5

Page 6

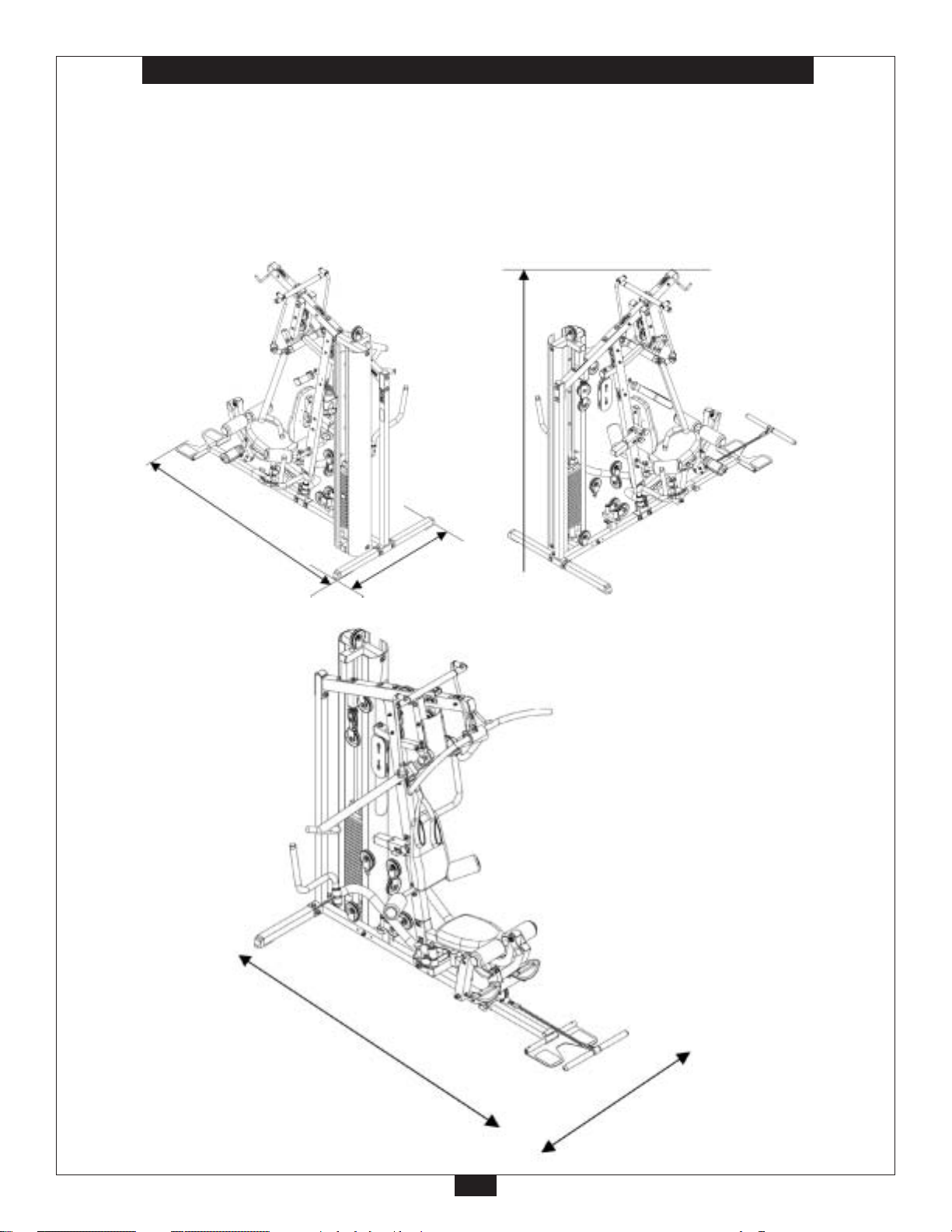

Dimensions

The room layout diagram below will help you decide the best placement for your G6B.

The dimensions of the G6B are: width 4’ X length 7’1”. The ceiling height requirement for the G6B is 7’.

The usage space is: width 7’ X length 10’ 4” (The usage space is the overall space needed for operation.)

The usage space needed for the G6B could be more, depending on the user, allow enough room for the Low Row Station.

6’ 11.5”

Dimensions

7’ 1”

Height

4’

Suggested usage space

10’ 4”

7’

6

Page 7

Safety Guidelines

Successful resistance training programs have one prominent feature in common...safety. Resistance training

has some inherent dangers, as do all physical activities. The chance of injury can be greatly reduced or

completely removed by using correct lifting techniques, proper breathing, maintaining equipment in good

working condition, and by wearing the appropriate clothing.

1. It is highly recommended that you consult your physician before beginning any exercise program.

This is especially important for individuals over the age of 35, or persons with pre-existing health

problems.

2. Always warm up before starting a workout. Try to do a total body warm up before you start. It is

especially important to warm up the specific muscle groups you are going to be using. This can

be as simple as performing a warm up set of high repetitions and light weight for each exercise.

3. Use proper form. Focus on only working the muscle groups intended for the exercise you are doing.

If there is strain elsewhere, you may need to re-evaluate the amount of weight that is involved with

the lift. Keeping proper form also includes maintaining control through an entire range of motion.

4. Breath properly. Inhale during the eccentric phase of the exercise, and exhale during the lifting, or

concentric phase. Never hold your breath during any part of an exercise.

the entire range of motion.

5. Always wear the appropriate clothing and shoes when exercising. Wearing comfortable athletic shoes

with good support and loose fitting, breathable clothing will reduce the risk of injury.

suitable, breathable clothing will reduce the risk of injury.

6. Maintaining equipment in proper operating condition is of utmost importance for a safe resistance

training program. Pulleys and cables should be checked for wear frequently and replaced as needed.

Equipment should be lubricated as indicated by the manufacturer.

7. Read and study all warning labels on this machine. It is absolutely necessary that you familiarize

yourself and all others with the proper operation of this machine prior to use.

8. Keep hands, limbs, loose clothing and long hair well out of the way of all moving parts.

9. Do not attempt to lift more weight than you can control safely.

10.Inspect the machine daily for loose or worn parts. If a problem is found do not allow the machine to

be used until all parts are tightened or worn or defective parts are repaired or replaced.

7

Page 8

Preparations

CAUTION: To set up this unit, you will need assistance. Do not attempt assembly by yourself.

You must review and follow the instructions in this Owner’s Manual. If you do not assemble and use the G6B

according to these guidelines, you could void the Body-Solid warranty.

Required Tools

The tools that you must obtain before assembling

the G6B include:

c

3mm Allen Key

c

4mm Allen Key

c

5mm Allen Key

c

6mm Allen Key

c

8mm Allen Key

c

9/16” Open-End W

c

11/16” Open-End Wr

c

13/16” Open-End Wrench

c

3/4” Open-End Wrench

c

9/16” Box Wrench

c

11/16” Box Wrench

c

13/16” Box Wrench

c

3/4” Box Wrench

rench

ench

CAUTION: Obtain assistance! Do not attempt to assemble

the G6B by yourself. Review the Installation

Requirements before proceeding with the following

steps.

The G6B unit comes in eight boxes. Be careful to

assemble components in the sequence presented in

this guide.

NOTE: With so many assembled parts, proper alignment

and adjustment is critical. While tightening the nuts

and bolts, be sure to leave room for adjustments.

Installation Requirements

Follow these installation requirements when assembling

the G6B:

Set up the G6B on a solid, flat surface. A s

surface under the machine helps keep it level. A

level machine has fewer malfunctions.

Provide ample space around the machine. Open

space around the machine allows for easier access.

Insert all bolts in the same direction. For aesthetic

purposes, insert all bolts in the same direction unless

specified (in text or illustrations) to do otherwise.

Leave room for adjustments. Tighten fasteners such as

bolts, nuts, and screws so the unit is stable, but leave

room for adjustments. Do not fully tighten fasteners

until instructed in the assembly steps to do so.

Fill out and mail warranty card.

mooth, flat

8

Page 9

Assembly Instructions

Assembly of the G6B takes professional installers about 3 hours to complete. If this is the first time you have

assembled this type of equipment, plan on significantly more time.

Professional installers are highly recommended!

However, if you acquire the appropriate tools, obtain assistance, and follow the assembly steps sequentially,

the process will take time, but is fairly easy.

Assembly Tips

Read all “Notes” on each page before beginning each step.

While you may be able to assemble the G6B using the

illustrations only, important safety notes and other tips are

included in the text.

Some pieces may have extra holes that you will not use. Use

o

nly those holes indicated in the instructions and illustrations.

