BME T-34 Service manual

Service & Repair Manual

Infusion System

Manufacturer:

Ref: 100:090SS

E-mail:

c-m-e@internet

-

zahav.net

19/06/2007

T34 Syringe Pump

0473

BME June 2006

Tel. +1-800-323-575-00

Staufenburgstr. 23 Lichtenstein

P.o.b. 1248 Lichtenstein 72805 Germany

SERVICE MANUAL

Service & Repair Manual

1

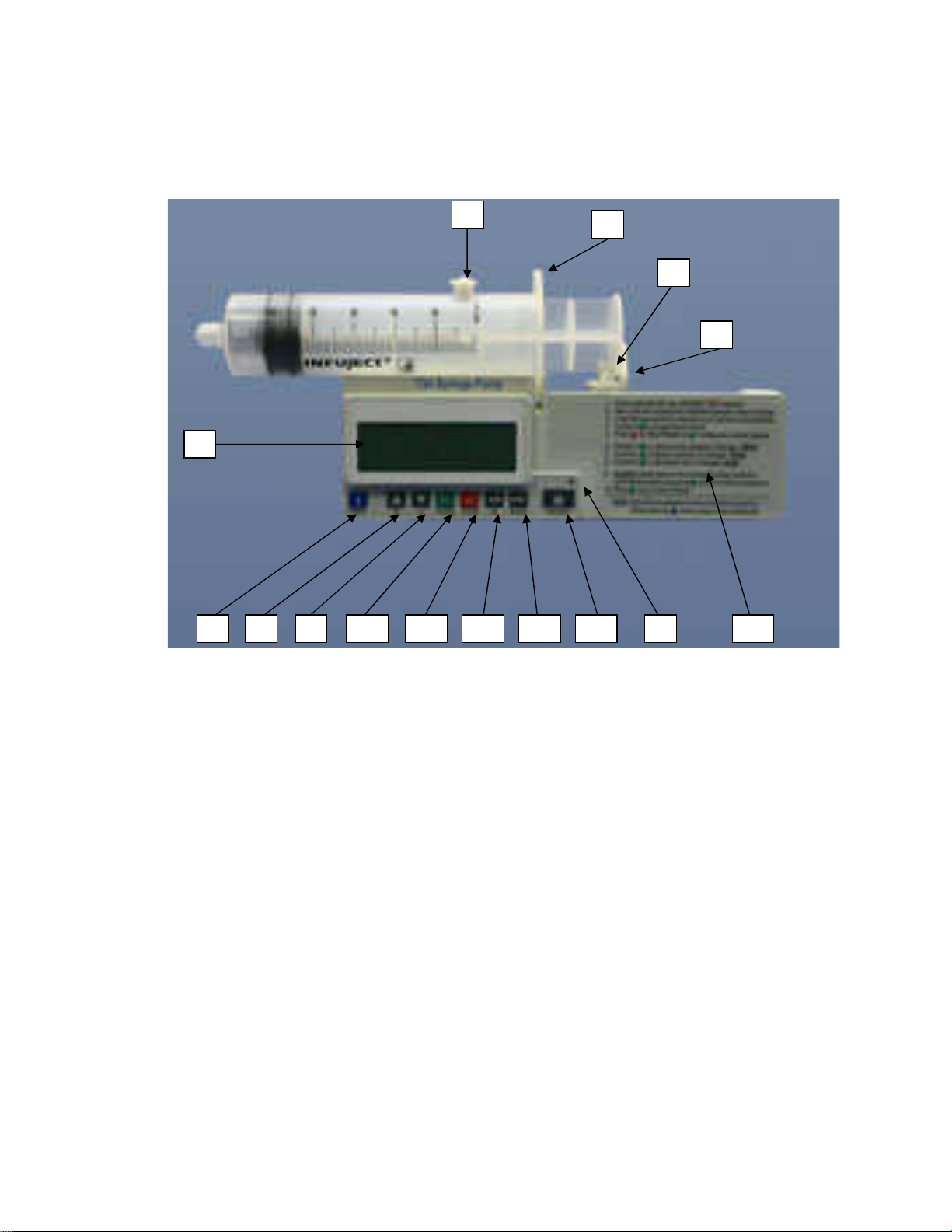

2

3

6

4

5 7 8 9 10

1112 13 14 15

19/06/2007

T34 Syringe pump

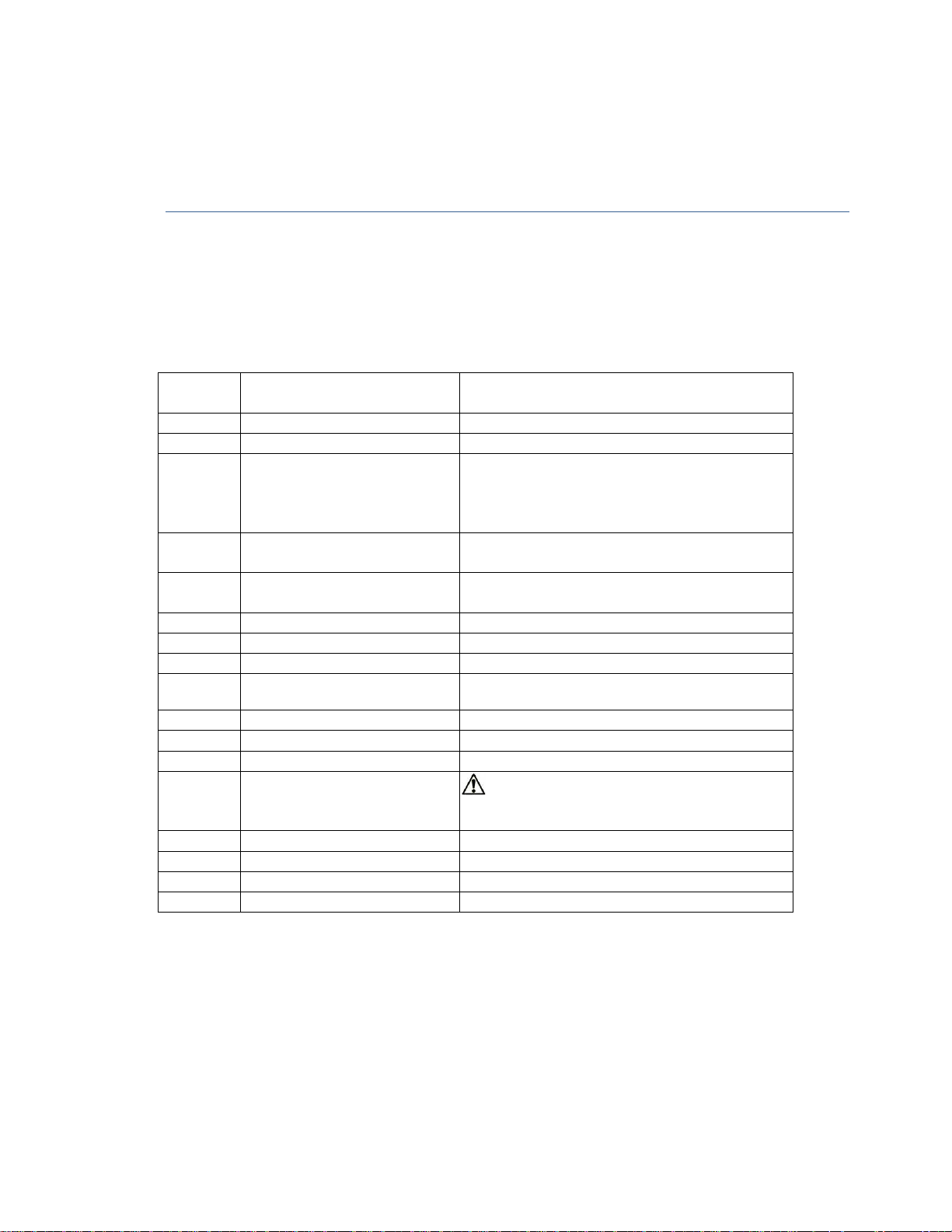

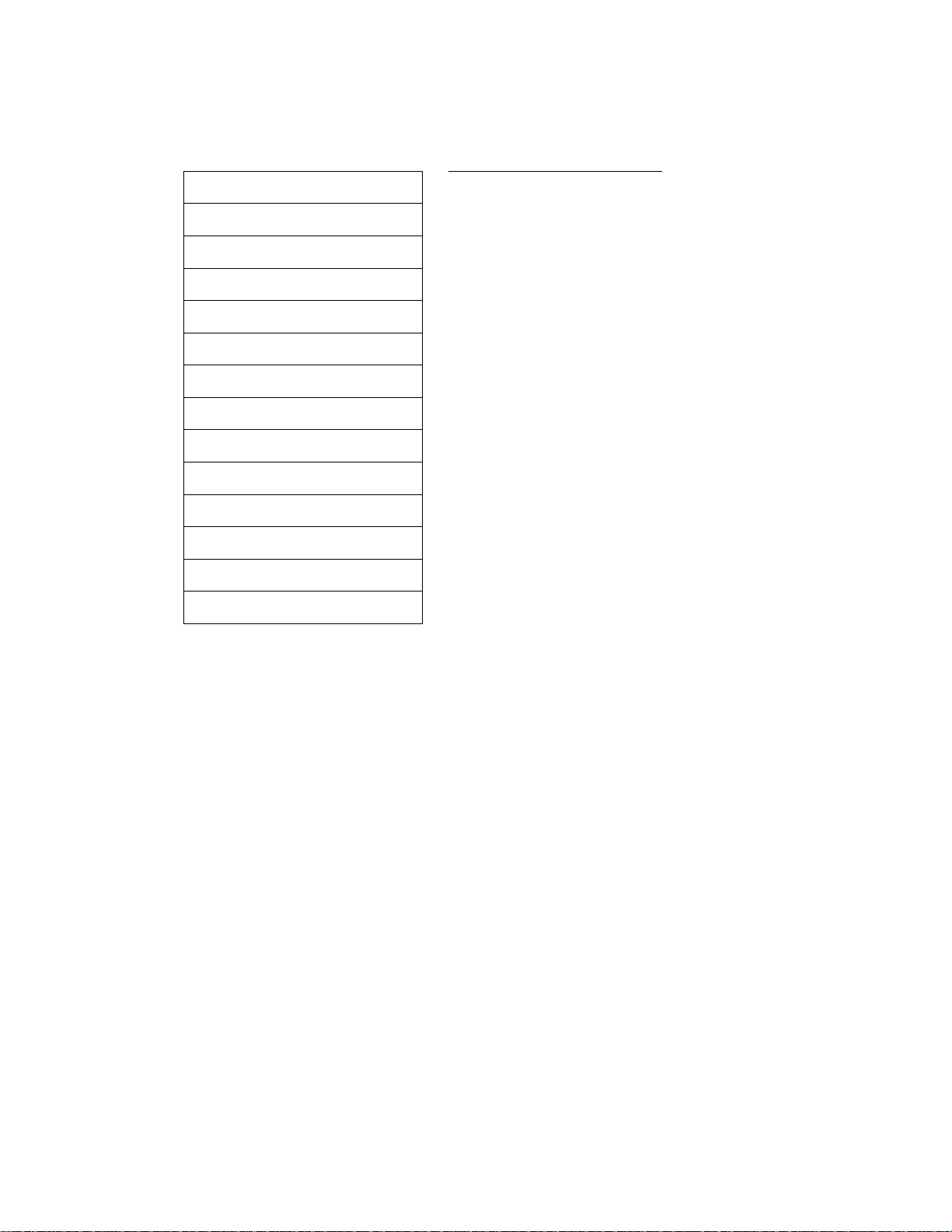

1. Barrel Clamp arm

(

detects Syringe size/width of barrel)

2. Syringe ear/collar sensor

3. Plunger sensor

4. 4 line LCD display

5. Operation LED

6. Actuator

7. Info Key

Long press will lock/unlock keypad)

8. Up arrow key

options)

9. Down arrow key (

10. YES/START key

11. NO/STOP key

12. FF (Forward) key

13. Back (Reverse) key

(detects correct loading of syringe plunger)

(back light (can be disabled) when any key pressed)

(green shows infusing (can be disabled), red when stopped or alarm)

(drives the syringe plunger to deliver syringe contents)

(a. shows Event Log, Volume infused, volume to be infused and battery status. b.

(a. increase infusion parameters during programming/use. b. Scrolls between

