™

SAM 935

Surveillance and Measurement System

Instruction Manual

Berkeley Nucleonics Corporations

3060 Kerner Boulevard #2

San Rafael, CA 94901 USA

800-234-7858

415-453-9955

fax: 415-453-9956

http:/www.berkeleynucleonics.com

Firmware Release 02.05.19

U. S. Patent No. 5608222

© 1995-1999 All rights reserved.

Printed in U.S.A. - 03/30/00

WARRANTY

Berkeley Nucleonics Corporation warrants all instruments, including component parts, to be free from defects in material and

workmanship, under normal use and service for a period of one year. If repairs are required during the warranty period, contact the

factory for component replacement or shipping instructions. Include the serial number of the instrument. This warranty is void if the

unit is repaired or altered by others than those authorized by Berkeley Nucleonics Corporation.

IMPORTANT!! PLEASE READ CAREFULLY

NOTIFICATION OF COPYRIGHT

THE FIRMWARE IN THIS DEVICE IS PROTECTED BY COPYRIGHT LAWS AND INTERNATIONAL TREATY. YOU MUST TREAT

THE FIRMWARE LIKE ANY OTHER COPYRIGHTED MATERIAL. COPYRIGHT LAWS PROHIBIT MAKING ADDITIONAL COPIES

OF THE FIRMWARE FOR ANY REASON OTHER THAN SPECIFICALLY DESCRIBED IN THE LICENSE BELOW. YOU MAY NOT

COPY THE WRITTEN MATERIALS ACCOMPANYING THE PRODUCT.

2 SAM 935™ Instruction Manual

Table of Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.1 How To Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Quick Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.1 Power On the SAM 935 . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.2 Quick Calibration and Background Reading . . . . . . . . . . . . . . . . 3

1.2.3 Take Samples and Review Alarms. . . . . . . . . . . . . . . . . . . . . 5

2 Connecting Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.1 Connecting Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Connecting to a Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Connecting to a Remote Computer . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Connecting an Optional External Detector . . . . . . . . . . . . . . . . . . . . . . 7

3 Configuring the SAM 935 . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.1 Starting Up the SAM 935 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Recalibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2.1 Automatic Coarse Calibration . . . . . . . . . . . . . . . . . . . . . . 11

3.2.2 Acquire a Background Spectrum . . . . . . . . . . . . . . . . . . . . . 12

3.2.3 Fine Energy Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.4 Calibration with Three Coefficients . . . . . . . . . . . . . . . . . . . . 17

3.3 Configure Dose Rate Units and Trigger . . . . . . . . . . . . . . . . . . . . . . 17

3.4 Dose Rate Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4 Operating the SAM 935 . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1 Recommended Daily Operating Procedure . . . . . . . . . . . . . . . . . . . . 20

4.2 Powering the SAM 935 On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2.1 Quick Calibration Adjustment. . . . . . . . . . . . . . . . . . . . . . . 22

4.3 Powering the SAM 935 Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.4 Taking Readings in Surveillance Mode . . . . . . . . . . . . . . . . . . . . . . 24

4.5 Reviewing Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.6 The SAM 935 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.6.1 The Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.6.2 Function Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.6.3 Scrolling Through Long Menus. . . . . . . . . . . . . . . . . . . . . . 27

4.6.4 Editing Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.6.5 The Utilities Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5 SAM 935 Modes of Operation . . . . . . . . . . . . . . . . . . . . . . 30

5.1 The Surveillance Mode of Operation . . . . . . . . . . . . . . . . . . . . . . . . 30

5.2 The Monitor Mode of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.3 The Detail Mode of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.4 Manual Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.4.1 MCA Presets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.4.2 Manual Hardware Adjustments. . . . . . . . . . . . . . . . . . . . . . 35

5.4.3 Manual Mode Utilities. . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.5 Background Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

SAM 935™ Instruction Manual 1

5.6 Calibration Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.6.1 Manual Coarse Adjust with Cs137 . . . . . . . . . . . . . . . . . . . . 38

5.6.2 Fine Energy Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6 Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.1 Area Monitor Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.1.1 Set the Sample Time . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.1.2 Select Triggers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.1.3 Set the Default Trigger Levels . . . . . . . . . . . . . . . . . . . . . . 43

6.1.4 Preventing False Alarms . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.1.5 Calibrate Dose Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.1.6 Configure Alarm Hardware . . . . . . . . . . . . . . . . . . . . . . . . 47

6.2 Clear Stored Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.3 Edit Isotopes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.3.1 Adding a New Isotope. . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.3.2 Enable/Disable Isotopes . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.3.3 Editing an Isotope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.4 Edit Isotope Radiations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.5 Print Databases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.6 Edit Calibration Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.6.1 Adding a Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.6.2 Deleting a Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.6.3 Editing a Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.7 Select / Edit Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.8 Analysis Tools Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.9 Select Spectrum Draw Style . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.10 Show System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.11 Set Serial Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.12 Set Report Title String . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.13 Set System Clock—Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.14 Set Backlight Delay Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.15 Print Stored Spectra . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.16 Clear Stored Spectra . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.17 Switch to Remote . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.18 Clear ALL Data and Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7 Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.1 Area Monitor Report of Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.2 Background Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.3 Energy Calibration Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.4 Manual MCA Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.5 Database Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Appendix A: AutoLoad . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

A.1 Installing AutoLoad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

A.2 Using AutoLoad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

A.3 Device-Specific Notes for the SAM 935 . . . . . . . . . . . . . . . . . . . . . . . 65

2 SAM 935™ Instruction Manual

1. Introduction

Welcome to the SAM 935™, a portable surveillance and measurement system for detecting and identifying

multiple nuclides.The SAM 935 identifies mixed isotopes, providing quantified results and time-slice

analysis.

The SAM 935 has a large feature set that addresses almost any gamma radiological task. It can be used in

a very simple mode that does not require any radiological experience. The purpose of the Quick Reference

in Section 1.2 is to give the operator the information needed to use the SAM 935 for radiation detection

and isotopic identification. Complete discussions of the full SAM 935 functionality can be found in the

remainder of the manual.

The modes of operation are described in Section 5. The SAM 935 is not just a MCA since it has many

automated and easy-to-use features with real time analysis. Therefore, operation solely from the Manual

mode does not use the intelligence that makes the SAM a very unique instrument. The operator should be

aware that the SAM 935 is designed to be operated primarily in the Surveillance, Monitor, or Detail mode.

In any of these modes an alarm may be stored, reviewed, and dragged into the manual MCA for further

analysis. This not only makes for ease of operation but allows greater functionality and immediate identification of isotopes. Furthermore, these primary modes of operation allow review and printout of each stored

alarm. The Manual mode will not allow review of stored events, dose-rate measurements, neutron measurements, or many of the time slice features built into this instrument.

QuantumMCA and QuantumGold are PC software packages that allow up to 8 MCAs to be controlled at

one time with up to 16K of real time display. QuantumMCA is the standard software and QuantumGold is

the premier software for quantitative analysis. These packages are available with their own documentation

on operation. Appendix A of this manual gives instructions for loading the PC software (see also Section

6.17 for remote access). This software will allow analysis in 256 QCC or linear, 512 QCC or linear, and

1024 linear modes. When using the SAM 935 without a PC, operation is limited to 256 and 512 QCC. However, all stored data (including 1024 linear that is not stored) may be transferred from the SAM to the PC

for analysis.

1.1 How To Use This Manual

This manual uses the following typographic conventions:

File Menu names are shown in bold mixed case, indicating the SAM 935

screen mode.

E

NTER, F1…F4 Small capital letters are used for the names of keys to be pressed on the

SAM 935.

Calibrate Area Monitor

SAM 935™ Instruction Manual 1

Choices in menu listings and on-screen prompts are shown in italics.

This page intentionally blank.

2 SAM 935™ Instruction Manual

1.2 Quick Reference

Operating the SAM 935 is a simple 3-step process:

