BMW 335 User Manual

BMW 3- & 5-Series

Service and Repair Manual

A K Legg LAE MIMI and Larry Warren

Models covered

3-Series (E30)

316 (83 to 88), 316i (88 to 91), 318i (83 to 91), 320i (87 to 91), 325i (87 to 91).

Also Touring and Convertible versions of these models

5-Series (E28)

518 (81 to 85), 518i (85 to 88), 525i (81 to 88), 528i (81 to 88), 535i (85 to 88), M535i (85 to 88)

5-Series (E34)

518i (90 to 91), 520i (88 to 91), 525i (88 to 91), 530i (88 to 91), 535i (88 to 91)

Engines covered

1596 cc, 1766 cc, 1795 cc, 1990 cc, 2494 cc, 2788 cc, 2986 cc & 3430 cc

Does not cover Diesel, dohc or V8 engines, or four-wheel-drive models

© Haynes Publishing 1997

A book in the Haynes Service and Repair Manual Series

All rights reserved. No part of this book may be reproduced or transmitted

in any form or by any means, electronic or mechanical, including

photocopying, recording or by any information storage or retrieval system,

without permission in writing from the copyright holder.

ISBN 1 85960 236 3

British Library Cataloguing in Publication Data

A catalogue record for this book is available from the British Library.

Printed by J H Haynes & Co. Ltd, Sparkford, Nr Yeovil,Somerset

BA22 7JJ, England

Haynes Publishing

Sparkford, Nr Yeovil, Somerset BA22 7JJ, England

Haynes North America, Inc

861 Lawrence Drive, Newbury Park, California 91320, USA

Editions Haynes S.A.

147/149, rue Saint Honoré, 75001 PARIS, France

Haynes Publishing Nordiska AB

Box 1504, 751 45 Uppsala, Sweden

(1948-256-11AA3)

ABCDE

FGHIJ

KLMNO

PQRST

1 2 3

LIVING WITH YOUR BMW

Introduction Page 0•4

Safety First! Page 0•6

Anti-theft audio system Page 0•7

Instrument panel language display Page 0•7

Roadside Repairs

Jacking, towing and wheel changing Page 0•8

Jump starting Page 0•9

Identifying leaks Page 0•10

ROUTINE MAINTENANCE

Routine Maintenance and Servicing Page 1•1

Lubricants and fluids Page 1•3

Maintenance schedule Page 1•4

Weekly checks Page 1•7

Every 6000 miles Page 1•11

Every 12 000 miles Page 1•16

Every 24 000 miles Page 1•23

Every 60 000 miles Page 1•26

Contents

REPAIRS & OVERHAUL

Engine and Associated Systems

In-car engine repair procedures Page 2A•1

General engine overhaul procedures Page 2B•1

Cooling, heating and air conditioning systems Page 3•1

Fuel and exhaust systems Page 4•1

Engine electrical systems Page 5•1

Engine management and emission control systems Page 6•1

Transmission

Manual transmission Page 7A•1

Automatic transmission Page 7B•1

Clutch and driveline Page 8•1

Brakes

Braking system Page 9•1

Suspension

Suspension and steering systems Page 10•1

Body Equipment

Bodywork and fittings Page 11•1

Electrical

Body electrical systems Page 12•1

Wiring Diagrams Page 12•10

REFERENCE

MOT Test Checks

Checks carried out from the driver’s seat Page REF•1

Checks carried out with the vehicle on the ground Page REF•2

Checks carried out with the vehicle raised Page REF•3

Checks carried out on your vehicle’s exhaust emission system Page REF•4

Tools and Working Facilities Page REF•5

General Repair Procedures Page REF•8

Fault Finding Page REF•9

Conversion factors Page REF•17

Automotive chemicals and lubricants Page REF•18

Buying spare parts and vehicle identification numbers Page REF•19

Glossary of Technical Terms Page REF•20

Index Page REF•25

Contents

0•4

Introduction

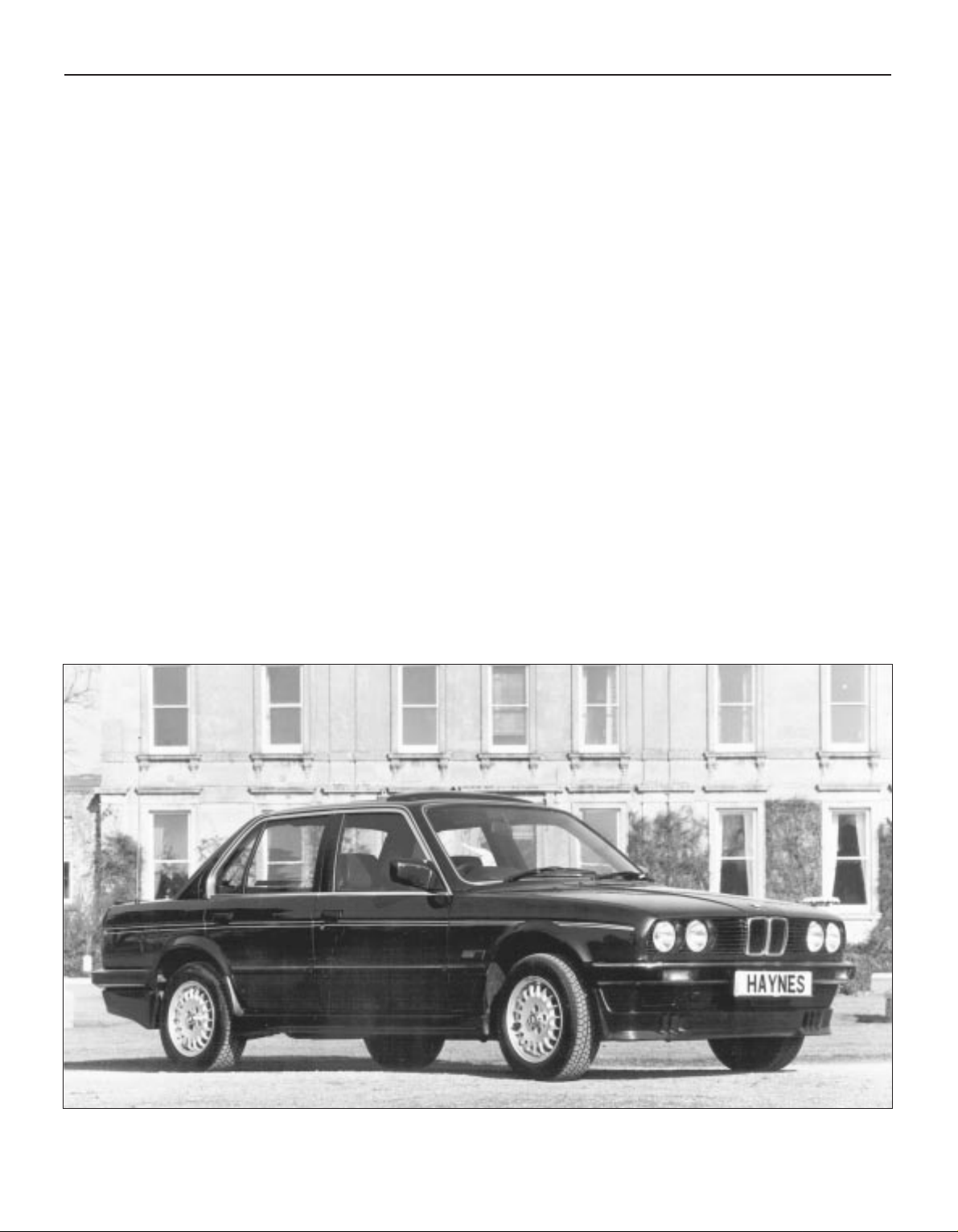

The E30 3-Series range first became

available in the UK in March 1983, and

continued in production until April 1991, when

the revised E36 3-Series range (not covered

by this manual) was introduced. Convertible

and Touring (Estate) models were introduced

for 1988, and these models have continued in

E30 form to date.

The E28 5-Series models were introduced

in October 1981, and were superseded in

June 1988 by the revised E34 5-Series range,

Touring versions of which became available

from March 1992. Throughout this manual,

E28 models are also referred to as “oldshape”, while E34 models are designated

“new-shape”.

The models covered by this manual are

equipped with single overhead cam in-line

four- and six-cylinder engines. Early 316 and

518 models are fitted with carburettors, but all

other models are fitted with fuel injection

systems. Transmissions are a five-speed

manual, or three- or four-speed automatic.

The transmission is mounted to the back of

the engine, and power is transmitted to the

fully-independent rear axle through a twopiece propeller shaft. The final drive unit is

bolted solidly to a frame crossmember, and

drives the rear wheels through driveshafts

equipped with inner and outer constant

velocity joints.

The front suspension is of MacPherson

strut type, with the coil spring/shock absorber

unit making up the upper suspension link. The

rear suspension is made up of coil springover-shock absorber struts, or coil springs

and conventional shock absorbers,

depending on model.

The brakes are disc type at the front, with

either drums or discs at the rear, depending

on model. Servo assistance is standard on all

models. Some later models are equipped with

an Anti-lock Braking System (ABS).

All models are manufactured to fine limits,

and live up to the BMW reputation of quality

workmanship. Although many of the models

covered by this manual appear complex at

first sight, they should present no problems to

the home mechanic.

Note for UK readers

The greater part of this manual was

originally written in the USA. Some of the

photographs used are of American-market

models, but the procedures given are fully

applicable to right-hand-drive models (or have

been amended where necessary).

Acknowledgements

Thanks are due to Champion Spark Plug,

who supplied the illustrations showing spark

plug conditions. Thanks are also due to

Sykes-Pickavant Limited, who provided some

of the workshop tools, and to all those people

at Sparkford who helped in the production of

this manual. Technical writers who

contributed to this project include Robert

Maddox, Mark Ryan and Mike Stubblefield.

We take great pride in the accuracy of

information given in this manual, but

vehicle manufacturers make alterations

and design changes during the production

run of a particular vehicle of which they do

not inform us. No liability can be accepted

by the authors or publishers for loss,

damage or injury caused by any

errors in, or omissions from, the

information given.

Project vehicles

The main project vehicle used in the

preparation of this manual for the UK market

was a 1988 BMW 318i with an M40/B18

engine.

Introduction to the BMW 3- and 5-Series

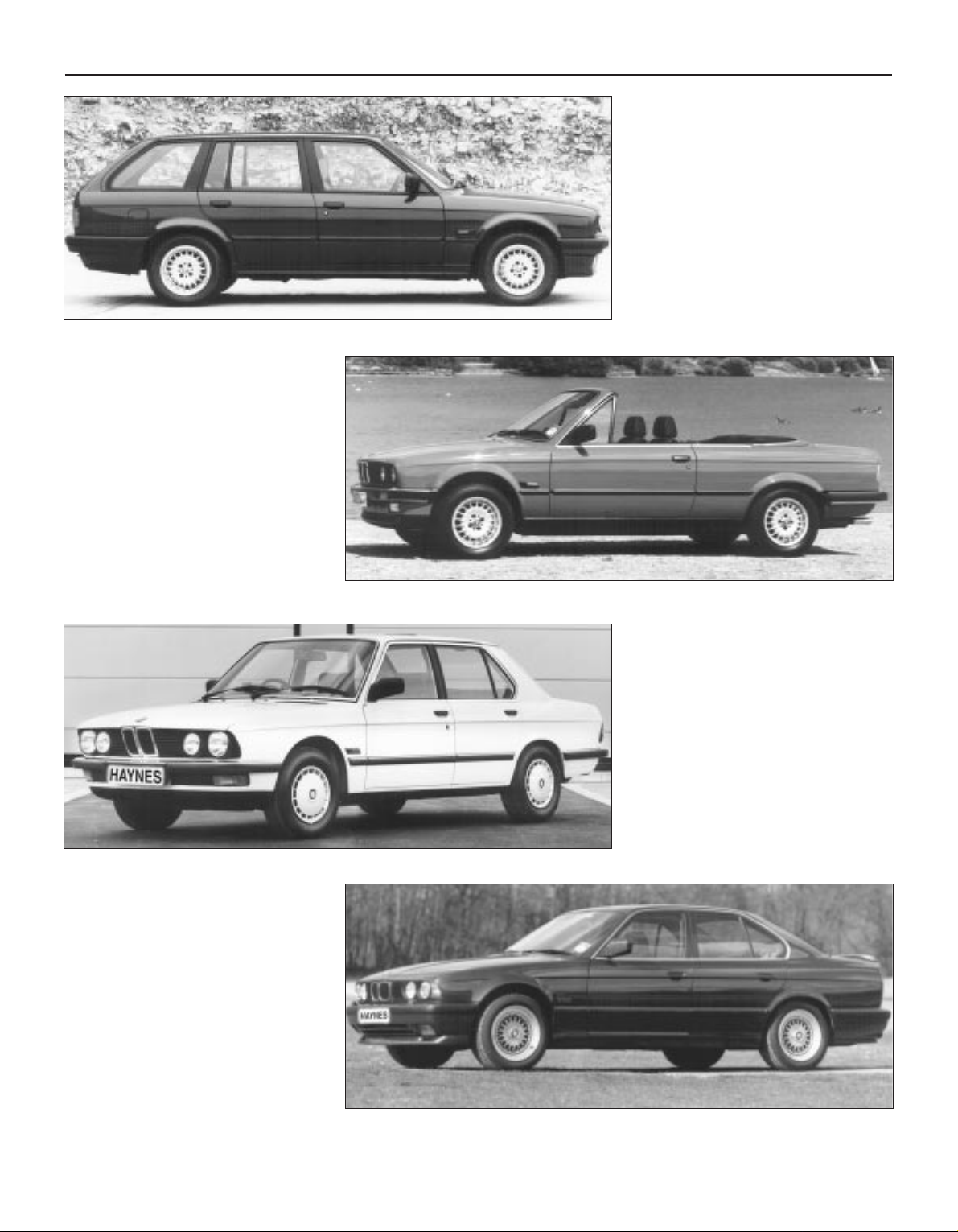

BMW 320i Saloon (E30)

0•5

Introduction

BMW 518i (E28)

BMW 325i Touring (E30)

BMW 535i (E34)

BMW 325i Convertible (E30)

0•6

Safety First!

Working on your car can be dangerous.

This page shows just some of the potential

risks and hazards, with the aim of creating a

safety-conscious attitude.

General hazards

Scalding

• Don’t remove the radiator or expansion

tank cap while the engine is hot.

• Engine oil, automatic transmission fluid or

power steering fluid may also be dangerously

hot if the engine has recently been running.

Burning

• Beware of burns from the exhaust system

and from any part of the engine. Brake discs

and drums can also be extremely hot

immediately after use.

Crushing

• When working under or near

a raised vehicle,

always

supplement the

jack with axle

stands, or use

drive-on

ramps.

Never

venture

under a car which

is only supported by a jack.

• Take care if loosening or tightening hightorque nuts when the vehicle is on stands.

Initial loosening and final tightening should

be done with the wheels on the ground.

Fire

• Fuel is highly flammable; fuel vapour is

explosive.

• Don’t let fuel spill onto a hot engine.

