Instructions for Installation and Operation

Filtered SCR Brushless DC

Motor Speed Controls (NEMA-12)

Model 3912, 0-2,500 rpm

Model 3913, 0-10,000 rpm

SPECIFICATIONS

Product Type.......................................... ABL-3912E/ABL-3913E

Input Voltage: ......................................... 115 VAC ± 10%, 50/60 Hz (Single Phase)

Input Current: ......................................... 12 Amps rms

Output Voltage: .......................................0 to 130 VDC

Continuous Output Current.............................. 3.0 Amps

Peak Output Current ...................................6.0 Amps

Ambient Temperature: .................................0° to 40° C (Maximum)

Control Hp Range: .....................................Up to 3/8 Hp

Control Speed Range: .................................. Up to 30:1

www.bodine-electric.com

07400212.C

IMPORTANT

Read this manual completely and carefully. Pay special attention to all

warnings, cautions, and safety rules. Failure to follow the instructions

could produce safety hazards which could injure personnel or damage

the control, motor, or other equipment. If you have any doubts about

how to connect the control or motor, refer to the detailed sections of

this manual.

QUICK REFERENCE

HAVE YOU?

❑ Read the installation and operation instructions contained

in this manual.

❑ Read and understood all of the precautions outlined in this

manual pertaining to potential hazards to personal safety

and equipment.

❑ Mounted the control properly. Details on Page 9.

❑ Connected the circular connector on the control output

cable to the corresponding circular connector on the

Bodine Brushless DC motor. Details on Page 9.

❑ Selected the proper control horsepower settings for the

motor being used. Details on Page 9.

❑ Installed the motor fuse. Details on Page 11.

❑ Provided an adequate grounded source of AC power.

Details on Page 11.

❑ Refer to the Operation Section of this manual for

preliminary start-up details and specific control functions.

Page 12.

2

www.bodine-electric.com

TABLE OF CONTENTS

QUICK REFERENCE CHECK LIST ..............................................2

GENERAL INFORMATION ...................................................4

CONTROL DESCRIPTION AND FEATURES ......................................4

SPECIFICATIONS ...........................................................5

IMPORTANT SAFETY PRECAUTIONS ..........................................6

INSTALLATION INSTRUCTIONS ..............................................9

Mounting the Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Electrical Connections ...................................................9

Motor Cable Connection ..................................................9

Horsepower (DIP Switch) Settings .........................................9

Line Fuse Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Motor Fuse Installation ..................................................11

Control Input Connections ...............................................11

AC Power Connections ..................................................11

OPERATING INSTRUCTIONS ................................................12

Preliminary Checks .....................................................12

Operating the Control ...................................................12

Internal Adjustments ....................................................13

Minimum and Maximum Speed ........................................13

Torque (Current) Limiting Adjustment ...................................14

Acceleration Adjustment .............................................14

Deceleration Adjustment .............................................14

TROUBLESHOOTING .......................................................15

SPECIALIZED WIRING APPLICATIONS .......................................17

Motor Cable ...........................................................18

Connecting Control Inputs From Remote Locations .........................19

Remotely Located Speed Control .........................................19

Remotely Located Braking (Disable), Direction of Rotation and

Deceleration Controls ...................................................20

Electronic Control Input Connections .....................................20

Electronic Speed Control ................................................21

Logic Signal Control of Braking, Direction of Rotation, and Deceleration .......21

Signal Isolation Using a Bodine Model 3984 Interface Module ................21

WARRANTY ...............................................................23

FIGURES

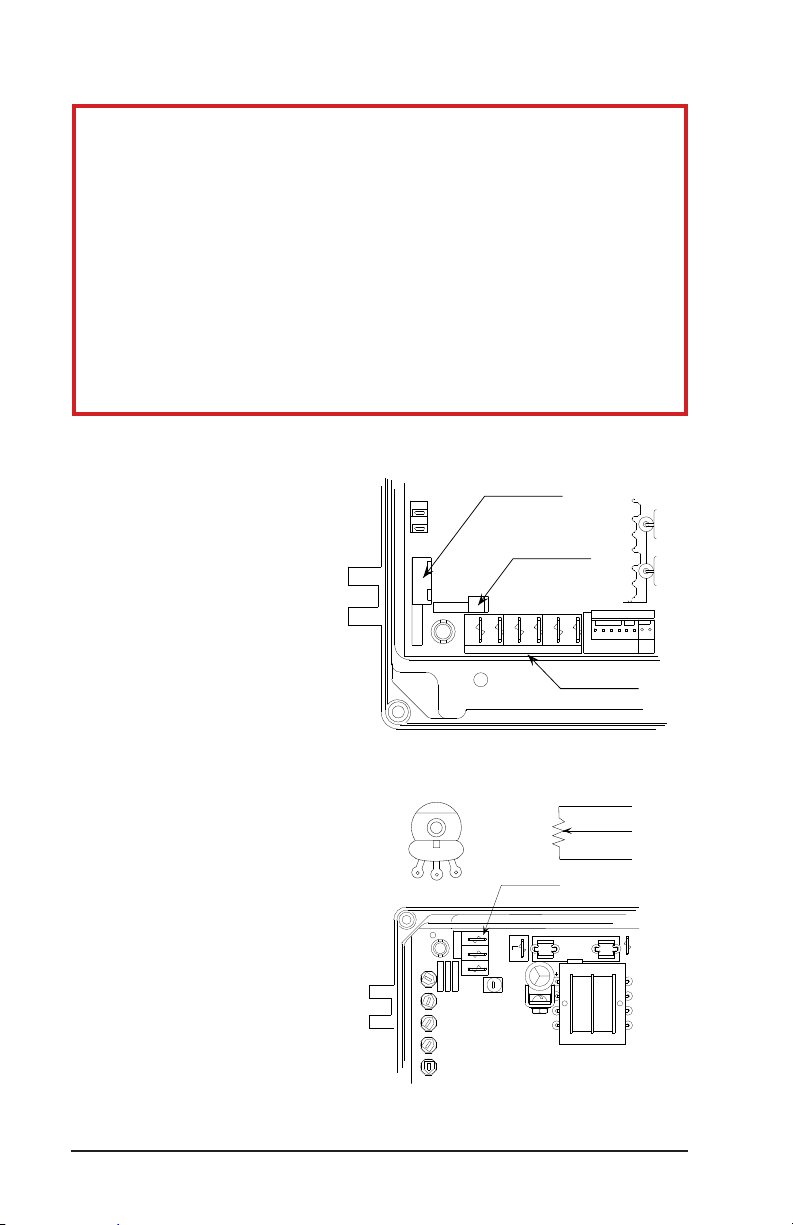

Figure 1 – Detail of Control Circuit Board in Enclosure ..........................10

Figure 2 – DIP Switch 7 and 8 Speed Range Settings ...........................10

Figure 3 – Horsepower (DIP Switch) Settings and Fuse Selection Chart ..........10

Figure 4 – Speed/Torque Curve Showing Reduced Torque at Lower Speeds .......14

Figure 5 – Interface Connector Detail ........................................19

Figure 6 – Remote Speed Control Connections ................................19

Figure 7 – Manual Switch and Relay Control Inputs ............................20

Figure 8 – Manual Speed Potentiometer/Interface Details ......................21

© 2017 Bodine Electric Company.