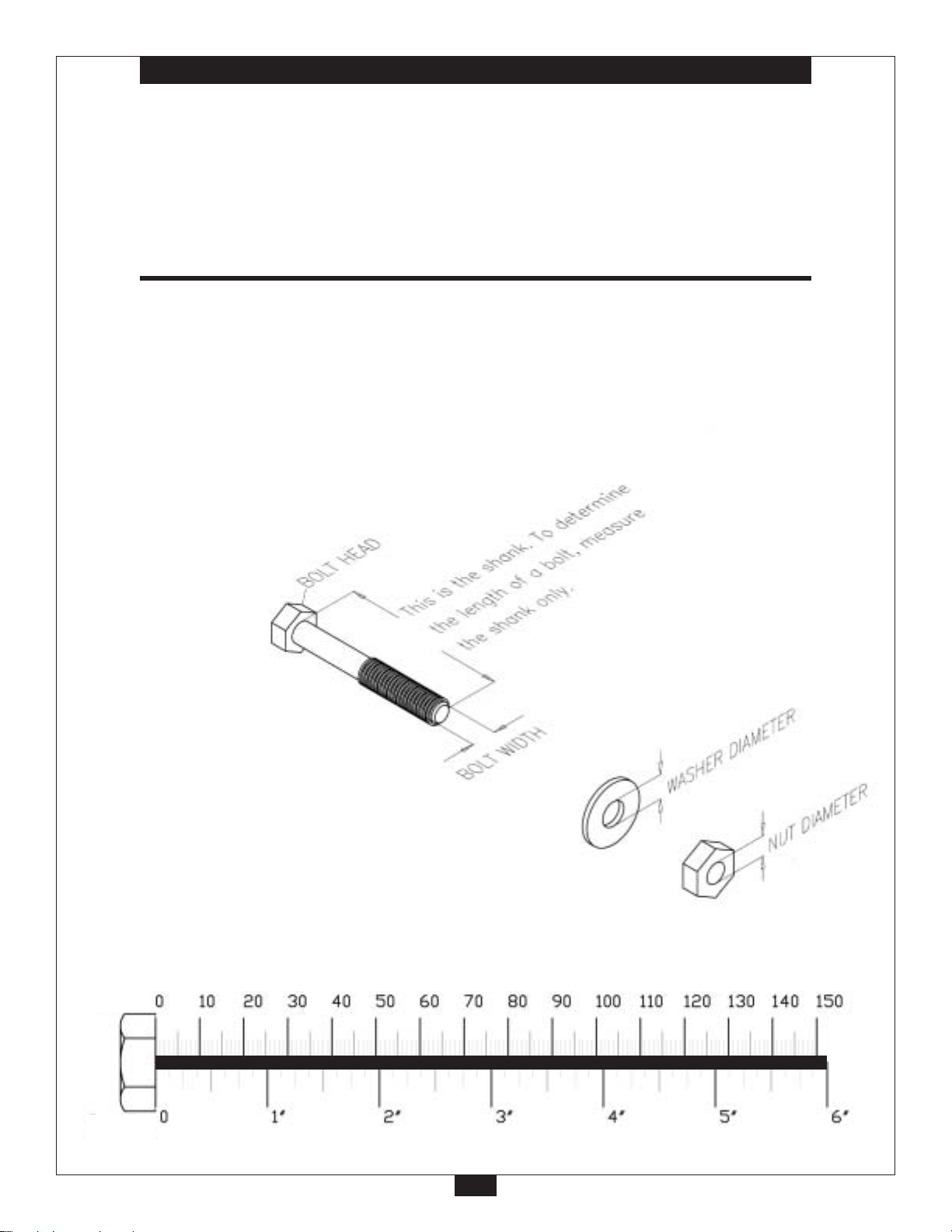

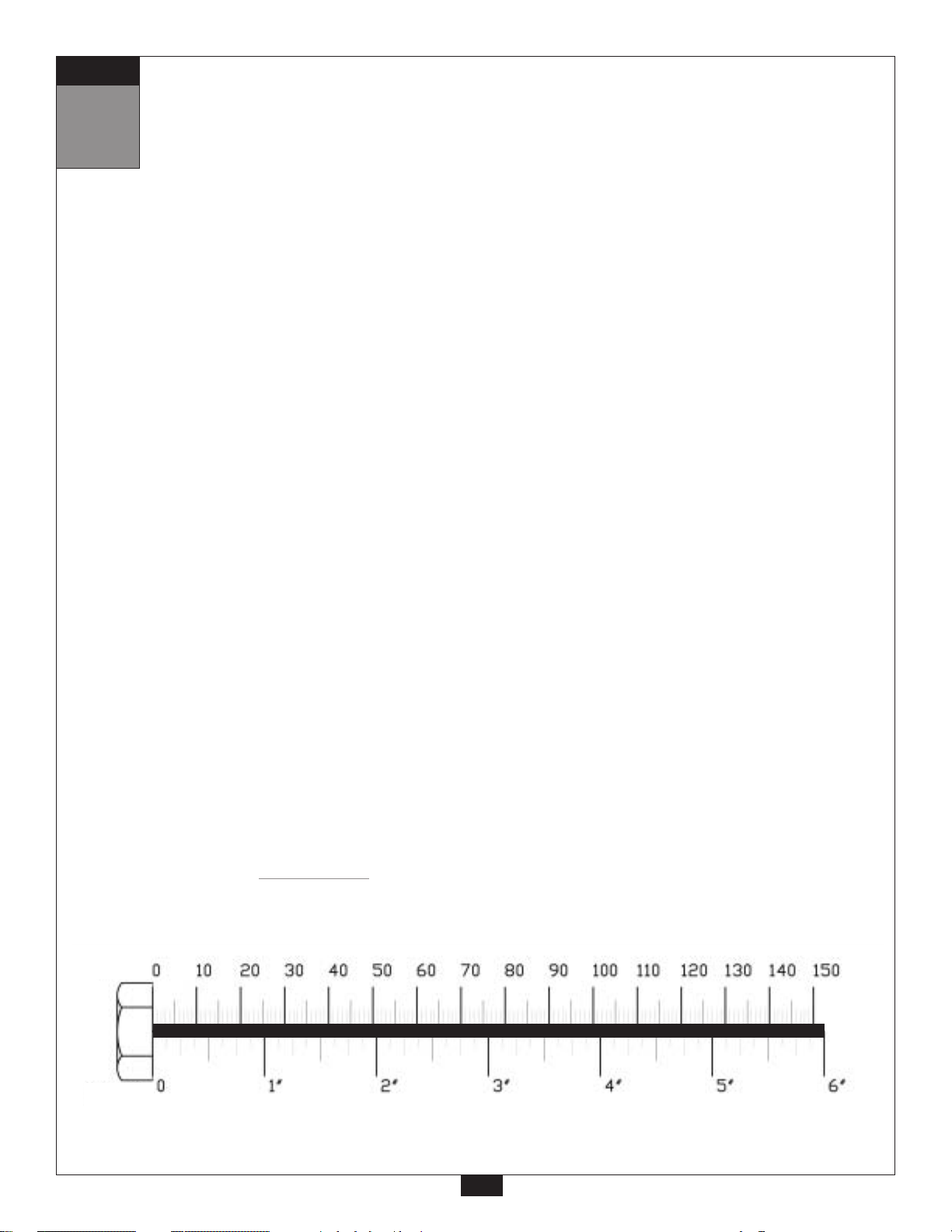

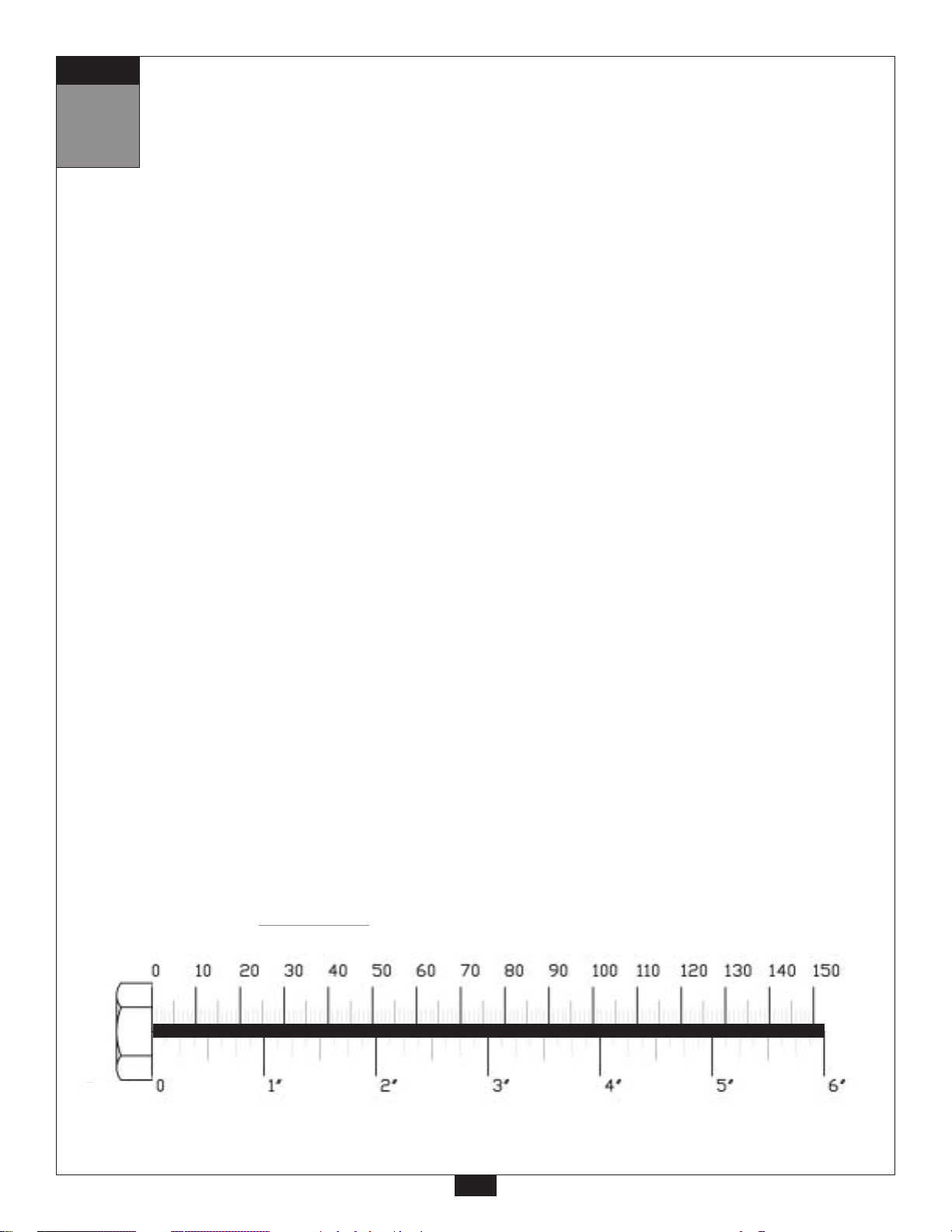

NOTE: To find out the length of a particular bolt, measure its

shank (the long, narrow part beneath the head). Refer to the

following diagram:

IMPORTANT!

Before you begin you should fold-out pages 86, 87 and 88.

This is a quick reference guide that shows all hardwar

parts (in actual size) along with the corresponding key

numbers on the assembly instructions.

e

Do not fully tighten bolts until instructed to do so.

Note: After assembly, you should check all functions

to ensure correct operation. If you experience

problems, first recheck the assembly instructions

to locate any possible errors made during assembly.

If you are unable to correct the problem, call the

dealer from whom you purchased the machine or

call 1-800-833-1227 for the dealer nearest you.

mm

Inch

9

Page 10

STEP

1

Be careful to assemble all components

in the sequence they are presented.

NOTE:

Finger tighten all har

A. Attach Frame Leveler (10) to Main Base Frame (A) as shown.

Insert two Weight Stack Shims (11) to Main Base Frame (A) as shown.

Insert Convex End Cap (28) to the opening in Main Base Frame (A) as shown.

B. Attach Main Base Frame (A) to Rear Base Frame (B) and Rear Vertical Frame (C) using:

Two 40 (1/2” x 3 1/4” hex head bolt)

Four 73 (1/2” washer)

Two 70 (1/2” nylon lock nut)

Also use:

Two 55 (3/8” x 2 3/4” hex head bolt)

T

wo 74 (3/8” washer)

Two 71 (3/8” nylon lock nut)

C. Insert two Foot Caps (6) to the ends of Rear Base Frame (B).

Inser

t Convex End Cap (2) to the top of Rear Vertical Frame (C) as shown.

dware in this step. Do Not

wrench tighten until end of step 3.

mm

Inch

10

Page 11

STEP

1

11

Page 12

STEP

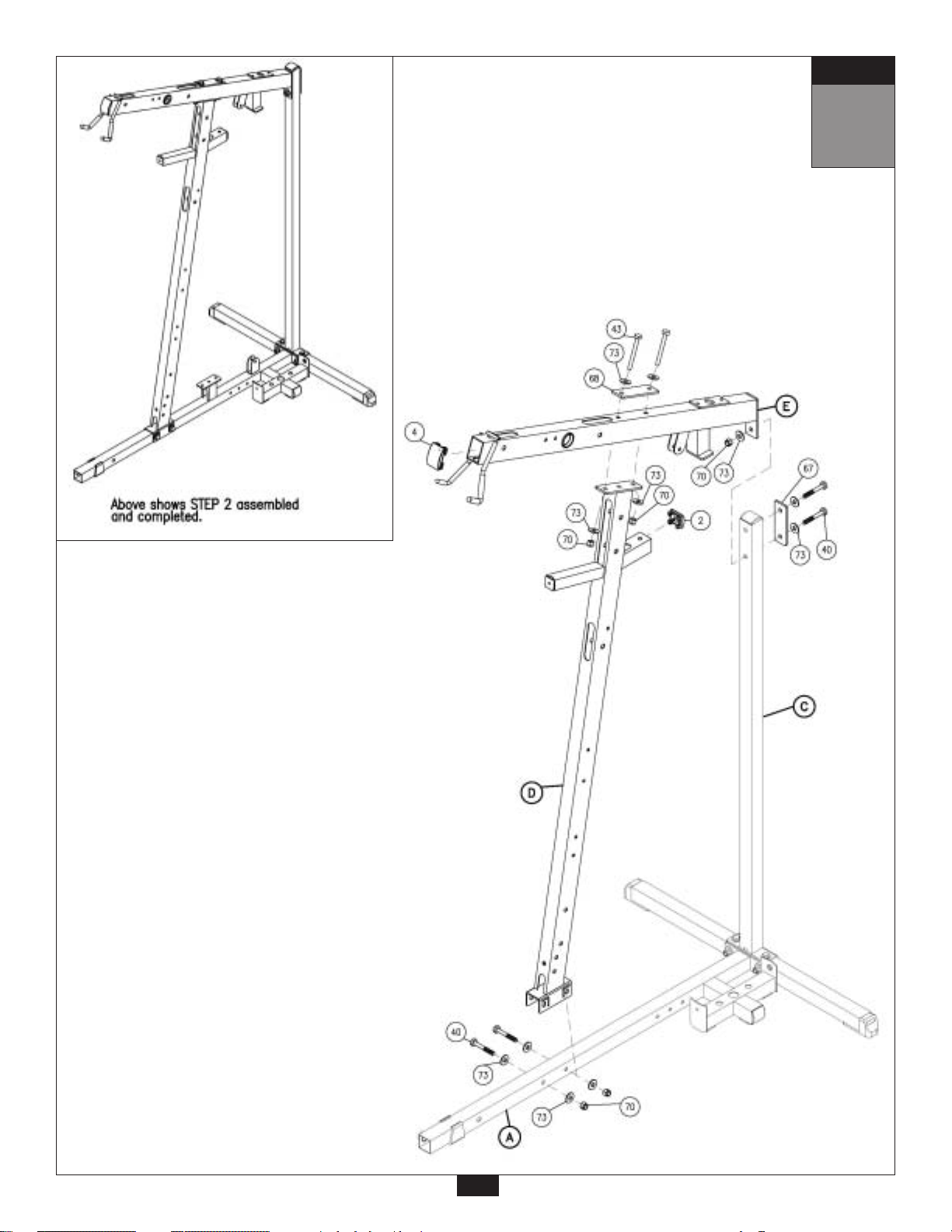

2

Be careful to assemble all components

in the sequence they are presented.

NOTE:

Finger tighten all har

A. Attach Angled Support Frame (D) to Main Base Frame (A) using:

Two 40 (1/2” x 3 1/4” hex head bolt)

Four 73 (1/2” washer)

Two 70 (1/2” nylon lock nut)

dware in this step. Do Not

wrench tighten until end of step 3.