a. decrease infusion parameters. b. Scrolls between options)

(confirms choices during programming, begins infusion)

(takes user back a step during programming, stops pump)

(moves actuator forward when no syringe present)

(moves actuator backwards when no syringe present)

14. ON/OFF key

15. Instructions for infusion setup

(

detects correct loading of syringe collar)

Service & Repair Manual

19/06/2007

TABLE OF CONTENTS

Introduction 4

Terms used in manual 4

Alarm Conditions 5

Info Mode 6

Access Code list 7

Technician Menu 9

Operational Checklist 10

Trouble Shooting 13

Maintenance Flow Chart 18

Maintenance Procedures 19

Battery Operation 24

Service Information 25

Failure Identification 25

Corrective Actions 25

Volume Test 29

Occlusion Pressure Calibration 30

Syringe Travel Calibration 32

Syringe Diameter Calibration 33

Change Setup 34

Lock Mode 36

Service and Maintenance 38

Symbols, Warnings and Cautions 39

Intended Use 40

Warnings 40

Service Centre Recommended Parts 42

T34 Syringe Pump Default Settings 43

LIMITED WARRANTY 45

Drawings 46

Bill of Materials 58

3

Service & Repair Manual

19/06/2007

INTRODUCTION

• The T34 Syringe Pump provides the following features:

• Small, light and compact.

