Instructions for Installation and Operation

Bodine 12 or 24VDC Type 34B/SR-WX

Variable Speed Brushless DC

™

INTEGRAmotor

This apparatus is suitable for use in Class I, Division 2,

Groups A, B, C, D, or unclassified locations.

Specifications

Speed (RPM) .....................................................0.6-658

Torque (lb-in.).......................................................9-205

Gear Ratio Range ...........................................3.8:1 to 312.4:1

Power (HP)........................................... 1/5 (12V) or 1/4 (24V)

Control Input

Max. Continuous Amps ...............................19.0 (12V) or 11.0 (24V)

www.bodine-electric.com

07401116.A

TABLE OF CONTENTS

This manual contains the basic information needed to install and operate

a Bodine INTEGRAmotor 34B4/SR-WX brushless DC gearmotor & control

system that is certified for use in Class I Division 2 hazardous locations.

This manual does not profess to cover all details or variations in equipment,

nor to provide for every possible contingency associated with installation,

operation, or maintenance. No warranty of fitness for purpose is expressed

or implied. It is the responsibility of the user to determine whether the

installation location is hazardous, and to what degree it is hazardous. Should

further information be desired or should particular problems arise which are

not covered sufficiently for the user’s purpose, the matter should be referred

to the Bodine Electric Company.

IMPORTANT SAFETY PRECAUTIONS ..................................3

QUICK REFERENCE ..................................................4

PRODUCT SPECIFICATIONS ..........................................5

INSTALLATION .....................................................6

Step 1 – Mount the 34B4/SR-WX Gearmotor ..........................6

Step 2 – Remove the Control Enclosure Cover ........................8

Step 3 – Attach Conduit to Control Enclosure .........................8

Step 4 – Make Electrical Connections ...............................8

Step 5 – Attach the Control Enclosure Cover.........................10

Step 6 – Operate the 34B4/SR-WX Gearmotor .......................10

Step 7 – Control Calibration (Optional) ..............................11

TROUBLESHOOTING ...............................................13

WARRANTY .......................................................15

FIGURES

Figure 1 – Quick Reference for Installation and Operation ...............4

Figure 2 – Mounting Dimensions .....................................7

Figure 3 – Installed Conduit Hub .....................................8

Figure 4 – Location of Control Components and Connections. ............9

Figure 5 – 34B4/SR-WX Gearmotor Shown with Cover Attached ........11

RoHS COMPLIANCE

This document certifies that the Bodine Electric type 34B4/SR-WX gearmotor

is manufactured with materials and processes that comply with European

Directive 2011/65/EU on the Restriction of Hazardous Substances (RoHS).

© Copyright 2015 Bodine Electric Company.

All rights reserved. All data subject to change without notice. Printed in U.S.A.

2

www.bodine-electric.com

IMPORTANT SAFETY PRECAUTIONS

The use of electric motors and gearmotors, like the use of all electronically

powered equipment, is potentially hazardous. The degree of hazard can

be greatly reduced by proper design, selection, installation, and use, but

hazards cannot be completely eliminated. The reduction of hazard is the joint

responsibility of the user, the manufacturer of the driven or driving equipment,

and the manufacturer of the motor or generator.

The Bodine type 34B motor was evaluated by Underwriters

Laboratories (UL) for compliance to UL standards 508C and

1004-1 and CSA standards C22.2 No. 14 and C22.2 No. 100. Motor

construction recognition is documented in UL file E47177. The gearmotor is also

a UL listed product, documented in UL file E474208 for hazardous locations. This

product was also evaluated by Underwriters Laboratories for compliance to

UL standard 1836, CSA standard C22.2 No. 213, and ISA standard 12.12.01. It is

suitable for use in Class I, Division 2, Groups A, B, C, D hazardous locations and

bears the mark shown above.

Please read through this operations manual in detail and observe those

paragraphs with the safety alert symbol.

!

WARNING

This indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

This indicates a potentially hazardous situation which,

CAUTION

if not avoided, may result in property damage.

!

WARNING/AVERTISSEMENT

Explosion hazard. Do not disconnect while the circuit is live or unless the

area is known to be free of ignitable concentrations.