1. Power on the SAM 935.

2. If prompted to do so, take a quick calibration and background reading.

3. Take samples and review any alarms.

1.2.1 Power On the SAM 935

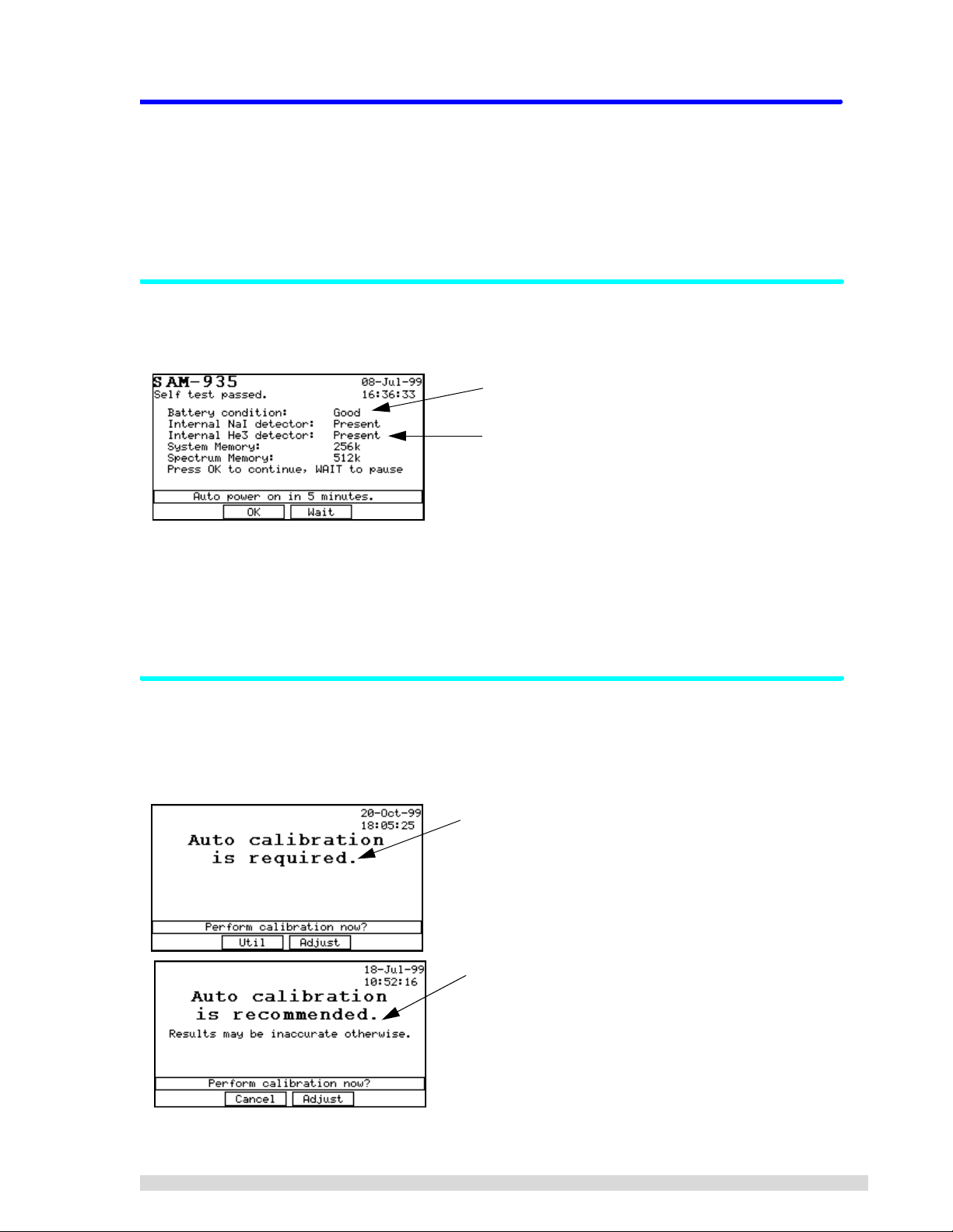

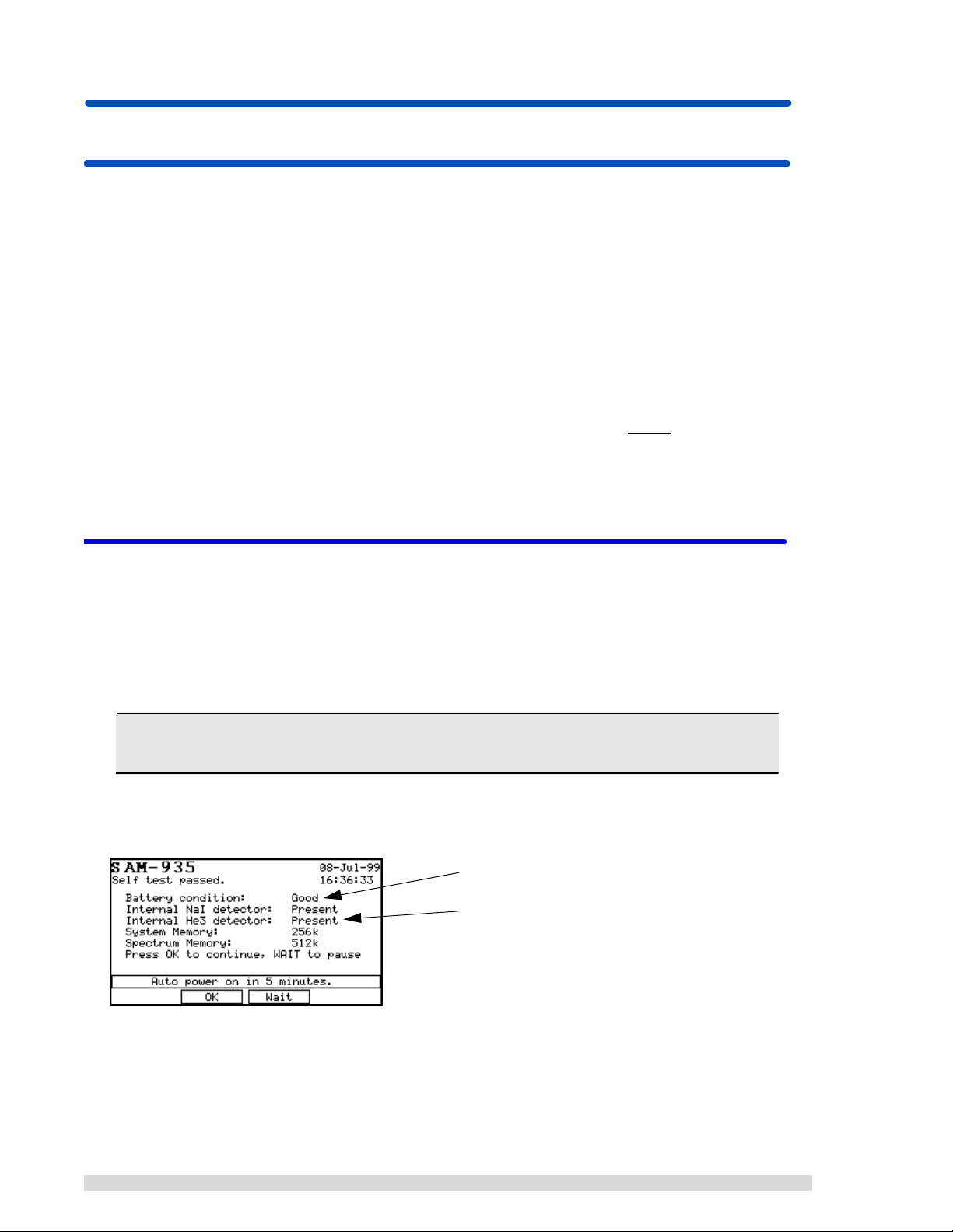

When you power on the SAM 935, it will first run a self-test as shown below:

Note the battery condition here.

Note the type of detector(s) installed here.

After the self-test has run, the SAM 935 will proceed to auto-start after 5 minutes have elapsed, after which

you can begin operating the unit.

Y ou can also press OK (F2) to immediately start up. Press W

AIT (F3) to delay startup for another 5 minutes.

If you are not prompted to take a calibration, you can proceed to take readings; skip to Section 1.2.3.

1.2.2 Quick Calibration and Background Reading

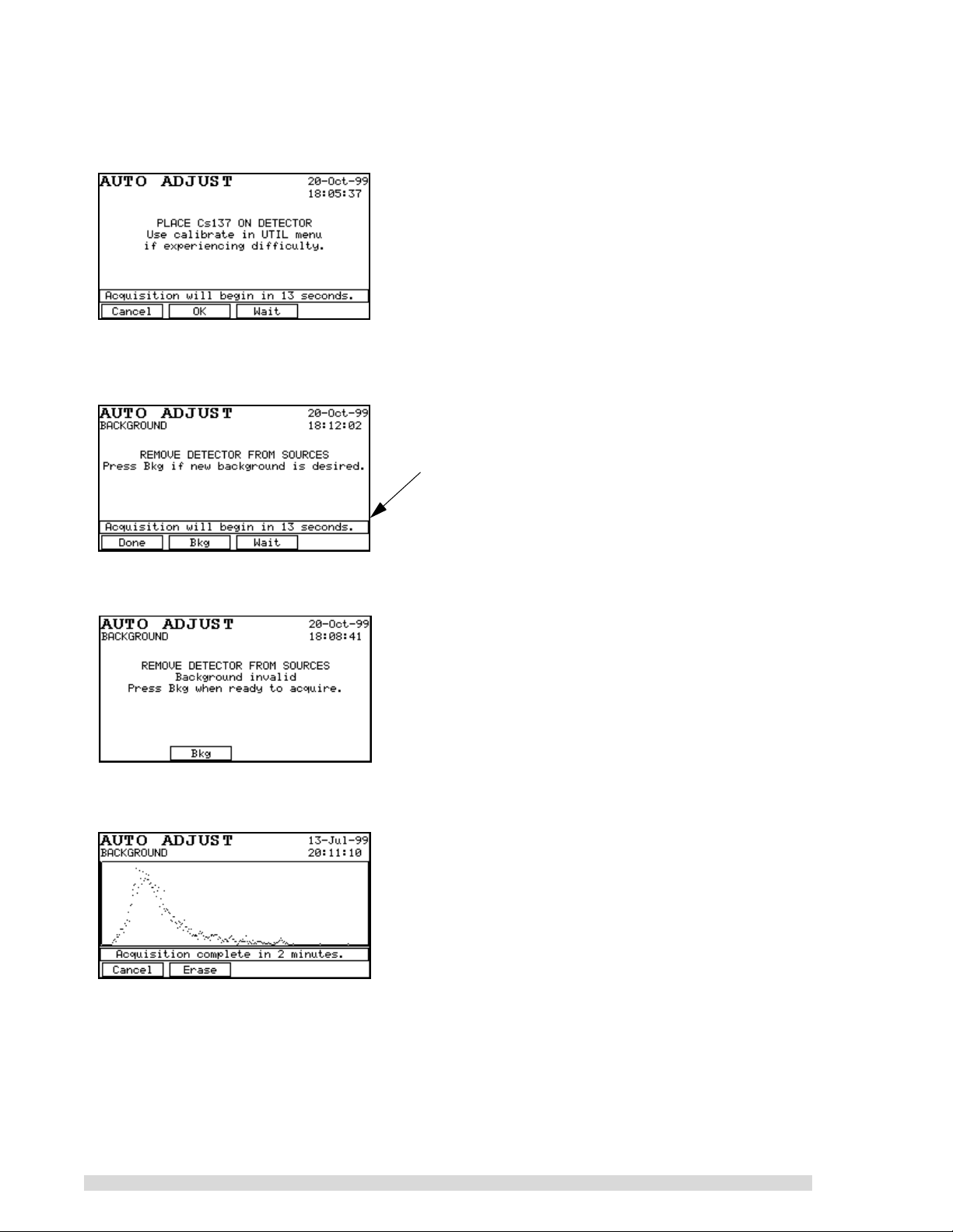

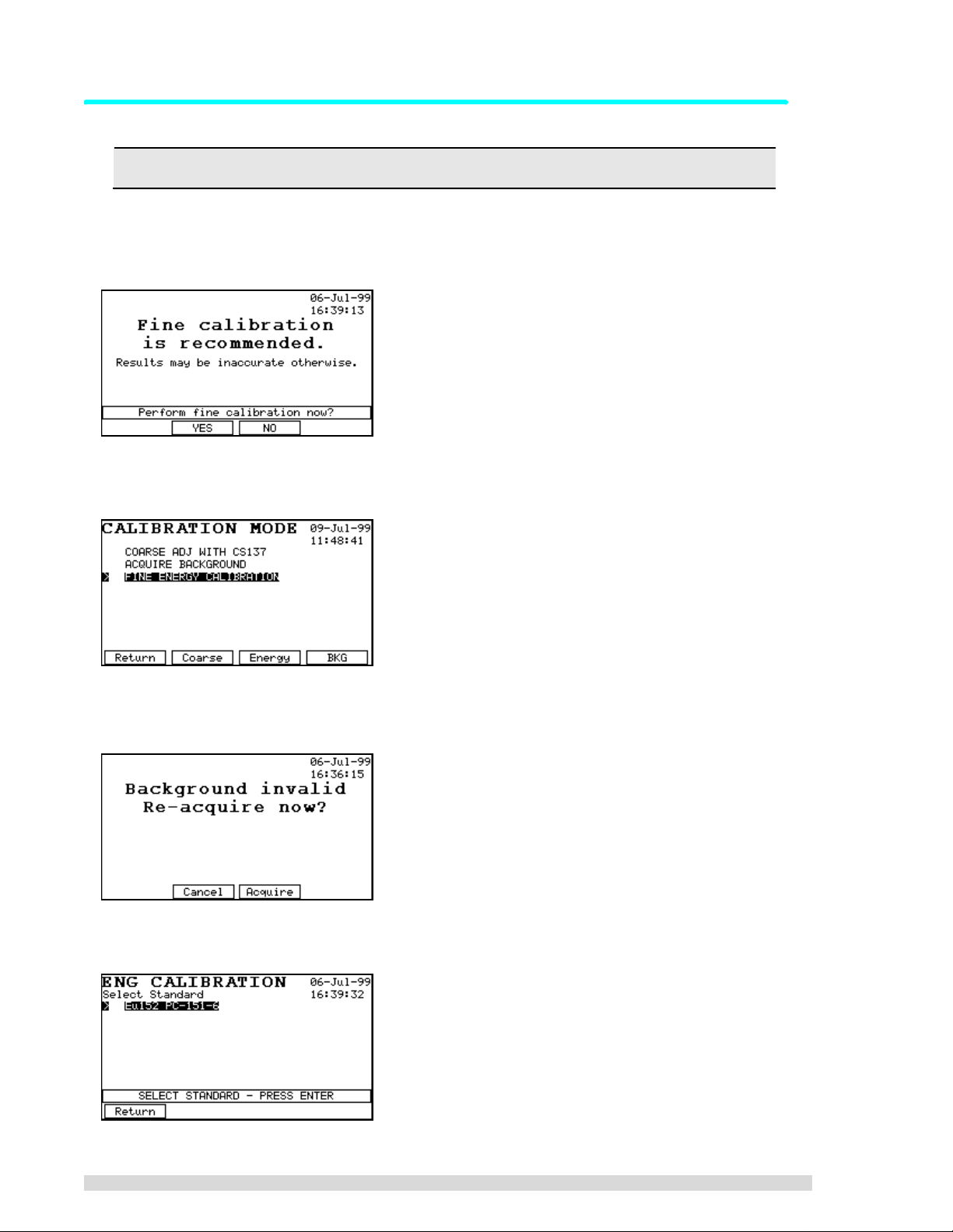

After the self-test, the SAM 935 may detect that a calibration and background reading are needed. If it

does, you will see one of the two prompts shown below. Until you perform the adjustment, these messages

will show up every time the SAM 935 is powered on.

“Calibration required” means this is the first time the SAM

935 has been powered up, or some important setting

changed that requires calibration. Note that your two

choices are to perform the cal ibration adj ustment (F3) or to

enter the Utilities menu to adjust the instrument settings

(F2).

The “calibration recommended” prompt appears when a

calibration has not been performed in over a week. Note

that your two choices are to perform the calibration adjustment (F3) or to continue with st artup witho ut perfor ming the

calibration (F2). If you choose to skip the calibration, the

monitoring results may not be reliable.

SAM 935™ Instruction Manual 3

1. Press the ADJUST (F3) button.

2. You will be prompted to place the Cs137 standard in front of the detector. Position the standard as

closely as possible to the right front corner of the SAM 935, where the internal detector resides:

3. After the SAM 935 has finished its coarse calibration, it will beep two times and give you the opportunity to take a background spectrum. Remove the Cs137 source from the vicinity of the detector

and press B

KG (F2) to begin taking the background reading:

If you do not take a background reading, the SAM 935 will

enter its monitoring mode after a preset 15-second delay.