• Accuracy +/-5%

• 9v single Alkaline battery (Duracell MN1604)

• Ability to download current patient history and last 500 events

• Post-occlusion bolus prevention

• Free flow protection built in to set.

• 3 secure lock levels of keys and program

Infusion Rate: 0.1 to 1000ml/hr

Operated with a customised safe administration set

Can be latched in to docking station, which is mounted to IV pole

Silent operation

BEFORE ATTEMPTING TO CARRY OUT ANY PROCEDURES DETAILED

IN THIS SERVICE MANUAL YOU MUST HAVE BEEN TRAINED AND

CERTIFIED BY EITHER BME PERSONNEL OR AUTHORISED TRAINER.

YOU WILL ALSO NEED A COPY OF THE USER OPERATIONS MANUAL

AT HAND FOR REFERENCE

TERMS USED IN MANUAL

WARNING: I

circumstances that could result in injury or death to the patient or operator. Read and

understand this manual and all warnings completely before operating the T34 syringe

pump.

Caution:

that could result in damage to the devise. Read and understand this manual and all

cautions completely before operating the T34 syringe pump.

ndicates that the information is a warning. Warnings advise you of

Indicates the information is a caution. Cautions advise you of circumstances

Note:

Indicates that the information that follows is additional important information

or a tip that will help you operating the T34 syringe pump

4

Service & Repair Manual

19/06/2007

ALARM CONDITIONS

At any time, when the pump detects a problem, an alarm is activated and the following will

occur:

• An alarm message appears on the display, stating the cause of the alarm and indicates

instructions for continual use. The operation LED will light Red.

• An audible alarm sounds.

• The infusion stops

ALARMS

• Down Occlusion

• Pump unattended

• Low battery

• End battery

• Internal malfunction

• End program

• End travel

• Syringe displaced

• Near end 15 minutes before completion

The Troubleshooting Table describes the pump’s alarm conditions and remedies.

5

Service & Repair Manual

19/06/2007

INFO MODE

Pressing on the INFO key during operation will

Event Log, Volume infused and Volume to be infused.

The screen will be displayed for 7 seconds

VTBI 3.8 VI 1.3

d

isplay, VOLUME INFUSED

Pressing twice on the INFO key during operation will

display the battery status. The screen will display for

7 seconds. 98%

EMPTY FULL

Note: Exit from the INFO mode is automatic after 10 sec, or can be

achieved by pressing the INFO key

BATTERY LEVEL

6

Service & Repair Manual

19/06/2007

ACCESS CODE LIST

The T34 syringe pump has 2 access codes & a Key lock feature to control user access to

authorised personnel only and prevent tampering. Service Technicians will need to be familiar

with these codes to access all area of the pump to effect service and repair.

Code ‘99’ – Access to pump “Change Set-up” allows locking program parameters.

Code ‘123’ – Allows authorised technicians to access testing and service menu.

Key lock – Enables user to lock all but the INFO and STOP keys to prevent tempering with

the pump

BEFORE PERFORMING ANY MAINTENANCE PROCEDURE:-

a. You must have training and certification from either the manufacturer

or distributor and have recommended equipment and authorised spare

parts at hand to perform the required maintenance or repair.

b. Check the history events to define the frequency and nature of the

complaint, and record program and calibration settings at time of the

event.

c. Enter the Technician menu (power on the pump while holding the INFO

& POWER key simultaneously until the Technician Code prompt

appears). Enter code 123. Press YES key to confirm

d. Scroll to perform ‘Main Self Test’ and record any failures or issues

identified during the test.

7

Service & Repair Manual

1. User Error

Refer issu

es back to

department head

and

2. Fault with Syringe or Administration Set

Check correct syringe is used. Is it on the

3. Failure of pump

Perform Main Self

Test on Tech Menu

4. Mechanical failure

Change the defective part

5. Electronic malfunction

Change the relevant PCB

6. Failure of sensors: Syringe detection,

Replace the module

19/06/2007

SERVICE DECISION PATHWAY

When a T34 syringe pump is returned for service or repair after a ‘fault’ is reported by a user

always request a full explanation and description of the fault experience by the user and, if

possible and appropriate, ask for the return of the administrator set in use at the time of the

fault. Be mindful of the following factors as part of service/repair procedure:-

1. Has the user operated the pump correctly? Cross reference their report with the

Operations manual to ensure the steps they took prior to the alarm did not cause

or result in the alarm state or error cause.

2. Was the fault in one of the pump sensors (identify which one and replace it) or one

of the circuit boards (identify which PCB failed and replace the board). Use on the

Technician mode, either, Main Self test to pass all the testable options or Manual

Test to select a specific function.

Possible Issues:-

sensors 1-3.

Corrective Action:-

suggest training/alerting all users to

prevent the same error being reported

approved list of syringes?