• Do not smoke or allow naked lights

(including pilot lights) anywhere near a

vehicle being worked on. Also beware of

creating sparks

(electrically or by use of tools).

• Fuel vapour is heavier than air, so don’t

work on the fuel system with the vehicle over

an inspection pit.

• Another cause of fire is an electrical

overload or short-circuit. Take care when

repairing or modifying the vehicle wiring.

• Keep a fire extinguisher handy, of a type

suitable for use on fuel and electrical fires.

Electric shock

• Ignition HT

voltage can be

dangerous,

especially to

people with heart

problems or a

pacemaker. Don’t

work on or near the

ignition system with

the engine running or

the ignition switched on.

• Mains voltage is also dangerous. Make

sure that any mains-operated equipment is

correctly earthed. Mains power points should

be protected by a residual current device

(RCD) circuit breaker.

Fume or gas intoxication

• Exhaust fumes are

poisonous; they often

contain carbon

monoxide, which is

rapidly fatal if inhaled.

Never run the

engine in a

confined space

such as a garage

with the doors shut.

• Fuel vapour is also

poisonous, as are the vapours from some

cleaning solvents and paint thinners.

Poisonous or irritant substances

• Avoid skin contact with battery acid and

with any fuel, fluid or lubricant, especially

antifreeze, brake hydraulic fluid and Diesel

fuel. Don’t syphon them by mouth. If such a

substance is swallowed or gets into the eyes,

seek medical advice.

• Prolonged contact with used engine oil can

cause skin cancer. Wear gloves or use a

barrier cream if necessary. Change out of oilsoaked clothes and do not keep oily rags in

your pocket.

• Air conditioning refrigerant forms a

poisonous gas if exposed to a naked flame

(including a cigarette). It can also cause skin

burns on contact.

Asbestos

• Asbestos dust can cause cancer if inhaled

or swallowed. Asbestos may be found in

gaskets and in brake and clutch linings.

When dealing with such components it is

safest to assume that they contain asbestos.

Special hazards

Hydrofluoric acid

• This extremely corrosive acid is formed

when certain types of synthetic rubber, found

in some O-rings, oil seals, fuel hoses etc, are

exposed to temperatures above 4000C. The

rubber changes into a charred or sticky

substance containing the acid. Once formed,

the acid remains dangerous for years. If it

gets onto the skin, it may be necessary to

amputate the limb concerned.

• When dealing with a vehicle which has

suffered a fire, or with components salvaged

from such a vehicle, wear protective gloves

and discard them after use.

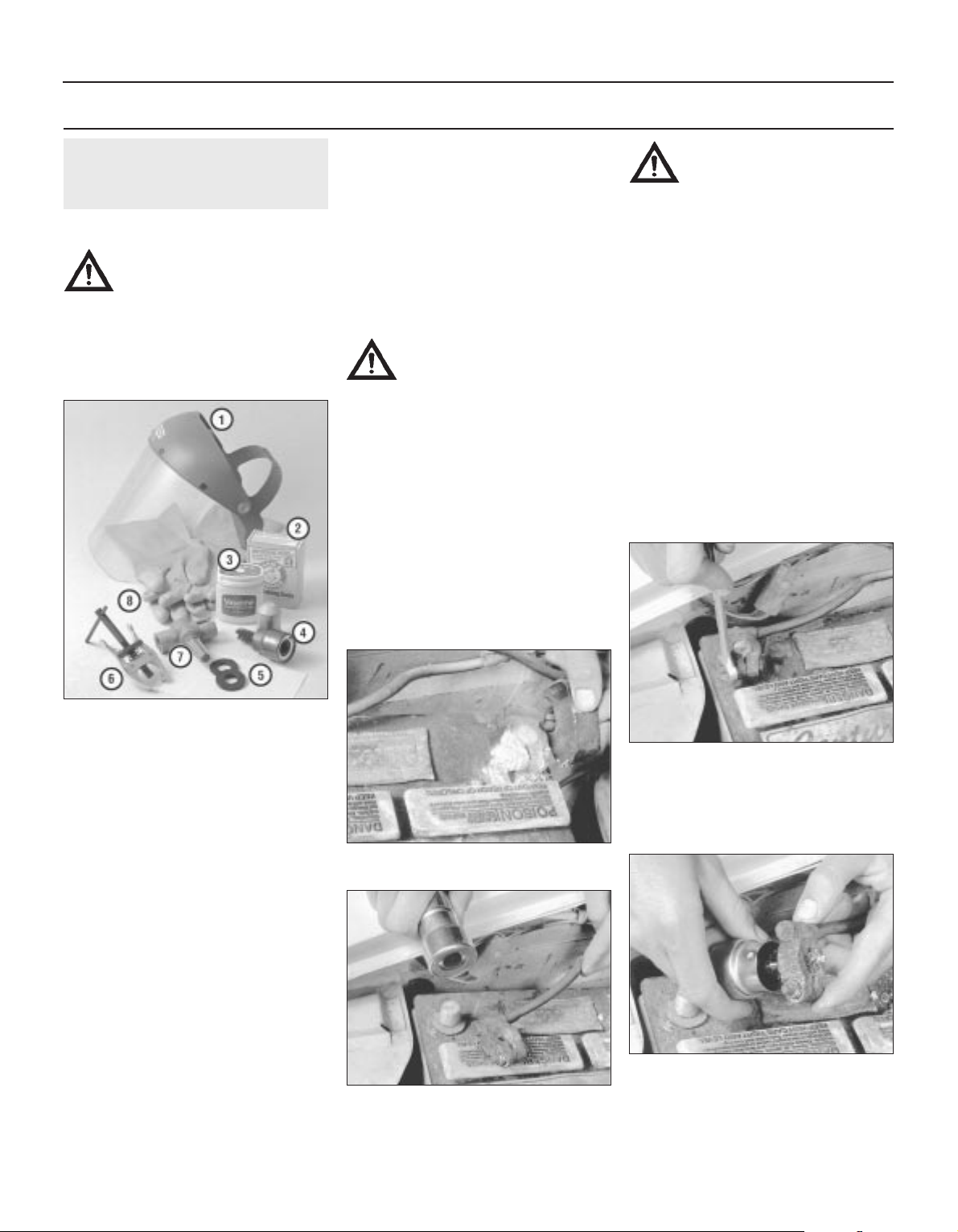

The battery

• Batteries contain sulphuric acid, which

attacks clothing, eyes and skin. Take care

when topping-up or carrying the battery.

• The hydrogen gas given off by the battery

is highly explosive. Never cause a spark or

allow a naked light nearby. Be careful when

connecting and disconnecting battery

chargers or jump leads.

Air bags

• Air bags can cause injury if they go off

accidentally. Take care when removing the

steering wheel and/or facia. Special storage

instructions may apply.

Diesel injection equipment

• Diesel injection pumps supply fuel at very

high pressure. Take care when working on

the fuel injectors and fuel pipes.

Warning: Never expose the hands,

face or any other part of the body

to injector spray; the fuel can

penetrate the skin with potentially fatal

results.

Remember...

DO

• Do use eye protection when using power

tools, and when working under the vehicle.

• Do wear gloves or use barrier cream to

protect your hands when necessary.

• Do get someone to check periodically

that all is well when working alone on the

vehicle.

• Do keep loose clothing and long hair well

out of the way of moving mechanical parts.

• Do remove rings, wristwatch etc, before

working on the vehicle – especially the

electrical system.

• Do ensure that any lifting or jacking

equipment has a safe working load rating

adequate for the job.

A few tips

DON’T

• Don’t attempt to lift a heavy component

which may be beyond your capability – get

assistance.

• Don’t rush to finish a job, or take

unverified short cuts.

• Don’t use ill-fitting tools which may slip

and cause injury.

• Don’t leave tools or parts lying around

where someone can trip over them. Mop

up oil and fuel spills at once.

• Don’t allow children or pets to play in or

near a vehicle being worked on.

0•7

Anti-theft audio system

Anti-theft audio system

General information

Some models are equipped with an audio

system having an anti-theft feature that will

render the stereo inoperative if stolen. If the

power source to the stereo is cut, the stereo

won’t work even if the power source is

immediately re-connected. If your vehicle is

equipped with this anti-theft system, do not

disconnect the battery or remove the stereo

unless you have the individual code number

for the stereo.

Refer to the owner’s handbook supplied

with the vehicle for more complete

information on this audio system and its antitheft feature.

Unlocking procedure

1 T urn on the radio. The word “CODE” should

appear on the display.

2 Using the station preset selector buttons,

enter the five-digit code. If you make a

mistake when entering the code, continue

the five-digit sequence anyway. If you hear

a “beep,” however, stop immediately and

start the sequence over again. Note: You

have three attempts to enter the correct

code. If the correct code isn’t entered in

three tries, you’ll have to wait one hour, with

the radio on, before you enter the codes

again.

5 Once the code has been entered correctly,

the word “CODE” should disappear from the

display, and the radio should play (you’ll have

to tune-in and enter your preset stations,

however).

6 If you have lost your code number, contact

a BMW dealer service department.

Instrument panel language display

On some later models, disconnecting the

battery may cause the instrument panel

display to default to the German language

(this does not usually apply to UK models). If

it is necessary to reset the correct language

after the battery is reconnected, proceed as

follows. With all the doors shut and the

ignition on (engine not running), press the trip

reset button until the panel displays the

desired language. There are eight languages

available. If you wish to bypass a particular

selection, release the reset button and press

again - this will cause the display to advance

to the next language. Once the correct

language has been selected, continue holding

the reset button until the display reads “I.O.

Version 2.0”. Continue holding the button until

it reads “H.P. Version 3.4”, then release the

button.

0•8

Roadside Repairs

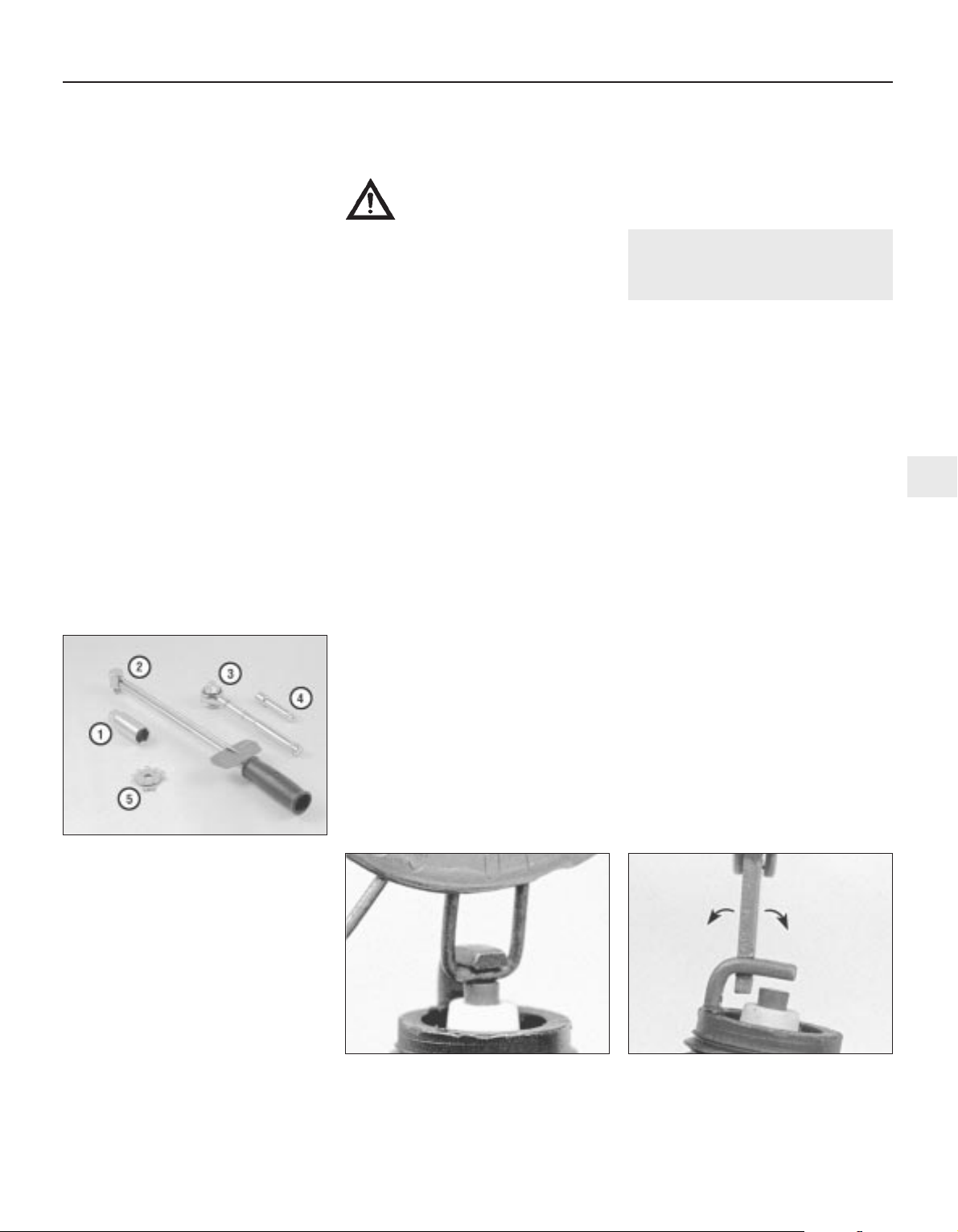

Jacking and wheel

changing

The jack supplied with the vehicle should

be used only for raising the vehicle when

changing a tyre or placing axle stands under

the frame.

Warning: Never crawl under the

vehicle or start the engine when

this jack is being used as the

only means of support.

When changing a wheel, the vehicle should

be on level ground, with the handbrake firmly

applied, and the wheels chocked. Select

reverse gear (manual transmission) or Park

(automatic transmission). Prise off the hub

cap (if equipped) using the tapered end of the

wheel brace. Loosen the wheel bolts half a

turn, leaving them in place until the wheel is

raised off the ground.

Position the head of the jack under the side

of the vehicle, making sure it engages with the

pocket made for this purpose (just behind the

front wheel, or forward of the rear wheel).

Engage the wheel brace handle and turn it

clockwise until the wheel is raised off the

ground. Unscrew the bolts, remove the wheel

and fit the spare.

Refit the wheel bolts and tighten them

finger-tight. Lower the vehicle by turning the

wheel brace anti-clockwise. Remove the jack

and tighten the bolts in a diagonal pattern to

the torque listed in the Chapter 1

Specifications. If a torque wrench is not

available, have the torque checked by a BMW

dealer or tyre fitting specialist as soon as

possible. Refit the hubcap.

Towing

Vehicles with manual transmission can be

towed with all four wheels on the ground, if

necessary. Automatic transmission-equipped

vehicles can only be towed with all four

wheels on the ground providing that the

speed does not exceed 35 mph and the

distance is not over 50 miles, otherwise

transmission damage can result. For

preference, regardless of transmission type,

the vehicle should be towed with the driven

(rear) wheels off the ground.

Proper towing equipment, specifically

designed for the purpose, should be used,

and should be attached to the main structural

members of the vehicle, not to the bumpers or

bumper brackets. Sling-type towing

equipment must not be used on these

vehicles.