B. Insert Convex End Cap (4) to the fr

Attach T

T

Three 73 (1/2” washer)

One 70 (1/2” nylon lock nut)

*NOTE:

One bolt (40) goes into an internally threaded nut inside T

C. Attach Top Frame (E) and Plate (68) to Angled Support Frame (D) using:

Two 43 (1/2” x 4 1/4” hex head bolt)

Four 73 (1/2” washer)

T

D. Insert Convex End Cap (2) to the small horizontal ar

op Frame (E) and Plate (67) to the Rear Vertical Frame (C) using:

wo 40 (1/2” x 3 1/4” hex head bolt)*

wo 70 (1/2” nylon lock nut)

ont of the Top Frame (E).

op Frame (E).

m on Angled Support Frame (D) as shown.

mm

Inch

12

Page 13

STEP

2

13

Page 14

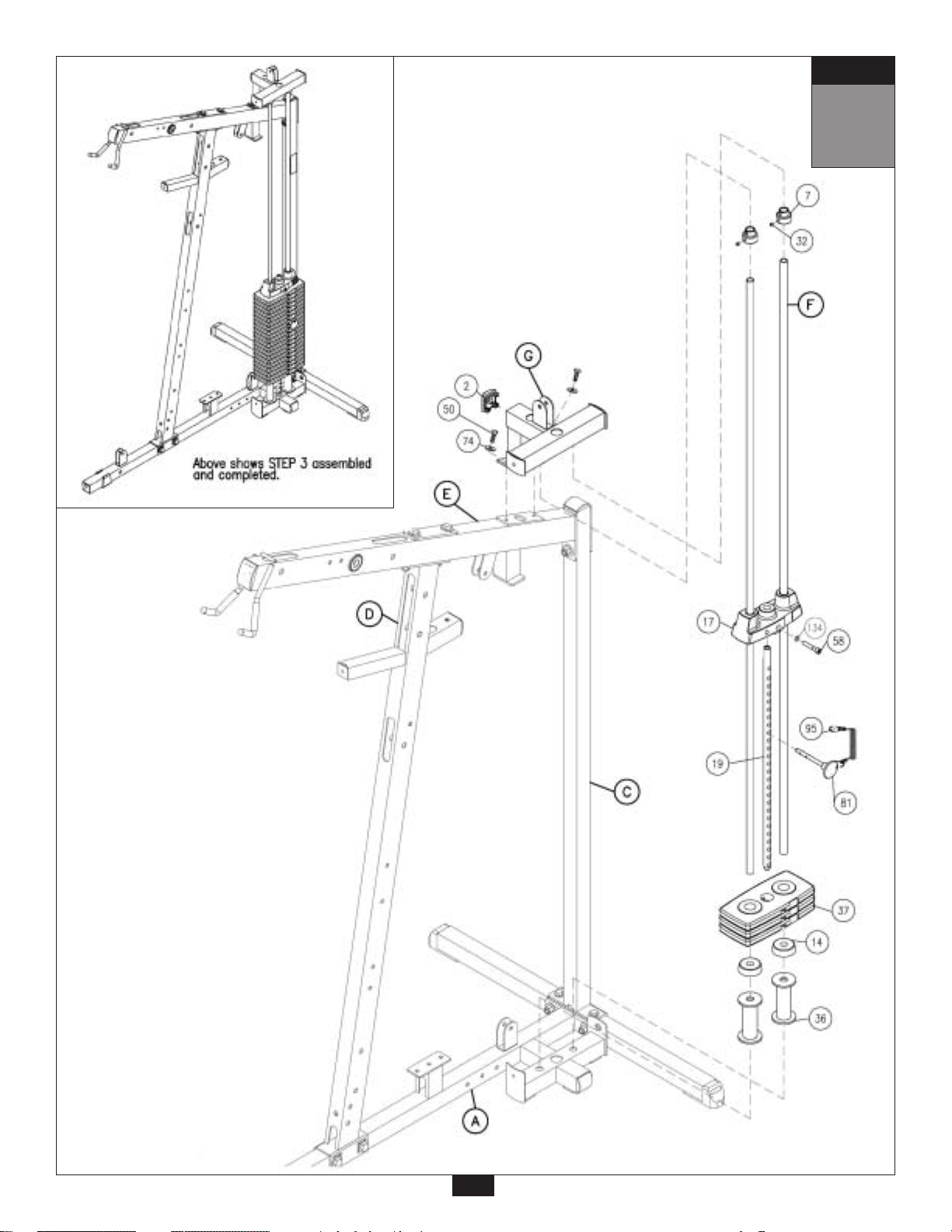

STEP

3

Be careful to assemble all components

in the sequence they are presented.

NOTE:

At this point you must make sure that the gym is level, stable and in the right location.

A. Place two Weight Stack Risers (36) and two Rubber Donuts (14) onto Main Base Frame (A) as

shown. Slide two Guide Rods (F) through the Rubber Donuts (14), through the two Weight

Stack Risers (36), and into the Main Base Frame (A).

B.

*NOTE:

Use fifteen 10lb. plates for a 160lb. weight stack.

Use twenty 10lb. plates for a 210lb. weight stack. See NOTE after Step 1B.

C. Connect Top Plate (17) to the Selector Rod (19) using:

D.

E. Insert Guide Rods (F) into T

F

. Slide Shaft Collars (7) up into the Top W

G. You can now wrench tighten all bolts and nuts on the main frame unit.

Slide Weight Stack Plates (37)* onto Guide Rods (F). Make sure the opening in each Weight

Stack Plate (37), for the Weight Stack Pin (81), is facing outwar

One 58 (3/8” x 2” round allen head)

One 134 (3/8” spring lock washer)

Slide Top Plate (17) and Selector Rod (19) onto Guide Rods (F).

Slide two Shaft Collars (7) onto the two Guide Rods (F) as shown.

op Weight Stack Frame (G), and Attach Top Weight Stack

Frame (G) to Top Frame (E) using:

Two 50 (3/8” x 1” hex head bolt)

T

wo 74 (3/8” washer)

Attach Convex End Cap (2) to Top Weight Stack Frame (G) as shown.

eight Stack Frame (G) and turn the Shaft Collar, so it

locks onto the Top Weight Stack Frame (G), Now tighten each Allen Screw (32) in Shaft Collars (7).

d.

mm

Inch

14

Page 15

STEP

3

15

Page 16

STEP

4

Be careful to assemble all components

in the sequence they are presented.

A. Attach two Convex End Caps (2) to the top of Seated Press Arm Support (H).

Attach Seated Press Arm Support (H) to Top Frame (E) using Shaft (33), and tighten

Allen Screws (34).

B. Attach Bi Angular Bars (J) to Top Frame (E) using:

Two 53 (3/8” x 3” hex head bolt)

Four 74 (3/8” washer)

T

wo 71 (3/8” nylon lock nut)

Also using:

Two 80 (3/8” x 1/2” hex head bolt)

T

wo 79 (3/8” washer)

C. Attach Press Arm Holder (K) to Seated Press Arm Support (H) using Shaft (35), and tighten

Allen Scr

ews (34).

D. Attach Left Press Ar

One 37 (1/2” x 3/4” hex head bolt)

One 73 (1/2” washer)

And tighten Allen Screws (34).

E.

F

. Connect Bi Angular Bars (J) to Left Press Ar

G. Connect Bi Angular Bars (J) to Right Pr

Note:

You should now w

Attach Right Press Arm (M) to Pr

One 37 (1/2” x 3/4” hex head bolt)

One 73 (1/2” washer)

And tighten Allen Screws (34).

Two 74 (3/8” washer)

T

wo 36 (3/8” x 5/8” round allen bolt)

Two 74 (3/8” washer)

T

wo 36 (3/8” x 5/8” round allen bolt)

r

m (L) to Press Arm Holder (K) using Shaft (KA), and:

ench tighten all bolts and nuts in this step.

mm

ess Arm Holder (K) using Shaft (KB), and:

m (L) using Shaft (39) and:

ess Arm (M) using Shaft (39) and:

Inch

16

Page 17

STEP

4

17

Page 18

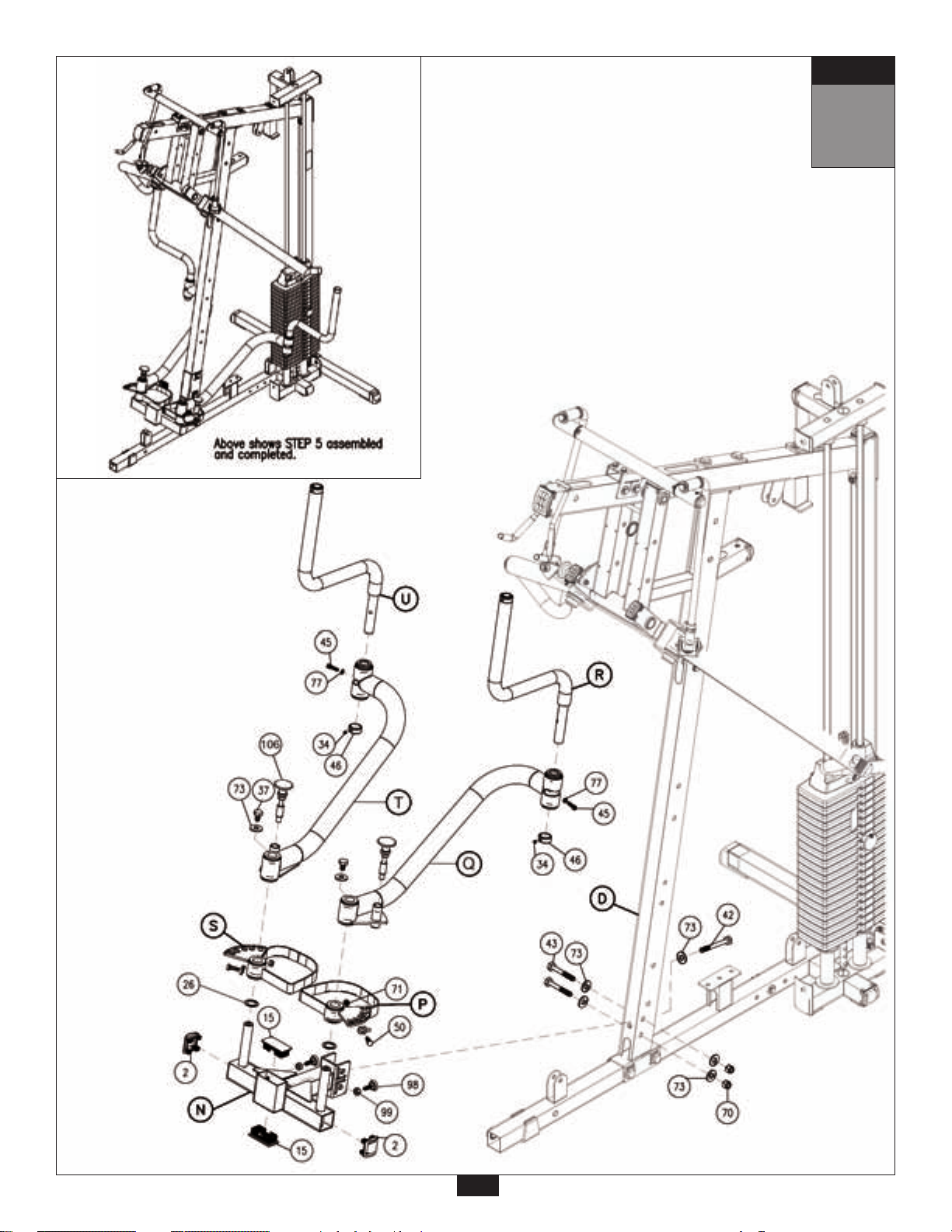

STEP

5

Be careful to assemble all components

in the sequence they are presented.

A. Attach Pec Dec Frame (N) to Angled Support Frame (D) in the bottom two holes as shown using:

One 42 (1/2” x 3 3/4” hex head bolt)*

Two 43 (1/2” x 3 1/4” hex head bolt)

Five 73 (1/2” washer)

Two 70 (1/2” nylon lock nut)

Attach two End Caps (15) to the top and bottom of the Pec Dec Frame (N) as shown.

*Note:

Hex Head Bolt (42) goes into an inter

Attach two Convex End Caps (2) to the sides of the Pec Dec Frame (N) as shown.

nally threaded nut inside Pec Dec Frame (N).

B. Slide Oilite W

side of the Pec Dec Frame (N) as shown, Attach using:

One 37 (1/2” x 3/4” hex head bolt)

One 73 (1/2” washer)

C. Attach Left Pec Dec Handle (R)* to the Left Pec Dec Arm (Q) using:

One 45 (5/16” x 3/4” flat allen head)

One 77 (5/16” spring lock washer)

Slide Chrome Collar (46) onto the bottom of the Left Pec Dec Handle (R) as shown, and tighten

Allen Scr

*Note:

Left Pec Dec Handle (R) should bend out, away from the the gym.

D. Slide Oilite Washer (26), Right Pec Dec Cam (S) and then the Right Pec Dec Ar

Right side of the Pec Dec Frame (N) as shown, attach using:

One 37 (1/2” x 3/4” hex head bolt)

One 73 (1/2” washer)

E. Attach Right Pec Dec Handle (U)* to the Right Pec Dec Arm (T) using:

One 45 (5/16” x 3/4” flat allen head)

One 77 (5/16” spring lock washer)

Slide Chrome Collar (46) onto the bottom of the Right Pec Dec Handle (U) as shown, and tighten

Allen Scr

*Note:

Right Pec Dec Handle (U) should bend out, away from the gym.