8

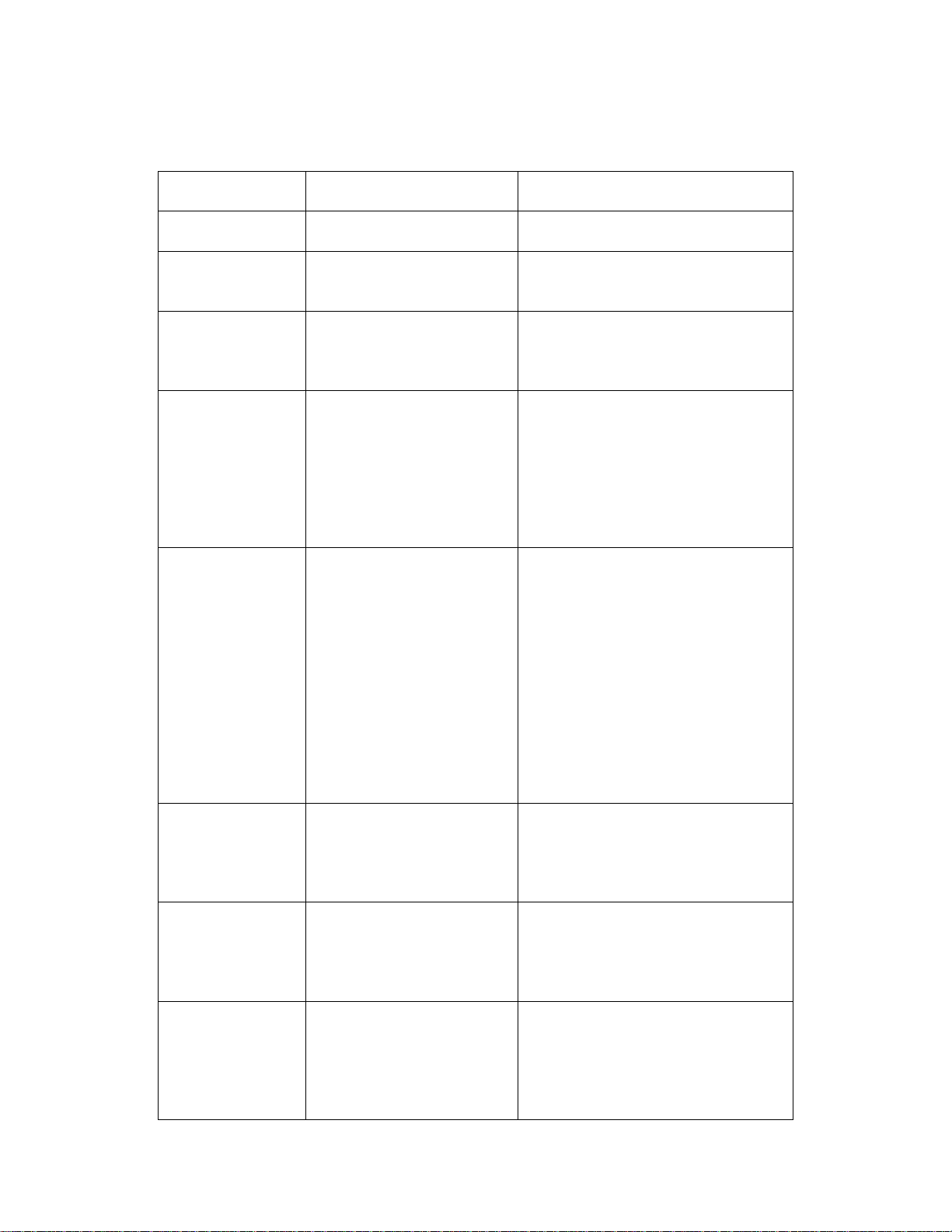

Service & Repair Manual

Menu

Setting

Screen

1 Exit from Technician

Exit Technician mode

2 Serial Number

Displays

serial number and production date

3 Main

Self-test Runs through keypad, display, alarm sound,

4 Manual Test

Same as Main Self

-

test but with a menu to focus

5 Syring

e setup

Adjust default diameter on the list of approved

6 Pressure calibration

Allows calibration and pressure settings

7 Factory Press. test

Fine tuning of pressure calibrations

8 Pressure test

Tests actual pressure

9 Syringe travel

Calibrati

on of syringe travel movement

10 Diameter calibration

Tests the syringe barrel sensor

11 Syringe dead space

The actuators limitations to deliver all volume

12 Volume test

Performing flow rate test

13 Factory setting

CAUTION

–

press

ing START/YES will restore

14 Operation hours

Hours from last service

15 Service interval

Number of Hrs before Send for Service message

16 Purge Volume

Set maximum volume user can purg

e

17 Maximum Rate

Set rate limit

19/06/2007

TECHNICIAN MENU

To access the Technician Menu, press and hold the INFO key and the POWER key at the same

time until Technician code prompt appears. The display will show the software version for 2

seconds before the access code prompt. Enter code 123 to access the technical menu.

The pump will display all the parameters that can be set, calibrated and tested. The technician

can scroll through all parameters using the ARROW keys.

Item

syringe sensor test, syringe diameter test,

syringe travel test, battery test, voltage test and

exit

the user on individual tests.

syringes

(about

68mm)

factory defaults and delete all pre-set protocols

and set-up changes

9

Service & Repair Manual

19/06/2007

OPERATIONAL CHECKLIST

INTRODUCTION

The operational checklist detailed in this section determines if the device is operating correctly

and should be carried out before and after any service or repair work. If the device fails in any

test in the checklist, the fault must be recorded and corrected prior to placing the device back

in to clinical use. Please become familiar with the checklist procedures prior to carrying out

any test.

The following test equipment is required to perform the tests in the Operational Checklist:-

o Syringe 50/60 ml filled with tap water

o Pressure gauge

o Electronic balance, burette or Infusion tester.

o Leakage current testing device (for safety test)

o Connecting flat cable between front and rear housing

Once a problem has been identified and isolated to a single assembly, the assembly should be

replaced in accordance with the disassembly procedure provided in this manual.

After all repairs are completed, the Operation checklist should be repeated and the device

should be re-calibrated.

PUMP SET UP FOR TESTING

Please ensure you have, & are familiar with, the device Operation Manual before performing

these tests. The procedure in this section are designed to check that the syringe pump is

infusing correctly prior to testing the effectiveness of the alarms. If the pump fails to

perform as described or displays an error cause – troubleshoot and repair before repeating

the test. The pump will display Restart Pump message, press the info key for more details

1. Switch the pump on; allow preloading procedure to be completed. Verify that the syringe

holder is set down.

2. Verify that all sensors (syringe holder, barrel ear and plunger ear) are blinking.

3. Load a syringe, verify that the pump detects the syringe size and brand; the pump may

detect a different brand but never a different size. (see Operation Manual)