Risque d’explosion – avant de deconnecter l’equipement, couper le courant

ou s’assurer que l’emplacement est designe non dangereux.

!

WARNING/AVERTISSEMENT

Explosion hazard. Substitution of components may impair suitability for

Class I, Division 2.

Risque d’explosion – La substitution de composants peut rendre cet

équipement inadapté à une utilisation en environnement de Classe I, Div. 2.

www.bodine-electric.com

3

QUICK REFERENCE

IMPORTANT

Read this manual completely and carefully before making any connections.

Pay special attention to all warnings, cautions, and safety rules. Failure to

follow the instructions could produce safety hazards which could injure

personnel or damage the control, gearmotor, or other equipment. If you

have any doubts about how to connect the control or gearmotor, refer to

the detailed sections of this manual.

This apparatus is suitable for use in Class I, Division 2, Groups A, B, C, D, or

unclassified (non-hazardous) locations.

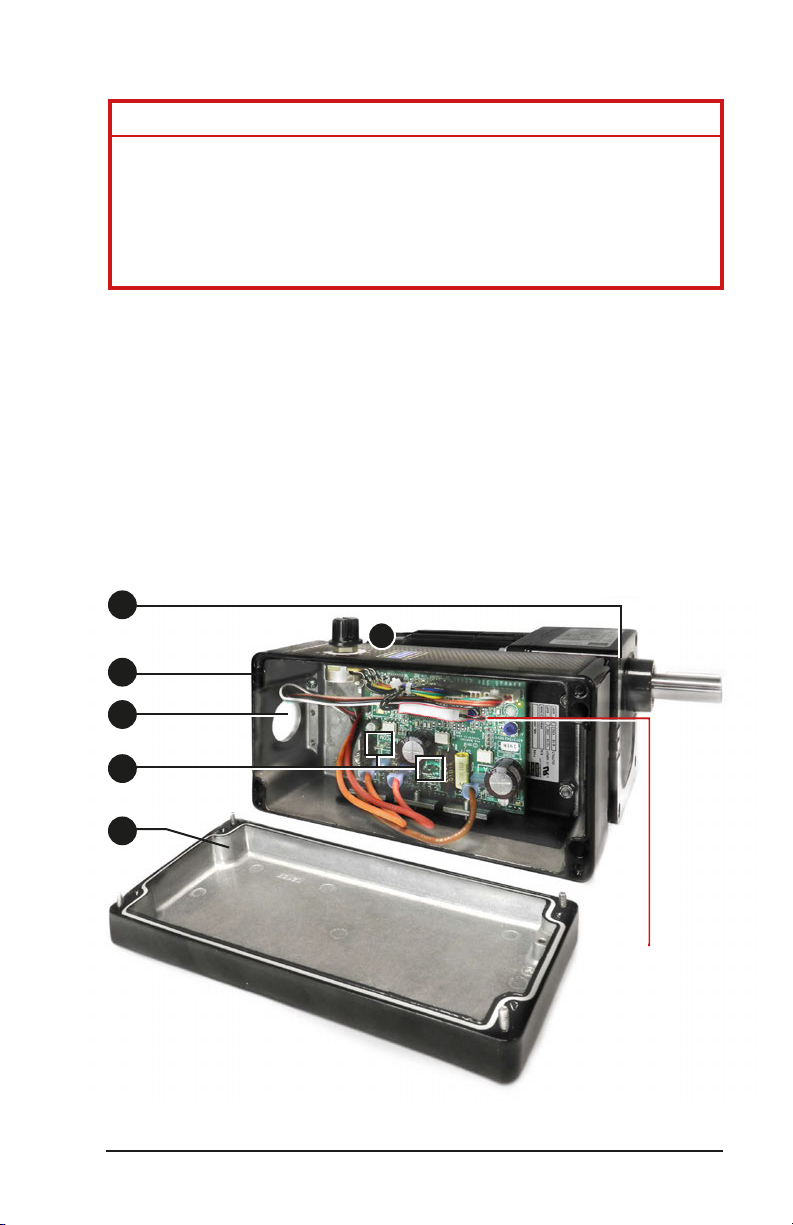

1. Mount the gearmotor using the threaded holes in the face of the gearbox

and couple the load mechanism to the gearmotor drive shaft.