Note:

You should now wr

asher (26), Left Pec Dec Cam (P) and then the Left Pec Dec Arm (Q) onto the left

ew (34).

ew (34).

ench tighten all bolts and nuts in this step.

m (T) onto the

mm

Inch

18

Page 19

STEP

5

19

Page 20

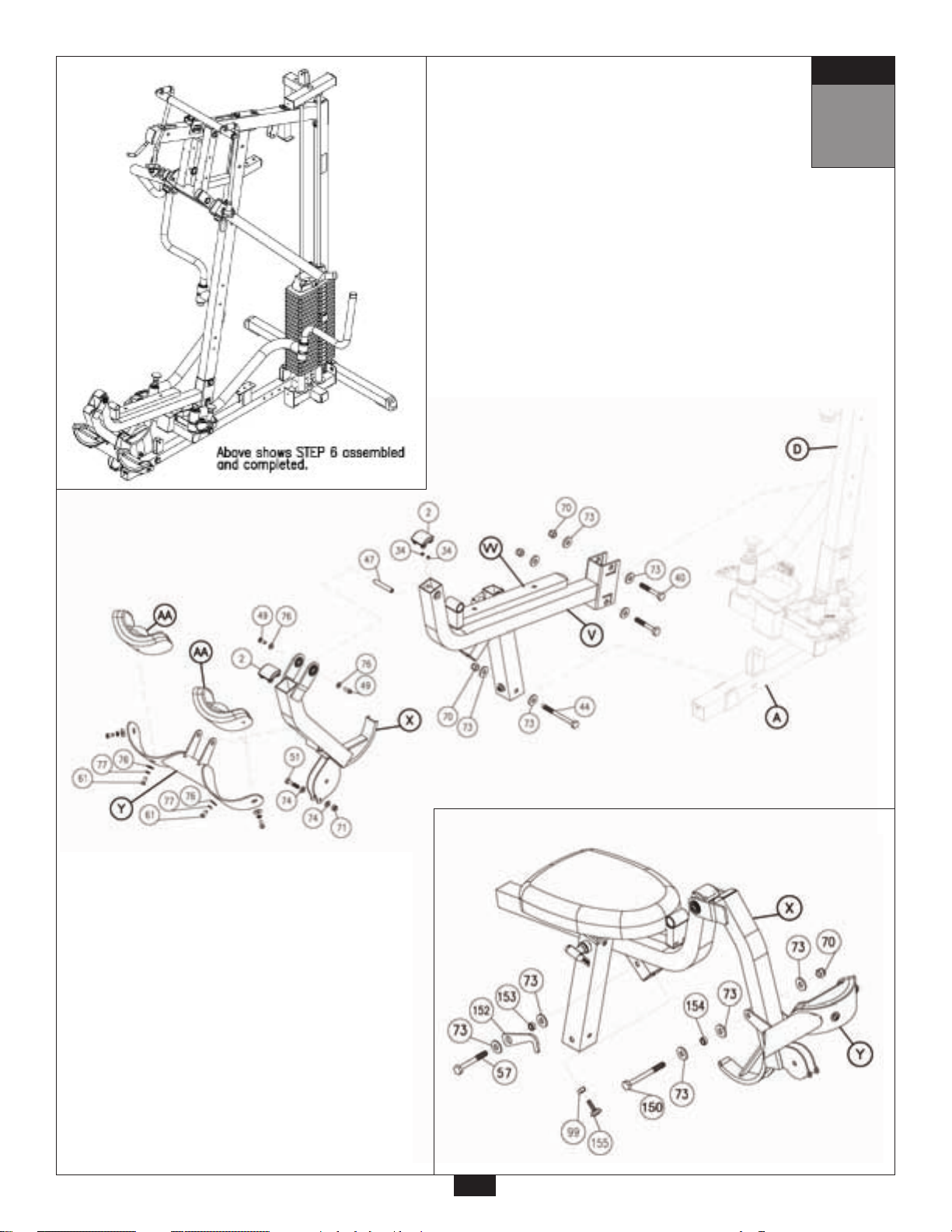

STEP

6

Be careful to assemble all components

in the sequence they are presented.

NOTE:

LEG EXTENSION FRAME (V) AND THE SEAT PAD FRAME (W) ARE PRE-ASSEMBLED AS

ONE PIECE.

A. Attach Leg Extension Frame (V) to Angled Support Frame (D) using:

Two 40 (1/2” x 3 1/4” hex head bolt)

Four 73 (1/2” washer)

T

wo 70 (1/2” nylon lock nut)

B. Attach the bottom of Leg Extension Frame (V) to Main Base Frame (A) using:

One 44 (1/2” x 5 1/2” hex head bolt)

T

wo 73 (1/2” washer)

One 70 (1/2” nylon lock nut)

C. Attach Leg Extention Arm (X) to Leg Extension Frame (V) with pr

using:

Two 49 (5/16” x 1/2” round allen head bolt)

T

wo 76 (5/16” washer)

D. Tighten the two Allen Screws (34) to lock down Shaft (47) in Leg Extension Frame (V).

Attach two Convex End Caps (2) one to the top of Leg Extension Frame (V) and one to the top of

the Leg Extension Ar

E. Attach Lock Down Hook (152) to Leg Extension Frame (V) as shown in the REVERSE SIDE

DRAWING using:

One 57 (3/8” x 2 1/2” hex head bolt)

T

wo 73 (1/2” washer)

One 153 (5/16” wide spacer)

F. Attach Leg Extension Pad Holder (Y) and 1/4” Wide Spacer (154) to Leg Extension Ar

One 150 (1/2” x 4 1/2” hex head bolt)

Thr

ee 73 (1/2” washer)

One 70 (1/2” nylon lock nut)

G. Attach Leg Pads (AA) to Leg Extension Pad Holder (Y) using:

Four 61 (5/16” x 3/4” round allen head bolt)*

Four 77 (5/16” spring lock washer)

Four 76 (5/16” washer)

*

Do NOT over-tighten these bolts. Tighten these bolts until spring lock washer is flat.

Over - tightening these bolts will cause T - nuts in pads to strip out.

m (X) as shown.

e-installed Shaft (47) as shown

m (X) using:

Note:

You should now wr

Do NOT re-tighten any of the pad bolts.

ench tighten all bolts and nuts in this step.

mm

Inch

20

Page 21

STEP

6

REVERSE SIDE DRAWING

21

Page 22

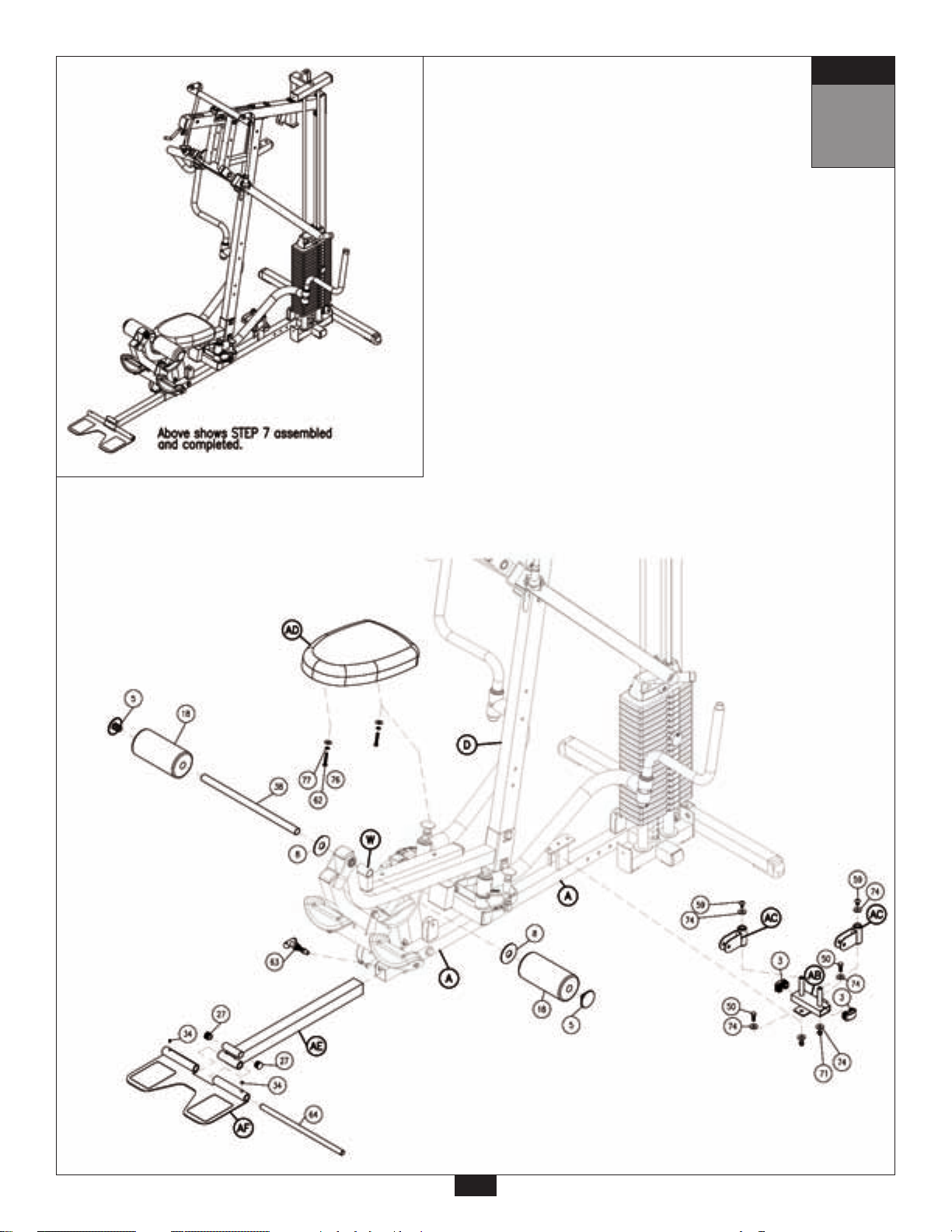

STEP

7

Be careful to assemble all components

in the sequence they are presented.

A. Attach Pulley Platform (AB) to Main Base Frame (A) as shown using:

Two 50 (3/8” x 1” hex head bolt)

Four 74 (3/8” washer)

Two 71 (3/8” nylon lock nut)

B. Attach two Pulley Swivels (AC) to Pulley Platform (AB) as shown using:

T

wo 59 (3/8”x 5/8” round allen head bolt)

T

wo 74 (3/8” washer)

Insert two Curved End Caps (3) into Pulley Platform (AB) as shown.

C.

*D

Over - tightening these bolts will cause T - nuts in pads to strip out.

D. Slide 4”x 8” Foam Rollers (18) onto Foam Roller Bar (38) and attach to Seat Pad Frame (V). Hold

E. Slide Foot Brace Adjuster (AE) into Main Base Frame (A) and hold in place with Pop Pin (63).

F.

Note:

You should now wr

Do NOT re-tighten any of the pad bolts.

Insert two Curved End Caps (3) into Seat Pad Frame (W) as shown.

Attach Seat Pad (AD) to Seat Pad Frame (W) using:

T

wo 62 (5/16” x 1 3/4” hex head bolt)*

T

wo 77 (5/16” spring lock washer)

Two 76 (5/16” washer)

o NOT over-tighten these bolts. Tighten these bolts untill spring lock washer is flat.

Foam Rollers (18) in place with 3” Plastic W

on the outside as shown.

Attach Foot Brace (AF) to Foot Brace Adjuster (AE) with Shaft (64).

Tighten Allen Screws (34).