4. Select the correct brand and press YES to confirm

5. The pump will display the calculated volume. Verify this detection is correct, if not return

to step 1

6. Confirm or change data of time default, calculated rate, and accumulated screen, start

infusion

7. Verify the operation LED changes from red to flashing green.

10

Service & Repair Manual

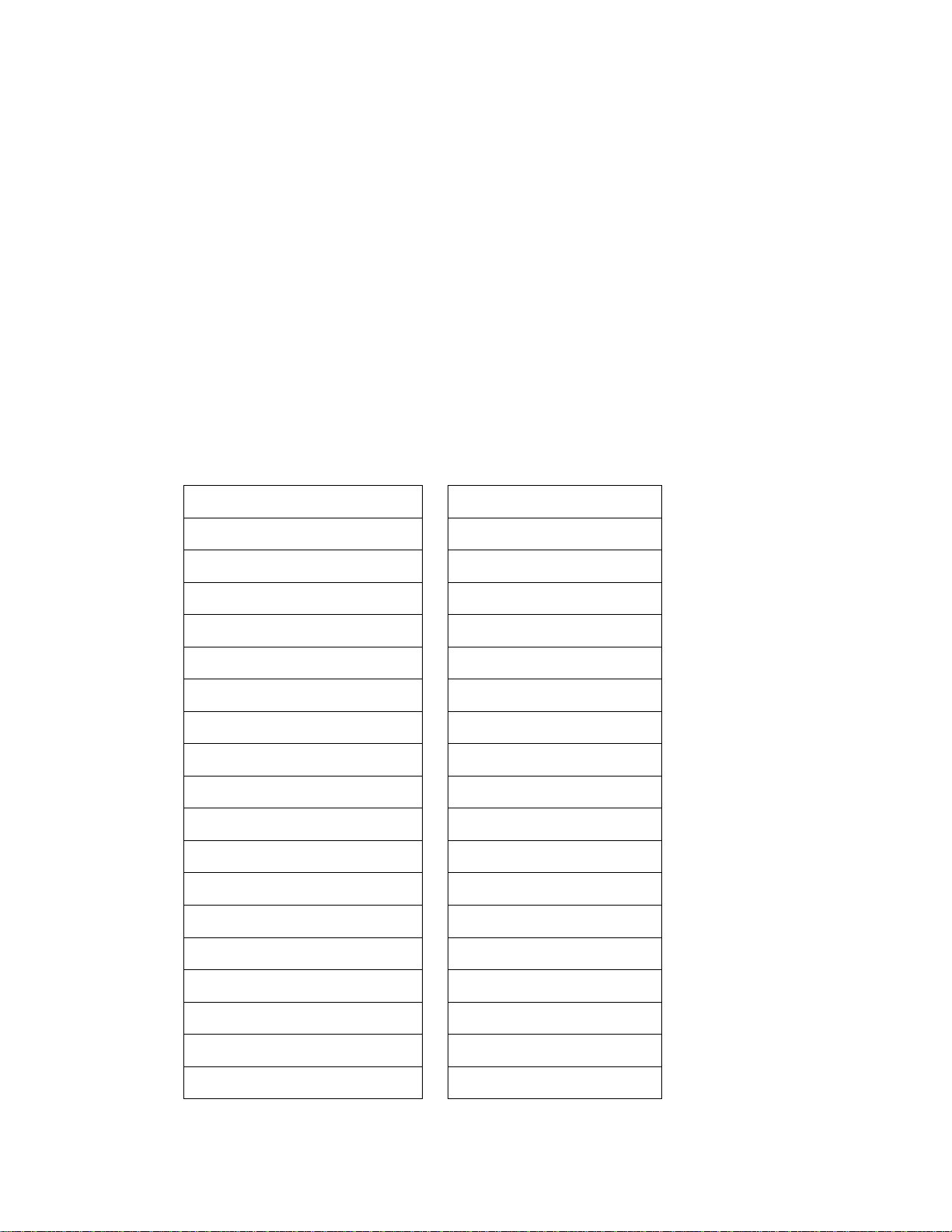

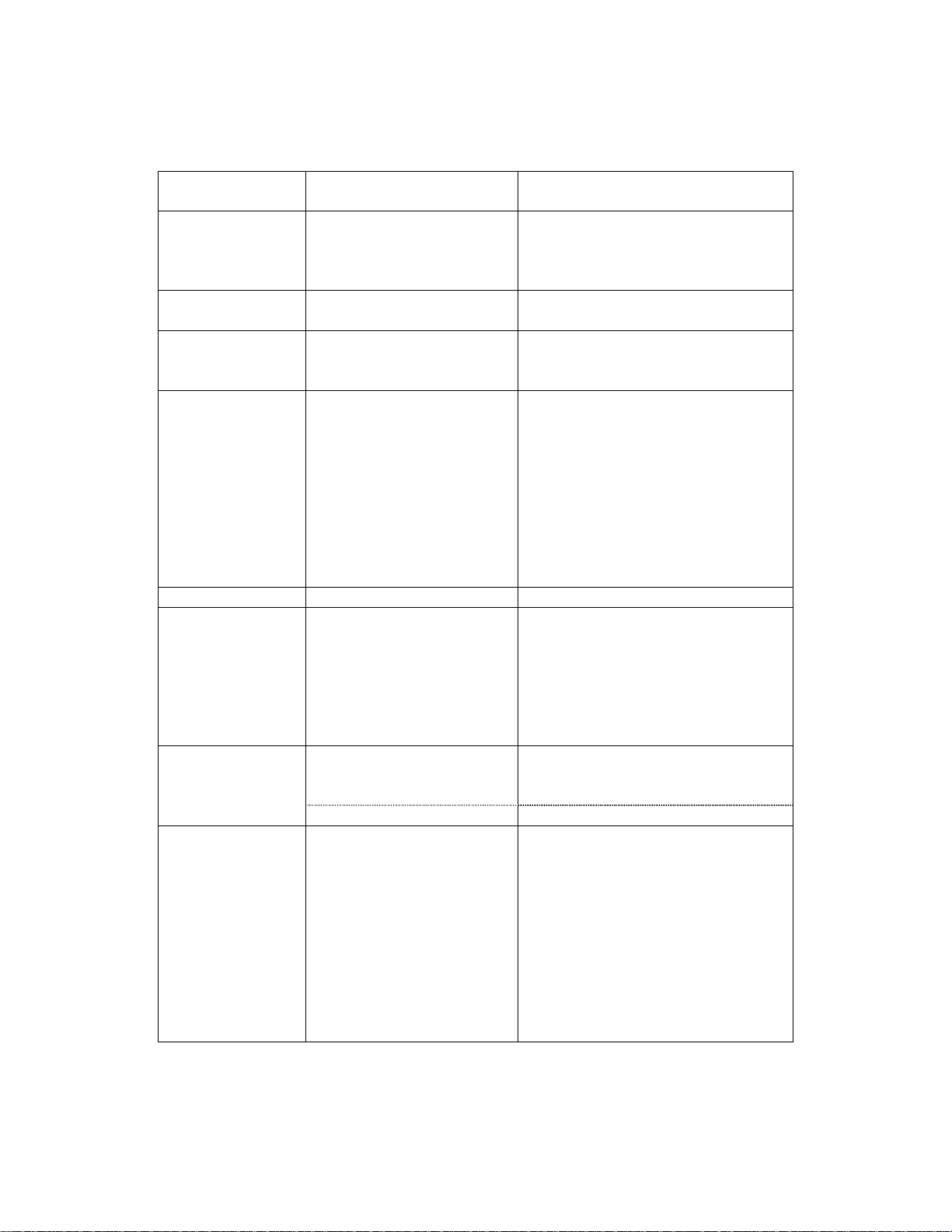

A

larms

Operation Events

Timer communication fail

Event No

External EEPROM fail

Date & time

Timer battery fail

Switch on

Internal EEPROM fail

Info: Volume infused

Hardware rest

Volume to be infused

Setting test fail

Rate

Start

-

up motor stop fai

l

Type of syringe

Watch dog current

Length in ml/mm

Watch dog timer error

Pressure setting: 0

-

10psi

CPU test error

Pressure actual

Shadow compare error

Battery voltage

ADC converter fail

Rate titration

Oscillator fail

Stop

STAC overflow

Low battery

UPD counter overflow

Pump unattended

External light fail

Down occlusion

Revolution encoder fail

End travel

No motor steps

- 20min

Syringe displaced

19/06/2007

INFUSION TEST

The following test checks that the pump does not exhibit alarms or error causes during normal

operation:-

1. Switch the pump on using the ON/OFF key. Allow pre-loading procedure to be completed

2. Load a syringe (refer to Operation Manual for a list of approved syringes)

3. Verify that the pump will detect the syringe correctly. To confirm syringe type press the

YES key or use arrow key to select another brand

4. Verify the displayed volume, confirm with the YES key.

5. Change the calculated rate to 5ml/h and press YES, verify the warning screen will appear.

6. Press YES to confirm the calculated/set rate.

7. Check accumulated data on the screen and confirm.

8. Press the YES key to begin infusion.

9. If the pump stops infusing and reports an alarm, troubleshoot using the table on page 37.

10. Below is a list of events and alarms that can appear in the event log

11

Service & Repair Manual

Motor voltage overflow

Long revolution time

Short revolution time

Over rev. in m

inute

Less rev. in minute

No rotation detected

Actual rate test err.

Start up motor move fail

Ends sensor fail

Current sensor fail

Syringe type diameter

Wrong volume length

Long stop mode int.

Reset by COP counter

19/06/2007

11. To restart infusion, press he START/YES key.

12. When the pump has delivered the selected volume, an audible alarm will be activated

while the display will show ‘Program End’ and default to ‘KVO’ if enabled. To stop the

alarm press the STOP/NO key

13. Check the pump is infusing the KVO rate

12

Service & Repair Manual

Alarms or

Possible Cause

Action

Volume accuracy is

Wrong detection of syringe or

1. Check that the correct syringe was

Pressure accuracy is

If during maintenance the

Recalibrate pressure accuracy as

Pump does not

Batte

ry depleted

Change battery

ON/OFF key

malfunction

Replace the main PCB

1. External interrupt or

1. Restart the pump

Pump will not

The syringe holder is located

Set syringe holder to down position

The FF