Press Wait (F3) to restart the 15-second countdown if you

need more time to remove the source.

If the SAM 935 detects that the background reading is unusable or non-existent, it will present this

screen that requires you to take a background reading:

4. The automatic background adjustment will take 1 minute (the factory setting). You will see the

spectrum resolve on screen as it is acquired:

5. The SAM 935 may recommend a fine calibration at this point, if the external detector was changed

or if the fine calibration has been corrupted (refer to Section 3.2.3). Normally, however, only the

coarse adjustment and background reading are required.

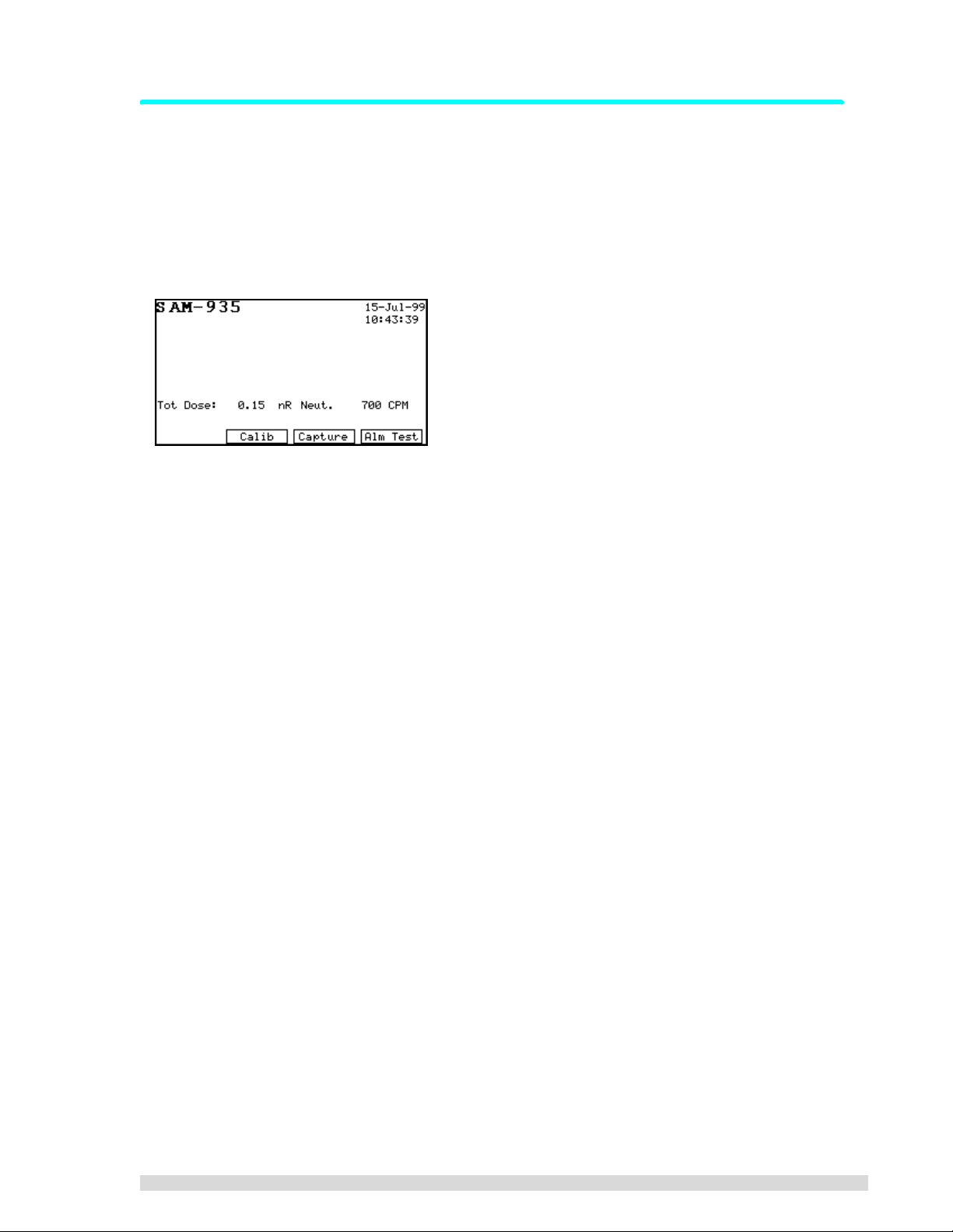

6. When the calibration adjustments are done, the dose rate monitoring screen will appear and you

can begin taking samples.

For more information on quick calibration, refer to Section 4.2.1.

4 SAM 935™ Instruction Manual

1.2.3 Take Samples and Review Alarms

The monitoring display of the SAM 935 will look different depending on the operating mode of the instrument. The default operating mode for the SAM 935 is Surveillance mode, also called dose rate monitoring.

In Surveillance mode, the SAM 935 continuously takes readings and analyzes isotopes in dose rate units,

saving and reporting any alarm conditions (when the dose rate exceeds the dose rate trigger).

The dose rate monitoring screen will look something like this (depending on how the SAM 935 was

configured):

1. Hold the SAM 935 in front of you so you can read the display.

2. Take readings by pointing the right front corner of the detector at the sample, as closely as possible. (The internal detector is installed on the right side of the SAM 935. If using the

factory-supplied, optional external detector, position the detector and sample in close proximity to

each other.) The SAM 935 will take continuous readings.

3. To manually save a reading or alarm, press C

alarm, if any, will be terminated when you press C

APTURE (F3) to save the current display. The current

APTURE. If the condition continues to alarm, a

new alarm will be created and you will again have the choice to capture it or not.

4. To review alarms, use the right and left arrow buttons. Use the right arrow button to review the

alarms in order they were taken (newest to oldest). Use the left arrow button to review alarms in

reverse order (oldest to newest).

SAM 935™ Instruction Manual 5

2. Connecting Hardware

This chapter describes how to connect optional, peripheral devices to the SAM 935. The SAM 935 consists

of the spectrometer electronics, internal detector(s), and optionally, an external detector. Simply follow the

instructions below for connecting a printer or personal computer, and if purchased, the optional external

detector.

There are two tubes on each end of the SAM 935; the left tube (if you are holding the SAM 935 in normal

operating mode) holds the battery pack. The right tube holds the internal detector. The optional internal

neutron detector is installed along the front edge of the SAM 935.

The connection ports for the analog power cord and peripheral devices are located on the front left side of

the SAM 935 (when holding the unit in normal operating mode), next to the battery pack tube. Slide the

cover back to reveal the ports.

An RS-232 serial connector (DB9M), above the power port, is used to connect the SAM 935 to a printer or

to a host computer; see Sections 2.2 and 2.3 for more information.

2.1 Connecting Power

The SAM 935 operates off of an internal battery pack, which is located in the left tube (if you are holding

the unit in normal operating mode).

To guarantee good results, recharge the SAM 935’s battery pack when you first receive the unit from the

factory. Thereafter, the clock on the top panel display will be replaced with a

the battery pack needs to be recharged or replaced.

1. To recharge the battery pack, simply plug the factory-supplied battery charger in to the power port

on the front panel (holding the unit in normal operating mode). The power port is located below the

RS-232 port and next to the power on/off button.

2. Plug the other end into a standard wall outlet. It will take approximately 4 hours to recharge a completely empty battery pack. The batteries will recharge only if the SAM 935 is turned off during this

time.

Always use the factory-supplied battery charger to ensure that the batteries are not damaged.

3. The SAM 935 can be operated continuously from the battery charger; however, it cannot simultaneously be powered on and recharge the internal battery pack.

4. The SAM 935's power switch is the push button next to the power port.

Battery Low

message when

2.2 Connecting to a Printer

The SAM 935 may be connected to a printer for printing a variety of reports. If you purchased a preconfigured printer from BNC, simply attach the printer to the serial port on the front panel of the SAM 935,

located above the power on/off switch, and it is ready for use.

If you are using another printer, follow the instructions in the rest of this section:

6 SAM 935™ Instruction Manual

Most printers compatible with the Epson command set (9-pin,

24-pin, and ink jet printers) are supported. If your printer does not

have an option for a serial port connection, you may need to purchase an RS-232 serial to Centronics parallel adapter (available as

an option from BNC). Otherwise, the printer may be attached to the

SAM 935 in exactly the same fashion as you would attach it to the

serial port of any computer.

Set the printer serial configuration to 19,200 baud (or another baud

rate if you have changed the SAM 935 defaults), 8 data bits, 1 start

bit, 1 stop bit, no parity. It is also important, if your printer has this

feature, to set the font to the Latin1/European font rather than the

italic font so that special characters will be printed correctly. See

SAM 935 RS-232 Connections

Power

Receive Data

Transmit Data

No Connection

Ground

No Connection

Request to Send

Clear to Send

No Connection

VCC

RX

TX

GND

TRS

CTS

1

2

3

4

5

6

7

8

9

your printer manual for details.

After starting up the SAM 935, set the serial speed to match the printer’s in the SAM 935 Utilities menu;

see Section 6.11.

2.3 Connecting to a Remote Computer

The SAM 935 may be connected to a remote computer running the PGT QUANTUM MCA® software. The

Quantum software comes with AutoLoad, a program for uploading spectra saved in SAM 935 to a personal

computer. The installation and use of this program is covered in Appendix A: AutoLoad.

To make the hardware connection between the SAM 935 and the personal computer, a null modem cable

is required. The SAM 935 may be connected to any serial port of the host computer, provided that this

serial port is accessible from Microsoft Windows

®

.

1. Simply align the connector on one end of the cable with the 9-pin serial connector on the SAM 935

(RS-232), and press to insert.

2. Repeat with the connector on the host computer.

3. After starting up the SAM 935, set the serial speed to match the printer’s in the SAM 935 Utilities

menu; see Section 6.11.

4. In the hardware search program, select the baud rate and COM port to which the SAM 935 is

attached.

5. On the SAM 935, press the U

6. Press the U

PDATE button. The Quantum hardware search software should automatically detect the

SAM 935 when you press the U

TIL key. Select REMOTE (F4).

PDATE button in its MCA Devices Auto Configuration window.

2.4 Connecting an Optional External Detector

If you purchased an optional external detector with the SAM 935, attach the supplied LEMO connector to

the port on the right-hand side of the SAM 935 (holding the unit in normal operating mode). The other end

of the LEMO connector attaches to the external detector.

SAM 935™ Instruction Manual 7

3. Configuring the SAM 935

This chapter describes in detail how to set up the SAM 935 for daily operation. Most of the setup takes

place in the Utilities menu.

Summary of Steps to Take:

1. Connect the hardware as described in the previous section.

2. Power on the SAM 935 and let it self-test and start up.

3. Perform a recalibration of the SAM 935: (a) a coarse adjustment, (b) a background spectrum, and

if using a new detector, (c) a fine energy calibration. T o complete all three calibration steps, you will

need a Cs137 source and an Eu152 source.

N

OTE: When you first install the SAM 935 and whenever the temperature changes drastically, you must

perform a coarse adjustment with Cs137 and a background spectrum. You MUST

with both sources (including a fine energy calibration) if you change the detector.

4. Configure the dose rate units of measurement and alarm trigger.

5. Configure any other settings found in the Utilities menu (for details, see Section 6).

3.1 St arting Up the SAM 935

do a recalibration

After connecting the hardware as described in the previous section, press the white power on/off switch to

turn on the SAM 935. It will automatically perform a self-test before starting up. The examples below show

the different self-test results that you may see.

The SAM 935 display screen has a backlight that will come on automatically when a key is pressed, unless

the default settings are changed.

Note: If you just performed a memor y reset, you will be prompted to selec t a detector before

the self-test screen appears. See Section 6.18 for more information.

A successful self-test will look something like this:

Note the battery condition here

Note the type of detector(s) installed here.