All rights Reserved. All data subject to change without notice. Printed in U.S.A.

www.bodine-electric.com

3

GENERAL INFORMATION

Thank you for selecting a Bodine Type ABL Encased Brushless DC Motor

Control. Your new control will provide the same excellent performance and

reliability that have been a Bodine tradition since 1905. Bodine Electric

Company takes pride in the quality of its products and in satisfying its

customers. Every effort has been made to provide you with a product free

of defects in design, workmanship, and materials. In order for us to maintain

our tradition of quality, please report any cases of unsatisfactory service or

products to Bodine Electric Company promptly.

About This Manual

This manual contains the basic information needed to install and operate

a Bodine Type ABL-3912E and ABL-3913E Brushless DC Motor Control. It is

organized in a systematic, step-by-step fashion so that the system may be set

up safely in the shortest possible time. It does not profess to cover all details

or variations in equipment, nor to provide for every possible contingency

associated with installation, operation, or maintenance. No warranty of fitness

for purpose is expressed or implied. Should further information be desired or

should particular problems arise which are not covered sufficiently for the

user’s purpose, the matter should be referred to the Bodine Electric Company.

The issuance of this manual does not confer to the recipient any license

to manufacture under any patents owned or controlled by the Bodine

Electric Company.

Safety Standards

Bodine products are designed and manufactured to comply to applicable

safety standards and in particular to those issued by ANSI (American

National Standards Institute), NEMA (National Electrical Manufacturers

Association), U.L. (Underwriters Laboratories, Inc.), and CSA (Canadian

Standards Association).

Bodine equipment “recognized by U.L., Inc.” are either labeled

with the UR or cURus marks. In addition, products that are CSA

certified are identified by the CSA mark. If you need specific

information regarding the third-party approval status of Bodine

products, contact the nearest Bodine representative, or the

home office.

CONTROL DESCRIPTION AND FEATURES

The ABL-3912E, and ABL-3913E Brushless DC Motor Controls are encased

style controls. They are supplied in their own enclosure to simplify mounting.

The controls operate from a nominal 115 VAC, 50/60 Hz. power source. They

provide electronic commutation and phase current switching needed to

4

www.bodine-electric.com

operate brushless DC motors. DIP switch selectable current limit settings

allow the ABL-3912E and ABL-3913E to be used with a wide range of fractional

horsepower motors and gearmotors.

The ABL-3912E and ABL-3913E provide a 130-Volt filtered output for improved

form factor, plus a built-in dynamic braking module. Motor speed is controlled

by a speed potentiometer mounted on the enclosure front panel. Direction

of rotation and braking are controlled from a “Forward-Brake-Reverse”

(F-B-R) switch also located on the front panel. Trim potentiometers on the

control circuit board allow additional fine tuning of minimum and maximum

speed settings, torque, acceleration and deceleration times. A built-in “Smart

Reverse™” circuit prevents plug reversing by dynamically braking the motor

to a stop before changing its direction. A built-in shutdown circuit disables

the control during over-voltage, under-voltage, or invalid commutation sensor

state conditions. Specific Bodine motor sizes which can be used with these

controls are listed in the Chart in Figure 3.

Accessory Items

• Model 3982 Extension Cable – extends cable between motor and control by six feet.

Both ends equipped with circular connectors for simplified connection. Length: 6 ft.

• Model 0895 Enclosure Sealing Kit – seals the ABL-3912E enclosure to provide

IP-44 level splash proof protection.

• Model 3984 Isolation Module – isolates the control from system controller

inputs, which may be at different potentials. This module is not required unless

the ABL-3912E is connected to a separate control system. See the “Specialized

Application Wiring” section of this manual.