and BACK

1. A syringe is loaded

1. Remove syringe

Purge d

isabled

The pump was switched on

Remove syringe, switch off and back on

Volume

cannot

be

The pump will not allow to

Software protection

Syringe holder

Syringe detection sensor

Replace syringe holder

Operation LED

Operation LED is not

Check setup, if enabled. Change main

19/06/2007

TROUBLESHOOTING

Complaints

not accurate

not accurate

switch on

incorrect setting of hard

height

pressure readings are faulty

electronic malfunction

(electrostatic discharge)

2. Encoder plate not

mounted properly

3. Encoder LEDs or

Phototransistors are

damaged

4. In the case motor can’t

turn

5. If the problem persists

selected.

2. Perform syringe travel calibration

(tech menu)

3. Check Hard height measurement in

tech menu

described in pressure calibration

section

2. Remount the encoder plate

3. Replace the encoder PCB

4. Replace motor

5. Replace main PCB

perform preloading

keys will not

function

in the upper position

2. Syringe holder is up

3. Syringe sensor

malfunction

while a syringe was loaded

increased

increase volume above the

volume of the syringe

sensor is not sliding

malfunction

malfunction

functioning during operation

2. Place syringe holder down

3. Replace syringe sensor

4. Check connection on the front

pumping block. If it has no fault

replace slide pot.

again

PCB

13

Service & Repair Manual

Alarms or

Possible Cause

Action

Maximal basal rate

The maximal rate was west to

Change the maximal rate to higher

Rate titration

1. In the Change Setup the

1. Enable titration mode

Down occ

lusion

Occlusion detection

Recalibrate pressure accuracy as

Hardware reset or

1. External noise.

1. Turn the pump off and on again. if

Setting test fail

1. RAM corruption

1. Turn pump off and on again with

Long Stopmode int

Timer communication fail

1. Restart the pump, if problem

Startup mot or stop

1. Failure during switch on

1. Re

start the pump, if problem

Actual rate test

1. Mechanical malfunction

Check syringe, pump is calibrated to

Complaints

19/06/2007

limited

disabled

Reset by external

pin

a lower value

rate titration is disabled

2. Program is in Lock state

malfunction

2. 9V battery low or

depleted

3. Battery contact dirty

4. Mechanical malfunction

5. Motor PCB malfunction.

6. Main PCB malfunction

2. Syringe data out of range

3. Data settings corrupted

4. Device not calibrated

after main PCB

replacement

5. Corruption of serial no.

production date and dead

space

limit in ‘Change Setup’

2. Unlock program

described in Pressure Calibration

section.

Replace main PCB

problem continues send to

manufacture

2. Replace battery

3. Clean battery contacts

4. Check motor and replace

5. Replace motor PCB

6. Replace main PCB

same syringe, if problem continues

send to manufacturer

2. Enter technician menu and check

the data for the current syringe

3. Restore data with Factory Reset

4. Perform calibration of: syringe

travel, syringe diameter and

pressure calibration with 50ml

syringe

5. Enter those parameters and

confirm

or reset by COP

counter

fail

error or Long Rev.

