BMC GTC60S2-ADNX, GTC60S2-ADCX, GTC36S2-ADNX, GTADP-3642-B, GTADP-3642-C User Manual

...

MIS-2830

WATER SOURCE HEAT PUMP

MODELS:

INSTALLATION

INSTRUCTIONS

GTB1-A Blower Section

GTA3600UD1AA Coil Section

GTA4860UD1AA Coil Section

GTADP-3642-B Coil Section

GTADP-3642-C Coil Section

GTADP-4860-C Coil Section

GTC36S2-ADCX Compressor Section

GTC48S2-ADCX Compressor Section

GTC60S2-ADCX Compressor Section

GTC36S2-ADNX Compressor Section

GTC48S2-ADNX Compressor Section

GTC60S2-ADNX Compressor Section

BMC, Inc.

Bryan, Ohio 43506

Earth Loop Fluid

Temperatures 25° - 110°

Ground Water Temperatures 45° - 75°

Manufactured under the following

U.S. patent number:

8,127,566

Manual: 2100-537I

Supersedes: 2100-537H

File: Volume I, Tab 8

Date: 10-11-12

Manual 2100-537

Page 1 of 54

I

CONTENTS

Getting Other Informations and Publications ..............3

General Information Geo-Trio (GT Series)

Water Source Nomenclature .................................................... 4

Blower Conversion & Line Power Connect ............................ 15

Application and Location

General ............................................................................ 18

Shipping Damage ................................................................... 18

Application ............................................................................ 18

Dual Fuel Heating / Cooling

Location ............................................................................ 18

Ductwork ............................................................................ 18

Filters ............................................................................ 19

Condensate Drain .................................................................. 19

Piping Access to Unit ..............................................................19

................................................... 18

Wiring Instructions

General ............................................................................ 22

Control Circuit Wiring.............................................................. 22

Wall Thermostats & Low Voltage Connections

....................... 22

Ground Loop (Earth Coupled Water Loop Applications)

Note ............................................................................ 24

Circulation System Design ..................................................... 24

Start Up Procedure for Ground Loop System ........................ 25

Ground Water (Well System Applications)

Note ............................................................................ 27

Water Connections .................................................................27

Well Pump Sizing ...........................................................27 & 28

Start Up Procedure for Ground Water System ....................... 29

Water Corrosion .............................................................29 & 30

Remedies of Water Problems ................................................. 30

Lake and/or Pond Installations .......................................30 & 31

Desuperheater

Description ............................................................................ 32

Location ............................................................................ 32

Electrical Connection .............................................................. 32

Installation Procedure - General ............................................. 32

Oper. of Heat Recovery Unit ..................................................33

Start Up & Checkout ............................................................... 33

Maintenance & Control Board Seq. of Operation ...........33 & 37

Sequence of Operation

Blower ............................................................................ 38

Part / Full Load Cooling

Part / Full Load Heating .......................................................... 38

Supplementary Electric Heat .................................................. 38

Geothermal Logic Controls ..................................................... 38

High / Low Pressure Switch

Freeze Stat ............................................................................ 39

Condensate Overow ............................................................ 39

Under/Over Voltage Protection ...............................................39

Intelligent Reset ...................................................................... 39

Alarm Output

Pressure Service Ports

System Start Up ..................................................................... 39

.......................................................................... 39

.......................................................... 38

................................................... 39

........................................................... 39

Refrigerant Charge

Line Set Installation (GTA Coil Sections) ................................ 42

Charge Adjustment ..............................................................42

Refrigerant Fitting Attachment

Checking Charge Quantity

General / GTADP Coi Sections .............................................. 43

Line Set Installation (GTADP Coil Sections) ........................... 43

General / Topping Off System / Safety Practices ................... 44

............................................ 42

..................................................... 42

Service

Service Hints .......................................................................... 47

Unbrazing System Components ............................................. 47

Compressor Solenoid ............................................................. 47

Troubleshooting GE ECM 2.3 Motors .............................48 & 49

Troubleshooting Table ............................................................ 50

Power Connector T able ..........................................................50