2. Remove the cover of control enclosure.

3. Attach conduit to control enclosure using a UL listed conduit fitting.

4. Run wire through the conduit and connect to control circuit board.

5. Reinstall cover on control enclosure.

6. Turn on power and adjust speed with the potentiometer on the control

enclosure.

1

6

2

3

4

5

Control enclosure

cover (steps 2 and 5)

4

Direction Connector

(jumper)

Figure 1 – Quick Reference for Installation and Operation

www.bodine-electric.com

PRODUCT SPECIFICATIONS

Parameter

Specification

GEARMOTOR OUTPUT

CONTROL INPUT

Wt.

(lbs)

Speed

(rpm)

Torque

(lb-in)

Gear

Ratio

Volts

(VDC)

Max Cont.

Amps

GEARMOTOR OUTPUT

CONTROL INPUT

Wt.

(lbs)

Speed

(rpm)

Torque

(lb-in)

Gear

Ratio

HP

Volts

(VDC)

Max Cont.

Amps

Locations: Hazardous locations Class I, Division 2, Groups A, B, C, D or

Power Supply Voltage: 12-Volt models: 12 to 14 VDC

Ambient Temperature: -20º to 40º C (operating)

Speed Regulation: 2% at 2500 RPM

Speed Range

(at high speed shaft or rotor):

Acceleration Time: adjustable, 0.35 to 8.0 seconds

(non-hazardous) unclassified locations.