Safety is a major consideration while

towing. The handbrake should be released,

and the transmission should be in neutral. The

steering must be unlocked (ignition switch

turned to position “1”). Remember that

power-assisted steering (where fitted) and the

brake servo will not work with the engine

switched off.

Jacking, towing and wheel changing

0•9

Roadside Repairs

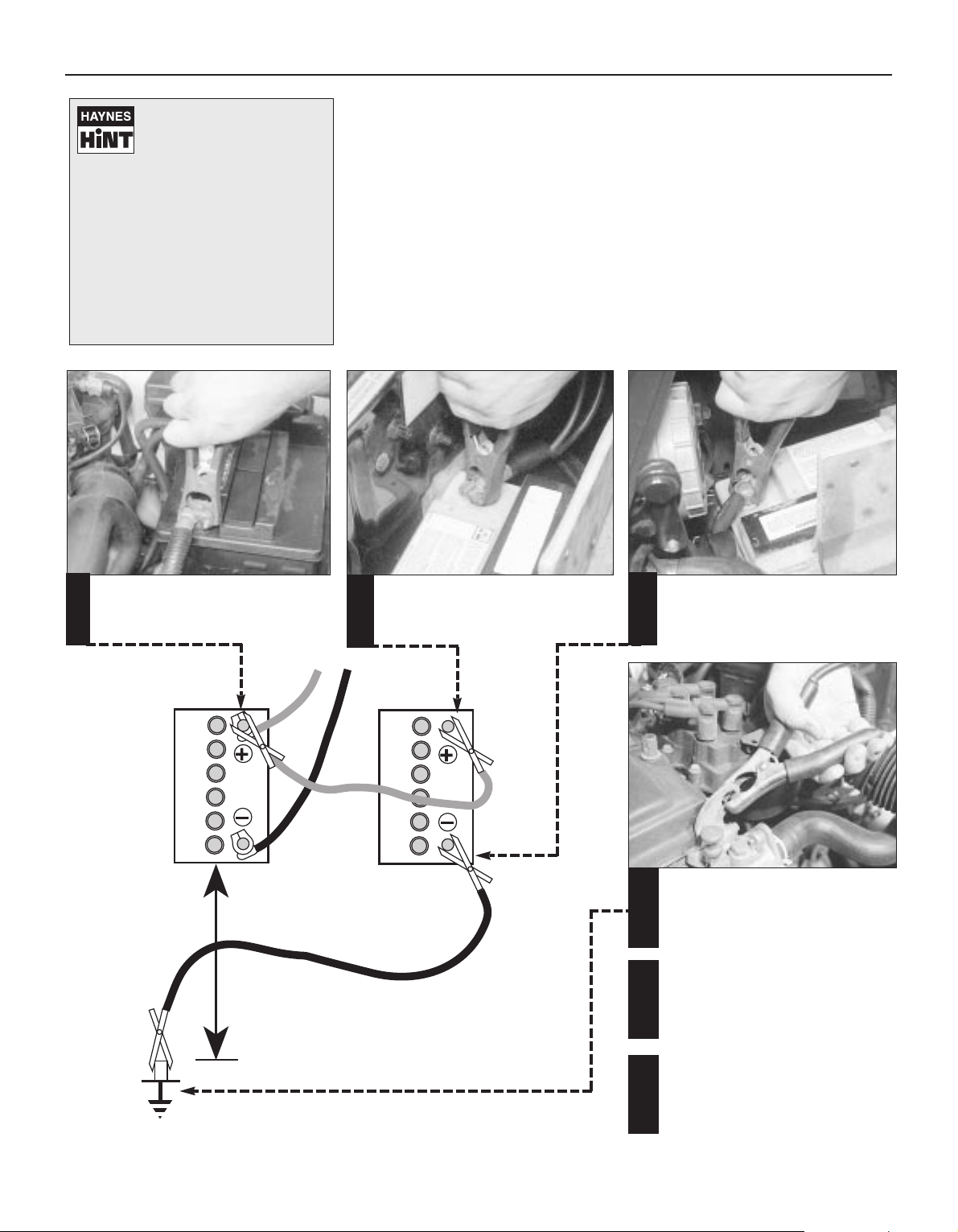

When jump-starting a car using a

booster battery, observe the following

precautions:

4 Before connecting the booster

battery, make sure that the ignition is

switched off.

4 Ensure that all electrical equipment

(lights, heater, wipers, etc) is

switched off.

4 Make sure that the booster battery is

the same voltage as the discharged

one in the vehicle.

4 If the battery is being jump-started

from the battery in another vehicle,

the two vehcles MUST NOT TOUCH

each other.

4 Make sure that the transmission is in

neutral (or PARK, in the case of

automatic transmission).

Jump starting will get you out

of trouble, but you must correct

whatever made the battery go

flat in the first place. There are

three possibilities:

1

The battery has been drained by

repeated attempts to start, or by

leaving the lights on.

2

The charging system is not working

properly (alternator drivebelt slack

or broken, alternator wiring fault or

alternator itself faulty).

3

The battery itself is at fault

(electrolyte low, or battery worn out).

Connect one end of the red jump lead to

the positive (+) terminal of the flat

battery

Connect the other end of the red lead to

the positive (+) terminal of the booster

battery.

Connect one end of the black jump lead

to the negative (-) terminal of the

booster battery

Connect the other end of the black

jump lead to a bolt or bracket on the

engine block, well away from the

battery, on the vehicle to be started.

1

2

3

4

Make sure that the jump leads will not

come into contact with the fan, drivebelts or other moving parts of the

engine.

5

Start the engine using the booster

battery, then with the engine running at

idle speed, disconnect the jump leads in

the reverse order of connection.

6

Jump starting

0•10

Roadside Repairs

Puddles on the garage floor or drive, or

obvious wetness under the bonnet or

underneath the car, suggest a leak that needs

investigating. It can sometimes be difficult to

decide where the leak is coming from,

especially if the engine bay is very dirty

already. Leaking oil or fluid can also be blown

rearwards by the passage of air under the car,

giving a false impression of where the

problem lies.

Warning: Most automotive oils

and fluids are poisonous. Wash

them off skin, and change out of

contaminated clothing, without

delay.

Identifying leaks

The smell of a fluid leaking

from the car may provide a

clue to what’s leaking. Some

fluids are distinctively

coloured. It may help to clean the car

carefully and to park it over some clean

paper overnight as an aid to locating the

source of the leak.

Remember that some leaks may only

occur while the engine is running.

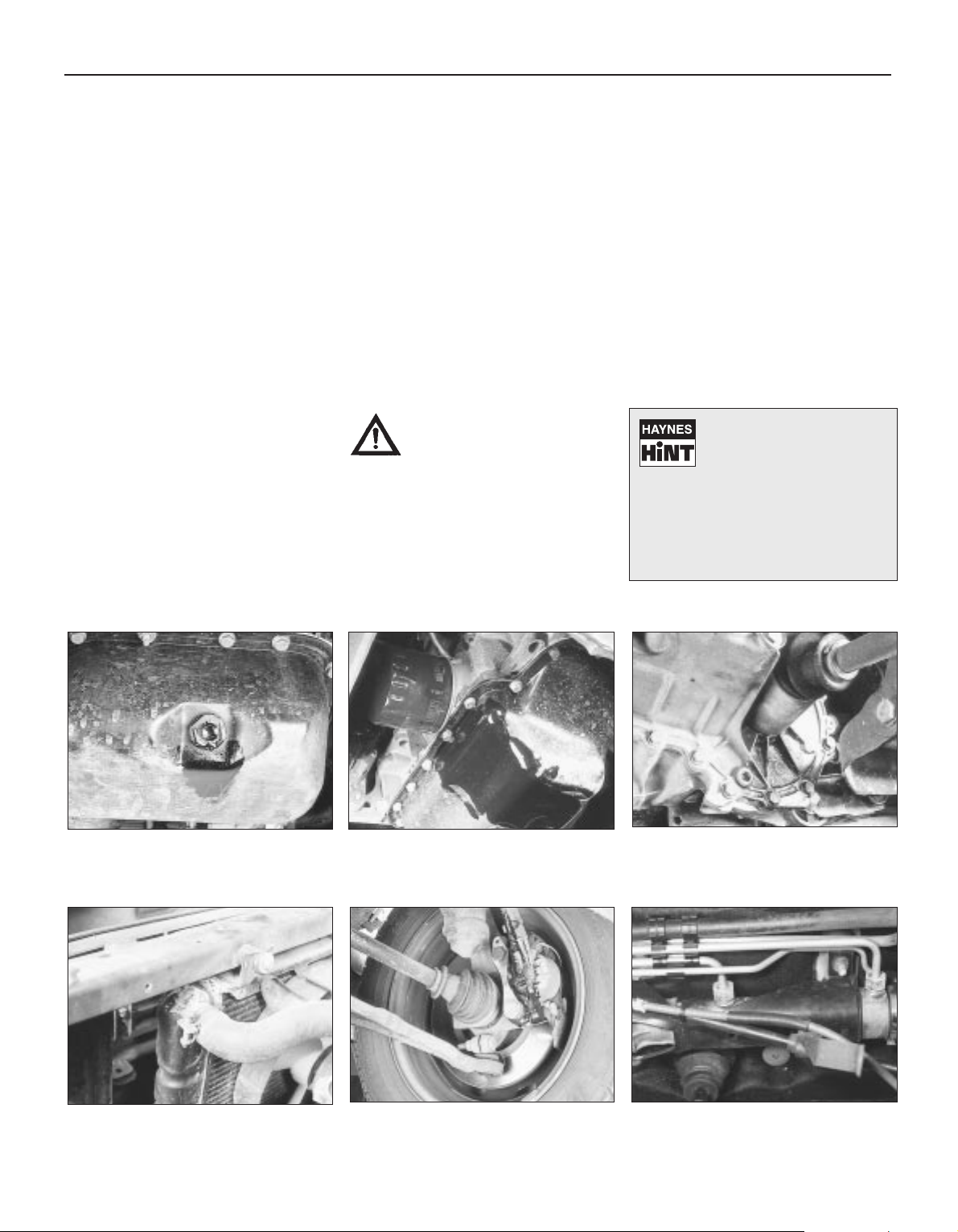

Sump oil Gearbox oil

Brake fluid Power steering fluid

Oil from filter

Antifreeze

Engine oil may leak from the drain plug... ...or from the base of the oil filter.

Leaking antifreeze often leaves a crystalline

deposit like this.

Gearbox oil can leak from the seals at the

inboard ends of the driveshafts.

A leak occurring at a wheel is almost

certainly brake fluid.

Power steering fluid may leak from the pipe

connectors on the steering rack.

1

Engine

Oil filter

M10 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion C121

M20 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion C160

M30 engines

3-Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion C160

5-Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion X115

M40 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion X120

Valve clearances (intake and exhaust)

M10 engines

Cold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.20 mm

Hot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.25 mm

M20 engines

Cold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.25 mm

Hot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.30 mm

M30 engines

Cold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.30 mm

Hot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.35 mm

M40 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hydraulic adjusters

Cooling system

Antifreeze mixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40% antifreeze/60% water

Chapter 1

Routine maintenance and servicing

Air filter renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Automatic transmission fluid and filter change . . . . . . . . . . . . . . . . . 28

Automatic transmission fluid level check . . . . . . . . . . . . . . . . . . . . . 8

Battery check, maintenance and charging . . . . . . . . . . . . . . . . . . . . 13

Brake system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Cooling system - draining, flushing and refilling . . . . . . . . . . . . . . . . 29

Cooling system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Differential lubricant change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Differential lubricant level check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Driveshaft gaiter check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

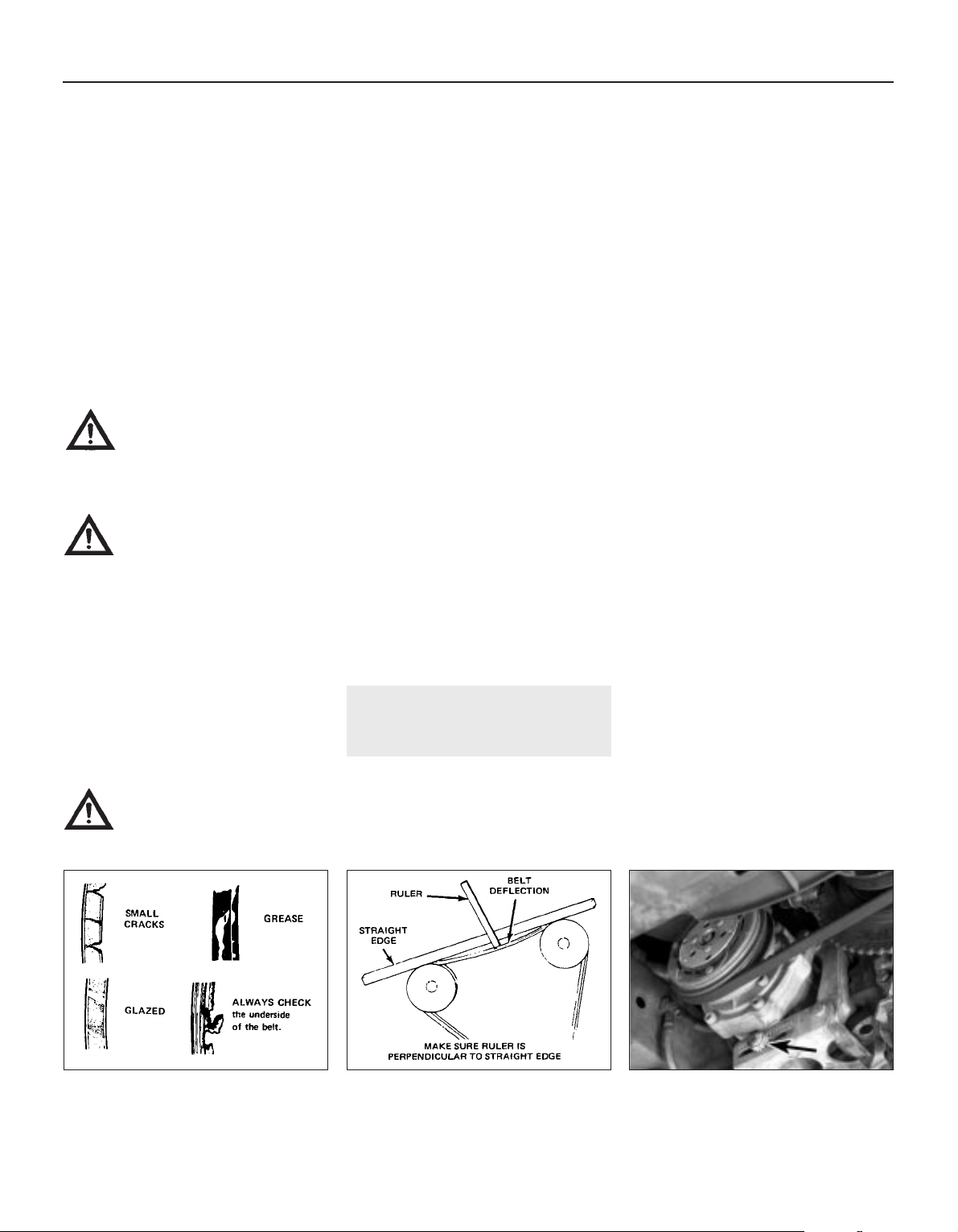

Drivebelt check, adjustment and renewal . . . . . . . . . . . . . . . . . . . . . 11