8 SAM 935™ Instruction Manual

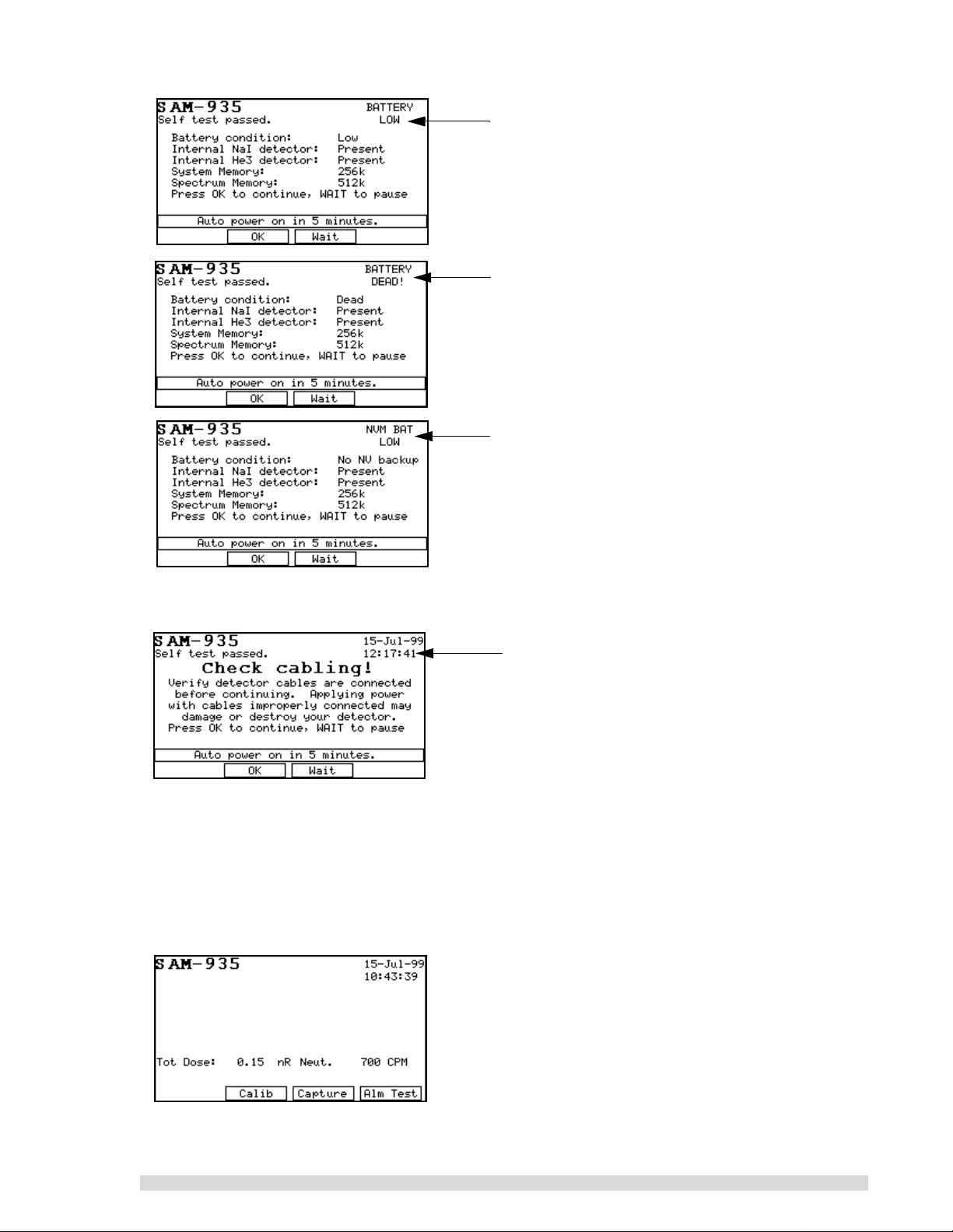

Example of a self-test with a low battery condition. The

Battery Low message will replace the clock. The SAM

935 will proceed with the auto-start, but you should

recharge as soon as possible.

A self-test example where the batteries need to be

recharged. The SAM 935 will completely shut down

within approximately 15 seconds of the Battery Dead

message appearing.

Example of a self-test where the battery backup for

non-volatile information (including spectra and alarms)

has failed. The SAM 935 should be returned to an authorized service center for battery replacement.

If you do not have an internal NaI detector, the SAM 935 will prompt you to check the cabling to the external detector after it completes the self-test:

Check the cabling to the external detector and press

OK (F2) if it’s acceptable. If it’s not, you can press

Wait (F3) to delay the auto-start another 5 minutes.

After the self-test has run, the SAM 935 will wait 5 minutes and then start up. You can press OK (F2) to

immediately start up. Press W

AIT (F3) to delay startup for another 5 minutes.

At this point, the SAM 935 may require an automatic calibration. If so, a prompt will give you the choice to

begin the quick calibration (F2) or to perform a recalibration from the Utilities menu (F3). See Sections

4.2.1 and 3.2, respectively.

When the SAM 935 is ready for operation, the dose rate monitoring screen will appear:

SAM 935™ Instruction Manual 9

The dose rate analysis measures and records isotopes in dose rate units (rather than the confidence levels

used by the Monitor mode). The different modes of operation are explained in Section 5.

An example of the main dose rate monitoring screen is shown below:

}

If there are stored alarms, you can review them by pressing the ← or → arrow keys from the main

Surveillance monitori ng scr een:

If other display modes are enabled, they will show up as options under the F1 function key. Display modes

are discussed in Section 5.

The dose rate units are recorded in metric abbreviations

of Sievert (Sv) or REMs (R ).

Press F2 to return to Surveillance mode and take more

readings.

Press F3 to print the stored alarm(s); see Section 7.1

for more information about this report.

3.2 Recalibration Procedure

Follow the directions in this section to perform a complete recalibration of the SAM 935. To ensure accurate, reliable results, you should recalibrate the SAM 935:

• when you first install it. It is calibrated at the factory, but it should be recalibrated on site to ensure

reliable results. This requires only a coarse adjustment and background spectrum, and can be

done with the one-button quick calibration on the main screen (F2). See Section 4.2.1 for details.

• whenever the temperature changes drastically (such as moving from indoor to outdoor monitoring). This requires only a coarse adjustment and background spectrum, and can be done with the

one-button quick calibration (F2). See Section 4.2.1 for details.

• if you change the type of detector you are using with it; this requires a coarse and fine calibration.

• If you perform a memory reset.

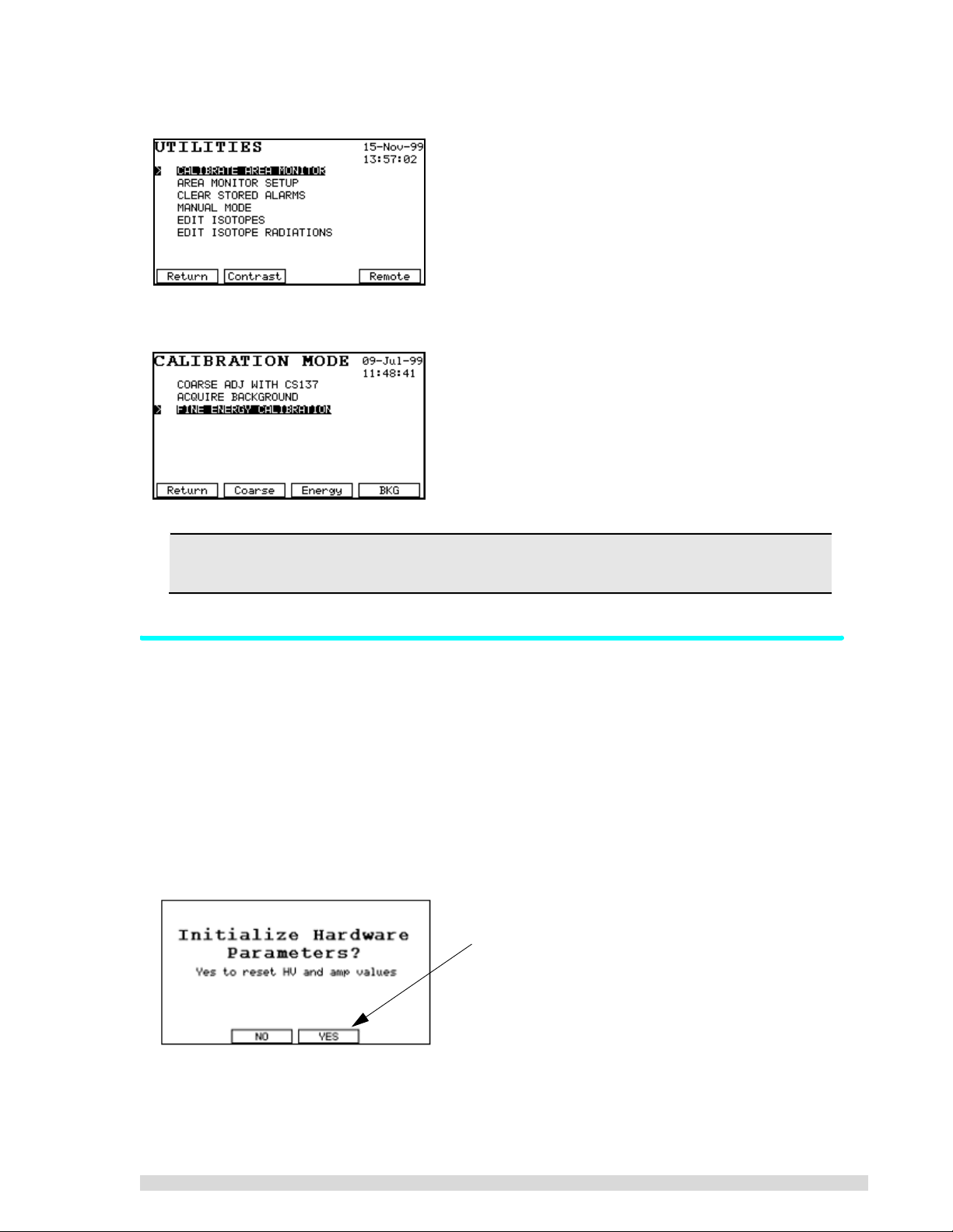

You perform this 3-step recalibration process from the

This calibration method automatically adjusts hardware parameters such as high voltage and amplifier

gain to achieve a proper energy calibration for the system. The quick calibration method described in Sections 1.2.2 and 4.2.1 does not.

1. Press the U

TIL key to bring up the Utilities menu.

Calibrate Area Monitor

option in the Utilities menu.

10 SAM 935™ Instruction Manual

2. Select

Calibrate Area Monitor

from the menu:

The 3 steps needed to perform a recalibration are listed in the order they should be done:

Before beginning the rec alibration process, mak e sure the proper detector is selected using

the

Select/Edit Detector

function under the UTIL key.

3.2.1 Automatic Coarse Calibration

This process requires only a Cs137 source. It may take up to several minutes depending on the activity of

the source.

1. Press the U

2. Select

3. Select

4. If your SAM 935 was factory-calibrated, you will see the message below. Press Y

time you do a coarse calibration; this will cause the SAM 935 to start its hardware adjustment algorithm from scratch. Answer N

bration process quicker) .

5. Point the right front corner of the detector at the Cs137 standard (of approximately 0.5 to 2.0 µCi)

and press S

TIL key.

Calibrate Area Monitor

Coarse Adj With Cs137

TART (F2) to begin data acquisition.

from the list.

from the list, or just press F2.

O (F2) after the initial coarse adjustment (this will also make the cali-

ES (F3) the first

Answer Yes the first time you do a coarse calibration;

answer No thereafter.

SAM 935™ Instruction Manual 11

The spectrum being measured will be displayed as it develops, and if everything is connected correctly, you should be able to watch the spectrum resolve. After each adjustment attempt, a tone

will sound to indicate that the SAM 935 is still adjusting itself. For details about the coarse adjustment, refer to Section 5.6.1.

6. When the adjustment is complete, the two Cs137 peaks will be highlighted, the unit will beep three

times, the

able. At this point, the display should look like the one shown below. If not, press C

check that you have the correct source and retry the operation. If everything is correct, press S

Adjustment Co mp le te

message will appear, and the SAVE (F4) function key will be avail-

ANCEL (F1) and

AVE

(F4) to save the new hardware parameters in memory.

If you experience difficulty during the coarse calibrat ion, press CAN CEL (F1) and the n select

Calibrate Area Monitor

from the

Utilities

menu to start over.