Ground Source Heat Pump

Performance Report ................................................51-52

Wiring Diagrams

......................................................53-54

Figures

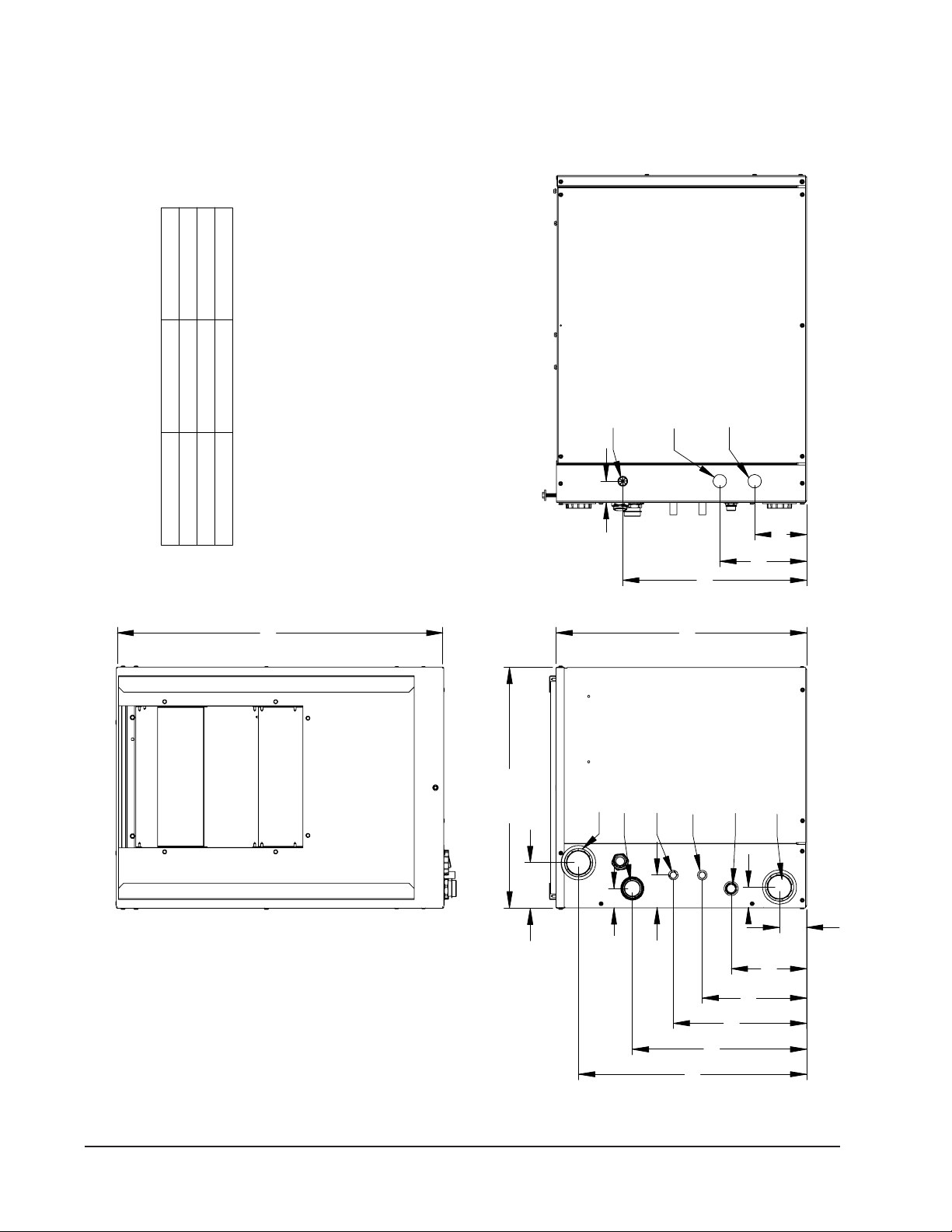

Fig u r e 1 A GTA****UD1AA Dimensions ................................. 7

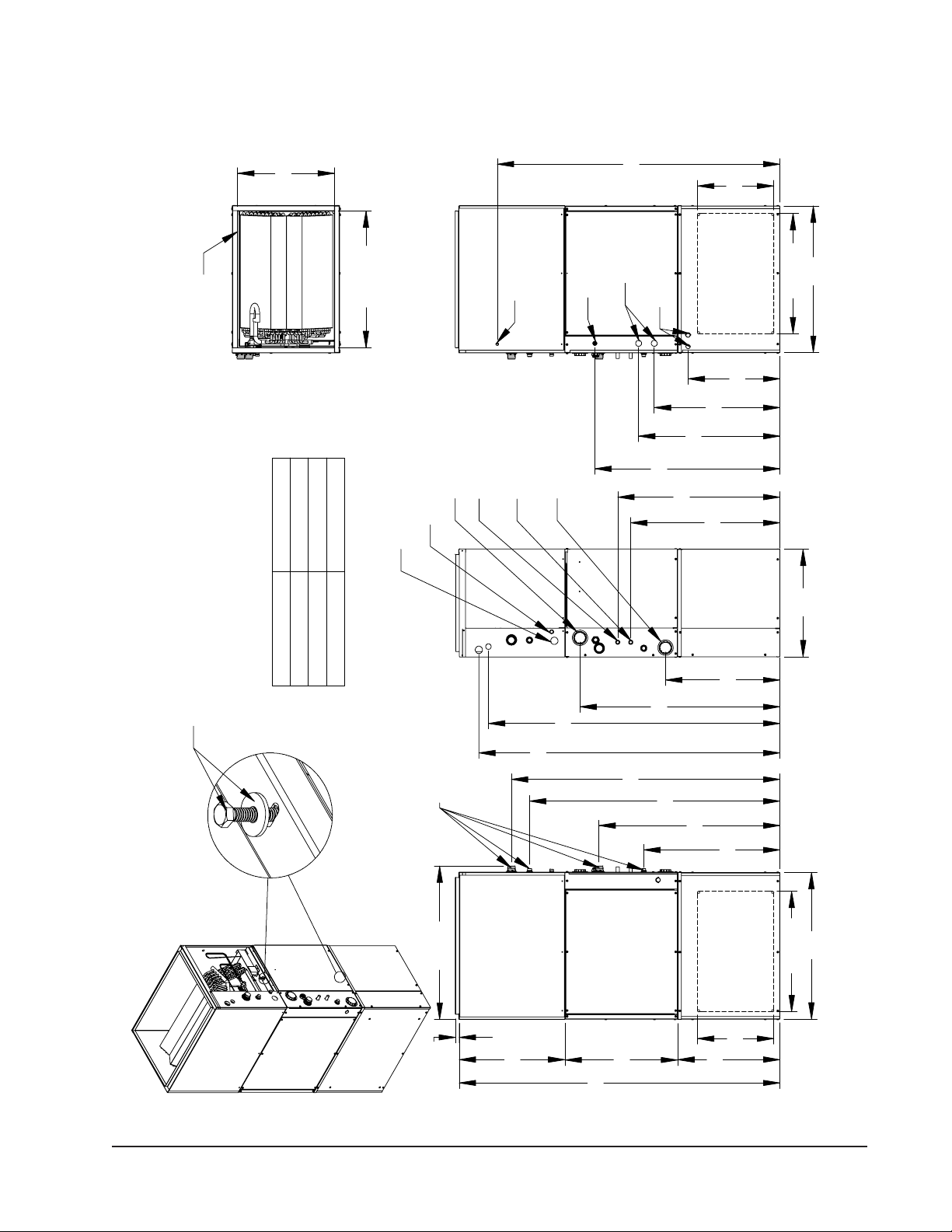

Figure 1B GTADP Fossil Fuel ADP Coil Dimensions ............ 8

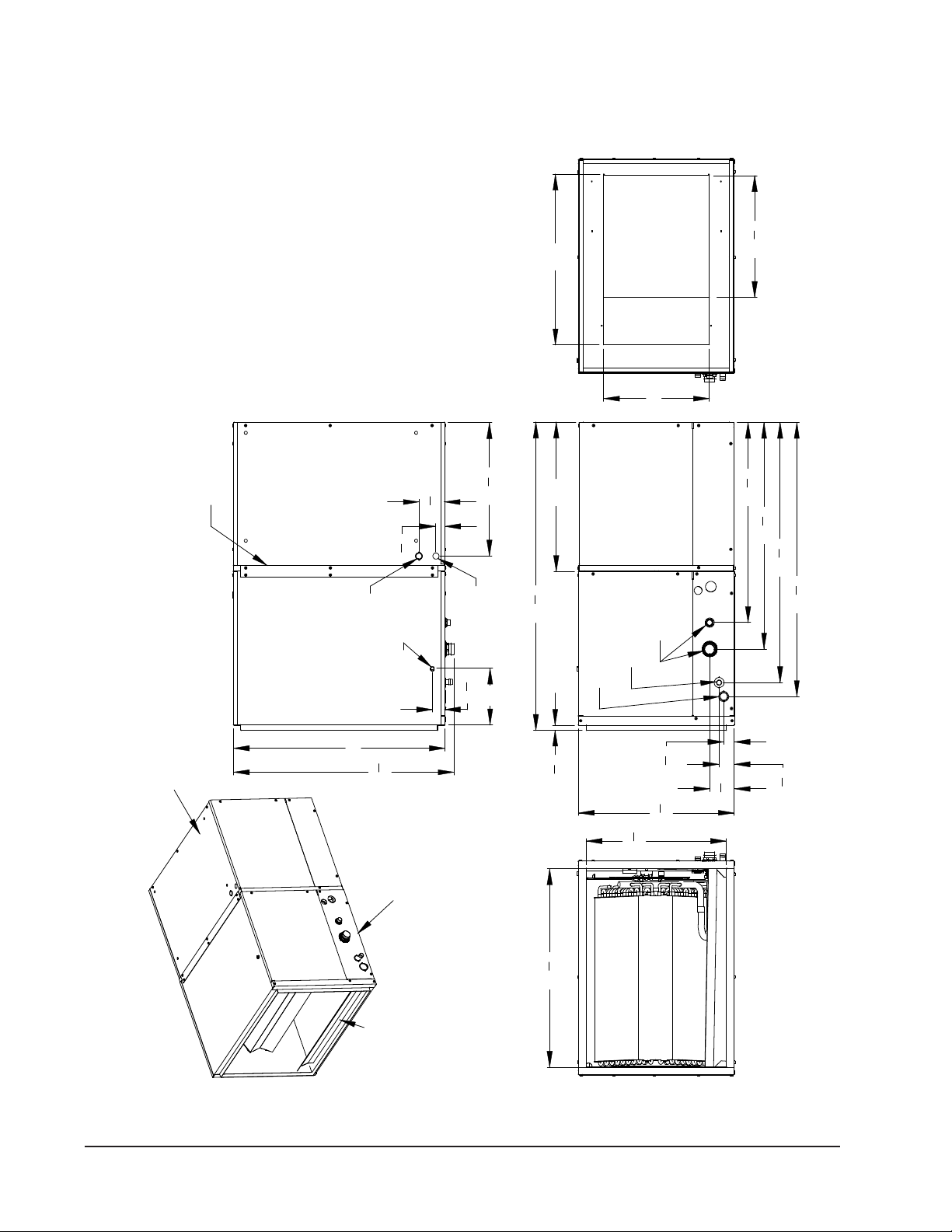

Figure 1C GTB1-A Dimensions ............................................. 9

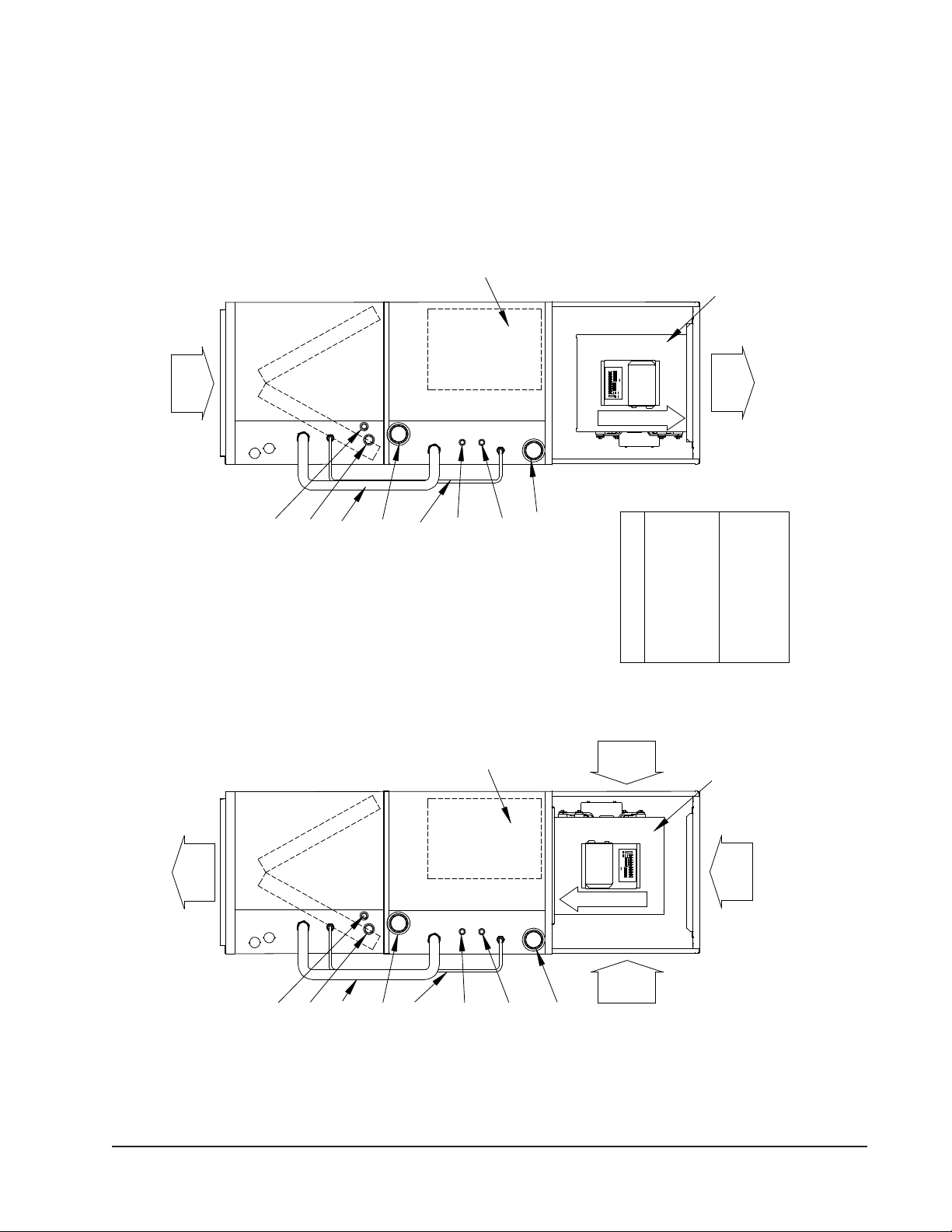

Figure 1D GTC**S2-D Dimensions .....................................10

Figure 1E Assembled Upow/Counterow App. .................11

Figure 1F Horizontal App. Dimensions ............................... 12

Figure 2A Upow & Counterow Ducting Cong. ................. 13

Figure 2B Horiz. & Counterow Ducting Cong. .................. 14

Figure 3 Blower Conguration ..........................................16

Figure 4 Blower Power Connections ................................17

Figure 5A Upow Air Filter Applications .............................. 21

Figure 5B Counterow Air Filter Applications ...................... 21

Figure 5C Horiz. Left Discharge Air Filter App. .................... 21

Figure 5D Horiz. Front Discharge App. ............................... 21

Figure 6 Thermostat Wiring ..............................................23

Figure 7 Circulation System Design .................................24

Figure 8 Temperature & Pressure Measurement .............. 26

Figure 9 Perf. Model DORFC-1 Flow Ctr. ......................... 26

Figure 10 Perf. Model DORFC-2 Flow Ctr. ......................... 26

Figure 11 Water Connection Components.......................... 28

Figure 12 Cleaning Water Coil ............................................ 30

Figure 13 Lake or Pond Installation ....................................31

Figure 14 Wiring Diagram ...................................................34

Manual 2100-537I

Page 2 of 54

Figure 15A Desuperheater Single Tank System ...................... 35

Figure 15B Desuperheater Dual Tank System ....................... 36

Figure 16 Thermistor ..........................................................37

Figure 17 Component Location ..........................................40

Figure 18 Control Panel ......................................................40

Figure 19 Refrigerant Flow Diagrams .................................41

Figure 20 Coil Spacer .........................................................43

Figure 21 Pressure Tables .................................................. 45

Figure 22 Control Disassembly ........................................... 49

Figure 23 Winding Test ....................................................... 49

Figure 24 Drip Loop ............................................................49

Figure 25 Control Connector Motor Half .............................50

Tables

Table 1 Indoor Blower Performance .................................. 5