Engine idle speed and CO level check and adjustment . . . . . . . . . . 12

Engine oil and filter change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Engine timing belt renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Exhaust system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Evaporative Emissions Control (EVAP) system check . . . . . . . . . . . 33

Fluid level checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Fuel filter renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Fuel system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Manual transmission lubricant change . . . . . . . . . . . . . . . . . . . . . . . 31

Manual transmission lubricant level check . . . . . . . . . . . . . . . . . . . . 16

Power steering fluid level check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Routine maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Service light resetting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Spark plug check and renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Spark plug HT leads, distributor cap and rotor - check

and renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Steering and suspension check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Throttle linkage - check and lubrication . . . . . . . . . . . . . . . . . . . . . . 19

Tyre and tyre pressure checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Tyre rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Tune-up general information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Underbonnet hoses - check and renewal . . . . . . . . . . . . . . . . . . . . . 10

Valve clearances - check and adjustment . . . . . . . . . . . . . . . . . . . . 18

Wiper blades - check and renewal . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1•1

Easy, suitable for

novice with little

experience

Fairly easy, suitable

for beginner with

some experience

Fairly difficult,

suitable for competent

DIY mechanic

Difficult, suitable for

experienced DIY

mechanic

Very difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Specifications

Contents

Fuel system

Idle speed

3-Series, E30

316 with M10/B18 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 850 ± 50 rpm

316i with M40/B16 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 800 ± 40 rpm

318i with M10/B18 engine (manual transmission) . . . . . . . . . . . . . 850 ± 50 rpm

318i with M10/B18 engine (automatic transmission) . . . . . . . . . . . 750 ± 50 rpm

318i with M40/B18 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 800 ± 40 rpm

320i with M20/B20 engine (L-Jetronic) . . . . . . . . . . . . . . . . . . . . . . 800 ± 50 rpm

320i with M20/B20 engine (Motronic) . . . . . . . . . . . . . . . . . . . . . . . 760 ± 40 rpm

325i with M20/B25 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 760 ± 40 rpm

5-Series, E28 (“old-shape”)

518 and 518i with M10/B18 engine . . . . . . . . . . . . . . . . . . . . . . . . 800 ± 50 rpm

All other models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 850 ± 50 rpm

5-Series, E34 (“new-shape”)

518i with M40/B18 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 800 ± 40 rpm

520i with M20/B20M engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 760 ± 40 rpm

525i with M20/B25M engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 760 ± 40 rpm

530i with M30/B30M engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 800 ± 50 rpm

535i with M30/B35M engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 850 ± 50 rpm

CO% at 3000 rpm

3-Series, E30

316 with M10/B18 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.5 to 1.0

316i and 318i with M40/B16 engine . . . . . . . . . . . . . . . . . . . . . . . . 0.7 ± 0.5

318i with M10/B18 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 maximum

320i with M20/B20 engine (L-Jetronic) . . . . . . . . . . . . . . . . . . . . . . 1.0 ± 0.5

320i with M20/B20 engine (Motronic) . . . . . . . . . . . . . . . . . . . . . . . 0.7 ± 0.5

325i with M20/B25 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 ± 0.5

5-Series, E28 (“old-shape”)

518 and 518i with M10/B18 engine . . . . . . . . . . . . . . . . . . . . . . . . 1.0 maximum

525i with M30/B25 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 ± 0.5

528i with M30/B28 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 maximum

535i with M30/B34 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.3 to 1.5

M535i with M30/B34 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.3 to 1.5

5-Series, E34 (“new-shape”)

All models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.7 ± 0.5

Air filter element

M10 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion W155 (round) or U504 (square)

M20 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion U504 or U527

M30 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion U504 or U527

M40 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion U527

Fuel filter (all fuel injection engines) . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion L206

Ignition system

Spark plug type

M10, M20 and M30 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion N9YCC

M40 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion C9YCC

Spark plug gap* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.8 mm

Spark plug (HT) leads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion type not available

* The spark plug gap quoted is that recommended by Champion for their specified plugs listed above. If spark plugs of any other type are to be

fitted, refer to their manufacturer’s spark plug gap recommendations.

Brakes

Disc brake pad thickness (minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 mm

Drum brake shoe lining thickness (minimum) . . . . . . . . . . . . . . . . . . . . . 2.0 mm

Wiper blades

Windscreen

3-Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion X-5103

3-Series passenger side from 1991 . . . . . . . . . . . . . . . . . . . . . . . . . . Champion X-5103 (20 inch) or Champion X-5303 (21 inch)

5-Series, E28 (“old-shape”) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion X-4503

5-Series, E34 (“new-shape”) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion type not available

Tailgate

3-Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion X-4503

5-Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion type not available

1•2

Servicing Specifications

Tyre pressures (cold) - bars (psi) Front Rear

3-Series, E30

316 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.9 (28) 2.1 (30)

316i

Saloon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 (29) 2.1 (30)

Estate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 (29) 2.2 (32)

318i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.8 (26) 1.9 (28)

320i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.9 (28) 2.0 (29)

325i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2 (32) 2.3 (33)

5-Series, E28 (“old-shape”)

518 and 518i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 (29) 2.0 (29)

525i and 528i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2 (32) 2.2 (32)

535i and M535i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.3 (33) 2.5 (36)

5-Series, E34 (“new-shape”)

518i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 (29) 2.0 (29)

520i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2 (32) 2.1 (30)

525i, 530i and 535i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 (29) 2.3 (33)

Torque wrench settings Nm

Automatic transmission sump bolts

Three-speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 to 9

Four-speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 to 7

Spark plugs

M10 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 to 30

Except M10 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 to 33

Oxygen sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 to 33

Wheel bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Lubricants and fluids

Component or system Lubricant type/specification

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Multigrade engine oil, viscositySAE 10W/40 to 20W/50, to API SG

Cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ethylene glycol-based antifreeze with corrosion inhibitors

Manual transmission* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Gear oil, viscosity SAE 80 to API-GL4, or single-grade mineral-based

engine oil, viscosity SAE 20, 30 or 40 to API-SG

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Dexron ll type ATF

Final drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . BMW-approved hypoid gear oil, viscosity SAE 90**

Brake and clutch hydraulic systems . . . . . . . . . . . . . . . . . . . . . . . . . . Hydraulic brake fluid to SAE J 1703 or DOT 4

Power steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Dexron ll type ATF

* E34 520i & 525i with air conditioning, E34 530i & 535i - Dexron II type ATF)

** Only available in bulk; refer to your BMW dealer

Capacities*

1•3

1

Engine oil

M10 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.0 litres

M20 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.3 litres

M30 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.8 litres

M40 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.0 litres

Cooling system

M10 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.0 litres

M20 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.5 litres

M30 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12.0 litres

M40 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.0 litres

Fuel tank

3-Series, E30

Saloon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 litres (early),

64 litres (later)

Estate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63 litres (early),

70 litres (later)

5-Series

E28 (“old-shape”) . . . . . . . . . . . . . . . . . . . . . . . . 70 litres

E34 (“new-shape”) . . . . . . . . . . . . . . . . . . . . . . . 81 litres

Manual transmission

ZF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2 litres

Getrag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 to 1.5 litres

Automatic transmission (refill)

3-speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 litres

4-speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.0 litres

Final drive capacity (drain and refill)

3-Series, E30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.9 litres

5-Series, E28 (“old-shape”) . . . . . . . . . . . . . . . . . . 0.9 litres

5-Series, E34 (“new-shape”) . . . . . . . . . . . . . . . . . 1.7 litres

*All capacities approximate

Servicing Specifications

Maintenance schedule

The following maintenance intervals are based on the assumption

that the vehicle owner will be doing the maintenance or service work,

as opposed to having a dealer service department do the work.

Although the time/mileage intervals are loosely based on factory recommendations, most have been shortened to ensure, for example, that

such items as lubricants and fluids are checked/changed at intervals

that promote maximum engine/driveline service life. Also, subject to

the preference of the individual owner interested in keeping his or her

vehicle in peak condition at all times, and with the vehicle’s ultimate

resale in mind, many of the maintenance procedures may be

performed more often than recommended in the following schedule.

We encourage such owner initiative.

When the vehicle is new, it should be serviced initially by a factoryauthorised dealer service department, to protect the factory warranty.

In many cases, the initial maintenance check is done at no cost to the

owner (check with your dealer service department for more

information).

1•4

Maintenance and servicing

Every 250 miles or weekly, whichever

comes first

mm Check the engine oil level (Section 4)

mm Check the engine coolant level (Section 4)

mm Check the brake fluid level (Section 4)

mm Check the clutch fluid level (Section 4)

mm Check the washer fluid level (Section 4)

mm Check the tyres and tyre pressures (Section 5)

Every 6000 miles or 6 months,

whichever comes first

All items listed above, plus:

mm Change the engine oil and oil filter (Section 6)

mm Check the power steering fluid level (Section 7)

mm Check the tyres, and rotate if necessary (Section 9)

mm Check the automatic transmission fluid level

(Section 8)

mm Check the underbonnet hoses (Section 10)

mm Check/adjust the drivebelts (Section 11)

mm Check engine idle speed and CO (Section 12)

Every 12 000 miles or 12 months,

whichever comes first

All items listed above, plus:

mm Check/service the battery (Section 13)

mm Check the spark plugs (Section 14)

mm Check/renew the HT leads, distributor cap and

rotor (Section 15)

mm Check/top-up the manual transmission lubricant

(Section 16)

mm Check the differential oil level (Section 17)

mm Check the valve clearances, and adjust if

necessary - does not apply to M40 engines

(Section 18)

mm Check and lubricate the throttle linkage (Section 19)

mm Renew the air filter (Section 20)

mm Check the fuel system (Section 21)

mm Inspect the cooling system (Section 22)

mm Inspect the exhaust system (Section 23)

mm Inspect the steering and suspension components

(Section 24)

mm Check the driveshaft gaiter(s) (Section 25)

mm Inspect the brakes (Section 26)

mm Inspect/renew the windscreen wiper blades

(Section 27)

Every 24 000 miles or 2 years,

whichever comes first

All items listed above plus:

mm Change the automatic transmission fluid and filter

(Section 28)

mm Drain, flush and refill the cooling system (Section 29)

mm Renew the spark plugs (Section 14)

mm Check/renew the spark plug HT leads (Section 15)

mm Renew the fuel filter (Section 30)

mm Change the manual transmission lubricant (Section 31)

mm Change the differential oil (Section 32)

mm Check the evaporative emissions system, where

applicable (Section 33)

mm Reset the service indicator lights (Section 34)

mm Renew brake fluid by bleeding (see Chapter 9)

mm Check the handbrake operation (see Chapter 9)

Every 60 000 miles

mm Renew the timing belt (Section 35)

1•5

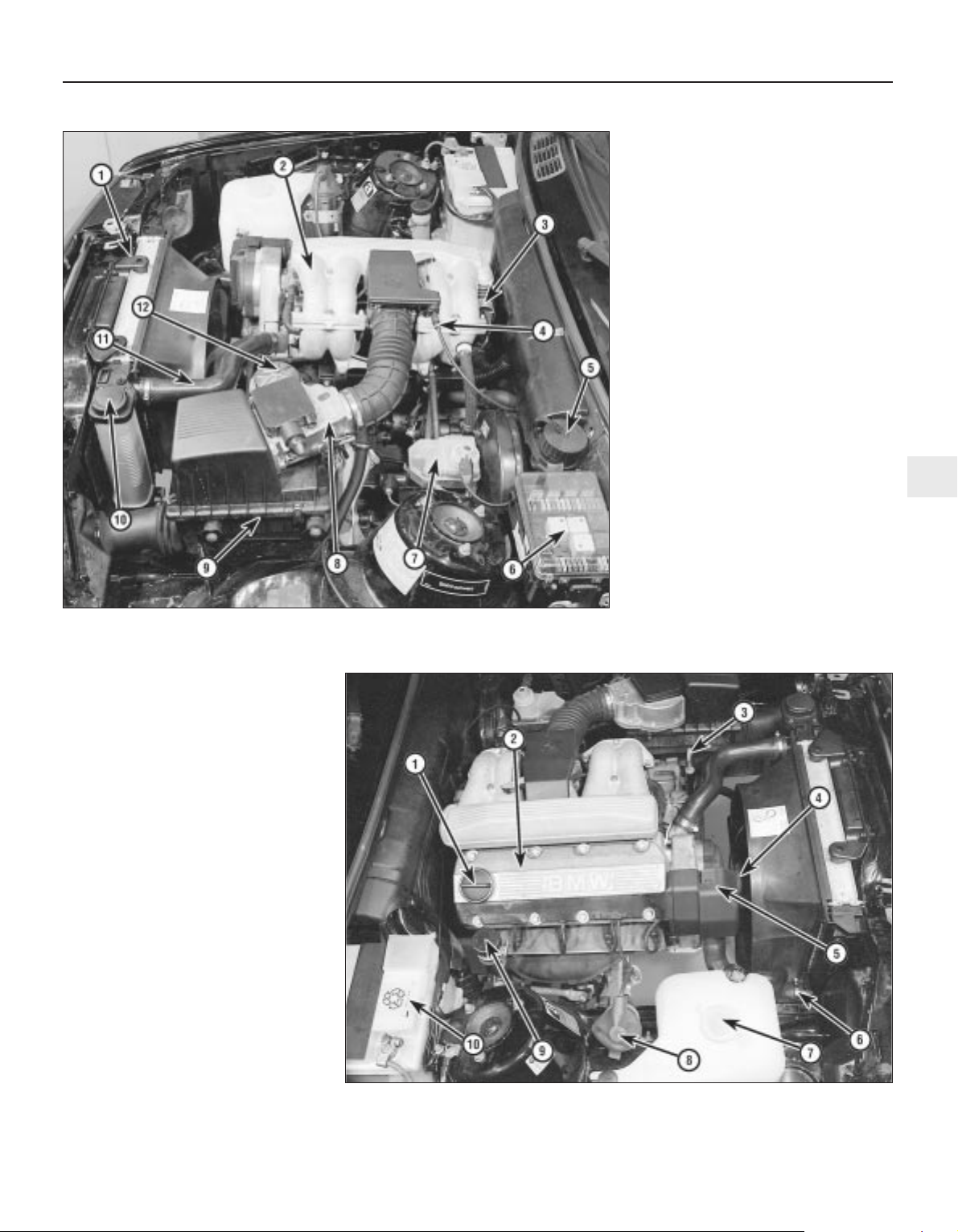

Underbonnet view (left-hand side) of a

UK model 318i (1988)

1 Radiator

2 Intake manifold

3 Idle control valve

4 Accelerator cable

5 Diagnostic/service indicator resetting

socket

6 Fuse/relay box

7 Brake hydraulic fluid reservoir

8 Airflow meter

9 Air cleaner unit

10 Radiator filler cap

11 Radiator top hose

12 Oil filter housing

Underbonnet view (right-hand side) of a

UK model 318i (1988)