Insert Round End Caps (27) to Foot Brace Adjuster (AE), and attach Grip Tape (16) to

Foot Brace (AF) as shown.

ench tighten all bolts and nuts in this step.

asher (8) on the inside and Plastic Roller End Cap (5)

mm

Inch

22

Page 23

STEP

7

23

Page 24

STEP

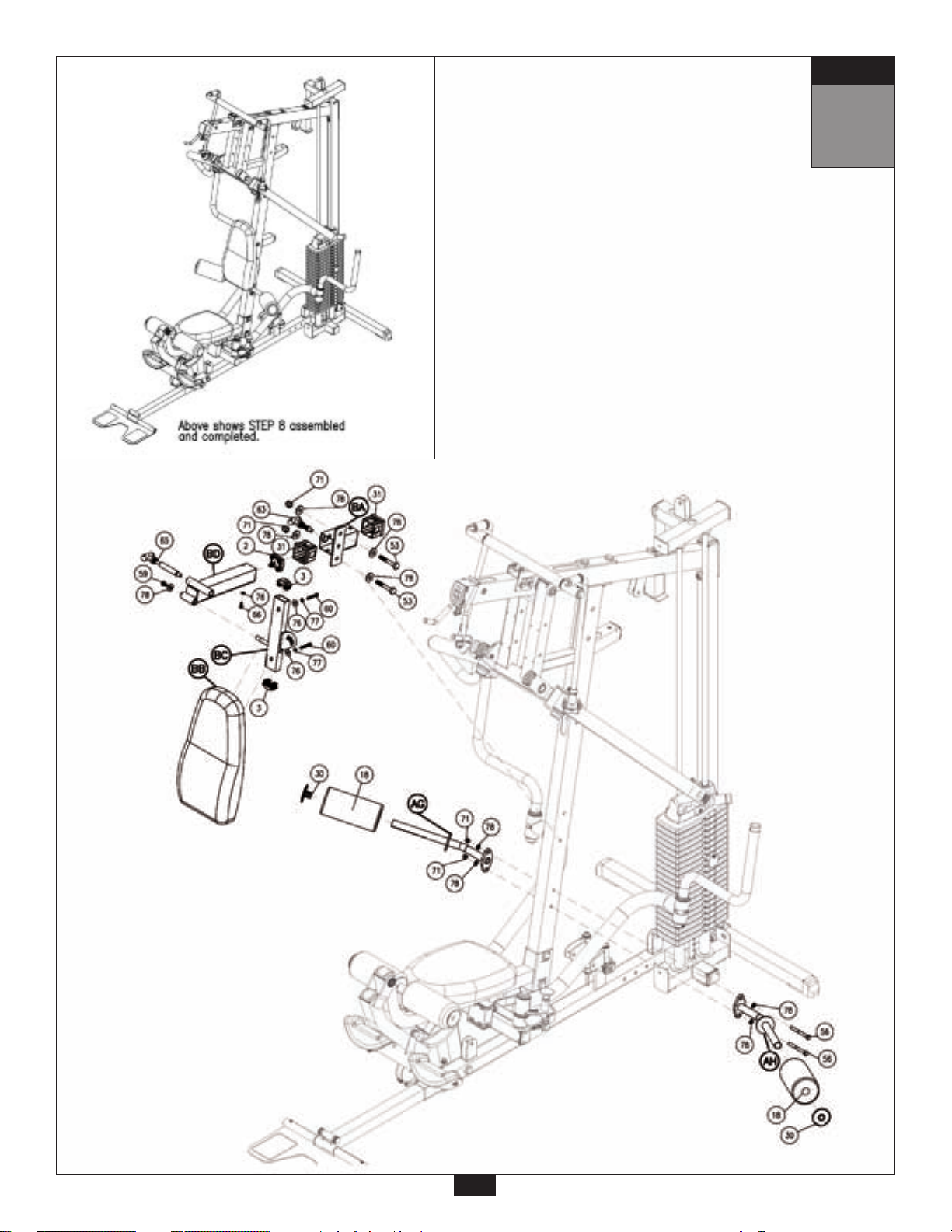

8

Be careful to assemble all components

in the sequence they are presented.

A. Attach Right Leg Hold Down (AG) and Left Leg Hold Down (AH) to the Angled Support Frame (D)

using:

Two 56 (3/8” x 3 1/4” hex head bolt)

Four 78 (3/8” washer)

Two 71 (3/8” nylon lock nut)

Slide two 4”x 8” Foam Rollers (18) onto the two Leg Hold Downs (AG) and (AH). Hold in place

with two

B. Insert two Nylon Bushings (31) into Back Pad Holder (BA).

Attach Back Pad Holder (BA) to Angled Suppor

Two 53 (3/8” x 3” hex head bolt)

Four 78 (3/8” washer)

T

wo 71 (3/8” nylon lock nut)

Plastic Roller End Caps (30).

t Frame (D) using:

C. Slide two Convex End Caps (3) into the top and bottom of Back Pad Frame (BC).

Attach Back Pad (BB) to Back Pad Frame (BC) using:

Two 60 (5/16” x 1 1/2” hex head bolt)*

T

wo 77 (5/16” spring lock washer)

Two 76 (5/16” washer)

*D

o NOT over-tighten these bolts. Tighten these bolts until spring lock washer is flat.

Over - tightening these bolts will cause T - nuts in pads to strip out.

D. Attach Back Pad Frame (BC) to Back Pad Adjuster (BD) with Pop Pin (65) and using:

One 59 (3/8” x 5/8” allen head bolt)

One 78 (3/8” washer)

E. Slide Convex End Cap (2) into the Back Pad Adjuster (BD).

Slide Back Pad Adjuster (BD) into Back Pad Holder (BA) and hold in place with Pop Pin (63) and

using:

One 66 (5/16” x 1/2” flat allen head bolt)

One 76 (5/16” washer)

NOTE:

Y

ou should now make sure all bolts and nuts are

Do NOT re-tighten any of the pad bolts.

Also, leave all pulley bolts finger-tight untill after STEP 15.

ench tight.

wr

mm

Inch

24

Page 25

STEP

8

25

Page 26

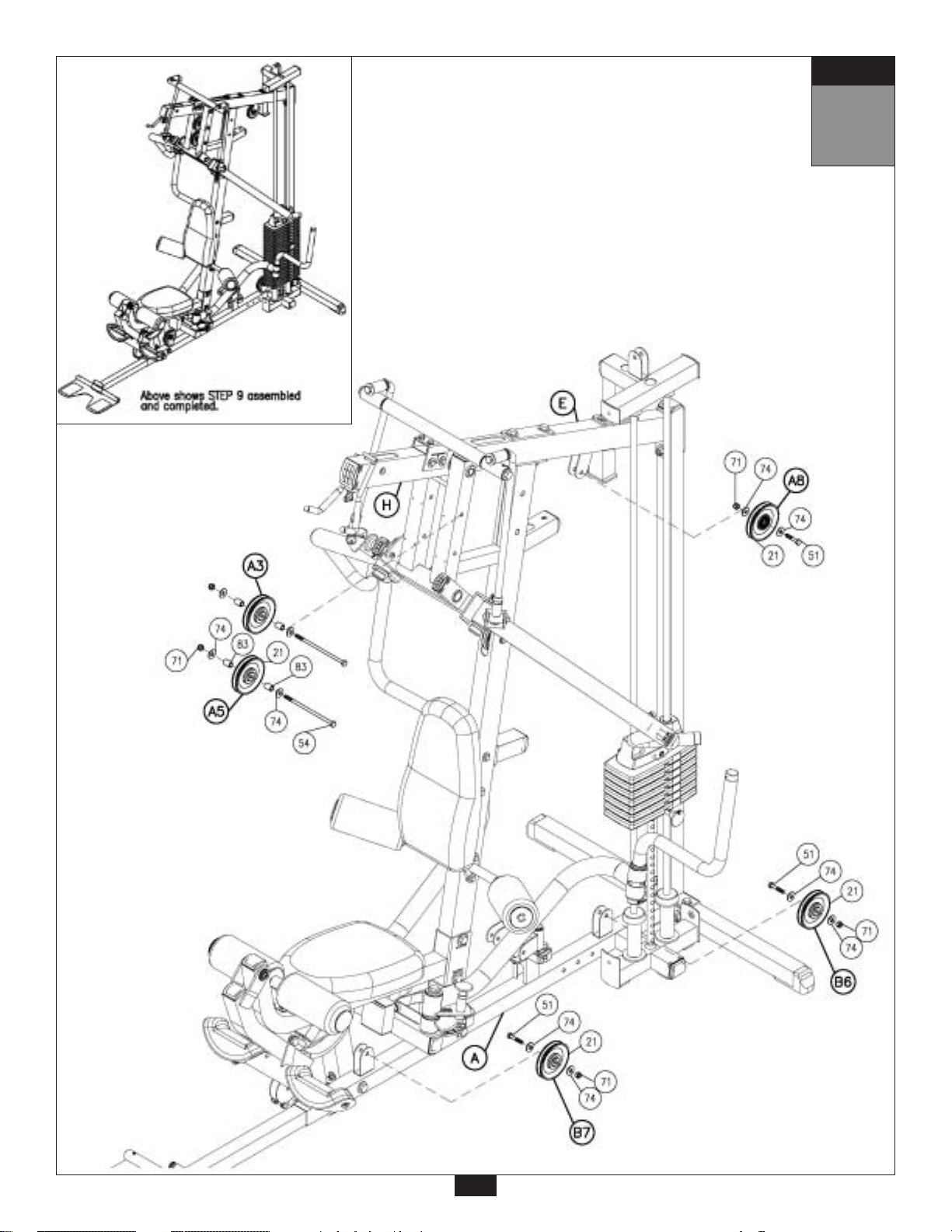

STEP

9

Be careful to assemble all components

in the sequence they are presented.

NOTE:

Leave all pulley bolts hand tight until step 15 is completed.

A. Install Pulley (A3) and Pulley (A5) into Seated Press Arm Support (H) using for each pulley:

One 54 (3/8” x 7 1/4” hex head bolt)

Two 74 (3/8” washer)

Two 83 (steel bushing)

One 71 (3/8” nylon lock nut)

B. Install Pulley (A8) into the pulley flange on T

One 51 (3/8” x 1 3/4” hex head bolt)

Two 74 (3/8” washer)

One 71 (3/8” nylon lock nut)

C. Install Pulley (B6) onto Main Base Frame (A) as shown using:

One 51 (3/8” x 1 3/4” hex head bolt)

T

wo 74 (3/8” washer)

One 71 (3/8” nylon lock nut)

D. Install Pulley (B7) onto Main Base Frame (A) as shown using:

One 51 (3/8” x 1 3/4” hex head bolt)

T

wo 74 (3/8” washer)

One 71 (3/8” nylon lock nut)

op Frame (E) as shown using:

mm

Inch

26

Page 27

STEP

9

27

Page 28

STEP

10

Be careful to assemble all components

in the sequence they are presented.

High Pulley Cable (85)

Ball Stop End

5110 mm

Note:

Leave all pulley bolts hand tight until step 15 is completed.

A. Begin at the high pulley station. Route the metal ball end of the High Pulley Cable (85) up

through the opening where Pulley (A1) will be installed. Route the metal ball end under the

Bi-Angular Bars (J) and then down

B. Install Pulley (A1) under Cable (85) and into Top Frame (E) as shown using:

One 52 (3/8” x 2 3/4” hex head bolt)

T

wo 84 (nylon bushing)

One 71 (3/8” nylon lock nut)

C. Install Pulley (A2) under Cable (85) and into Top Frame (E) as shown using:

One 52 (3/8” x 2 3/4” hex head bolt)

T

wo 84 (nylon bushing)

One 71 (3/8” nylon lock nut)

D. Route Cable (85) over

Route Cable (85) around Pulley (A4) and install Pulley (A4) into Angled Support Frame (D) using:

One 52 (3/8” x 2 3/4” hex head bolt)

Two 84 (nylon bushing)

One 71 (3/8” nylon lock nut)

the top and around pre-installed Pulley (A3) as shown.

through the next opening where Pulley (A2) will be installed.

16’ 9”

Metal Ball End

and

E. Route Cable (85) between Pulley (A3) and pre-installed Pulley (A5).

Route Cable (85) ar

ound Pulley (A5) and back through Angled Support Frame (D).

mm

Inch

28

Page 29

Diagram 1

Cable Installation

Start here at high pulley

station by inserting the

metal ball end here.

STEP

Lat Pulldown

Cable

10

Diagram 2

Pulley Installation

29

Page 30

STEP

11

Be careful to assemble all components

in the sequence they are presented.

High Pulley Cable (85)

Ball Stop End

5110 mm 16’ 9”

Note:

Leave all pulley bolts hand tight until step 15 is completed.

A. Install Pulley (A6) under Cable (85) and into Angled Support Frame (D) using:

One 52 (3/8” x 2 3/4” hex head bolt)

Two 84 (nylon bushing)

One 71 (3/8” nylon lock nut)

Route Cable (85) down

B. Route Cable (85) through the top of the Double Pulley Holder (CA). Install Pulley (A7) using:

One 51 (3/8” x 1 3/4” hex head bolt)

T

wo 74 (3/8” washer)

One 71 (3/8” nylon lock nut)

through the small arm sticking out of the Angled Support Frame (D).

Metal Ball End

C. Route Cable (85) up

Pulley Holder (CB).

Route Cable (85) through the top of the 45 Degree Double Pulley Holder (CB). Install Pulley (A9) using:

One 51 (3/8” x 1 3/4” hex head bolt)

T

wo 74 (3/8” washer)

One 71 (3/8” nylon lock nut)

C. Route Cable (85) up

One 51 (3/8” x 1 3/4” hex head bolt)

Two 74 (3/8” washer)

One 71 (3/8” nylon lock nut)

Route Cable (85) up

stack.

D. The Metal Ball End of Cable (85) should be hanging just above the weight stack. Remove Allen Bolt (102)

from Selector Rod Top Bolt (103), slide Metal Ball End of Cable (85) through Selector Rod Top Bolt (103).