Table 2 Flow Rates for Various Fluids ...............................5

Table 3 Specications ....................................................... 5

Table 4 Water Coil Pressure Drop ..................................... 6

Table 5 Electrical Heat Specications ............................. 19

Table 6 Filter Sizing Chart ............................................... 20

Table 7 Control Circuit Wiring .......................................... 22

Table 8 Constant Flow Valves .........................................27

Table 9 Pre-Charged Line Set Qty .................................. 42

Quick Reference Troubleshooting Chart ................................46

GETTING OTHER INFORMATION AND PUBLICATIONS

These publications can help you install the air

conditioner or heat pump. You can usually nd these

at your local library or purchase them directly from the

publisher. Be sure to consult current edition of each

standard.

National Electrical Code .......................ANSI/NFPA 70

Standard for the Installation ...............ANSI/NFPA 90A

of Air Conditioning and Ventilating Systems

Standard for W arm Air .......................ANSI/NFPA 90B

Heating and Air Conditioning Systems

Load Calculation for Residential ......ACCA Manual J

Winter and Summer Air Conditioning

Duct Design for Residential ..............ACCA Manual D

Winter and Summer Air Conditioning and Equipment

Selection

Closed-Loop/Ground Source Heat Pump ........IGSHPA

Systems Installation Guide

Grouting Procedures for Ground-Source .........IGSHPA

Heat Pump Systems

Soil and Rock Classication for ......................IGSHPA

the Design of Ground-Coupled Heat Pump Systems

FOR MORE INFORMATION, CONTACT

THESE PUBLISHERS:

ACCA Air Conditioning Contractors of America

1712 New Hampshire Avenue

Washington, DC 20009

Telephone: (202) 483-9370

Fax: (202) 234-4721

ANSI American National Standards Institute

11 West Street, 13th Floor

New York, NY 10036

Telephone: (212) 642-4900

Fax: (212) 302-1286

ASHRAE American Society of Heating Refrigerating,

and Air Conditioning Engineers, Inc.

1791 Tullie Circle, N.E.

Atlanta, GA 30329-2305

Telephone: (404) 636-8400

Fax: (404) 321-5478

NFPA National Fire Protection Association

Batterymarch Park

P.O. Box 9101

Quincy, MA 02269-9901

Telephone: (800) 344-3555

Fax: (617) 984-7057

Ground Source Installation Standards .............IGSHPA

Closed-Loop Geothermal Systems ..................IGSHPA

– Slinky Installation Guide

IGSHPA International Ground Source

Heat Pump Association

490 Cordell South

Stillwater, OK 74078-8018

Manual 2100-537I

Page 3 of 54

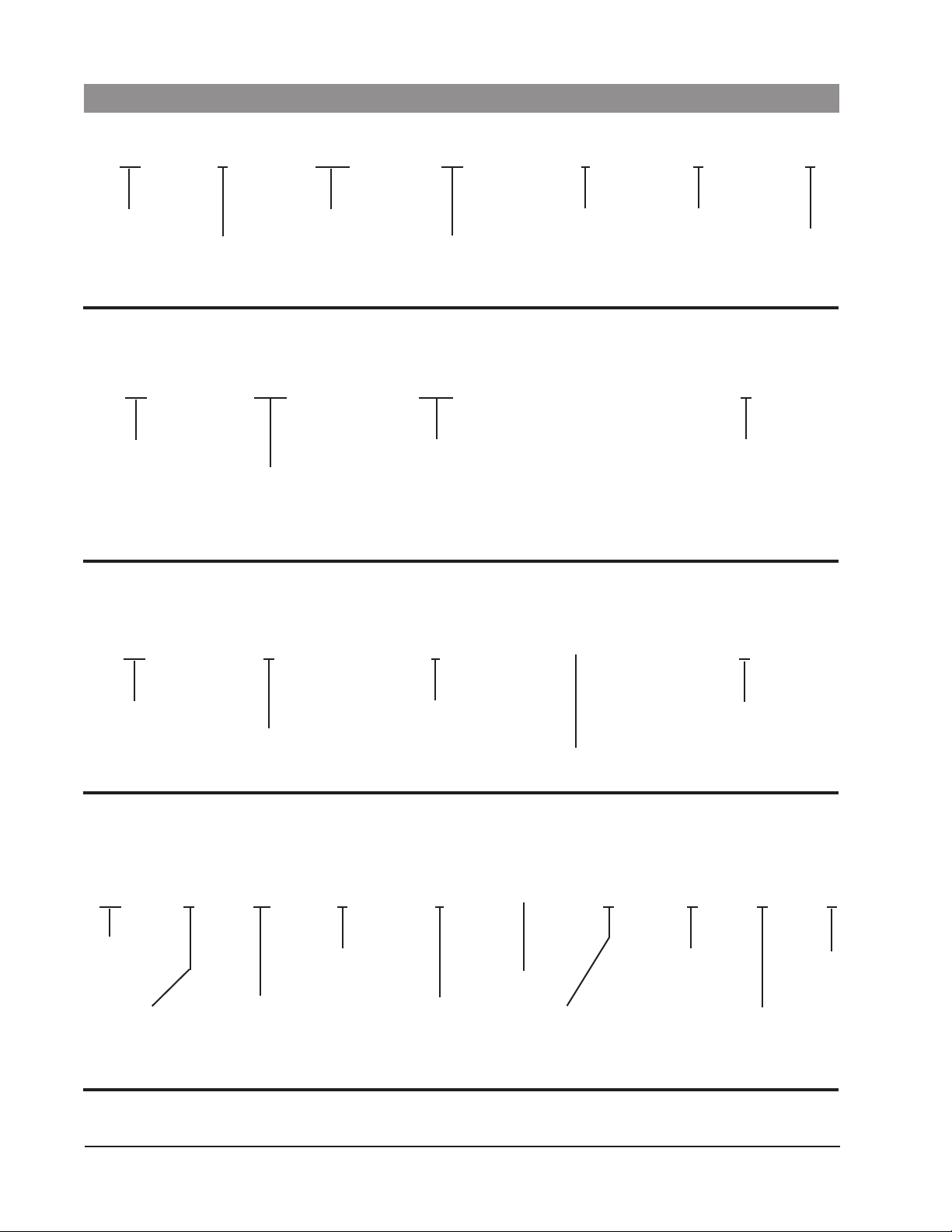

Geo-Trio™ GT Series Geothermal / Water Source Heat Pump Nomenclature

“A” Coil Section

GT A 3600 UD 1 A A

Geo-Trio

“A” = Coil Section

3600 (3 Ton)

4860 (4 & 5 Ton)

Series

Revision

Level

A = E Coated Coils

Fossil Fuel “A” Coil Section

GT ADP – 3642 – B

Geo-Trio

ADP = Advanced

Distributor Products

3642 (3 Ton)

4860 (4 & 5 Ton)