24-Volt models: 24 to 35 VDC

12.5:1 (200 to 2500 RPM) at rated load

and rated supply voltage

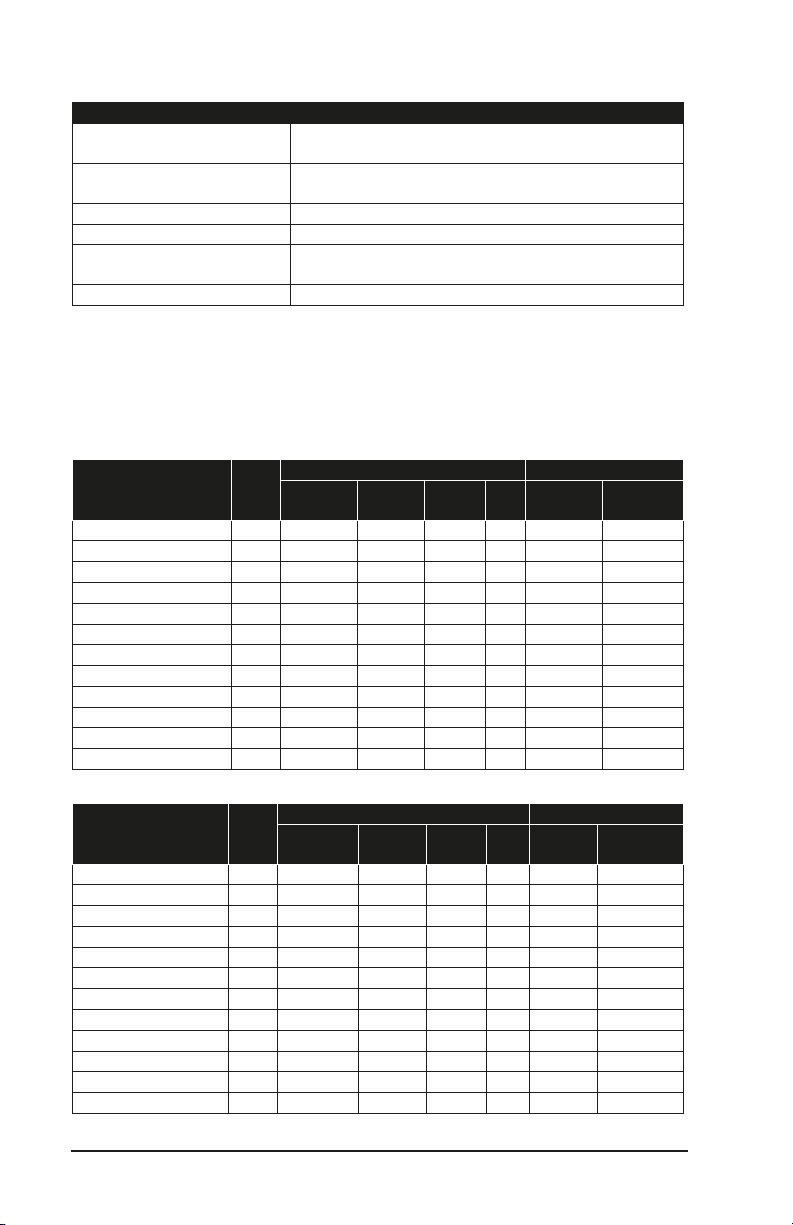

Tables 1 and 2 list the current models available, which are all parallel shaft

gearmotors. Other configurations of Bodine’s type 34B/SR gearmotor with

different gear reducers are possible. Contact Bodine for details on those.

TABLE 1 - 12 Volt Models

Type

34B4BEBL/SR-WX4 11.6 0.6 to 8 205 312.4:1 1/5 12 19.0

34B4BEBL/SR-WX4 11.6 1.2 to 15 200 172.1:1 1/5 12 19.0

34B4BEBL/SR-WX4 11.6 2.0 to 26 185 97.5:1 1/5 12 19.0

34B4BEBL/SR-WX3 11.6 3.0 to 38 190 65.5:1 1/5 12 19.0

34B4BEBL/SR-WX3 11.6 3.6 to 46 185 54.7:1 1/5 12 19.0

34B4BEBL/SR-WX3 11.6 4.5 to 57 157 43.9:1 1/5 12 19.0

34B4BEBL/SR-WX3 11.6 6.7 to 99 106 29.7:1 1/5 12 19.0

34B4BEBL/SR-WX2 11.6 9.8 to 123 77 20.4:1 1/5 12 19.0

34B4BEBL/SR-WX2 11.6 14 to 181 46 13.8:1 1/5 12 19.0

34B4BEBL/SR-WX2 11.6 21 to 266 31 9.4:1 1/5 12 19.0

34B4BEBL/SR-WX2 11.6 36 to 455 18 5.5:1 1/5 12 19.0

34B4BEBL/SR-WX2 11.6 52 to 658 9 3.8:1 1/5 12 19.0

TABLE 2 - 24 Volt Models

HP

34B4BEBL/SR-WX4 11.6 0.6 to 8 205 312.4:1 1/4 24 11.0

34B4BEBL/SR-WX4 11.6 1.2 to 15 200 172.1:1 1/4 24 11.0

34B4BEBL/SR-WX4 11.6 2.0 to 26 185 97.5:1 1/4 24 11.0

34B4BEBL/SR-WX3 11.6 3.0 to 38 190 65.5:1 1/4 24 11.0

34B4BEBL/SR-WX3 11.6 3.6 to 46 185 54.7:1 1/4 24 11.0

34B4BEBL/SR-WX3 11.6 4.5 to 57 157 43.9:1 1/4 24 11.0

34B4BEBL/SR-WX3 11.6 6.7 to 99 106 29.7:1 1/4 24 11.0

34B4BEBL/SR-WX2 11.6 9.8 to 123 77 20.4:1 1/4 24 11.0

34B4BEBL/SR-WX2 11.6 14 to 181 46 13.8:1 1/4 24 11.0

34B4BEBL/SR-WX2 11.6 21 to 266 31 9.4:1 1/4 24 11.0

34B4BEBL/SR-WX2 11.6 36 to 455 18 5.5:1 1/4 24 11.0

34B4BEBL/SR-WX2 11.6 52 to 658 9 3.8:1 1/4 24 11.0

www.bodine-electric.com

Type

5

INSTALLATION

This product should only be installed by a qualified person familiar with its

operation and associated hazards, and knowledgeable about the special

requirements for installation in hazardous locations. The National Electrical

Code (NEC), local electrical and safety codes, and when applicable, the

Occupational Safety and Health Act (OSHA) should be observed to reduce

hazards to personnel and property.