1 Oil filler cap

2 Valve cover

3 Engine oil filler dipstick

4 Viscous cooling fan

5 Distributor cap cover

6 Bottom hose

7 Windscreen washer fluid reservoir

8 Ignition coil

9 Clutch hydraulic fluid reservoir

10 Battery

1

Maintenance and Servicing

1•6

Maintenance and Servicing

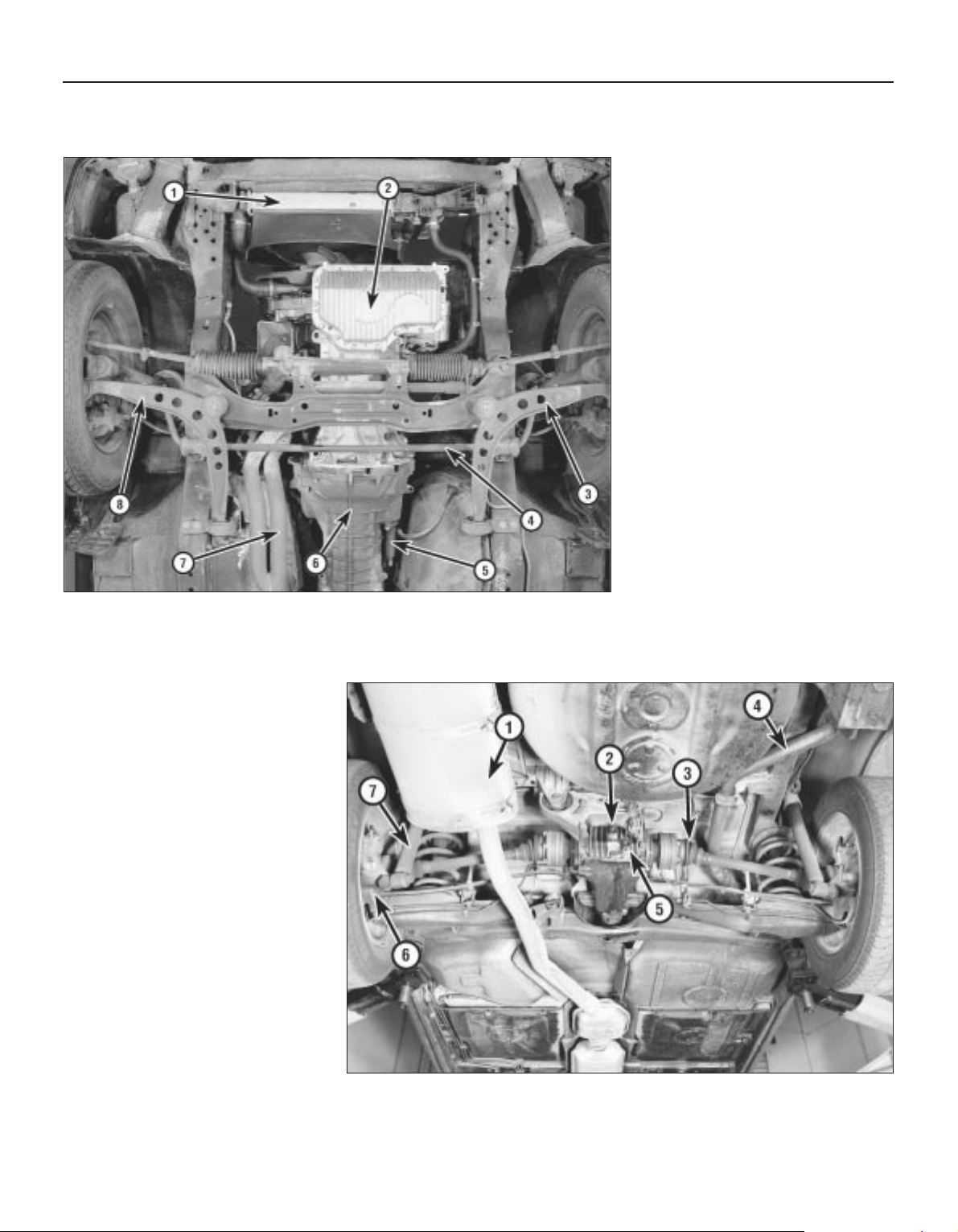

Front underbody view of a UK model 318i

(1988)

1 Radiator

2 Engine oil drain plug

3 Front suspension control arm (left-hand

side)

4 Front anti-roll bar

5 Clutch slave cylinder

6 Transmission

7 Exhaust downpipe

8 Front suspension control arm (right-hand

side)

Typical rear underside components

1 Exhaust system

2 Differential fill/check plug

3 Driveshaft boot

4 Fuel tank filler tube

5 Differential drain plug

6 Rear brake

7 Rear shock absorber

1 Introduction

This Chapter is designed to help the home

mechanic maintain his or her vehicle with the

goals of maximum performance, economy,

safety and reliability in mind. Included is a

master maintenance schedule, followed by

procedures dealing specifically with each item

on the schedule. Visual checks, adjustments,

component renewal and other helpful items

are included. Refer to the accompanying

illustrations of the engine compartment and

the underside of the vehicle for the locations

of various components. Servicing the vehicle,

in accordance with the mileage/time

maintenance schedule and the step-by-step

procedures, will result in a planned

maintenance programme that should produce

a long and reliable service life. Keep in mind

that it is a comprehensive plan, so maintaining

some items but not others at specified

intervals, will not produce the same results.

2 Routine maintenance

As you service the vehicle, you will discover

that many of the procedures can - and should

- be grouped together, because of the nature

of the particular procedure you’re performing,

or because of the close proximity of two

otherwise-unrelated components to one

another. For example, if the vehicle is raised

for chassis lubrication, you should inspect the

exhaust, suspension, steering and fuel

systems while you’re under the vehicle. When

the wheels are removed for other work, it

makes good sense to check the brakes, since

the wheels are already removed. Finally, let’s

suppose you have to borrow a torque wrench.

Even if you only need it to tighten the spark

plugs, you might as well check the torque of

as many critical nuts and bolts as time allows.

The first step in this maintenance

programme is to prepare yourself before the

actual work begins. Read through all the

procedures you’re planning to do, then gather

up all the parts and tools needed. If it looks

like you might run into problems during a

particular job, seek advice from a mechanic or

an experienced do-it-yourselfer.

3 Engine “tune-up” -

general information

The term “tune-up” is used in this manual to

represent a combination of individual

operations rather than one specific procedure.

If, from the time the vehicle is new, the

routine maintenance schedule is followed

closely, and frequent checks are made of fluid

levels and high-wear items, as suggested

throughout this manual, the engine will be

kept in relatively good running condition, and

the need for additional work will be minimised.

More likely than not, however, there will be

times when the engine is running poorly due

to a lack of regular maintenance. This is even

more likely if a used vehicle, which has not

received regular and frequent maintenance

checks, is purchased. In such cases, an

engine tune-up will be needed outside of the

regular maintenance intervals.

The first step in any tune-up or diagnostic

procedure to help correct a poor-running

engine is a cylinder compression check. A

compression check (see Chapter 2B) will help

determine the condition of internal engine

components, and should be used as a guide

for tune-up and repair procedures. If, for

instance, a compression check indicates

serious internal engine wear, a conventional

tune-up will not improve the performance of

the engine, and would be a waste of time and

money. Because of its importance, the

compression check should be done by

someone with the right equipment, and the

knowledge to use it properly.

The following procedures are those most

often needed to bring a generally poorrunning engine back into a proper state of

tune.

Minor tune-up

Check all engine-related fluids (Section 4)

Check all underbonnet hoses (Section 10)

Check and adjust the drivebelts (Sec-

tion 11)

Clean, inspect and test the battery (Sec-

tion 13)

Renew the spark plugs (Section 14)

Inspect the spark plug HT leads, distributor

cap and rotor (Section 15)

Check the air filter (Section 20)

Check the cooling system (Section 22)

Major tune-up

All items listed under minor tune-up, plus . . .

Check the ignition system (see Chapter 5)

Check the charging system (see Chapter 5)

Check the fuel system (see Chapter 4)

Renew the spark plug HT leads, distributor

cap and rotor (Section 15)

1•7

1

Routine Maintenance

Weekly checks

4 Fluid level checks

1

Note: The following are fluid level checks to

be done on a 250-mile or weekly basis.

Additional fluid level checks can be found in

specific maintenance procedures which

follow. Regardless of intervals, be alert to fluid

leaks under the vehicle, which would indicate

a fault to be corrected immediately.

1 Fluids are an essential part of the

lubrication, cooling, brake and windscreen

washer systems. Because the fluids gradually

become depleted and/or contaminated during

normal operation of the vehicle, they must be

periodically replenished. See “Lubricants and

fluids” at the beginning of this Chapter before

adding fluid to any of the following

components. Note: The vehicle must be on

level ground when any fluid levels are

checked.

Engine oil

2 Engine oil is checked with a dipstick, which

is located on the side of the engine (refer to

the underbonnet illustrations in this Chapter

for dipstick location). The dipstick extends

through a metal tube down into the sump.

3 The engine oil should be checked before

the vehicle has been driven, or at least

15 minutes after the engine has been shut off.

4 Pull the dipstick out of the tube, and wipe

all of the oil away from the end with a clean

rag or paper towel. Insert the clean dipstick all

the way back into the tube, and pull it out

again. Note the oil at the end of the dipstick.

At its highest point, the oil should be between

the two notches or marks (see illustration).

5 It takes one litre of oil to raise the level from

the lower mark to the upper mark on the

dipstick. Do not allow the level to drop below

the lower mark, or oil starvation may cause

4.4 The oil level should be kept between

the two marks, preferably at or near the

upper one - if it isn’t, add enough oil to

bring the level to the upper mark

If the oil is checked

immediately after driving the

vehicle, some of the oil will

remain in the upper part of

the engine, resulting in an inaccurate

reading on the dipstick.

engine damage. Conversely, overfilling the

engine (adding oil above the upper mark) may

cause oil-fouled spark plugs, oil leaks, or oil

seal failures.

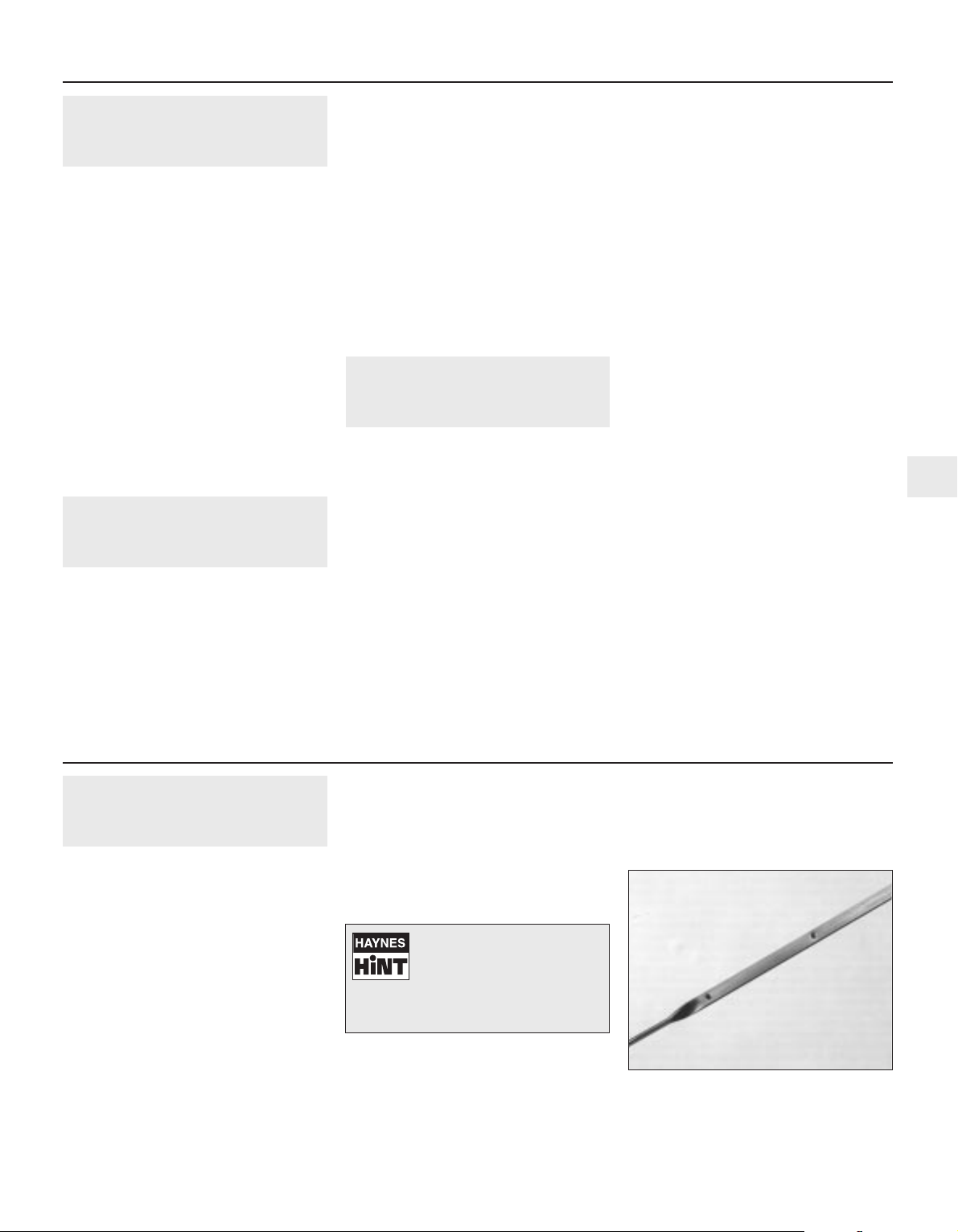

6 To add oil, remove the filler cap located on

the valve cover (see illustrations). After

adding oil, wait a few minutes to allow the

level to stabilise, then pull the dipstick out and

check the level again. Add more oil if required.

Refit the filler cap, tightening it by hand only.

7 Checking the oil level is an important

preventive maintenance step. A consistently

low oil level indicates oil leakage through

damaged seals or defective gaskets, or oil

burning (internal leakage past worn rings or

valve guides). The condition of the oil should

also be noted. If the oil looks milky in colour or

has water droplets in it, the cylinder head

gasket may be blown, or the head or block

may be cracked. The engine should be

repaired immediately. Whenever you check

the oil level, slide your thumb and index finger

up the dipstick before wiping off the oil. If you

see small dirt or metal particles clinging to the

dipstick, the oil should be changed (see

Section 6).

Engine coolant

Warning: Do not allow antifreeze

to come in contact with your

skin, or with the vehicle

paintwork. Rinse off spills immediately

with plenty of water. Antifreeze is highly

toxic if ingested. Never leave antifreeze

lying around in an open container, or in

puddles on the floor; children and pets are

attracted by its sweet smell, and may drink

it. Check with local authorities about

disposing of used antifreeze. Local

collection centres may exist, to see that

antifreeze is disposed of safely.