B = 17.50" Wide Furnace

C = 21.00" Wide Furnace

Blower Section

GT B 1 – A

Option

Geo-Trio

B = Blower

Section

Revision

Level

Option

A = 230 Volt 1-Phase

Compressor Section

GT C 36 S 2 – A D C X

Geo-Trio

C = Compressor

Section

Manual 2100-537I

Page 4 of 54

Nominal Capacity

S = Step Capacity

36 = 36K

48 = 48K

60 = 60K

Revision

Level

Option

A = 230 Volt 1-Phase

D = Desuperheater

C = Copper Coil

N = Cupronickel Coil

X = Future

Use

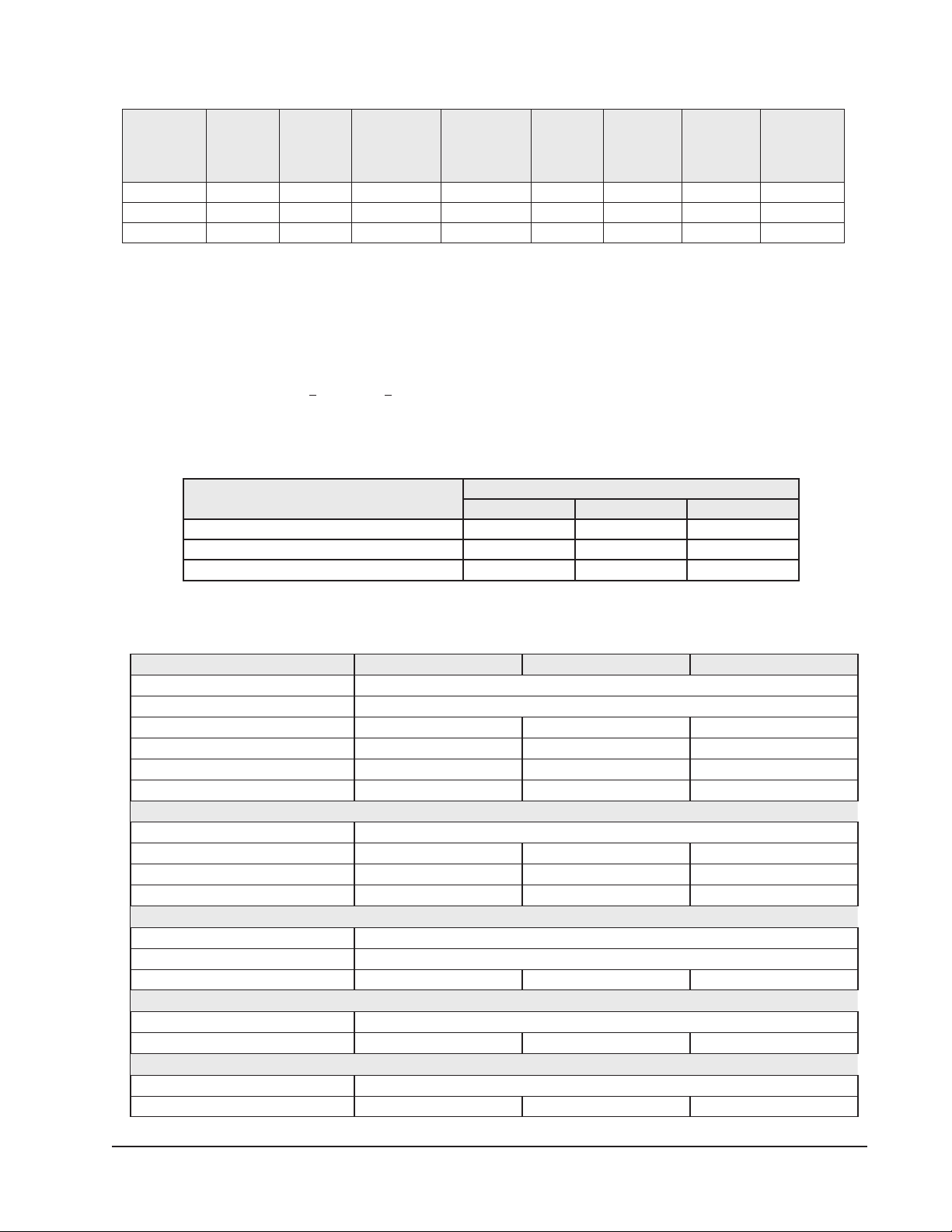

TABLE 1 — INDOOR BLOWER PERFORMANCE (RATED CFM)

MODEL

GTC36S2 0.15 0.60 600 700 850 1200 1300 2.6

GTC48S2 0.20 0.60 750 875 1075 1500 1600 3.2

GTC60S2 0.20 0.60 900 1050 1300 1800 1800 3.6

Rated

ESP

MAX

ESP

Continuous

Airow

Mild Climate

Operation

in Part Load

Cooling

Part Load

Airow

Full Load

Airow

Electric Heat

Airow

Minimum Air

Filter Face

Area Ft.2

Motorwillautomaticallystepthroughthevariousairowswiththermostaticcontrol

ESP = External Static Pressure (inches of water)

Maximum allowable duct static

ContinuousairowistheCFMbeingcirculatedwithmanualfanoperationwithoutanyadditionalfunctionoccurring.

Willoccurautomaticallyforrst5minutesofPartLoadCoolingOperation.

WilloccurautomaticallyafterveminutesofPartLoadCoolingOperation.

Will occur automatically with control signal input.

As per ASHRAE Guidelines of 500 FPM Velocities.

NOTE: All values can be changed + 10% via the + adjustment dip switches on the tap select control inclusive in the GTB1-A Blower Section

(see instructions later in this manual, or on wiring diagram in blower section).

TABLE 2 — FLOW RATES FOR VARIOUS FLUIDS

APPLICATION

Ground Loop (15% Methanol, Propylene Glycol, etc.) 8 12 15

Ground Water 6 7 9

Water Loop (Cooling Tower) 9.2 12.1 14.3

GTC36S2 GTC48S2 GTC60S2

MODELS

TABLE 3 — SPECIFICATIONS

MODEL GTC36S2 GTC48S2 GTC60S2

Electrical Rating (60HZ/1PH) 230/208-60-1

Operating Voltage Range 253-197 VAC

Minimum Circuit Ampacity 24.5 33.1 39.7

+Field Wire Size #10 #6 #4

Ground Wire Size #10 #10 #10

++Delay Fuse or Circuit Breaker Max. 35 50 60

COMPRESSOR

Volts 230/208-60-1

Rated Load Amps (230/208) 10.6 / 11.9 15.3 / 17.0 20.2 / 22.7

Branch Circuit Selection Current 15.3 21.2 25.6

Locked Rotor Amps (230/208) 82 / 82 104 / 104 153 / 153

BLOWER MOTOR

Horsepower (ECM Motor) 3/4 Variable Speed

Volts 230/208-60-1

Motor Amps (Stage #2 @ Rated CFM) 3.4 4.3 4.4

FLOW CENTER (Based on DORFC-2)