!

WARNING/AVERTISSEMENT

Explosion hazard. Do not disconnect while the circuit is live or unless the

area is known to be free of ignitable concentrations.

Risque d’explosion – avant de deconnecter l’equipement, couper le courant

ou s’assurer que l’emplacement est designe non dangereux.

!

WARNING/AVERTISSEMENT

Explosion hazard. Substitution of components may impair suitability for

Class I, Division 2.

Risque d’explosion – La substitution de composants peut rendre cet

équipement inadapté à une utilisation en environnement de Classe I,

Division 2.

Step 1: Mount the 34B4/SR-WX Gearmotor

CAUTION

The PCB of this 34B4/SR-WX gearmotor is vulnerable to static electrical

charges. This gearmotor is packaged in an anti-static bag and should

be removed from the bag only in an area protected from electrostatic

discharges (ESD).

This apparatus is suitable for use in Class I, Division 2, Groups A, B, C, D or

unclassified locations.

Install this 34B4/SR-WX gearmotor onto a secure mounting surface by

inserting screws into the four threaded holes in the face of the gearbox. See

Figure 2 for size and location of the mounting holes. An optional L-bracket kit,

Bodine model number 0970, is available for floor mounting.

If this 34B4/SR-WX gearmotor is operated or used outdoors, it must be

installed under a cover that protects it from direct exposure to rain or snow.

6

www.bodine-electric.com

(.8625) typ.

4.06±.02 Sq.

typ.

3.375±.010

(1.6875) typ.

[4] 1/4-28 UNF-2B

Depth .50 min.

Note: The following dimensions may differ

on custom 34B/SR-WX designs

a. Drive shaft dimensions and position

in relation to the control box

b. Speed potentiometer location

c. Conduit hole location and size

.6250

.6245

ø

4.02 Max.

7.983 max.

6.973 max.

typ.

3.375±.010

(3.548)

7.874 max.

(1.6875)

b

(1.93)

2.00±.03

(5.81)

typ.

(1.11)

.1875/.1855 sq. x

1.12 long key

.560±0.15

ø .802

max.

ø 1.31

not machined

a

(1.76)

c

[4] Terminal box cover screws

field installation tightening torque

18-26 lb-in.

Figure 2 – Standard 34B/SR-WX Mounting Dimensions

www.bodine-electric.com

(3.189)

14-18 lb-in.

field installation

tightening torque

[2] ground screws

(7.265)

3.937 Max.

ø 1.125/1.063

(hole for 3/4 NPT

conduit hub)

7

Step 2: Remove the Control Enclosure Cover

!

WARNING/AVERTISSEMENT

Open circuit before removing cover. Keep cover tight while circuits are alive.

Coupez l’alimentation avant de retirer le couvercle. Ce couvercle doit être

en place pendant que le circuit est sous tension.

The cover of the control enclosure is fastened with the four provided screws,

one at each corner. Either a Philips or a flat screwdriver can be used to loosen

the captive screws and remove the cover.

Figure 3 – Installed Conduit Hub.

Step 3: Attach Conduit to the Control Enclosure

Figure 2 shows the location of a 1.125” / 1.063” diameter hole in the side of the

control enclosure. The hole is for installation of a UL listed 3/4” NPT conduit

hub. The conduit hub shown in the Figure 3 is McMaster part number 7864T42

and is one example. Follow the manufacturer’s instructions for installing the

hub onto the control enclosure and then attach the conduit.

Step 4: Make Electrical Connections

CAUTION

The printed circuit board (PCB) of the 34B4/SR-WX gearmotor is vulnerable

to electrostatic discharges (ESD). Do not contact the PCB unless precautions

are followed to prevent ESD.

This 34B4/SR-WX gearmotor is factory-wired so that the drive is enabled as

soon as power is applied and speed is controlled using the potentiometer

in the side of the control enclosure. If remote control of the gearmotor is

desired, please contact our technical support staff at 773-478-3515 or via

info@bodine-electric.com.