8 All vehicles covered by this manual are

equipped with a pressurised coolant recovery

system. On most models, a white plastic

expansion tank (or coolant reservoir) located

in the engine compartment is connected by a

hose to the radiator. As the engine heats up

during operation, the expanding coolant fills

the tank. As the engine cools, the coolant is

automatically drawn back into the cooling

system, to maintain the correct level.

9 The coolant level in the reservoir (see

illustrations) should be checked regularly.

Add a 40%/60% mixture of ethylene glycolbased antifreeze to water (see illustration).

Warning: Do not remove the

expansion tank cap or radiator

cap to check the coolant level,

unless the engine is completely

cold! The level in the reservoir varies with

the temperature of the engine. When the

engine is cold, the coolant level should be

above the LOW mark on the reservoir.

Once the engine has warmed up, the level

should be at or near the FULL mark. If it

isn’t, allow the engine to cool, then remove

the cap from the reservoir.

10 Drive the vehicle and recheck the coolant

level. If only a small amount of coolant is

required to bring the system up to the proper

level, plain water can be used. However,

repeated additions of water will dilute the

antifreeze. In order to maintain the proper

ratio of antifreeze and water, always top-up

the coolant level with the correct mixture.

11 If the coolant level drops consistently,

there must be a leak in the system. Inspect

the radiator, hoses, filler cap, drain plugs and

water pump (see Section 29). If no leaks are

noted, have the expansion tank cap or

radiator cap pressure-tested by a BMW

dealer.

12 If you have to remove the cap, wait until

the engine has cooled completely, then wrap

a thick cloth around the cap and turn it to the

first stop. If coolant or steam escapes, let the

engine cool down longer, then remove the

cap.

13 Check the condition of the coolant as

well. It should be relatively clear. If it’s brown

or rust-coloured, the system should be

drained, flushed and refilled. Even if the

coolant appears to be normal, the corrosion

1•8

4.9d Adding antifreeze mixture4.9c On some 5-Series models, the

expansion tank (coolant reservoir) is

located on the bulkhead

4.9b On other models, the expansion tank

(coolant reservoir) is located on the side of

the engine compartment - remove the cap

to add coolant

4.9a On some models, the expansion tank

(coolant reservoir) is mounted on the

radiator - make sure the level is kept at or

near the FULL mark (arrowed)

4.6b Topping-up the engine oil4.6a The threaded oil filler cap is located

in the valve cover - always make sure the

area around the opening is clean before

unscrewing the cap

Weekly Checks

inhibitors wear out, so it must be renewed at

the specified intervals.

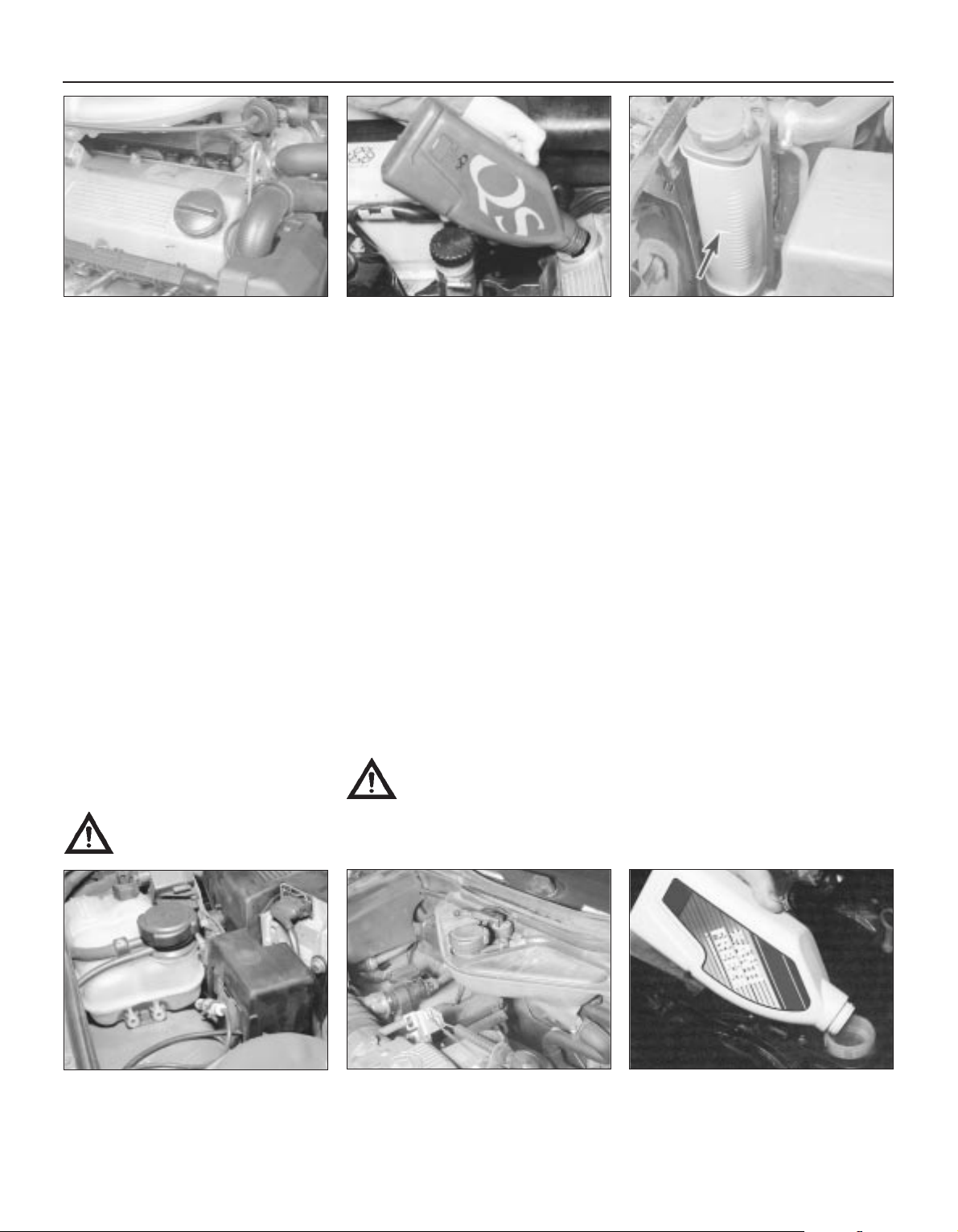

Brake and clutch fluid

Warning: Brake fluid can harm

your eyes and damage painted

surfaces, so use extreme caution

when handling or pouring it. Do

not use brake fluid that has been standing

open or is more than one year old. Brake

fluid absorbs moisture from the air, which

can cause a dangerous loss of brake

effectiveness. Use only the specified type

of brake fluid. Mixing different types (such

as DOT 3 or 4 and DOT 5) can cause brake

failure.

14 The brake master cylinder is mounted at

the left rear corner of the engine

compartment. The clutch fluid reservoir

(manual transmission models) is mounted on

the right-hand side.

15 To check the clutch fluid level, observe

the level through the translucent reservoir.

The level should be at or near the step

moulded into the reservoir. If the level is low,

remove the reservoir cap to add the specified

fluid (see illustration).

16 The brake fluid level is checked by looking

through the plastic reservoir mounted on the

master cylinder (see illustration). The fluid

level should be between the MAX and MIN

lines on the reservoir. If the fluid level is low,

first wipe the top of the reservoir and the cap

with a clean rag, to prevent contamination of

the system as the cap is unscrewed. Top-up

with the recommended brake fluid, but do not

overfill.

17 While the reservoir cap is off, check the

master cylinder reservoir for contamination. If

rust deposits, dirt particles or water droplets

are present, the system should be drained

and refilled.

18 After filling the reservoir to the proper

level, make sure the cap is seated correctly, to

prevent fluid leakage and/or contamination.

19 The fluid level in the master cylinder will

drop slightly as the disc brake pads wear.

There is no need to top up to compensate for

this fall provided that the level stays above the

MIN line; the level will rise again when new

pads are fitted. A very low level may indicate

worn brake pads. Check for wear (see Section 26).

20 If the brake fluid level drops consistently,

check the entire system for leaks immediately.

Examine all brake lines, hoses and

connections, along with the calipers, wheel

cylinders and master cylinder (see Section 26).

21 When checking the fluid level, if you

discover one or both reservoirs empty or

nearly empty, the brake or clutch hydraulic

system should be checked for leaks and bled

(see Chapters 8 and 9).

Windscreen washer fluid

22 Fluid for the windscreen washer system is

stored in a plastic reservoir in the engine

compartment (see illustration).

23 In milder climates, plain water can be

used in the reservoir, but it should be kept no

more than two-thirds full, to allow for

expansion if the water freezes. In colder

climates, use windscreen washer system

antifreeze, available at any car accessory

shop, to lower the freezing point of the fluid.

This comes in concentrated or pre-mixed

form. If you purchase concentrated antifreeze,

mix the antifreeze with water in accordance

with the manufacturer’s directions on the

container.

Caution: Do not use cooling

system antifreeze - it will damage

the vehicle’s paint.

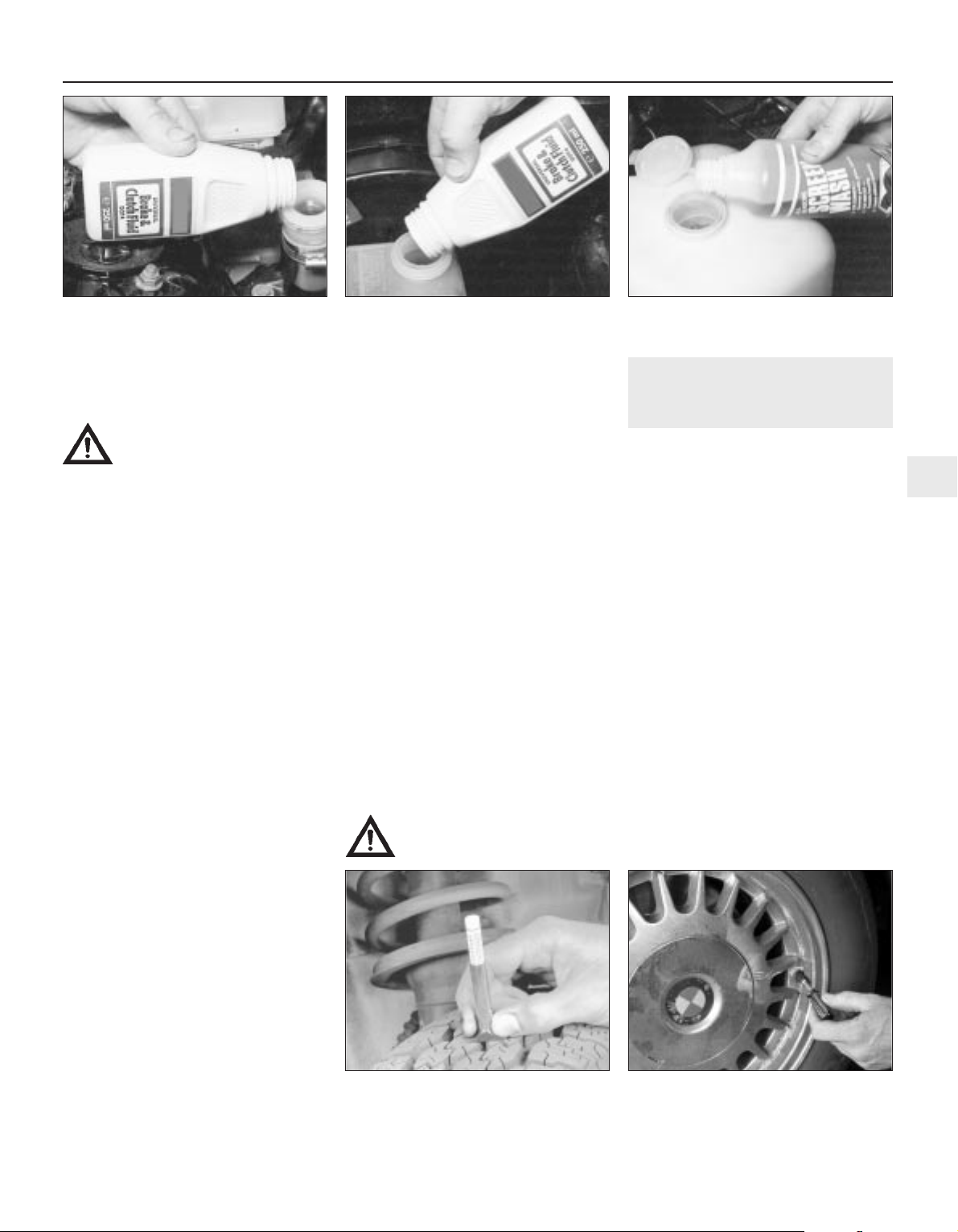

5 Tyre and tyre pressure

checks

1

1 Periodic inspection of the tyres may save

you the inconvenience of being stranded with

a flat tyre. It can also provide you with vital

information regarding possible problems in

the steering and suspension systems before

major damage occurs.

2 Tyres are equipped with bands that will

appear when tread depth reaches 1.6 mm, at

which time the tyres can be considered worn

out. This represents the legal minimum tread

depth; most authorities recommend renewing

any tyre on which the tread depth is 2 mm or

less. Tread wear can be monitored with a

simple, inexpensive device known as a tread

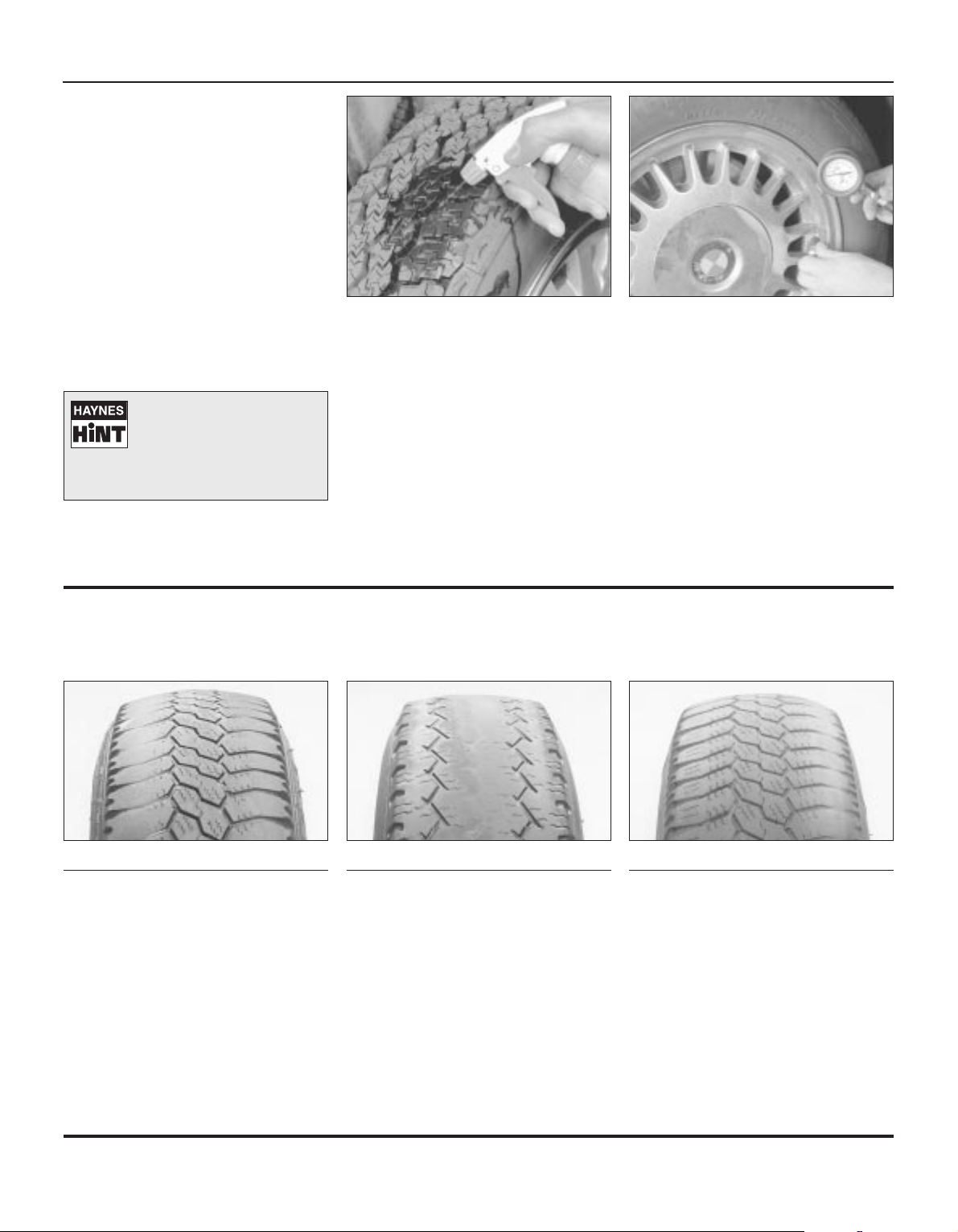

depth indicator (see illustration).