time or Over rev, in

minutes or Less rev

in minutes

test

2. Motor PCB malfunction

3. Main PCB malfunction

or high friction of syringe

2. End of travel, forcing

against housing

3. See revolution counter

fail

14

continues send to manufacturer

2. Check lithium battery or replace

motor PCB

3. Replace main PCB

continues send to manufacturer

2. Replace motor PCB

3. Replace main PCB

operate new syringes or replace pump

assembly

Service & Repair Manual

Alarms or

Possible Cause

Action

Watch dog current

1. External noise during

1. Restart the pump, if problem

Watch dog timer

Main PCB malfunction

Replace main PCB

Shadow compare

1. Corruption

of RAM

1. Restart the pump, if problem

Oscillator fail

1. External noise due to

1. Turn the pump off and on

again

. If

Stack overflow

Microprocessor malfunction

Replace

main PCB

UPD counter

1. Mechanical malfunction

1. Perform

syringe travel calibration

ADC converter fail

External interrupt or

Turn the pump off and on again. If

Electronic malfunction

Replace main PCB

Exter

nal light fail

1. Encoder detects external

1. Make sure pump case is closed

Complaints

19/06/2007

error

error

overflow or

Motor current

overflow

switch on

2. Motor PCB malfunction

3. Main PCB malfunction

2. Main PCB malfunction

electrostatic discharge

2. Water ingress

3. The connector between

PCB pins dirty

4. Lithium battery less 3V

5. Motor PCB malfunction

6. Main PCB malfunction

2. Motor PCB or connection

to main PCB

3. Encoder PCB malfunction

4. Encoder plate loose

continues send to manufacturer

2. Replace motor PCB

3. Replace main PCB

continues send to manufacturer

2. Replace main PCB

problem continues send to

manufacture

2. Dry the device and inspect for

damage.

3. Clean the pins of connectors

between main and motor PCBs

4. Check and replace battery

5. Replace motor PCB

6. Replace main PCB

2. Replace pumping block

3. Replace motor PCB and clean

connectors

4. Replace encoder PCB or Fasten

encoder plate

electronic malfunction

(electrostatic discharge)

light

2. External noise

3. Malfunction of encoder

PCB

4. Connecting cable

between encoder and

main PCB damaged

5. Main PCB malfunction

15

problem continues replace main PCB

correctly with 6 screws and not

damaged.

2. Turn the pump off and on again. If

fault continues return to

manufacturer

3. Replace encoder PCB

4. Check or replace

5. Replace main PCB

Service & Repair Manual

Alarms or

Possible Cause

Action

Revolution encoder

1. External noise

1. Turn the pump off and on again. If

No motor step for

Main PCB malfunction

Replace main PCB

Internal EEPROM

Microprocessor malfunction

Replace main PCB

Memory malfunction

Turn the pump off and on again. If

No rotation

Encoder malfunction

1. Turn the pump off and on again

Start up motor

1. Lock at end travel

1. Move manually out of locking

Ends sensor fail

1. Limit sensor malfunction

1. Check or replace READ switches

Current sensor fail

1. Motor PCB malfunction

1. Replace motor PCB

Syringe type

Syringe diameter not

Enter Manual Test and perform syringe

Complaints

19/06/2007

fail

20 minutes

fail

2. Magnet on motor

adaptor weak or broken

3. READ switch 1, 2 broken

4. Encoder plate loose

problem continues send to

manufacture

2. Replace magnet on motor adaptor

3. Replace motor PCB

4. Tighten encoder plate

problem continues:-

1. Perform factory settings from

technician menu, if problem

continues...

2. Perform reset calibration and

calibrate pump again. If problem

continues...

3. Burn software again (refer to

instructions Do not save previous

calibration). Calibrate the pump

again. If problem continues...

4. Replace the main PCB

detected

move fail

diameter

Motor malfunction

2. Mechanical or motor

malfunction

3. Motor PCB malfunction

4. Main PCB malfunction

5. Encoder plate loose

6. Encoder or connecting

malfunction

2. Magnet or actuator weak

3. Flat cable malfunction

2. Main PCB malfunction

calibrated

2. Replace block assembly

3. Replace main PCB

4. If problem continues sent to

manufacture

2. Turn the pump off and on again. If

problem continues replace pump

mechanics

3. Replace motor PCB and check pins

of connector to main PCB

4. Replace main PCB

5. Tighten encoder plates

6. Check and replace encoder PCB and

flat to main PCB.

2. Replace encoder magnet

3. Check or replace flat cable

2. Replace main PCB

diameter test, recalibrate if required

16

Service & Repair Manual

Alarms or

Possible Cause

Action

Wrong vol. lengths

Wrong data entered mm/ml

Recalibrate syrin

ge

CPU test error

Microprocessor malfunction

Replace main PCB

Timer

1. External noise during

1. Turn the pump off and on again

Timer battery fail

1. It is the first pump

1. Turn the pump off and on again

External EEPROM

1. External noise during

1. Turn the pump off and on again and

Complaints

19/06/2007

communication fail

2. Timer battery low

3. Motor PCB malfunction

4. Main PCB malfunction

2. 3v battery low/damaged

fail

2. Motor PCB malfunction

3. Main PCB malfunction

Note: In order to prevent the possibility of wrong syringe detection,

we recommend using only approved brands. Avoid using brands that their

external diameter is close, less than 0.5mm. The medical institution will

have to decide on one of them.

communication

operation after service.