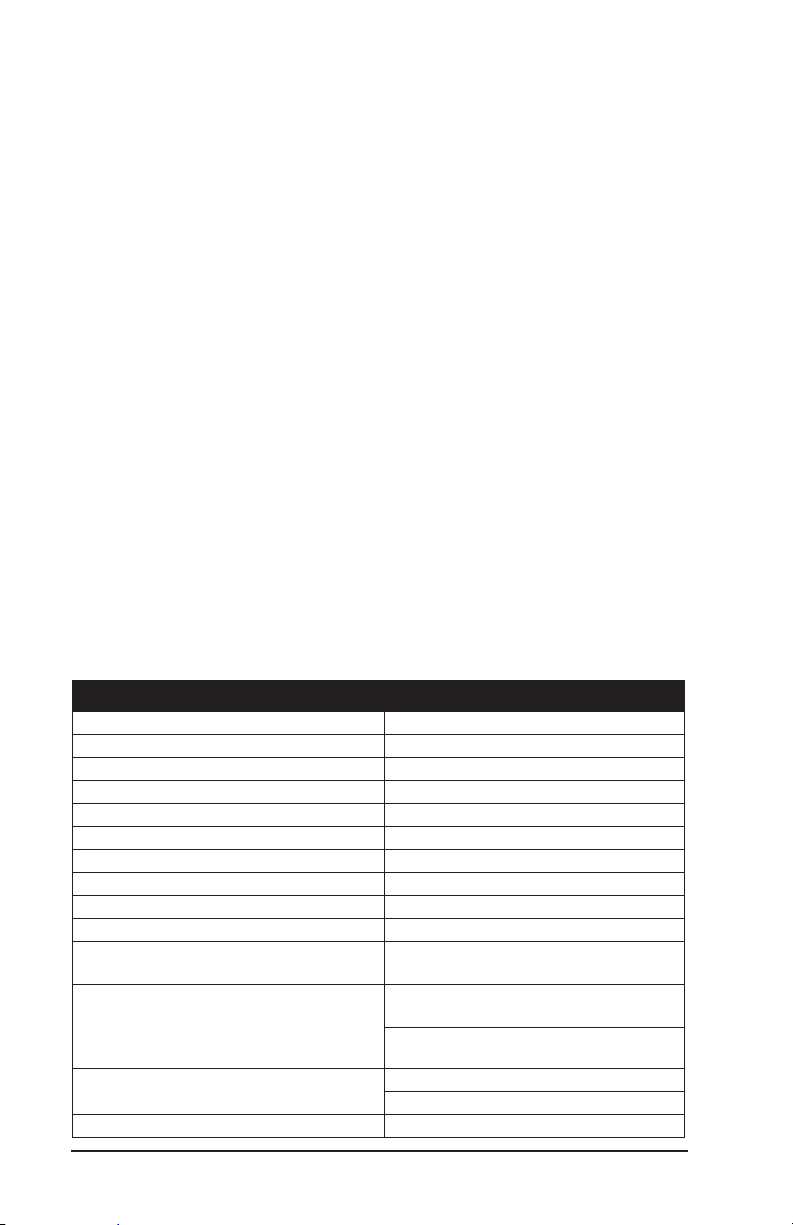

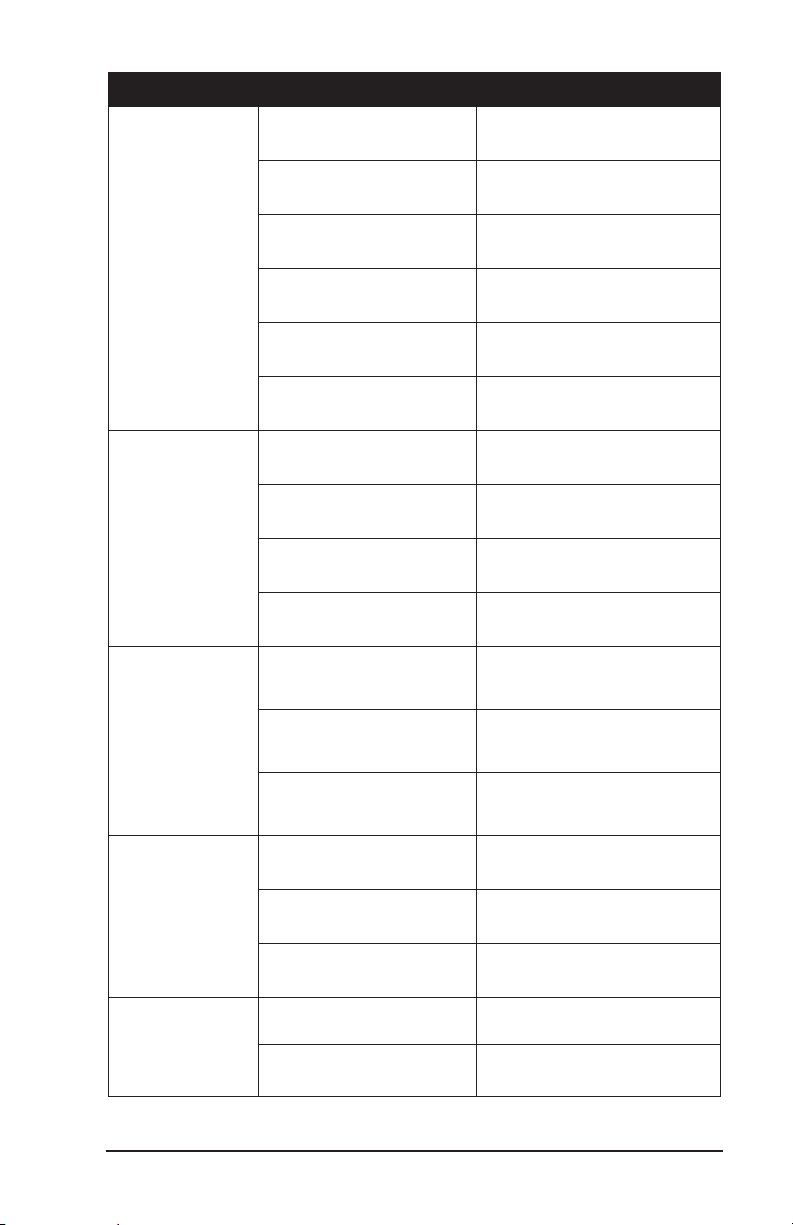

Parameter Specification

Product Type ABL-3912E/ABL-3913E

Input Voltage: 115 VAC ± 10%, 50/60 Hz (Single Phase)

Input Current: 12 Amps rms

Output Voltage: 0 to 130 VDC

Continuous Output Current 3.0 Amps

Peak Output Current 6.0 Amps

Ambient Temperature: 0° to 40° C (Maximum)

Control Hp Range: Up to 3/8 Hp

Control Speed Range: Up to 30:1

Control Speed Regulation: Less than 1% of rated (Typical)

Line Voltage Compensation: Negligible speed change with changes

in line voltage

Acceleration Time Range: (Model 3912): 0.2 to 10 seconds

(0 to full speed)

(Model 3913): 0.5 to 30 seconds

(0-full speed)

Dimensions: inches: ( 6.2 W x 4.0 D x 8.5 H);

cm: (15.8 W x 10.2 D x 21.6 H)

Net Weight: 7.5 lbs. (3.4 kg.)

www.bodine-electric.com

5

IMPORTANT SAFETY PRECAUTIONS

The following safety precautions must be observed during all phases of

installation, operation, service, and repair of this motor control product.

Failure to comply with these precautions or with specific warnings elsewhere

in this manual violates safety standards of design, manufacture and intended

use of the products. Bodine Electric Company assumes no liability for the

customer’s failure to comply with safety requirements and practices.

The use of electric motors and generators, like that of all utilization of

concentrated power, is potentially hazardous. The degree of hazard can

be greatly reduced by proper design, selection, installation, and use but all

hazards cannot be completely eliminated. The reduction of hazards is a joint

responsibility between the user, the manufacturer of the driven or driving

equipment and the manufacturer of the control or motor.

The user should refer to Publication No. ANSI C5.1/NEMA MG 2. Safety

Standard for Construction and Guide for Selection, Installation and Use of

Electric Motors and Generators available from:

National Electrical Manufacturers Association

www.nema.org

Warnings (such as the example below) highlight procedures which present

potential danger to people. Cautions highlight possible danger to equipment.

Both are used throughout this manual and must always be followed.

WARNING

Dangerous voltages may be present in the electronic control and motor.

These voltages could cause serious injury or death. Use extreme caution

during handling, testing, and adjusting. Properly guard the electronic

control and motor to prevent accidental contact by all persons.

The chance of explosions, fires, or electric shocks can be reduced

with thermal and over-current protection, proper grounding, enclosure

selection, and good maintenance. The following safety considerations

are not intended to be all-inclusive. Specific references throughout this

manual should also be consulted.

CAUTION

These controls are designed to provide optimum performance when

used with Bodine Electric Company motors. They should not be used with

other manufacturer’s motors without first contacting the Bodine Electric

Company. Failure to contact Bodine in advance could cause damage to

the control or the motor.

6

www.bodine-electric.com

Inspecting the Control

Check the items you received against your purchase order. Carefully examine

the control (and any optional kits or parts) for shipping damage. Parts errors

should be reported to Bodine. Shipping damage claims should be made to the

freight carrier.

Before installation, review the application to confirm that the proper motor

and control have been selected. This should be done after reading this

manual and all applicable safety standards. If in doubt, contact your Bodine

representative, or the home office if there is no representative in your area.

Although Bodine Electric Company assists its customers in selecting motors

and controls for specific applications, determination of fitness for purpose or

use is solely the customer’s responsibility.

Normal Operating Conditions

Unless otherwise agreed to by Bodine, all control nameplate ratings are

based on the following normal operating conditions. Consult Bodine Electric

Company if variations beyond these limits are anticipated.

1. Continuous Duty: without frequent reversals or starts and stops.

2. Maximum Ambient Temperature: 50° C (122° F) for chassis controls; 40° C

(104° F) for all encased controls.

3. Voltage: Within 10% of nameplate rating.

4. Frequency: Within 5% of nameplate rating.

5. Combined Variation of Voltage and Frequency: Within a total of 10%

providing frequency variation does not exceed 5%.