3 Note any abnormal tyre wear (see

illustration overleaf). Tread pattern irregular-

ities such as cupping, flat spots and more

wear on one side than the other are

indications of front end alignment and/or

wheel balance problems. If any of these

conditions are noted, take the vehicle to a tyre

specialist to correct the problem.

4 Look closely for cuts, punctures and

embedded nails or tacks. Sometimes, after a

nail has embedded itself in the tread, a tyre

will hold air pressure for a short time, or may

1•9

4.22 The windscreen washer fluid reservoir

is located in the right front corner of the

engine compartment on most models

4.16 The brake fluid level should be kept

above the MIN mark on the translucent

reservoir - unscrew the cap to add fluid

4.15 Adding hydraulic fluid to the clutch

fluid reservoir

5.4a If a slow puncture is suspected,

check the valve core first to make sure it’s

tight

5.2 Use a tyre tread depth indicator to

monitor tyre wear - they are available at

car accessory shops and service stations,

and cost very little

1

Weekly Checks

leak down very slowly. If a slow puncture

persists, check the valve stem core to make

sure it is tight (see illustration). Examine the

tread for an object that may have embedded

itself in the tyre, or for a previous repair that

may have begun to leak. If a puncture is

suspected, it can be easily verified by

spraying a solution of soapy water onto the

puncture (see illustration). The soapy

solution will bubble if there is a leak. Unless

the puncture is unusually large, a tyre

specialist can usually repair the tyre.

5 Carefully inspect the inner sidewall of each

tyre for evidence of brake fluid leakage. If you

see any, inspect the brakes immediately.

6 Correct air pressure adds miles to the life

span of the tyres, improves fuel economy, and

enhances overall ride quality. A tyre pressure

gauge is essential.

7 Always check the tyre pressures when the

tyres are cold (ie before driving the vehicle).

Checking the pressures when the tyres are

warm, or hot, will result in higher readings,

due to heat expansion. On no account should

air be let out of the tyres in this case, or the

tyres will effectively be under-inflated when

cold.

8 Unscrew the valve cap protruding from the

wheel or hubcap, and push the gauge firmly

onto the valve stem (see illustration). Note

the reading on the gauge, and compare the

figure to the recommended tyre pressures

shown in the Specifications listed at the

beginning of this Chapter. Be sure to refit the

valve cap to keep dirt and moisture out of the

valve stem mechanism. Check all four tyres

and, if necessary, add enough air to bring

them to the recommended pressure.

9 Don’t forget to keep the spare tyre inflated

to the specified pressure.

1•10

5.8 To extend the life of the tyres, check

the air pressure at least once a week with

an accurate gauge (don’t forget the spare!)

5.4b If the valve core is tight, raise the

vehicle, and spray a soapy water solution

onto the tread as the tyre is turned slowly -

leaks will cause small bubbles to appear

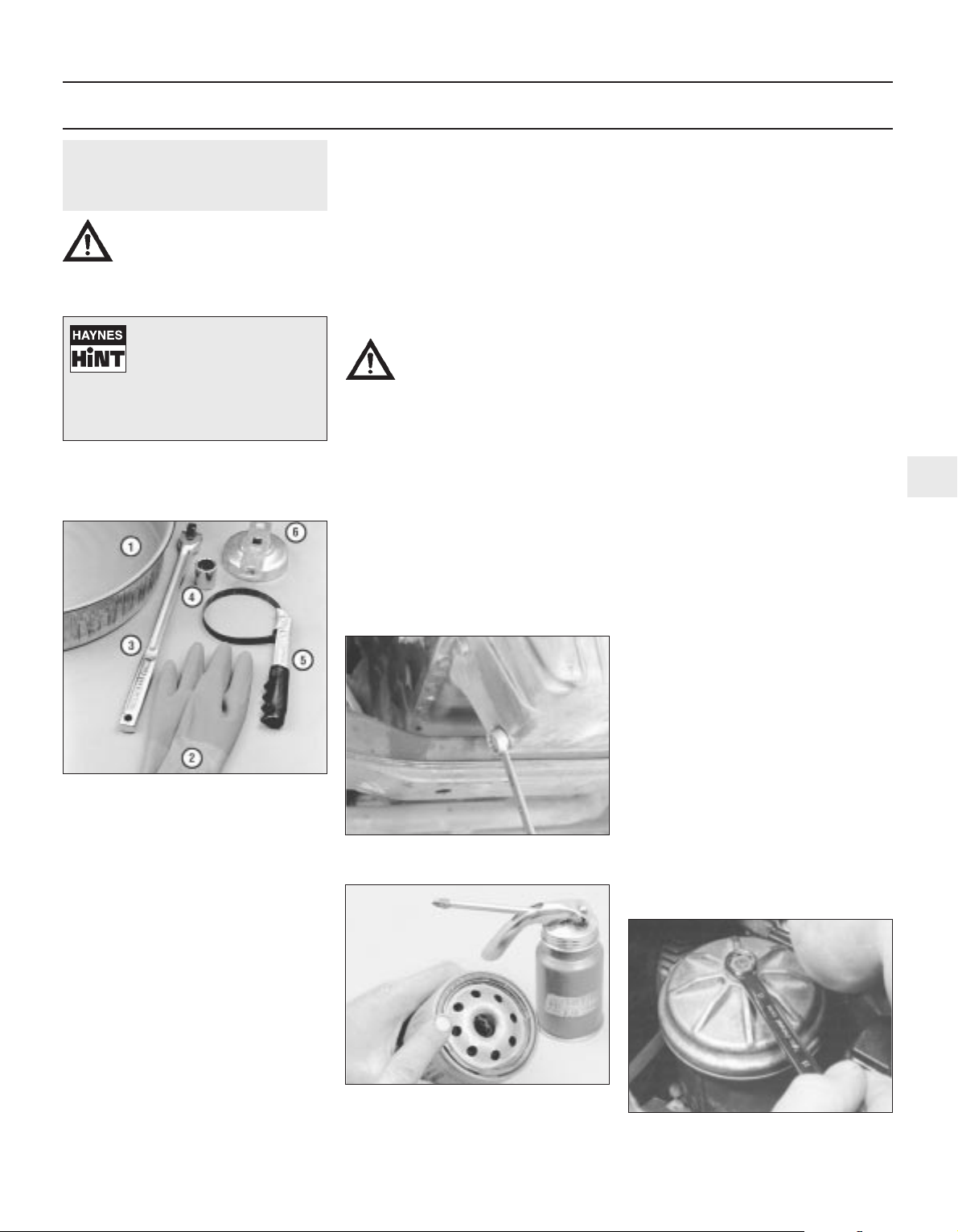

Tyre tread wear patterns

Shoulder Wear

Underinflation (wear on both sides)

Under-inflation will cause overheating of the

tyre, because the tyre will flex too much, and

the tread will not sit correctly on the road

surface. This will cause a loss of grip and

excessive wear, not to mention the danger of

sudden tyre failure due to heat build-up.

Check and adjust pressures

Incorrect wheel camber (wear on one side)

Repair or renew suspension parts

Hard cornering

Reduce speed!

Centre Wear

Overinflation

Over-inflation will cause rapid wear of the

centre part of the tyre tread, coupled with

reduced grip, harsher ride, and the danger of

shock damage occurring in the tyre casing.

Check and adjust pressures

If you sometimes have to inflate your car’s

tyres to the higher pressures specified for

maximum load or sustained high speed, don’t

forget to reduce the pressures to normal

afterwards.

Uneven Wear

Front tyres may wear unevenly as a result of

wheel misalignment. Most tyre dealers and

garages can check and adjust the wheel

alignment (or "tracking") for a modest charge.

Incorrect camber or castor

Repair or renew suspension parts

Malfunctioning suspension

Repair or renew suspension parts

Unbalanced wheel

Balance tyres

Incorrect toe setting

Adjust front wheel alignment

Note: The feathered edge of the tread which

typifies toe wear is best checked by feel.

Weekly Checks

Keep an accurate gauge in

the glove compartment. The

pressure gauges attached to

the nozzles of air hoses at

service stations are often

inaccurate.

Every 6000 miles or 6 months, whichever comes first

1•11

6.17a Unscrew the bolt . . .

1

Every 6000 miles

6 Engine oil and filter change

1

Warning: Prolonged skin contact

with used engine oil is

hazardous. Use a barrier cream

and wear gloves during this procedure.

Change out of oil-soaked clothing

immediately.

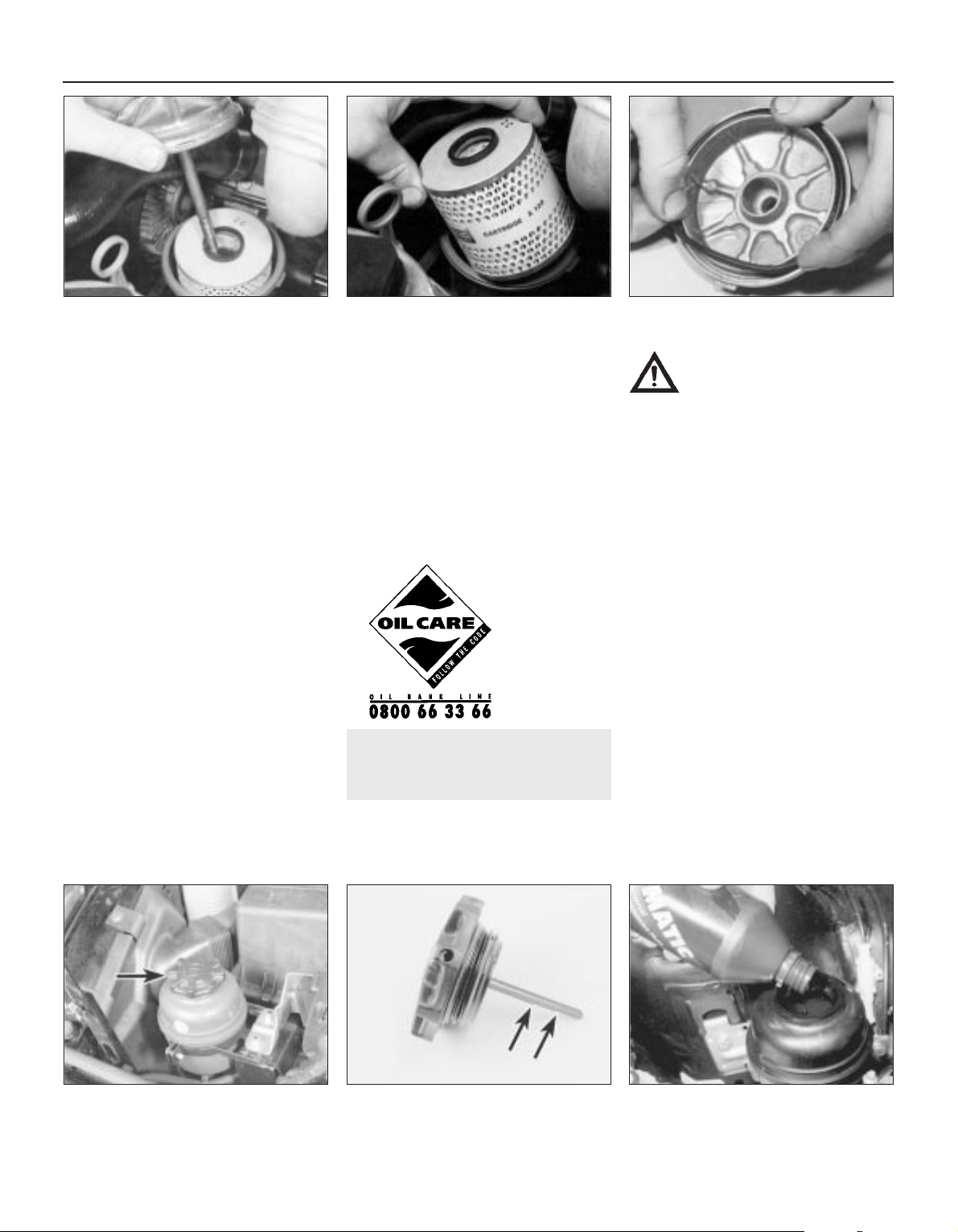

1 Make sure that you have all the necessary

tools before you begin this procedure (see

illustration). You should also have plenty of rags

or newspapers handy for mopping up oil spills

2 Start the engine and allow it to reach

normal operating temperature - oil and sludge

will flow more easily when warm. If new oil, a

filter or tools are needed, use the vehicle to go

and get them, thus warming up the engine oil

at the same time.

3 Park on a level surface, and switch off the

engine when it’s warmed up. Remove the oil

filler cap from the valve cover.

4 Access to the oil drain plug and filter will be

improved if the vehicle can be lifted on a hoist,

driven onto ramps, or supported by axle

stands.

Warning: DO NOT work under a

vehicle supported only by a

hydraulic or scissors-type jack always use axle stands!

5 If you haven’t changed the oil on this

vehicle before, get under it, and locate the

drain plug and the oil filter. Note that on some

engines, the oil filter is located on the top lefthand side of the engine. The exhaust

components will be hot as you work, so note

how they are routed to avoid touching them.

6 Being careful not to touch the hot exhaust

components, position a drain pan under the

plug in the bottom of the engine.