Volts 230/208-60-1

Amps 2.14 2.14 2.14

DESUPERHEATER PUMP MOTOR

Volts 230/208-60-1

Amps 0.15 0.15 0.15

+75°C copper wire ++ HACR type circuit breaker

Manual 2100-537I

Page 5 of 54

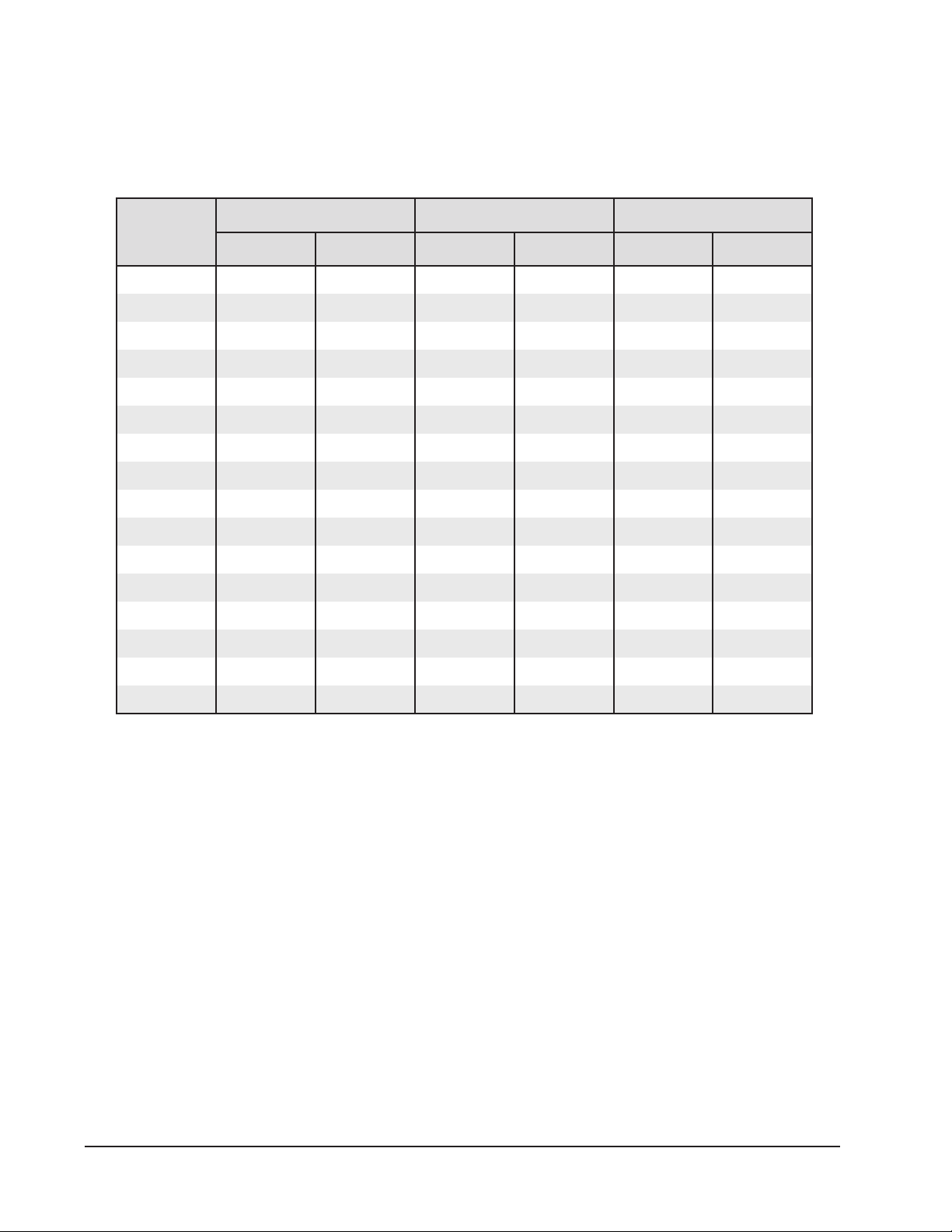

TABLE 4

WATER COIL PRESSURE DROP

Model GTC36S2 GTC48S2 GTC60S2

GPM PSID Ft. Hd. PSID Ft. Hd. PSID Ft. Hd.

3 0.1 0.23

4 0.5 1.15 0.9 2.08

5 1.2 2.77 1.4 3.23

6 1.7 3.92 2.3 5.31

7 2.3 5.31 3.2 7.38 2 4.61

8 3.1 7.15 4.1 9.46 2.5 5.77

9 4.1 9.46 5.1 11.77 3.2 7.38

10 6.1 14.07 3.9 9.00

11 7.1 16.38 4.7 10.84

12 8.2 18.92 5.5 12.69

13 9.4 21.69 6.4 14.76

14 10.6 24.45 7.3 16.84

15 8.1 18.69

16 9 20.76

17 9.9 22.84

18

Manual 2100-537I

Page 6 of 54

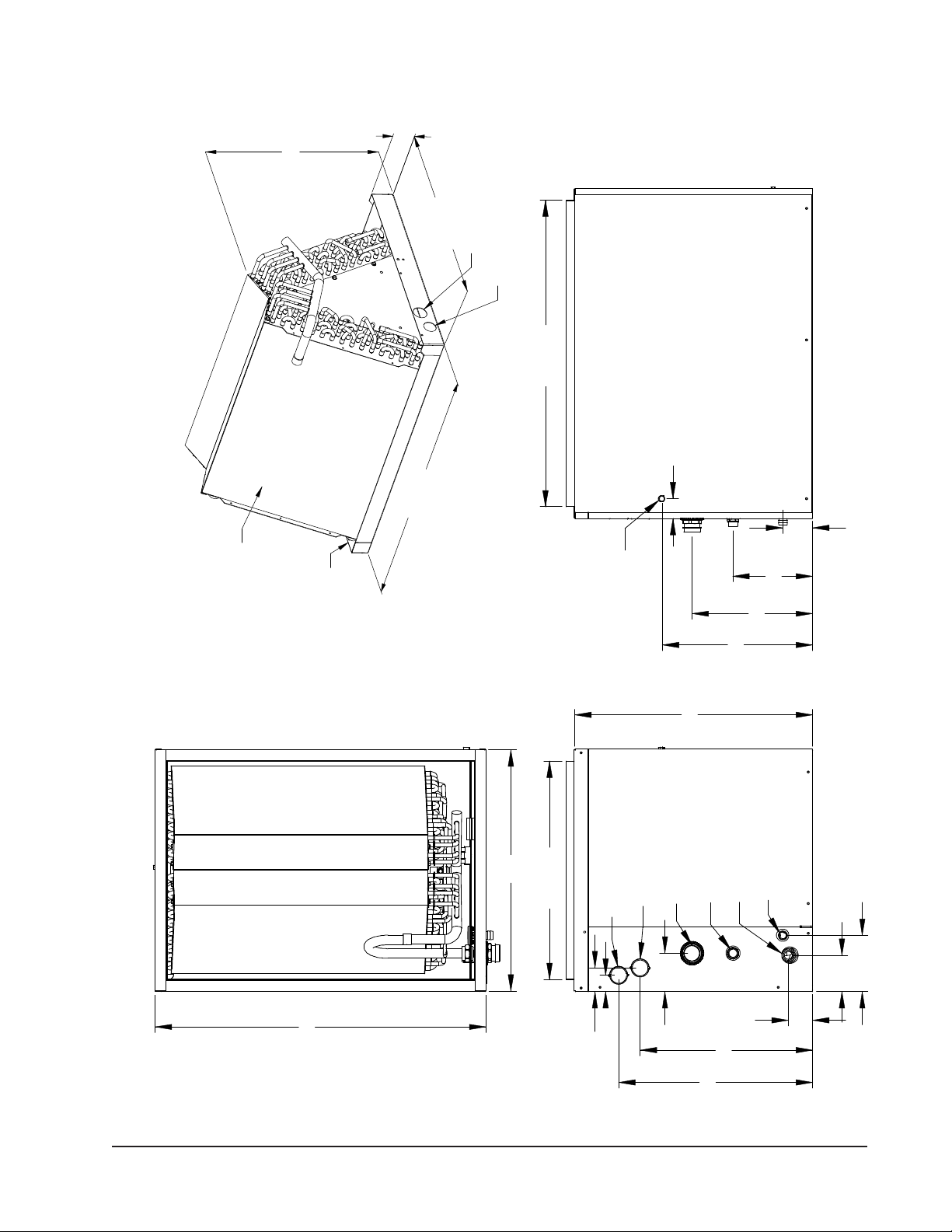

2 3/16"

3 5/16"

5 1/8"

15 11/16"

17 5/8"

1 1/2"

10 15/16"

7 1/4"

2 3/4"

MIS-2818

HORIZ. MAIN DRAIN K.O.

HORIZ. OVERFLOW K.O.

SUCTION CONNECTION

LIQUID CONNECTION

OVERFLOW

MAIN DRAIN

19 15/16"

3 1/2"

21 5/8"

2 3/16"

CONDENSATE

OVERFLOW WIRES

27 15/16"

13 5/8"

1 13/16"

22"

30"