Grounding

Both electronic controls and motors must be securely mounted and adequately

grounded. Failure to ground properly may cause serious injury to personnel.

Fusing

Both the control input and output are fused. When fuses are replaced, they

must always conform to the values and ratings specified on the control’s

nameplate or in the fuse chart in Figure 4.

Live Circuitry

Open-type electronics should be properly guarded or enclosed to prevent

accidental human contact with live circuitry. No work should be performed on

or close to the control or motor while the control is connected to the AC line.

If an AC line switch is used, it should be a Double Pole Single Throw (DPST),

so that both sides of the AC line are disconnected

Note: Motor over temperature sensing is not provided by this control.

www.bodine-electric.com

7

Environment

Open controls or controls in ventilated enclosures may emit flame during

failure. Bodine’s totally enclosed products are not explosion-proof, and Bodine

does not offer an explosion-proof motor, gearmotor, or control for hazardous

locations (e.g., in an environment of flammable or explosive gas, vapor, or

dust). Bodine recommends use of only approved explosion-proof products

in hazardous locations. The National Electric Code (NEC) allows exceptions,

but NEC and NEMA safety standards should be studied thoroughly before

exercising this option.

Moisture increases the electrical shock hazard of electrical insulation.

Therefore, open-type or unsealed controls not specifically designed for such

use, should be protected from contact with liquids or moisture.

Ventilated Products

Open, ventilated products are suitable for clean, dry locations where cooling air is

not restricted. Do not insert anything into a product’s ventilation openings.

Servicing

Emergency field repairs must be made only by authorized Bodine service

representatives. Repairs made by persons not authorized by the Bodine

Electric Company will void the warranty. Field repairs must be limited to

replacing an entire printed circuit board assembly. Because of the danger

of introducing safety hazards, do not install substitute parts or perform any

unauthorized modifications to electronic PC boards, components or motors.

To ensure continued compliance with the design specifications and safety

standards, the electronic control or motor should be returned to Bodine

Electric Company or an Authorized Service Center for servicing.

WARNING

To avoid injury because of unsuspected mechanical motion, always

disconnect the 115 VAC power to the control before performing any

service procedures on the motor, control, or driven equipment.

This manual does not purport to cover all details or variations in equipment,

nor to provide for every possible contingency to be met in connection with

installation, operation, or maintenance — no warranty of fitness for purpose

is expressed or implied. Should further information be desired or should

particular problems arise which are not covered sufficiently for the user’s

purpose, the matter should be referred to the Bodine Electric Company.

The issuance of this manual does not confer to the recipient any license to

manufacture under any patents owned or controlled by the Bodine Electric

Company.

8

www.bodine-electric.com

INSTALLATION INSTRUCTIONS

WARNING

This control should only be installed by a qualified technician, electrician,

or electrical maintenance person familiar with its operation and associated

hazards. The National Electrical Code (NEC), local electrical and safety

codes, and when applicable, the Occupational Safety and Health Act

(OSHA) should be observed to reduce hazards to personnel and property.

Circuitry is not at ground potential. Do not perform work on or near the

control while it is connected to the AC line.

CAUTION

Exposed circuit boards should be protected from electrostatic discharge.

The control board uses CMOS circuitry. Static discharge into the control

board must be avoided to prevent component damage.

Mounting the Control

Detailed mounting dimensions and CAD drawings are available online. The

control should be mounted vertically so that the control panel is readable

and the cabling extends from the bottom of the enclosure. This arrangement

provides optimum air flow around the control.

Electrical Connections

Read the following instructions as well as all of the applicable safety

recommendations, before making any electrical connections between the

control, motor, or other motion control electronics.

Motor Cable Connection

All electrical connections for motor phase outputs and commutation sensor

control inputs are prewired and terminated in a circular connector and cable

assembly attached to the control enclosure. To connect the ABL-3912E or

ABL-3913E controls simply mate the circular connector from the control to

the circular connector on the associated Bodine motor.

Horsepower (DIP Switch) Settings

Figure 1 shows the Horsepower Select switch on the main control board. It

contains eight switch levers numbered 1 through 8. The chart in Figure 3 shows

the proper DIP switch settings for various Bodine motor types. Determine the

first four digits of the motor’s type number from the nameplate. Find the same

four digits in the chart in Figure 3 to determine the proper settings of the DIP

switches. An insulated tool should be used to adjust the switch settings.

www.bodine-electric.com

9

(4.64)

Figure 1 - Detail of Control Circuit Board in Enclosure.

3.88 Max.

1.48 Min.

8.45 Max.

External Speed Pot Connections

MAX speed adjust

(CW increase)

MIN speed adjust

(CW increase)

Acceleration time

(CW increase)

Deceleration time

(CW increase)

Torque adjust

(CW increase)

RED FAULT

LIGHT

(Indicates a

problem with the

commutation

sensor

connections)

(4.55 Typ.)

Line Fuse

AC Line

Horsepower Settings

Motor Fuse

Commutation

Sensor Inputs

Control Inputs

Shown with optional

mounting brackets in the

vertical position.

AC Neutral

Motor

Phase

Outputs

Motor Fuse

A

B

C

Figure 1 - Detail of Control Circuit Board in Enclosure.

Typical MAX Motor Speeds with 10 K Speed Pot

DIP Switch

7

DIP Switch 8

CCW MAX

Pot

Calibrated

MAX Pot

CW MAX

1

Pot

T-Out Pulse

Width (µS)

ON ON 4400 6600 8800 275

ON OFF 6600 10,000 13,000 190

Factory

Setting

OFF ON 6600 10,000 13,000 190

OFF OFF 13,000 20,000 26,000 90

1. Max. Speed obtainable is dependent on motor winding (voltage, speed rating, resistance),

line voltage and load conditions.

Figure 2 – DIP Switch 7 and 8 Speed Range Settings

(.57 Typ.)

(.57 Typ.)

(9.20) Typ.

Control Motor or Rated DIP Switch Line Motor AC rms

Model Gearmotor Speed Levers in the Fuse Fuse Input

Number Type Hp (RPM) “On” Position (F1) (F2) Current

22B2… 1/16 2, 6, 8 MDA 6/10 2.7

ABL-3912E 22B4… 1/8 2500 1, 3, 6, 8 ABC 15 MDA 1-1/4 4.8

ABL-3913E

22B3… 1/11 1, 2, 6, 8 MDA 8/10 3.6

34B3… 1/5 1, 2, 3, 6, 8 MDA 1-1/2 6.7

34B4… 1/4 2, 4, 6, 8 MDA 2 8.0

34B6… 3/8 1, 5, 6, 8 MDA 2-1/2 11.1

22B4… 1/5

34B4… 1/3 1, 3, 4, 6, 8 MDA 2-1/2 9.5

10,000

1, 2, 3, 6, 8

ABC 15

MDA 1-1/2 6.7

Figure 3 - Horsepower (DIP Switch) Settings and Fuse Selection Chart

10

www.bodine-electric.com

Motor Commutation Phasing (60° standard)

All standard (stock) brushless DC motors and gearmotors manufactured by

Bodine Electric Company are designed for 60° commutation. The factory

setting for our BLDC speed controls is also for 60° commutation. It is possible

to configure our BLDC stock controls to operate non-Bodine BLDC motors

and gearmotors with 120° commutation angle. To change the sensor phasing

output on our stock controls for 120° commutated gearmotors or motors, set

DIP switch number 6 to the “Off” position. Please note that further application

details must be considered to properly match a non-Bodine BLDC motor with

one of our stock BLDC controls. To avoid damage or system performance

issues, please consult our Technical Support staff at 773-478-3515 or via

E-mail: info@bodine-electric.com.