7 Clean the area around the plug, then

remove the plug (see illustration). It’s a good

idea to wear a rubber glove while unscrewing

the plug the final few turns, to avoid being

scalded by hot oil. Hold the drain plug against

the threads as you unscrew it, then pull it

away from the drain hole suddenly. This will

place your arm out of the way of the hot oil, as

well as reducing the chances of dropping the

drain plug into the drain pan.

8 It may be necessary to move the drain pan

slightly as oil flow slows to a trickle. Inspect

the old oil for the presence of metal particles,

which could give early warning of engine

wear.

9 After all the oil has drained, wipe off the

drain plug with a clean rag. Any small metal

particles clinging to the plug would

immediately contaminate the new oil.

10 Refit the plug and tighten it securely. Use

a new washer if necessary.

11 Move the drain pan into position under the

oil filter.

Canister-type oil filter

12 Loosen the spin-off type oil filter by

turning it anti-clockwise with a filter spanner.

Any standard filter spanner will work.

13 Sometimes the spin-off type oil filter is

screwed on so tightly that it can’t be easily

loosened. If it is, punch a metal bar or long

screwdriver directly through it, and use it as a

T-bar to turn the filter. Be prepared for oil to

spurt out of the canister as it’s punctured.

14 Once the filter is loose, use your hands to

unscrew it from the block. Just as the filter is

detached from the block, immediately tilt the

open end up to prevent oil inside the filter

from spilling out.

15 Using a clean rag, wipe off the mounting

surface on the block. Also, make sure that

none of the old sealing ring remains stuck to

the mounting surface. It can be removed with

a scraper if necessary.

16 Compare the old filter with the new one,

to make sure they are the same type. Smear

some engine oil on the rubber sealing ring of

the new filter, and screw it into place (see

illustration). Overtightening the filter will

damage the sealing ring, so don’t use a filter

spanner. Most filter manufacturers

recommend tightening the filter by hand only.

Normally, they should be tightened threequarters of a turn after the sealing ring

contacts the block, but be sure to follow the

directions on the filter or container.

6.1 These tools are required when

changing the engine oil and filter

1 Drain pan - It should be fairly shallow in

depth, but wide enough to prevent spills

2 Rubber gloves - When removing the drain

plug and filter, you will get oil on your

hands (the gloves will prevent burns)

3 Socket bar - Sometimes the oil drain plug

is tight, and a long bar is needed to loosen

it. The correct-size ring spanner may work

just as well

4 Socket - To be used with the bar or a

ratchet (must be the correct size to fit the

drain plug - six-point preferred)

5 Filter spanner - This is a metal band-type

spanner, which requires clearance around

the filter to be effective. This tool is not

required on all engines.

6 Filter spanner - This type fits on the bottom

of the filter and can be turned with a ratchet

or breaker bar (different-size spanners are

available for different types of filters) This

tool is not required on all engines.

6.7 Using a ring spanner to remove the oil

drain plug

6.16 Lubricate the oil filter sealing ring

with clean engine oil before refitting the

filter on the engine

Frequent oil changes are the

most important preventive

maintenance procedures that

can be done by the home

mechanic. As engine oil ages, it

becomes diluted and contaminated,

which leads to premature engine wear.

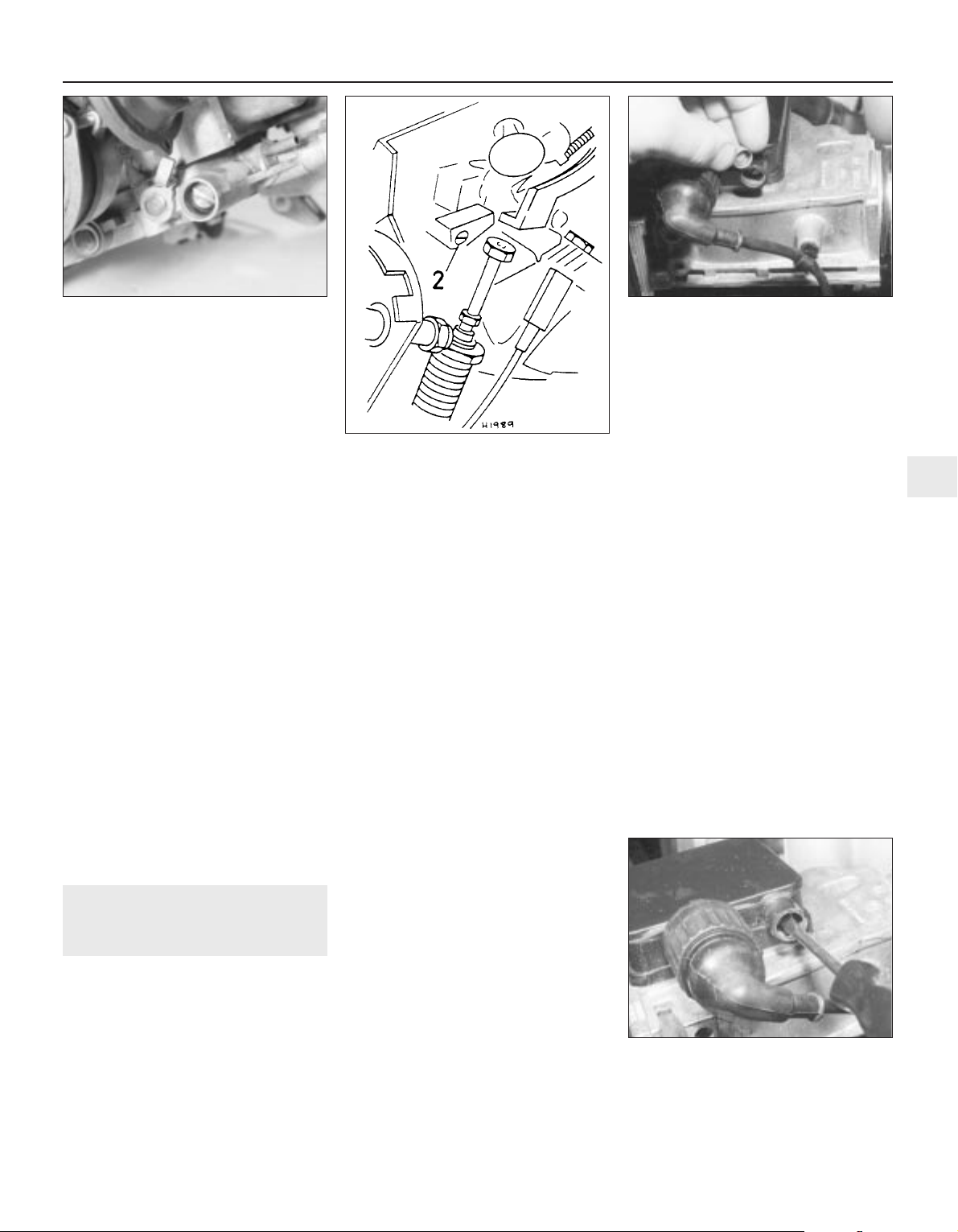

Cartridge-type oil filter

17 Some models are equipped with a

cartridge-type oil filter. Unscrew the bolt,

remove the cover, and lift the filter out (see

illustrations).

18 Compare the new cartridge with the old

one, to make sure they are the same type,

then lower it into the housing.

19 Using a clean rag, wipe off the mounting

surface of the housing and cover. If necessary,

renew the rubber O-ring (see illustration).

Smear some clean oil on the O-ring and refit

the cover and bolt. Tighten the bolt securely.

All models

20 Remove all tools and materials from under

the vehicle, being careful not to spill the oil

from the drain pan, then lower the vehicle.

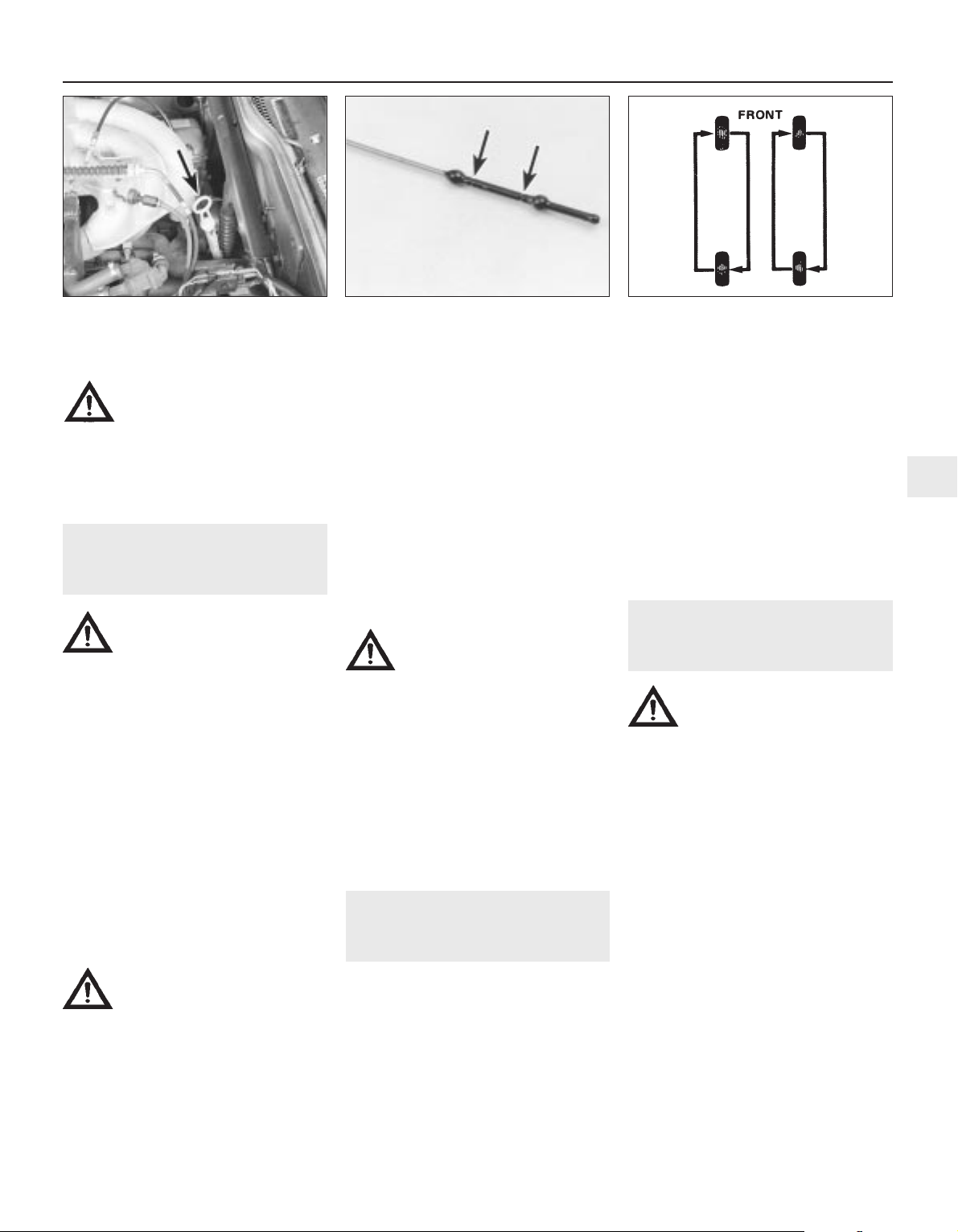

21 Add new oil to the engine through the oil

filler cap in the valve cover. Use a funnel to

prevent oil from spilling onto the top of the

engine. Pour the specified quantity of fresh oil

into the engine. Wait a few minutes to allow the

oil to drain into the sump, then check the level

on the dipstick (see Section 4 if necessary). If

the oil level is correct, refit the filler cap.

22 Start the engine and run it for about a

minute. The oil pressure warning light may

take a few seconds to go out while the new

filter fills with oil; don’t rev the engine while

the light is on. While the engine is running,

look under the vehicle, and check for leaks at

the sump drain plug and around the oil filter. If

either one is leaking, stop the engine and

tighten the plug or filter slightly.

23 Wait a few minutes, then recheck the level

on the dipstick. Add oil as necessary.

24 During the first few days after an oil

change, make it a point to check frequently

for leaks and proper oil level.

25 The old oil drained from the engine cannot

be re-used in its present state, and should be

discarded. Oil reclamation centres and some

service stations will accept the oil, which can

be recycled. After the oil has cooled, it can be

transferred into a container for transport to a

disposal site.

7 Power steering fluid level

check

1

1 Check the power steering fluid level

periodically to avoid steering system

problems, such as damage to the pump.

Proceed as follows.

Caution: Do not hold the steering

wheel against either stop (full-left

or full-right lock) for more than

five seconds. If you do, the power

steering pump could be damaged.

2 On some models, the power steering fluid

reservoir is located on the left side of the

engine compartment, and has a twist-off cap

with an integral fluid level dipstick (see

illustration). Other models use a hydraulic

power steering and brake servo system which

combines the fluid in one reservoir, located at

the right rear corner of the engine

compartment.

3 Park the vehicle on level ground, and apply

the handbrake.

4 On models with a fluid dipstick, run the

engine until it has reached normal operating

temperature. With the engine at idle, turn the

steering wheel back and forth several times to

get any air out of the steering system. Switch

off the engine, remove the cap by turning it

anti-clockwise, wipe the dipstick clean, and

refit the cap. Remove the cap again, and note

the fluid level. It must be between the two

lines (see illustration).

5 On hydraulic servo models, pump the brake

pedal about ten times or until the pedal is firm.

Remove the nut, lift the cap off, and make

sure the fluid is within 6.0 mm of the top of the

reservoir.

6 Add small amounts of fluid until the level is

correct (see illustration).

1•12

7.6 Adding fluid to the power steering

reservoir

7.4 The power steering fluid level should

be kept between the two arrows near the

upper step on the dipstick

7.2 The power steering fluid reservoir

(arrowed) is located on the left side of the

engine compartment

6.19 Renewing the rubber O-ring in the

cover

6.17c . . . and lift out the cartridge

Every 6000 miles

6.17b . . . remove the cover . . .

Note: It is

antisocial and

illegal to dump

oil down the

drain. To find

the location of

your local oil

recycling

bank, call this

number free.

Caution: Do not overfill the

reservoir. If too much fluid is

added, remove the excess with a

clean syringe. Refit the cap.

7 If frequent topping-up is needed, check the

power steering hoses and connections for

leaks and wear (see Section 10).

8 Check the condition and tension of the

drivebelt (see Section 11).

8 Automatic transmission fluid

level check

1

Caution: The use of transmission

fluid other than the type listed in

this Chapter’s Specifications

could result in transmission

malfunctions or failure.

1 The automatic transmission fluid should be

carefully maintained. Low fluid level can lead

to slipping or loss of drive, while overfilling

can cause foaming and loss of fluid. Either

condition can cause transmission damage.

2 Since transmission fluid expands as it heats

up, the fluid level should only be checked

when the transmission is warm (at normal

operating temperature). If the vehicle has just

been driven over 20 miles (32 km), the

transmission can be considered warm. You

can also check the fluid level when the

transmission is cold. If the vehicle has not

been driven for over five hours and the fluid is