Press Save to finish the coarse calibration.

After you save the coarse calibration adjustment, the SAM 935 will return to the Calibration menu. Continue with calibration by taking a background spectrum next.

3.2.2 Acquire a Background Spectrum

To get accurate identification results, a background spectrum should be taken frequently, and it must be

collected in the same physical location where the monitoring will occur. The background is very important

because it is the point of reference against measured activities.

A new background spectrum should be acquired whenever the ambient background changes, i.e., if the

instrument is moved to a new location or if a patient having received a radionuclide dose enters or leaves

the vicinity. A background spectrum is also required before doing the more accurate fine energy calibration. Background spectra can be acquired at any point. After one week, the SAM 935 will require that you

take another background spectrum.

1. At the Calibration menu, select

2. A background spectrum may not be taken without a prior coarse adjustment. If this is attempted,

the SAM 935 will ask whether you wish to perform the adjustment first. If so, press F3 to perform

the coarse adjustment.

Acquire Backgroun d

Press F2 (Util) if the coarse calibration is not required.

This will take you to the Utilities menu where you can

choose Calibrate Area Monitor to do the background

spectrum.

and press ENTER, or just press F4.

Press F3 (Adjust) if you have not performed a coarse calibration yet. The SAM 935 will complete the coarse

adjustment before resuming acquisition of the background spectrum.

3. Remove all sources from the vicinity of the detector.

12 SAM 935™ Instruction Manual

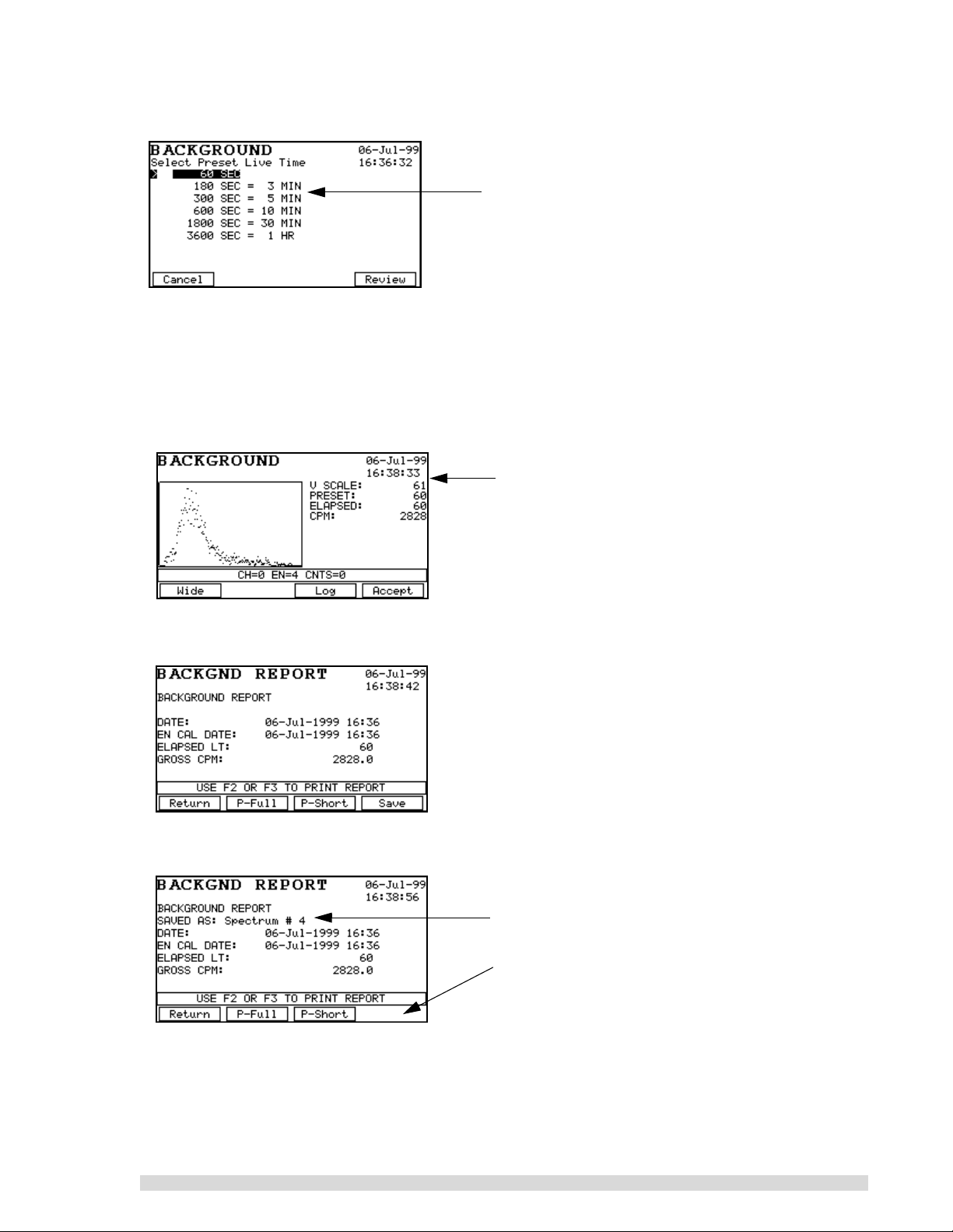

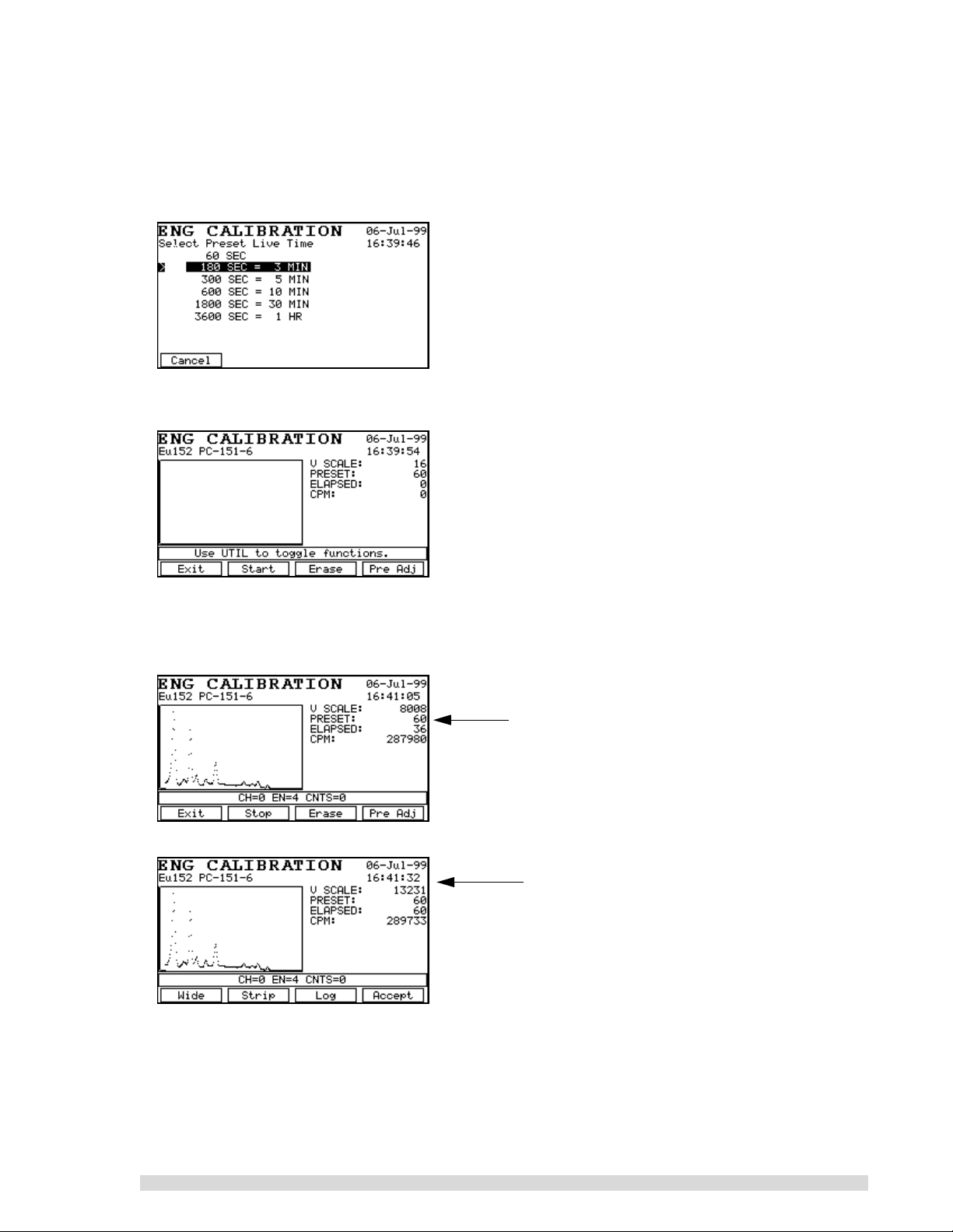

4. The Preset Live Time screen will appear as shown below. Select a live time for background collection and press E

NTER:

For most SAM 935 operations, a collection period of

180 or 300 seconds is generally adequate.

Acquiring a background spectrum takes only a few minutes, depending on the live time preset

selected. For the error in the background spectrum counting statistics to be small compared to the

spectrum of the unknown, the live time preset of the background spectrum should be large compared to that of the unknown spectrum.

5. Once a live time has been selected, the SAM 935 enters the acquire mode for background spectra. Press S

TART (F2) to begin the data acquisition. Data will appear on screen, and the Elapsed

Time will begin counting off:

When the elapsed time matches the live time preset,

the SAM 935 will beep to indicate that data acquisition

is complete. This is a good example of what a background spectrum should look like when complete.

6. Press A

CCEPT (F4), and the SAM 935 will generate a report that can be reviewed on screen and

printed:

7. Press S

AVE (F4) to save the background spectrum, if desired. This will allow the background spec-

trum to be uploaded to a remote computer if needed.

The Background Report will show you when the spectrum has been saved.

Notice that the Save (F4) function goes away after saving the spectrum.

You may also print the report if needed.

8. Press R

ETURN (F1) to leave the background reading. The MCA display will appear. Press Exit, and

the SAM 935 will return to the Calibration menu. Continue with the fine energy calibration.

For more information on the background mode, see Section 5.5.

SAM 935™ Instruction Manual 13

3.2.3 Fine Energy Calibration

Always perform a fine energy calibration if the external detector is changed.

If the SAM 935 has not been previously fine energy calibrated with a multi-line standard such as Eu152,

you will see the message shown below. If no Eu152 source is available, enter the three coefficient numbers as described in Section 3.2.4.

1. Press F2.

2. Select

3. If you have not taken a background spectrum recently, or have not taken one since the last coarse

adjust, you will be forced to do so now. If it’s needed, you will also be forced to do a coarse adjustment before the background reading.

4. You will be presented with a list of isotopes. Select the Eu152 standard from the list and press

E

Fine Energy Calibration

NTER:

from the Calibration menu, or just press F3.

14 SAM 935™ Instruction Manual

If you are using another standard that does not match one in this list, you will have to define it in

the Calibration Standards library. See Section 6.6 for instructions on how to define calibration standards.

5. Now select a preset live time: If your Eu152 source is between 0.5 and 2 µCi, select a time of 180

seconds. If higher or lower activity, make an appropriate adjustment in count time.

6. Place the standard in front of the detector and press S

TART (F2).

7. When the SAM 935 beeps to indicate that data acquisition is complete, check the spectrum to verify you have counted the correct standard (i.e., about ten peaks covering nearly the entire energy

range), and if so, press A

CCEPT (F4).

Example of a fine energy calibration in progress.

Note how the function keys change in this screen

versus the next one.

Example of a completed fine energy calibration.

Press Accept (F4) after reviewing.