Line Fuse Installation

The control input is protected by factory-installed fuse (F1) shown in Figure 1.

It should always be replaced with a fuse of the same type and rating as

indicated in the chart in Figure 3.

Motor Fuse Installation

The control output contains a motor fuse (F2) shown in Figure 1. The rating of

F2 will vary with the size of the motor used. To determine the proper rating,

locate the first four digits of your motor’s type number on the motor nameplate.

Find the same four digits in the chart in Figure 3 and use only the fuse which is

recommended. The ABL-3912E and ABL 3913E are supplied with a motor fuse

kit containing all of the fuses listed in Figure 3.

Control Input Connections

The controls on the front panel of the ABL-3912E and ABL-3913E are used to

adjust motor speed, braking and direction of rotation. The controls are prewired at the factory. Refer to the Operating Instructions for additional details.

AC Power Connections

AC power is supplied to the control through a pre-wired power cord. The

power cord should be the last connection made during installation and

always be disconnected first before servicing.

WARNING

The ABL-3912E and ABL-3913E must be plugged into a grounded AC outlet

using the power cord supplied. The outlet should be capable of providing

a continuous current of 12 amps. Do not defeat the safety feature of the

three-pronged plug. If your outlet is not a grounding-type AC outlet, have a

licensed electrician replace it with one that is.

www.bodine-electric.com

11

OPERATING INSTRUCTIONS

WARNING

Explosions, fires, or electric shock hazards can be reduced through

thermal and over-current protection, good maintenance, proper

grounding, and enclosure selection. Review safety considerations

outlined in “Safety Precautions” and “Installing the Control.”

Preliminary Checks

1. Before starting the control, check all fuses, connections, and adjustments

such as horsepower DIP switch settings.

2. Proper consideration should be given to all rotating members. Before

starting, be sure keys, pulleys, etc. are securely fastened. Proper guards

should be provided to prevent hazards to personnel while the equipment

is rotating.

3. Mechanical considerations such as proper mounting and alignment of

products, and safe loads on shafts and gears should be reviewed. Do not

depend upon gear friction to hold loads.

4. The motor or gearmotor should be securely mounted (because of possible

reaction torque). Test the motor/gearmotor unloaded to be certain that

proper connections have been made.

Operating the Control

WARNING

The 115 VAC line cord should be disconnected before starting

1. Toggle the input power switch to OFF and set the speed potentiometer to

ZERO (fully counterclockwise).

2. Set the F-B-R switch to the “Brake” position.

3. Connect the 115 VAC power cord to the external power source. Then toggle

the 115 VAC input power switch to the ON position.

4. Set F-B-R switch to forward or reverse depending on the direction of shaft

rotation you require.

5. Turn speed potentiometer knob until motor rotates. Then adjust the

potentiometer to achieve the desired speed. If you wish to reduce the

torque level, refer to Internal Adjustments below.

6. If the motor does not operate, check first if the POWER lamp on the outside

of enclosure and the red FAULT light on the inside are on. Then disconnect

the AC power cord and check all connections and fuses. If a fuse is blown

and the motor is not locked (stalled) or overloaded, do not replace the fuse.

The control may be damaged. Refer to Troubleshooting on page 15 and

follow instructions. If the motor is overloaded, reduce the load and replace

blown fuses with new ones of the proper type and rating. (See Figure 3.)

12

www.bodine-electric.com

Internal Adjustments

Your control has been factory-adjusted for the following settings:

Minimum speed: 0 RPM

Maximum speed: ABL-3912E: 2500 RPM; ABL-3913E: 10,000 RPM

Acceleration: ABL-3912E: 2 seconds; ABL-3913E: 5 seconds

Deceleration: ABL-3912E: 2 seconds; ABL-3913E: 5 seconds

Torque: 200% of rated (based on DIP switch settings)

Refer to Figure 1 for the trim potentiometer locations and approximate initial

settings. If you need to readjust the control for your specific applications,

proceed as follows:

WARNING

Use a non-metallic or insulated adjustment tool (such as a television

alignment tool) for internal adjustments. Circuit components are not at

ground potential and accidental short circuiting and shock hazard may

occur with conducting tools. Adjustment should be made only by

qualified service personnel.

Minimum and Maximum Speed:

The MIN and MAX trim potentiometers have been factory calibrated. The

lowest MIN trim potentiometer setting (fully counterclockwise) corresponds

to 0 RPM and the highest MIN setting (fully clockwise) corresponds to

approximately 30% of rated speed.

The lowest MAX trim potentiometer setting (fully counterclockwise)

corresponds to 60% of rated speed and the highest MAX trim potentiometer

setting (fully clockwise) corresponds to approximately 120% of rated speed.

Refer to Figure 1 for trim potentiometer location and settings. Adjustment of

the MIN and MAX trim potentiometers may have to be repeated several times

to arrive at the desired speeds.

NOTE: Increasing the MIN potentiometer setting will increase the maximum speed beyond

nameplate speed. The MAX trim potentiometer will need to be readjusted.

www.bodine-electric.com

13

Torque (Current) Limiting Adjustment

The TORQ trim potentiometer (Figure 1) has been calibrated so that the motor

will never see more than 200% to 250% of its rated current input. The motor’s

torque output can be reduced to zero or stall torque. Set the torque based

on the system load requirements. Torque may be reduced on lightly loaded

systems to protect drive mechanisms, such as gearing, from damage due to

overloads. Turn the TORQ trim potentiometer counterclockwise to decrease

the torque and clockwise to increase the torque.

RPM

2500

1725

250

172

0

0 100

Figure 4 - Speed/Torque Curve Showing Reduced Torque at Lower Speeds

50

100%

80 oz-in.

oz-in.

150

Filtered stall (140 oz-in.)

Acceleration Adjustment

Adjusting the ACCEL trim potentiometer (See Figure 1) counterclockwise

decreases the motor’s acceleration time down to a minimum of approximately

0.2 seconds (ABL-3912E) or 0.5 seconds (ABL-3913E). A clockwise adjustment

increases the rate up to a maximum of approximately 10 seconds (ABL-3912E)

or 30 seconds (ABL-3913E).

Deceleration Adjustment

Adjusting the DECEL trim potentiometer (See Figure 1) counterclockwise

decreases the motor’s deceleration time down to a minimum of approximately

0.2 seconds (ABL-3912E) or 0.5 seconds (3913E). A clockwise adjustment

increases the rate up to a maximum of approximately 10 seconds (3912E) or

30 seconds (3913E).