Attach Cable End Shaft (100) and securely tighten Allen Bolt (101). Pull Cable (85) tight, so Cable End

Shaft (100) fits securely inside Selector Rod Top Bolt (103). Reinstall Allen Bolt (102) in Selector Rod Top

Bolt (103) and tighten Nylon Lock Nut (71) to hold in place.

NOTE:

Make sur

inch. Make sure Spring Lock Washer (105) is in place and wrench tighten Jam Nut (104).

e the Selector Rod Top Bolt (103) is threaded inside Selector Rod (19) at least one half

to Top Frame (E), over pre-installed Pulley (A8), and down to 45 Degree Double

through the Top Weight Stack Frame (G). Install Pulley (A10) using:

over Pulley (A10) and down through Top Weight Stack Frame (G) and toward weight

mm

Inch

30

Page 31

Diagram 1

Cable Installation

STEP

Lat Pulldown

Cable

11

Diagram 2

Pulley Installation

!

WARNING

Selector Rod Top Bolt (103) must be threaded a

minumum of 1/2” into the Selector Rod (19), and

Jam Nut (104) tightened securely against spring

lock washer (105) to ensure proper connection.

Check the Jam Nut (104) once a week to make

sure it is tight.

!

31

Page 32

STEP

12

Be careful to assemble all components

in the sequence they are presented.

Low Pulley Cable (86)

Small Ball Stop End

5080 mm 16’ 8”

Note:

Leave all pulley bolts hand tight until step 15 is completed.

A. Insert either end of Low Pulley Cable (86) into the opening in Angled Support Frame (D),

above Back Pad (BB), and pull entir

B. Install Pulley (B1), under

One 57 (3/8” x 2 1/2” hex head bolt)

Two 84 (nylon bushing)

One 71 (3/8” nylon lock nut)

C. Route Cable (86) through the top of the 90 Degr

installing Pulley (B2) using:

One 51 (3/8” x 1 3/4” hex head bolt)

T

wo 74 (3/8” washer)

One 71 (3/8” nylon lock nut)

Cable (86) and into Angled Support Frame (D) as shown using:

e length of Cable (86) through.

ee Pulley Holder (CC) and hold in place by

Small Ball Stop End

D. Route Cable (86) up

One 51 (3/8” x 1 3/4” hex head bolt)

Two 74 (3/8” washer)

One 71 (3/8” nylon lock nut)

E. Route Cable (86) down

One 51 (3/8” x 1 3/4” hex head bolt)

Two 74 (3/8” washer)

One 71 (3/8” nylon lock nut)

mm

Inch

and through the bottom of Double Pulley Holder (CA). Install Pulley (B3) using:

and through the Single Pulley Holder (CD). Install Pulley (B4) using:

32

Page 33

Diagram 1

Cable Installation

Start here at the Ab-Crunch

station by inserting either

end here.

STEP

12

Low Pulley Cable

Diagram 2

Pulley Installation

33

Page 34

STEP

13

Be careful to assemble all components

in the sequence they are presented.

Low Pulley Cable (86)

Small Ball Stop End

Small Ball Stop End

5080 mm

16’ 8”

Short Cable (87)

Stamped Eye End

757 mm

NOTE:

Leave all pulley bolts hand tight until step 15

A. Route Cable (86) up

Pulley (B5) using:

One 51 (3/8” x 1 3/4” hex head bolt)

Two 74 (3/8” washer)

One 71 (3/8” nylon lock nut)

B. Route Cable (86) down

Route Cable (86) forward and through the opening in Angled Support Frame (D).

Route Cable (86) under

Insert Cable (86) through Leg Extension Arm (X) and install Pulley (B8) using:

One 51 (3/8” x 1 3/4” hex head bolt)

Two 74 (3/8” washer)

One 71 (3/8” nylon lock nut)

E. Attach Short Cable (87) to Main Base Frame (A) as shown using:

One 53 (3/8” x 3” hex head bolt)

T

wo 74 (3/8” washer)

One 71 (3/8” nylon lock nut)

and through the bottom of 45 Degree Double Pulley Holder (CB). Install

, around pre-installed Pulley (B6). Remove and re-install pulley as needed.

pre-installed Pulley (B7). Remove and re-install pulley as needed.

Stamped Eye End

2’ 6”

F. Attach the other end of Cable (87) to the hook on the bottom of Pulley Holder (CD) as shown.

mm

Inch

34

Page 35

Diagram 1

Cable Installation

STEP

13

Low Pulley

Cable

Short Cable

Diagram 2

Pulley Installation

Short Cable 87

Diagram

35

Page 36

STEP

14

Be careful to assemble all components

in the sequence they are presented.

Pec Dec Cable (88)

Stamped Eye End

2055 mm 6’ 9”

NOTE:

Leave all pulley bolts hand tight until step 15

A. Bolt Pec Dec Cable (88) to Left Pec Dec Cam (P) as shown in diagram 1 using:

One 50 (3/8” x 1” hex head bolt)

One 71 (3/8” nylon lock nut)

B. See diagram 1. Route Cable (88) through Pulley Swivel (AC) on the left side, hold cable in place

with Pulley (C1) using:

One 51 (3/8” x 1 3/4” hex head bolt)

T

wo 74 (3/8” washer)

One 71 (3/8” nylon lock nut)

C. See diagram 1. Route Cable (88) up and into 90 Degree Double Pulley Holder (CC) and install

Pulley (C2) using:

One 51 (3/8” x 1 3/4” hex head bolt)

T

wo 74 (3/8” washer)

One 71 (3/8” nylon lock nut)

B. Insert Cable (88) thr

Pulley (C3) as shown in diagram 2 using:

One 51 (3/8” x 1 3/4” hex head bolt)

T

wo 74 (3/8” washer)

One 71 (3/8” nylon lock nut)

ough Pulley Swivel (AC) on the right side, hold cable in place by installing

Stamped Eye End

C. Attach Cable (88) to Right Pec Dec Cam (S) as shown in diagram 1 using:

One 50 (3/8” x 1” hex head bolt)

One 71 (3/8” nylon lock nut)

mm

Inch

36

Page 37

Diagram 1

Cable Installation

Pec Dec

Cable

Diagram 2

Cable Installation

STEP

14

Pec Dec Cable

Start routing cable here

by bolting cable to Left

Pec Dec Cam (P).

Diagram 3

Pulley Installation

37

Page 38

STEP

15

Be careful to assemble all components

in the sequence they are presented.

NOW IS THE TIME TO MAKE ALL NECESSARY

CABLE ADJUSTMENTS

After cable installation is complete you must check all cables for proper tension. Obvious signs that

cable tension problems exist include:

c Top Plate (17) does not rest directly on the top Weight Stack Plate (38).

c The holes in the Selector Bar (19) do not line up with holes in the Weight Stack Plates (38).

c Cable(s) are sloppy and there is no resistance from the weight stack for the first few

inches of the exer

cise.

There are FIVE ar

A. Selector Rod Top Bolt (103).*

B. TWO adjustments in Double Pulley Holder (CA).

C. TWO Rubber Stops (98) and (155).

*SEE NOTE 1 ON PAGE 39

If there is to much tension, and the Top Plate (17) is not resting directly on the top weight stack plate:

1st. -Move pulley (A7) up, or Pulley (B3) down in the Double Pulley Holder (CA).

2nd. Turn and tighten one of the Rubber Stops (98) and (155).

If there is to much play or excessive slack:

1st. -T

2nd. Move Pulley (A7) down, or Pulley (B3) up in the Double Pulley Holder (CA).

3rd. -Screw the Selector Rod Top Bolt (103) farther into the Selector Rod (19).

NOTE:

Cables should be inspected daily and adjusted periodically to ensure safe and

smooth operation.

NOTE:

After cable adjustment is complete, go back and tighten all pulley bolts.

eas for cable adjustment on the G6B:

urn and loosen the Rubber Stops (98) and (155).

38

Page 39

STEP

15

Turn and loosen Rubber Stop (98)

to take up space and tighten cable.

Loosen

Turn and loosen Rubber Stop (105)

to take up space and tighten cable.

!

WARNING

Selector Rod Top Bolt (103) must be

threaded a minimum of 1/2” into the

Loosen

Selector Rod (19), and Jam Nut (104)

tightened securely against spring lock

washer (105) to ensure proper connection.

39

NOTE 1

Check Jam Nut (104)

weekly to be sure it is

tight and locked onto

the Selector Rod (19).

!

Page 40

STEP

16

Be careful to assemble all components

in the sequence they are presented.

SEE NOTE 1 ON PAGE 41:

A. Apply weight stack numbers to weight stack Top Plate (17) and each Weight Stack Plate (38)

as shown.

SEE NOTE 2 ON PAGE 41:

B. Weight Stack Shroud (DA) is pre-assembled with Shroud Insert (DB).

Attach W

Bolt onto Main Base Frame (A) at the bottom and Top W

Two 89 (3/8” x 5/8” round allen head)

T

wo 74 (3/8” washer)

eight Stack Shroud (DA) to the side of the weight stack as shown.

eight Stack Frame (G) using:

C. Attach Back Weight Stack Shr

Frame (A) at the bottom and to the T

Two 89 (3/8” x 5/8” r

Two 74 (3/8” washer)

D. Attach Press Ar

Four 90 (1/8” x 3/8” round allen head)

E. Connect the Water Bottle Bracket (91) to the Weight Stack Shroud (DA) using:

Two 92 (1/8” x 3/8” screw)

F. Slide the Water Bottle Holder (93) onto the Water Bottle Bracket (91) as shown.

m Shroud (DD) to the Seated Press Arm Support (H) using:

oud (DC), to the back side of the weight stack, onto the Main Base

op Weight Stack Frame (G) as shown using:

ound allen head)

mm

Inch

40

Page 41

NOTE 2

This is the top view of the two Weight Stack Shrouds.

Note the shape of each shroud for proper placement.

2” flat side

3/4” flat side

STEP

16

#1

41

NOTE 1

#2

Apply weight stack numbers to the Weight

Stack Plates (38). Start at the Top Plate (17)

with the number 1, and the first plate

should be number 2. The following Weight

Stack Plates (38) should be numbered in

sequential order down through the stack.

Page 42

Adjustments

Congratulations! You are done. After assembly, you should check all functions to ensure correct

operation. If you experience problems, first recheck the assembly instructions to locate any possible

errors made during assembly. If you are unable to correct the problem, call the dealer from whom you

purchased the machine or call 1-800-833-1227 for the dealer nearest you.

Note: If any bolts seem to loosen periodically, use Loctite 242 for a long-term cure.

This gym is capable of a variety of different exercises, as well as, smooth and user-friendly adjustment

features. The following pages of adjustments will help you to familiarize yourself with your new gym. We

hope you are completely satisfied with this product and wish you many years of enjoyment.

1. SEATED PRESS ARMS ADJUSTMENT

A. Grasp the Right Press Arm (M) with one hand.

B. Pull the Flat Head Pop Pin (94) with your other hand to release the Press Arm Holder (K).

C. Adjust the Press Arm Holder (K) to the desired position (depending on the exercise

you are performing).

D. Release the Flat Head Pop Pin, and make sure it is fully

selector hole.

engaged into the

2. BACK PAD (BB) ADJUSTMENT

A. Grasp Back Pad (BB).

B. Turn the T-Shaped Pop Pin (63) in Back Pad Holder (BA) counter clockwise to unlock it,

and then pull the Pop Pin to release the Back Pad Adjuster (BD). Adjust the Back

Pad to the desired position.

C. Release the T-Shaped Pop Pin (63) and make sure it is fully

hole in the Back Pad Adjuster (BD). Turn T-Shaped Pop Pin clockwise to lock it in place.

D. For certain exercises you may wish to change the angle of the Back Pad.

Pull the T-Shaped Pop Pin (65) on the Back Pad Adjuster (BD), this will allow you

to change to the desired angle.

E. Release the T-Shaped Pop Pin (65) and make sure it is fully

engaged into the selector

engaged into the selector hole.

42

Page 43

WARNING

!

Pay special attention to the plunger on this Pop Pin (65).

Always be sure that the plunger is fully engaged into the hole

you select. Also, be sure that the spring in the Pop Pin (65)

operates freely. Failure to do so may result in serious injury.

!

1.

!

Pay special attention to the plunger on both Pop Pins (63) and (65).

Always be sure that the plunger is fully engaged into the hole you

select. Also, be sure that the spring in both Pop Pins (63) and (65)

operates freely. Failure to do so may result in serious injury.

WARNING

!

2.

43

Page 44

Adjustments

3. SEAT PAD (AD) ADJUSTMENT

A. Grasp the Seat Pad (AD).

B. Turn the T-Shaped Pop Pin (63) in Leg Extension Frame (W) counter clockwise to unlock

it, and then pull the Pop Pin to release the Seat Pad Frame (W).

C. Adjust the Seat Pad (AD) to the desired position.

D. Release the T-Shaped Pop Pin and make sure it is fully engaged into the selector

hole. Turn T-Shaped Pop Pin (63) clockwise to lock it in place.