Power and ground connections are made using three wires routed through

the conduit and into the 34B4/SR-WX gearmotor control enclosure. The

power wires must be terminated with ¼” quick disconnect receptacles.

8

www.bodine-electric.com

Connect the (+) side of the power supply to the tab labeled “+VM” on the

circuit board inside the control enclosure. Connect the (-) side of the power

supply to the tab labeled “PCOM”. Use one of the two copper ground screws

in the bottom of the control enclosure to attach the ground wire. See Figure

4 for location of the three connections.

Select Direction of Drive Shaft Rotation

Bodine 34B4/SR-WX gearmotors can be configured so that the drive shaft

rotates either clockwise or counterclockwise. The drive shafts of gearmotors

with an even number of gearing stages (indicated by an even number at

the end of the product type, as in 34B4BEBL/SR-WX2) are factory-set to

rotate counterclockwise. Drive shafts of gearmotors with an odd number

of gearing stages, such as 34B4BEBL/SR-WX3 will rotate clockwise. If the

application requires the drive shaft to rotate opposite the factory setting,

simply remove the plug-in direction connector inside the control enclosure.

See Figure 4 for location of the connector.

Fusing: The 34B4/SR-WX gearmotor must be protected by a user-supplied

fuse. In a system with multiple INTEGRAmotors, each one must be protected

separately. Make sure the fuse is connected in series with the (+) lead of the

power supply. The power supply must be fused with a JDYX2 fuse with a

maximum rating of 25 Amps. The fuse must be located outside the hazardous

location area or installed in a suitable enclosure.

Route all wires through conduit hub

(not shown).

Connect ground

wire with one of

the copper screws.

Connect wire from (-) side of

power supply to “PCOM”

www.bodine-electric.com

MX (Max Speed)

adjustment pot

Figure 4 – Location of Control Components and Connections

TQ (Torque/Current)

adjustment pot

Direction Connector

(jumper)

Connect wire from (+) side of

power supply to “+VM”

ACC (Acceleration)

adjustment pot

J4 Connector

9

Step 5: Attach the Control Enclosure Cover

!

WARNING/AVERTISSEMENT

Open circuit before removing or attaching the cover. Keep cover tight while

circuits are alive.

Coupez l’alimentation avant de retirer le couvercle. Ce couvercle doit être

en place pendant que le circuit est sous tension.

The cover of the control enclosure is fastened with the four provided M4

screws, one at each corner. Either a Phillips or a flat screwdriver can be used

to tighten the captive screws to 14-18 lb-in. and attach the cover.

Step 6: Operate the 34B4/SR-WX Gearmotor

!

WARNING

• Recheck all connections.

• Do not remove the cover over the electronics when the power is ON to

avoid personal injury caused by electrical shock.

• Do not attempt to install or remove the electrical connector when the power

supply is turned on. Do not attempt to wire circuitry while power is on.

CAUTION

• Check that gearmotor is securely mounted.

• Test 34B4/SR-WX gearmotor unloaded first.

• Check all rotating members. Be sure keys, pulleys, etc. are securely

fastened and safety guards are in place.

• Check for proper mounting and alignment of products, and verify safe

loading on shafts and gears.

1. Start the Gearmotor

a. Turn the DC power supply on.

b. The gearmotor should start running at the set speed if there is no remote

switch to enable the drive. The factory setting is zero speed, so a new

gearmotor should not turn at this point. But if the speed pot has already

been moved by a previous user, the gearmotor will run at the speed set by

that user.

2. Adjust Speed

a. Turn speed potentiometer.

3. Stop the Gearmotor

a. Turn the DC power supply off.

10

www.bodine-electric.com

Speed

Potentiometer

Figure 5 – 34B4/SR-WX gearmotor shown with cover attached to control

enclosure and showing the location of the speed potentiometer.

Step 7: Control Calibration (Optional)

!

WARNING

Do not remove the control box cover when the power is ON in a Class I,

Div. 2 hazardous location. Always adjust the control outside the hazardous

location area.

!