14

www.bodine-electric.com

TROUBLESHOOTING

WARNING

Disconnect the 115 VAC power cord from the power source before

working on the control, motor, or driven equipment.

All Bodine controls undergo extensive testing and calibration procedures to

detect and eliminate defects. Your control should not require maintenance under

normal conditions. If you encounter a problem, read all applicable instruction

literature provided with this control and accessories, and double check the

wiring. The charts on the following pages provide assistance in troubleshooting

common problems which occur during normal installation and operation.

If the problem persists, contact your source of purchase and describe

the problem in detail. Include all the nameplate data. Do not disassemble

the product unless authorized by Bodine Electric Company. Performing

unauthorized repairs or removing screws will void the Warranty.

ABNORMALITY CHECK POINT COUNTERMEASURE

CONTROL

BLOWS LINE

FUSE

MOTOR WILL

NOT START

Control or motor connected

to or shorted to earth ground

Shorted phase leads,

wiring incorrect

Damaged control Components

Open line fuse or motor fuse

Open power switch Set power switch to ON

Motor overloaded

TORQ trim pot is out

of adjustment

Speed potentiometer

set to zero

F-B-R switch in

BRAKE position

Damaged motor Repair or replace motor.

Check for shorts and

repair as required.

Correct wiring.

Contact Bodine for

assistance.

Replace fuse. Refer to

Figure 3 for proper value.

Correct load or choose

larger motor.

Visually check setting

(Figure 1). Adjust TORQ

trim pot, page 14.

Increase speed

potentiometer setting

Set switch to FORWARD

or REVERSE.

www.bodine-electric.com

15

ABNORMALITY CHECK POINT COUNTERMEASURE

MAX trim pot set too low Adjust trim pot, page 13.

MOTOR WILL

NOT COME UP

TO SPEED

MOTOR SPEED

IS ADJUSTABLE

OR PULSATES

MOTOR WILL

NOT MAINTAIN

SPEED UNDER

LOAD

Speed potentiometer

set to low

Motor overloaded

TORQ trim pot is out

of adjustment

Wrong horsepower setting

Damaged component

on the control board

Increase speed

potentiometer setting.

Re-examine the load

parameters

Visually check setting (Figure 1)

Adjust TORQ trim pot, page 14.

Check DIP switch

setting, page 10.

Contact Bodine for assistance.

Wrong horsepower setting Check DIP switch setting, page 10.

Motor and load not

correctly aligned

Perform alignment.

Damaged motor Repair or replace motor.

Speed potentiometer

set too low

Wrong horsepower setting

TORQ trim pot is out

of adjustment

Motor overloaded

Increase speed

potentiometer setting.

Check DIP switch

setting, page 10.

Visually check setting (Figure 1).

Adjust TORQ trim pot, page 13.

Re-examine the load

parameters.

MOTOR WILL

NOT STOP WITH

SPEED POT

ADJUSTED

NO SPEED

ADJUSTMENT

16

MIN trim potentiometer

is set too high

Open connection on

speed potentiometer

Defective speed

potentiometer

Defective speed

potentiometer

Open connection on

speed potentiometer

Turn the MIN trim pot

CCW until motor stops.

Check potentiometer

connections.

Replace the potentiometer.

Contact Bodine for assistance.

Replace the potentiometer.

Contact Bodine for assistance.

Check potentiometer

connections.

www.bodine-electric.com

SPECIALIZED WIRING APPLICATIONS

The Bodine ABL-3912E and ABL-3913E encased controls provides optimum

performance and easy installation when used with Bodine Brushless DC

motors and gearmotors. The control can be used with brushless DC motors

from other manufacturers provided electrical specifications and performance

requirements are compatible. The user bears the responsibility for determining

if another motor is fit for use with the ABL control. If you have doubts, Bodine

will assist you in determining if another motor is fit for use with this control.

The ABL-3912E and ABL-3913E are designed for applications where the

motor and control act as a stand-alone system. If the motor and control are

to be part of a larger motion control system requiring electronic control or

operation from a remote control panel, the model ABL-3910C or ABL-3921C or

ABL-3911C Chassis Type Controls are recommended.

If however, the ABL-3912E, and ABL-3913E must be adapted to fit a unique

situation, the following information should be reviewed carefully and

understood before proceeding with any wiring changes.

WARNING

The 115 VAC power line to the control should be the very last connection

made. Disconnect the power line before making any other electrical

connections.

CAUTION

The control board signal common is not at ground potential, any external

signal or equipment connected to the control must be electrically isolated

from ground (e.g., relay or optically isolated). Nonisolated signals will

damage the control and/or associated external equipment.

CAUTION

Read the following instructions as well as all of the applicable safety

recommendations, before making any electrical connections between the

control, motor, or motion control electronics.

www.bodine-electric.com

17

Motor Cable

Motor Cable

The ABL-3912E, and ABL-3913E Encased Controls are equipped with a pre-

wired cable which mates with the cable on associated Bodine Brushless DC

Motors. If the cables supplied with the motor and control are not long enough,

they can be extended using the Bodine Model 3282 Extension Cable. No more

than one 3282 extension should be used. This assures that the 12 ft. maximum

recommended distance between the control and the motor will be maintained.

The pin designations for the circular connector are as follows:

The ABL-3912E, and ABL-3913E Encased Controls are equipped with a

prewired cable which mates with the cable on associated Bodine Brushless

DC Motors. If the cables supplied with the motor and control are not long

enough, they can be extended using the Bodine Model 3982 Extension Cable.

No more than one 3982 extension should be used. This assures that the 12 ft.

maximum recommended distance between the control and the motor will

be maintained.

The pin designations for the circular connector are as follows:

Pin No. Lead Color Wire Gage Circuit Designation

1 Brown 18 Motor Phase A

2 Red 18 Motor Phase B

3 Orange 18 Motor Phase C

4 Grn/Yel Tracer 24 Chassis ground

10 Black 24 Circuit Common

12 Brown 24 Hall Sensor A

9 Red 24 +12 VDC

13 White 24 Hall Sensor B

14 Green 24 Hall Sensor C

11 Shield 24 Drain*

* The drain is terminated at the control board. Do not terminate the

The shield common is at a dangerous potential above ground and presents

a voltage hazard. Contact with the shield could cause serious injury or

death. If a non-Bodine cable is used or if a special cable is fabricated,

care should be taken to insulate all exposed shield to avoid serious injury.

The shield should only be connected to COM terminal on the Commutation

Sensor Input Connector at the control. No other shield connection should

be made.

drain at the motor.

WARNING

CAUTION

Only copper wire with a minimum 60° C rated insulation is recommended

if Bodine cable assemblies are not used.

18

www.bodine-electric.com

Connecting Control Inputs From Remote Locations

11

U23

R83

RP1

J1

1

J3

1

R82

R84

R81

J2

HB

EN1

HC

HA

EN2

INTERFACE

120

FSEL

BRAKE OUT

DIR

CONTROL INPUTS

DECLCOM

DECEL

DISCOM

DISABLE

DIRCOM

H+

H-

COM

COMMUTATION

Control Inputs

INTERFACE CONNECTOR -

Disconnect whenever external

inputs are used.