4. FOOT BRACE (AE) ADJUSTMENT

A. Grasp the Foot Brace Adjuster (AE).

B. Turn the T-Shaped Pop Pin (63) in Main Base Frame (A) counter clockwise to unlock it,

then pull to release the Foot Brace Adjuster (AE).

C. Adjust to the desired position.

D. Release the T-Shaped Pop Pin and make sure that it is fully

hole in the Foot Brace Adjuster (AE). Turn clockwise to lock in place.

engaged into the selector

5. PEC DEC ARMS (Q),(T) ADJUSTMENT

A. Grasp Pec Dec Arm (Q) or (T).

B. Pull the Flat Pop Pin (106) to release the Pec Dec Arm (Q) or (T).

C. Adjust the Pec Dec Arm to the desired position.

D. Release the Ball Head Pop Pin (106) and make sure that it is fully

selector hole.

engaged into the

44

Page 45

!

Pay special attention to the plunger on this Pop Pin (63).

Always be sure that the plunger is fully engaged into the hole

you select. Also, be sure that the spring in the Pop Pin (63)

operates freely. Failure to do so may result in serious injury.

WARNING

!

3.

5.

4.

!

Pay special attention to the plunger on this Pop Pin (104). Always be

sure that the plunger is fully engaged into the hole you select. Also,

be sure that the spring in the Pop Pin (104) operates freely. Failure

to do so may result in serious injury.

WARNING

!

Pay special attention to the plunger on this Pop Pin (63).

Always be sure that the plunger is fully engaged into the hole

you select. Also, be sure that the spring in the Pop Pin (63)

operates freely. Failure to do so may result in serious injury.

45

!

WARNING

!

Page 46

Warning, Safety & Maintenance

Be sure that all users carefully read and understand all

warning, safety and maintenance labels on the machine

before each use. Failure to do so may result in serious injury.

It is imperative that you retain this Owner’s Manual and be

sure all warning labels are legible and intact. Replacement

Owner’s Manuals and labels are available from your local

Body-Solid dealer. If you have any questions about the

operation, set up or maintenance of this machine please call

our customer service department at 1 (800) 556-3113.

#DWRULE-4

Warning Label for Rules

#DWSM-5

Warning Label for Maintenance

46

Page 47

Warning

Safety and Maintenance of Cables

Although Body-Solid provides the highest quality of materials and

workmanship in its products, the fact remains that component parts eventually wear

out over time and with use. This is particularly true with reference to pliable

moving parts such as cables. In spite of any expressed and/or implied warranties,

intervening factors such as improper use, unusually heavy use, improper installation,

improper alignment, poor maintenance, etc. serve to drastically reduce the usable

life and safety of cables.

Be advised that dangerous conditions can arise even during warranty

periods and that any expressed and/or implied warranties Do Not Negate the

owner’s responsibility to thoroughly, carefully and daily inspect all cables on this

machine.

Serious injury can occur if you are struck by falling weights or moving parts.

The risk that you assume by using this type of equipment can be reduced by

following a few simple steps:

Cable inspection should be performed daily

nylon coating on all cables and the area near the fittings at each end of each cable.

Replace any damaged or worn cables immediately. Do not allow the machine to

be used until damaged or worn cables are replaced.

Important: Cables are wear items. It is your responsibility to prevent

unexpected breakage. The actual wire strands, the fittings and the nylon coating

itself must all be scrutinized. Using or allowing a machine to be used with a suspect

cable can result in serious injury.

The nylon coating on a cable is essential for cable life and safety. V

inspect all cables and pulleys. Look at the cables as they travel around the cams

and pulleys. Acable that is wearing may exhibit a “ballooned” or broken coating in

the area that passes over the pulley. Damage to the coating is an early warning

signal. Acable should be replaced if the nylon coating is missing, is damaged in

anyway, has pulled or shrunk from the fittings at the end of the cables, or if it is

discolored. Discoloration of the cable coating is an early indication of internal

problems such as wear or fraying.

Annual cable replacement (semiannual in multi-user settings) is strongly

recommended as an additional precaution. The rate at which cables wear depends

on many factors including: number of users, number of repetitions, weight setting,

misuse, abuse, etc. Because of this, periodic cable replacement is not a sufficient

safeguard against unexpected breakage.

Nothing short of a thorough, careful, daily inspection constitutes an

adequate safety program.

. Inspect all cables, the

isually

47

Page 48

Warning, Safety & Maintenance

Precision craftsmanship assures Body-Solid’s ability to

consistently deliver products of the highest standards. Our

products have been carefully designed to ensure safe, efficient

long term operation.

However, it must be realized that safe use of this equipment

requires that owners carefully read and follow the Body-Solid

use recommendations, warnings, and maintenance guidelines

in this Owners Manual.

Routine inspection and maintenance is of critical importance to

ensure the maximum safety and performance of the G6B.

Body-Solid uses the highest quality materials available, but wear

is inevitable. Therefore, you must carefully inspect your

equipment as outlined in the Maintenance Schedule on the next

page.

Be advised that dangerous conditions can arise even during a

warranty period. A warranty does not negate the owner’s

responsibility to thoroughly, carefully and daily inspect the

machine.

Including maintaning the equipment the owner’s responsibility is

also to:

l Be sure to always provide adequate

supervision to all end-users.

l Be sure to instruct all end-users of proper

usage.

l Be sure all supervisors and personal trainers

who instruct end-users on equipment use ar

properly trained and know the function and

importance of ever

Also, be sure these trainers provide proper

instruction to end-users on the fundamentals

of strength training.

y adjustment and setting.

e

CABLES:

UPHOLSTERY:

NUTS/BOLTS/F

GUIDE RODS:

l While the machine is not in use. Carefully run your

fingers along the cable to feel for thinning or

bulging ar

the first sign of damage or wear. Do not use

equipment until damaged cable has been

replaced.

isually inspect the cables for fraying, cracking,

l V

peeling or discoloration.

l Check slack in cables and re-adjust cable tension

if needed. See pages 38-39.

l Check that the jam nut on the selector rod top

bolt is tight.

l Wipe down after every workout.

l Periodically take the time to use a mild soap or a

mild vinyl upholster

abrasive cleaner not intended for use on vinyl.

l Keep sharp or pointed objects out of your

pockets and clear of all upholster

l Periodically inspect all nuts and bolts. Tighten if

needed. If bolts seem to loosen periodically, use

Loctite 242 for a long-term cure.

l Go thr

to ensure that all hardware is pr

l Wipe clean with a dust free rag. Lubricate with a

Silicon or Teflon based lubricant.

eas. Replace cables immediately at

y cleaner. Avoid using any

y.

ASTENERS:

ough a re-tightening sequence periodically

operly tensioned.

ADJUSTMENTS / LOCKING PINS / TIGHTENING

KNOBS:

ANTI-SKID SURFACES:

WARNING INSTRUCTION LABELS:

l Check all pieces for signs of visible wear or

damage.

l Check springs in Snap Links and Pop Pins for

proper tension and alignment.

l If the spring sticks or has lost its rigidity, replace

it immediatly

l Replace if they appear worn or become slipper

l Inspect and familiarize yourself with all safety

warnings and other user information on decals.

.

y.

48

Page 49

MAINTENANCE

SCHEDULE

CABLES: CHECK TENSION, END FITTINGS, AND

COATING.

CHECK THAT JAM NUTON THE SELECTOR ROD TOP

BOLT IS TIGHT.

UPHOLSTERY: WIPE DOWN AND DRY

CLEAN AND CONDITION.

FRAME: WIPE DOWN AND DRY

POLISH/WAX

CHROME: WIPE DOWN AND DRY

POLISH/LUBRICATE

NUTS/BOLTS/FASTENERS:

TIGHTEN AND/OR ADJUST AS NEEDED

GUIDE RODS:

LUBRICATE AND CLEAN

LINEAR RODS:

LUBRICATE AND CLEAN

DAILY

a

a

a

a

WEEKLY

a

a

a

a

a

a

LATEST DATE ENTRY

SEAT SLEEVES:

LUBRICATE AND CLEAN

ADJUSTMENTS / LOCKING PINS /

TIGHTENING KNOBS

WEIGHT STACK PINS

WARNING INSTRUCTION LABELS

SPRINGS / POP PINS

ANTI-SKID SURFACES

HAND GRIPS / ROLLERS

a

a

a

a

a

a

a

a

FOR BODY-SOLID CUSTOMER SERVICE:

1-800-556-3113

*Make several copies of this page to keep track of your maintenance.

You can print more copies of this page by going to:

http://www.bodysolid.com/support/docs.html

49

Page 50

PHRASES, TERMS, TIPS

& GUIDELINES

BEGINNER’S GUIDELINES

• Work out at least two times a week.

• Include six to eight exercises that train major muscle groups.

• Perform two or three sets of at least eight to 12 repetitions.

AEROBIC

Exercise that primarily uses oxygen to burn fuel at low to moderate levels of intensity. Running

and jogging are examples of aerobic exercise.

ANAEROBIC

Exercise that primarily uses the body’s stored fuel for energy. Intense weightlifting is an

example of an anaerobic exercise.

ATROPHY

Decrease of a muscle caused by the decrease in the size of its cells because of inactivity.

EXERCISE LARGE MUSCLES FIRST

You should work your large muscle groups first (ie. squat, bench press, lat pulldown) before

you exercise your small muscle groups (ie. bicep curls, tricep pressdowns, lateral raises).

EXERCISE PROGRAM DURATION

A weight training routine should take anywhere from 45 minutes to one hour to complete. Add

another 20 to 60 minutes when you include stretching, warm-up, aerobics and cool-down.

GIVE YOUR MUSCLES A REST

You’ll get the most out of strength training if you give your muscles at least 48 hours rest to

recover and rebuild between strength training workouts.

BALLISTIC STRETCHING

A stretching technique that involves a bouncing or bobbing movement during the stretch. The

final position is not held. This is not

a recommended stretching technique.

HYPERTROPHY

Enlargement of a muscle caused by an increase in the size of its cells in response to weight

training.

BREATHING

Never hold your breath during any part of an exercise. Holding your breath may cause severe

intra-thoracic pressure and raise blood pressure leading to dizziness, blackout or other

complications. The rule of thumb is to exhale on exertion and inhale on the return part of the

exercise.

CARDIOVASCULAR

Referring to the heart, lungs, and other periphery systems involved in the transport of oxygen

throughout the body.

INTENSITY

The degree to which the body is worked during exercise.

ISOKINETIC EXERCISE

Resistance is given at a fixed velocity of movement with accommodating intensity. A machine

that moves you through an entire range of motion at a preset speed and will not change no

matter how much pressure is put forth by the individual.

ISOMETRIC EXERCISE

CHALLENGE YOUR MUSCLES

All strength training should progress gradually, using increases in weight until your goals are

reached. Then, change your workout to include increased reps or a higher weight resistance.

Alter the order of your exercises, perform multiple sets or different exercises to maintain

results or reach new goals.

Contracts the muscle statically without changing its length. Example: Attempting to lift a

weight heavier than you can handle, but cannot move.

ISOTONIC EXERCISE

Shortens and lengthens the muscle through a complete range of motion. This defines weight

training with full range of motion.

CHANGE ROUTINE

Beginner’s please note: If you want to make changes in the exercise routine that you do,

wait until about the six to eight week point. Advanced lifters may want to change routines to

avoid plateus in gaining size or strength.

MUSCLE FATIGUE

Fatigue is when you can’t possibly do another rep without sacrificing form.

MUSCULAR ENDURANCE

CIRCUIT TRAINING

Exercise stations that consist of various combinations of weight training, flexibility,

calisthenics, and aerobic exercise.

The ability to perform repetitive muscular contractions against some resistance.

MUSCULAR STRENGTH

The maximum force that can be applied by a muscle during a single maximum contraction.

CONCENTRIC MUSCLE ACTION

The muscle shortens while contracting against resistance.

OSTEOPOROSIS

A decrease in bone density.

ECCENTRIC MUSCLE ACTION

The muscle lengthens while contracting against resistance.

EXERCISE FREQUENCY

Exercise each muscle group 2-3 times per week. Allow a minimum of 48 hours rest for each

muscle group worked. If you are doing a total-body workout, three training sessions per

week, performed on every second day, is adequate.

PLYOMETRIC EXERCISE

A technique that includes specific exercises which encompass a rapid stretch of a muscle

eccentrically, followed immediately by a rapid concentric contraction of that muscle for the

purpose of facilitating and developing a forceful explosive movement over a short period of

time. Examples of these are using medicine balls for upper extremity and depth jumping for

lower extremeity.

50

Page 51

PHRASES, TERMS, TIPS

& GUIDELINES

STARTING RESISTANCE LEVEL

If you begin weight training at too high a level, you risk serious injury. You will also develop poor form,

which will hinder your efforts and discourage you. Use this as a guideline: if you cannot lift the weight

eight times with proper form, the weight is too heavy. Similarly, don’t choose too light a weight; the

last two or three repetitions of your set should be difficult.