20.50

-.000

+.125

WIDTH

16.13

-.000

+.125

HEIGHT

DRAIN PAN

GTA Coil Dimensions If Used Without Cabinet

PRIMARY DRAIN HOLE

SECONDARYDRAIN HOLE

MIS-2876 A

COATED

COIL

.125

2.25

-.000

+

28.25

-.000

+.125

DEPTH

FIGURE 1A – GTA****UD1AA

A-COIL SECTION DIMENSIONS

Manual 2100-537I

Page 7 of 54

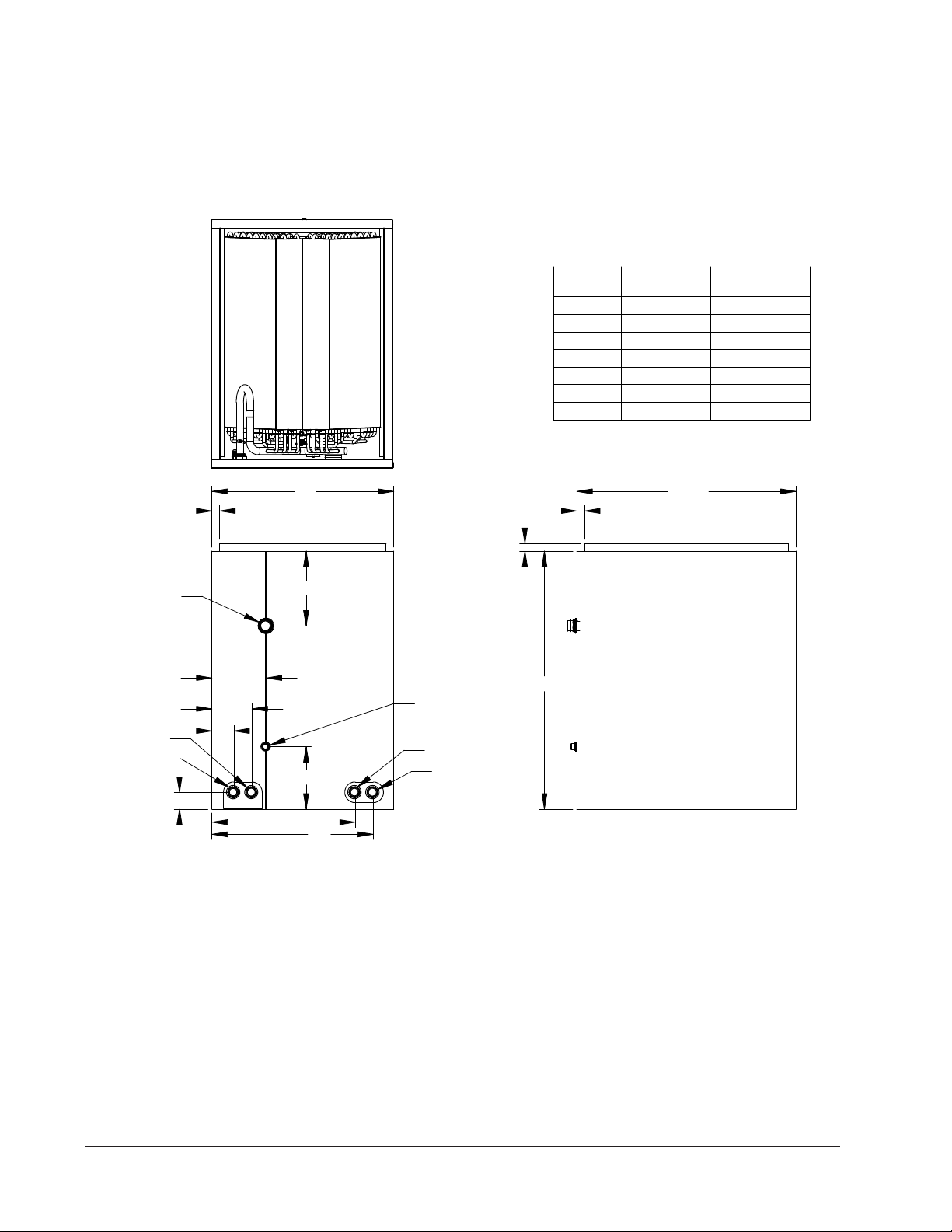

FIGURE 1B – GTADP****-*

FOSSIL FUEL ADP COIL SECTION DIMENSIONS

FIGURE 1B - GTADP****-*

FOSSIL FUEL ADP COIL SECTION DIMENSIONS

SUCTION

CONNECTION

OVERFLOW

MAIN DRAIN

3/4"

TYP

1 5/8"

5 1/4"

"E"

"D"

"A"

"F"

"C"

6 1/16"

"G"

LIQUID

CONNECTION

OVERFLOW

MAIN DRAIN

3/4"

TYP

DIMENSION GTADP-3642-B

"A" 17 5/8" 21 1/8"

"B" 25 1/2" 27 1/2"

"C" 7 1/4" 6 3/4"

"D" 2 1/8" 2 1/2"

"E" 3 7/8" 4 1/4"

"F" 13 7/8" 16 7/8"

"G" 15 5/8" 18 5/8"

3/4"

TYP

"B"

21 1/4"

GTADP-3642-C

GTADP-4860-C

MIS-3119

Manual 2100-537I

Page 8 of 54

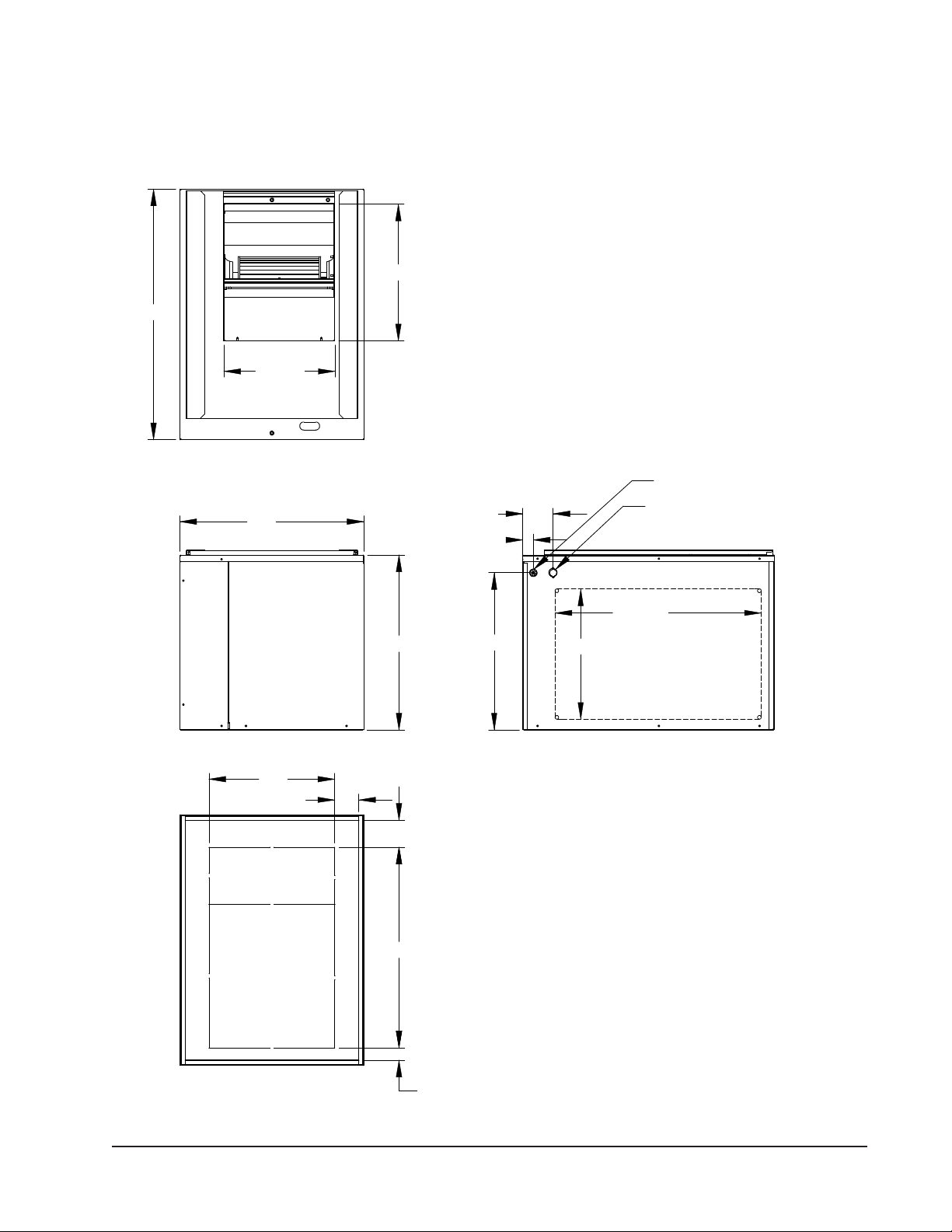

15 5/8"

24 9/16"

MIS-2819

30"

13 1/4"

16 3/8"

LOW VOLTAGE ENTRANCE

OPENING ON BOTH SIDES

OPTIONAL SIDE RETURN

HIGH VOLTAGE K.O. FOR

REMOTE APPLICATIONS ONLY

3 5/8"

18 13/16"

1 1/4"

24"

15"

3 5/16"

1 1/2"

2 7/8"

21"

22"

FIGURE 1C – GTB1-A

BLOWER SECTION DIMENSIONS

Manual 2100-537I

Page 9 of 54

MODEL DIM. A DIM. B

GTC36S2 21" 4 1/8"

GTC48S2 20" 3 7/8"

GTC60S2 18 1/2" 3 3/4"

DESUPERHEATER

WATER OUT

LIQUID LINE

SUCTION LINE

WATER IN

WATER OUT

DESUPERHEATER

WATER IN

12 1/4"

3"

9 5/8"

B

2 1/2"

23 1/16"

1 7/8"

16 1/16"

6 15/16"

A

1 3/4"

22 1/16"

30"

HIGH VOLTAGE UNIT

LOW VOLTAGE WIRE ENTRANCE

POWER ENTRANCE

HIGH VOLTAGE OPTIONAL

FLOW CENTER WI RE ENTRANCE

MIS-2820 A

8"

4 13/16"

16 15/16"

1 15/16"

FIGURE 1D – GTC**S2-D

COMPRESSOR SECTION DIMENSIONS

Manual 2100-537I

Page 10 of 54

15 5/8"

24 9/16"

27 7/8"

37 1/16"

51 1/4"

55"

24 9/16"

15 5/8"

VOLTAGE

LOW

VOLTAGE

LOW VOLTAGE

HIGH

LOW VOLTAGE

18 13/16"

57 7/8"

25 3/4"

28 15/16"

37 7/8"

30"

REFRIGERANT

CONNECTIONS

65 5/8"

30"

21"

23"

21 5/8"

3/4"

31 1/4"

TOP DUCT OUTLET FLANGE

27 15/16"

19 13/16"

SECURE SECTIONS TOGETHER

USING BOLT PART #1012-015

AND WASHER PART #1012-109

MAIN DRAI N OUTLET

INLET

OVERFLOW DRAIN OU TLET

WATER OUT

OUTLET

DESUPERHEATER

DESUPERHEATER

WATER IN

61 5/8"

59 11/16"

33 1/4"

22"

23 7/16"

30 9/16"

"A"

MODEL DIM. A

GTC36S2 39 7/16"

GTC48S2 40 15/16"

GTC60S2 41 15/16"

RIGHT SIDEFRONT

LEFT SIDE

(UPFLOW ONLY)

ENTRANCE

TOP

AIR

(UPFLOW ONLY)

AIR

ENTRANCE

MIS-2821 B

FIGURE 1E – ASSEMBLED UPFLOW / COUNTERFLOW APPLICATION DIMENSIONS

Manual 2100-537I

Page 11 of 54

36

5

8

"