DO NOT REMOVE

"BRAKE OUT"

Connector

Figure 4 - Interface Connector Detail

CAUTION

The INTERFACE connector on the main control circuit board must be

disconnected if the ABL front panel controls are overridden by remotely

located controls or by a system controller. See Figure 5.

NOTE

The red plastic plug at the bottom of the ABL enclosure may be removed

to accommodate remote signal cables. It should be replaced with a IP-44

grade cord grip. If IP-44 splash protection is not required, any cord grip or

strain relief designed to fit a 3/8-18 NPT tapped hole may be used.

INTERFACE CONNECTOR -

Remotely Located Speed Control:

To connect a remote speed

potentiometer, proceed as follows:

1. Solder the three leads of

appropriate length to a 10K

ohm potentiometer as shown

in Figure 6.

2. Attach 1/4” female quick

disconnect terminals to

the other ends of the three

potentiometer leads.

3. Mount the potentiometer in the

desired location.

4. Connect the speed pot leads

to the ABL control board as

follows:

• Blue to Terminal “S1”

• Orange to Terminal “S2”

• Yellow to Terminal “S3”

FSEL

120

INTERFACE

Figure 5 - Interface Connector Detail

Front View

S1

60618 USA

CHICAGO IL

R93R92 R95

R94R91

TORQMINMAX DECELACCEL

LED2

Figure 6 - Remote Speed Control Connections

Disconnect whenever external

inputs are used.

J3

J2

BRAKE OUT

1

DECLCOM

DECEL

DO NOT REMOVE

"BRAKE OUT"

Connector

DISCOM

CONTROL INPUTS

Ohms

S3

S2

SPEED POT

C 1992

S1

S2

COMPANY

ELECTRIC

S3

BODINE

CAL

R90

DIRCOM

DISABLE

DIR

Control Inputs

10K

Speed Pot Terminals

LINE FUSE

F1

D3

D2

C3

COMMUTATION

Yellow

Orange

Blue

R82

R81

R84

R83

U23

11

RP1

1

COM

EN2

EN1

HC

HB

HA

H+

H-

J1

S3

S2

S1

PILOT

www.bodine-electric.com

19

Remotely Located Braking (Disable), Direction

4000 Series CMOS

of Rotation, andDeceleration Controls

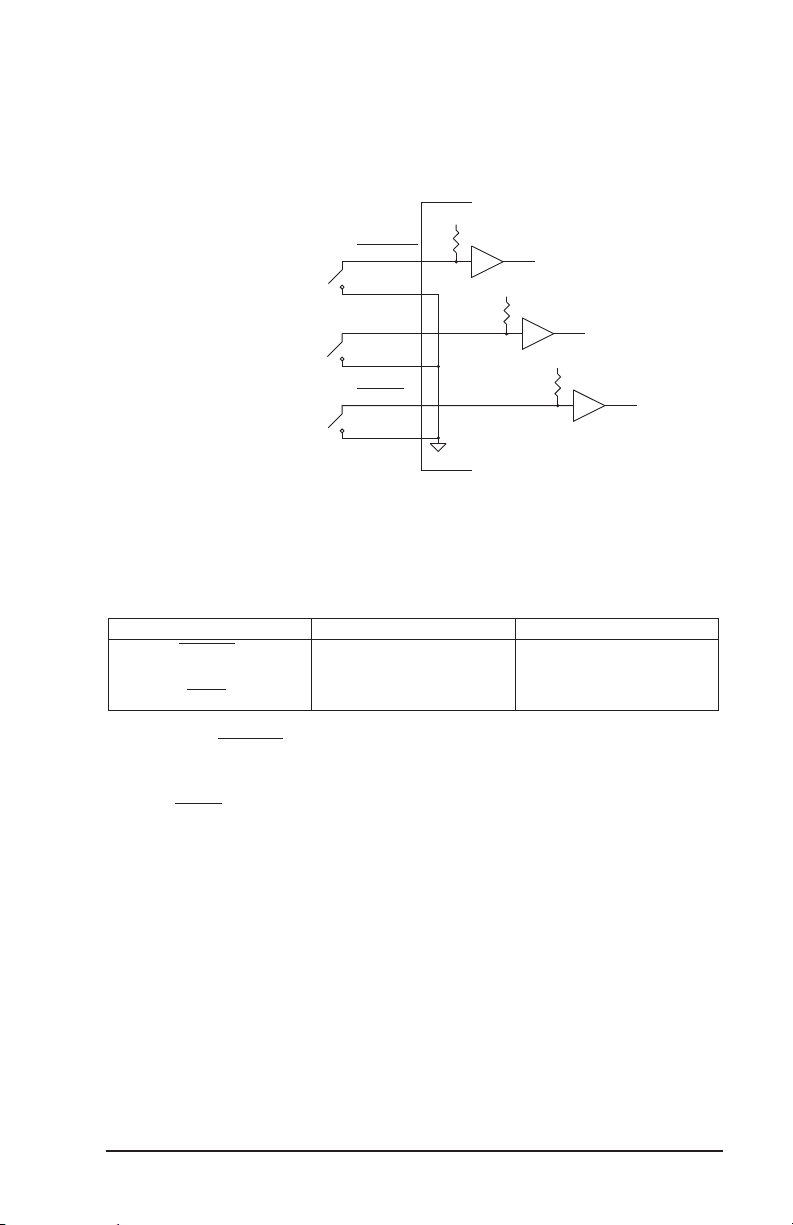

Mechanical switches or relays can be used to switch the control inputs

shown in Figure 5. Figure 7 shows a schematic representation of manual or

relay switched inputs.

NOTE: The

DISCOM,

DIRCOM,

DECLCOM,

S1, and COM

terminals on the

control board are

all connected in

common.

DISABLE

DISCOM

Manual

Switches

or Relay

Contacts

Figure 7 - Manual Switch and Relay Control Inputs.

DIR

DIRCOM

DECEL

DECLCOM

12V

10K

Signal

Common

4000 Series CMOS

12V

10K

4000 Series CMOS

12V

10K

The following chart lists the control functions relative to the state of the

mechanical switches or relays.

Switch Closed Open

1

DISABLE

2

DIR

3

DECEL

1. When the DISABLE switch is closed the motor will be dynamically braked.

2. A “Smart Reverse Circuit” prevents plug reversing when the DIR switch is

opened or closed. The motor will brake to a stop before changing direction.

3. The DECEL switch controls soft stops and starts. The degree of acceleration and

deceleration can be varied with the trim potentiometers on the control board.

See Page 14.

4. The output shafts of gearmotors with odd number of stages (Bodine type

designations ending with W3, E1, or E3) will rotate in the opposite direction.

Stop Run

4

CW

Decelerate Accelerate

CCW

4

Electronic Control Input Connections

Optional Interface Boards are available from Bodine and other manufacturers.

They provide electrical isolation between the input signal and the brushless

DC motor control circuitry, and are recommended for motion control

applications requiring electronic control of motor speed, rotational direction,

deceleration, and braking.