SAM 935™ Instruction Manual 15

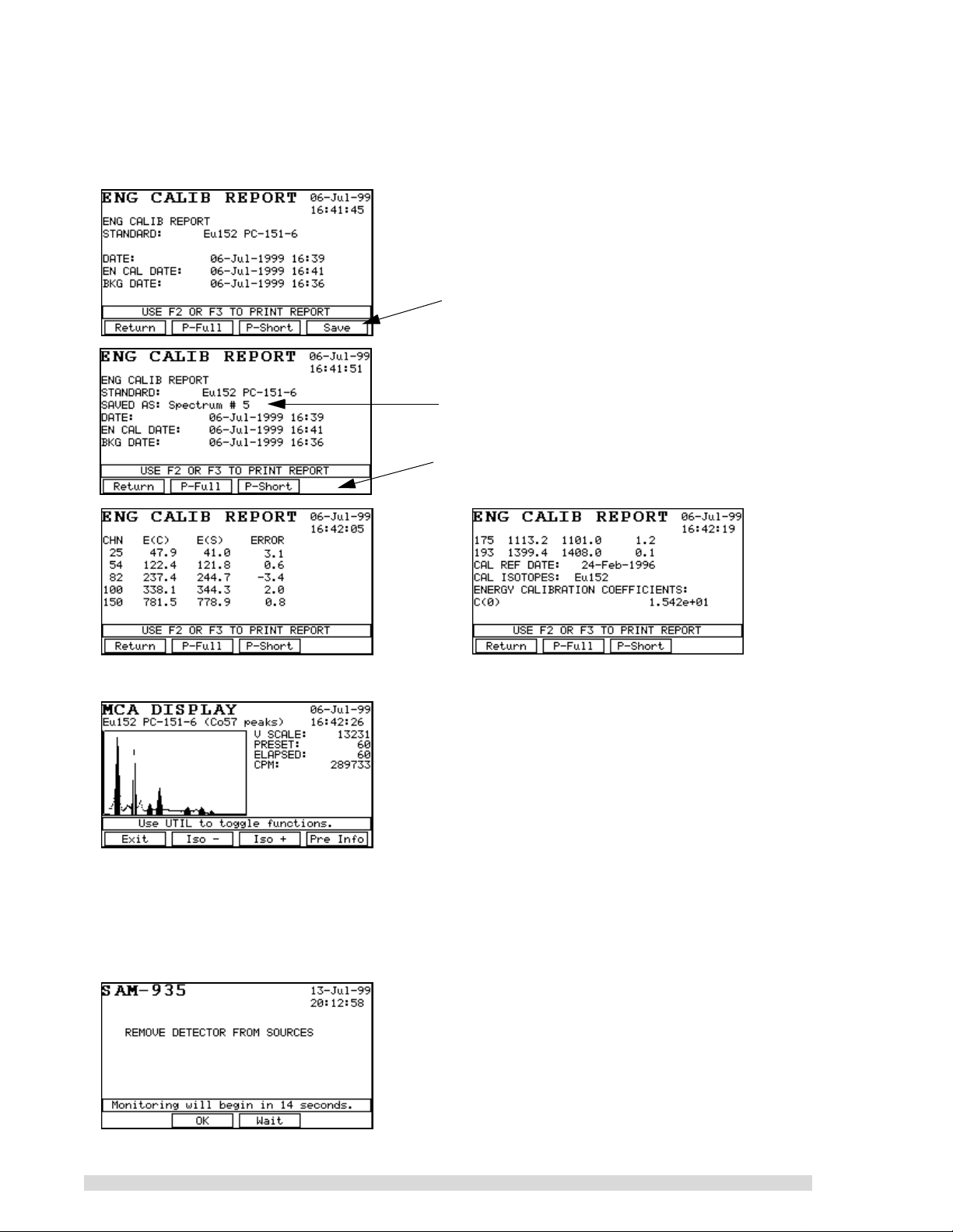

8. The calibration report will appear on the display after you accept the calibration; scroll through it

using the arrow keys to see all of it. The SAM 935 should find seven peaks and the energy errors

th

(4

column) should be in the range ±5 keV. Use the arrow keys to see the details of the report or

print short or long versions using the P-F

ULL and P-SHORT keys.

Press F4 to save the fine energy calibration, if

desired. This allows the fine calibration to be

uploaded to a PC if needed.

The Energy Calibration Report will show you when

the spectrum has been saved.

Notice that the Sav e (F 4) function goes away after

saving the spectrum.

9. When you press R

ETURN (F1) to leave the energy calibration report, the spectrum will display

10. Remove the Eu152 source from the vicinity of the detector.

11. Press E

XIT (F1) to leave the spectrum display; press RETURN (F1) once more to leave the

Calibration menu.

12. You will be prompted to remove the Eu152 source from the vicinity of the detector. The SAM 935

will begin its automatic countdown to begin dose rate monitoring:

16 SAM 935™ Instruction Manual

3.2.4 Calibration with Three Coefficients

To enter the energy calibration factors manually, the factors from a previous live energy calibration for this

unit and matching detector must be available. These numbers can be found on the printout normally done

at the end of a live energy calibration. Alternatively, the numbers can be those recorded earlier from a previous manual calibrati on with the thr ee coe fficients.

1. Press the U

Setup

2. Do NOT change anything in this screen. Press C

TIL key to bring up the Utilities menu. Use the arrow keys to select

. The first screen is the Energy Match Window:

ANCEL (F1) 10 times until you see the question

Analysis Tools

SET FINE ENGY COEFF?

3. Press Y

ES (F2).

The next three screens are standard number entry screens. Change the factors as needed. On

each screen, when the correct value is shown, press E

NTER.

4. Return to the normal operating screen.

3.3 Configure Dose Rate Units and Trigger

Because the SAM 935 operates in Surveillance mode by default (also called dose rate monitoring), configure the Dose Rate Units and Dose Rate Trigger options in the Monitor Setup menu:

1. Press the U

TIL key to bring up the Utilities menu.

SAM 935™ Instruction Manual 17

2. Select

Area Monitor Setup

through the setup screens:

. The Setup menu takes up several screens; the arrow keys will scr oll

Select

Dose Rate Units

measurement.

to choose the units of

3. Use the arrow keys to highlight

Select Dose Rate Units

and press ENTER.

4. Select the units of measurement you want to use when monitoring: F2 for REMs per hour (R/hr) or

F3 for Sievert per hour (Sv/hr). The message line above the function key labels tells you the currently selected units.

5. The display will immediately return to the Monitor Setup menu. Select

Select Dose Rate Trigger

from the menu:

18 SAM 935™ Instruction Manual

The value shown on this screen is the alarm trigger; an alarm will be generated and saved whenever any monitored target exceeds this value:

Allowable range is 0.001 to 999.999 in units of mR/hr or

mSv/hr.

6. Use the arrow keys to move from digit to digit, and to increase or decrease the highlighted value.

Press E

7. Press R

NTER to save the change.

ETURN (F1) until you are out of the Utilities menu and back to the Surveillance monitoring

screen.

If the SAM 935 is operated in another mode (Monitor or Detail), you may want to configure other Setup

options. See Section 6.1 for more information about the other options.

3.4 Dose Rate Calibration

To perform a Dose Rate Calibration, select

1. Select

Calibrate Dose Rate

from the menu and again press ENTER:

Area Monitor Setup

from the Utilities menu. Press ENTER.

The current value will be 1.00 if no Dose Rate Calibration has been done before. At this point, you

may either press E

DIT (F3) to enter the previously determined calibration factor or CALIB (F2) to

calibrate the unit with a10 µCi Cs137 source whose calibration date and activity are known.

2. Press Calib. This screen will time out after about 10 seconds or when you press E

NTER:

3. The next screen is a standard number input screen for the user to input the activity of the calibration source. Press E

NTER when correct:

4. The next screen is a standard Date edit screen. Key in the calibration date of the Cs137 standard.

Press E

NTER when correct:

5. The next screen prompts you to place the source 20 cm away from the end of the detector. 20 cm

is equal to 7.87 inches. Press OK (F2) when ready to start the calibration run:

6. When the calibration is complete, a screen showing the new calibration factor is presented. Write

this number down for future use in case the instrument is reset and the calibration source is not

available.

7. Return to the normal operating screen.

See Section 6.1.5 for more details.

SAM 935™ Instruction Manual 19

4. Operating the SAM 935

If the proper procedures are followed, the SAM 935 will give an outstanding performance in monitoring

your radiation environment. The key to optimum performance is establishing a routine for measurement

that guarantees the system is operating correctly and is properly calibrated.

To get consistent results, it is important that the system be stable thermally. In the field, this can present a

real problem if the temperature is varying rapidly. The SAM 935’s electronics are very stable against tem-

perature variations; however, NaI detectors exhibit a gain shift of up to two percent per degree Centigrade.

You can compensate for temperature drifts in the detector by periodically doing a quick calibration (F2 in

the main display).

If you need help navigating the SAM 935 software or using the front panel controls, see

Section 4.6.

4.1 Recommended Daily Operating Procedure

As long as you use the same detector with samples in the same geometry, your daily routine can be quite

simple. Each day we recommend that your work be organized as follows:

1. Power on the SAM 935. If prompted to do so, calibrate the instrument.

2. Measure each sample, spectra will be saved to memory as you go.

3. If the temperature fluctuates, perform the quick calibration adjustment periodically. (Press F2 while

in any of the three acquisition screens.)

4.2 Powering the SAM 935 On

1. Power on the SAM 935 using the On/Off push button on the front panel, located behind the sliding

door. It will automatically begin its self-test. A successful self-test will look something like this:

Note the battery condition here.

Note the type of detector(s) installed here.

20 SAM 935™ Instruction Manual

2. If you do not have an internal NaI detector, the SAM 935 will prompt you to check the cabling to the

detector after it completes the self-test. Check that any cables are properly connected and then

press OK (F2) to start monitoring.

Check the cabling to the detector and press OK

(F2) if it is acc eptab le. If it is not, you can press W a it

(F3) to delay the auto-start another 5 minutes.

After the self-test has run, the SAM 935 will wait 5 minutes and then start up, ready for operation. You can

also press OK (F2) to immediately begin operation. Press W

When the SAM 935 is ready for operation, the dose rate monitoring screen will appear:

AIT (F3) to delay startup for another 5 minutes.

The dose rate analysis displays isotopes in dose rate units (rather than the confidence levels used by the

Monitor mode). The different modes of operation are explained in Section 5.

An example of SAM 935 dose rate screen as it is actively monitoring isotopes is shown below:

}

The electronics in the SAM 935 stabilize approximately 10 minutes after power is turned on. However,

tests with NaI detectors indicate that some detectors require as much as 2 hours to fully stabilize, especially if the detector is cold. Determine how much time is needed for stable operation, and then be consistent in the elapsed time between power-up and when you start calibration.

The dose rate units are recorded in metric

abbreviations of Sievert (Sv) or REMs (R).

SAM 935™ Instruction Manual 21

4.2.1 Quick Calibration Adjustment

After the self-test, the SAM 935 may prompt you to run a quick calibration adjustment before going to the

dose rate monitoring screen:

Calibration required means this is the first time the

SAM 935 has been powered up, or some important

setting changed that requires calibration. Note that

your two choices are to perform the calibration adjustment (F3) or to enter the Utilities menu to adjust the

instrument settings (F2).

-

OR

-

The calibration recommended prompt appears when

a calibration has not b ee n performed in over a week.

Note that your two choices are to perform the cal ibra tion adjustment (F3) or to continue to monitoring

mode without performing the calibration (F2). If you

choose to skip the calibration, the monitoring results

may not be reliable.

1. Press the A

DJUST (F3) button.

2. You will be prompted to place the Cs137 standard in the detector. (Point the right front corner of

the SAM 935 at the standard.)

Press F2 to immediately begin the coarse adjustment, or wait for the 15-second countdown to

elapse.

The spectrum will bed displayed on screen as it

resolves. When the coars e cal ib ration is complete, the S

AVE (F4) function key will appear.

3. After the SAM 935 has finished its coarse calibration, it will beep twice and give you the opportunity to take a background spectrum:

If you do nothing, the SAM 935 will skip the background reading an d enter its mon itoring mo de after

a preset 15-second delay.

Press Wait (F3) to restart the 15-second delay if

you need more time to remove the source.

22 SAM 935™ Instruction Manual

If the SAM 935 detects that the background reading is unusable or non-existent, it will present this

screen, which

requires

you to take a background reading:

Remove the Cs137 standard and press F2 to

immediately begin the background reading.

4. To take the background reading, first remove the Cs137 standard from the vicinity of the detector.

Then press B

KG (F2) to begin acquiring the background spectrum.