38

1

2

"

1

1

2

"

2

1

8

"

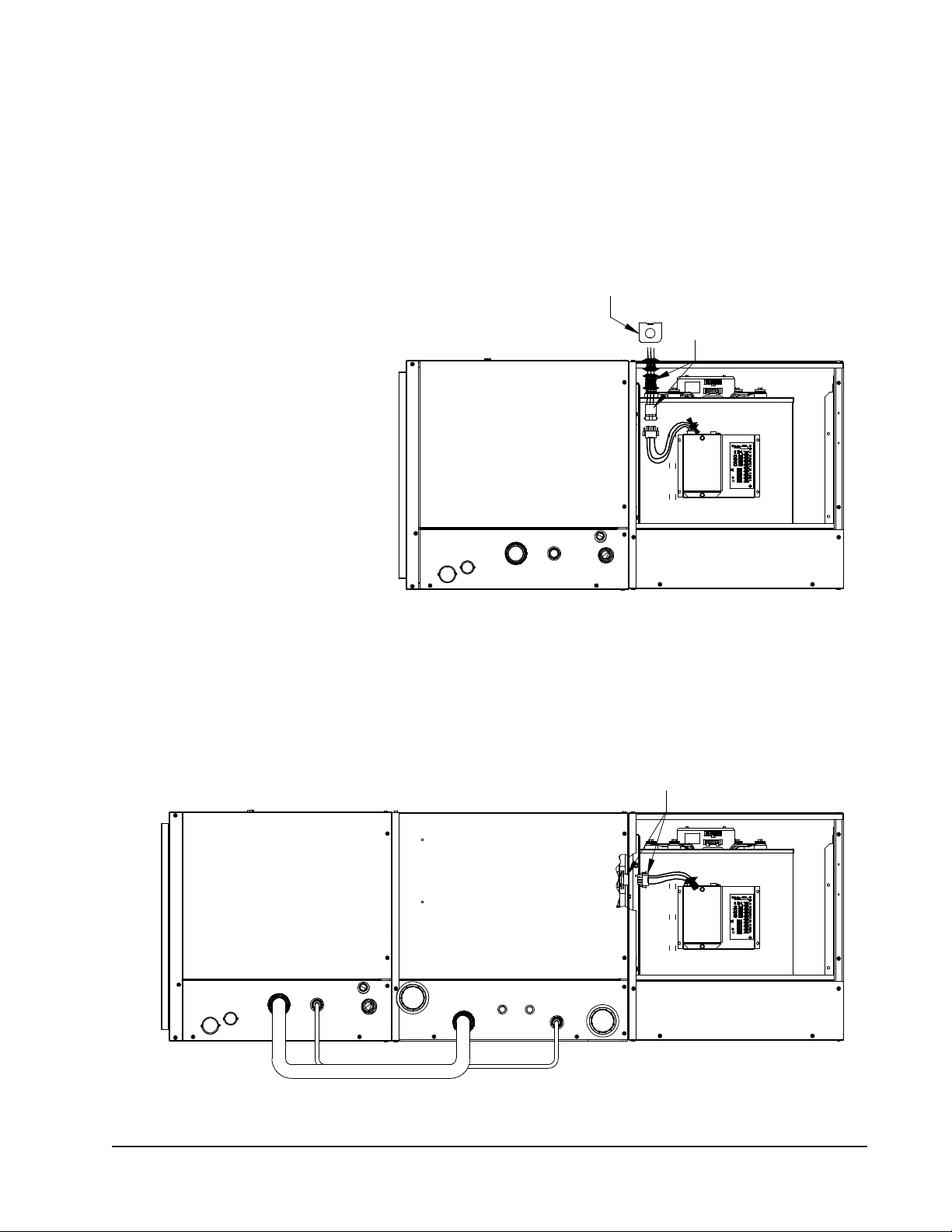

Section

Blower

Section

Evaporator

GTHZ1

Horizontal

Drain Pan

(Req'd)

Horiz. Support Bracket

Low Voltage

Entrance

High Voltage

Entrance

Low Voltage

Entrance

Top View

30"

"

"

"

4311

"

4183

"

1

4

211

3

1

3

4

8"

Front View

7

"27

8

19

7

8

"

Opening

Evaporator Opening Blower

Right Side View

24"

15"

17

1

8

"

Overflow Drain

Outlet

Outlet

Main Drain

Refrigerant

Connections

7

"31

8

"

21"

8221

"

3

8

"

4433

"

8281

3

1

2

"

MIS-2824

Left Side View

Evaporator and Blower in Horizontal Position

(Remote Compressor Section)

NOTE:

Requires

horizontal

drain pan kit

Model GTHZ-1

FIGURE 1F – HORIZONTAL APPLICATION DIMENSIONS

Manual 2100-537I

Page 12 of 54

Blower Air

Evap. Coil

Counterflow

Position

Cond. Coil

Water Out

Cond. Coil

Desuper.

Water In

Water In

Desuper.

Water Out

Supply

Return

Main Drain

Blower in

Alternate Position

7/8" Line Set

3/8" Line Set

Blower Air

Evap. Coil

Upflow

Cond. Coil

Position

Cond. Coil

Water Out

Desuper.

Water In

Desuper.

Water In

Water Out

Supply

Return

Return

Secondary

Return

Drain

Main Drain

Blower in

Shipped Position

7/8" Line Set

Control Panel

MIS-2828

Control Panel

3/8" Line Set

Drain

Secondary

Air Filter Required

One FR23 (16 x 25 x 1) or

field supplied equivalent

required for upflow side

return installation

Bottom return upflow and

top return counterflow filter

provision must be field

supplied

NOTE:

Requires Switch #4 on Tap Select

Control to be Turned On.

FIGURE 2A – UPFLOW & COUNTERFLOW DUCTING CONFIGURATIONS

Manual 2100-537I

Page 13 of 54

Blower Air

Blower Air

Blower Air

Blower Air

Return

Remote Condenser Section

Supply

Supply

Supply

Return

Return

Return

Counterflow

Return

Main Drain

Horizontal, Left Discharge

Return

MIS-2826

Evap. Coil

Evap. Coil

Evap. Coil

Evap. Coil

Position

Optional Top

Horizontal, Right Discharge

Drain

Desuper.

Secondary Drain

Position

Upflow

Drain

Main Drain

Secondary Drain

Secondary

Main Drain

Blower in

Shipped Position

Blower in

Shipped Position

Blower in

Alternate Position

Alternate Position

Blower in

Supply

Cond. Coil

Water Out

Cond. Coil

Water In

Desuper.

Water In

Water Out

Secondary

Main Drain

Refrigerant

Return

Refrigerant

Connections

Refrigerant

Connections

Connections

Refrigerant

Connections

Model GTLID

NOTE:

Requires Switch #4

on Tap Select Control

to be Turned On.

FIGURE 2B – HORIZONTAL & COUNTERFLOW DUCTING CONFIGURATIONS

Manual 2100-537I

Page 14 of 54

NOTE: Requires horizontal

drain pan kit Model GTHZ-1

< >

Air Filter Required on Return Air Side for All Installations

Upowinstallationscanuse(1)FR23(16x25x1)oreldsuppliedequivalentoneithersideofthe

blower section. Use of (2) on both sides is optional.

Bottomreturnforupowandtopreturnfordownowmustbeeldsupplied.

Forhorizontalatticorcrawlspaceinstallationslterarrangementmustbeeldsupplied&should

be located in readily accessible location for the user.

See additional information on Pages 19 & 20.