communication

and set pump to operate on

0.1ml/hr. If problem continues

send to manufacturer

2. Check lithium battery. If less than

3V replace

3. Replace motor PCB

4. Replace main PCB

2. Replace 3V battery

set pump to operate on 0.1ml/hr. If

problem continues send to

manufacturer

2. Replace motor PCB

3. Replace main PCB

17

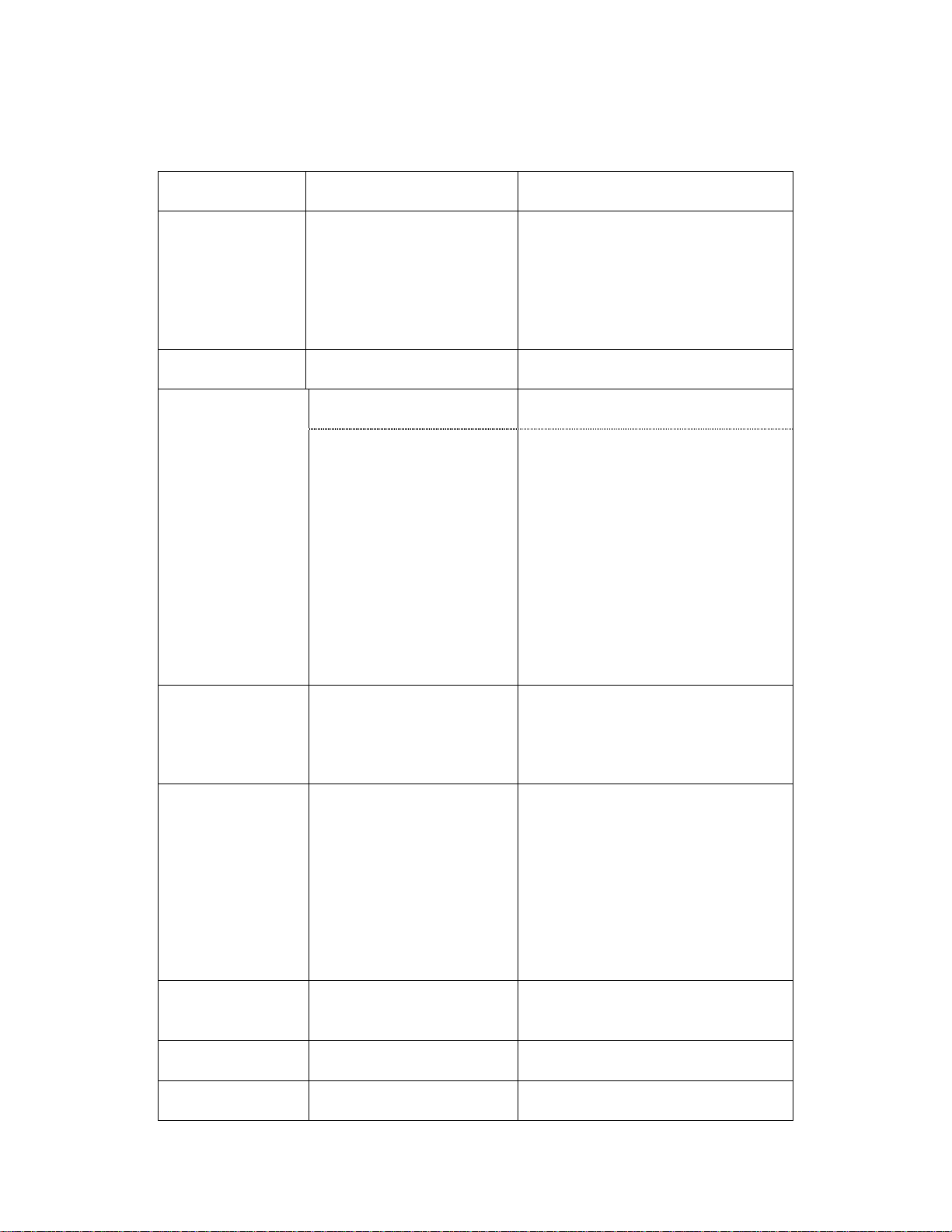

Service & Repair Manual

Pump returned for

Log receipt, pump serial numb

er

Power on the pump, note serial

Check history events and

note type & frequency of

Perform all tests in the

Does device pass

Checklist?

Troubleshoot

Recalibrate if any

Record that the pump

19/06/2007

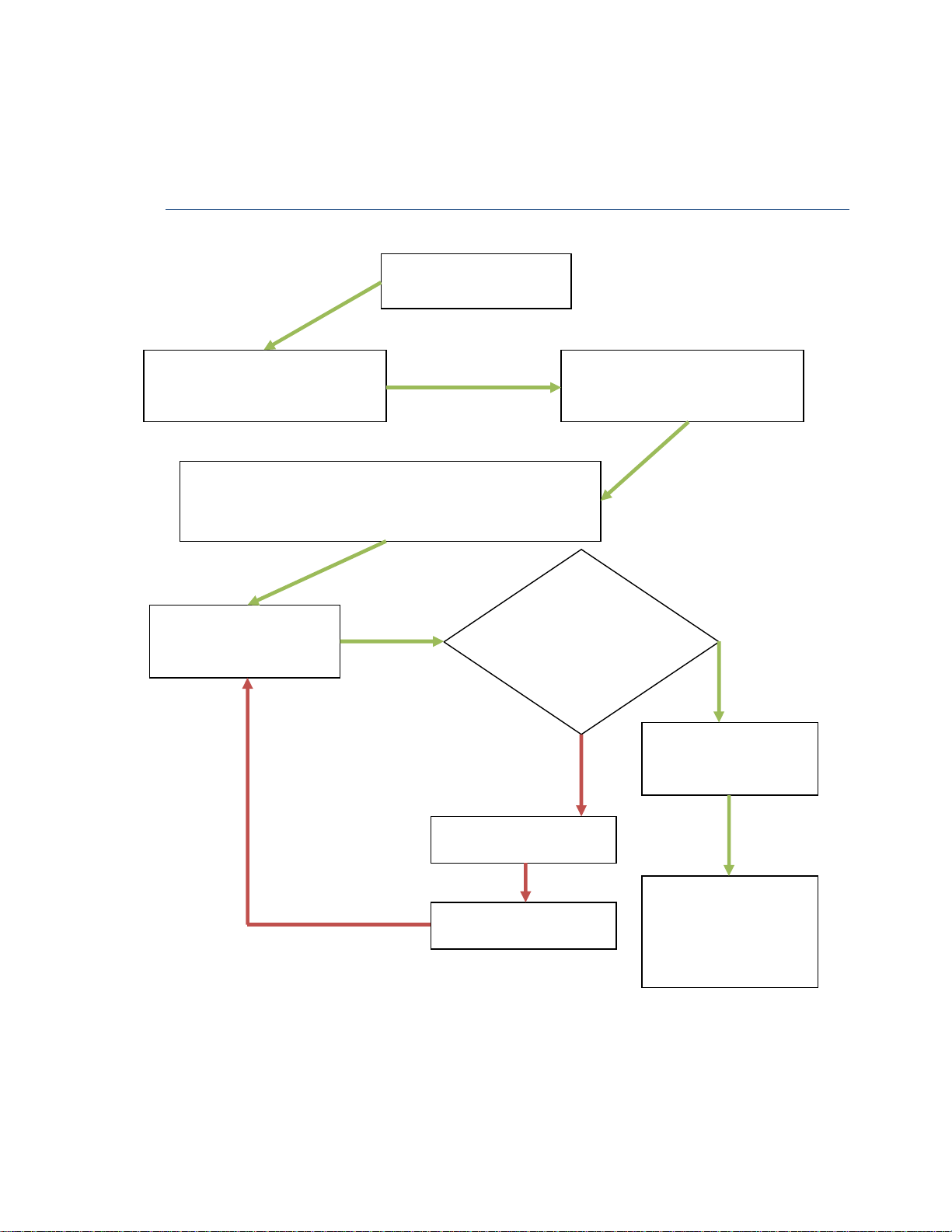

MAINTENANCE FLOW CHART

service or repair

& physical appearance (i.e.

damage, signs of tampering)

alarms/alerts. Check the IV set and the liquid type that was

infused (make not of the set used and serial number)

Operational Check List

(found on page 11)

number and software version &

access Technician menu

all test and

Operation

repairs or disassembly

NO

has been undertaken

YES

18

Repair

has passed service.

Clean and return to

user group

Loading...

Loading...