Boca Research Muon Liquid Handling System User Manual

Muon Liquid Handling System

User Guide

C. Johnson, S.P. Cottrell et al

Version 0.2

- 1 -

Contents

1 Getting Started 3

1.1 Layout of the liquid handling system 3

1.2 Layout of the in situ sample stick 4

1.3 Layout of the pump 4

2 General procedures 6

2.1 Sample loading 6

2.1.1 Loading Vessel 1 6

2.1.2 Loading Vessel 2 6

2.2 Evacuation of the system 6

2.2.1 Removing air from Vessel 1 7

2.2.2 Removing air from Vessel 2 7

2.2.3 Removing air from Vessel 3 7

2.2.4 Evacuation of the sample cell 7

2.3 Freeze-Pump-Thaw cycle 8

2.3.1 Sample in Vessel 1 8

2.3.2 Sample in Vessel 2 8

2.3.3 Sample in Vessel 3 9

2.4 Liquid transfers 9

2.4.1 Vessel 1 to sample cell 9

2.4.2 Vessel 3 to sample cell 10

2.4.3 Recovery of liquid in manifold to Vessel 2 10

2.4.4 Recovery of liquid in sample cell to Vessel 1 11

2.4.5 Recovery of liquid in sample cell to Vessel 2 11

2.4.6 Recovery of liquid in sample cell to Vessel 3 11

3 Example Experiment 13

- 2 -

1 Getting Started

This manual describes the liquid handling system and the in situ sample cell as used

on the DEVA instrument with the “RF” spectrometer, for either normal muon spins

relaxation or RF resonance experiments.

1.1 Layout of the liquid handling system

The Muon Liquid Handling System has been designed to facilitate the in situ

degassing and transfer of samples into and out of the sample cell. The main features

of the liquid handling system are shown in Figure 1.

To pump

Inlet 1

Baratron

Vessel 1

Inlet 2

Vessel 2

Gas

pressure

Cell

pressure

Vessel 3

Figure 1 The layout of the front panel on the muon liquid handling system.

In general, the rig consists of three glass vessels for the storage of liquid samples, any

of which can be opened to a vacuum for the purposes of degassing by the freezepump-thaw method. Once degassed, the sample liquid can be transferred to the

sample cell contained within a cryostat without further exposure to the air. In

addition, samples may be returned to the rig for further freeze-pump-thaw cycles or

for disposal.

To cell

- 3 -

1.2 Layout of the in situ sample stick

The liquid sample stick is designed to fit into the DEVA flow cryostat, details of

which can be found in the DEVA manual. It consists of a shapol target cell 30 mm x

30 mm with a mylar window upon which may be mounted an RF coil. Two stainless

steel capillaries provide a means of flowing liquid into and out of the cell along with

feed throughs for an RF excitation signal and a pick-up coil.

Figure 2 The liquid-sample cell mounted on a sample stick with a flat coil suitable for RF µSR.

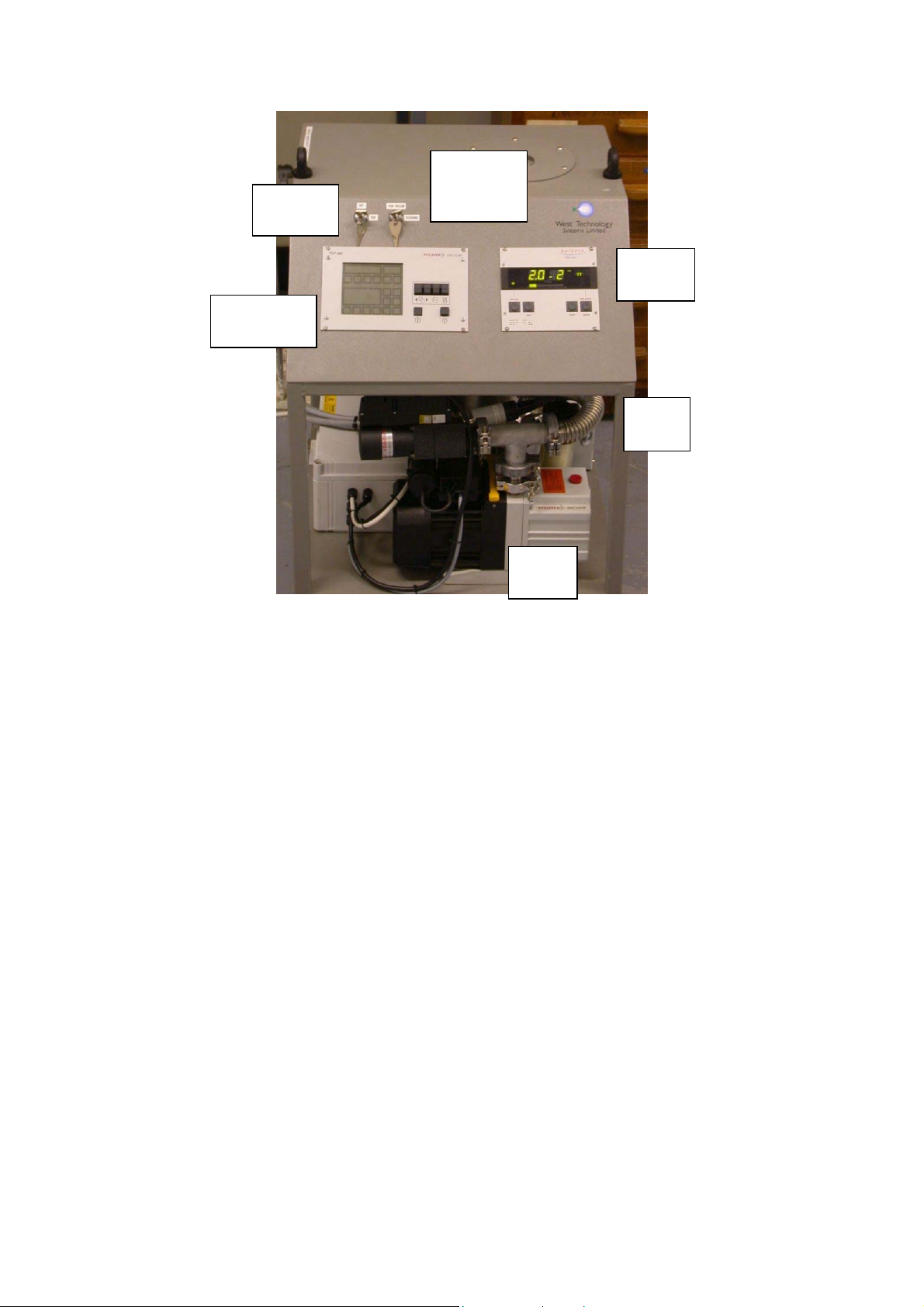

1.3 Layout of the pump

The pump used with the Muon Liquid Handling System consists of a rotary pump

used to reduce the pressure of large volumes of gas and a turbo pump to achieve a

high vacuum. The main features pump used on the liquid handling system are shown

in the diagram below.

- 4 -

Roughing/

Turbo

Off/Run

switch

Turbo

control panel

switch

Rotary

Pump

Pressure

reading

Turbo

Pump

Figure 2 The layout of the front panel on the vacuum pump used with the muon liquid handling

system.

- 5 -

Loading...

Loading...