POWER

Power is the rate of performing work. Power during a repetition is defined as the weight

lifted times the vertical distance the weight is lifted divided by the time to complete the

repetition. Power during a repetition can be increased by lifting the same weight the same

vertical distance in a shorter period of time. Power can also be increased by lifting a heavier

resistance the same vertical distance in the same period of time as a lighter resistance.

REST INTERVAL

Allow a brief pause between sets to give your muscles a chance to partially recover before

working them again. For power and muscle size development allow a 3 to 4 minute rest

interval between sets. For muscular endurance and definition allow a 30 second rest interval.

For strength training allow a 60 to 90 second rest interval.

RISK SHOULD NOT EXCEED BENEFIT

PROGRESS GRADUALLY

Increase reps before increasing resistance. Reduce rest intervals between sets to increase

intensity.

PROGRESSIVE RESISTANCE

The principle of continually adding more weight to a specific exercise as your muscles

become stronger to adapt to the heavier weights.

If the risk of a specific exercise exceeds its potential benefit, it is best to stay on the

conservative side. There are several ways to work specific muscle groups. Choose those that

provide minimal risk. Ask a fitness professional for guidance.

ROUTINE

The specific exercises, sets, reps and weight for a specific body part.

SET

PROPER FORM

Focus on the proper motion of the exercise and concentrate on the specific muscles being

used. Do not sacrifice proper form to lift heavier weight or to perform more repetitions. Proper

form also means lifting in a smooth, fluid motion. If you feel strain elsewhere, you should

re-evaluate the amount of weight you are lifting or have a qualified professional critique your

exercise motion.

PROPER POSTURE

Maintaining proper posture will greatly reduce chances of injury and maximize exercise

benefit. When standing always keep your feet shoulder-width apart. Do not lock your knees.

Locking your knees can put unnecessary strain on them. Keep your back flat and straight,

making sure not to twist or arch it in order to complete a repetition.

This is a group of repetitions performed continuously without stopping. While a set can be

made up of any number of repetitions, sets typically range from 1 to 15 repetitions.

SMALL MUSCLE GROUP EXERCISE

Single joint movement and isolation exercises (i.e. bicep curls, tricep pressdowns and leg

extensions).

SPEED OF MOVEMENT

Strength training movements should be slow and controlled. Do not use momentum to complete

an exercise movement. Momentum puts unnecessary stress on tendons, ligaments and joints.

Using momentum in your exercise movements does not develop increased strength.

STATIC STRETCHING

PROPER TECHNIQUE

To get the most out of strength training and to reduce the chance of injury, use proper weight

training techniques. These include working your muscles through their full range of motion

(but not locking any joints), lifting at a speed at which you can control the weight and stop

easily if necessary.

RANGE OF MOTION

Moving through a complete range of motion (ROM) allows the muscles to stretch before

contraction and increases the number of muscle fibers being recruited. This produces

maximum contraction and force. By working the full ROM, flexibility will be maintained and

possibly increased.

A stretching technique that involves holding a specific muscle or muscle group at a desired

length for a certain period of time. This type of stretching is highly recommended.

STOP TRAINING IF YOU FEEL PAIN

If you feel pain during a specific exercise stop immediately. Any continuation may aggravate

an existing injury. Re-evaluate your routine to make sure that you are doing a proper warm up.

Decrease the amount of weight you are lifting. Talk to a qualified personal trainer, health

professional or your doctor.

STRENGTH

Strength is the maximal amount of force a muscle or muscle group can generate in a

specified movement pattern at a specified velocity of movement.

REPETITION

A repetition is one complete movement of an exercise. It normally consists of two phases: the

concentric muscle action, or lifting of the resistance, and the eccentric muscle action, or

lowering of the resistance.

REPETITION MAXIMUM (RM)

This is the maximum number of repetitions per set that can be performed at a given

resistance with proper lifting technique. Thus, a set at a certain RM implies the set is

performed to momentary voluntary fatigue. 1RM is the heaviest resistance that can be used

for one compete repetition of an exercise. 10 RM is a lighter resistance that allows completion

of 10 (but not 11) repetitions with proper exercise technique.

WARM UP

This cannot be stressed enough. Many workout-related injuries can be avoided by a proper

warm up routine. Try to do a total body warm up before you start training. A good example of

a total body warm up is using a stationary bike, treadmill, elliptical, rowing or skiing machine.

It is especially important to warm up specific muscle groups you are going to be using. Your

muscles need a 5 to 15 minute warm up as well as a brief cool down. This can be as simple

as performing a warm up set of high repetitions and light weight (25% to 50% of your training

weight) for each exercise.

WORKOUT

The routine, specific exercises, weights, sets, and reps for one or more body parts.

51

Page 52

NUTRITION

Good nutrition is a diet in which foods are eaten in

proper quantities and with the needed distribution of

nutrients to maintain good health. Malnutrition, on

the other hand, is the result of a diet in which

there is an underconsumption, overconsumption, or

unbalanced consumption of nutrients that leads to

disease or an increased susceptibility to disease.

What is stated in the above definitions is the fact that

proper nutrition is essential to good health. A history of

poor nutritional choices will eventually lead to poor

health consequences.

There are many substances necessary for the proper

functioning of the body. Nutrients are the substances

that the body requires for the maintenance of health,

growth, and to repair tissues. Nutrients can be divided

into six classes: carbohydrates, fats, proteins, vitamins,

minerals and water. Carbohydrates, or "carbs", are

nutrients that are composed of carbon, hydrogen and

oxygen, and are essential sources of energy in the

body. Grains, vegetables, and fruits are excellent

sources of carbohydrates. It is recommended that

at least 55% to 60% of the total number of calories

consumed come from carbohydrates (American

Diabetes Association, Diabetes & Exercise, 1990). It is

further recommended that 10% or less of the total

calories consumed come from simple sugars like a

candy bar.

One of the many benefits of consuming foods that are

high in complex carbohydrates, such as rice, pasta,

and whole grain breads, is that they also typically

contain dietary fiber. Dietary fiber is a term used when

referring to substances found in plants that cannot be

broken down by the human digestive system. Although

fiber cannot be digested, it is important in helping to

avoid cancers of the digestive system, hemorrhoids,

constipation, and diverticular disease because it helps

food move quickly and easily through the digestive

system. It is recommended that people consume

20 to 30 grams of fiber per day (American Diabetes

Association, Diabetes & Exercise, 1990). Excellent

sources of dietary fiber are grains, vegetables,

legumes, and fruit.

Fats are an essential part of a healthy diet and serve

vital functions in the human body. Among the functions

performed by fats are temperature regulation,

protection of vital organs, distribution of some vitamins,

energy production, and formation of component parts

of cell membranes. Like carbohydrates, fats are

composed of carbon, hydrogen, and oxygen.

However, their chemical structure is different.

Both animals and plants provide sources of fat.

Saturated fats come primarily from animal sources

and are typically solid at room temperature. Plant

sources of saturated fats are palm oil, coconut oil,

and cocoa butter. A high intake of saturated fats is

directly related to increased cardiovascular disease.

Unsaturated fats are typically liquid at room temperature.

Corn, peanut, canola, and soybean oil are sources of

unsaturated fats. It is recommended that no more than

30% of one’s diet be composed of fats. Ten percent or

less of the total calories consumed should come from

saturated fats. One way to reduce saturated fat intake

would be to substitute margarine for butter.

Proteins are substances composed of carbon, hydrogen,

oxygen, and nitrogen. Proteins are made by combining

amino acids. Amino acids are nitrogen-containing

building blocks for proteins that can be used for energy.

Amino acids can combine in innumerable ways to form

proteins, and it is estimated that tens of thousands of

different types of proteins exist in the body. It is the

ordering of the amino acids that provides the unique

structure and function of proteins.

There are proteins in both meat products and plant

products. Animal sources of protein such as milk,

meat and eggs contain the eight essential amino

acids (amino acids that the body cannot synthesize

and therefore must be ingested). Plant sources of

protein such as beans, starchy vegetables, nuts, and

grains do not always contain all eight amino acids.

Because of this, vegetarians must consume a variety

of protein-containing foods. It is recommended that

proteins make up 10% to 15% of one’s daily calories.

This will ensure adequate protein for growth,

maintenance, and the repair of cells. Protein

requirements for adults are not as high as those

recommended for infants, children, and young adults.

Note: individuals who are training intensely will have

an increase in their protein requirements.

Vitamins are organic substances that are essential to

the normal functioning of the human body. Although

vitamins do not contain energy to be used by the body,

these substances are essential in the metabolism of

fats, carbohydrates and proteins. Because of the

critical role vitamins play, it is necessary that they exist

in proper quantities in the body.

Minerals are inorganic molecules that serve a variety

of functions in the human body. The minerals that

appear in the largest quantities (calcium, phosphorus,

potassium, sulfur, sodium, chloride, and magnesium)

are often called macrominerals. Other minerals are

also essential to normal functioning of the body, but

because they exist in smaller quantities (chromium,

iron, copper, fluoride, iodine, manganese, molybdenum,

selenium, and zinc) they are called microminerals.

A mineral that is often consumed in inadequate

amounts by Americans is calcium. Calcium is a

mineral important in the mineralization of bone,

muscle contraction, and the transmission of nerve

impulses. Osteoporosis is a disease characterized by

a decrease in the total amount of bone mineral in the

body and by a decrease in strength of the remaining

bone. This condition is most common in the elderly

but may also exist in younger people who have diets

inadequate in calcium or vitamin D or both.

Iron is another mineral that is often underconsumed

by Americans. This is especially true of women. The

oxygen-carrying properties of hemoglobin (blood)

depend on the presence of iron. Anemia is a condition

characterized by a decreased capacity to transport

oxygen in the blood, and is also common in those

lacking a sufficient amount of iron intake. Red meat

and eggs are excellent sources of iron. Additionally

spinach, lima and navy beans, and prune juice are

excellent vegetarian sources of iron.

Sodium, on the other hand, is a mineral that many

Americans over-consume. High sodium intake has

been linked with hypertension, as well as high blood

pressure. People can substantially reduce their

sodium intake by limiting consumption of processed

foods and decreasing the amount of salt added to

foods when cooking.

In conclusion...don’t forget hydration. Water is

considered an essential nutrient because of its vital

role in the normal functioning of the body. Water

contributes approximately 60% of the total body

weight and is essential in creating an environment

in which all metabolic processes occur. Water is

necessary to regulate temperature and to transport

substances throughout the body.

FOLLOW THESE BASIC NUTRITIONAL GUIDELINES

FOR GAINS IN STRENGTH AND LEAN MUSCLE MASS:

1. Choose your foods carefully. Try getting your

carbohydrates from sources such as rice,

vegetables, beans, whole grains, pasta and fruit.

Good protein sources include fish, chicken,turkey,

lean meat and low-fat or nonfat dairy products.

2. Minimize your fat intake.

3. Drink a minimum of 10 eight-ounce glasses of

water each day.

4. Eat four to six small meals a day, about three

hours apart. Small meals are more easily digested

and result in greater nutrition absorption.

5. Avoid eating junk food and fast food.

6. Time your protein intake of 40-55 grams

approximately 75 minutes after your workout.

7. Immediately following your workout, replenish

your glycogen stores with approximately

50-75 grams of carbohydrates.

For more information on nutrition visit your local

library or book store. There are many excellent books

available.

52

Page 53

EXERCISE

PRESCRIPTION

Sets

Sets are defined as a combination of any number of reps of one exercise. The number

of sets used in a workout is directly related to training results. Typically, two to three sets

are used by intermediate and advanced lifters to achieve optimum gains in strength.

Experts agree that multiple-set systems work best for the development of strength and

muscular endurance. Gains will be made at a faster rate by using a multiple-set

system than gains achieved through a single-set system. The use of a single set of an

exercise is recommended and very effective for individuals who are untrained or

just beginning a resistance training program. One-set programs might also be used

for simple maintenance once you are in shape. It is important to note that low-volume

set programs will increase strength in untrained individuals, but more complex

physiological adaptations, such as gains in muscle mass, tone, size, and performance

usually requires higher-volume set training for the best results. Multiple sets of an

exercise present a more intense training stimulus to the muscles during each set.

Once your desired initial fitness level has been achieved, multiple-set performances

of the exercise using the proper resistance (with specific rest periods between sets)

will take you to the next level of strength training, endurance, and muscular development.

Resistance Used

The amount of resistance used for a specific exercise is probably the most important

variable in resistance training. When designing a resistance training program, a weight

for each exercise must be chosen. The use of repetition maximums (RM): the exact

resistance that allows only a specific number of repetitions to be performed, is probably

the easiest method for determining a resistance. Typically, one uses a training RM target

or a RM target zone. Example: If your RM zone is 8 to 12 repetitions and you cannot lift

the weight at least 8 times using proper form, the weight is too heavy. On the other

hand, if you can easily lift the weight 12 times, the weight is too light. In either case, the

weight needs to be changed. As the strength level of the lifter changes over time, the