5. The automatic background adjustment will take 1

minute (the factory setting); the spectrum will be displayed on screen as it resolves:

6. When the calibration adjustments are done, the dose rate monitoring screen will appear and you

can begin taking samples:

If the SAM 935 i s unable to coarse ad ju st, i t wi ll t ell y ou . ( You may notice that th e p eak is to o

far to the right of the screen or off the screen because the high voltage and gain are too high.)

If you see this message, it usually means the energy range was too high before the quick calibration was started. Press C

to reset hardware values, ans wer Y

ANCEL and go to the Utilities menu to calibrate. When prompted

ES. Perform a coarse calibrati on a nd ba ck gr ou nd reading;

the fine calibration does not need to be redefined if the last one was valid.

4.3 Powering the SAM 935 Off

Whenever the SAM 935 is turned off, all information is saved in battery-backed-up RAM. This allows you to

start up again without loss of calibrations and other information. Note that if the internal lithium battery has

failed, the self-test display will indicate the problem.

1. Power off the SAM 935 using the On/Off push button on the front panel, located behind the sliding

door.

SAM 935™ Instruction Manual 23

4.4 Taking Readings in Surveillance Mode

The monitoring display of the SAM 935 will look different depending on the operating mode of the instrument. The default operating mode for the SAM 935 is Surveillance mode, also called dose rate monitoring.

In Surveillance mode, the SAM 935 continuously takes readings and analyzes isotopes in dose rate units,

saving and reporting any alarm conditions (when the dose rate exceeds the dose rate trigger).

1. The blank Surveillance monitoring screen will look like this:

2. Point the detector at the sample to be monitored and watch the front panel display:

3. Press C

when you pre s s C

will again have the choice to capture it or not.

An alarm condition is triggered when any of the items being monitored exceeds the trigger level for at least

the On Hysteresis number of sample intervals. The trigger level can be dose rate or peak-to-background

ratio. The alarm condition continues until the radiation level drops below the trigger level for at least the Off

Hysteresis number of samples.

During an alarm, the SAM 935 acquires and stores an integrated spectrum for the entire alarm period. The

alarm level displayed for each monitored item is the highest level encountered during any time interval of

the alarm. This allows the SAM 935 to detect a transient trigger on one isotope that might otherwise be

masked by a longer alarm generated by another isotope.

If you suspect that isotopes are being reported incorrectly, you may want to temporarily

increase the sample count time to get more stable readings. If this does not resolve the issue,

re-do the coarse and fine calibrations. Note that if the Cs137 source is too “hot”, or if it is positioned at a distance from the detector, the X-ray peaks will not register correc tly. The SAM

935 may think it is ca librated wit hout using the X-ray peak. T he other ca use of incorrec t isotope reporting may be poor detector resolution, or the parameters in the Analysis Tools Setup

(energy match windows) may be adversely affecting the readings.

APTURE (F3) to save the currently displayed reading. The current alarm will be terminated

APTURE. If the condition continues to alarm, a new alarm will be created and you

24 SAM 935™ Instruction Manual

4.5 Reviewing Alarms

The SAM 935 can store over 250 alarm events. Each stored alarm consists of a spectrum and all of the

information necessary to analyze the spectrum. Stored alarms can be viewed by using the ← and → arrow

keys:

Review stored alarms by pressing the ← or → arrow keys from the main Surveillance monitoring screen:

• From the main display, press the ← (left) arrow key to display the previous (most recent) alarm.

• From the main display, press the → (right) arrow key to display the first stored (oldest) alarm.

Once you are in review mode, the ← and → arrow keys move from alarm to alarm in a circular fashion as

shown in this example below:

Main 935 Display

Press

Press

(most recent) Alarm #4

Press

Alarm #3

Live (current) alarm

Press

Press

• At any time in the review process, pressing the R

ETURN (F2) key will bring you back to the main

Press

Press

(oldest) Alarm #1

Press

PressPress

Alarm #2

monitoring screen.

• Press P

RN SEL (F3) to print the selected stored alarm through the serial port. An example of this

printout is shown on page 59, Section 7.1.

• Press MCA (F4) to enter the Manual mode of operation; see Section 5.4 for more information.

A Memory Full message will appear on screen if the stored alarms approach the memory capacity. When

memory is full, the earliest alarms will be discarded to make room for the most recent alarms being stored.

If you see the Memory Full message, you can download the stored alarms to a remote computer, if

desired, and then

Clear Stored Alarms

in the Utilities menu.

SAM 935™ Instruction Manual 25

4.6 The SAM 935 Interface

This section explains the SAM 935 interface controls.

4.6.1 The Front Panel

The front panel of the SAM 935 has an LCD screen where instructions and data are displayed. At the top

of each screen is a mode name (e.g., “Utilities” or “SAM-935” in the example below). In some screens, a

description of the current step appears below the screen mode name (e.g., “Edit Isotopes” or “Auto

Adjust”).

Screen mode

Message line

Function keys

name

Function key

labels

Utilities key

In the middle of the screen, just above the function key labels, is a message line, which displays important

information about the current state or mode. In some screens (such as Edit Isotopes), it simply provides

directions.

Below the screen are two rows of keys. The first row of keys, F1 through F4, control a variety of functions

throughout the software. The current function of each of these keys varies according to the screen that is

displayed: the function labels are displayed at the bottom of the screen directly above the corresponding

function key.

A row of arrow keys below the function keys are used to select items from lists in some screens and to

move a software cursor in others.

Finally, the U

TIL key provides access to utility programs (see Section 6), and the ENTER key is used to

make selections and to indicate when certain tasks have been completed.

26 SAM 935™ Instruction Manual

4.6.2 Function Keys

The labels just above the function keys show what function each key will perform.

Some function keys perform a single defined function, such as R

when available. R

ETURN is used to exit from the current screen when done. CANCEL is used to abort from a

ETURN, which always appears over F1

step, typically without saving any of the changes that might have been made.

Other function keys, such as E

pressed (E

NABLE becomes DISABLE, for instance).

NABLE, are toggles; the meaning of the button will change each time it is

4.6.3 Scrolling Through Long Menus

Many of the screen modes allow (or require) you to select an

item from a list of alternatives, such as the list of isotopes

shown here. To scroll through this list, use the ↑ and ↓ arrow

keys to highlight an item, and the E

NTER key to select it.

Some lists are too long to be displayed on one screen—simply keep scrolling with the down arrow key. When you scroll

down past the last item displayed, it will jump to the next

screen of the menu. Or use the ← or → arrow keys to more

quickly turn to the previous or the next menu screen,

respectively.

4.6.4 Editi ng Inst ruct ions

A few screen modes require a text description or a numerical value to be entered. Since the SAM 935 keyboard has only 10 keys, entering this information requires some care. However, all data in the SAM 935 is

battery-backed-up so most information of this type will have to be edited only once during the life of the

instrument.

When new entries are created, the SAM 935 may automatically enter a default value, such as “Name”. You

will want to delete this entry before entering your data.

SAM 935™ Instruction Manual 27

Editing Text

An example of text editing is shown in this Edit Standard Name screen. The current value of the text is

shown in highlight on the screen.

1. Each character must be entered by highlighting it in the grid (the letter “A” is highlighted here)

using the arrow keys, and then pressing S

ELECT (F2). The selected character(s) will appear in the

highlighted field.

2. To edit the text in the highlighted field: press D

ELETE (F3) to delete a character; press SPACE (F4)

to enter a blank space.

3. When you’ve finished editing the text, press E

saving the changes, pres s C

ANCEL (F1). Y ou will be asked to confirm the cancel.

NTER to save it. If you wish to cancel the edit without

Editing Numbers

The edit radiations screen is shown as an example of editing numerical data in the system. Editing numerical data is similar to editing text, but is restricted to the few characters that might appear in a floating point

number (including exponents). As with text, the current numerical value is shown in highlight on the

screen.

1. To clear the entire value in the highlighted field: press C

2. To backspace and delete one value at a time, press B

LEAR (F4) to delete the value.

ACK (F3).

3. To enter a new value, use the arrow keys to highlight it in the list at the top of the screen (the number “0” is highlighted here), and then press S

ELECT (F2). The selected character(s) will appear in

the highlighted field. Numbers can be entered in fixed (xxx.xx) or floating (x.xxxe±xx) format.

4. When you’ve finished editing the number(s), press E

without saving the changes, press C

ANCEL (F1). You will be asked to confirm the cancel.

NTER to save it. If you wish to cancel the edit

Other screens for editing numerals use the ← and → arrow keys and the ↑ and ↓ arrows to change the

value:

1. Edit one field at a time. To move to the next character, use N

ous character, use P

REV (F1) or ←.

2. Increase the value of the highlighted character using the I

with the D

EC (F4) key or ↓.

EXT (F2) or →. To move to the previ-

NC (F3) key or ↑. Decrease the value

28 SAM 935™ Instruction Manual

4.6.5 The Utilities Screen

Press the UTIL key from the main screen to bring up the Utilities menu, which has more items than will fit on

one screen:

Use the ↑ and ↓ keys to scroll through the list, and the ← and → keys to move to the next page. You can

also get to the end of the list quickly by pressing the ↑ key at the top of the list. Y ou can directly access

three of the choices, or exit, using the function keys:

R

ETURN F1 Returns to the main menu.

ONTRAST F2 Allows you to adjust the screen display contrast.

C

R

EMOTE F4 Switch to remote (external computer control) mode.

All of the utilities are discussed in detail in Section 6.

SAM 935™ Instruction Manual 29

5. SAM 935 Modes of Operation

The SAM 935 default operation is the Surveillance mode, also called dose rate monitoring. Dose rate monitoring is the focus of this manual. In addition, options in the Utilities menu allow you to operate the SAM

935 in Monitor, Detail, or Manual modes. Y ou toggle the modes of operation from the Utilities menu:

Monitor Setup

:

Select Display Modes

:

The default setup for the SAM 935: only the

Surveillance operating mode is enabled.

This example shows all operat ing modes enabled.

Area

Press F2 to enable or disable Monitor mode, also called peak-to-background monitoring.

Press F3 to enable or disable Detail mode.

Press F4 to enable or disable the Surveillance mode of operation; this mode is enabled by default.

A Manual mode of operation is also available as a separate selection in the Utilities menu. This mode of

operation is described in Section 5.4.

5.1 The Surveillance Mode of Operation

The majority of SAM 935 operations begin from the main Surveillance monitoring screen shown below:

Date and time display will change to Battery Low

message when the battery pack needs to be

recharged or replaced.

30 SAM 935™ Instruction Manual

The Surveillance screen when alarms have been triggered looks something like this:

The function keys on the Surveillance monitoring display are:

•C

ALIB (F2) performs the quick, one-button calibration adjustment that is described in Section 4.2.1

and in the Quick Reference.

•C

APTURE (F3) saves the currently displayed reading. The current alarm will be terminated when

you press C

APTURE. If the condition continues to alarm, a new alarm will be created and you will

again have the choice to capture it or not.

•S

ILENCE (F4) turns off the audible alarm. If there are no alarms currently going on, then the F4

Function key bec omes ALM TEST. Pressing ALM TEST will activate the alarm indicators for test pur-

poses; each press of the A

LM TEST key will cause the alarm indicators to turn on for 5 seconds.

• When in the alarm review mode, the F2, F3, and F4 function keys become R

ETURN, PRN SEL, and

MCA, respectively. These functions are described above in Section 4.5.

5.2 The Monitor Mode of Operation

The primary element of the monitor mode display is the alarm meter. This “graphics equalizer” type of bar

graph shows a continuous readout of the signal strength associated with each trigger being monitored.

The display is drawn in terms of sigma’s above background.

For each trigger, a dashed line shows the alarm threshold for that trigger. When an alarm occurs, the word

Alarm and the alarm value will be displayed next to the bar graph. Once an alarm has occurred, the word

Alarmed will flash at the top center of the screen with the number of stored alarms immediately below it.

The time of the alarm will be displayed in the message line immediately below the bar graphs.

The order in which the bar graphs are presented changes with every measurement interval: the most

intense alarm measured during the interval is presented first; least intense is shown last.

The function keys on the main monitor display are:

•D

ETAIL (F1) switches to the Detail mode, if it is enabled. This mode is described in the next section.

ALIB (F2) performs the quick, one-button calibration adjustment that is described in Section 4.2.1

•C

and in the Quick Reference.