WARNING

Use a non-metallic or insulated adjustment tool for internal adjustments.

Circuit components are not at ground potential and accidental short

circuiting and shock hazard may occur with conducting tools. Adjustment

should be made only by qualified service personnel.

!

WARNING

Never rely on logic circuitry as a means of disabling the gearmotor or

control. To prevent unsuspected mechanical motion and potential injury,

the AC power should always be disconnected from the control power

supply whenever logic circuits or the driven equipment are serviced. When

a battery is used, the DC supply to the control should be disconnected.

The factory settings of the control are satisfactory for most applications.

However, there may be some cases where it is desirable to limit the maximum

speed of the gearmotor, or to limit its stall torque, or to change how quickly

it accelerates. These performance characteristics can be adjusted with

potentiometers on the control board inside the terminal box. Because the

control enclosure must be opened and the gearmotor must be running when

these adjustments are made, this must be done before the gearmotor is

installed in the hazardous location.

www.bodine-electric.com

11

See Figure 4 for the location of the following adjustment potentiometers.

Maximum Speed Potentiometer: The gearmotor is calibrated to run at the

speed listed on its nameplate when the external speed potentiometer is

set to “100”. Turn the Max Speed (MX) potentiometer on the control board

counterclockwise to reduce the maximum speed.

Torque (Current) Limit Potentiometer: The TQ potentiometer (Figure 4) has

been calibrated so that the peak current limit of the 12 volt model is factoryset to 30 Amps and the peak current limit of the 24 volt model is factory-set to

27 Amps. In some cases, it may be desirable to reduce the peak current limit

to a level less than the factory setting, in order to protect drive mechanisms,

such as gearing, from damage due to overloads. Turn the TQ trim potentiometer

counterclockwise to decrease the torque and clockwise to increase the torque.

Acceleration Adjustment Potentiometer: The ACC potentiometer (See Figure 4)

can be used to adjust the gearmotor’s acceleration time. A counterclockwise

adjustment decreases the acceleration time down to a minimum of

approximately 0.35 seconds from zero to full speed. A clockwise adjustment

increases the rate up to a maximum of approximately 8 seconds from zero to

full speed.

12

www.bodine-electric.com

TROUBLESHOOTING

!

WARNING

• Do not remove the cover over the electronics when the power is ON to

avoid personal injury caused by electrical shock.

• Do not attempt to install or remove the electrical connector when the power

supply is turned on. Do not attempt to wire circuitry while power is on.

If you encounter a problem, read all instructions and double-check the wiring.

Even if the 34B4/SR-WX gearmotor itself is defective, it may be that another

defective component in the system caused it to fail, in which case replacing

the gearmotor alone and not tending to the root cause of the failure may

result in another damaged product. Table 3 may assist in troubleshooting

foreseeable problems which may occur during installation and operation.

If problems persist, contact your source of purchase or a Bodine Authorized

Service Center and describe the problem in detail. Do not disassemble

the product unless authorized by Bodine Electric Company. Performing

unauthorized repairs will void the warranty and invalidate third-party

certifications.

General Evaluation – Knowing the circumstances under which the problem

occurred can help to identify the root cause of the problem. The following

are two questions you should ask yourself before disassembling the system:

Has the system ever operated properly? If the system was just installed and

hasn’t worked right from the beginning, then it is possible that something

wasn’t done correctly in the installation. Review all wiring or incorrect

programming of remote devices. If the system has been working for an

extended period of time and just recently stopped working, then this would

indicate that the system was initially installed properly but has somehow

changed. Focus instead on failed components or deteriorated wiring.

Is the problem continuous or intermittent? If the problem always occurs and

never goes away, then it would indicate something inherently wrong in the

connections or a defective component. On the other hand, if the system operates

properly most of the time and only occasionally does something wrong, then

this might indicate loose connections or electrical noise interference.

www.bodine-electric.com

13

TABLE 4 - General problem evaluation method

SYMPTOM

PROBABLE CAUSE

CORRECTIVE ACTION

Incorrect power

supply wiring

Incorrectly sized

power supply

Does not operate

Operates, but speed

can’t be adjusted

Operates, but won’t

come up to speed

Operates, but with abnormal

speed variations

Operates, but won’t stop

with zero speed signal

Operates, but won’t

maintain speed under load

Blown fuse Replace fuse.