20

www.bodine-electric.com

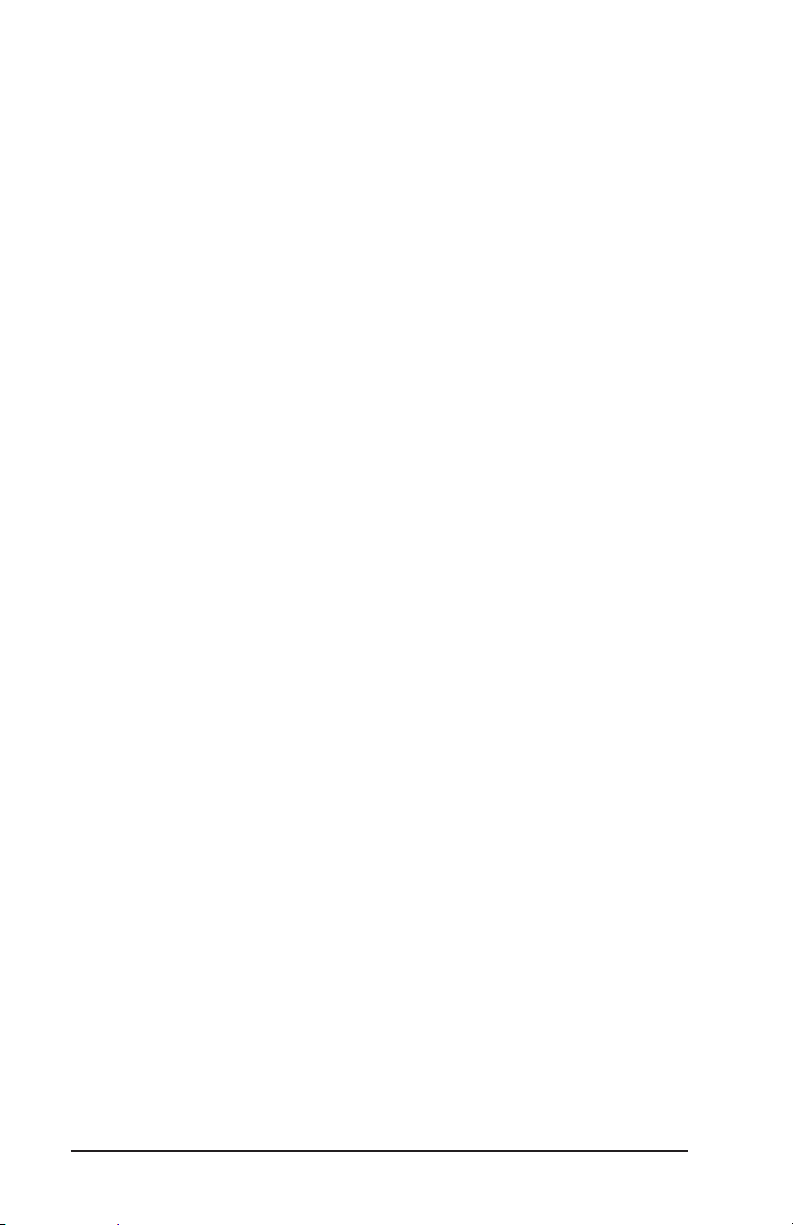

Electronic Speed Control

Motor speed can be controlled with a 0 to +10 VDC isolated signal with 0.1 mA

current capability in lieu of the manual speed potentiometer. This speed

control input should be connected to terminal S2 on the control board. The

common side of the signal must also be isolated and connected to terminal

S1 on the main control board.

Logic Signal Control of Braking, Direction of Rotation, and Deceleration

Motor braking (or disable), direction of rotation and deceleration can be

controlled using optically isolated logic signals from a programmable

controller, personal computer, or other electronics.

WARNING

Never rely on logic circuitry as a means of disabling the motor or control.

To prevent unsuspected mechanical motion and potential injury, the 115

VAC power should always be disconnected whenever logic circuits or

the driven equipment are serviced.

Exercise extreme caution when using Programmable Logic Controllers (PLCs).

Although some may claim to have optically isolated output modules, their output

commons may be connected to other circuitry either within or connected to the

PLC. In such cases, the PLC outputs should be isolated from the ABL control, by

a relay or by an electronic isolation module, to prevent damage to the PLC or the

ABL control.

If a Programmable Controller with a

relay output module is not available,

AC or DC outputs from the PLC can

be used to drive separate relay coils.

See PLC user’s manual for application

information. See Figure 6 to determine

how to connect relay contacts to the

ABL-3912E and ABL-3913E.

Signal Isolation Using a Bodine

Model 3984 Interface Module:

Follow the installation instructions

provided with the module to isolate

the input signals between the

control electronics and the ABL

Control. See Figure 7 for control

input connections and Figure 8 for

speed control interface details.

www.bodine-electric.com

10K

12V

10K

Maximum

Speed

Adjustment

100K

S3

S2

S1

Potentiometer/ Interface Details

100K

Signal Common

Figure 8 - Manual Speed

10K

Minimum

Speed

Adjustment

10K

Signal Common

51.1K

–

+

21

NOTES

BODINE LIMITED WARRANTY

The Bodine Electric Company warrants all products it manufactures to be free

of defects in workmanship and materials when applied in accordance with

nameplate specifications. Bodine motors and gearmotors purchased with

and used only with appropriately applied Bodine controls are covered by this

warranty for a period of 24 months from the date of purchase or 30 months from

date of manufacture, whichever comes first. Bodine motors and gearmotors

used with non-Bodine controls and Bodine controls used with non-Bodine

motors and gearmotors are covered by a 12 month warranty period. The

Bodine Electric Company will repair, replace, or refund at its option, any of

its products which has been found to be defective and within the warranty

period, provided that the product is shipped freight prepaid, with previous

authorization, to Bodine or to a Bodine Authorized Service Center. Bodine

is not responsible for removal, installation, or any other incidental expenses

incurred in shipping the products to or from Bodine. This warranty is in lieu

of any other expressed or implied warranty – including, but not limited to,

any implied warranties of merchantability and/or fitness for a particular use.

Bodine’s liability under this warranty shall be limited to repair or replacement

of the Bodine product and Bodine shall not be liable, under any circumstances,

for any consequential, incidental or indirect damages or expenses associated

with the warranted products. Proof of purchase of motor or gearmotor and

matching control as a system must be provided with any claim.

Control Type:_____________________ Serial No.____________________

Date of Purchase:____________ Place of Purchase:_______________

www.bodine-electric.com

23

Bodine offers over 1,200 standard

gearmotors, motors and

system-matched speed controls.

Visit www.bodine-electric.com

for our large selection of 24 VDC

brushless DC motors and gearmotors

Bodine offers the widest selection of variable-speed

AC, permanent magnet DC and brushless DC fractional

horsepower gearmotors and motors in the industry. For

complete specifications, 3D CAD drawings, or to order

online, visit bodine-electric.com.

201 Northfield Road | Northfield IL 60093 U.S.A. | Tel: 773.478.3515 | Fax: 773.478.3232

info@bodine-electric.com | www.bodine-electric.com

07400212.C

Loading...

Loading...