SAM 935™ Instruction Manual 31

•CAPTURE (F3) saves the currently displayed reading. The current alarm will be terminated when

you press C

APTURE. If the condition continues to alarm, a new alarm will be created and you will

again have the choice to capture it or not.

•S

ILENCE (F4) turns off the audible alarm. If there are no alarms currently going on, then the F4

function key becomes A

poses; each press of the A

LM TEST. Pressing ALM TEST will activate the alarm indicators for test pur-

LM TEST key will cause the alarm indicators to turn on for 5 seconds.

• When in the alarm review mode, the F2, F3, and F4 function keys become R

ETURN, PRN SEL, and

MCA, respectively. These functions are described above in Section 4.5.

5.3 The Detail Mode of Operation

In Detail mode, the actual spectrum being acquired is displayed. If an alarm is in progress, the displayed

spectrum is the accumulated spectrum for the entire alarm:

The function keys on the detail display are:

URVEIL (F1) will switch to the Surveillance mode of operation.

•S

•C

ALIB (F2) performs the quick, one-button calibration adjustment that is described in Section 4.2.1

and in the Quick Reference.

•C

APTURE (F3) saves the currently displayed reading. The current alarm will be terminated when

you press C

again have the choice to capture it or not.

•S

ILENCE (F4) turns off the audible alarm. If there are no alarms currently going on, then the F4

function key becomes A

poses; each press of the A

APTURE. If the condition continues to alarm, a new alarm will be created and you will

LM TEST. Pressing ALM TEST will activate the alarm indicators for test pur-

LM TEST key will cause the alarm indicators to turn on for 5 seconds.

• When in the alarm review mode, the F2, F3, and F4 function keys become R

ETURN, PRN SEL, and

MCA, respectively. These functions are described above in Section 4.5.

5.4 Manual Mode

Manual mode is a sophisticated, alternate mode of operating the SAM 935. Use this mode to acquire data;

view and edit hardware parameters; set, clear, and edit regions of interest (ROIs); and perform qualitative

analyses.

1. Press the U

the Utilities menu

32 SAM 935™ Instruction Manual

TIL button and choose

Manual Mode

from

The Manual mode screen will appear:

Note this message: Pressing the Util key in Manual

mode toggles a different set of function keys; see

Section 5.4.3.

2. Begin taking readings. When a spectrum is displayed, the message line will normally display the

cursor readout. Displayed are the cursor channel (CH), the energy (EN, if calibrated), and the

counts in the cursor channel (CNTS).

3. If everything is correct, press A

CCEPT. The spectrum will be analyzed and the results displayed on

the screen. You can print either short or long versions of the analysis report by using the function

keys on the report screen. The long version includes: 1) system setup information, 2) a graphical

printout of the spectrum, 3) detailed peak analysis, and 4) the details of the isotope cross correlation analysis. The short version of the report includes only items (1) and (3). An example of this

report can be found in Section 7.4.

4. When you exit the report screen you are back in the Manual mode screen. You can edit ROIs, take

data for longer, etc., and then press S

5. To analyze another sample, simply E

TART (F2) again to repeat the analysis.

RASE (F3) the data and start again.

The cursor can be controlled with the arrow keys. The ← and → keys move the cursor one channel at a

time along the spectrum, while the ↑ and ↓ keys move the cursor 1/16 of the spectrum at a time. The spectrum display is initially in its narrow mode, with the area at the right of the spectrum displaying a variety of

information. The initial set of information is called the “data” screen. Here the vertical scale, preset live

time, elapsed live time, and count rate in CPM is displayed. The information displayed in this area can be

changed by pressing F4. Just above the spectrum display is an area in which instructions, sub-mode titles,

or current spectrum data are displayed.

The initial set of function keys in the Manual mode have the following functions:

Exit (F1) The E

XIT key causes you to exit from the mode. Data acquisition is

stopped and nothing is saved.

Start (F2) The S

TART key begins data acquisition. Once it is pressed t he label

changes to Stop. Data acquisition can be started and stopped as many

times as desired.

Erase (F3) The E

RASE key erases the data and resets the elapsed real and live times

to zero. The key may be pressed at any time.

WARNING: NO CAUTION IS GIVEN THAT DATA IS ABOUT TO BE ERASED

Pre Adj (F4) The P

RE ADJ key changes what is displayed on the right side of the

screen to a display of the preset values of the system as shown below.

SAM 935™ Instruction Manual 33

5.4.1 MCA Presets

When PRE ADJ (F4) is selected, the presets are displayed in the data area. When the presets are displayed, the F4 function key changes to read HW A

935 has the following types of preset controls:

ON/OFF When the preset enable is set to OFF presets will have no effect. It is the

same as setting all presets to zero.

LT Pre Preset live time.

RT Pre Preset real time.

Pk Pre Preset peak count.

Int Pre Preset integral.

DJ (or HW INFO when not in Manual mode). The SAM

Note: Preset live and rea l time will be e xact, whil e in prese t peak and integ ral, the actual

values may exceed the preset slightly.

If you are in the manual MCA mode, the presets may be adjusted from this screen. Pressing the ↓ and ↑

arrows moves from preset to preset. The currently selected preset is displayed in the message line. Use

the ← and → arrows to change the value of the selected preset.

34 SAM 935™ Instruction Manual

5.4.2 Manual Hardware Adjustments

HW Adj/HW Info This key switches the information displayed in the data window to the

hardware parameters.

When HW A

data window. The F4 function key becomes a D

DJ/HW INFO is selected from the Presets screen, a set of hardware parameters is listed in the

ATA key that returns the system to the data mode.

HV Supp Displays the state of the bias voltage supply – on or off.

BIAS Current bias voltage setting. This voltage ranges from 200 to 1000 volts.

CG Amplifier coarse gain. Available values are 1, 2, 4 and 8.

FG Amplifier fine gain. Range is 1.00 to 2.55 in steps of 0.01.

LLD Low level discriminator. Range is from 0 to 105 percent of full scale in

steps of approximately 0.4%. For normal work the LLD should be set to

0.8 or 1.2.

ULD Upper level discriminator. Range is from 0 to 105 percent of full scale in

steps of approximately 0.4%. For normal work the ULD should be set to

105%.

ZERO ADC zero setting. Range is ±5% of full scale.

XFRM Conversion m ode . Th e s yst em is op t im i ze d fo r QCC (SQRT) mod e . Al l o f

the analyses should be done in this mode. Standard linear mode is pro-

vided for those who desire it.

Under manual MCA mode (the HW A

screen modes (HW I

NFO), they may only be viewed.

DJ mode), it is possible to adjust these hardware parameters. In other

SAM 935™ Instruction Manual 35

5.4.3 Manual Mode Utilities

When you are in the Manual mode display, the UTIL key has a special function: it switches to alternate sets

of function keys. When the U

set of function keys are displayed:

Wide This key changes the spectrum display so that the spectrum occupies the full width of

the display.

Strip This key displays the spectrum with the ambient background subtracted. When

pressed, the label changes to N

play to its normal (unstripped) mode.

Log This changes the display to a log display as shown above. The function key label

changes to L

TIL button is pressed while the initial Manual screen is displayed, the following

ORMAL. Pressing the STRIP key again returns the dis-

INEAR. Pressing the key again returns to linear mode.

Accept At various times the F4 key may display A

CCEPT or RETURN. When ACCEPT

is displayed, it means that data has been collected and the opportunity is given to accept it,

erase and start over, or cancel the operation. Pressing A

CCEPT causes the analysis to

proceed, and offers the opportunity to place the spectrum into the spectrum storage as

well.

Except in background mode (where there are no ROIs), pressing U

TIL again from this set of function keys

brings up the ROI editing keys shown below:

Start This key begins an ROI. Use the cursor keys to position the cursor at the desired start-

ing channel. Press S

TART. The START key will change to STOP. Now use the cursor

keys to sweep out the ROI. When the desired end channel has been set, press the

S

TOP key. As many ROIs can be set as desired. NOTE: ROIs may not overlap. If an ROI

is set over an existing ROI, the portion of the old ROI overlapped will be replaced with

the new ROI.

Clr Cur Removes the ROI in which the cursor is located.

Clr All Removes all ROIs.

From the previous set of function keys (display keys or ROI keys depending on the mode), the next press

of the U

TIL key brings up the library peak labeling function.

36 SAM 935™ Instruction Manual

The peak labeling function allows you to display the gamma lines associated with particular nuclides

superimposed on the current spectrum. This feature is available both during and at the end of data acquisition. The I

SO - (F2) and ISO + (F3) keys cycle through the list of all enabled nuclides in the nuclide data-

base. For each, the enabled lines are shown with a height proportional to the log of their intensity.

Note: he hardware controls, preset controls, and ROI controls are only functional in

manual MCA mode.

5.5 Background Mode

The SAM 935 requires that an ambient background spectrum be taken before it will allow fine energy calibration and will not perform monitoring operations without one. The procedure for taking background spectra is described in Section 3.2.2.

The background mode screen looks like this:

The initial set of function keys have the following functions:

Wide This key changes the spectrum display so that the spectrum occupies the full width of

the display.

Log This changes the display to a log display. The function key label changes to L

INEAR.

Pressing the key again returns to linear mode.

AcceptAt various times the F4 key may display A

CCEPT or RETURN. When ACCEPT

is displayed, it means

that data has been collected and the opportunity is given to accept it, erase and start over, or cancel the

operation. Pressing A

CCEPT causes the operation (usually an analysis of some kind) to proceed, and the

spectrum will be placed into the spectrum storage as well.

The ambient background spectrum is stored and then subtracted from other spectra on a channel-

by-channel basis before they are analyzed. This provides a correction for any ambient radioactivity in the

vicinity of the detector and for background from cosmic rays, etc.

Because the counting statistics in the background spectrum directly affect the uncertainty in the analyzed

spectra, it is very important that the background be counted for a long time relative to the sampling interval.

SAM 935™ Instruction Manual 37

If you are operating with a 5-second sample time (the default), a background of 180 seconds or longer is

desirable.

Once the background spectrum is taken, you are given the opportunity to review the report generated or to

print it in long or short form. Check the gross CPM displayed on the report screen carefully

conditions, you should expect this number to be between 3000 CPM and 4000 CPM.

Two of the most likely causes for high backgrounds are radioactive materials near the counter in the form

of samples or standards, or high concentrations of natural radioactive material such as K40 in the materials of the building. High background levels are sometimes associated with concrete or cement block construction. High radon levels are also a possibility. The SAM 935 has the unique ability to operate well in a

wide range of background environments.

. Under normal

5.6 Calibration Mode

Accurate calibrations are essential for the SAM 935 to give accurate results. The calibration routines provided with the SAM 935 give you the tools to accurately calibrate and to maintain the calibrations easily.

Note: Before your SAM 935 left th e factory, it was carefully calibr ated using a set of calibration sources. T hese calibrations ( stored in the battery-b acked-up memory of the system) were made with your detector and shou ld be correct. Under no rmal circumstances,

you will be able to simply use the one-button quick calibration (F2 in the main display).

5.6.1 Manual Coarse Adjust with Cs137

The primary purpose of the coarse adjust procedure is to adjust the high voltage, coarse gain, and fine

gain of the SAM 935 to put the reference peaks (32.89 and 661.66 keV) of Cs137 into known channels of

the MCA.

The coarse adjust algorithm first adjusts the high voltage of the SAM 935 and then the coarse and fine

gains to achieve this goal. When complete, the 661.66 keV line for Cs137 will be in the correct channel to

within 0.8 percent. This is close enough so that calibrations can be maintained across adjustments of the

electronics.

If the SAM 935 has been previously calibrated either by you or at the factory, a screen will appear to ask if

you want to initialize the hardware parameters. If the SAM 935 has been previously adjusted and has not

been subjected to large swings in temperature, select N

its adjustment at the existing values for the high voltage and coarse and fine gains. All parameters will be

adjusted if necessary to achieve proper calibration.

If there have been large temperature changes or this is the first time you have adjusted the SAM 935,

select Y

goes through the entire algorithm. Both will result in the same calibration; however, starting where you

were last time can be much faster. In rare circumstances such as a change of detectors, the operation may

succeed when parameters are reset when it fails keeping the original values.

During each acquisition sequence, the spectrum being measured will be displayed as it develops, and if