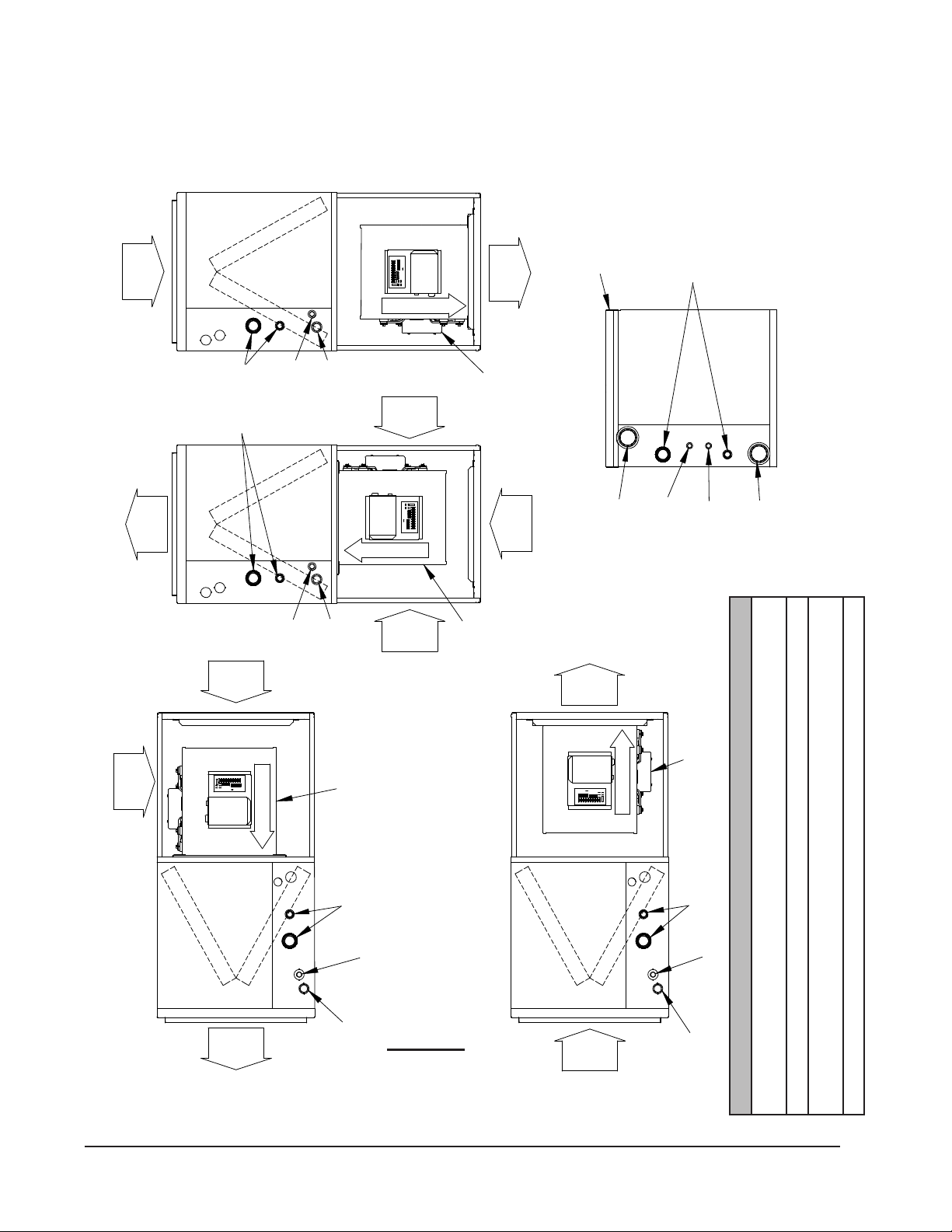

BLOWER CONVERSION FROM UPFLOW

TO COUNTERFLOW OR HORIZONTAL

RIGHT DISCHARGE

Following the directions on Figure 3 for counterow and

horizontal right discharge, the indoor blower must be

removed and turned over in its mounting conguration.

• Step 1 Remove both front service panels from the

GTB1-A.

• Step 2 Remove two screws securing blower at top

of GTB1-A (See Figure 3), and slide the

blower forward and out of the chassis.

• Step 3 Remove two screws from front ll plate on

bottom of GTB1-A, and slide both pieces of

metal forward and out of chassis.

• Step 4 Dip switch #4 on blower tap select control

must be turned “on”. (Refer to Wiring

Diagram 4117-100.)

• Step 5 While turning on tap #4 above, adjust the

other taps accordingly for the tonnage of unit

being applied. (Refer to Wiring Diagram

4117-100.)

• Step 6 Turn blower over and slide into rails of

bottom rear of the GTB1-A front ll plate

that was removed in Step 3 above.

• Step 7 Remove bottom rear ll plate from bottom

front ll plate (discard rear), and resecure

front ll plate into unit base and front of

blower.

• Step 8 Replace GTB1-A front service doors after

making line and control voltage wiring

connections.

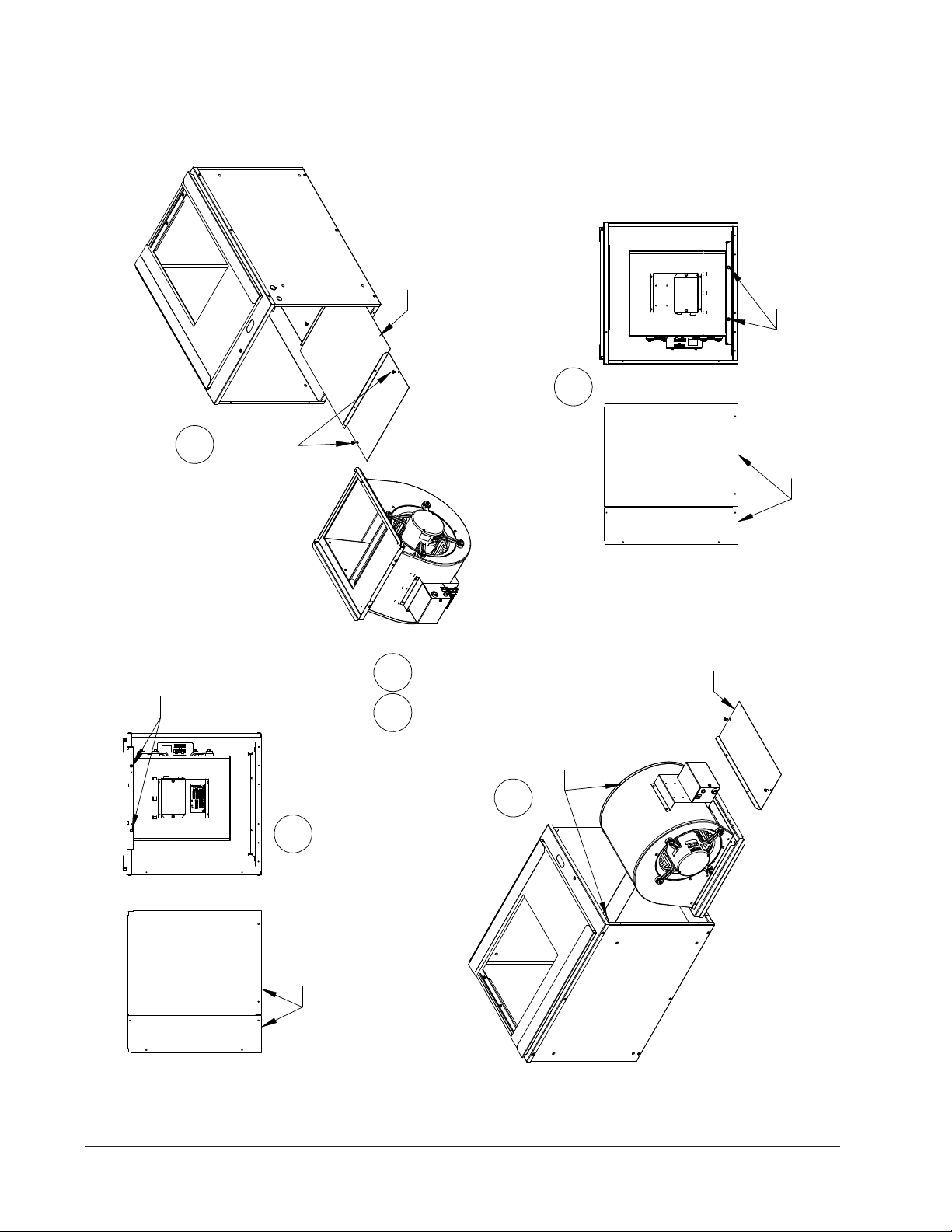

BLOWER LINE POWER CONNECTION

Power connections for the GTB1-A can be made two

different ways.

The rst is in “stacked” congurations, the blower can

be plugged into an electrical connection from the bottom

of the compressor (GTC**S2 Model Unit). This will

work for either upow or counterow applications. All

electrical sizing has been sized to accommodate this.

The second is with “remote” blower (meaning separate

from the compressor section). Supplied in the GTB1-A

is an adaptor wire harness. On the right-hand side of the

GTB1-A chassis is a ½" electrical knockout. This harness

can be installed through this knockout with the supplied

strain relief into a standard electrical junction box (eld

supplied). Electrical load sizing is included on the serial

plate of the GTB1-A for the required separate branch

circuit (See Figure 4).

Manual 2100-537I

Page 15 of 54

FRONT PANELS

REMOVE BOTH

REMOVE (2) SCREWS

SECURING BLOWER

AND SLIDE BLOWER

OUT OF CABINET

1

SECURING BLOWER TO

FRONT FILL PLATE

REINSTALL (2) S CREWS

REINSTALL BOTH

FRONT PANELS

5

4

6

2

REMOVE (2) SCREWS FROM

FRONT FILL PLATE AND SLIDE

BACK FILL PLATE OUT OF CABINET

DISCARD BACK

FILL PLATE

3

ROTATE BLOWER AND SLIDE

INTO BOTTOM OFFSETS

REINSTALL

FRONT FILL PLATE

MIS-2842 A

FIGURE 3 – BLOWER CONFIGURATIONS

Manual 2100-537I

Page 16 of 54

STACKED CONFIGURATIONS

UPFLOW AND COUNTERFLOW

CONDENSER BASE FOR BOTH

PLUG BLOWER POWER

CONNECTOR INTO POWER

PLUG PROTRUDING THROUGH

MOUNT FIELD

SUPPLIED SINGLE

GANG ELECTRICAL

BOX ALIGNED OVER

HIGH VOLTAGE K.O.

MIS-2843

REMOVE SUPPLIED

WIRE HARNESS AND

STRAIN RELIEF BUSHING

FROM BLOWER POWER PLUG.

ROUTE WIRE HARNESS

THROUGH STRAIN RELIEF

AND INTO ELECTRICAL BOX

TO MAKE FIELD POWER

CONNECTION

FIGURE 4 – BLOWER POWER CONNECTIONS

Manual 2100-537I

Page 17 of 54

Loading...

Loading...