No speed signal

Gearmotor is overloaded

Gearmotor is damaged

Defective speed

potentiometer

Gearmotor is overloaded

Incorrectly sized

power supply

Speed setting too low

Defective speed

potentiometer

Incorrectly sized

power supply

Gearmotor is overloaded

Check that power source

is switched on.

Check connections.

Look for shorts and

repair as required.

Replace power supply

with unit having sufficient

voltage and current

capacity to provide rated

voltage under full load

Check if speed

potentiometer is

working properly.

Check wiring for speed

potentiometer

Reduce load

Replace gearmotor

with stronger model

Contact Bodine or an

Authorized Service

Center for assistance.

Contact Bodine or an

Authorized Service

Center for assistance.

Reduce load

Replace gearmotor

with stronger model

Replace power supply

with unit having sufficient

voltage and current

capacity to provide rated

voltage under full load

Increase speed

Replace gearmotor

with model having

higher gear ratio

Contact Bodine or an

Authorized Service

Center for assistance.

Replace power supply

with unit having sufficient

voltage and current

capacity to provide rated

voltage under full load

Reduce load

Replace gearmotor

with stronger model

14

www.bodine-electric.com

BODINE LIMITED WARRANTY

The Bodine Electric Company warrants all products it manufactures to be free

of defects in workmanship and materials when used under Normal Operating

Conditions and when applied in accordance with nameplate specifications.

When Bodine motors and gearmotors have been purchased with and used

only with appropriately applied Bodine controls, this warranty shall be in

effect for a period of twenty-four months from date of purchase or thirty

months from date of manufacture, whichever comes first. Bodine motors and

gearmotors used with non-Bodine controls and Bodine controls used with

non-Bodine motors and gearmotors are covered by a standard twelve-month

warranty period.

The Bodine Electric Company will repair, replace, or refund at its option, any of

its products, which has been found to be defective and is within the warranty

period, provided that the product is shipped freight prepaid, with previous

authorization, to Bodine Electric, or to the nearest Bodine Authorized Service

Center. At its option, all return shipments are F.O.B. Bodine’s plant or Authorized

Service Center. Bodine is not responsible for removal, installation, or any other

incidental expenses incurred in shipping the products to or from Bodine.

This warranty is in lieu of any other expressed or implied warranty - including

(but not limited to) any implied warranties of merchantability and/or fitness for

a particular use or purpose.

Bodine’s liability under this warranty shall be solely limited to repair or

replacement of the Bodine product within the warranty period and Bodine

shall not be liable, under any circumstances, for any consequential, incidental

or indirect damages or expenses associated with the warranted products.

Commutator and/or brush wear and its associated effects are normal

occurrence and are not covered by this warranty unless otherwise agreed

to by Bodine in writing.

Proof of purchase of motor or gearmotor and matching control as a system

must be provided with any claim.

Product Type:_____________________ Serial No.____________________

Date of Purchase:____________ Place of Purchase:_______________

www.bodine-electric.com

15

Bodine offers over 1,200 standard

C

E

R

T

I

F

I

E

D

Q

U

A

L

I

T

Y

M

A

N

A

G

E

M

E

N

T

S

Y

S

T

E

M

gearmotors, motors and

system-matched speed controls.

Visit www.bodine-electric.com

for all your motion control needs.

Bodine offers the widest selection of variable-speed AC, permanent magnet DC and

brushless DC fractional horsepower gearmotors and motors in the industry. For

complete specifications, 3D CAD drawings, or to order online, visit bodine-electric.com.

A

N

M

A

G

Y

T

E

I

M

L

E

A

N

U

Q

D

E

I

F

I

T

R

E

C

T

S

Y

S

T

ISO

ISO

E

M

9001:2008

201 Northfield Road | Northfield IL 60093 U.S.A. | 773.478.3515

info@bodine-electric.com | www.bodine-electric.com

07401116.A

Loading...

Loading...